Grease lubrication bearing system

A grease lubrication and bearing technology, applied in the field of grease lubricated bearing systems, can solve the problems of reducing the service life of the bearing structure, damaging the bearing structure, and deteriorating the grease, so as to reduce the cost of lubrication, reduce the wear particles, and restore the characteristics of the grease.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

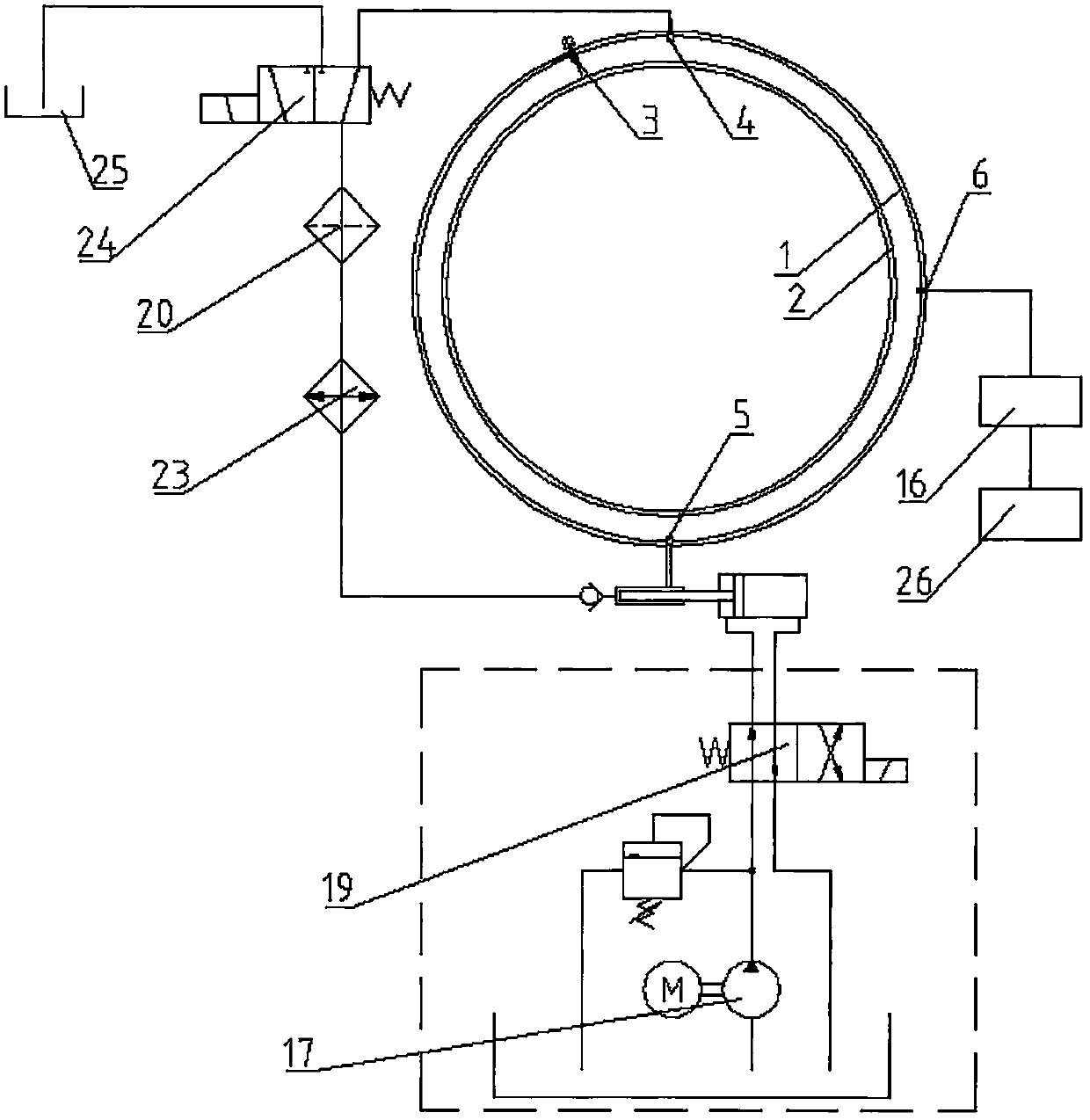

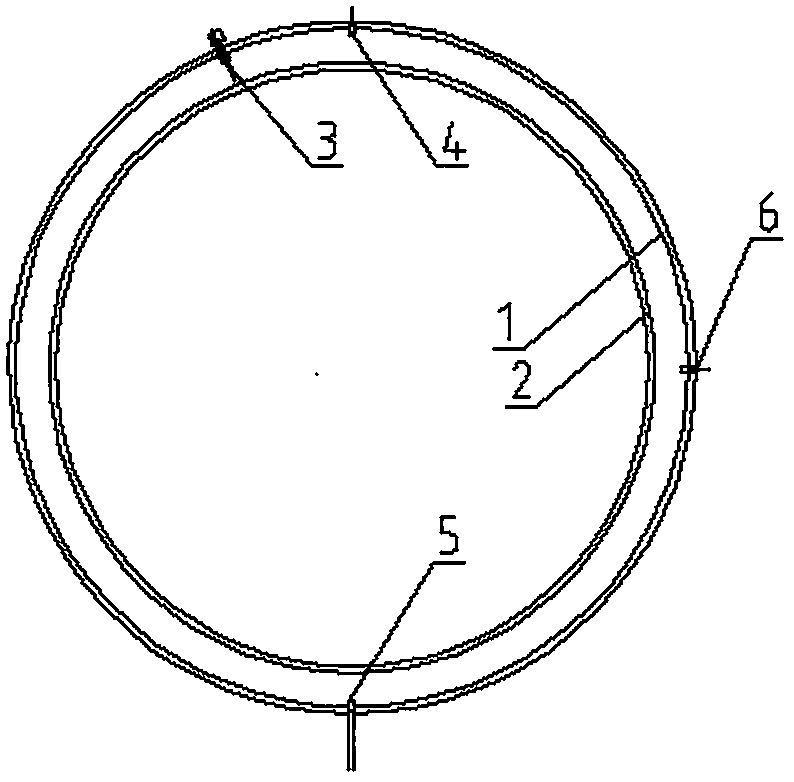

[0023] Embodiment 1 of a grease lubricated bearing system, in figure 1 , figure 2 and image 3 Among them, the bearing structure in this embodiment is a sliding bearing without rolling elements. The outer ring 1, the inner ring 2 and the oil seals at both ends form a lubricating space, and the lubricating space is used for setting lubricating oil. An oil injection hole 4, an oil discharge hole 5 and a breathing port 3 are opened on the outer ring 1 of the bearing structure, and the oil filling hole 4, the oil discharge hole 5 and the breathing port 3 are all in communication with the lubricating space. An air filter device is arranged on the breathing port 3 .

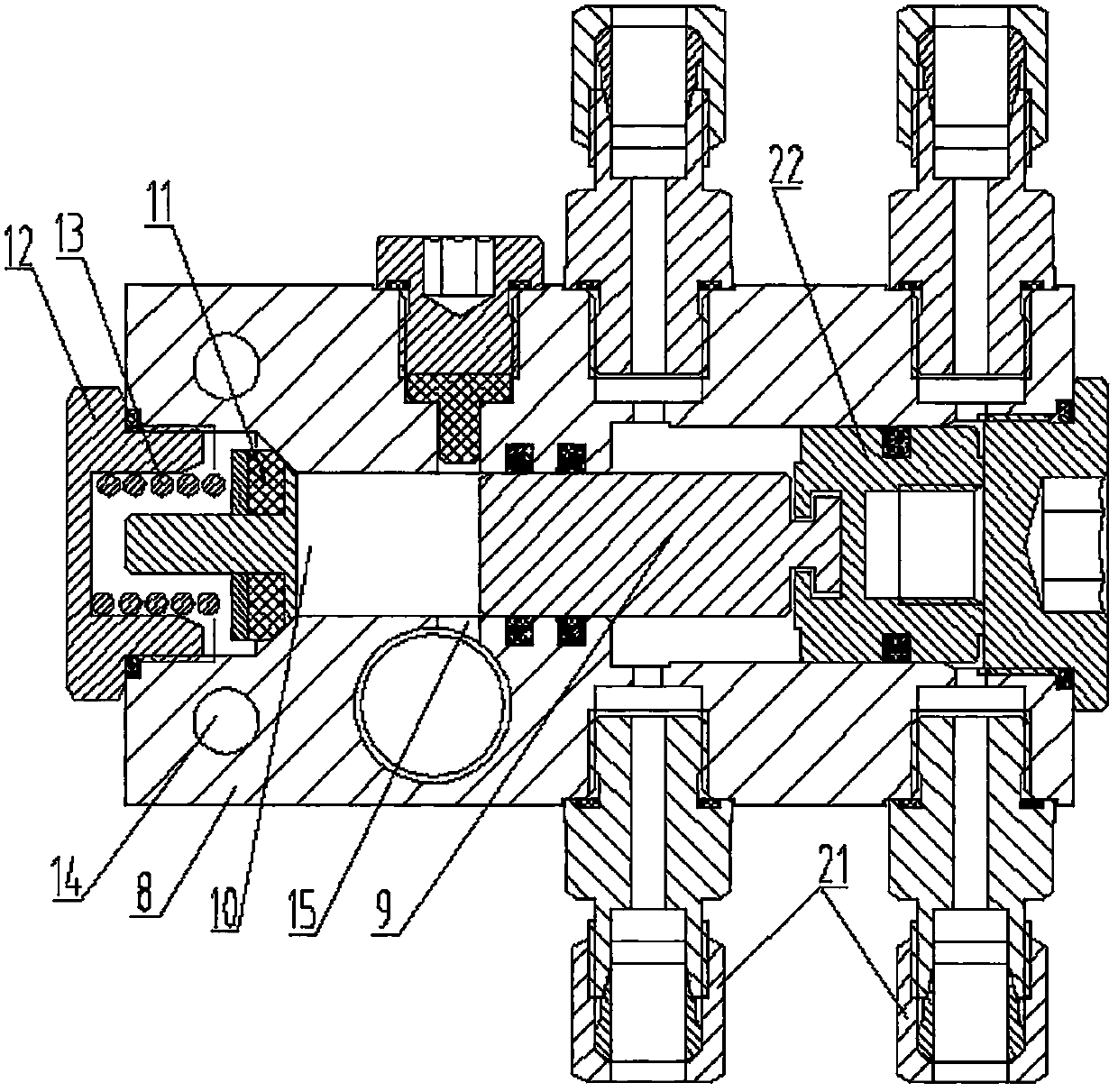

[0024] On the oil discharge hole 5, a grease circulation drive device is communicated with, and the grease circulation drive device here is a grease sucker 7, such as image 3 As shown, the liposuction device 7 has a housing 8, one end of the inner chamber of the housing 8 is sealed and slidably provided with a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com