Copper strengthening molten pool smelting furnace and smelting method

A molten pool smelting furnace and smelting furnace technology, applied in the field of metallurgy, can solve the problems of poor acid production efficiency, high occurrence rate of smoke and dust, damage to metallurgical equipment, etc., and achieves reduction of fuel allocation, strong adaptability of raw materials, and improvement of production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

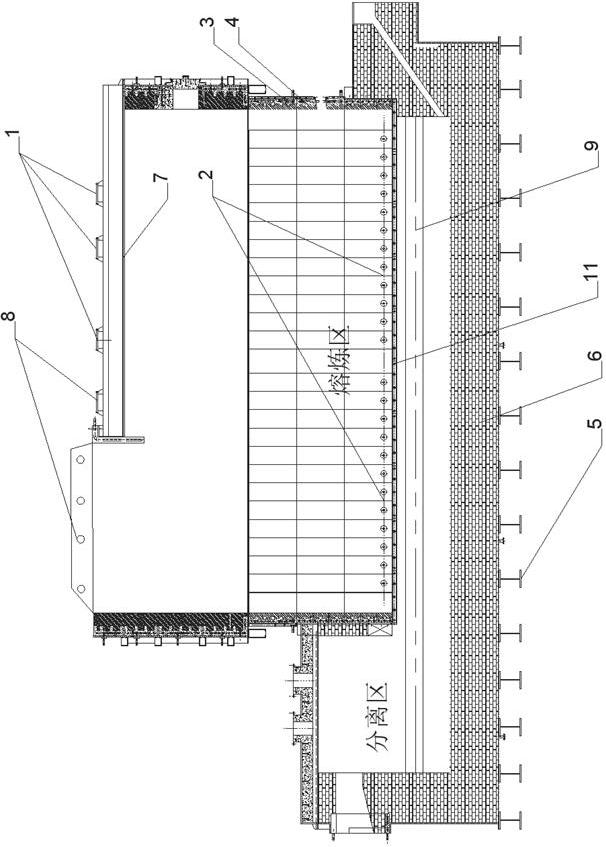

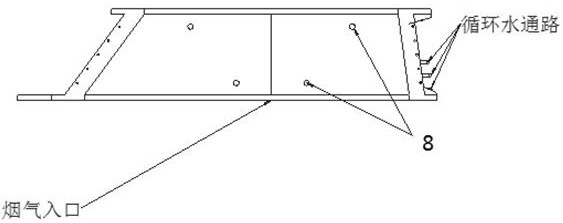

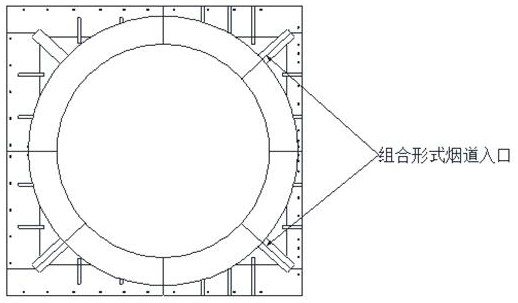

[0040] Such as Figure 1-7 As shown, among them: the smelting zone is divided into the reaction zone and the depletion zone, the depth of the molten pool in the smelting zone is 2100mm, the thickness of the copper matte is 1000mm, and the thickness of the slag layer is 1100mm.

[0041] The metallurgical process is as follows:

[0042] Add copper concentrate, flux, and return material (blowing slag, refining slag, soot, lump coal) to the feed port 1 on the upper part of the furnace body in the smelting zone. The content is 85vol%, the pressure is 0.12MPa, the reaction zone is violently stirred by high-pressure oxygen-enriched air to form a high-temperature bubbling melt with a height of 5-7m, the raw material and the bubbling area melt and react, and precipitate and separate under the tuyere, and the output is 70-75% copper matte and slag;

[0043] 70-75% of the copper matte is discharged intermittently or continuously through the siphon channel at the bottom of the molten po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com