Patents

Literature

35results about How to "Reduce lubrication costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature environment-friendly water-based ionic liquid lubricant

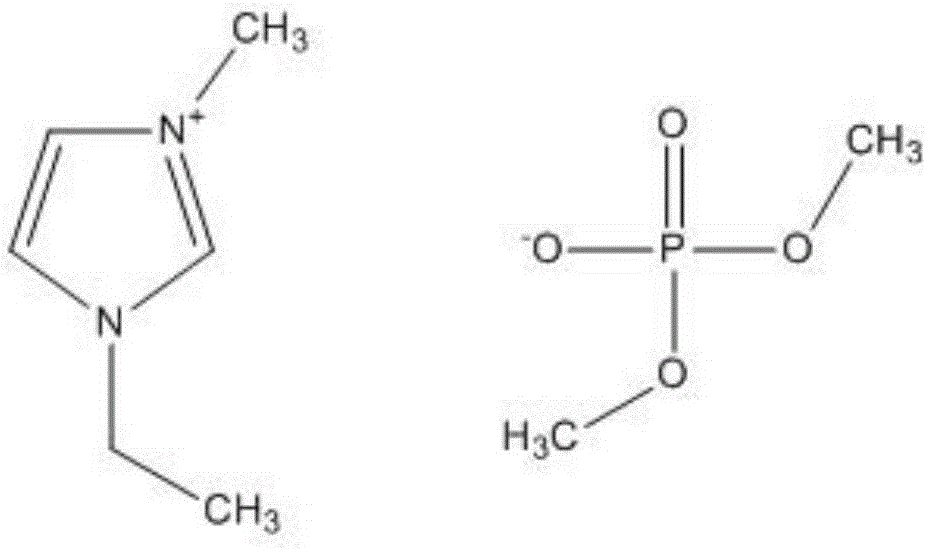

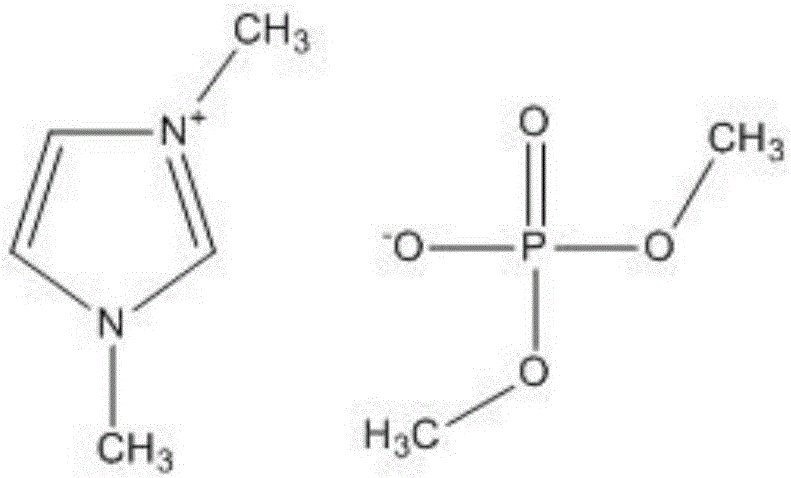

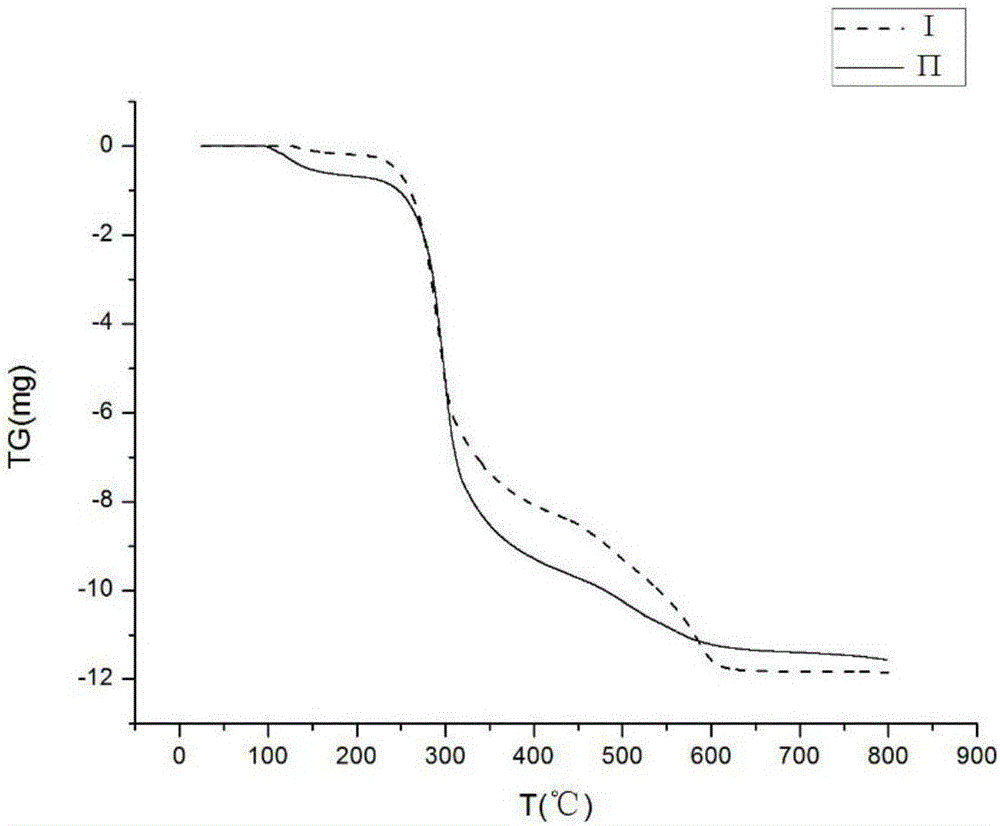

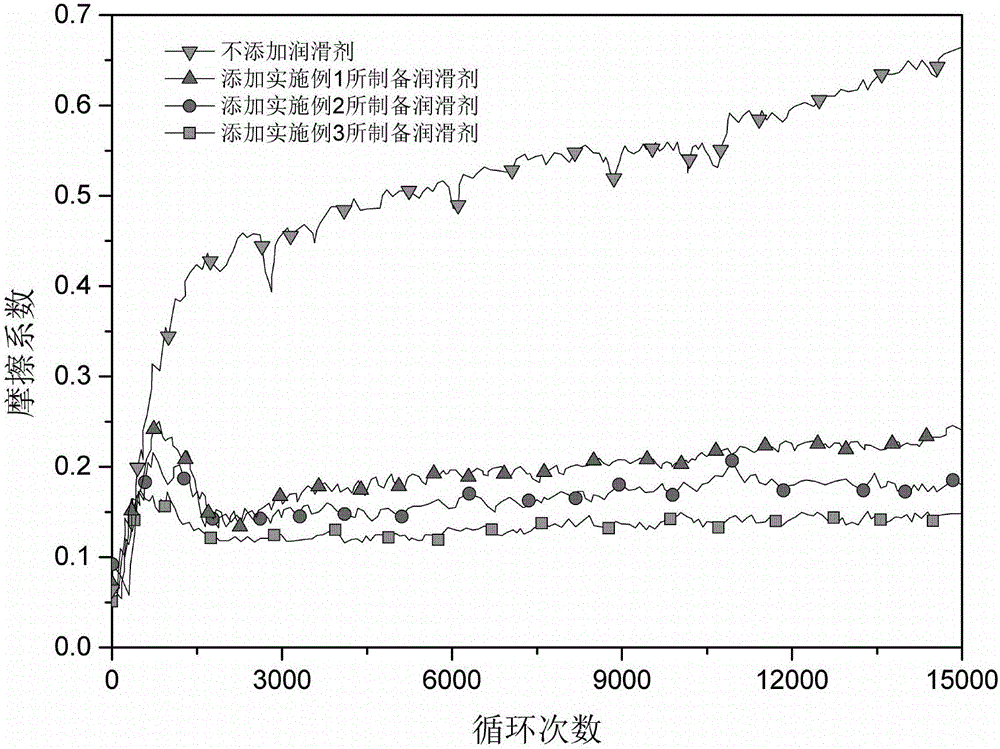

The invention discloses a high-temperature environment-friendly water-based ionic liquid lubricant and belongs to the technical field of liquid lubricants. The lubricant comprises the following raw materials in percentage by mass: 0.5-1% of 1-ethyl-3-methylimidazole dimethyl phosphate; 0.1-0.5 % of 1,3-dimethylimidazolium dimethyl phosphate; 1-2% of a corrosion inhibitor; 0.01-2% of a bactericide, and 90-95% of water to prepare the water-based solution. According to the invention, the high-temperature environment-friendly water-based ionic liquid lubricant has very high thermal stability, extremely low volatility and excellent high-temperature antifriction and anti-wear properties. Performance detection is carried out on the lubricant provided by the invention, and the result shows that the thermal decomposition temperature of the lubricant is about 300 DEG C and the metal has good oxidation resistance, friction resistance and wear resistance. According to the invention, no pollution is caused to the environment, so that the lubricant has good popularization and application prospect.

Owner:UNIV OF SCI & TECH BEIJING

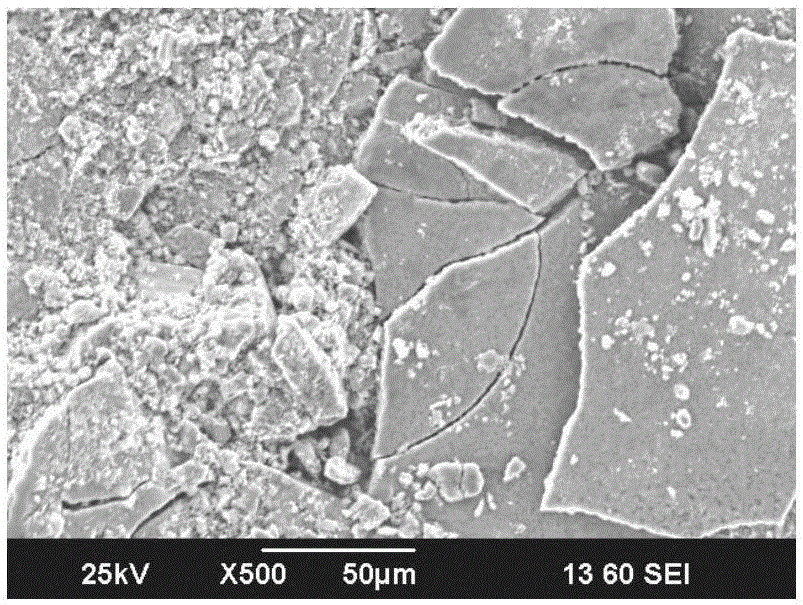

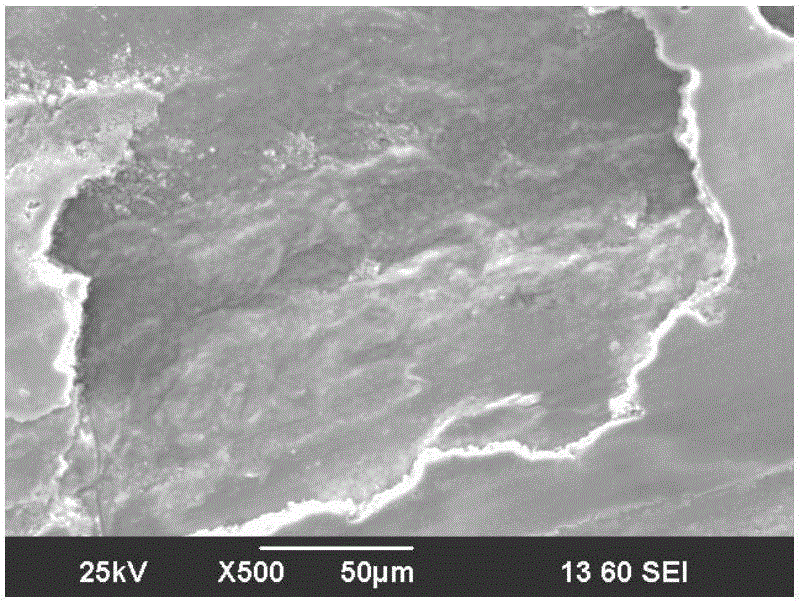

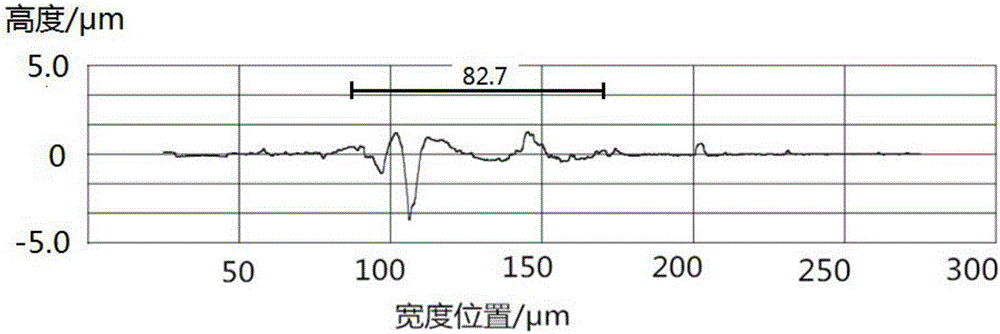

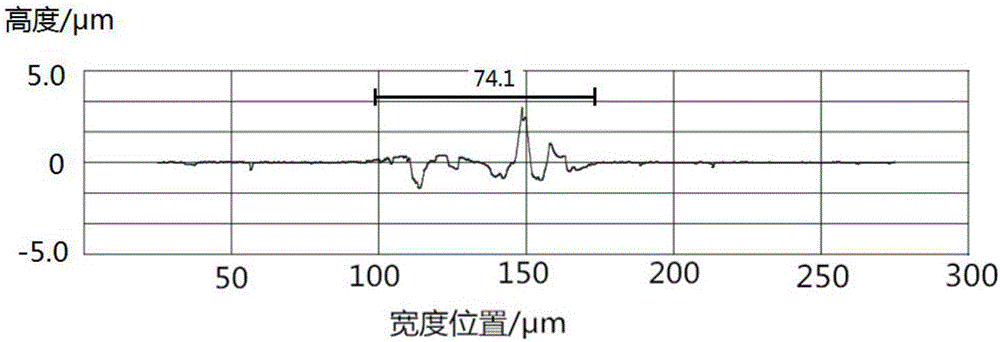

Rolling-use water base nano lubricant based on graphene oxide (GO) and preparation method thereof

ActiveCN106566647AReduce friction and wearImprove contact surface qualityLubricant compositionWater bathsWater based

The invention provides a rolling-use water base nano lubricant based on GO and a preparation method thereof. The lubricant is composed of GO, an oxide nano powder, polyphosphates, polyvinylpyrrolidone, and deionized water. The preparation method includes the steps of: adding the polyphosphates to deionized water to completely dissolving the polyphosphates to obtain a primary solution; adding the polyvinylpyrrolidone to the solution with stirring to obtain a clear liquid; adding the oxide nano powder to perform surface modification and dispersion; and finally adding GO powder and performing water-bath ultrasonic dispersion so as to prevent aggregation of the GO and other nano particles. The lubricant has good stability and wear-resisting durability, excellent lubricating performance and cooling performance, and is very low in corrosion on a substrate. A lubricating film formed by the lubricant has strong adsorption property and good adhesion property, thereby inhibiting oxidization of surface of a roller well. The lubricant has excellent lubricating effects in both cold-rolling and hot-rolling status.

Owner:UNIV OF SCI & TECH BEIJING

Power transmission method and device for engineering machinery

InactiveCN101660598AGuaranteed integrityEasy to installGearboxesGear lubrication/coolingLow noiseGear wheel

The invention discloses power transmission method and device for engineering machinery. In the method, an input interface arranged on a lower casing is connected with a dual-function interface and anoutput interface which are arranged on an upper casing through a middle casing; the input interface changes the direction of input power through a pair of bevel gears arranged inside the lower casingand transfers the power to the upper casing through a long axis arranged inside the middle casing, and changes the direction of the power from the long axis through a pair of bevel gears in the uppercasing; the speed of the power is changed through a driving gear, a transition gear and a driven gear; and both ends of the driven gear are respectively used as the dual-function interface and the output interface. The device is an integrated gear reducer which can ensure the integrity of a transmission system and is L shaped, thereby being convenient for installation. The device has the advantages of simple structure, less quantity of used parts, low manufacturing cost, high transmission efficiency, stable operation and low noise. The device can adopt a simple lubrication mode during operation, thereby reducing the lubrication cost.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

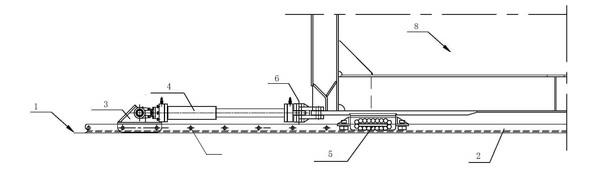

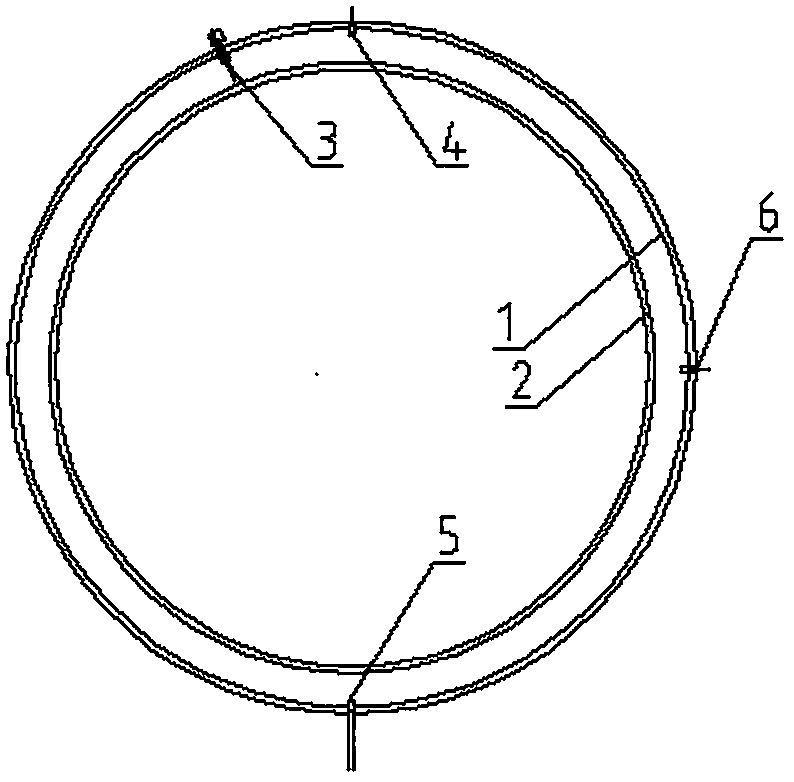

Device and method for moving buoyancy tank of semi-submersible ship

InactiveCN102120485ARelieve pressureReduce frictionVessel safetyRolling resistanceMarine engineering

The invention discloses a device and a method for moving a buoyancy tank of a semi-submersible ship. The device comprises a plurality of parallel guide rails which are arranged side by side on a the surface of a deck and provided with a plurality of corresponding fixing positions, and each guide rail can be detachably fixed at one fixing position by a fixing seat; each guide rail is provided with a stretching oil tank, one end of the stretching oil tank is fixed on the guide rail by the fixing seat, and the other end of the stretching oil tank is fixedly connected with a pulling plate arranged at the bottom of a buoyancy tank; and each guide rail is provided with a plurality of rolling devices which are arranged at intervals. when the buoyancy tank is moved, the buoyancy tank is put on the guide rails by the rolling devices, therefore, the buoyancy tank can be moved with a small pulling force just by overcoming the rolling friction, and the stretching oil tank can be pulled easily; therefore, the device has the advantages of low power consumption and high efficiency and is simple and convenient to operate.

Owner:中船海洋与防务装备股份有限公司

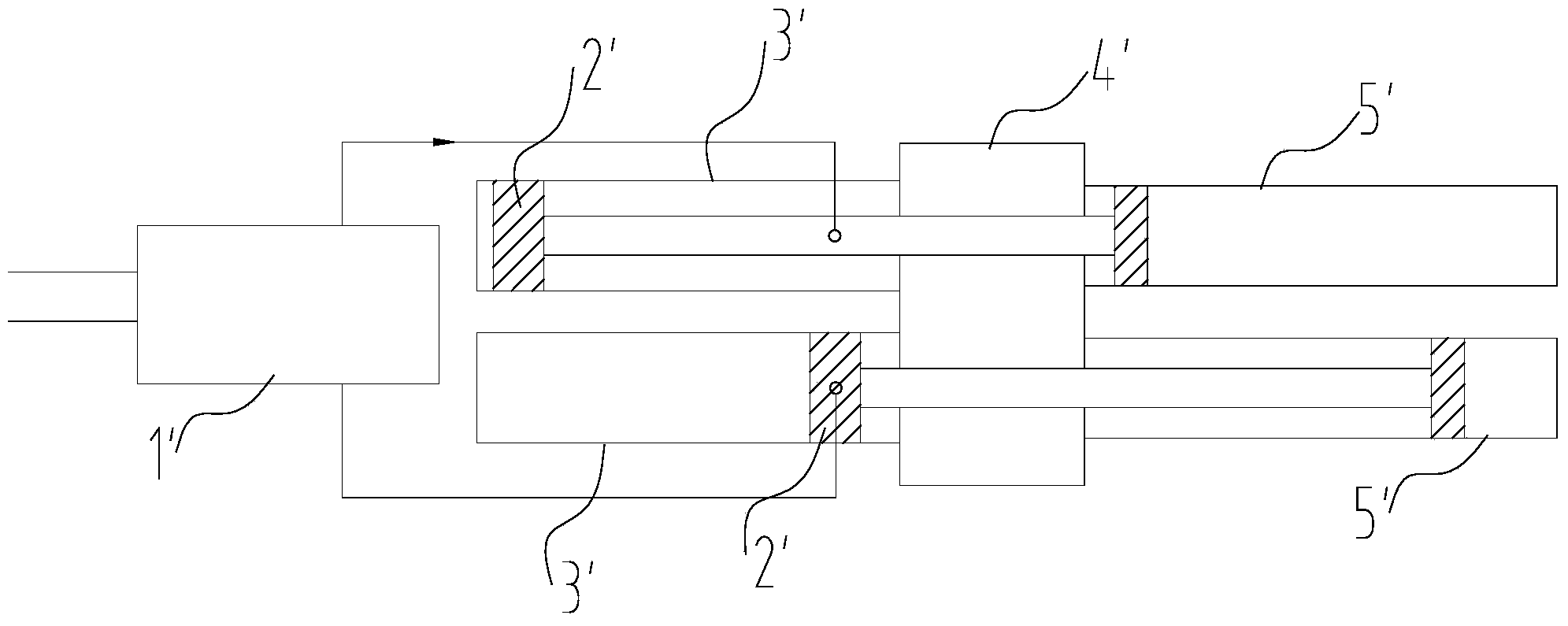

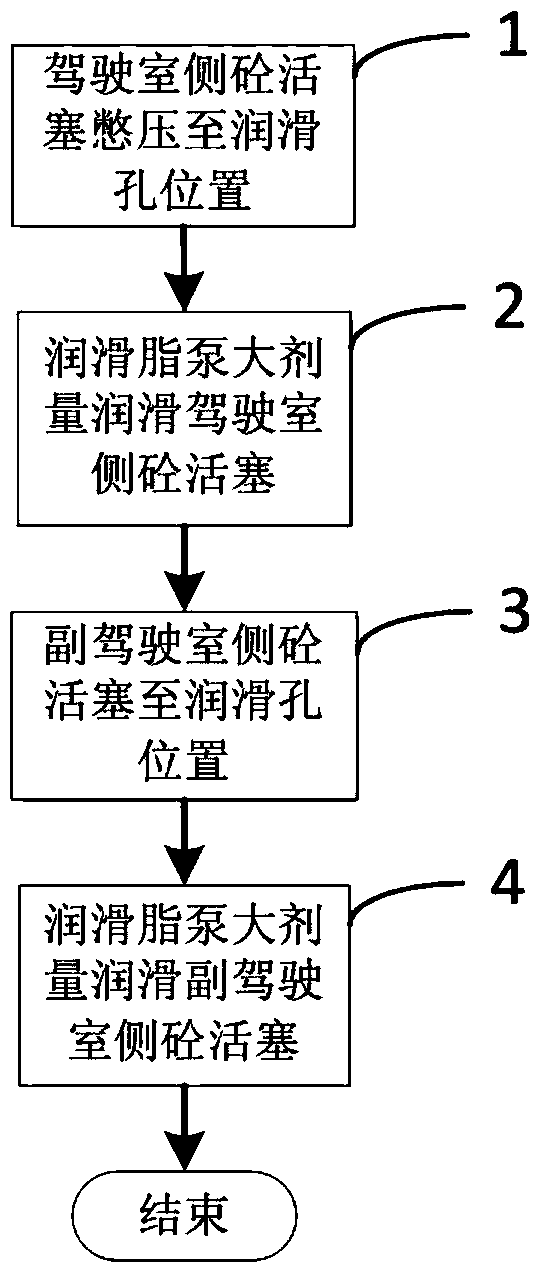

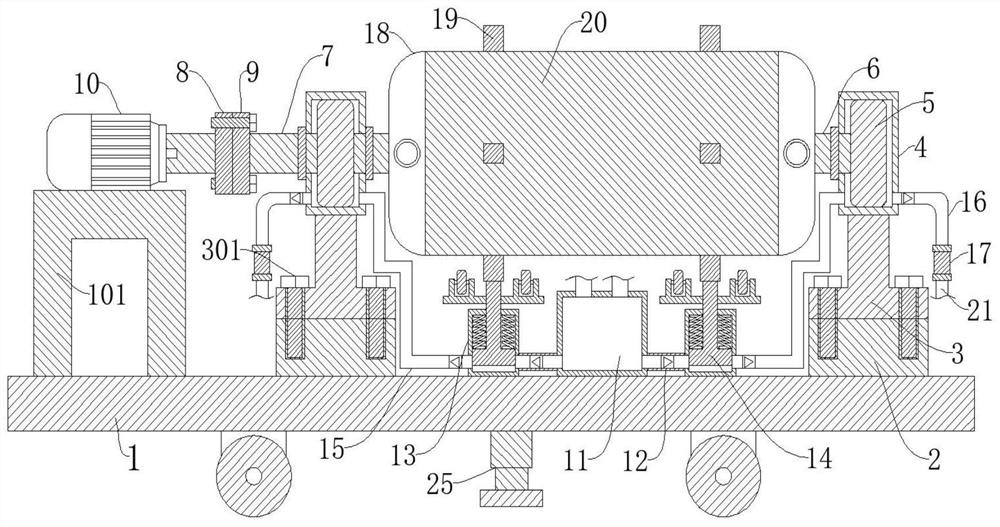

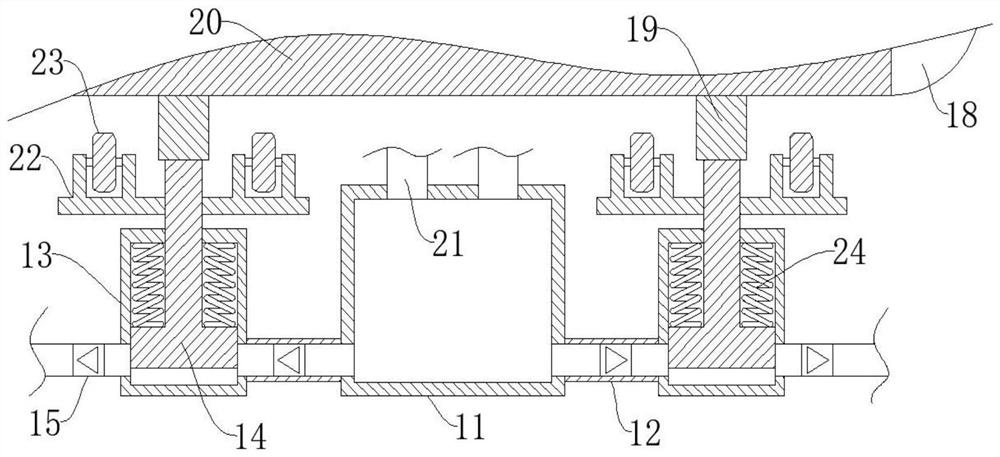

Concrete pump and concrete piston lubricating system thereof

ActiveCN103967772APrevent flow to one sidePrevent the situationPositive displacement pump componentsPumpsStructural engineeringConcrete pump

The invention discloses a concrete pump and a concrete piston lubricating system of the concrete pump. The concrete piston lubricating system comprises a position detection device, a control device and a lubricant distribution device. The position detection device is used for detecting the position of a concrete piston. The control device is connected with the position detection device and the lubricant distribution device. The lubricant distribution device is connected with a lubricating hole corresponding to the concrete piston. In the process of lubrication, the control device controls a main oil cylinder to move to retract the concrete piston. After the position detection device detects that the concrete piston returns in place, the control device controls the lubricant distribution device to make lubricant flow to the lubricating hole, so that an oil groove of the concrete piston is filled with the lubricant. By the adoption of a concentrated lubrication mode, a large amount of lubricant can be injected into the concrete piston and the concrete piston lubricating system has the advantages of being good in lubricating effect, low in lubricating cost, small in environmental pollution and the like.

Owner:SANY AUTOMOBILE MFG CO LTD

Lubricator

Owner:HANIL LUBTEC

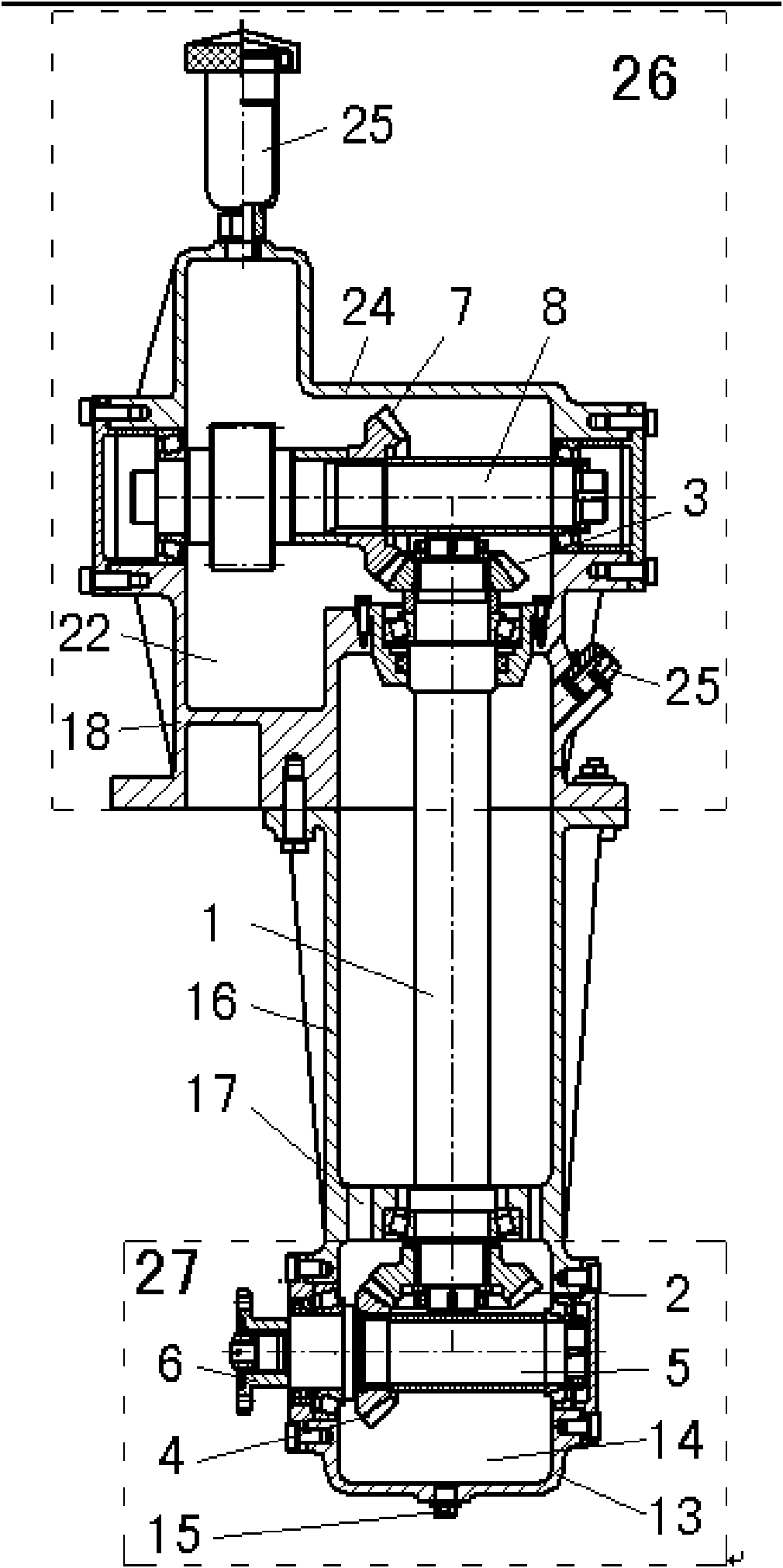

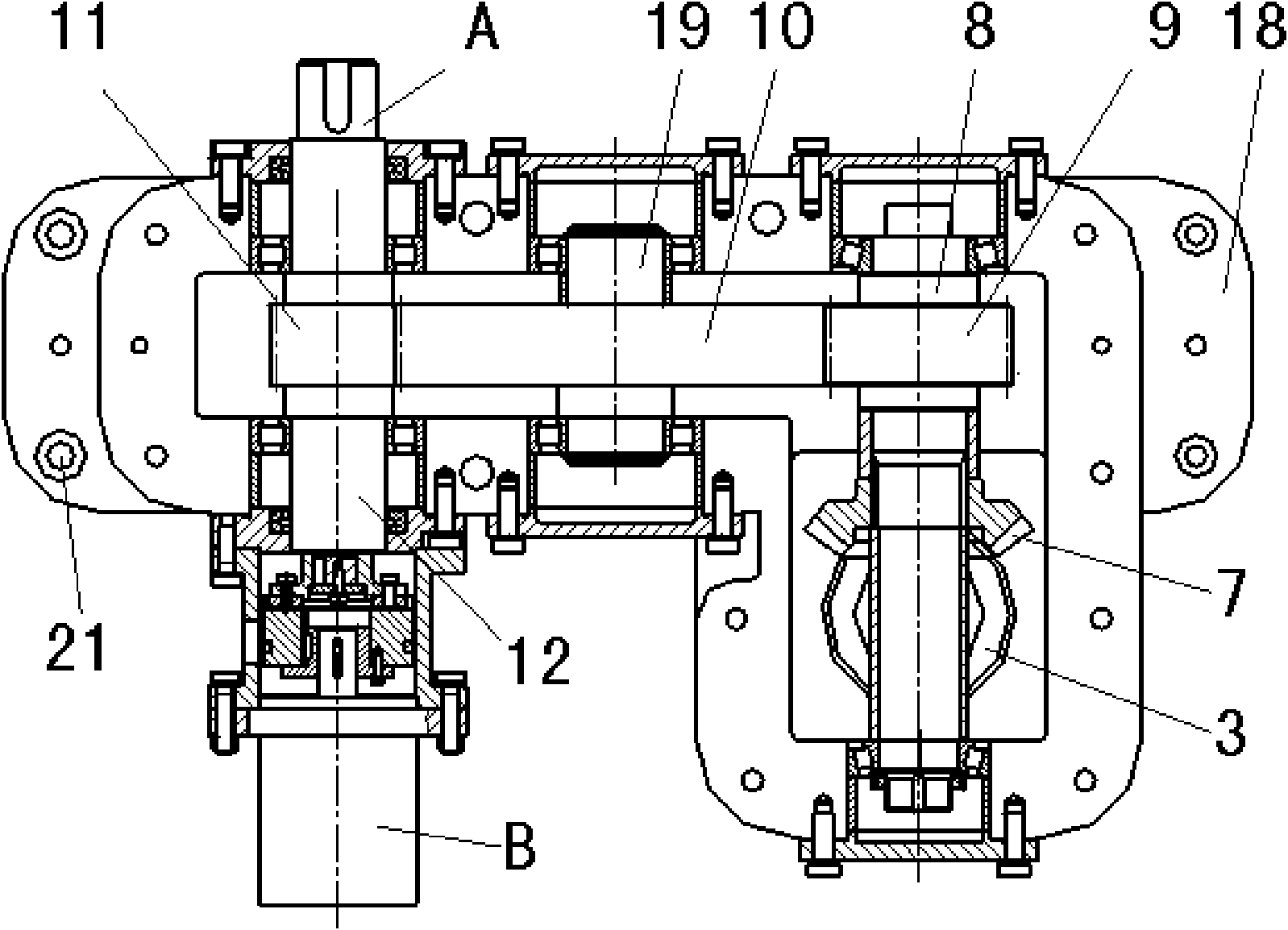

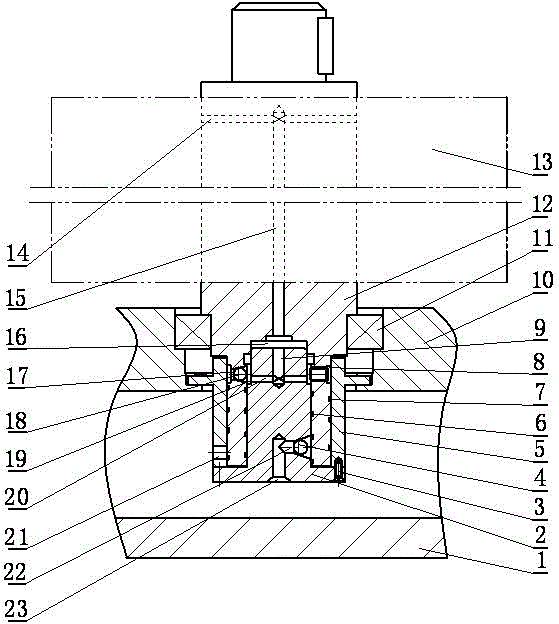

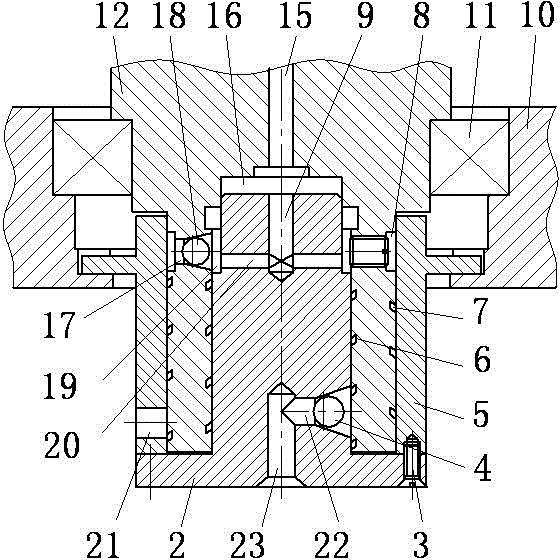

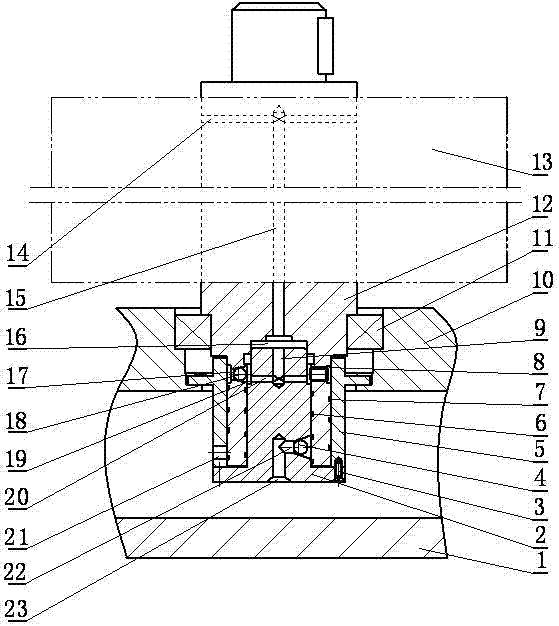

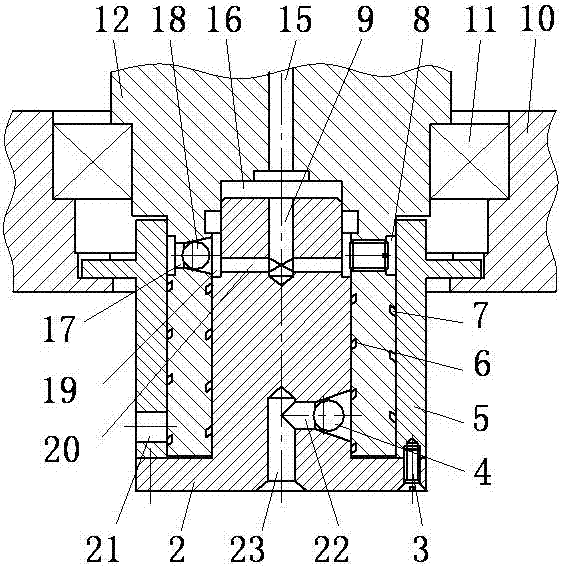

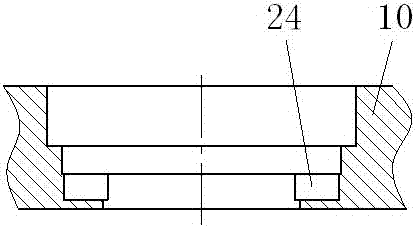

Self-circulation lubricating method and device of vertical gear reducer with forward-reverse alternative rotation function

ActiveCN104455352AReduce weightReduce lubrication costsGear lubrication/coolingReduction driveReducer

The invention discloses a self-circulation lubricating method and device of a vertical gear reducer with a forward-reverse alternative rotation function. In the method, the bottom of an input shaft of the gear reducer is in the shape of a round tube, a section of an inner helix groove is arranged in the inner wall of the round tube, and an inner pump composed of a pump core is arranged in the round tube; in addition, the outer circle of the round tube of the bottom of the gear reducer is provided with a section of outer helix groove, and the outer helix groove is sleeved with a pump sleeve to form an outer pump; meanwhile, a main oil passage allowing lubricating oil to ascend is arranged in the input shaft, when the input shaft rotates forwards or reversely, the lubricating oil at the bottom of a case of the gear reducer is pumped to the upper portion of a gear reducer part through the inner pump or outer pump so as to lubricate the part of the upper portion of the gear reducer, and then the lubricating oil returns to the bottom of the case, so that self-circulation lubrication of the gear reducer is realized. The self-circulation lubrication mode different from an existing full-oil type oil bath lubricating mode and an outer-circulation lubricating mode is adopted, the structure and the appearance of the gear reducer are simpler, and size and weight of the gear reducer can be reduced. Overall performance of the gear reducer is improved.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

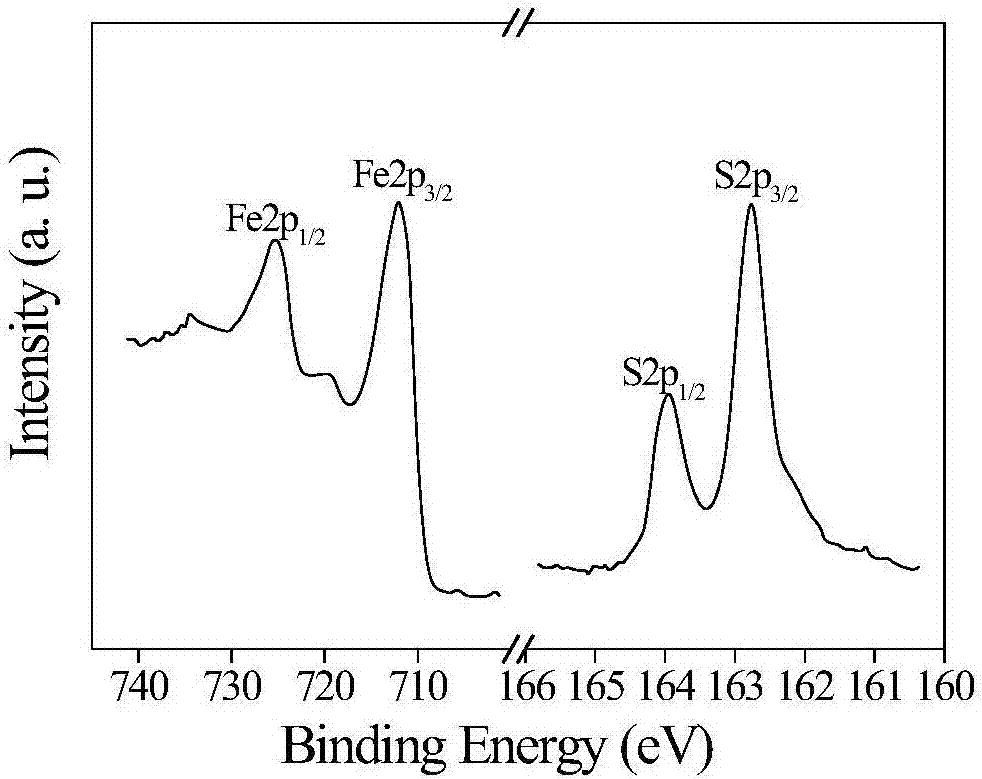

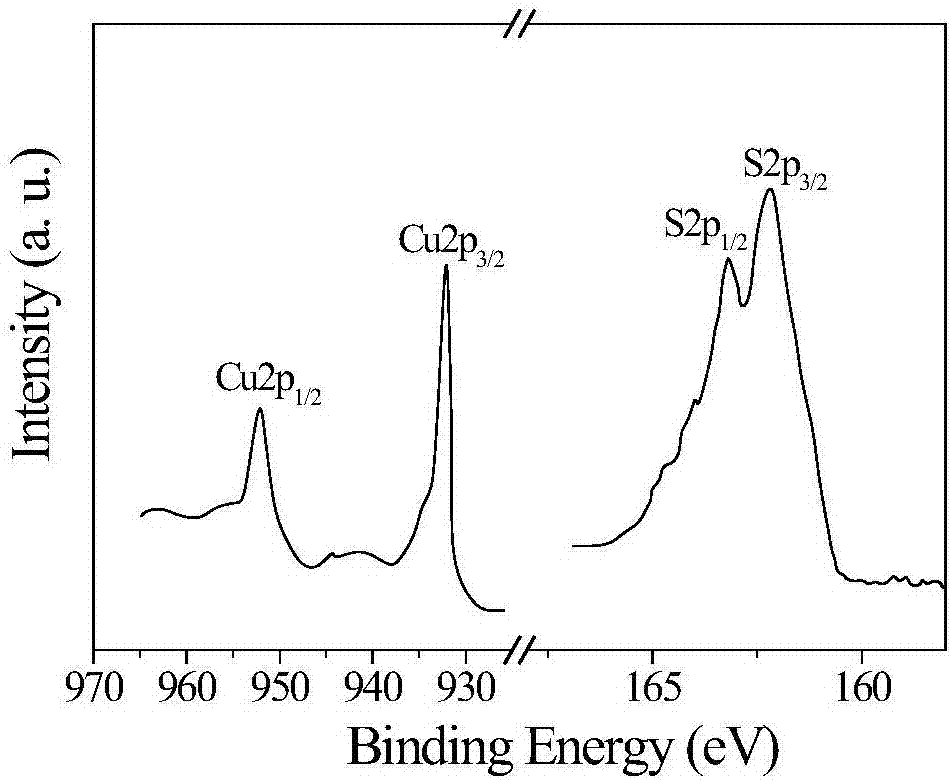

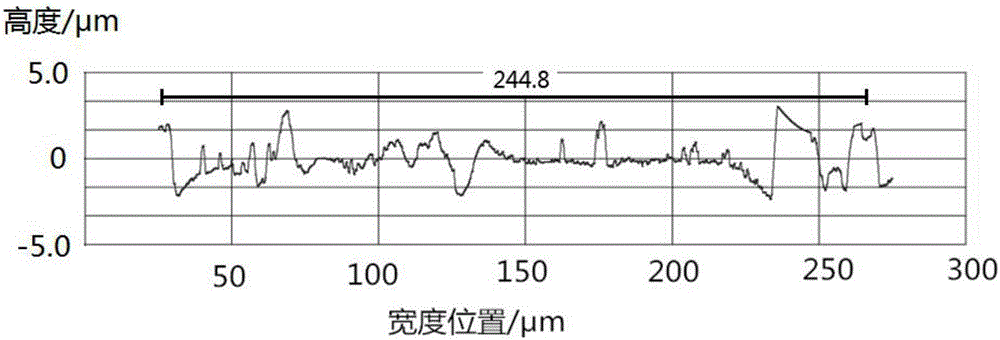

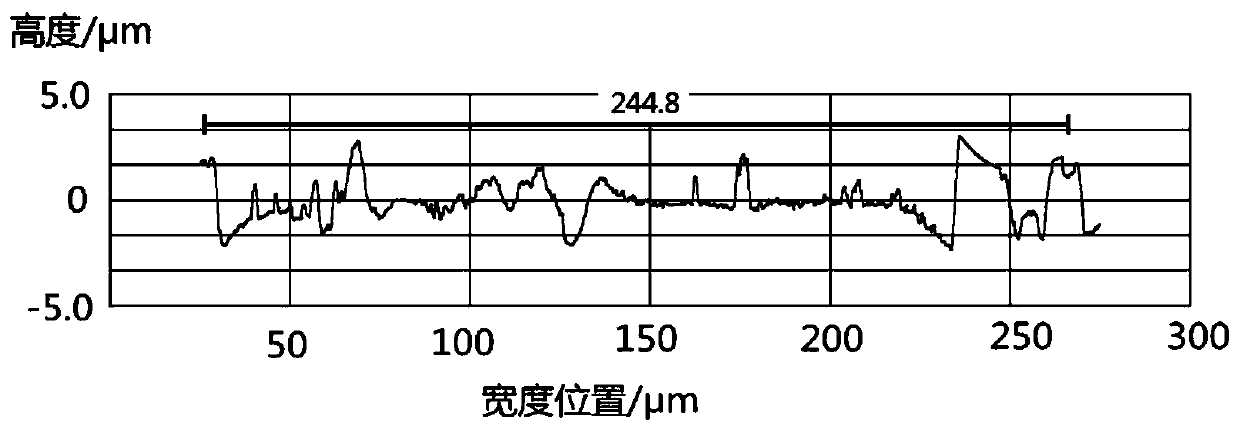

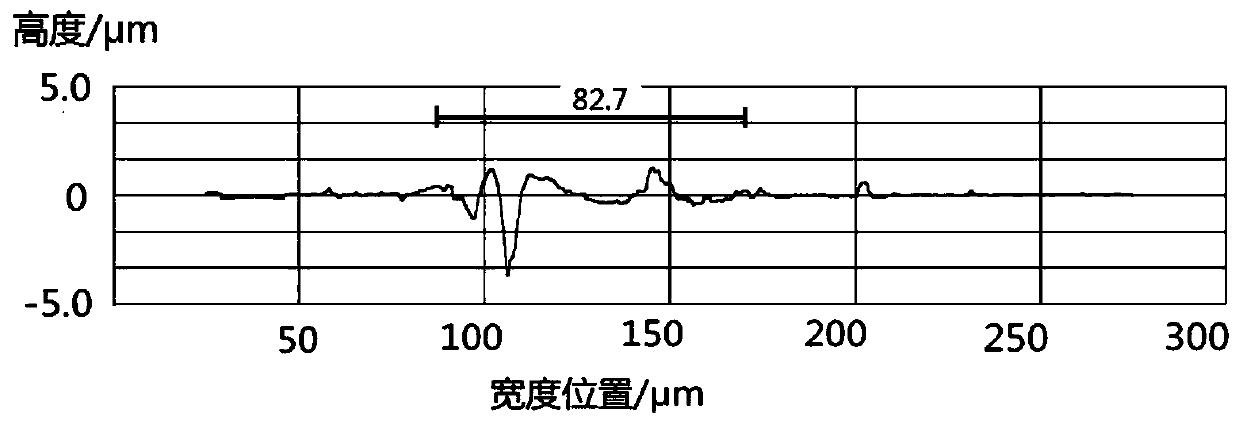

Method for lowering friction coefficient through surface filming performed in friction shear induced chemical reaction mode

ActiveCN107101084AReduce the temperature of the chemical reactionRapid anti-friction lubrication effectEngine lubricationChemical reactionFriction & shear

The invention discloses a method for lowering the friction coefficient through surface filming performed in a friction shear induced chemical reaction mode. Specifically, the method comprises the steps that in an ultrahigh vacuum environment, dialkyl disulfide is guided into a system, adheres to the surface of metal, and chemically reacts with the surface of the metal to form film through corresponding friction, and the friction coefficient is lowered. The method provided by the invention has good application and popularization prospects in lowing temperatures of certain chemical reactions, lowering the friction coefficient of the system and prolonging the service life of a friction pair.

Owner:HEFEI UNIV OF TECH

Alcohol fuel with lubricating property

The invention relates the alcohol fuel which has lubricating property, comprising methyl alcohol and petrol. The alcohol fuel comprises castor oil, and the volumetric proportion of castor oil is 0.5-1%. The invention has the advantages of convenient usage and low cost.

Owner:SHANGHAI ZHONGYOU ENTERPRISE GRP CO LTD

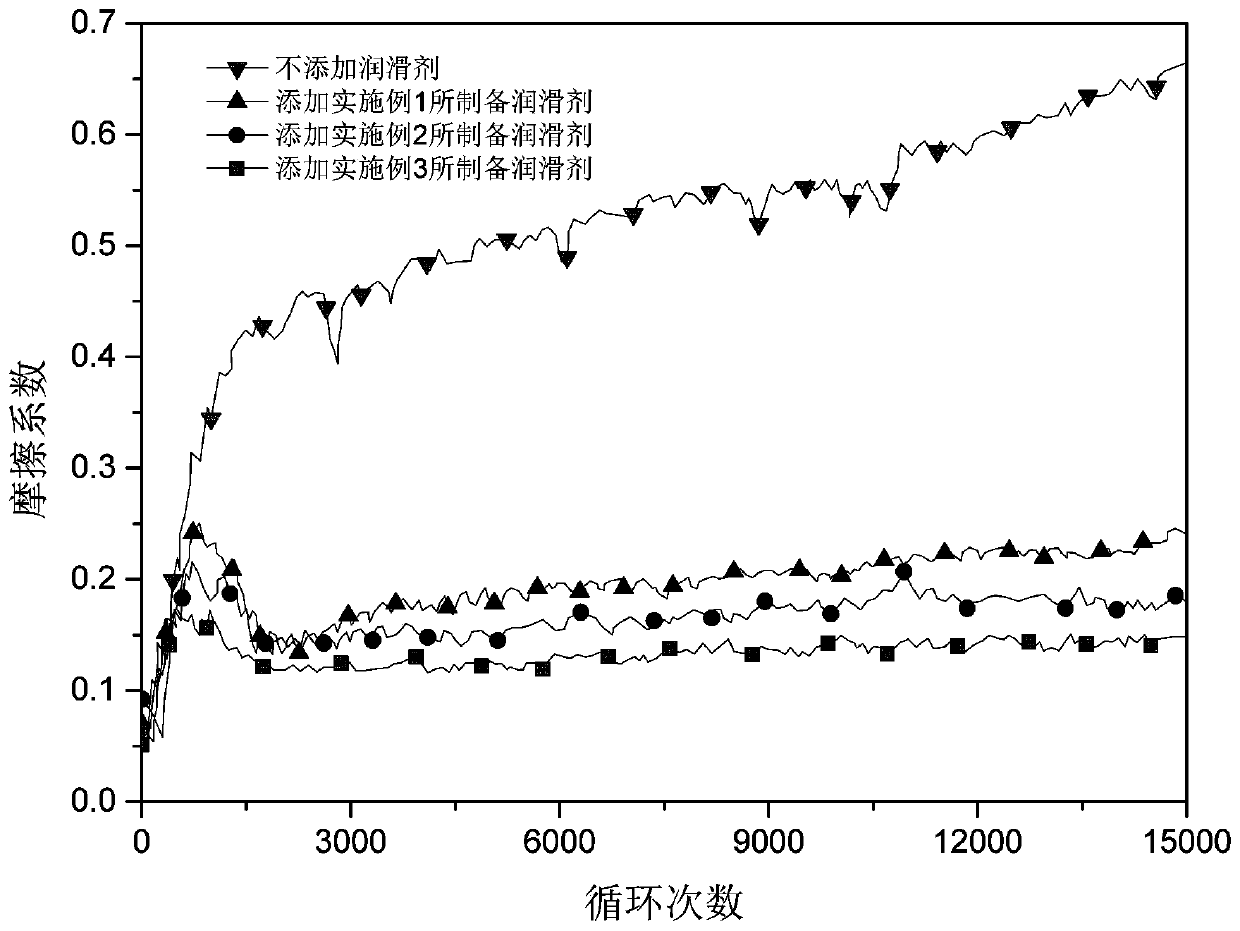

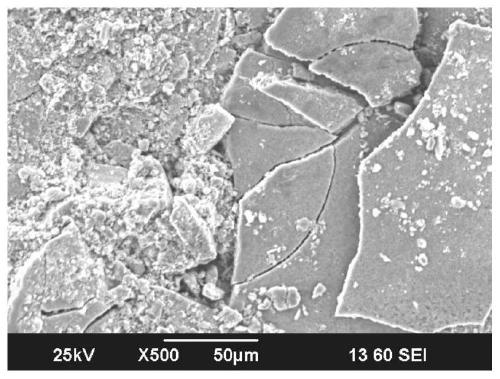

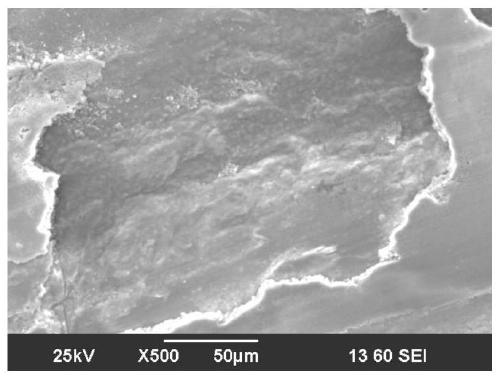

Liquid-solid mixed lubricating agent based on graphene strengthening and preparation method thereof

ActiveCN106544149AGood adaptive lubrication effectReduce friction and wearAdditivesUltrasonic oscillationAqueous dispersion

The invention discloses a liquid-solid mixed lubricating agent based on graphene strengthening and a preparation method thereof. The liquid-solid mixed lubricating agent is prepared from the following raw materials in percent by mass: 10-15% of polyphosphate, 0.005-0.015% of graphene, 5-10% of sodium dihydrogen phosphate and 75-85% of deionized water. The preparation method of the lubricating agent comprises the following steps: firstly dissolving sodium dihydrogen phosphate into deionized water to obtain a primary liquid; then dissolving polyphosphate into the primary liquid; and finally adding graphene aqueous dispersion, and carrying out ultrasonic oscillation to obtain a finished product. The liquid-solid mixed lubricating agent disclosed by the invention has self-adaptability to carrying capacity, excellent antifriction property and good thermal stability and high temperature wear resistance durability and is extremely low in corrosivity on a base, green and pollution-free, so that the liquid-solid mixed lubricating agent has great market competitiveness.

Owner:UNIV OF SCI & TECH BEIJING

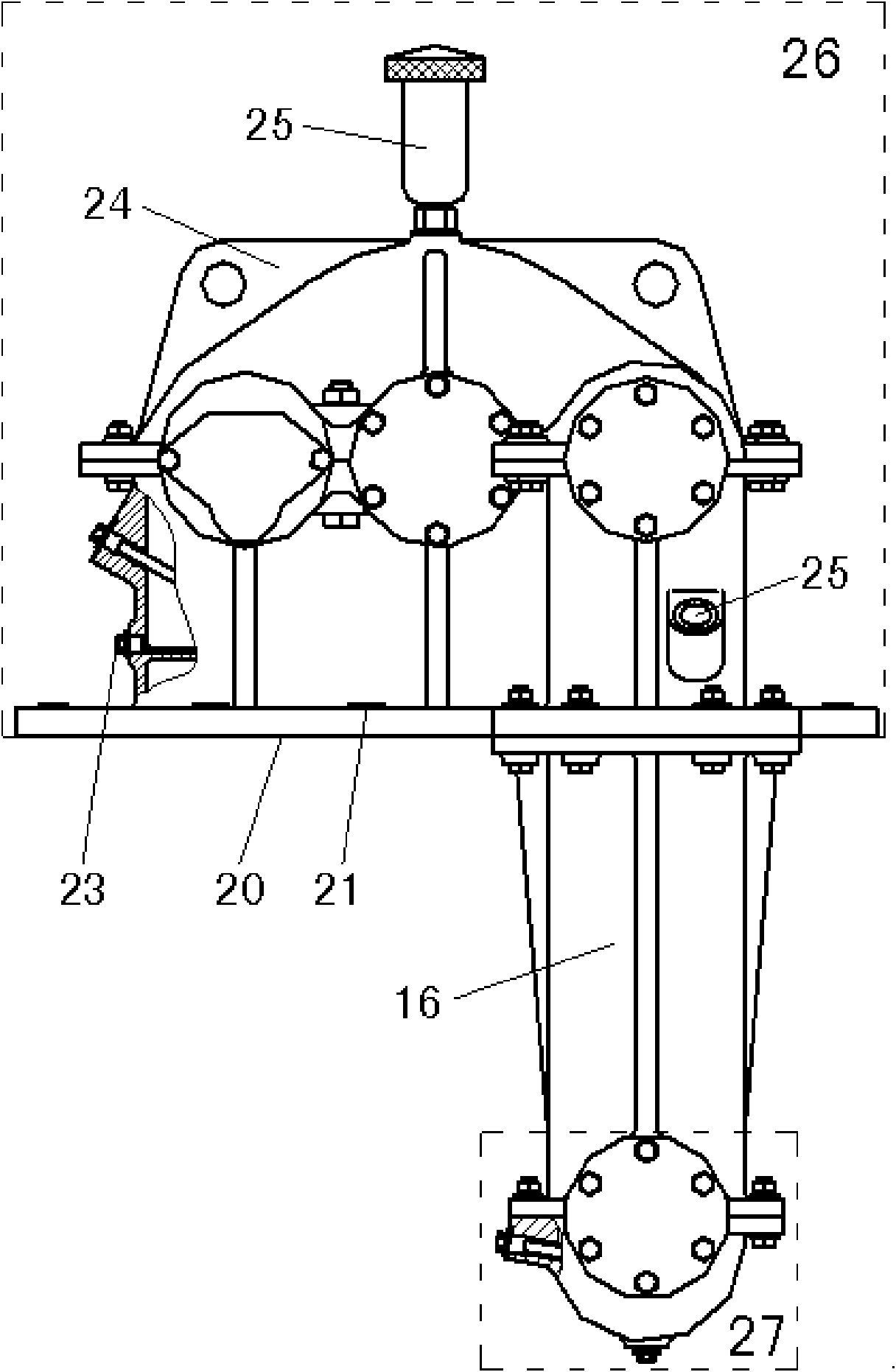

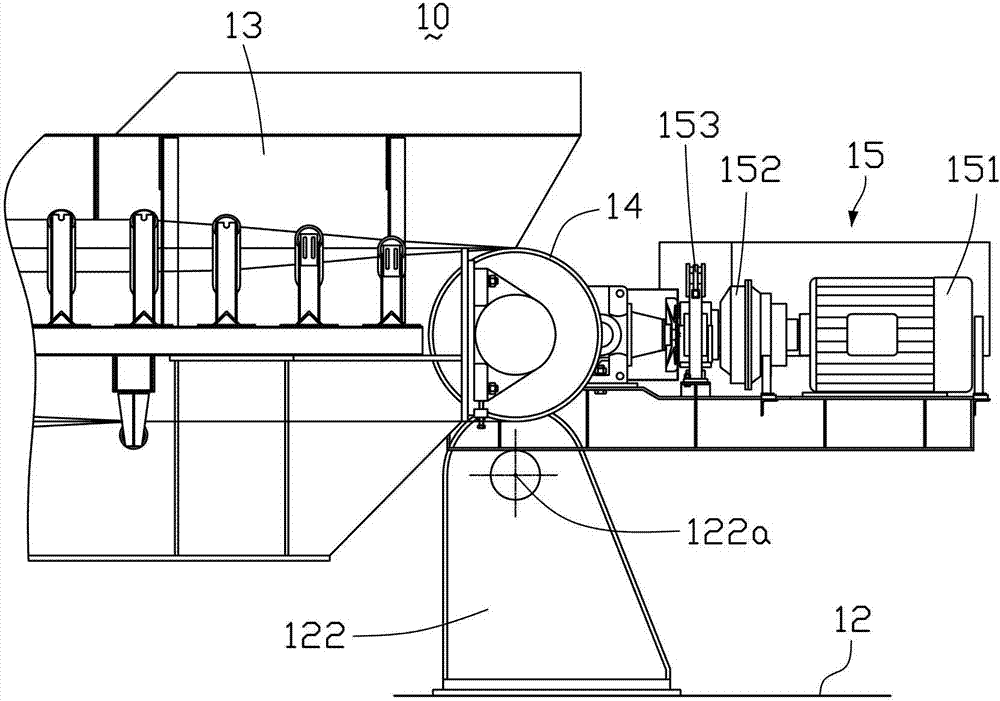

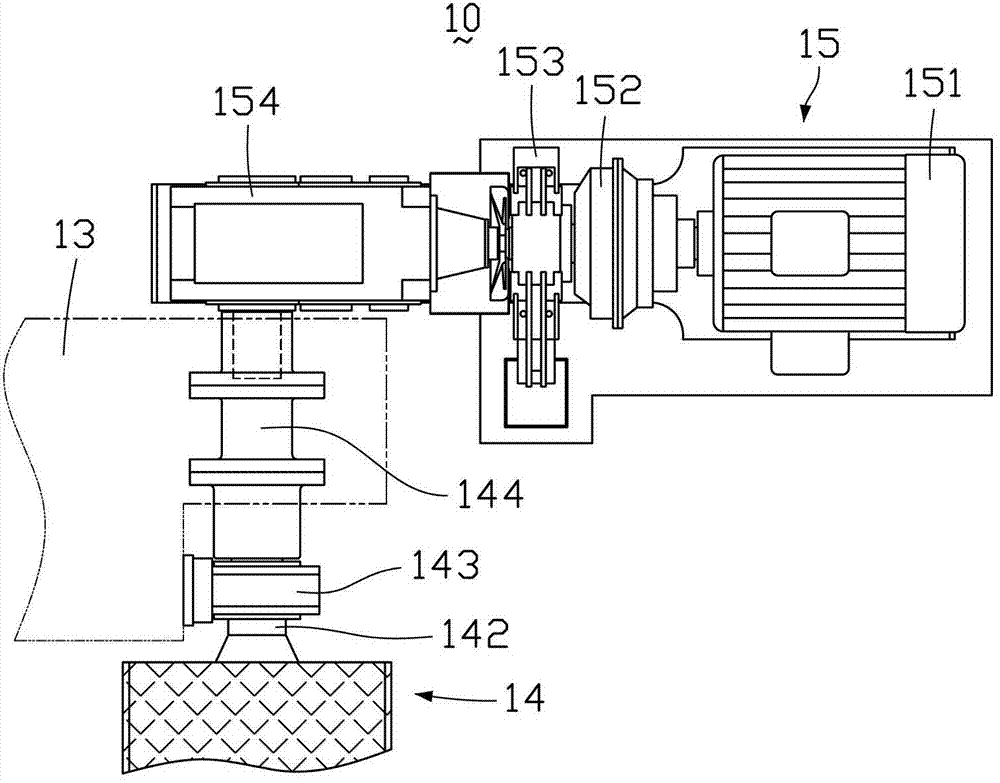

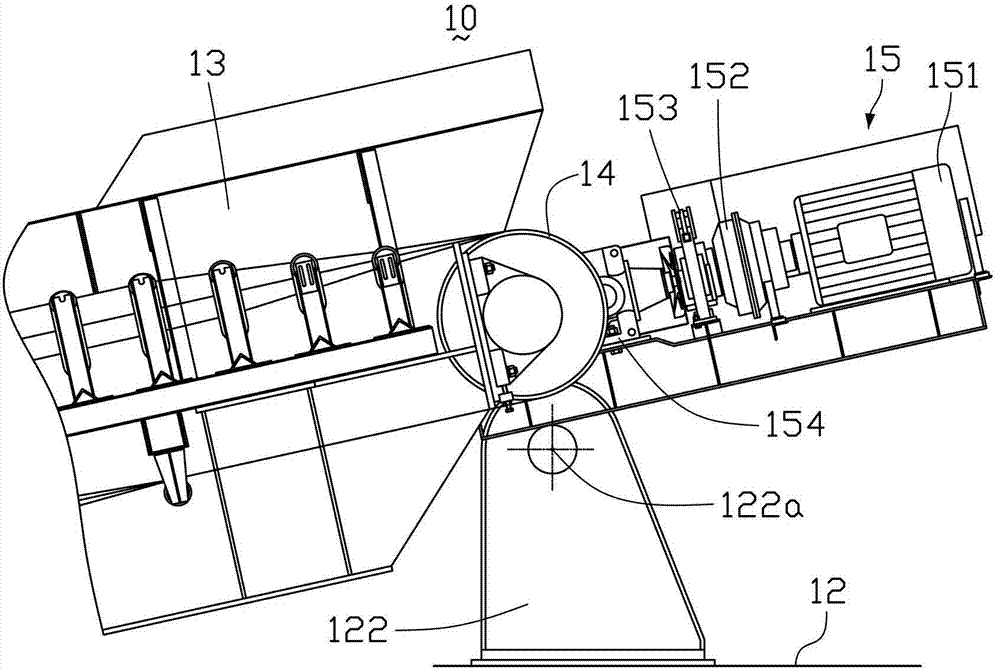

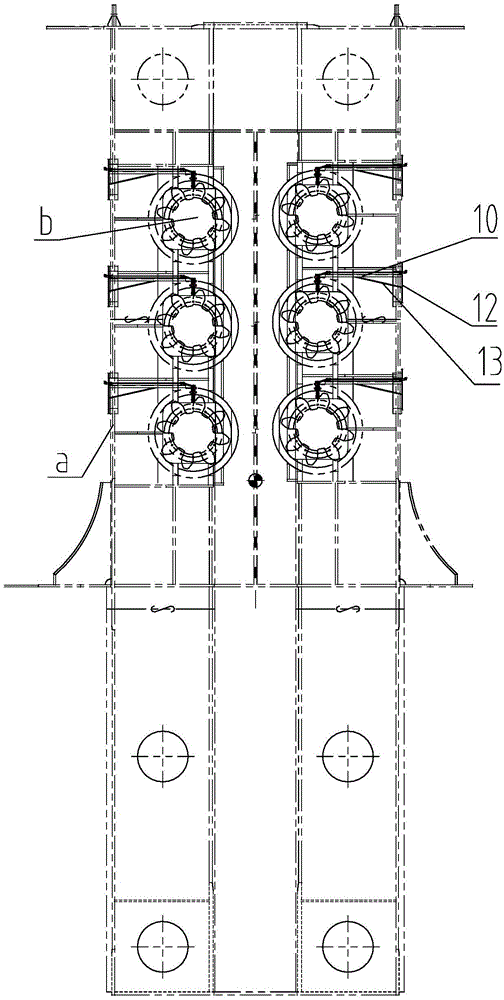

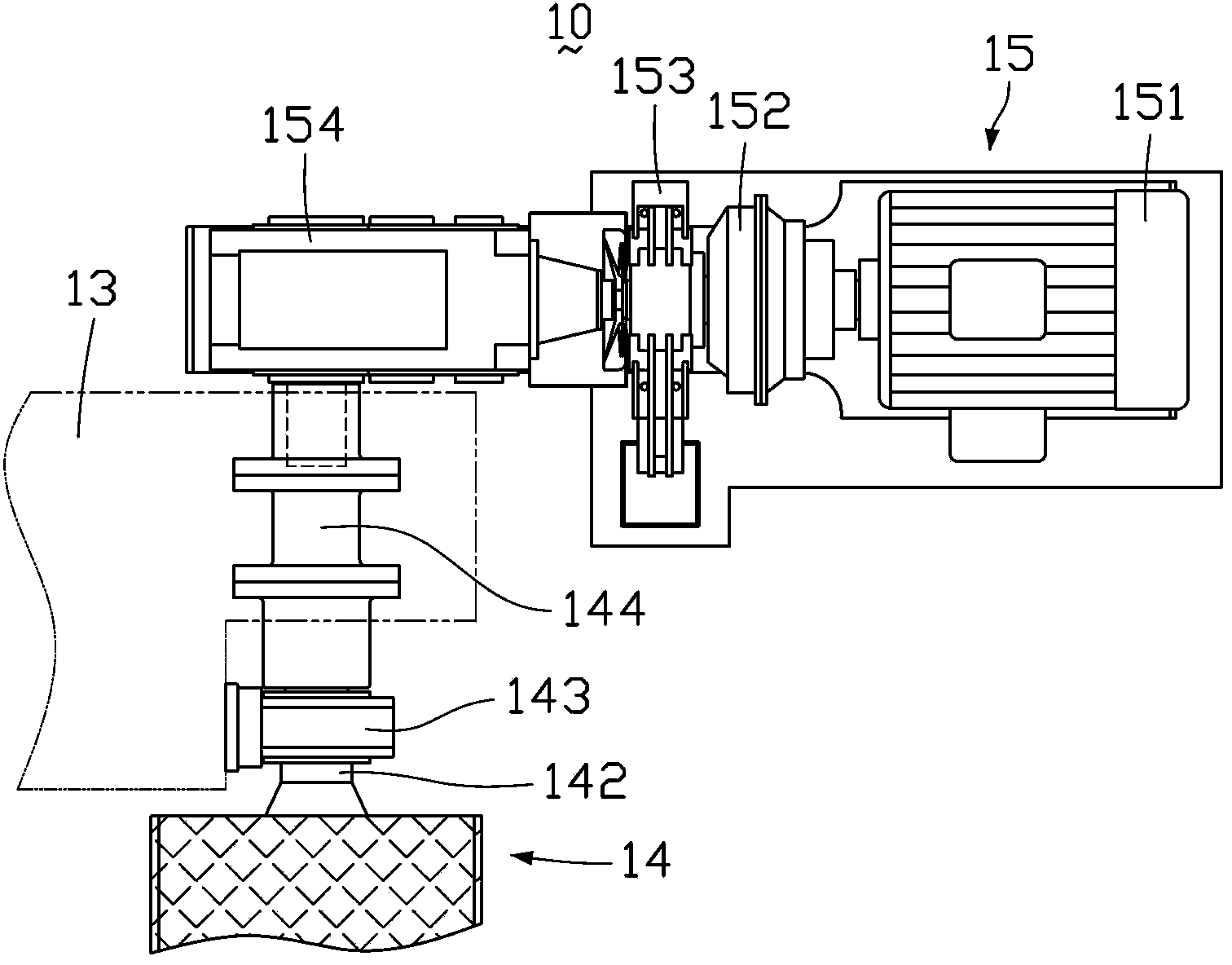

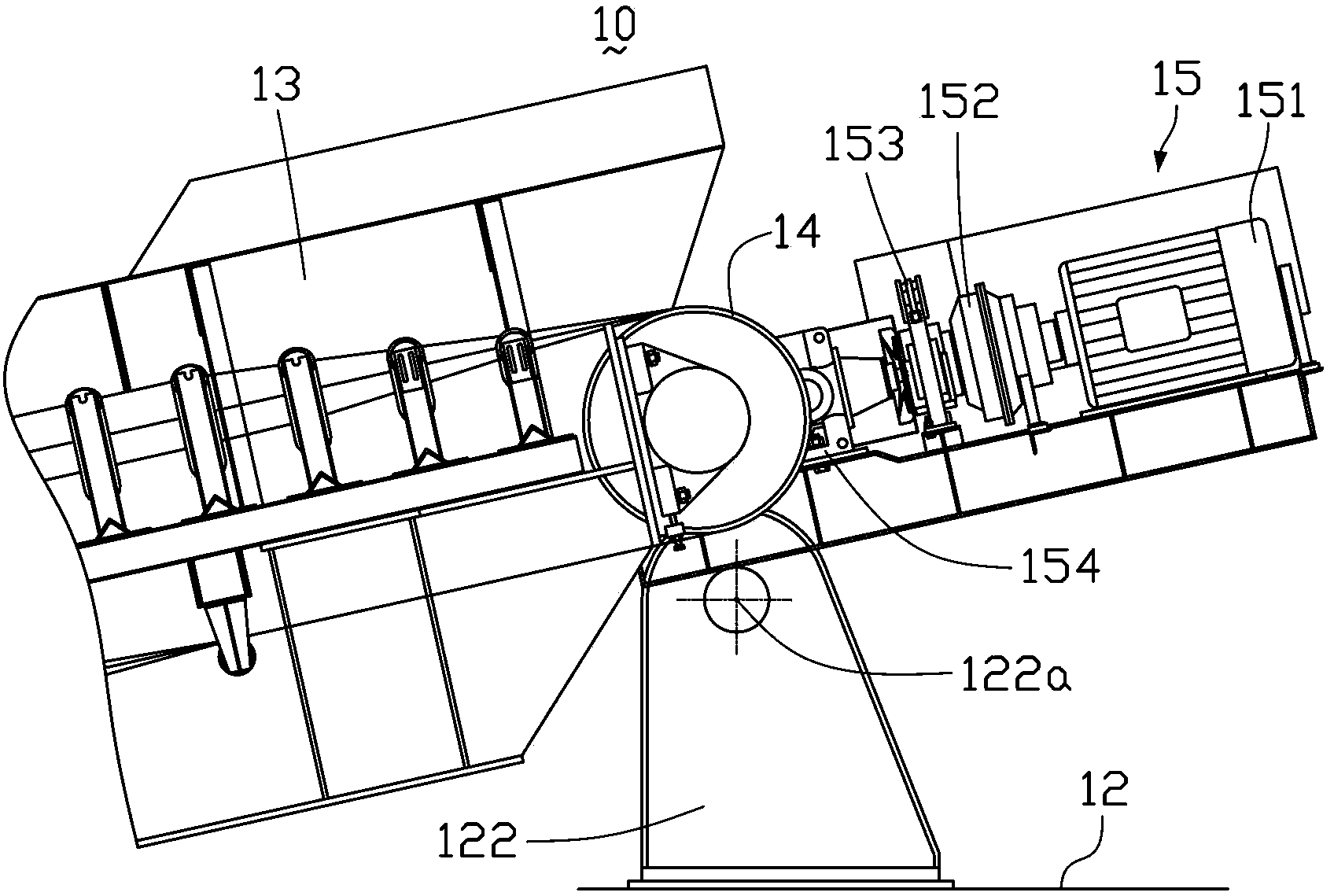

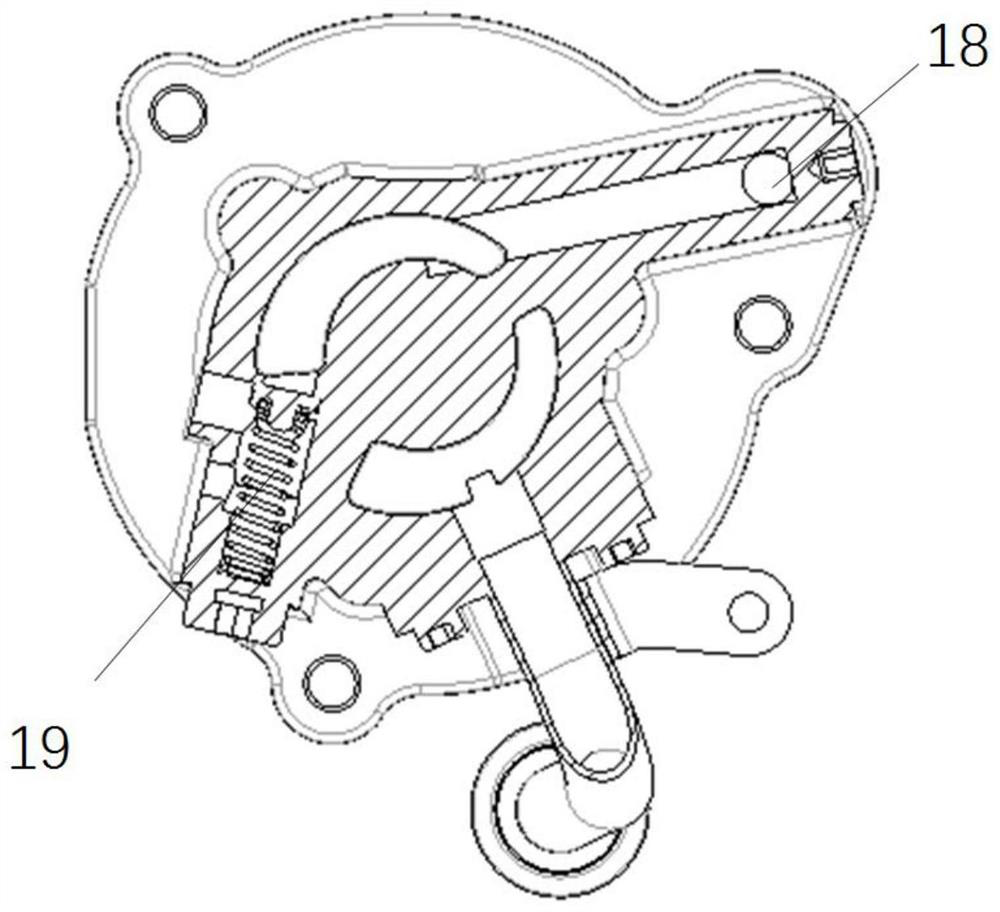

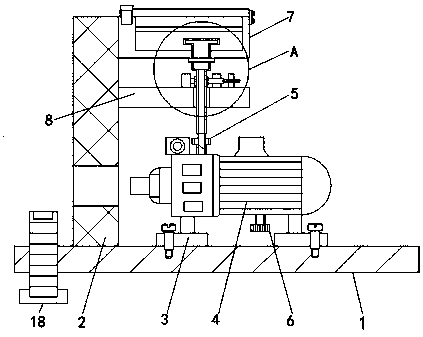

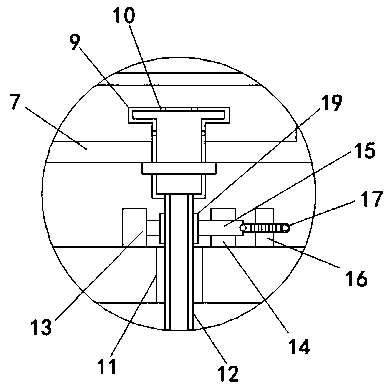

Mechanical equipment and anti-deflection mechanism thereof

ActiveCN102923493AEnsure adequate lubricationReduce lubrication costsLoading/unloadingEngineeringReducer

The invention discloses an anti-deflection mechanism which comprises a fixing platform, a pitching member and a drive device, wherein the pitching member is in hinge joint on the fixing platform and can make pitching motion around the hinge-joint axis; and an output end of the drive device is mounted on the pitching member. The anti-deflection mechanism also comprises a connecting rod component; the connecting rod component comprises a connecting rod; the connecting rod has a first end part and a second end part opposite to the first end part; the first end part is in hinge joint on the fixing platform; and the second end part is in hinge joint on the drive device. The invention also provides mechanical equipment. The mechanical equipment and the anti-deflection mechanism disclosed by the invention can prevent the drive device from deflecting substantially along with the pitching member, avoid non-enough gear lubrication of a speed reducer of the drive device, and are favorable for reducing the lubrication cost.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

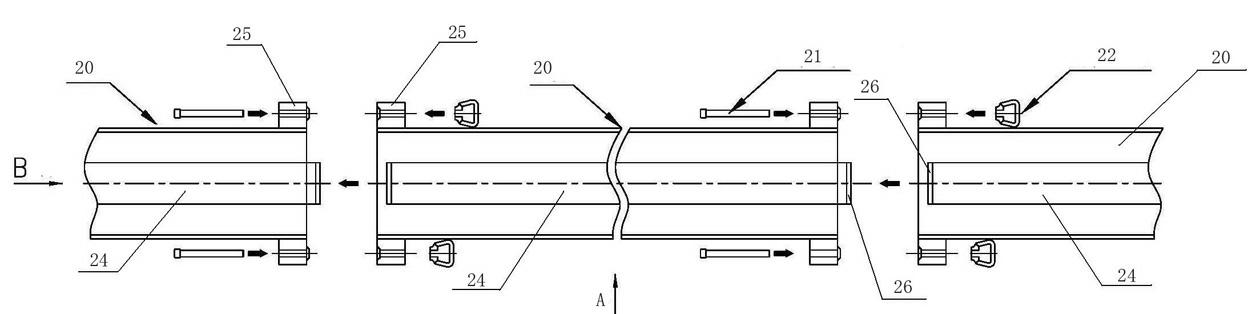

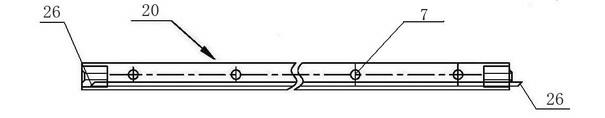

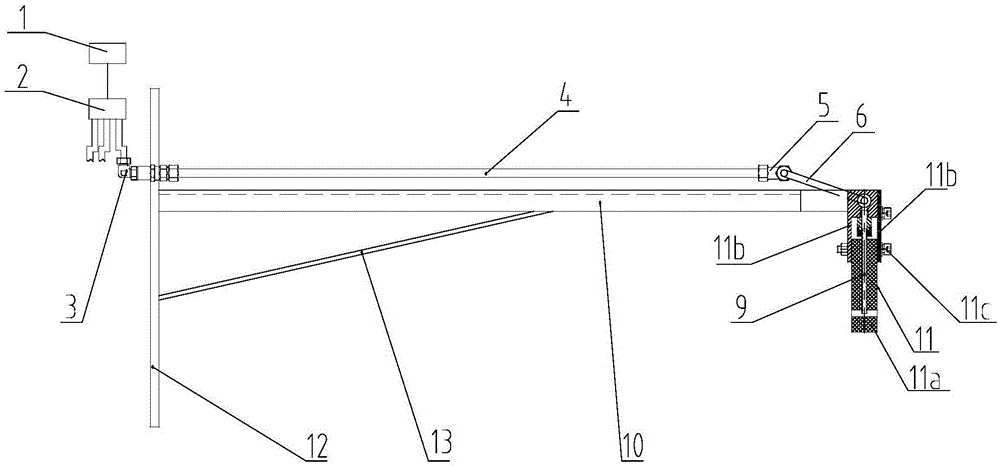

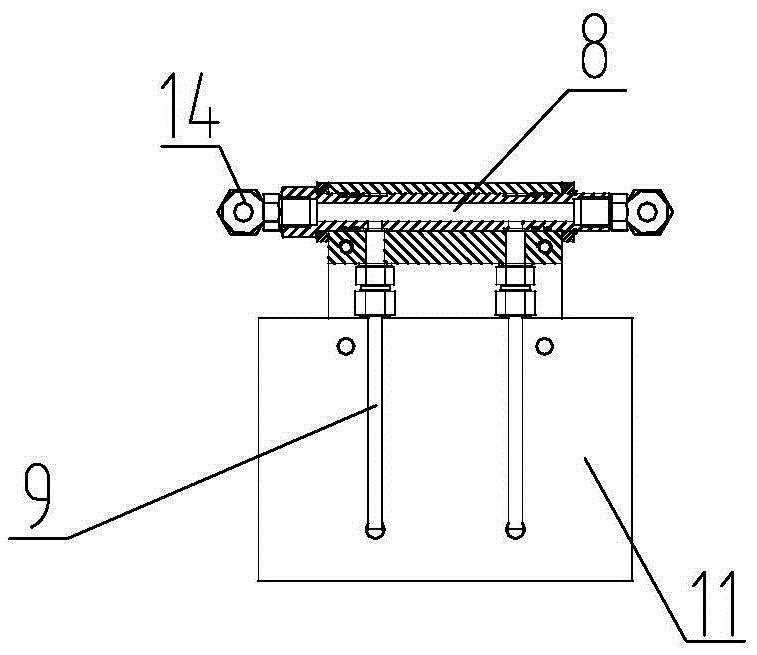

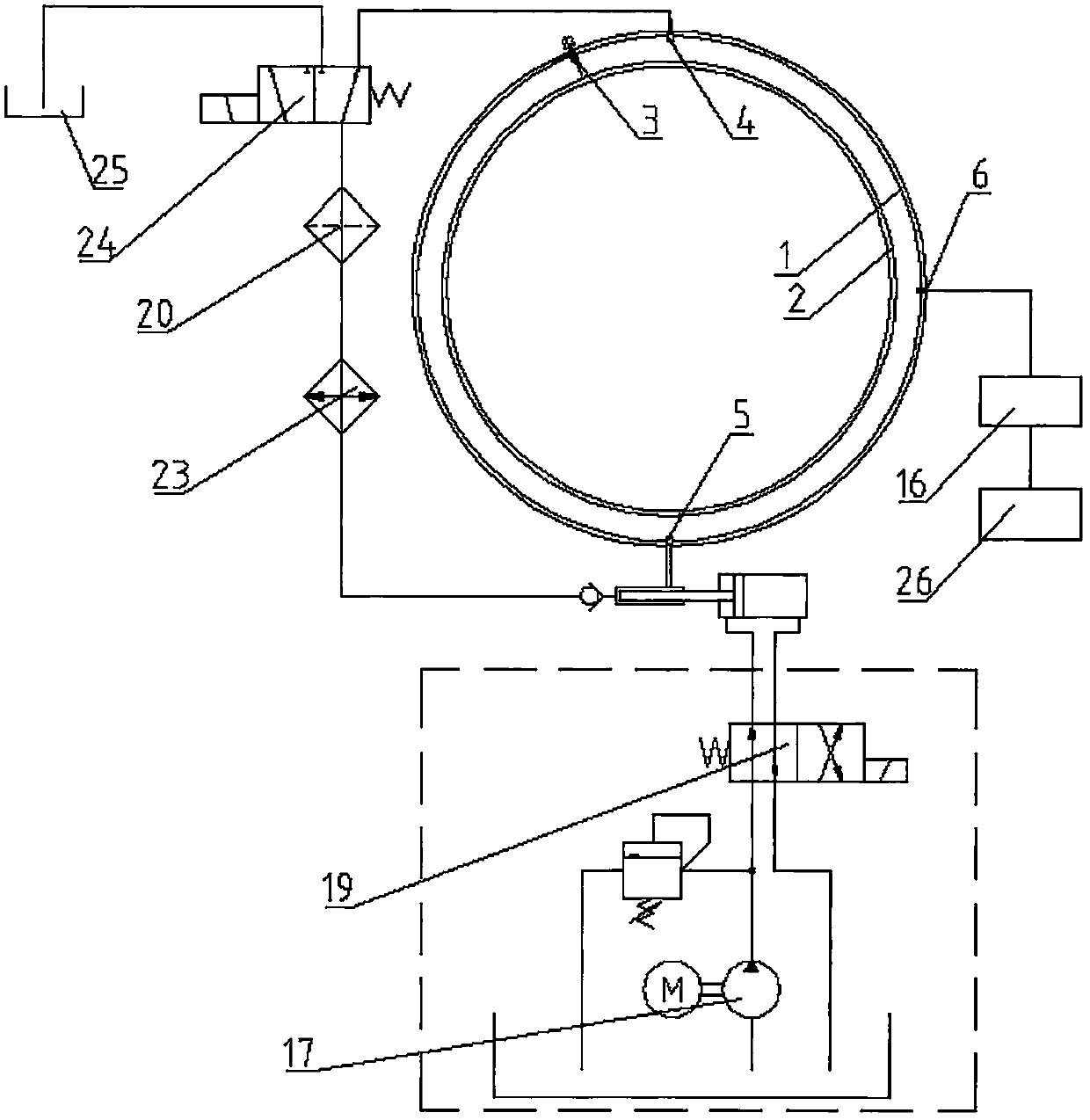

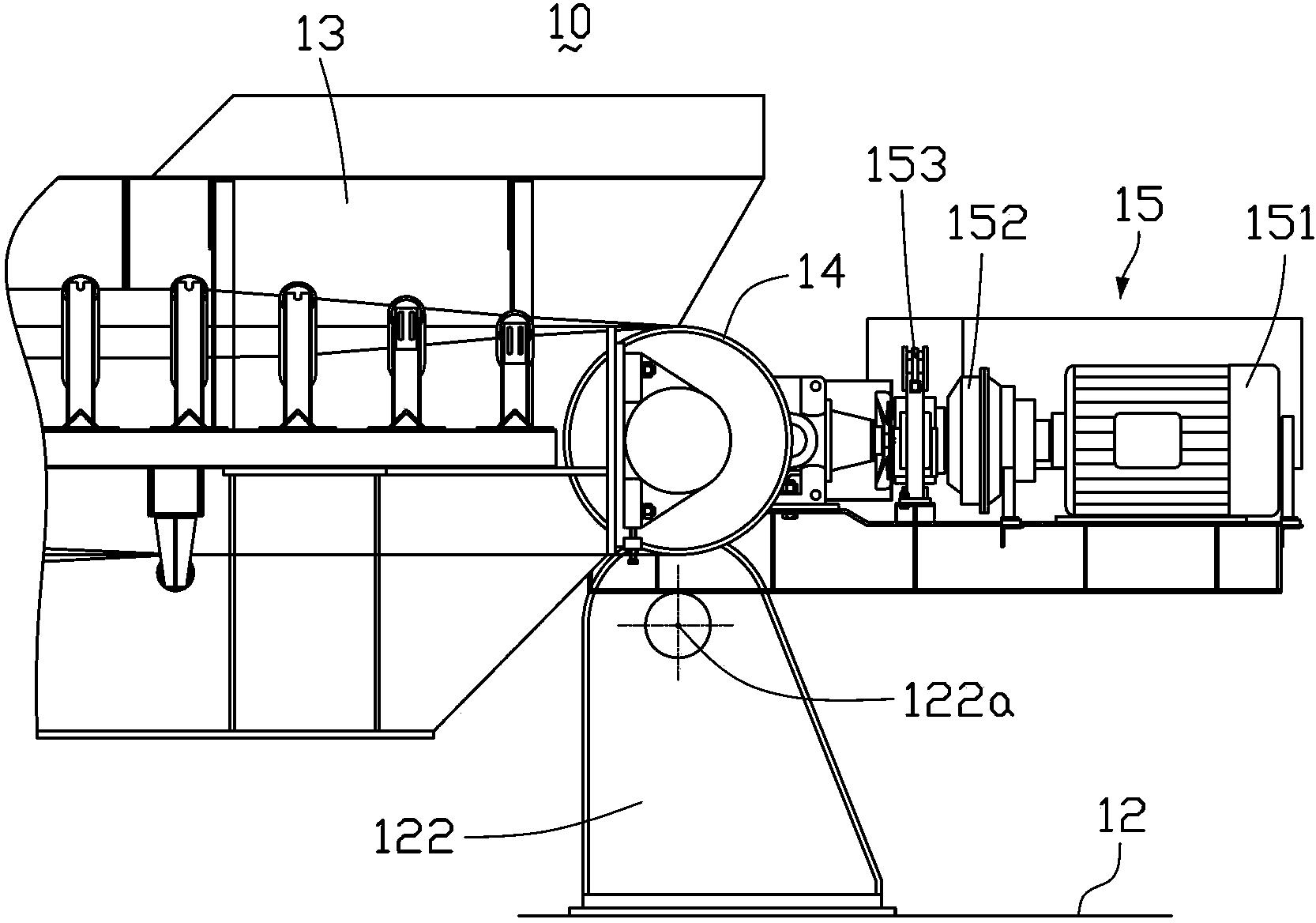

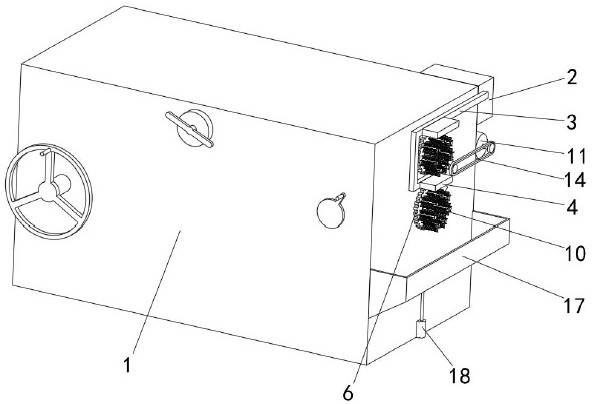

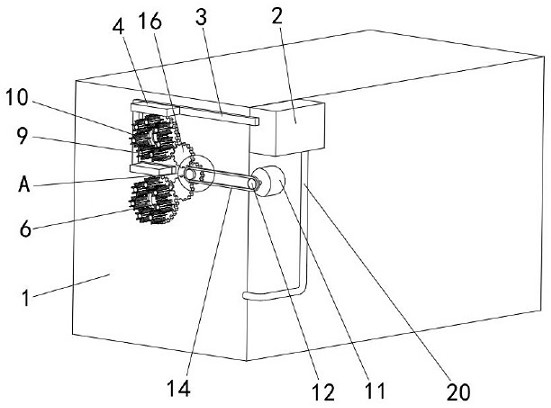

Self-lubricating felt of gear-rack jacking system

ActiveCN105465584ASimple structureEasy to manufactureLifting framesEngine lubricationDistributorLubrication

The invention discloses a self-lubricating felt of a gear-rack jacking system and belongs to the field of gear-rack jacking systems. The self-lubricating felt comprises: an electric lubrication pump, a distributor and a plurality of self-lubricating assemblies; an oil outlet of the electric lubrication pump communicates with an oil inlet of the distributor; a plurality of oil outlets of the distributor communicate with the plurality of self-lubricating assemblies, respectively; each self-lubricating assembly comprises: an oil inlet connector, a first oil inlet pipe, a three-way pipe, a second oil inlet pipe, a third oil inlet pipe, a first oil leading pipe, a fixed plate and a felt brush, and one end of the oil inlet connector communicates with one oil outlet of the distributor, while the other end of the oil inlet connector is connected with a first end of the first oil inlet pipe. The self-lubricating felt is capable of achieving the purpose of lubrication instead of artificial application, and therefore, high safety and high lubrication efficiency in a lubrication process are realized; further, the self-lubricating felt is simple in structure, easy to manufacture and relatively low in cost; as a result, lubrication costs are reduced.

Owner:WUHAN MARINE MACHINERY PLANT

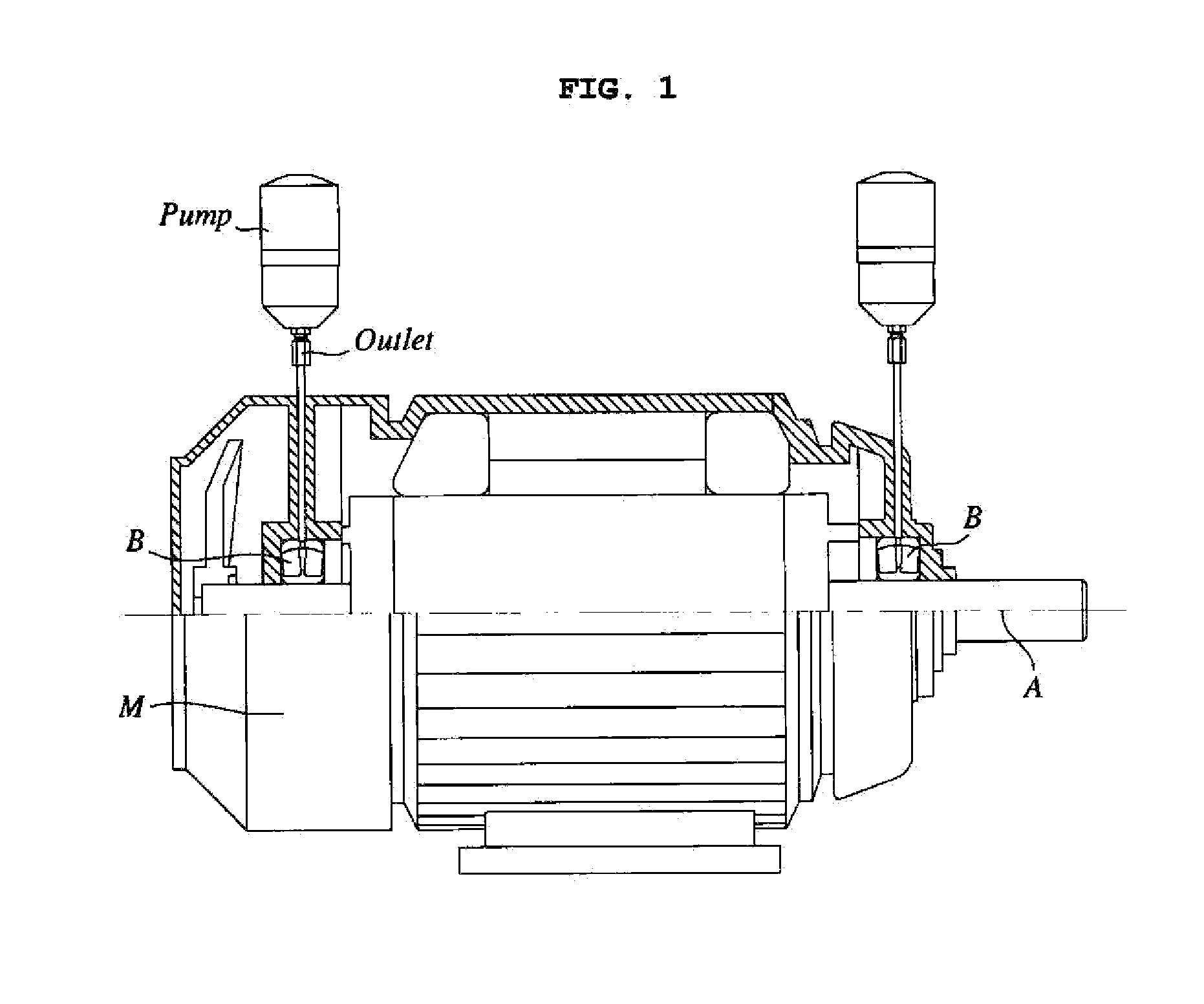

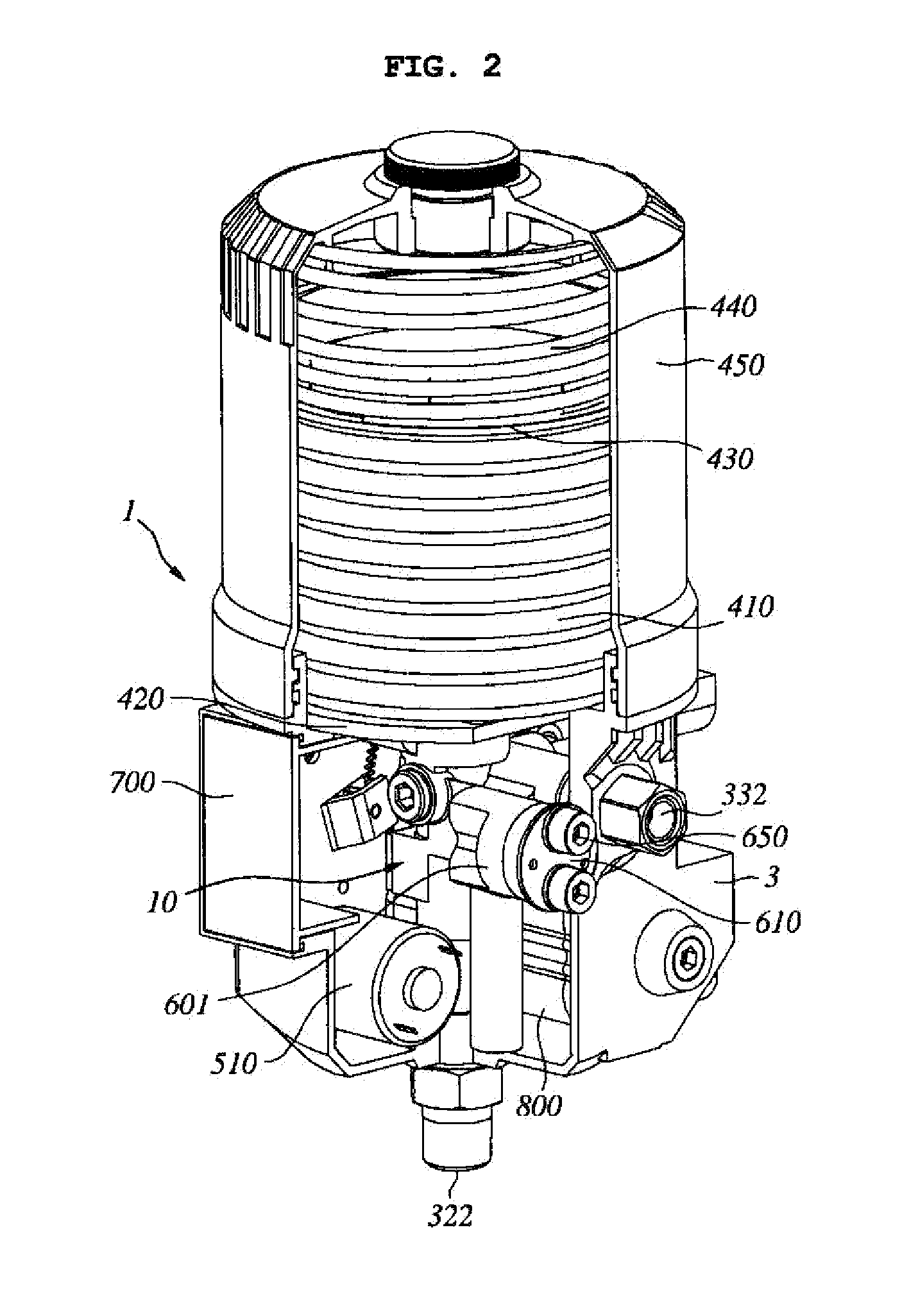

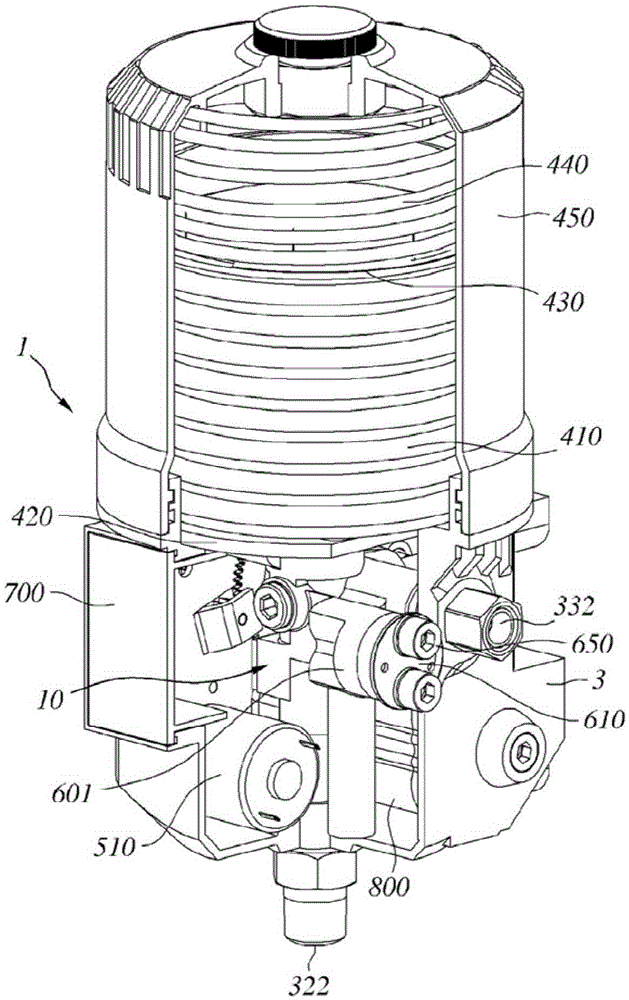

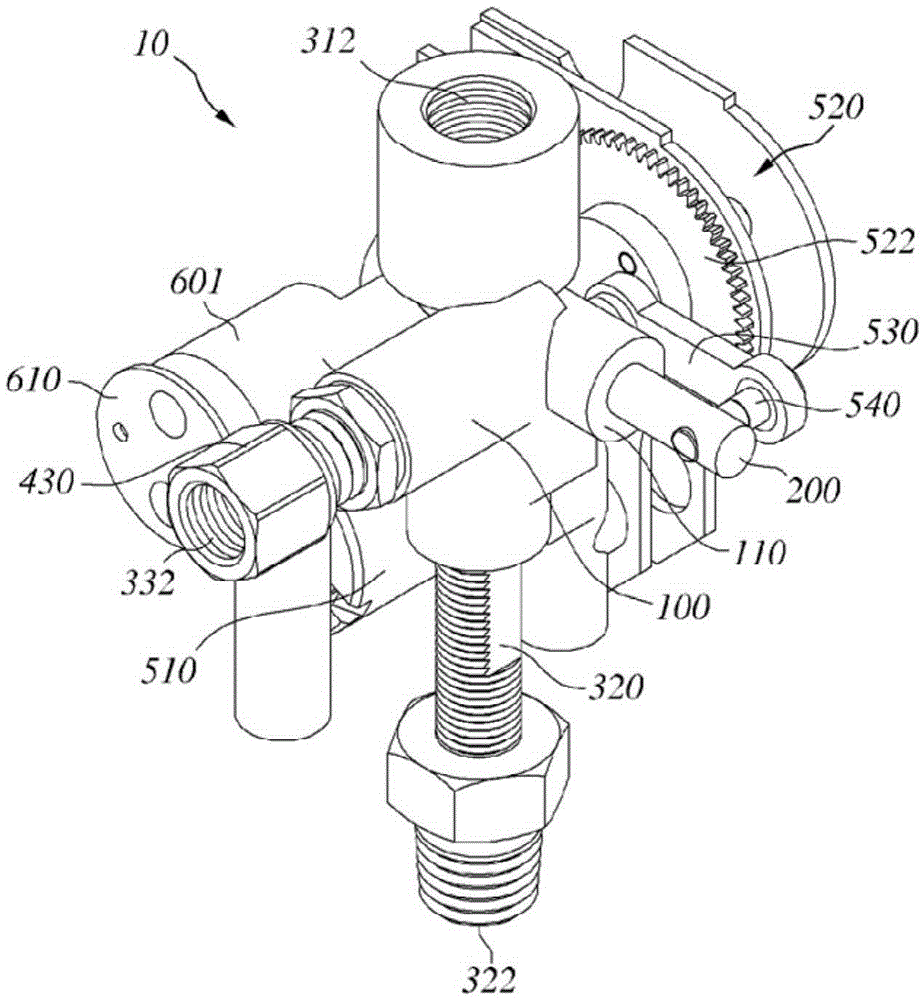

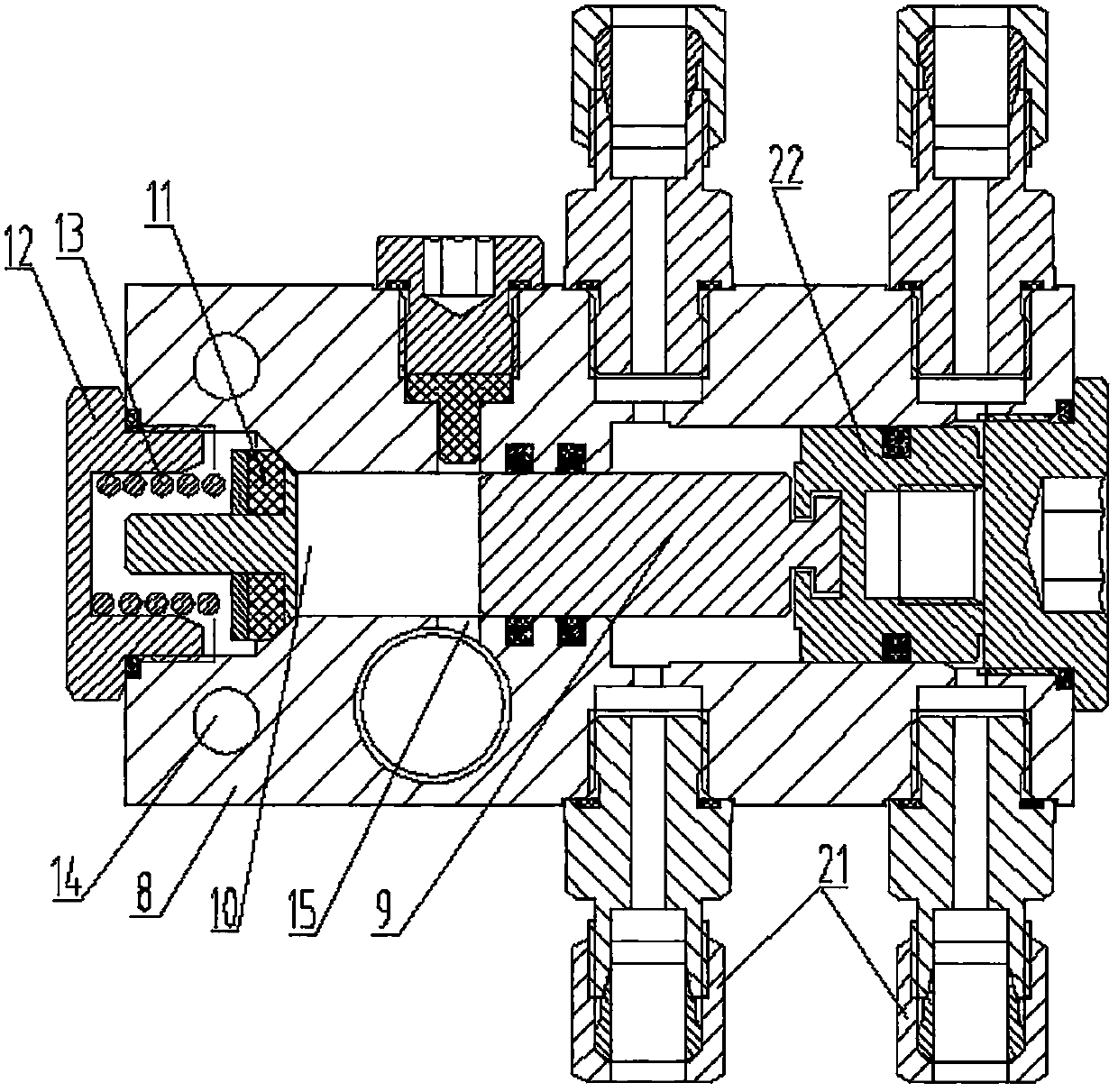

Lubricator

InactiveCN105408673AReduce lubrication costsEasy to handleLubricating pumpsDistribution equipmentCheck valveLubrication

The present invention relates to a lubricator capable of efficiently supplying a lubricant to two portions requiring lubrication without a separate distribution device, the lubricator comprising a pump and two outlets. To this end, provided is a lubricator comprising: a pump body; a piston; first to fourth check valves; a lubricant storage unit; and a piston driving unit. The pump body comprises: a cylinder; an inlet flow path; a first outlet flow path; and a second outlet flow path, wherein one end of the cylinder is closed and the other end of the cylinder is opened, the inlet flow path is formed in one end side of the cylinder such that the inlet flow path is vertically connected with the cylinder, the first outlet flow path is formed to be connected with the cylinder while facing the inlet flow path, the second outlet flow path is formed to be connected with the cylinder while being spaced apart by a predetermined distance in the direction of the other end of the cylinder from the position where the inlet flow path and the first outlet flow path are formed. The piston comprises an internal flow path which connects an inlet hole formed in one end of the piston and a circumference groove formed to be spaced apart from the inlet hole by a predetermined distance in the direction of the other end of the piston. The piston is adapted to be inserted into the cylinder. The first to fourth check valves are respectively positioned in the inlet side of the inlet flow path, the outlet side of the first and second outlet flow paths, and the internal flow path of the piston. The lubricant storage unit in which the lubricant is stored is connected to a first check valve. The driving unit drives the piston such that the inlet hole of the piston reciprocates between one end of the cylinder and one position of the first and second outlet flow paths.

Owner:HANIL LUBTEC

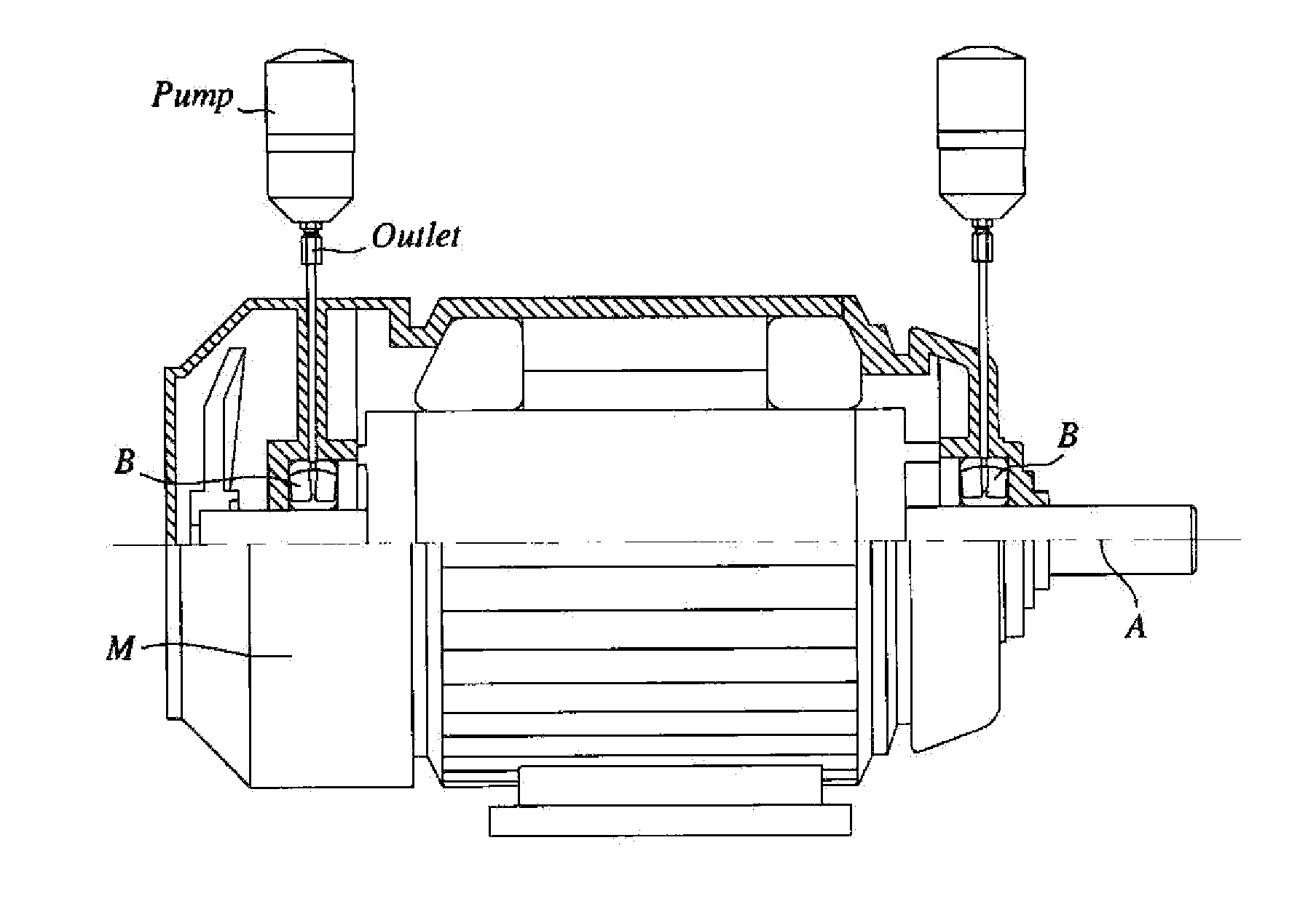

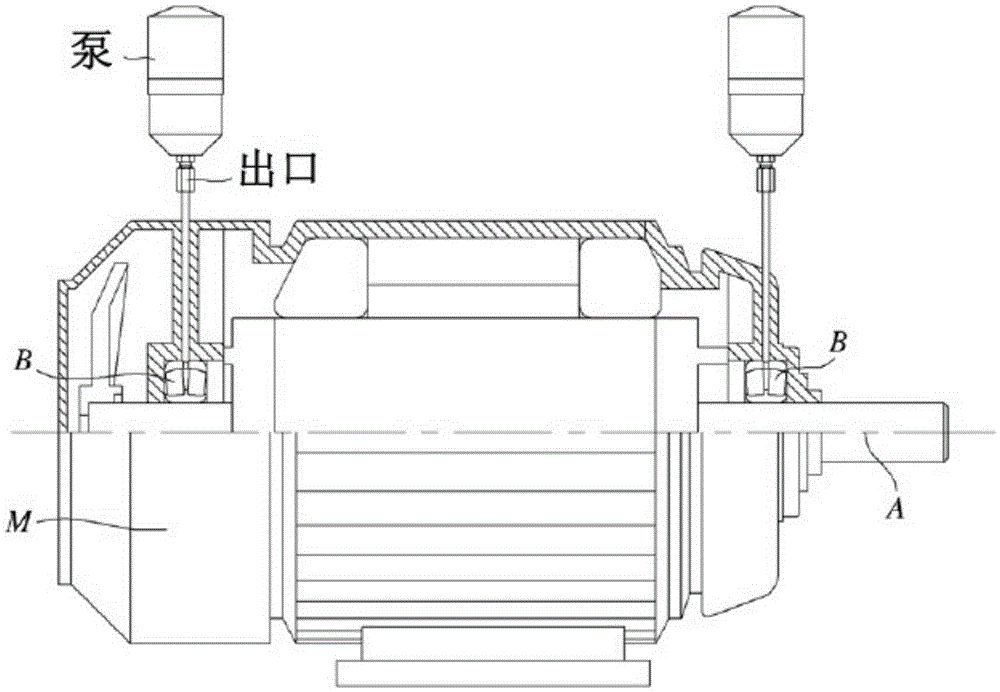

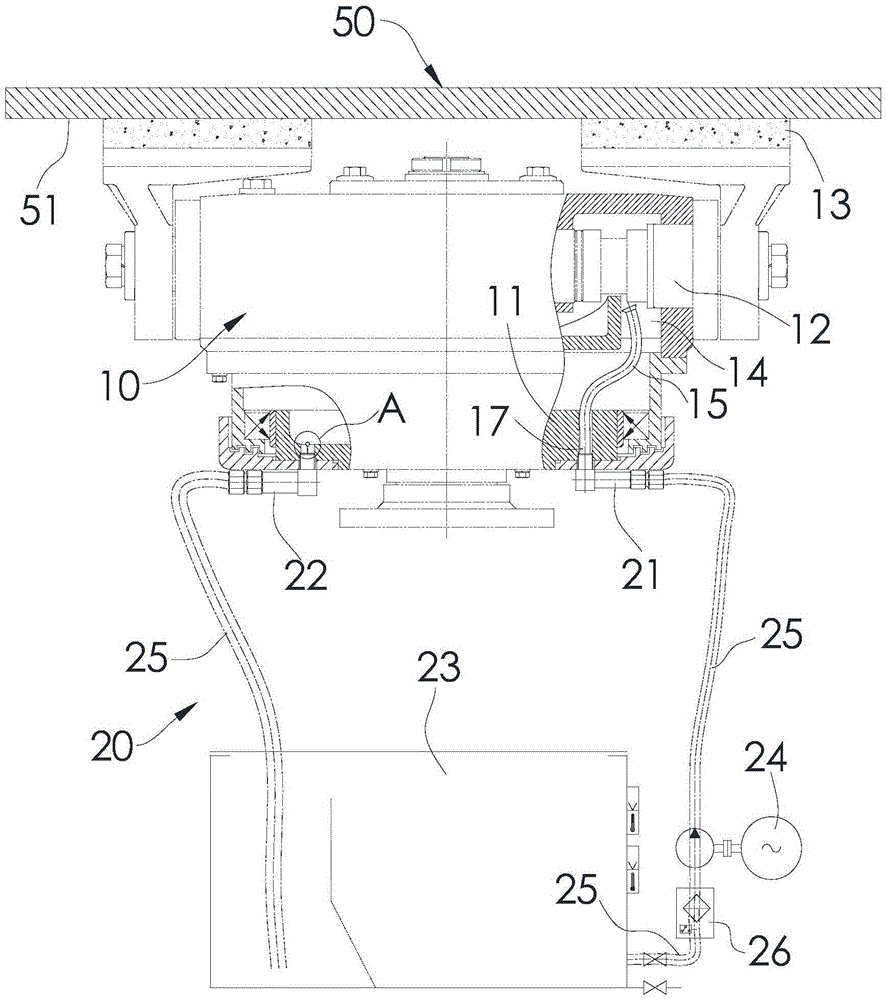

Grease lubrication bearing system

InactiveCN107701901ASolve the technical problem of lubrication without cooling functionAvoid pollutionRolling contact bearingsShaftsEngineeringLubrication

The invention discloses a grease lubrication bearing system. The grease lubrication bearing system comprises a bearing structure and a lubricating grease circular drive device; according to the bearing structure, a lubricating space used for containing lubricating oil is arranged between the outer ring and the inner ring of the bearing structure, an oil injection hole and an oil draining hole communicating with the lubricating space are formed in the bearing structure, the oil draining hole is connected with a grease absorbing opening of the lubricating grease circular drive device, a grease outlet of the lubricating grease circular drive device is connected with the oil injection hole of the bearing, and a lubricating grease filter device and / or a cooling device are / is arranged between the lubricating grease circular drive device and the oil injection hole in a series manner. The lubricating grease filter device and / or a cooling device are / is arranged, harmful substance can be cleanedthrough the lubricating grease circular device, the optimal lubricating state can be maintained, the time of the optimal lubricating state is prolonged, the good lubricating is obtained, the servicelife of the bearing is prolonged, through the cooling device, the lubricating grease temperature is reduced, the lubricating grease liquidity is improved, the lubricating grease is injected into the bearing again, and the lubricating grease characteristic effect can be restored.

Owner:AUTOL TECH

A formula of a cooling lubricating fluid used for machine tools

InactiveCN107541323AReduce pollutionLow costDrilling compositionLubricant compositionEngineeringMachine tool

The invention discloses a formula of cooling lubricating fluid for machine tools. This lubricating fluid is composed of wood pulp tall oil soap, water, diesel oil and non-ionic surfactant. Its composition weight percentage is: wood pulp tall oil soap dry powder or ointment is 20-30, water is 60-70, diesel oil is 10-20, and nonionic surfactant is 2-5. The lubricating fluid has good lubricating performance, low cost and simple processing conditions.

Owner:黄成科

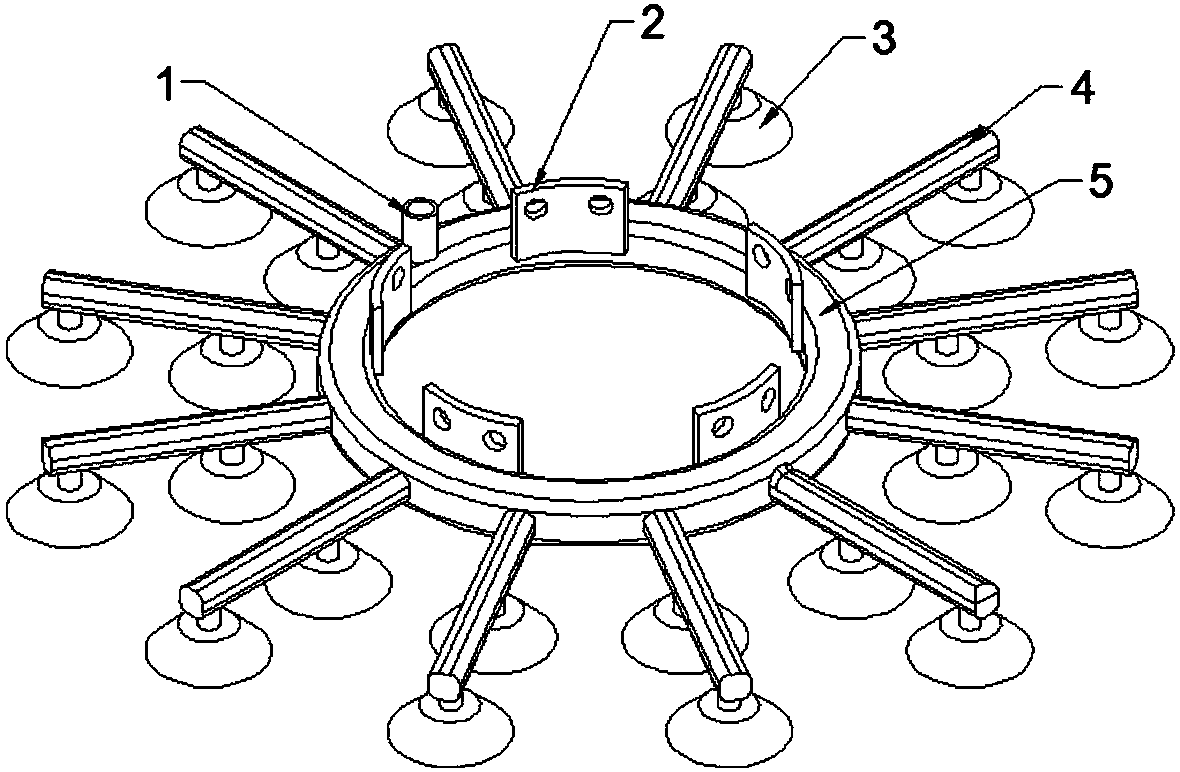

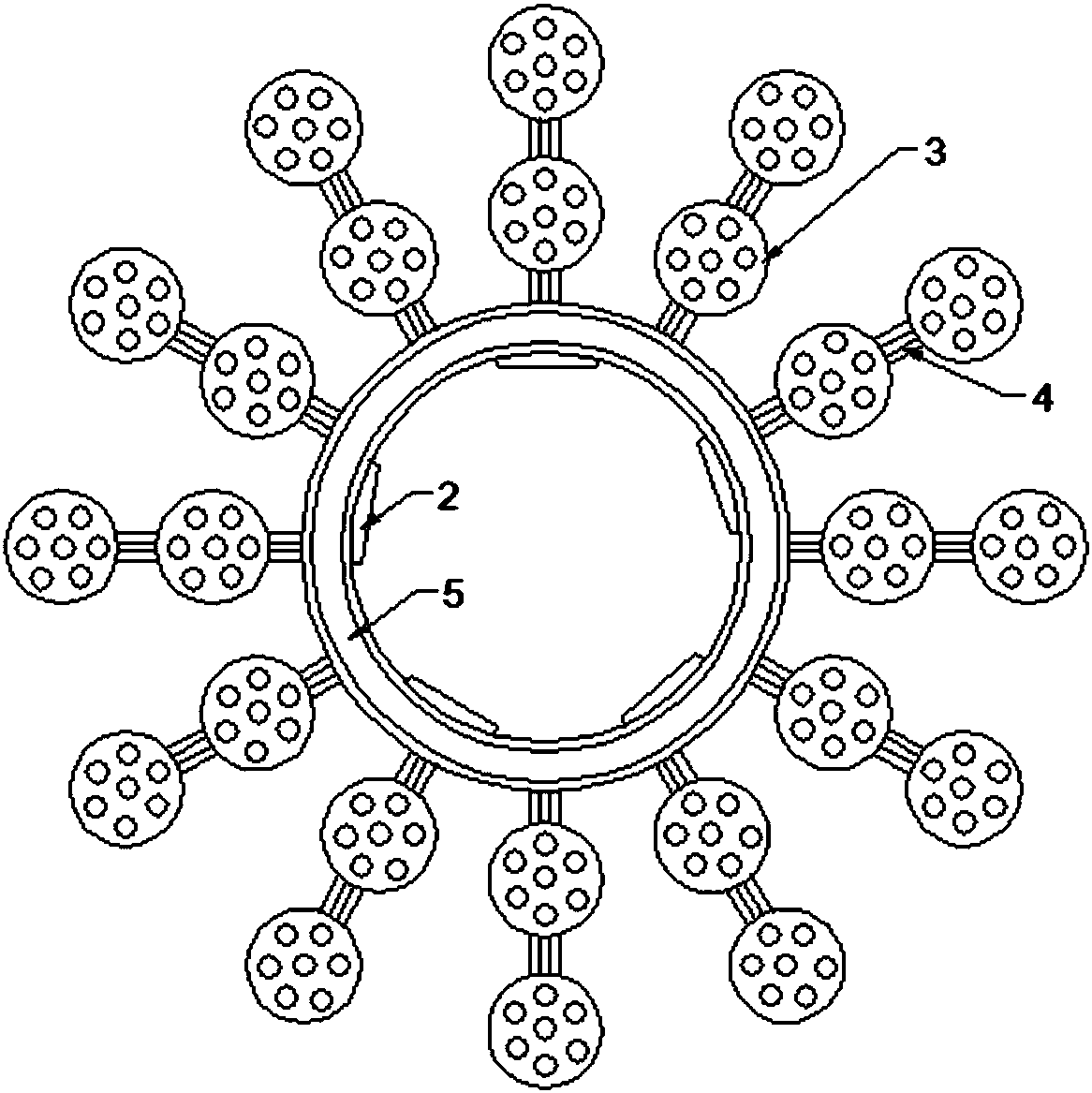

Oil spraying equipment based on closing plate

InactiveCN108506714AImprove uniformityReduce lubrication costsConduits/junctionsMechanical equipmentLarge size

The invention provides oil spraying equipment based on a closing plate. The oil spraying equipment comprises a closed annular main pipeline and a plurality of branch pipelines communicating with the main pipeline, wherein the multiple branch pipelines are uniformly distributed on the periphery of the main pipeline in a circular array form; the circular array formed by the branch pipelines and themain pipeline are coaxial; a plurality of oil discharge pores are uniformly distributed in the branch pipelines; an oil feed pipe is connected to the main pipeline, the inner side of the main pipelineis provided with a plurality of installation sheets which are uniformly distributed in a circular array form, and the circular array formed by the installation sheets and the main pipeline are coaxial; and installation holes are formed in the installation sheets. The oil spraying equipment has the beneficial effects that the oil pipelines are simplified, using is more convenient, lubricating oilforms small oil drips to be uniformly scattered in overall large-size equipment by arranging the multiple oil spraying pores, all parts can be lubricated by the lubricating oil, through the design, the spraying uniformity of the lubricating oil can be remarkably improved, the advantage of saving oil is achieved, and the lubricating cost of the large-size mechanical equipment can be substantially reduced.

Owner:TIANJIN SANXIN SUNSHINE

A self-circulating lubrication method and device for a positive and negative alternate rotation vertical reducer

ActiveCN104455352BReduce weightReduce lubrication costsGear lubrication/coolingRotation functionReduction drive

The invention discloses a self-circulation lubricating method and device of a vertical gear reducer with a forward-reverse alternative rotation function. In the method, the bottom of an input shaft of the gear reducer is in the shape of a round tube, a section of an inner helix groove is arranged in the inner wall of the round tube, and an inner pump composed of a pump core is arranged in the round tube; in addition, the outer circle of the round tube of the bottom of the gear reducer is provided with a section of outer helix groove, and the outer helix groove is sleeved with a pump sleeve to form an outer pump; meanwhile, a main oil passage allowing lubricating oil to ascend is arranged in the input shaft, when the input shaft rotates forwards or reversely, the lubricating oil at the bottom of a case of the gear reducer is pumped to the upper portion of a gear reducer part through the inner pump or outer pump so as to lubricate the part of the upper portion of the gear reducer, and then the lubricating oil returns to the bottom of the case, so that self-circulation lubrication of the gear reducer is realized. The self-circulation lubrication mode different from an existing full-oil type oil bath lubricating mode and an outer-circulation lubricating mode is adopted, the structure and the appearance of the gear reducer are simpler, and size and weight of the gear reducer can be reduced. Overall performance of the gear reducer is improved.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

Mechanical equipment and anti-deflection mechanism thereof

ActiveCN102923493BEnsure adequate lubricationReduce lubrication costsLoading/unloadingReducerMechanical equipment

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

A new type of ball mill equipment

ActiveCN112024061BPrevent leakageImprove stabilityBearing componentsLubricating pumpsElectric machineryProcess engineering

Owner:QINGHAI UNIV FOR NATITIES

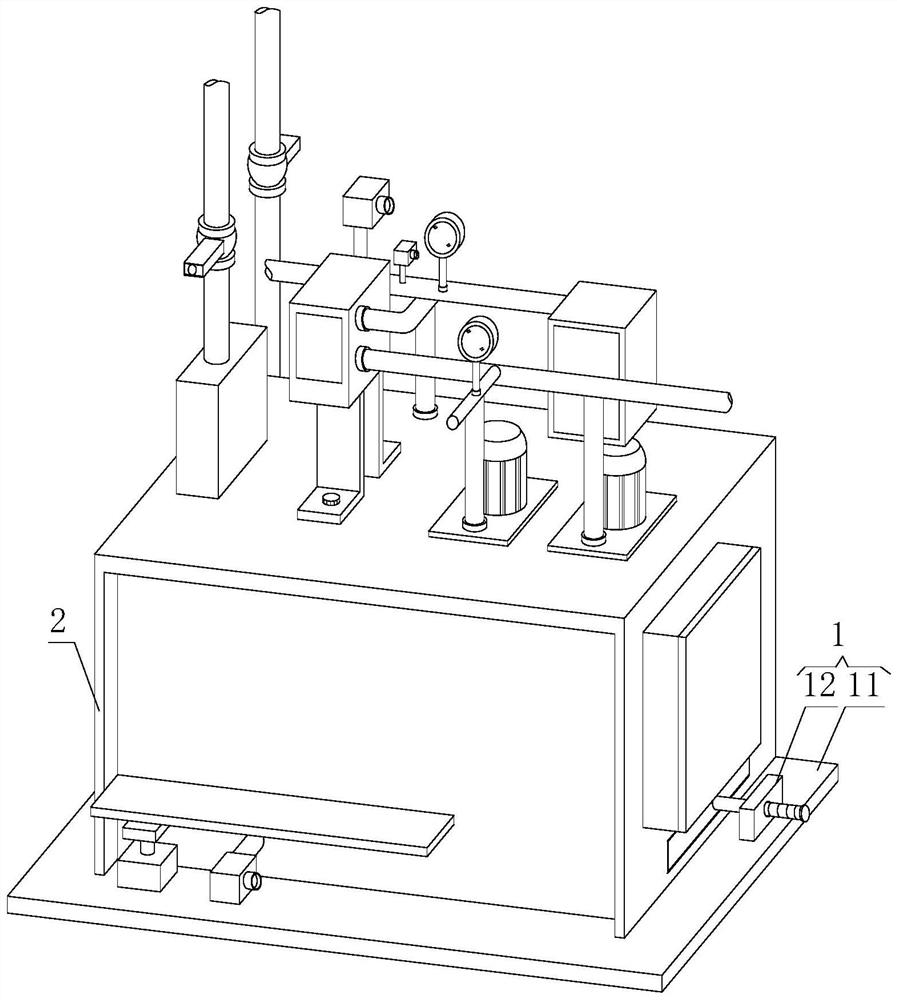

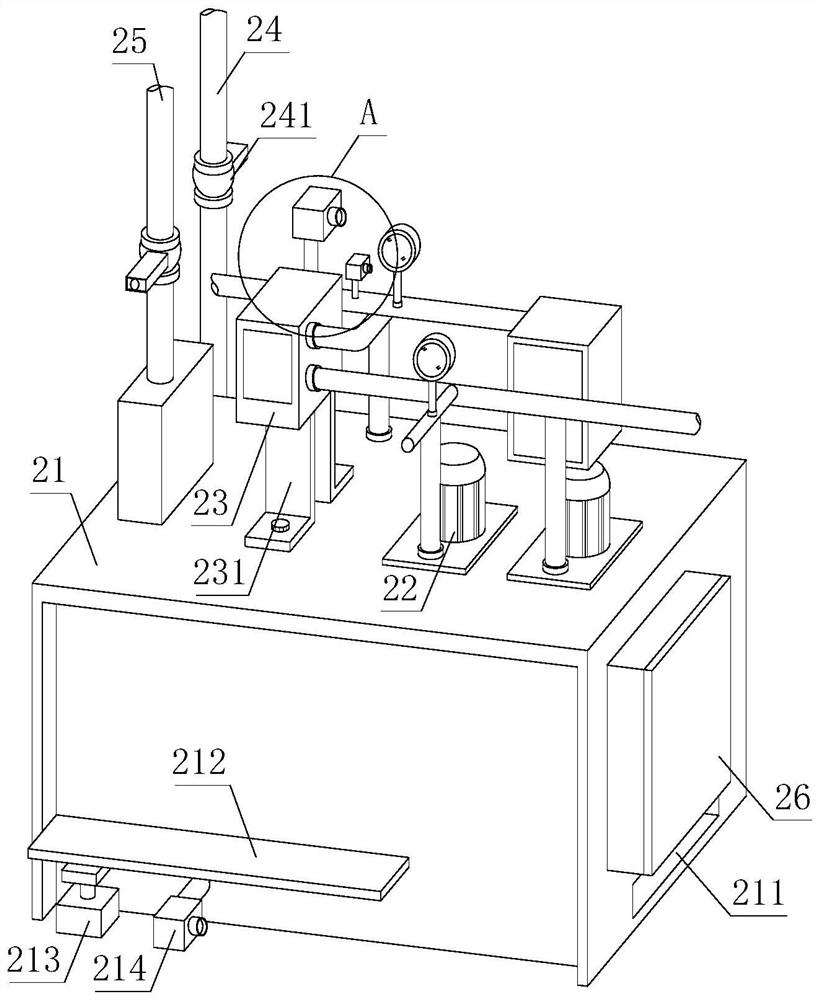

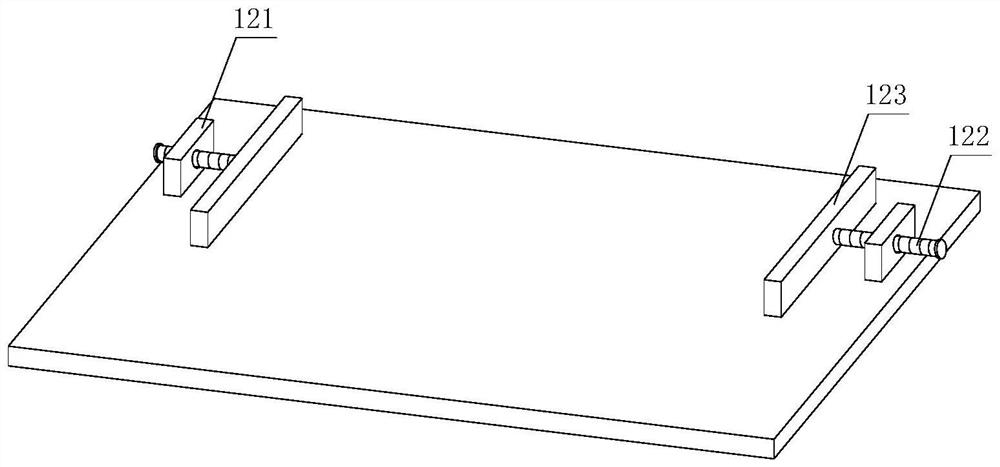

Refined lubricating oil station

PendingCN113236951AAvoid offsetRefined control objectivesLubrication containersAutomatic controlData acquisition

The invention discloses a refined lubricating oil station. The refined lubricating oil station comprises a base structure and an oil station assembly, and the oil station assembly is arranged at the upper end of the base structure. An oil tank liquid level transmitter, an oil tank temperature transmitter, an oil supply temperature transmitter, an oil supply pressure transmitter and a flow transmitter are all electrically connected with a data acquisition cabinet and are connected to an industrial control network through a switch, a PLC is controlled at an engineer station, starting and stopping of a single oil pump and double oil pumps are automatically controlled according to signals sent by the two point positions of the oil supply pressure transmitter and the flow transmitter, a central control worker can manually switch operation of the two oil pumps when the single oil pump operates, the feasibility that the single oil pump is maintained without stopping host equipment is provided, operation of the oil station assembly is jointly controlled according to the oil supply pressure transmitter and the flow transmitter, the lubrication state of equipment is guaranteed, the reliability of the equipment is improved, and an operator connects the oil supply temperature transmitter with an operation signal of the heater, so that automatic control over the heater is achieved.

Owner:DATONG JIDONG CEMENT CO LTD

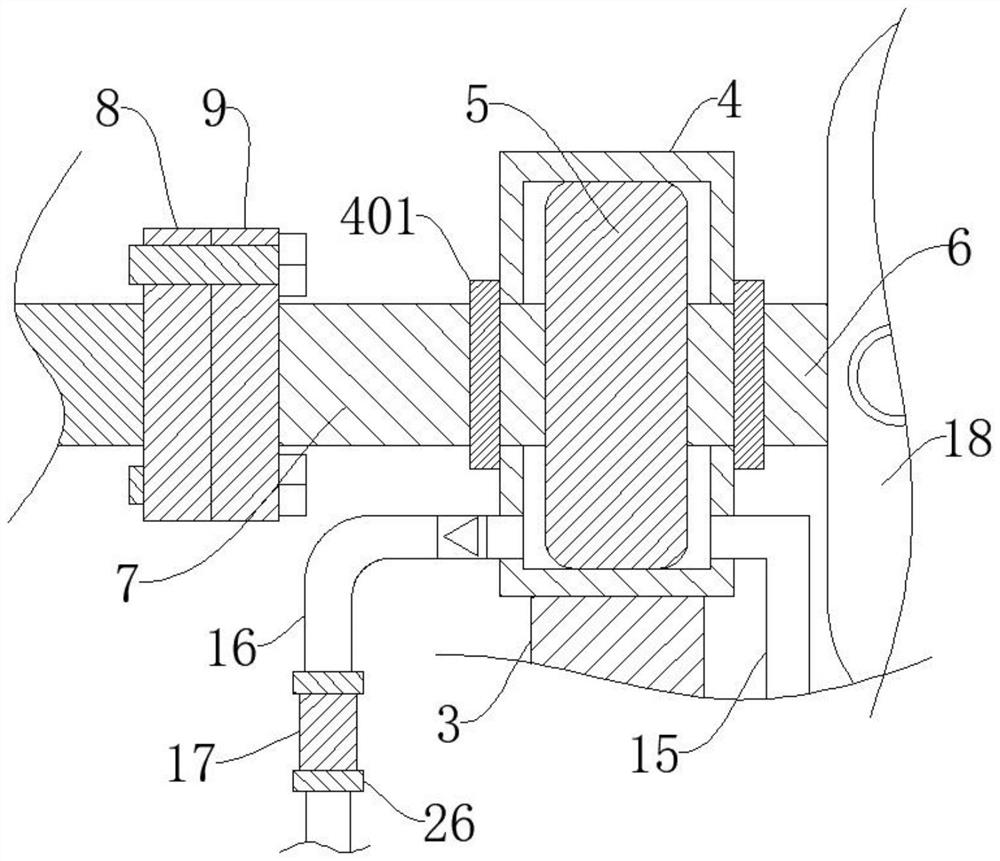

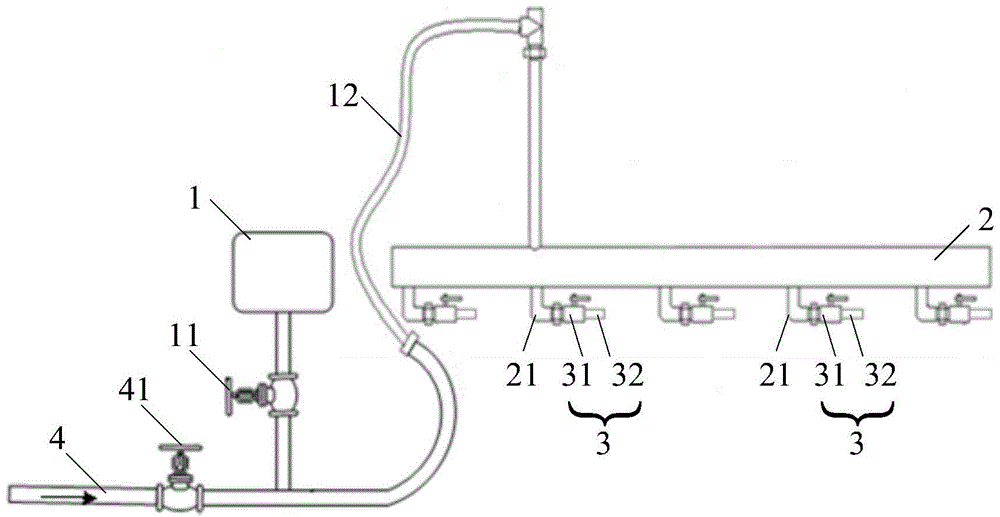

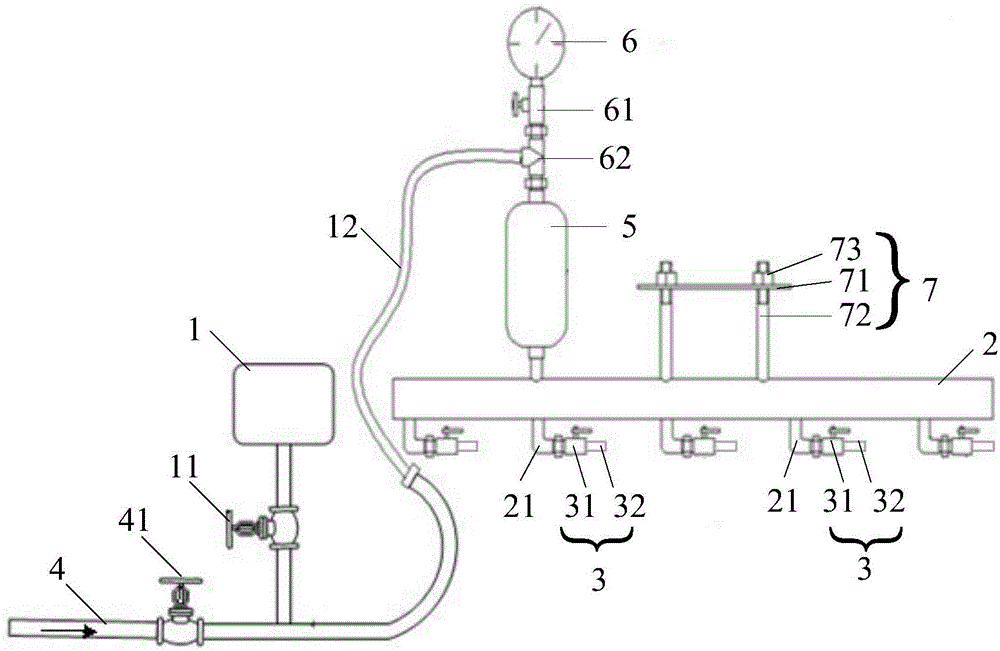

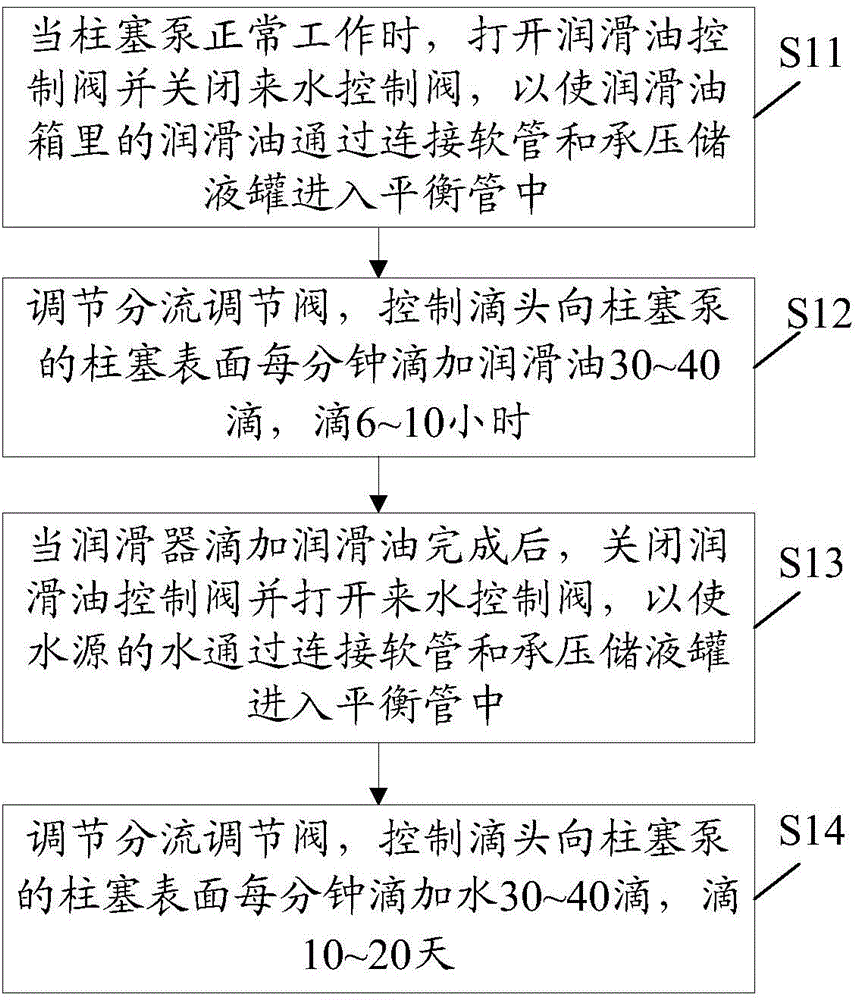

Lubricator used for reciprocating plunger pump and use method of lubricator

ActiveCN105649973AReduce lubrication costsTake advantage ofPositive displacement pump componentsLiquid fuel engine componentsWater sourceControl valves

The invention discloses a lubricator used for a reciprocating plunger pump and a use method of the lubricator and belongs to the technical field of oil field water injection machines. The lubricator comprises a lubricating oil tank, a lubricating oil control valve, a balance pipe and a water dropper installed above a plunger of the plunger pump. The lubricating oil tank communicates with the balance pipe. At least one bend is evenly distributed on the balance pipe in the axis direction of the balance pipe. One end of each bend is connected with one end of a diversion adjusting valve, and the other end of each diversion adjusting valve is connected with a liquid dropping nozzle. The lubricator further comprises an inflow water pipeline communicating with a water source and an inflow water control valve. The incoming water pipeline communicates with the balance pipe through a connecting hose. By means of the lubricator used for the reciprocating plunger pump and the use method of the lubricator, the incoming water pipeline communicating with the water source and the incoming water control valve are newly additionally arranged so that the lubricator can be used for controlling dropping of lubricating oil and water into the plunger of the plunger pump in sequence, the plunger is lubricated through the lubricating oil which is not completely emulsified, the use amount of the lubricating oil can be reduced, the lubricating cost is reduced, meanwhile, the lubricating oil adsorbed to the interior of a packing can be fully utilized, and the utilization rate of the lubricating oil is increased.

Owner:PETROCHINA CO LTD

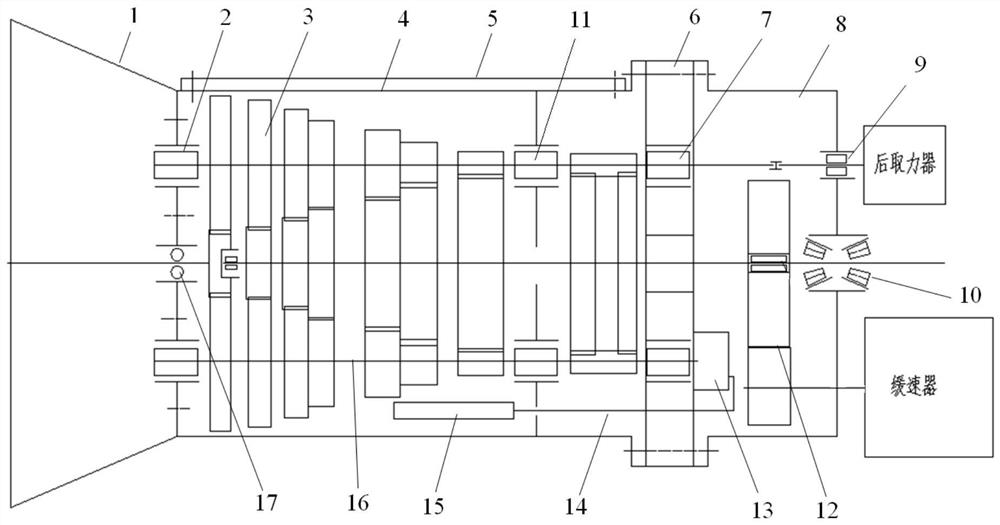

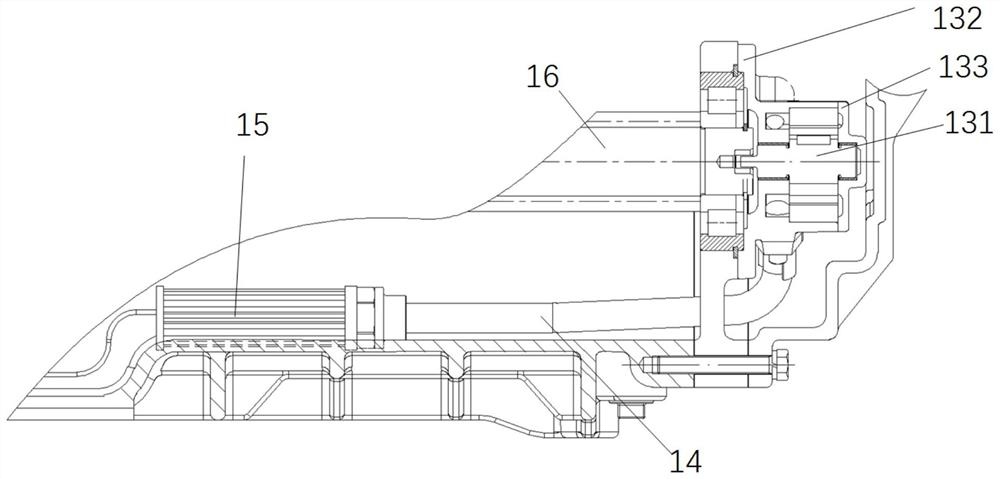

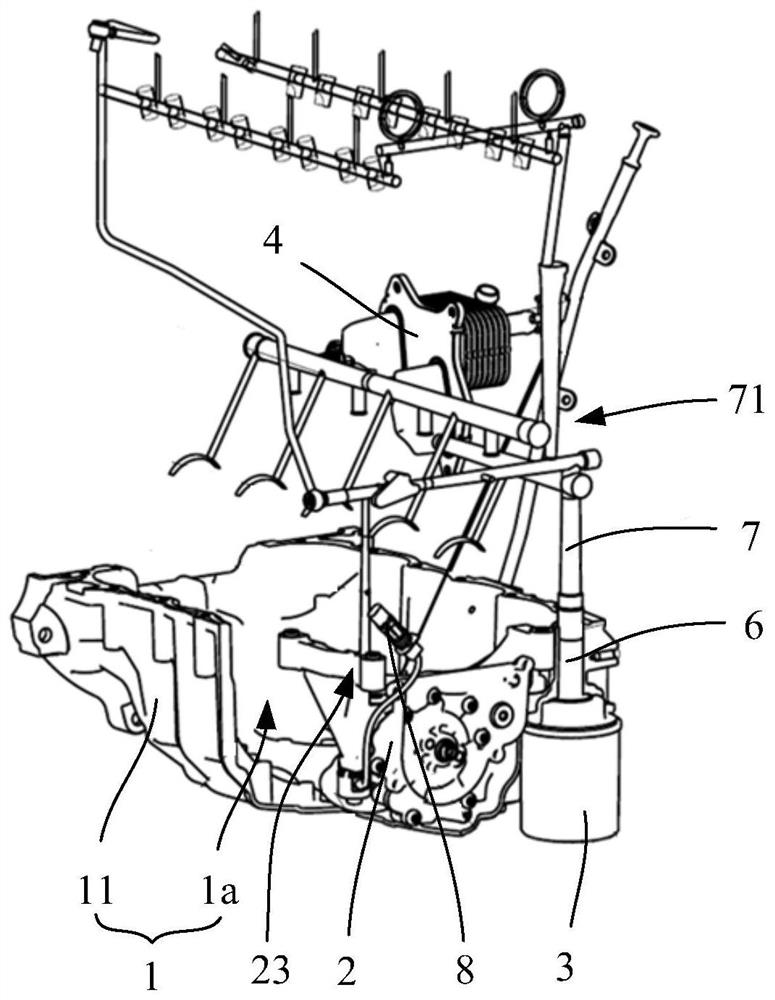

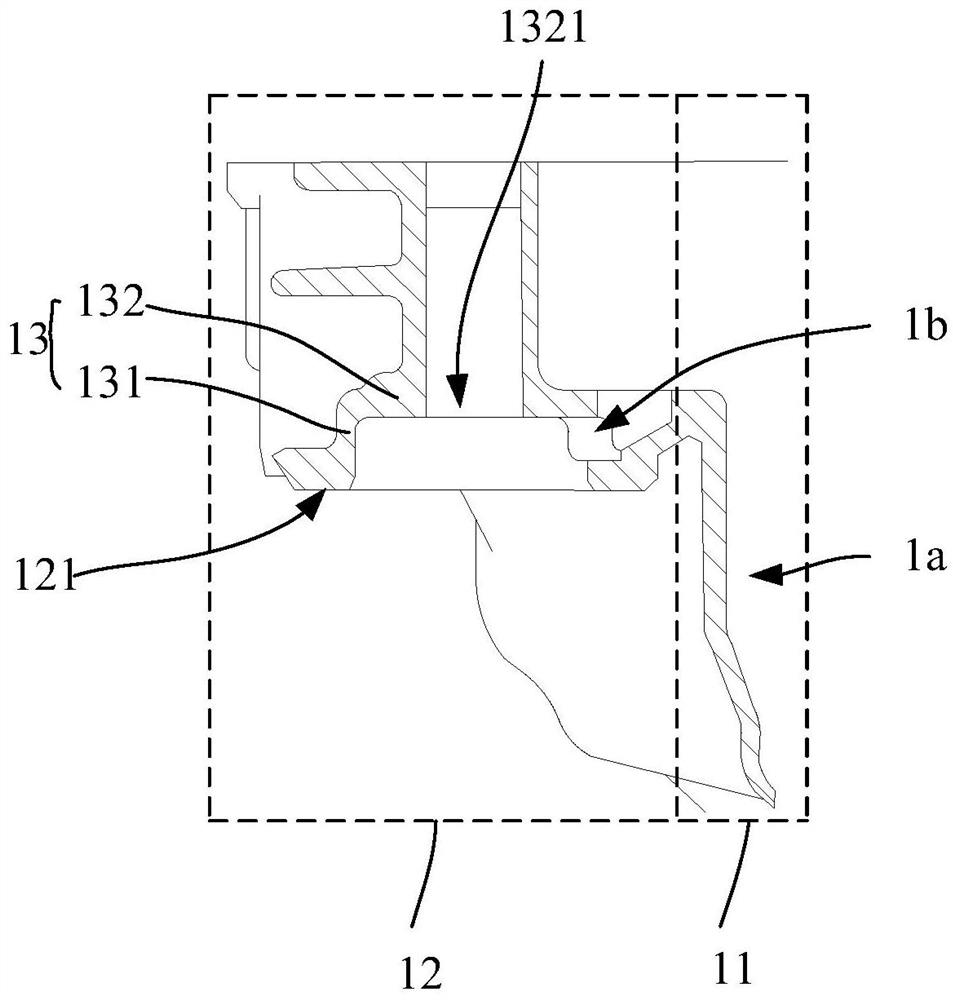

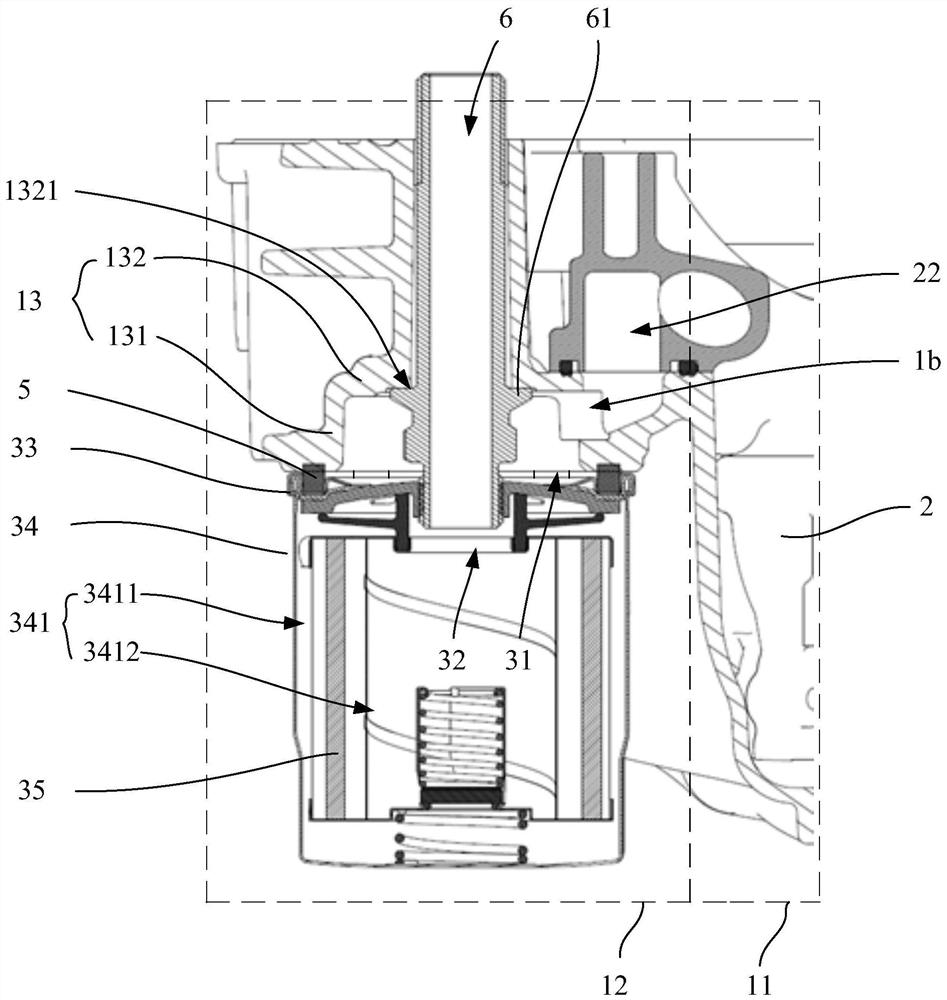

A transmission lubricating cooling system

ActiveCN113007332BExtended service lifeMeet the lubrication temperature requirementsGearboxesGear lubrication/coolingEngineeringLubrication

The invention provides a transmission lubricating and cooling system, aiming at solving the problem of insufficient lubrication, reduced service life of the transmission, high risk of oil leakage, inconvenient installation, large loss of oil passage and high efficiency of the oil pump in the transmission lubrication of the existing single box three countershaft structure. lower question. The system adopts oil pump pressure lubrication, and realizes the lubrication of the upper lubrication points of the three-countershaft transmission through the combination of the casing oil passage and the oil pipe. At the same time, a strong cooling interface is reserved at the beginning of the oil passage, and a forced cooling system can be connected externally to control the transmission oil. Temperature within a reasonable range, prolong the service life of oil and transmission.

Owner:SHAANXI FAST GEAR CO

A kind of liquid-solid mixed lubricant based on graphene strengthening and preparation method thereof

ActiveCN106544149BGood adaptive lubrication effectReduce friction and wearAdditivesUltrasonic oscillationAqueous dispersion

Owner:UNIV OF SCI & TECH BEIJING

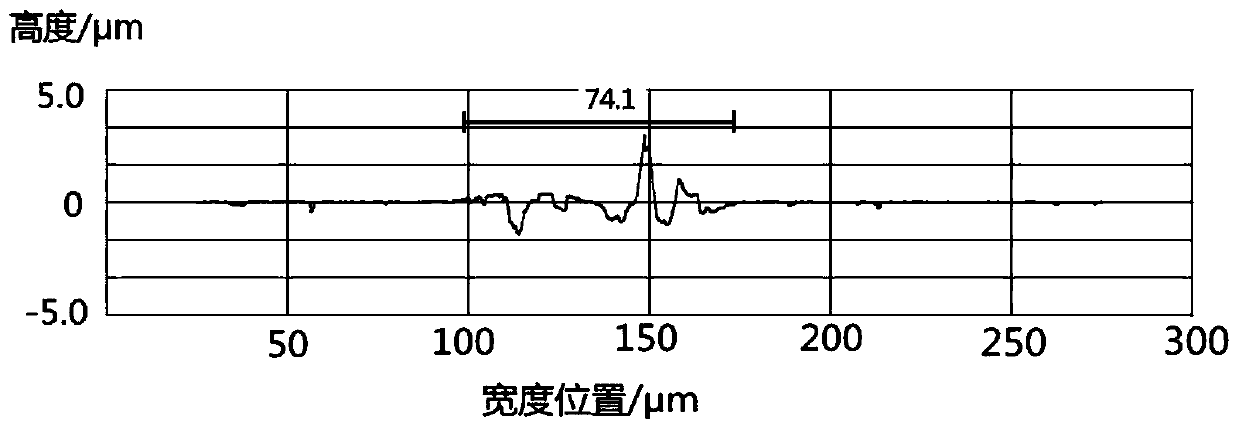

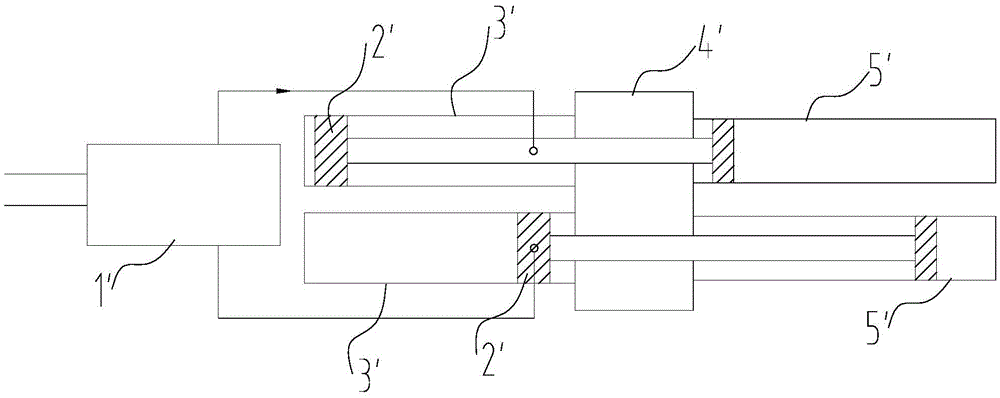

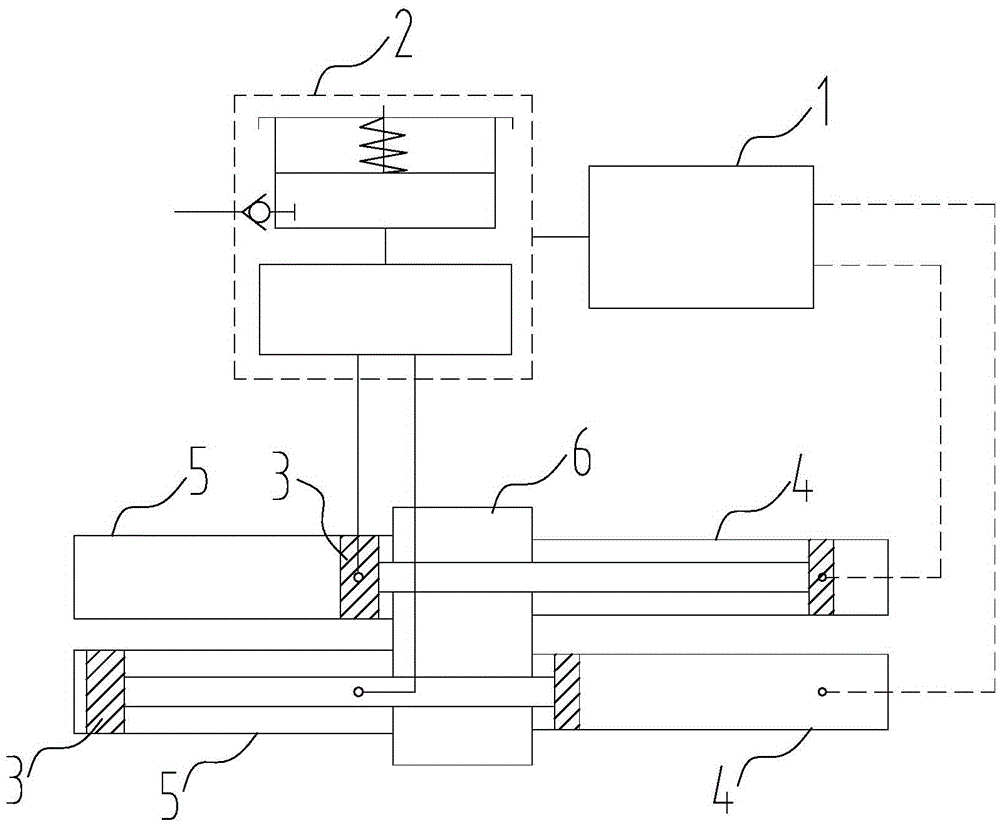

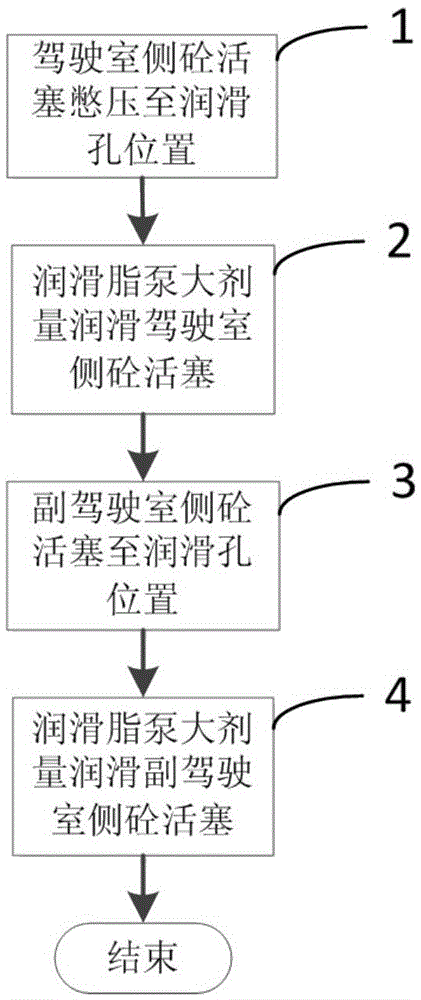

A concrete pump and its concrete piston lubrication system

ActiveCN103967772BImprove the lubrication effectReduce wearPositive displacement pump componentsPumpsControl theoryConcrete pump

The invention discloses a concrete pump and a concrete piston lubricating system of the concrete pump. The concrete piston lubricating system comprises a position detection device, a control device and a lubricant distribution device. The position detection device is used for detecting the position of a concrete piston. The control device is connected with the position detection device and the lubricant distribution device. The lubricant distribution device is connected with a lubricating hole corresponding to the concrete piston. In the process of lubrication, the control device controls a main oil cylinder to move to retract the concrete piston. After the position detection device detects that the concrete piston returns in place, the control device controls the lubricant distribution device to make lubricant flow to the lubricating hole, so that an oil groove of the concrete piston is filled with the lubricant. By the adoption of a concentrated lubrication mode, a large amount of lubricant can be injected into the concrete piston and the concrete piston lubricating system has the advantages of being good in lubricating effect, low in lubricating cost, small in environmental pollution and the like.

Owner:SANY AUTOMOBILE MFG CO LTD

A kind of water-based nano-lubricant based on graphene oxide rolling and preparation method thereof

ActiveCN106566647BReduce friction and wearImprove contact surface qualityLubricant compositionWater basedWater baths

The invention provides a rolling-use water base nano lubricant based on GO and a preparation method thereof. The lubricant is composed of GO, an oxide nano powder, polyphosphates, polyvinylpyrrolidone, and deionized water. The preparation method includes the steps of: adding the polyphosphates to deionized water to completely dissolving the polyphosphates to obtain a primary solution; adding the polyvinylpyrrolidone to the solution with stirring to obtain a clear liquid; adding the oxide nano powder to perform surface modification and dispersion; and finally adding GO powder and performing water-bath ultrasonic dispersion so as to prevent aggregation of the GO and other nano particles. The lubricant has good stability and wear-resisting durability, excellent lubricating performance and cooling performance, and is very low in corrosion on a substrate. A lubricating film formed by the lubricant has strong adsorption property and good adhesion property, thereby inhibiting oxidization of surface of a roller well. The lubricant has excellent lubricating effects in both cold-rolling and hot-rolling status.

Owner:UNIV OF SCI & TECH BEIJING

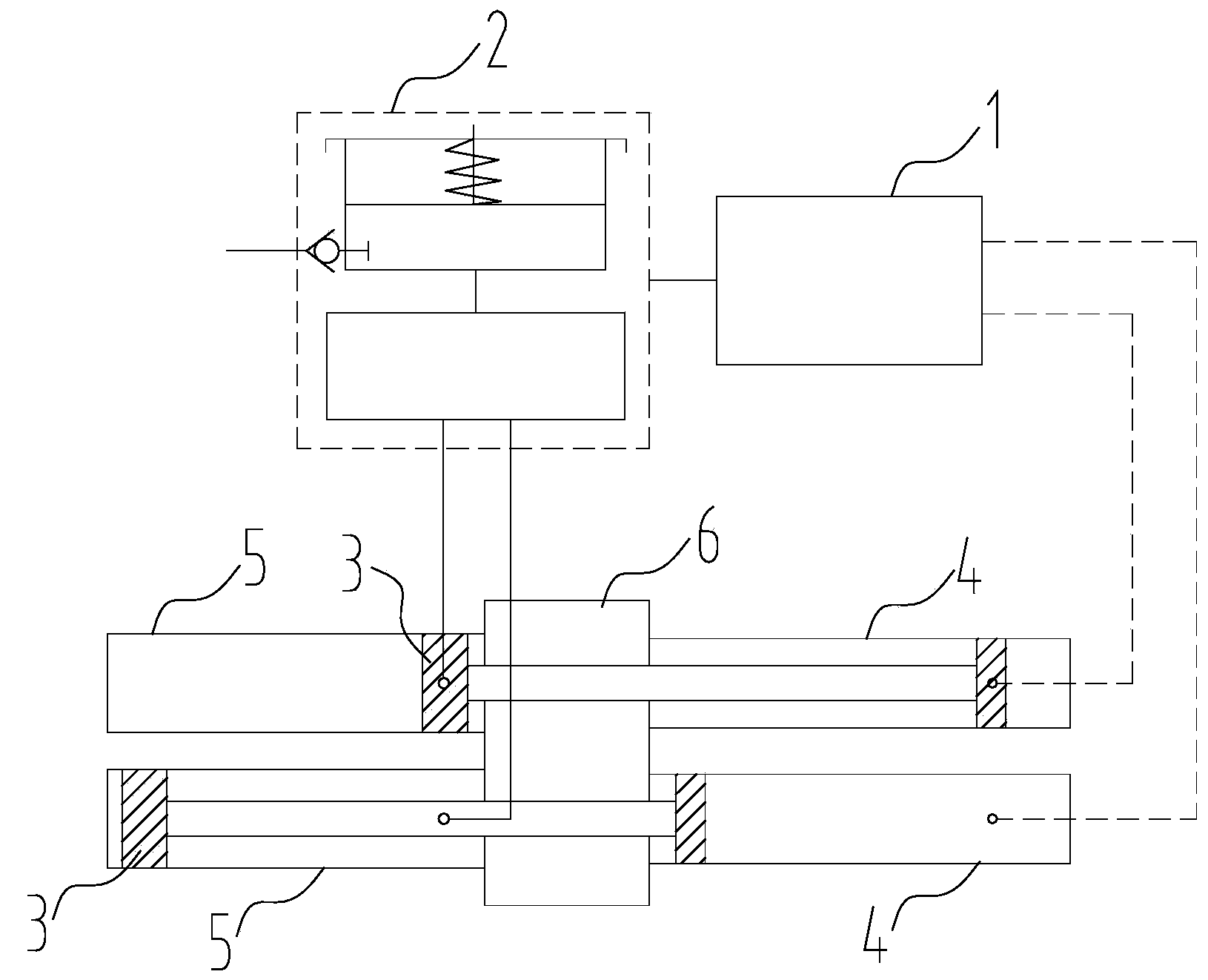

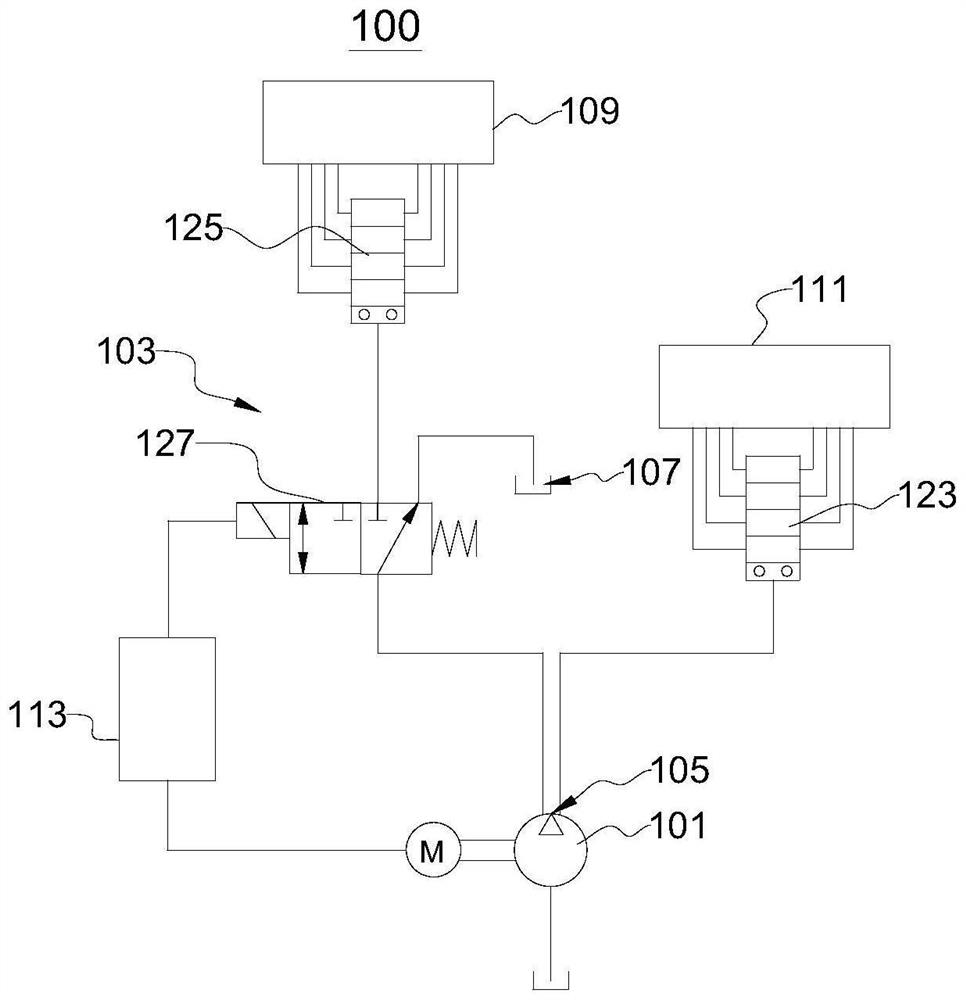

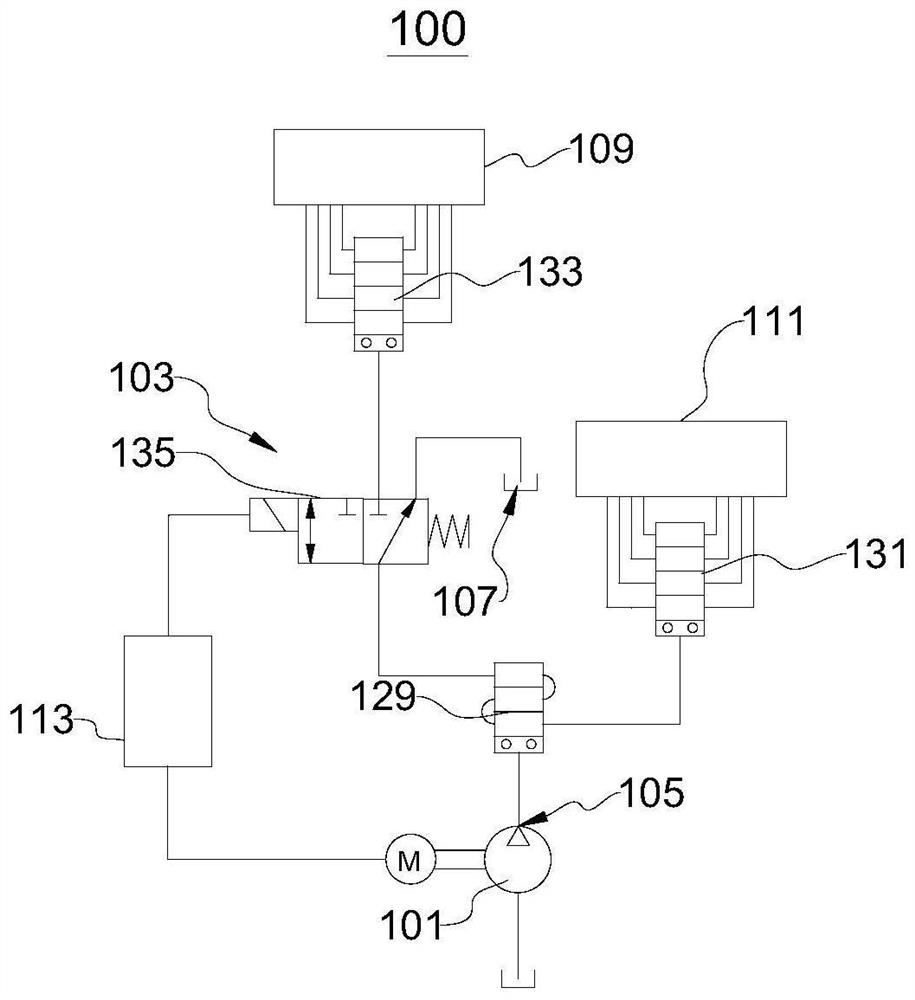

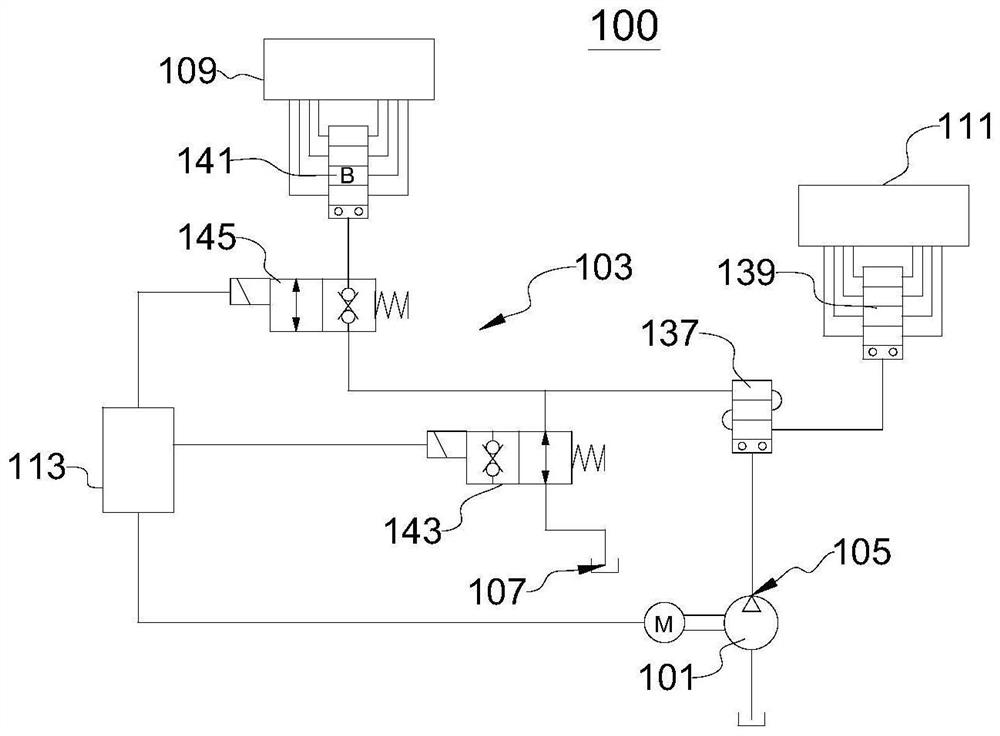

Automatic lubricating system, automatic lubricating method and mechanical equipment

PendingCN114542934AGuaranteed work efficiencyReduce lubrication costsDistribution equipmentThermodynamicsMechanical equipment

The invention discloses an automatic lubricating system, an automatic lubricating method and mechanical equipment, and relates to the technical field of automatic lubricating. The automatic lubricating system is used for lubricating mechanical equipment, the mechanical equipment is provided with a less-oil lubricating point and a more-oil lubricating point, and the automatic lubricating system comprises an electric lubricating pump and a distribution device; the electric lubricating pump is provided with an oil outlet and an oil return port; and the distribution device is communicated with the oil outlet and is used for selectively distributing the lubricating grease output by the oil outlet to at least one of the at least oil lubricating point, the multi-oil lubricating point and the oil return port according to the operation time of the mechanical equipment and the electric lubricating pump. According to the automatic lubricating system, all the lubricating points of the mechanical equipment can be lubricated at the same time through the distribution device, lubricating grease can be reasonably distributed to at least one oil lubricating point and multiple oil lubricating points, the actual lubricating requirements of all the lubricating points can be met, and therefore the lubricating cost can be reduced, the lubricating efficiency can be improved, and the working efficiency of the mechanical equipment can be fully guaranteed.

Owner:广东皓耘科技有限公司

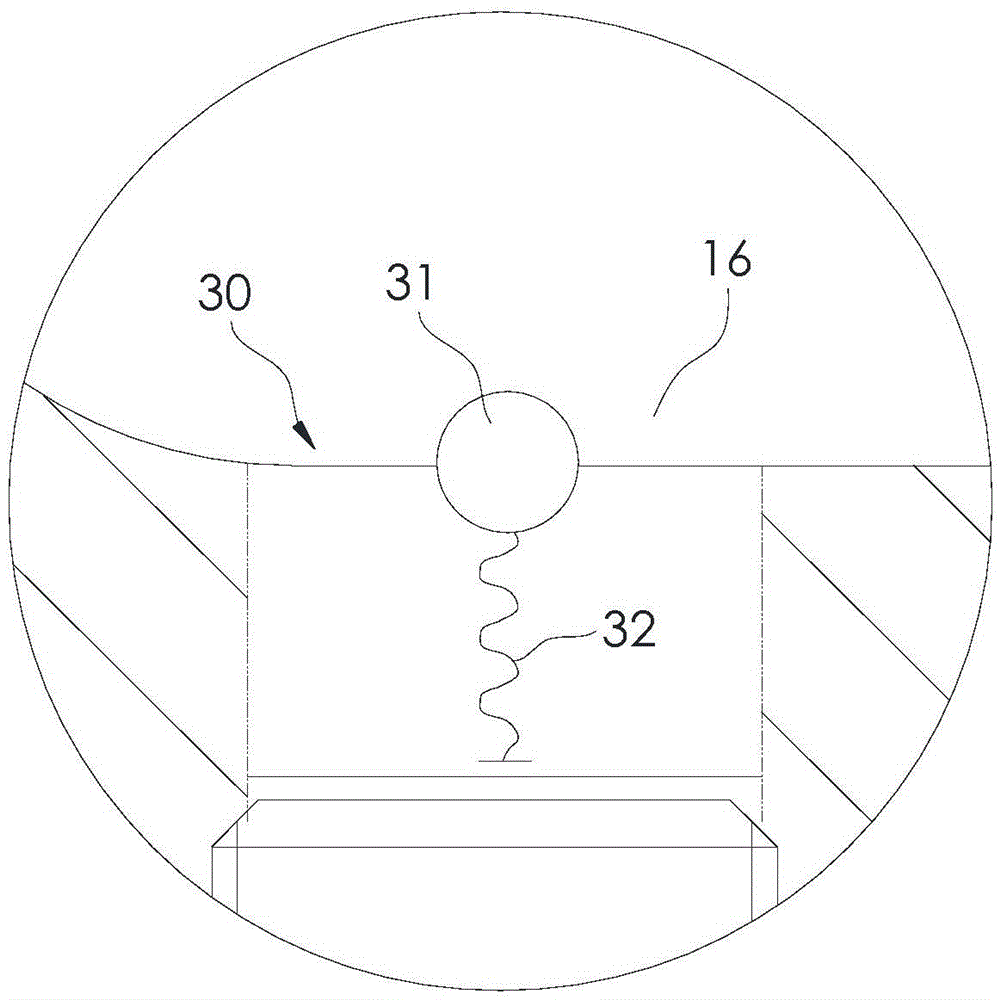

Lubricating structure of polishing grinding head

ActiveCN104842276BReduce wearEvenly lubricatedGrinding headsGrinding/polishing safety devicesInlet channelEngineering

A lubricating structure of a polishing grinder comprises the polishing grinder and an oil supply loop, wherein the oil supply loop comprises an oil outlet end and an oil return end; the polishing grinder comprises a mounting seat, a grinding disc and a grinding block; the mounting seat is fixedly arranged on a rack of polishing equipment; the grinding disc is rotatably arranged on the mounting seat; the grinding block is arranged on the grinding disc and is positioned on the outer side of the mounting seat; the grinding disc and the mounting seat surround a closed oil cavity; and the mounting seat is provided with an oil inlet channel and an oil outlet. When the lubricating structure of the polishing grinder works, oil is delivered to a position, which is in friction contact with the inner structure of the mounting seat, of the grinding disc through the oil inlet channel and is crushed into fine oil drops by the grinding disc rotating at high speed and the mounting seat, and the fine oil drops are thrown to various portions of the inside of the oil cavity; and the lubricating effect is high, the lubricating oil can circulate to the outside, the circumstance that the lubricating oil is always hidden in the oil cavity and gets dirty gradually is avoided, and abrasion of the grinding disc is reduced effectively.

Owner:GUANGDONG EDING IND

Cycloidal-pin wheel speed reducer easy to lubricate

InactiveCN108662132AImprove the lubrication effectGood transmission effectGear lubrication/coolingAgricultural engineeringFuel tank

The invention relates to the technical field of a cycloidal-pin wheel speed reducer and discloses a cycloidal-pin wheel speed reducer easy to lubricate. The cycloidal-pin wheel speed reducer easy to lubricate comprises a bottom plate; a vertical plate is fixedly arranged at the top of the bottom plate; a supporting base is fixedly arranged at the top of the bottom plate and positioned on the rightside of the vertical plate; a speed reducer body is fixedly arranged at the top of the supporting base; the top of the speed reducer body is communicated with an oil inlet pipe; the bottom of the speed reducer body is communicated with an oil outlet pipe; an oil storage box and a limiting plate are fixedly arranged on the right side of the vertical plate sequentially from top to bottom; and a connecting head communicated with the internal part of the oil storage box is fixedly arranged at the bottom of the oil storage box. The speed reducer provided by the technical scheme is provided with aspecial lubricating oil injection structure, so that automatic injection of the lubricating oil can be realized, external tools are not needed, the lubrication of the speed reducer is changed to be simple and convenient, the transmission property of the speed reducer is improved, and the service life of the speed reducer is prolonged.

Owner:淮安市华东减速机制造有限公司

An oil injection device for lubricating parts of CNC machine tools

ActiveCN111890121BAvoid dripping on the bottom surfaceAvoid slip and fall situationsMaintainance and safety accessoriesNumerical controlGear wheel

The invention relates to the technical field of numerically controlled machine tools, and discloses an oiling device for lubricating parts of numerically controlled machine tools, comprising a slide box, an oil tank is fixedly installed on the rear side of the slide box, and an oil outlet pipe is fixedly installed at the front end of the oil tank , the front end of the oil outlet pipe is equipped with a nozzle, the right side of the slide box is fixedly equipped with a positioning shaft, and the right end of the positioning shaft is movably connected with a driven gear. The invention sprays the lubricating oil in the oil tank downward through the oil outlet pipe through the nozzle, and the sprayed lubricating oil is absorbed by the brush tube. When the ball screw is lubricated, the sliding crate moves to the right, and the brush tube and the machine tool The surface of the ball screw is in contact with the upper ball screw, so that the surface of the ball screw is lubricated. It is not necessary to spray the lubricating oil directly on the ball screw to avoid the situation where the lubricating oil drips on the bottom surface and prevents the operator from slipping. situation, improving the safety of the device.

Owner:湖北山鹰注油器股份有限公司

Engine lubrication system and automobile

ActiveCN111636943BReduce energy consumptionShorten the flow distanceOilsumpsMachines/enginesOil intakeLubrication

The invention discloses an engine lubricating system and an automobile, belonging to the technical field of automobile engines. It includes oil pan, oil pump, oil filter and oil cooler. The oil pan has an oil storage cavity, and the side wall of the oil pan has connecting holes. The oil pump is fixed in the oil storage cavity. The first part of the oil pump The oil inlet is connected with the oil storage chamber, the oil outlet of the oil pump is connected with the connection hole; the oil filter is fixedly connected to the side wall of the oil pan, the inlet of the oil filter is connected with the connection hole, and the oil filter The outlet of the device is connected to the oil cooler. The lubricating system can reduce the energy consumption of the lubricating system and reduce the lubricating cost.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com