Automatic bearing waste grease collecting system and automatic bearing grease changing system

A technology of automatic collection and waste grease, which is applied in the direction of bearing components, shafts and bearings, engine components, etc., can solve the problem of damage to the bearing structure, and achieve the effect of ensuring the amount of grease, ensuring the pressure, and the pressure state is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0048] Embodiment 3 of an automatic collection system for bearing waste grease. The difference between this embodiment and Embodiment 1 is that an oil pressure sensor is provided in the oil pressure system of the hydraulic cylinder.

Embodiment 4

[0049] Embodiment 4 of an automatic collection system for bearing waste grease. The difference between this embodiment and Embodiment 1 is that a position sensor is provided on the piston of the hydraulic cylinder.

[0050] The grease suction device of the bearing waste oil automatic collection system in the above embodiment can also be driven by a pneumatic cylinder, and the pneumatic cylinder and the hydraulic cylinder belong to the same technical features.

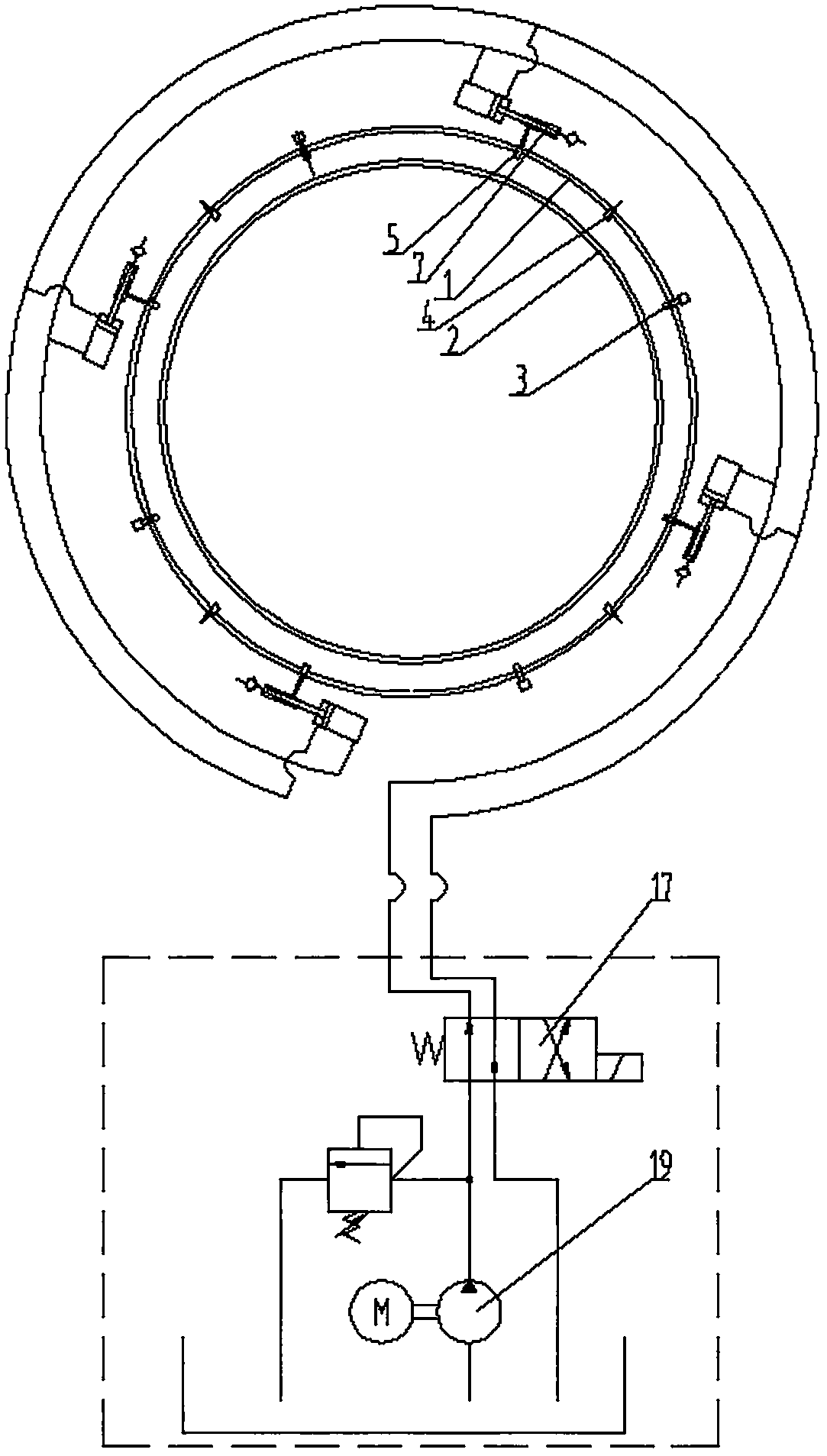

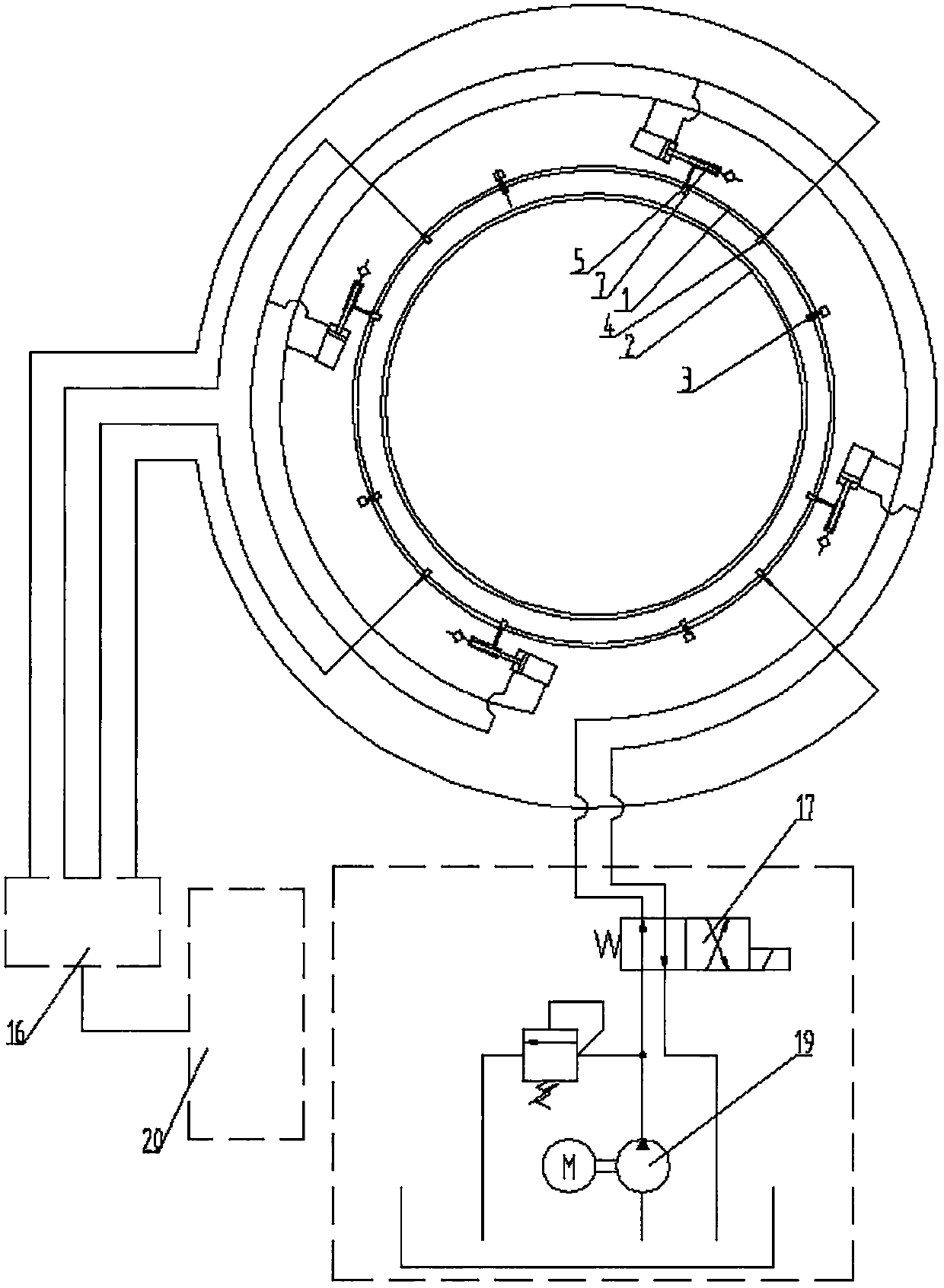

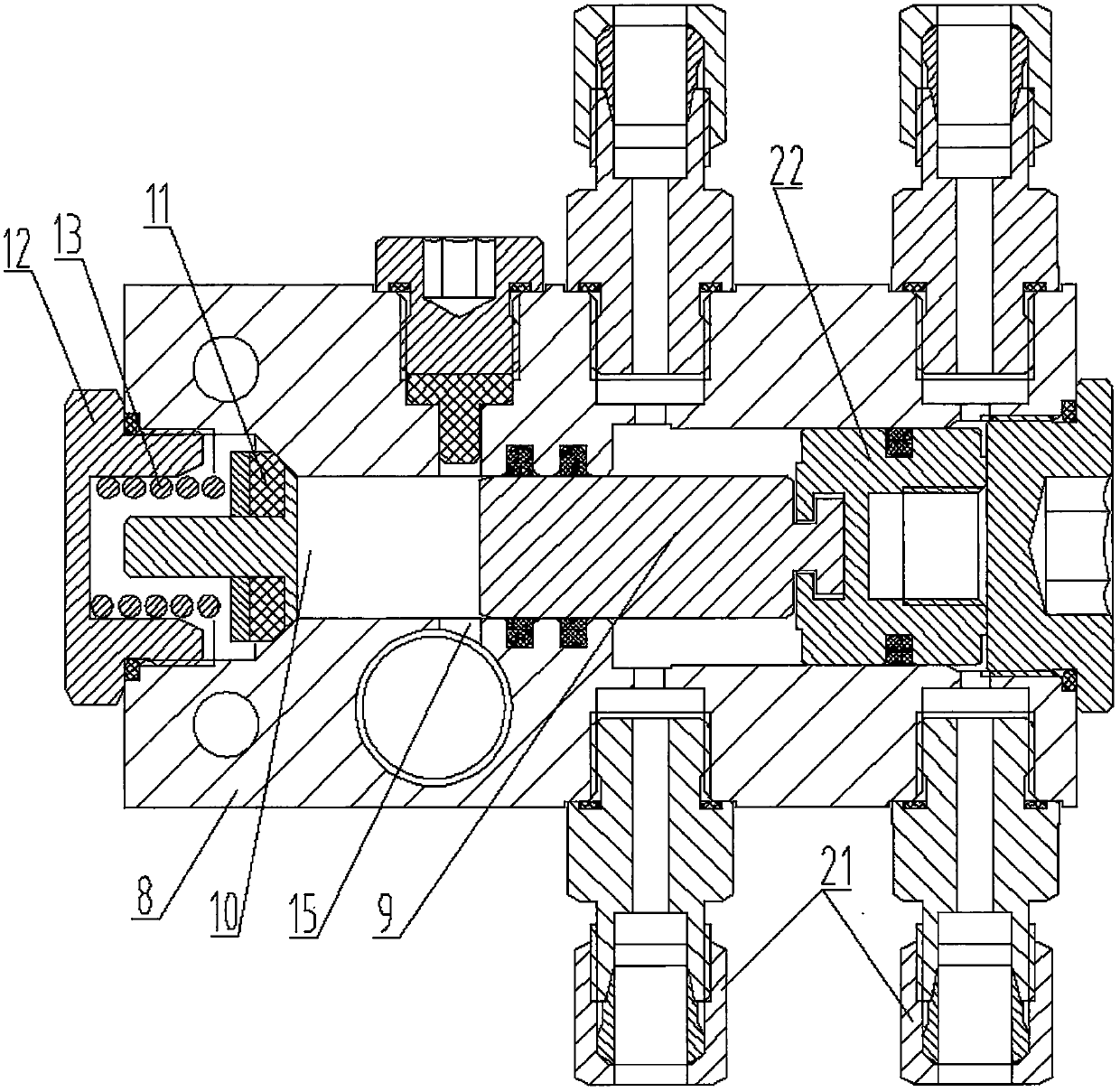

[0051] Embodiment 1 of a bearing automatic grease changing system, in figure 2 , Figure 5 as well as Figure 7 Among them, the bearings in the bearing structure of the bearing automatic grease changing system are sliding bearings without rolling elements. The outer ring 1, the inner ring 2 and the oil seals at both ends form a lubricating space, and the lubricating space is used to set grease. An oil inlet 4, an oil outlet 5 and a breathing port 3 are provided on the outer ring 1 of the bearing structure, and the oi...

Embodiment 5

[0058] Embodiment 5 of an automatic bearing grease changing system. The difference between this embodiment and Embodiment 1 of the bearing automatic grease changing system is that an oil pressure sensor is provided in the oil pressure system of the hydraulic cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com