Energy-saving diesel engine oil and preparation method thereof

A diesel engine oil, energy-saving technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problem of not meeting the requirements of users' fuel-saving rate, and achieve the effects of saving fuel consumption, saving fuel, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

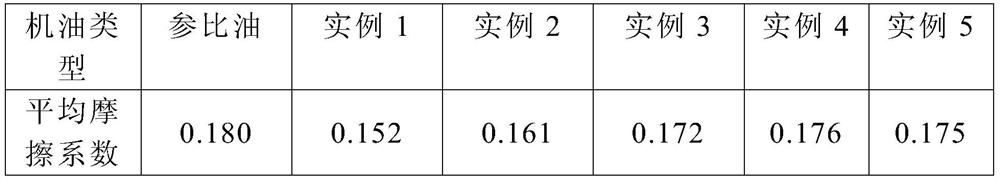

Examples

Embodiment 1

[0026] The preparation method of energy-saving diesel engine oil comprises the steps of:

[0027] (1) Preparation components:

[0028] 67% base oil: 95% polyalphaolefin PAOs and 5% alkylnaphthalene ANs composite; PAOs is the composite of PAO4 and PAO10 according to the mass ratio of 5:7; alkylnaphthalene ANs is the composite of AN5 and AN12 according to the mass ratio of 3:4 complex;

[0029] 3% anti-friction additive: 50% tungsten disulfide and 50% molybdenum disulfide co-doped compound;

[0030] 5% detergent: overbased sulfurized calcium alkylphenate;

[0031] 12% dispersant: 50% borated polyisobutylene succinimide T154B and 50% PIBSA-PE polyisobutylene succinic anhydride-polyisobutylene succinic anhydride;

[0032] 3% antioxidant: ZDTC zinc dialkyldithiocarbamate;

[0033] 10% viscosity index agent: OCP ethylene propylene copolymer, wherein the molar ratio of ethylene propylene is 48:52.

[0034] (2) Add base oils PAO4, PAO10, AN5, AN12 into the blending tank for blend...

Embodiment 2

[0039] The preparation method of energy-saving diesel engine oil comprises the steps of:

[0040] (1) Preparation components:

[0041] 60% base oil: 85% polyalphaolefin PAOs and 15% alkylnaphthalene ANs compound; PAOs is the compounding of PAO4 and PAO10 according to the mass ratio of 5:7; alkylnaphthalene ANs is the compounding of AN5 and AN12 according to the mass ratio of 3:4 complex;

[0042] 1.5% anti-friction additive: 60% tungsten disulfide and 40% molybdenum disulfide co-doped compound;

[0043] 10% Detergent: Overbased sulfurized calcium alkylphenate;

[0044] 5.5% dispersant: 60% borated polyisobutylene succinimide T154B and 40% PIBSA-PE polyisobutylene succinic anhydride-polyisobutylene succinic anhydride;

[0045] 3% antioxidant: ZDTC zinc dialkyldithiocarbamate;

[0046] 20% viscosity index agent: OCP ethylene propylene copolymer, wherein the molar ratio of ethylene propylene is 48:52.

[0047] (2) Add base oils PAO4, PAO10, AN5, AN12 into the blending tank for...

Embodiment 3

[0052] The preparation method of energy-saving diesel engine oil comprises the steps of:

[0053] (1) Preparation components:

[0054] 70% base oil: 90% poly-α-olefin PAOs and 10% alkylnaphthalene ANs composite; PAOs is the composite of PAO4 and PAO10 according to the mass ratio of 5:7; alkylnaphthalene ANs is the composite of AN5 and AN12 according to the mass ratio of 3:4 complex;

[0055] 0.5% antifriction additive: 55% tungsten disulfide and 45% molybdenum disulfide co-doped compound;

[0056] 5.6% Detergent: overbased sulfurized calcium alkylphenate;

[0057] 20% dispersant: 55% borated polyisobutylene succinimide T154B compounded with 45% PIBSA-PE polyisobutylene succinic anhydride-polyisobutylene succinic anhydride;

[0058] 0.1% antioxidant: ZDTC zinc dialkyldithiocarbamate;

[0059] 3.8% viscosity index agent: OCP ethylene propylene copolymer, wherein the molar ratio of ethylene propylene is 48:52.

[0060] (2) Add base oils PAO4, PAO10, AN5, AN12 into the blendi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersion coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com