Coal-based fully-synthetic low-temperature hydraulic oil and preparation method thereof

A fully synthetic, hydraulic oil technology, applied in the field of hydraulic oil, can solve the problems of shortened oil change cycle, poor high temperature resistance, poor oxidation resistance, etc. Shear and heat and oxygen resistance, the effect of meeting the anti-foaming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

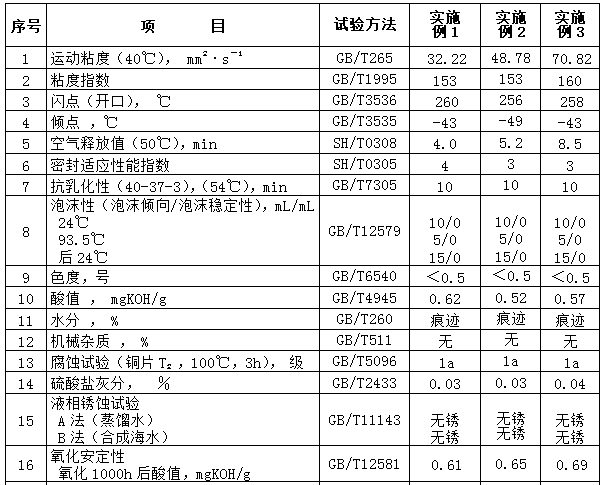

Embodiment 1

[0038] A coal-based fully synthetic low-temperature hydraulic oil obtained by reacting the following components in mass fractions: 98.0wt% base oil, 0.4wt% extreme pressure antiwear agent, 0.2wt% antioxidant, 0.5wt% metal deactivator, 0.5wt% anticorrosion and antirust agent, 0.4wt% cleaning and dispersing agent.

[0039] The base oil is composed of 90wt% coal-derived Group III+CTL4 base oil, 9wt% coal-derived polyalphaolefin PAO40 base oil and 1wt% coal-derived polyalphaolefin PAO150 base oil.

[0040] The extreme pressure antiwear agent is composed of triphenyl phosphite and isobutylene sulfur at a mass ratio of 1:4.

[0041] The antioxidant is compounded by dioctyldiphenylamine and 2,6-di-tert-butyl-p-cresol at a mass ratio of 1:2.

[0042] The metal deactivator is benzotriazole.

[0043] The anti-corrosion and anti-rust agent is calcium petroleum sulfonate.

[0044] The detergent dispersant is calcium salt of alkylphenate.

[0045] The method for preparing the low-tempe...

Embodiment 2

[0051]A coal-based fully synthetic low-temperature hydraulic oil obtained by reacting the following components in mass fractions: 99.0wt% base oil, 0.2wt% extreme pressure antiwear agent, 0.1wt% antioxidant, 0.15wt% metal deactivator, 0.3wt% anticorrosion and antirust agent, 0.2wt% cleaning and dispersing agent and 0.05wt% pour point depressant.

[0052] The base oil is composed of 80wt% coal-derived Group III+CTL4 base oil, 17wt% coal-derived polyalphaolefin PAO40 base oil and 3wt% coal-derived polyalphaolefin PAO150 base oil.

[0053] The extreme pressure antiwear agent is composed of triphenyl phosphite and isobutylene sulfur at a mass ratio of 1:3.

[0054] The antioxidant is compounded by dioctyldiphenylamine and 2,6-di-tert-butyl-p-cresol at a mass ratio of 1:1.5.

[0055] The metal deactivator is benzotriazole.

[0056] The anti-corrosion and anti-rust agent is calcium petroleum sulfonate.

[0057] The detergent dispersant is calcium salt of alkylphenate.

[0058] T...

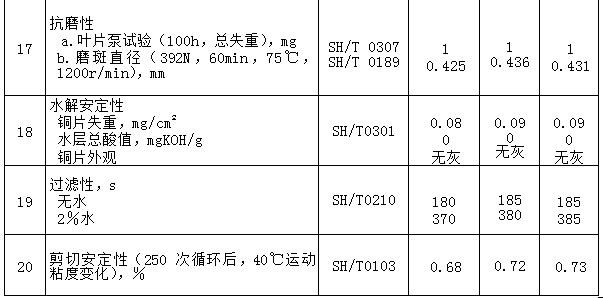

Embodiment 3

[0065] A coal-based fully synthetic low-temperature hydraulic oil obtained by reacting the following components in mass fractions: 99.5wt% base oil, 0.1wt% extreme pressure antiwear agent, 0.05wt% antioxidant, 0.1wt% metal deactivator, 0.1wt% anticorrosion and antirust agent, 0.05wt% cleaning and dispersing agent and 0.1wt% pour point depressant.

[0066] The base oil is composed of 70wt% coal-derived Group III+CTL4 base oil, 25wt% coal-derived polyalphaolefin PAO40 base oil and 5wt% coal-derived polyalphaolefin PAO150 base oil.

[0067] The extreme pressure antiwear agent is compounded by triphenyl phosphite and isobutylene sulfur at a mass ratio of 1:4.

[0068] The antioxidant is compounded by dioctyldiphenylamine and 2,6-di-tert-butyl-p-cresol at a mass ratio of 1:2.

[0069] The metal deactivator is benzotriazole.

[0070] The anti-corrosion and anti-rust agent is calcium petroleum sulfonate.

[0071] The detergent dispersant is calcium salt of alkylphenate.

[0072] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com