Patents

Literature

1407results about How to "Strong designability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

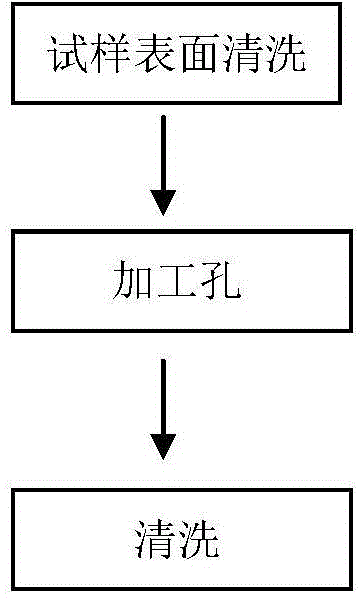

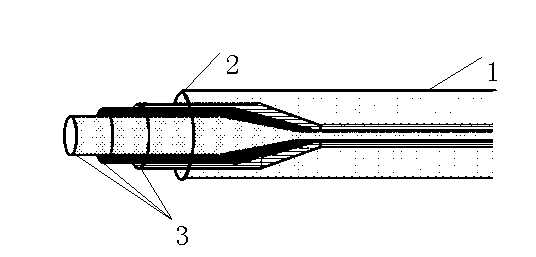

Method for hole machining with picosecond laser

ActiveCN103143841AImprove forming qualityGood processing designabilityLaser beam welding apparatusPicosecond laserOptoelectronics

A method for hole machining with picosecond laser realizes hole machining on CMC-SiC (Ceramic Matrix Composite-Silicon Carbide) material according to the characteristics of fiber composite materials and the machining feature that picosecond laser is suitable for various materials due to superhigh peak power of picosecond laser. According to the method, round holes or square holes are machined in the CMC-SiC material layer by layer in a distributed machining mode; the influence of tiny cracks can be ignored during machining; the stability is good; and the method is particularly suitable for mass repeated micro-hole machining. Layer-by-layer machining in a heliciform way is adopted when round holes are machined; and layer-by-layer machining in a linear scanning way is adopted when square holes are machined. The method has the advantages of good stability of the machining technology, strong designability, high precision and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

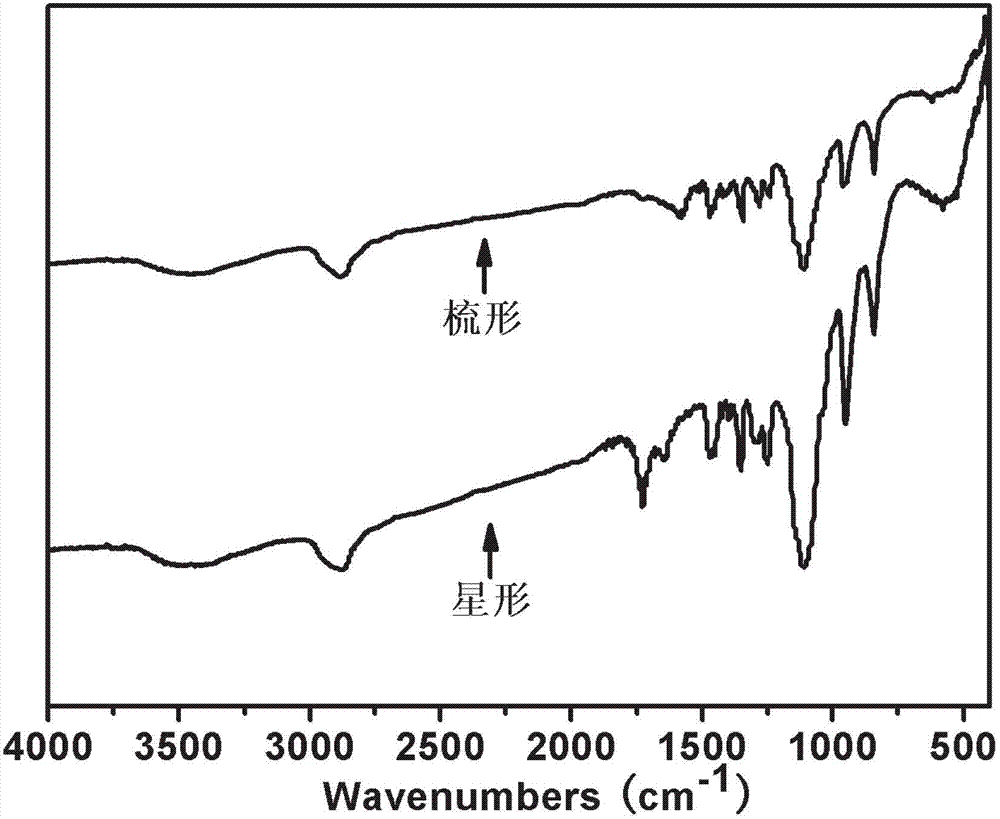

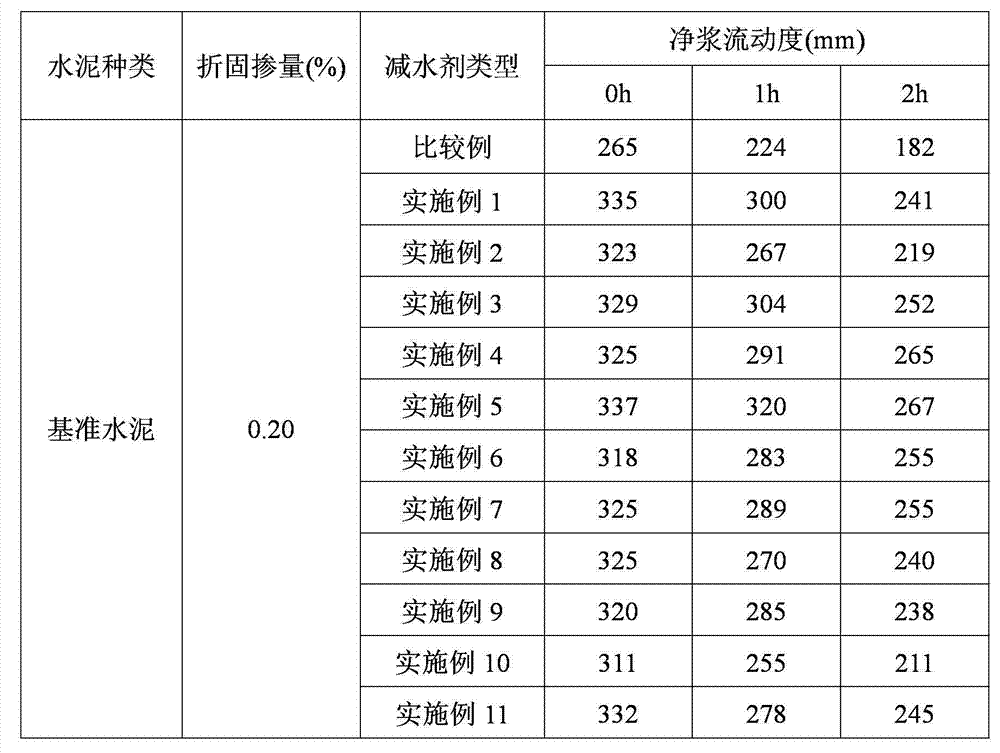

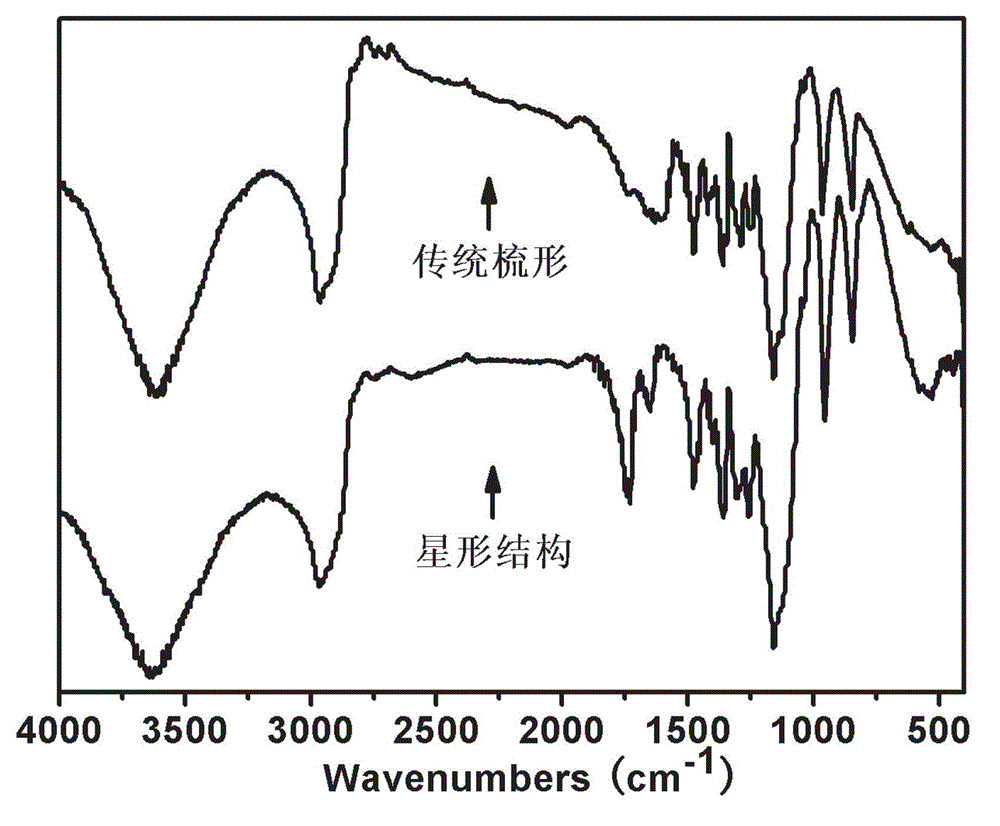

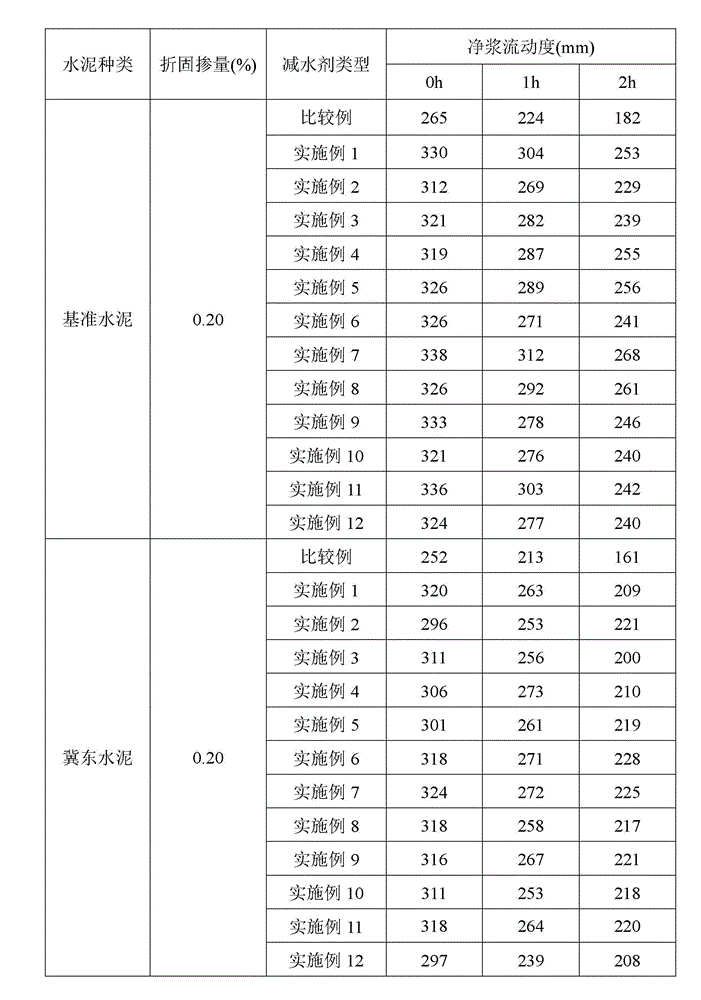

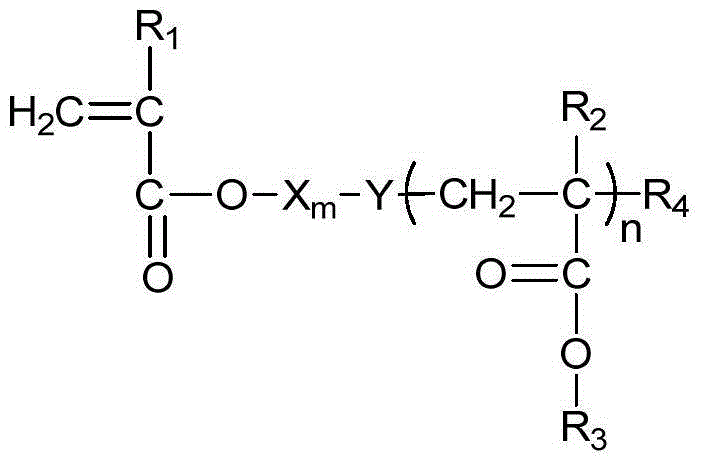

Preparation method of star polycarboxylic acid high-performance water reducing agent

ActiveCN102887979AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesWater reducerPollution

The invention relates to a preparation method of a star polycarboxylic acid high-performance water reducing agent. Polybasic alcohol and (methyl) acrylic acid used as main raw materials for esterification are esterified and polymerized to prepare the star polycarboxylic acid high-performance water reducing agent material: the (methyl) acrylic acid and polybasic alcohol used as reactants are esterified under the action of a catalyst to firstly prepare a star polymerizable active terminal, and free-radical polymerization reaction is carried out with unsaturated polyethenoxy ether, molecular weight regulator and unsaturated carboxylic acid monomer under the action of an initiator to prepare the star polycarboxylic acid high-performance water reducing agent. The invention is easy to control, and has the advantages of high polymerization degree, low cost and no pollution; the esterification reaction is carried out form an active core, and the free-radical polymerization is carried out to generate the chain arm, thereby implementing the polycarboxylic acid high-performance water reducing agent in a star molecular structure; and under the condition of common doping amount and low doping amount, the star polycarboxylic acid high-performance water reducing agent has better cement paste flowability and holding capacity than the traditional linear and comb polycarboxylic acid water reducing agents, and has favorable cement adaptability and concrete application performance.

Owner:GUIZHOU DR SHI TECH

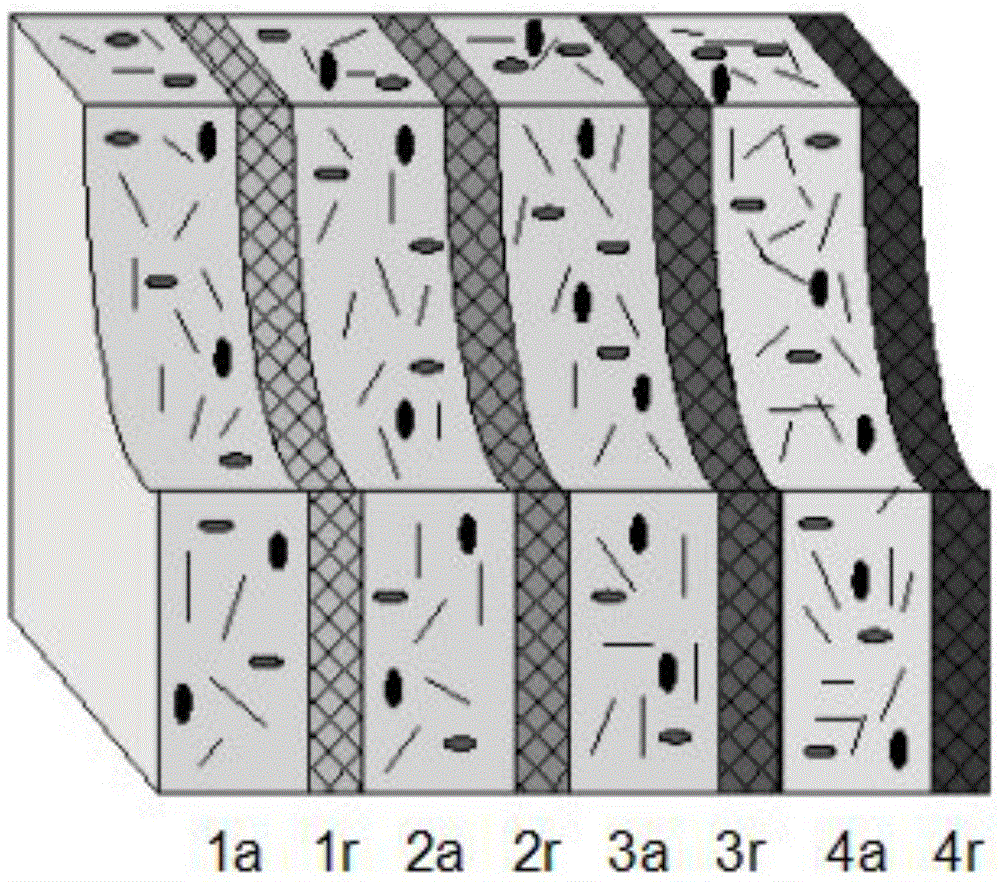

Process for preparing self-sealing silicon carbide ceramic based composite material

The invention relates to a method for manufacturing a self-healing silicon carbide ceramic matrix composite. The method comprises the following steps: preparing fiber preform; filtrating a pyrolytic carbon interface layer by chemical gas phase; carrying out thermal treatment on the interface layer; infiltrating silicon carbide and boron carbide substrate by chemical gas phase alternately; and depositing three silicon carbide coatings by the chemical gas phase. The method has strong designability, simple process and good repeatability. The ceramic matrix composite manufactured by the method has good high temperature resistance and oxidation resistance, has excellent mechanical performance and thermal performance, and can meet the use requirement of a sealing strip / an adjustment sheet, an interior cone and other components of a high thrust-weight ratio aeroengine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

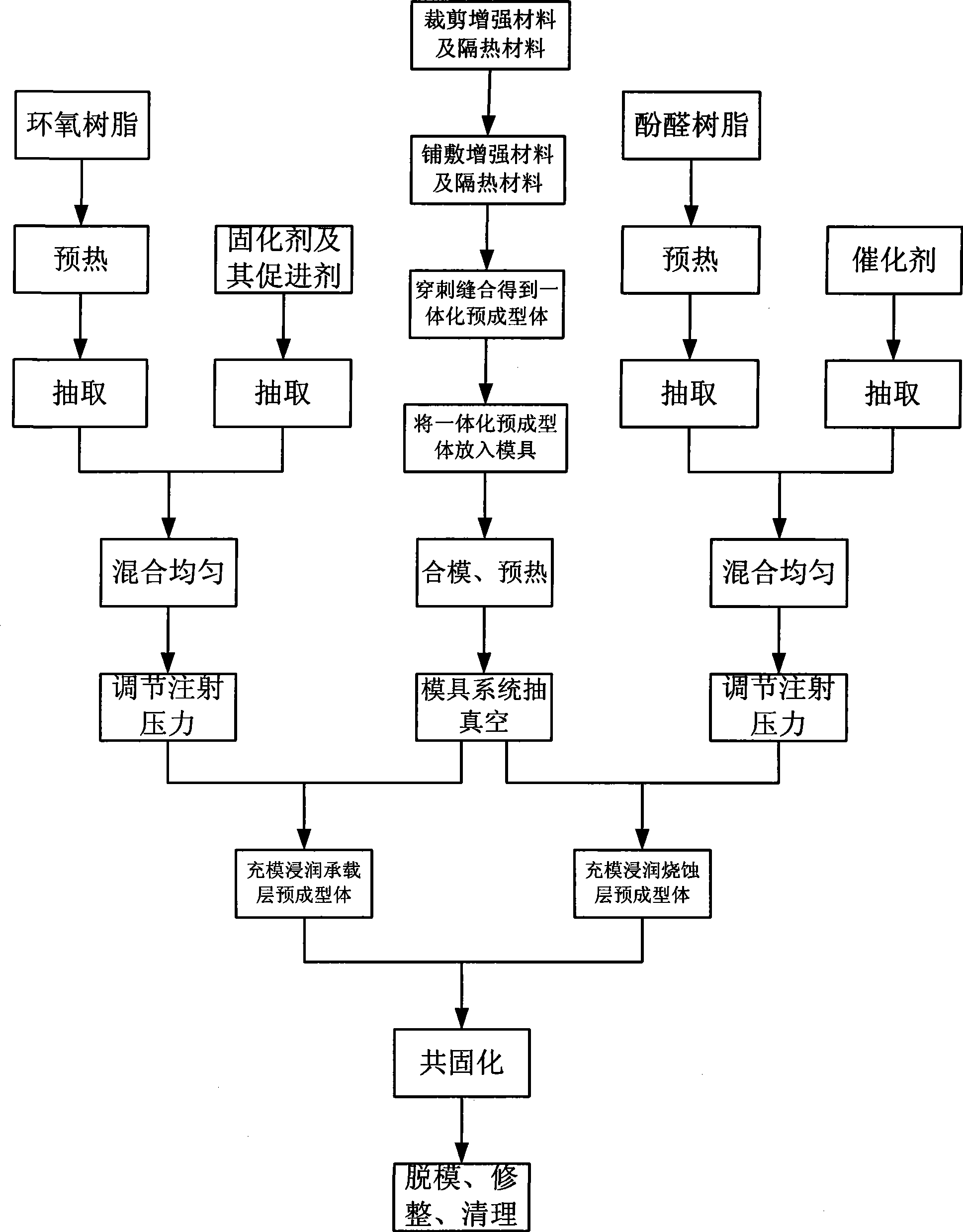

Bearing/insulating/ablating all-in-one sandwich structure composite material and preparation method thereof

InactiveCN101417516AImprove layer performanceIncreased interlaminar shear strengthLayered productsEpoxyInsulation layer

A composite material of sandwich structure integrating loading, heat insulation and ablation and the manufacturing method are characterized in that an integrated pre-forming body is acquired by puncture and suture of the reinforcing material of a bearing layer, the reinforcing material of an ablating cover, and a heating insulation layer positioned between the two layers; an epoxy resin system and a phenolic resin system are injected simultaneously into a vacuum-pumped mould, in which the integrated forming body is pre-placed, by two sets of RTM injection systems respectively, then, the reinforcing materials of the bearing layer and the ablating layer are soaked by epoxy resin and phenolic resin respectively; and the composite material of sandwich structure integrating loading, heat insulation and ablation can be obtained by solidified molding after mould filling. The invention has the advantages that the composite material of sandwich structure integrating loading, heat insulation and ablation is put forward and can be integrally formed by one-time operation, the function of the interlayer between every layer of the composite material is enhanced greatly, the integrality is good; the stratifying and peeling of the composite can be reduced effectively, and the products have good designable property and can be widely applied to the structural parts of aerospace which need heating insulation and thermal protection.

Owner:NAT UNIV OF DEFENSE TECH

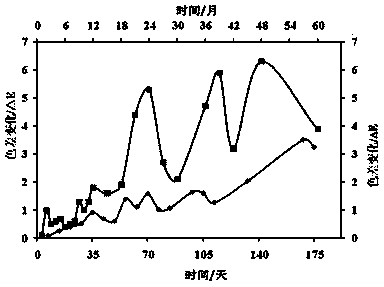

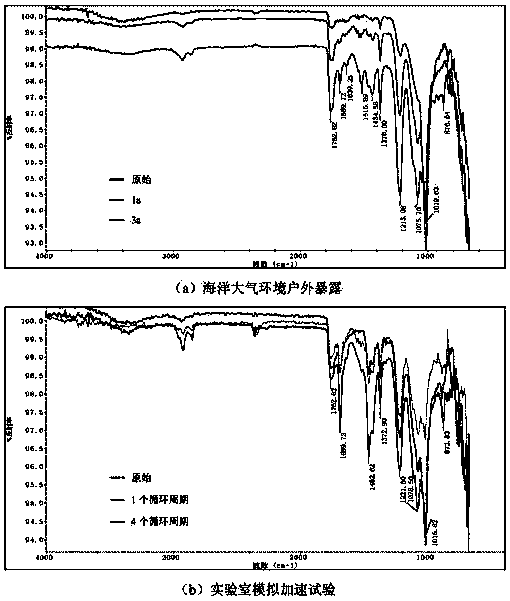

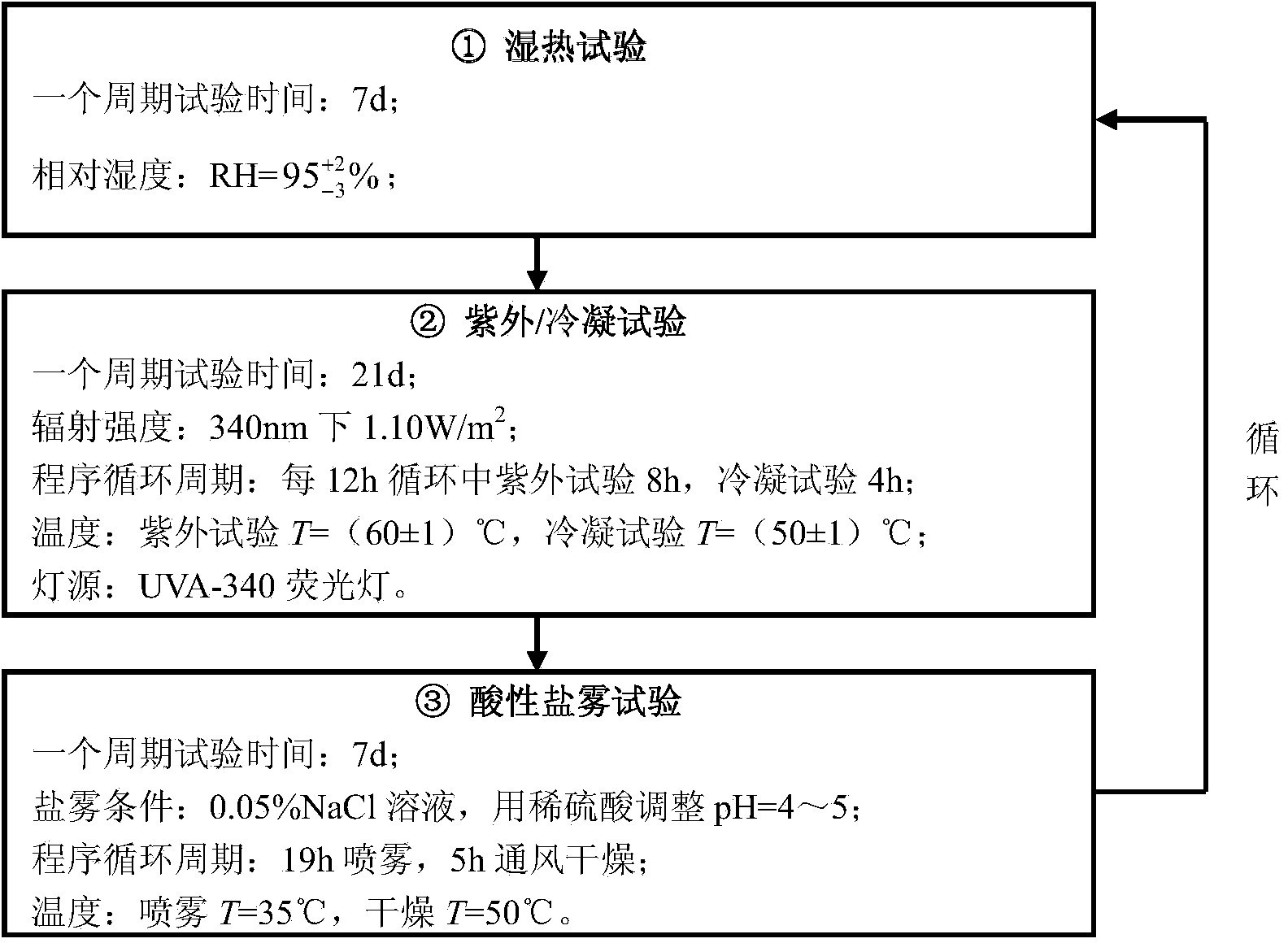

Marine atmosphere simulated accelerated testing method for coating

ActiveCN103954550AImprove accuracyAccurately assess fitnessWeather/light/corrosion resistanceDamp heatSalt spray test

The invention provides a marine atmosphere simulated accelerated testing method for a coating. The marine atmosphere simulated accelerated testing method is characterized in that the damp heat test, the ultraviolet condensation test and the salt spray test are carried out sequentially and are determined according to the conversion principle of natural environment spectrum equivalent of the simulated practical environment, so that the combined circulation test can be carried out according to the action sequence of the practical environmental factors; the environmental element intensity, the duration time, the occurrence frequency and the time scale of the simulated practical environment, which have a leading role for coating ageing, are subjected to analytic statistics, the natural environment spectrum is developed, and the accelerated testing environment spectrum block formation, the test parameter magnitude and the action time are designed and simulated based on the conversion principle of natural environment spectrum equivalent, so that the equivalent simulation of main factors of the marine atmosphere environment and the action sequence are ensured, the practical conditions such as high sunlight radiation in day time, condensation at night, alternation of wetting and drying, salt mist erosion in morning and evening and the like of the marine atmosphere environment are really reflected, the accuracy of simulating multi-factor coupling effect in a laboratory simulation is greatly improved, and the purpose of rapidly and accurately evaluating the coating environment adaptation is achieved through a short-period laboratory acceleration test.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

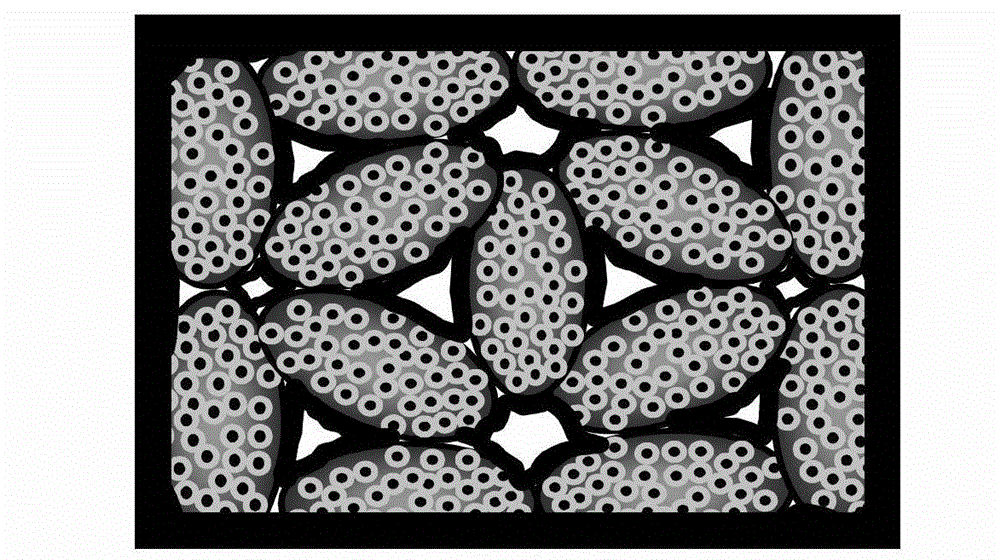

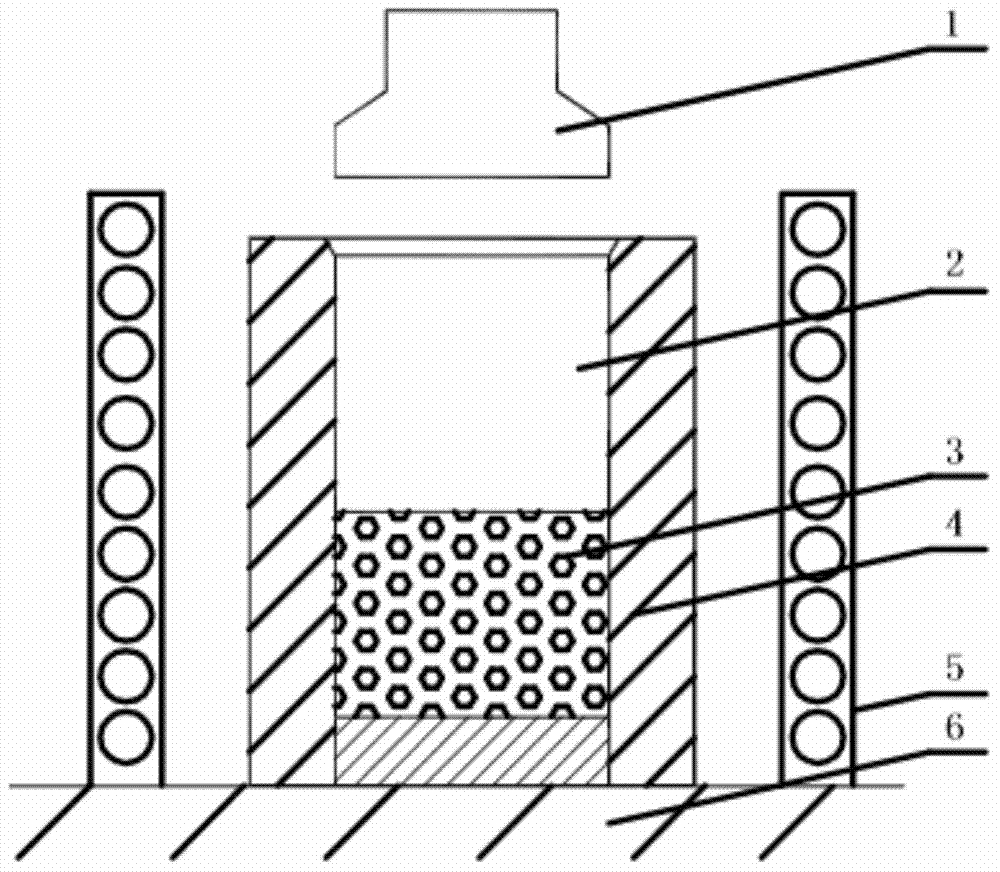

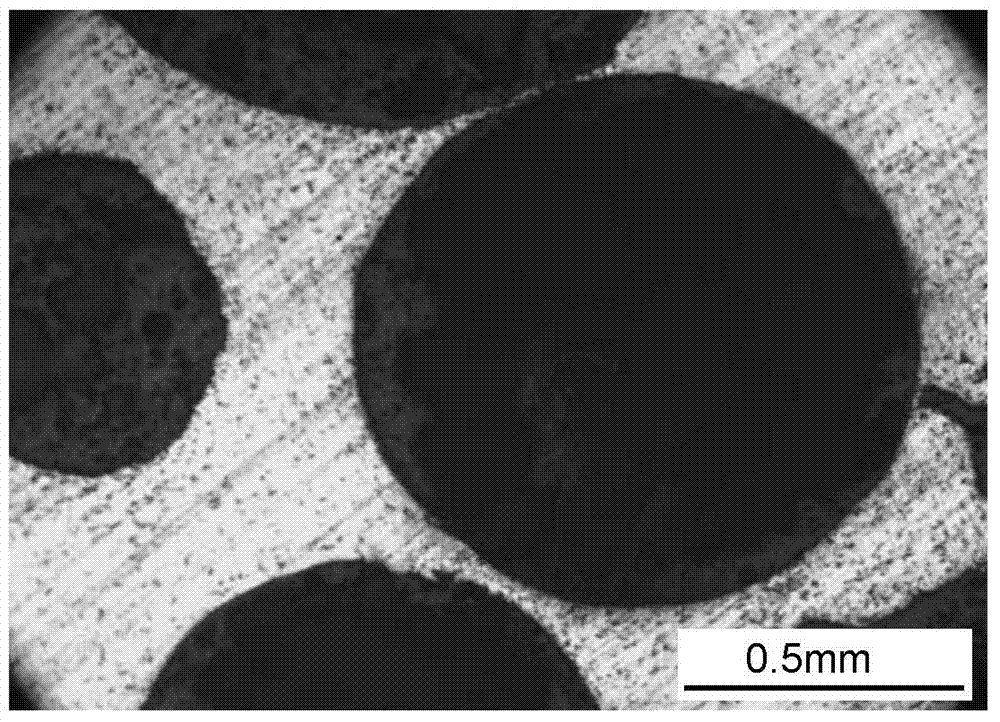

Preparation method for Al2O3 hollow sphere/aluminum porous composite material

ActiveCN103614586AImprove mechanical propertiesAdjustable sizeMold removalAluminum matrix composites

The invention provides a preparation method for an Al2O3 hollow sphere / aluminum porous composite material, relates to a preparation method for an aluminum-based porous composite material, which solves the problems that the strength of a traditional foam aluminum material is low, the process conditions are harsh and the cost is high in an existing preparation method. The preparation method 1 comprises the following steps: step 1. filling an Al2O3 hollow sphere; step 2. pre-heating; step 3. pouring; step 4. pressurizing and immersing; and step 5. maintaining pressure, cooling and carrying out de-molding to obtain the Al2O3 hollow sphere / aluminum porous composite material. The preparation method 2 comprises the following steps: step 1. mixing the Al2O3 hollow spheres with different grain diameters and filling; step 2. pre-heating; step 3. pouring; step 4. pressurizing and immersing; and step 5. maintaining pressure, cooling and de-molding to obtain the Al2O3 hollow sphere / aluminum porous composite material. The Al2O3 hollow sphere / aluminum porous composite material is prepared by immersing aluminum or aluminum alloy into a gap between Al2O3 hollow ball prefabricated blocks; porous structure characterizes of the Al2O3 hollow spheres are maintained and a strengthening mechanism of the aluminum-based composite material is introduced, so that the mechanical properties of materials are improved. According to the preparation method, the operation is convenient, the cost is low, the process is simple, and the production cost is reduced.

Owner:HARBIN INST OF TECH

Heat-preservation hard composite carbon fiber felt and preparation method thereof

The invention discloses a heat-preservation hard composite carbon fiber felt and a preparation method thereof. The preparation method comprises the following steps: forming a carbon fiber vacuum filtration layer, compositing a viscose-based carbon fiber felt or polyacrylonitrile-based carbon fiber felt, soaking a binding agent, needling, coating an upper surface processing layer, forming and postprocessing. The heat-preservation hard composite carbon fiber felt and the preparation method thereof provided by the invention have the advantages that the cost performance optimization design is carried out on a product according to a specific operating environment, the designability of the density of the whole felt is high, the density of an organic padding is relatively low, a high density fiber stacking structure which is corresponding to a high temperature surface is effectively formed, a heat insulation effect is excellent, a low density fiber stacking structure which is corresponding to a low temperature surface is effectively formed, and the cost is economic.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

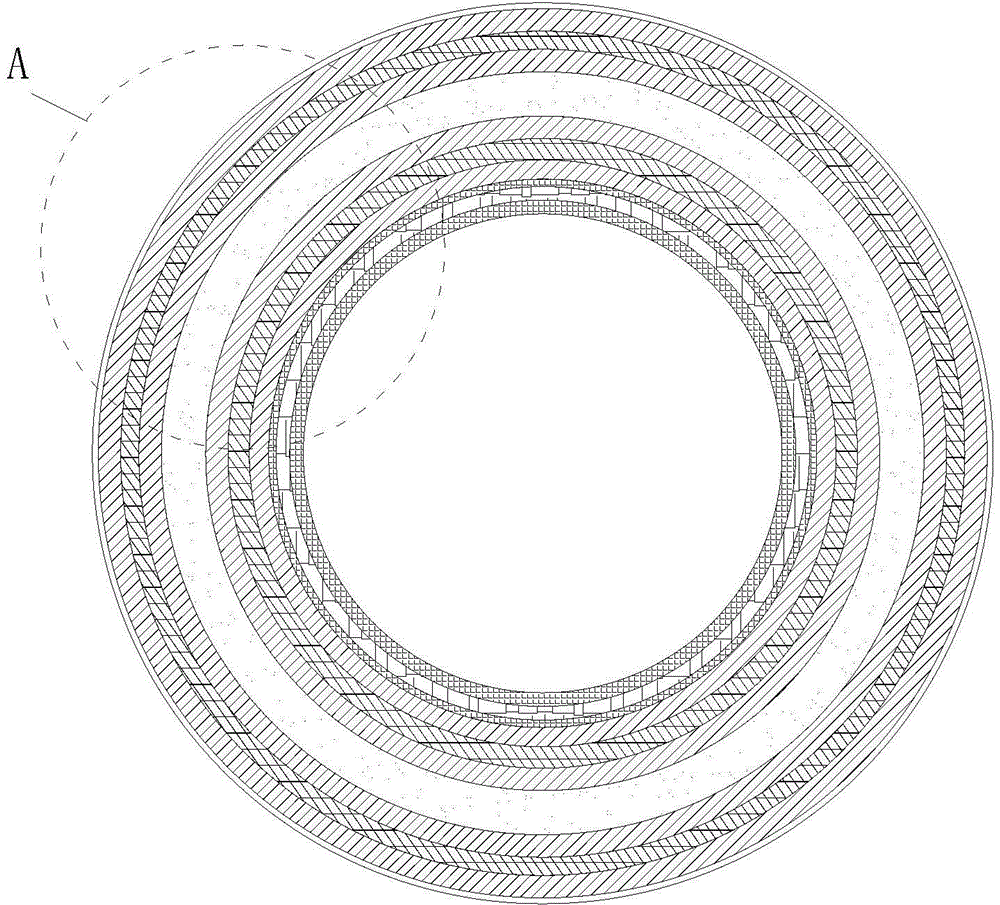

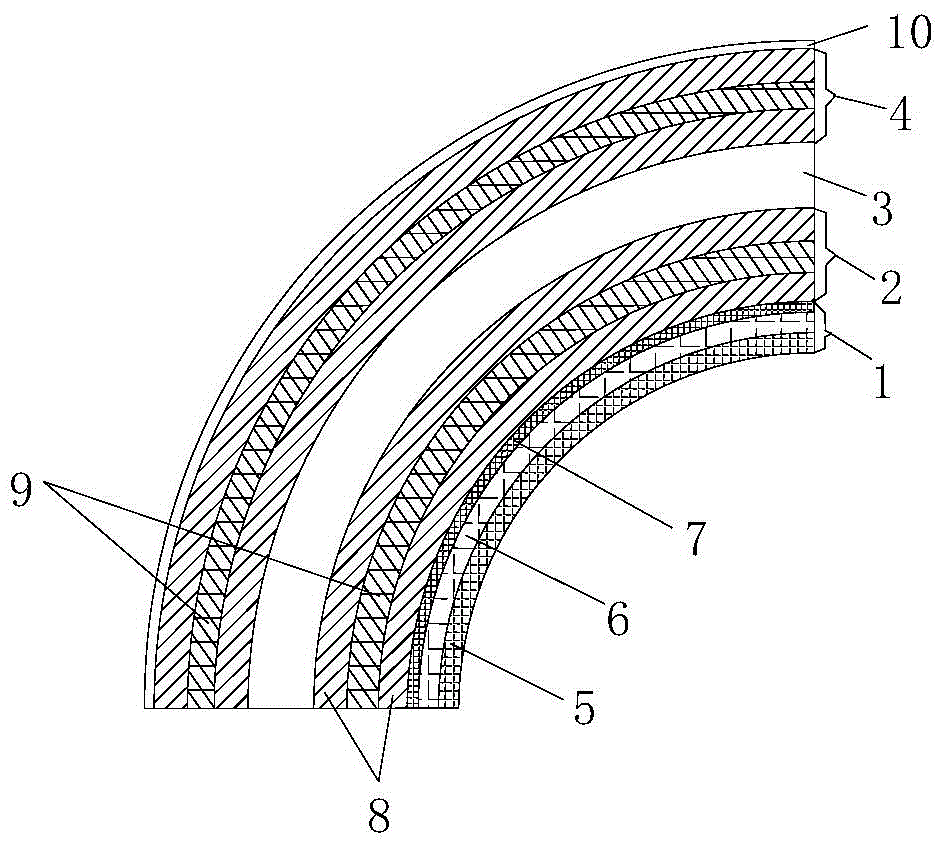

High-strength glass fiber-reinforced plastic pipeline and production method thereof

The invention discloses a high-strength glass fiber reinforced plastic pipeline and a production method thereof, and belongs to the technical field of glass fiber reinforced plastic pipelines and production methods thereof. The high-strength glass fiber reinforced plastic pipeline is a circular pipeline, and is characterized by comprising a lining layer, an inner structural layer, a middle sand inclusion layer and an outer structural layer, wherein the lining layer is formed by soaking and bonding a glass fiber surface felt layer, a glass fiber knitted felt layer and a grid cloth layer in sequence through lining resin from inside to outside; the inner structural layer and the outer structural layer are constructed by one or more glass fiber yarn annular winding layers and one or more glass fiber yarn crossed winding layers; the annular winding layers and the crossed winding layers are formed at intervals; the middle sand inclusion layer consists of upper layer sand inclusion cloth, lower layer sand inclusion cloth and a sand material compressed and clamped between the upper layer sand inclusion cloth and the lower layer sand inclusion cloth; the sand material is formed by mixing quartz sand and sand adhesion resin. The pipeline has the advantages of high compressive strength, high axial tensile strength, large pipe diameter span, light weight, high hydraulic performance, freeness from scaling, insulation, flame retardance and corrosion resistance.

Owner:HUNAN XIAOXIANGYUAN TECH DEV

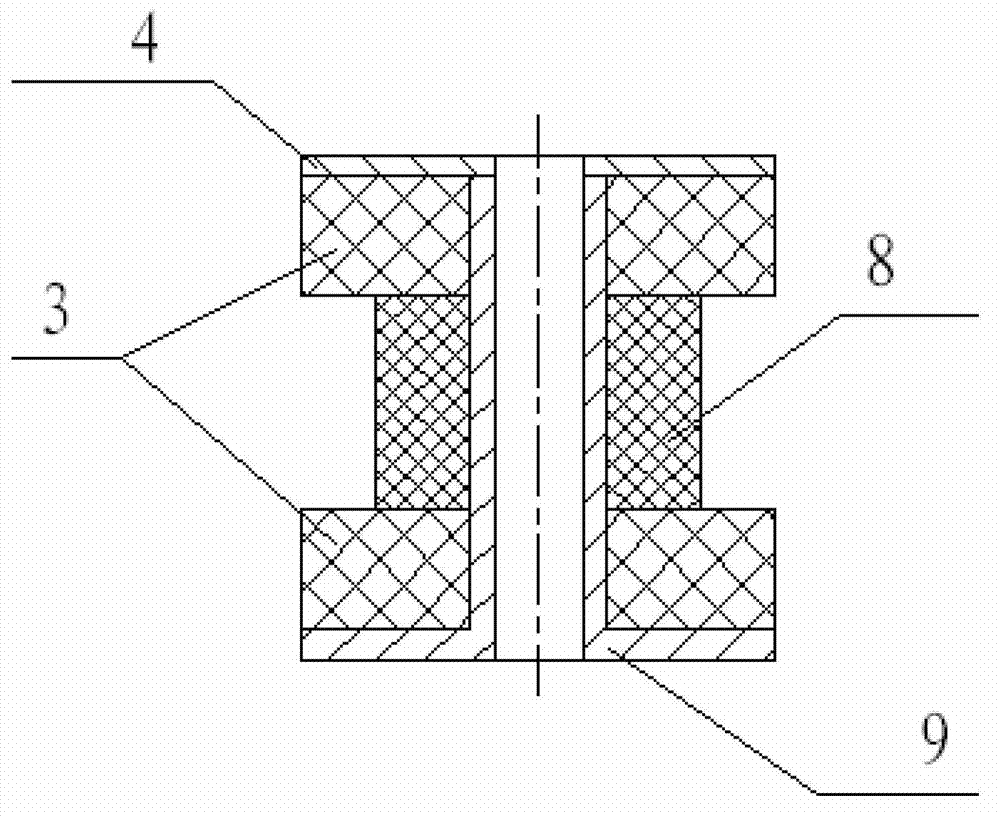

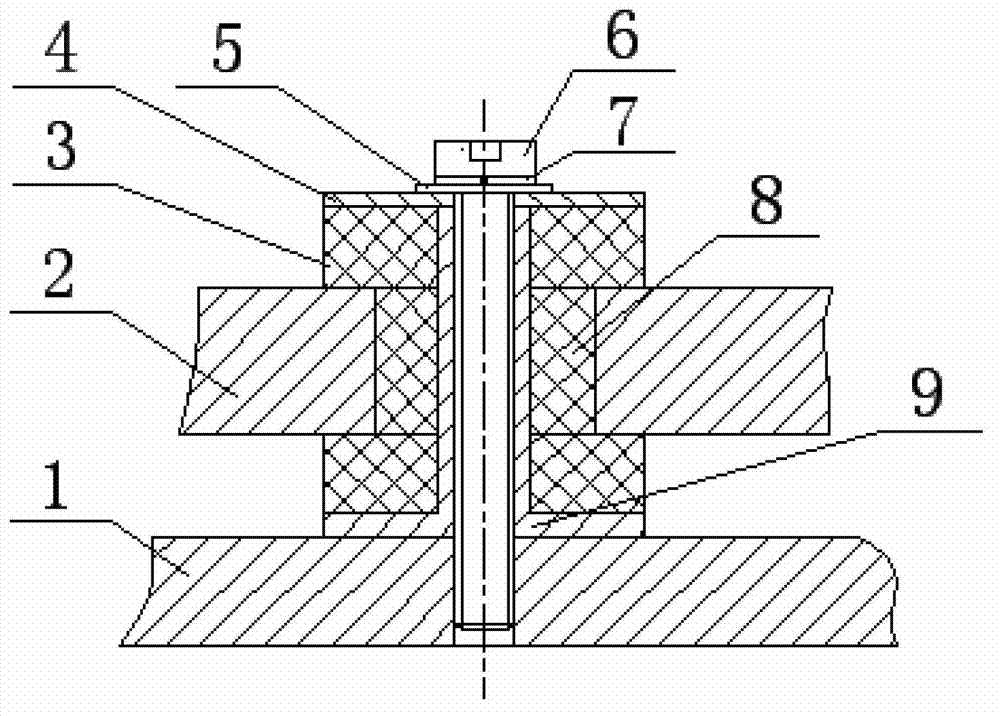

Combined type rubber shock absorber

ActiveCN103115100AImprove reliabilityStrong designabilityMultiple spring combinationsRubber materialEngineering

The invention relates to a combined type rubber shock absorber and belongs to the technical field of rubber vibration isolators. The combined type rubber shock absorber is mainly used for vibration and buffering processing of electronic equipment or instruments. The combined type rubber shock absorber comprises a rubber anti-vibration pad, a rubber anti-vibration column, a metal limiting lining and a metal limiting gasket. According to the combined type rubber shock absorber, vibration and impact energy is translated into heat energy and deformation energy of rubber materials through the deformation of rubber parts by means of a combined shock absorber structure, the rubber anti-vibration pad is capable of reducing dynamic energy of an instrument with vibration to be isolated in the axial direction, the rubber anti-vibration column is capable of reducing dynamic energy of the instrument with the vibration to be isolated in the radial direction, the metal limiting lining and the metal limiting gasket are used in a matching mode, dynamic displacement of the shock absorber is limited due to the fact that the shock absorber is installed on a base plate of the instrument through bolts, and then an installation function and a limiting function are achieved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

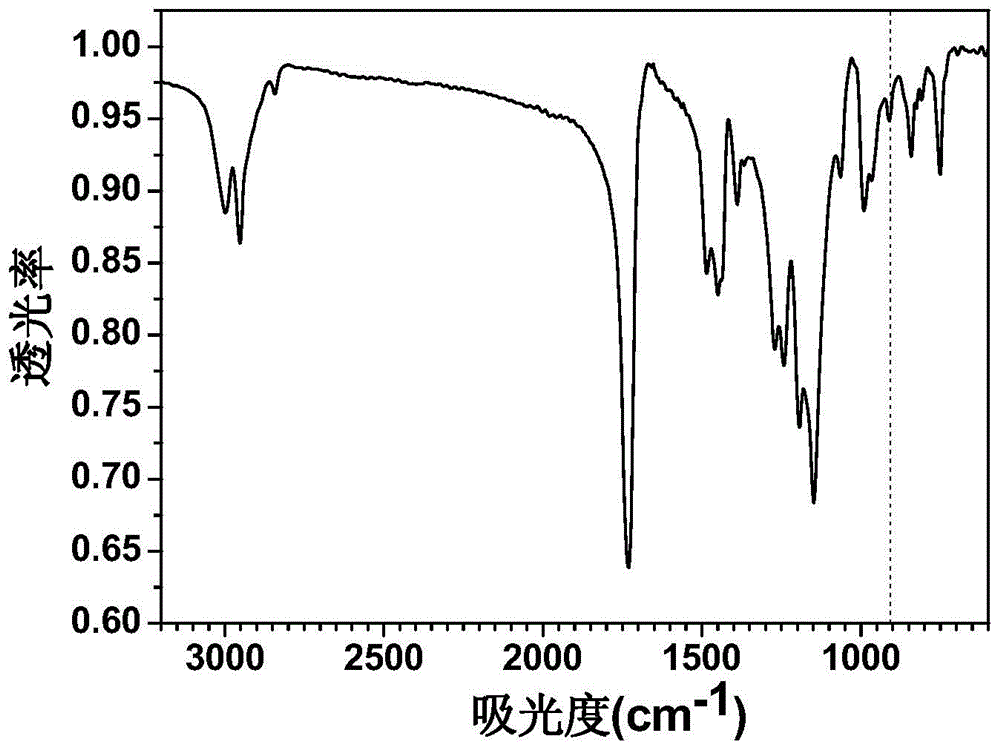

Synthesis method of polycarboxylic acid high-performance water reducing agent of star-like structure

ActiveCN102911322AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesSynthesis methodsPolyethylene glycol

The invention discloses a synthesis method of a polycarboxylic acid high-performance water reducing agent of a star-like structure, belonging to the field of a water reducing agent. According to the synthesis method, polybasic alcohol, (methyl) acrylic acid, a polyethylene glycol compound and the like are used as esterification raw materials, and the polycarboxylic acid high-performance water reducing agent of the star-like structure is prepared through a sequential esterification and polymerization method, i.e., the (methyl) acrylic acid and the polybasic alcohol are used as reactants, a star-like polymerizable active end is prepared through esterification reaction under the action of a catalyst, and then the polycarboxylic acid high-performance water reducing agent is prepared from the star-like polymerizable active end and esterification macromolecule, a molecular weight regulator and an unsaturated carboxylic acid monomer under the action of an initiator through free radical polymerization reaction. The synthesis method has the advantages of simplicity, easiness in control, high polymerization degree, low cost, no pollution, capability of realizing the polycarboxylic acid high-performance water reducing agent of the star-like structure connected with a plurality of polycarboxylic acid molecules, and more superior cement paste fluidity and holding capacity, good cement adaptability and concrete application performance compared with the conventional linear and comb-shaped polycarboxylic acid water reducing agent in the case of normal and low added amount.

Owner:GUIZHOU DR SHI TECH

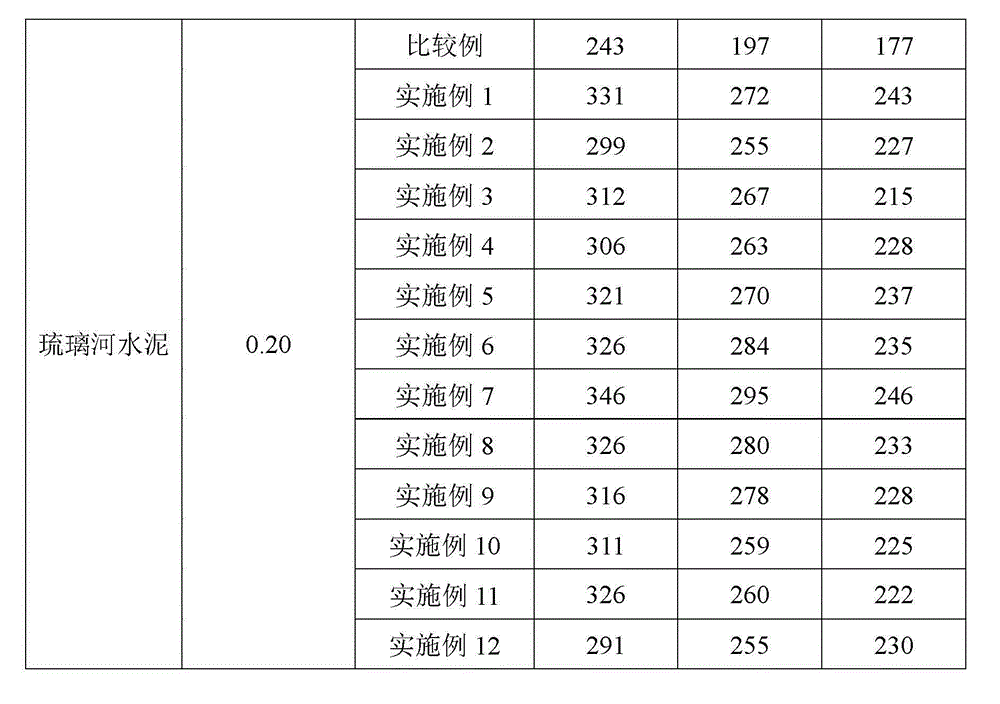

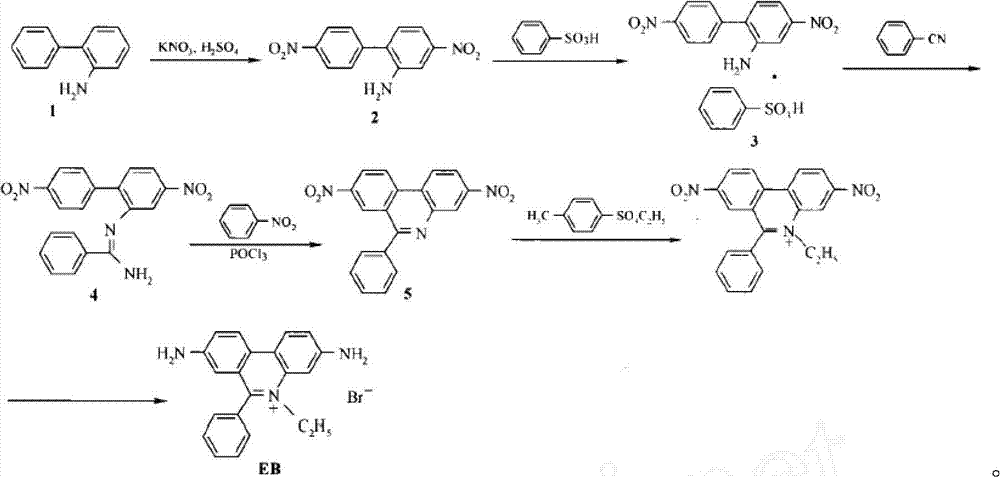

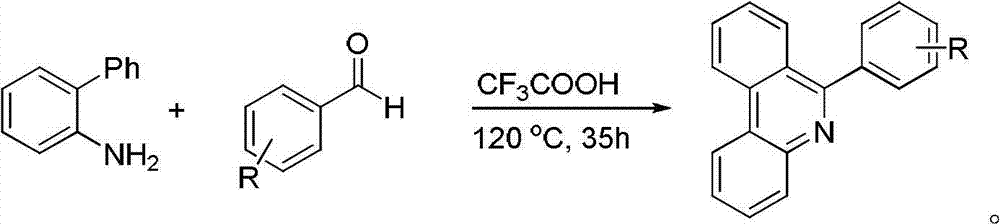

Preparation method for phenanthridine derivative

InactiveCN102827077AStrong designabilityHigh yieldGroup 5/15 element organic compoundsOrganic solventPalladium catalyst

The invention discloses a preparation method for a phenanthridine derivative. The preparation method comprises the following steps of: adding a catalyst, an oxidant, acid, a 2-phenylaniline compound and an olefin compound into organic solvent; after reaction, carrying out post treatment to obtain the phenanthridine derivative, wherein the catalyst is a bivalent palladium catalyst. According to the preparation method for the phenanthridine derivative disclosed by the invention, the adoption of reagents with high toxicity and high corrosiveness is avoided. The preparation method has the advantages of environment friendliness, easiness in operation, higher yield and simplicity and convenience in post treatment. In addition, a substrate obtained by the method is strong in designability and can be used for designing to synthesize a compound with the required structure according to actual requirements, and thus stronger practicability is realized.

Owner:ZHEJIANG UNIV

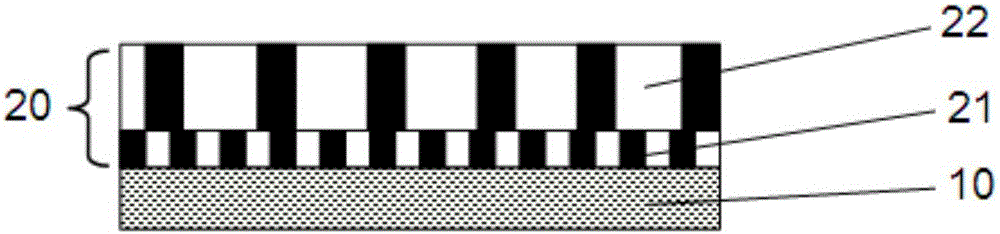

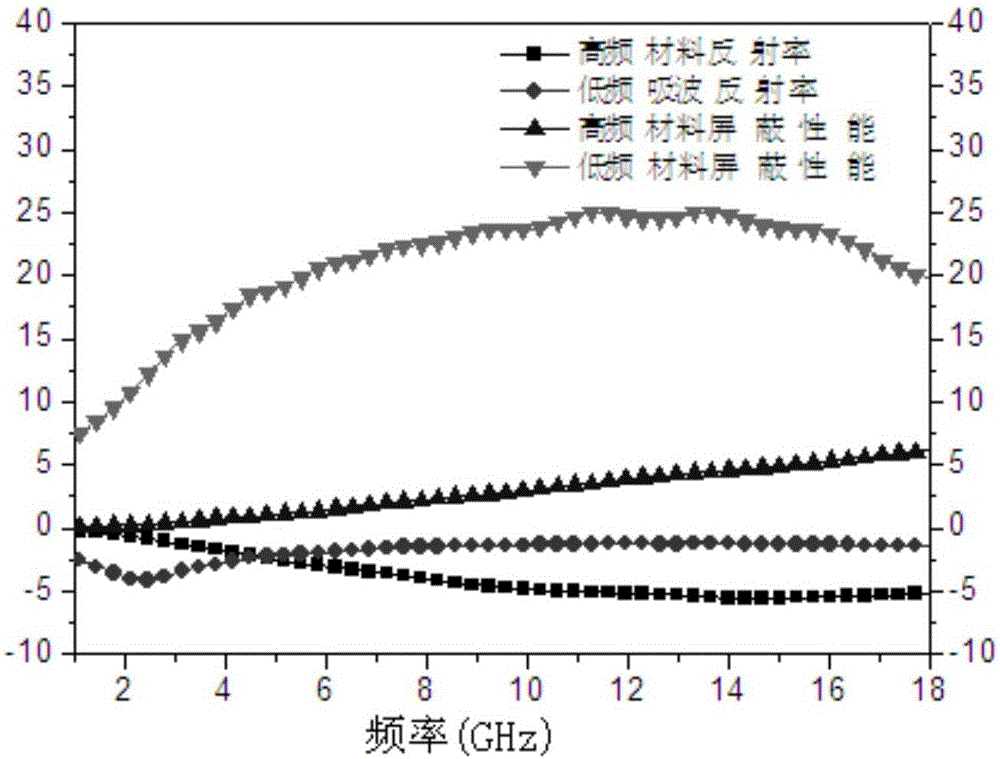

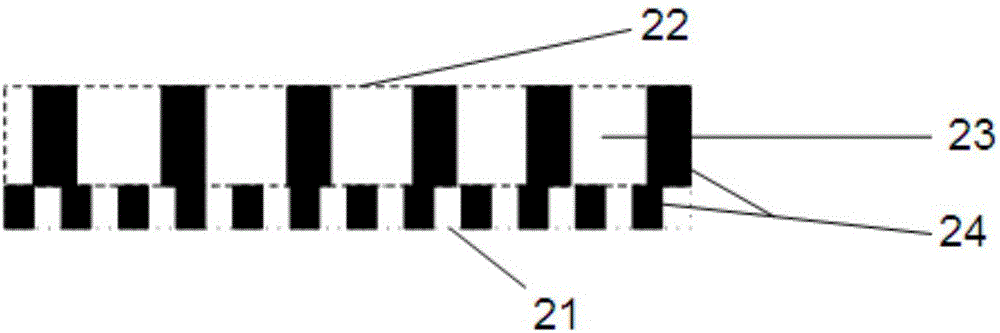

Broadband wave-absorbing material and preparation method thereof

The invention discloses a broadband wave-absorbing material and a preparation method thereof. The broadband wave-absorbing material is composed of a low frequency wave-absorbing material bottom layer and a high frequency wave-absorbing material surface layer. The high frequency wave-absorbing material surface layer comprises a plurality of high frequency wave-absorbing layers with different concentrations. FeSi or FeSiAl particles are taken as the additive of the low frequency wave-absorbing material, and carbonyl iron particles are taken as the additive of the high frequency wave-absorbing material. A rolling method is adopted to prepare the low frequency wave-absorbing material bottom layer, and a three-dimensional moulding technology is adopted to prepare the high frequency wave-absorbing material surface layer. The multilayer lamination manufacturing method combines a multi-rolling technology and three-dimensional moulding together and has the advantages that the binding force between layers can be ensured, multiple repeated mould pressing is avoided, the thickness of each layer, the internal structure, and particle distribution can be adjusted so as to satisfy the predetermined electromagnetic property requirements; the broadband wave-absorbing performance of the wave-absorbing material and designable performance of a shielding material can be realized; the integrated manufacturing of space structure of the wave-absorbing material is achieved, and the preparation cost is low at the same time.

Owner:SHANGHAI RADIO EQUIP RES INST

Carbon-based polymer composite material capable of being ceramized and preparation method thereof

The invention relates to a carbon-based polymer composite material capable of being ceramized and a preparation method thereof. The carbon-based polymer composite material is formed by mixing and pressing carbon-based resin, a fiber-reinforced material, a high temperature-resistant coupling agent, aluminium silicate mineral powder and non-oxide ceramic powder, and the carbon-based polymer composite material specifically comprises the following components in parts by weight: 20-50 parts of the carbon-based resin, 10-40 parts of the fiber-reinforced material, 0.5-2 parts of the high temperature-resistant coupling agent, 10-50 parts of the aluminium silicate mineral powder and 1-10 parts of the non-oxide ceramic powder. Compared with the prior art, the composite material disclosed by the invention has the advantages of good thermal protection performance and anti-scour performance; a forming process of the composite material is simple, and aerobic thermal protection and ceramic formationare integrated; the ceramization temperature is lower and the ceramic conversion rate is higher; and the polymer composite material further has the advantages of capability of being formed by the polymer composite material process, strong designability, good mechanical properties at medium and low temperature, high ceramic conversion rate, low thermal weight loss rate, high retention rate of high-temperature strength and the like.

Owner:WUHAN UNIV OF TECH

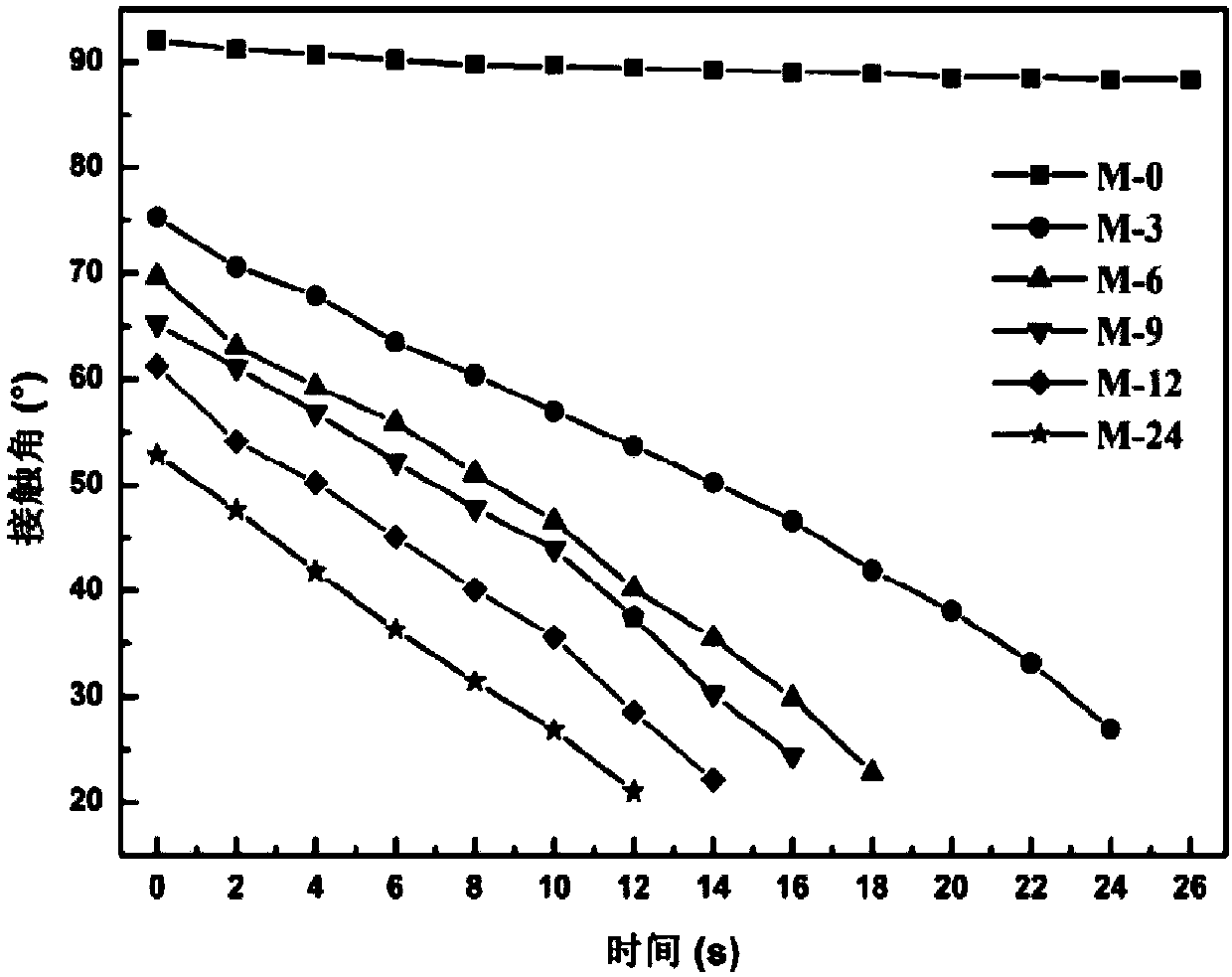

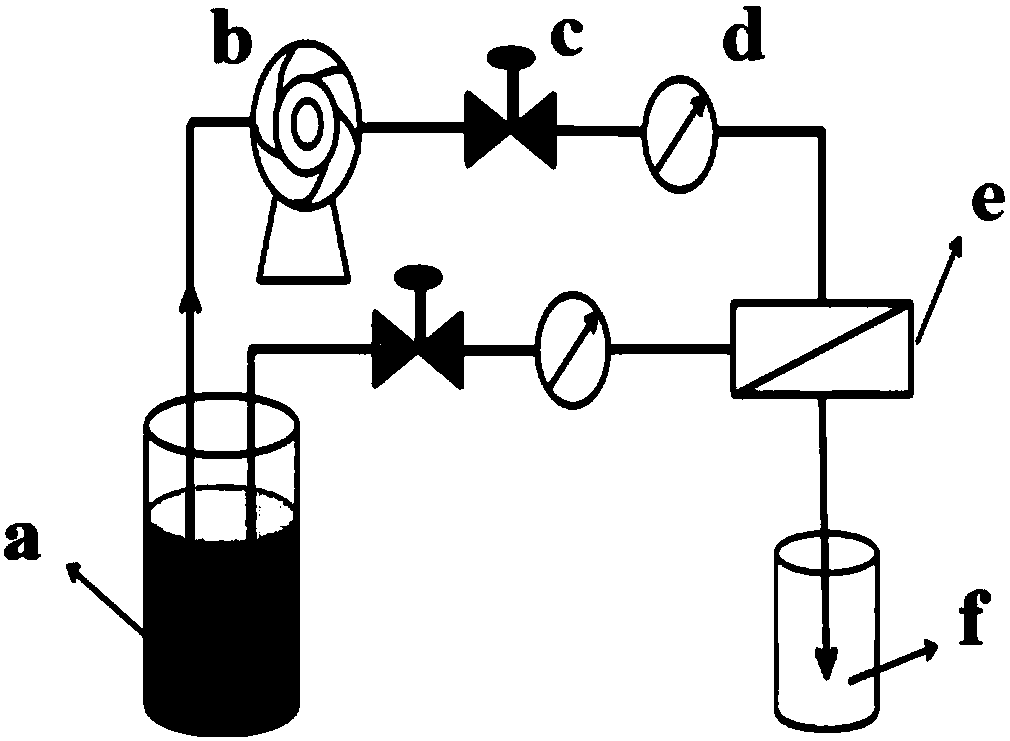

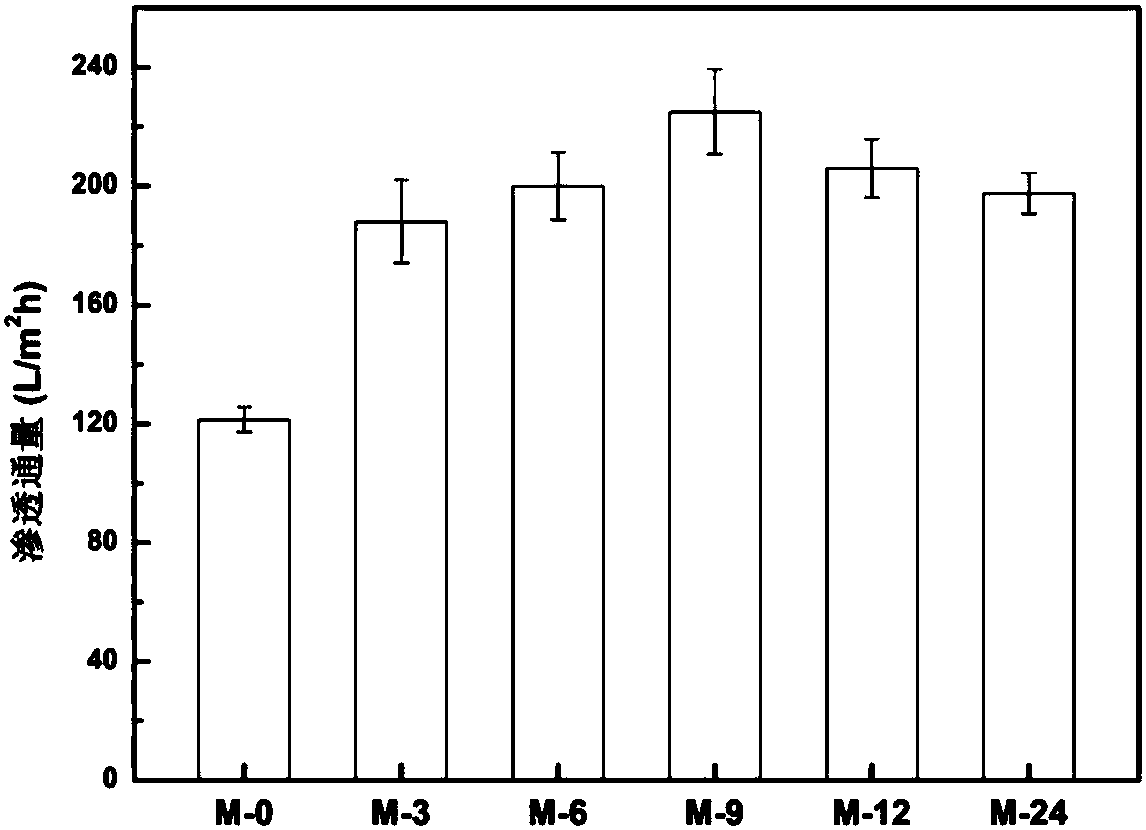

Plant polyphenol modified polymer membrane as well as preparation method and application thereof

ActiveCN107670513AAvoid performance damageAvoid pollutionMembranesSemi-permeable membranesHydrophilic coatingPolymer science

The present invention discloses a plant polyphenol modified polymer membrane as well as a preparation method and application thereof, in particular relates to the field of modified polymer membranes with anti-fouling properties. In the prior art, due to low surface energy of the polymer membrane, the polymer membrane is susceptible to contamination with proteins, oils and the like and causes a series of temporary or permanent pollution problems. The polymer membrane provided by the invention utilizes the super-strong adhesive ability of plant polyphenols and the coordination of polyphenols andmetal ions to build a hydrophilic coating on the surface of a hydrophobic polymer membrane. The polymer membrane provided by the invention has the advantages of simplicity, high efficiency, mild reaction condition and strong practicability. The controllable hydrophilic modification of a hydrophobic polymer can be realized by changing the conditions of the dip-coating time, the concentration of aplant polyphenol mixed solution, the pH, the temperature and the like, and a high permeation flux can be maintained in the course of cross-flow continuous work, so that the polymer membrane has a verygood application prospect in the field of water treatment. The invention also opens up an effective way, which is simple and easy to operate and has strong universality, for modification of polymer membranes under mild conditions.

Owner:TIANJIN POLYTECHNIC UNIV

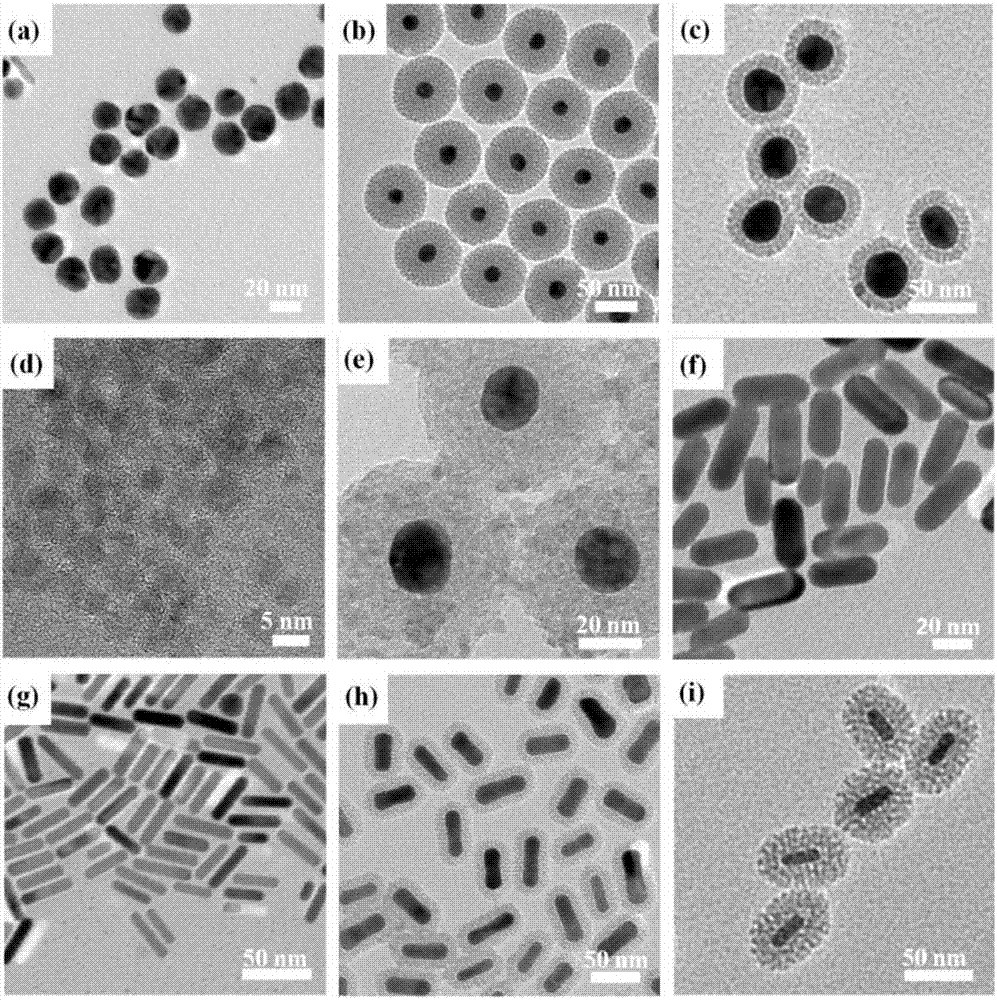

PH-responsive anti-tumor drug carrier material and preparation and application of pH-responsive anti-tumor drug carrier material

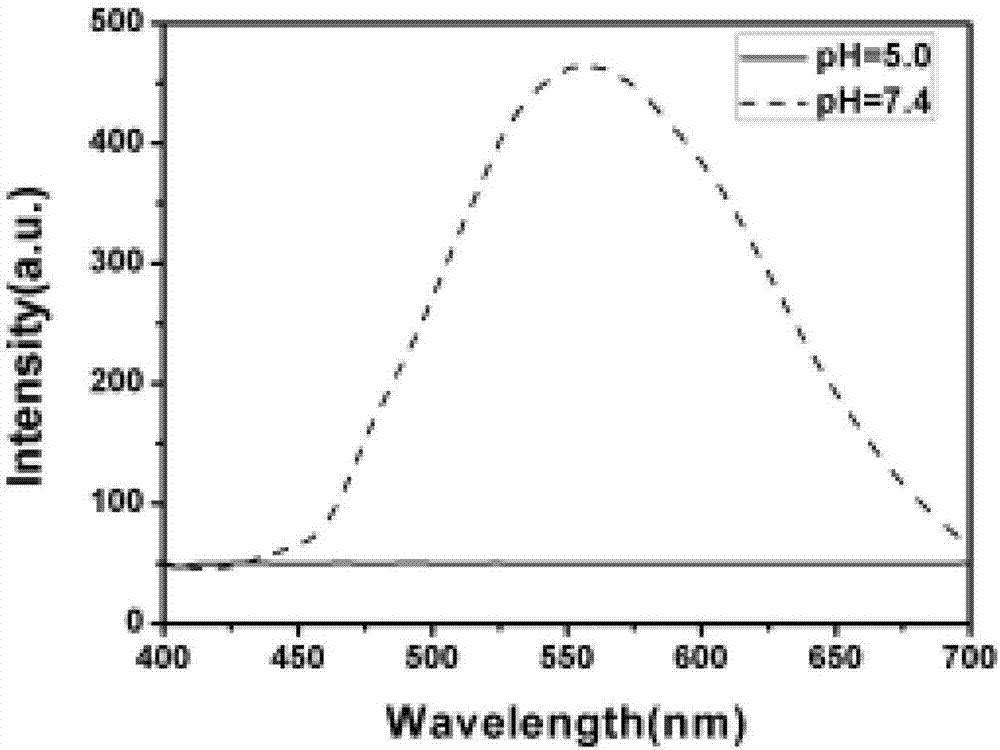

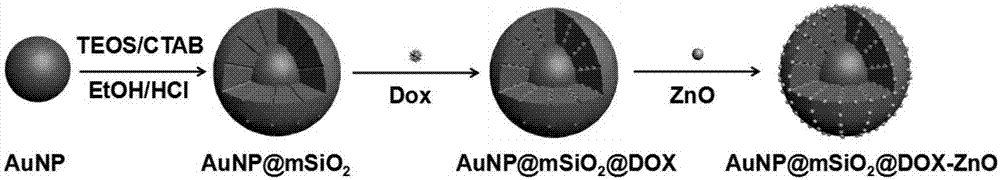

ActiveCN107412195AIncrease loadUniform particle sizeOrganic active ingredientsEnergy modified materialsSide effectMesoporous silica

The invention discloses a pH-responsive anti-tumor drug carrier material and a preparation and application of the pH-responsive anti-tumor drug carrier material. The preparation method comprises the following steps that (1) gold nanoparticles wrapped by mesoporous silica are prepared, and the gold nanoparticles comprise gold nanospheres or gold nanorods; (2) gold nanoparticles wrapped by carboxylation mesoporous silica are prepared; (3) water-soluble zinc oxide quantum dots are prepared; and (4) the pH-responsive anti-tumor drug carrier material is prepared. According to the pH-responsive anti-tumor drug carrier material and the preparation and application of the pH-responsive anti-tumor drug carrier material, the whole technological process design of the preparation method, the parameter conditions adopted by the reaction steps and the like are optimized, and the existing problems that drug releasing is uncontrollable, the drug loading capacity is low, and side effects are prone to being caused when the gold nanoparticles wrapped by the mesoporous silica serve as a drug carrier can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

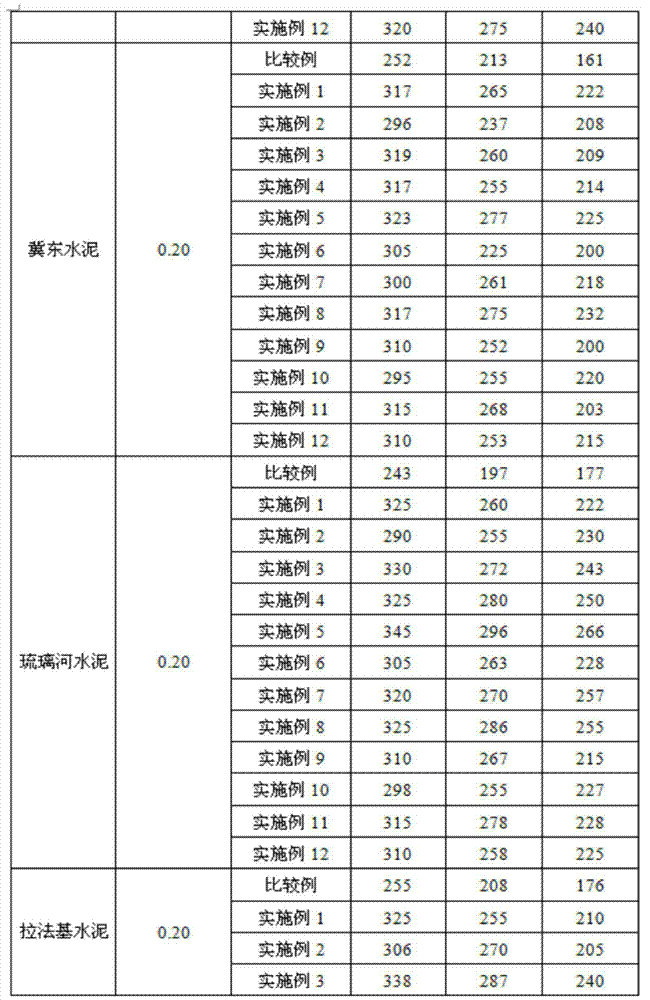

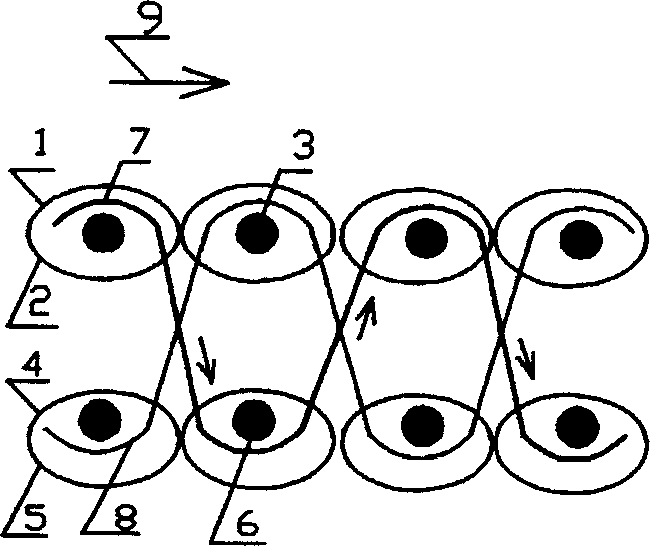

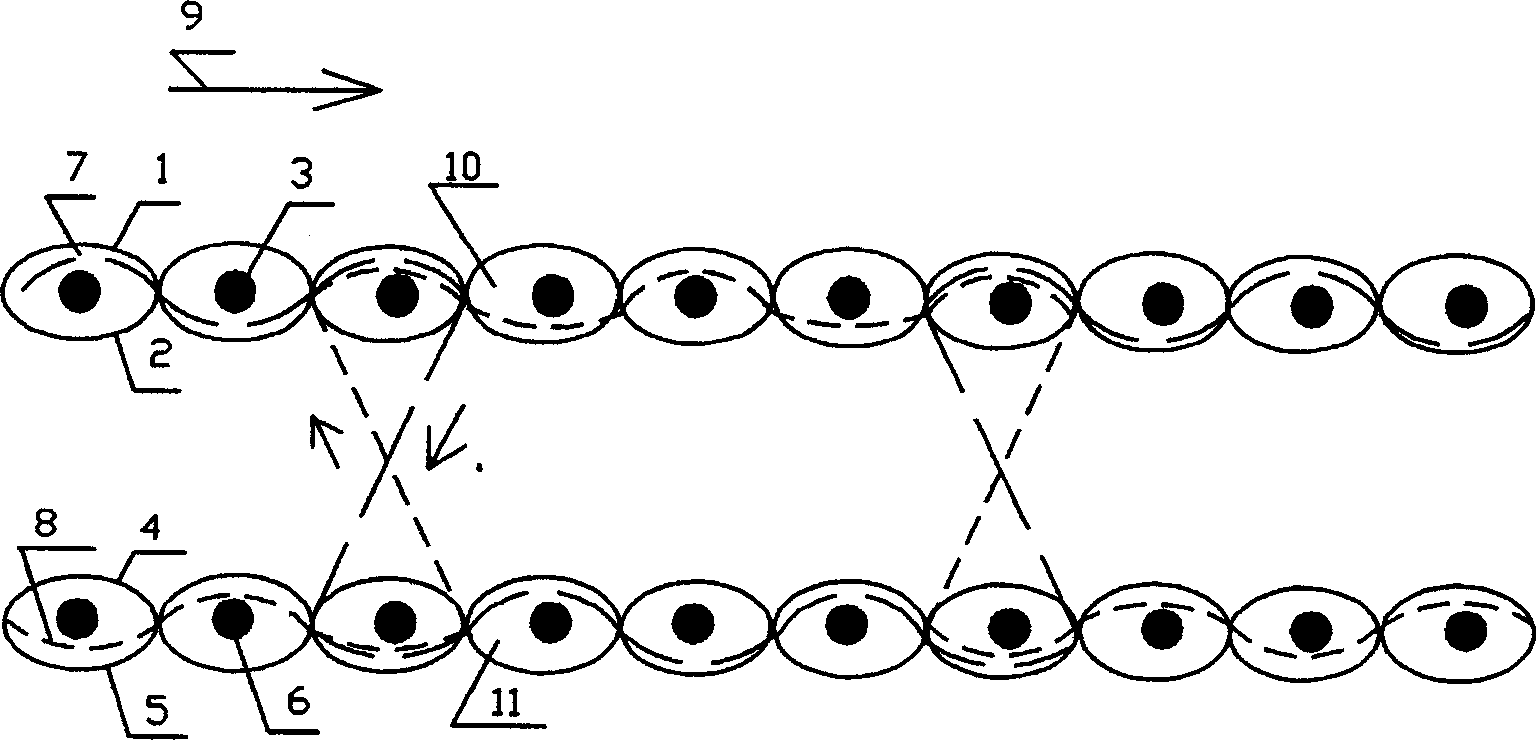

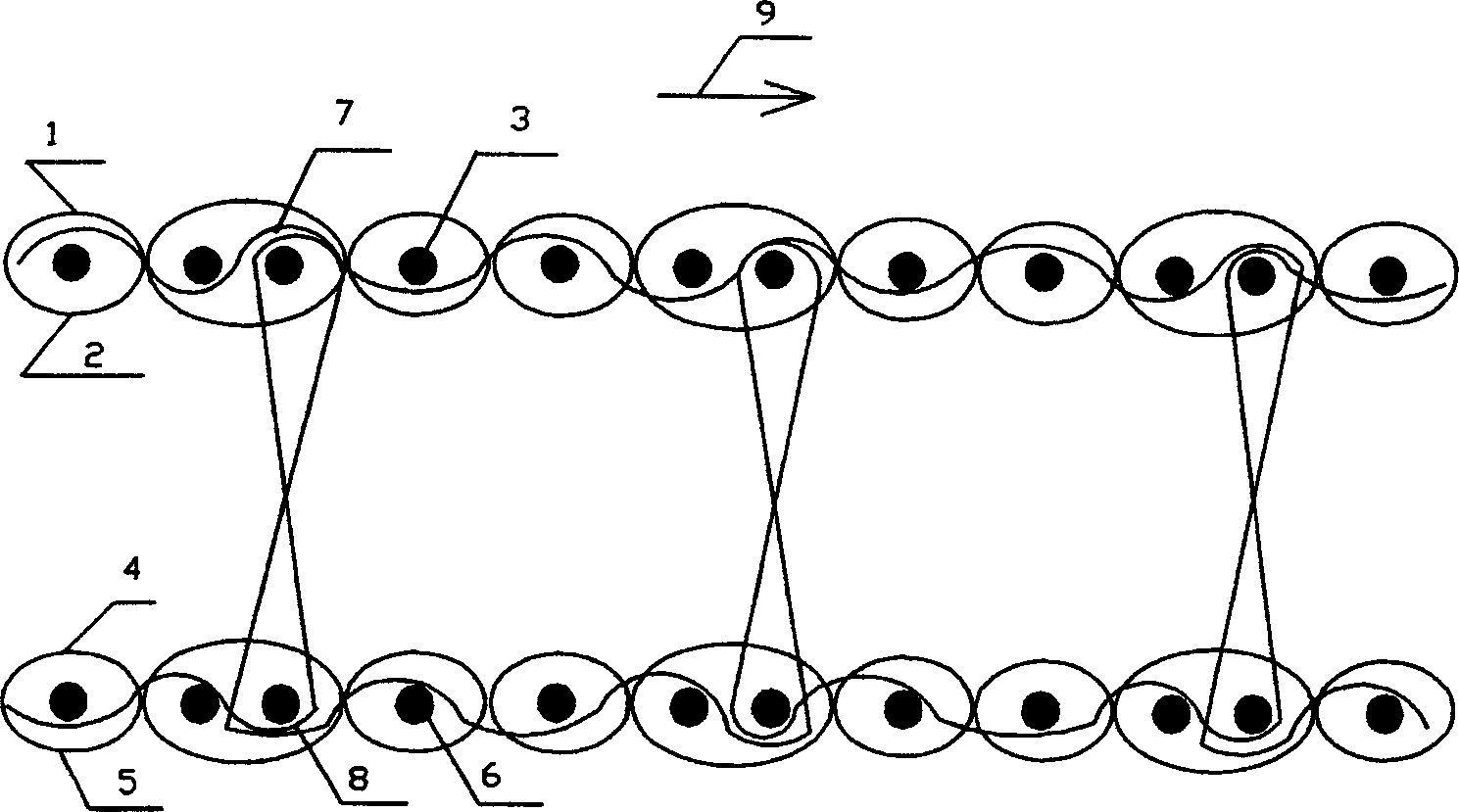

Three-dimensional woven hollow layer-connecting fabric

ActiveCN1807731AGood vertical supportAnti-corrosionOrnamental textile articlesMulti-ply fabricsSpatial structureMechanical engineering

This invention relates to a three-dimensional machine-weaving hollow layer contiguous fabric, which includes the superstratum face (10) that is formed from interweaving by the superstratum warp thread (1), (2) and weft thread (3), the substrate face (11) interweaved by the substrate warp thread (4), (5) and weft thread (6), wherein the weft thread (3) and (6) also interweave with the figured texture weave (7), (8) besides interweaving with the warp thread (1), (2) and (4), (5), and when the weft thread is weaving from one layer from another layer of the fabric, its space walking direction is contrary to the inducing thread direction of the fabric. The frame characteristic of the layer contiguous fabric in this invention is obvious; the vertical supporting action of the figured texture weave between the two faceplates is well. The configuration of the space structure is various, and it is fit for sweeping weaving. And the material enhanced by this invention has the character of preventing corrosion, preventing filter, light weight, nice mechanical performance.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

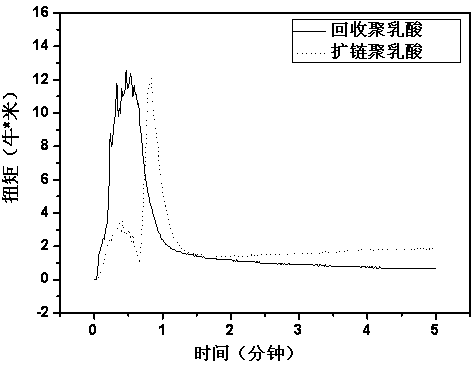

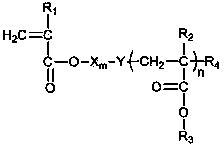

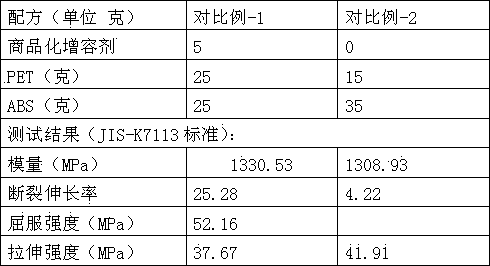

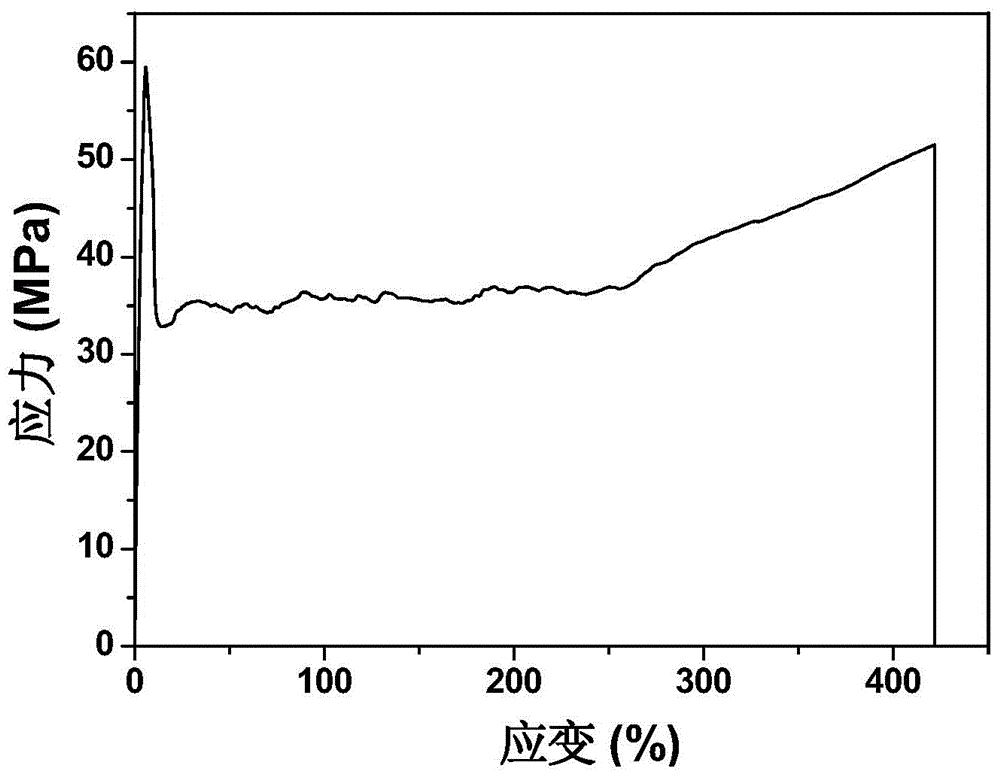

Comb-shaped stem grafting copolymer containing reactive group and preparation method and application thereof

The invention discloses a comb-shaped stem grafting copolymer containing reactive group and a preparation method and application thereof. The copolymer is a comb-shaped stem grafting copolymer by taking small molecule monomer B as the main chain, and giant molecule monomer A as the side chain. According to the method, the giant molecule monomer A and the small molecule monomer B are copolymerized to form the comb-shaped stem grafting copolymer of which the main chain is the small molecule monomer B and the side chain is the giant molecule monomer A. The comb-shaped stem grafting copolymer disclosed by the invention can serve as the chain extender of a polymer or a polymer blend, the compatibilizer of the polymer blend, the hydrolytic stabilizer, adhesive and anti-leakage agent of the polymer blend, and is used for coatings of wood, metal or plastic. The reactive group in the copolymer has very high reaction activity, and can react with various end groups of polyamide and polyester. Methacrylate monomers have thermodynamics compatibility with various polymers. The reactive group can react with the end hydroxyl group or the end carboxy group of polyester, so that the comb-shaped stem grafting copolymer can serve as the chain extender, and the processing and application properties of the material are improved.

Owner:HANGZHOU NORMAL UNIVERSITY

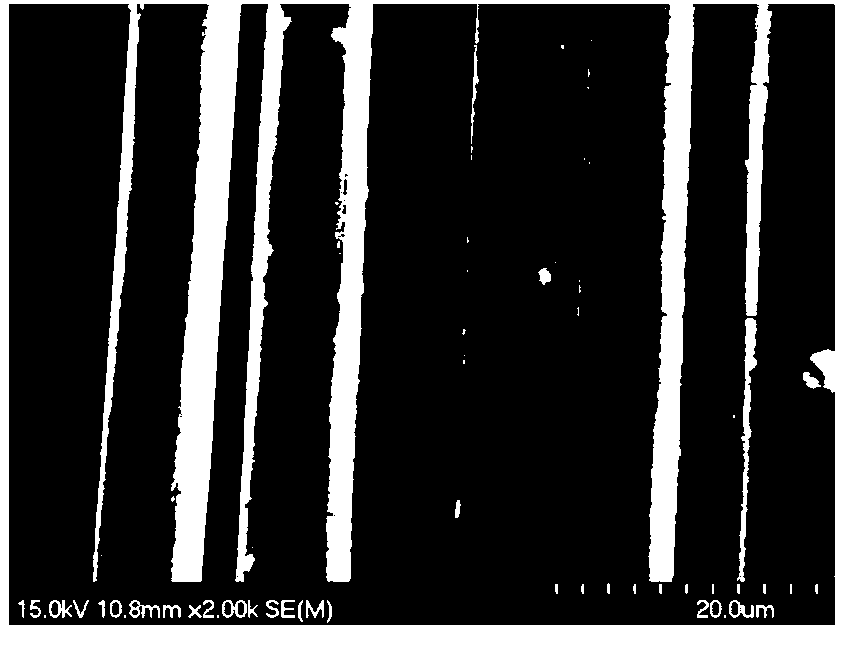

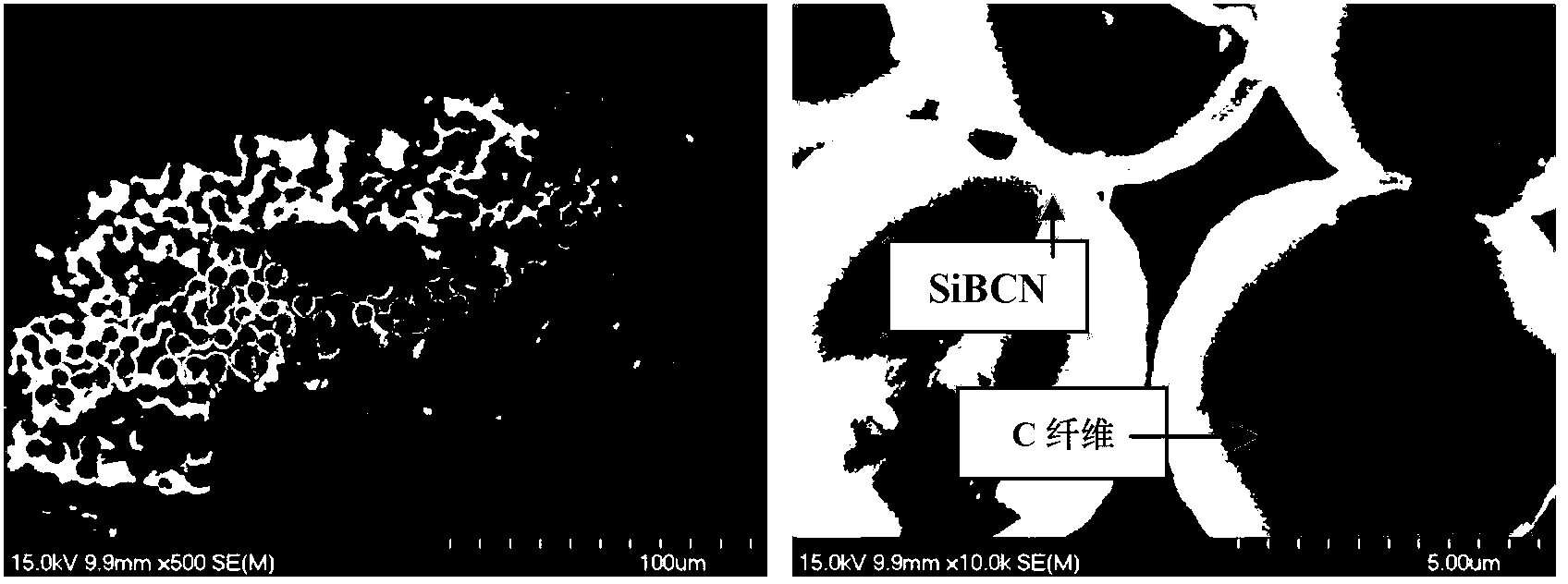

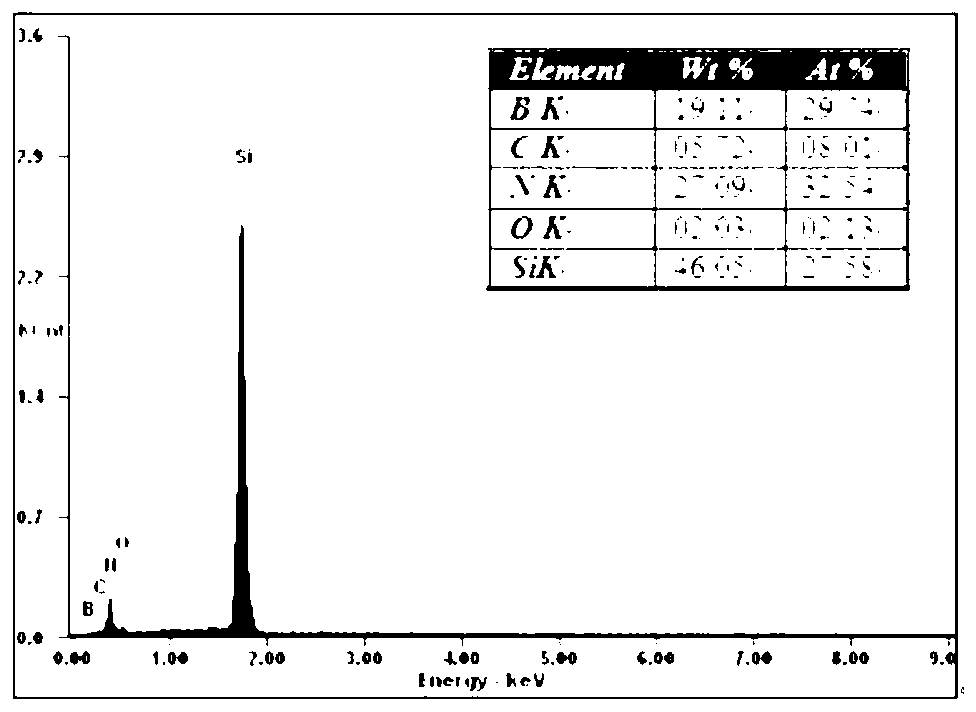

Chemical vapor deposition method of Si-B-C-N amorphous ceramic

The invention relates to a chemical vapor deposition method of a Si-B-C-N amorphous ceramic. The chemical vapor deposition method comprises the following steps of: suspending a substrate material on a matching sample bracket of a vacuum furnace, putting samples in a centre of an isothermal region in the furnace and preparing even Si-B-C-N amorphous ceramic on the surface / interior of the substrate material by using a CVD (Chemical Vapor Deposition) / CVI (Chemical Vapor Infiltration) method. The Si-B-C-N amorphous ceramic prepared by the chemical vapor deposition method can be applied to an interface, a matrix and a coating of a continuous fiber-reinforced ceramic matrix composite, has the advantages of excellent properties such as good high-temperature stability, good anti-oxidation property, strong creep resisting capability, low density, low coefficient of thermal expansion and low heat conductivity coefficient and the like, can replace materials such as SiC and Si3N4, further improves the using temperatures and prolongs the service lives of thermal structure ceramics and ceramic matrix composites and has a great application potentiality in the isothermal and long-life field of aircraft engines and industrial gas turbines; and meanwhile, the Si-B-C-N amorphous ceramic also has electrical properties similar to the semiconductors and interesting optical properties and is widely used in the fields of high-temperature invisibility, semiconductors, photoelectricity, communication and control.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Electromagnetic shielding composite material

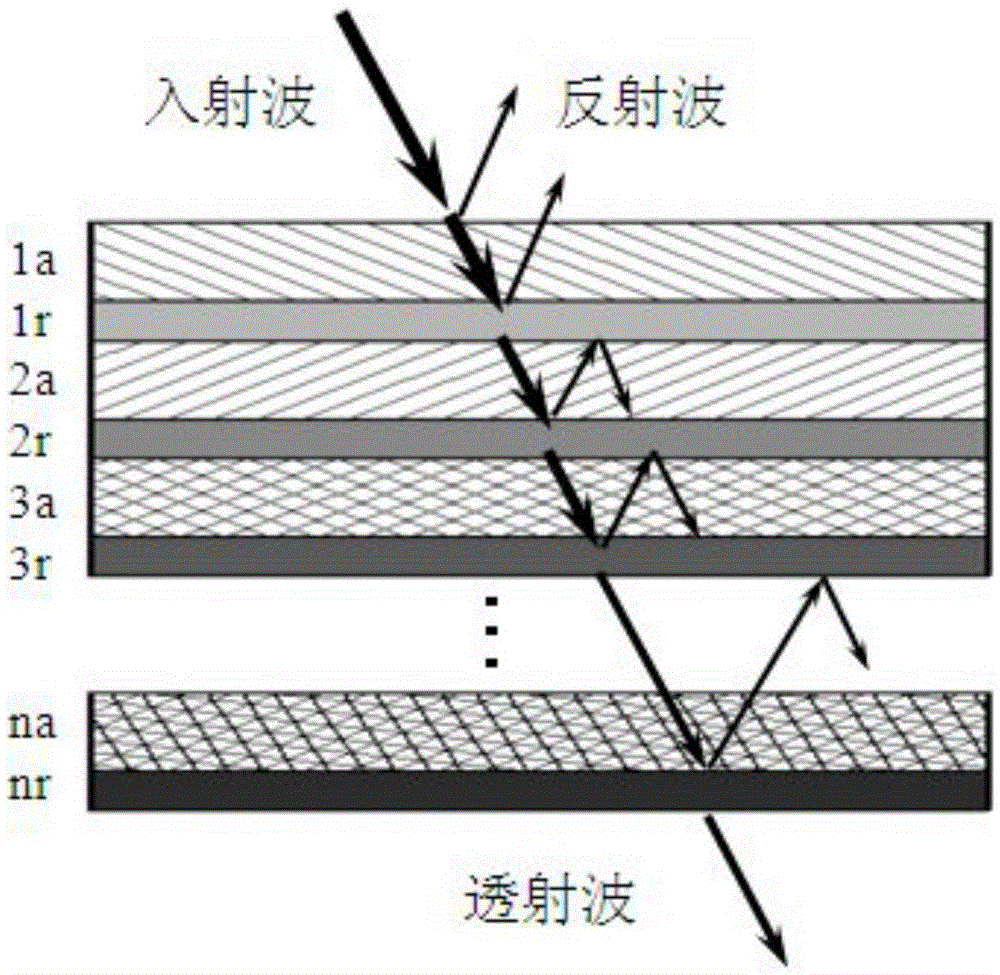

InactiveCN105555112AImprove shielding effectExtended propagation pathShielding materialsFiberReflection loss

The invention discloses an electromagnetic shielding composite material. Electromagnetic wave absorption layers and electromagnetic wave reflection layers are alternately overlapped to form electromagnetic shielding function bodies; the electromagnetic wave absorption layers are formed by compositing matrix resin, fiber carriers and electromagnetic absorption function bodies; the electromagnetic wave absorption layers are formed by compositing matrix resin and electromagnetic gradient reflection function bodies; in the overlapped electromagnetic wave reflection layers, the mass percentage compositions of short cut carbon fibers increase in gradient along the incident directions of the electromagnetic waves. According to the electromagnetic shielding composite material of the invention, the incident electromagnetic waves generate multi-reflection; the propagation paths of the electromagnetic waves in the material are increased; increase of the multi-reflection loss and absorption loss enables the shielding efficiency of the material to be increased; in adoption of the reflection layers of gradient structure, the electromagnetic waves will not escape away from the shielding material rapidly for reflection; more electromagnetic waves can enter the next shielding unit; therefore, the shielding efficiency of the material is further improved.

Owner:WUHAN UNIV OF TECH

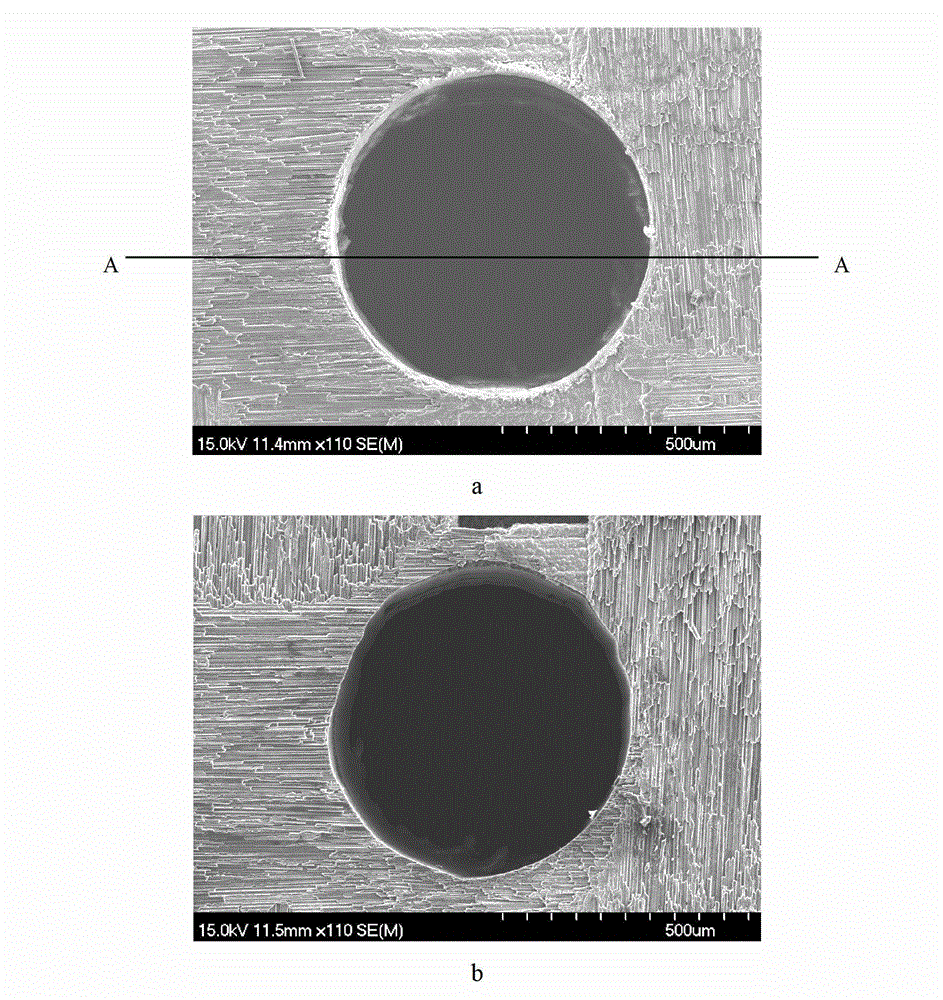

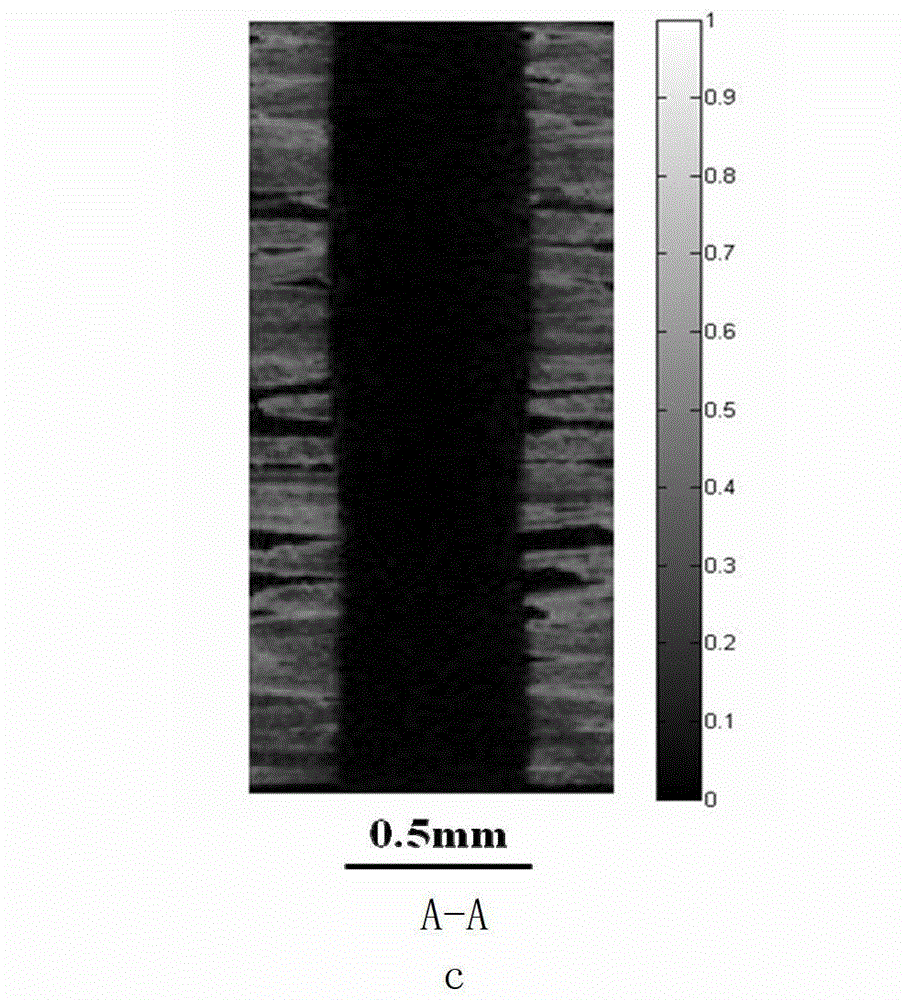

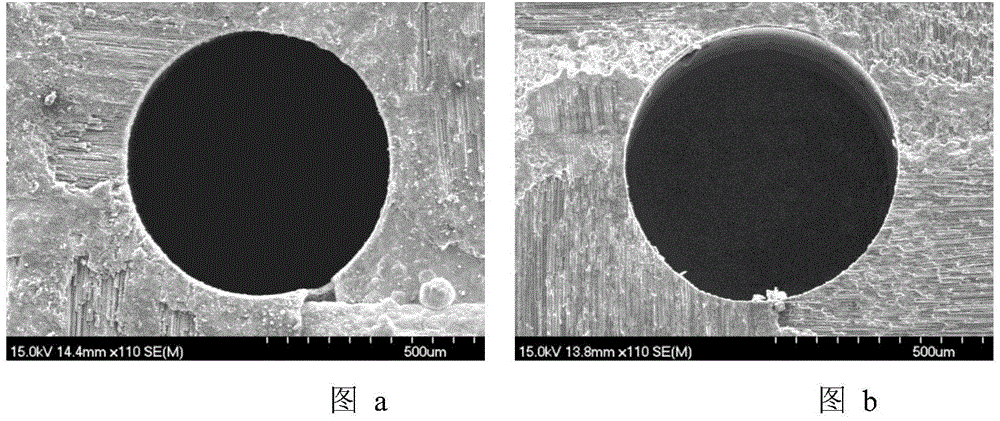

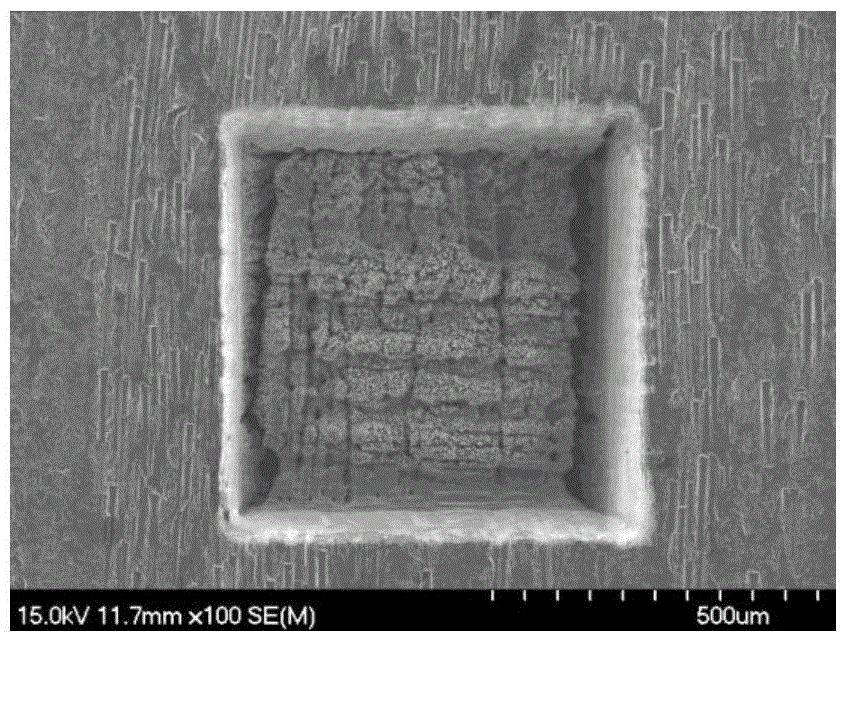

Method for machining micro holes in ceramic matrix composite through femtosecond lasers

ActiveCN104607808AHigh peak powerShort pulse widthWelding/soldering/cutting articlesLaser beam welding apparatusWavelengthLayer removal

The invention relates to a method for machining micro holes in a ceramic matrix composite through femtosecond lasers. According to the method, the silicon carbide ceramic matrix composite sample is placed on a working table and machined layer by layer in a spiral line mode through the femtosecond lasers or machined in a linear scanning mode, wherein the thickness of the sample is smaller than 3 mm; in the micro-machining process, the wave length of femtosecond laser machining ranges from 400 nm-1500 nm, the pulse width ranges from 80 fs to 500 fs, the output power of the lasers is determined according to the requirements of micro-machining and ranges from 20 mW to 20 W, and the repetition frequency of the lasers is determined according to the requirements of micro-machining and ranges from 50 K to 25 MHz; the sample is machined in a layer-by-layer removal mode, wherein the rotation speed of a machining head is 2400 rev / s. In the machining process, the method has the advantages that machining damage is small, and because material around the damage region is still in a cold state after machining, the heat effect is small; machining precision is high, energy of the femtosecond lasers is in Gaussian distribution, absorption and action of the energy in the machining process are limited within the size of which the focus center is quite small, and the machining dimension is expressed from a micro form to a sub-micro form.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Solvent-free method for preparing non-ionic water-borne polyurethane

ActiveCN104530370AReduce adverse effectsSolve the problem that the viscosity is too high and need to add solvent to reduce the viscosity to emulsifyEmulsionPolyol

The invention relates to a solvent-free method for preparing non-ionic water-borne polyurethane. The method comprises the following steps: firstly, synthesizing a Y-shaped side chain nonionic hydrophilic chain extender containing two terminal hydroxyl groups; secondly, reacting poly(dihydric alcohol) with isocyanate, and adding the Y-shaped side chain nonionic hydrophilic chain extender for chain extending to generate a side chain prepolymer with a -NCO terminal-group; thirdly, adding one or mixture of two of small-molecular dihydric alcohol and oligomer polyol, uniformly stirring, and immediately adding a deionized water solution to disperse at high speed; and finally heating to react to obtain a stable solvent-free nonionic waterborne oligomer emulsion. Compared with the prior art, the method has the advantage that the stable solvent-free nonionic waterborne oligomer emulsion is prepared under conditions of no additional emulsifier and little co-stabilizer.

Owner:上海材料研究所靖江先进材料技术研究院 +1

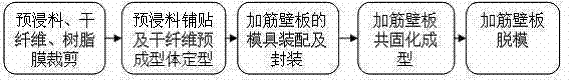

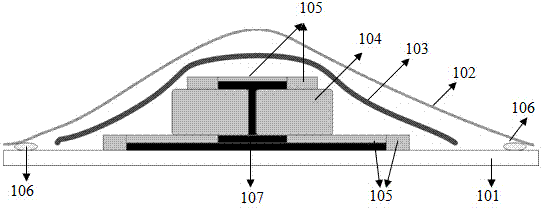

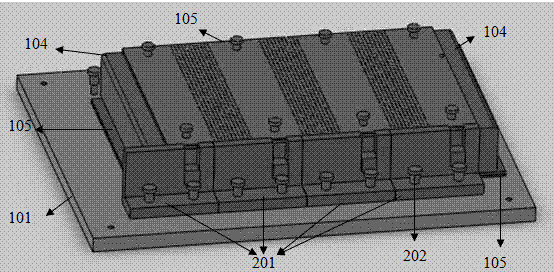

Prepreg/resin film infiltration co-curing forming method for composite stiffened wallboards

The invention discloses a prepreg / resin film infiltration co-curing forming method for composite stiffened wallboards. The method comprises the following steps: 1, tailoring prepregs, dry fibers and resin films; 2, spreading the prepregs and sizing dry fiber preforms; 3, assembling and packaging a mould for the stiffened wallboards; 4, co-curing and forming the stiffened wallboards; and 5, demolding the stiffened wallboards. According to the method, a skin is prepared by adopting prepreg spreading, ribs are prepared by the dry fiber preforms and the resin films, and in combination with the characteristics of a prepreg autoclave process and a resin film melting process, the ribs, the skin and the adhesive interface of the ribs and the skin are cured in an autoclave at the same time, thus realizing the co-curing forming of the stiffened wallboards with different rib forms and different material systems. The method can significantly improve the forming efficiency of the stiffened wallboard structure, reduce the manufacture cost, improve the quality of products and improve the flexibility and designability of the manufacturing process and is of great significance to the efficient low-cost manufacture of the composite material stiffened wallboard structure.

Owner:SHANGHAI AIRCRAFT MFG +1

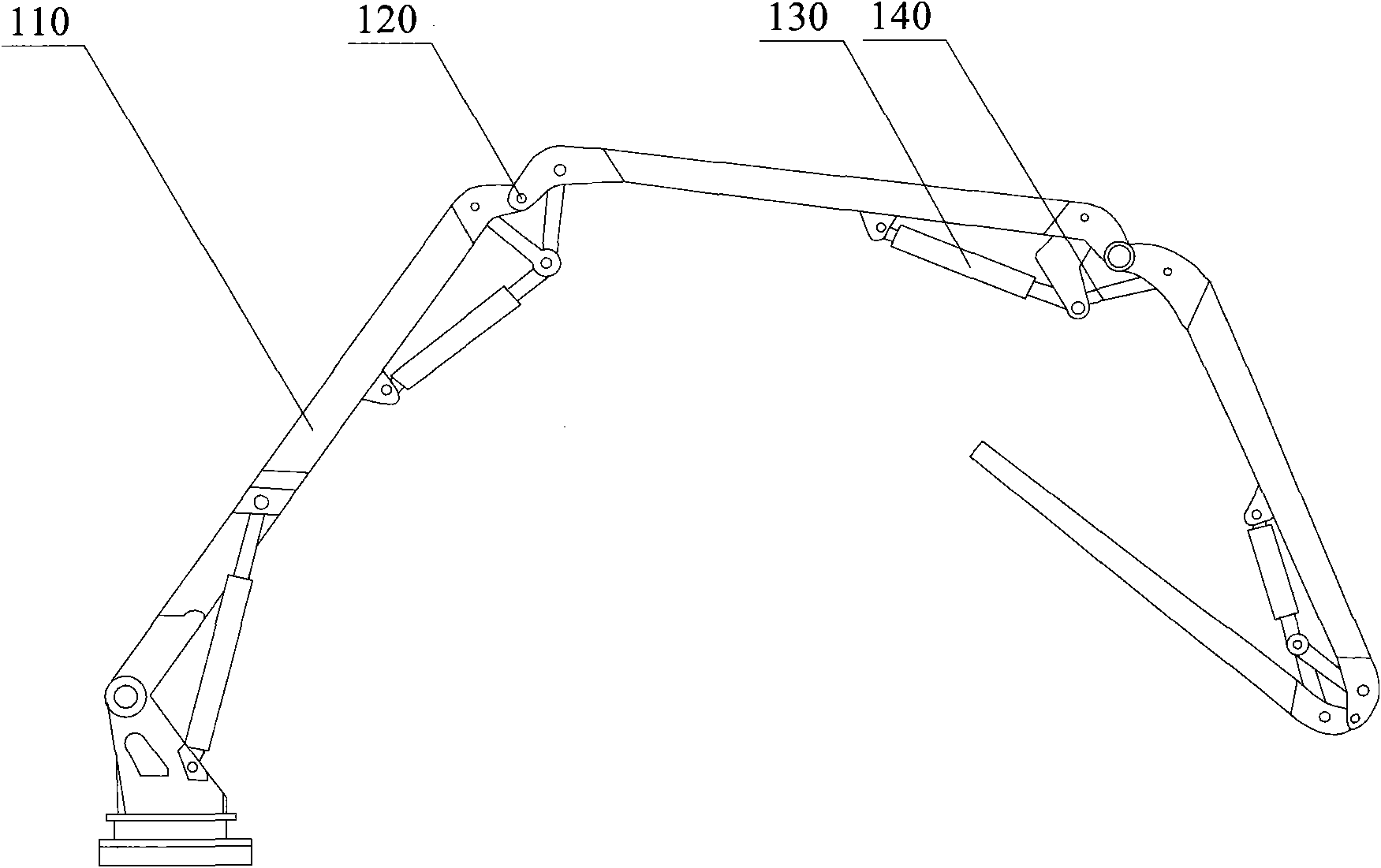

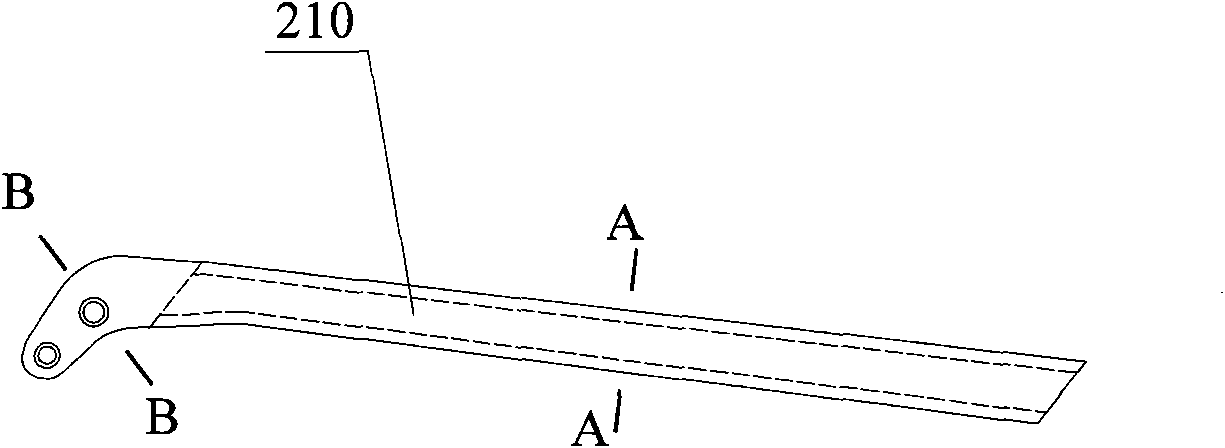

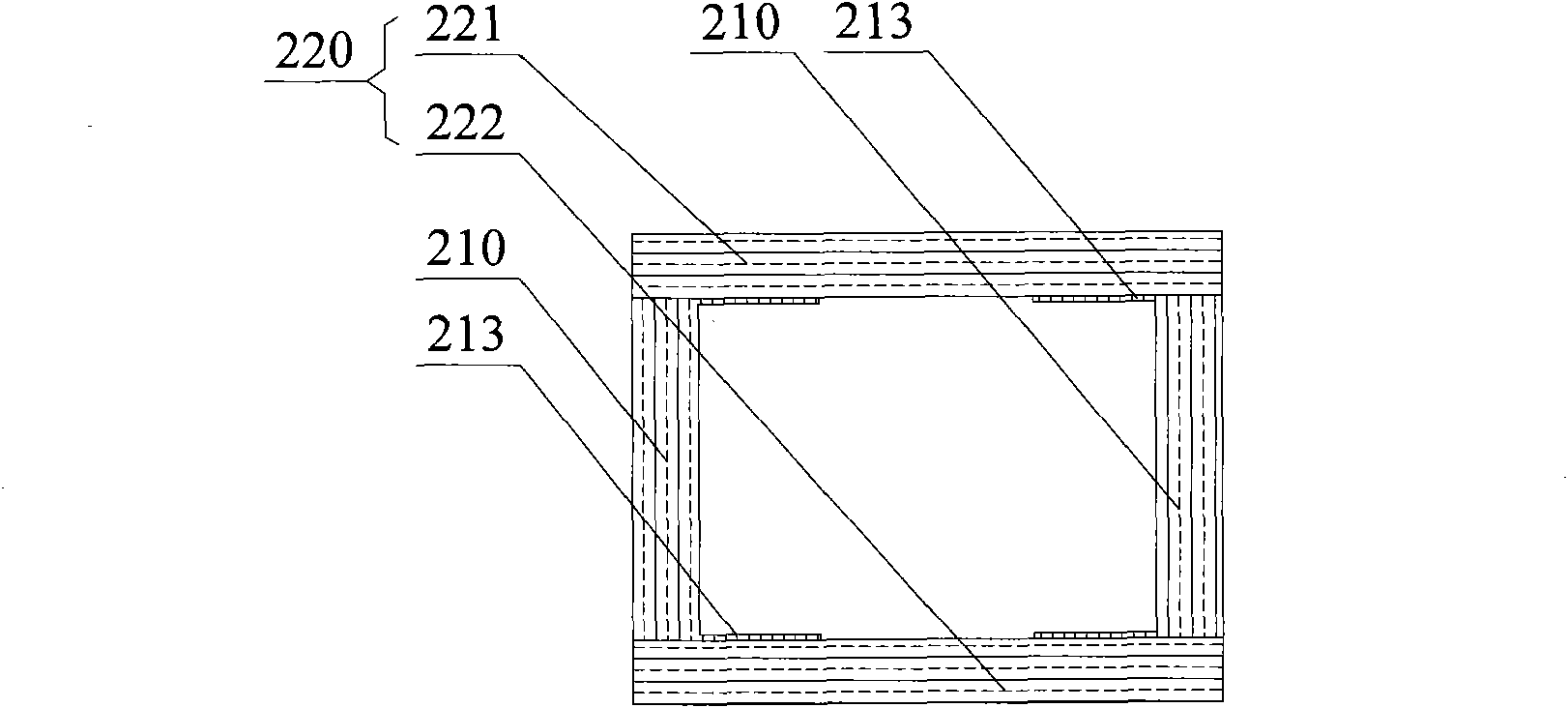

Joint arm of cloth arm bracket and manufacturing method thereof as well as concrete conveying machine

The invention discloses a joint arm of a cloth arm bracket and a manufacturing method thereof and also relates to a concrete conveying machine provided with the joint arm. The joint arm of the cloth arm bracket comprises a transverse plate and a vertical plate, wherein in the longitudinal direction, the transverse plate and the vertical plate extend along the same direction; in the transverse section, the transverse plate extends horizontally, and the vertical plate extends vertically; the side of the vertical plate has flanging, and the side of the vertical plate and the horizontal flanging are fixed with the transverse plate; and the transverse plate and the vertical plate are respectively provided with a composite material layer which comprises resin and fiber. The joint arm can maintain less weight while ensuring higher strength and fatigue resistance, and also can reduce the adverse effect for the joint arm caused by welding; furthermore, the joint arm provided by the invention also has damping performance and corrosion resistance, thus prolonging the service life of the joint arm.

Owner:SANY HEAVY IND CO LTD (CN)

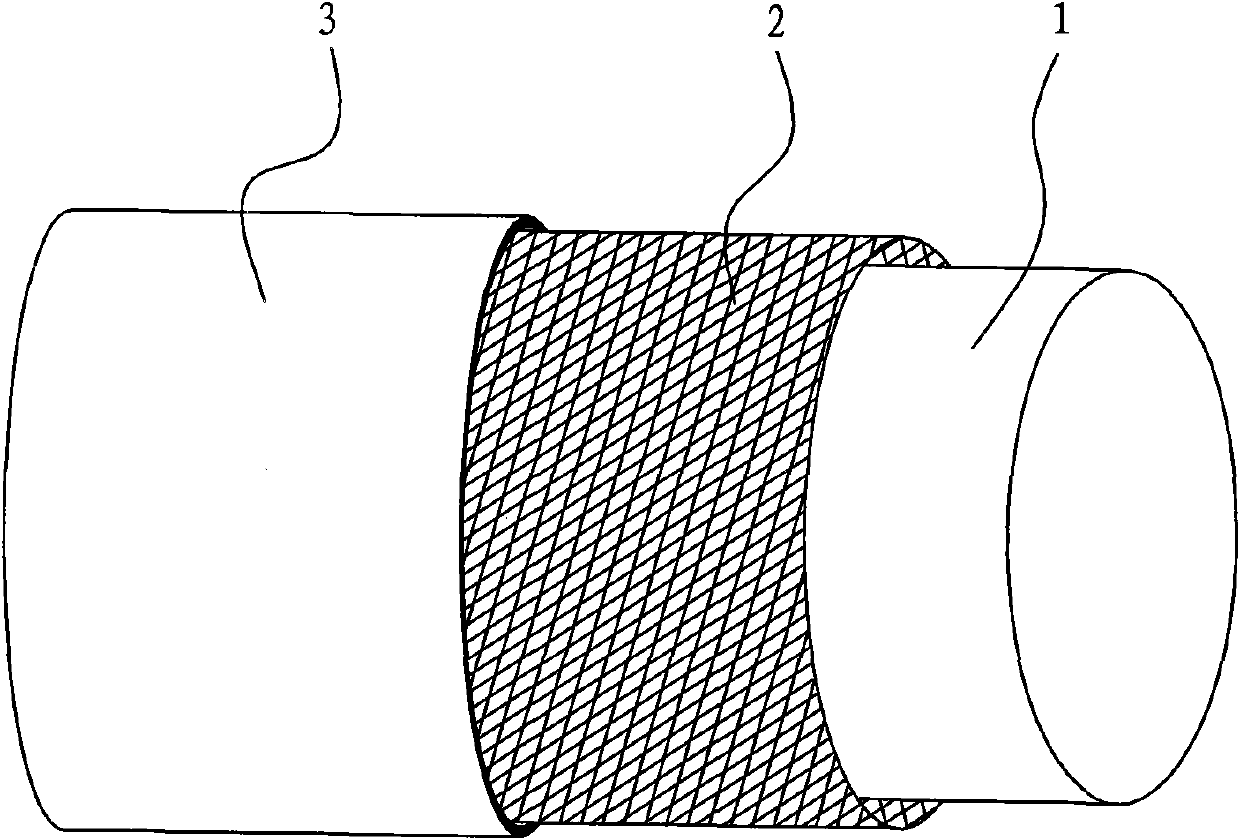

Continuous preparation method of composite material tube

InactiveCN102642316AAchieve adjustmentAchieve designabilityTubular articlesResin matrixFiber-reinforced composite

The invention relates to a continuous preparation method of composite material tube, comprising two basic processes of: (1) winding: winding a circle on a surface to be processed after the continuous fiber prepreg is pre-heated and forming a prepreg winding layer; and (2) binding: binding the continuous fibers of the impregnated resin matrix glue solution to the surface to be processed, wherein the fibers are neither overlapped nor separated and are distributed to the surface to be processed uniformly and continuously to form a fiber binding layer; when layering, the process (1) and the process (2) are carried out in turn on the same device; and the composite material tube is formed through curing and demoulding. According to the invention, the fiber layering layer of the fiber enhanced composite material tube can be layered at any angle from 0 to 90 degrees through the manner of winding fibers and binding prepreg in turn; and the fiber enhanced composite material tube has higher circumferential strength, excellent axial strength and bending rigidity.

Owner:DONGHUA UNIV

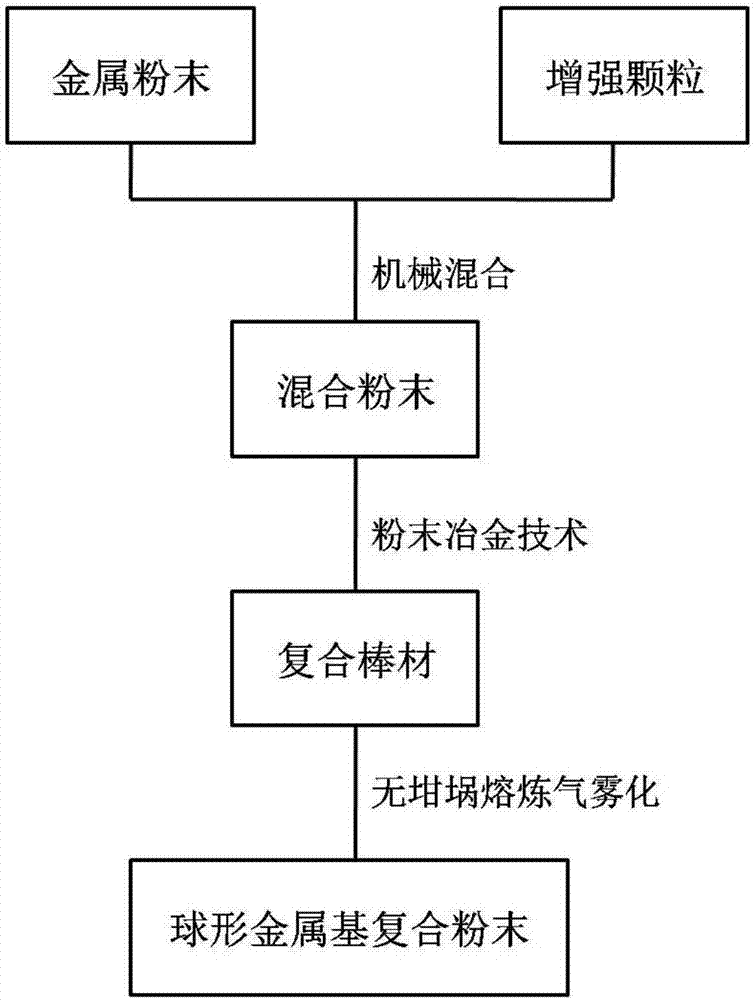

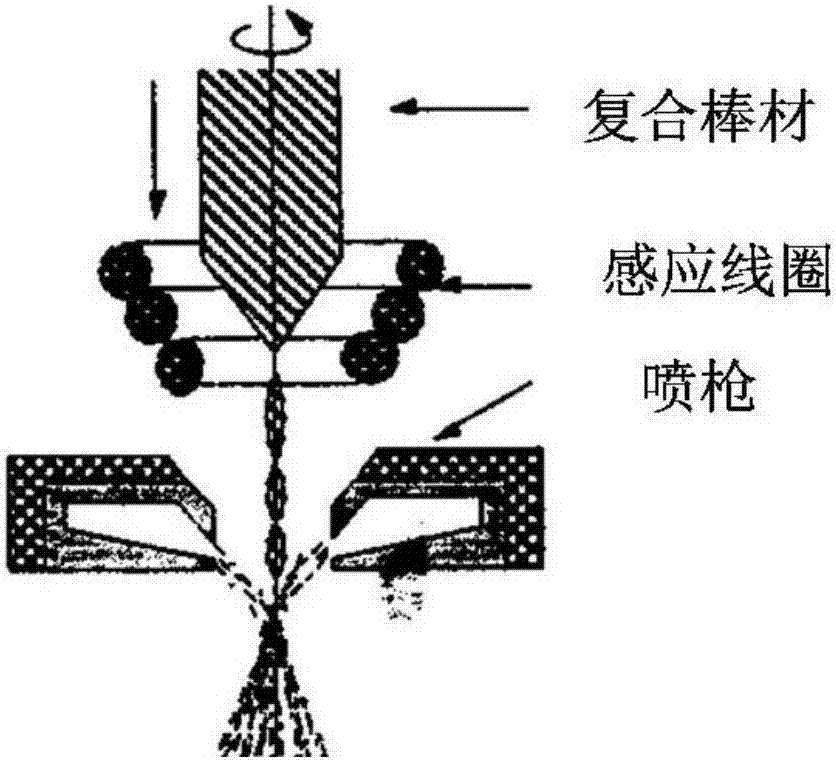

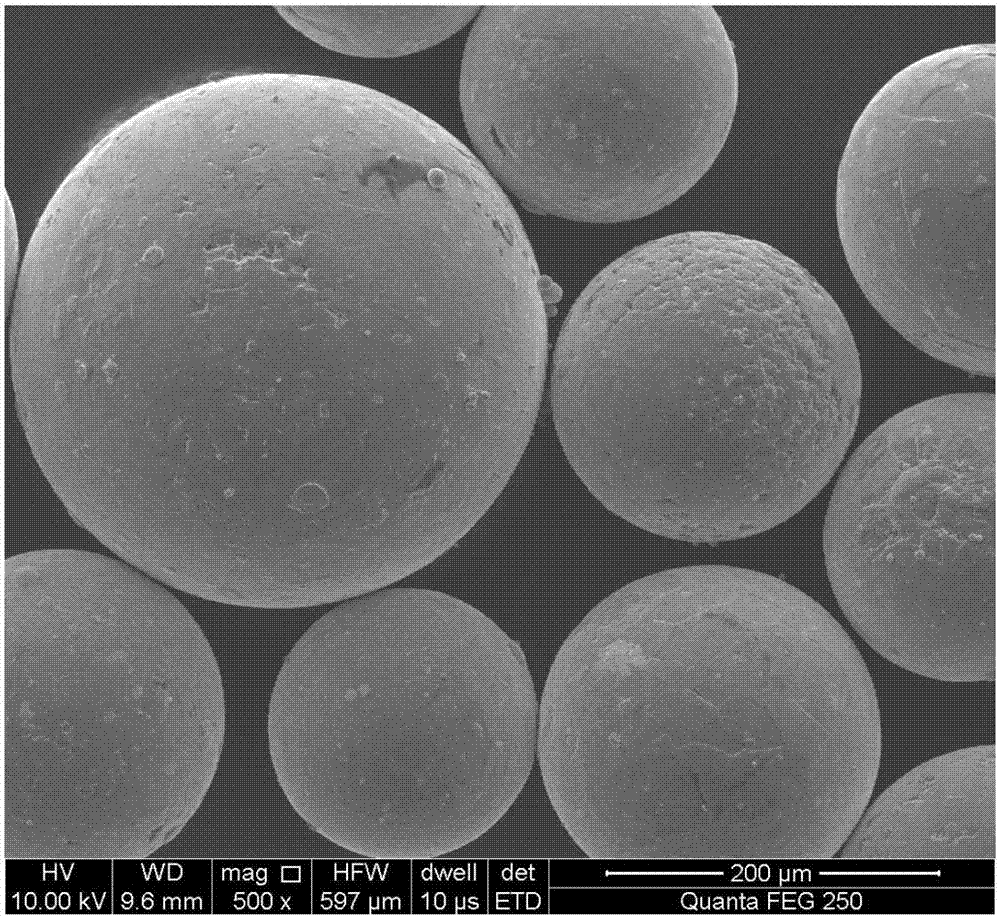

Preparation method for particle reinforced metal-based composite spherical powder material with uniform reinforcing phase distribution

ActiveCN107262729AHigh purityReduce the amount of introductionTransportation and packagingMetal-working apparatusApparent densityCrucible

The invention discloses a preparation method for a particle reinforced metal-based composite spherical powder material with uniform reinforcing phase distribution. According to the preparation method, after metal powder and reinforced phase powder are mechanically mixed, the mixture is molded through a powder metallurgy technology and sintered to form composite bars, and the composite rods are used for preparing the particle reinforced metal-based composite spherical powder material with uniform reinforcing phase distribution by utilizing a crucible-free smelting gas atomization technology. The composite powder prepared by the method has few impurities and uniform reinforcing phase distribution, is spherical or near-spherical, has excellent fluidity and high apparent density, has unique advantages and irreplaceability when used as raw materials for powder metallurgy, injection molding, 3D printing and the like, and can form a device with excellent comprehensive performance.

Owner:CENT SOUTH UNIV

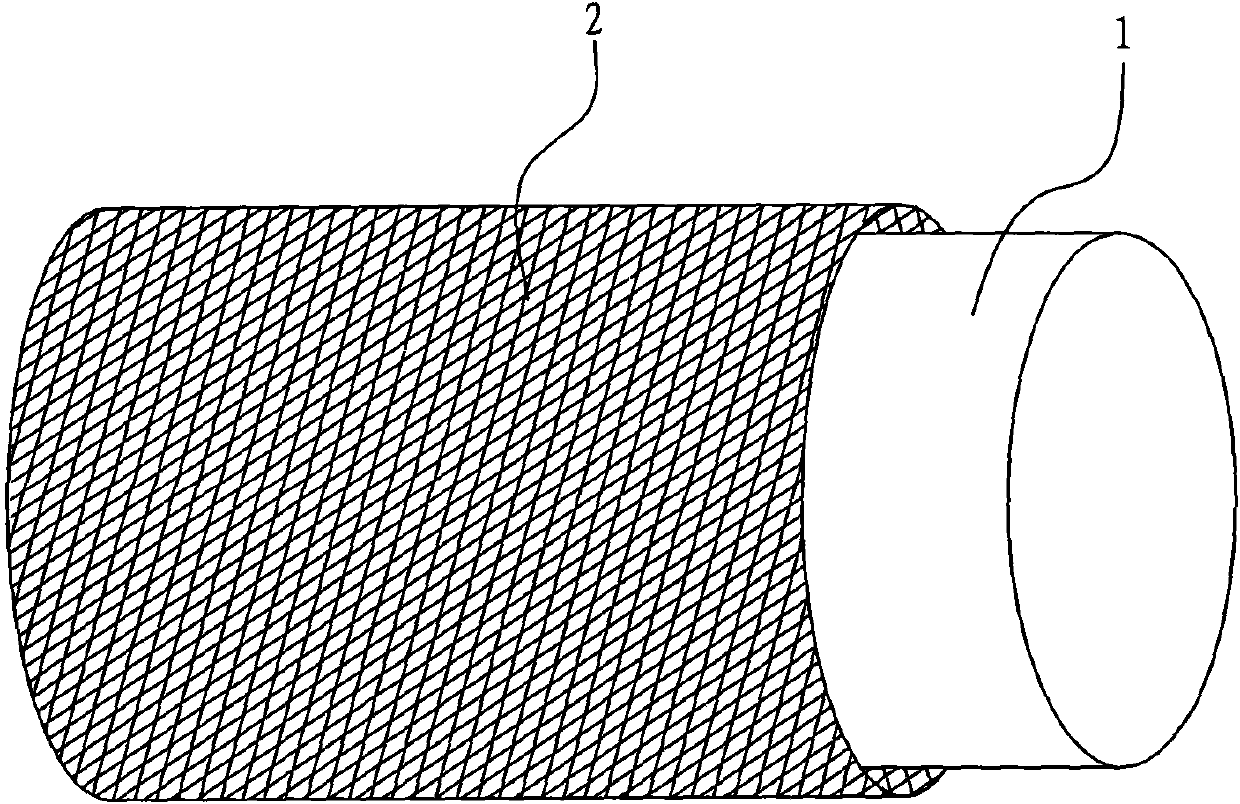

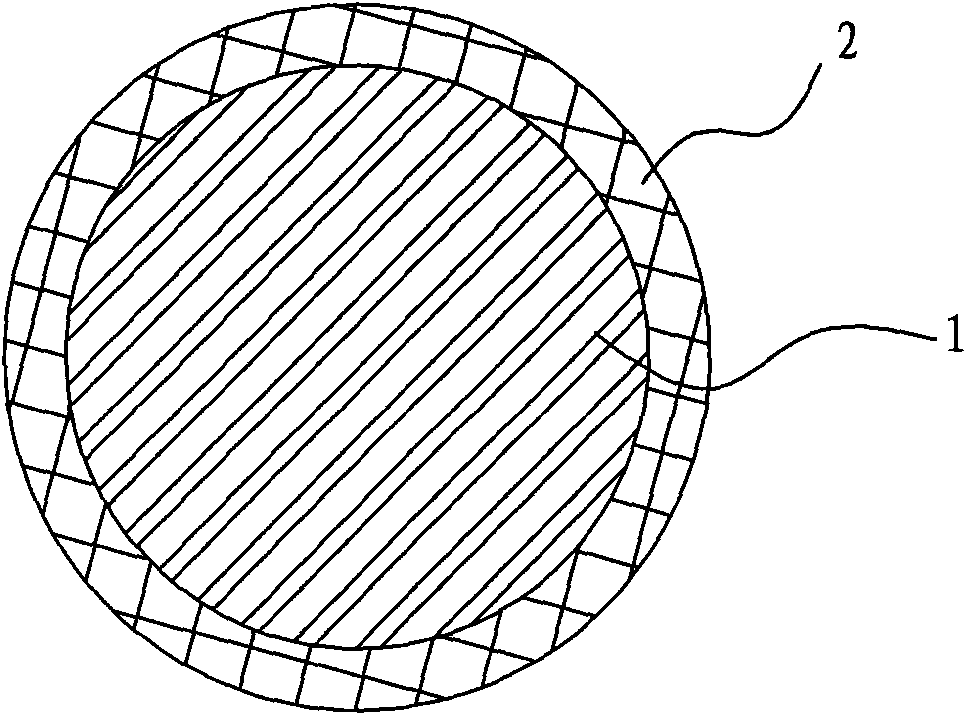

Composite material core used for enhanced cable, preparation process thereof and enhanced cable

InactiveCN102024517AImprove lateral strengthImprove fatigue resistance and fatigue resistanceInsulated cablesCable/conductor manufactureElectrical conductorFiber bundle

The invention relates to a composite material core used for an enhanced cable, a preparation process and the enhanced cable. The composite material core comprises an inner core and an outer layer, wherein the inner core is composed of fiber and thermosetting resin; the outer layer comprises a fiber woven pipe and thermosetting resin which are composited to form the outer layer; and the fiber woven pipe of the outer layer is a network structure which is woven by interlacing a plurality of fiber bundles. The transversal strength of the composite material core is greatly improved by the interlaced network structure, the fatigue resistance of the composite material core is greatly improved, and the service life of the composite material core and a power transmission cable is prolonged; and the problem that the composite material core is broken when the composite material core is stranded, wound and extruded by a conductor in the manufacturing process of the cable is completely avoided. As the fiber woven pipe is adopted by the outer layer, the flexibility of the outer layer is greatly increased by the interlaced and woven structure, thereby meeting the requirement of manufacturing composite material core with major diameter.

Owner:JIANGSU JIATAI TECH MATERIAL

Reactive group-contained comb-type graft copolymer, and preparation method and application thereof

ActiveCN104610515AHigh reactivityThermodynamically compatibleCoatingsGraft polymer adhesivesBackbone chainOrganic chemistry

The invention discloses a reactive group-contained comb-type graft copolymer, and a preparation method and application thereof. A small molecular monomer A and a macromolecular monomer B are copolymerized to form the comb-type graft copolymer with the small molecular monomer A as a main chain and the macromolecular monomer B as a side chain; the weight of the macromolecular monomer B accounts for 0.1-80wt% of the mass of the comb-type graft copolymer; the weight of the small molecular monomer A accounts for 99.9-20wt% of the mass of the comb-type graft copolymer. The reactive group-contained comb-type graft copolymer is the comb-type graft copolymer containing a reactive group on the side chain, and can be used as a compatibilizer and a chain extender.

Owner:HANGZHOU NORMAL UNIVERSITY

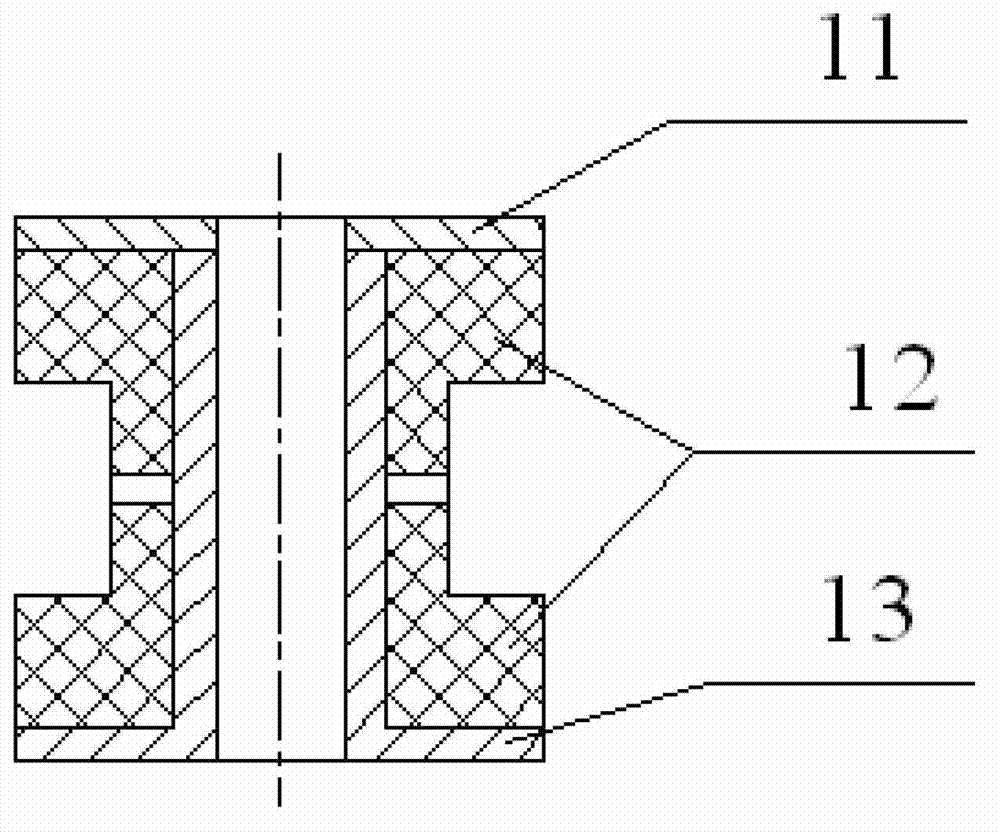

Fiber with multiple core-shell structures and preparation method thereof

InactiveCN103132163AShape is easy to controlOptimal Control StructureHollow filament manufactureFilament/thread formingFiberLiving cell

The invention discloses a fiber with multiple core-shell structures. The fiber is provided with the multiple core-shell structures. The diameter of the fiber is 10 microns to 1*106 microns, and the length of the fiber is more than one 1 micron. The cross section of the fiber is in a circular shape or a hollow ring shape. The invention further provides a preparation method of the fiber. With the structure, the fiber with the multiple core-shell structures is controllable in morphology and structure, and the preparation method is convenient and fast to operate, and designability and piratical applicability of the fiber are strong. Packaging miscellaneous nano particles, medicines or living cells can be achieved. The fiber with the multiple core-shell structures can be applied in the fields of cell cultivation, medicine sustained release, tissue engineering and the like.

Owner:SOUTHEAST UNIV

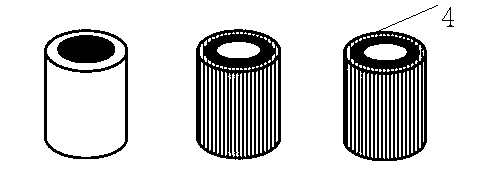

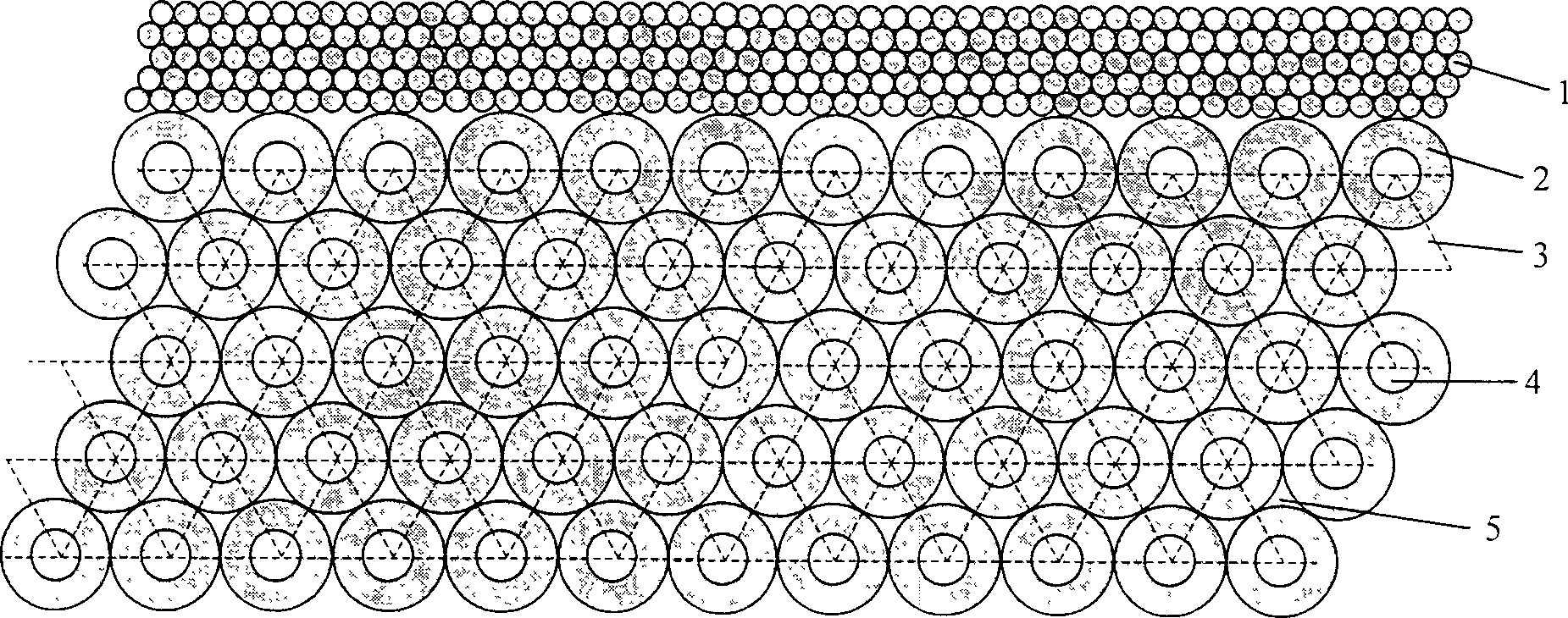

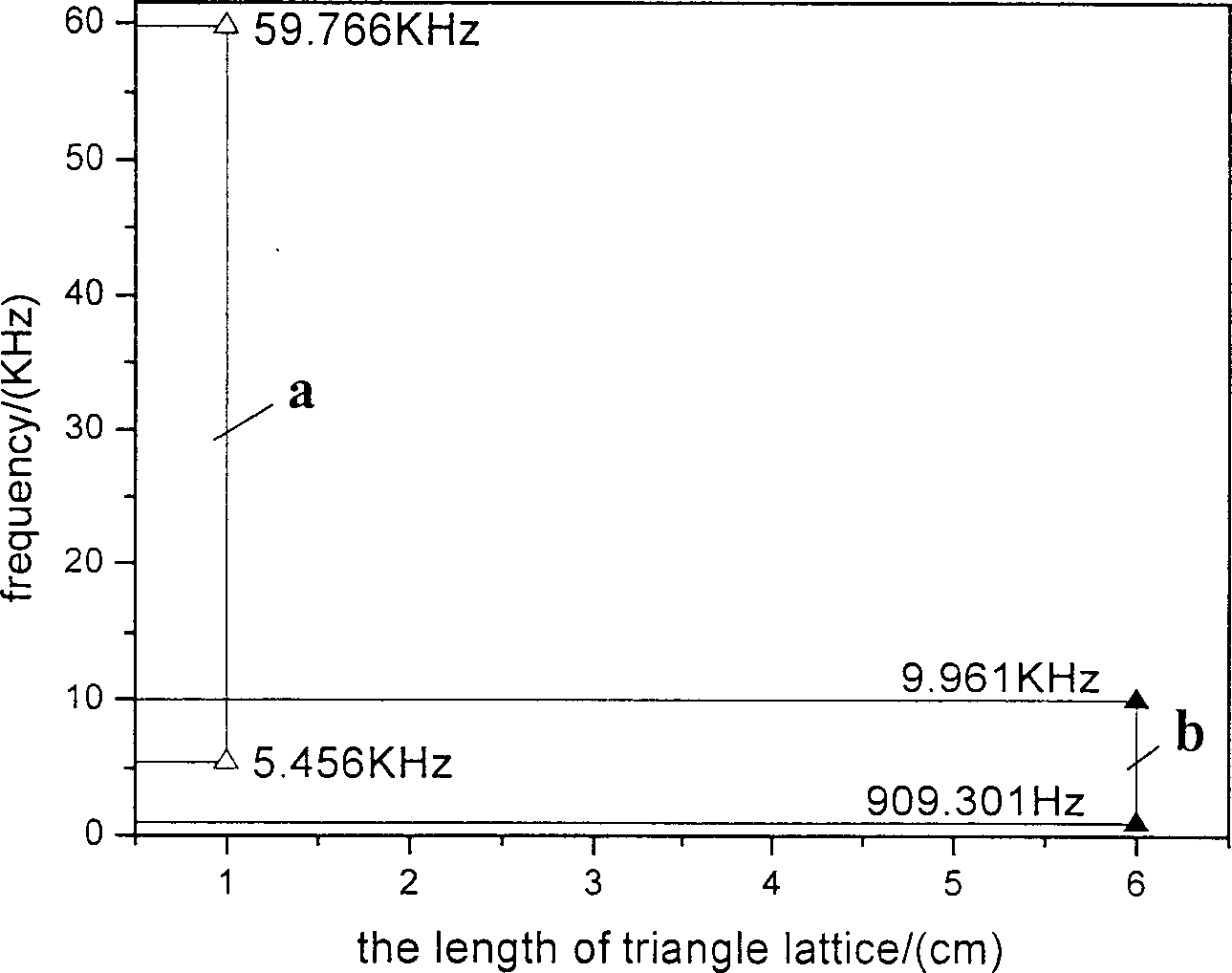

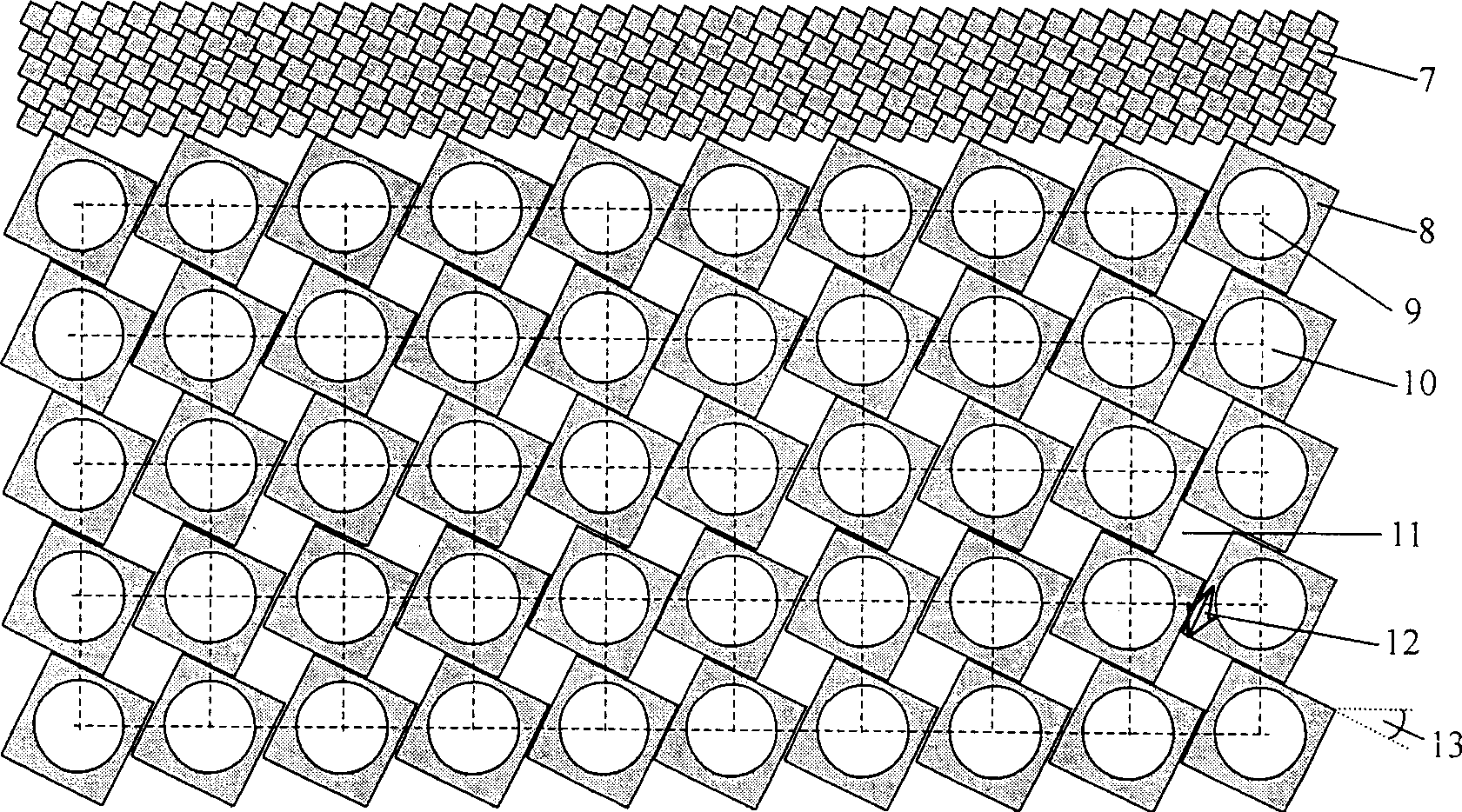

Acoustic construction of 2D phonon crystal

InactiveCN1797541AImprove sound insulationSimple preparation processSound producing devicesCrystal structureAcoustic wave

The invention discloses a 2D phonon crystal sound insulation structure, composed of parallel rigid cylinders arranged in 2D lattice periodical structure in the air; for effectively insulating sound wave, each structural mode at least needs five layers of cylinders; for broadening the frequency range of sound wave band gap, cascading and combining several structures with different lattice constants together. And it has good sound insulating effect, simple making process and strong designability, suitable for wall materials insulating medium- and high- frequency range sound waves or making sound insulation.

Owner:GUANGDONG UNIV OF TECH

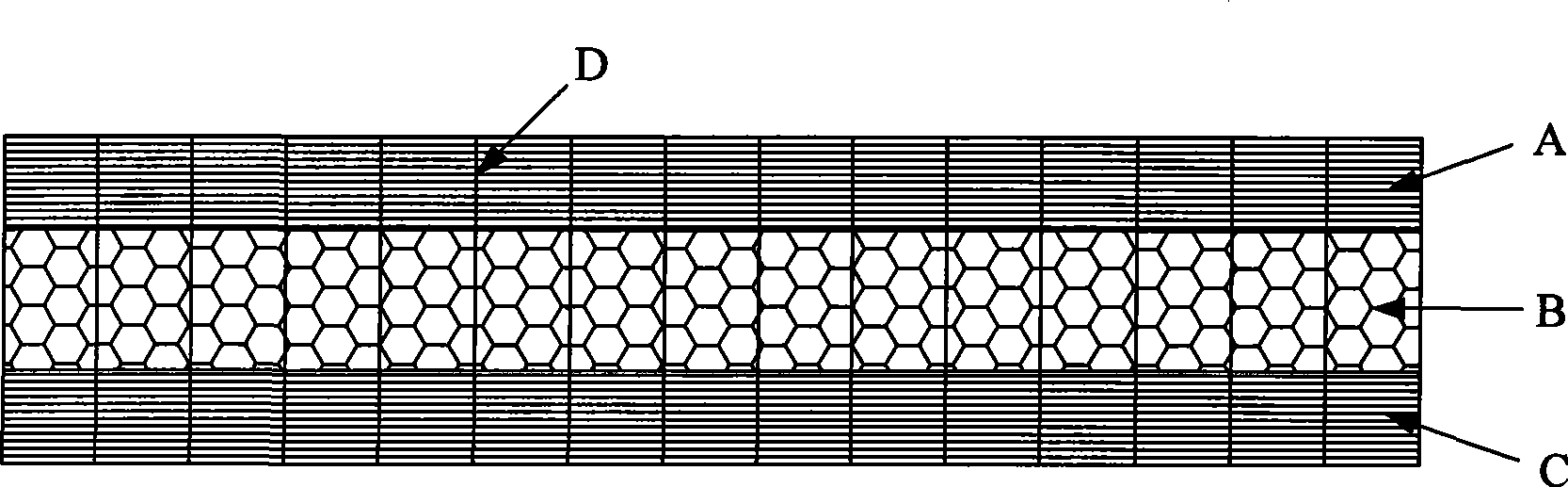

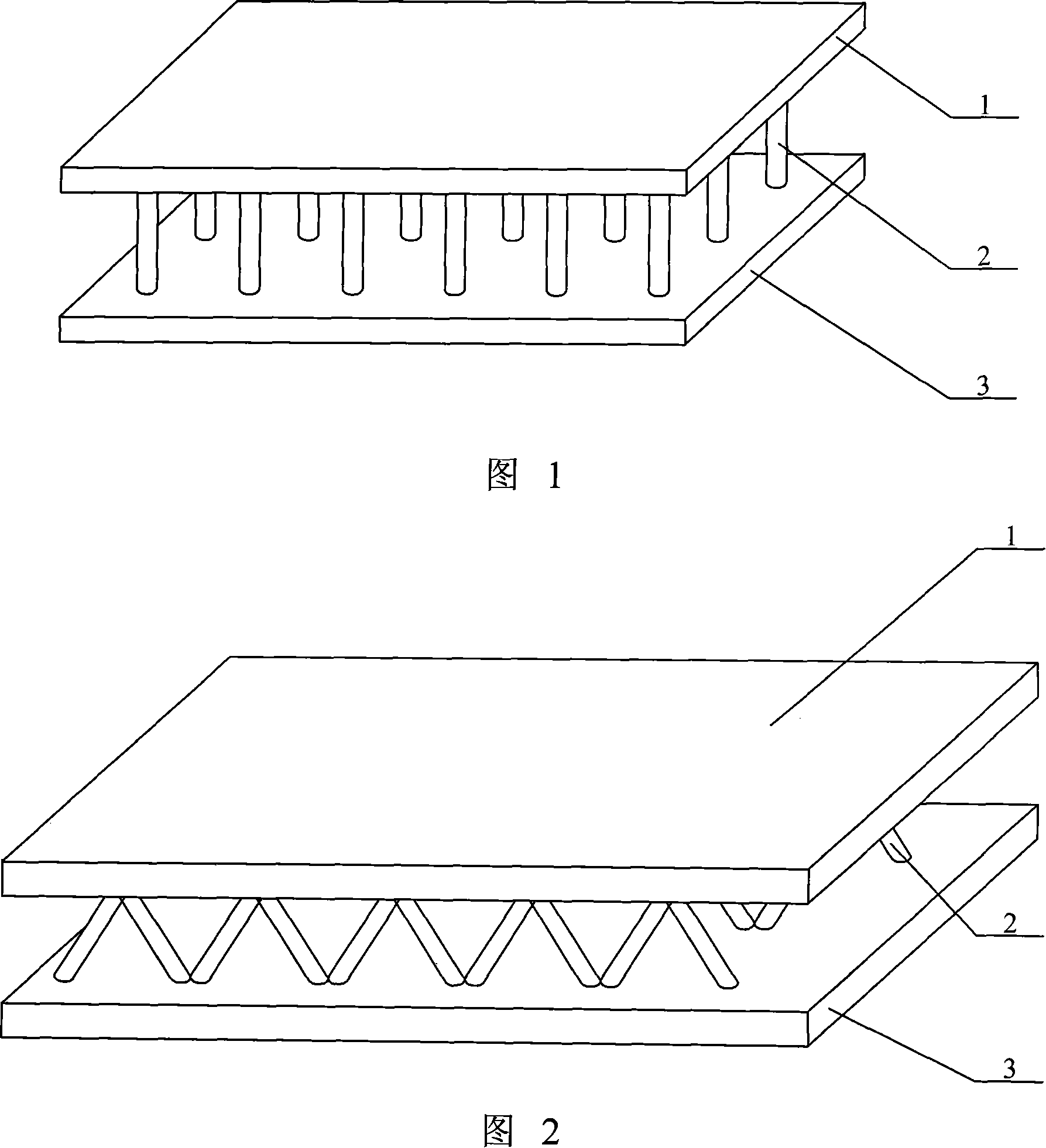

Fibre-reinforced composite lattice sandwich plate and its preparing process

The invention is a lattice sandwich plate made of reinforced composite fiber material and a manufacture method of the sandwich plate, and relates to a lattice sandwich plate and a manufacture method of the sandwich plate. The invention settles the problem that a prior lattice sandwich plate is difficult to be molded and materials used are limited to metal materials. A lattice of the invention is arranged between an upper fiber composite panel (1) and a lower fiber composite panel (3), and consists of a plurality of fiber composite columns (2). The upper ends of the fiber composite columns (2) are connected with the upper fiber composite panel (1) in a fixing way, while the lower ends of the fiber composite columns (2) is connected with the lower fiber composite panel (3) in a fixing way. The manufacture method is as follows: 1. a cleaning mould is designed and a demoulding agent is applied on the mould; 2. a pre-immersed material is cut into the designed size and filed into a pole, which is put into a mould hole; 3. the upper panel and the lower panel are laid; (4) solidification by heating and pressurizing is done, and the reinforced composite fiber material lattice sandwich plate is made. Compared with a traditional metal lattice sandwich plate, the reinforced composite fiber material lattice sandwich plate of the invention is provided with the higher intensity and rigidity, and can be designed easily.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com