Engine oil suitable for pluralities of fuel

An engine oil and fuel technology, which is applied in base materials, petroleum industry, additives, etc., can solve the problem that engine oil cannot better meet the performance requirements of the engine, and achieve the effects of good low temperature fluidity, good anti-wear and anti-friction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

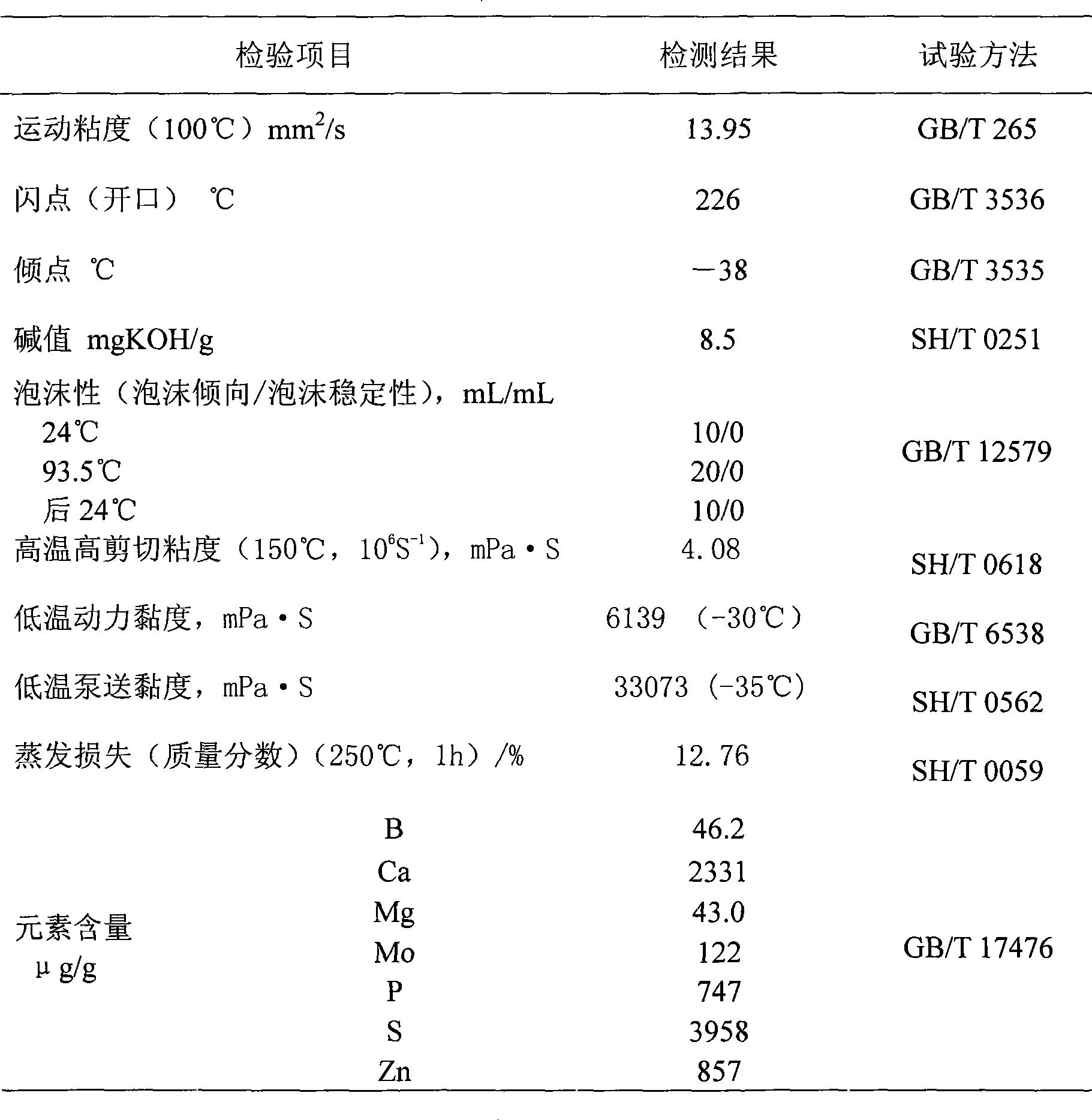

Image

Examples

Embodiment 1

[0030] Comprising raw materials in the following ratios in parts by mass:

[0031] Base oil 150SN 33 kg,

[0032] Base oil VHVI H350 (Group III) 22 kg,

[0033] polyalphaolefin 15 kg,

[0034] 2 kg of C8-C10 ester oil,

[0035] Viscosity index improver: 11 kg of ethylene-propylene copolymer with a molecular weight of 63,000 to 108,000,

[0036] Anti-oxidation, anti-corrosion, anti-wear additives: 0.4 kg of zinc dialkyldithiophosphate;

[0037] Detergent: 1.1 kg of calcium alkylphenate, 1.9 kg of calcium sulfonate;

[0038] Dispersant: 3.8 kg of polyisobutylene succinimide;

[0039] Defoamer: 0.001 kg of methyl silicone oil.

[0040] The preparation method is as follows: the equipment and parameters adopted therein are conventional equipment and parameters in this field, and the following examples are the same, specifically as follows:

[0041] At a temperature of 60°C, use part of the base oil 150SN in a dissolving tank to dissolve and dilute the viscosity index improve...

Embodiment 2

[0044] Comprising raw materials in the following ratios in parts by mass:

[0045] Base oil 150SN 34.5 kg,

[0046] Base oil VHVI H350 (Group III) 23 kg,

[0047] polyalphaolefin 16 kg,

[0048] 3 kg of C8-C10 ester oil,

[0049] Viscosity index improver: 12 kg of ethylene-propylene copolymer with a molecular weight of 63,000 to 108,000,

[0050] Anti-oxidation, anti-corrosion, anti-wear additives: 0.8 kg of zinc dialkyldithiophosphate;

[0051] Detergent: 2.9 kg of calcium alkylphenate, 2.2 kg of calcium sulfonate;

[0052] Dispersant: 4.4 kg of polyisobutylene succinimide;

[0053] Defoamer: 0.002 kg of methyl silicone oil.

[0054] The preparation method is as follows:

[0055] At a temperature of 70°C, use part of the base oil 150SN to dissolve and dilute the viscosity index improver into a uniform liquid in a dissolution tank;

[0056] Import the above diluted liquid and the remaining base oil 150SN and VHVI H350 (Type III) into the blending tank, heat to 60°C, ad...

Embodiment 3

[0058] Comprising raw materials in the following ratios in parts by mass:

[0059] Base oil 150SN 36 kg,

[0060] Base oil VHVI H350 (Group III) 24 kg,

[0061] polyalphaolefin 17 kg,

[0062] C8-C10 ester oil 4 kg,

[0063] Viscosity index improver: 13 kg of ethylene-propylene copolymer with a molecular weight of 63,000 to 108,000,

[0064] Anti-oxidation, anti-corrosion, anti-wear additives: 1.2 kg of zinc dialkyldithiophosphate;

[0065] Detergent: 4.8 kg of calcium alkylphenate, 2.5 kg of calcium sulfonate;

[0066] Dispersant: 5.0 kg of polyisobutylene succinimide;

[0067] Defoamer: 0.003 kg of methyl silicone oil.

[0068] The preparation method is as follows:

[0069] At a temperature of 80°C, use part of the base oil 150SN to dissolve and dilute the viscosity index improver into a uniform liquid in a dissolution tank;

[0070]Import the above diluted liquid and the remaining base oil 150SN and VHVI H350 (Type III) into the blending tank, heat to 65°C, add othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com