Indirect evaporation type cooling/condensing device

An evaporative cooling and condensing device technology, applied in the field of evaporative condensers, closed cooling towers, and fluid cooling/condensing devices, can solve the problem of not being able to reduce the temperature of the cooling medium, reduce energy consumption, improve cooling efficiency, The effect of prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

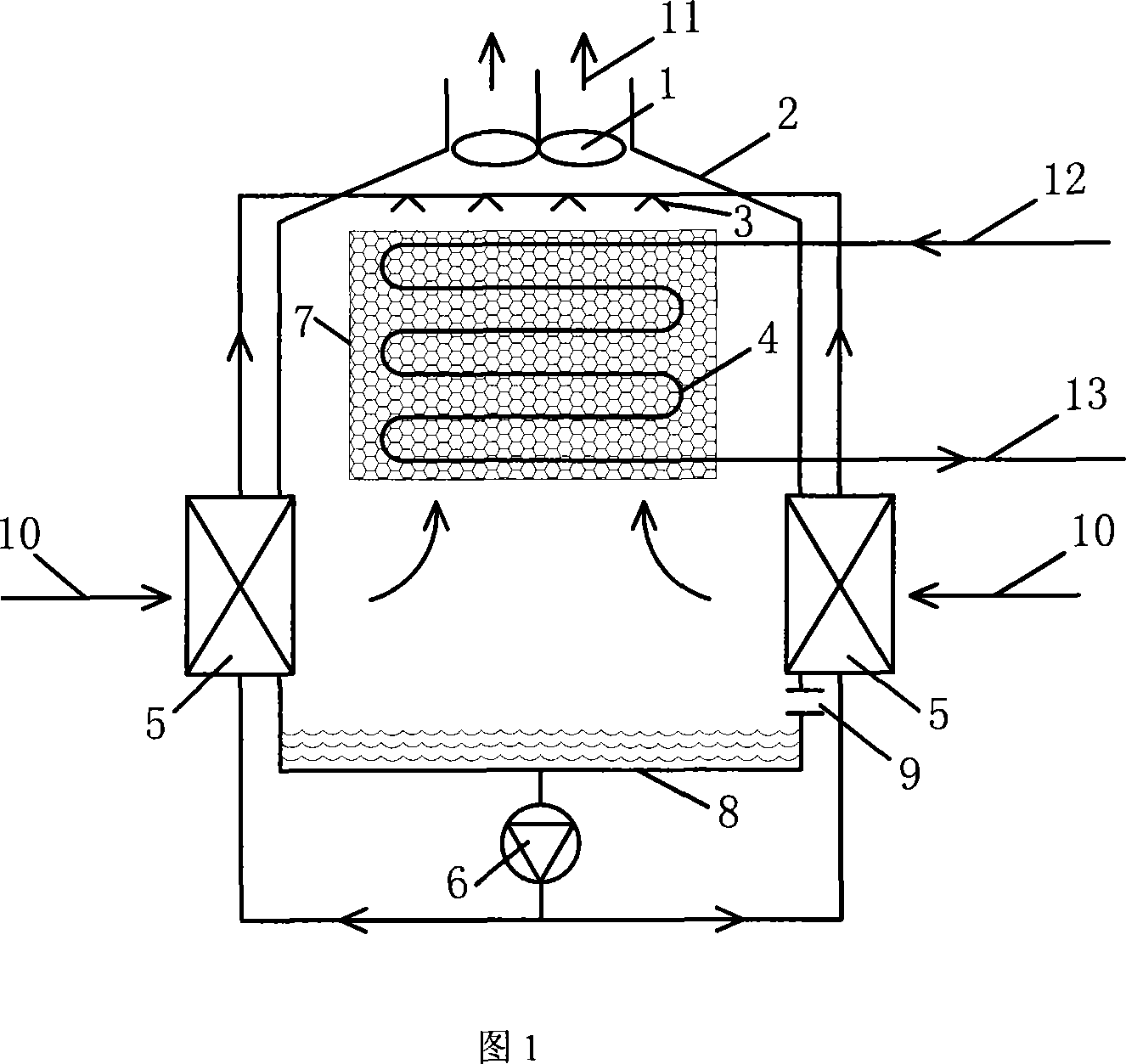

[0020] As shown in Figure 1, an indirect evaporative cooling / condensing device provided by the present invention includes a fan 1, a housing 2, a shower 3, a partition heat exchanger 4, a water pump 6 and a water collecting tray 8; The fan is arranged on the top of the casing, the shower is arranged on the upper part of the casing, the partition heat exchanger is arranged on the lower part of the shower 3, and on the casing wall below the partition heat exchanger An air inlet 10 is provided, and the water collecting tray is arranged at the bottom of the housing. The water collecting tray 8 is provided with a water supply port 9. The water collecting tray is connected to the inlet of the water pump 6 at the lower part of the water collecting tray through a pipeline, and the outlet of the water pump 6 passes through The pipeline is connected to the shower 3; an air-water heat exchanger 5 is arranged at the air inlet 10, and the water side of the air-water heat exchanger is connec...

Embodiment 2

[0030] In the above-mentioned indirect evaporative cooling / condensing device provided by the present invention, when the condensed medium in the partition heat exchanger 4 adopts a high-temperature gas such as a refrigerant or a gas-liquid two-phase fluid, the device can be used as a vapor compression refrigeration unit. System or indirect evaporative condenser for chemical system. Since the refrigeration system or chemical cooling system needs to be refrigerated throughout the year, there are generally the following two operating modes:

[0031](1) Operation mode 1: In summer working conditions, the water pump 6 is turned on, and the circulating water is sprayed, and the high-temperature gas or gas-liquid two-phase fluid such as refrigerant entering the partition heat exchanger 4 dissipates heat to the spraying water to achieve condensation effect. Driven by the fan 1, the outdoor air first passes through the air-water heat exchanger 5 for pre-cooling, and then enters the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com