Patents

Literature

707 results about "Ethylene propylene copolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultimately, Ethylene/Propylene/Styrene Copolymer is used in skin care products to create a gel-like consistency and stabilize the formula. According to The Cosmetics Database, it is a polymer of ethylene, propylene and styrene that has been hydrogenated.

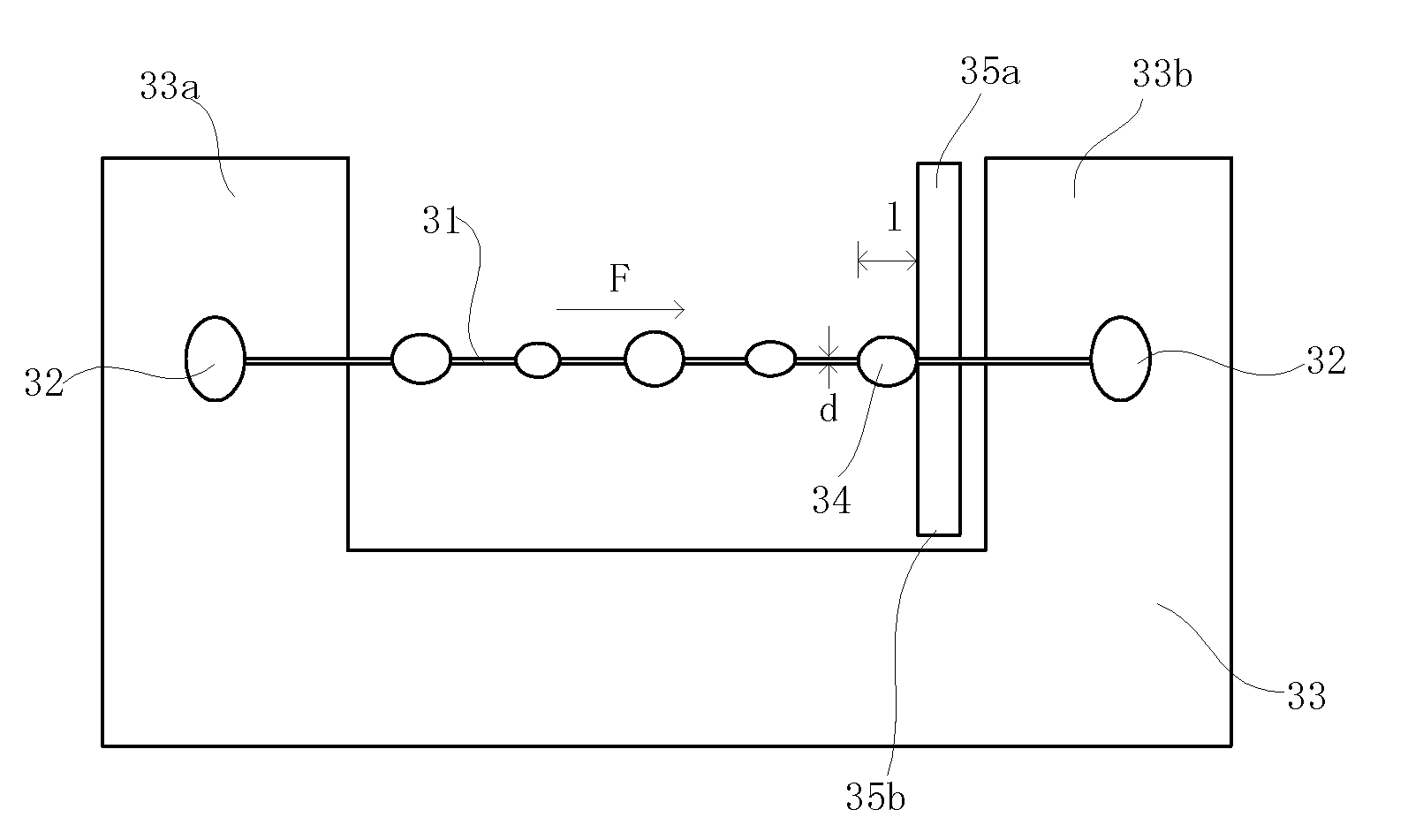

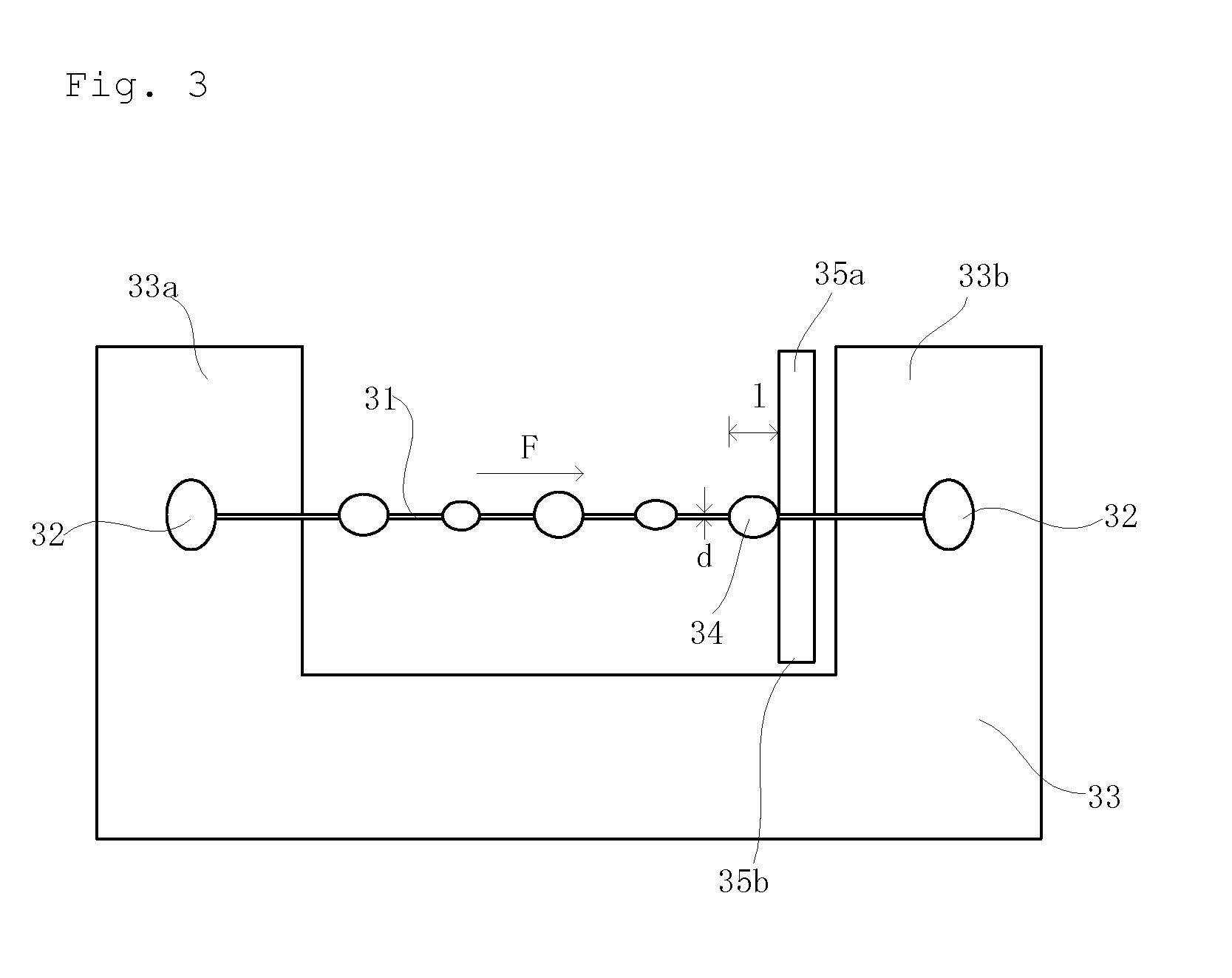

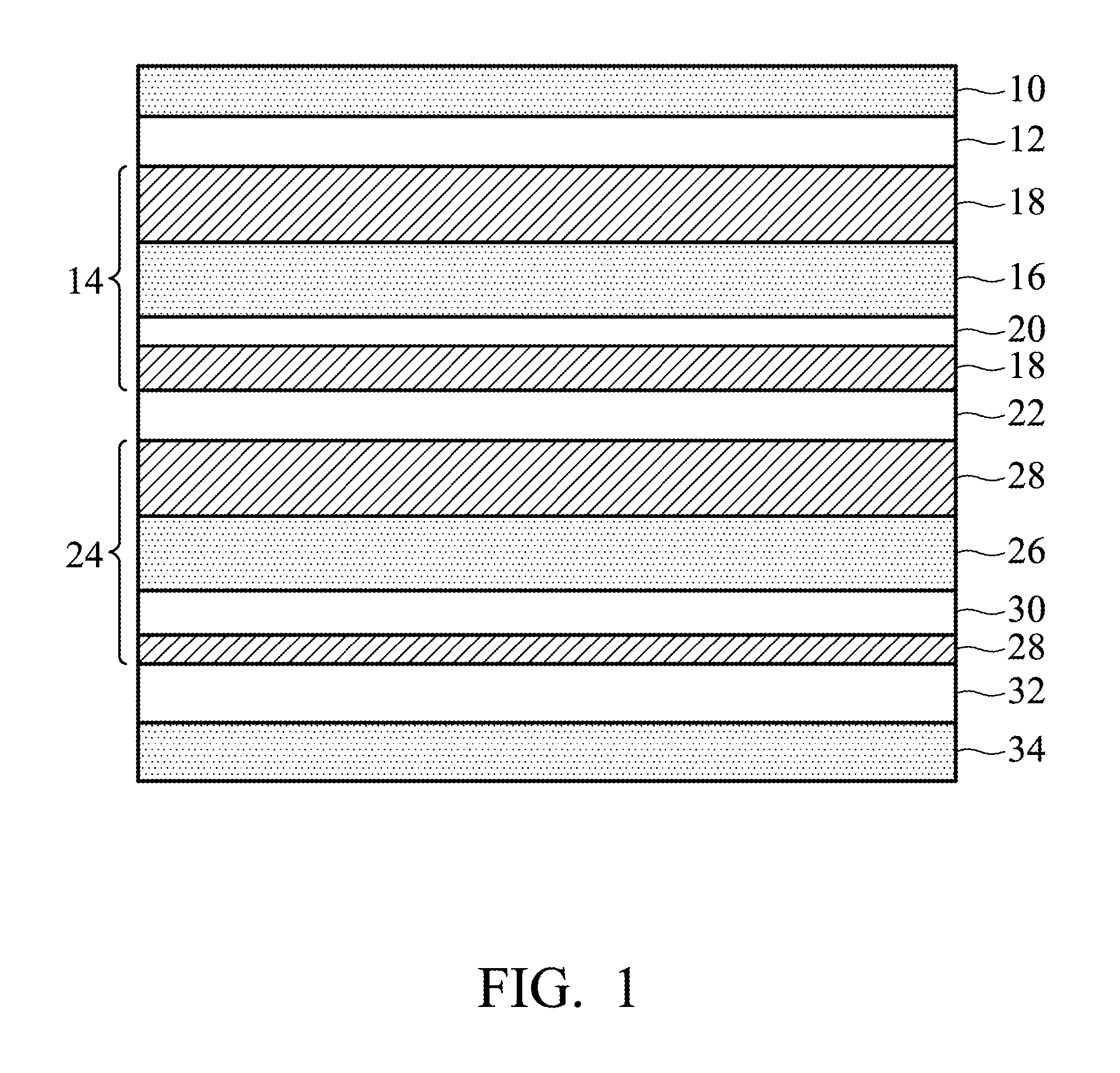

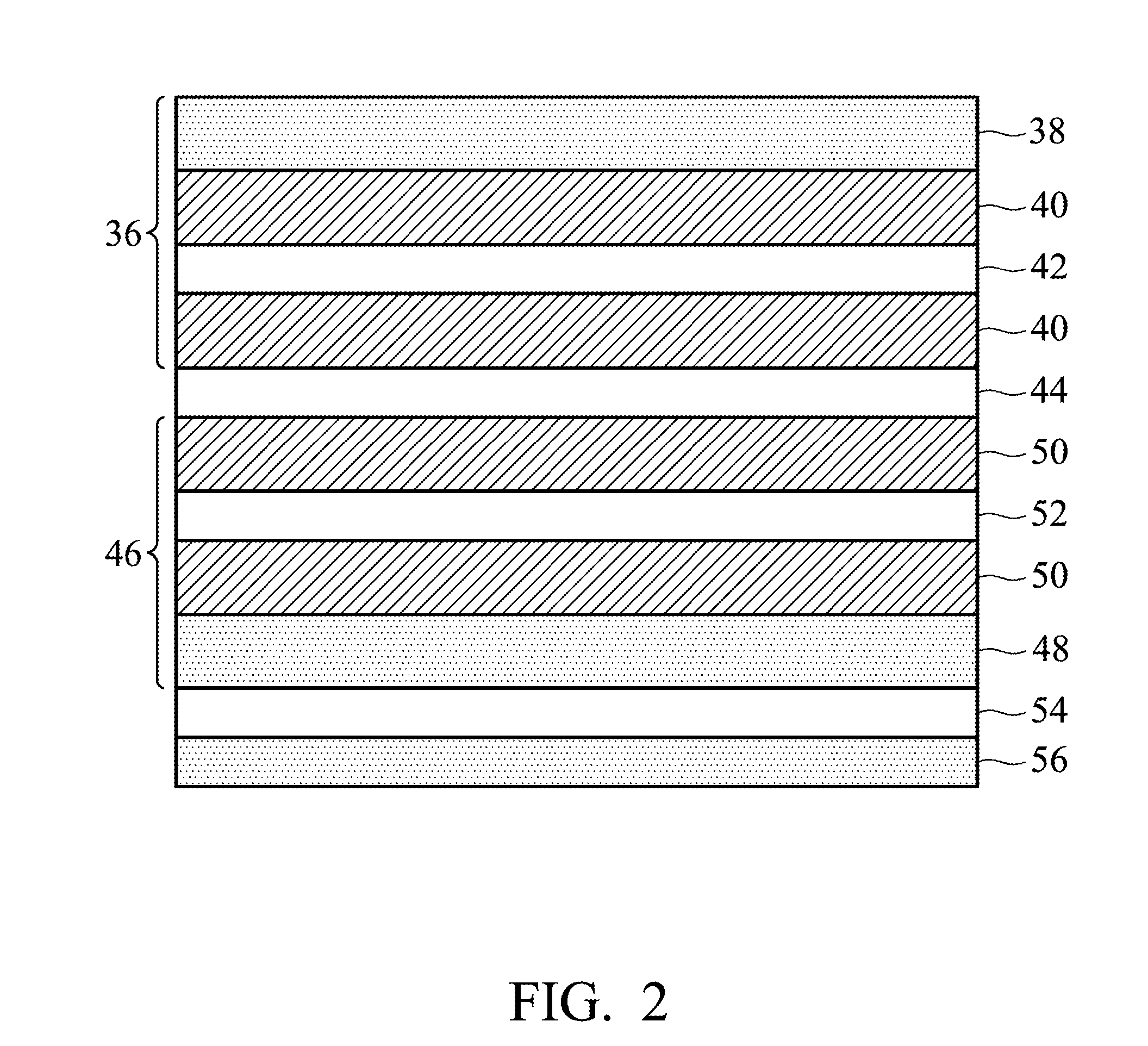

Heat-shrinkable polymeric films

InactiveUS6908687B2High and predictable and controlled shrinkage characteristicGood optical claritySynthetic resin layered productsSausage casingsOptical transparencyControl layer

The present invention relates to oriented or hot-blown shrink films which may be manufactured from by a number of processes. The oriented films may be manufactured by double bubble, LISIM, tape bubble, trapped bubble or tenter framing processes. The films of the present invention are useful as a shrink film to package and label a variety of products. The films exhibit a high degree of MD shrinkage in a very controlled and consistent manner while providing a number of other positive characteristics such as optical clarity, puncture and abrasion resistance, controlled gauge, and superior web winding and handling characteristics. The shrink control layers of the films of the present invention contain a modifier component selected from plastomers and / or metallocene catalyzed ethylene-propylene copolymers and blends thereof.

Owner:JINDAL INNOVATION CENT SRL

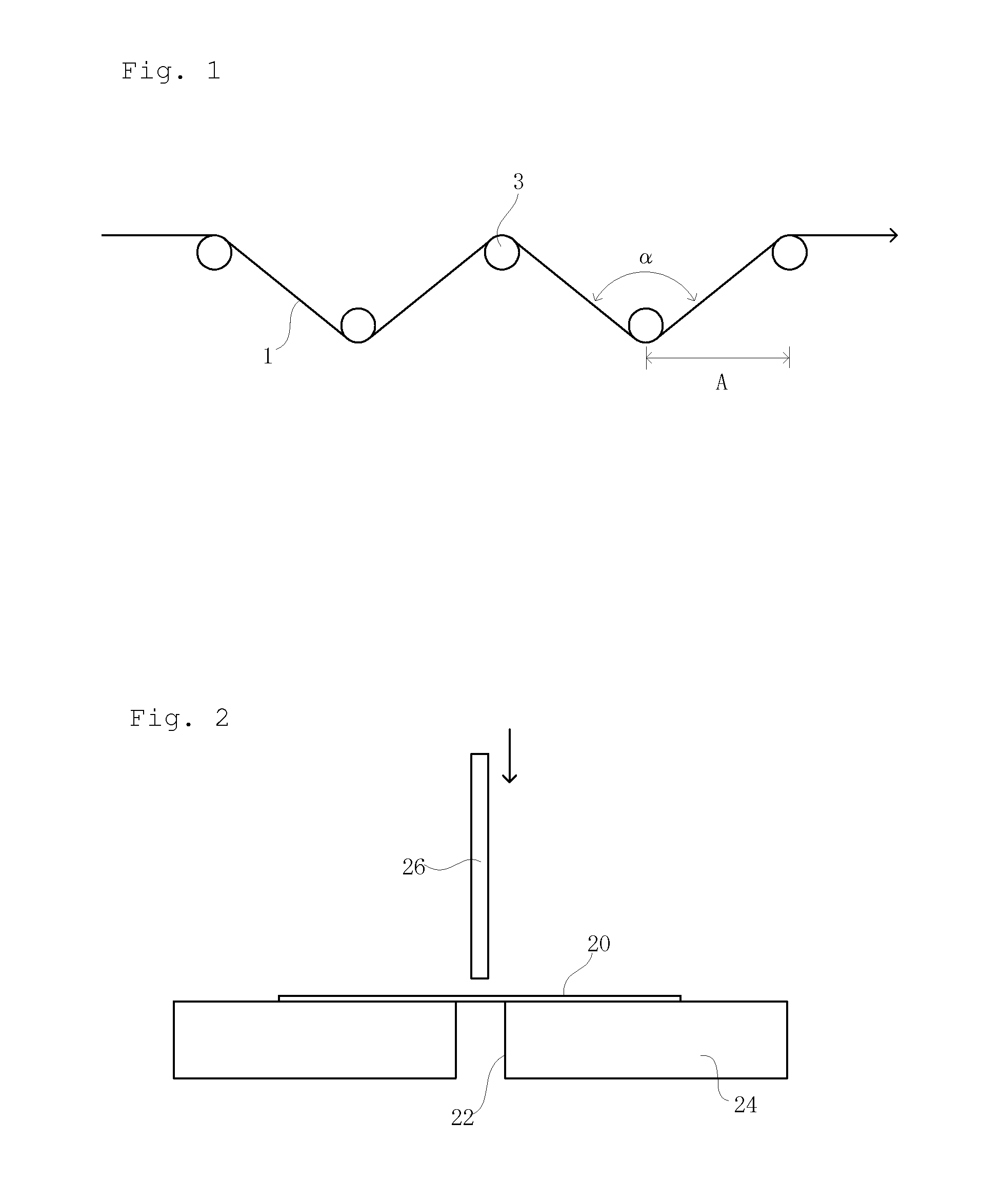

Polyalkylene microporous diaphragm for lithiam ion battery and manufacturing method thereof

InactiveCN101000952AImprove securityImprove heat resistanceSynthetic resin layered productsCell component detailsPolyolefinPhase separation process

Owner:许贵斌

Carbon Fiber Strand for Reinforcing Thermoplastic Resins and Method of Producing the Same

InactiveUS20090062426A1Superior in adhesivityHigh mechanical strengthCarbon fibresPretreated surfacesFiberButene

There are disclosed a carbon fiber strand for reinforcement of thermoplastic resin, wherein a sizing agent containing a resin composition obtained by mixing a component [A], i.e. an acid-modified polyolefin copolymer having a weight-average molecular weight of 15,000 to 150,000, which has, as the main chain, an ethylene-propylene copolymer, a propylene-butene copolymer or an ethylene-propylene-butene copolymer and in which the main chain has been modified with 0.1 to 20% by mass of an unsaturated carboxylic acid, and a component [B], i.e. an acid-modified polypropylene having a weight-average molecular weight of 3,000 to 150,000, which has, as the main chain, a polypropylene and in which the main chain has been modified with 0.1 to 20% by mass of an unsaturated carboxylic acid, at a mass ratio of 1:20 to 10:5, is adhered to 100 parts by mass of a carbon fiber in an amount of 0.1 to 8.0 parts by mass; a method for producing the above strand; and a carbon fiber-reinforced thermoplastic resin containing the above strand.

Owner:TEIJIN TECHNO PRODUCTS LTD

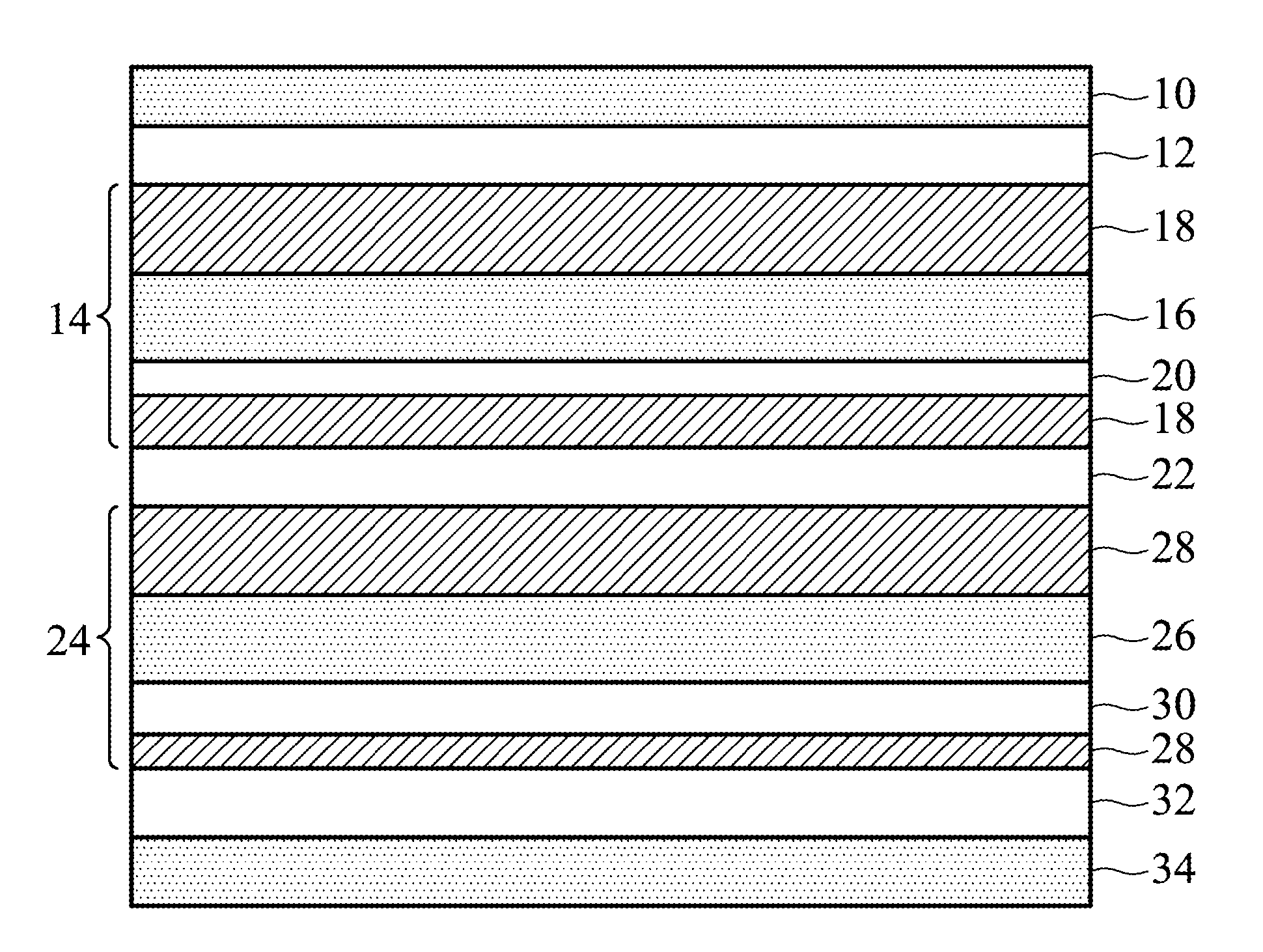

Gas-barrier heat-seal composite films and vacuum insulation panels comprising the same

ActiveUS20120148785A1High gas barrierImprove adhesionSynthetic resin layered productsRecord information storageLow-density polyethyleneLinear low-density polyethylene

A gas-barrier heat-seal composite film is provided. The gas-barrier heat-seal composite film includes a heat-seal layer including very low density polyethylene (VLDPE), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), high density polyethylene (HDPE), metallocene polyethylene (mPE), metallocene linear low density polyethylene (mLLDPE), ethylene vinyl acetate (EVA) copolymer, ethylene-propylene (EP) copolymer or ethylene-propylene-butene (EPB) terpolymer, and a gas-barrier layer formed on the heat-seal layer, wherein the gas-barrier layer includes a plurality of composite layers, each including a polymer substrate and a single layer or multiple layers of metal or oxide thereof which is formed on one side or both sides of the polymer substrate, and the polymer substrate includes uniaxial-stretched or biaxial-stretched polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyimide (PI), ethylene / vinyl alcohol (EVOH) copolymer or a combination thereof. The invention also provides a vacuum insulation panel including the composite film.

Owner:IND TECH RES INST

Tie-layer for polyolefin films

ActiveUS20060257652A1Improve barrier propertiesExcellent gas barrier performanceSynthetic resin layered productsBagsPolymer sciencePolyolefin

A laminate film including a first polyolefin layer comprising of a blend of 50-95% ethylene-propylene copolymer and 50-5% ethylene polar terpolymer with a polar polymer layer on one side of said first polyolefin resin-containing layer is disclosed. The laminate film could further have additional layers such as a second polyolefin resin-containing layer, a metal layer, or combinations thereof.

Owner:TORAY PLASTICS AMERICA

High temperature stable thermal interface material

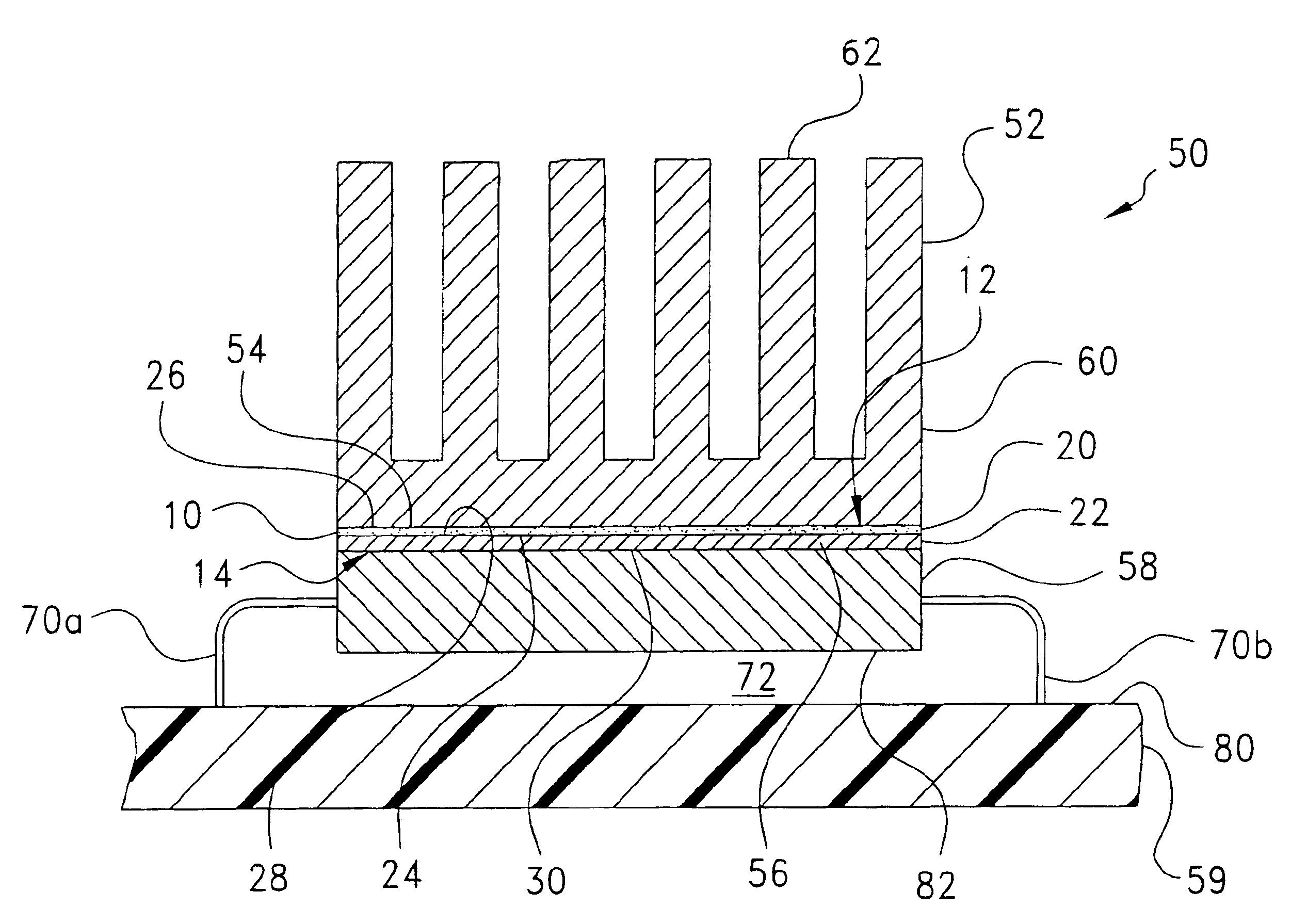

InactiveUS6956739B2Reduce thermal resistanceImprove performanceSemiconductor/solid-state device detailsSynthetic resin layered productsParticulatesLiquid resin

A thermally-conductive interface interposable intermediate a first heat transfer surface and an opposing second heat transfer surface to provide a thermal pathway therebetween. The interface includes a thermally-conductive compound formed into a layer which is conformable between the first and second heat transfer surface. The compound is an admixture of: (a) a liquid resin constituent; and (b) a particulate filler constituent. The liquid resin constituent may be an ethylene-propylene copolymer (EPM) or a terpolymer (EPDM) of ethylene and propylene and a diene which may be ethylidene norbornene (ENB) or dicyclopentadiene (DCPD).

Owner:PARKER INTANGIBLES LLC

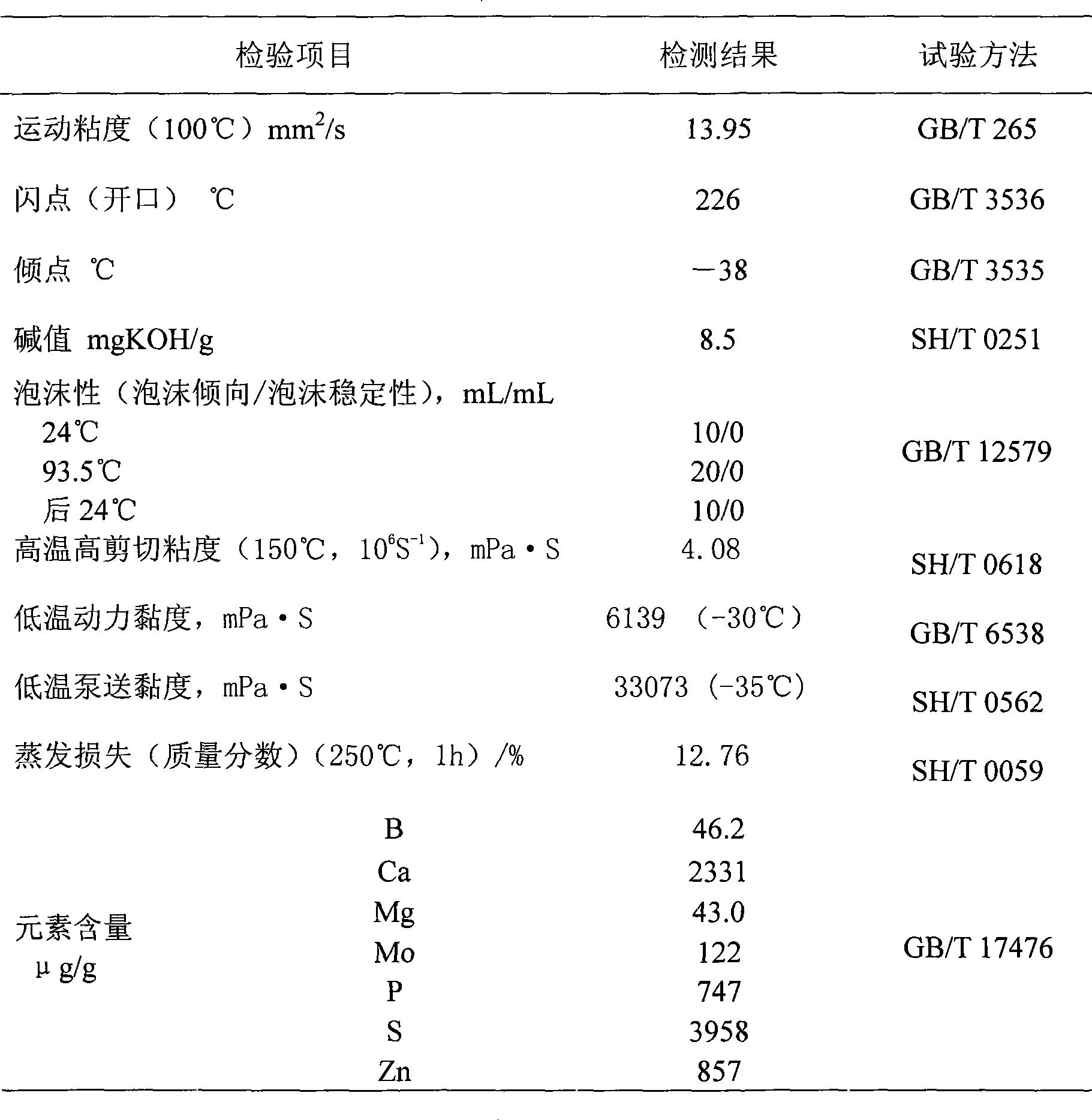

Engine oil suitable for pluralities of fuel

InactiveCN101418250AHave performance requirementsImprove anti-friction and anti-wear effectAdditivesBase-materialsPhenolDiesel engine

The invention relates to engine oil suitable for multiple fuels, and belongs to the field of engine oil for an automobile. The engine oil comprises the following raw materials in mass portion: 33 to 36 portions of base oil 150SN, 22 to 24 portions of base oil VHVI H350 (type III), 15 to 17 portions of poly alpha-alkene, 2 to 4 portions of ester oil of C8 to C10, 11 to 13 portions of ethylene-propylene copolymer the molecular weight of which is between 63,000 and 108,000 as viscosity index improver, 0.4 to 1.2 portions of zinc dialkyl dithiophosphate as additive for resisting oxidation and corrosion as well as abrasion, 1.1 to 4.8 portions of alkyl phenol calcium and 1.9 to 2.5 portions of calcium sulfonate as detergent, 3.8 to 5.0 portions of polyisobutene succimide as dispersant, and 0.001 to 0.003 portion of methyl silicone oil as antifoaming agent. The engine oil meets performance requirements of automobile and engine manufacturers at home and abroad on gasoline engine oil and sedan diesel engine oil.

Owner:CHANGCHUN YONGCHANG PETROCHEM

Thermoplastic elastomer composition

Disclosed is a thermoplastic elastomer composition including a thermoplastic elastomer (A) having a side chain having at least one member selected from the group consisting of imino group, nitrogen-containing heterocycle and covalent crosslink site, and a carbonyl-containing group, and an ethylene-propylene copolymer (B) comprising propylene block and ethylene-propylene block. The thermoplastic elastomer of the present invention exhibits excellent high temperature flowability and mechanical strength while retaining its excellent flexibility.

Owner:THE YOKOHAMA RUBBER CO LTD

Composite carrier of catalysts for propylene polymerization, a catalyst component and a catalyst comprising the same

InactiveUS20040229748A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationElectron donorSilicon dioxide

The present invention is to provide a composite carrier, which is spheric particles obtainable by contacting magnesium halide with one or more electron donor compounds to form a solution, then mixing the solution with silica material having an average particle size of less than 10 microns to form a mixture, and drying the mixture through spray drying process. The present invention is also to provide a catalyst component comprising said composite carrier. When the catalyst component is used together with a cocatalyst component in propylene polymerization, it exhibits higher polymerization activity and stereospecificity, and can be used to prepare high impact resistant ethylene-propylene copolymer having high ethylene content.

Owner:CHINA PETROCHEMICAL CORP +1

Catalyst for catalytic pyrolysis

ActiveCN101428233AHigh hydrothermal stabilityIncrease acidityMolecular sieve catalystsBulk chemical productionCatalytic pyrolysisPetroleum naphtha

The invention relates to a catalyst for catalytic cracking and mainly solves the problems of high service temperature and low yield of ethylene-propylene copolymer in the prior catalyst for catalytic cracking in ethylene-propylene copolymer synthesis. In order to solve the problems, the technical scheme is as follows: the catalyst is obtained by loading at least one element of the group IB or the group IIB in the periodic table of elements on a ZSM-5 / mordenite molecular sieve, ZSM-5 / beta-zeolite molecular sieve or ZSM-5 / Y-zeolite molecular sieve. The catalyst is applied to the industrial production of ethylene-propylene copolymer via catalytic cracking of petroleum naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

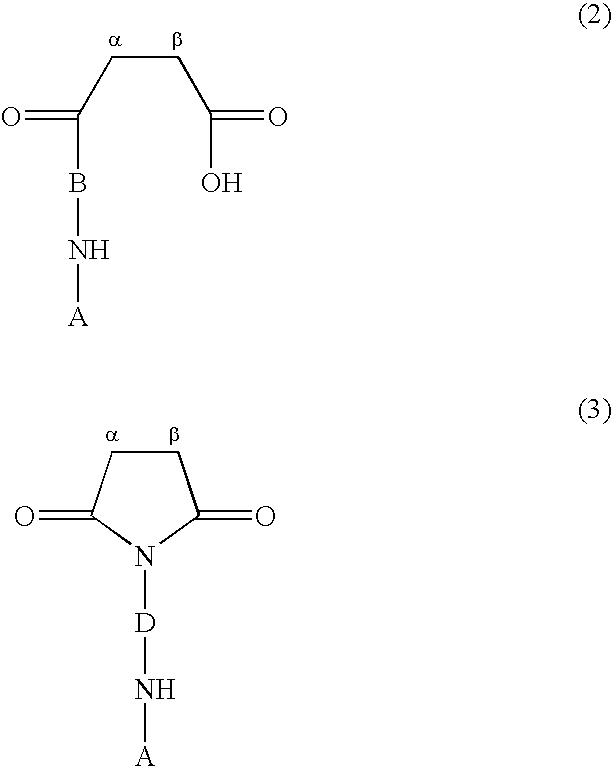

Rubber mixtures

ActiveCN102731915AHysteresis loss is smallImproved Dynamic BehaviorThin material handlingPolyesterPolymer science

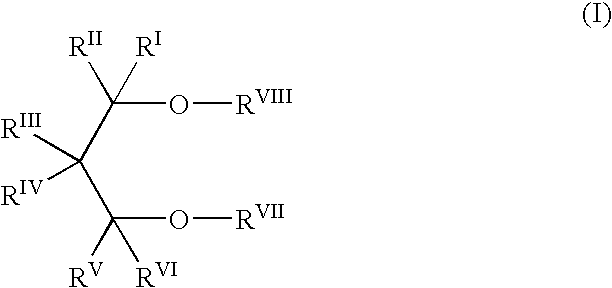

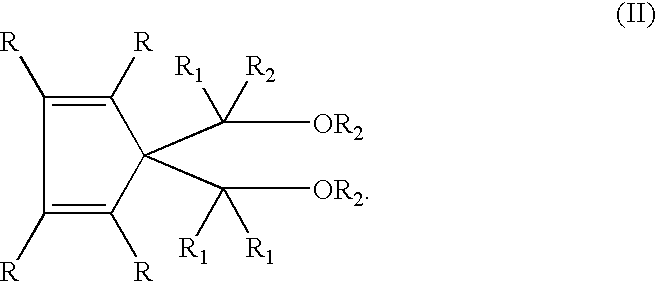

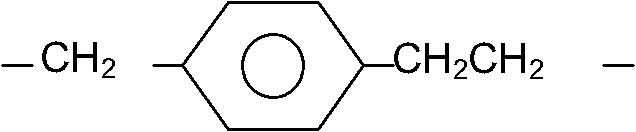

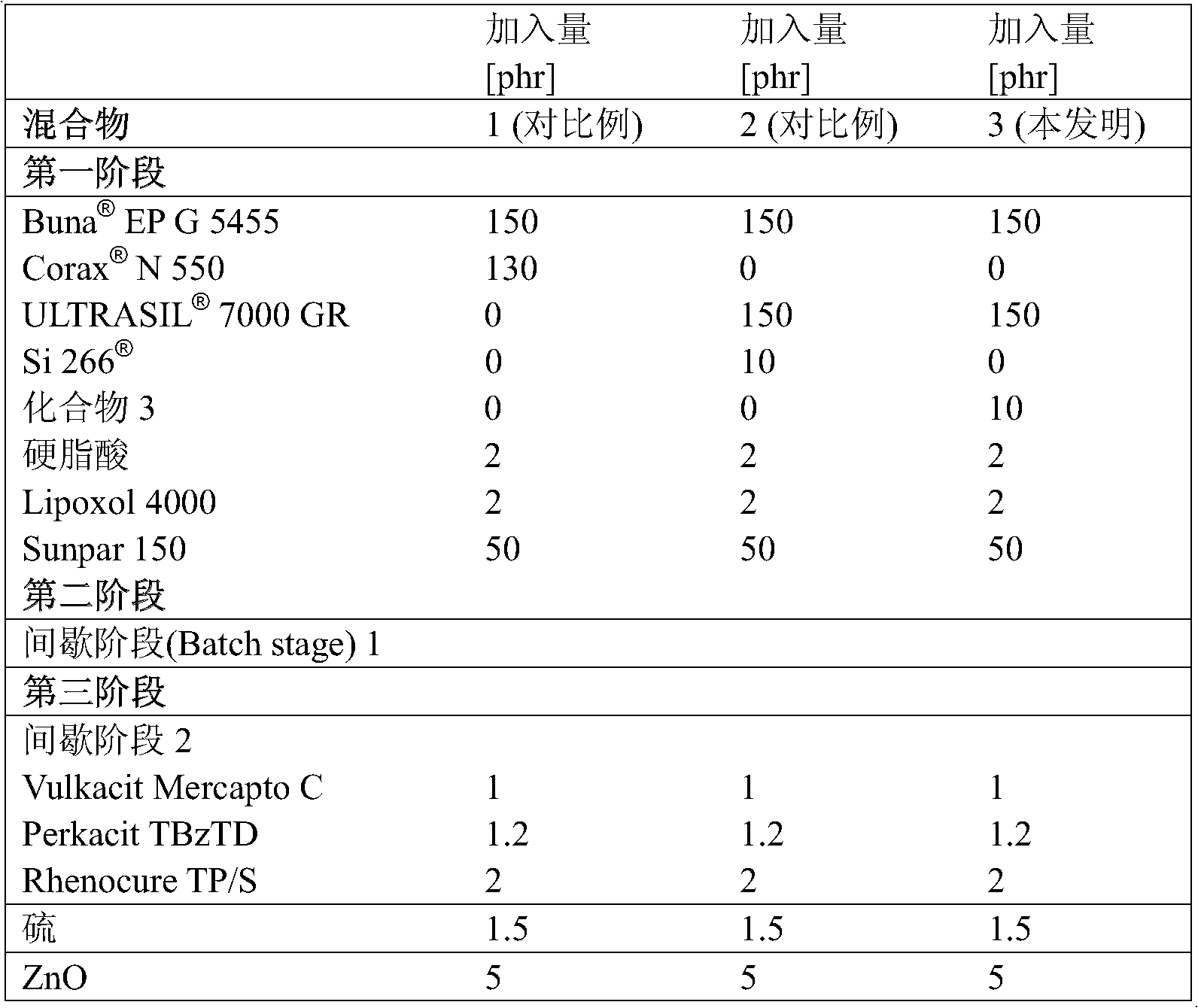

A rubber mixture, comprising (A) at least one rubber selected from the group of ethylene-propylene-diene copolymer (EPDM), ethylene-propylene copolymer (EPM), chloroprene rubber (CR), chloropolyethylene (CM), chloro-isobutene-isoprene (chlorobutyl) rubber (CIIR), chlorosulfonyl polyethylene (CSM), etylene-vinyl acetate copolymer (EAM), alkyl acrylate copolymer (ACM), polyester polyurethan (AU), polyether polyurethane (EU), bromo-isobutene-isoprene (bromobutyl)rubber (BIIR), polychlorotrifluoroethylene (CFM), isobutene-isoprene rubber (butyl rubber, IIR), isobutene rubber (IM), polyisoprene (IR), thermoplastic polyester polyurethane (YAU), thermoplastic polyether polyurethane (YEU), silicone rubber with methyl groups on the polymer chain (MQ), hydrogenated acrylonitrile-butadiene rubber (HNBR), acrylonitrile-butadiene rubber (NBR) or carboxylated acrylonitrile-butadiene rubber (XNBR), (B) at least one oxidic filler, and (C) at least one silicon containing azodicarbamide of the general formula I (R 1 ) 3-a (R 2 ) a Si-R I -NH-C(O) -N=N-C (O)-NH-R I -Si(R 1 ) 3-a (R 2 ) a (I) . The rubber mixture is produced by mixing at least one rubber, at least one oxidic filler, and at least one silicon containing azodicarbamide of the general formula I. It may be used for moldings.

Owner:EVONIK OPERATIONS GMBH

Cross-linked multilayer porous polymer membrane battery separators

ActiveUS20150056492A1Improve compatibilityImprove mechanical propertiesSecondary cellsCell component detailsCross-linkPolyolefin

A cross-linkable polyolefin composition (polyethylene, polypropylene or an ethylene-propylene copolymer) is coextruded with ultrahigh molecular weight polyethylene to form two-layer separator membranes, or three-layer separator membranes, for lithium-ion battery cells. In three-layer separator membranes, the cross-linkable polyolefin is formed as the outer faces of the separator for placement against facing surfaces of cell electrodes. The polymer materials initially contain plasticizer oil, which is removed from the extruded membranes, and the extruded membranes are also stretched to obtain a suitable open pore structure in the layered membranes to provide for suitable infiltration with a liquid electrolyte. The cross-linked polyolefin layer provides strength at elevated temperatures and the lower-melting, ultrahigh molecular weight polyethylene layer provides the separator membrane with a thermal shutdown capability.

Owner:GM GLOBAL TECH OPERATIONS LLC

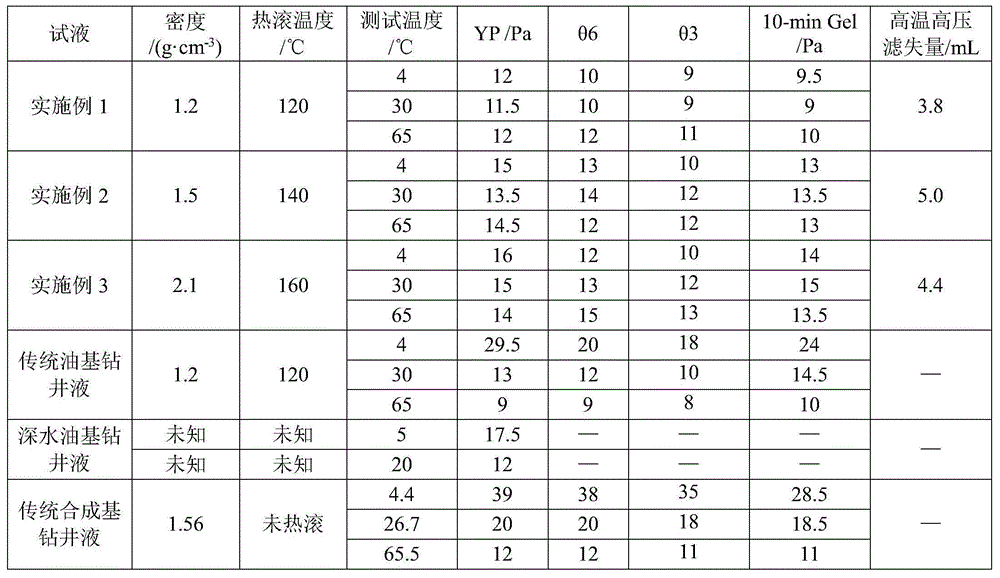

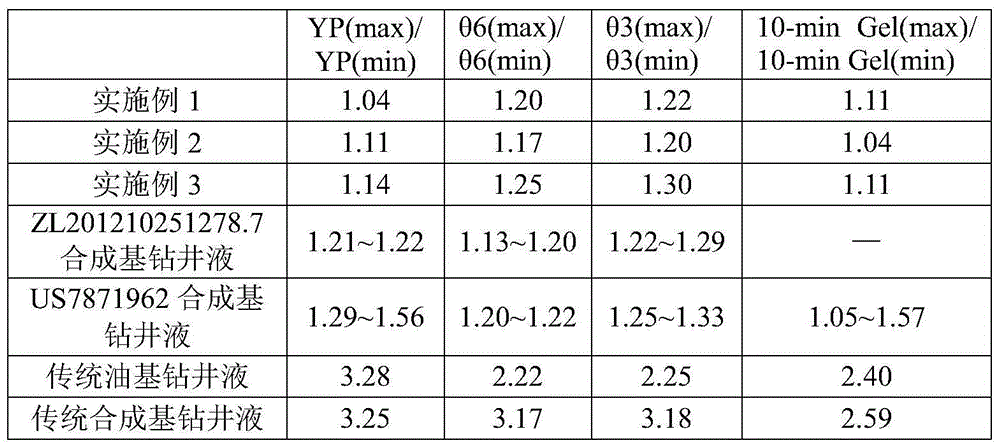

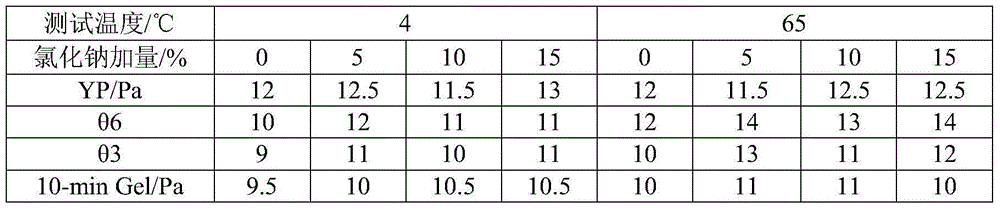

Deepwater constant-rheology oil base drilling fluid

ActiveCN104861944ARaw material requirements are relaxedLow costDrilling compositionDimer acidWhite oil

The invention discloses a deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling. The deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling comprises the following components in parts by weight: 70-100 parts of white oil, 0-30 parts of a calcium chloride aqueous solution, 1.5-5 parts of a fluid type conditioning agent, 1-4 parts of an emulsifying agent, 0.5-2.5 parts of a wetting agent, 1-3.5 parts of organic soil used for drilling fluid, 1.5-5 parts of a filtrate reducer, 0.2-0.6 parts of calcium oxide and 0-260 parts of a weighting agent. The fluid type conditioning agent is at least one of ethylene-propylene copolymer, polymethacrylate, trimeric acid, phenolic resin, copolymer generated from reaction of dimer acid, cholamine and polyethylene polyamine and copolymer generated from reaction of acrylamide, styrene and methacrylic acid. The movable shearing force and six-speed viscometer of the oil base drilling fluid is respectively less than 6 r / min and 3 r / min, and the 10-min static shearing force can be kept steady within 4-65 DEG C; constant eheology is realized in the temperature range of the barrel of the deepwater drilling, technical demands on sea deepwater drilling can be satisfied, requirements on base oil raw material are loose, and the cost is low.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Novel Propylene Polymer Blends

InactiveUS20070299173A1Maintain good propertiesHigh transparencyGroup 5/15 element organic compoundsSpecial tyresLinear low-density polyethyleneThermoforming

The invention relates to propylene polymer blends comprising 70-92 wt % of a propylene homopolymer, 5-15 wt % of an elastomeric ethylene-propylene copolymer, 3-15 wt % of a linear low density polyethylene and an a-nucleating agent. The propylene polymer blends have an excellent impact strength / stiffness balance and optical properties. They are especially suitable for thermoforming and extrusion blow moulding.

Owner:BOREALIS TECH OY

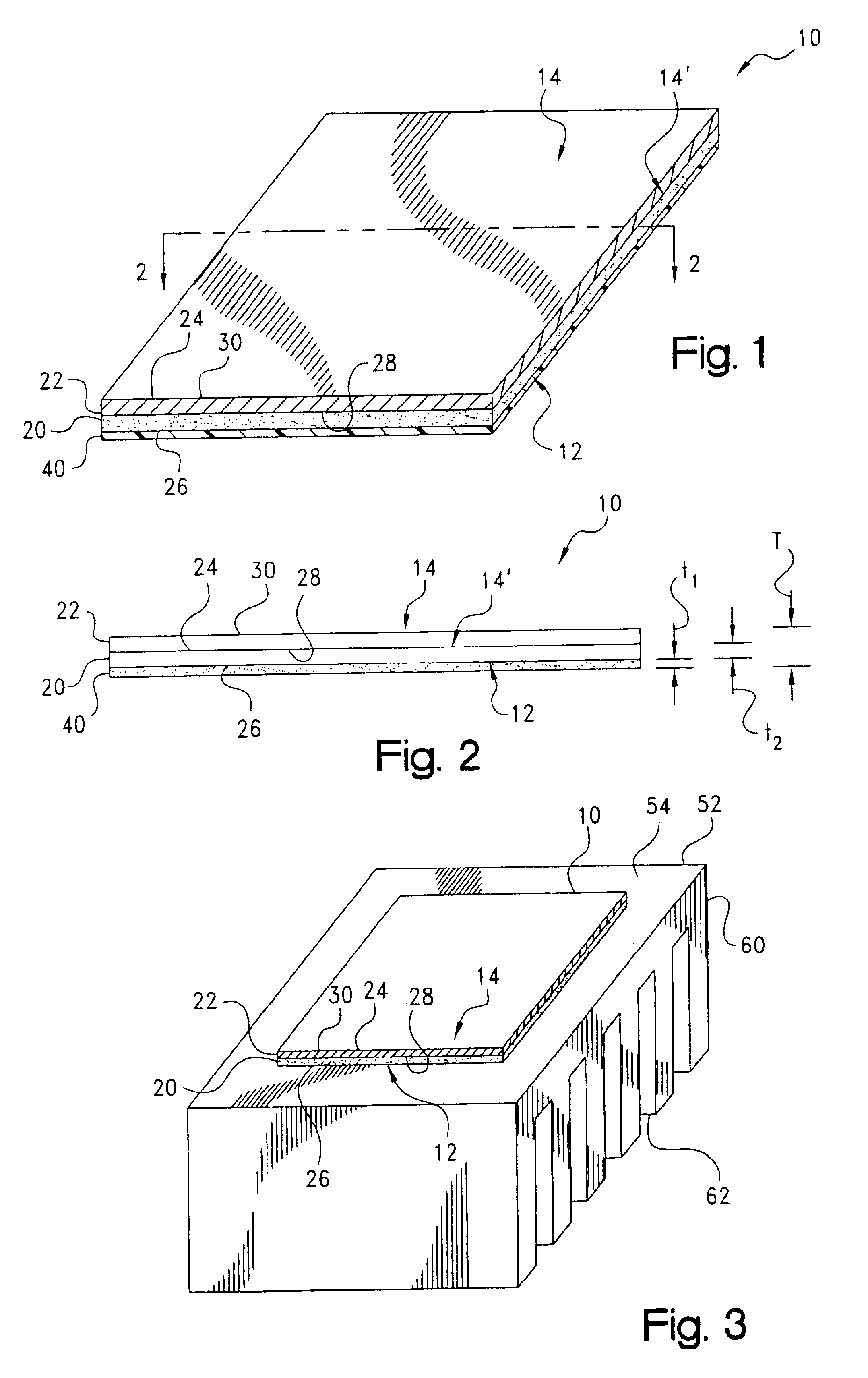

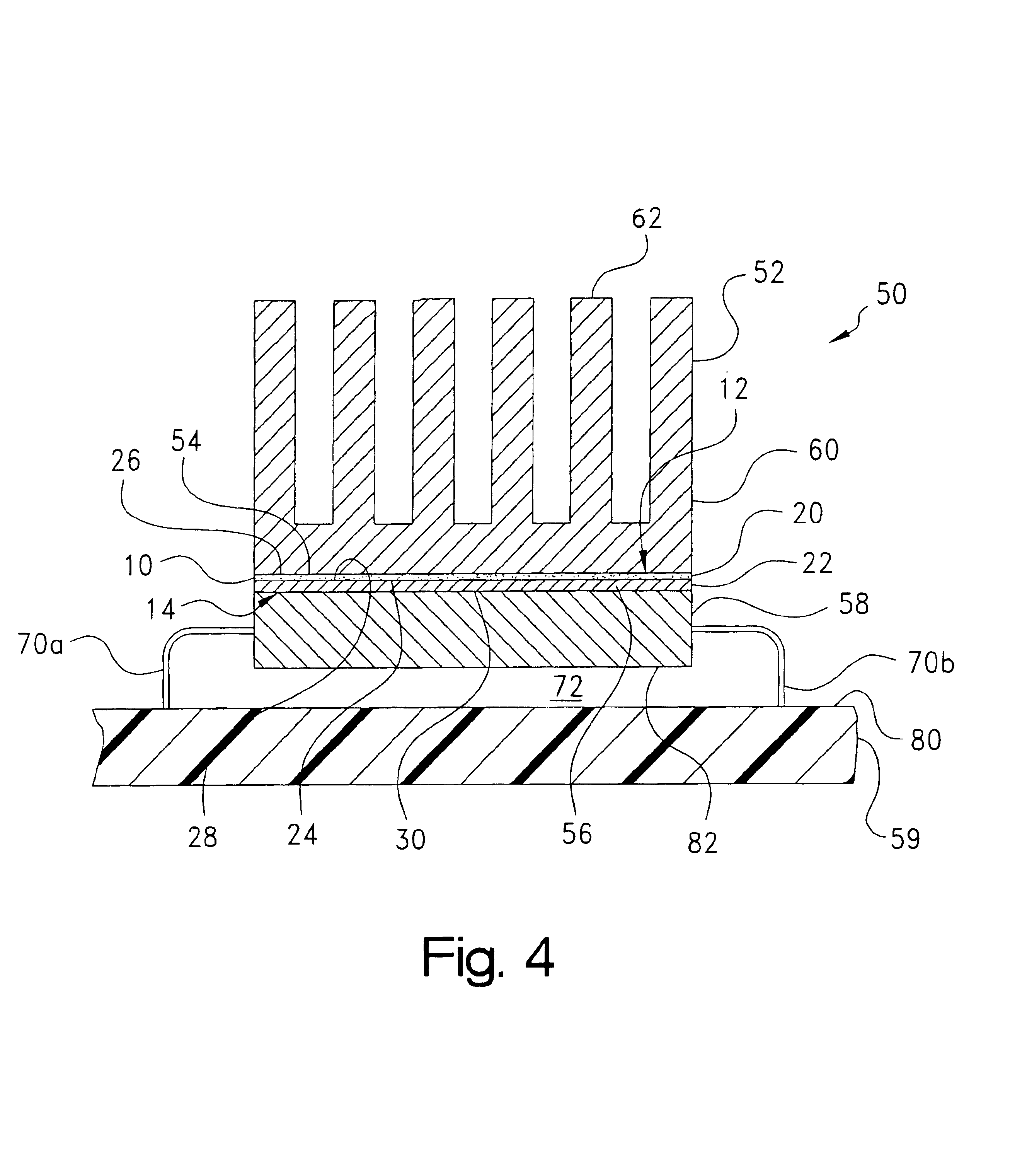

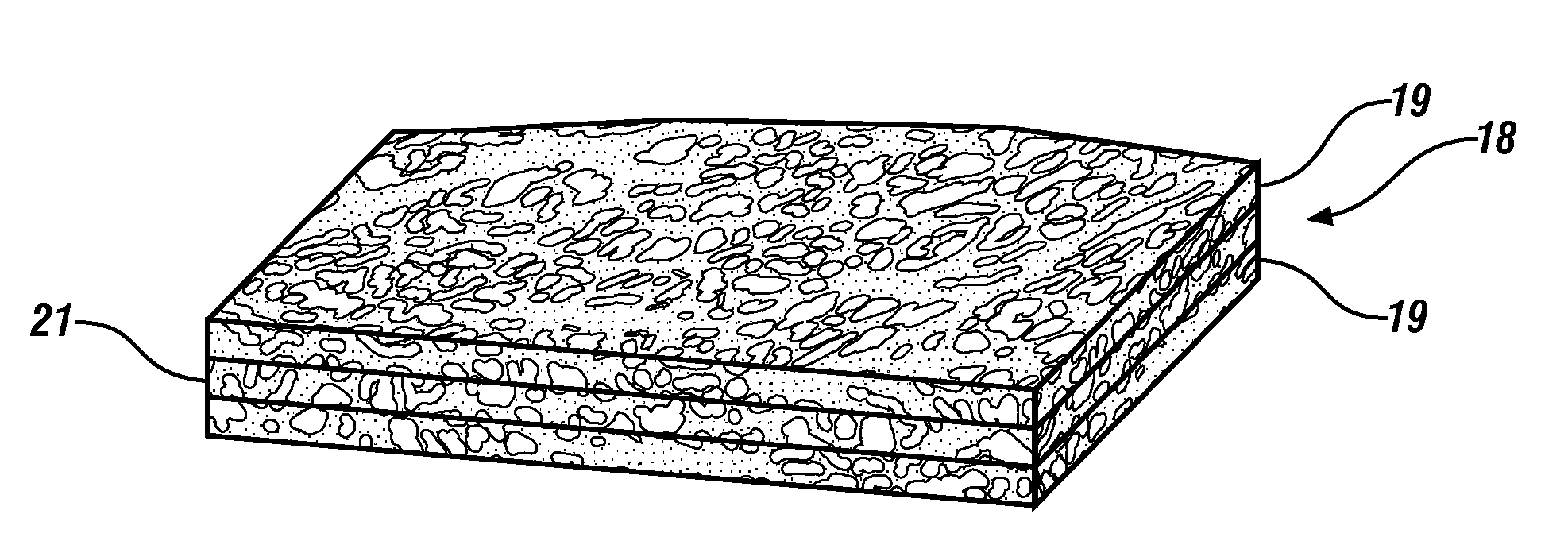

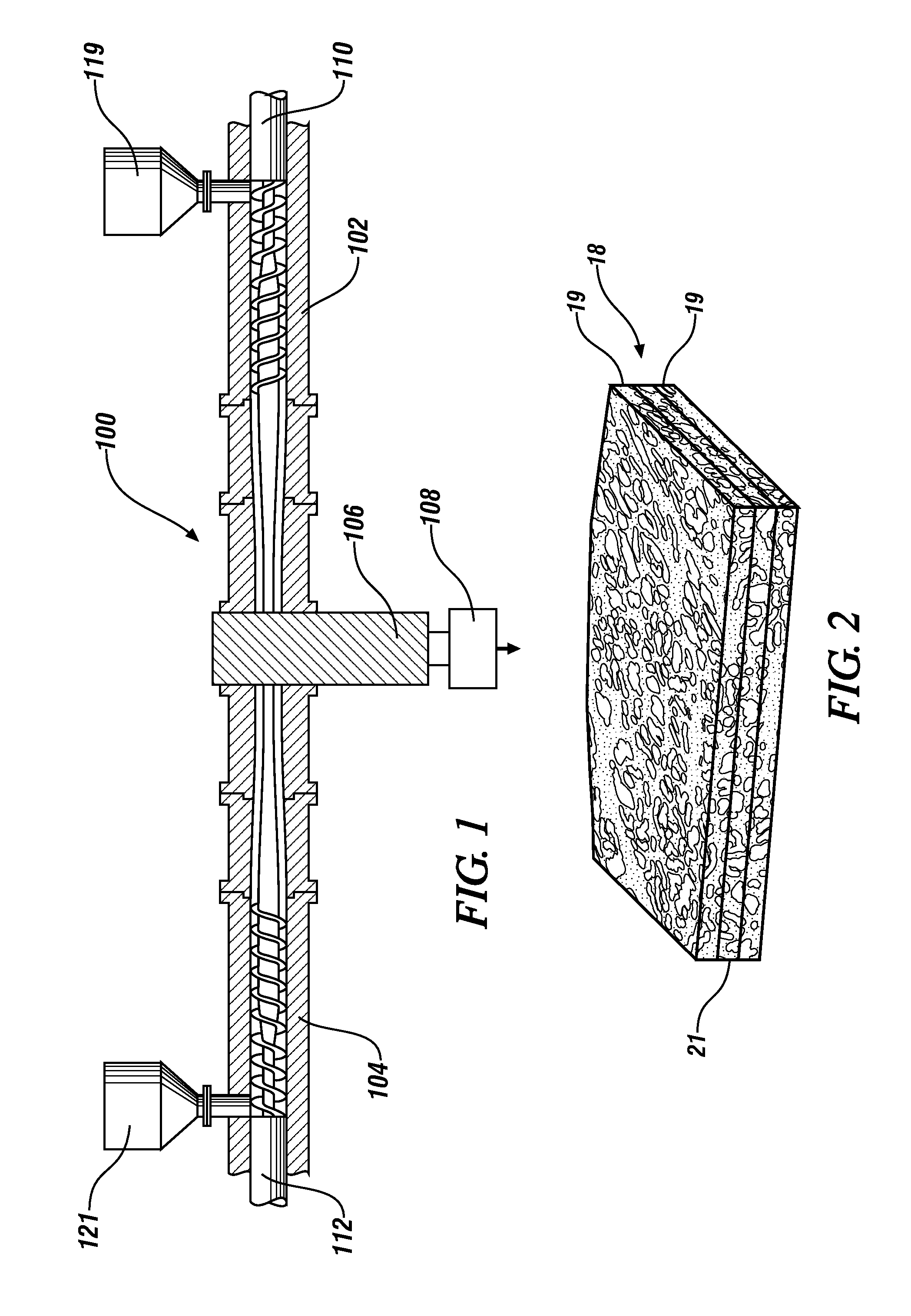

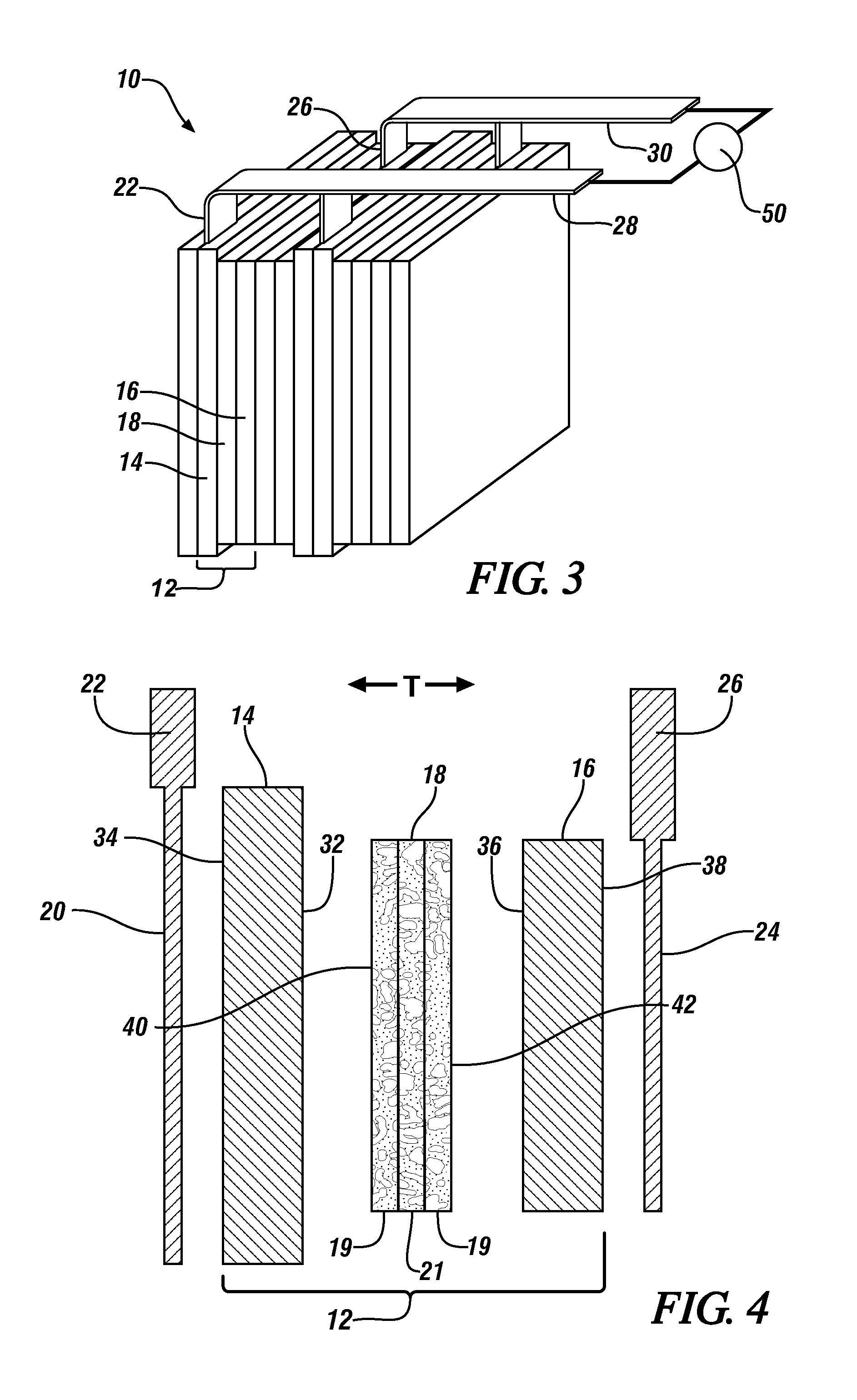

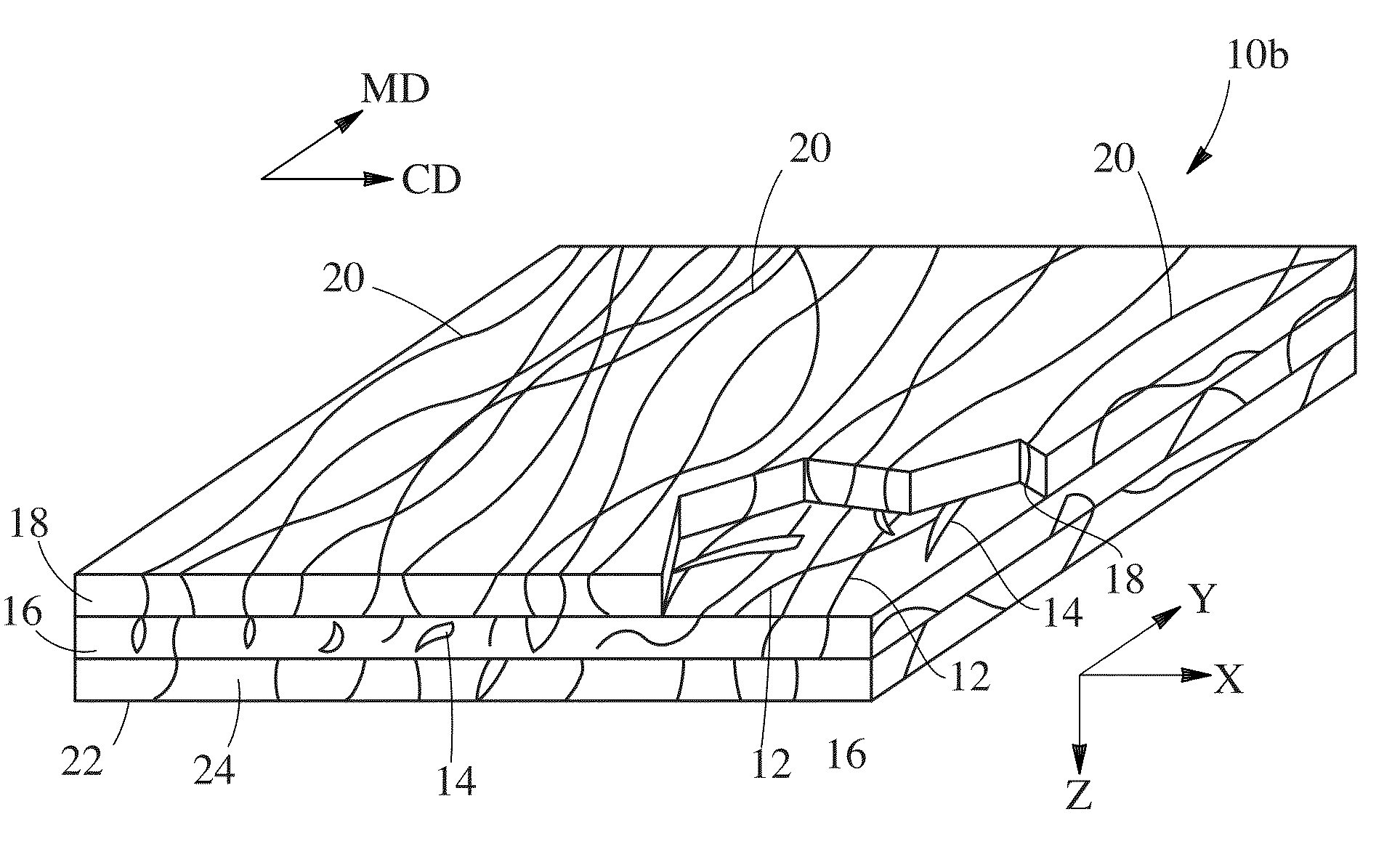

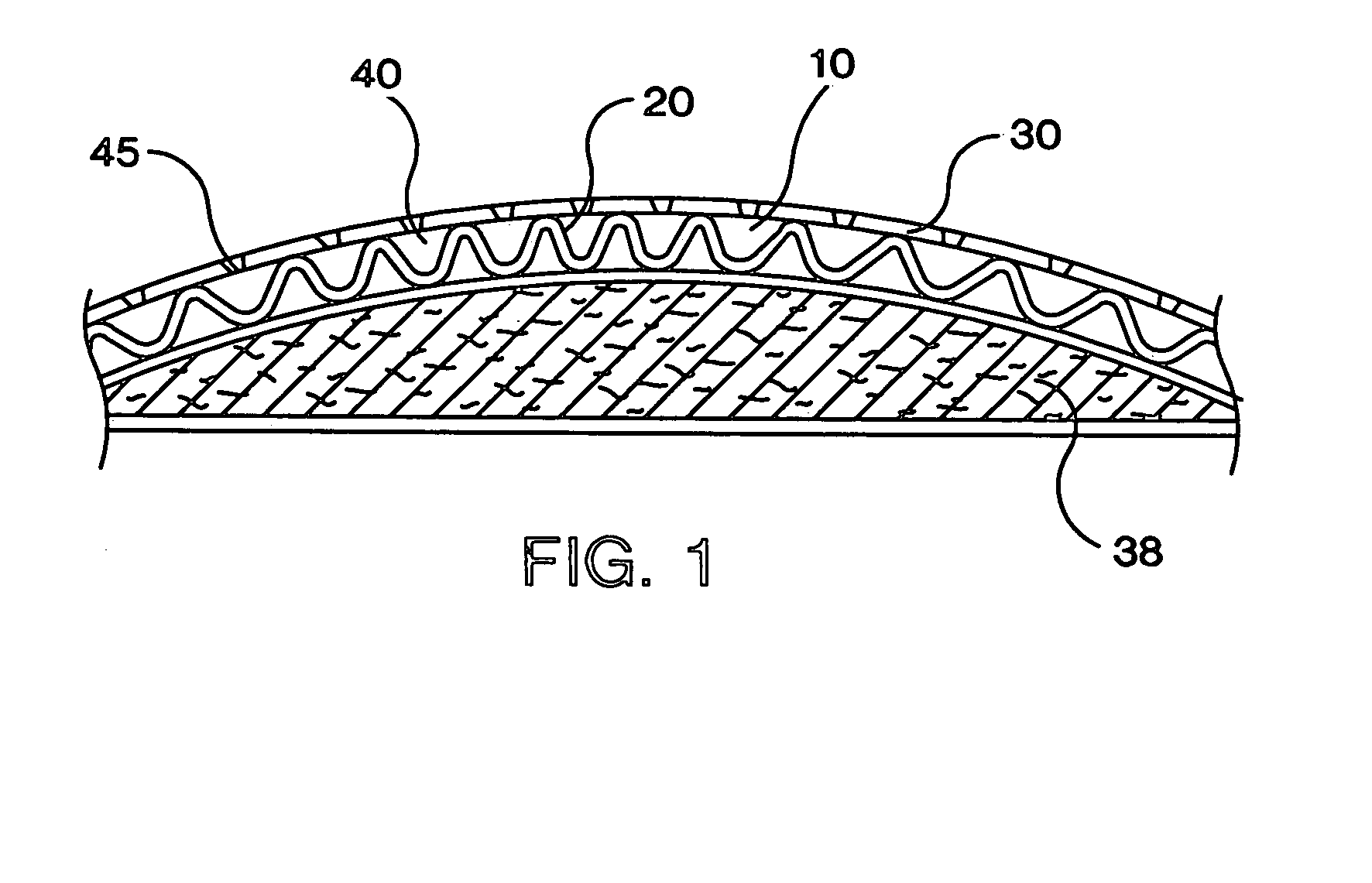

Structured material having apertures and method of producing the same

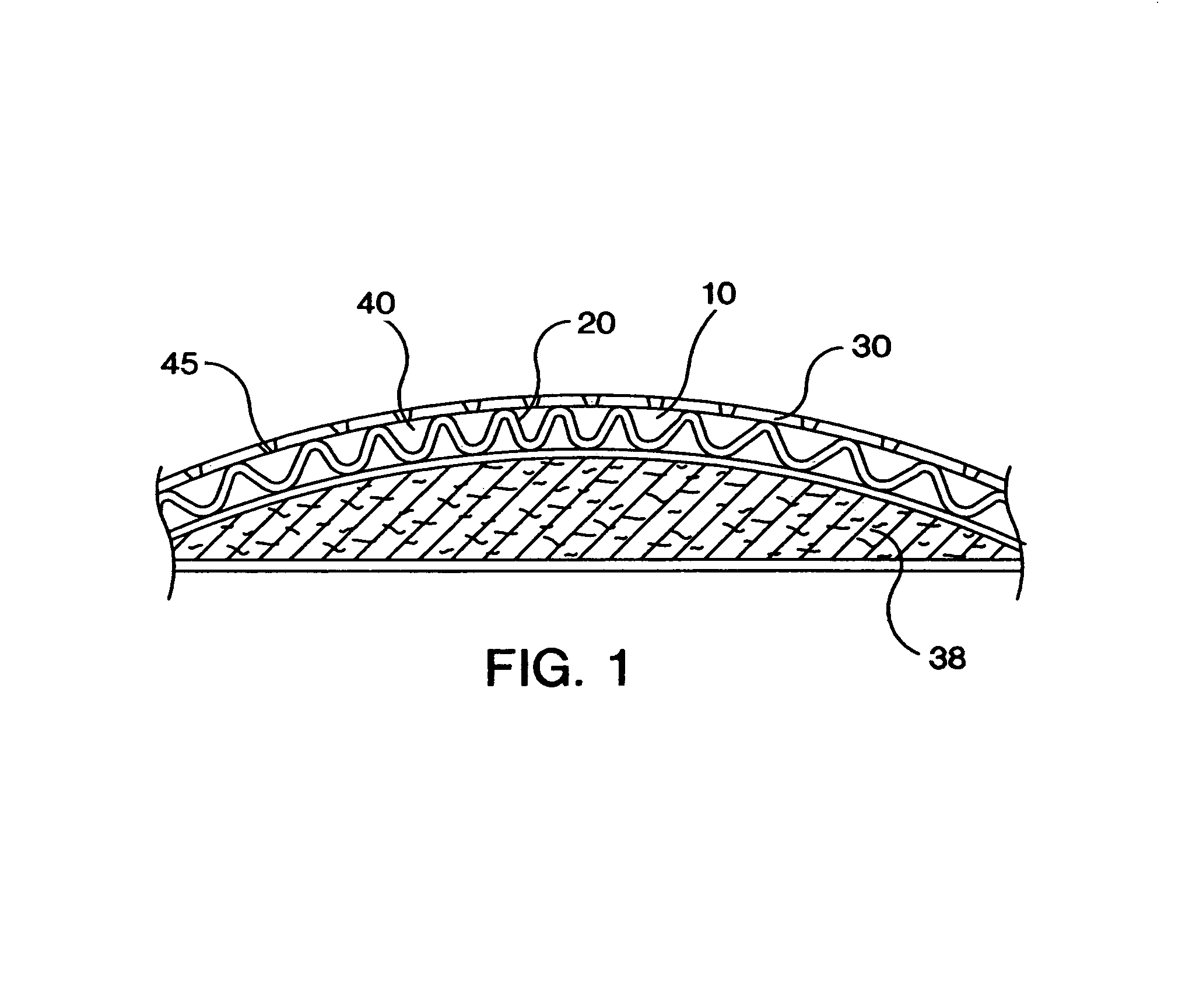

InactiveUS7118639B2Quickly and efficiently handleFast intake rateMechanical working/deformationLamination ancillary operationsFiberPolypropylene

A method for producing an apertured structured material for accommodating passage of fluids, particularly high viscosity fluids, through the apertured structured material. In one embodiment, the apertured structured material is a composite material formed by differential shrinkage of a shrinkable second layer, for example an ethylene-propylene copolymer, which is laminated to a first layer, for example a polypropylene polymer. During the differential shrinkage process, a plurality of slits which are formed in the second layer open to form uniformly-shaped apertures. In another embodiment, an apertured structured heterogenous material is made of a heterogeneous mixture of at least two homogeneous fiber sets or components having different shrinkage extents.

Owner:KIMBERLY-CLARK WORLDWIDE INC

High-efficiency and novel biological carrier for sewage biological treatment and preparation method thereof

InactiveCN101538083AHigh mechanical strengthAvoid deformationBiological water/sewage treatmentWastewaterWaste rubber

The invention relates to a high-efficiency and novel biological carrier for a sewage biological treatment and a preparation method thereof. The biological carrier is prepared by comprising the following steps of: blending, extruding or injection-molding the following components: PP, PE, and ethylene-propylene copolymer, compatilizer, inorganic materials, plant materials, magnetic particles, and waste rubber according to a certain proportion, thus providing a biological carrier with large specific surface area, high hydrophilicity and easy hanged membrane on surfaces. The shapes of the biological carriers can be spherical, fibrous and polyhedral or powdery with various forms. The chemical or physical methods such as grinding, acid base reaction, coating on surface and the like can also be carried out to prepare the biological carrier, thus further improving the specific surface area, strengthening the adhesive ability of the biological membrane on the carrier, and improving the microorganism concentration. The preparation method of the biological carrier provided by the invention is simple, has wide adjusting range of the carrier density, easy obtaining materials, low cost, high efficiency of eliminating COD and variety shapes, can be lighter or heavier than water, and is applicable to all biological wastewater treatments.

Owner:常州华钛化学有限公司

Ethylene-propylene copolymer low noise film additive

The invention pertains to an ethylene-propylene copolymer which when added to stretch film used in palletizing reduces the noise involved in use. The ethylene-propylene copolymer tackifier has a weight average molecular weight in the range of 7,000 to 18,000 and an ethylene content of 15-28 weight percent and results in polyethylene stretch films having both desirable cling and noise levels.

Owner:ILLINOIS TOOL WORKS INC

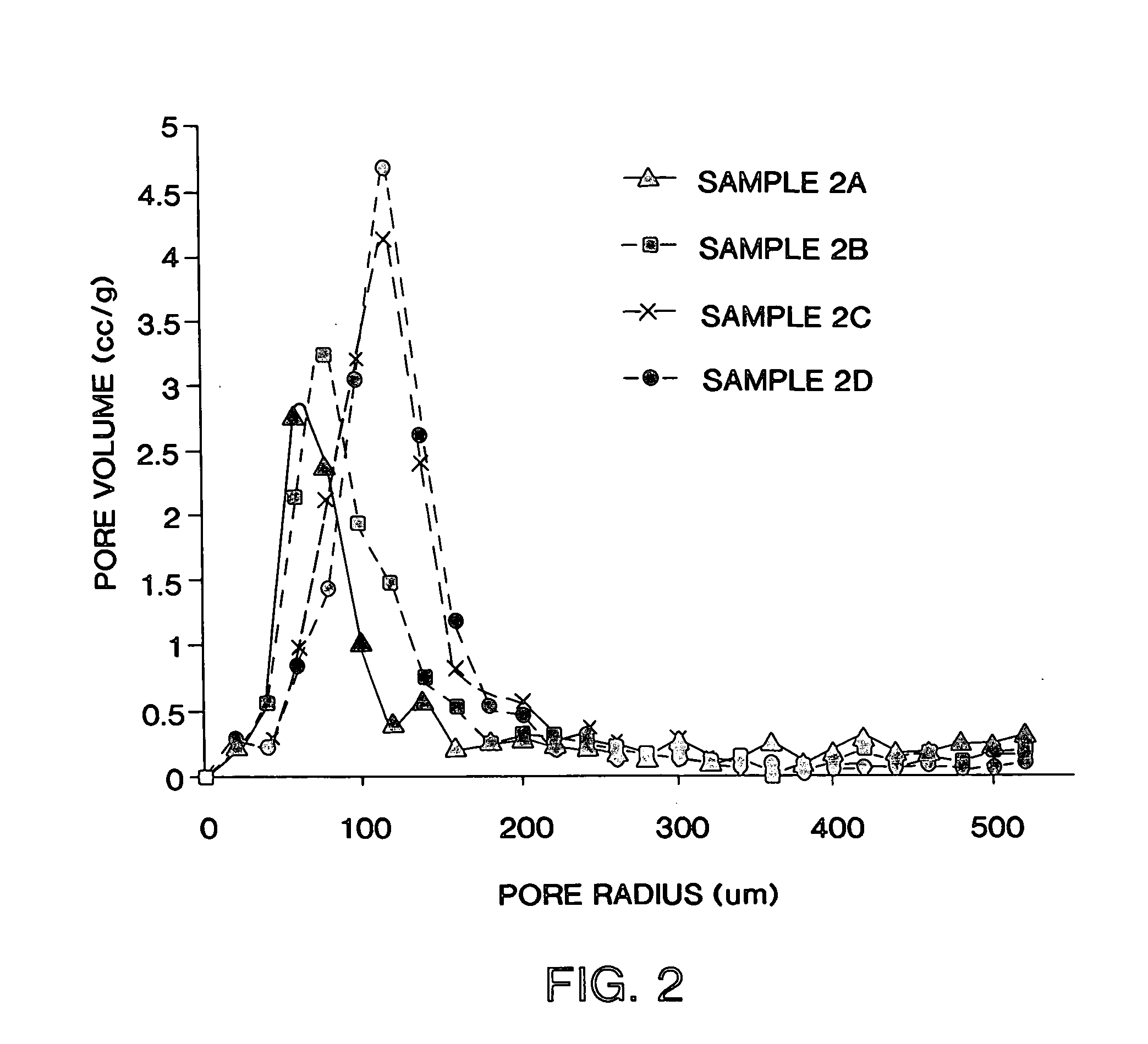

Polymerization and propylene block copolymer

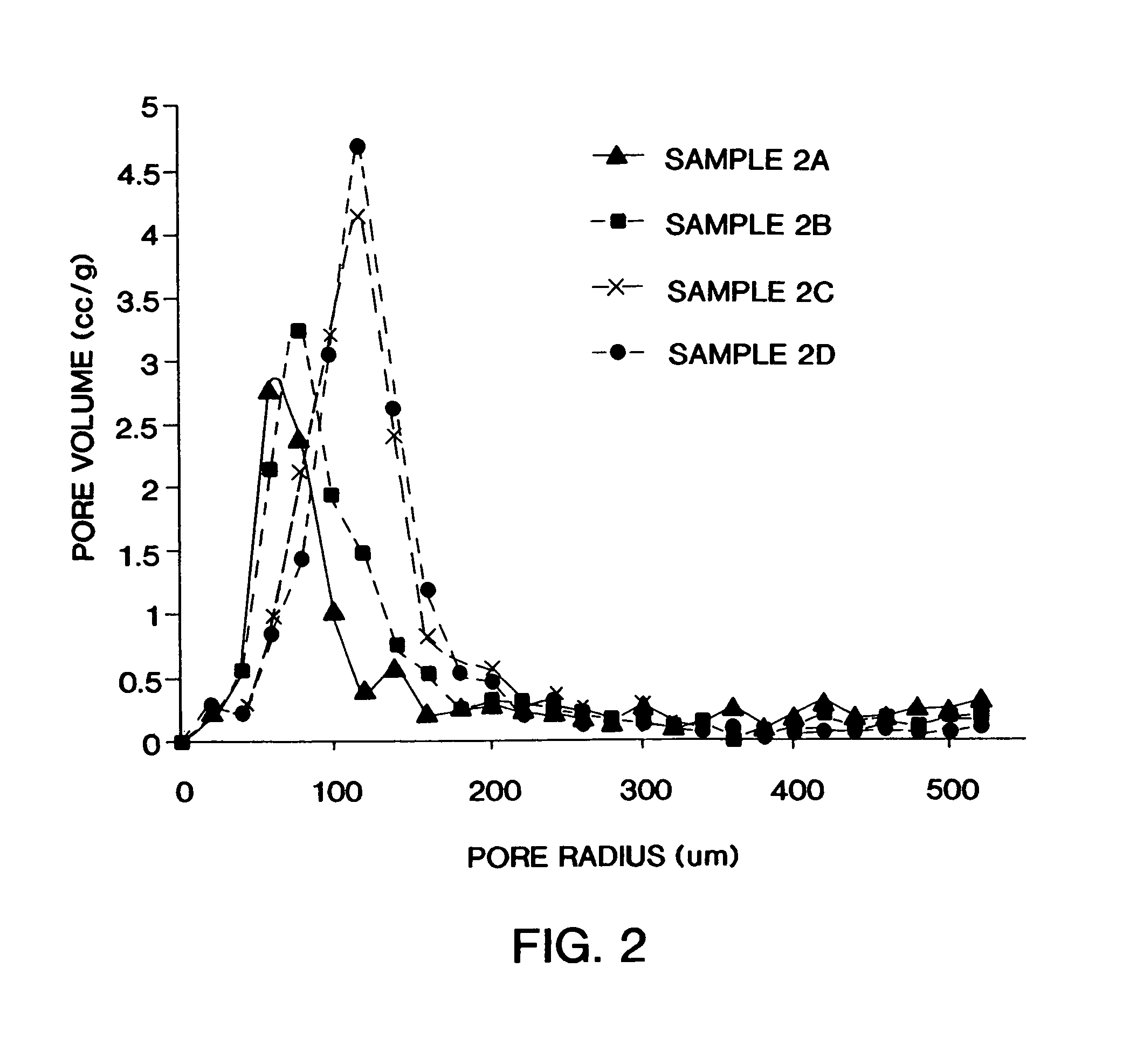

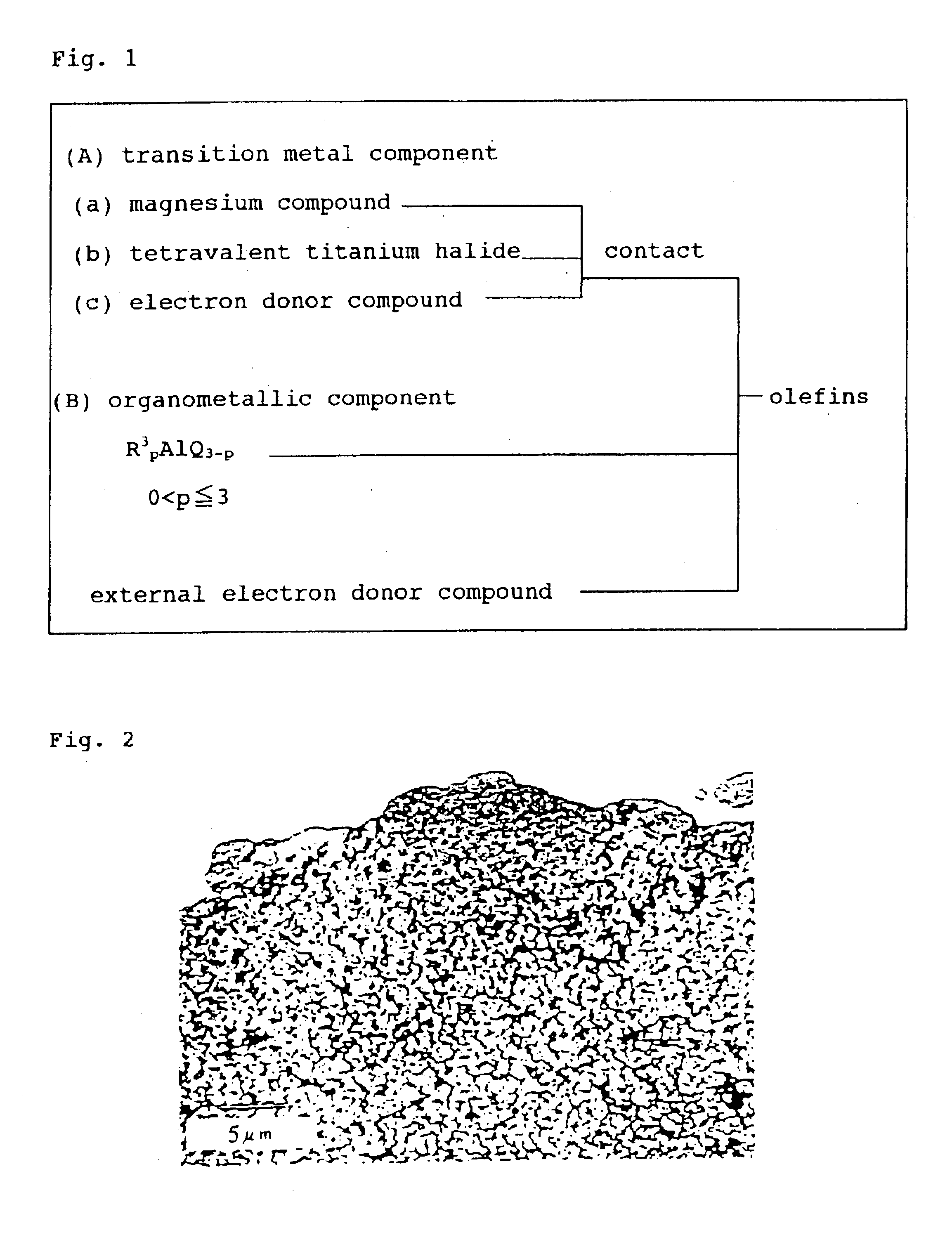

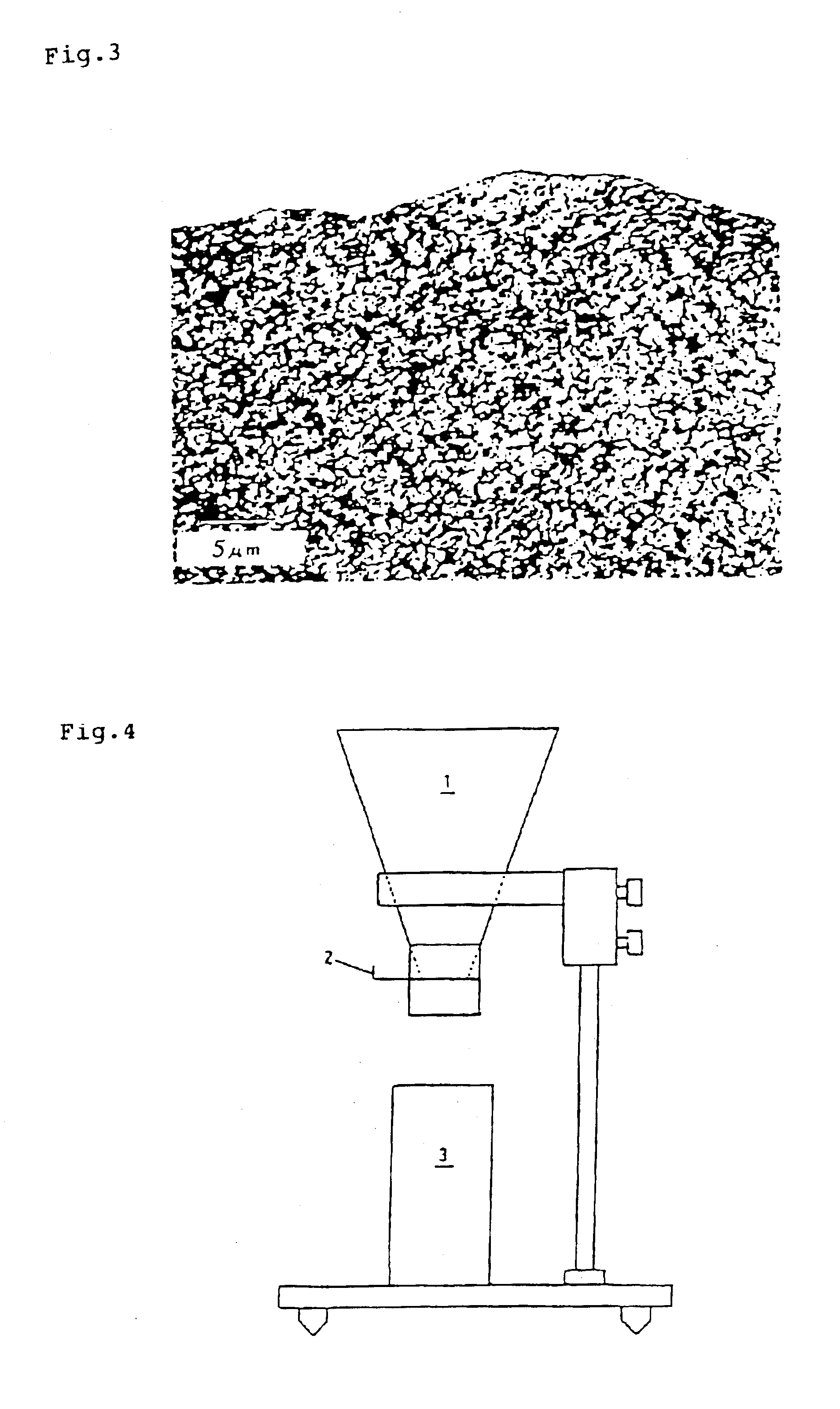

InactiveUS6855656B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHalogenTitanium

A propylene block copolymer with a high proportion of ethylene-propylene copolymer particles (rubber component) well dispersed in a propylene polymer exhibiting well-balanced rigidity and impact resistance can be obtained by using a solid catalyst for polymerization of olefins comprising (a) a solid catalyst component with controlled morphology, comprising magnesium, titanium, and a halogen atom, having an average particle diameter, specific surface area, and pore volume in a specific range, and having a pore size distribution in which an cumulative pore volume with a pore size of 100 Å or less is more than 50%, (b) an organoaluminum compound, and (c) an organosilicon compound. The block copolymer is very useful particularly for the application of vehicle parts such as a bumper and parts for household electric appliances.

Owner:TOHO TITANIUM CO LTD

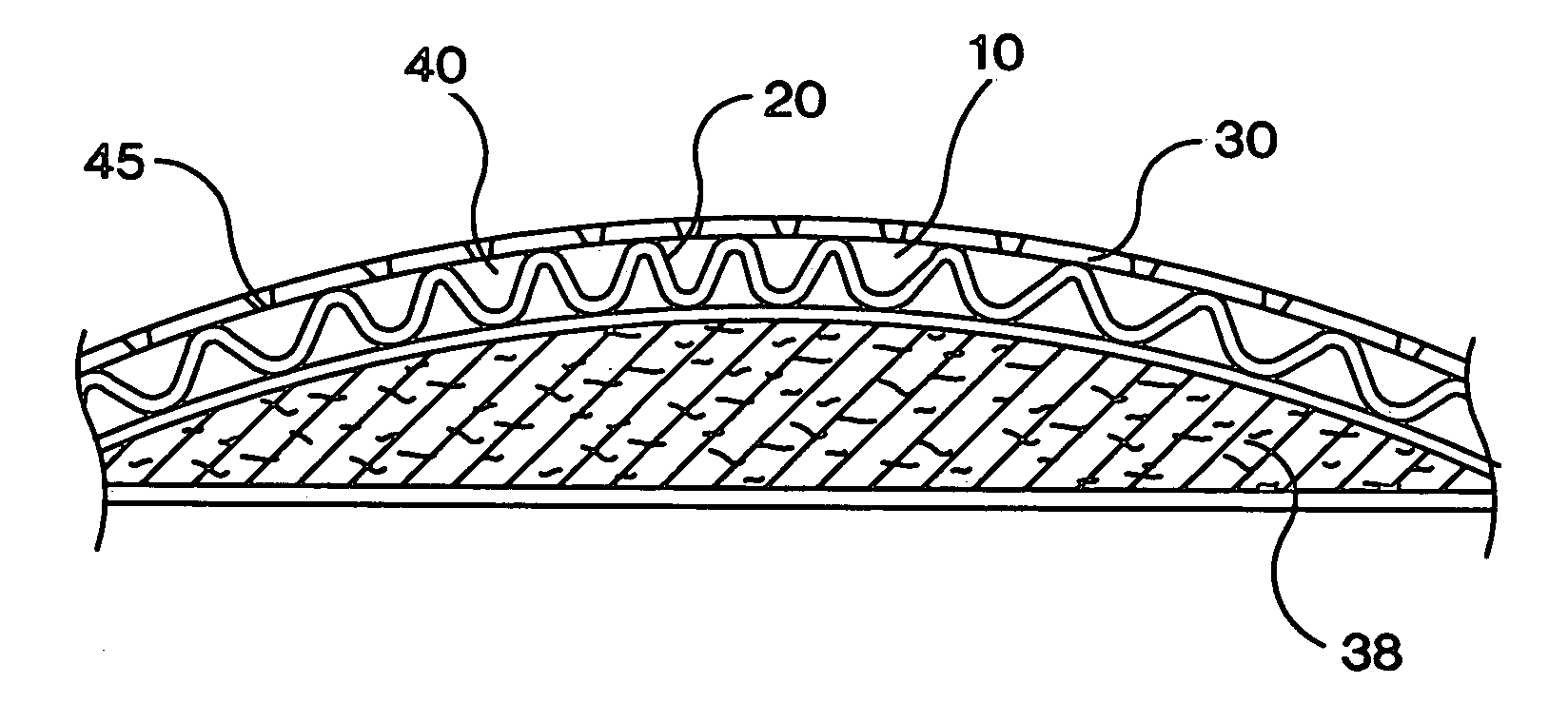

Fibrous structures derived from renewable resources

Disclosed herein are co-formed fibrous structures that are composed of (a) a plurality of filaments that have a biobased content of at least about 25% and selected from the group consisting of polypropylene, polyethylene, polymethylpentene, polybutylene-1, polyisobutylene, ethylene propylene copolymer, ethylene propylene diene monomer copolymer or rubber, and mixtures thereof; and, (b) a solid additive including a cellulosic fiber. The solid additive is present in an amount of at least about 30 wt. %, based on the total weight of the fibrous structure. The co-formed fibrous structures of the invention can themselves be articles, such as, paper, fabrics, and absorbent pads.

Owner:THE PROCTER & GAMBLE COMPANY

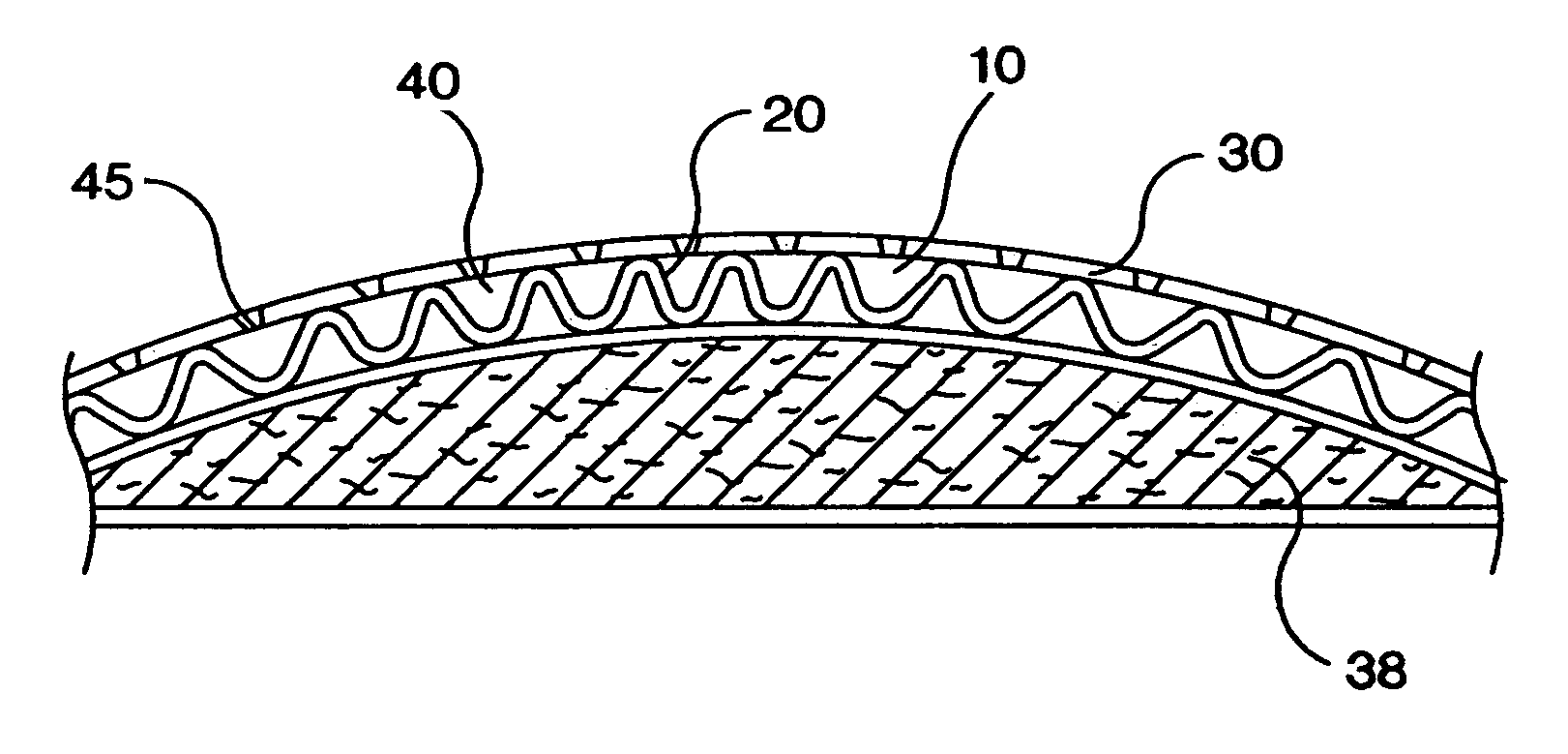

Structured material and method of producing the same

InactiveUS7045029B2Quickly and efficiently handleFast intake rateMechanical working/deformationPersonal careFiberPolymer science

A method for producing a structured material for accommodating passage of fluids, particularly high viscosity fluids, through the structured material. In one embodiment, the structured material is a composite material formed of a first layer, for example a polypropylene polymer, having a first shrinkage extent and a second layer bonded to the first layer, for example an ethylene-propylene copolymer, having a second shrinkage extent different from the first shrinkage extent. In another embodiment, a structured heterogenous material is made of a heterogeneous mixture of at least two homogeneous fiber sets or components having different shrinkage extents.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method for preparing functionalization polyolefin resin

The preparation process of functional polyolefin resin includes electronic beam or gamma-ray pre-irradiation treatment of functional polyolefin resin; mechanical mixing of polyolefin resin after pre-treatment, functional monomer and electron donor reagent; and reacting extrusion for the polyolefin resin in molten state and functional monomer to produce grafting reaction. The polyolefin resin includes polyethylene, polypropylene, ethylene-propylene copolymer, ethylene-styrene copolymer, polystyrene, etc; the functional monomer is unsaturated organic acid or its derivative with amino group, isocyanate, hydroxyl group or other reactive functional group; and the electron donor reagent includes electron-rich compound with P, N, S or O element, p-benzoquinone, triphenyl phosphite, triphenyl phosphate, etc.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

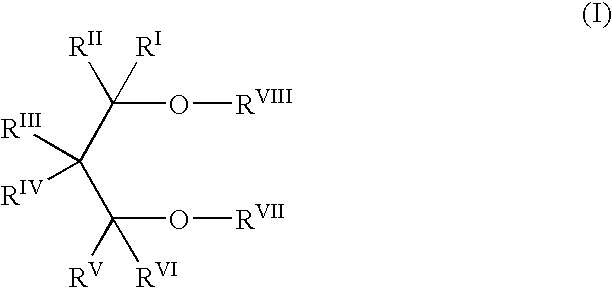

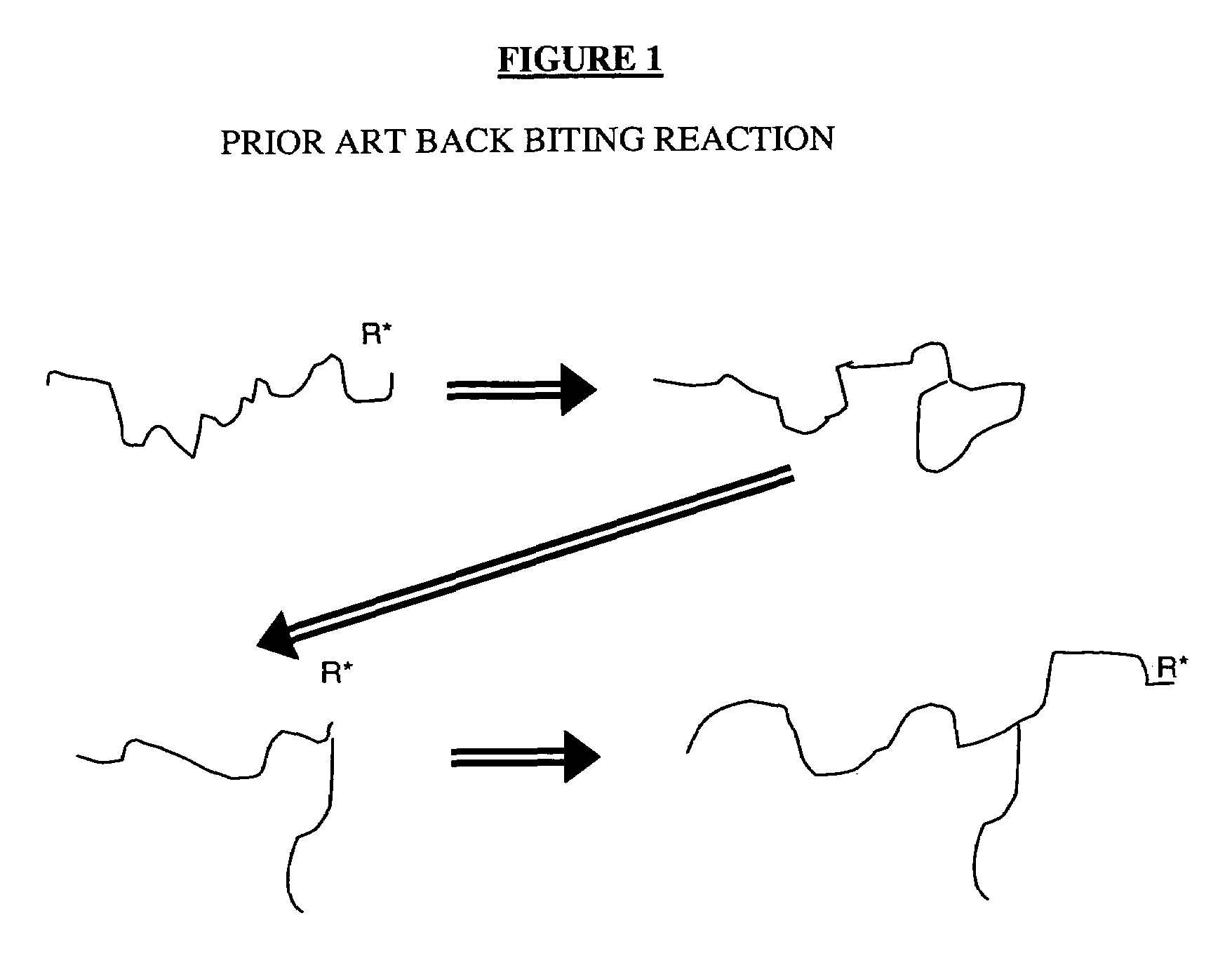

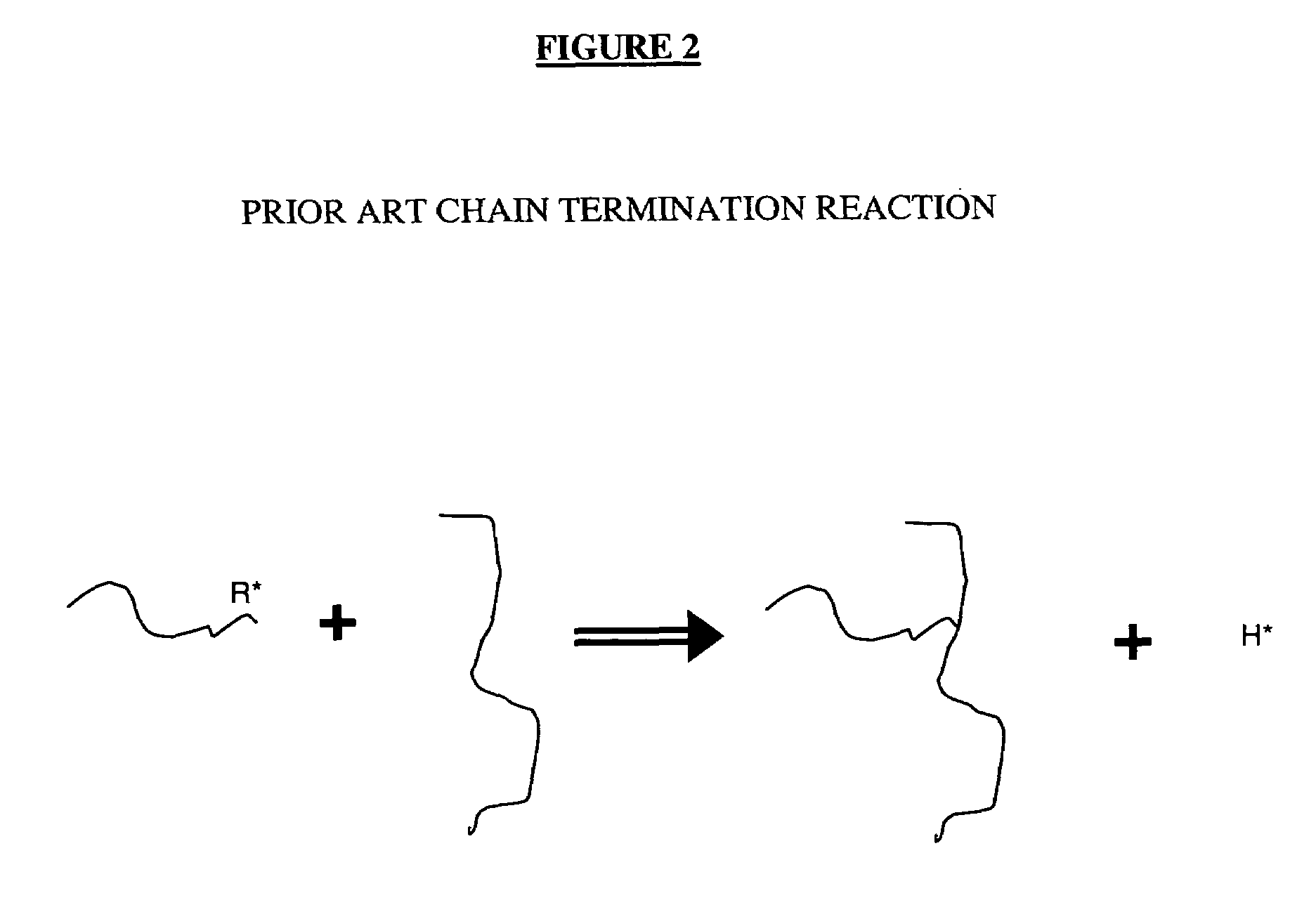

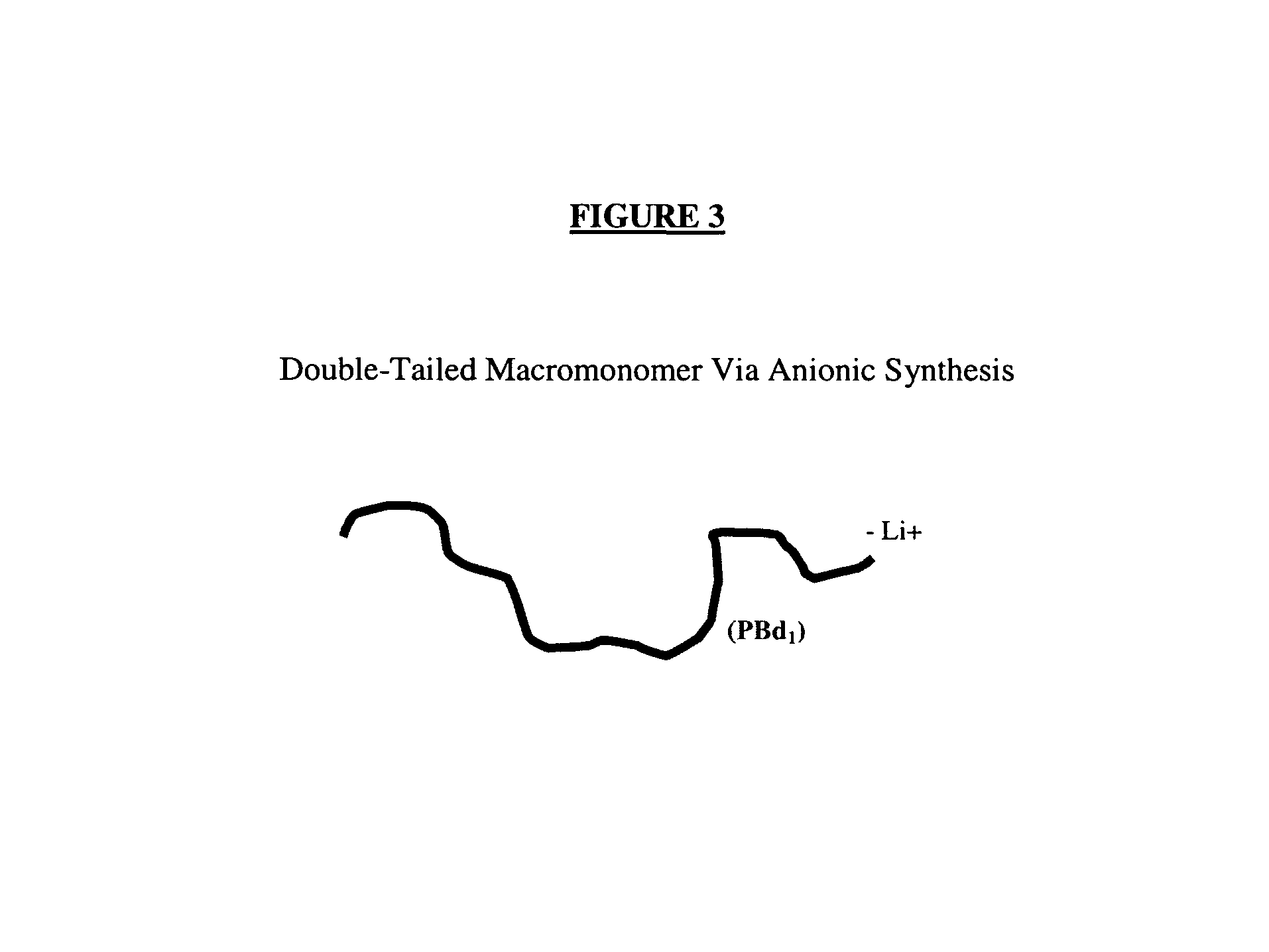

Synthesis and use of well-defined, highly-branched saturated hydrocarbon polymers

The present invention relates to a method to produce highly branched polymers with a polyolefin backbone structure of ethylene and precise control of the nature of the branching. In particular, the distribution of branch length and number of branches can be more precisely controlled via the polymerization method of the present invention. The method comprises using anionic chemistry to make unsaturated polydienes with a well-defined, highly-branched structure, and then hydrogenating these polydienes to form highly branched or dendritic saturated hydrocarbon polymers. Highly branched or dendritic polyethylene, ethylene-propylene copolymer and atactic polypropylene are among the saturated hydrocarbon polymers that can be anionically synthesized via the proper selection of diene monomer type, coupling agent, and hydrogenation conditions. These polymers find application in injection molding and extrusion processes as a minor additive for improving processability of linear polyolefins by delaying the onset of melt fracture, and correspondingly increasing melt throughput rates.

Owner:EXXON RES & ENG CO

Molded article for interior parts of a car

ActiveUS6964997B2Good formabilityGloss and scratch resistanceLayered productsConductive materialShell moldingAlpha-olefin

The present invention relates to interior parts of a car comprising a new propylene resin composition. The present resin composition has good molding abilities and a good balance of physical properties as well as a good appearance, lower gloss and scratch resistance. Specifically, the present invention relates to a molded article for interior parts of a car comprising a polypropylene resin composition comprising the following components; a crystalline homopolypropylene having MFR of 500 to 3,000 g / 10 min.; a polypropylene consisting of a crystalline homopolypropylene and an ethylene-propylene copolymer rubber having 45 to 80% by mass of a ethylene content; a polypropylene consisting of a crystalline homopolypropylene and an ethylene-propylene copolymer rubber having 25% by mass or more to below 45% by mass of a ethylene content; and an ethylene-α-olefin copolymer rubber.

Owner:NISSAN MOTOR CO LTD

Copolymers, compositions thereof, and methods for making them

Provided are amorphous ethylene propylene copolymer, compositions thereof, and methods for making same, whereby the copolymer can include of from about 40 wt. % to about 60 wt. % ethylene derived units; and of from about 60 wt. % to about 40 wt. % propylene derived units. The copolymer can be characterized by having no discernable melting point as measured by DSC, an MFRR (MI (21.6 kg; 230° C.) / MI (2.16 kg; 230° C.)) (MI (2.16 kg; 230° C.)) of about 38 or more, a molecular weight distribution (MWD) of from about 1.5 to about 2.5, and a shear viscosity η* at 0.01 rad / sec measured at 70° C. that satisfies the relation |η*|(70° C.; 0.01 rad / sec)>1.2*106*|MFR|−0.77, wherein MFR is the melt flow rate.

Owner:EXXONMOBIL CHEM PAT INC

Polypropylene impact copolymer compositions

The present invention relates to an impact-resistant olefin polymer composition including a polypropylene matrix having a weight average molecular weight and an ethylene-containing polymer including an ethylene-propylene copolymer having a molecular weight higher than the weight average molecular weight of the polypropylene matrix, the composition containing about 20 to 35 percent xylene solubles, and the xylene solubles fraction of the composition containing less than about 39 weight percent ethylene units, based on the combined weight of olefin monomers in the copolymer. The present invention further relates to impact copolymer compositions with a melt flow rate greater than about 8 that meet or exceed all pallet testing requirements. The compositions have superior stiffness-impact balance performance and excellent gloss and are useful for a number of applications including, but not limited to pallets, water-storm chambers, automotive compounding, septic tanks, bins, pales, crates, totes and plastic containers.

Owner:BRASKEM AMERICA

High-barrier semi-high temperature cooking liquid packaging material and packaging bag made of the same

The invention relates to a high-barrier semi-high temperature cooking liquid packaging material and a packaging bag made of the same. The high-barrier semi-high temperature cooking liquid packaging material is a composite membrane prepared by stacking a polyester film (PET) layer, an aluminum foil (Al) layer, a nylon (PA) layer and a polyethylene film (PE) layer from top to bottom by a dry compound machine. The PE layer is prepared by coextrusion blow molding on a surface layer, a middle layer and a heat seal layer; the surface layer is prepared by blending metallocene PE and LDPE in a weight ratio of 2-4:1; the middle layer is prepared by blending metallocene PE and LDPE in a weight ratio of 3-5:1, and adding ethylene propylene copolymer elastomer accounting for 10%-15% of the total weight of the middle layer; and the heat seal layer is prepared by blending metallocene PE and zinc neutralized ethylene copolymer in a weight ratio of 3-5:1. The invention employs a high quality material containing metallocene PE, which is added with a proper amount of an ethylene propylene copolymer elastomer, and especially the heat seal layer is added with the zinc neutralized ethylene copolymer; and the PE layer prepared through blow molding by a three-layer co-extrusion film blowing machine.

Owner:浙江诚信包装有限公司

Lubricating grease used for automobile hub bearing and preparation method thereof

ActiveCN102399615AThe formula is scientific and reasonableSimple preparation processLubricant compositionAntioxidantEngineering

Owner:WUXI FEITIAN GREASE

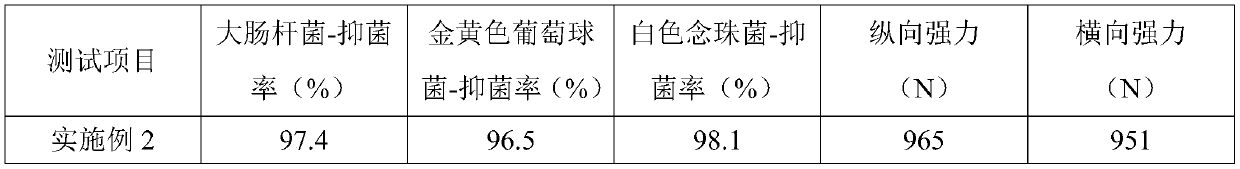

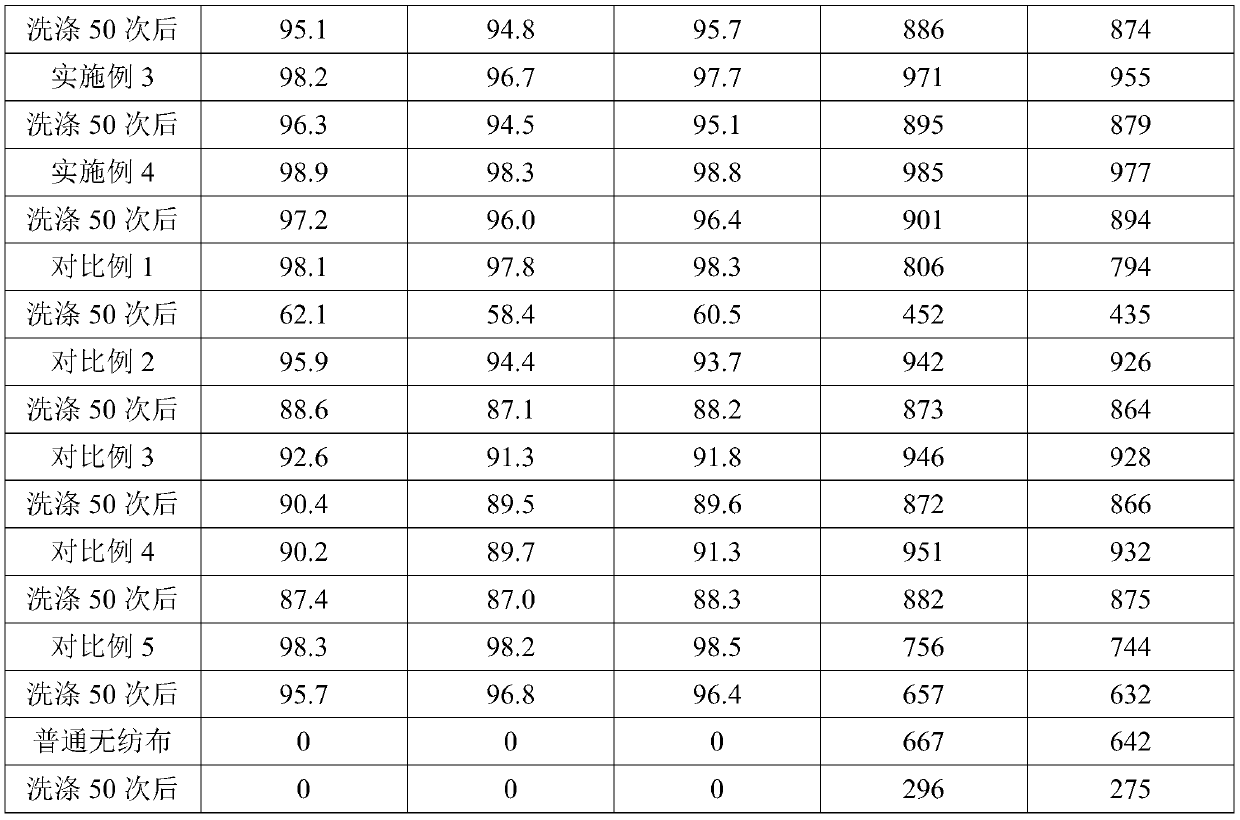

Antibacterial ES composite short fiber used for surface layer of hot-air non-woven fabric and preparation method of fiber

ActiveCN110093681AHigh antibacterial efficiencyImprove antibacterial propertiesFilament/thread formingConjugated synthetic polymer artificial filamentsPolypropyleneAntibacterial agent

The invention discloses an antibacterial ES composite short fiber used for a surface layer of a hot-air non-woven fabric. The ES composite short fiber has a skin-core structure, that is, the fiber iscomposed of a core layer and a skin layer; the core layer is prepared from, by weight, 90-97 parts of polypropylene and 2-5 parts of an ethylene-propylene copolymer; the skin layer is prepared from, by weight, 85-95 parts of polyethylene, 5-7.5 parts of methyl methacrylate graft modification polyethylene, 3-6 parts of an ethylene-propylene copolymer and 6-9 parts of a composite antibacterial agent; the composite antibacterial agent is prepared from, by weight, 70-85 parts of chitosan-grafted sodium polyacrylate super absorbent resin, 70-85 parts of a crylic acid-2-acrylamide-2-methyl propanesulfonic acid copolymer, 25-37 parts of silver nitrate and 5-9 parts of nanometer silver. The antibacterial ES composite short fiber used for the surface layer of the hot-air non-woven fabric is high inantibacterial efficiency and has a lasting antibacterial effect, and the prepared surface layer of the hot-air non-woven fabric is good in softness and texture, high in longitudinal and transverse strength and durable.

Owner:福建省福地化纤科技有限公司

Heterophasic polypropylene with high impact properties

The present invention relates to a heterophasic polypropylene resin comprising a polypropylene homo- or copolymer matrix phase (A) and an ethylene-propylene copolymer phase (B) dispersed within the matrix, wherein the heterophasic polypropylene resin has a fraction insoluble in p-xylene (XCU) at 25 DEG C with an intrinsic viscosity of 2.0 dl / g or less, determined according to DIN EN ISO 1628-1 and -3, and a fraction soluble in p-xylene (XCS) at 25 DEG C having an intrinsic viscosity of 2.0 to 4.5 dl / g, determined according to DIN EN ISO 1628-1 and -3, and an amount of ethylene monomer units of 60 to 85 mol%, a heterophasic polypropylene composition comprising such a resin, a process for preparing that resin, and an article made thereof.

Owner:ボレアリステクノロジーオイ

Metal processing oil for tapping

InactiveCN101880571AImprove the lubrication effectImprove extreme pressure performanceAdditivesAntioxidantHigh carbon

The invention provides metal processing oil for tapping and a preparation method thereof. The metal processing oil contains base oil, extreme-pressure agent, oiliness agent, viscosity regulator, anti-rusting agent and antioxidant, wherein the extreme-pressure agent contains chlorine, sulfur and phosphorus; the oiliness agent is vulcanizing grease; the viscosity regulator is ethylene-propylene copolymer or polyisobutene; the anti-rusting agent is dodecenyl succinic acid; and the antioxidant is one or mixture of 2,6-di-tert-butyl-methyl phenol, phenyl-alpha-naphthylamine, benzotriazole and derivatives thereof. The metal processing oil for tapping has excellent lubricating property, high extreme pressure and high cooling property, has a simple preparation method, and can be used for drillingand tapping of stainless steel, alloy steel and high carbon steel.

Owner:广东垠星科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com