Graphene high-elasticity rubber elastomer high polymer material and preparation method thereof

A technology of bulk polymers and graphene, which is applied in the field of rubber elastic polymer materials and its preparation, can solve the problems of destroying the crystal structure of graphene, poor resilience, and affecting the performance of graphene, etc., achieving simple process, easy operation, and saving manpower and equipment cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of graphene high elastic rubber elastomer macromolecular material is made of the raw materials comprising following parts by weight:

[0042] 45-50 parts of natural rubber, 15-19 parts of styrene-butadiene rubber, 10-14 parts of ethylene-octene copolymer, 13-16 parts of ethylene-butyl acrylate copolymer, 16-20 parts of ethylene-vinyl acetate copolymer, graphite 2.4-3.0 parts of alkene, 6.5-8.5 parts of silane coupling agent modified glass fiber, 1.6-2.1 parts of foaming agent, 0.82-0.95 parts of micropore regulator, 1.8-2.2 parts of bridging agent, 2-4 parts of polyethylene wax parts, 3-5 parts of maleic anhydride grafted polypropylene, 1.8-2.4 parts of crosslinking agent, 3.5-5.5 parts of antioxidant, 3-4 parts of heat stabilizer; the graphene is a nano-graphene microsheet; the The pore regulator is a mixture of zinc formate and zinc isooctanoate; the crosslinking agent is sulfur, 1,1-di-tert-butylperoxy-3,3,5-trimethylcyclohexane and zinc diacrylate mixture. ...

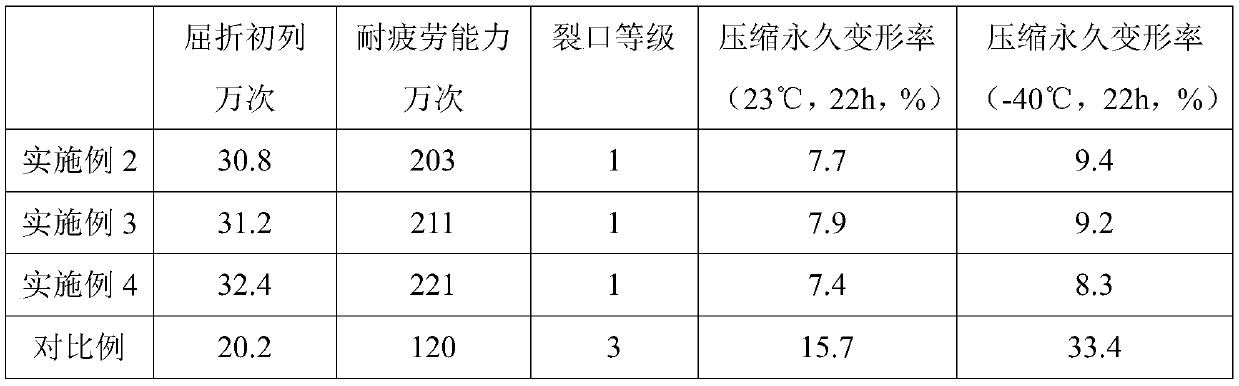

Embodiment 2

[0059] A kind of graphene high elastic rubber elastomer macromolecular material is made of the raw materials comprising following parts by weight:

[0060] 45 parts of natural rubber, 15 parts of styrene-butadiene rubber, 10 parts of ethylene-octene copolymer, 13 parts of ethylene-butyl acrylate copolymer, 16 parts of ethylene-vinyl acetate copolymer, 2.4 parts of graphene, modified by silane coupling agent 6.5 parts of glass fiber, 1.6 parts of foaming agent, 0.82 parts of micropore regulator, 1.8 parts of bridging agent, 2 parts of polyethylene wax, 3 parts of maleic anhydride grafted polypropylene, 1.8 parts of crosslinking agent, 3.5 parts of antioxidant , 3 parts of thermal stabilizers; the graphene is a graphene nanosheet; the micropore regulator is a mixture of zinc formate and zinc isooctanoate; the cross-linking agent is sulfur, 1,1-di-tert-butyl Mixture of peroxy-3,3,5-trimethylcyclohexane and zinc diacrylate.

[0061] In this embodiment, the VA content of the ethyl...

Embodiment 3

[0076] A kind of graphene high elastic rubber elastomer macromolecular material is made of the raw materials comprising following parts by weight:

[0077] 50 parts of natural rubber, 19 parts of styrene-butadiene rubber, 14 parts of ethylene-octene copolymer, 16 parts of ethylene-butyl acrylate copolymer, 20 parts of ethylene-vinyl acetate copolymer, 3.0 parts of graphene, modified by silane coupling agent 8.5 parts of glass fiber, 2.1 parts of foaming agent, 0.95 parts of micropore regulator, 2.2 parts of bridging agent, 4 parts of polyethylene wax, 5 parts of maleic anhydride grafted polypropylene, 2.4 parts of crosslinking agent, 5.5 parts of antioxidant , 4 parts of thermal stabilizers; the graphene is nano-graphene microsheets; the micropore regulator is a mixture of zinc formate and zinc isooctanoate; the cross-linking agent is sulfur, 1,1-di-tert-butyl Mixture of peroxy-3,3,5-trimethylcyclohexane and zinc diacrylate.

[0078] In this example, the VA content of the eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com