Assembly type mouth-shaped framework steel bridge abutment and construction method thereof

A mouth-shaped and assembled technology, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as cracking of concrete main beams or bridge decks, reduce bridge head jumps, have strong fatigue resistance, and improve overall deformation. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

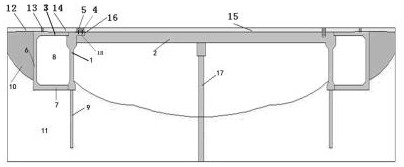

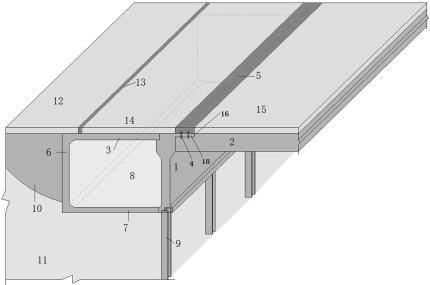

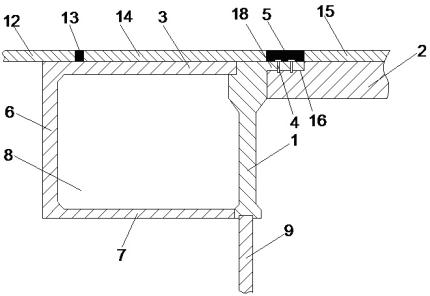

[0022] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

[0023] The fabricated steel abutment of the present invention comprises a main girder 2 and a bridge deck 15 arranged on the main girder 2. H-shaped steel piles 9 are embedded in the soil below the two ends of the main girder 2. In the width direction of 2, 3-4 groups of H-shaped steel piles 9 are arranged at intervals, and a steel flexible abutment 1 is fixed above the H-shaped steel piles 9. The steel flexible abutment 1 is a steel part made by precasting, A steel ground beam 7 is horizontally fixed on the rear side of the lower platform of the steel flexible abutment 1, and a steel secondary abutment 6 is vertically fixed on the rear end of the steel ground beam 7. The steel flexible abutment 1 A steel roof girder 3 is horizontally fixed between the steel se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com