Patents

Literature

191results about How to "Improve anti-friction and anti-wear effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Valve element sealing lubricating agent composition

InactiveCN102433204ASimple production methodImprove high temperature resistanceLubricant compositionBase oilWear resistance

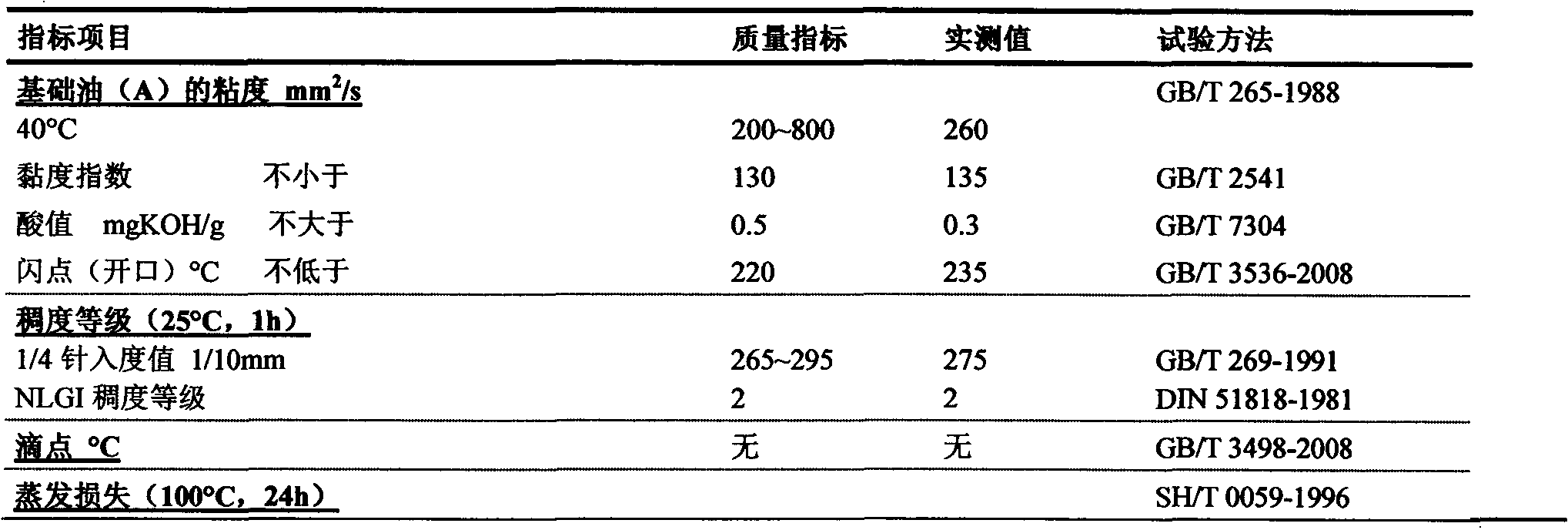

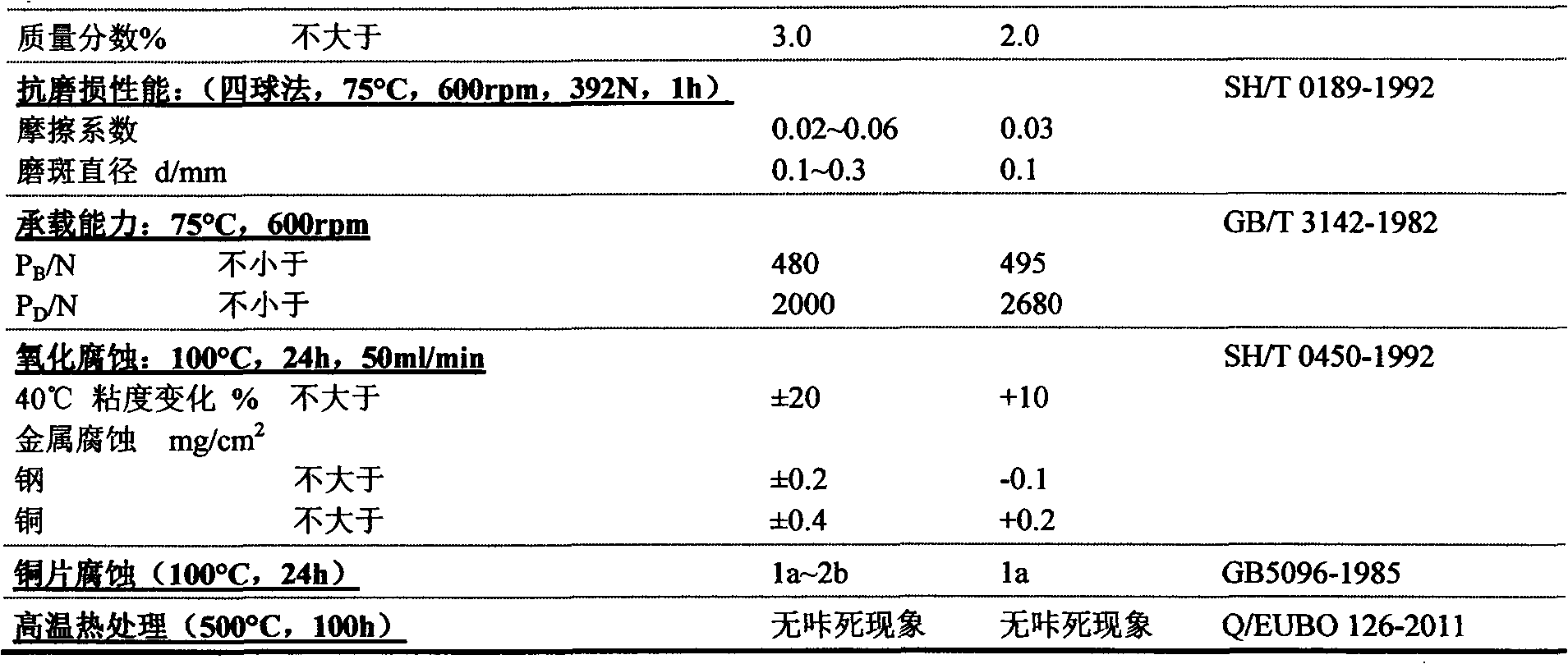

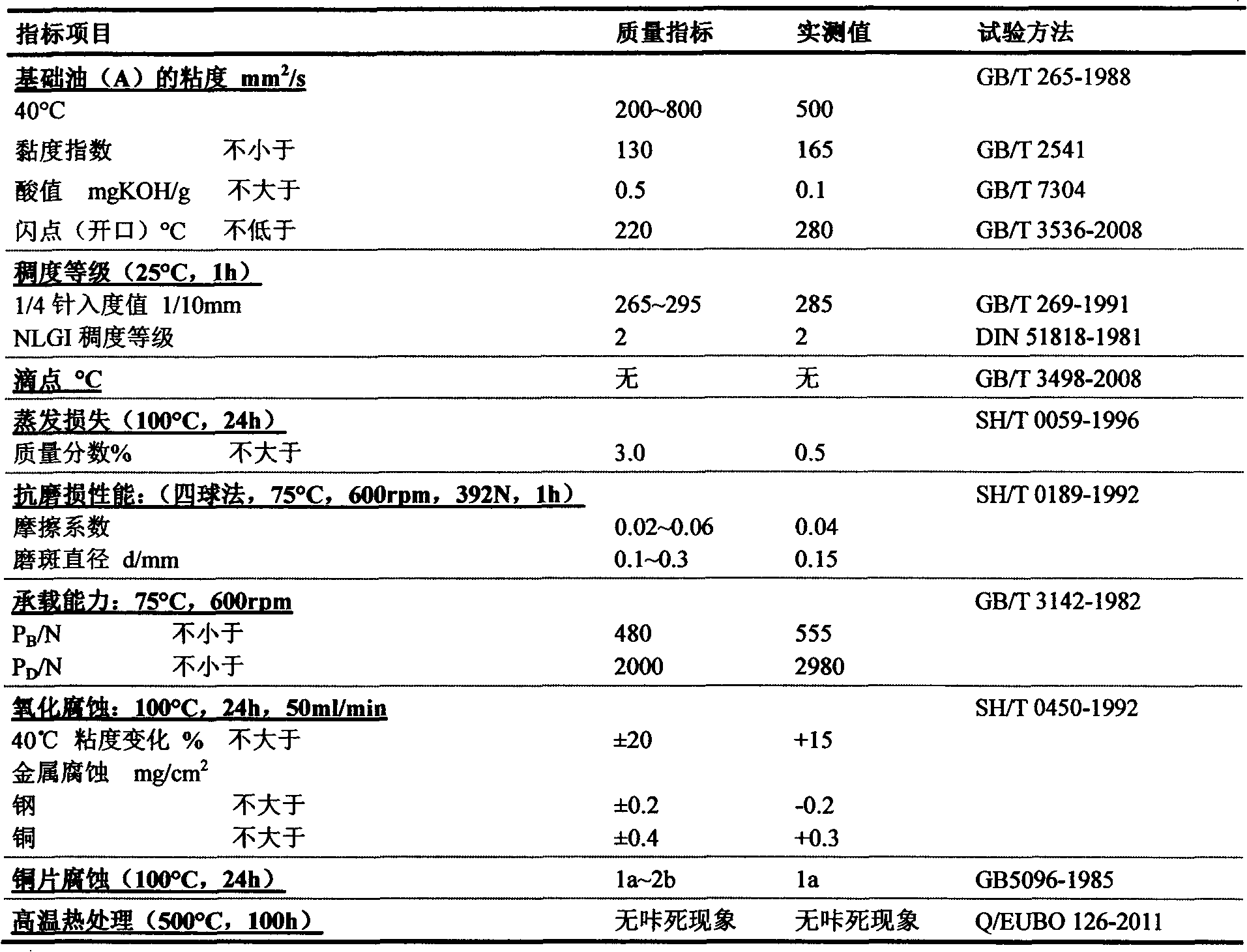

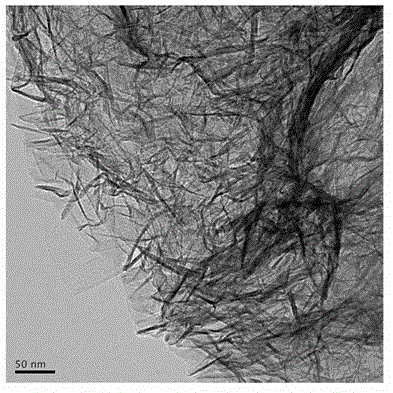

The invention relates to the field of lubricating materials, in particular to a valve core sealing lubricating agent composition, which comprises: (A) 100.0 weight parts of base oil; (B) 5.0 to 35.0 weight parts of thickening agent; (C) 3.0 to 55.0 weight parts of solid lubricating agent; (D) 0.1 to 3.0 weight parts of surfactant; (E) 0.1 to 2.5 weight parts of antioxygen; (F) 0.1 to 4.0 weight parts of extreme pressure antiwear agent; (G) 0.1 to 2.0 weight parts of metal passivating agent; and (H) 0.1 to 1.5 weight parts of antimicrobial agent. The finished lubricating agent prepared according to the mixing ratio has high high-temperature resistance, high antiwear and wear-resistance performance and high dead-locking-preventing performance. Meanwhile, the production and preparation method of the lubricating agent are simple, convenient and easy to implement and is suitable for large-scale batch production.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

High-thermal conductivity lubricating oil and preparation method thereof

ActiveCN102911762AImprove anti-friction and anti-wear effectImprove thermal conductivityAdditivesGrapheneBase oil

The invention relates to high-thermal conductivity lubricating oil and a preparation method thereof. The lubricating oil contains base oil and fluorinated graphene nanosheets, wherein the weight percent of content of the fluorinated graphene nanosheets is 0.01 to 10.0 %; and the preparation method comprises the steps as follows: firstly, preparing the fluorinated graphene nanosheets; and secondly, preparing the lubricating oil containing the fluorinated graphene nanosheets. The lubricating oil provided by the invention has the advantages of excellent antifriction effect, extremely high heat conduction capability and excellent stability and dispersibility.

Owner:青岛康普顿石油化工有限公司

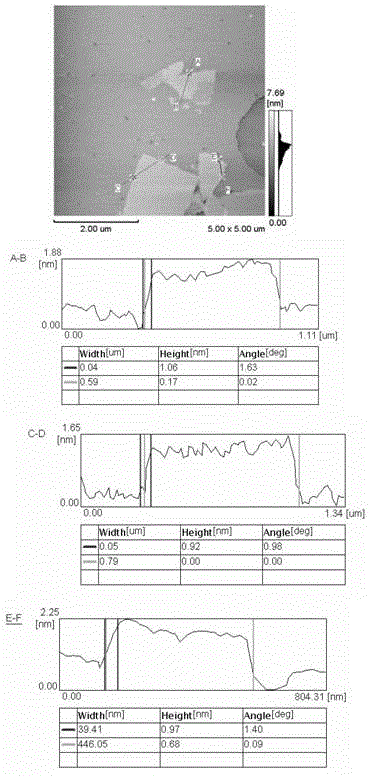

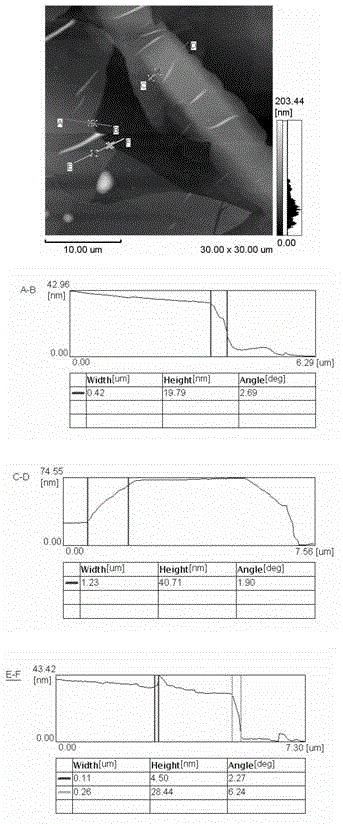

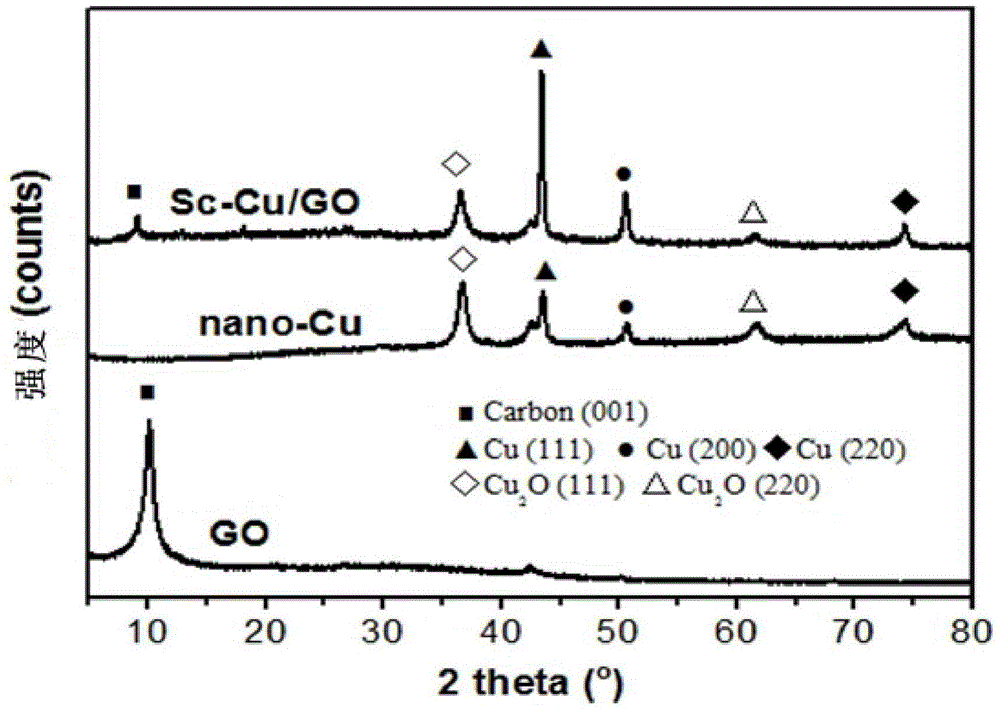

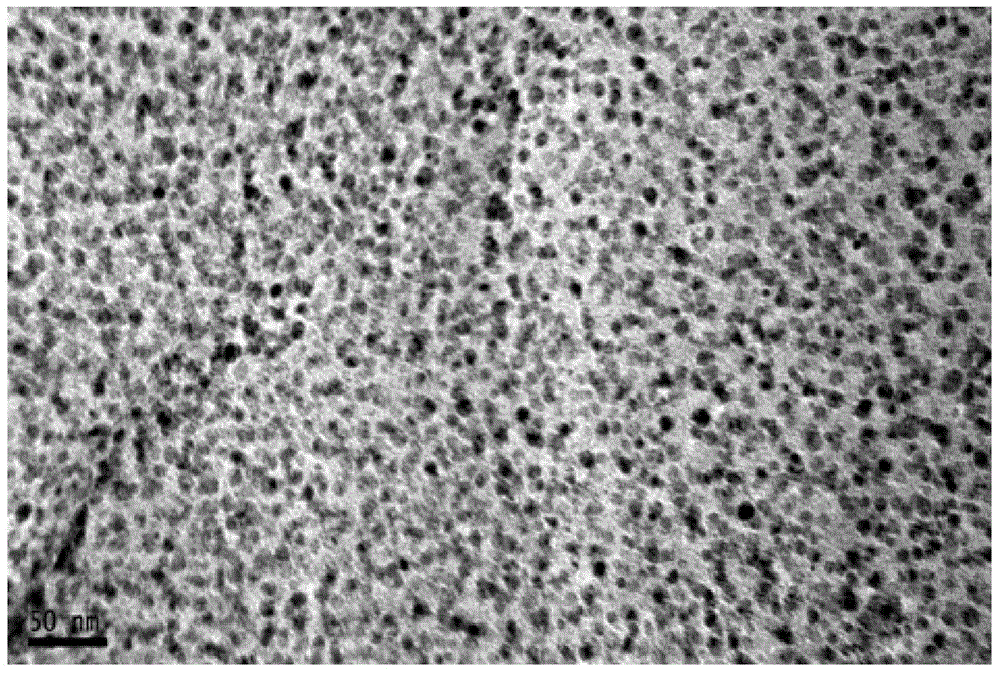

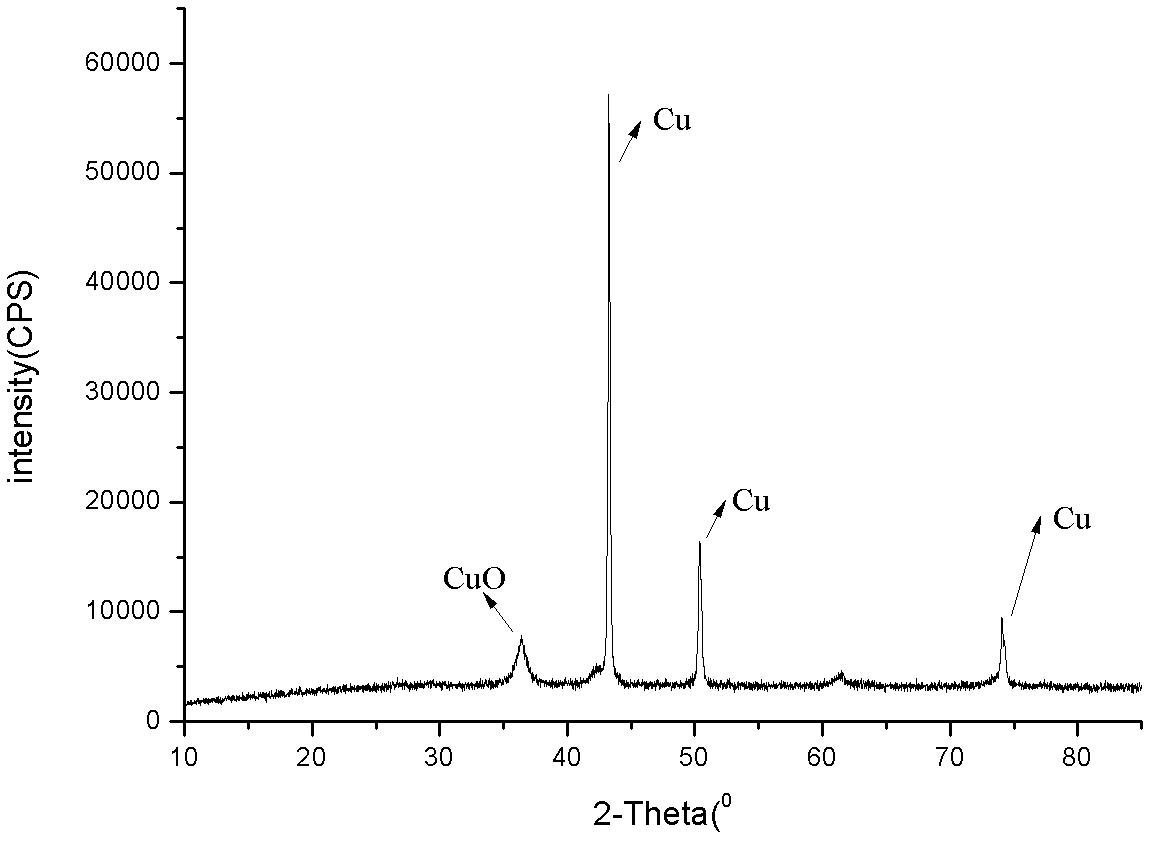

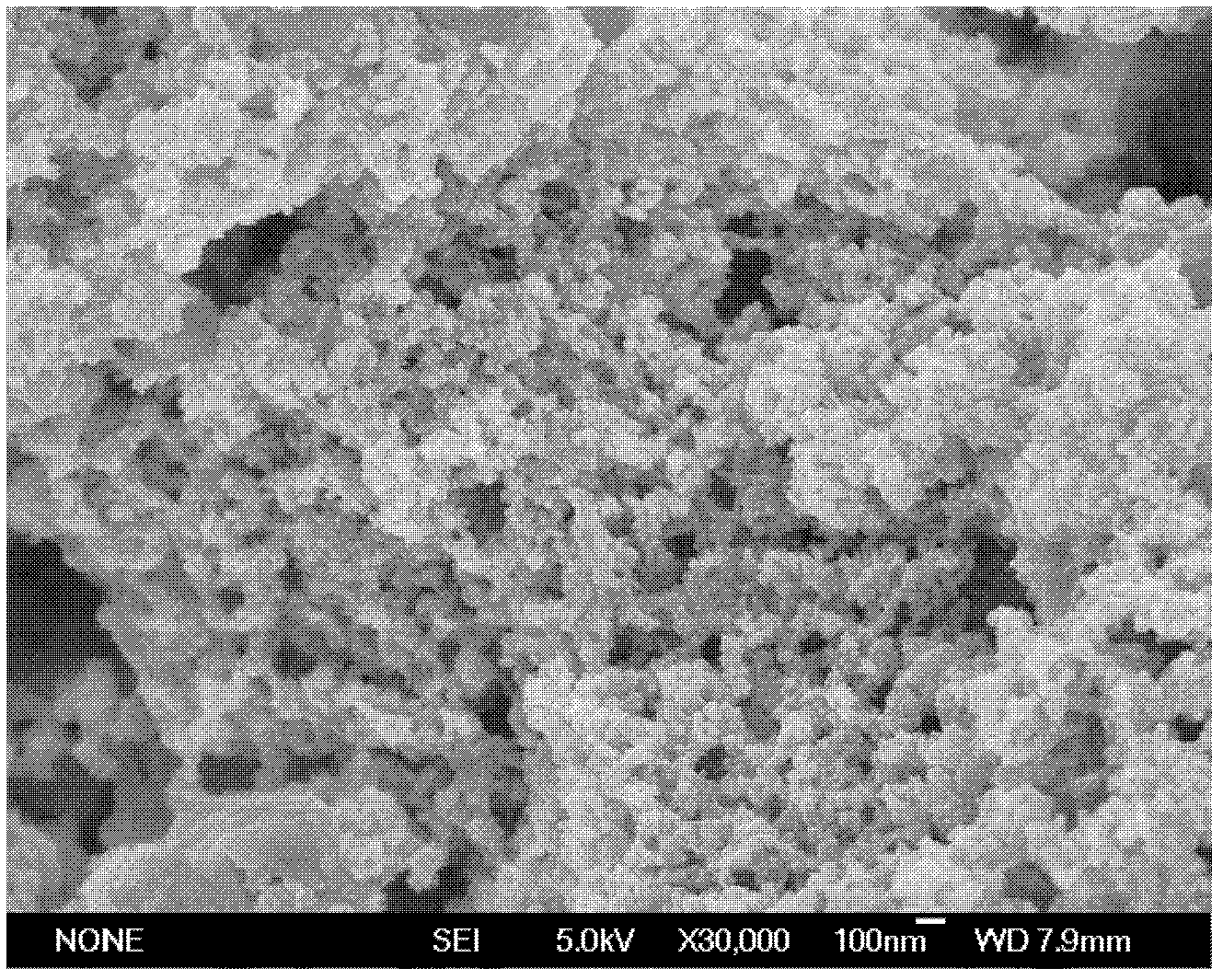

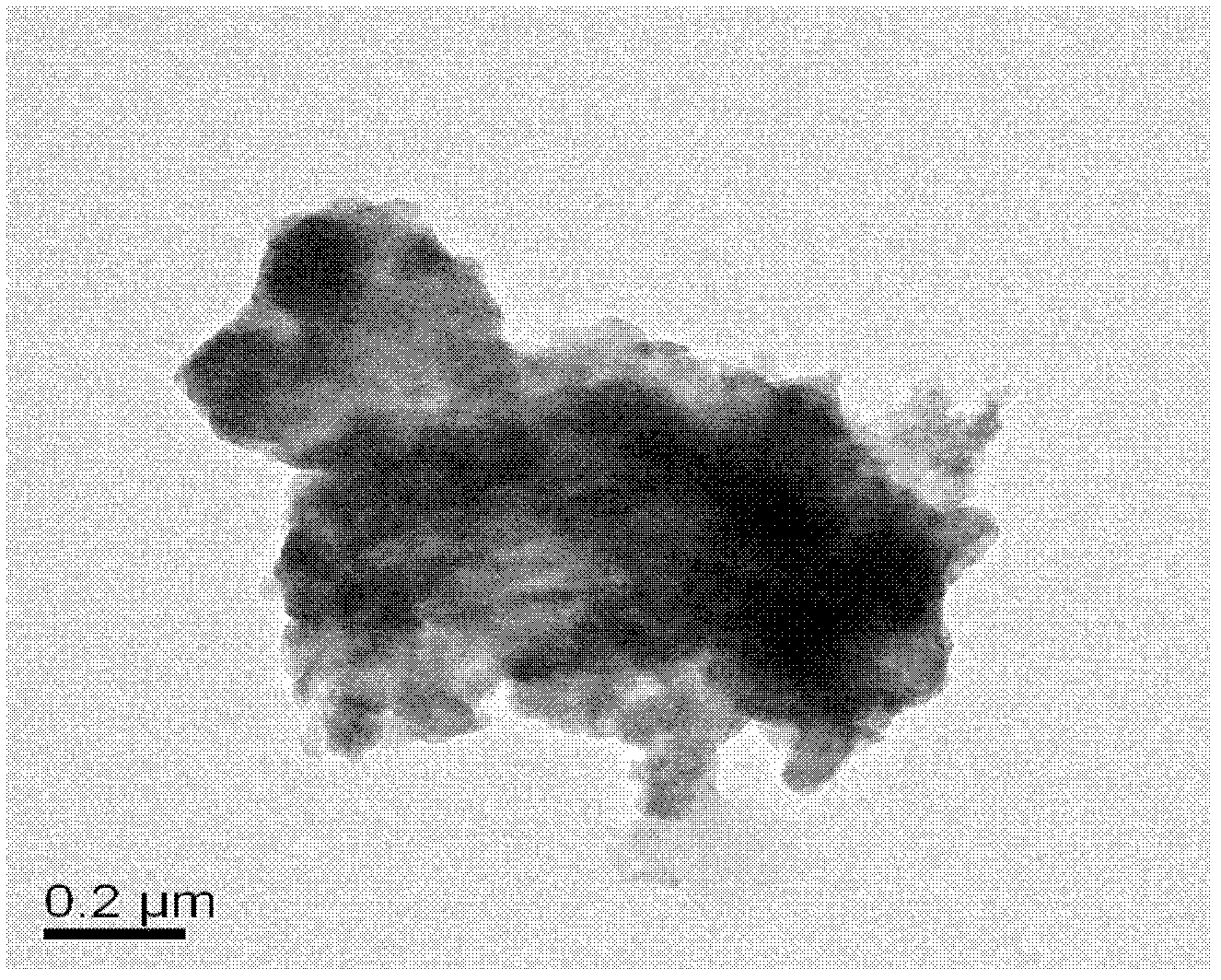

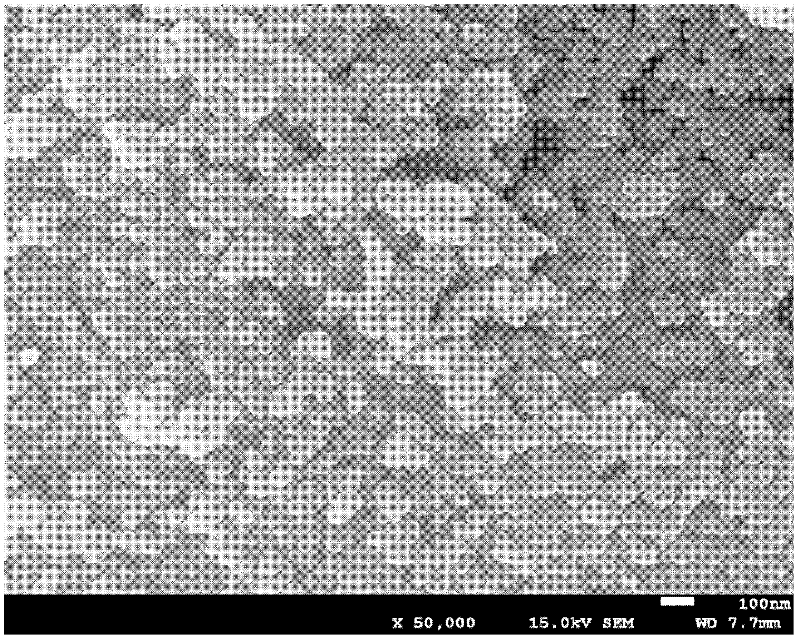

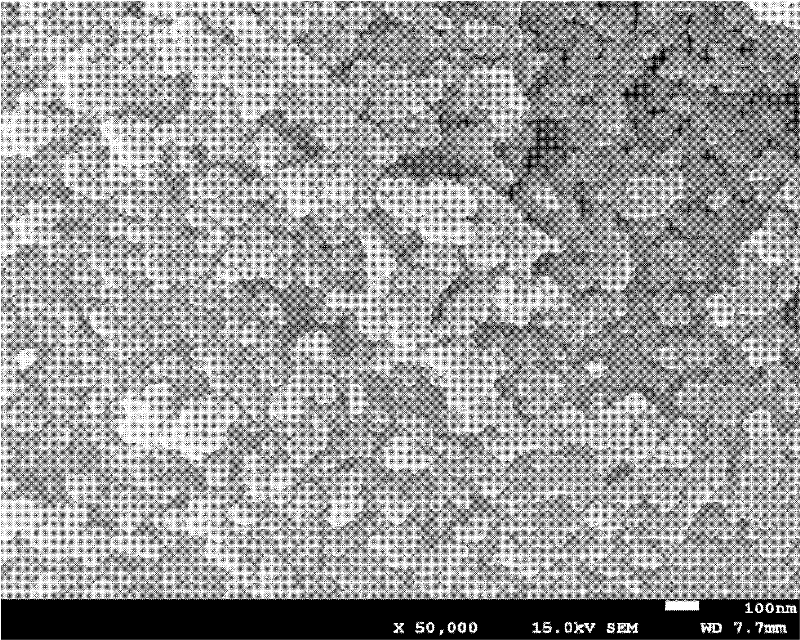

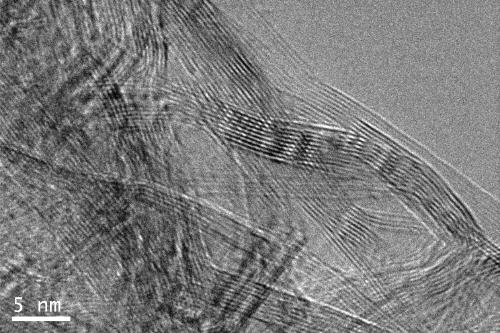

Nanometer copper/graphene composite material and preparation method and application thereof

InactiveCN104479804AThe preparation method is simple and quickShort processing timeAdditivesOil additiveSurface-active agents

The invention belongs to the technical field of new material preparation and lubricating oil additives, and discloses a nanometer copper / graphene composite material and a preparation method and application thereof. The preparation method comprises the following steps of: firstly dissolving a copper precursor compound, a surface active agent and a complexing agent into reducing alcohol, then adding graphene oxide, and carrying out ultrasonic dispersion to obtain a mixed solution; then adding a reducing agent to the mixed solution, transferring into a reaction kettle, introducing CO2 gas, and controlling gas pressure and temperature so that CO2 achieves a supercritical state; stirring the mixed solution inside the reaction kettle for reacting, cooling, decompressing, washing by centrifuging, and carrying out vacuum drying to obtain the nanometer copper / graphene composite material. The preparation method disclosed by the invention is simple, saved in time and fast. The prepared nanometer copper / graphene composite material has the characteristics of single phase, controllability in loading capacity, small nanometer copper particle size, uniformity in nanometer copper distribution on the surface of a graphene nanometer layer, and the like, has a synergetic lubricating effect, and can be used for outstandingly improving the antifriction and abrasion-resistant property of basic lubricating oil.

Owner:SOUTH CHINA UNIV OF TECH

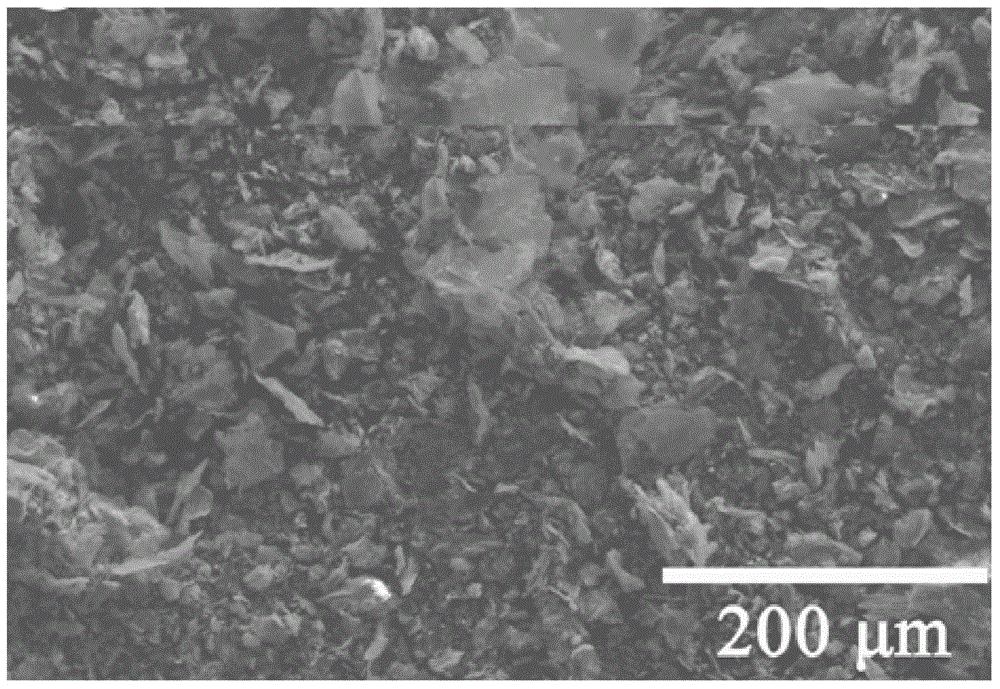

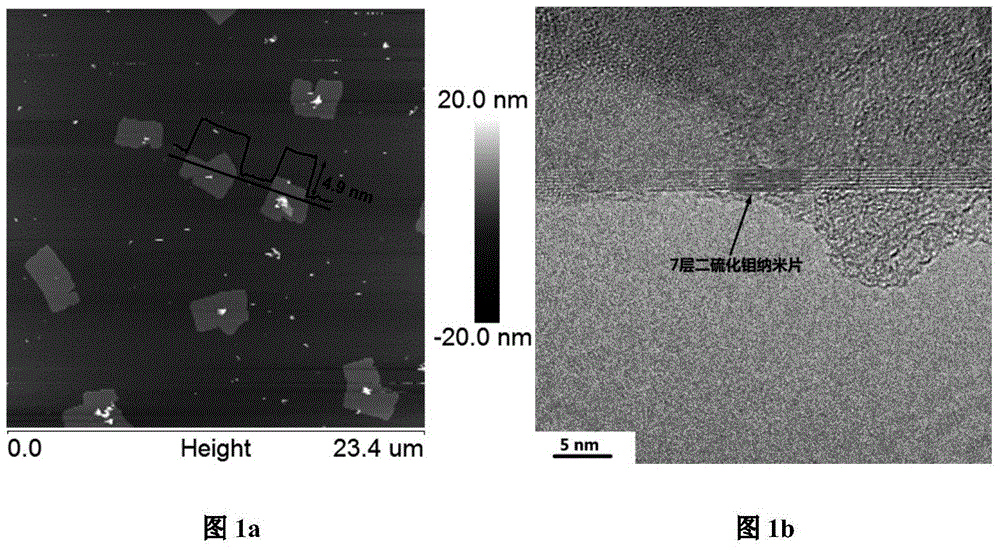

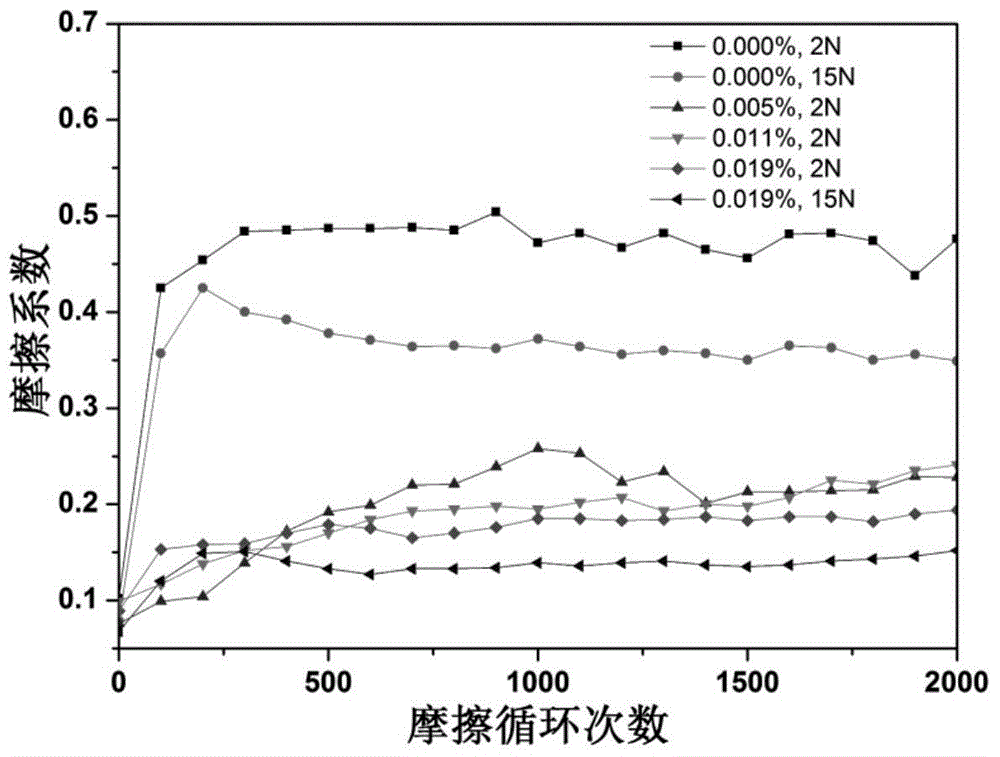

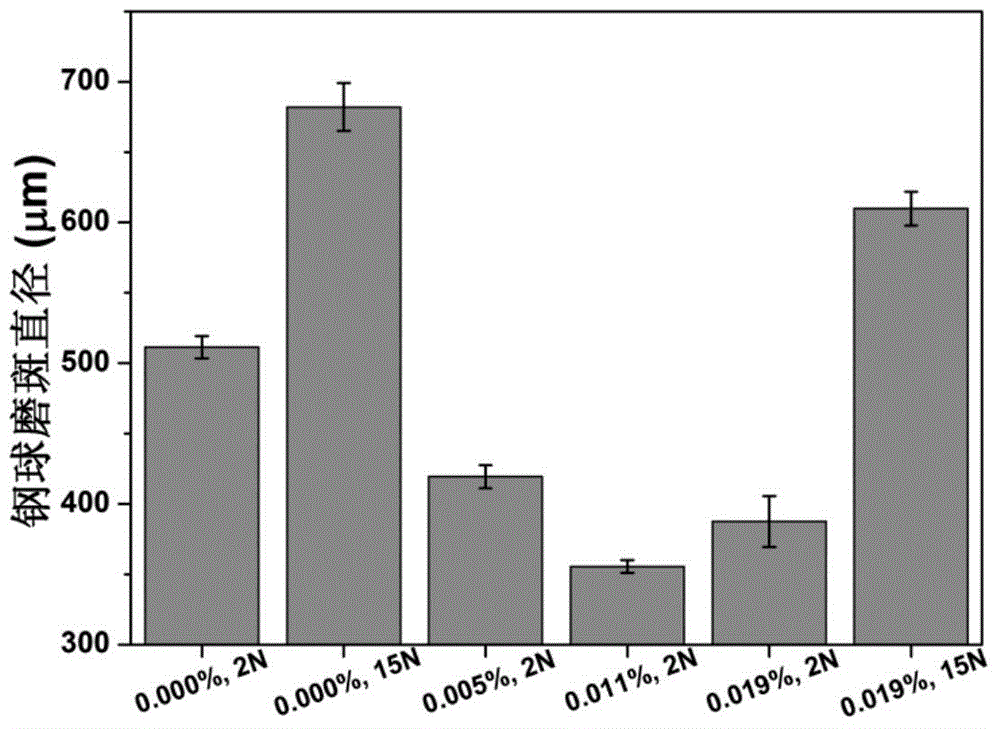

In-situ preparation method of water-based lubricant containing molybdenum disulfide nanosheet

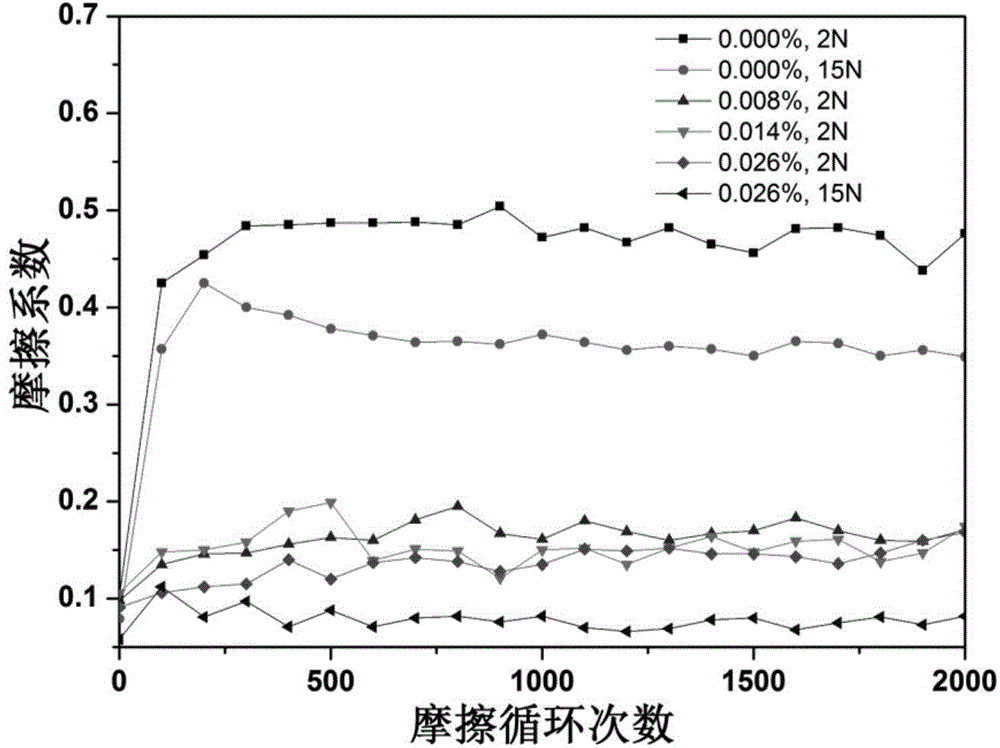

An in-situ preparation method of a water-based lubricant containing a molybdenum disulfide nanosheet comprises six steps as follows: (1), a surface active agent is dissolved in deionized water in a proportion to obtain a solution; (2), molybdenum disulfide powder is uniformly dispersed into the solution; (3), a molybdenum disulfide dispersion liquid is subjected to ultrasonic cavitation processing; (4), the solution is left to stand for a certain period of time, and a supernatant liquid of the solution is taken; (5), the obtained solution is subjected to centrifugal separation processing; (6) the supernatant liquid of the centrifugal solution is collected, and the water-based lubricant containing the in-situ prepared molybdenum disulfide nanosheet is obtained. The method is easy, convenient and feasible, and the dispersion stability of the molybdenum disulfide nanosheet is good. A friction experiment result indicates that the wear-resistant and anti-friction performance of the lubricant can be greatly improved by adding a small quantity of the molybdenum disulfide nanosheet on the premise that the original excellent characteristics of good cooling performance and processability and the like of the water-based lubricant are not influenced, and the addition quantity of the molybdenum disulfide nanosheet ranges from 0.001% to 1%.

Owner:BEIHANG UNIV

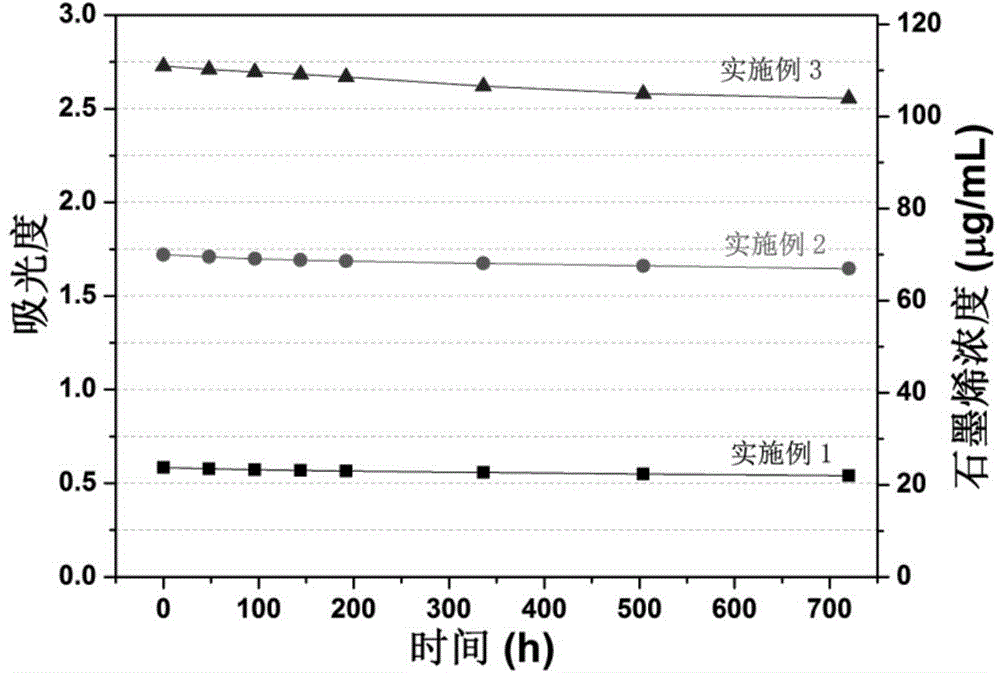

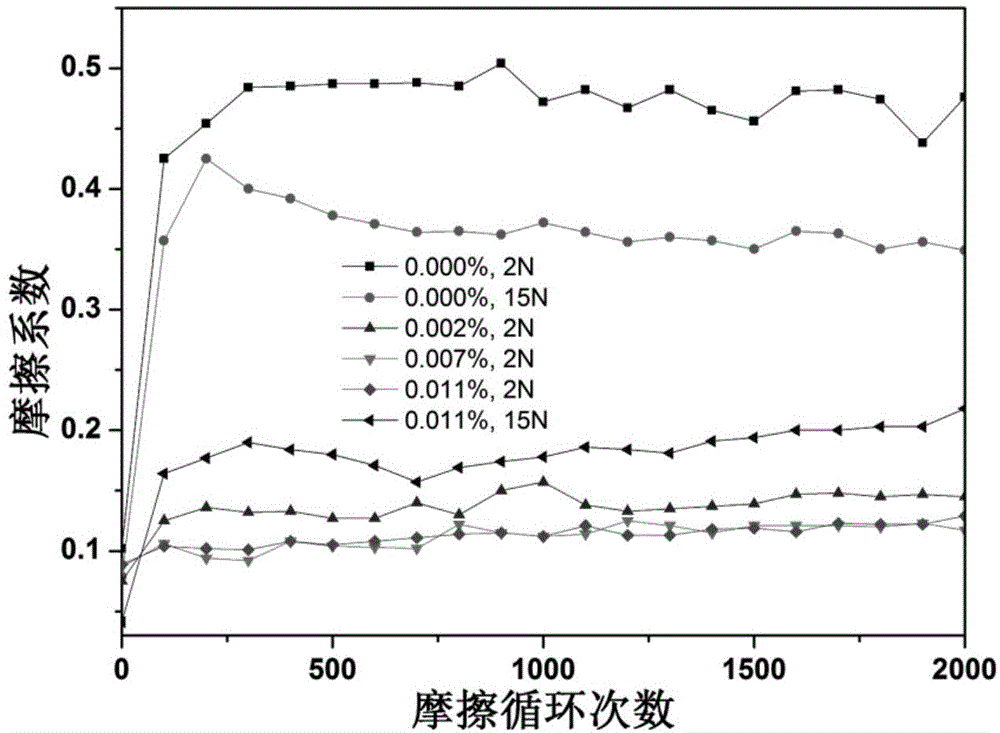

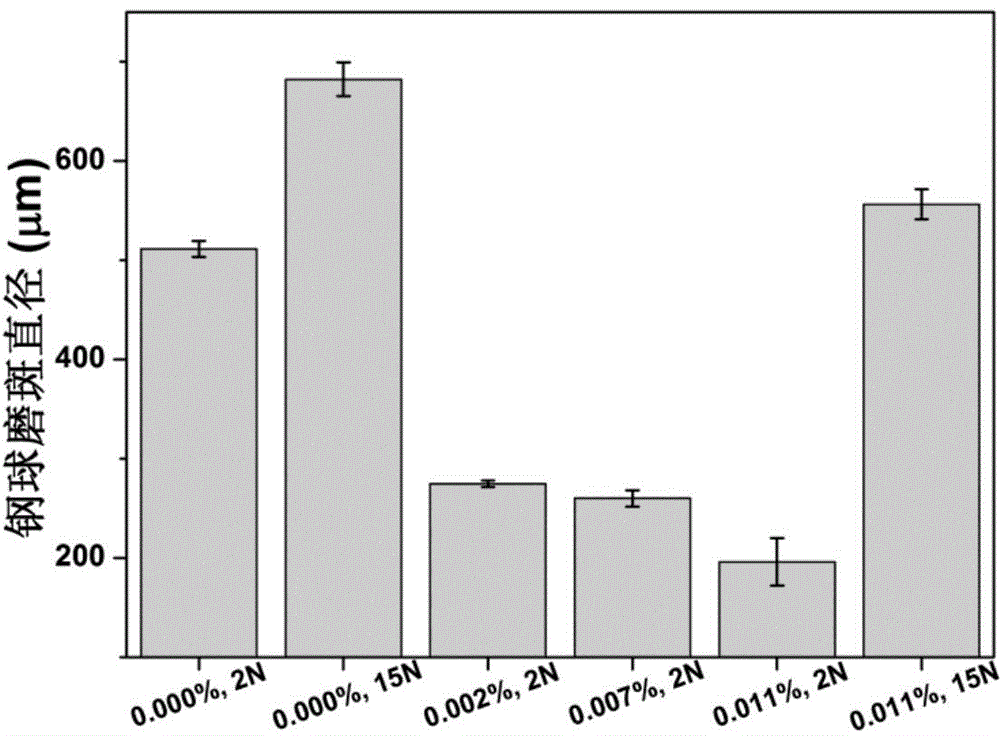

Method for preparing graphene water-based lubricating agent in situ

InactiveCN104593130ASimple preparation processEasy to prepareLubricant compositionWater basedFriction reduction

The invention discloses a method for preparing a graphene water-based lubricating agent in situ, belonging to the field of application of graphene serving as a nanometer lubricating additive. The lubricating agent consists of graphene nanoparticles, a surface modifier and purified water. The method comprises the following preparation steps: 1, dissolving a surfactant in deionized water according to a ratio, thereby obtaining a liquid; 2, uniformly dispersing graphene powder in the liquid; 3, performing ultrasonic cavitation treatment on the graphene dispersion liquid; 4, standing the liquid for a certain time, and taking the upper liquid; 5, performing centrifugal separation treatment on the obtained liquid; and 6, collecting the supernatant of the centrifuged liquid, thereby obtaining the water-based lubricating agent containing graphene prepared in situ. The method disclosed by the invention is simple in feasible, and the dispersion stability of the graphene is high. The friction test result proves that according to the extremely small addition amount (0.001-1 percent) of the graphene, the anti-wear and friction reduction properties of the lubricating agent can be greatly improved, and excellent characteristics such as good inherent cooling property, high machinability and environment friendliness of the water-based lubricating agent are not influenced.

Owner:BEIHANG UNIV

High-dispersion modified graphene lubricating oil and preparation method thereof

The invention discloses a high-dispersion modified graphene lubricating oil and a preparation method thereof. The lubricating oil comprises modified graphene, base oil and a dispersant, wherein the addition amount of the modified graphene is equivalent to 3 to 15wt% of the base oil; and the addition amount of the dispersant is equivalent to 0.5 to 1.0wt% of the base oil. Preferably, the lubricating oil also comprises stearic acid modified TiO2 nanoparticles, and the addition amount of the nanoparticles accounts for 2 to 5 wt% of the base oil. The invention also discloses preparation for the lubricating oil by adopting a microwave manner. The high-dispersion modified graphene lubricating oil provided by the invention has excellent dispersibility and stability among all components, and solves the problem of long-term stability of graphene used as an additive in the base oil.

Owner:CHONGQING DELING TECH

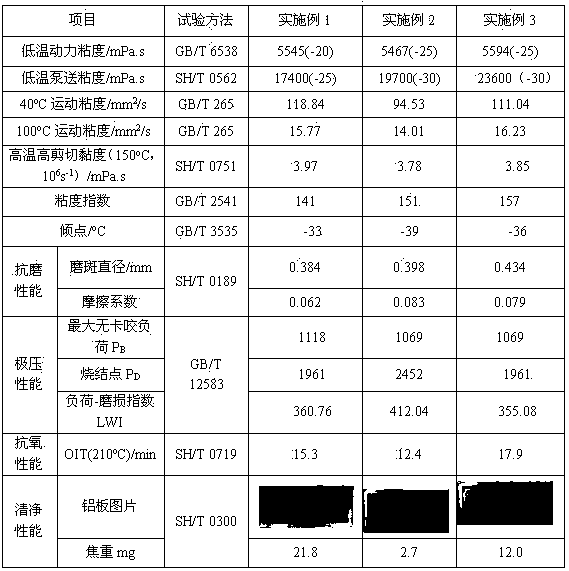

Energy-saving diesel engine oil with ultra-long oil change mileage and preparation method thereof

ActiveCN105542922AEasy to operateImprove solubilityAdditivesBase-materialsFriction reductionAntioxidant

The invention discloses energy-saving diesel engine oil with ultra-long oil change mileage and a preparation method thereof. The energy-saving diesel engine oil is prepared from, by mass, 10-18% of diesel engine oil complexing agent, 0.3-0.8% of anti-wear agent, 0.5-1.5% of antioxidant, 3-8% of viscosity index improver, 0.002-0.005% of anti-foaming agent and the balance synthesized basic oil. The energy-saving diesel engine oil has high wear resistance and friction reduction performance, high oxidation stability and high thermal stability, and the oil change cycle can be effectively prolonged; by means of the anti-wear agent without sulfur and phosphorus, the wear resistance and friction reduction performance are effectively improved, and the oxidation of an oil product can not be accelerated; alkyl multi-benzyl toluene is added to basic oil, and through the good complexing effect of alkyl multi-benzyl toluene and antioxidant, the antioxidant performance of the oil product is improved, the use cycle of the oil product is greatly prolonged, and the ultra-long oil change aim is achieved.

Owner:北京雅士科莱恩石油化工有限公司

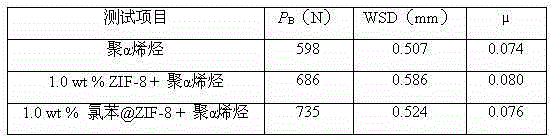

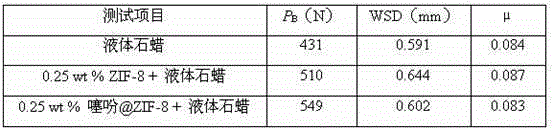

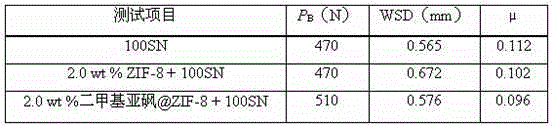

Lubricating oil, lubricating oil additive and preparation method therefor

InactiveCN105038905ASynthetic method is simpleEasy to operateAdditivesProcess engineeringRaw material

The present invention discloses lubricating oil, a lubricating oil additive and a preparation method therefor, and belongs to the technical fields of functional materials and preparation thereof. The lubricating oil provided by the present invention consists of the following raw materials: with the total number of parts being 100, 98-99.75 parts of base lubricating oil and 0.25-2 parts of a lubricating oil additive. The lubricating oil additive is a sulfur- or chlorine-filled ZIF-8 material. The lubricating oil additive provided by the present invention is simple in preparation method, convenient and easy in application, and stable in performance. Application of the lubricating oil additive product provided by the present invention can effectively improve the bearing capability of the lubricating oil.

Owner:TAIYUAN UNIV OF TECH

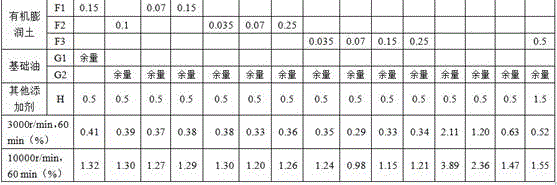

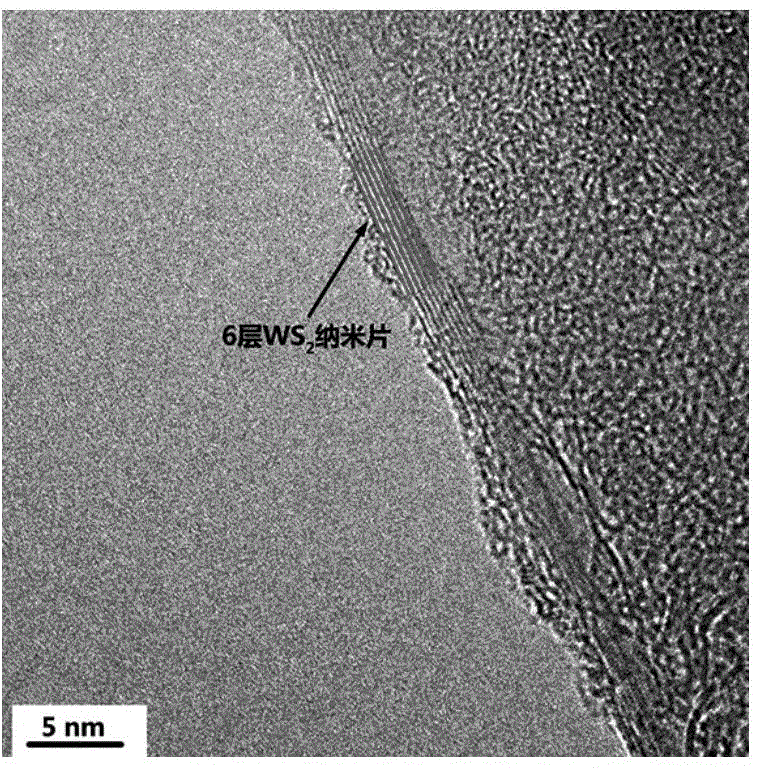

Nano-graphite concentrate liquid composition and lubricating oil prepared by using composition

The invention provides a nano-graphite concentrate liquid composition. The composition comprises, by mass, 0.1-10% of polyol ester, 0.1-10% of a purification dispersant, 0.1-5% of an extreme pressure anti-wear agent, 0.05-0.5% of a diphenylamine antioxidant, 0.5-15% of nano-graphite, 0.005-0.5% of organic bentonite, and the balance of base oil. The invention also provides a preparation method of the nano-graphite concentrate liquid composition, and an application of the composition in lubricating oil. The nano-graphite concentrate liquid composition has the characteristics of low settlement amount and excellent dispersibility, and makes original lubricating oil have the advantages of good high temperature purification dispersion and thermo-oxidative stability, excellent anti-wear and friction reduction properties, oil consumption saving and engine power improvement as a lubricating oil additive.

Owner:青岛天象石化有限公司

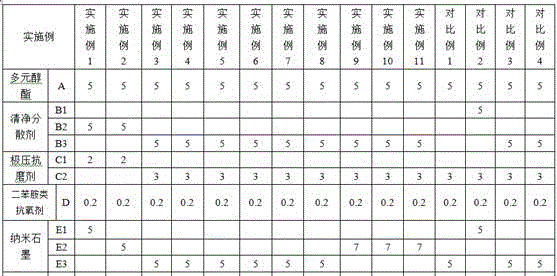

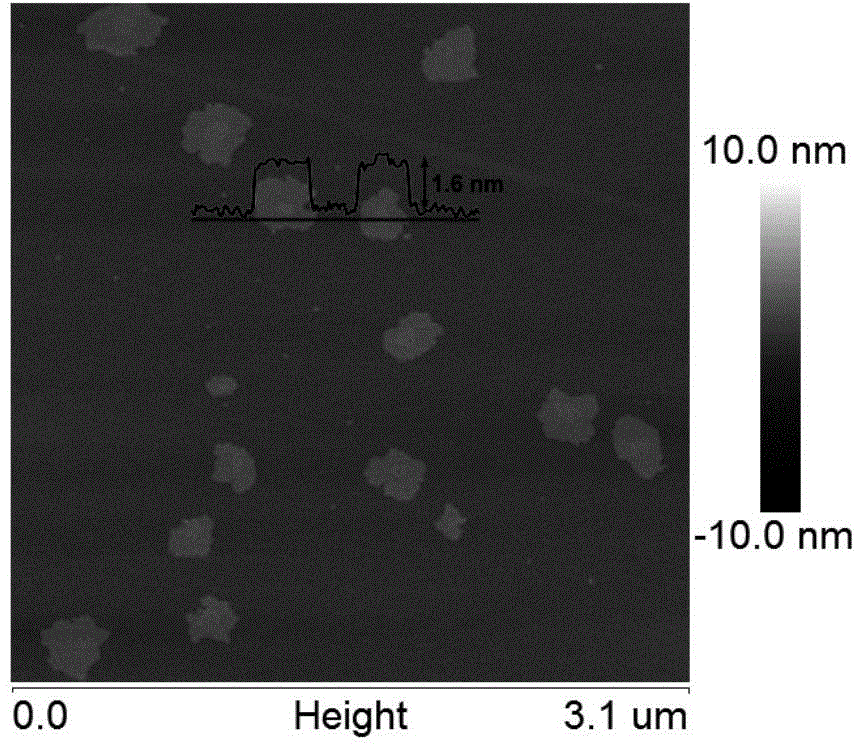

Method for preparing tungsten disulfide nanosheet water-based lubricating agent in situ

The invention discloses a method for preparing a tungsten disulfide nanosheet water-based lubricating agent in situ. The method comprises the following six steps: 1, dissolving a surfactant in deionized water according to a ratio, thereby obtaining a liquid; 2, uniformly dispersing tungsten disulfide powder in the liquid; 3, performing ultrasonic cavitation treatment on the tungsten disulfide dispersion liquid; 4, standing the liquid for a certain time, and taking the upper liquid; 5, performing centrifugal separation on the obtained liquid; and 6, collecting the supernatant of the centrifuged liquid, thereby obtaining the water-based lubricating agent containing tungsten disulfide nanosheets prepared in situ. The method disclosed by the invention is simple in feasible, and the dispersion stability of the tungsten disulfide nanosheets is high. The friction test result proves that according to the extremely small addition amount (0.001-1 percent) of the tungsten disulfide nanosheets, the anti-wear and friction reduction properties of the lubricating agent can be greatly improved, and excellent characteristics such as good inherent cooling property and high machinability of the water-based lubricating agent are not influenced.

Owner:BEIHANG UNIV

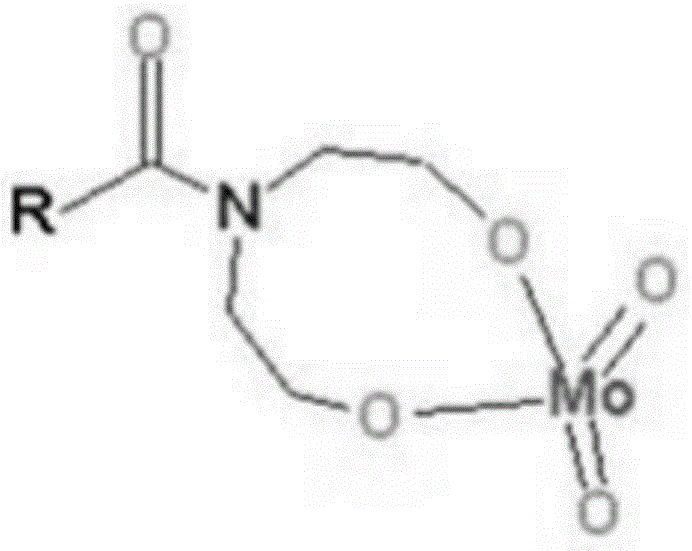

Gasoline engine lubricating coil composition and preparation method thereof

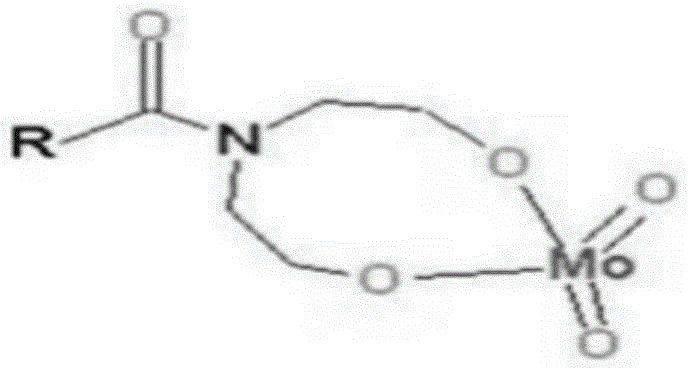

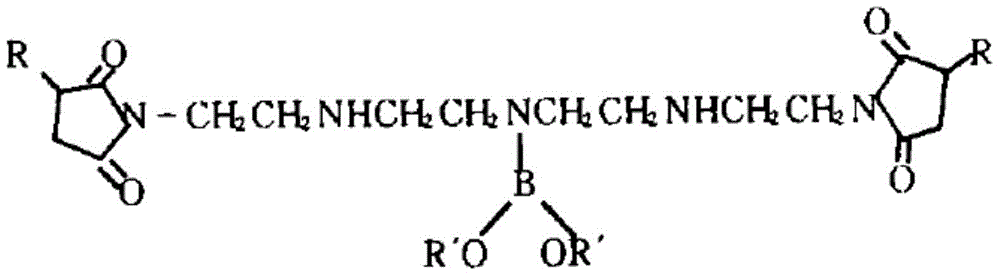

InactiveCN107760419AReduce usageGive full play to the synergistic effectLubricant compositionChemical compositionBoron containing

The invention discloses a gasoline engine lubricating coil composition and a preparation method thereof. The gasoline engine lubricating coil composition comprises the following components in percentby weight: (A) 0.1 to 6.0 percent of an ashless dispersing agent, (B) 0.1 to 8.0 percent of a clearing agent, (C) 0.01 to 1.5 percent of oil-soluble or dispersible oil stability boron-containing compound, (D) 0.003 to 0.5 percent of oil-soluble or dispersible oil stability molybdenum-containing compound, (E) 0.02 to 3.2 percent of zinc dialkyl dithiophosphate, (F) 0.01 to 3.0 percent of an antioxidant and (G) lubricating oil base oil with a main amount, wherein the boron molybdenum mass ratio of the component (C) to the component (D) ranges from 1:5 to 10:1. The blended gasoline engine oil composition contains all of the boron-containing compound, the molybdenum-containing compound and the zinc dialkyl dithiophosphate, completely exerts the synergistic effect between the additives, improves the anti-oxidation property, the anti-wear and friction-reducing properties and the extreme pressure property of the lubricating oil composition and reduces the ash content and the thionazin contentof the lubricating oil composition.

Owner:江西福安路润滑材料有限公司 +1

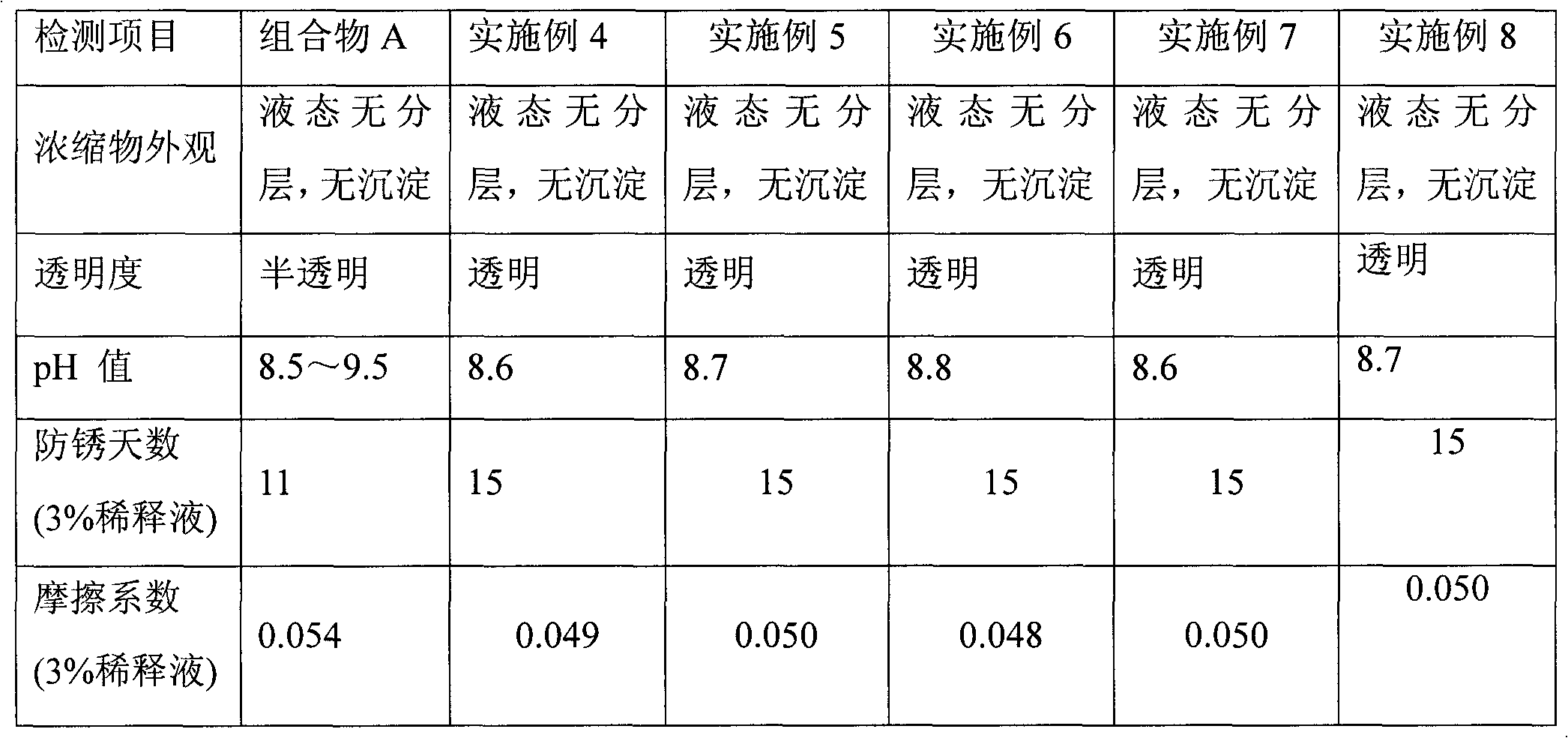

Water-soluble grinding fluid

ActiveCN102585986AMeet technical requirementsReduce frictionLubricant compositionHigh resistanceInorganic salts

The invention discloses a water-soluble grinding fluid. Based on the total weight of the water-soluble grinding fluid, the water-soluble grinding fluid consists of (A) 10-20 percent by weight of oiliness agent, (B) 4-8 percent by weight of inorganic salt rust inhibitor, (C) 15-30 percent by weight of organic synthesis rust inhibitor, (D) 5-15 percent by weight of nonionic surfactant, (E) 2-6 percent by weight of pH value regulator and (F) 30-60 percent by weight of deionized water. A water-soluble grinding fluid composition has high wear resistance, high antifriction performance and high rust resistance, is convenient to operate, and is easy to clean.

Owner:CHINA PETROLEUM & CHEM CORP +1

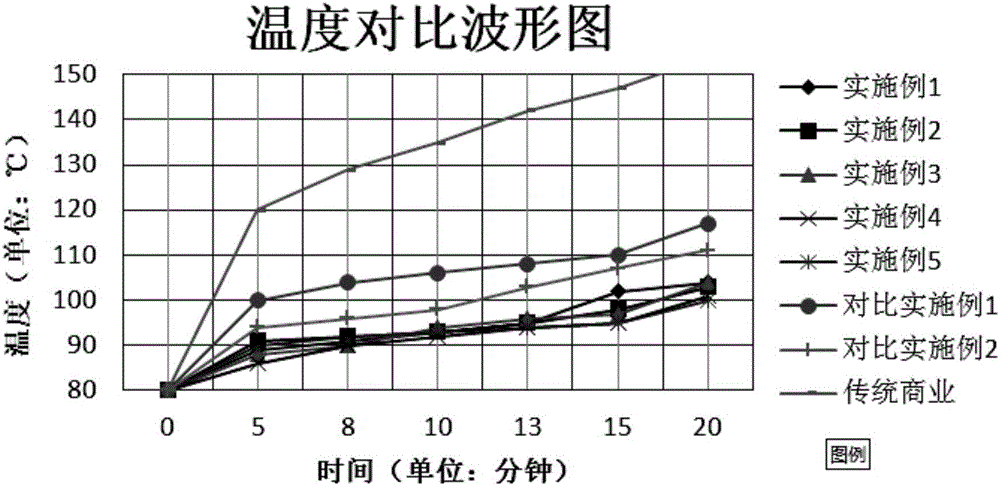

Ultra-low-viscosity energy-saving gasoline engine oil and preparation method thereof

The invention discloses ultra-low-viscosity energy-saving gasoline engine oil and a preparation method thereof. The ultra-low-viscosity energy-saving gasoline engine oil is composed of, by mass, 8.5-12.5% of a steam turbine oil complexing agent, 0.1-0.5% of antioxygen, 1-5% of viscosity index improver, 0-0.8% of an antiwear agent, 0.002-0.005% of an anti-foaming agent and the balance synthetic base oil. According to the base oil, alpha-olefin, esters and polyester oil are selected in cooperation with the special viscosity index improver, the mixture is combined and blended into ultra-low-viscosity totally-synthesized gasoline engine oil with the viscosity meeting the standard, characteristics of alpha-olefin type oil and ester type oil are utilized and reasonably matched, and the ultra-low-viscosity totally-synthesized gasoline engine oil which is excellent in performance is prepared; according to the ultra-low-viscosity energy-saving gasoline engine oil and the preparation method thereof, an anti-wear reinforcing agent is added to serve as oil soluble organic molybdenum and organic tungsten, the organic molybdenum and organic tungsten are used in a joint mode, engine oil plays good anti-wear and friction reduction functions in the whole stage of operation of an engine, the phenomena that the oil temperature is excessively high, and thus oil is oxidized and goes bad due to excessively high friction are effectively avoided.

Owner:北京雅士科莱恩石油化工有限公司

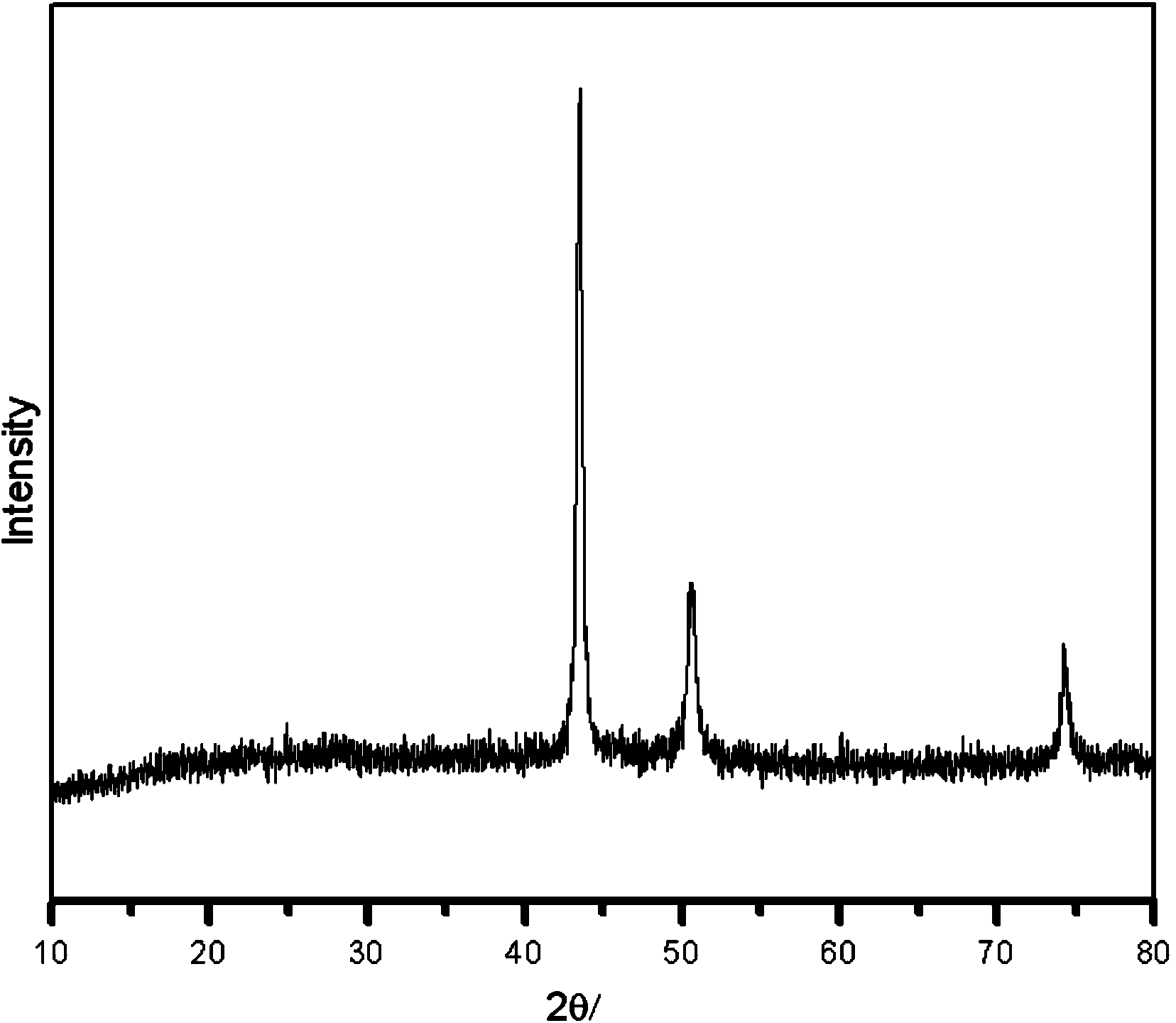

Method for preparing nano copper particle

The invention relates to a method for preparing a nano copper particle, in particular to a novel method for preparing a nano copper particle serving as a lubricating oil additive. The synthesis method comprises the following steps of: dissolving water-soluble divalent copper salt into water; adding a proper amount of acid organic extracting agent and coating agent into the solution; extracting divalent copper ions to an organic phase; and then simply and efficiently preparing spherical nano copper particles which have good dispersion, uniform particle size and good oxidation resistance by adopting a two-step liquid phase reduction method. The method provided by the invention has the advantages such as simple process, convenience for operation, low cost, easiness for industrialization and the like; and the prepared nano copper particle has the advantages of good dispersion, uniform particle size, good oxidation resistance, good friction property and the like.

Owner:CENT SOUTH UNIV

Modified graphene lubricating oil with good dispersibility and affinity and preparation method thereof

The invention discloses modified graphene lubricating oil with good dispersibility and affinity and a preparation method thereof, the modified graphene lubricating oil comprises modified graphene, base oil, an affinity agent and a dispersing agent, the adding amount of the modified graphene accounts to 3-15wt% of the base oil, the adding amount of the affinity agent accounts to 0.1-2wt% of the base oil, the adding amount of the dispersing agent accounts to 0.5-1.0wt% of the base oil, preferably, the lubricating oil also includes stearic-acid-modified TiO2 nanoparticles, and the adding amount of the nanoparticles accounts to 2 to 5wt% of the base oil. The invention also discloses a method for preparing the lubricating oil by microwave. The high dispersion modified graphene lubricating oil has excellent dispersion and stability, and solves the problem of long-term stability of the graphene as an additive in the base oil.

Owner:CHONGQING DELING TECH

Preparation method of carbon fiber and silicon dioxide nanosphere synergically filled ultra-high molecular weight polyethylene wear-resistant material

ActiveCN107663328AImprove anti-wear and anti-friction performanceImprove mechanical propertiesFiberCarbon fibers

The invention discloses a preparation method of a carbon fiber and silicon dioxide nanosphere synergically filled ultra-high molecular weight polyethylene wear-resistant material and relates to the field of nanotribology, in particular dispersion of a nano material in high molecular resin and tribological properties thereof. The preparation method comprises the following steps: firstly, modifyingthe carbon fibers with nitric acid to obtain nitric acid modified carbon fibers; loading silicon dioxide nanospheres on the surfaces of nitric acid modified carbon fibers by means of a sol-gel processto obtain a composite material of silicon dioxide nanospheres and carbon fibers, and performing surface coupling treatment to obtain coupled composite packing; and finally, mixing the coupled composite packing with ultra-high molecular weight polyethylene, and performing hot pressing and sulfidizing to obtain the carbon fiber and silicon dioxide nanosphere synergically filled ultra-high molecularweight polyethylene wear-resistant material. The composite material has relatively good mechanical property, frictional wear-resistant property, mortar wear property and machine shaping property.

Owner:YANGZHOU UNIV

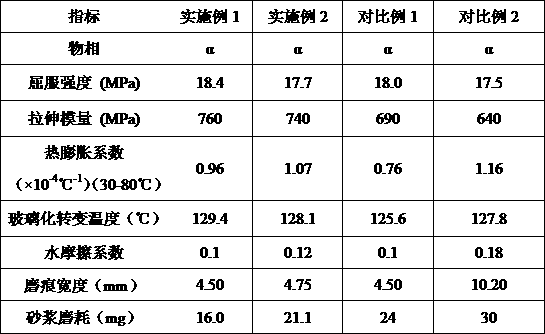

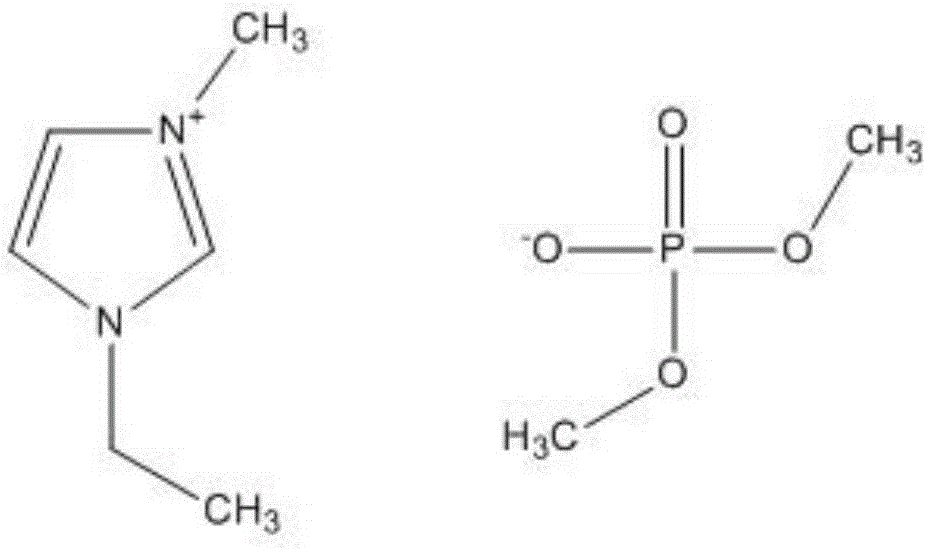

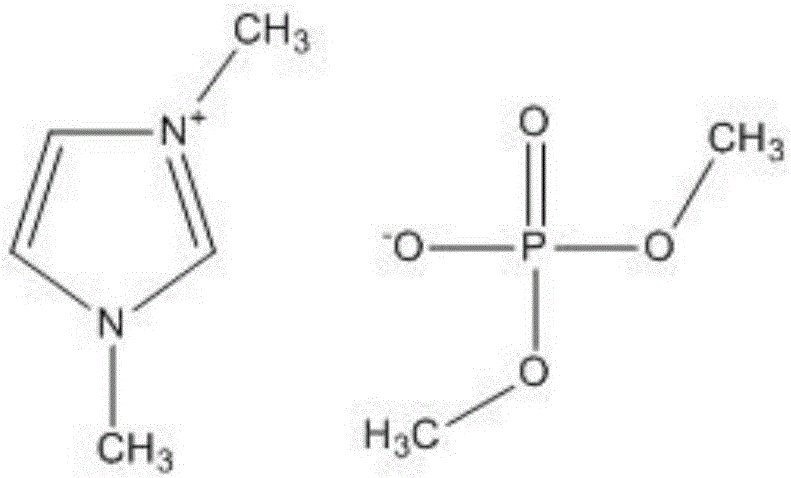

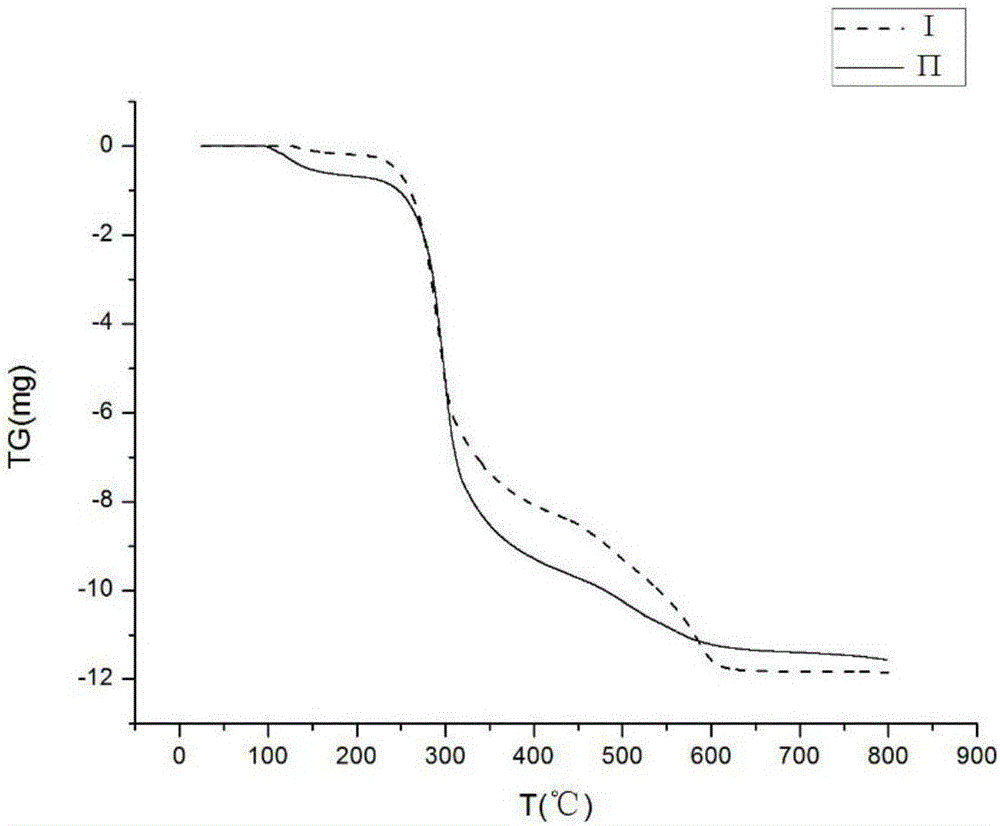

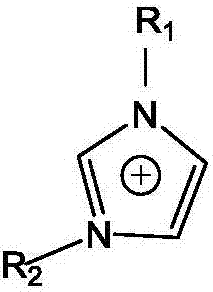

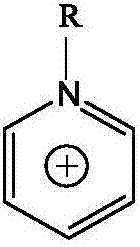

High-temperature environment-friendly water-based ionic liquid lubricant

The invention discloses a high-temperature environment-friendly water-based ionic liquid lubricant and belongs to the technical field of liquid lubricants. The lubricant comprises the following raw materials in percentage by mass: 0.5-1% of 1-ethyl-3-methylimidazole dimethyl phosphate; 0.1-0.5 % of 1,3-dimethylimidazolium dimethyl phosphate; 1-2% of a corrosion inhibitor; 0.01-2% of a bactericide, and 90-95% of water to prepare the water-based solution. According to the invention, the high-temperature environment-friendly water-based ionic liquid lubricant has very high thermal stability, extremely low volatility and excellent high-temperature antifriction and anti-wear properties. Performance detection is carried out on the lubricant provided by the invention, and the result shows that the thermal decomposition temperature of the lubricant is about 300 DEG C and the metal has good oxidation resistance, friction resistance and wear resistance. According to the invention, no pollution is caused to the environment, so that the lubricant has good popularization and application prospect.

Owner:UNIV OF SCI & TECH BEIJING

Process for preparing ZrO#-[2]/perfluoropolyether composite lubrication thin film

InactiveCN1635064ASolve protection problemsSolve lubricityBase-materialsPerfluoropolyetherDip-coating

The invention discloses a process for preparing ZrO#-[2] / perfluoropolyether composite lubrication thin film on the surface of solid materials, wherein the Sol-Gel process is employed to prepare ZrO2 ceramic film on slide glasses, monocrystalline silicon sheet, aluminum sheet or stainless steel substrate, then a Dip-coating method is employed for preparing single-layer all-fluorine polyether ultra-thin lubricant film on the ZrO2 ceramic film. The prepared lubricant film has good tribology performance, thus can be used as antifriction and antiwear protective coatings.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing nanoscale lubricant additive

InactiveCN102559338AGood dispersionImproved rust resistance and seal material compatibilityAdditivesChemistryEmulsion

The invention discloses a method for preparing a nanoscale lubricant additive, comprising the following steps: A, preparing solutions: weighing calcium chloride and boric acid according to the proportion of 1:2 of Ca and B and dissolving the calcium chloride and the boric acid respectively; B, carrying out ultrasonic reaction: mixing the two solutions by ultrasonic processing and stirring, adding a surfactant, and subjecting the solutions and the surfactant to reaction at room temperature to obtain a white emulsion; and C, extracting products: adding the mixed solution of oleic acid and petroleum ether into the white emulsion, processing ultrasonically and stirring continuously until a lower layer aqueous solution is clear and transparent, standing for layering, taking an upper white oil-phase precipitation, and drying to obtain the nano calcium borate lubricant additives, wherein the mixed solution of the oleic acid and the petroleum ether is used as the extractant. The performance of the lubricant additive is greatly improved, the process for preparing the lubricant additive is greatly simplified, and the cost for preparing the lubricant additive is reduced.

Owner:HEBEI UNIVERSITY

Synthetic ester refrigerator oil composition

InactiveCN105132088AGood extreme pressure and anti-wear propertiesGood anti-oxidation and anti-corrosion propertiesLubricant compositionViscosity gradeOrganic chemistry

The invention provides a synthetic ester refrigerator oil composition. The synthetic ester refrigerator oil composition comprises, by weight, 100.0 parts of synthetic ester base oil, 0.01-50.0 parts of other base oil, 0.5-10.0 parts of an anti-wear agent, 0.5-3.0 parts of an oxidation and corrosion inhibitor, 0.2-1.0 part of a multifunctional anti-wear, antifriction and energy saving additive, 0.1-0.5 parts of a metal deactivator, and 0.0001-0.01 parts of an antifoaming agent. The synthetic ester refrigerator oil composition can meet performance requirements of the viscosity grades of GB / T16630-2012 refrigerator oil of 7, 10, 15, 22, 32, 46, 68 and 100.

Owner:XINJIANG FUKE OIL PROD CO LTD

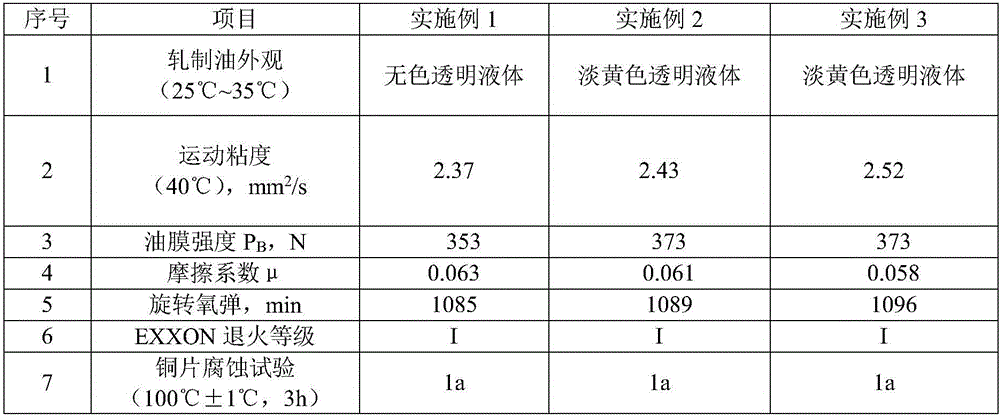

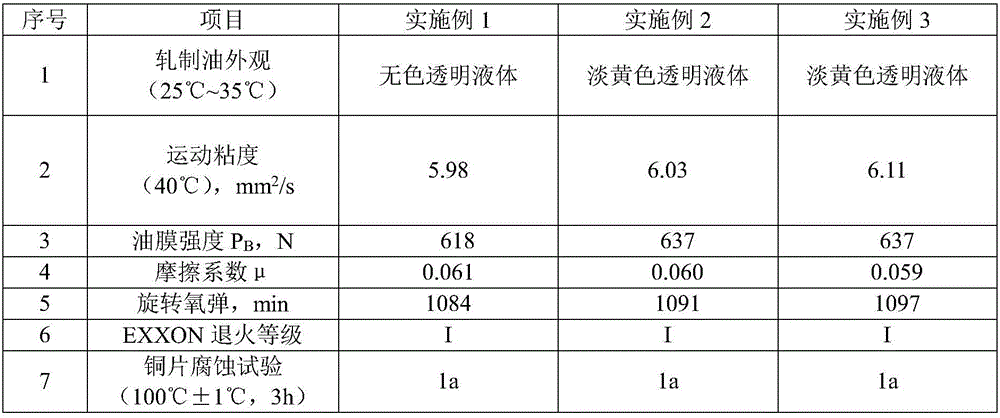

Universal nonferrous metal and stainless steel cold rolling oil composite additive and preparation method thereof

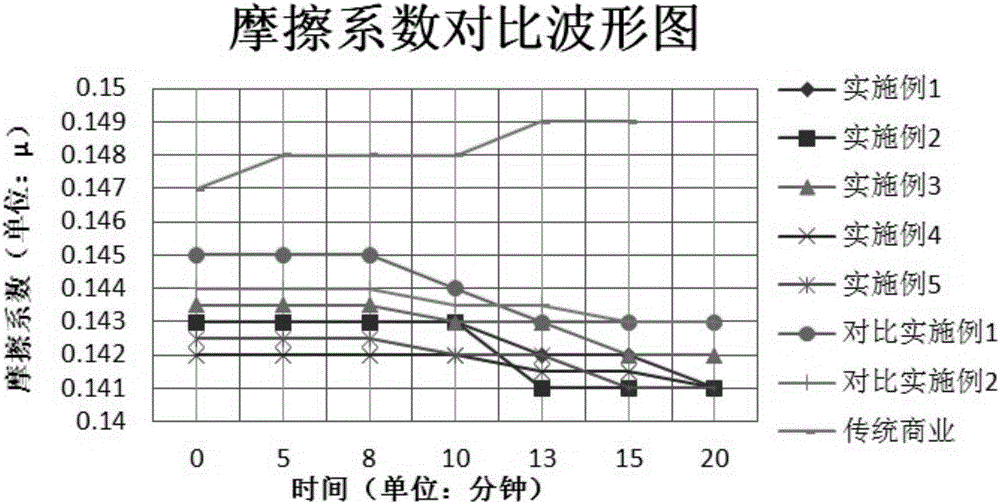

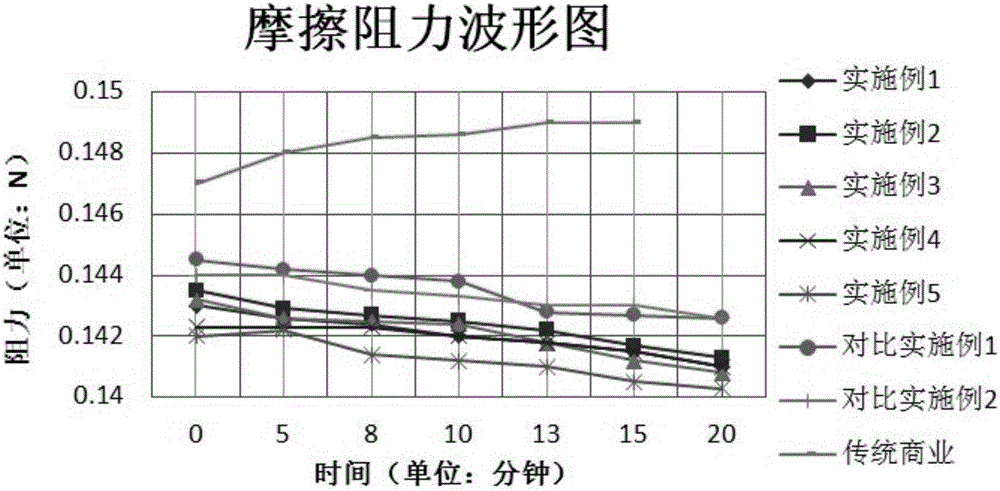

ActiveCN106566598AImprove anti-friction and anti-wear effectImprove anti-wear and anti-friction performanceAdditivesAntioxidantSolvent

The invention provides a universal nonferrous metal and stainless steel cold rolling oil composite additive and a preparation method thereof and belongs to the field of lubricating agents. According to the universal nonferrous metal and stainless steel cold rolling oil composite additive, lauryl alcohol, butyl stearate, pentaerythritol oleate and lauric acid are selected as oily agents; 2,6-di-tert-butyl-4-methylphenol is selected as an antioxidant; benzotriazole and thiadiazole derivatives are used as metal deactivators; dialkyl phosphorodithioate serves as an antiwear agent; and hydrogenated base oil serves as a solvent. The alcohol-ester type oily agents are mainly used for compounding with a little amount of acid oily agents as supplementation; a little amount of dialkyl phosphorodithioate is used as the antiwear agent to reinforce an oil film so as to improve the surface quality of a rolled stock; the service life of rolling oil is prolonged through a little amount of the antioxidant and the metal deactivators, the cyclic use frequency is increased, and rolled pieces are protected against corrosion. The universal nonferrous metal and stainless steel cold rolling oil composite additive is convenient to use, low in cost and little in dosage, and has the characteristics of high oil film strength, good antiwear and antifriction effect, high oxidation resistance and excellent annealing performance.

Owner:UNIV OF SCI & TECH BEIJING

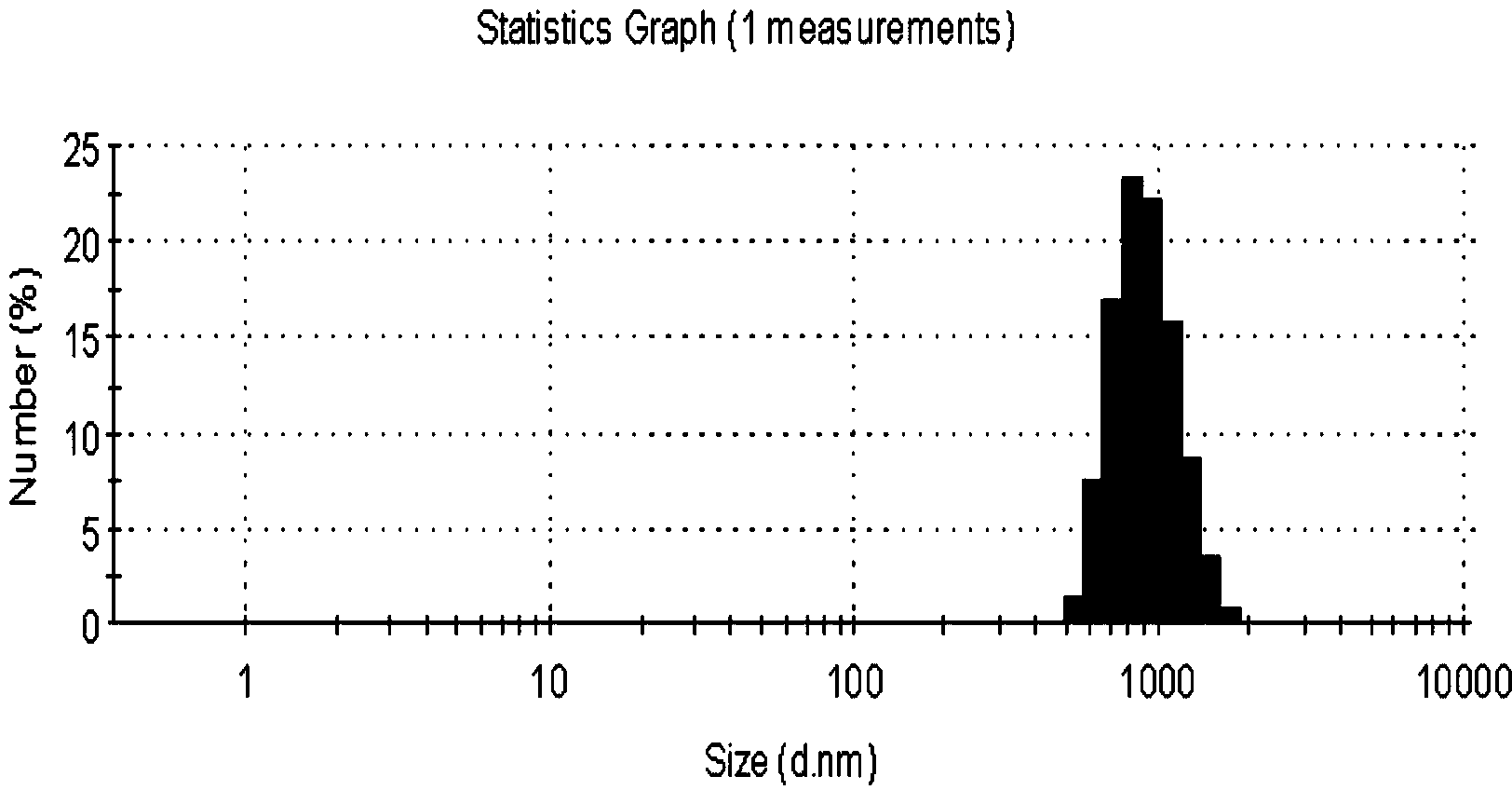

Method for recycling ultrafine copper powder from waste liquid containing complexing copper

ActiveCN103506632AImprove thermal conductivityImprove self-healing abilityRecovery methodLiquid waste

The invention discloses a method for recycling ultrafine copper powder from waste liquid containing complexing copper, and belongs to the technical field of chemical engineering recycling. According to the technical scheme, the method for recycling the ultrafine copper powder from waste liquid containing the complexing copper comprises the steps of adding a pvp dispersing agent in the waste liquid containing the copper, then adding glucose and NaOH, conducting heating and stirring to conduct a prereduction reaction, after the reaction, adding thiourea dioxide, conducting heating and stirring to conduct a reduction reaction, after the reaction is finished, conducting filtering, conducting washing for two times, conducting ethyl alcohol washing for two times, conducting vacuum drying, and obtaining the ultrafine copper powder. According to the method for recycling the ultrafine copper powder, the copper removal rate is 99%, the granularity of the recycled and obtained ultrafine copper powder can be 700nm-1500nm, the purity of the produced copper powder can be more than 99.95%, and the prepared ultrafine copper powder is applied to a plurality of fields of conducting resin, conductive coatings, conductive composite material raw materials, high-performance catalysts, lubricant additives, nanocrystalline copper, medicines and the like.

Owner:JINAN UNIVERSITY

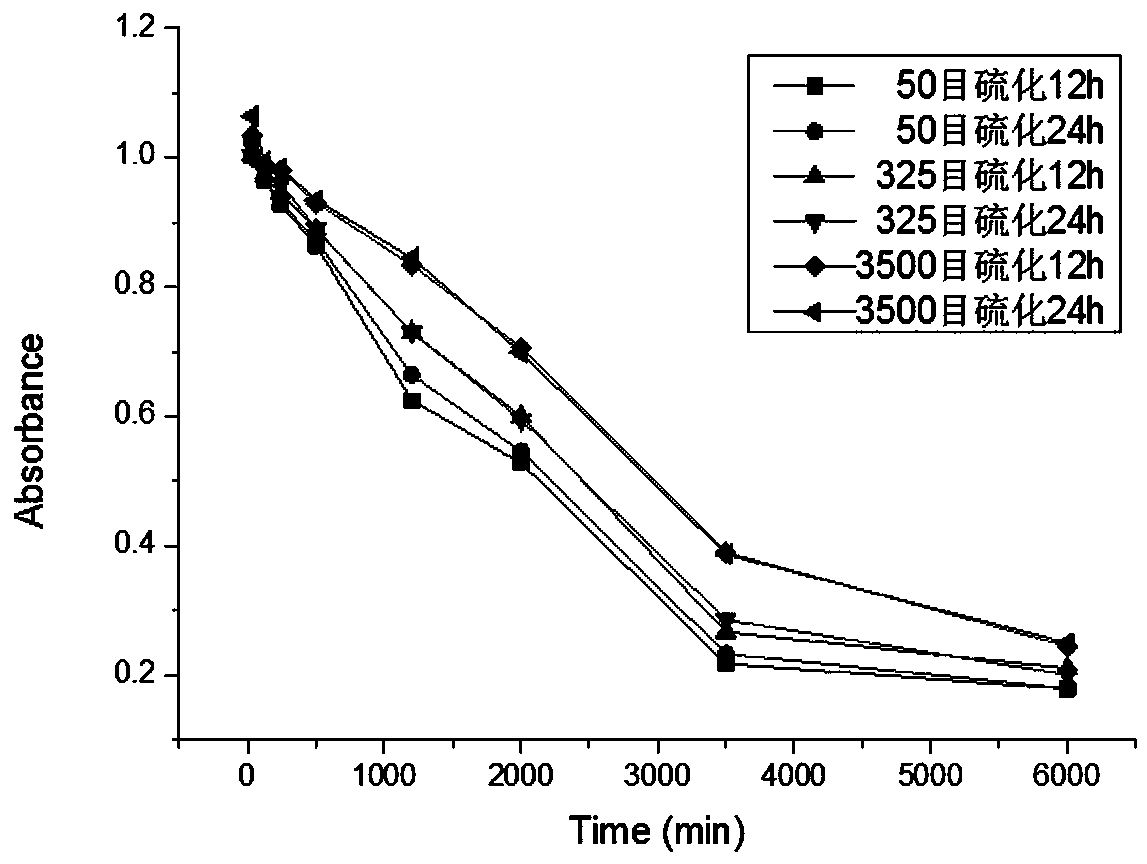

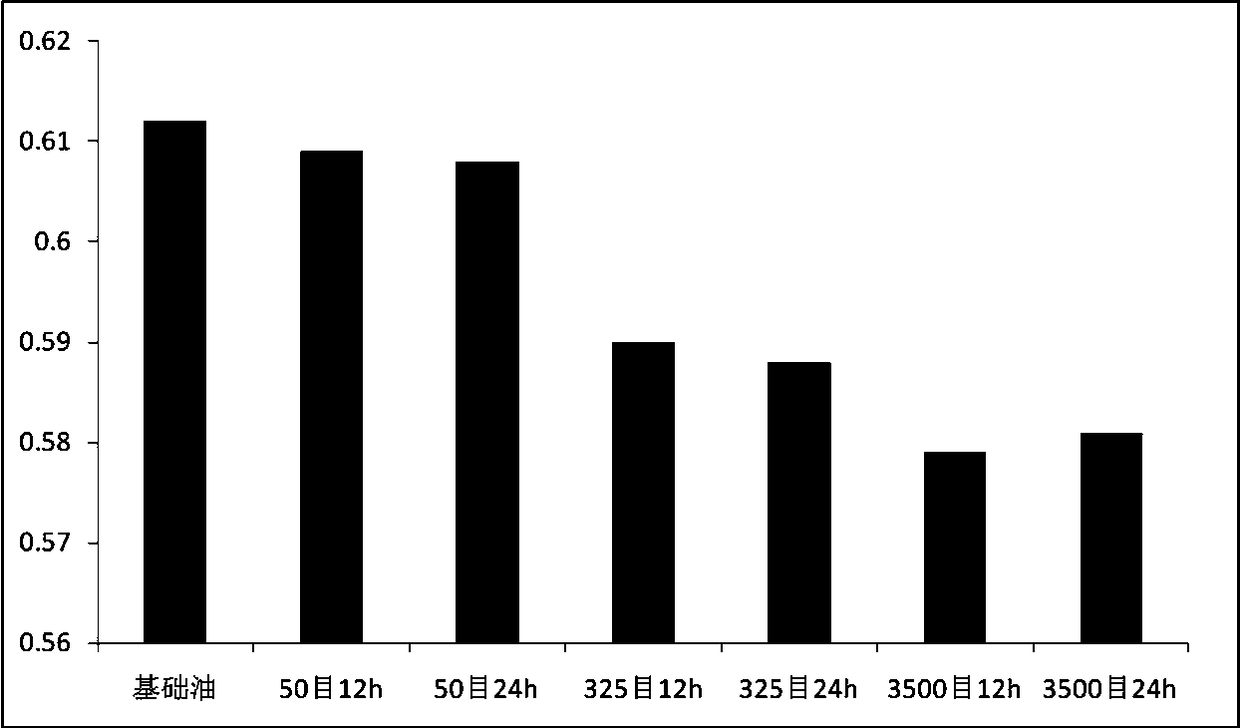

Preparation method of graphene sulfide

ActiveCN109486547AExcellent anti-wear and anti-friction propertiesImprove anti-friction and anti-wear effectCarbon compoundsAdditivesCvd grapheneChemistry

The invention relates to graphene sulfide as well as a preparation method and application thereof. The preparation method comprises the following steps: oxidizing graphene by using potassium permanganate and concentrated sulfuric acid, and then vulcanizing the oxidized graphene by using P4S10, thereby preparing the graphene sulfide. In addition, the dispersion performance and absorption performance of the graphene sulfide in lubricating oil basic oil are also researched, the tribological performance of a graphene reaction lubricating membrane is tested, and the lubricating mechanism is researched. The result shows that the dispersion performance of the graphene can be improved by virtue of vulcanization, and the wear-resisting and friction reducing effect of the graphene can be improved.

Owner:中国人民解放军空军勤务学院

Lubricating oil composition and method for improving detergency of lubricating oil

ActiveCN107987920AExcellent high temperature detergencyImprove Oxidation StabilityAdditivesDemulsifierAntioxidant

The invention provides lubricating oil composition and a method for improving detergency of lubricating oil. The lubricating oil composition is prepared from a compound detergent, a dispersant, an antioxidant, an anti-wear agent, a demulsifier and the balance of lubricating base oil, wherein the compound detergent is a mixture of alkylsalicylate, sulfurized alkyphenate and sulfonate. The lubricating oil composition has excellent high-temperature detergency, oxidation stability and antiwear and antifriction properties, particularly has excellent high-temperature detergency and emulsion resistance and is rapid and thorough in water separation and applicable to lubrication of diesel engines for ships and particularly, lubrication of crank cases of two-stroke and low-speed crosshead type diesel engines for ships and medium-speed piston type diesel engines.

Owner:CHINA PETROLEUM & CHEM CORP +1

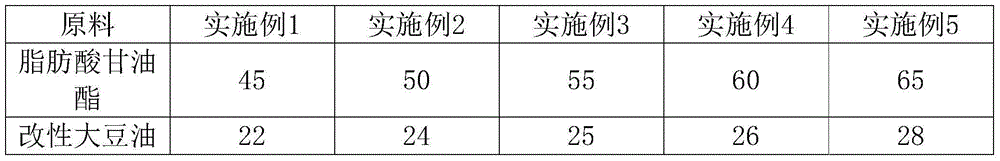

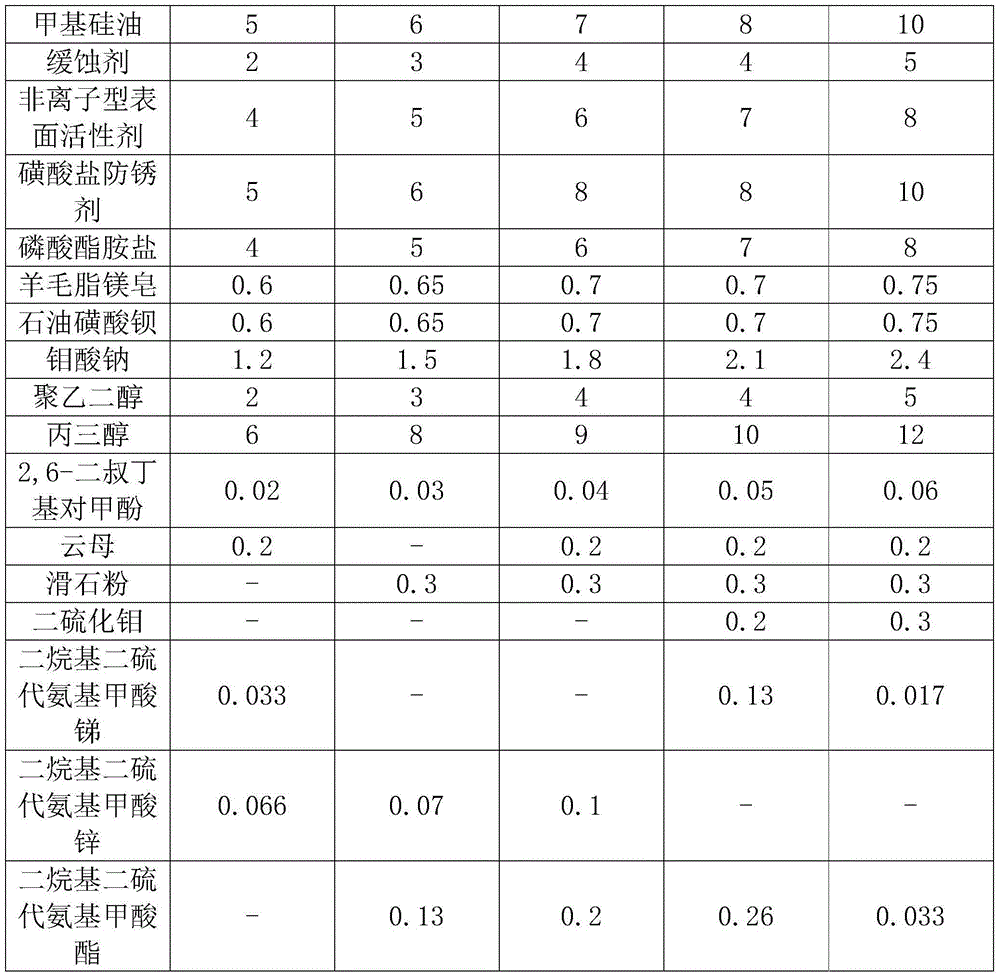

Antirust lubricant and preparation method thereof

InactiveCN104830491AHigh biodegradation rateHigh viscosity indexLubricant compositionVegetable oilPhosphate

The invention relates to the technical field of lubricants, particularly an antirust lubricant and a preparation method thereof. The antirust lubricant is composed of the following components in parts by mass: 45-65 parts of fatty glyceride, 22-28 parts of modified soybean oil, 5-10 parts of methyl silicone oil, 2-5 parts of corrosion inhibitor, 4-8 parts of non-ionic surfactant, 5-10 parts of sulfonate rust inhibitor, 4-8 parts of phosphate amine salt, 1.2-1.5 parts of antirust compound oil, 1.2-2.4 parts of sodium molybdate, 2-5 parts of polyethyleneglycol, 6-12 parts of glycerol, 0.02-0.06 part of 2,6-di-tert-butyl-para-cresol, 0.2-0.8 part of solid additive and 0.1-0.5 part of antioxidation preservative. By using the modified soybean oil as the base oil, the biodegradability is high. The antirust lubricant has the advantages of high viscosity index, favorable viscosity-temperature characteristics, favorable low-temperature fluidity, accessible raw materials and low cost. The antirust lubricant has excellent extreme pressure abrasion resistance since the vegetable oil polar molecules can form a protective film on the metal surface.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

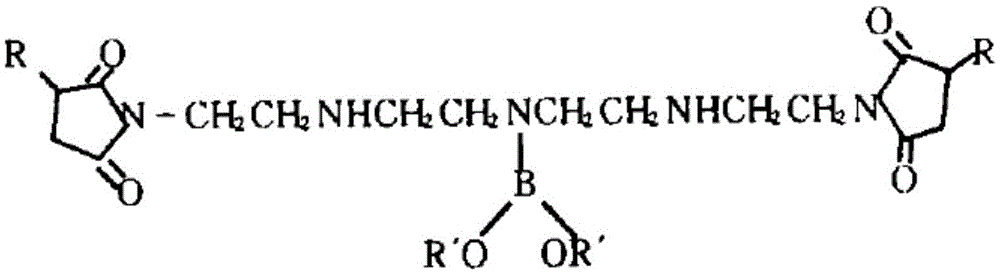

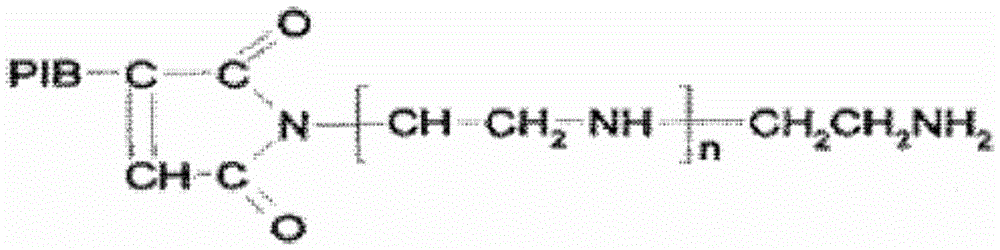

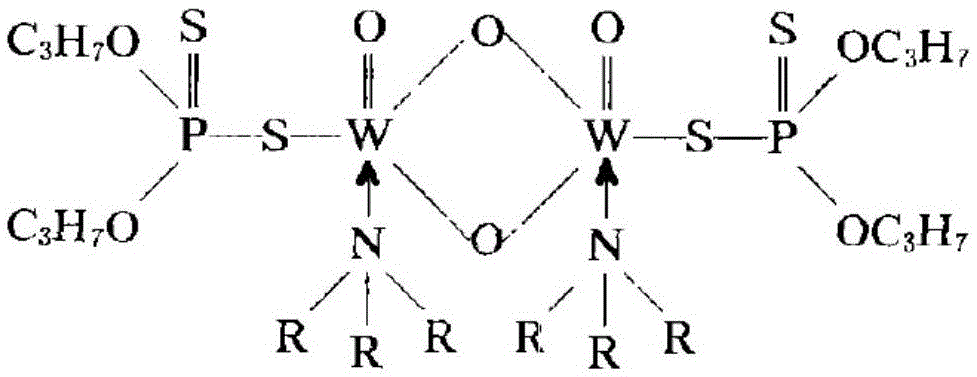

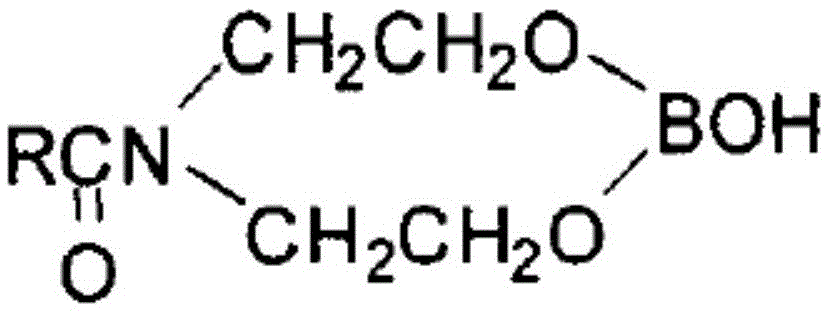

Antiwear agent for energy-saving engine and preparation method for antiwear agent

The invention discloses an antiwear agent for an energy-saving engine and a preparation method for the antiwear agent. The antiwear agent comprises the following raw materials in parts by weight: 6-9 parts of tungsten aminodiisopropyl dithiophosphate, 6-9 parts of diglycolamide oleate borate, 0.5-4.5 parts of modified nano-calcium borate, 15-25 parts of monoallyl succinimide, 12-18 parts of polymethacrylate, 6-9 parts of organic molybdenum and 20-40 parts of base oil. The antiwear agent for the energy-saving engine is simple in preparation method, can be widely applied to engines of overloaded heavy vehicles and old vehicles, achieves a very good antiwear repair effect for metal surfaces of slightly worn parts in the engines, and has excellent antiwear and antifriction properties, oxidation resistance, cleanliness and seal property; and the exhaust gas emission is reduced, the fuel consumption is reduced, the resources are saved, and the environmental protection requirements are met.

Owner:中沃能源(湖北)集团股份有限公司

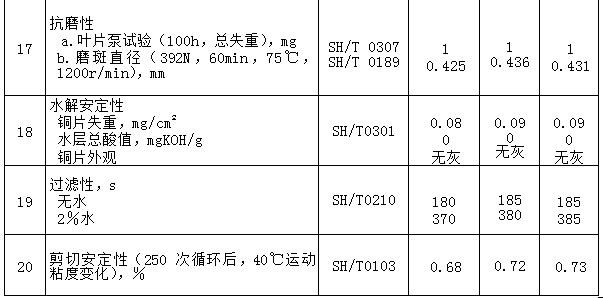

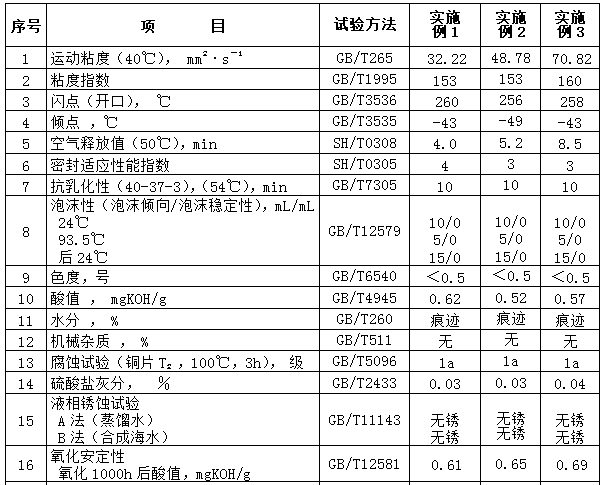

Coal-based fully-synthetic low-temperature hydraulic oil and preparation method thereof

InactiveCN111019743AMeet anti-foam performanceGood resistance to shearing and heat and oxygenLubricant compositionPolyolefinCoal

The invention belongs to the technical field of hydraulic oil, and particularly relates to coal-based fully-synthetic low-temperature hydraulic oil and a preparation method thereof, wherein the coal-based fully-synthetic low-temperature hydraulic oil is prepared from the following components by mass: 98.0-99.5 wt% of coal-based synthetic base oil and the balance of an additive, and the coal-basedsynthetic base oil is prepared from the following components by weight: 60-90 wt% of III type and CTL4 base oil prepared from coal, 0-25 wt% of poly alpha-olefin PAO40 base oil prepared from coal, and0-5 wt% of poly alpha-olefin PAO150 base oil prepared from coal. According to the invention, the traditional base oil formula is replaced with coal-based synthetic oil, so that the hydraulic oil canhave proper viscosity and high viscosity index without a viscosity index improver, the hydraulic oil has good shear resistance, heat resistance and oxidation resistance, and the oil change period is prolonged; and the preparation method of the industrial hydraulic oil has simple and environment-friendly steps and is easy to implement.

Owner:SHANXI LUAN MINING GRP +2

High-viscosity repair type engine anti-wear agent capable of reducing exhaust and preparing method of engine anti-wear agent

The invention discloses a high-viscosity repair type engine anti-wear agent capable of reducing exhaust and a preparing method of the engine anti-wear agent. The high-viscosity repair type engine anti-wear agent capable of reducing exhaust is prepared from, by mass, 5-10% of organic molybdenum, 5-10% of organic tungsten, 5-10% of nitrogenous boric acid ester, 0-5% of an extreme pressure anti-wear agent, 10-30% of a dispersing agent, 10-20% of high-viscosity polyester, 10-20% of composite ester and the balance base oil. The high-viscosity repair type engine anti-wear agent capable of reducing exhaust has good wear-resisting and friction-reducing performance, good resistance to oxidation, good cleanliness and good sealing performance and can be widely applied to engines of overload heavy vehicles and aged and used vehicles, a very good wear-resisting repair effect can be achieved on the metal surfaces of slightly-worn parts inside engines, and the service life of the engines is prolonged; especially, a good sealing effect can be achieved between one engine piston and a piston ring and between the engine piston and a cylinder sleeve, the problem of engine oil combustion caused by upward engine oil leakage and engine oil oxidation caused by downward gas leakage is solved, and the cylinder pressure is increased so that fuel oil can be sufficiently combusted, exhaust emission is reduced, fuel oil consumption can be reduced, engine noise can be effectively lowered, and the engine power can be improved; the content of sulfur and phosphate is low, and the requirement for environment friendliness is met.

Owner:北京雅士科莱恩石油化工有限公司

Vegetable-oil lubricating oil

InactiveCN105273815AStable in natureImprove oxidation resistanceLubricant compositionLow temperature depositionVegetable oil

The invention discloses vegetable-oil lubricating oil which comprises the following ingredients (by weight): 5-10 parts of borate, 3-5 parts of graphite nano-powder, 5-10 parts of paraffin, 10-15 parts of a viscosity index improver, 10-25 parts of a detergent-dispersant, 10-20 parts of an oxidation and corrosion inhibitor, 10-20 parts of a metal deactivator, 5-15 parts of an anti-wear reagent at extreme pressure and 80-100 parts of vegetable oil. The vegetable-oil lubricating oil of the invention has properties of good abrasion resistance, oxidation resistance, bearing corrosion resistance, high and low temperature deposition resistance and the like.

Owner:丘濠玮 +2

Graphene-based nano zero-valent cobalt-iron-copper lubricating oil and preparation method thereof

InactiveCN104449949AHigh mechanical strengthLarge specific surface areaAdditivesFriction reductionAntioxidant

The invention relates to graphene-based nano zero-valent cobalt-iron-copper lubricating oil. The lubricating oil comprises the following components: base oil, graphene-based nanoparticles, an antioxidant, a viscosity index-reducing improver, a dispersant and an anti-foaming agent, as well as other additives, wherein other additives comprise one or more of an anti-rust agent, a pour point depressant, a viscosity increaser, a detergent and a demulsifier, wherein the graphene-based nanoparticles certainly contain three substances, namely graphene-based nano zero-valent cobalt, graphene-based nano zero-valent iron and graphene-based nano zero-valent copper. The lubricating oil provided by the invention can improve conditions of the lubricating oil; and furthermore, all the components have excellent dispersivity and stability, so that excellent friction reduction and wear resistance effects can be realized, and the lubricating oil further has a good self-repair function.

Owner:HUNAN ORIENTOP GRAPHENE APPL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com