Patents

Literature

1136results about "Lubrication check valves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

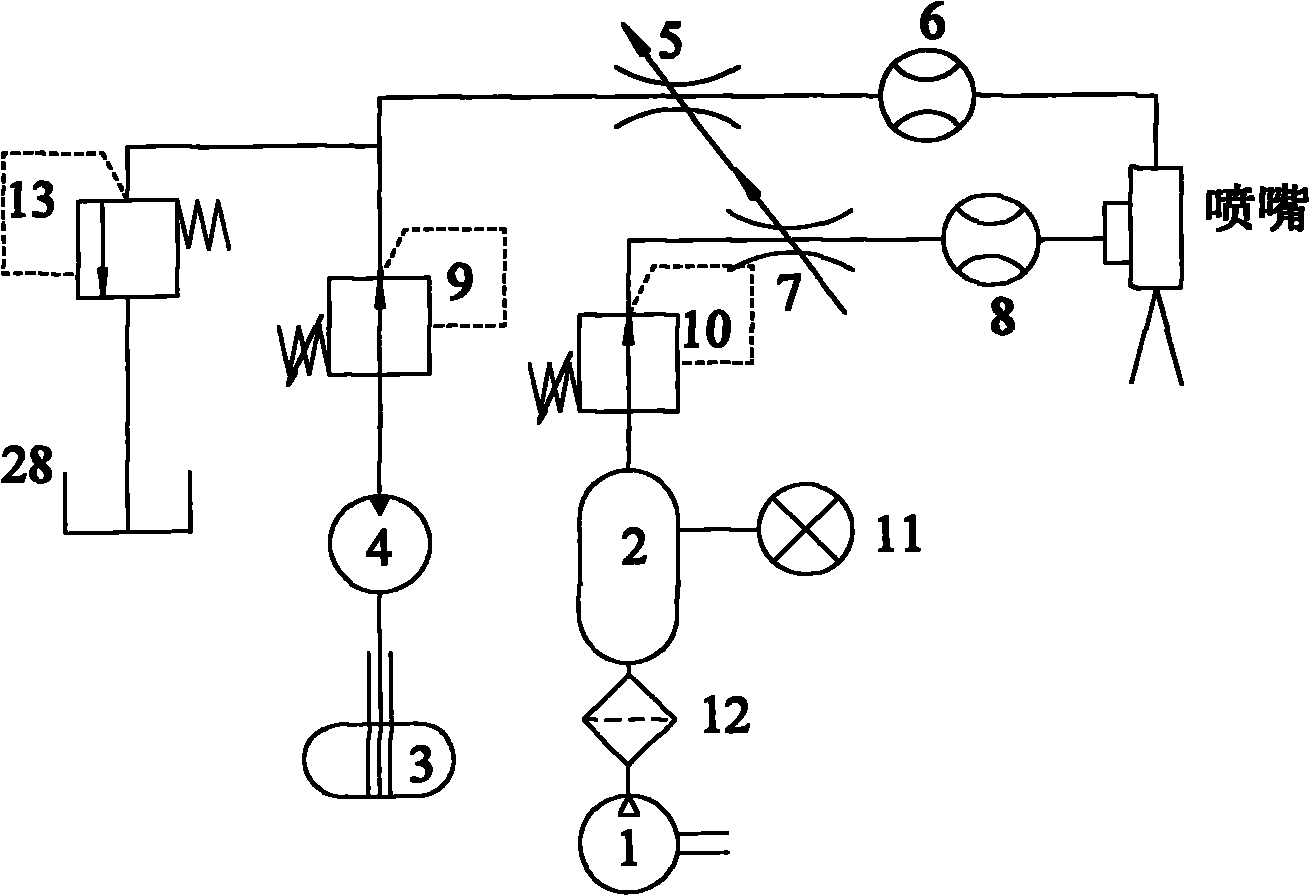

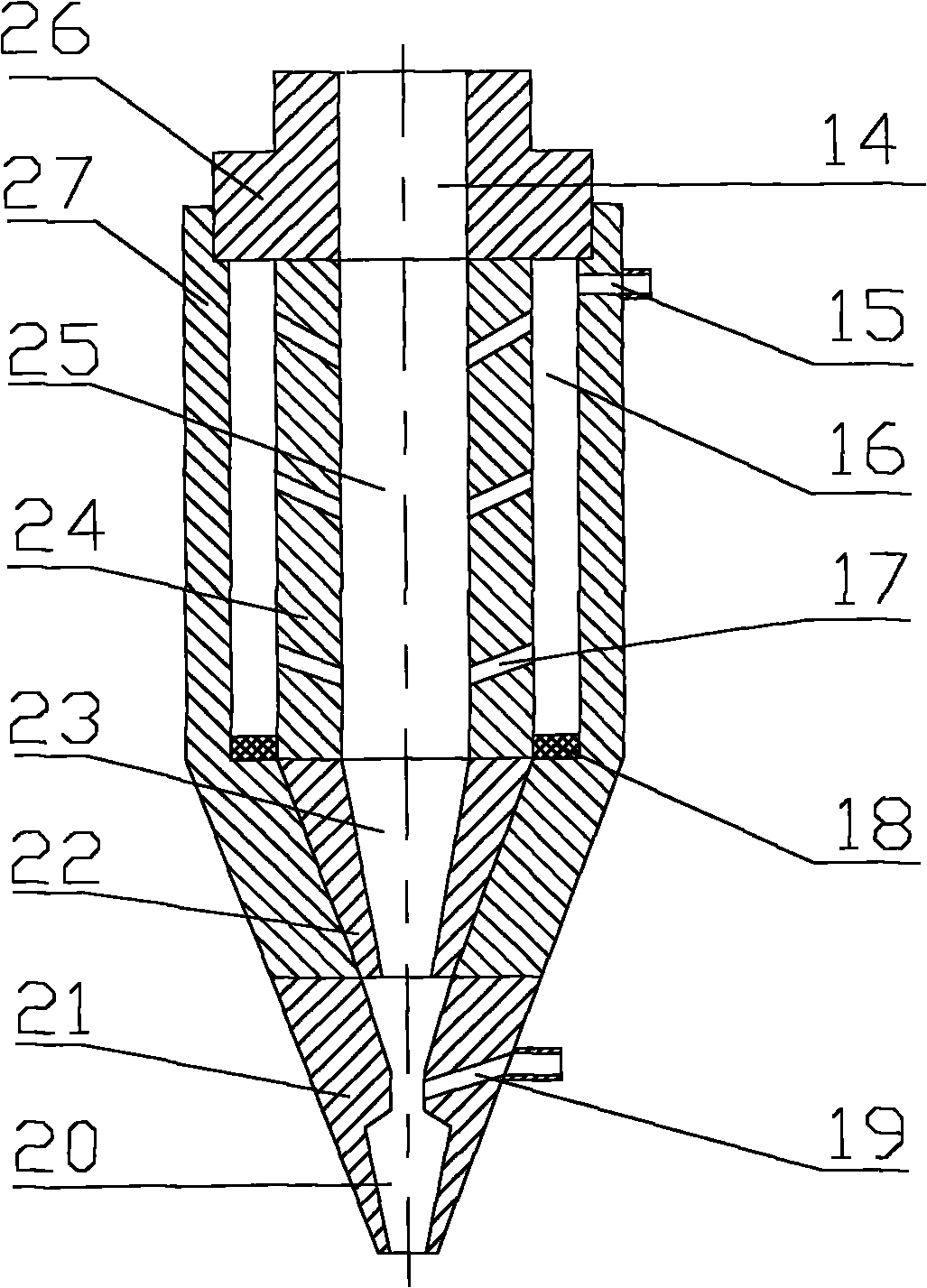

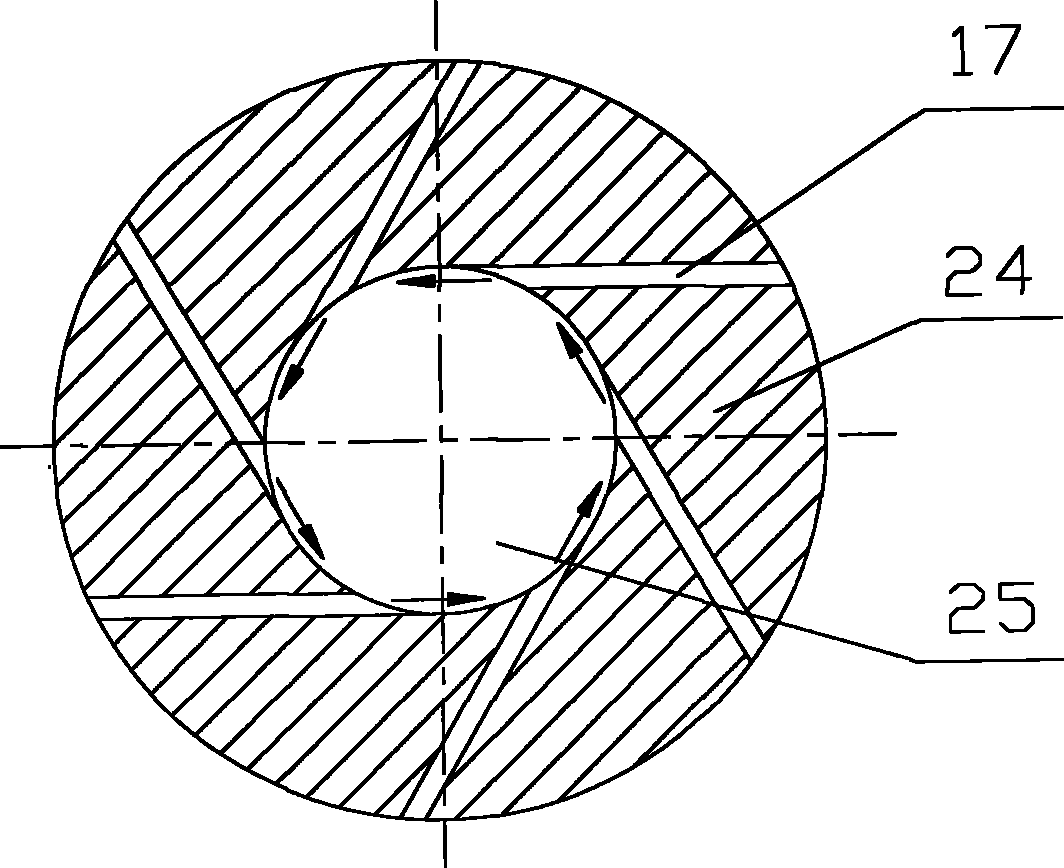

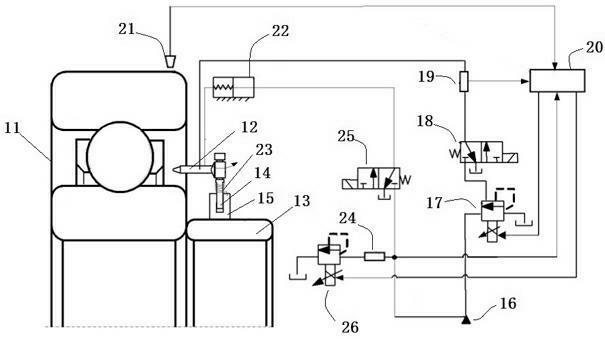

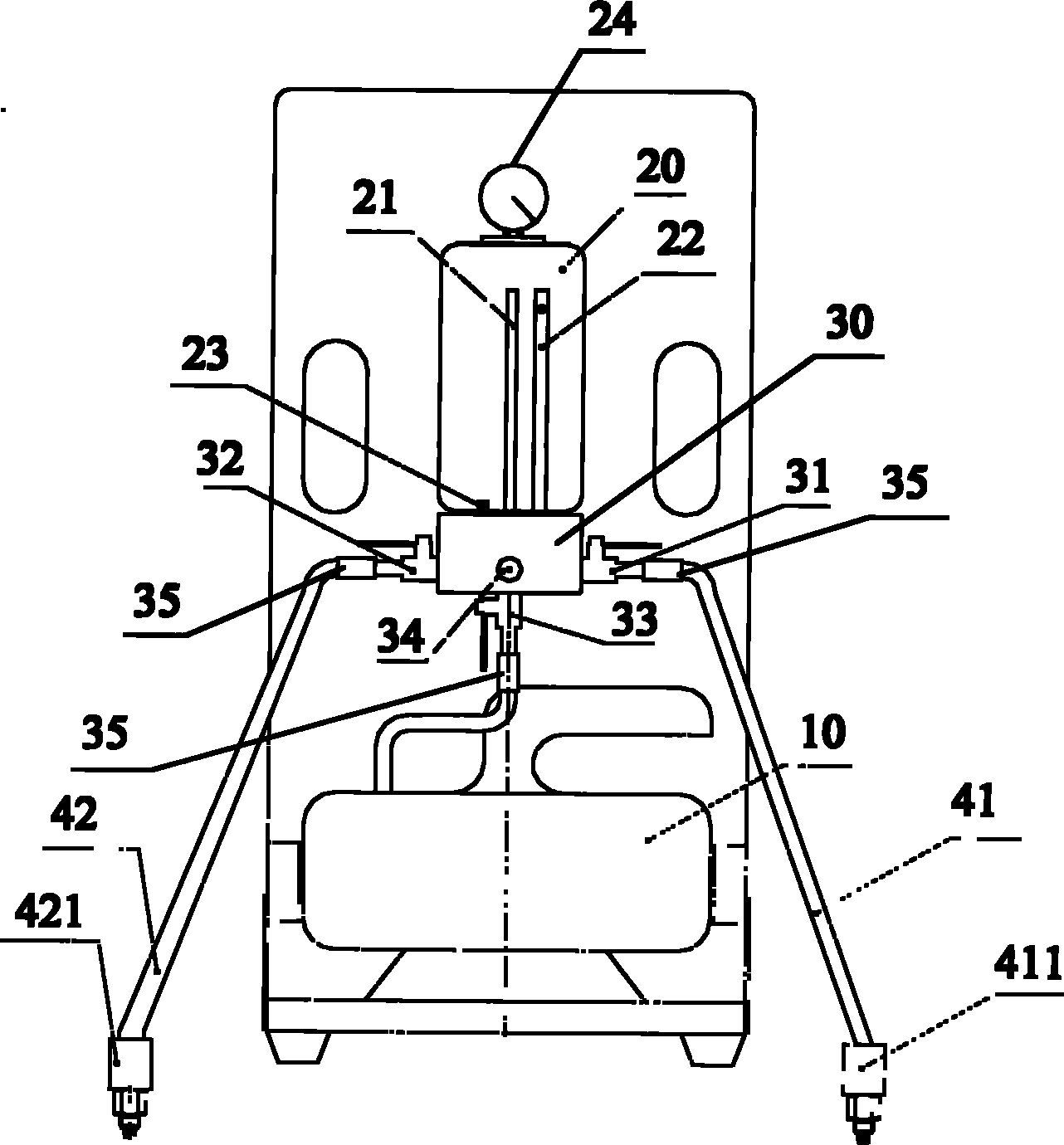

Three-phase flow supply system for nanoparticle jet micro-lubrication grinding

ActiveCN102287606AWell mixedIncrease the diameterConduits/junctionsLubrication check valvesEngineeringHigh pressure

The invention relates to the field of machining, in particular to a nano particle jet flow micro-scale lubricating and grinding three-phase flow supply system. The system is characterized in that: nano fluid is conveyed to a nozzle by a liquid path, high temperature gas enters the nozzle through a gas path at the same time, the high pressure gas and the nano fluid are fully mixed and atomized in the mixing room of the nozzle, the mixed high pressure gas and nano fluid are accelerated in an acceleration room and enter a vortex room, compressed gas enters from the vent hole of the vortex room, and a three-phase flow is further mixed and accelerated by rotating, and is jetted in the form of atomized liquid drops to a grinding area through the outlet of the nozzle. The system has the advantages that: the helical vent hole of the mixing room of the nozzle is tangent to the wall surface of the mixing room, and the nano fluid and the gas are uniformly mixed; pressure adjusting valves, throttles and flow meters are arranged in the gas path and the liquid path, and the pressure and the flow of the nano fluid and the high pressure gas can be adjusted as required so as to achieve an optimal micro-scale lubricating effect; and the problems of insufficient cooling capability in micro-scale lubricating, the large using quantity of a lubricant in pouring type grinding, high waste liquid processing cost and heavy environment pollution are solved.

Owner:青岛前瞻产业园区运营管理有限公司

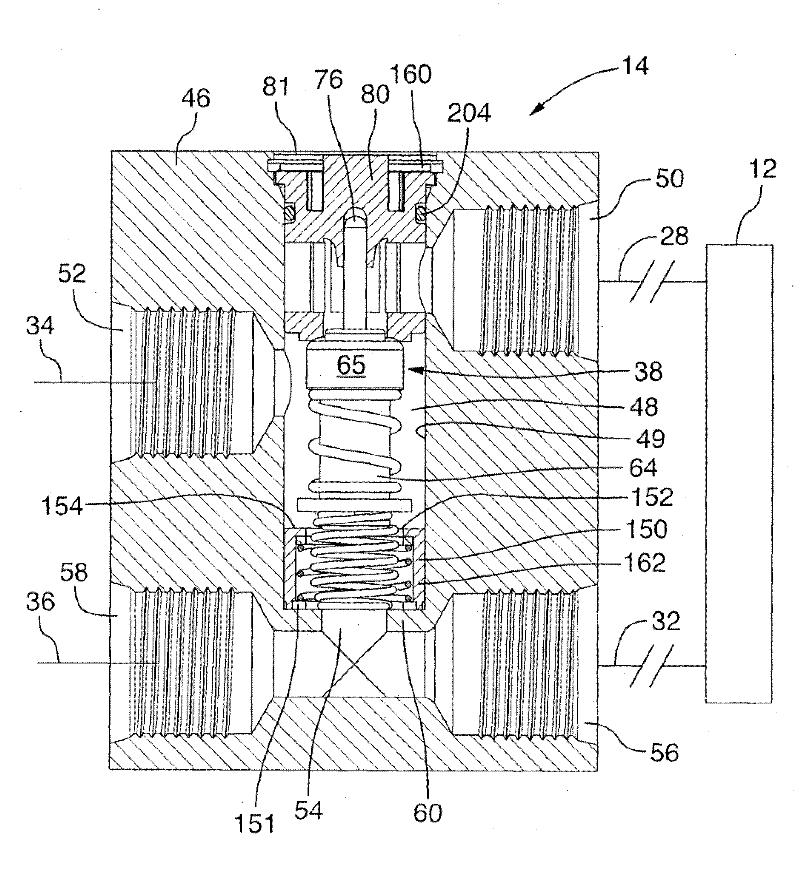

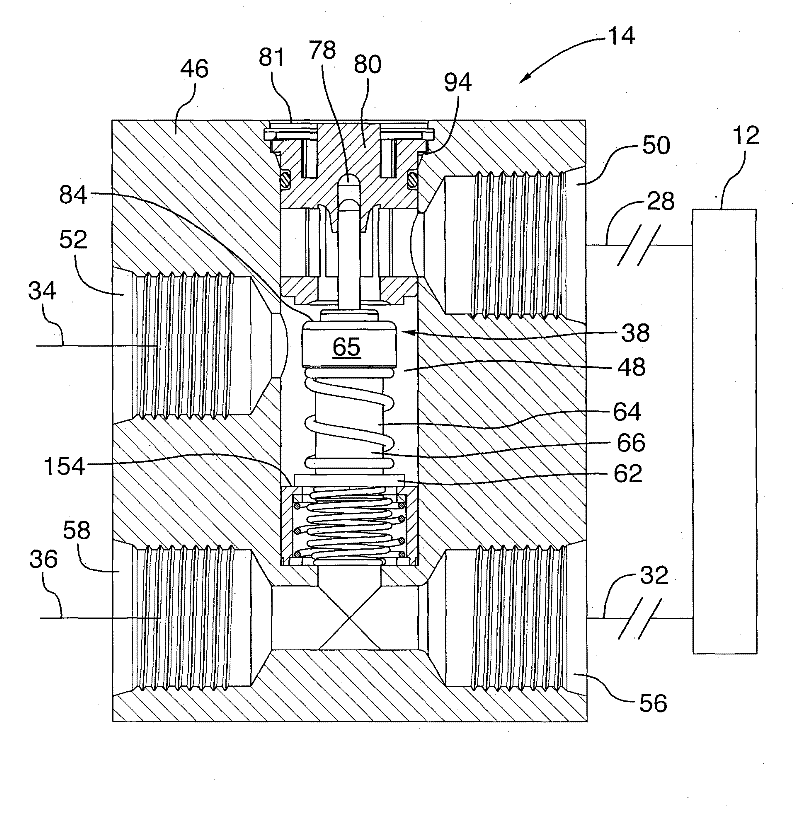

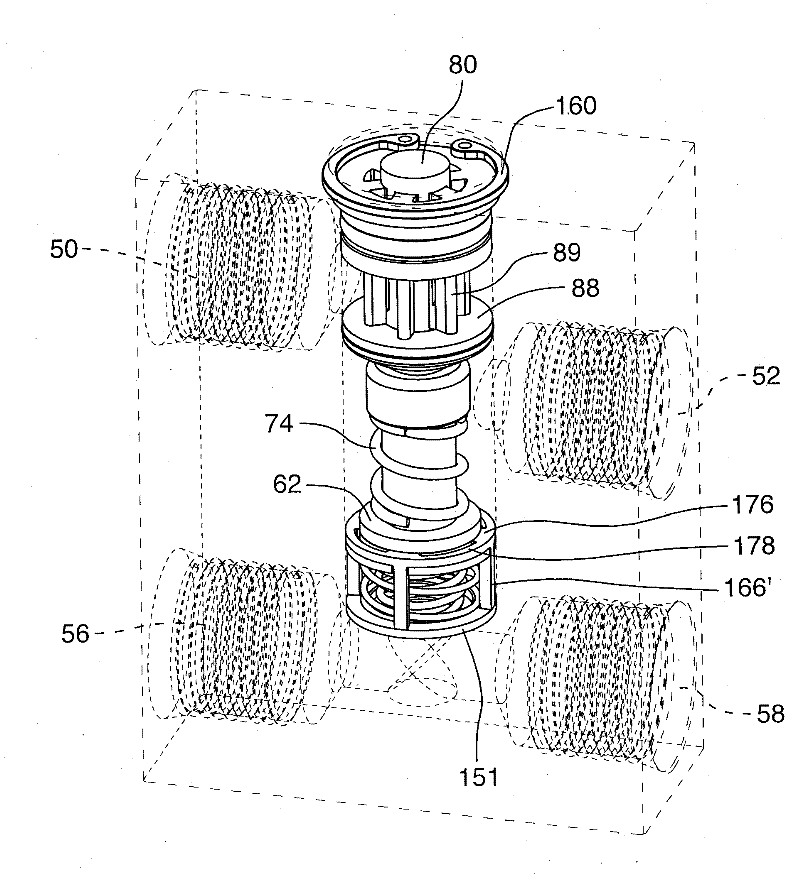

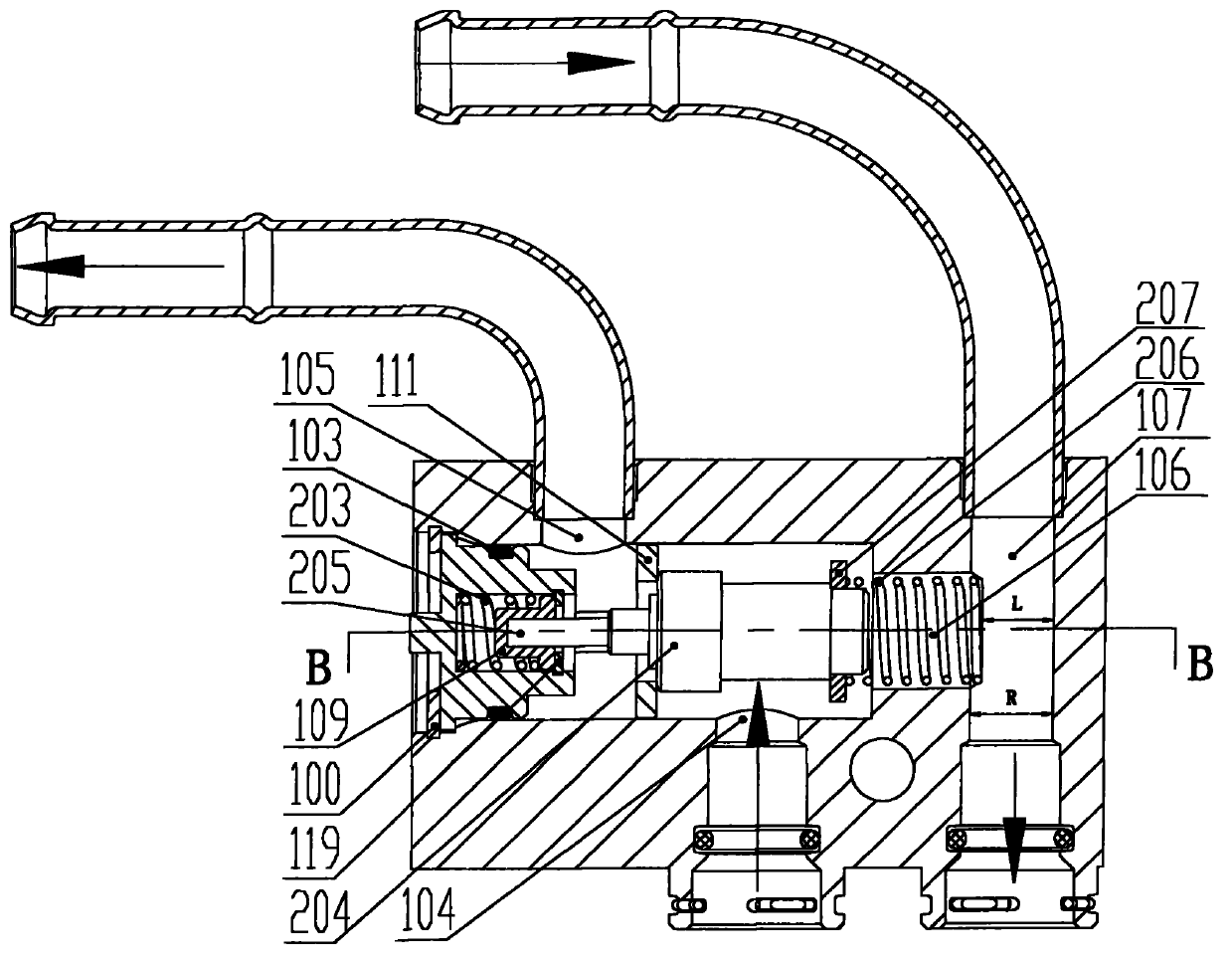

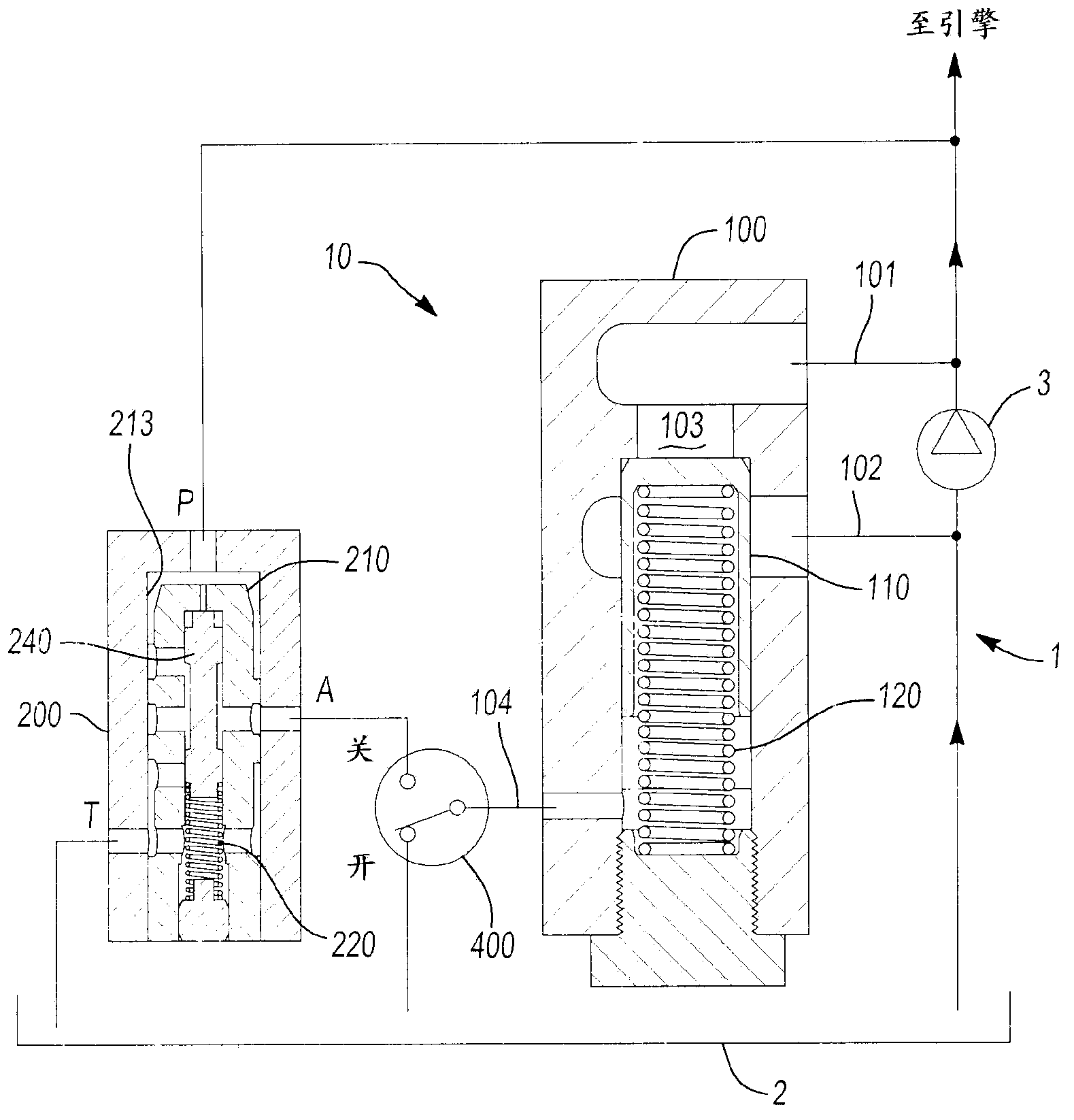

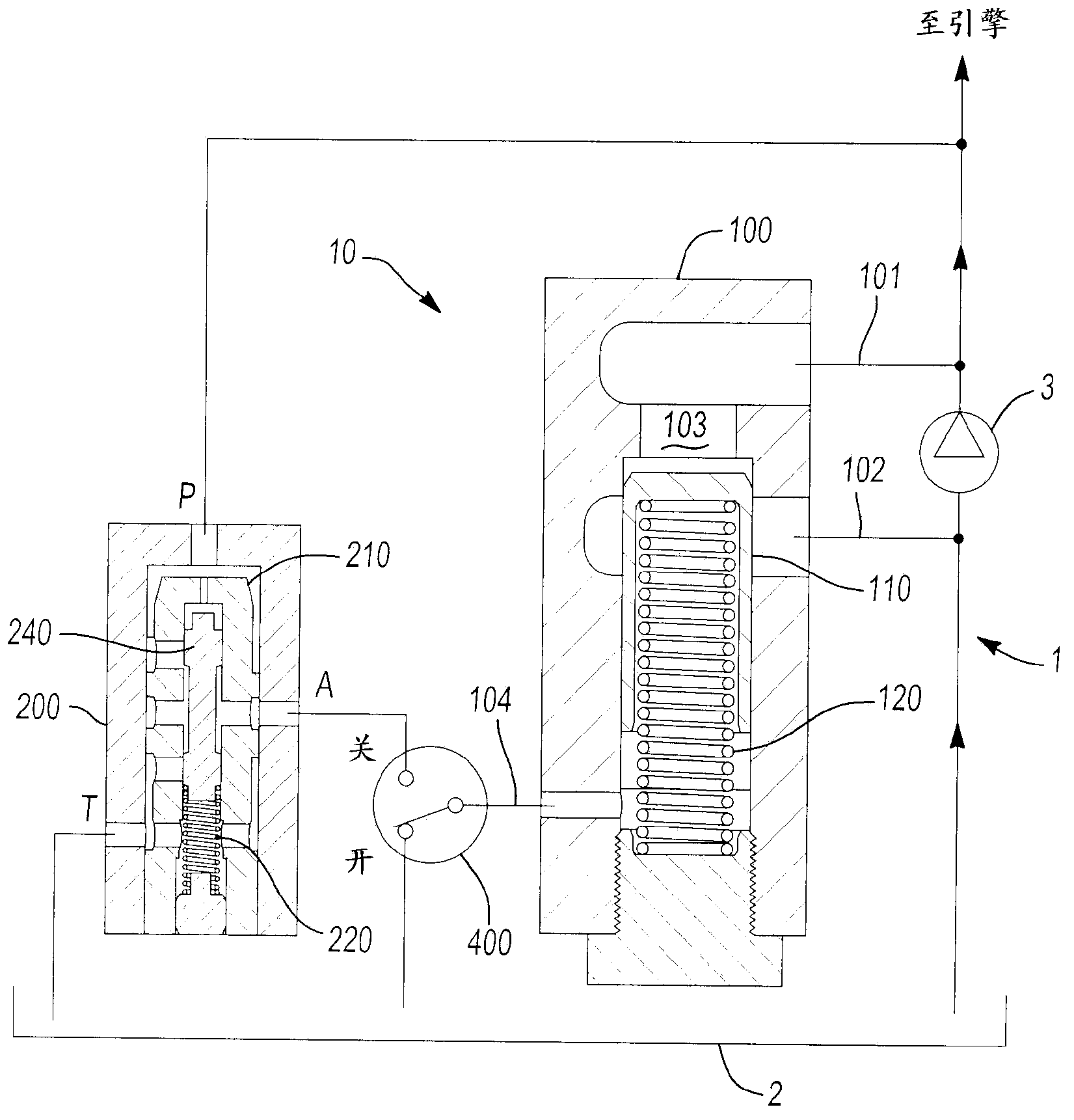

Thermal by-pass valve with pressure relief capability

ActiveCN102224367AOperating means/releasing devices for valvesCoolant flow controlActuatorValve seat

A by-pass valve for a heat exchanger circuit that includes a cooler (12) has a chamber (48) and ports for flow of fluid into and out of this chamber. A thermally sensitive actuator (64) is mounted in the chamber and can extend or retract in dependence on its body temperature as influenced by temperature of the fluid. A by-pass valve seat (154) is arranged in a valve housing along with a by-pass valve member (62) movable by the actuator into or out of engagement with the seat. A relief valve is mounted in the chamber and has a relief valve member (210) movable between closed and open positionsin order to close or open pressure relief ports. This relief valve member is biased towards the closed position. Excessive pressure build up in an end section of the chamber causes the relief valve member to move to its open position.

Owner:DANA CANADA CORP

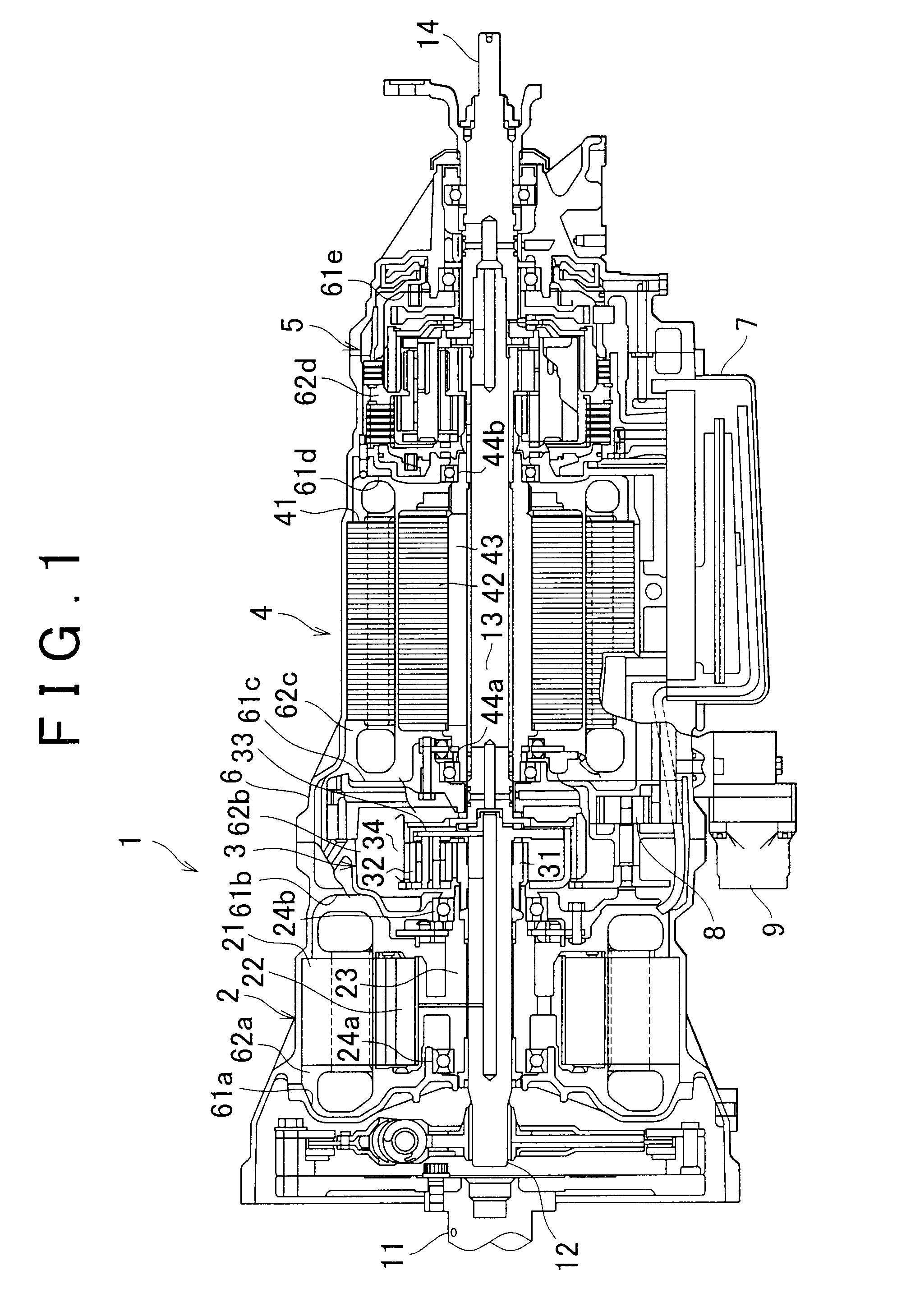

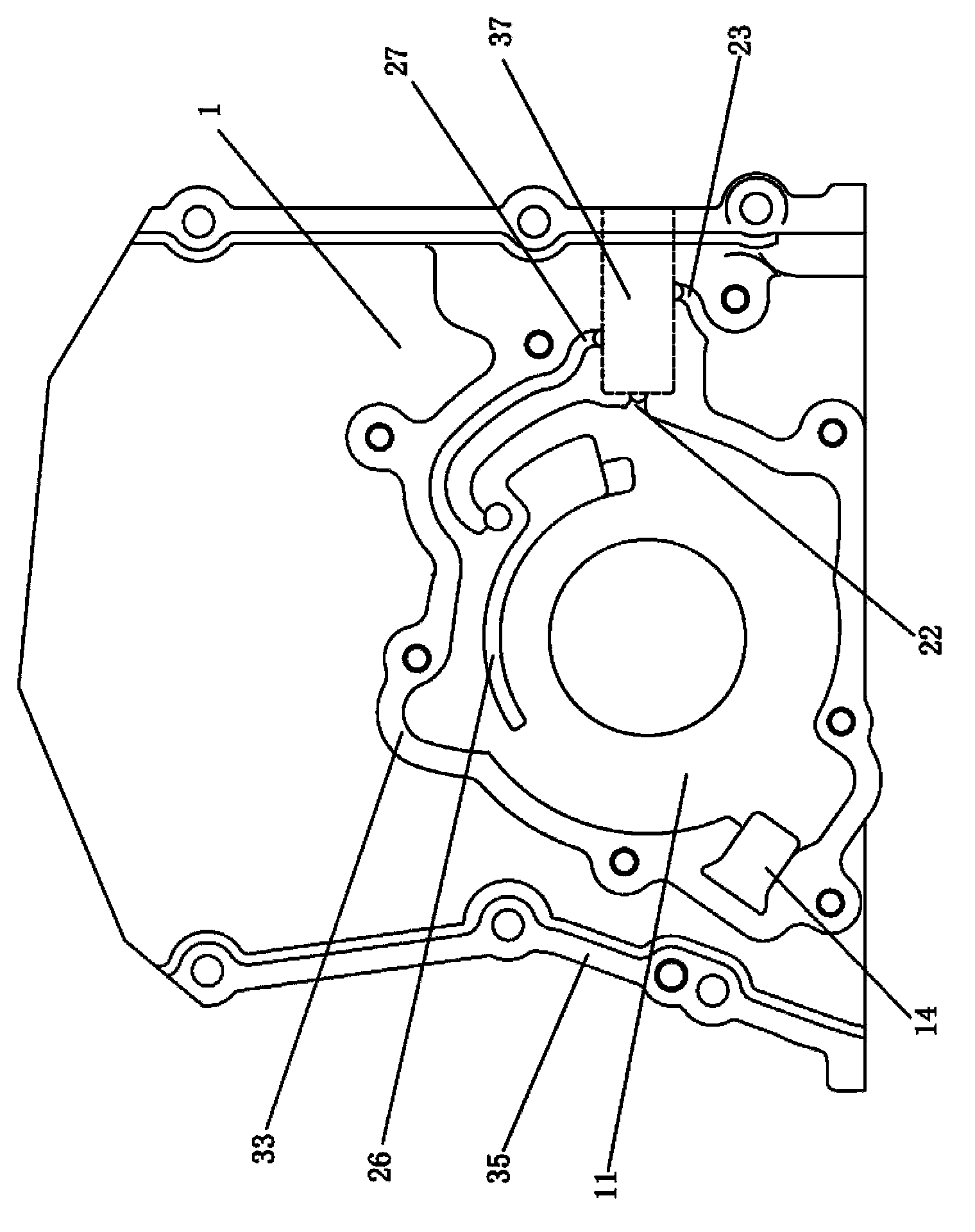

Oil lubricating structure

An oil lubricating structure includes a main body case having a housing chamber in which an element requiring a supply of oil is housed, an oil reservoir which is provided below the main body case and has an oil chamber in which oil collects, an oil supply portion which has an inlet port through which oil is drawn in from the oil chamber and which supplies oil collected in the oil chamber to the element requiring a supply of oil through the inlet port, and a duct member provided in the oil chamber. An oil return hole is provided which is formed in a bottom surface of the main body case toward the front of the oil reservoir and through which oil returns to the oil reservoir from the main body case. One end portion of the duct member is connected to the oil return hole and the other end portion of the duct member is positioned farther to the rear than the inlet port.

Owner:TOYOTA JIDOSHA KK +1

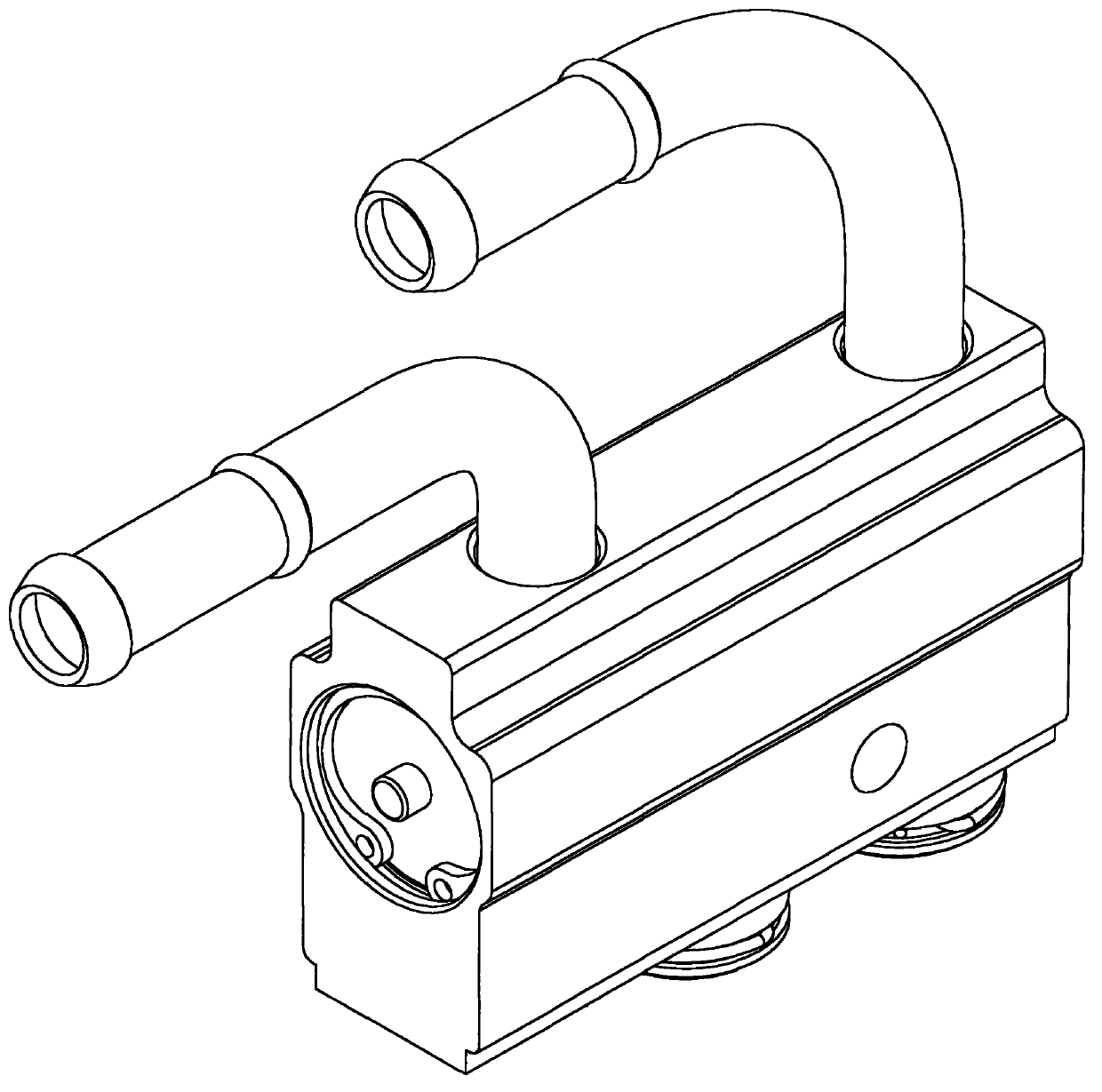

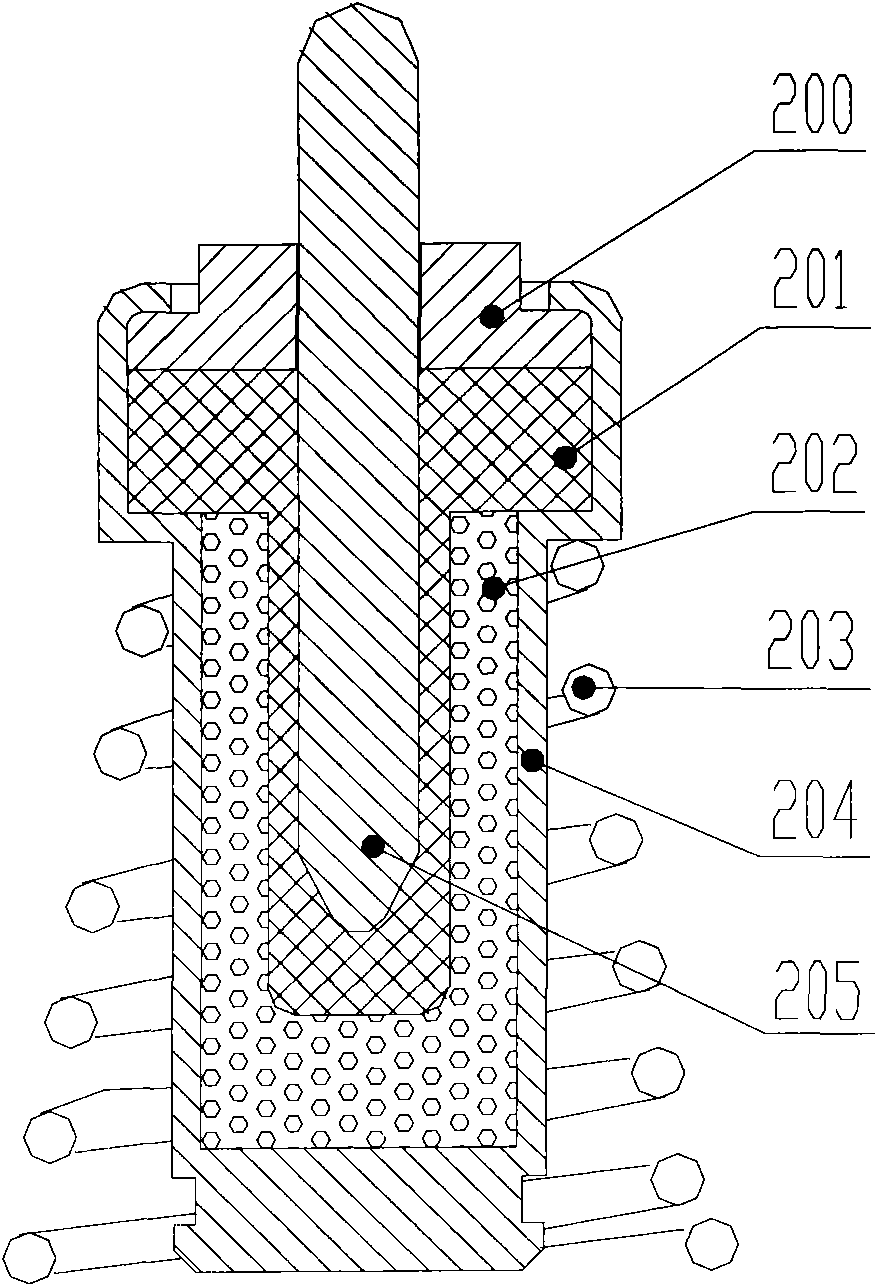

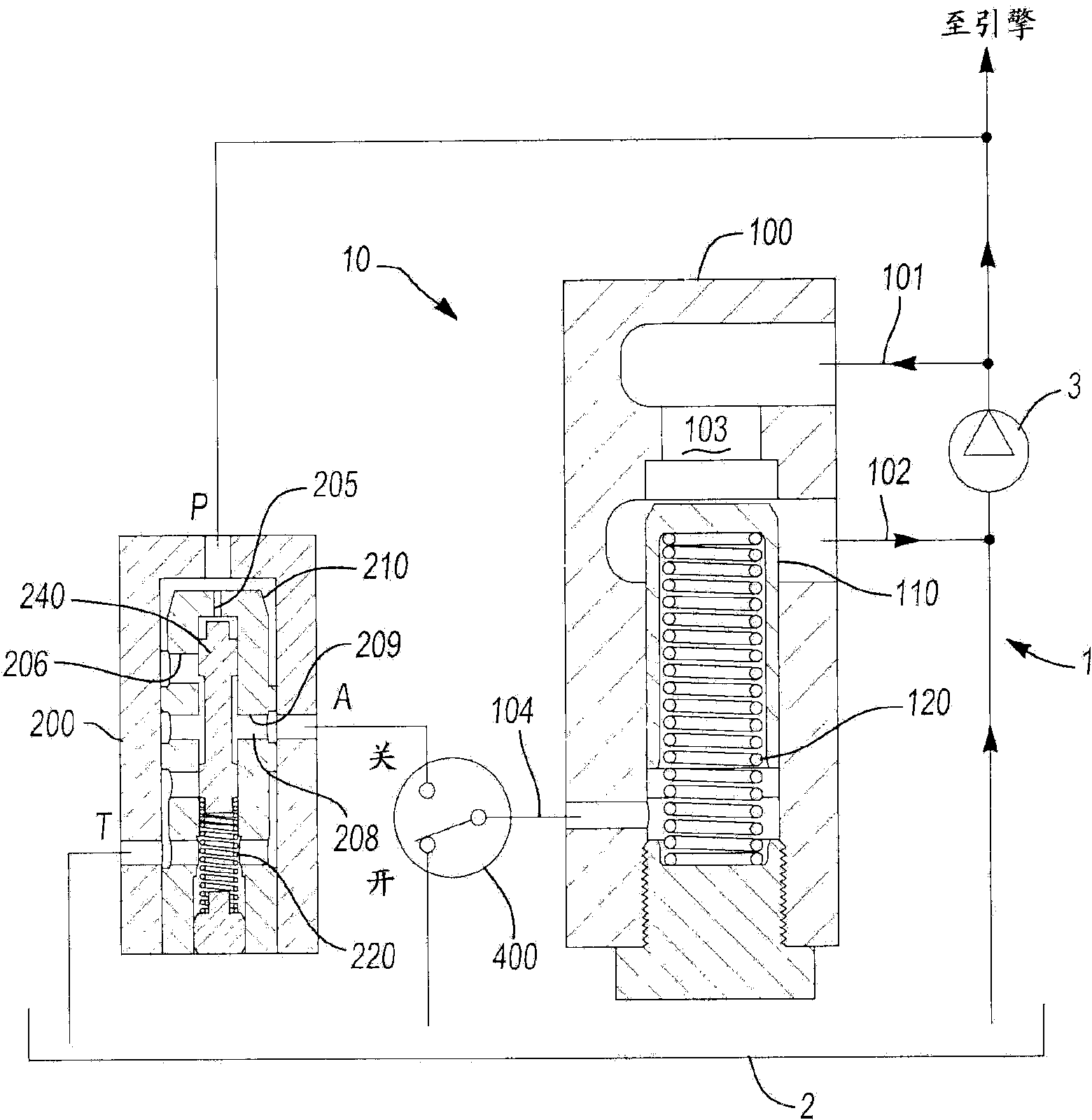

Temperature regulator

ActiveCN103867692APrevent leakageReduce leakageOperating means/releasing devices for valvesGear lubrication/coolingElastic componentHeat sensitive

The invention relates to a temperature regulator. The temperature regulator comprises a valve body and a thermodynamic element, wherein a cavity is formed in the valve body, and the thermodynamic element is mounted in the cavity; the cavity is communicated with the outside through at least three valve ports, namely a first valve port, a second valve port and a third valve port, the two ends of the thermodynamic element are respectively mounted in the valve body through elastic components, a flow cutoff ring which is of an annular component is mounted in the cavity in a sealed and fixed manner, and a thermodynamic element body is located between the third valve port and the flow cutoff ring. When the temperature of fluid is relatively low, a heat-sensitive material in the thermodynamic element contracts, and the thermodynamic element body moves towards the flow cutoff ring and closes an internal hole of the flow cutoff ring; when the temperature of the fluid is relatively high, the heat-sensitive material in the thermodynamic element expands, and the thermodynamic element body moves towards the third valve port until the third valve port is closed by the thermodynamic element body. The temperature regulator provided by the invention has the advantage that the internal leakage of temperature regulators in the prior art is lowered greatly.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

Temperature regulator

InactiveCN103851169ASmall processing depthEasy to processGear lubrication/coolingValve housingsEngineeringMachining

The invention relates to a temperature regulator. The temperature regulator comprises a valve body provided with an inner cavity, wherein a thermodynamic element is arranged in the inner cavity; the inner cavity of the valve body is a through hole; at least three internal connectors which are respectively communicated with the inner cavity are also formed in the valve body; the inner cavity is divided into two independent spaces by a sealing piece; the two independent spaces are respectively communicated with the two external connectors to form two flow channels which are isolated from each other. According to the temperature regulator disclosed by the invention, the inner cavity of the valve body is the through hole, the valve body can be machined from the two ends respectively, the machining depth is small, the machining is facilitated, and moreover, the manufacturing cost is low.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

Lubricant reservoir refilling system with shut-off

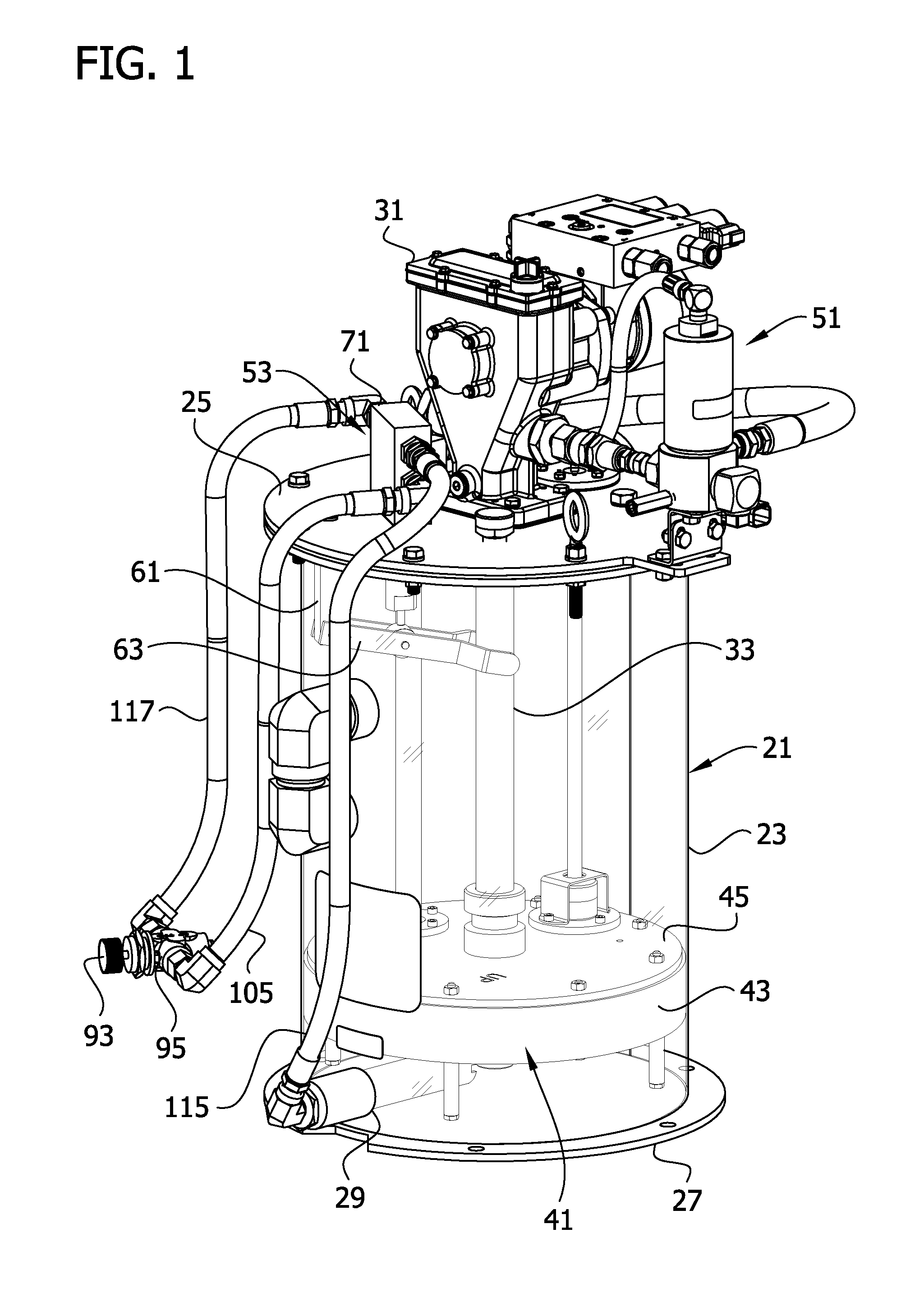

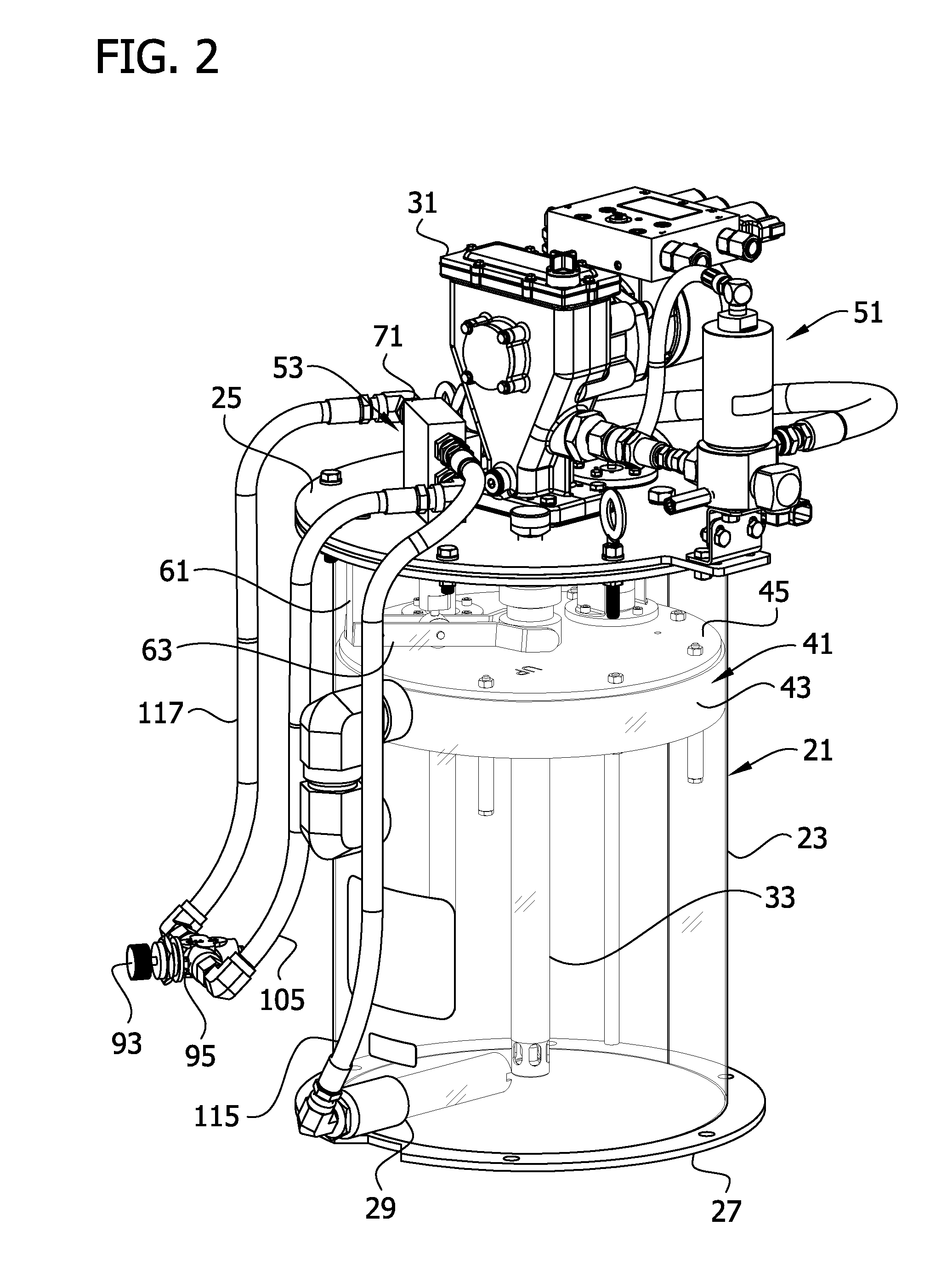

InactiveUS20130256062A1Hinder lubricant from flowingAvoid flowOperating means/releasing devices for valvesLubricant transferLiquid tankEngineering

A lubricant reservoir system. The system includes a reservoir for containing lubricant. The reservoir has a top, a bottom, a peripheral wall, and an inlet for delivering lubricant to the reservoir from a supply. The system also includes a follower in the reservoir slidingly and sealingly engaging the peripheral wall of the reservoir, the follower moving up and down in the reservoir in response to a changing level of lubricant in the reservoir. The lubricant reservoir system has a shut-off valve in fluid communication with the inlet for selectively preventing lubricant flow through the inlet. The valve is operatively connected to the follower for closing the valve and preventing lubricant flow through the inlet when lubricant in the reservoir reaches a predetermined level.

Owner:LINCOLN INDUSTRIES CORP

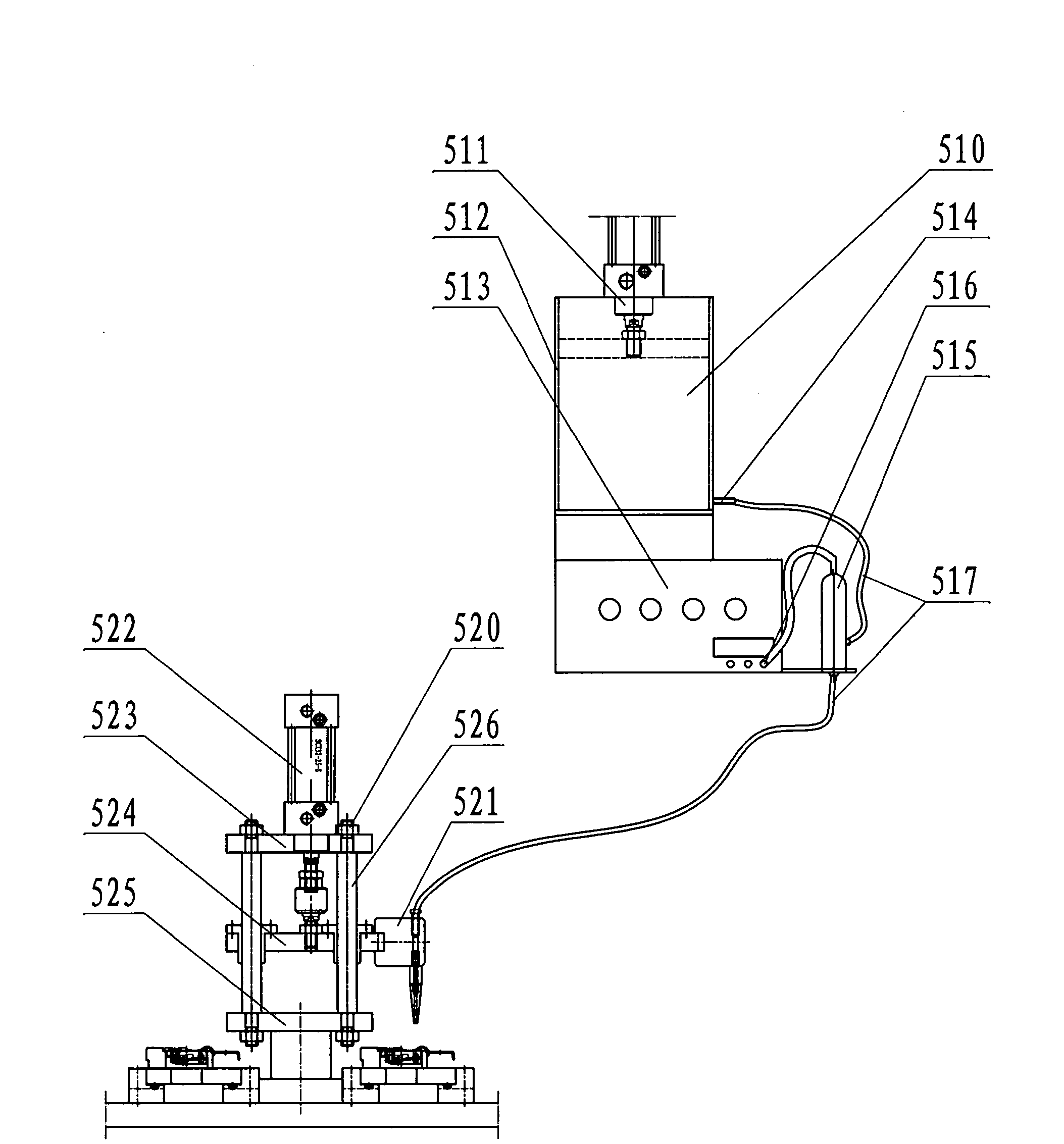

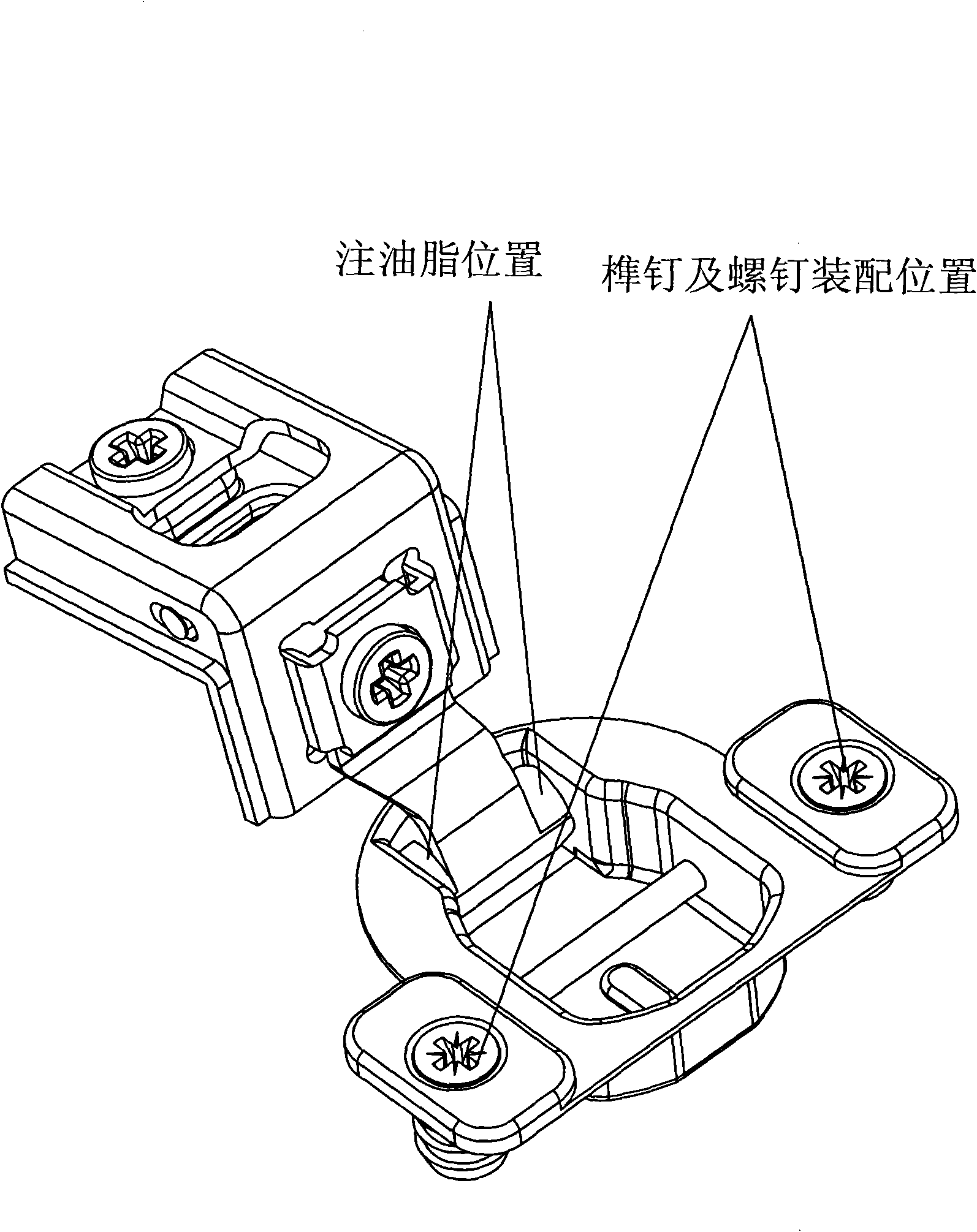

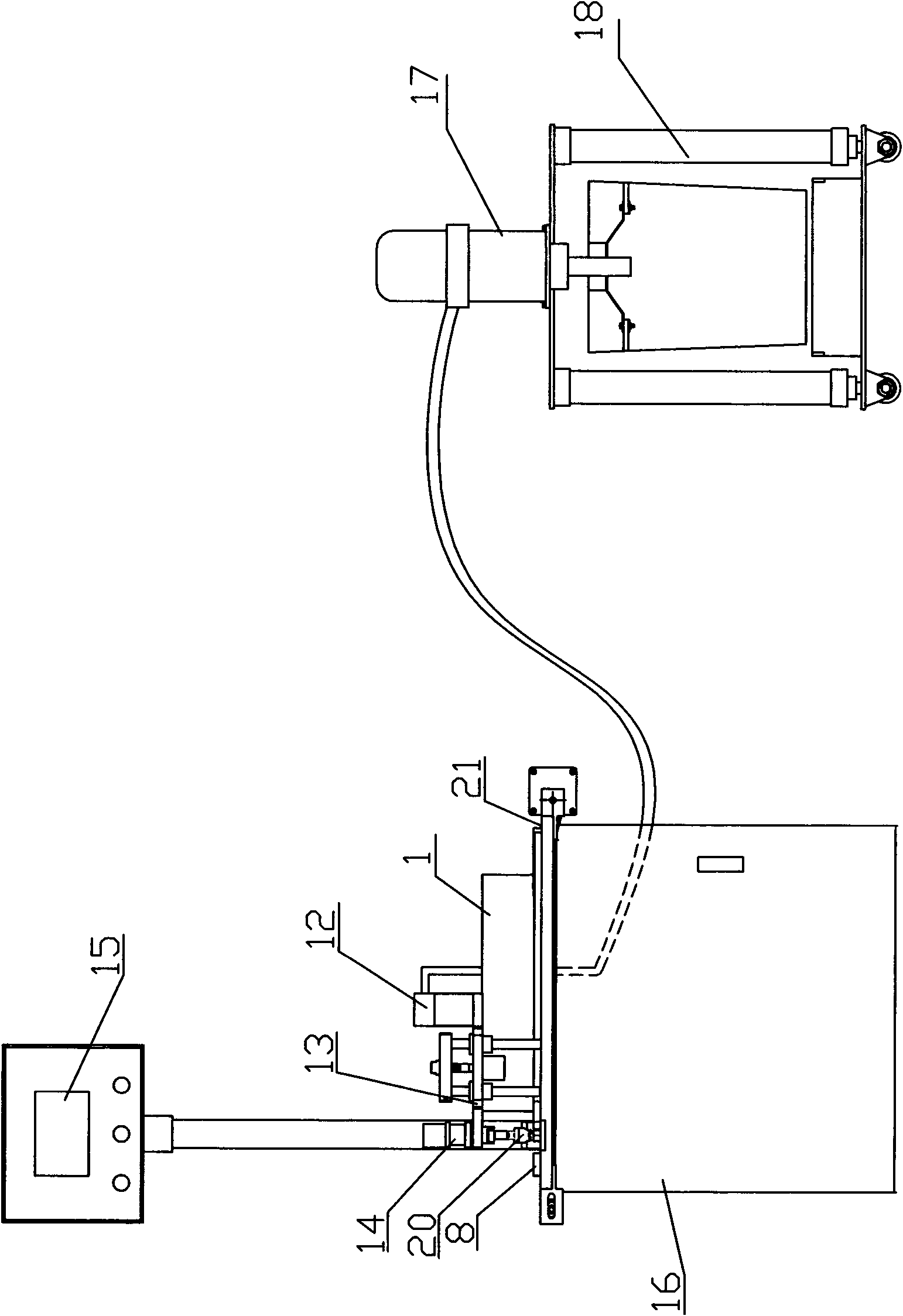

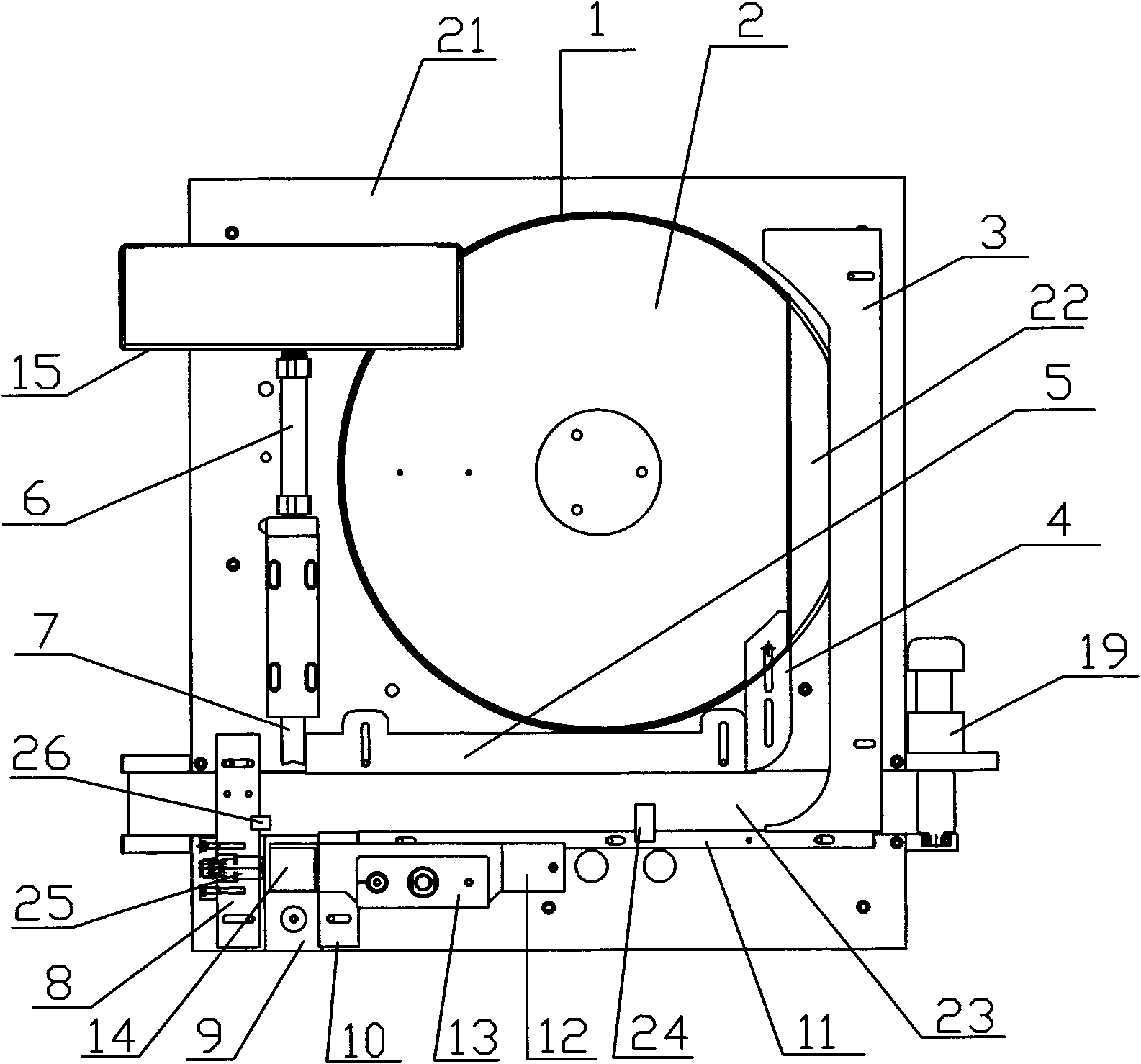

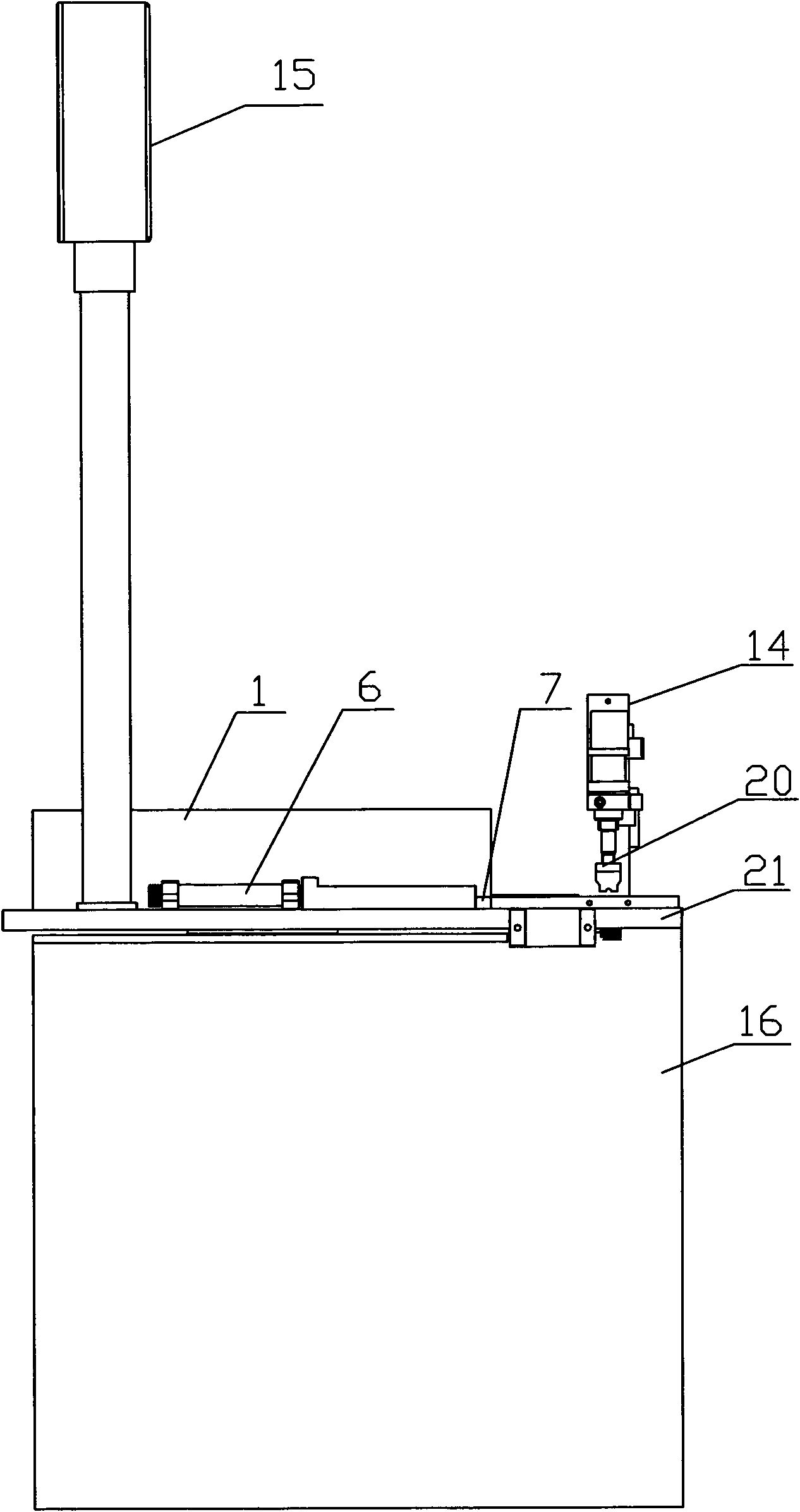

Automatic assembly equipment for hinge pre-installed tenon and oil injection process

InactiveCN102267047ARealize fully automatic assemblyImprove assembly productivityProportioning devicesLubricating pumpsSequence controlQuality assurance

The invention adopts the dowel pressing process, presses the metal screw into the center hole of the plastic dowel, the outer diameter of the screw is slightly larger than the diameter of the center hole of the dowel, and utilizes the elastic deformation and plastic deformation of the plastic dowel to make the screw and the dowel Tightly combined, so that it is firmly fixed on the fixed pocket of the hinge, and at the same time, the quantitative oil injection process is adopted to automatically inject the lubricating grease into the lubricating point quantitatively. The automatic assembly equipment of the present invention includes a dowel grasping mechanism, a dowel vibrating feeding mechanism, a dowel pre-installing mechanism, a screw vibrating feeding mechanism, a grease injection mechanism, a movable clamp cycle stepping and carrying mechanism and a microcomputer control system. Action sequence is controlled by microcomputer control system. The invention realizes the fully automatic assembly of dowel pre-installation and oil injection process, improves the assembly production efficiency and ensures the assembly quality.

Owner:GUANGDONG SACA PRECISION MFG CO LTD

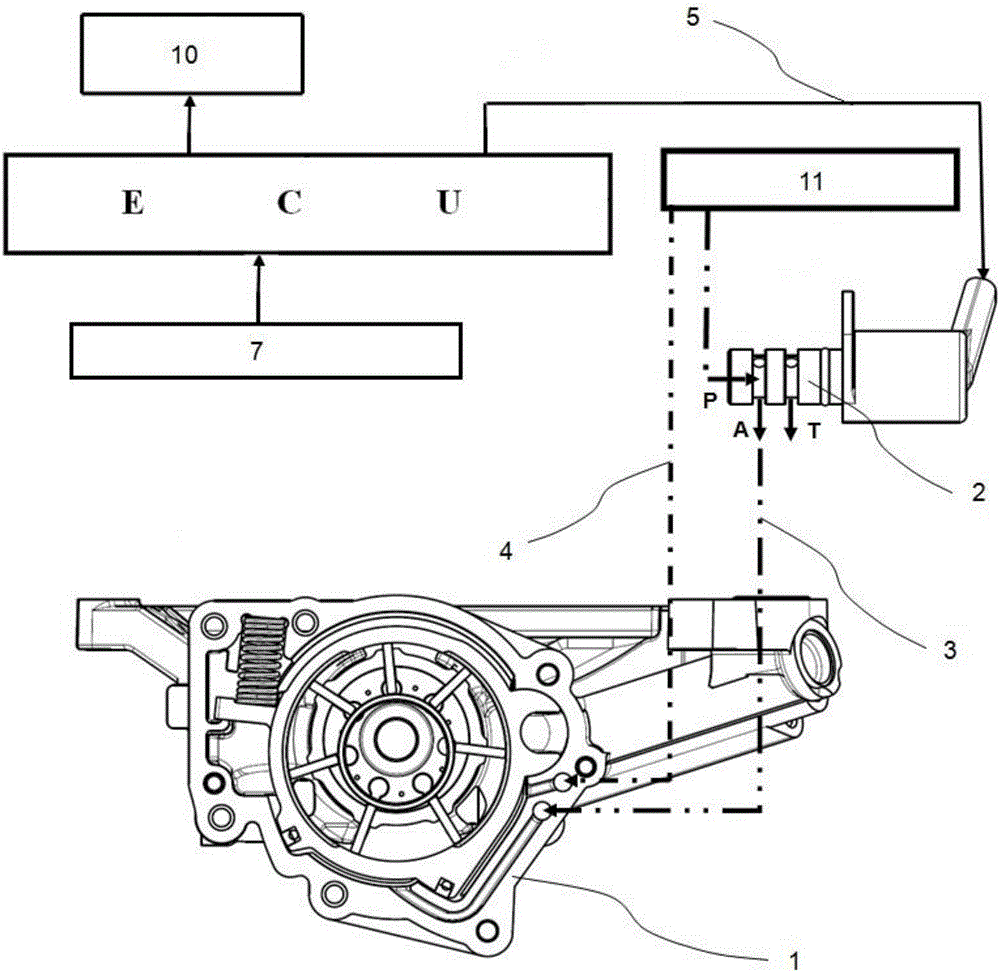

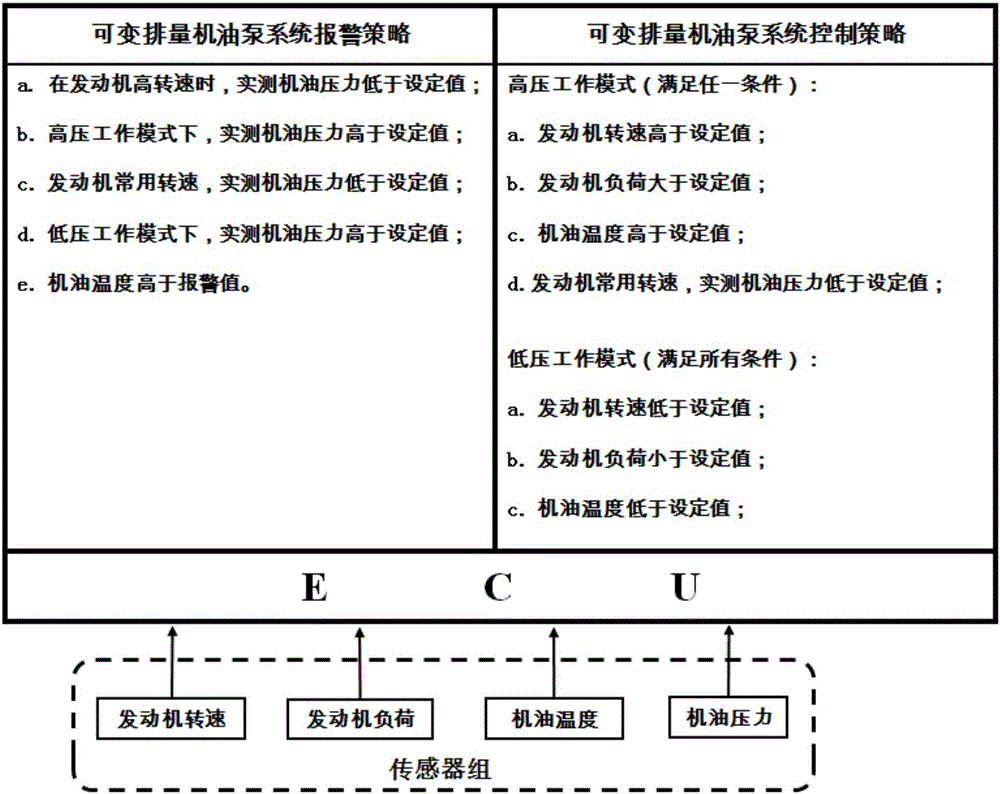

Variable displacement oil pump control system and control method thereof

InactiveCN106567755ADisplacement intelligent adjustmentSolve the problem of high fuel consumption due to excess oil pump capacityEngine loadEngine revolutionsControl signalControl system

The invention provides a variable displacement oil pump control system and a control method thereof. A first feedback oil duct and a second feedback oil duct of the control system are both connected between a main oil duct and a variable displacement oil pump. An electromagnetic valve is installed on the first feedback oil duct and is connected with an ECU through a wiring harness. A sensor set is in signal connection with the ECU. The ECU receives detection signals of the sensor set, control signals are sent to the electromagnetic valve after the detection signals are analyzed and judged by a control strategy module inside the ECU, and the electromagnetic valve executes corresponding movements according to the control signals. By the adoption of the control method, the ECU is used for receiving the engine rotating speed, engine loads, oil temperature signals and oil pressure signals sent by the sensor set, and the working mode of the variable displacement oil pump can be intelligently selected through the internal control strategy module inside according to the actual using conditions of an engine. By means of the variable displacement oil pump control system and the control method thereof, the displacement of the oil pump can be intelligently adjusted, the problem that the capacity of a commonly-used working condition oil pump of the engine is excessive and thus oil consumption is made high is solved, and the oil economy of an entire vehicle is improved.

Owner:CHINA FIRST AUTOMOBILE

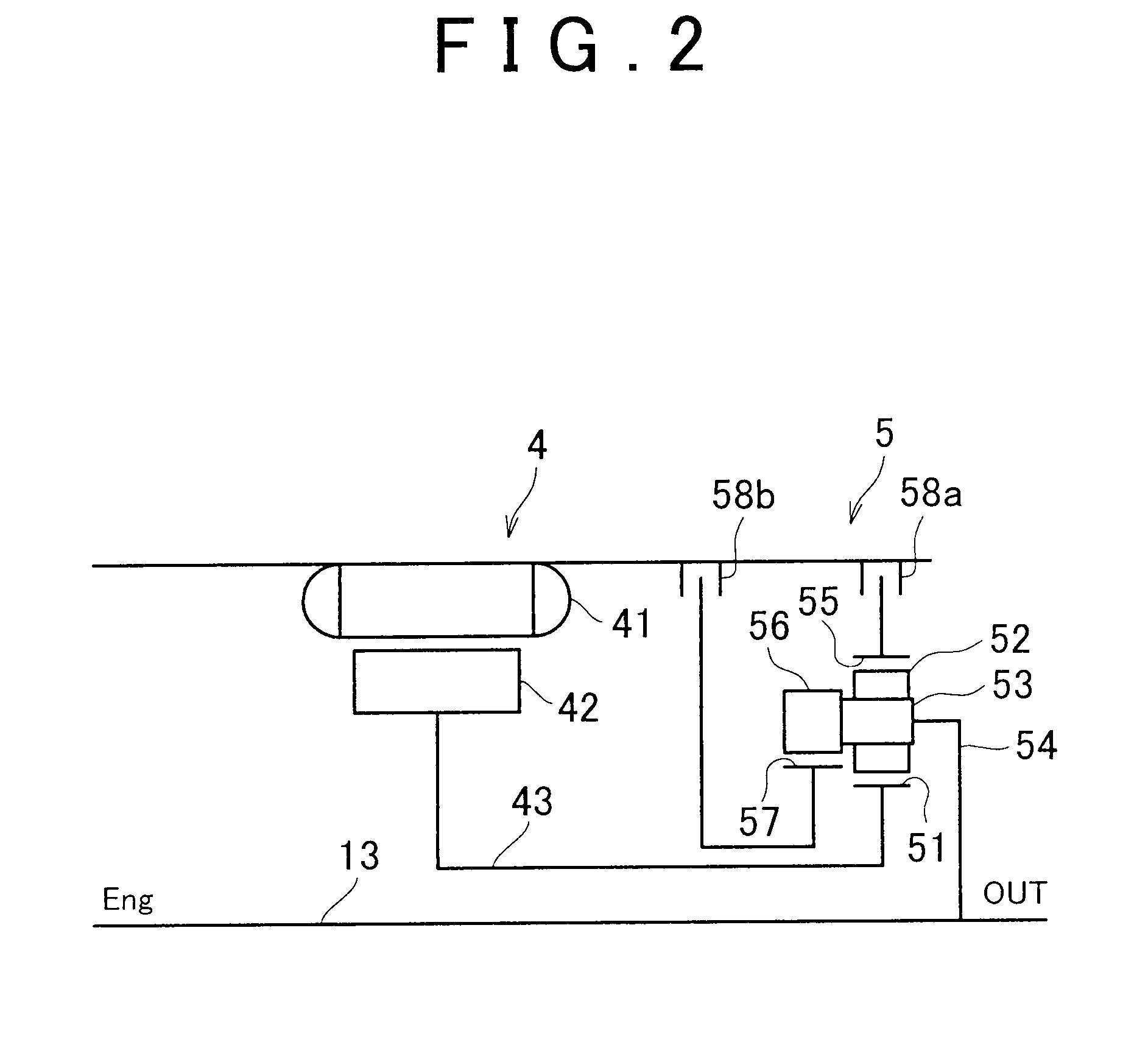

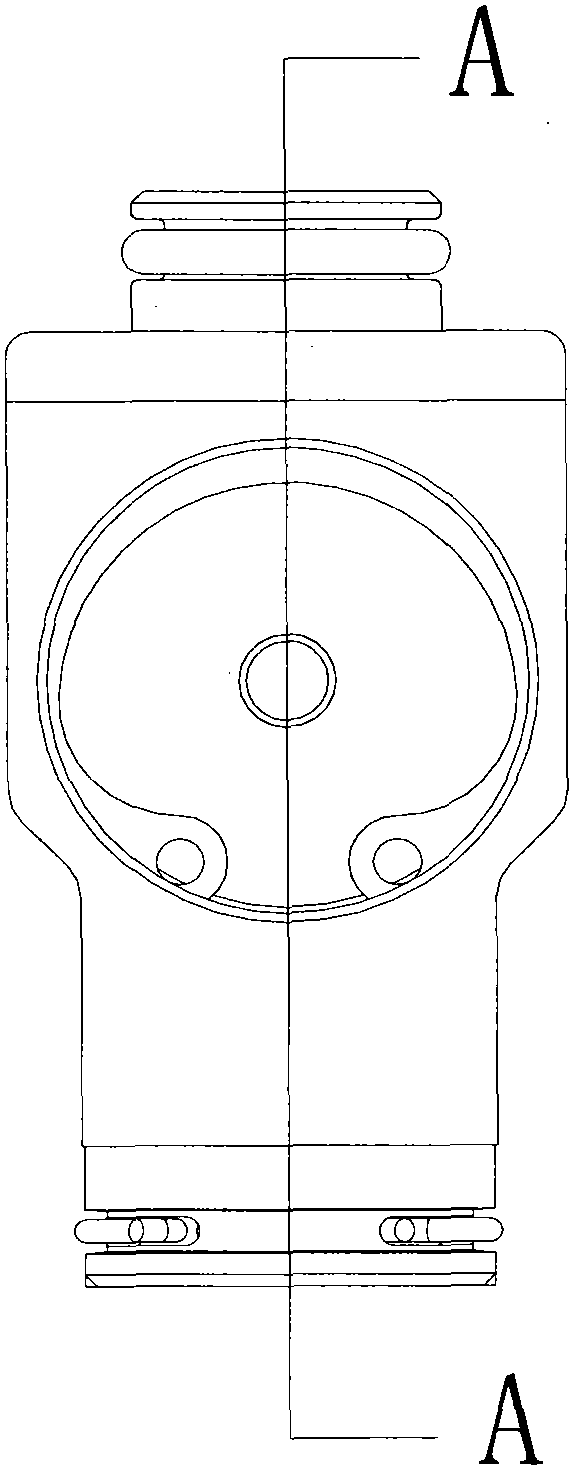

Temperature regulator for gearbox of vehicle

InactiveCN102359576AProtection worksImprove the lubrication effectGear lubrication/coolingLubrication check valvesEngineeringWorking temperature

The invention relates to a temperature regulator for a gearbox of a vehicle, and the temperature regulator comprises a valve body provided with a cavity, and a thermal power element installed in the cavity, wherein the valve body further comprises two through holes, namely a first hole and a second hole which are respectively communicated with the cavity; first ends of the second hole and the first hole are communicated with the inlet and outlet of an external fluid cooling device respectively, and second ends of the second hole and the first hole are respectively provided with a fluid inlet and a fluid outlet; one end of the cavity is communicated with the second hole through an intercommunicating pore; and the thermal power element is fixedly mounted in the cavity, and an elastic component is sleeved on the periphery of the thermal power element, one end of the elastic component tightly props against the thermal power element, and the other of the elastic component tightly props against the inner wall at the opening end, communicated with the second hole, of the cavity. By using the temperature regulator for the gearbox of the vehicle provided by the invention, the working temperature of lubricating oil can be controlled within an effective range, thereby maintaining the optimal state of the lubricating property of the lubricating oil.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS

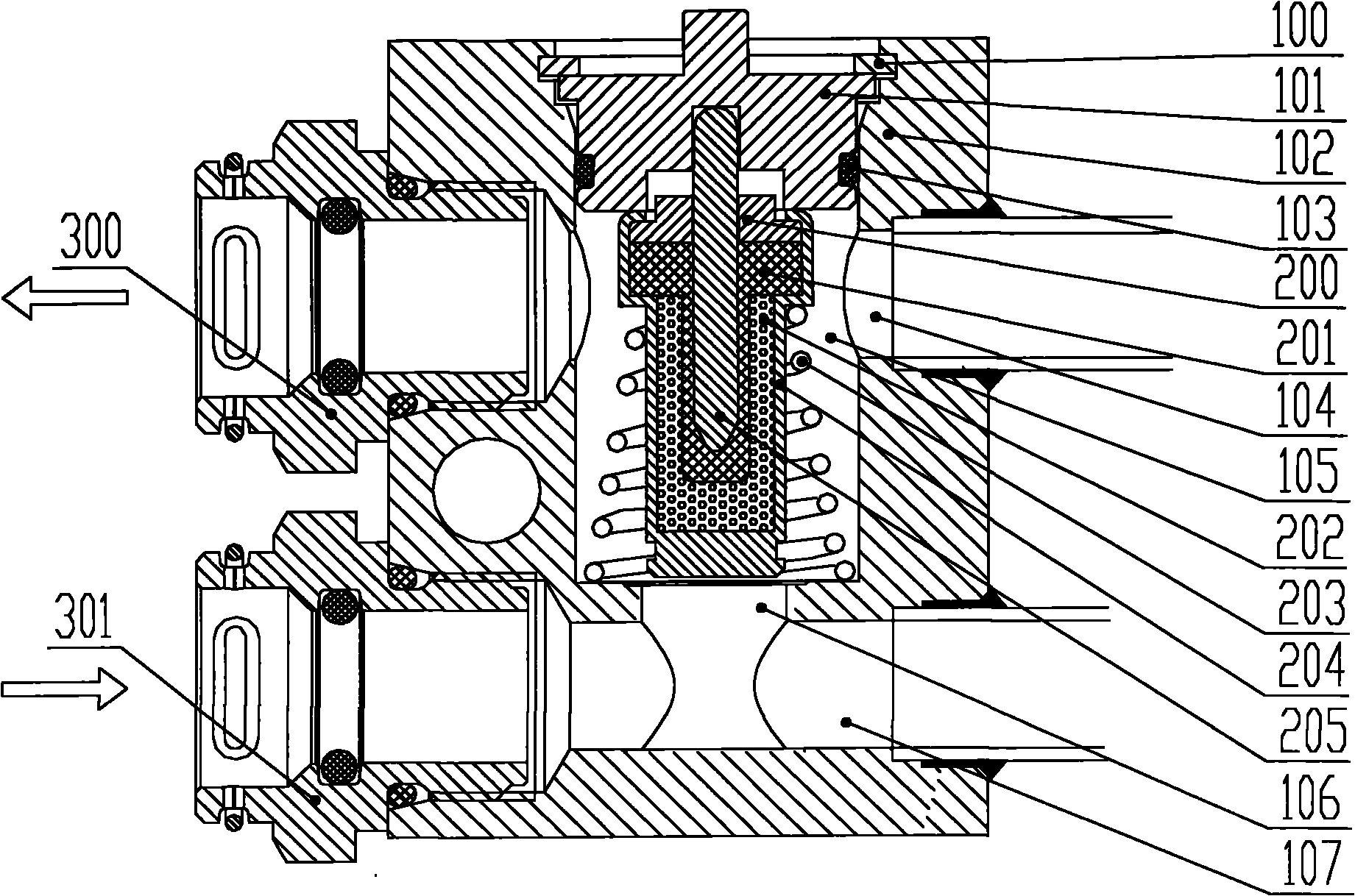

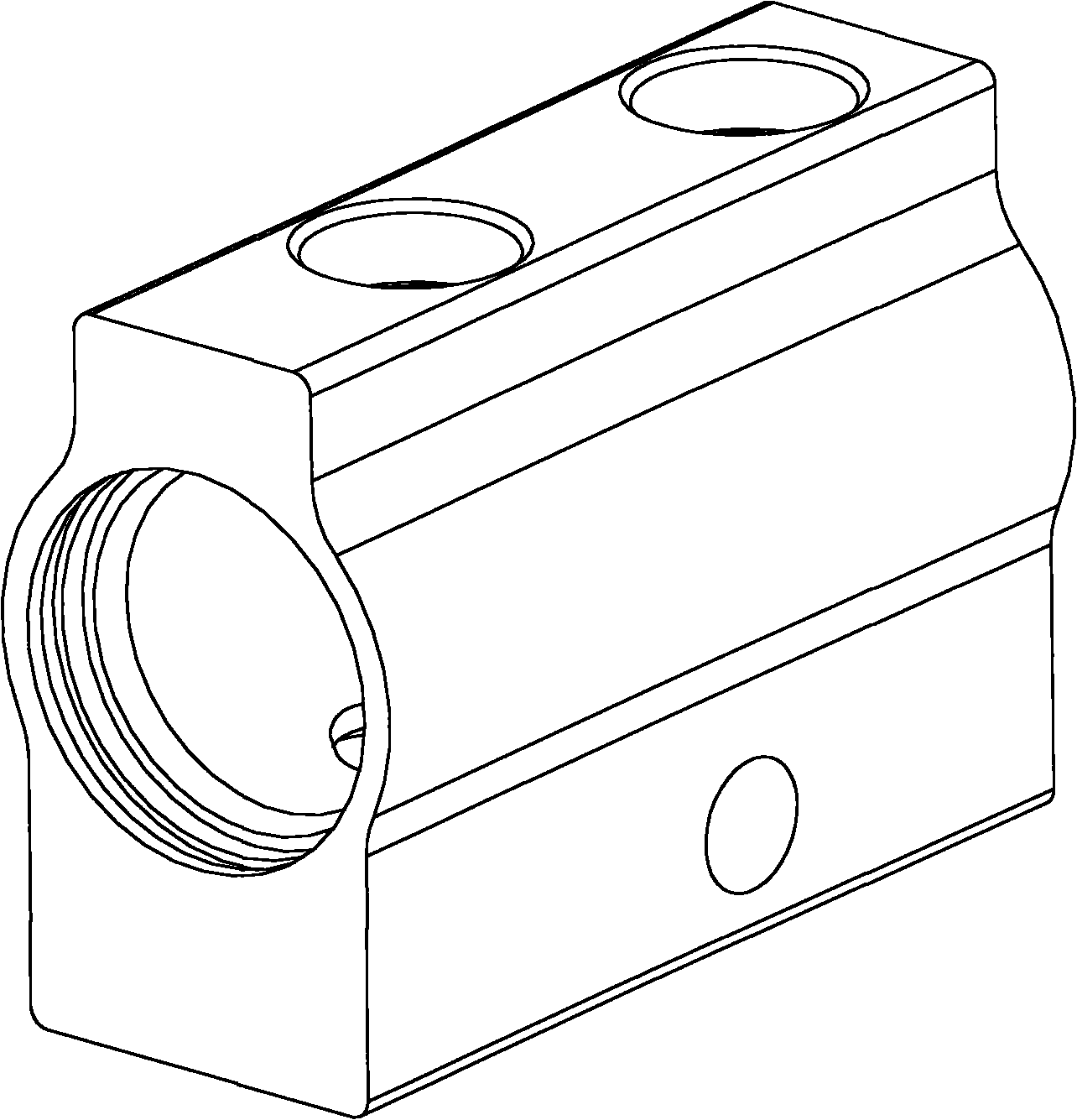

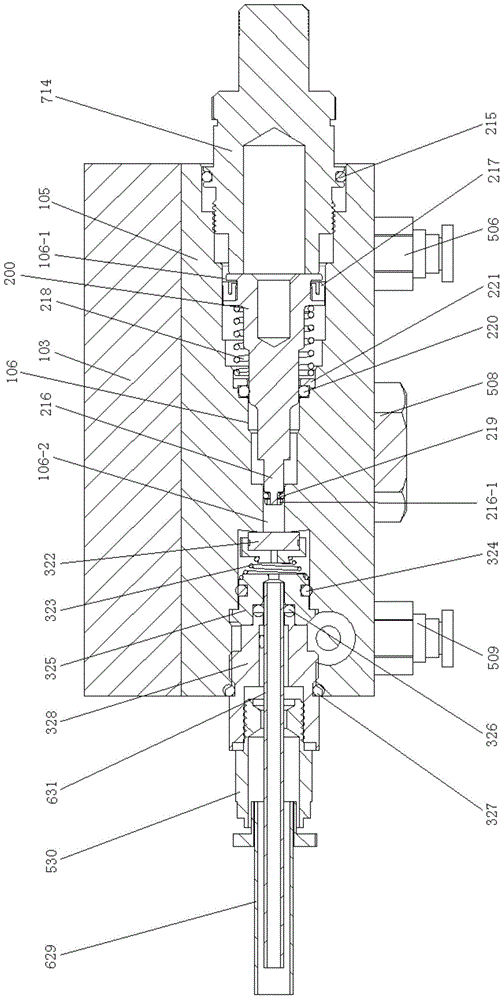

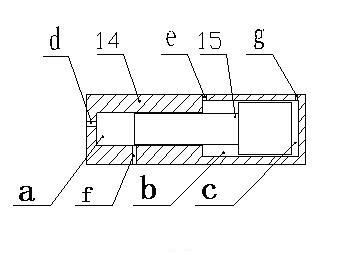

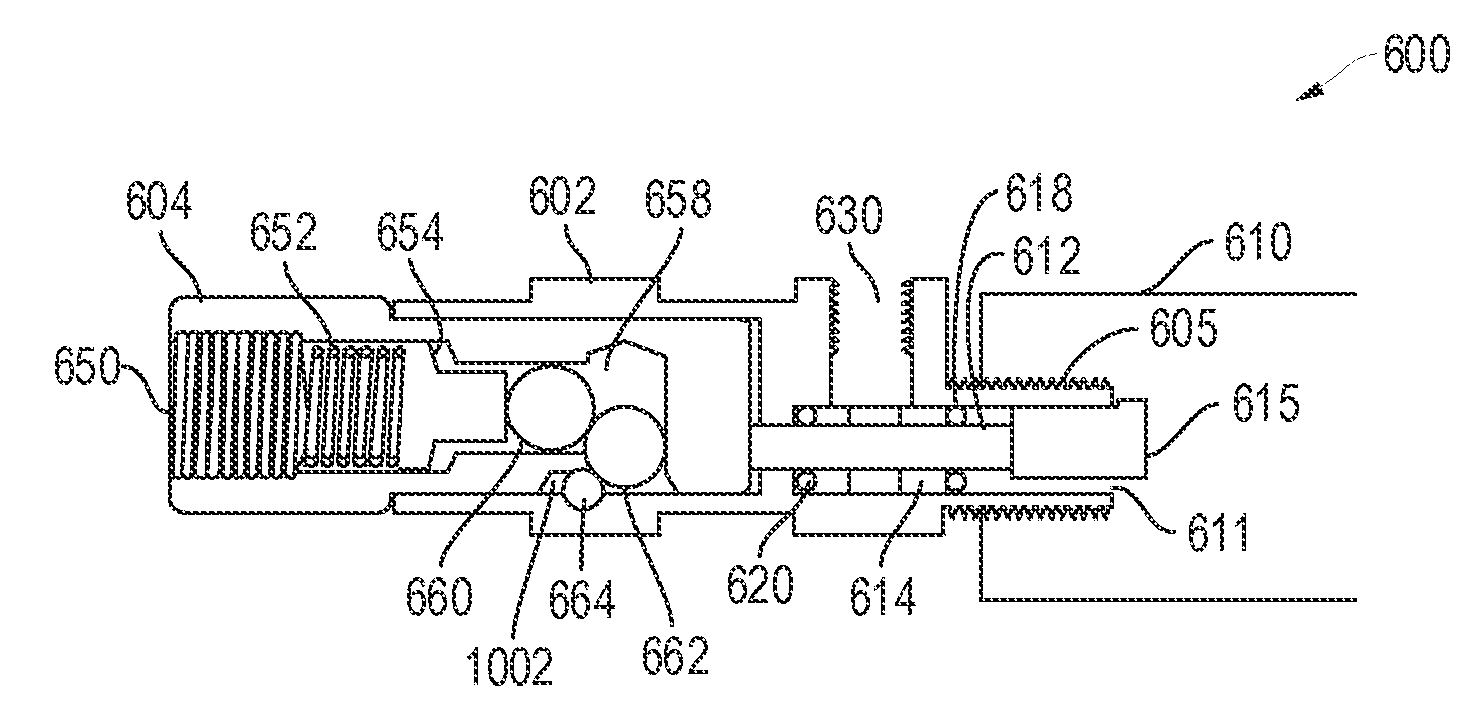

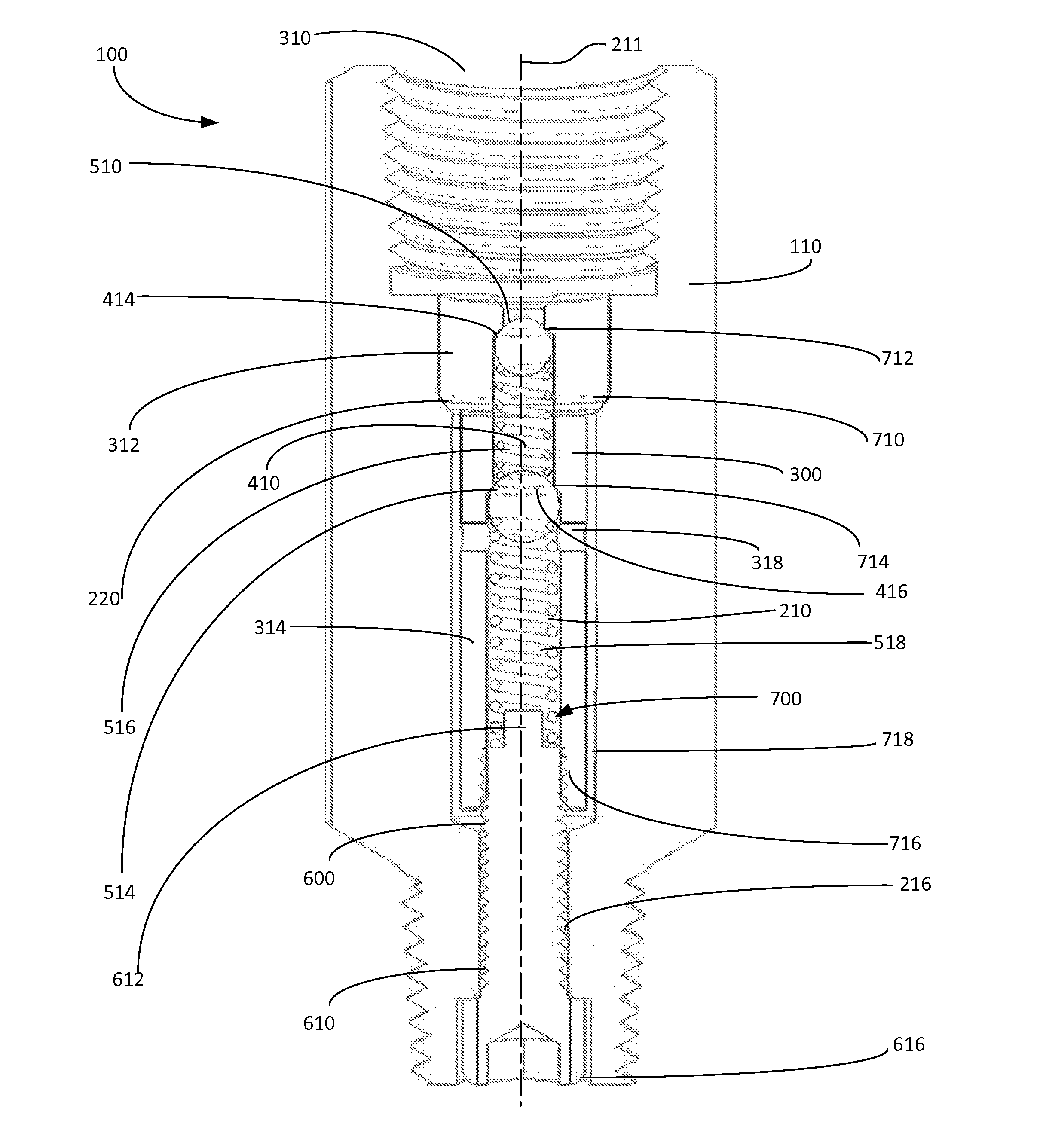

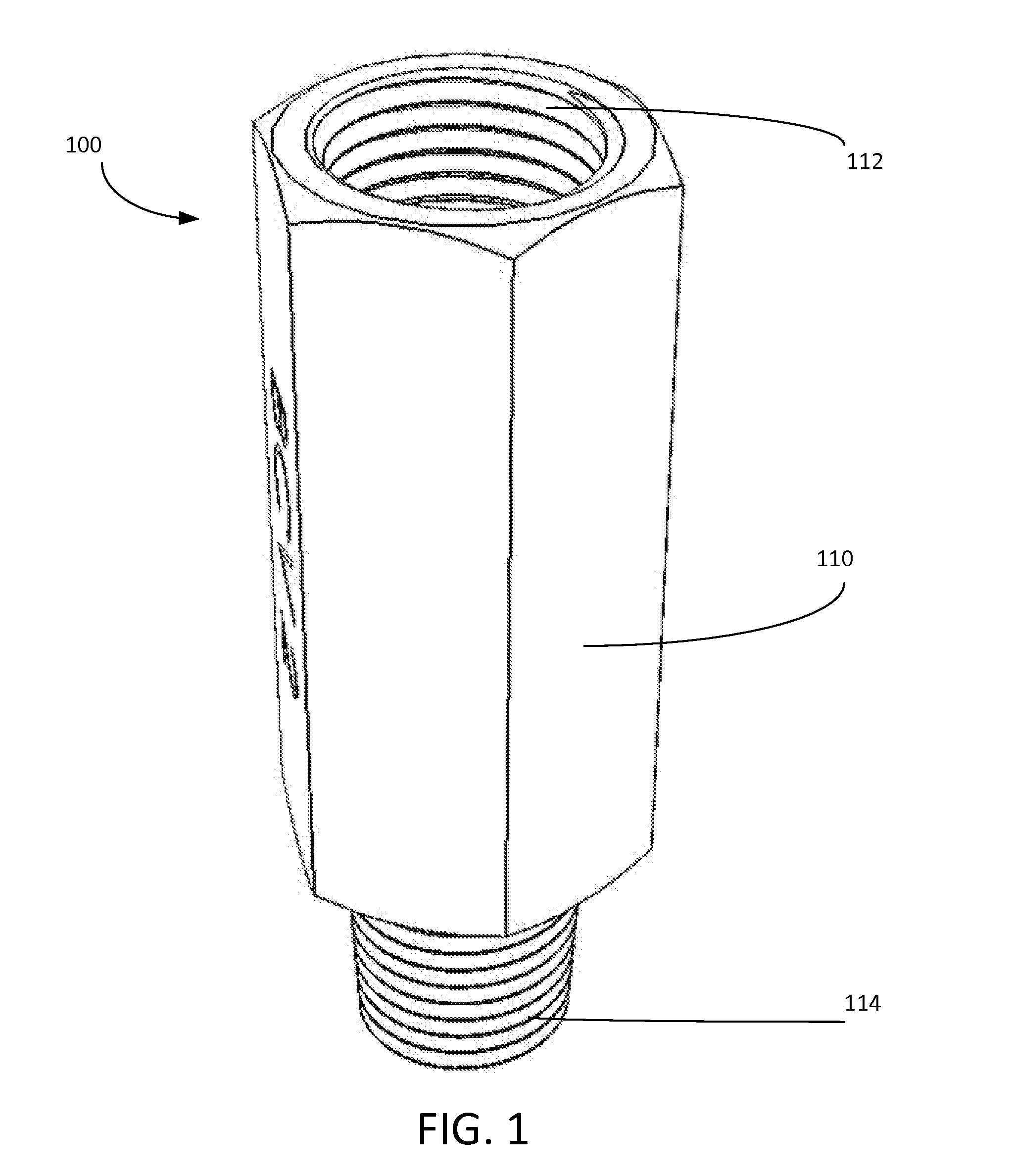

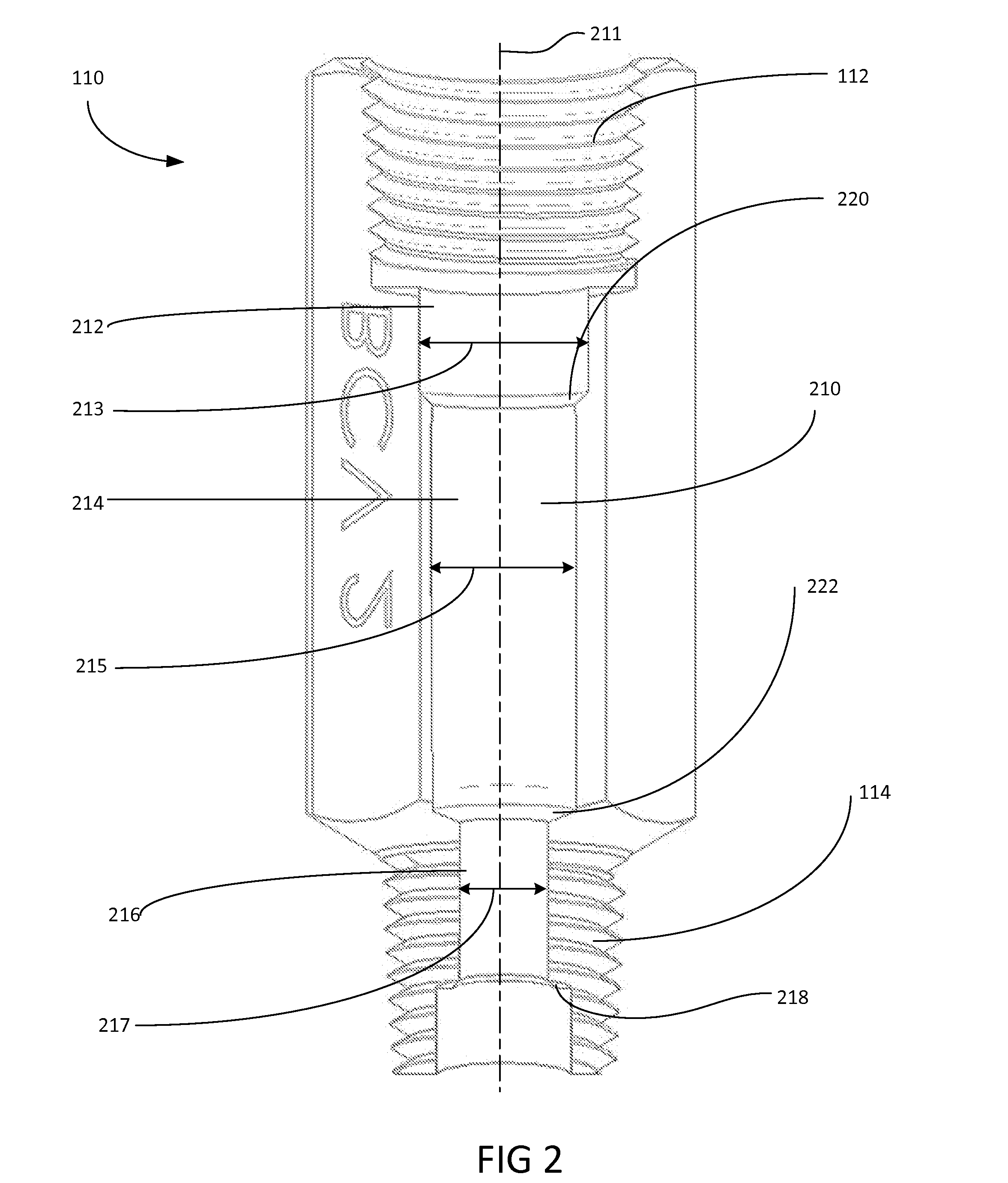

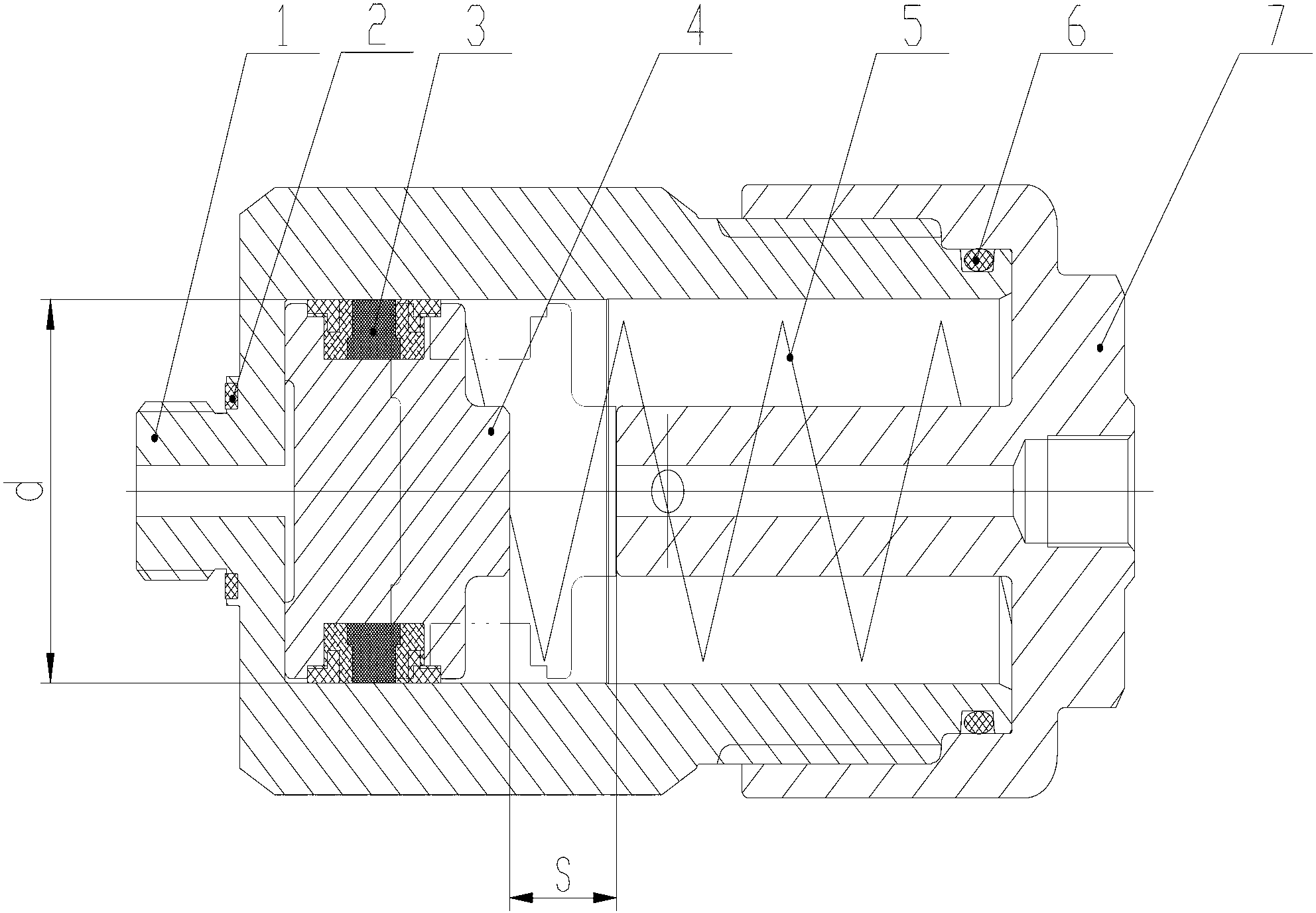

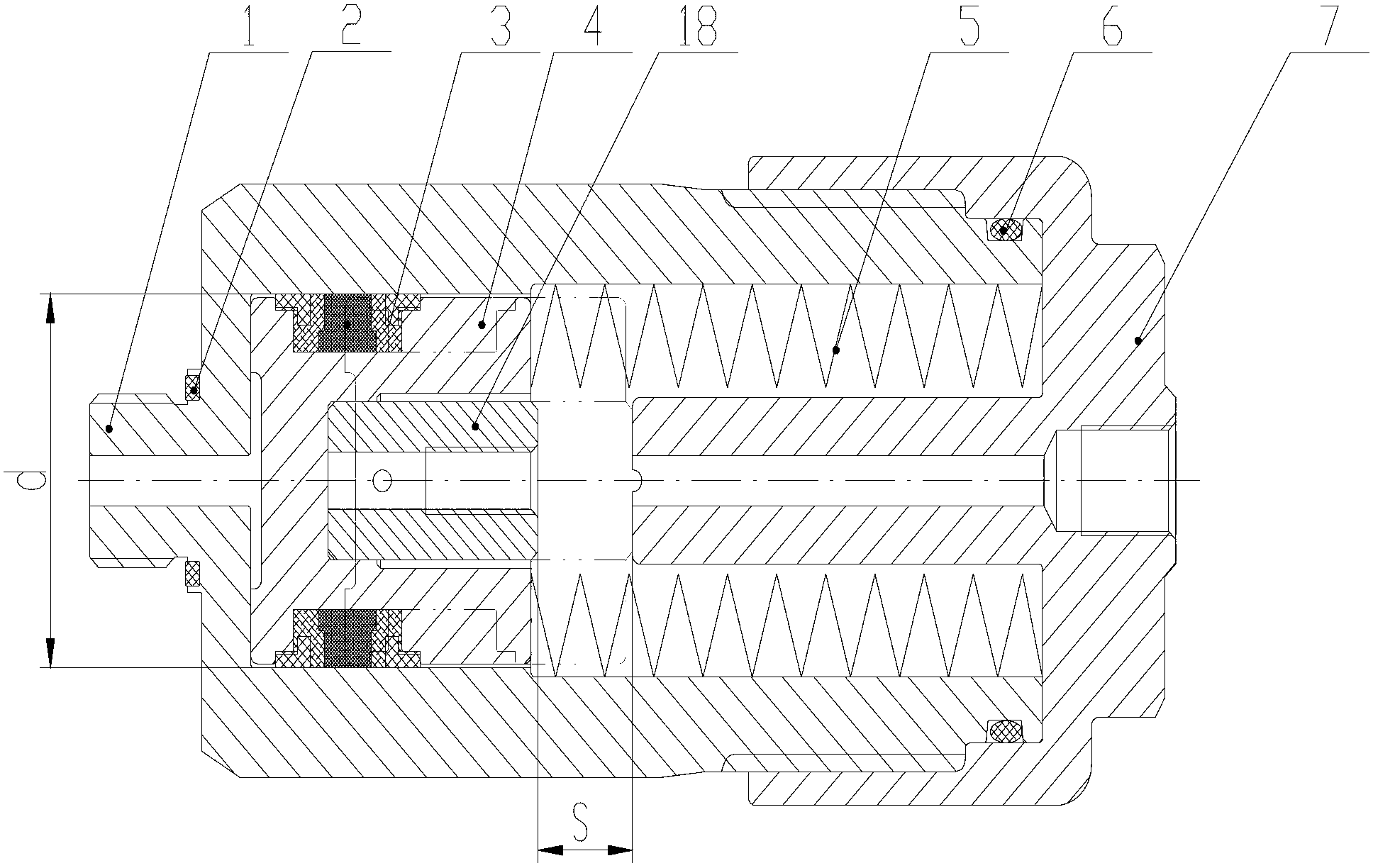

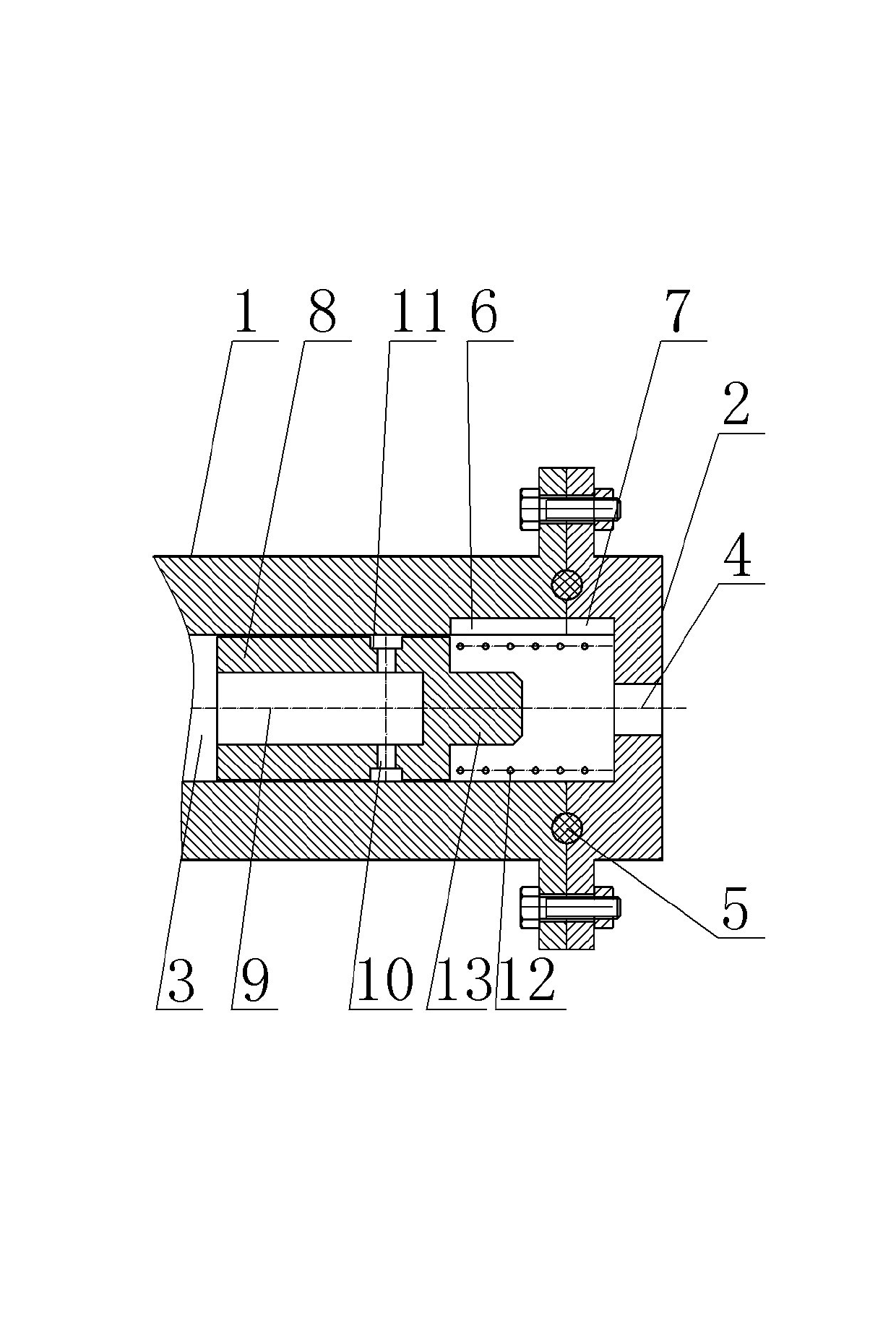

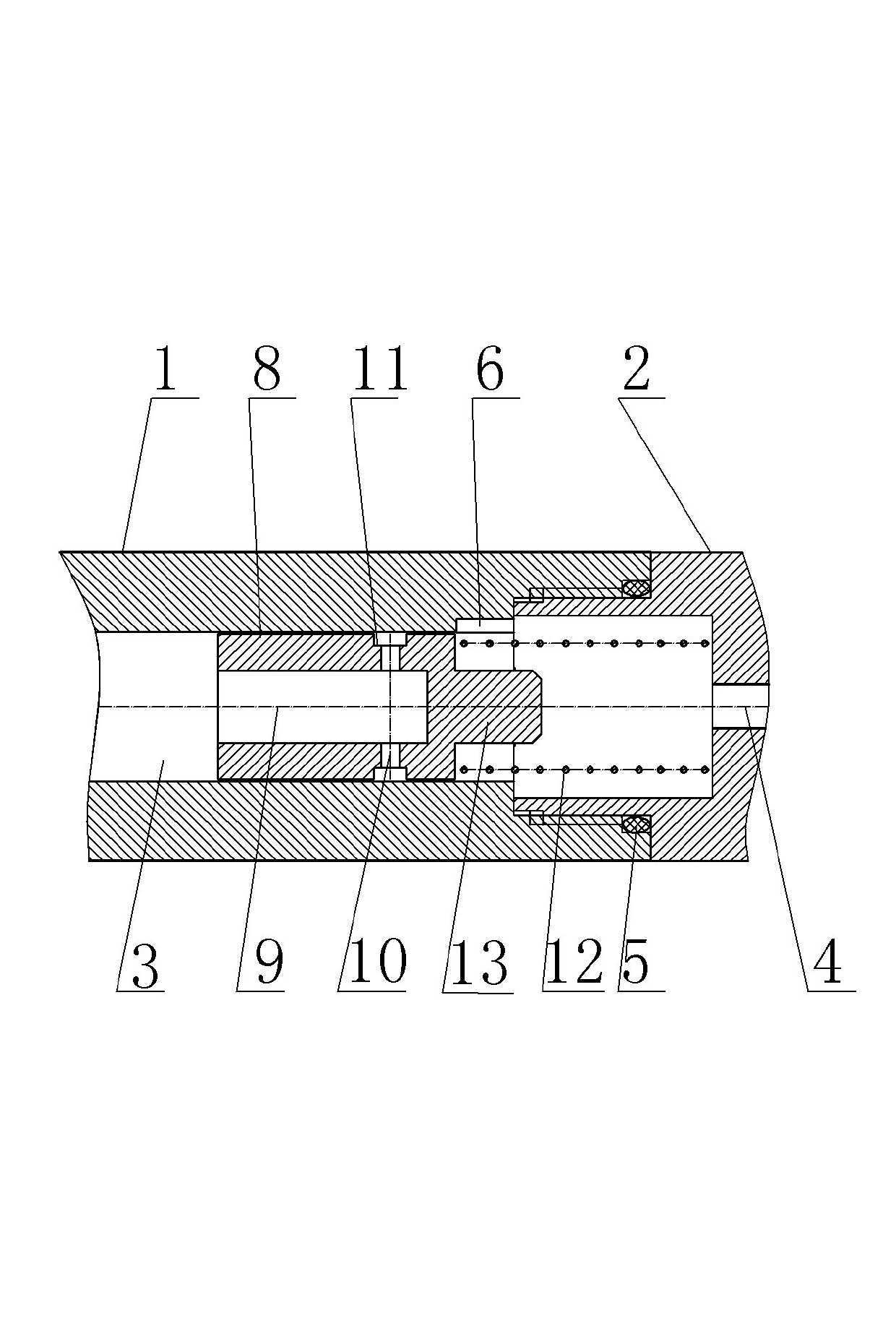

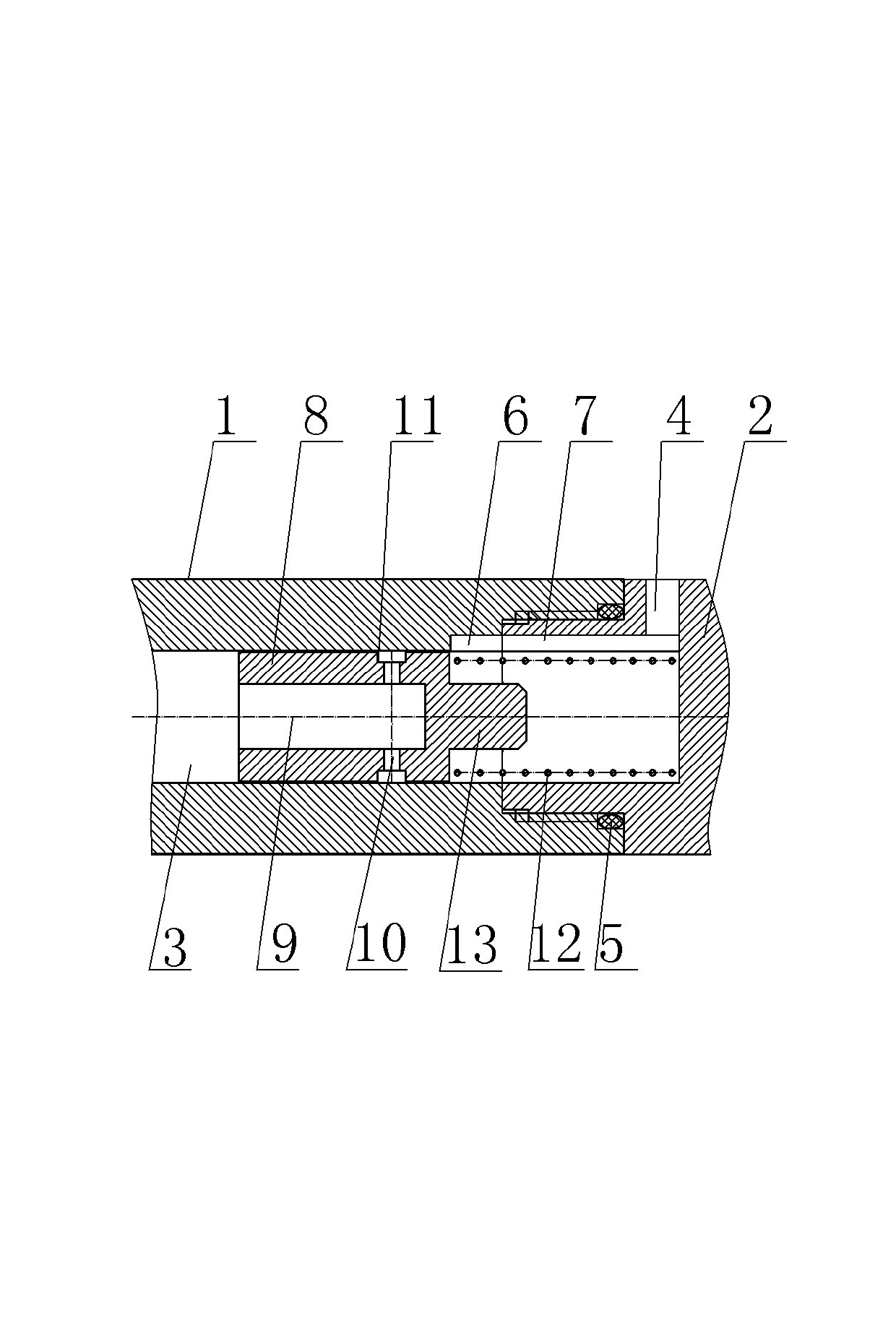

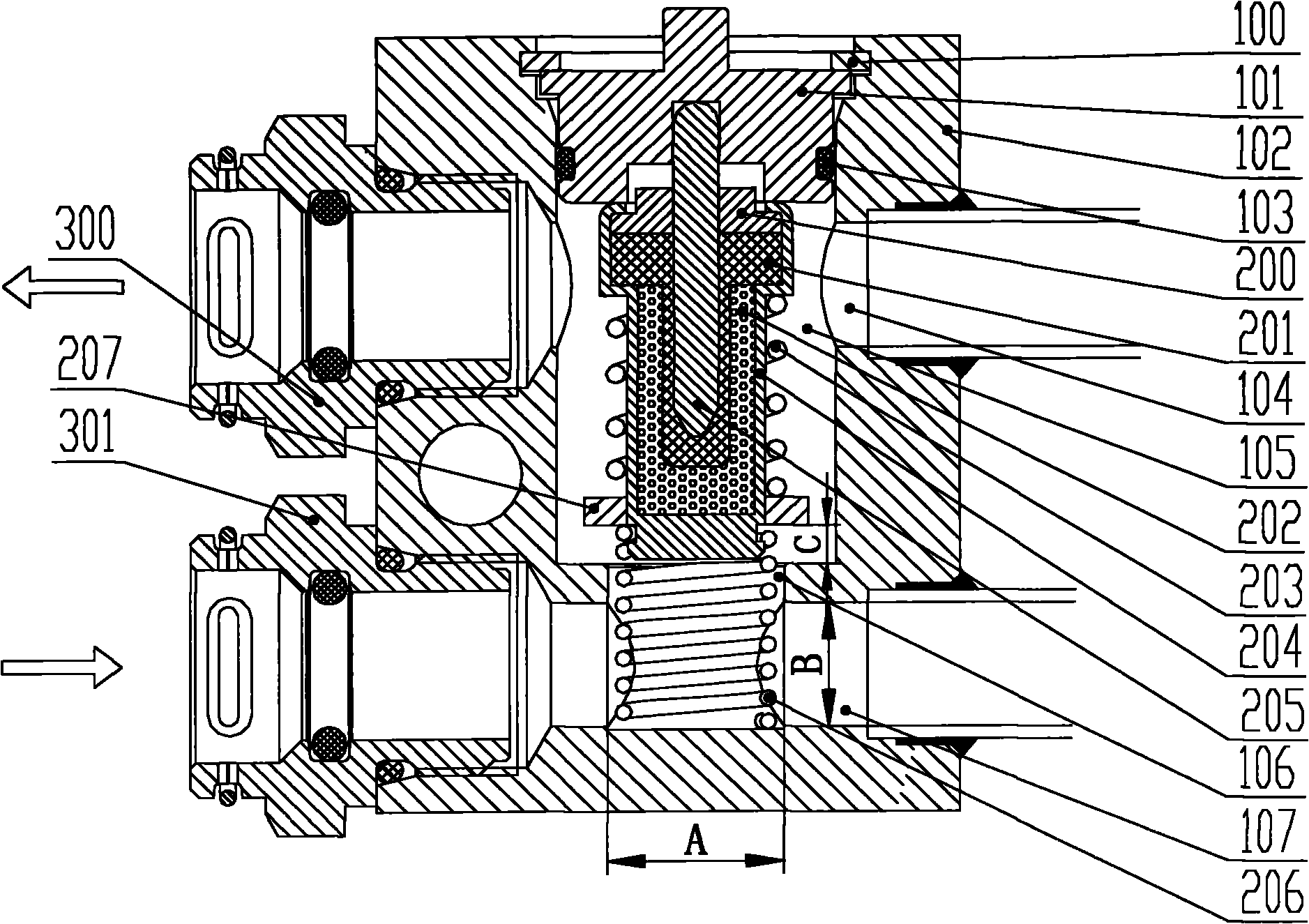

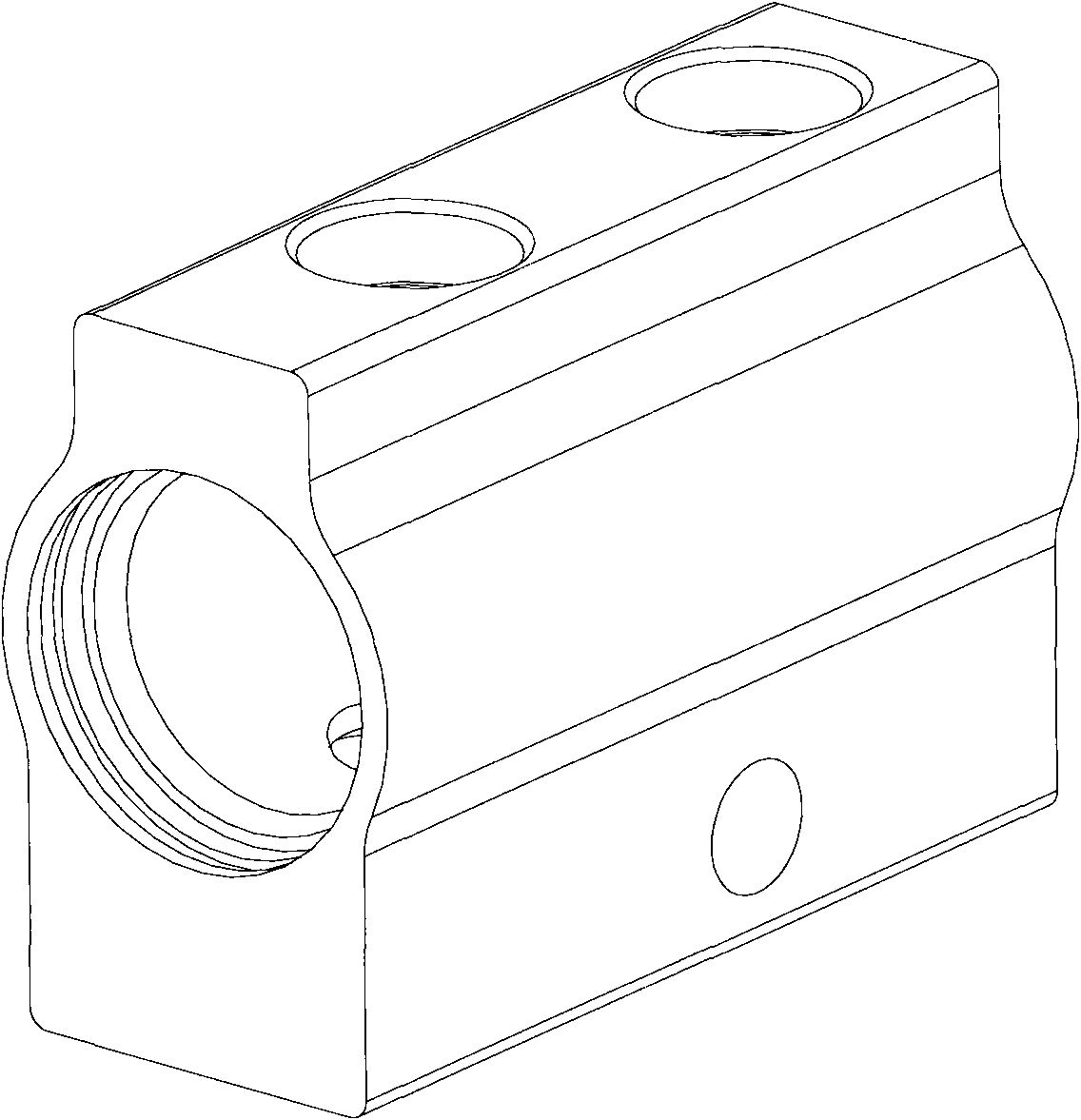

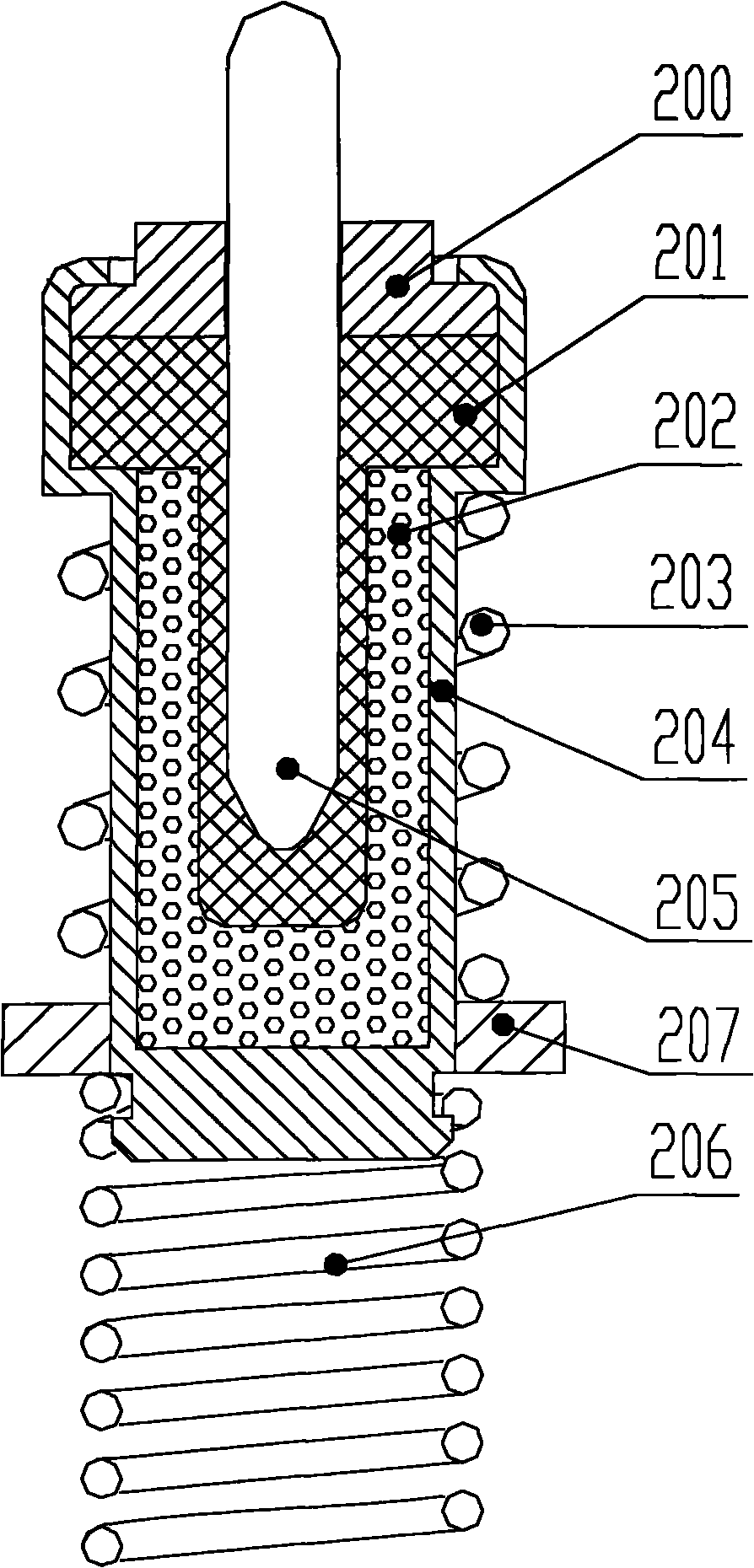

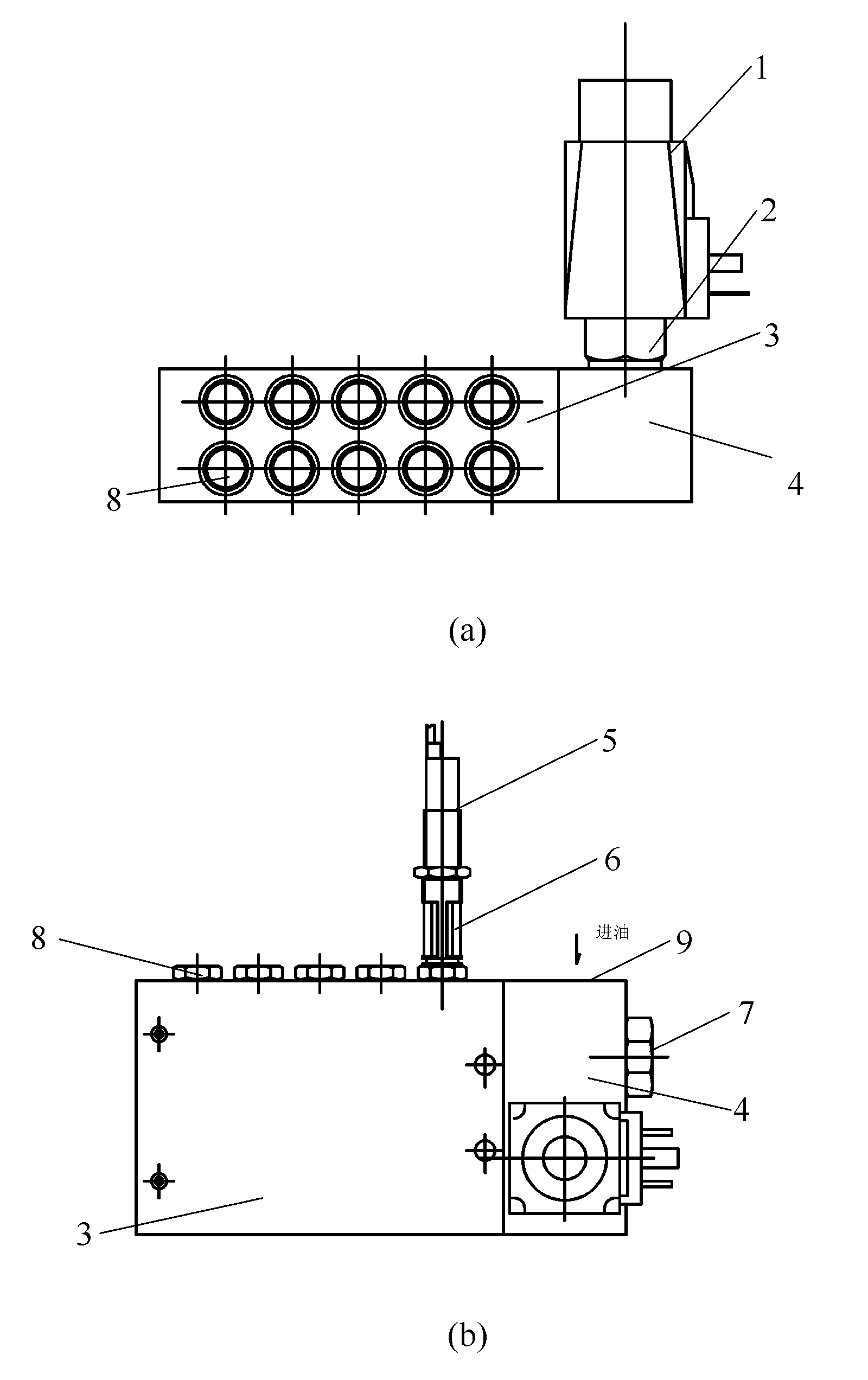

Minimal quantity lubrication system precise lubrication pump

ActiveCN104358996APrecise designPrecise micro oil supplyLubricating pumpsLubrication check valvesMetalworkingAir cavity

The invention provides a precise lubrication pump. Lubricating agents enter a liquid cavity from an oil inlet hole; compressed air is used for driving, when the compressed air enters an air cavity, the pressure at the tail part of a piston rod is increased, when the pressure is greater than the elastic force of a piston spring arranged at the front end of the piston, the piston rod forwards moves, the liquid cavity is reduced, the pressure is increased, when the pressure is greater than the elastic force of a one-way valve spring, a one-way valve plug is opened, and the lubricating agents are pumped out; the pressure of the liquid cavity is released, when the pressure is smaller than that of the one-way valve spring, the one-way valve spring is reset, and an oil outlet is sealed; when pressure of the air cavity is released, and when the pressure of the tail part of the piston rod is smaller than the elastic force of the piston spring, the piston rod is reset. The precise lubrication pump has the advantages that the miniature precise pneumatic pump capable of realizing precise oil supply is provided, the design is precise, and the precise lubrication pump is applicable to lubricating devices using various lubricating agents in metal processing.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH +1

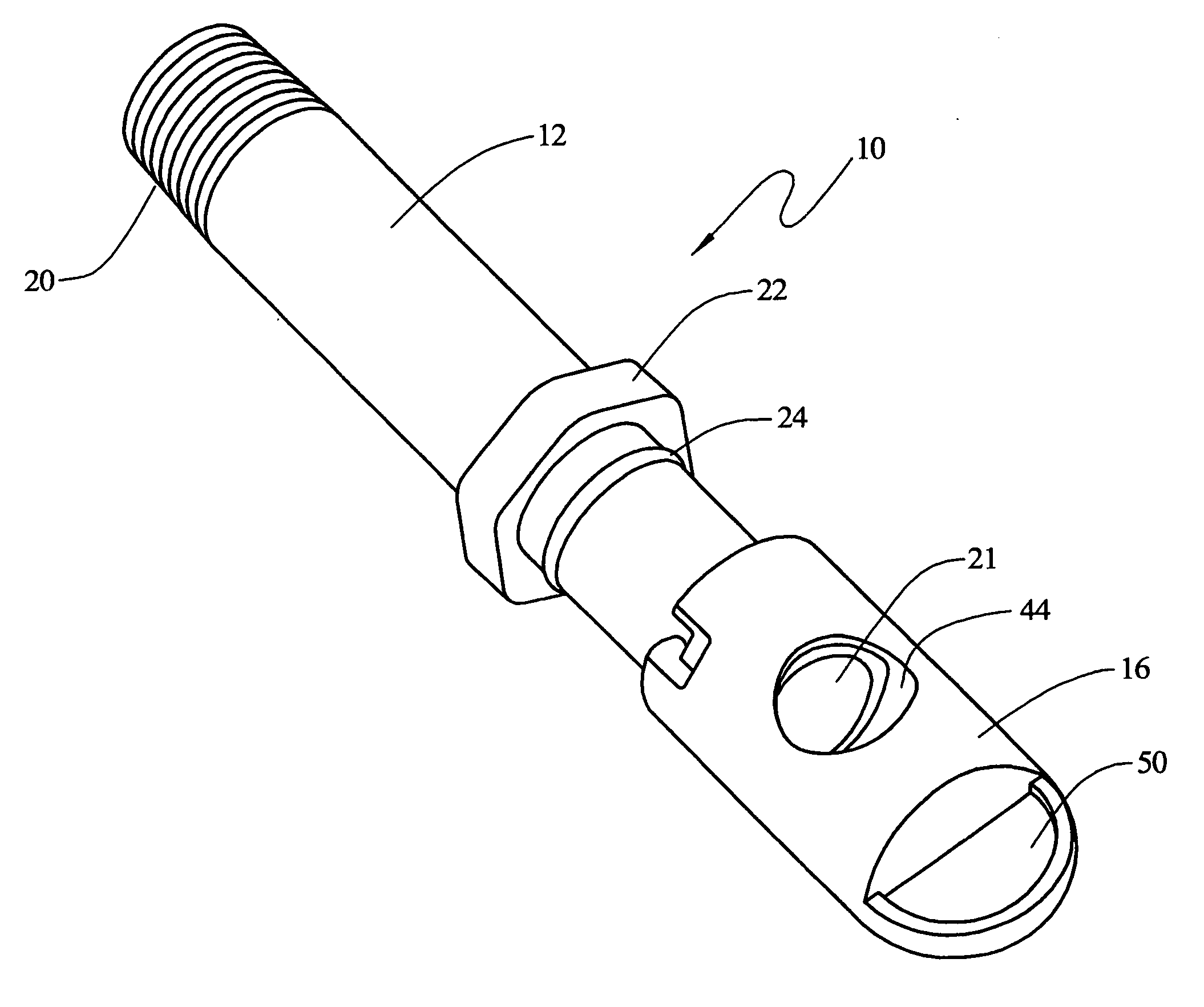

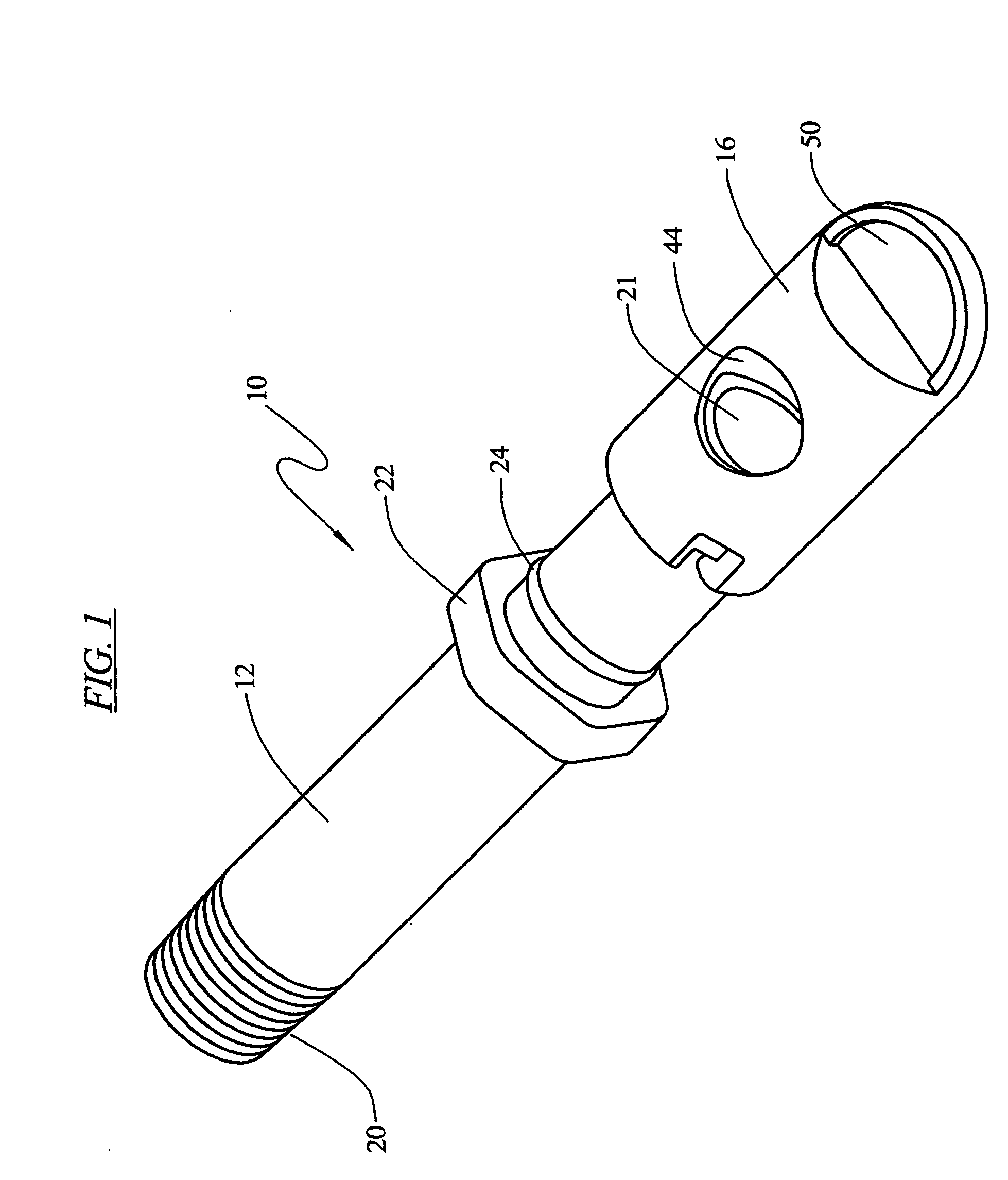

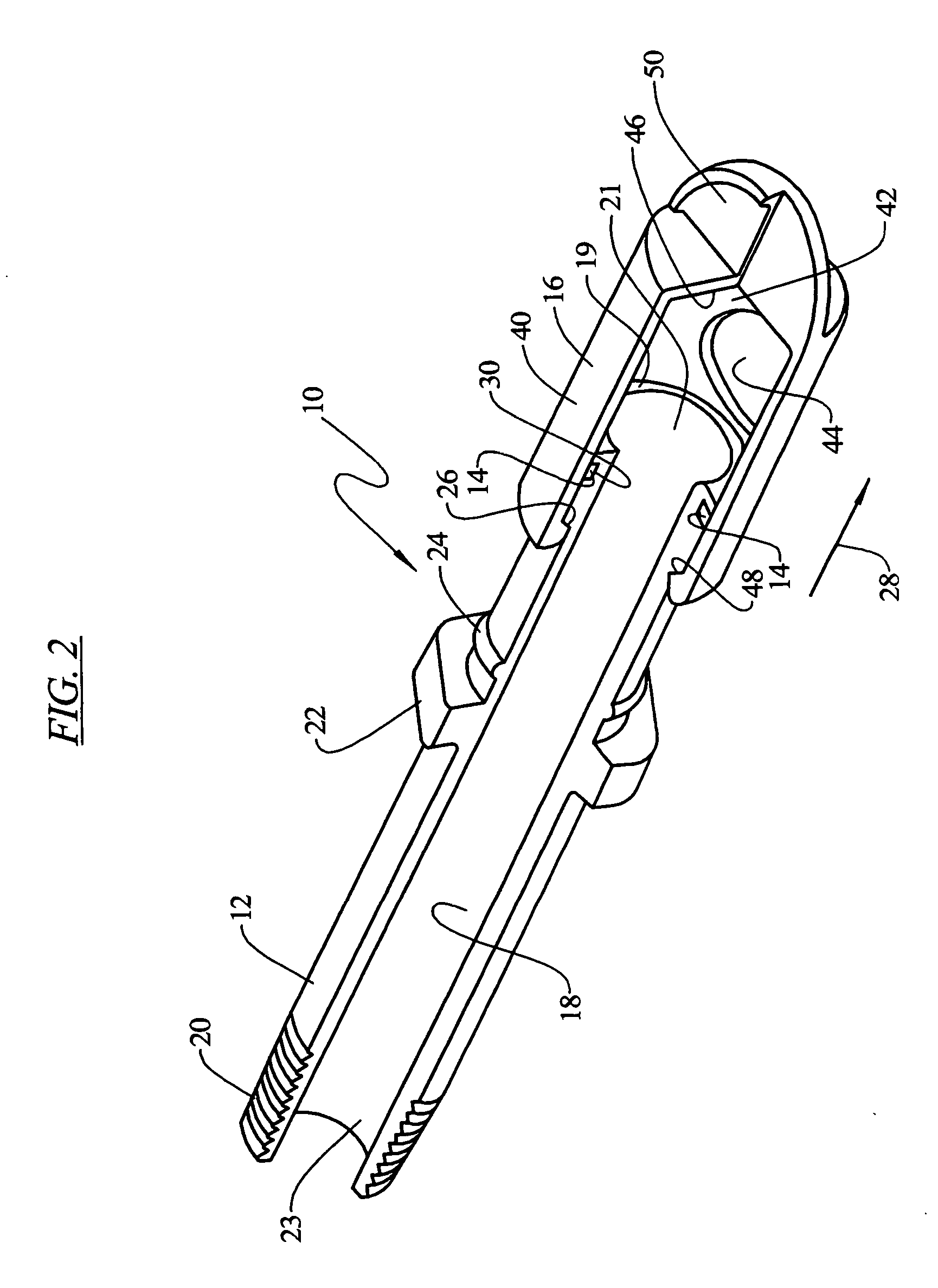

Oil drain plug of engine

InactiveUS6902038B2Prevent oil leakageImprove productivityCrankshaftsValve arrangementsCoil springEngineering

A new type of plug incorporating a normally closed valve for draining oil from an oil pan of a car engine, wherein the normally closed valve is incorporated in a through hole provided as an oil draining path in a bolt type member fixed to the oil pan, an oil draining dedicated jig is assembled to the plug so as to open the normally closed valve in order to drain the oil contained in the oil pan by sucking it with a negative pressure, a movable valve disc member installed in the through hole is installed so that it is engaged with a valve seat provided near the outer end part of the through hole by a coiled spring so as to form the normally closed valve, and the tip end of the plug is made flush generally with the internal surface of the oil pan so as to prevent any structure from projecting toward the inside.

Owner:TAKAHARA TAMOTSU +1

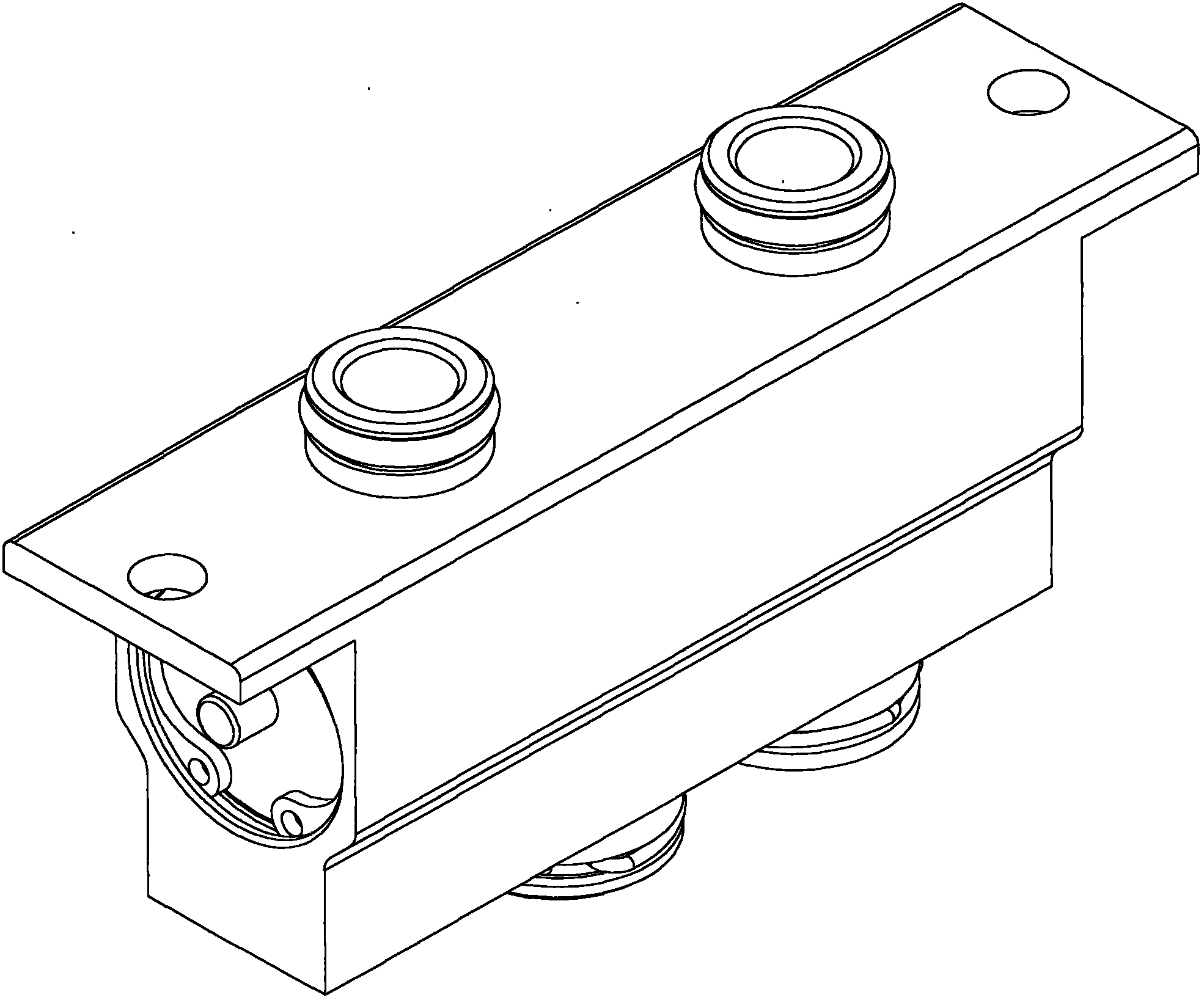

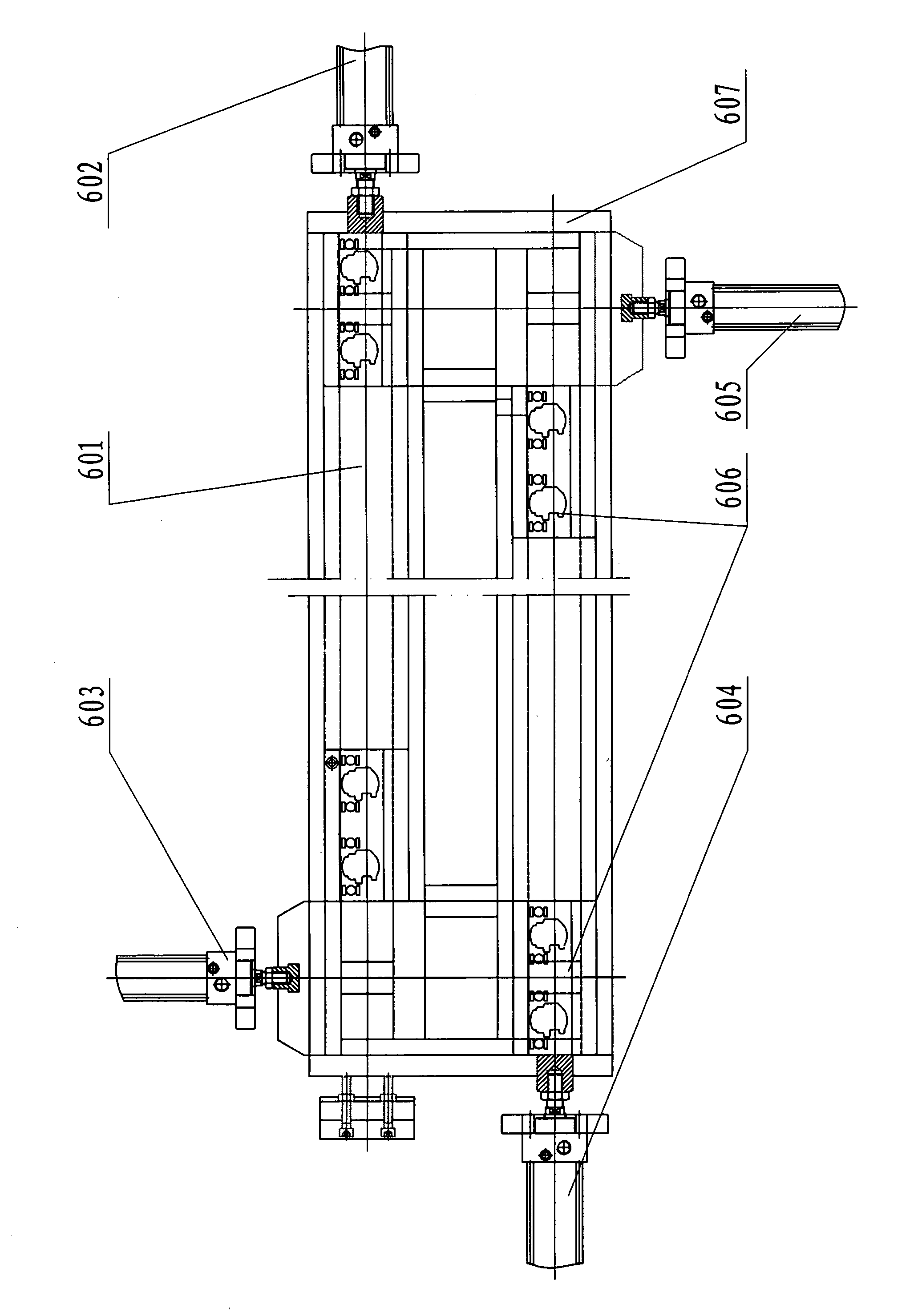

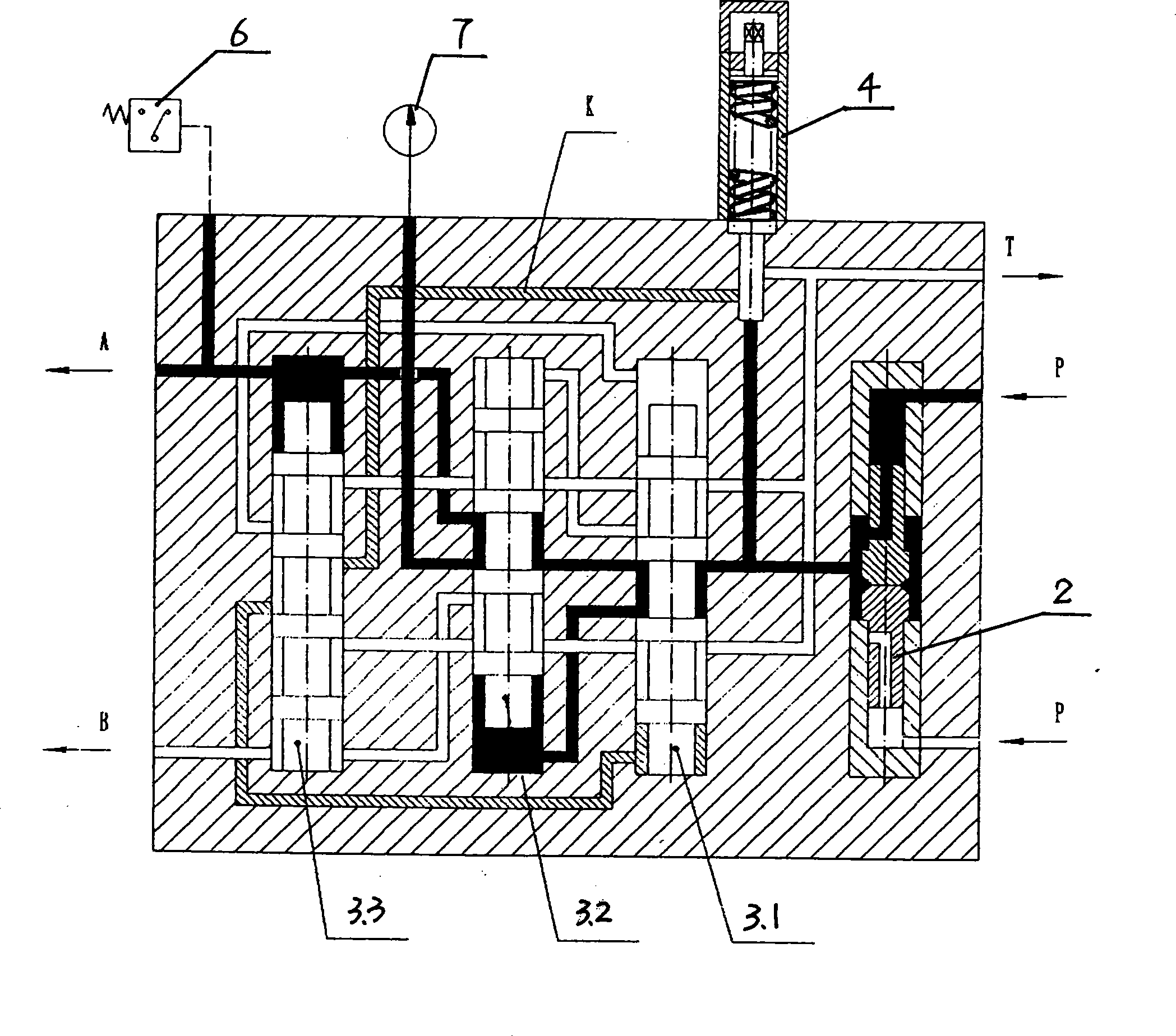

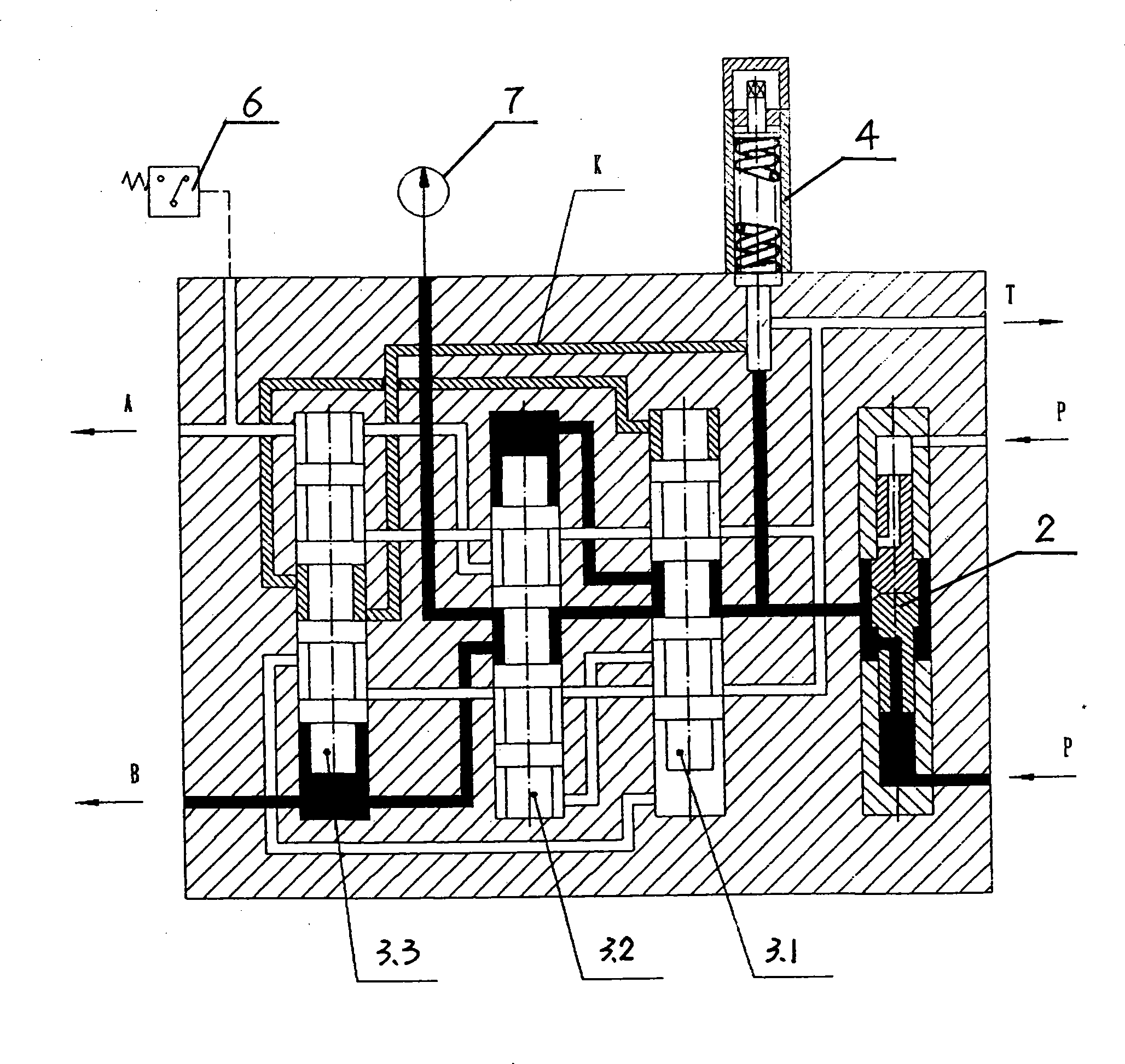

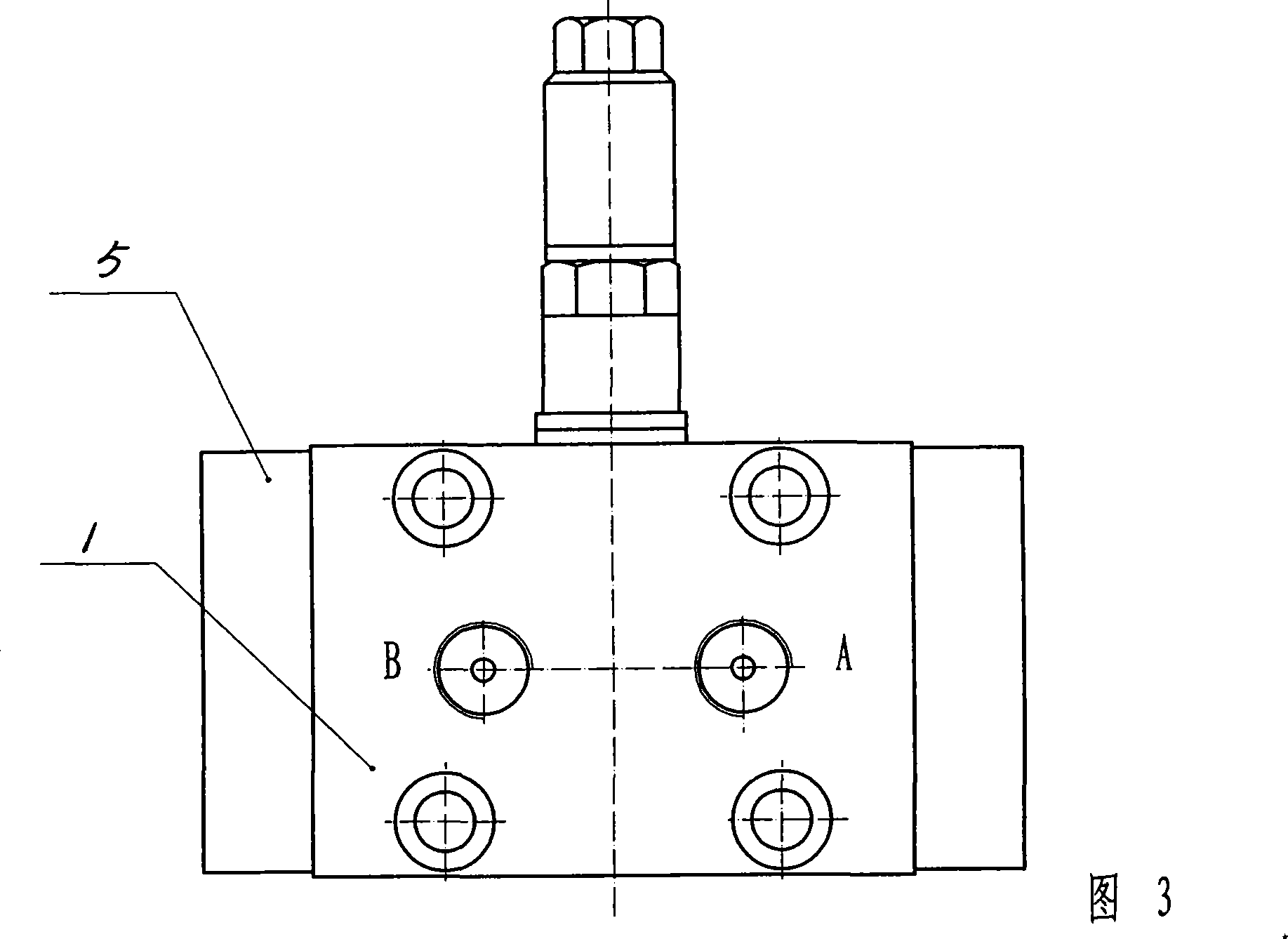

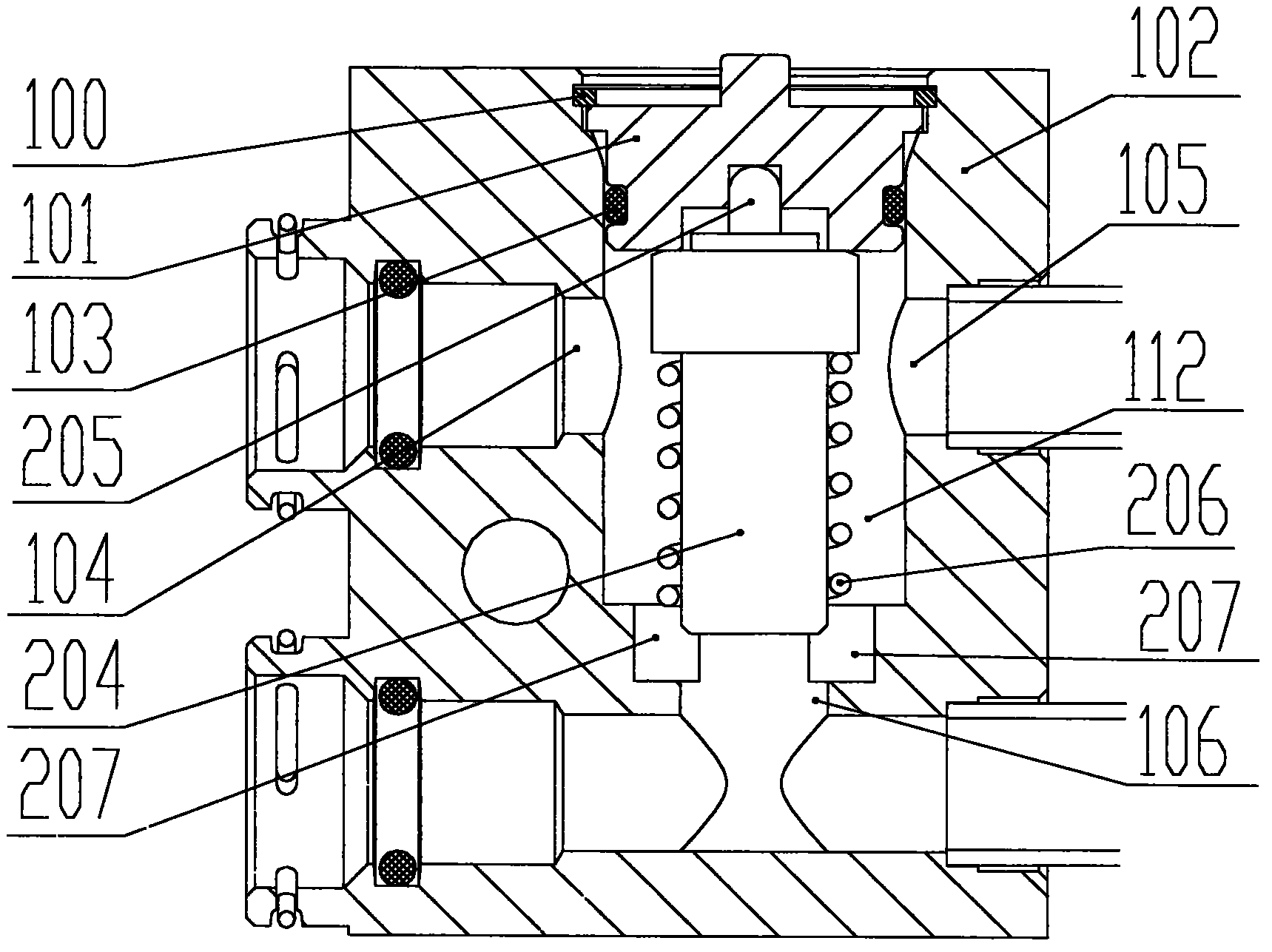

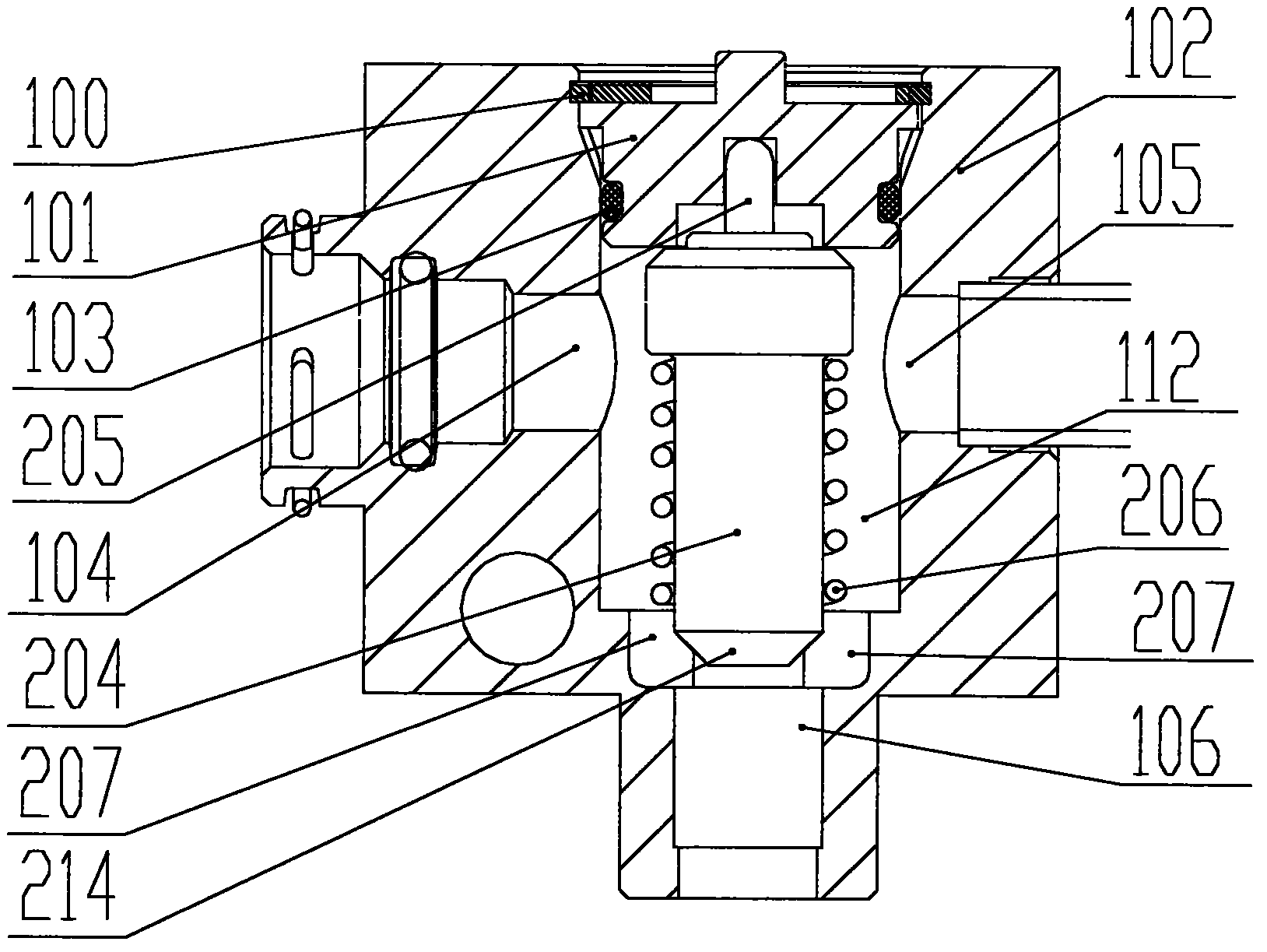

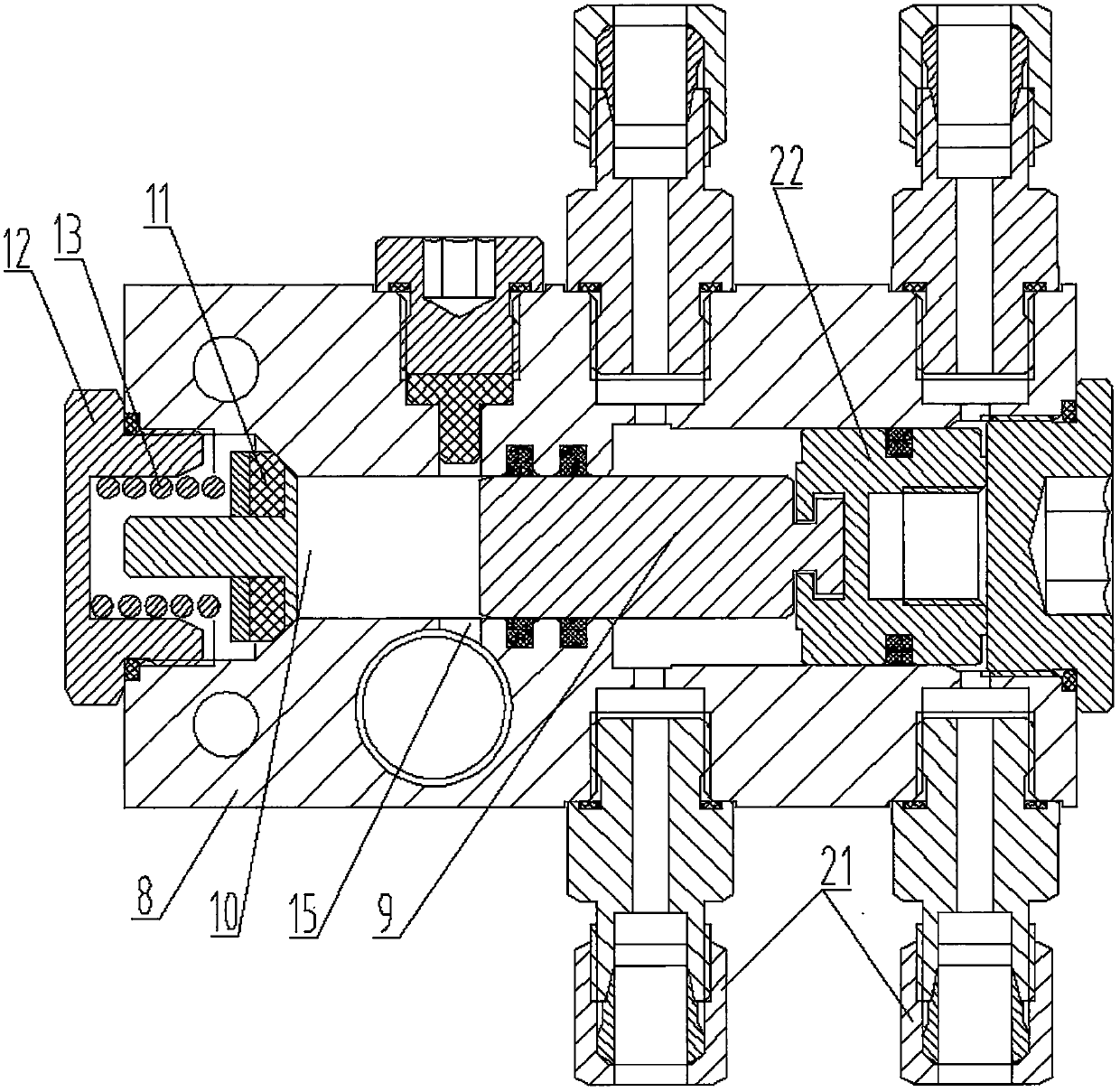

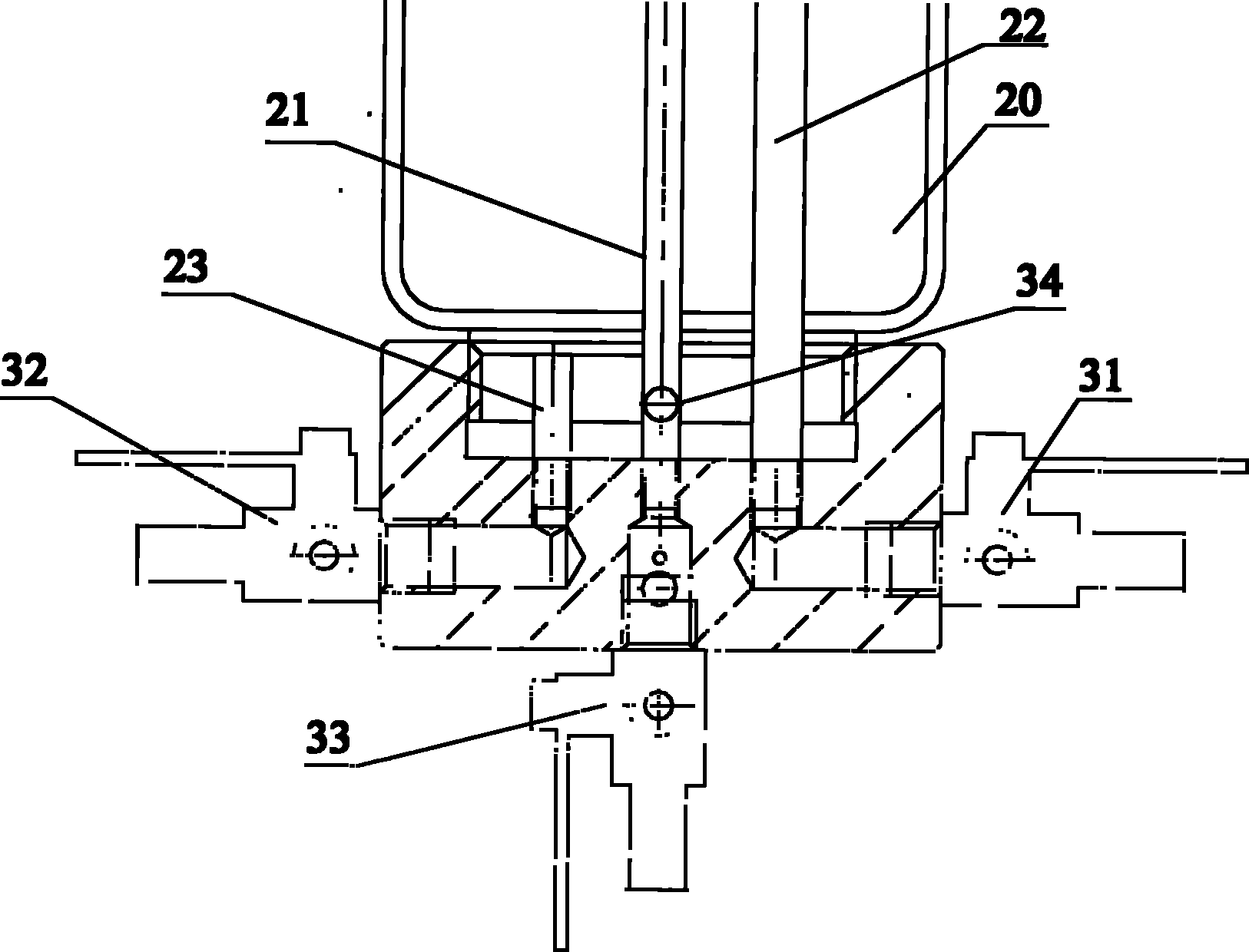

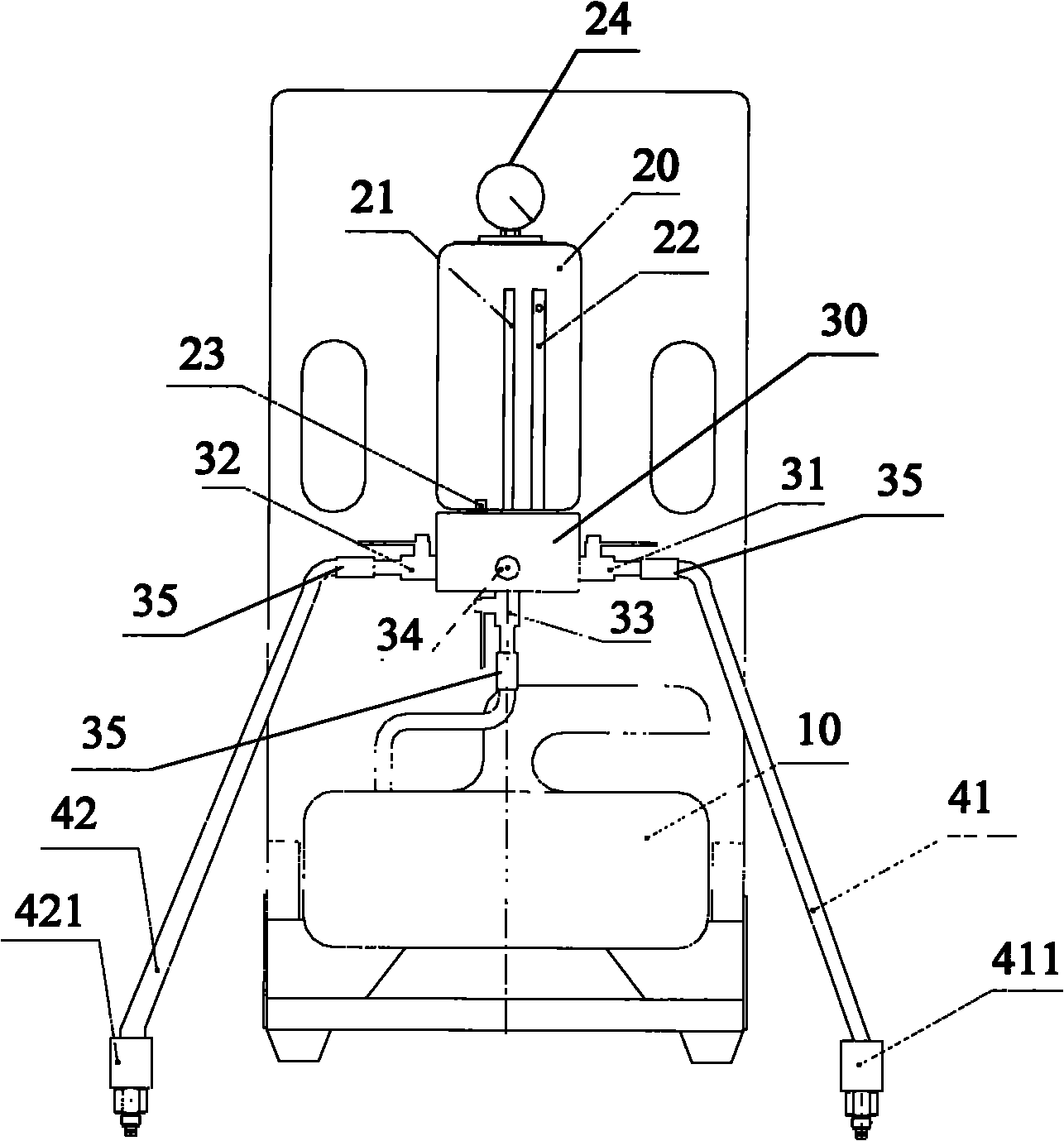

Hydraulic pressure pressure-regulating automatic reverse combined valve for double line grease lubricating system

InactiveCN101251225ALarge reversing pressure rangeFlexible commutationDistribution equipmentLubrication check valvesSpool valveCheck valve

The invention belongs to the hydraulic reversing valve technical field, particularly relates to an automatic hydraulic pressure-regulation reversing combination valve used for a double line grease lubricating system, and provides a reversing valve which is applicable to the grease supply of high-pressure electric grease pumps as well as middle and low pressure electric grease pumps. The automatic hydraulic pressure-regulation reversing combination valve used for a double line grease lubricating system comprises a valve body, the valve body is provided with two grease inlets and two grease outlets, and three reversing slide valves are arranged inside the valve body. The invention is characterized in that: two symmetrical plunger type grease distribution check valves are arranged between the grease inlets and the slide valves, the grease distribution check valves and a reversing slide valve grease path are connected with a pressure-regulation safety valve, and one grease outlet is provided with a pressure sensor interface. Compared with the prior art, the valve has the following advantages that: the valve adopts the hydraulic control to automatically change directions, is applicable to the lubrication systems less than 40MPa pressure, and has big reversing pressure-regulation range (from 3.5MPa to 35MPa), flexible direction change, no noise, strong anti-pollution capacity and reliable work.

Owner:义小毛

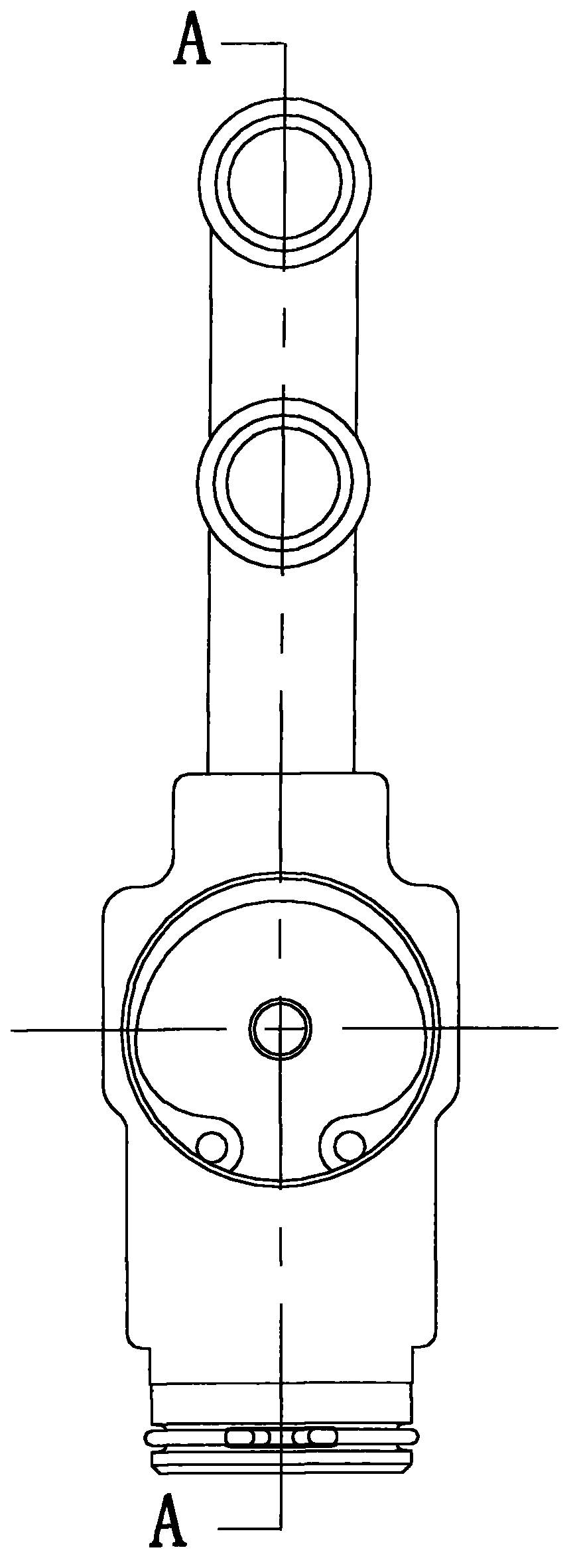

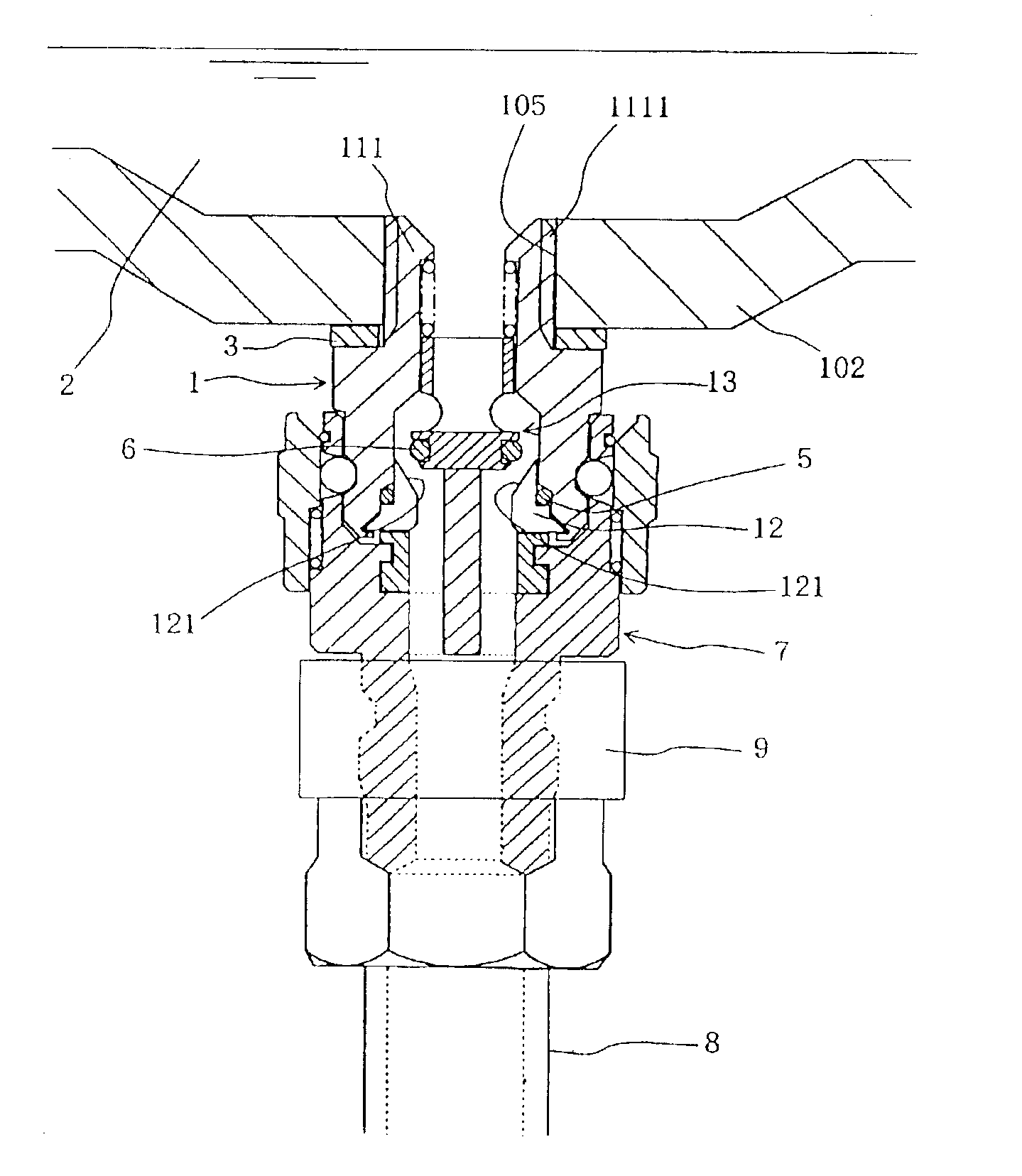

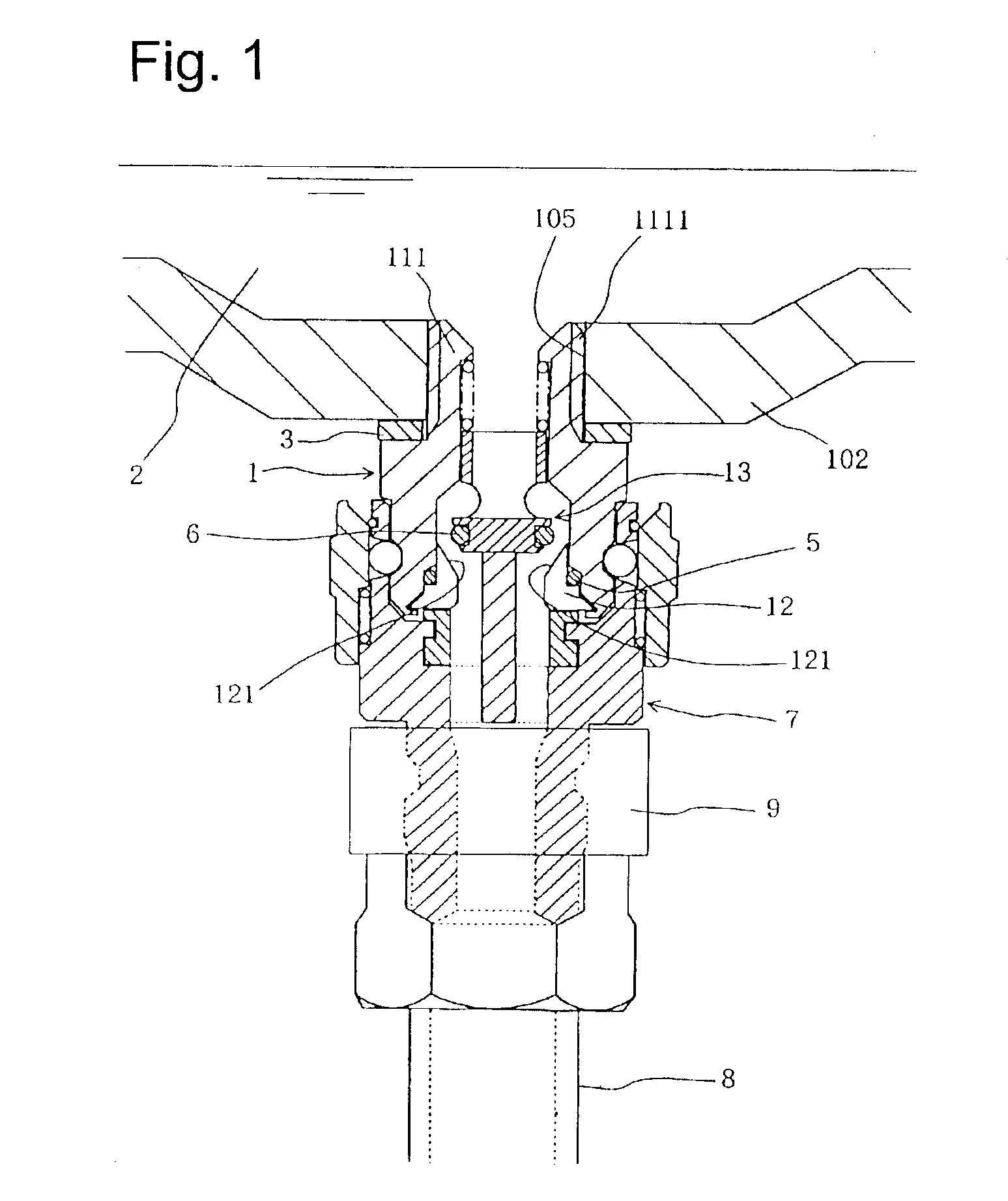

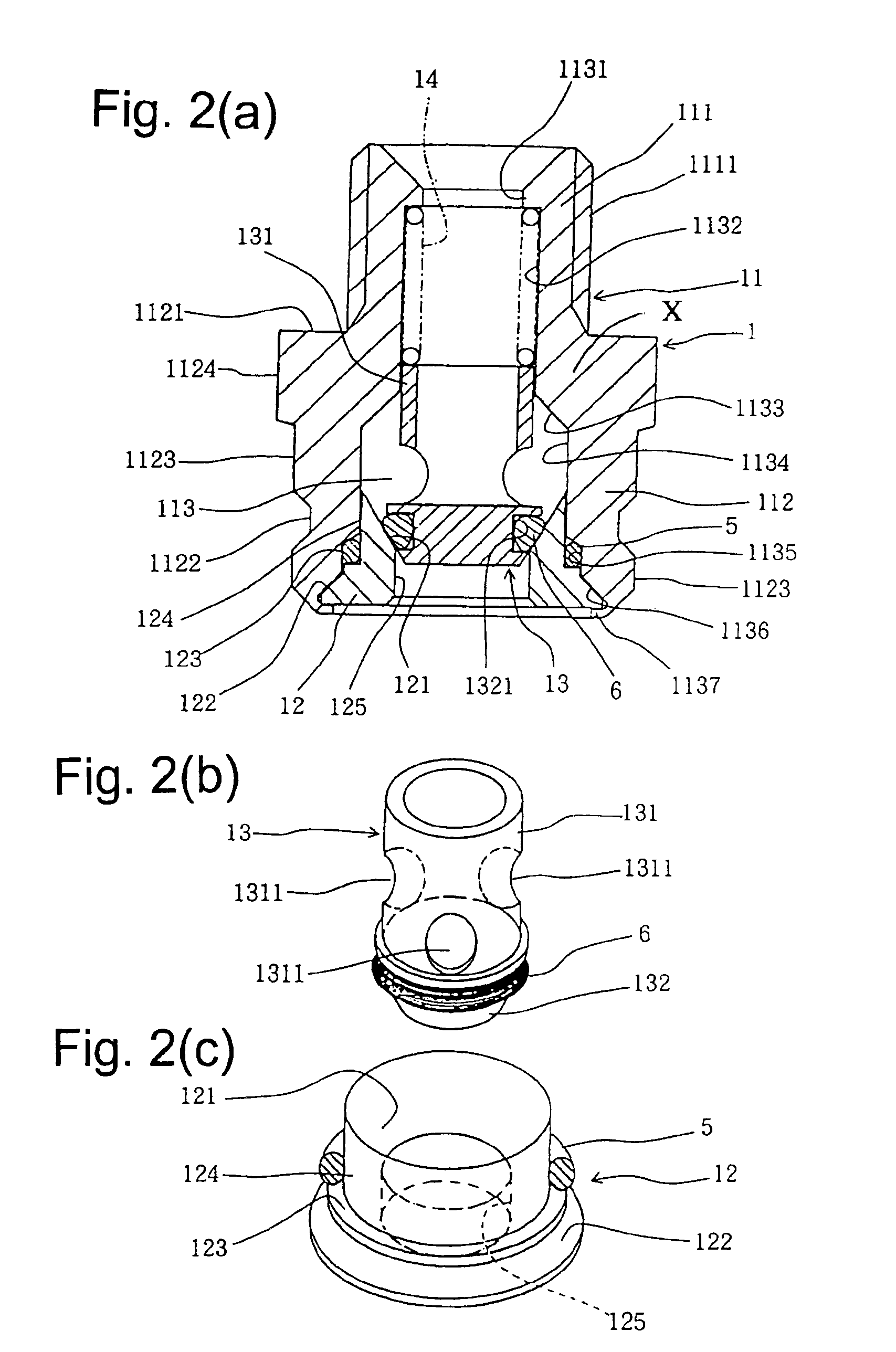

Thermostat for heat exchange loop

ActiveCN103574264ASimple structureReduce in quantityOperating means/releasing devices for valvesValve housingsWorking temperatureEngineering

The invention relates to a thermostat for a heat exchange loop. The thermostat for the heat exchange loop comprises a valve body provided with a cavity, and a thermal actuator arranged in the cavity in a matching way; the valve body also comprises two through holes including a first hole and a second hole which are respectively communicated with the cavity; the first ends of the second hole and the first hole are respectively communicated with an inlet and an outlet of an external fluid cooling device; the second ends of the second hole and the first hole are respectively a fluid inlet and a fluid outlet; the inner diameter of the cavity is larger than that of the second hole, and the cavity is communicated with the second hole; the end of the cavity close to the second hole is coincided with part of the second hole; an elastic part is sheathed at the peripheral side of the thermal actuator; one end of the elastic part leans against and is connected with the thermal actuator in a pressing way, and the other end of the elastic part leans against and is connected with a shoulder part formed by the bottom of the cavity and the second hole in a pressing way. After the thermostat for the heat exchange loop is adopted, the working temperature of lubricating oil is controlled to be within the effective range, and the lubricating property of the lubricating oil is maintained in the best state.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

Full-automatic bearing grease feeder

InactiveCN101956897ASave manpower and material resourcesSave materialLubrication check valvesOil and greaseMaterial resources

The invention discloses a full-automatic bearing grease feeder and belongs to a grease feeder. The grease feeder comprises a grease supplying device, an operation platform, a frame, a grease feeding device and a round plate, wherein the grease supplying device is connected to the grease feeding device; the grease feeding device comprises a rationally greasing valve, a grease transmitting plate and a grease injector; the lower part of the grease injector is provided with a grease head; a rotation plate is arranged in the round plate; the round plate is welded with the operation platform; the round plate is provided with a rejected type structure; one section of the joint between the round plate and a material channel is cut off; a clearance is leaved between the upper port on the cut part of the round plate and the bottom of the rotation plate; the rotation plate is connected to a motor; the upper surface of the rotation plate is in a same level with the upper surface of the operation platform; the operation platform is provided with a material pushing device and a touch screen; and the operation platform outside the round plate is provided with a discharge regulating device. The invention has simple manufacturing process, saves vast manpower and material resources, is easily regulated when the size is exchanged, has strong generality, can automatically remove the materials stored in the round plate, has small volume, is convenient to clean, and has the advantages of high efficiency, high intensity, light weight, material saving property, and the like.

Owner:SHANDONG XUNJIE PRECISION EQUIP

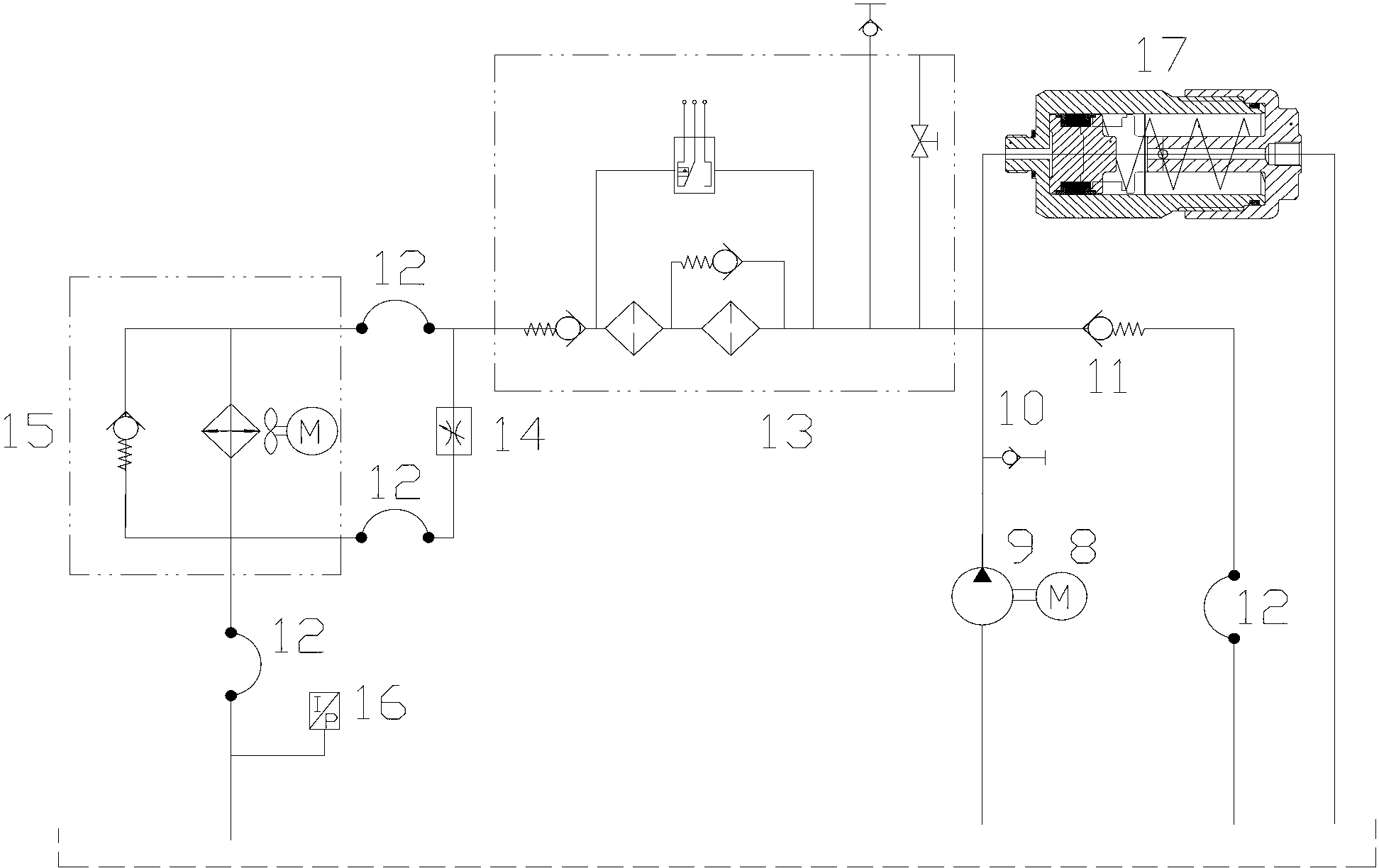

Hydraulic oil change device of gear casing of wind driven generator set

InactiveCN102359578ALow costSolve defects caused by repair and maintenanceGear lubrication/coolingConduits/junctionsWind drivenGear pump

The invention relates to an oil change device, in particular to a hydraulic oil change device of a gear casing of a wind driven generator set, which can be applied to the field of wind energy and can be used in a tower foundation so that lubricating oil of the gear casing of a blower can be replaced. The hydraulic oil change device of the gear casing of the wind driven generator set comprises the gear casing and an oil tank, wherein a gear pump is communicated with the oil tank through a pipeline, the gear pump is driven by a motor and is connected with a fine oil filter through a pipeline, the fine oil filter is connected with an oil exhaust hole of the gear casing through a pipeline, a manual reversing valve is arranged on the pipeline between the gear pump and the fine oil filter, a first branch pipeline is arranged on a pipeline between the manual reversing valve and the fine oil filter, and the end part of the first branch pipeline is provided with an overflow valve. The invention has the advantages of solving the defects caused by maintenance, improving the efficiency and the reliability in the maintenance process, and reducing the cost of the operation and the maintenance of the wind driven generator set.

Owner:沈阳瑞祥风能设备有限公司

Oil pump with selectable outlet pressure

ActiveCN103403307APositive displacement pump componentsPump controlInternal combustion engineManaging change

An oil pressure relief valve for use in the oil pump lubrication system of an internal combustion engine is controlled by both oil pump outlet pressure and by pilot pressure from a pilot valve which is selectively applied by a control member, preferably a two-way valve that is operated by the engine control module. The pilot valve selectively supplies one of the oil pump outlet pressure or the engine gallery pressure to the control member which selectively supplies pilot valve pressure to the oil pump pressure relief valve which has a single piston. The pilot valve includes first and second pistons for selectively controlling back pressure from the pressure relief valve and for managing changes in oil pressure due to changes in the engine gallery to maintain a virtually constant pressure even as oil pump speed increases when the control member connects the pilot valve to the pressure relief valve resulting in a fuel economy benefit and improved control of the oil pump pressure.

Owner:HANON SYST EFP CANADA LTD ONTARIO

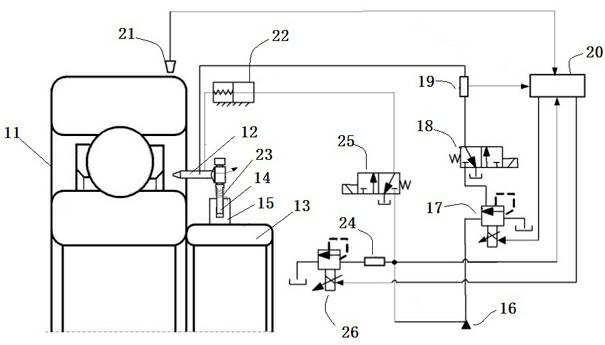

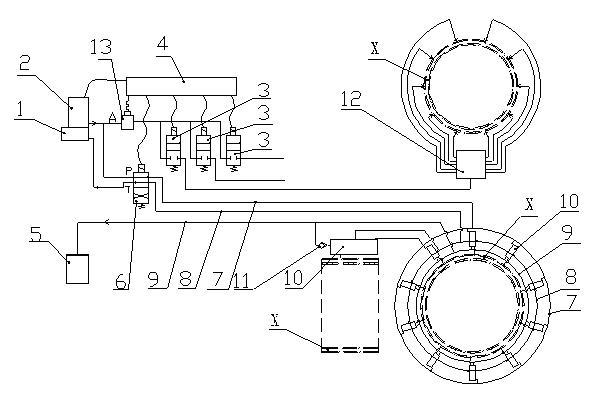

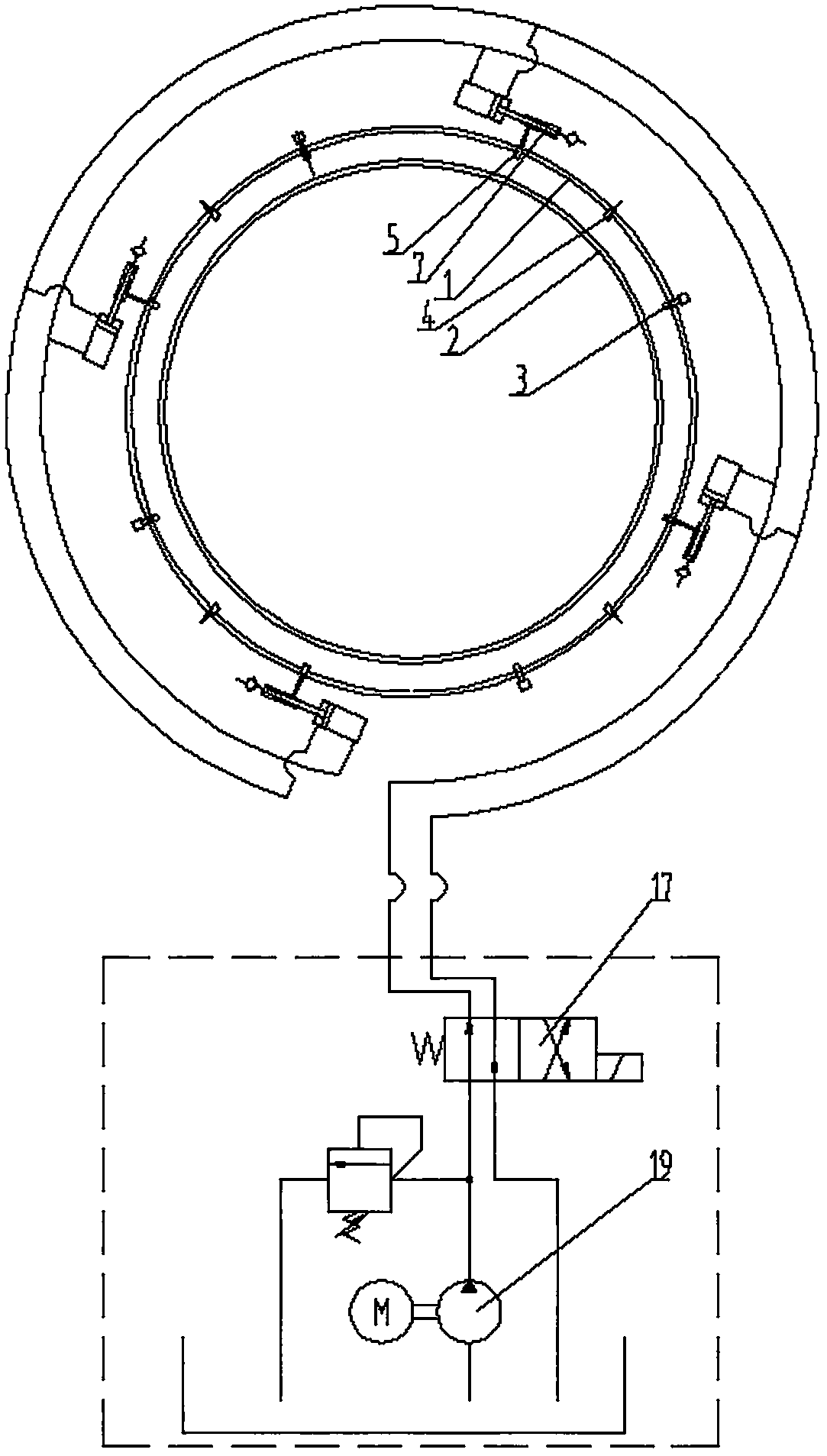

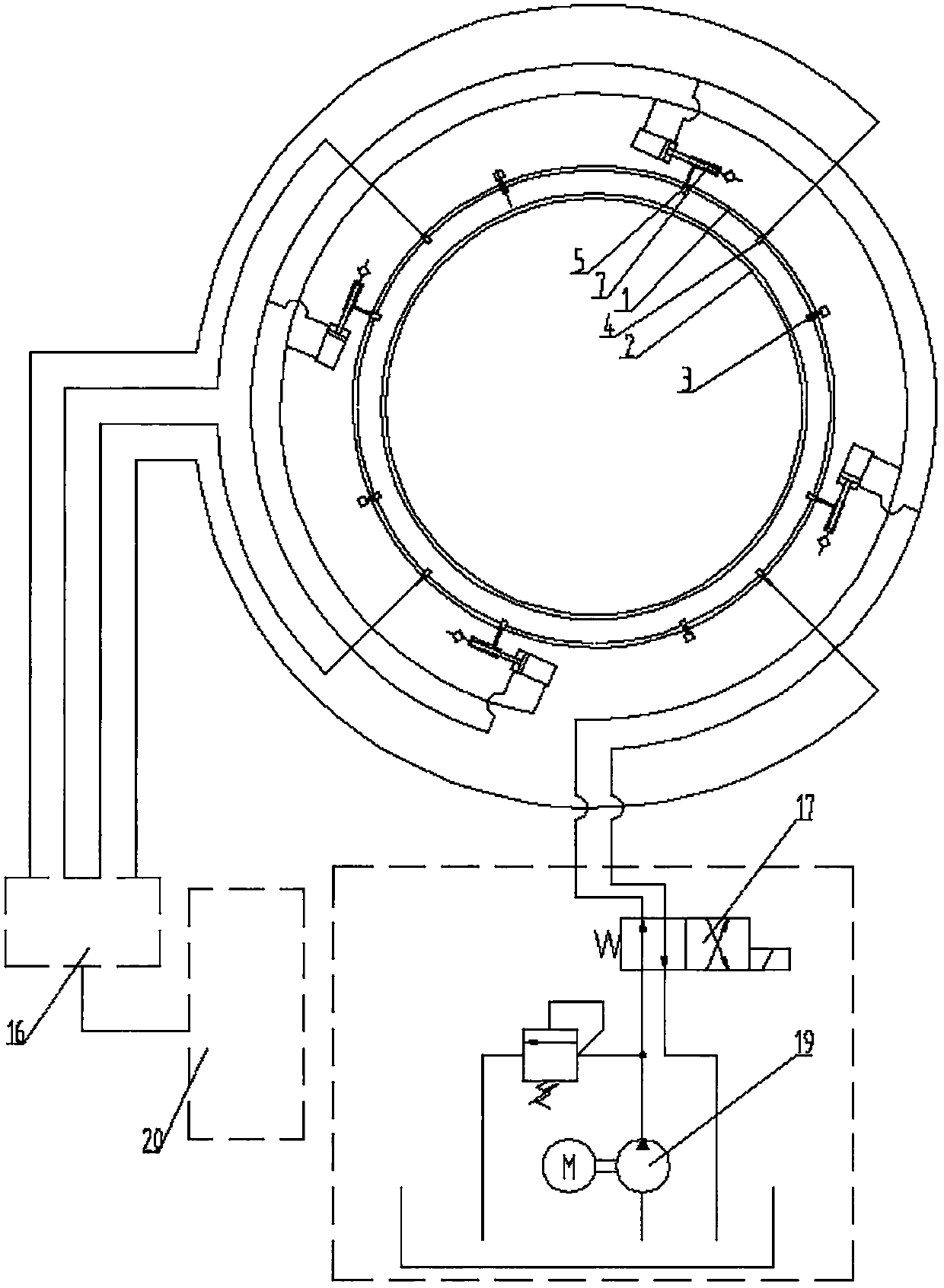

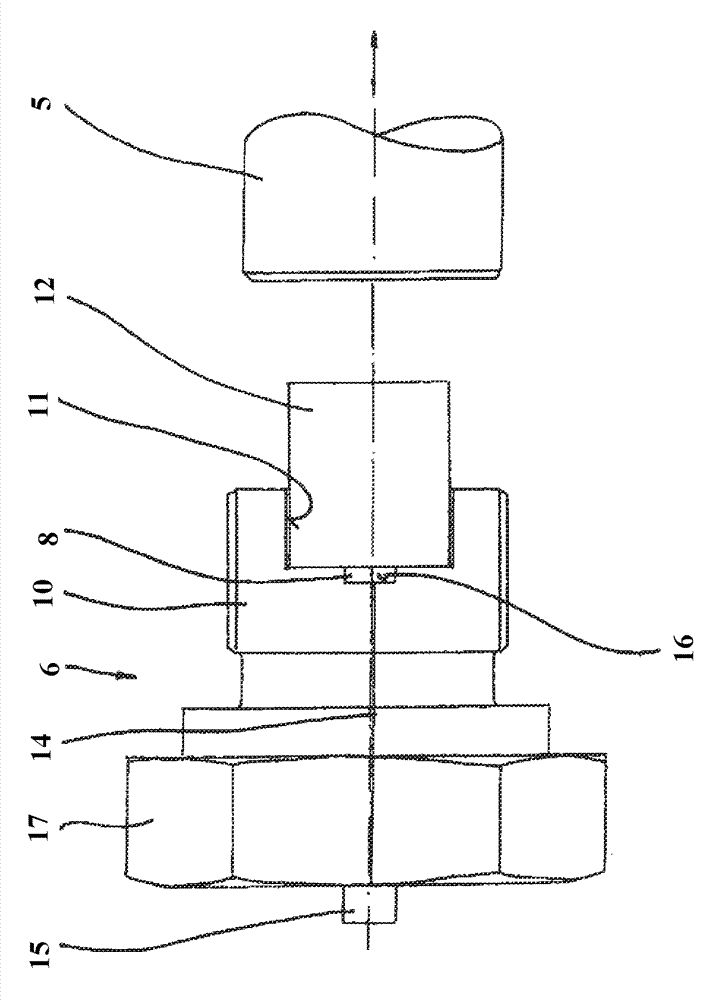

Method and device for implementing jet lubrication among rolling bearing rings

InactiveCN102679120AImprove lubrication statusImprove operating conditionsBearing assemblyLubrication check valvesRotational axisRolling-element bearing

The invention relates to a method and device for implementing jet lubrication among rolling bearing rings. The method for implementing jet lubrication among rolling bearing rings comprises the following steps of: 1) rotatablely arranging a nozzle on the axial side of a rolling bearing, wherein the rotational axis of the nozzle is perpendicular to the rotational axis of the rolling bearing, and a mouth of the nozzle faces a position between the inner ring of the rolling bearing and a cage; 2) connecting an oil pump on the nozzle, and setting the oil jet pressure and jet speed of the nozzle; and 3) rotatablely connecting a driving device for driving the nozzle to swing so as to adjust the inward-jet angle of lubricating oil on the nozzle, monitoring the rotating speed of the rolling bearing through a rotating speed sensor, transmitting a rotating speed signal of the rolling bearing to a controller, and presetting a proportion coefficient between the inward-jet angle of the lubricating oil and the DN (nominal diameter) of the rolling bearing in the controller, so that the controller controls the driving device to drive the nozzle to swing to a corresponding inward-jet angle of the lubricating oil according to the signals of the rotating speed sensor and the proportion coefficient between the inward-jet angle of the lubricating oil and the DN of the rolling bearing. According to the invention, the amount of oil jetted to the inside of the rolling bearing can be controlled.

Owner:HENAN UNIV OF SCI & TECH

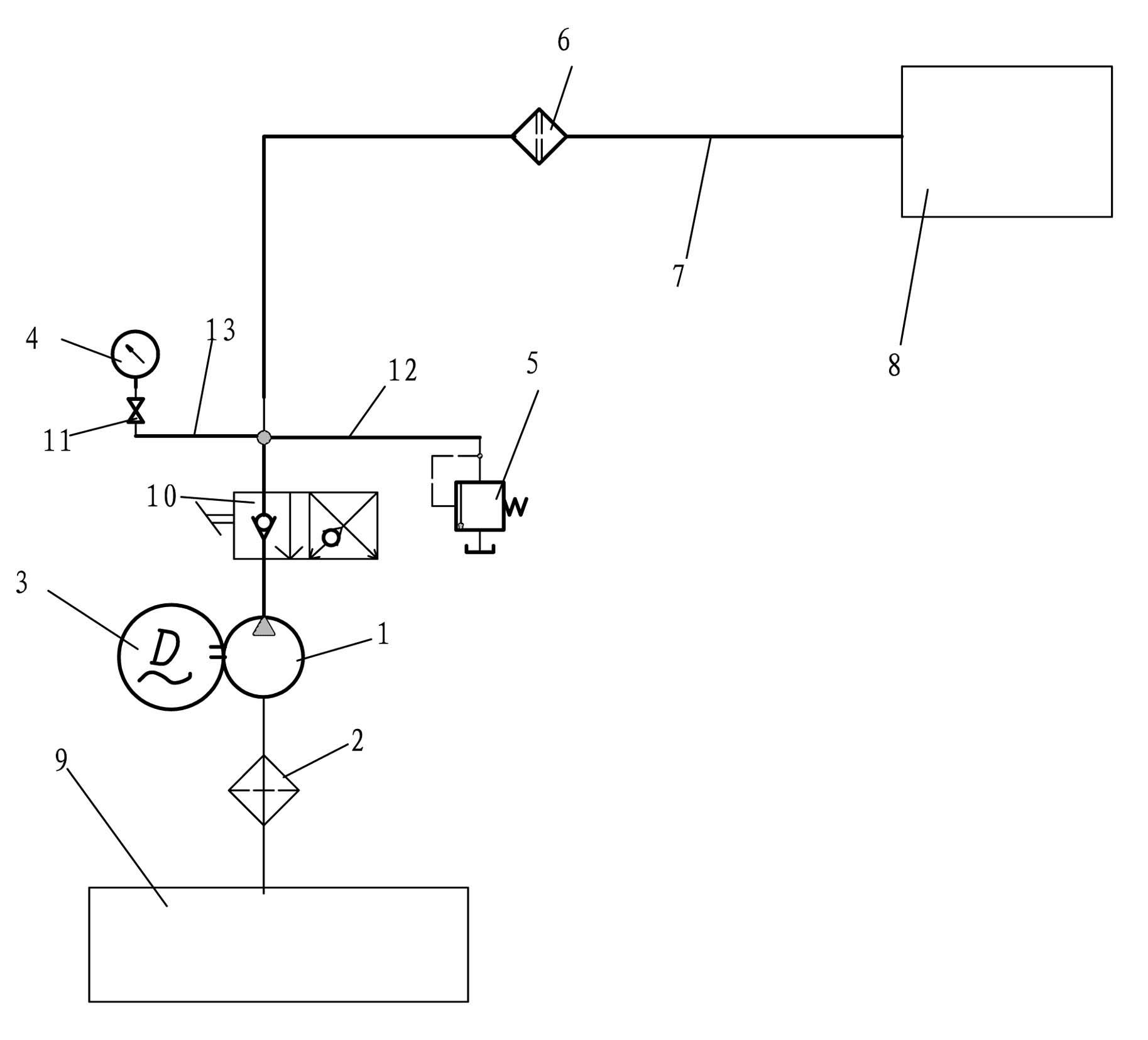

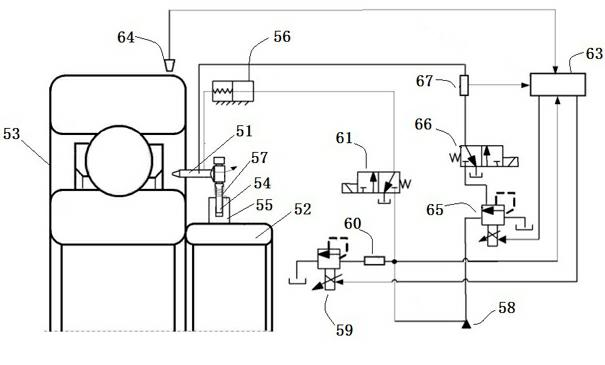

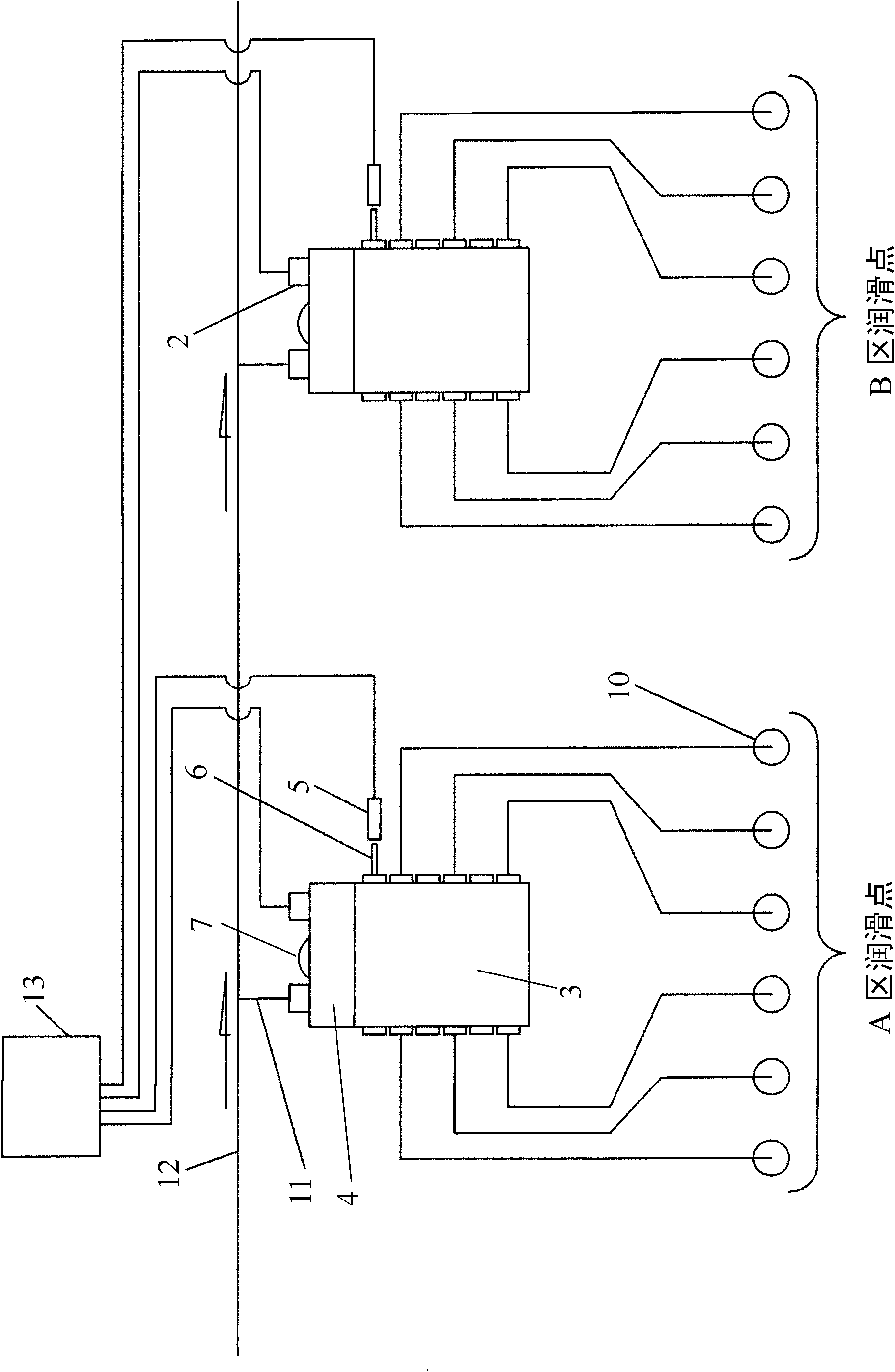

Grease centralized lubrication and recovery system

ActiveCN102322563AAutomatic recovery in timeLow costLubricating pumpsLubrication check valvesOil and greaseWaste oil

The invention relates to a grease centralized lubrication and recovery system. The system comprises a pressure oil pump, a two-position two-way electromagnetic valve, a waste oil collection device, an electronic control device and the like, wherein the pressure oil pump is provided with two oil outlet circuits; one oil outlet circuit is a lubrication oil supply circuit; the two-position two-way electromagnetic valve is connected to the lubrication oil supply circuit; the waste oil collection device comprises a pressure control oil circuit, a waste oil collection oil circuit, a waste oil collection container and the like; the other oil outlet circuit of the pressure oil pump supplies oil to the pressure control oil circuit; and the waste oil collection oil circuit comprises a waste oil collection pipe and a hydraulic piston pump. Under the control of the electronic control device, the pressure oil pump supplies grease to a lubrication point through the two-position two-way electromagnetic valve and the like, the pressure control oil circuit controls the hydraulic piston pump to suck waste grease from the lubrication point and press and discharge the waste grease in the waste oil collection pipe, and the waste grease is converged in the waste oil collection container.

Owner:AUTOL TECH

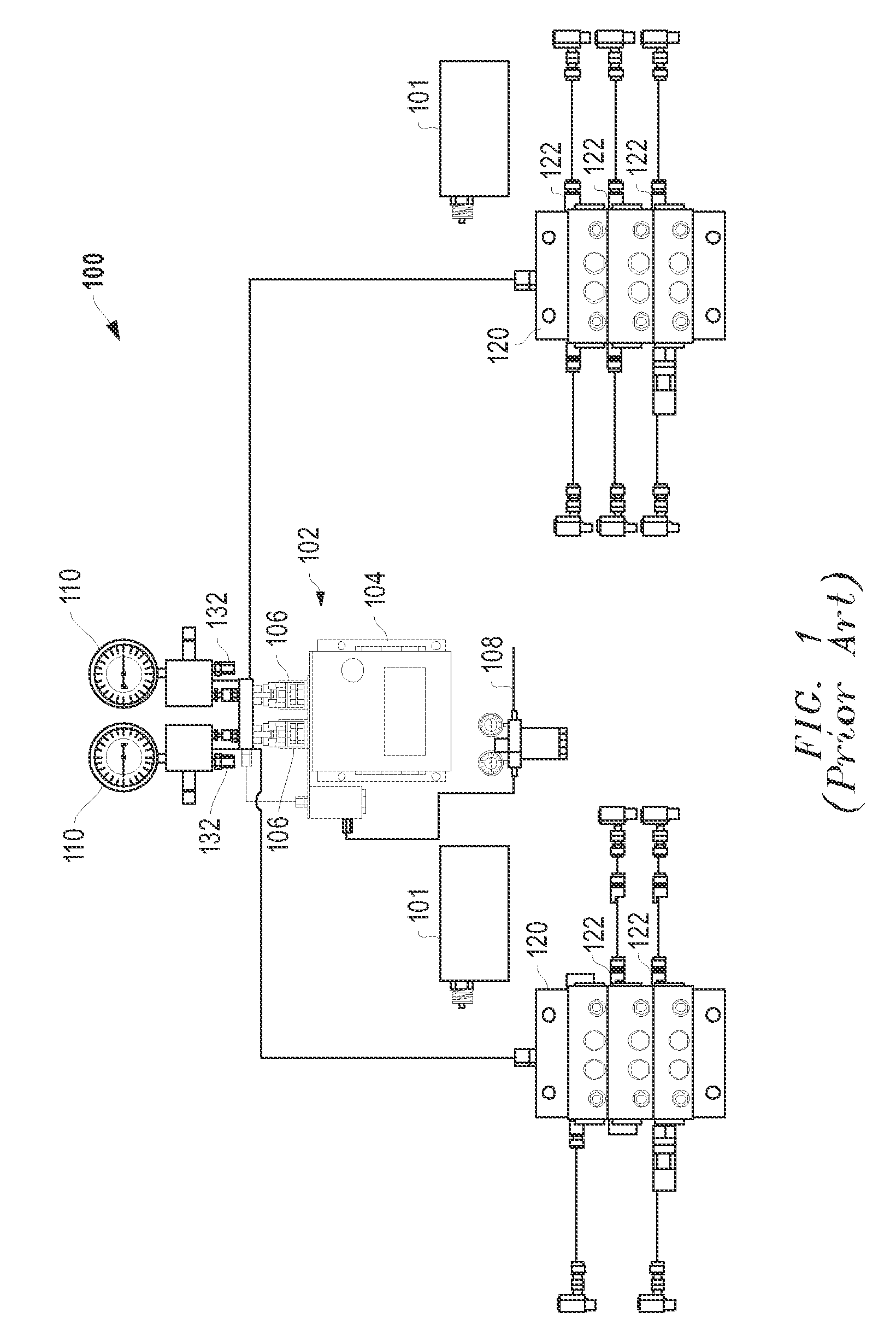

Environmental compressor protection assembly

A device that relieves lubricant pressure in a divider block lubrication system into a fluid reservoir, a container, or directly back into the compressor frame to which the tubing is connected. This eliminates housekeeping, environmental, safety, and compressor component failure concerns associated with current atmospheric rupture assemblies that relieve directly to the atmosphere. The environmental compressor protection assembly contains a spring set to a pre-determined pressure. Lubricant pressure in excess of this pre-determined set pressure results in spring compression and opening of a relief path. The assembly preferably remains in a full open position and must be must be manually reset to the closed position to prevent fluid flow in the system. A preferred assembly for maintaining the valve in either the open and closed position includes two balls, one of which remains trapped behind a pin during normal operation and is forced from behind the pin during an overpressure condition, the ball being prevented by the geometry of the housing from returning without manual intervention to its operating position. The relief path can lead to a fluid reservoir, a container, or directly back into the compressor frame. Flow of lubricant through the relief path results in loss of flow to the lubrication system. This triggers an alarm in the no-flow system and shutdown of the compressor. The relief path remains open until an operator resets the device. A visual indicator shows an operator if the relief valve is open or closed.

Owner:COMPRESSOR PROD INT

Oil drain valve

InactiveUS20050258392A1Easy to holdEliminate needCrankshaftsOperating means/releasing devices for valvesPush pullEngineering

A drain valve to be used with numerous drain applications, such as draining fluid from an engine, includes in an exemplary embodiment a valve body, an o-ring and a cap. In another exemplary embodiment, the drain valve includes a valve body, an o-ring, a cap retainer and a cap. The drain valve eliminates the need for a tool, such as a wrench, to drain the fluid from the engine, for example. The drain valve includes a push-pull or a twist-and-pull cap feature to manipulate the valve; however, the drain cap remains on the drain valve and therefore cannot be lost or misplaced. Moreover, the drain valve includes a drain cap that is rotatable to direct the fluid flow out the valve and also provides an easy grip for opening and closing the valve.

Owner:ILLINOIS TOOL WORKS INC

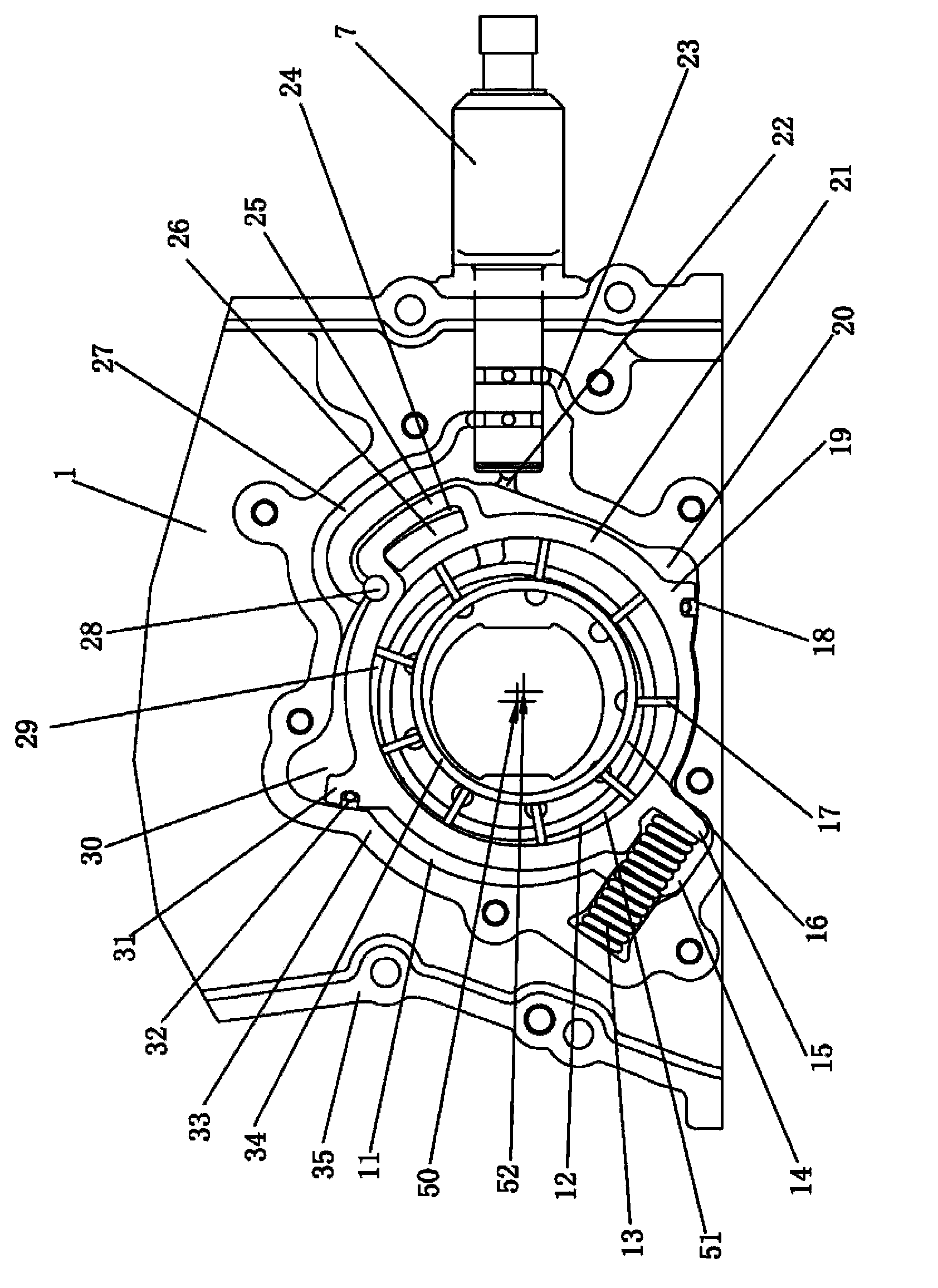

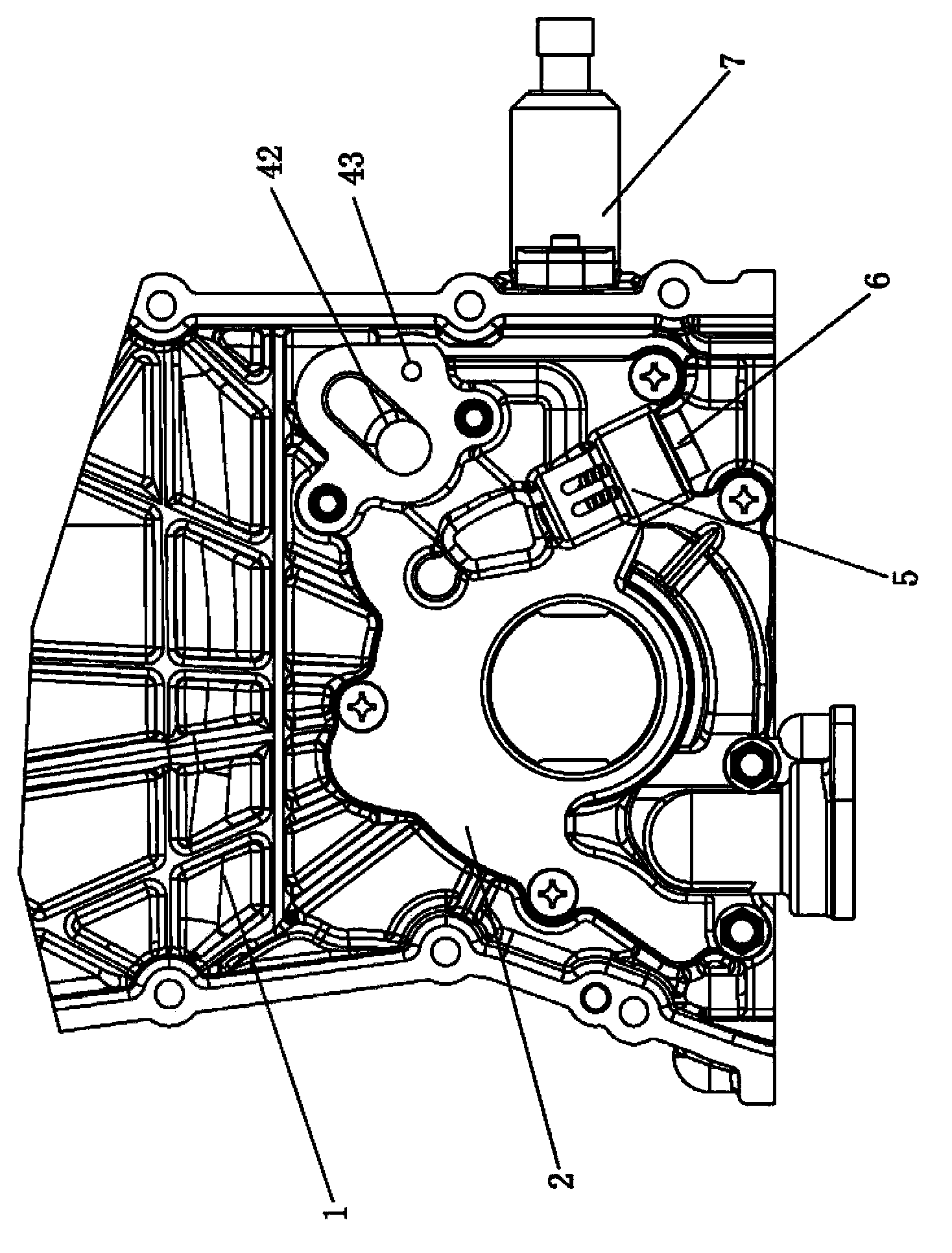

Oil pump with variable displacement

InactiveCN103775811AAvoid consumptionTo achieve the effect of energy saving and emission reductionLubricating pumpsLubrication check valvesControl roomEngine power

The invention discloses an oil pump with variable displacement. The oil pump with variable displacement comprises an inner cavity, wherein a stator, a rotor and an elastic element are arranged in the inner cavity, the stator and the rotor are eccentrically arranged, multiple blades are fixed to the rotor, a first control chamber is arranged between the stator and the inner cavity, a first oil line is communicated with a feedback oil line of a main oil gallery of an engine, a first protruding block is arranged on the stator, a second control chamber is arranged between the stator and the inner cavity, a second protruding block which extends into the second control chamber is arranged on the stator, the second control chamber is communicated with a second oil line, the first oil line is connected with the second oil line through a reversing valve, and the reversing valve is used for controlling the second control chamber to be communicated with the first control chamber or an oil pan. According to the oil pump with variable displacement, since the electrically-controlled two-stage variable displacement technology is adopted, the displacement of the oil pump can be adjusted according to different demands of the engine for engine oil flow under different working conditions, the situation that the oil pump consumes excessive engine power is avoided, and the effects of energy conservation and emission reduction of the whole oil pump are achieved.

Owner:北京汽车动力总成有限公司

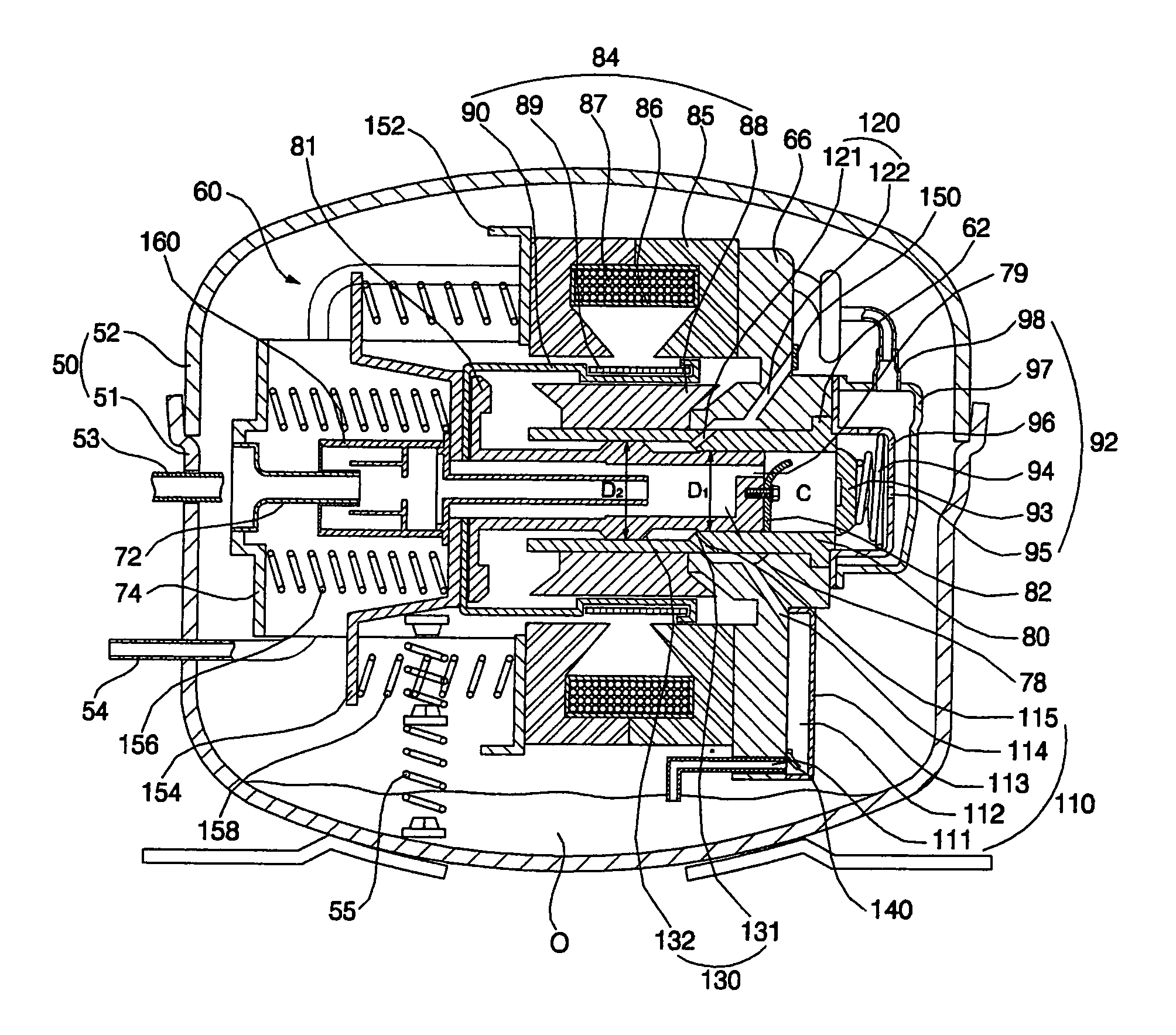

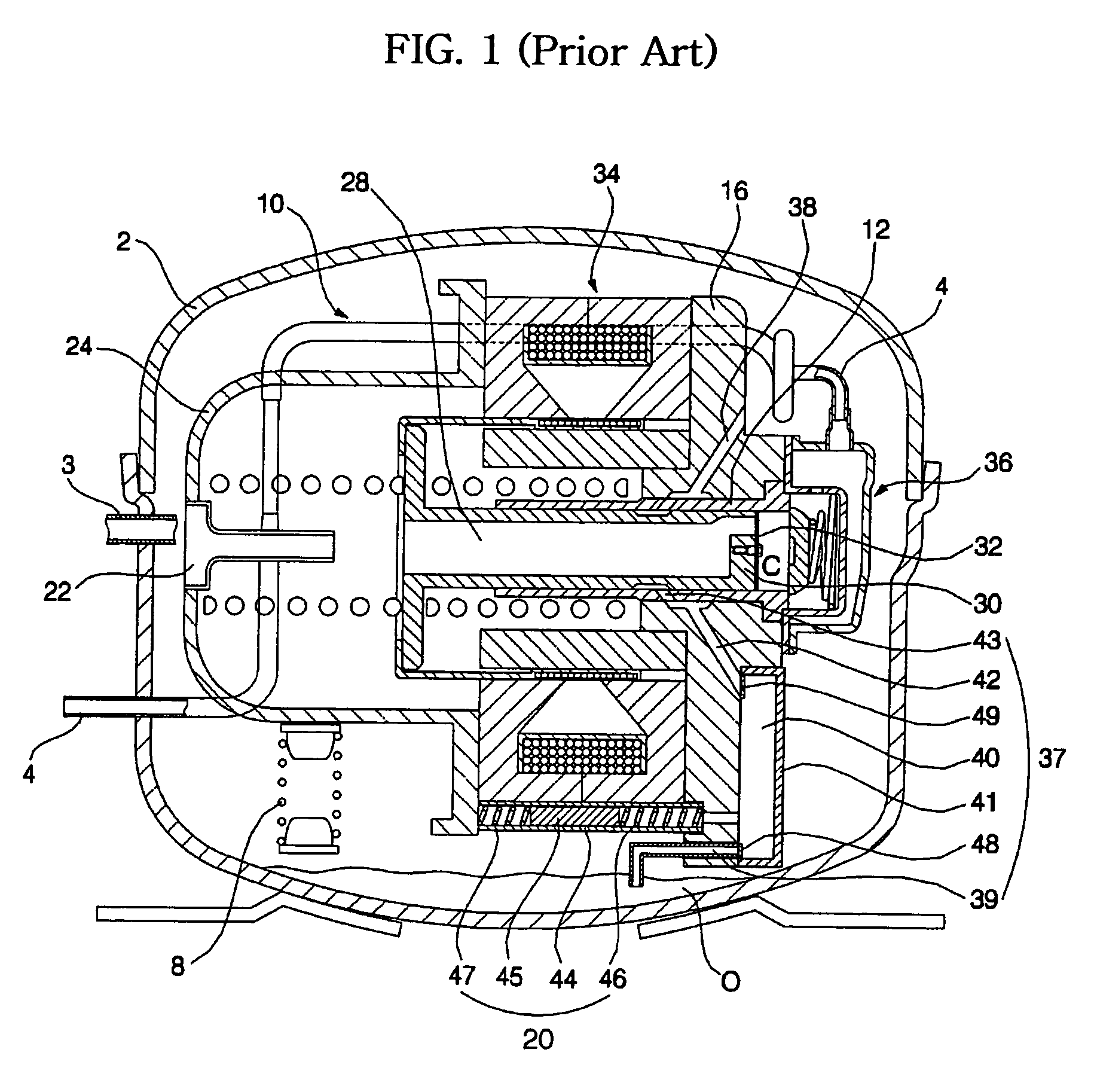

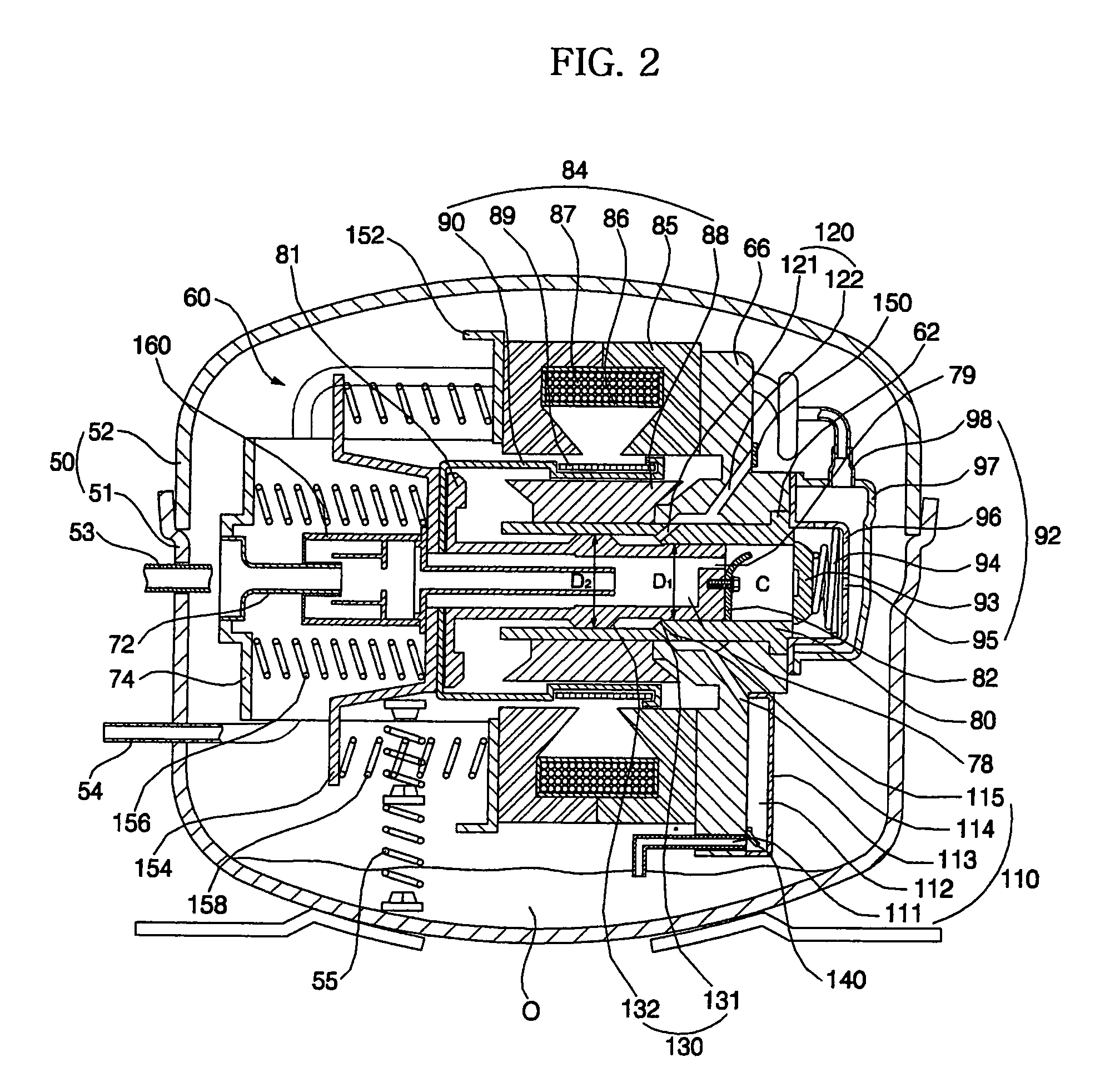

Linear compressor

InactiveUS7748963B2Simplified oil pumping structureLow costPositive displacement pump componentsEngine fuctionsLinear compressorHigh pressure

Disclosed herein is a linear compressor, which is designed in such a fashion that oil is suctioned into a space between a cylinder and a piston by a low pressure produced between the cylinder and the piston when the piston moves backward, and then is discharged to the outside by a high pressure produced between the cylinder and the piston when the piston moves forward, resulting in a simplified oil pumping structure and low cost.

Owner:LG ELECTRONICS INC

Check valve

ActiveUS20160097486A1Improve integrityAvoid checkingPositive displacement pump componentsCheck valvesEngineeringCheck valve

A check valve supplies fluid to a system and includes a fluid barrier protects the sealing elements and surfaces of the check valve preventing degradation from any backflow of gas and debris from the system to which fluid is supplied.

Owner:ROYS CURTIS

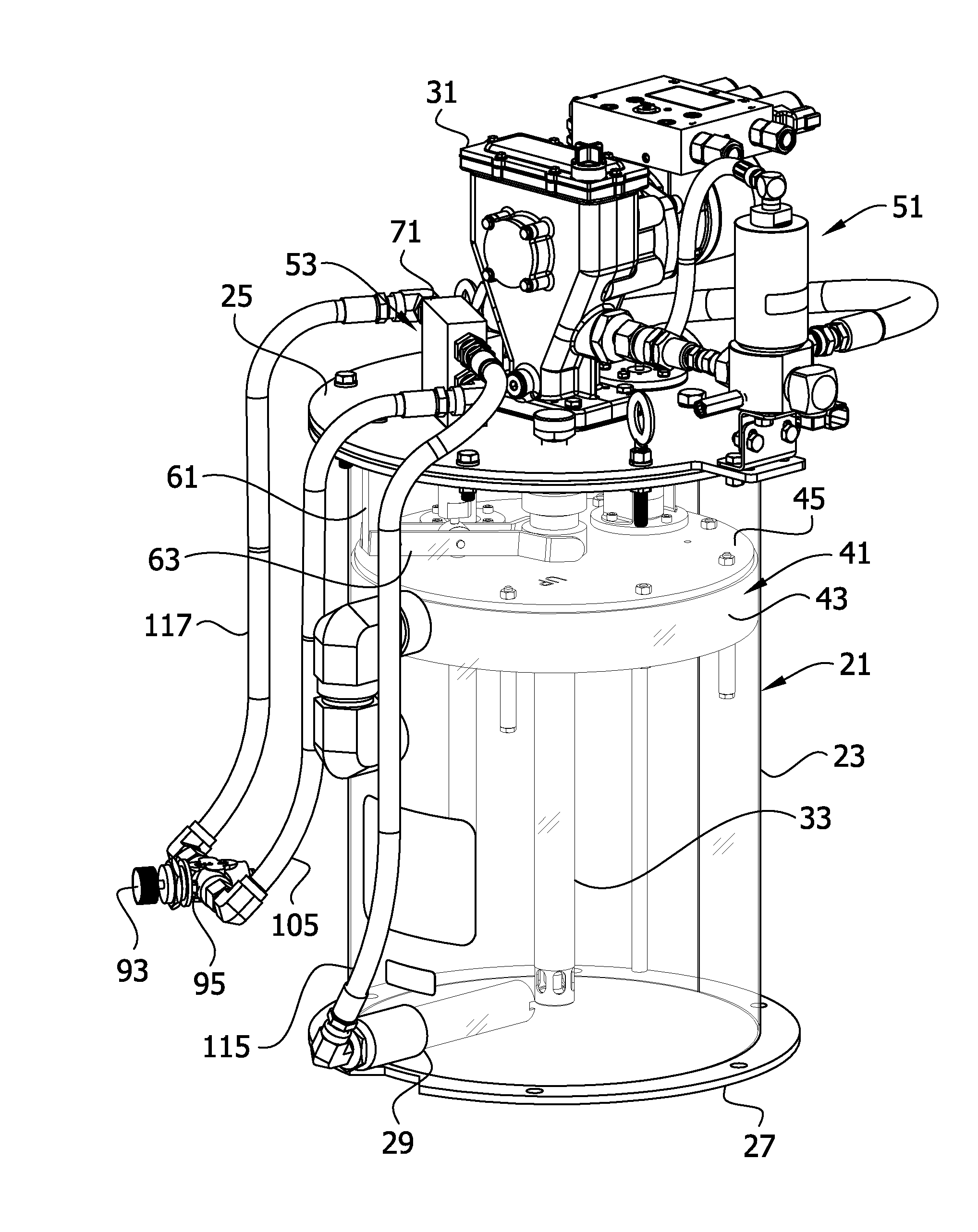

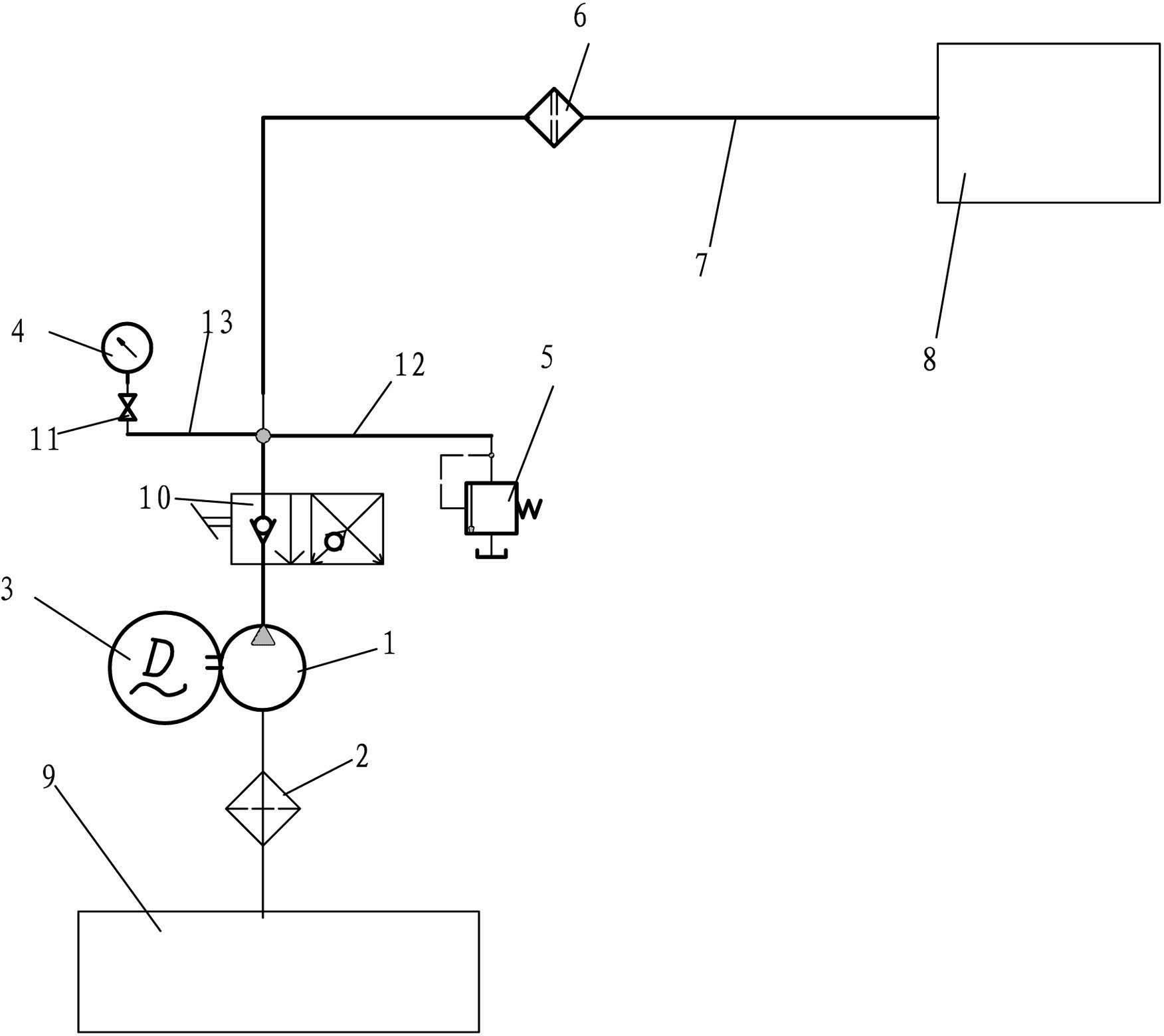

Wind-powered lubrication system with pressure buffer

ActiveCN103016934AReduce pressure shock peaksImprove safety performanceFinal product manufactureWind motor componentsElectricityTemperature control

The invention relates to a wind-powered lubrication system with a pressure buffer. The wind-powered lubrication system comprises a dual-speed motor, an electric oil pump, a pressure detection contact, a one-way valve, a filter device, a temperature control valve, an air cooler, a pressure sensor and the pressure buffer, wherein the pressure buffer is connected between an outlet of the electric oil pump and an interface of the filter, a piston type hydraulic cylinder with no piston rod is adopted as the pressure buffer, one side cavity of a piston is communicated with an outlet of the electric oil pump through a pipeline, a reset spring is arranged on the other side cavity, and the cavity with the reset spring is communicated with an interface of a gearbox or a fuel tank. The wind-powered lubrication system has the beneficial effects that the pressure impact peak in low-temperature startup of the wind-powered lubrication system can be reduced effectively, system pressure fluctuations at low temperature and room temperature can be absorbed, and the performance of the device for safety use can be improved; the pressure buffer has a simple structure, can be conveniently installed and is suitable for series mass production; and the work interval is large and cannot be affected by the ambient temperature.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

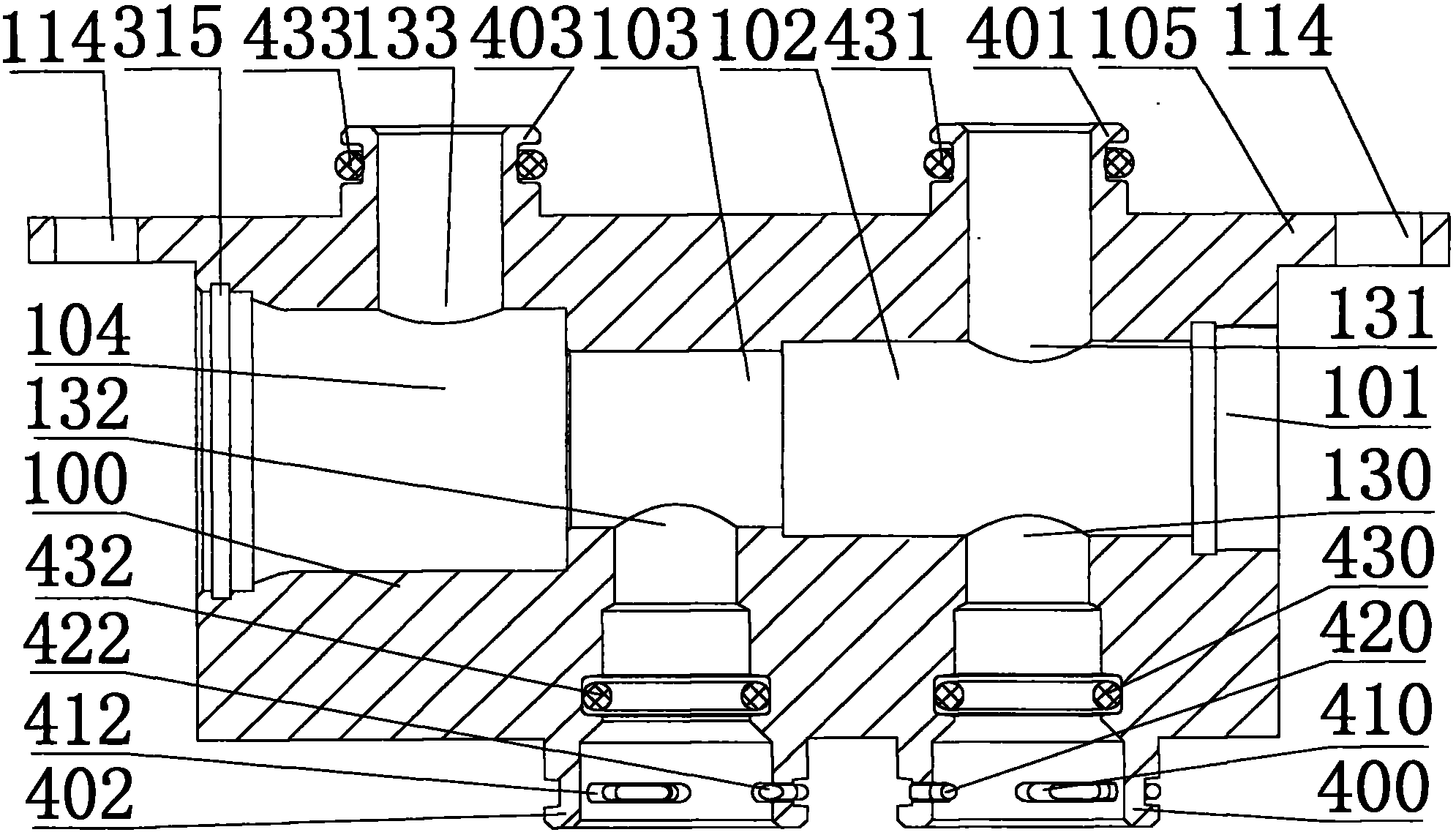

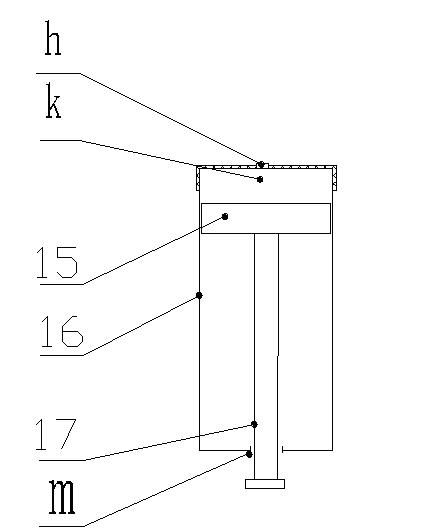

Automatic bearing waste grease collecting system and automatic bearing grease changing system

PendingCN107701902AReasonable stressEasy to startBearing componentsLubrication check valvesOil and greaseInternal pressure

The invention discloses an automatic bearing waste grease collecting system and an automatic bearing grease changing system. The automatic bearing waste grease collecting system of the automatic bearing grease changing system comprises a bearing structure, a lubricating space used for containing lubricating grease is arranged between an outer ring and an inner ring of the bearing structure, the bearing structure is provided with grease outlets which communicate with the lubricating space, a suction and discharge device is arranged at each grease outlet in a communicating manner, and each suction and discharge device is provided with an independent power system. According to the automatic bearing waste grease collecting system and the automatic bearing grease changing system, each suction and discharge device is provided with one independent power system and has nothing to do with an injection device, so that the suction and discharge devices can be started conveniently, the starting frequency of each suction and discharge device is adjusted according to practical requirements, suction and discharge work is conducted according to practical requirements, and therefore it is guaranteed that the internal pressure state of the bearing structure is reasonable.

Owner:AUTOL TECH

Auxiliary pressure relief valve

The invention relates to an auxiliary pressure relief valve which comprises a sliding valve body and a sliding valve core which is arranged in the valve body in a sliding way, wherein the sliding valve body is of a cylindrical structure with one open end, one end face of the sliding valve core, which is far away from the closed end of the valve body, is provided with an axial blind hole, the peripheral surface of the sliding valve body is provided with an oil outlet which is communicated with the axial blind hole, the sliding valve body is provided with an oil outlet channel which is communicated with the oil outlet after the sliding valve core bears an upstream oil-pumping pressure and is displaced; a pressure relief spring which is used for returning the sliding valve core after the upstream oil-pumping of the sliding valve core is completed is arranged between one end of the sliding valve core, which is far away from the axial blind hole, and the closed end of the sliding valve body; a sealing pressure relief route for downstream pressure relief during the returning process of the sliding valve core exists between the oil outlet and the inner wall face of the sliding valve body; and the peripheral face of the sliding valve core, which corresponds to the oil outlet, is provided with a peripheral ring groove, and / or the inner wall face of the sliding valve body, which corresponds to the oil outlet channel and matches with the oil outlet, is provided with a peripheral ring groove.

Owner:AUTOL TECH

Temperature regulator for gearbox of vehicle

InactiveCN102359577AImprove the lubrication effectAvoid interferenceGear lubrication/coolingLubrication check valvesElastic componentWorking temperature

The invention relates to a temperature regulator for a gearbox of a vehicle, and the temperature regulator comprises a valve body provided with a cavity, and a thermal power element installed in the cavity, wherein the valve body further comprises two through holes, namely a first hole and a second hole which are respectively communicated with the cavity; first ends of the second hole and the first hole are communicated with the inlet and outlet of an external fluid cooling device respectively, and second ends of the second hole and the first hole are respectively provided with a fluid inlet and a fluid outlet; one end of the cavity is communicated with the second hole through an intercommunicating pore; and the thermal power element is fixedly mounted in the cavity, and an elastic component is sleeved on the periphery of the thermal power element, one end of the elastic component tightly props against the thermal power element, and the other of the elastic component is in compacting contact with the wall of the second hole through a communicating hole. By using the temperature regulator for the gearbox of the vehicle provided by the invention, the working temperature of lubricating oil can be controlled within an effective range, thereby maintaining the optimal state of the lubricating property of the lubricating oil.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS

Speed oil filling device for pulse generator of wireless inclinometer and using method thereof

ActiveCN102080534AReduce residual air bubblesNo looseningSurveyLubrication check valvesVacuum pumpAtmosphere

The invention relates to a speed oil filling device for a pulse generator of a wireless inclinometer and a using method thereof, wherein the oil-filled device comprises a vacuum pump, an oil tank, an oil inlet pipeline and an oil outlet pipeline; the oil tank is internally provided with a suction pipe, an oil filling pipe and an oil charging pipe, wherein the suction pipe is connected with the vacuum pipe, and the communication is controlled by a third valve; the oil filling pipe is connected with the oil inlet pipeline, and the communication is controlled by a first valve; and the oil charging pipe is connected with the oil outlet pipeline, and the communication is controlled by a second valve; the lower end of the suction pipe is provided with a fourth valve for controlling the communication between the oil tank and the atmosphere; the ports of the oil inlet pipeline and the oil outlet pipeline are respectively provided with fast insertion type oil filling plugs; and each valve is in seal connection with the corresponding pipeline via a quick screwing type fast plug. The speed oil filling device provided by the invention has excellent sealing performance; a single-hole oil filling method or a double-hole oil filling method is provided; the air remained in an oil bag of the pulse generator is reduced as possible; and the oil is fast and conveniently filled in the pulse generator.

Owner:SHANGHAI GASOLINEEUM & CHEM EQUIP +1

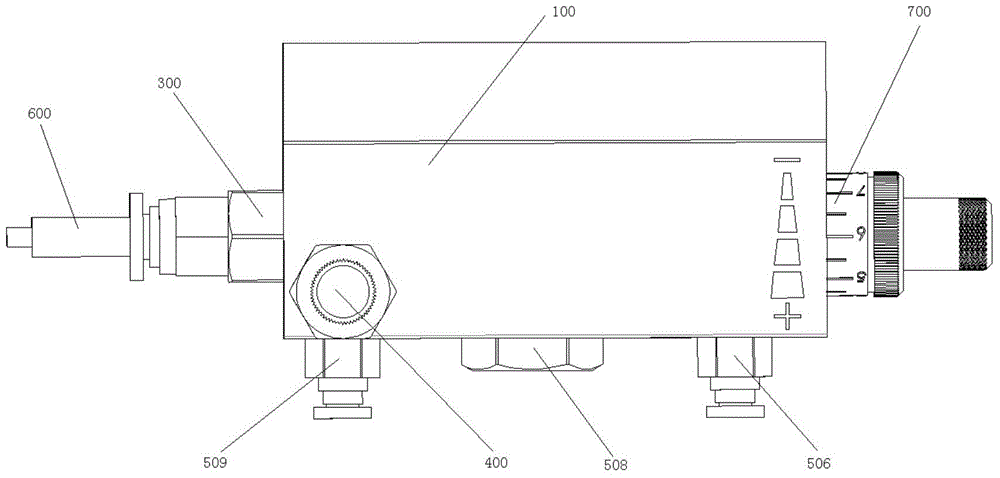

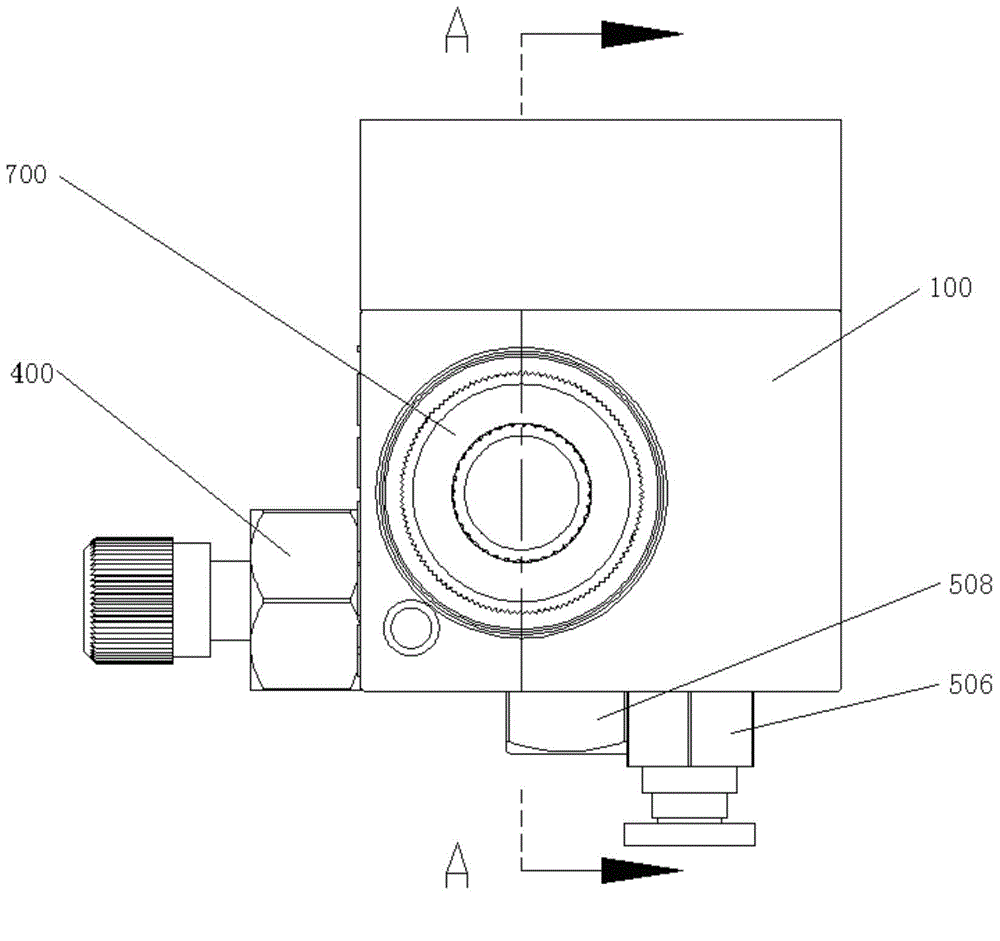

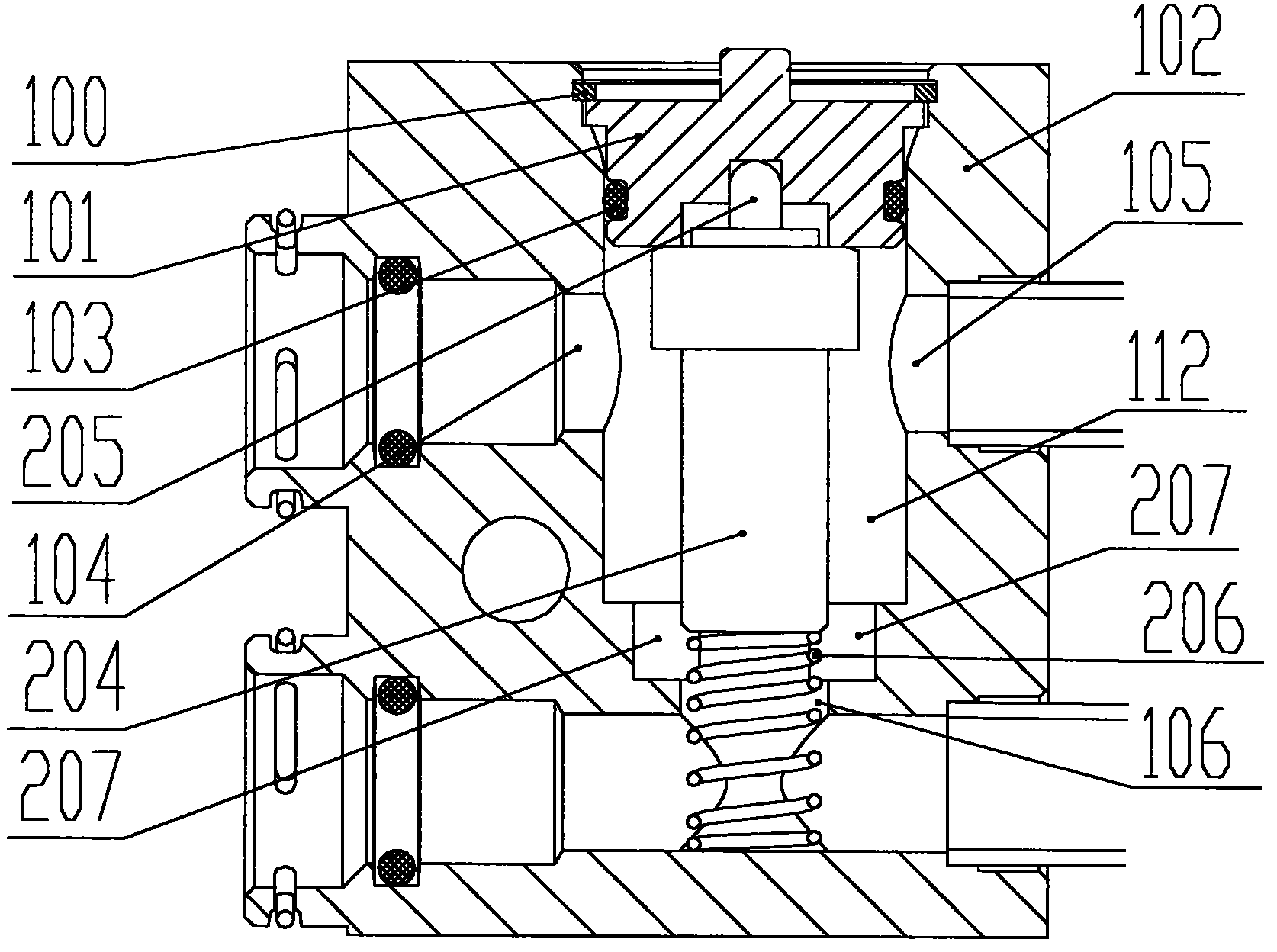

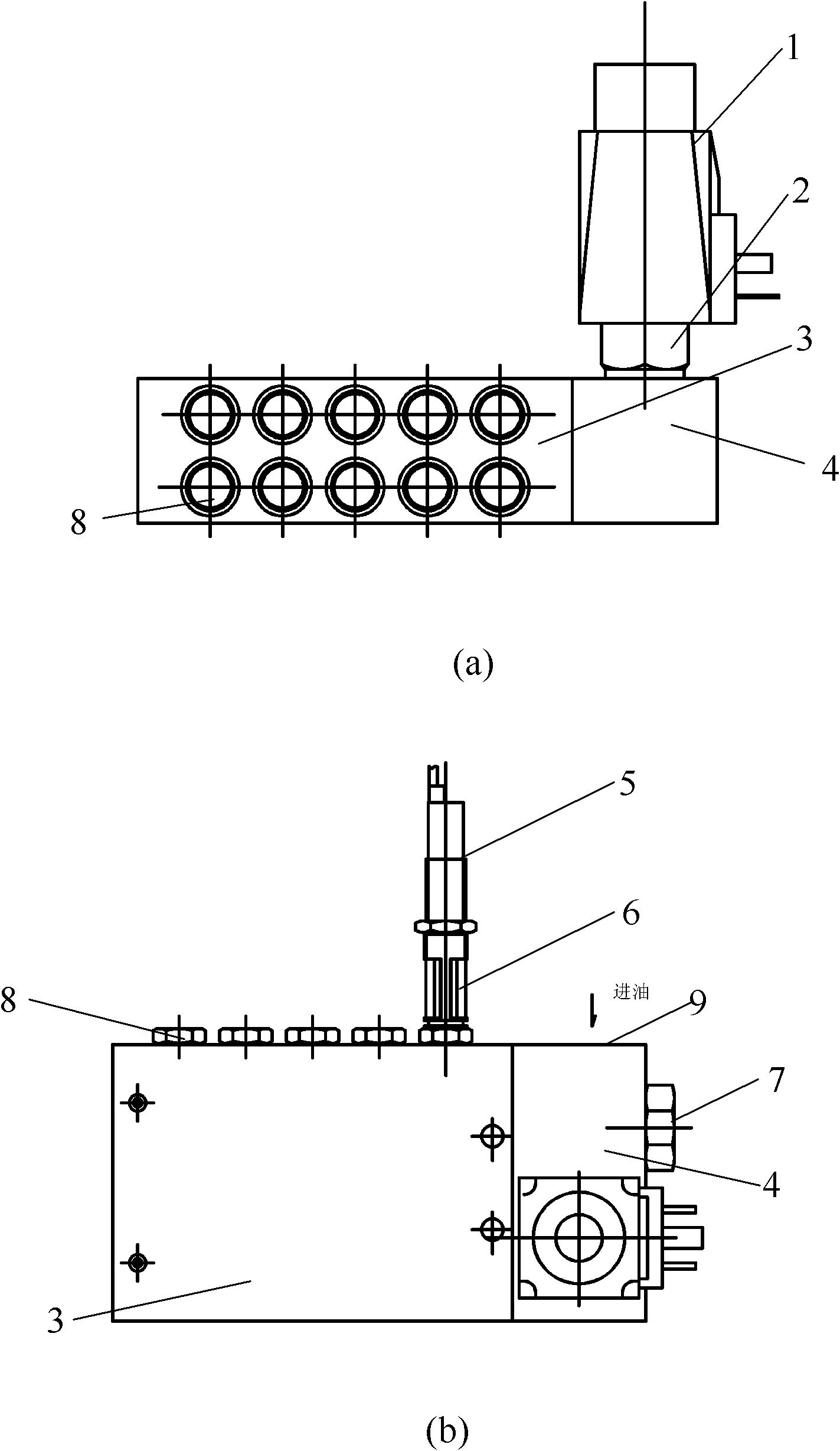

Single-wire intelligent lubricating oil distributor assembly

InactiveCN102072394APrecision lubricationAdd filtering partDistribution equipmentLubrication check valvesSolenoid valveDistributor

The invention provides a single-wire intelligent lubricating oil distributor assembly, which comprises a filter (7), a distributor valve body part (3) and a solenoid valve (2). The filter (7) is used for filtering lubricating oil entering the distributor assembly; the distributor valve body part (3) is used for distributing the lubricating oil; the solenoid valve (2) is arranged between the filter and the distributor valve body part and is used for controlling whether the lubricating oil enters the distributor valve body part; and the filter (7), the distributor valve body part (3) and the solenoid valve (2) are combined into a whole.

Owner:秦皇岛市隆达润滑技术研发有限公司

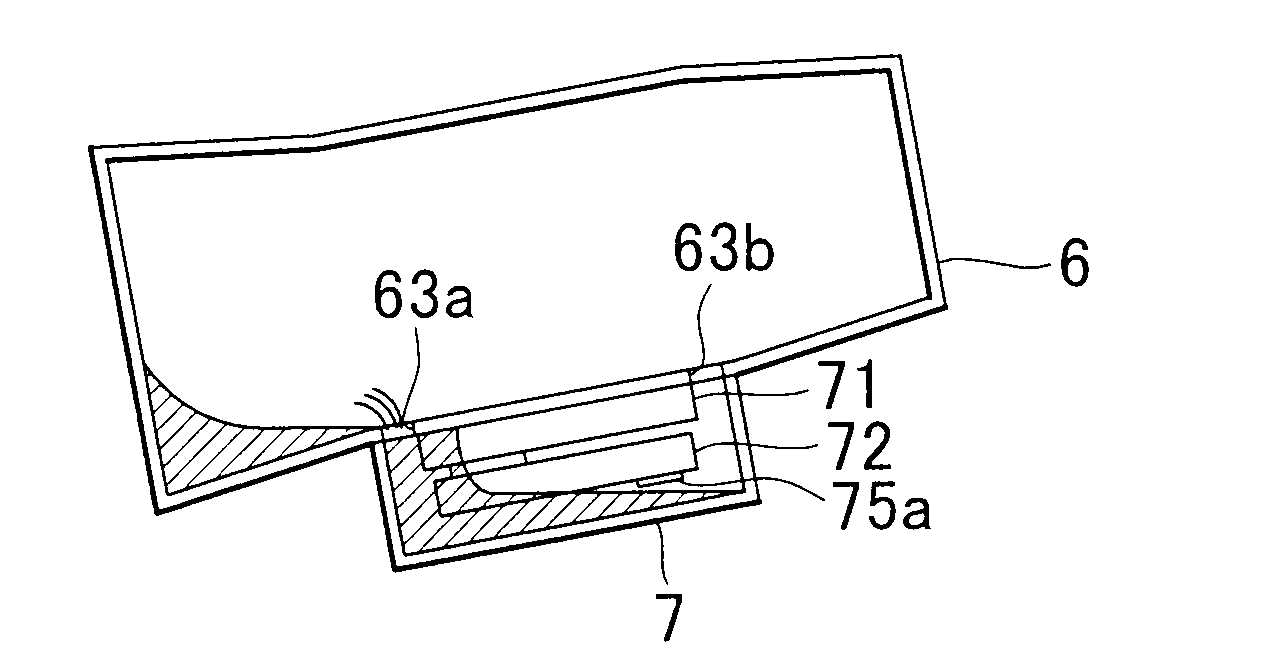

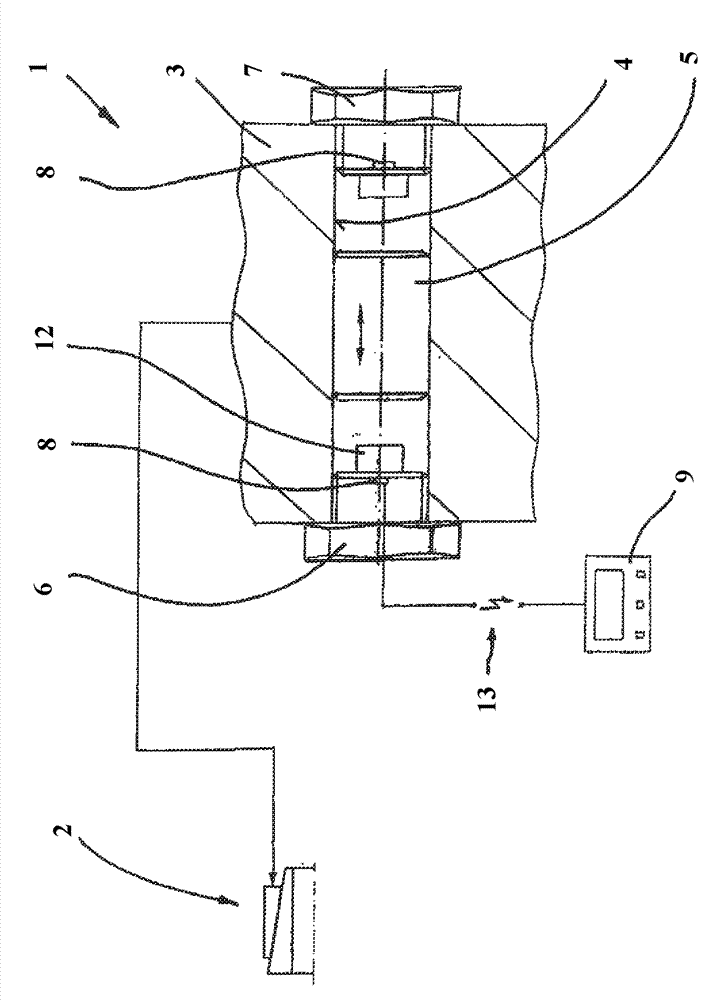

Lubricating device for supplying a tool with lubricant

InactiveCN103542246ATimely detection of wearAvoid damageEngine temperatureEngine pressureEngineeringLubricant

The invention relates to a lubricating device (1) supplying lubricating agents, especially lubricating grease or lubricating oil to a tool (2). The lubricating device (1) comprises a lubricating distributor (3). At least one piston hole (4) is introduced into the lubricating distributor. A piston (5) which can move back and forth is arranged inside the piston hole. The piston hole (4) parts in the axial end part areas can be locked respectively through locking bolts (6, 7). In order to guarantee the monitoring of a lubricating system especially when used in a pipe expanding tool, the invention has at least one sensor (8) arranged in or beside at least one locking bolt (6). The sensor is connected with a monitoring device (9) so as to detect and monitor at least one running parameter of the lubricating distributor (3).

Owner:SMS MEER

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com