A kind of method that adds crystal seed and prepares ammonium metavanadate

A technology of ammonium metavanadate and seed crystals, which is applied in chemical instruments and methods, vanadium compounds, inorganic chemistry, etc., can solve the problems of high vanadium content and long vanadium precipitation time, and achieve low equipment requirements, shortened reaction time, and vanadium The effect of liquid composition requirement relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

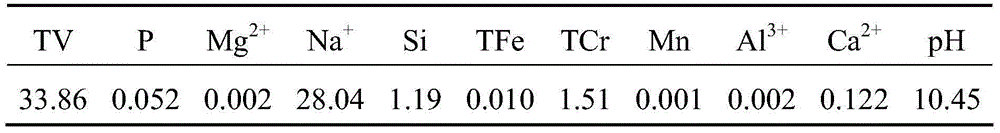

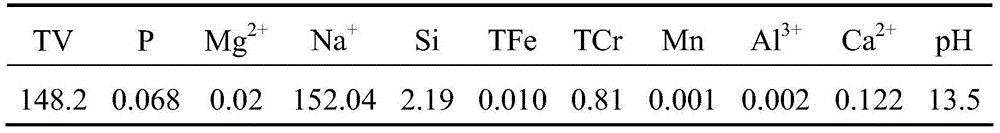

[0034] Add 1000mL of common vanadium liquid in Table 1 to a 2000mL clean beaker, adjust the pH value to 10.0 with sulfuric acid, add 1.70g ammonium polyvanadate at room temperature, dissolve the seeds according to the NH 4 + / V=1 Add ammonium sulfate, after the ammonium sulfate dissolves into the vanadium solution, react for 60 minutes, then filter to obtain wet ammonium metavanadate, put the wet ammonium metavanadate in an oven at 50°C for drying, the drying time for 12 hours. The vanadium content in the vanadium precipitation supernatant liquid was detected to be 0.34g / L, and the vanadium precipitation rate was 99%.

example 2

[0036] Add 1000mL of common vanadium liquid in Table 1 to a 2000mL clean beaker, adjust the pH value to 8.0 with sulfuric acid, add 0.3g ammonium polyvanadate at room temperature, 4 + / V=4 Add ammonium sulfate, after the ammonium sulfate dissolves into the vanadium solution, react for 30 minutes, then filter to obtain wet ammonium metavanadate, put the wet ammonium metavanadate into an oven at 50°C for drying, the drying time for 12 hours. The vanadium content in the vanadium precipitation supernatant liquid was detected to be 0.28g / L, and the vanadium precipitation rate was 99.2%.

example 3

[0038] Add 1000mL of common vanadium liquid in Table 1 to a 2000mL clean beaker, adjust the pH value to 9.0 with sulfuric acid, add 1.0g of sodium polyvanadate at room temperature, 4 + / V=2 Add ammonium sulfate, after the ammonium sulfate dissolves into the vanadium solution and react for 50 minutes, filter to obtain wet ammonium metavanadate, put the wet ammonium metavanadate into an oven at 50°C for drying, the drying time is 12 hours. The vanadium content in the vanadium precipitation supernatant was detected to be 0.17g / L, and the vanadium precipitation rate was 99.5%.

[0039] Composition / g L -1

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com