Patents

Literature

293results about How to "Strong fatigue resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medlar and red date enzyme and preparation method thereof

InactiveCN104872674AKeep natural colorImprove biostabilityNatural extract food ingredientsFood ingredient functionsRipeningHigh pressure

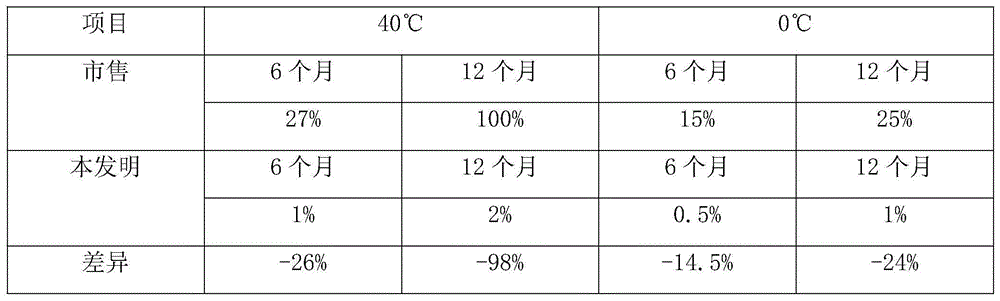

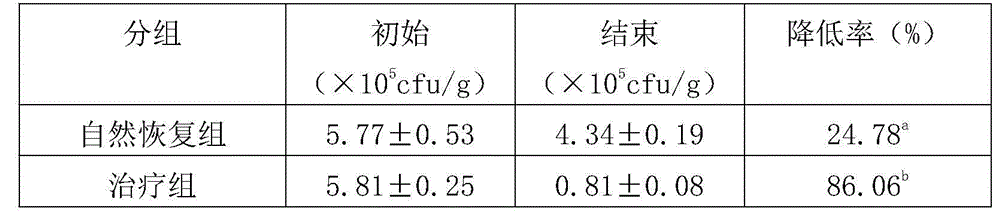

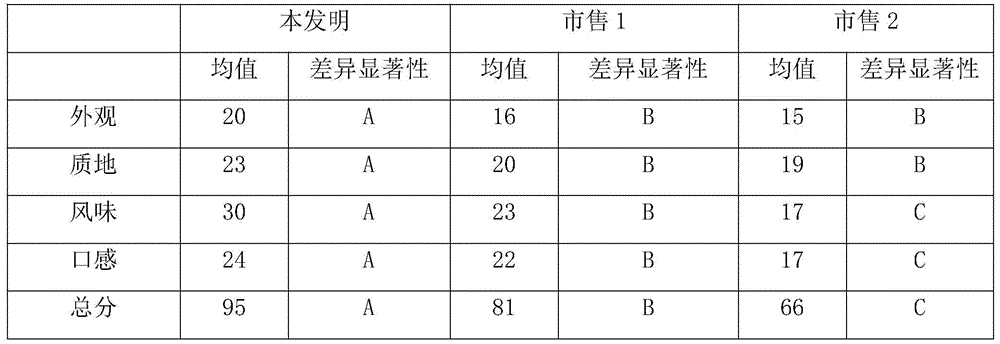

The invention discloses a medlar and red date enzyme and a preparation method thereof, which belong to the technical field of enzyme preparation. Multi-strain composite fungi powder is adopted as a leavening agent; the medlar and the red date are adopted as main raw materials; dietary fiber, pectin hydrolyzate, seasoner extracting liquor, Chinese herbal medicine extracting liquor, enzyme stabilizer and other multifunctional auxiliary raw materials are scientifically compounded and modified; low-temperature processing technology such as ultrasonic cleaning, cryogenic grinding, microwave-assisted high-voltage pulse electric field processing and ultrasonic ripening are mainly adopted in the whole process, so that the natural colors, the flavor, the taste and the content of the active materials of the medlar and the red date are maintained furthest, the biological stability, the non-biological stability and the biological activity of the medlar and red date enzyme are obviously enhanced, the introduction of chemical addition agent is reduced, and the juicing rate of the medlar and the red date as well as the food safety of the enzyme are improved. Finally, the medlar and red date enzyme with high biological activity, strong stability, strong taste, flavor and appetite, long expiration date and edible safety is prepared.

Owner:NINGXIA JINSHANGQI BIOTECH

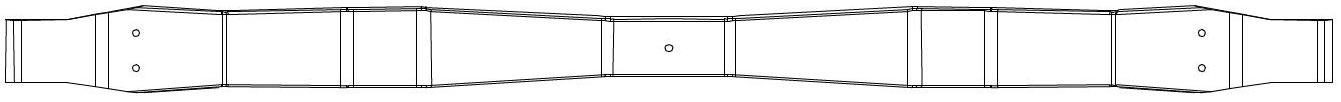

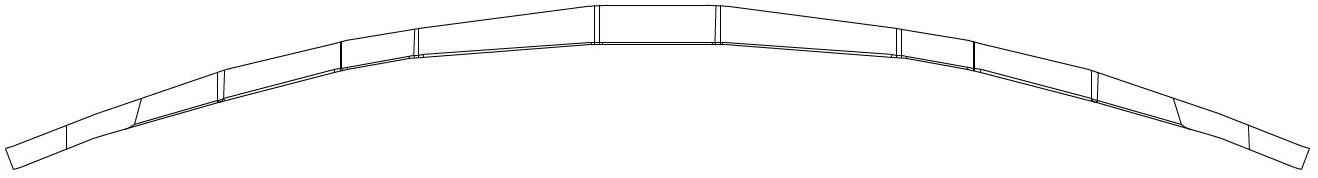

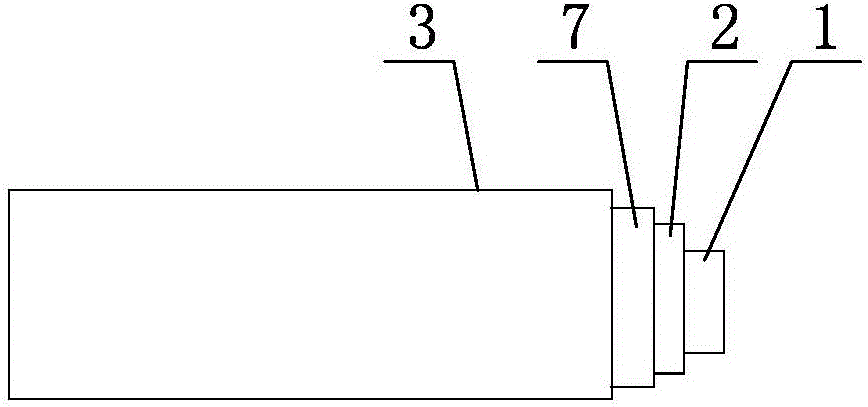

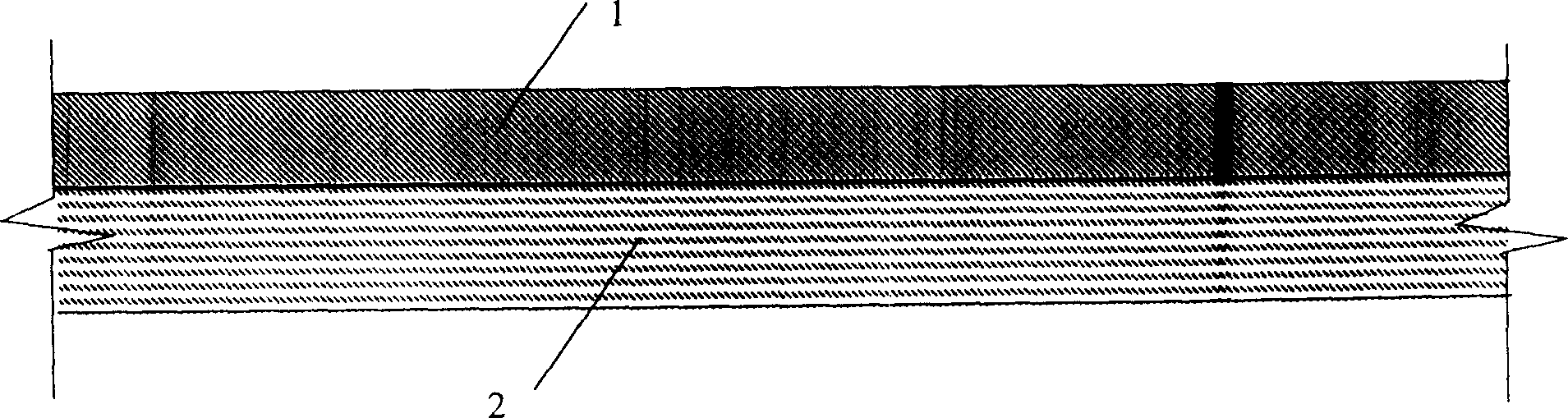

Preparation method for glass fibre reinforced resin composite plate spring

The invention relates to a preparation method for a glass fibre reinforced resin composite plate spring. The method comprises the following steps of: respectively soaking a glass fibre cloth and a glass fibre filament in epoxy resin, laying a layer on the upper and lower surfaces of a core model by using the glass fibre cloth; in the case of existing a preset value of the appropriate tensile force, winding the glass fibre filament on the core module, wherein the applied tensile force to the glass fibre filament gradually decreases along with the number of winding layers in the winding process; laying a layer of glass fibre cloth after the completion of winding; performing die assembly by the conventional manner to obtain an incompleted plate spring in embryo, and solidifying to obtain the glass fibre reinforced resin composite plate spring. The plate spring product prepared by the method provided by the invention has more excellent strength, is stronger in fatigue resistance than steel materials and is above 60% lighter in weight than the steel plate spring.

Owner:北京国材汽车复合材料有限公司

High-strength aluminum alloy welding wire and preparation method thereof

ActiveCN102114579ALight materialImprove performanceWelding/cutting media/materialsSoldering mediaSlagHeating temperature

The invention discloses a high-strength aluminum alloy welding wire which comprises the following chemical compositions in percentage by weight: 2.5-3.5 percent of Cu, 2.2-3.2 percent of Si, 0.1-0.25 percent of Ti, 0.1-0.25 percent of Zr, 0.1-0.2 percent of Mn and the balance of Al. The preparation method comprises the following steps: melting and ingot-casting raw materials so as to prepare intermediate alloy of Al-Cu50, Al-Mn10, Al-Si30, Al-Ti10 and Al-Zr10; pouring the pure aluminum ingot into a crucible according to composition proportion, raising temperature, adding and melting the intermediate alloy of Al-Mn10, Al-Cu50, Al-Ti10 and Al-Zr10 in sequence according to composition proportion after the aluminum ingot is entirely molten; after melting is finished, raising the temperature to 800 DEG C for heat preservation for 15 minutes, pressing hexachloroethane into the bottom of the alloy liquid with a graphite hood, stirring to conduct degassing and slagging, wherein the using amount of the hexachloroethane is 0.3-0.4 percent of the amount of a furnace, scattering a little amount of scouring agent to remove surface float slag after finishing slagging-off; continuing to raise the temperature to 820-850 DEG C, fully stirring, and discharging; conducting pull-casting to prepare high-strength aluminum alloy cast ingot; then taking out and sawing the cast ingot into segments and peeling; putting the cast ingot into an extruder at the heating temperature of 330-380 DEG C for extrusion; and conducting wiredrawing in a wiredrawer, and annealing in the drawing process, thus obtaining high-strength aluminum alloy welding wires when achieving the standard diameter.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

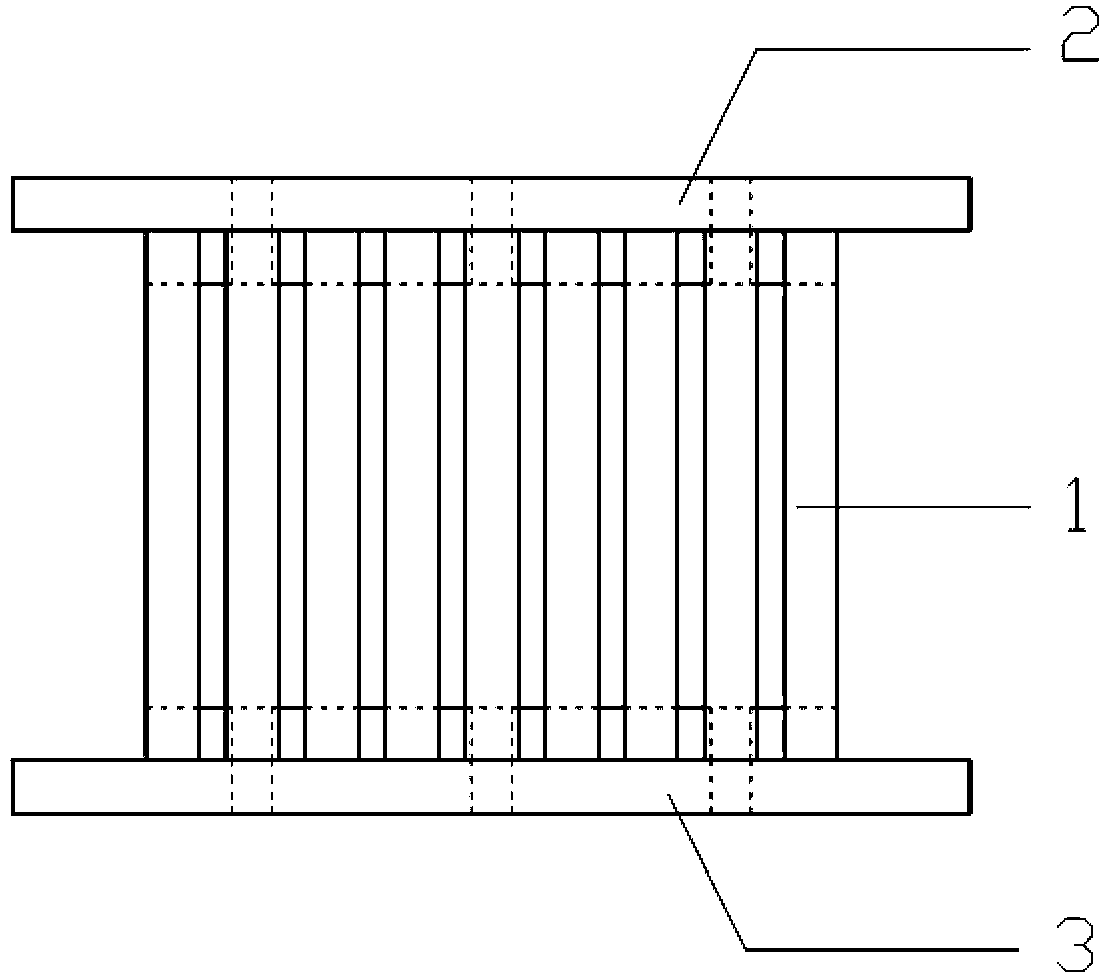

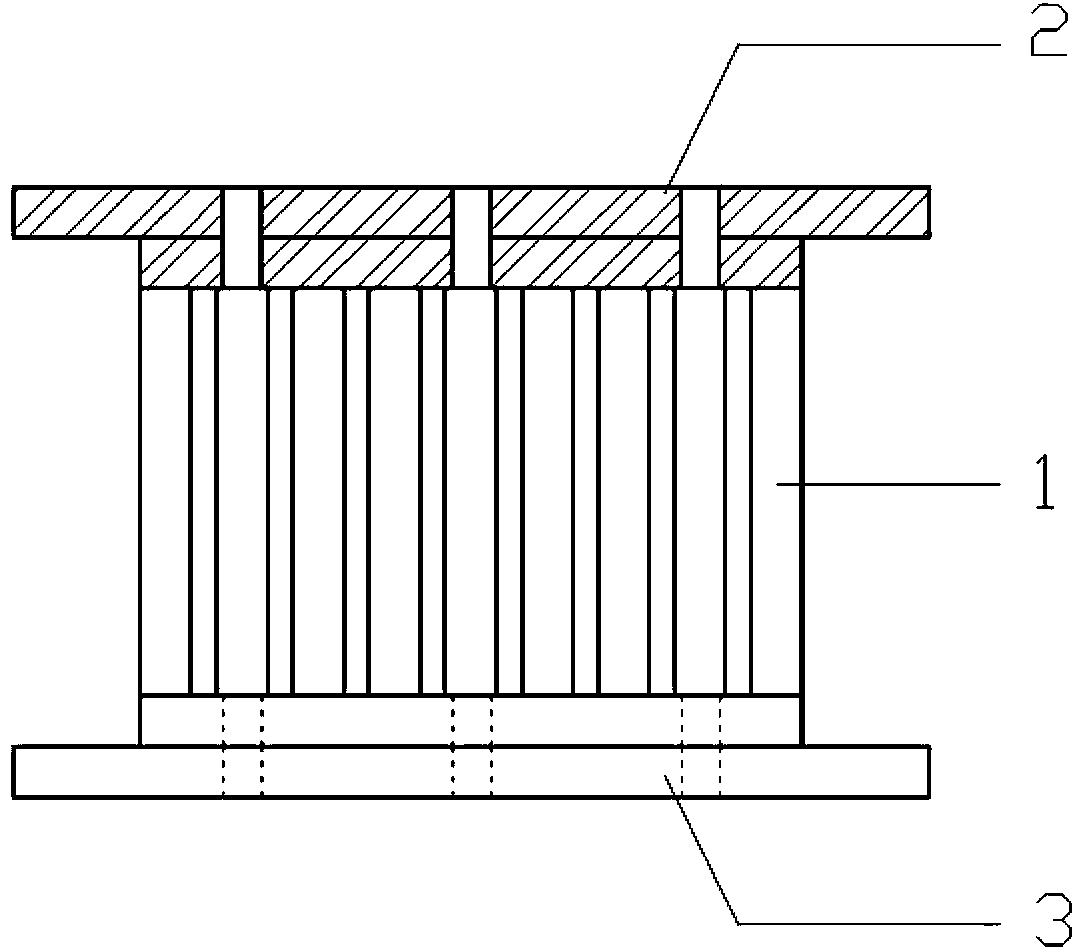

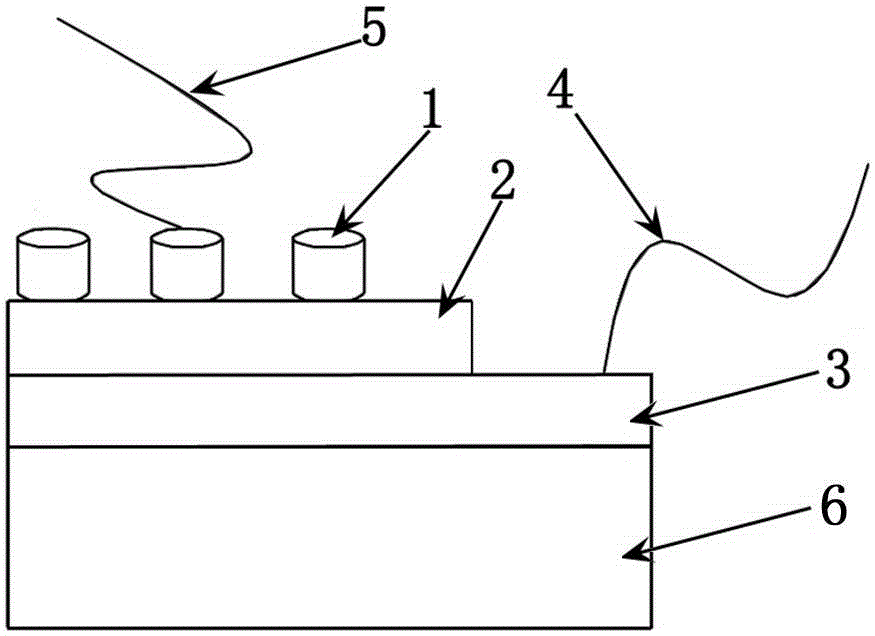

Metal damper and design method thereof

ActiveCN103397595ASolve the disadvantages of poor lateral stability and weak anti-fatigue abilityStrong designabilityBridge structural detailsShock proofingIn planeMetallic materials

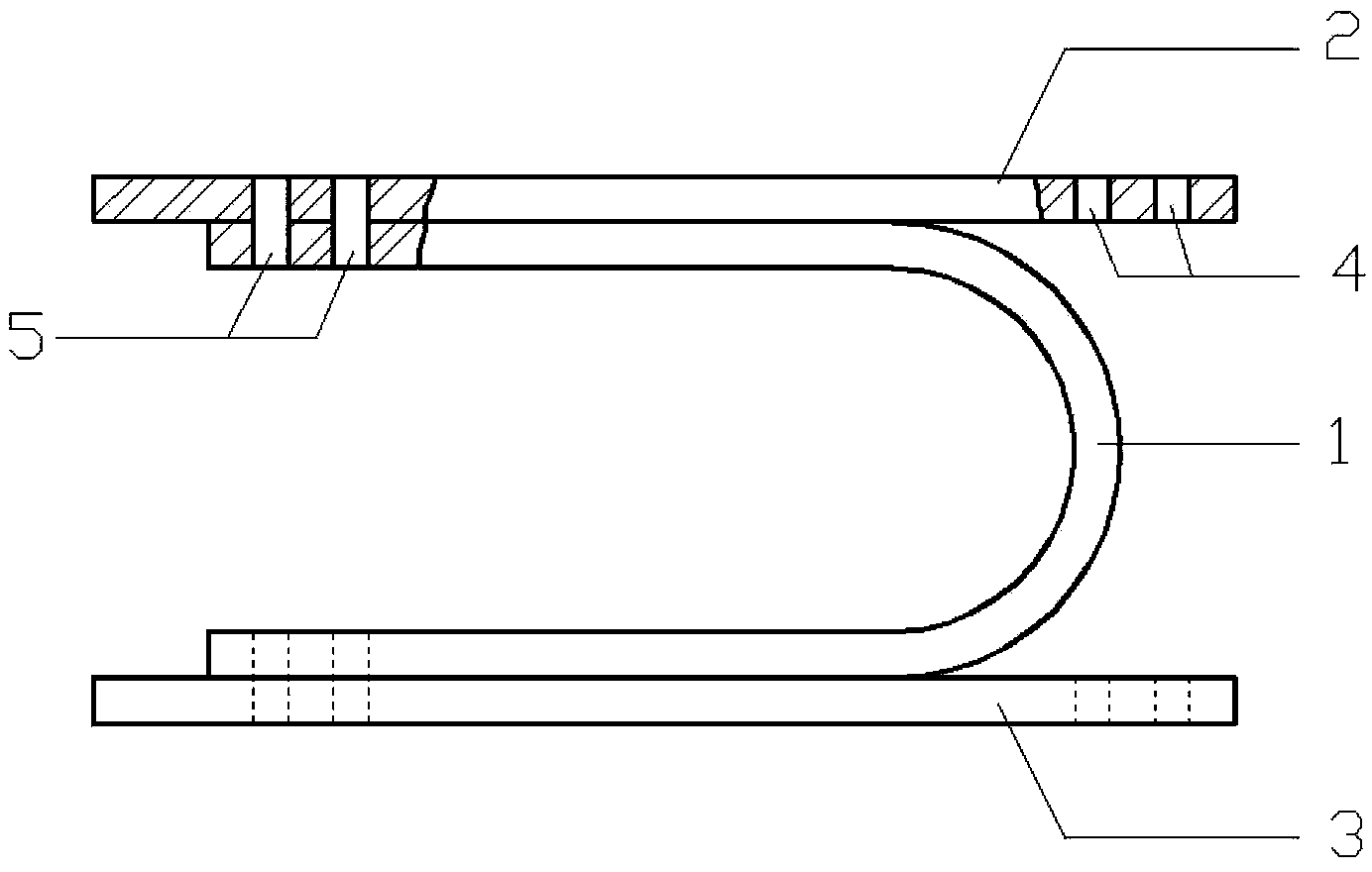

The invention provides a metal damper and a design method thereof, and belongs to the technical field of civil engineering structural shock absorption. The damper comprises an upper cover plate, a lower cover plate and a core energy-consuming metal element. The core energy-consuming metal element is a continuous U-shaped slotted metal plate and comprises a circular arc section and two straight sections. A plurality of continuous grooves are formed in the circular arc section and partial straight sections of the slotted metal plate in the width direction at intervals. In design, firstly, the height of the damper is determined according to a building; secondly, the numerical relationship of the thickness of a steel plate, the length of the straight sections and the width of the damper is obtained according to an in-plane resilience formula and an out-plane resilience formula; specific numerical values of the three parameters are adjusted according to an optimizing formula, so that a failure mode, out of expectation, of the damper does not occur; and ultimately, the number of the dampers and the size of a bolt are determined. According to the metal damper and the design method of the metal damper, energy consumption is achieved through metal materials with strong plastic deformation capacity, large longitudinal deformation is achieved through bending deformation, and large sideward deformability and anti-fatigue performance are achieved.

Owner:TSINGHUA UNIV

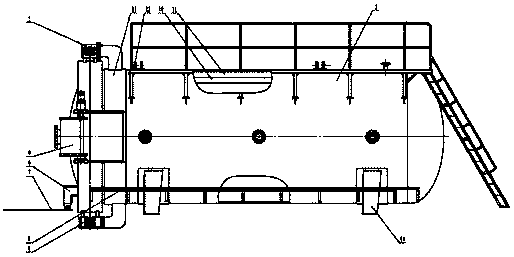

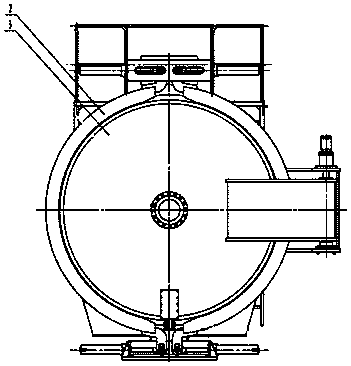

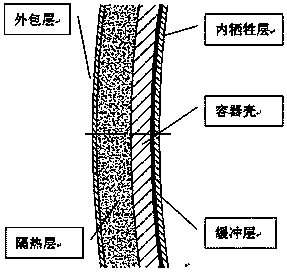

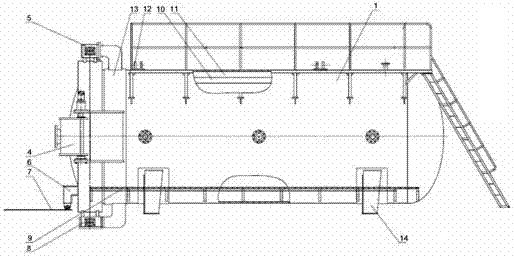

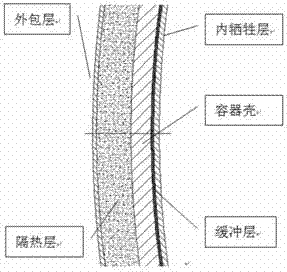

Low-temperature storage-transport container

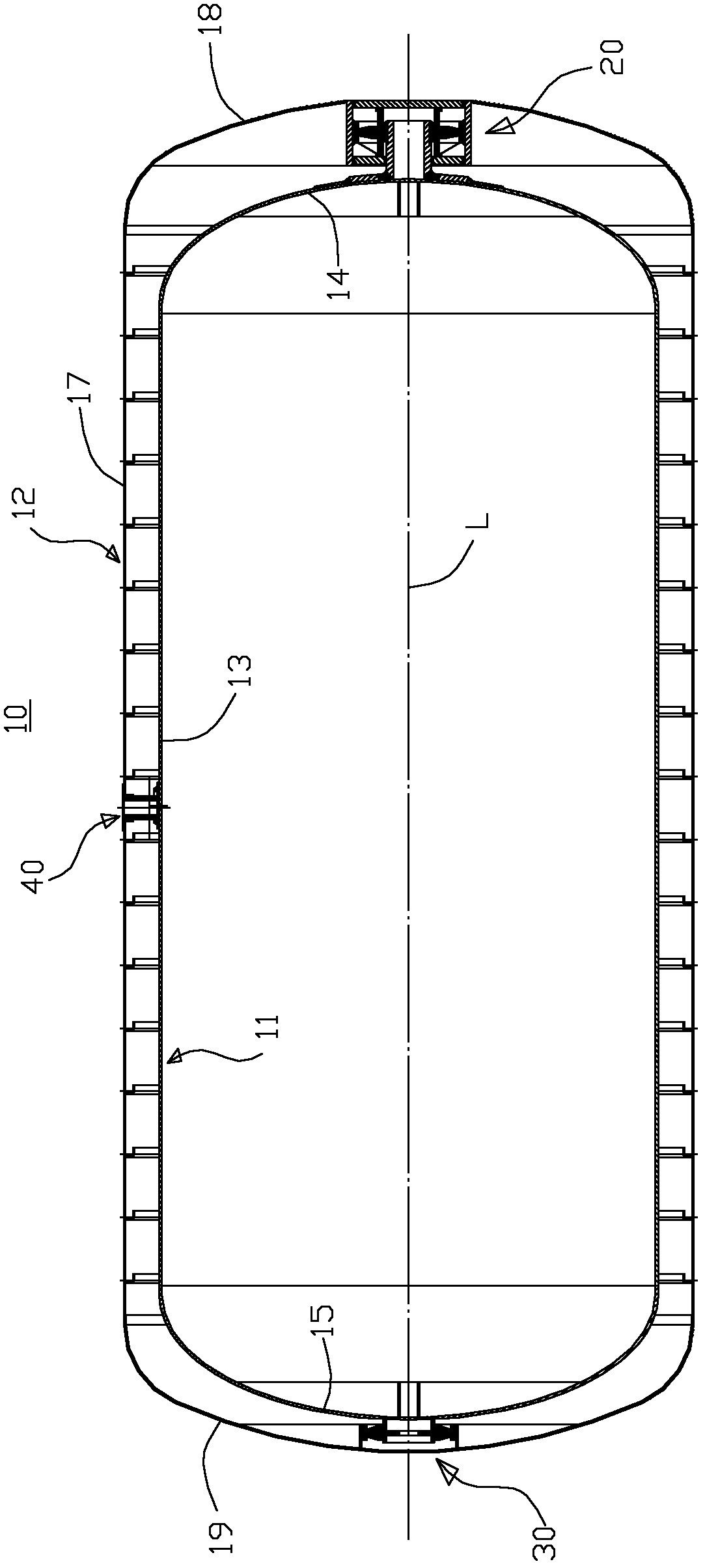

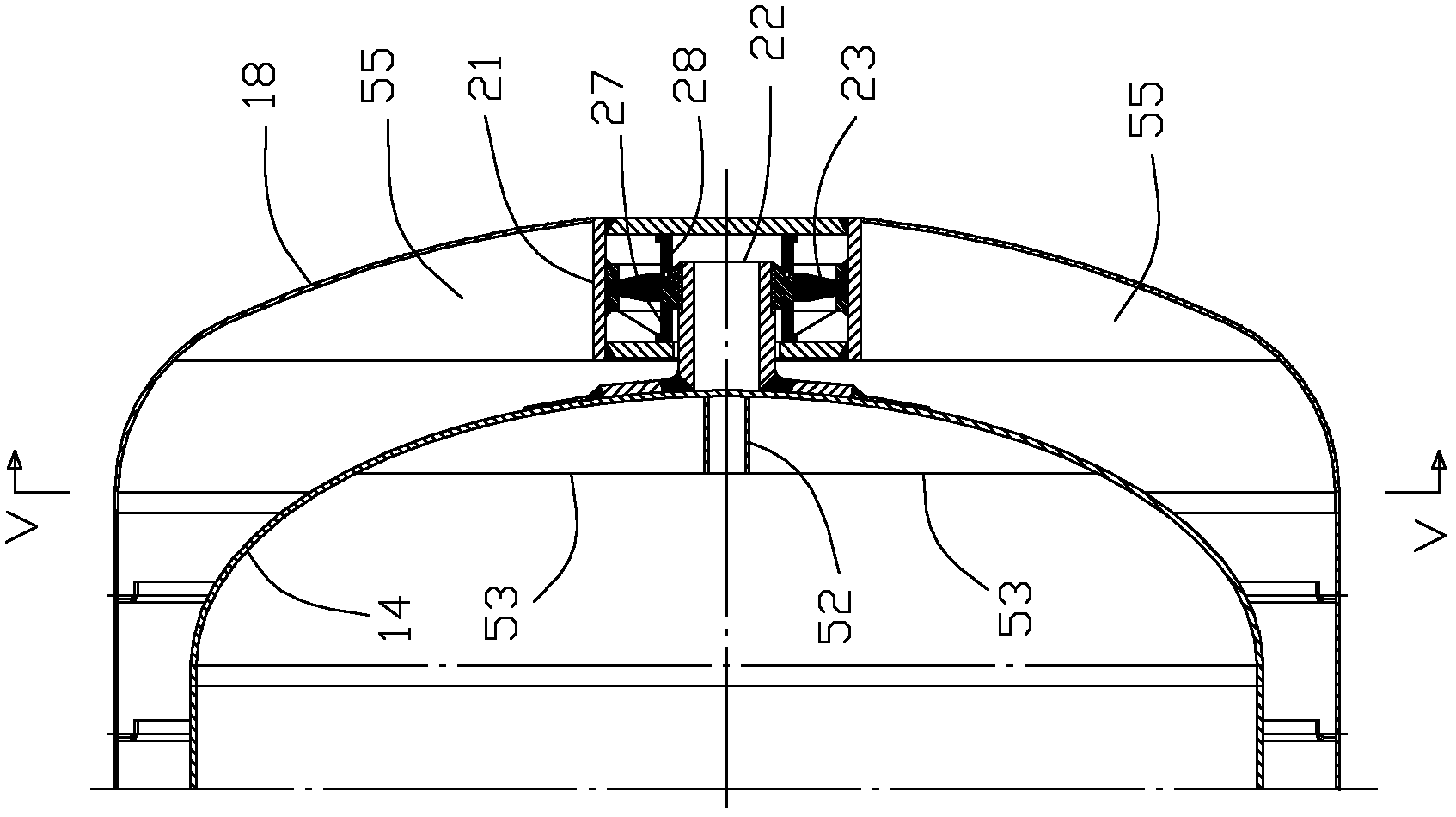

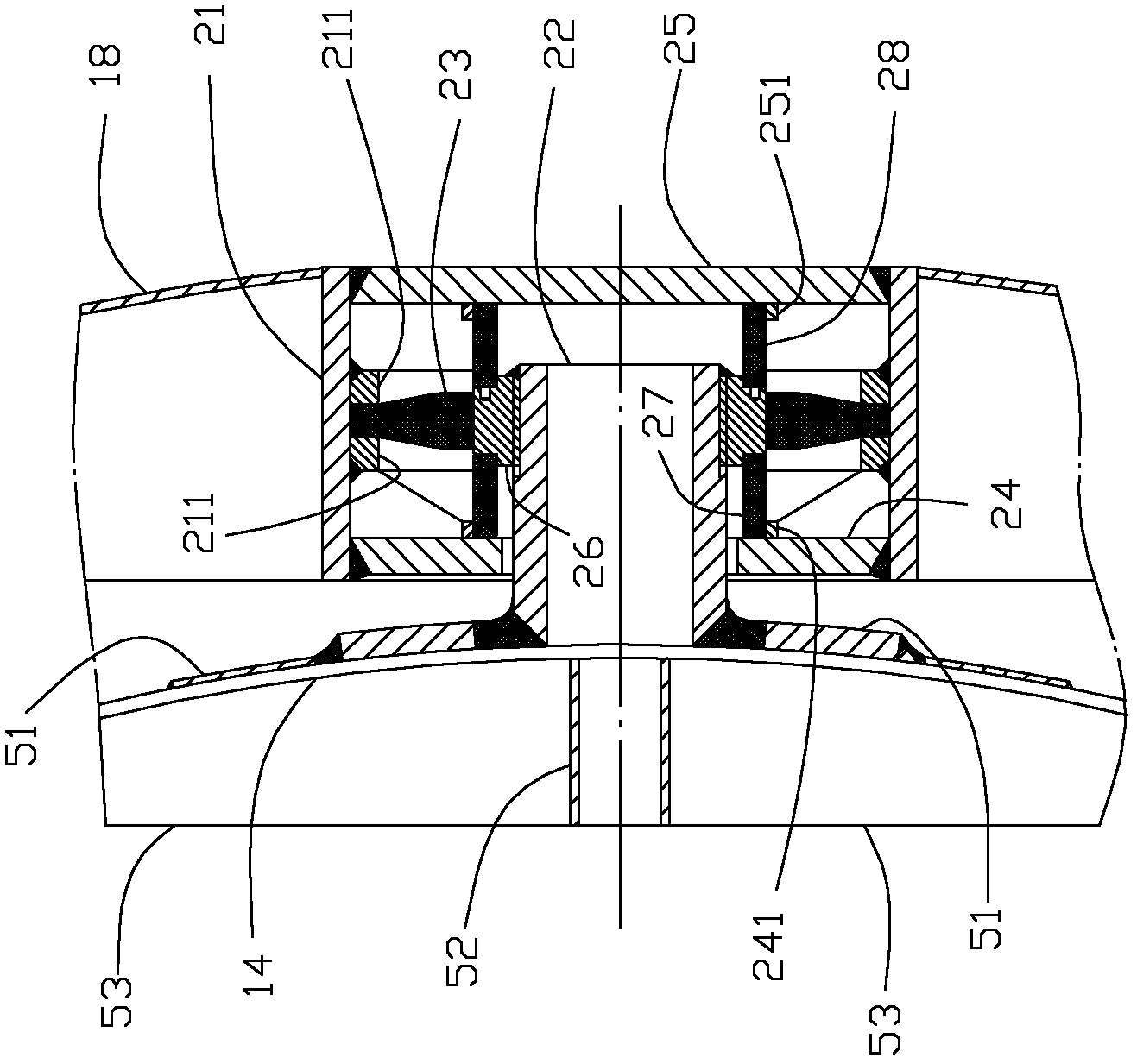

ActiveCN102997034AMeet the requirements of safe operationGood insulation performanceContainer filling methodsPressure vesselsEngineeringMechanical engineering

Owner:NANTONG CIMC TANK EQUIP CO LTD

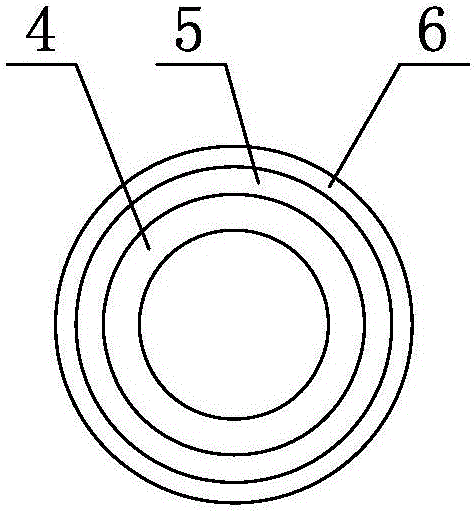

Ultra-deep water multifunctional flexible pipe and manufacturing method thereof

PendingCN106287027AImprove corrosion resistanceImproved resistance to gas permeationFlexible pipesTubular articlesChemical industryEngineering

The invention provides an ultra-deep water multifunctional flexible pipe and a manufacturing method thereof, and is used for solving the technical problem that the existing ocean pipeline is easy to corrode, easy to wear, relatively poor in pressure resistance, relatively poor in gas permeation resistance and relatively poor in flexibility. The ultra-deep water multifunctional flexible pipe is provided with a lining layer, wherein the exterior of the lining layer is connected with a reinforcing layer in a fusion manner, a functional layer is wound outside the reinforcing layer, and the functional layer is wrapped by a protective layer. The invention also provides a manufacturing method of the ultra-deep water multifunctional flexible pipe. The ultra-deep water multifunctional flexible pipe and the manufacturing method thereof can be widely applied to the fields such as petroleum, gas, chemical industry, municipal engineering and the like.

Owner:WEIHAI NACHUAN PIPE FITTINGS

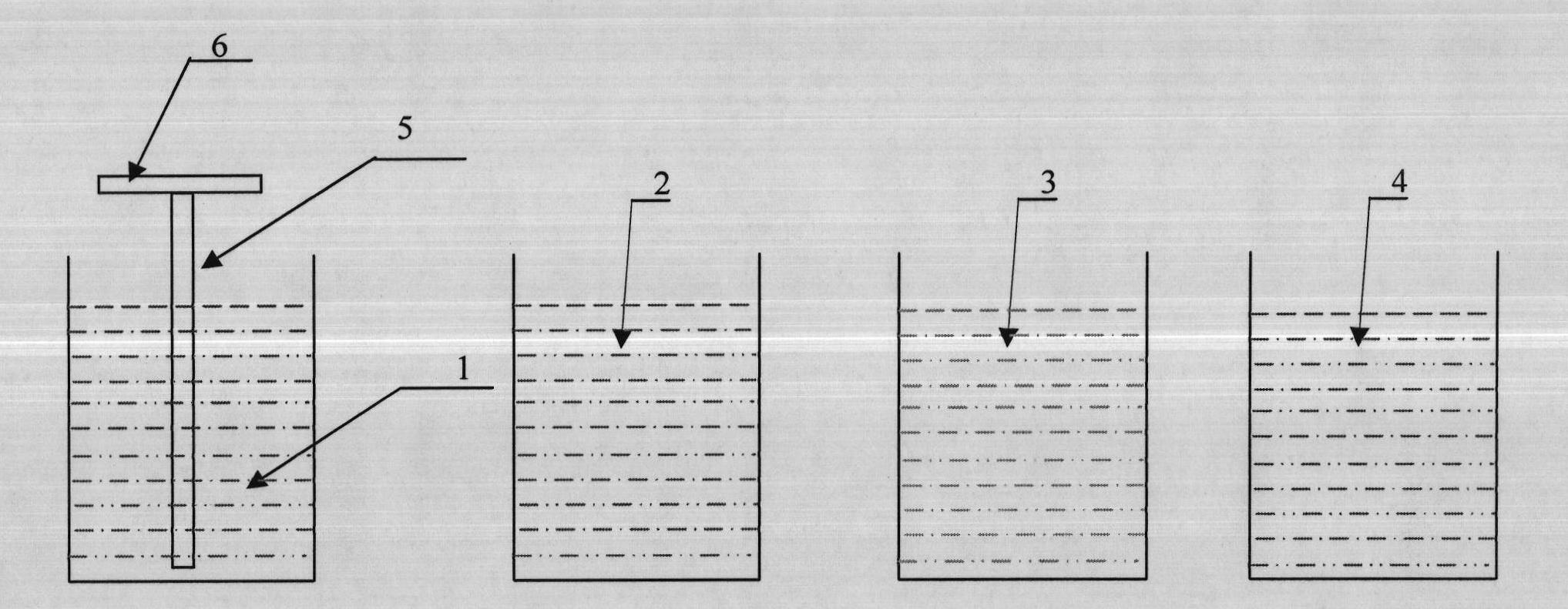

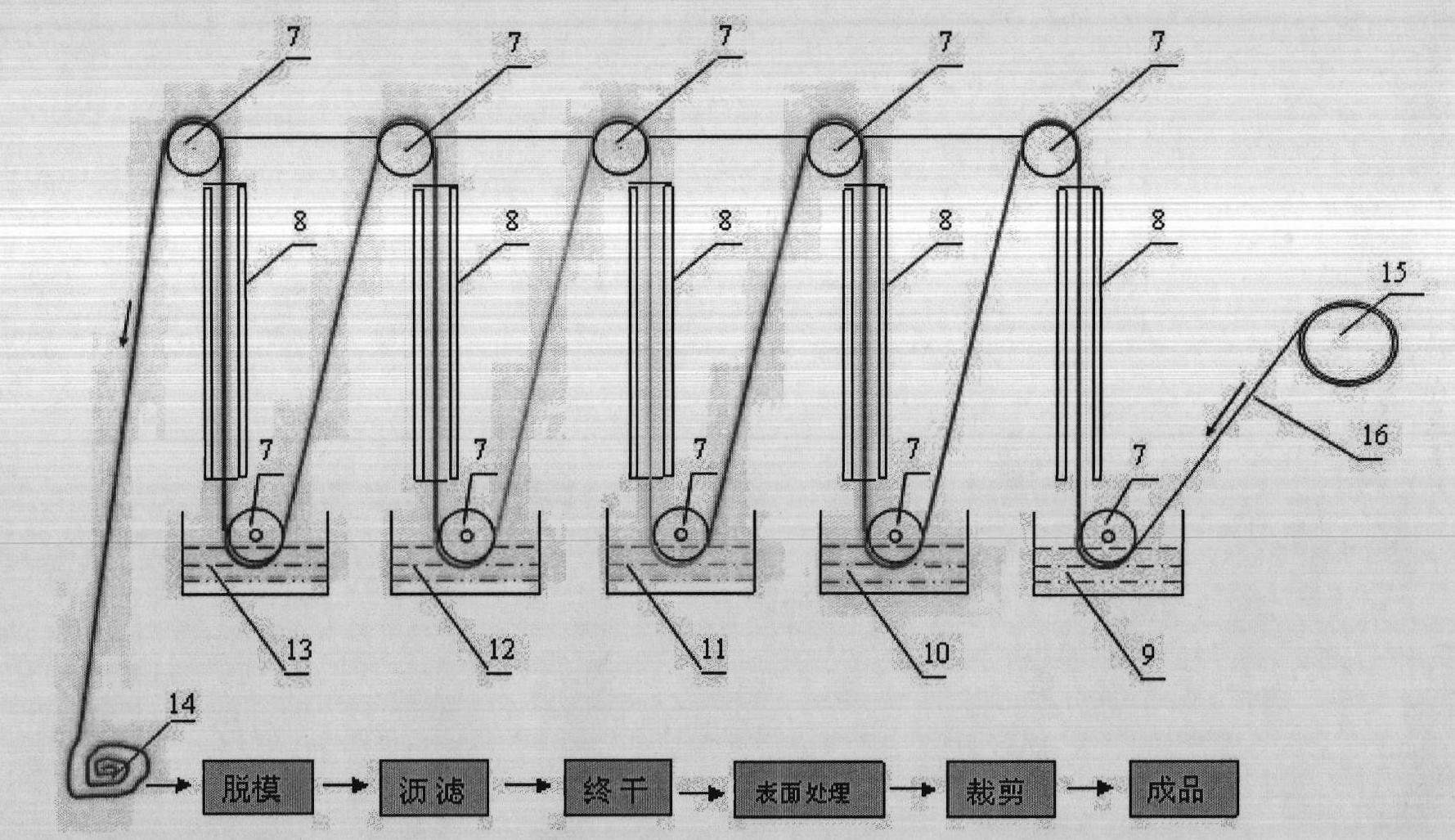

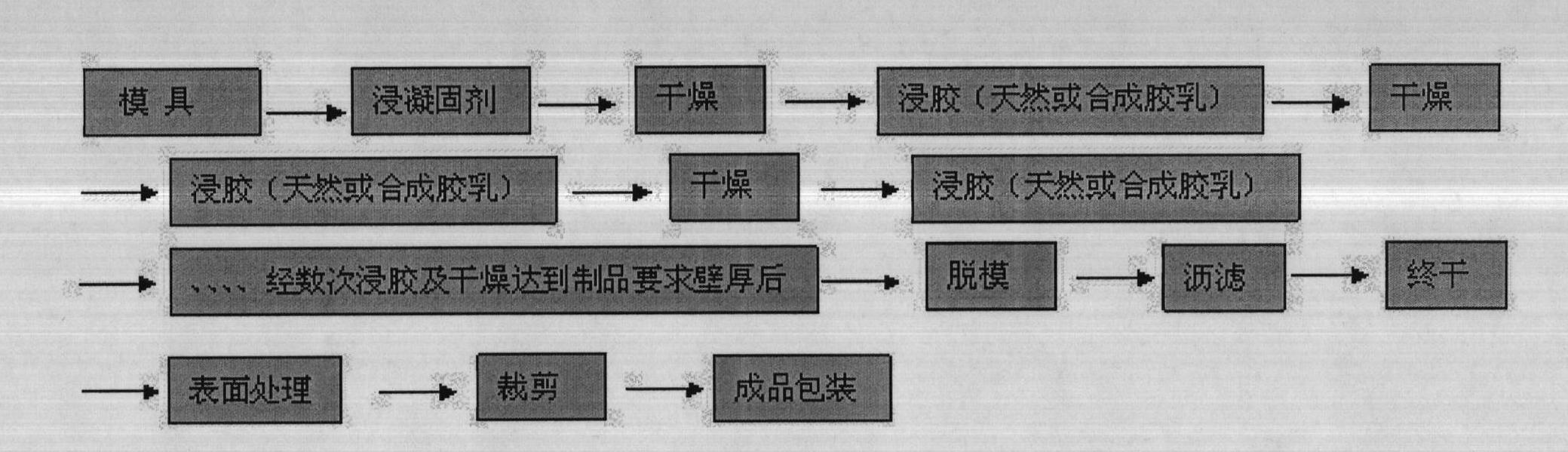

New process for producing multi-layer composite high-elasticity rubber hoses

The invention discloses a new process for forming and producing multi-layer composite high-elasticity rubber hoses by carrying out emulsion impregnating multiple times. The new process comprises a simple type production process and a continuous production process. According to the new process, manual or continuous mechanical mode is adopted, a mould is impregnated in a coagulator, then dried and cooled to room temperature, and then the mould is impregnated in emulsion and dried so that a layer of emulsion film is formed on the surface of the mould; every time the above operations are repeated, a layer of emulsion film is added on the surface of the dried emulsion film, wherein the coagulator impregnating step can be omitted; multi-layer composite rubber hoses with random thickness can be produced by implementing the combined process of emulsion impregnating and drying repeatedly; multiple layers are composited by heating and vulcanizing by virtue of a vulcanizer mixed in the emulsion; and then demoulding, leaching, final drying, surface treatment and cutting auxiliary process steps are carried out to finally obtain the finished product. Multi-layer composite high-performance rubber hoses with specific length, thickness, property and color can be produced by using the simple type production process and multi-layer composite high-performance rubber hoses with random length, thickness, property and color can be produced by using the continuous production process. Rubber hoses produced by using the new process have high quality and can meet special requirements of physical training.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI +1

Temperature and humidity adjusting device for safety test chamber system

InactiveCN104111677AEliminate pollutionStrong fatigue resistanceSimultaneous control of multiple variablesInherent safetyIntrinsic safety

The invention provides a temperature and humidity adjusting device for a chemical fire explosion safety test chamber system. The device provided by the invention comprises a temperature adjusting device and a humidity adjusting device. According to the chemical fire explosion safety test chamber system with the temperature and humidity adjusting device, harms of a runaway reaction, combustion explosion, decomposable explosion and the like which are generated during the process of large-scale chemical risk assessment test are eliminated, and simultaneously, effluents, exhaust gas and waste residues that are generated during collection test process undergo centralized processing. Inherent safety of the fire explosion risk test process is raised, and the effect of reducing environmental pollution is also achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

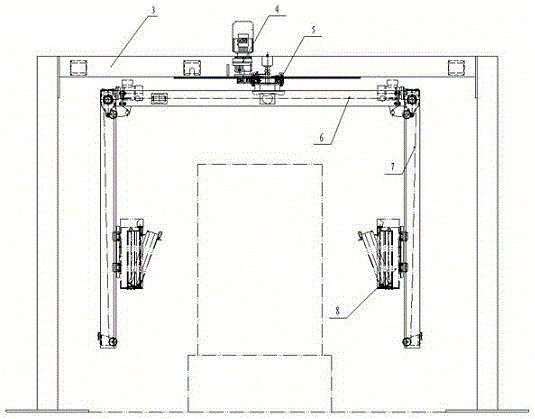

On-line rocker winding film packaging machine

ActiveCN102826246APrecise positioningImprove space utilizationConveyor wrappingPackaging machinesPhotoswitchWear resistant

The invention discloses an on-line rocker winding film packaging machine which has the functions of winding a film, coating the film, and automatically sending and breaking the film, and is matched with a conveyer line to complete an automatic packaging process; the framework of the packaging machine is in a four-vertical column square tube gantry structure, is firm and stable, is wear resistant, has high fatigue strength and is impact resistant; a rocker winding part is in a structure in which a gear is meshed with a slewing bearing, the rotary motion of a rocker is stable, and the positioning is precise; a mould frame lifting transmission part transmits with a chain, and is economical and durable; a novel door-opening mould frame is adopted, the appearance is attractive and generous, the practicality is strong and the packaging effect is good; the mould frame is provided with a photoelectric switch and can automatically detect the goods height; the speed of the whole equipment is governed through variable frequency, so that a customer can adjust the working speed as demanded, and the operation is simple and convenient; and the film clamping and breakage action is completed by a pneumatic structure, so that energy is saved, environment is protected, the installation and the maintenance are simple, the operation cost is effectively reduced, the emission is reduced and the effect is increased for an enterprise, and the space utilization rate is higher.

Owner:SHANDONG SINOLION MACHINERY CORP LTD

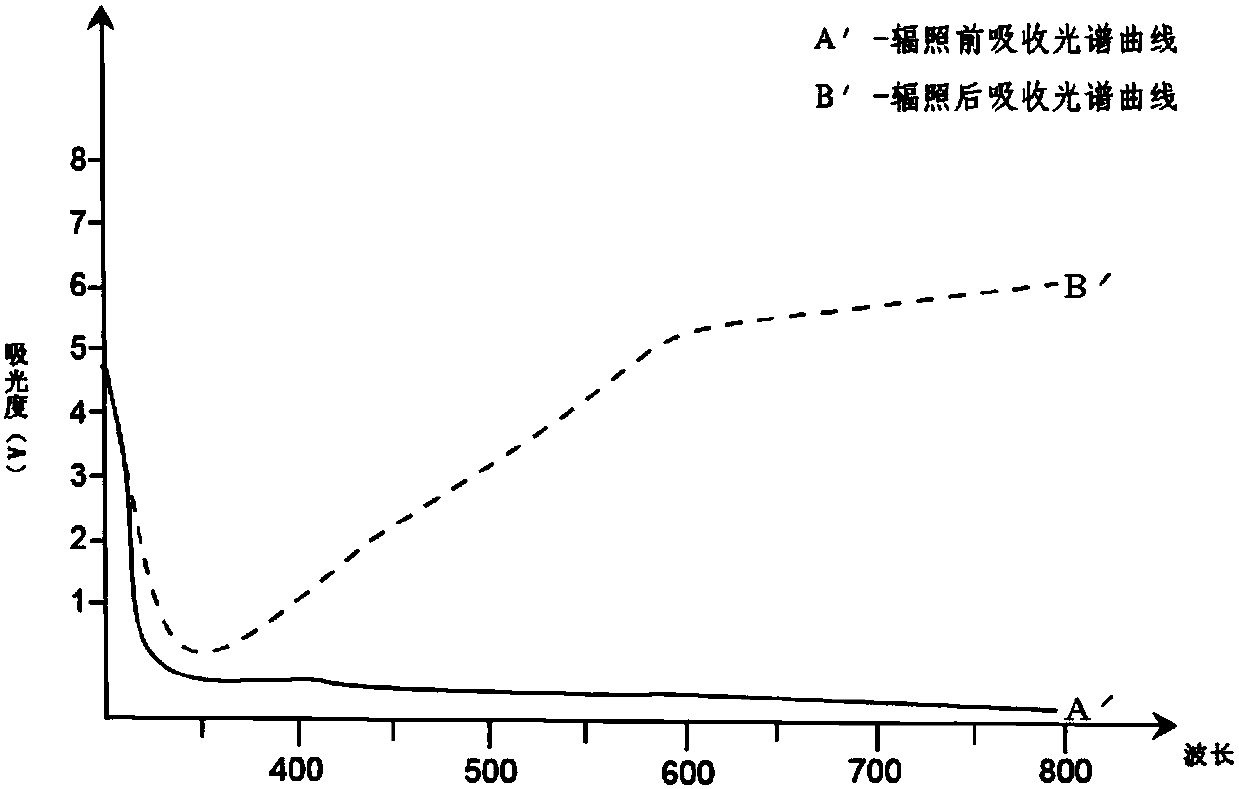

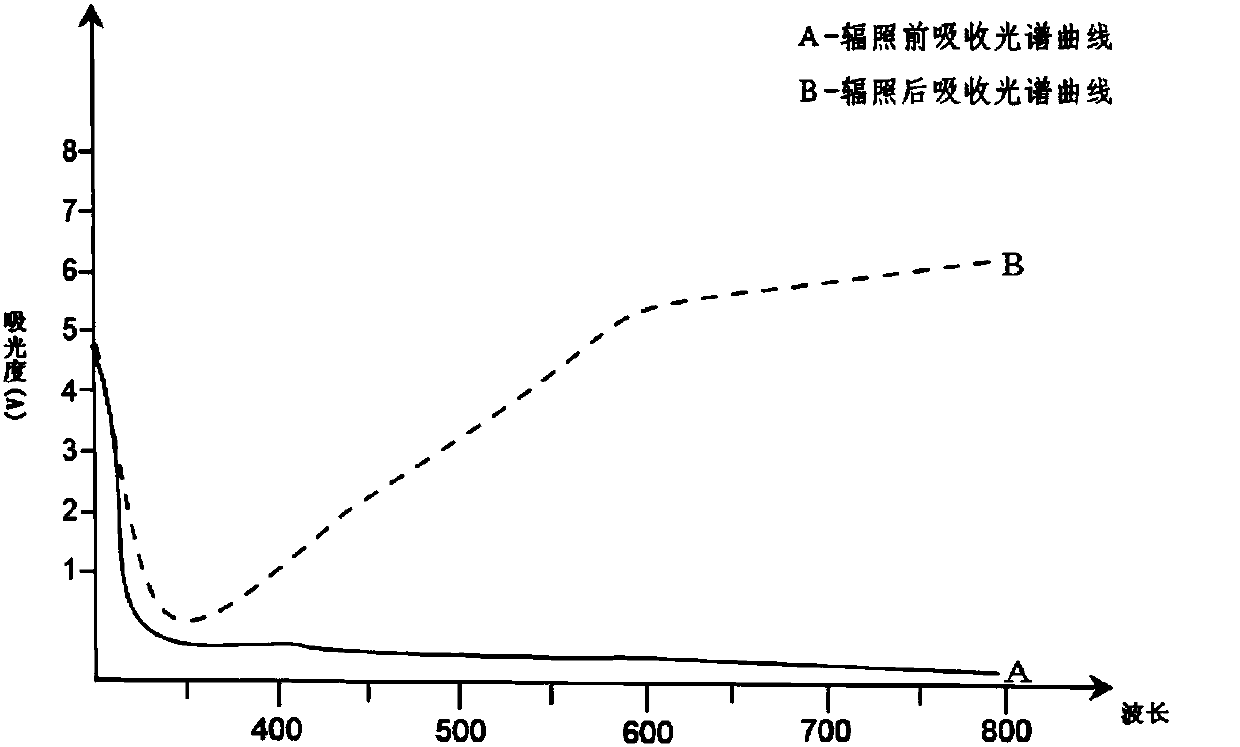

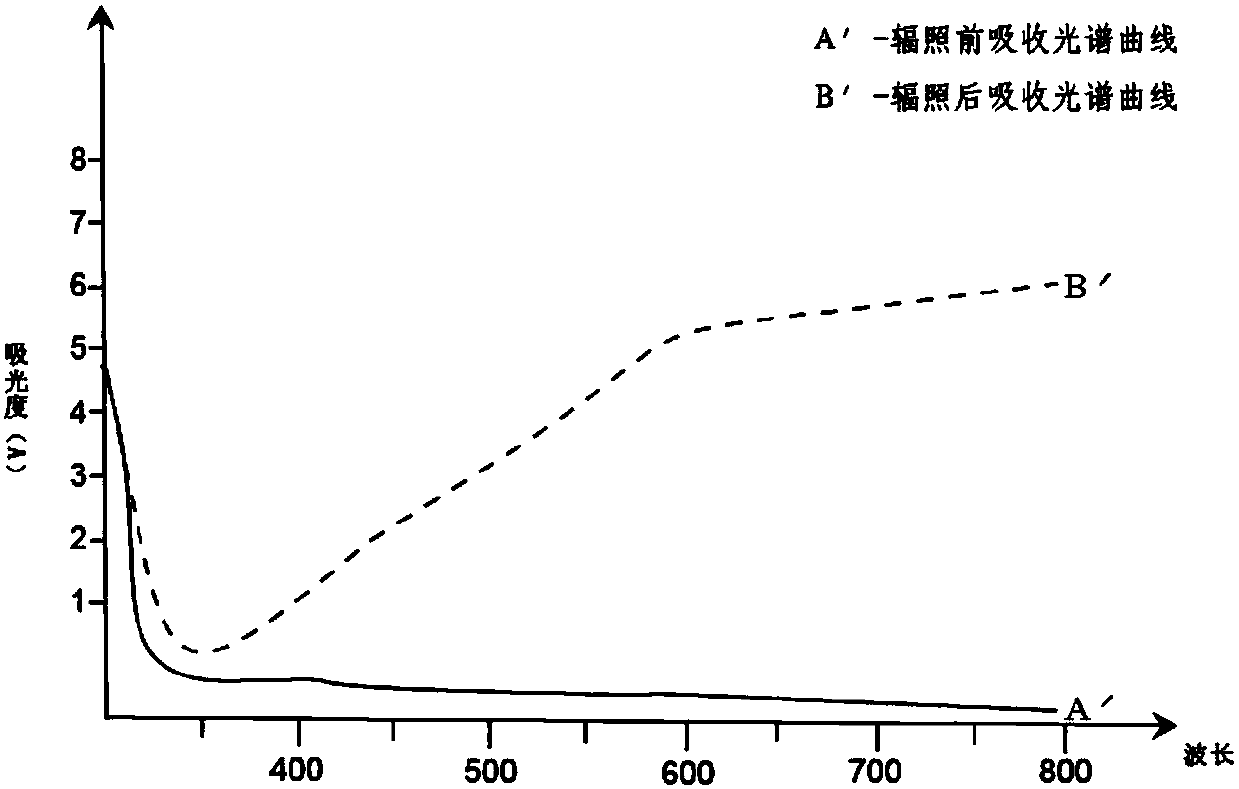

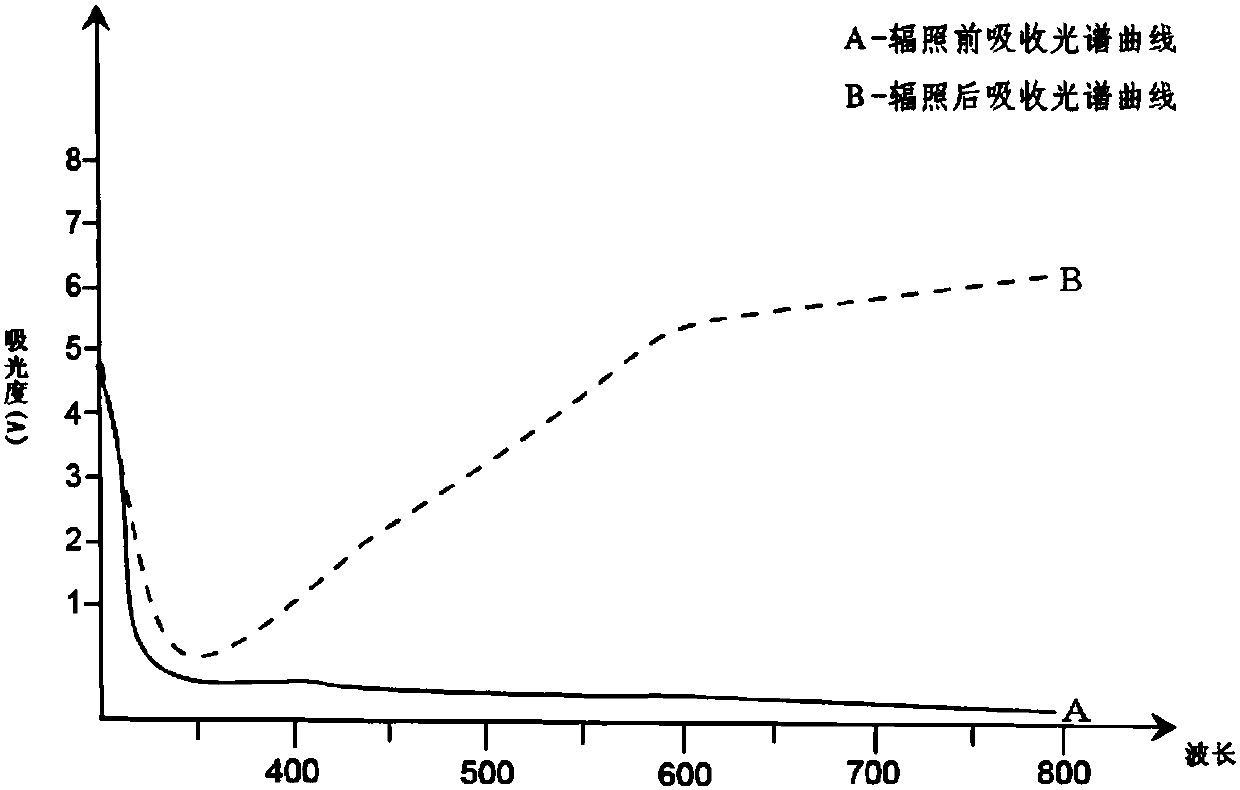

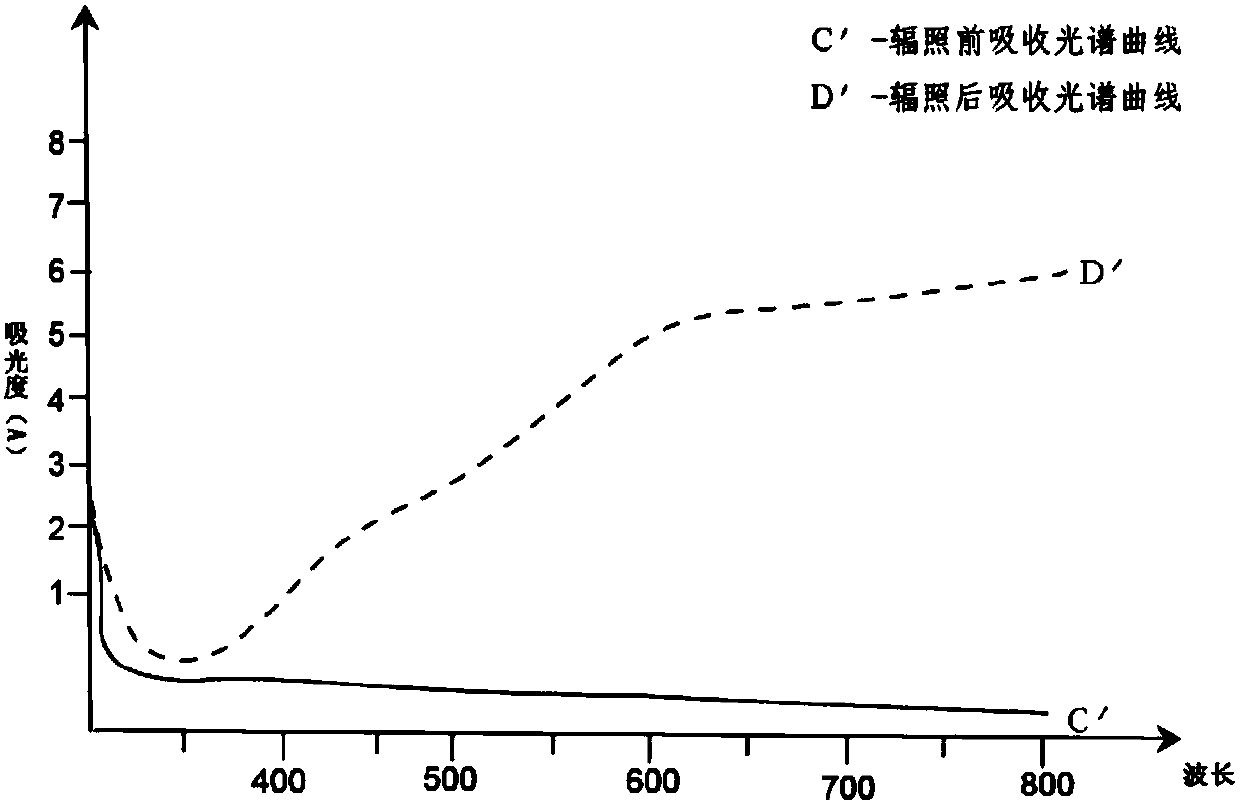

Spiropyrane photochromic optical material and preparation method thereof

ActiveCN107778510AFree from influenceIncrease space volumeOrganic chemistryCoatingsMicrosphereSulfate

The invention relates to a preparation method of a spiropyrane photochromic optical material. The surface of the optical material prepared by adopting the preparation method is coated with a photochromic coating, the coating contains a polyurethane / spiropyrane / zinc sulfide composite multilayer photochromic material, a core of the coating is zinc sulfide mesoporous nano microspheres, an intermediate layer is a photochromic layer composed of spiropyrane compounds, and a shell is polyurethane; and the outer diameter of the composite microspheres is 50-350nm, the diameter of the zinc sulfate mesoporous nano microspheres is 30-250nm, the thickness of the intermediate layer is 5-25nm, and the thickness of the shell is 5-25nm. The optical material prepared by adopting the preparation method can become colored from colorless under ultraviolet irradiation condition, can also be rapidly faded to be colorless after ultraviolet rays disappear and has the advantages of strong fatigue resistance, good stability and high color-changing speed.

Owner:南京米兰达视光科学研究院有限公司

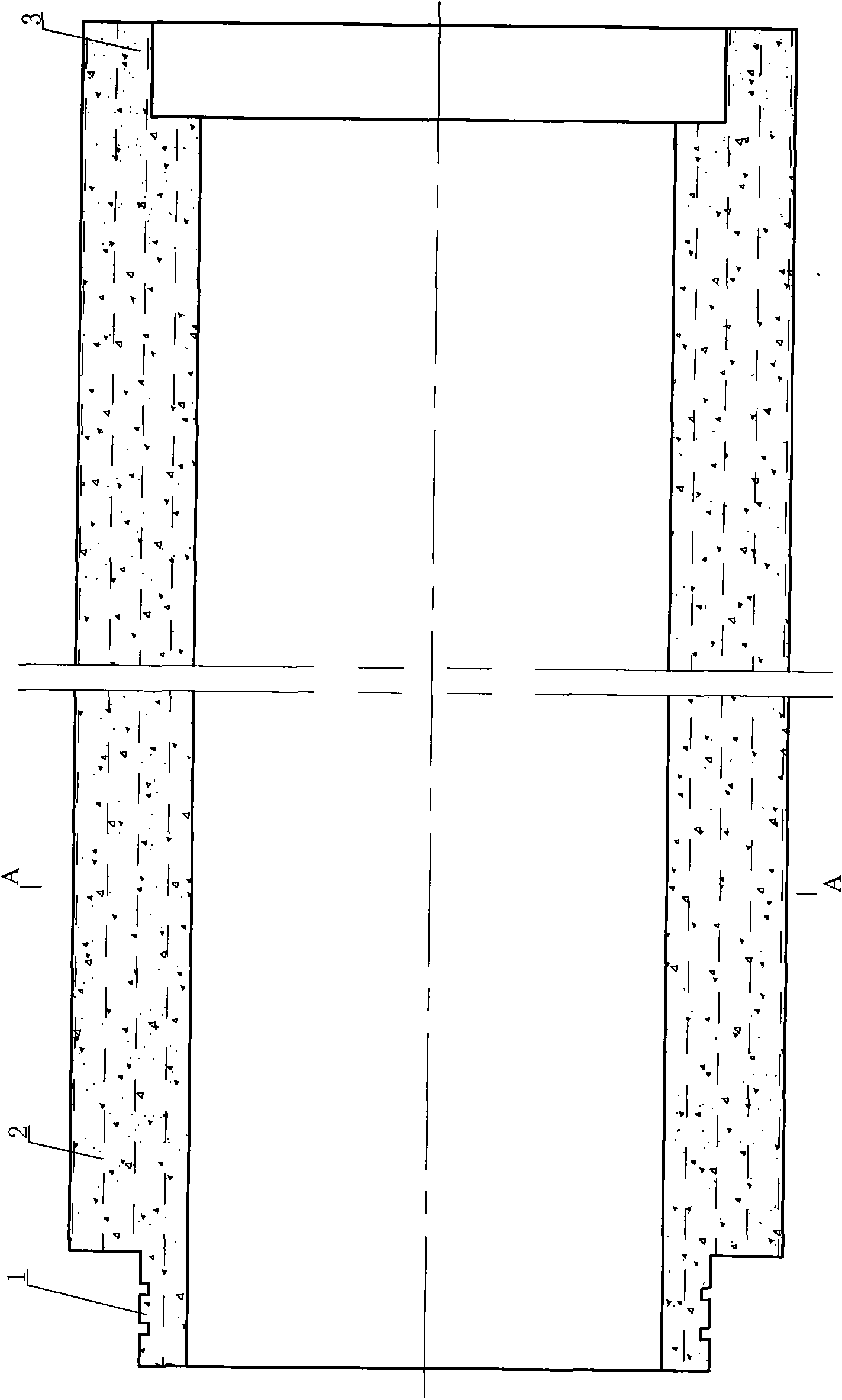

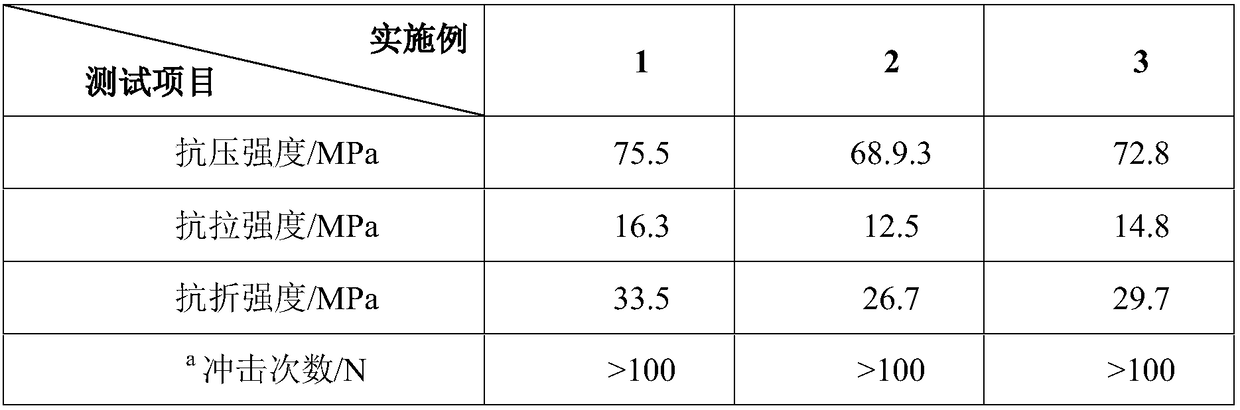

A high durability and high bearing capacity concrete pipe pile

The invention discloses a high-durability and high-bearing-capacity concrete pipe pile, which is characterized by comprising the following raw material in part by mass: 685 to 760 parts of common silicate cement, 170 to 200 parts of silicon powder with an average particle size of 0.30 mu m and a SiO2 content of more than or equal to 92 percent, 1,100 to 1,190 parts of quartz sand with a particle size between 0.16 to 1.25mm, 13 to 15 parts of superplasticizer, 165 to 190 parts of water, and 90 to 150 parts of copper-plated steel fibers with a diameter between 0.18 and 0.25mm and a length between 11 and 15mm. The preparation process of the pipe pile is to uniformly stir the steel fiber and fine quartz sand and the concrete, silicon powder, water and superplasticizer in turn to obtain a mixture, fill the mixture into a mold, form with vibrating, cure in a steam environment with a temperature between 75 and 95 DEG C and a humidity of not less than 95 percent for 36 to 48 hours and demold. The pipe pile has the advantages of high antifatigue performance and corrosion-resistance performance and small cross section thickness.

Owner:黄贺明

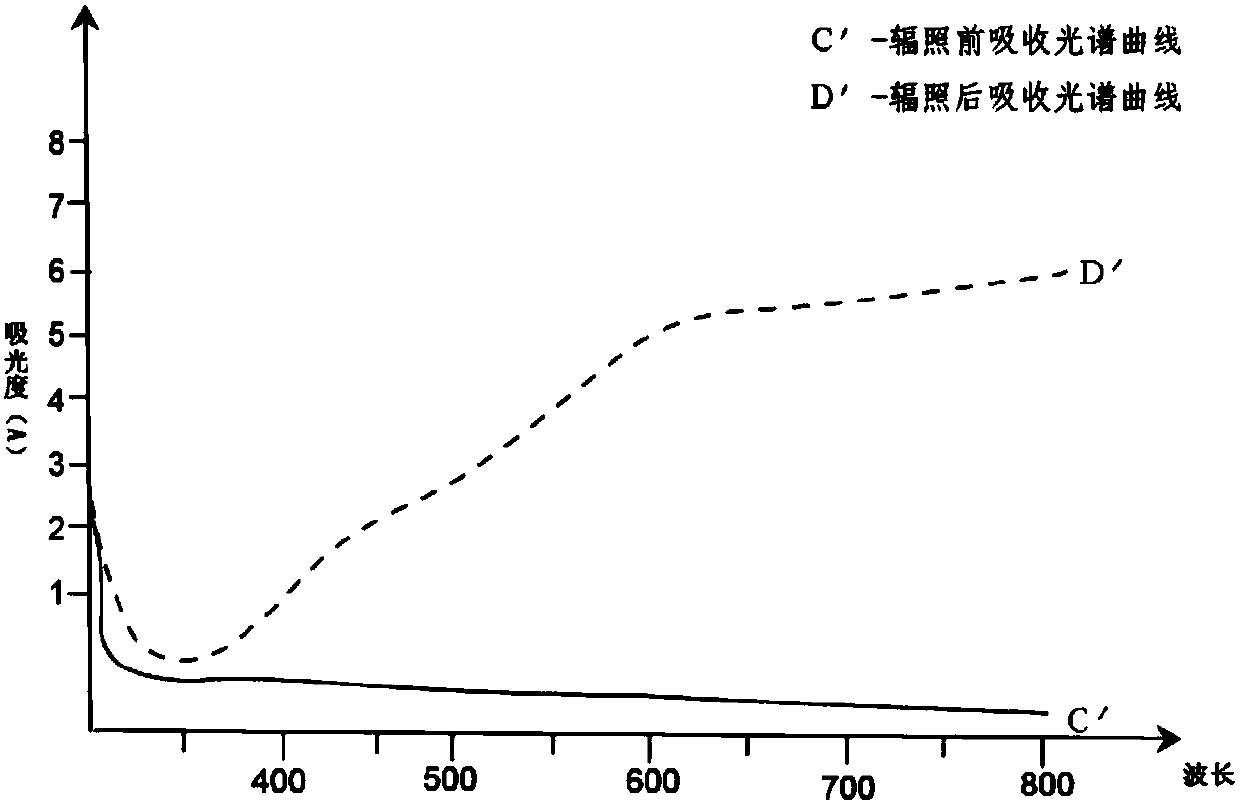

Photochromic nano composite microsphere and application thereof

ActiveCN107903889AThe van der Waals area growsIncrease space volumeTenebresent compositionsOptical partsMicrosphereUltraviolet

The invention discloses a photochromic nano composite microsphere and an application thereof. The photochromic composite microsphere has a three-layer composite core-shell structure, an inner core isa zinc sulfide mesoporous nano microsphere, a middle layer is a photochromic layer formed by a spiropyran compound, and an outer layer is polyurethane; and the outer diameter of the composite microsphere is 50-350nm, wherein the diameter of the zinc sulfide mesoporous nanosphere is 30-250nm, the thickness of the middle layer is 5-25nm, and the thickness of the outer shell is 5-25nm. The photochromic composite microsphere provided by the invention can be used to prepare a photochromic coating or doped into a resin optical material to prepare a photochromic material. The material can be changedfrom colorless to colored under the irradiation of ultraviolet rays, and after the ultraviolet rays disappear, the material can be quickly faded into colorless, and has the advantages of strong fatigue resistance, good stability, a fast color change speed and the like.

Owner:JIANGSU SHIKEXINCAI CO LTD

Mixed fiber concrete pipe

The invention relates to a mixed fiber concrete pipe, wherein mixed fiber concrete for forming the pipe comprises the following components according to the parts by weight: 322-540 parts of cement, 140-220 parts of water, 475-828 parts of sand, 864-1,306 parts of cobbles, 0.2-20 parts of polymer fibers and 20-140 parts of steel fibers. The mixed fiber concrete pipe has low raw material cost, light weight, high tensile strength, flexural strength, shearing strength and torsional strength, better durability and fatigue resistance, stronger capacities of shock resistance, abrasion resistance and cavitation resistance and better crack resistance, conforms to an energy saving and emission reduction policy and is a renewal product of the existing concrete pipes.

Owner:TIANJIN WATERLINE PIPELINE ENG CO LTD

Composition for repairing surfaces of metallic rubbing pairs and preparation thereof

InactiveCN101412943AReduce repair costsReduce difficultyAdditivesRestorative materialPhysical chemistry

The invention provides a composition for restoring the surface of a metallic rubbing pair and a preparation method thereof, and relates to the composition for restoring the surface of the metallic rubbing pair and the preparation method thereof. The invention solves the problem that the restoring film formed by the prior restoring material has limited thickness which can not reach over 0.5 millimeter and can not effectively control the clearance between the metallic rubbing pair. The composition consists of nickelous chloride powder, aluminum powder, nickel powder, ferric oxide powder, silicon dioxide powder, a powder suspending agent, a surface modifier and mineral lubricating oil. The preparation method is to put the nickelous chloride powder, the aluminum powder, the nickel powder, the ferric oxide powder, the silicon dioxide powder, the powder suspending agent, the surface modifier and the mineral lubricating oil in a high-speed viscolizer to be homogenized for 30 to 40 minutes. The composition for restoring the surface of the metallic rubbing pair and the preparation method thereof realize restoring modification to the surface of the metallic rubbing pair of which a restoration layer reaches 1.5 millimeters, and effectively control the clearance between the metallic rubbing pair.

Owner:三亚圣龙新材料开发有限公司

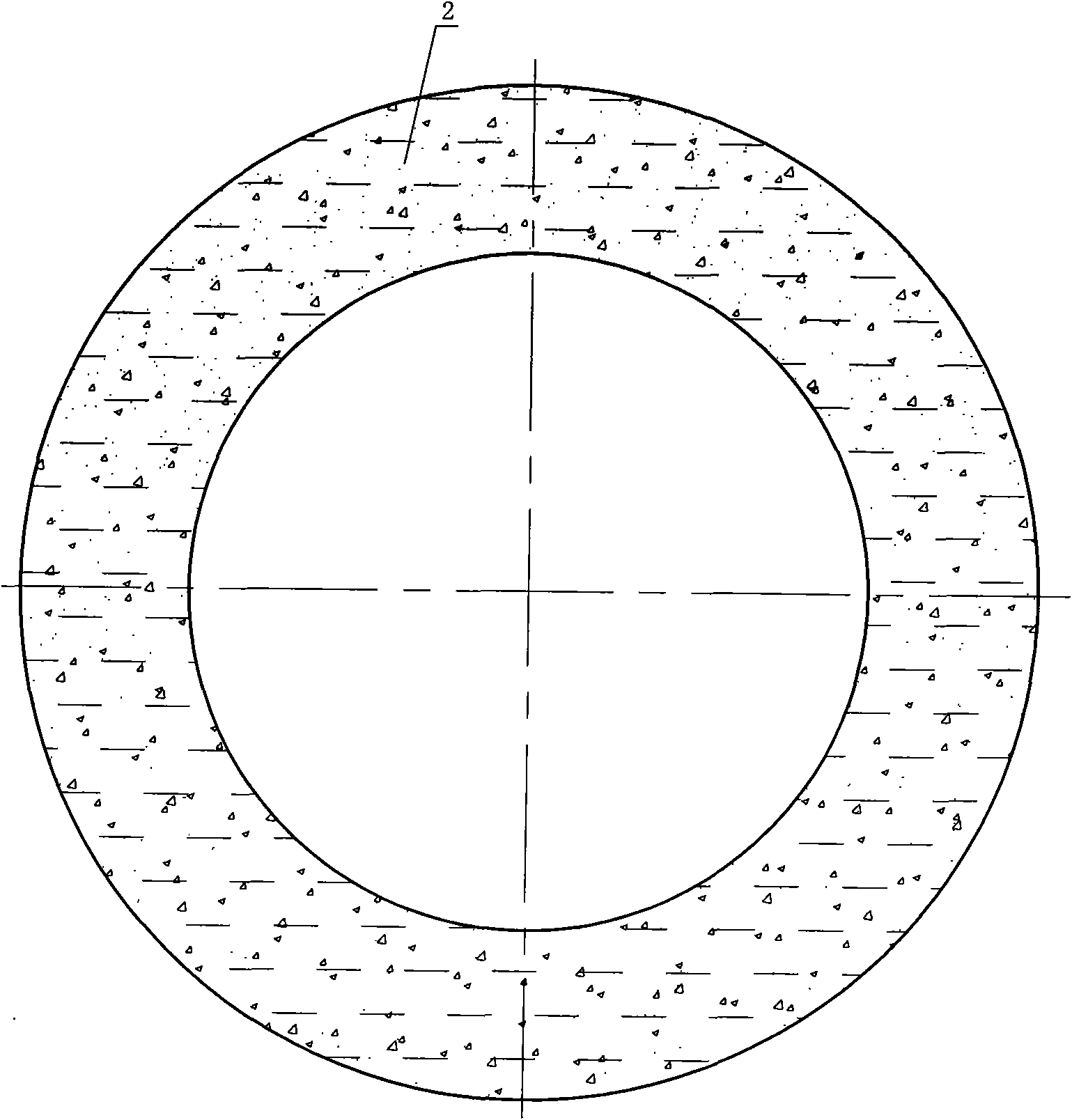

Organic material resistance random access memory element and manufacturing method thereof

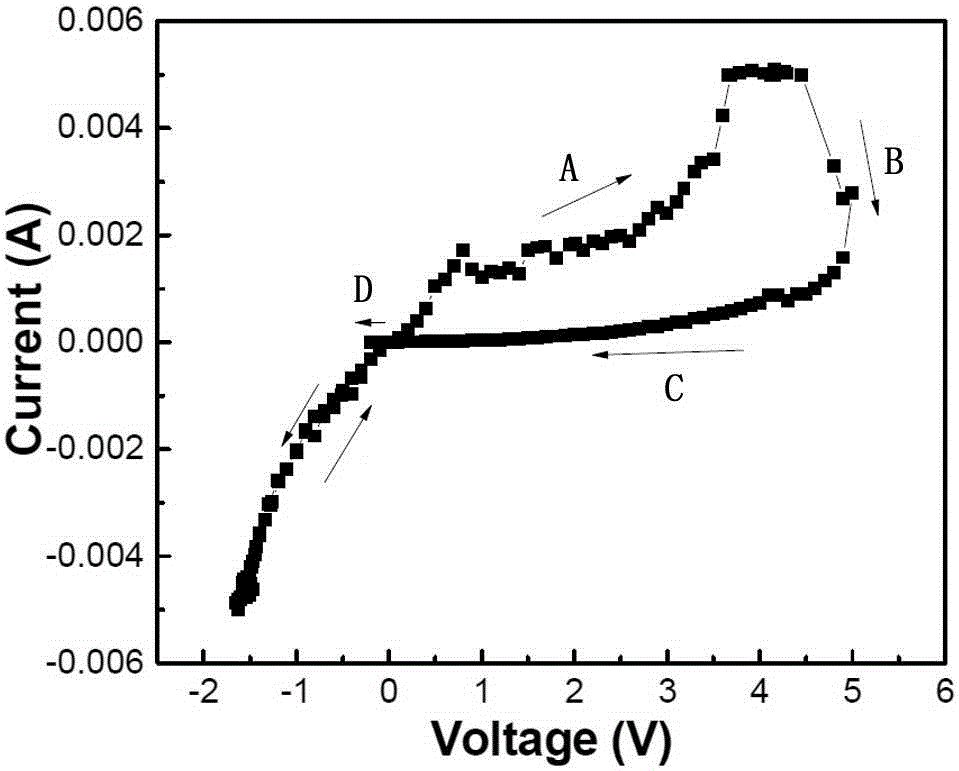

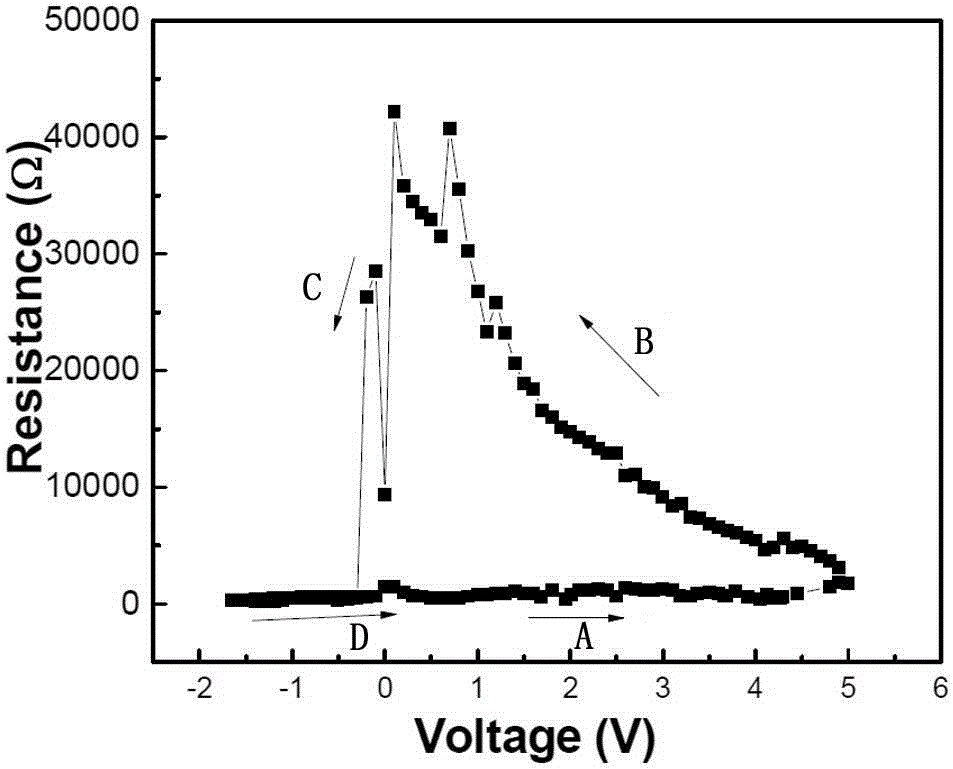

ActiveCN105185909AStrong fatigue resistanceSimple structureSolid-state devicesSemiconductor/solid-state device manufacturingRandom access memoryOptoelectronics

The invention provides an organic material resistance random access memory element and a manufacturing method thereof. The structure of the memory element comprises a lower electrode layer, a resistance random dielectric layer, and an upper electrode layer arranged in sequence from bottom to top. The lower electrode layer is an ITO layer. The resistance random dielectric layer is CH3NH3PbI(3-x)Cl3 layer. The upper electrode layer is an Ag layer or an Al layer. The manufacturing method for the organic material resistance random access memory element comprises: using a sol-gel method to form the CH3NH3PbI(3-x)Cl3 layer on the ITO layer of ITO glass, and then performing annealing treatment, and then using a vacuum evaporation method to deposit Ag or Al upper electrode layer on the CH3NH3PbI(3-x)Cl3 layer, and finally a resistance random access memory element whose heterostructure form is Ag or Al / CH3NH3PbI(3-x)Cl3 / ITO is formed. The organic material resistance random access memory element is stable in performance, and has relatively good fatigue resistance and holding property.

Owner:HEBEI UNIVERSITY

Method for producing glycyrrhizia polysaccharide by utilizing tissue culture method

InactiveCN102532337AHigh in polysaccharidesAntioxidant is goodAntinoxious agentsAntiviralsForcepsMicrobiology

The invention discloses a method for producing glycyrrhizia polysaccharide by utilizing a tissue culture method. The method comprises the following steps of: (1) culturing and inducing liquorice aseptic seedling; (2) adopting an embryonic axis to induce liquorice callus under the liquorice aseptic seedling; (3) selecting the liquorice callus with high growth speed, loose texture and light yellow color, crushing the liquorice callus with a pair of forceps, transferring the crushed liquorice callus into a liquid culture medium for suspension culture and obtaining liquorice suspension cells; (4) culturing the liquorice suspension cells by using a bubble type reactor; and (5) extracting the glycyrrhizia polysaccharide from the liquorice suspension cells obtained in the step (4) to obtain the glycyrrhizia polysaccharide powder. The glycyrrhizia polysaccharide produced by the suspension cells is higher in content than the wild liquorice, has obvious oxidation resistance, virus resistance, tumor resistance and immunoregulatory activity, and has very strong immunoregulatory and anti-fatigue effects. The method is not limited by seasons or regions, is convenient, is easy to operate, and has a wide development prospect.

Owner:TIANJIN UNIV

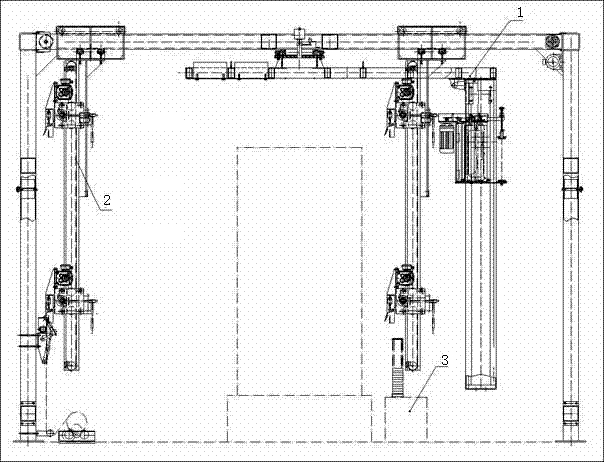

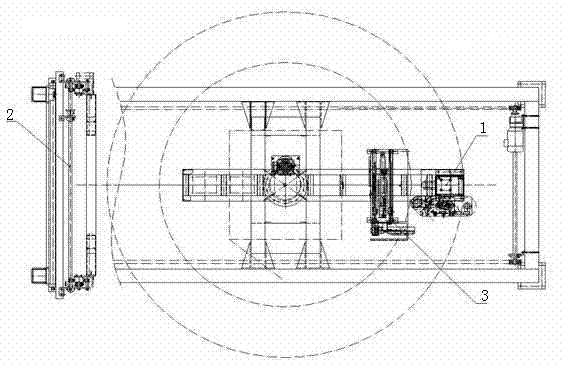

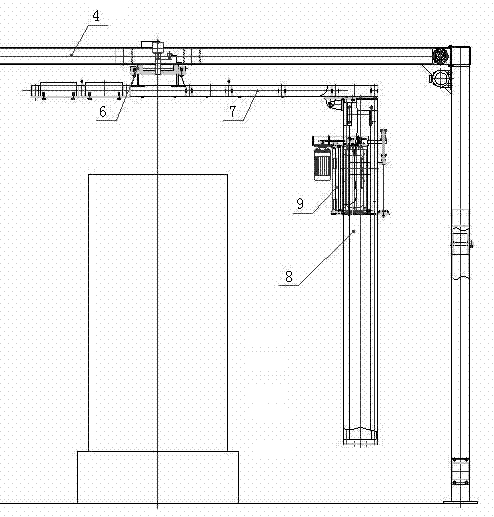

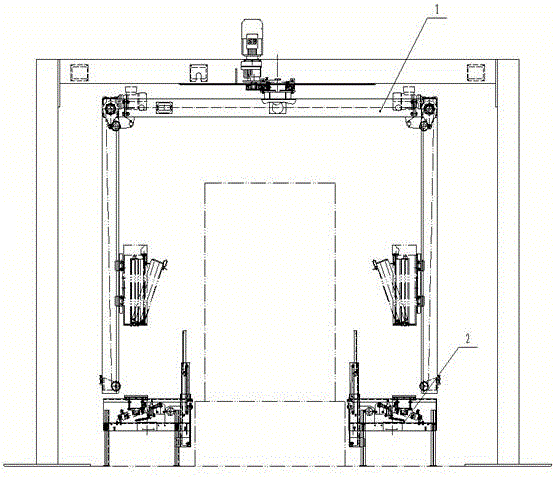

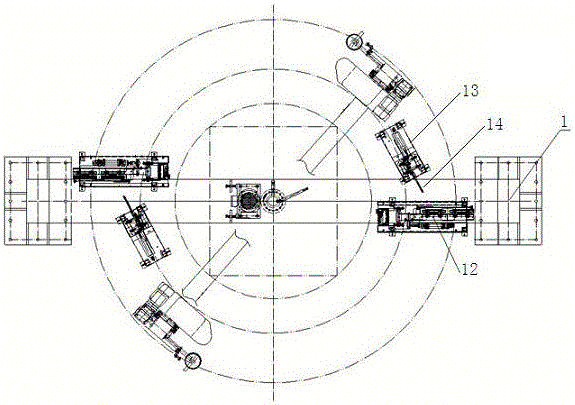

Dual-membrane-rack high-speed cantilever type winding machine

InactiveCN105644821ARotary motion stabilityPrecise positioningWeb rotation wrappingWinding machineCantilever

The invention relates to a dual-membrane-rack high-speed cantilever type winding machine which can greatly improve packing efficiency. The winding machine comprises a cantilever online type winding host and an automatic broken membrane feeding mechanism. The cantilever online type winding host comprises an installation frame. A rocker arm installed through a rotating support is arranged on the installation frame. A rocker arm speed reduction motor is arranged on the installation frame and meshed with the rotating support through a gear so as to drive the rocker arm to rotate around the rotating support. Vertical lifting frames are arranged below the two ends of the rocker arm respectively. The membrane racks capable of rising and falling along the lifting frames are arranged on the lifting frames. Membrane rack drive devices for driving the membrane racks to rise and fall are arranged on the lifting frames. The automatic broken membrane feeding mechanism comprises a broken membrane welding mechanism, a membrane clamping mechanism and an air blowing mechanism. Through the cooperation of the dual-membrane-rack winding mode and the corresponding automatic broken membrane feeding mechanism, the high efficiency requirement is met when the winding packing quality is ensured.

Owner:SHANDONG SINOLION MACHINERY CORP LTD

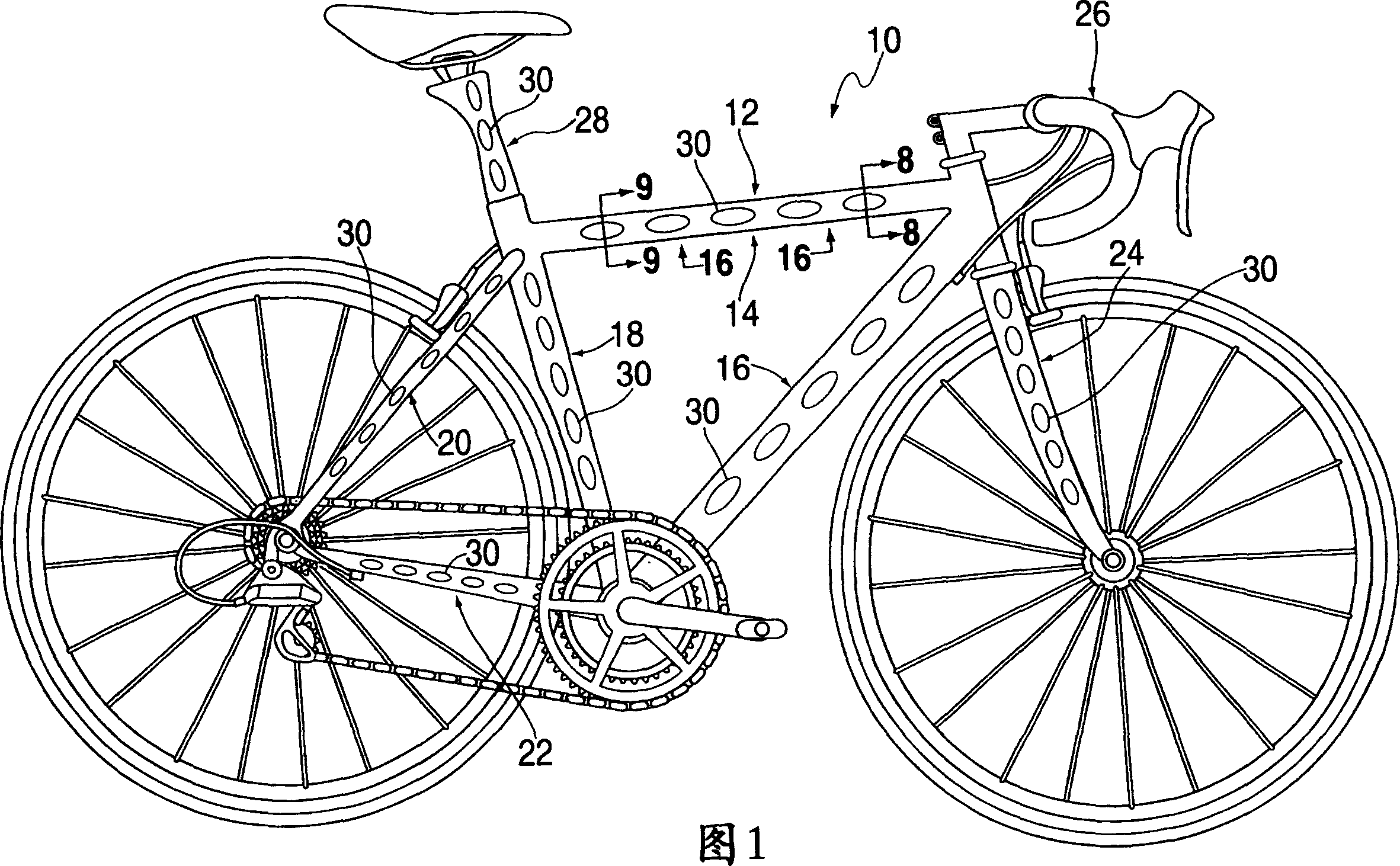

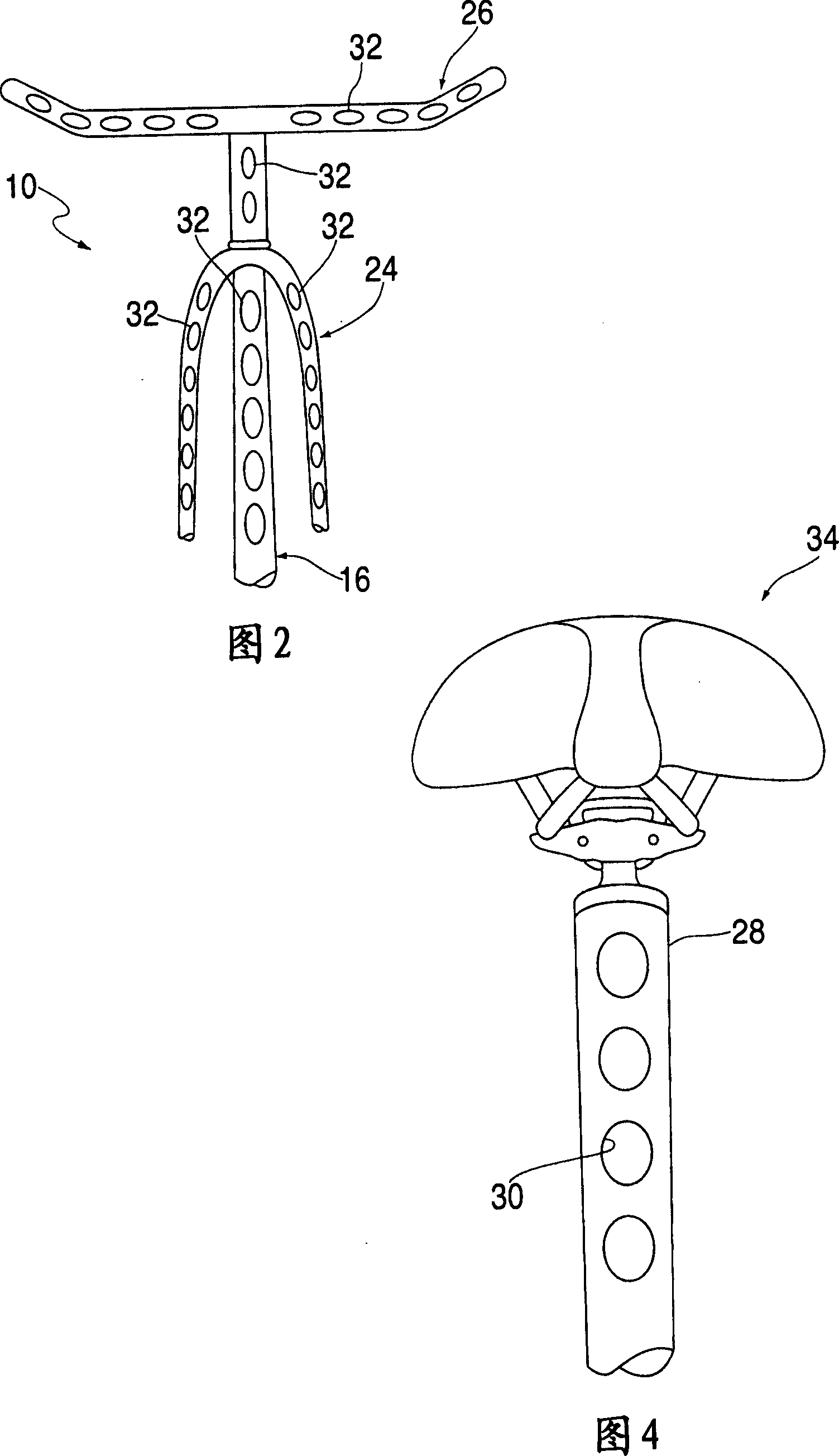

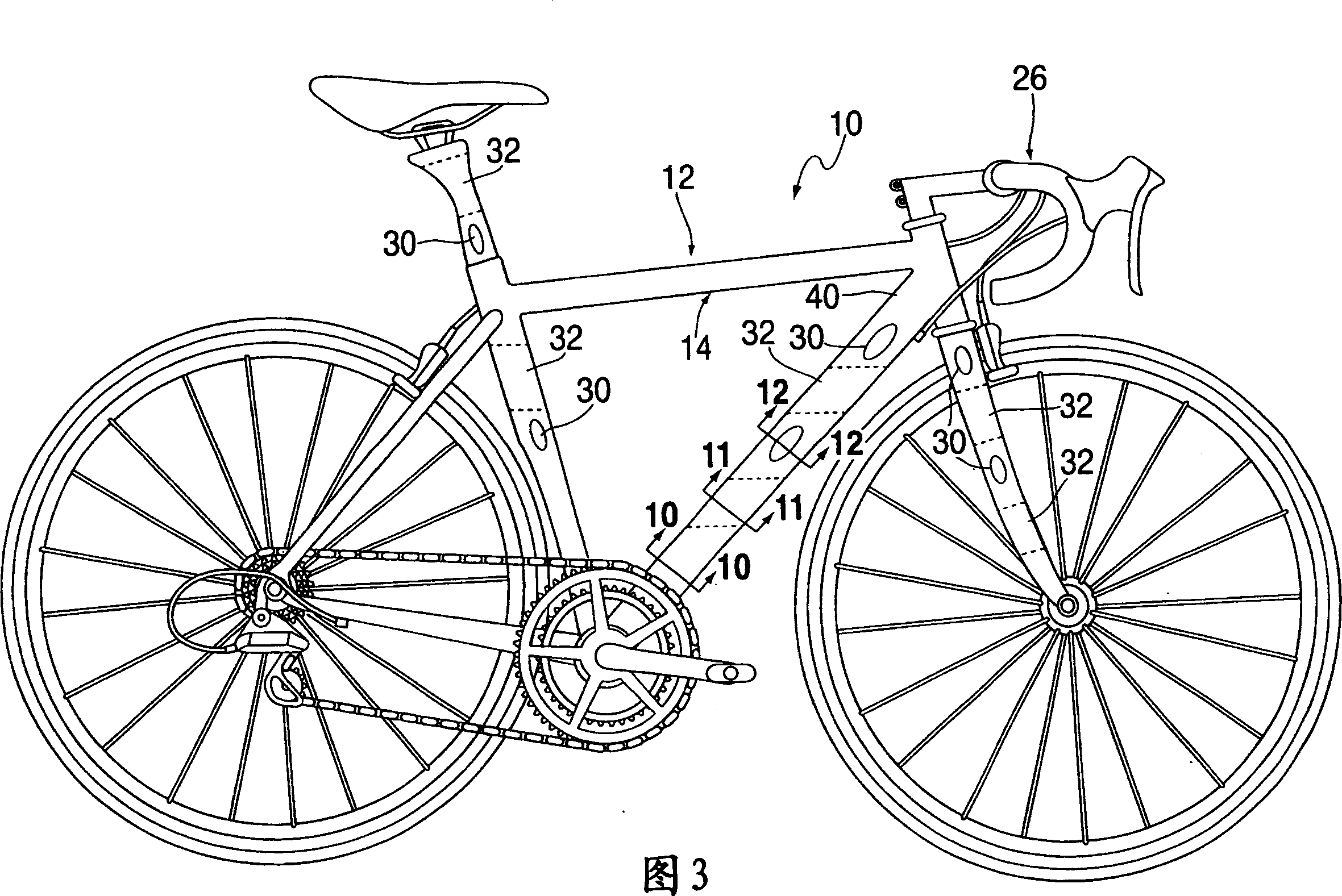

Bicycle having multiple tube frame structure.

InactiveCN1978274AEasy and Efficient ManufacturingDurableSteering deviceCycle saddlesVehicle frameAerodynamics

A structure for a bicycle frame system is described by using multiple composite tubes bonded to one another, wherein apertures, or ''ports'' are molded between the tubes to improve the stiffness, strength, aerodynamics and comfort of bicycle frame component.

Owner:PRINCE SPORTS LLC

Road surface structure of rolling flexiable fibre cement concrete and construction method thereof

InactiveCN100999889AReduce dosageImprove economyPaving reinforcementsIn situ pavingsFrostRoad surface

The present invention relates to road structure and construction technology, and is especially road structure of rolled flexible fiber cement concrete and its construction process. The base layer of rolled flexible fiber cement concrete and paved on the foundation layer is formed through mixing flexible fiber, cement and water to form cementing material, adhering broken stone, sand, stuffing, etc with the cementing material, and rolling. The rolled flexible fiber cement concrete has obviously improved early plastic shrinking, dry shrinking and hot shrinking performance, obviously raised anticracking performance, toughness, impact strength, frost resistance and erosion resistance, and doubled antifatigue performance. The road with the rolled flexible fiber cement concrete structure has the features of simple construction, fast construction, short curing period, wide application range and raised performance.

Owner:易志坚 +3

Deer penis and deer tail wine

InactiveCN101191112APhysiological metabolism is strongImprove anti-aging effectDigestive systemInanimate material medical ingredientsPenisMedicine

The invention discloses a deer pizzle deer tail wine and relates to a health care wine which is produced by dissolving, extracting and mixing deer pizzle, deer tail, deer antler, red ginseng, Desertliving Cistanche, Astragalus Root, Fossilizid, dodder, medlar, longan pulp, Radix Rehmanniae Preparata and Fructus Schisandrae Chinensis. The long-term drinking of the invention can nourish the vitality and enrich the blood, ensures that the elders have vigorous physiological metabolism, has better anti-aging effect, and possesses the effects of soothing nerves, benefiting intelligence, prolonging life and beautifying.

Owner:阚继承

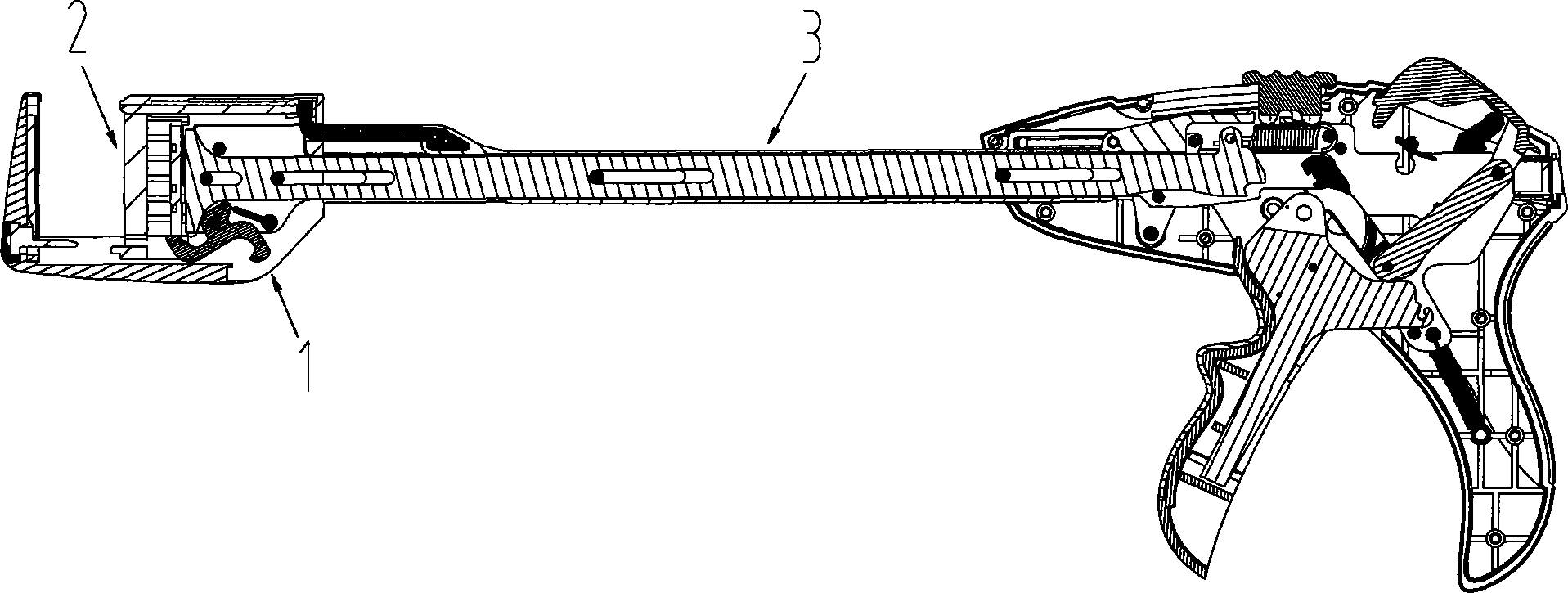

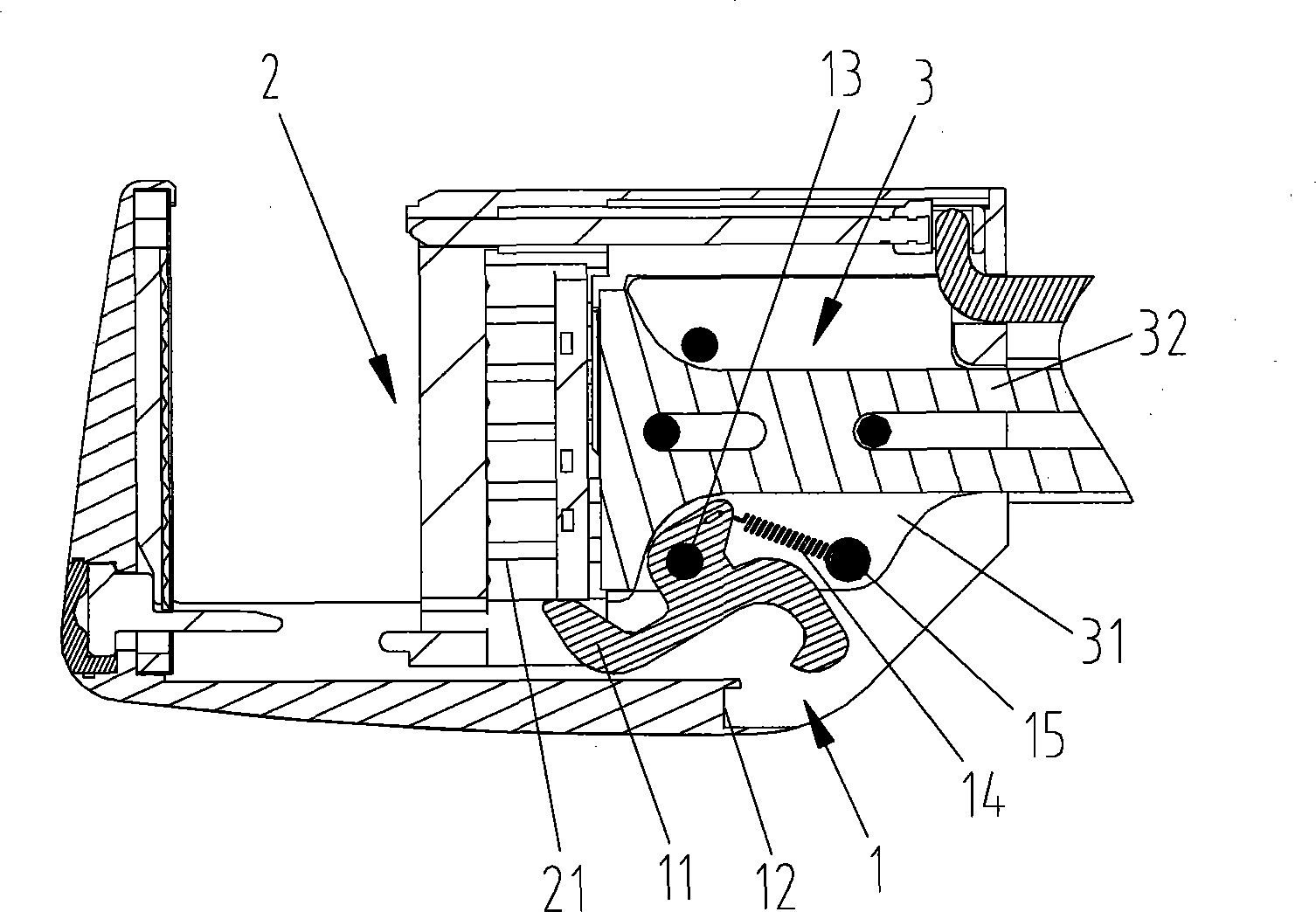

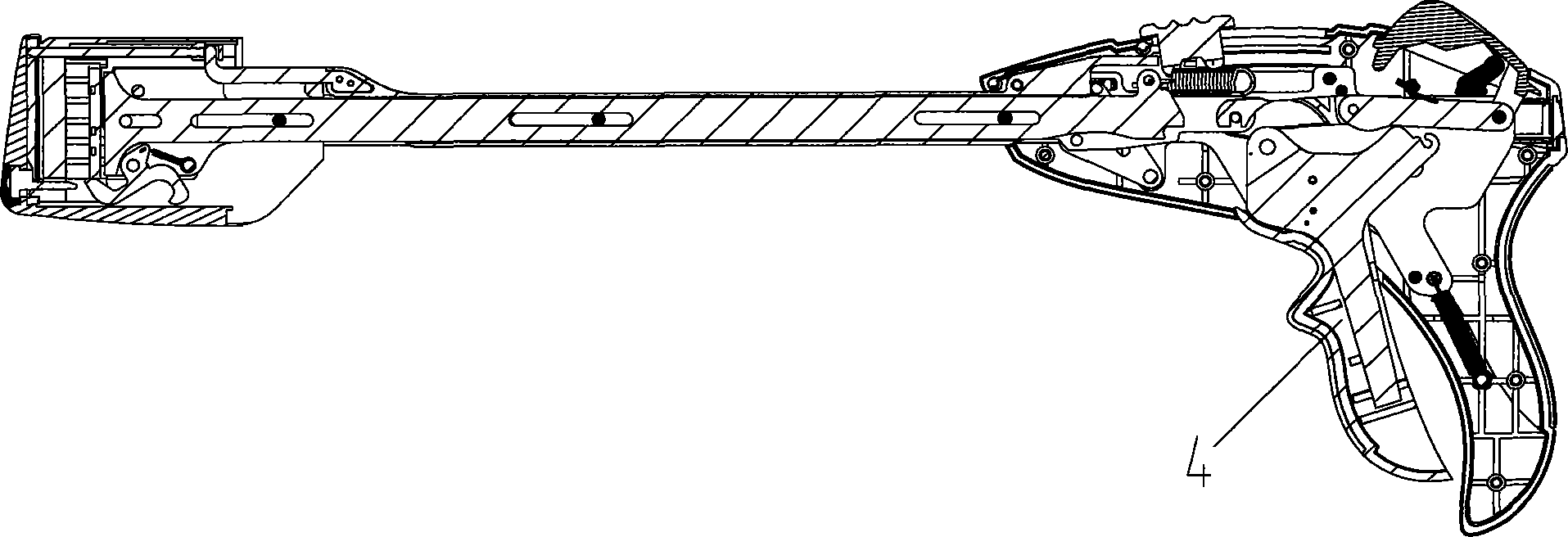

Surgical stitching instrument with safety device

ActiveCN103006282AHigh elastic modulusStrong fatigue resistanceSurgical staplesElastic modulusEngineering

The invention provides a surgical stitching instrument with a safety device. The surgical stitching instrument comprises a safety block, a pushing nail sheet and an elbow recess, wherein before the instrument is put in use, the pushing nail sheet is propped against the safety block; an elastic part is connected to the safety block; the elastic part does not include a plate spring; and after the firing of the instrument is finished and the pushing nail sheet is separated from the safety block, the safety block is rotated by the elastic part, so that a hook at the lower end of the safety block is propped against the elbow recess. According to the invention, the safety restoring force is provided by an extension spring; and as the extension spring has the advantages of large elastic modulus, high anti-fatigue capability and stable restoring force, the safety at the front end of the surgical stitching instrument is stabler and more reliable, and the defect that the elasticity of the plate spring is lost because the plate spring is easy to generate plastic deformation in the prior art is overcome.

Owner:B J ZH F PANTHER MEDICAL EQUIP

Composite concrete material and preparation method thereof

The invention discloses a composite concrete material belonging to the technical field of preparation of road materials and a preparation method of the composite concrete material. The composite concrete material is prepared by compounding a high void ratio epoxy resin gravel mixture with high fluidity polymer modified cement mortar; a specific compounding mode is to fill internal pores of the high void ratio epoxy resin gravel mixture with the high fluidity polymer modified cement mortar; a dense composite structure is formed by consolidating the high fluidity polymer modified cement mortar and the high void ratio epoxy resin gravel mixture. The preparation method comprises the following steps: firstly, preparing the high void ratio epoxy resin gravel mixture; secondly, pouring the high fluidity polymer modified cement mortar; thirdly, curing concrete. Compared with the prior art, the composite concrete material disclosed by the invention has the advantages of high comprehensive performance, good stability and durability, high price performance cost ratio, convenience in construction, long construction period and the like; the composite concrete material is more suitable for semi-flexible pavement paving engineering.

Owner:SHANXI PROVINCIAL RES INST OF COMM

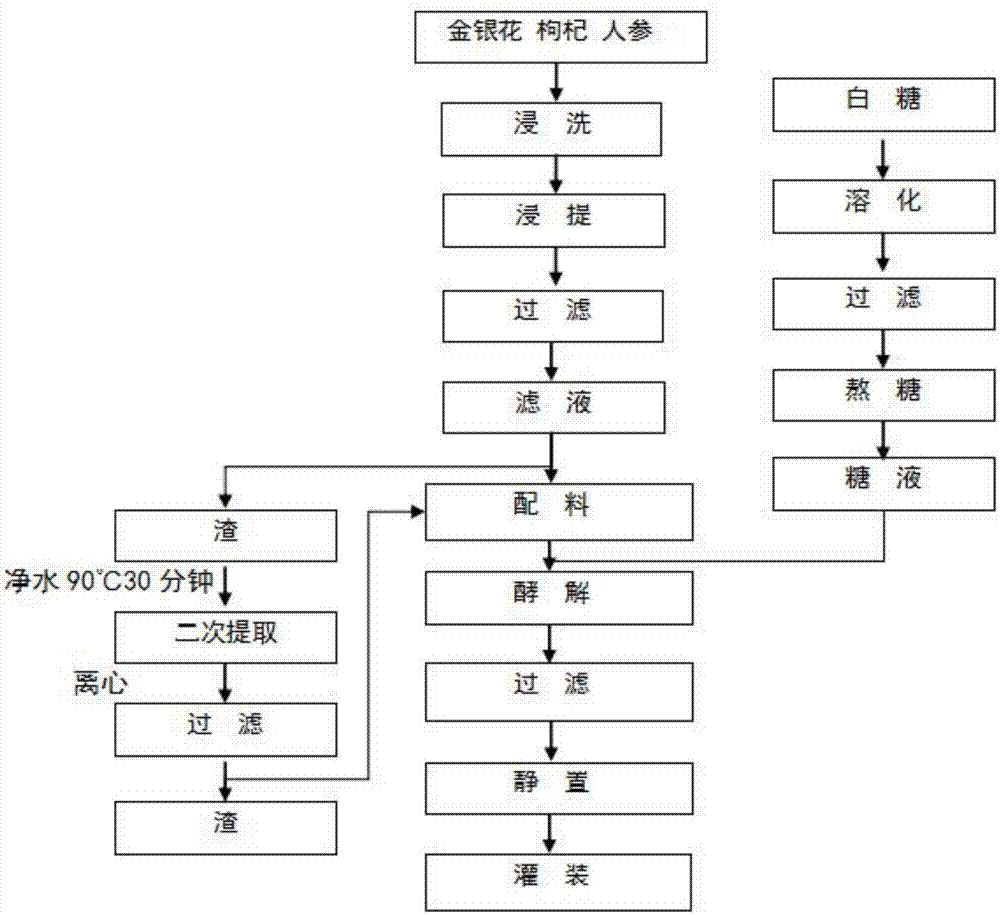

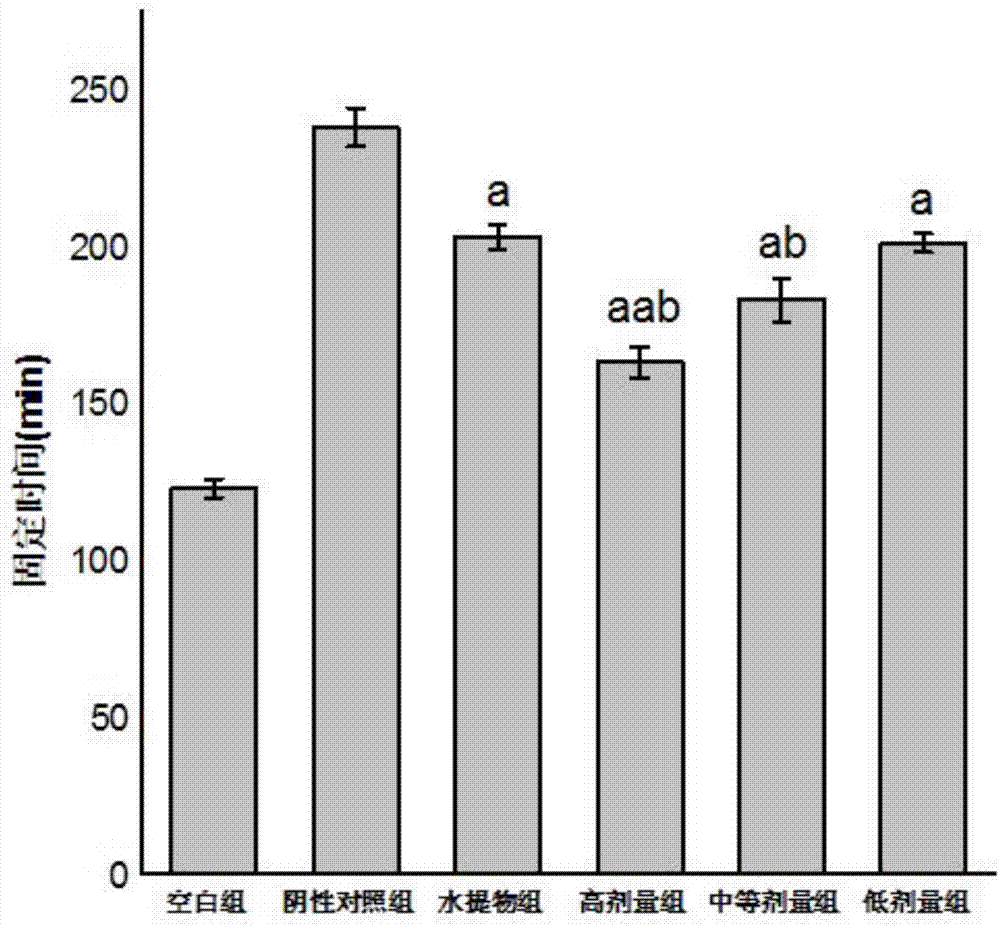

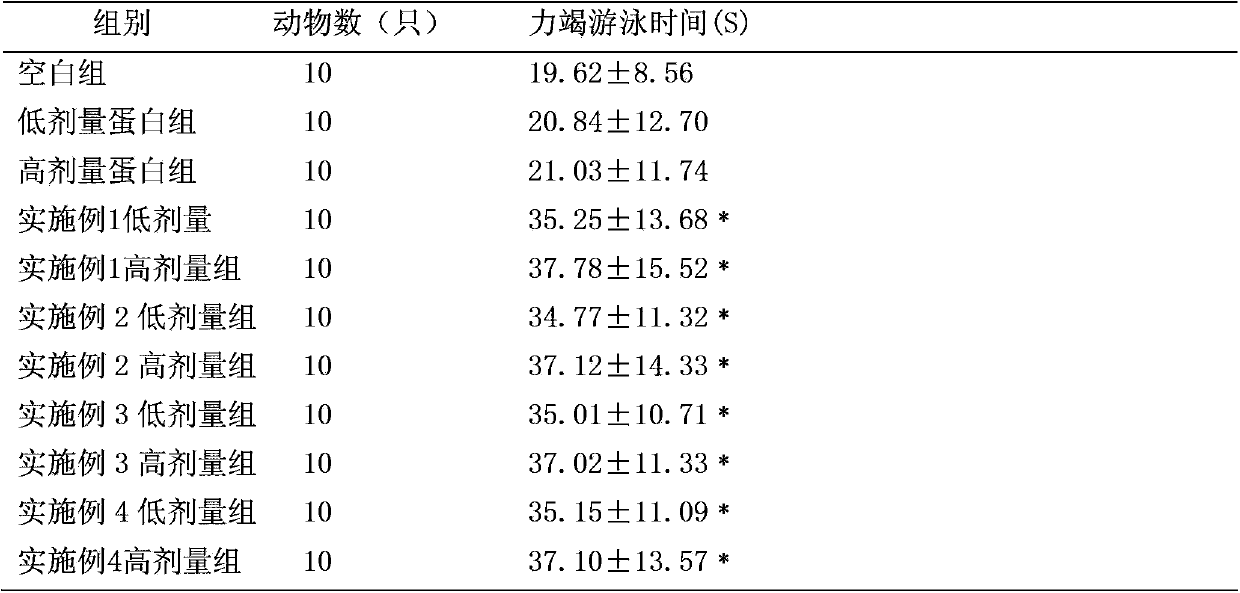

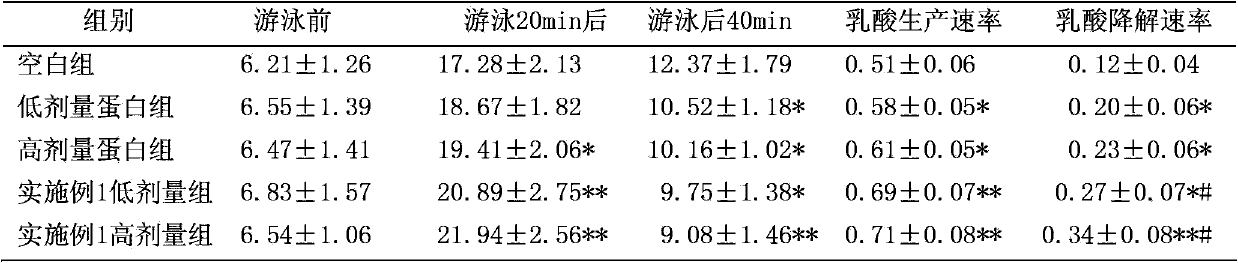

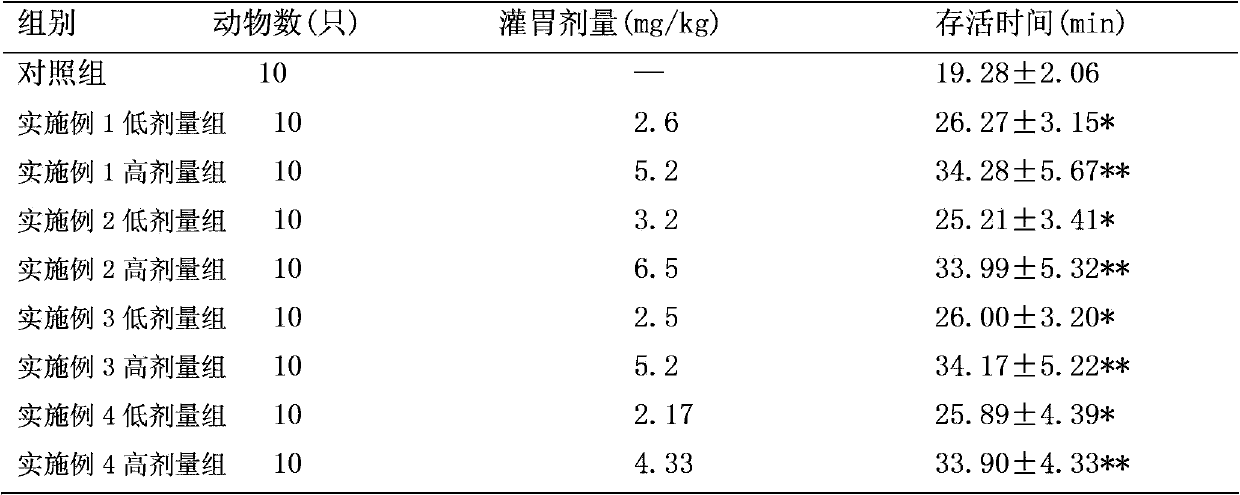

Fermented beverage having function of resisting weariness and preparation method

InactiveCN107343584AHigh acceptabilityStrong fatigue resistanceNatural extract food ingredientsFood ingredient functionsSugarAcetic acid bacteria

The invention relates to a fermented beverage having the function of resisting weariness. The fermented beverage having the function of resisting weariness is prepared by adding a sugar solution to a honeysuckle flower, ginseng and Chinese wolfberry fruit aqueous extract, and performing fermentation with mixed bacteria of lactic acid bacteria, acetic acid bacteria and microzymes. The honeysuckle flower, ginseng and Chinese wolfberry fruit aqueous extract is subjected to mixed fermentation with the acetic acid bacteria, the lactic acid bacteria and the microzymes, so that the capacity of resisting weariness can be effectively improved. Animal experiment indicate that after fermentation with the honeysuckle flower, ginseng and Chinese wolfberry fruit aqueous extract, the fermented beverage has strong effect of resisting weariness, and has the advantages of being sour and sweet in taste, and high in acceptability. Besides, in an experiment process, mice do not have any adverse reactions, so that the fermented beverage is worth of popularization in the market.

Owner:圣菌(天津)生物科技有限公司

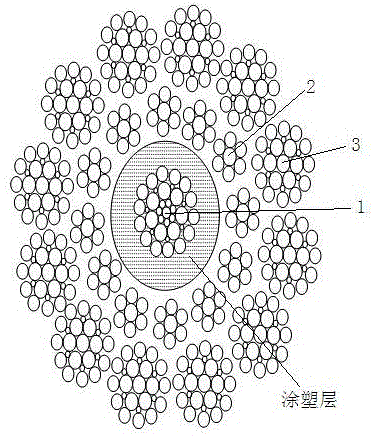

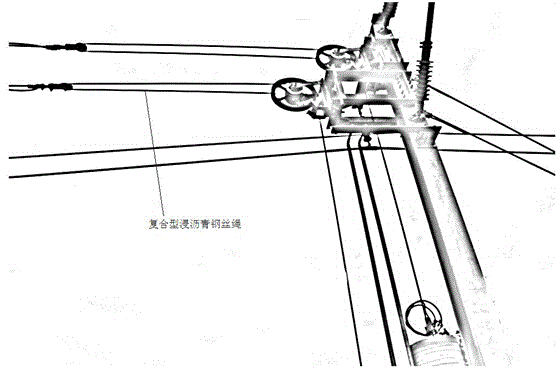

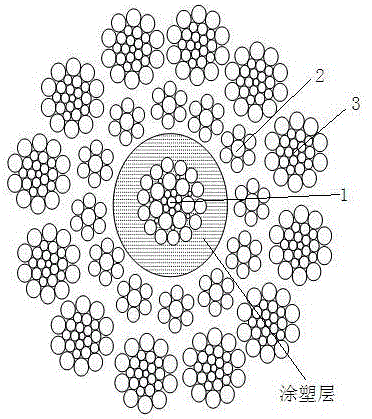

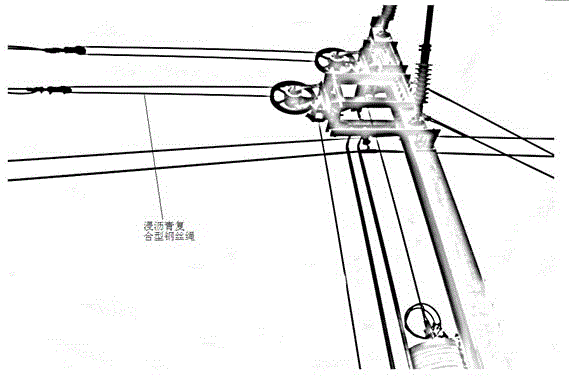

Composite type asphalt-impregnated steel wire rope for railway and production method thereof

ActiveCN104562815AHigh strengthImprove fatigue resistanceRope making machinesExtrusion cleaning devicesEngineeringContact layer

The invention belongs to the technical field of steel wire rope application and particularly relates to a composite type asphalt-impregnated steel wire rope for railway and a production method thereof. The composite type asphalt-impregnated steel wire rope comprises a central stand, inner layer strand which are arranged at the periphery of the central stand and arranged in the form of a dodecagon with the central strand as well as outer layer strand which are arranged at the peripheries of the inner strand and arranged in the form of a dodecagon with the inner layer strands, wherein the number of the inner layer strands is 12, the number of the outer layer strands is 12; the central strand and the inner layer strands, the inner layer strands and the outer layer strands are in point contact. The composite type asphalt-impregnated steel wire rope is simple in structure, low in production cost, relatively strong in tensile strength, fatigue resistance, corrosion resistance and long in service life. By repeatedly calculating and testing, designing and stimulating tests, a special electric railway steel wire rope which is high in strength and high in fatigue resistance is produced. Compared with the prior art, the steel wire rope is high in filling coefficient and thickened in contact layer surface steel wire, and has the advantages of being high in strength, high in fatigue resistance and high in electrical conductivity.

Owner:江苏亚盛金属制品有限公司

Fructus cannabis enzymolysis fermentation liquor having fatigue resistance and its preparation method and use

InactiveCN103385925AStrong fatigue resistanceBacteria material medical ingredientsAntinoxious agentsCannabisCopper chloride

The invention discloses a fructus cannabis enzymolysis fermentation liquor having fatigue resistance and its preparation method and use. The preparation method comprises the following steps of 1, preparing a solution A, 2, preparing a solution B, 3, mixing mixed strains, the solution A and the solution B, carrying out fermentation, adding potassium chloride, copper chloride, riboflavin tetrabutyrate and phosphatidylserine into the fermentation product, carrying out mixed strain secondary-inoculation, and carrying out fermentation culture to obtain a secondary fermentation liquor, and 4, adding an emulsifier into the secondary fermentation liquor, carrying out filtration, homogenization and pasteurization. The preparation method realizes mixing enzymolysis and fermentation of all components of fructus cannabis by a bioengineering technology. Compared with a fructus cannabis protein, the fructus cannabis enzymolysis fermentation liquor has stronger fatigue resistance and hypoxia resistance.

Owner:LOGISTICS UNIV OF CAPF

Repairing composite layer of amorphous/nanocrystalline cooling roller and preparation method of repairing composite layer

ActiveCN103895280AGood workmanshipInhibit sheddingElectrolytic coatingsMetallic material coating processesHigh power lasersHigh energy

The invention belongs to the technical field of material science, and particularly relates to a repairing composite layer of an amorphous / nanocrystalline cooling roller and a preparation method of the repairing composite layer. The composite layer consists of two layers, namely a copper-based alloy layer connected with base materials and a nickel-based alloy layer, wherein the copper-based alloy layer comprises the following components by weight percent: 7-9% of Ni, 8-12% of Sn, 5-15% of Co, 0.8-2% of Si and the balance being Cu; the nickel-based alloy layer comprises one of Ni-Co alloy, Ni-P alloy, Ni-Fe alloy and Ni-Cr alloy, and the weight content of Ni in alloy is 60-75%. The preparation method comprises the following steps of pretreating the surface of the cooling roller, electroplating the copper-based alloy layer and performing wide-strip cladding on the nickel-based alloy layer by a high-power laser. The prepared composite coating is uniform and compact, and excellent in wear resistance and heat resistance, and has the characteristics of high cladding efficiency and high energy absorptivity of the cooling roller to the laser beam.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

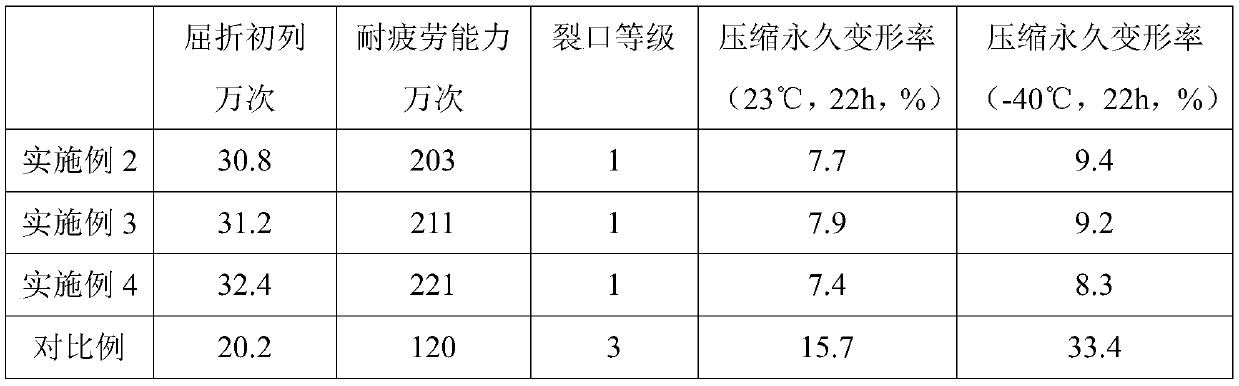

Graphene high-elasticity rubber elastomer high polymer material and preparation method thereof

The invention discloses a graphene high-elasticity rubber elastomer high polymer material and a preparation method thereof. The high polymer material is prepared from the following raw materials by weight: 45-50 parts of natural rubber, 15-19 parts of styrene-butadiene rubber, 10-14 parts of an ethylene-octene copolymer, 13-16 parts of an ethylene-butyl acrylate copolymer, 16-20 parts of an ethylene-vinyl acetate copolymer, 2.4-3.0 parts of grapheme, 6.5-8.5 parts of silane coupling agent modified glass fiber, 1.6-2.1 parts of a foaming agent, 0.82-0.95 part of a micropore regulator, 1.8-2.2 parts of a bridging agent, 2-4 parts of polyethylene wax, 3-5 parts of maleic anhydride grafted polypropylene, 1.8-2.4 parts of a cross-linking agent, 3.5-5.5 parts of an antioxidant and 3-4 parts of aheat stabilizer. The product disclosed by the invention has good resilience and memory function, also has high elasticity, still has very low permanent compression set value at -40DEG C, and has goodflexibility.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

Novel carbon-fiber composite sucker rod

InactiveCN102086296AStrong fatigue resistanceImprove wear resistanceDrilling rodsDrilling casingsEpoxyFiber

A novel carbon-fibre composite sucker rod comprises carbon fiber and epoxy resin, and the novel carbon-fiber composite sucker rod is characterized in that glass fiber thermoplastic is added, and the novel carbon-fiber composite sucker rod is composed of the following components in wt%: 72% of carbon fiber, 1% of glass fiber thermoplastic, and 27% of epoxy resin glue liquid. The invention possesses strong tensile strength, strong anti-fatigue capability, high wear resistance, light weight, and a high ratio of intensity and weight, simultaneously, the production process is simplified, and production cost is reduced.

Owner:DANCHEN TECH DALIAN

Chemical fire explosion safety test chamber system

InactiveCN103926376AEliminate pollutionStrong fatigue resistanceFuel testingIntrinsic safetyCombustion

The invention provides a chemical fire explosion safety test chamber system. The chemical fire explosion safety test chamber system comprises a test chamber body, a fire extinguishing and fighting device, a temperature and humidity regulating device, a gas replacement device, a test monitoring and controlling device and a main control device. The chemical fire explosion safety test chamber system eliminates harm on runaway reaction, combustion explosion, decomposition explosion and the like which are generated in the large-scale chemical risk assessment test process, meanwhile treats waste liquids, waste gases and waste residues which are generated in the collection test process in a centralized manner, and plays a role of alleviating environmental pollution as well as improving the intrinsic safety of the fire disaster explosion risk testing process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bitumen-impregnated type composite steel wire rope for railway and production method thereof

ActiveCN104611962AHigh strengthImprove fatigue resistanceHot-dipping/immersion processesRope making machinesEngineeringHigh intensity

The invention belongs to the technical field of steel wire rope application and particularly discloses a bitumen-impregnated type composite steel wire rope for a railway and a production method thereof. The bitumen-impregnated type composite steel wire rope is composed of a center strand, twelve inner layer strands and twelve outer layer strands, wherein the inner layer strands are arranged on the periphery of the center strand and arranged with the center strand in a dodecagon shape, and the outer layer strands are arranged on the periphery of the inner layer strands and arranged with the inner layer strands in a dodecagon shape. The center stand makes point contact with the inner layer strands, and the inner layer strands make point contact with the outer layer strands. The bitumen-impregnated type composite steel wire rope is simple in structure, low in production cost, high in extension strength, fatigue resistance, corrosion resistance and abrasive resistance and long in service life; through repeated calculation, tests, designs and stimulation tests, the high-strength and high-fatigue-resistance steel wire rope special for the electric railway is produced; compared with a conventional steel wire rope, the filling coefficient is high, contact layer steel wires are thickened, and therefore the steel wire rope has the advantages of being high in strength, fatigue resistance and conductive performance.

Owner:江苏亚盛金属制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com