Anti-condensation refrigerating system and method for refrigerator and refrigerator

A refrigeration system and anti-condensation technology, used in refrigeration and liquefaction, refrigerators, refrigeration components, etc., can solve the problems of increasing the heat load of the refrigerator, increasing the power consumption of the refrigerator, condensation, etc., achieving good results and improving power consumption. volume, the effect of lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

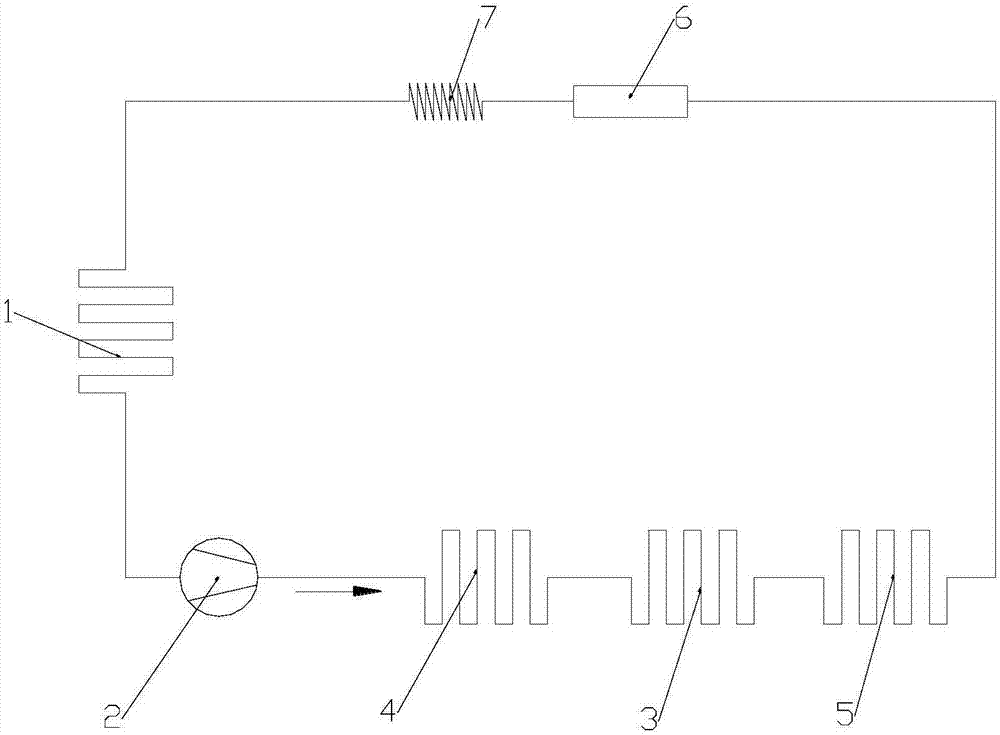

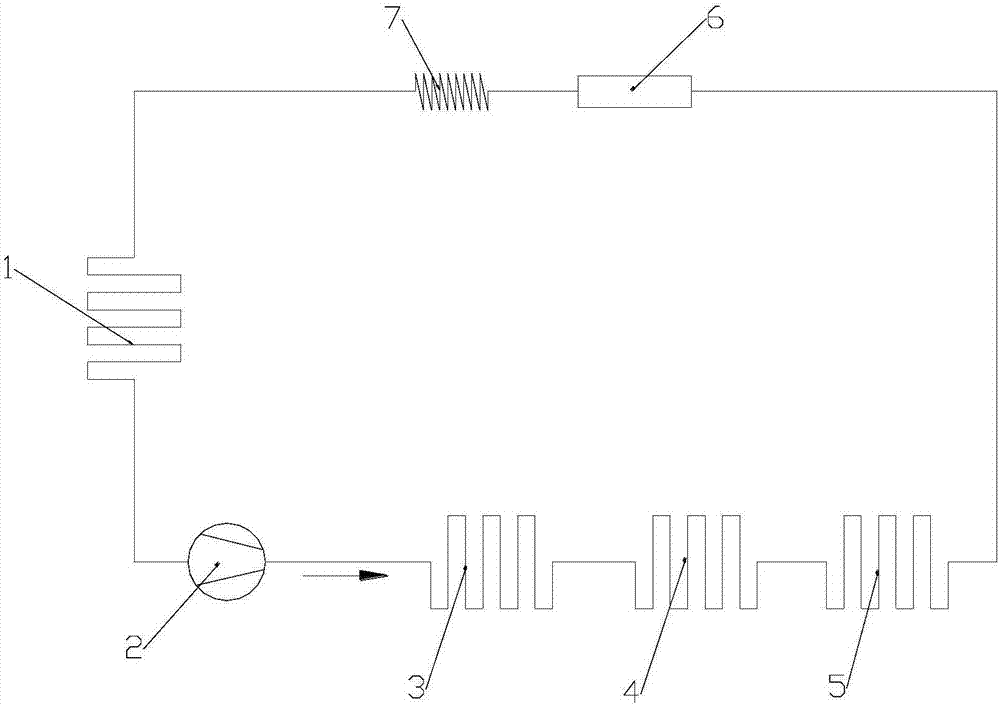

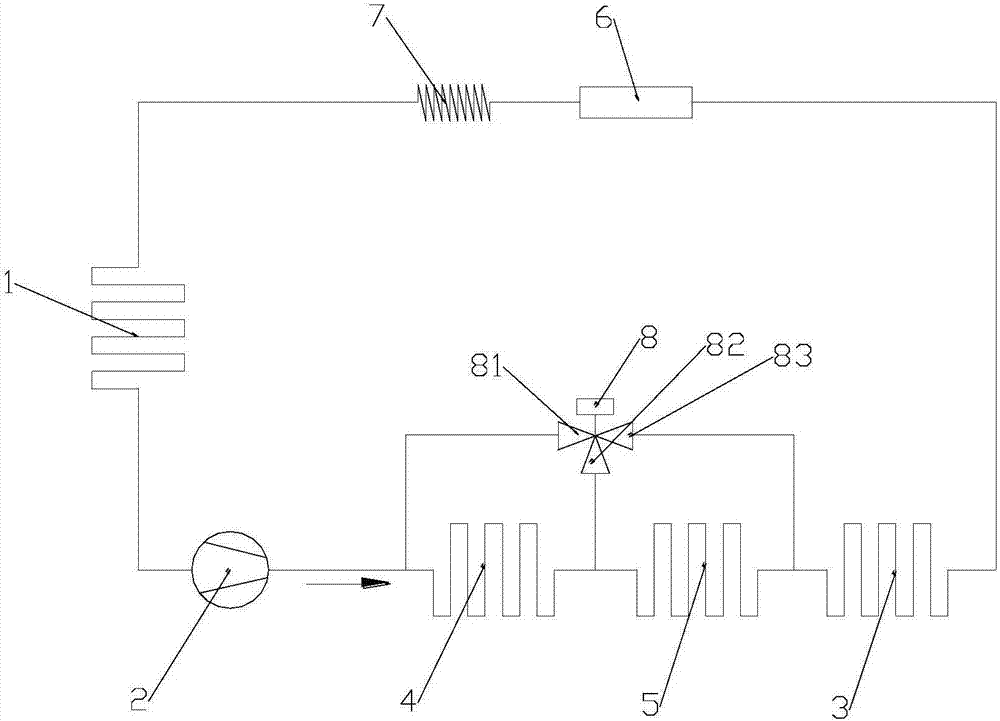

[0041] Such as Figure 3-Figure 4As shown, a refrigerator anti-condensation refrigeration system in this embodiment includes a controller 9, a humidity sensor 10, a solenoid valve 8, an evaporator 1, a compressor 2, multiple condensers, an anti-condensation tube 3 and a capillary tube 7 The evaporator 1, the compressor 2, multiple condensers, the anti-condensation tube 3 and the capillary tube 7 are sequentially connected to form a refrigerating cycle; the refrigerant circulates in the refrigerating cycle.

[0042] The electromagnetic valve 8 includes an inlet 81 and a plurality of outlets, the inlet 81 of the electromagnetic valve 8 communicates with the refrigerant outlet of the compressor 2, and the outlets of the plurality of electromagnetic valves 8 are connected to the plurality of outlets of the electromagnetic valve 8 respectively. The refrigerant outlets of the condenser are connected in one-to-one correspondence;

[0043] The humidity sensor 10 is used to collect th...

Embodiment 2

[0058] Such as Image 6 As shown, in this embodiment, a method for anti-condensation using the anti-condensation refrigeration system of the refrigerator described in Embodiment 1 includes the following steps:

[0059] S1, when the refrigeration system starts to operate, use the humidity sensor to collect the humidity value of the environment around the refrigerator;

[0060] S2, controlling the inlet and an outlet of the electromagnetic valve to open according to the humidity value.

[0061] The S2 specifically also includes, judging whether the humidity value is within a plurality of preset humidity ranges, the plurality of humidity ranges do not overlap each other and each of the humidity ranges corresponds to one of the outlets; when the humidity value When the humidity value is within the humidity range corresponding to one of the outlets, the outlet is controlled to be opened, and the other outlets are closed; when the humidity values are not within the humidity range...

Embodiment 3

[0065] A refrigerator in this embodiment includes the anti-condensation cooling system for the refrigerator described in Embodiment 1. The refrigerator of this embodiment has a better anti-condensation effect in a high-humidity environment, and can effectively reduce the temperature of the anti-condensation tube in a low-humidity environment, thereby improving the power consumption of the refrigerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com