Joint arm of cloth arm bracket and manufacturing method thereof as well as concrete conveying machine

A fabric arm frame and joint arm technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of cracking at welding points, poor welding performance of high-strength steel plates, and reduced fatigue strength, and achieve good impact resistance Performance and corrosion resistance, good vibration damping performance and corrosion resistance, high fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

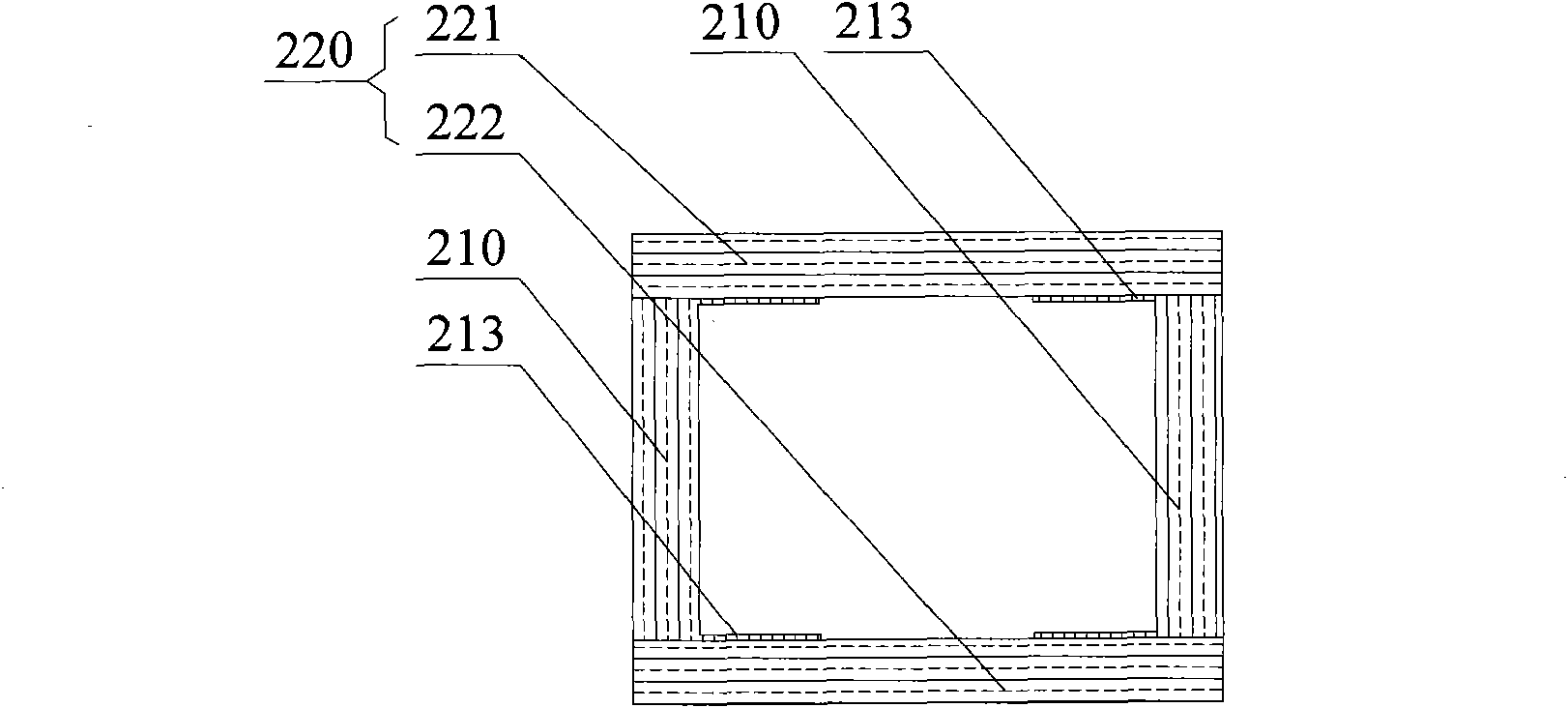

[0043] The joint arm provided by Embodiment 1 includes an upper horizontal plate 221, a lower horizontal plate 222 and two vertical plates 210, and the upper horizontal plate 221 and the lower horizontal plate 222 form the horizontal plate 220 of the joint arm; in the longitudinal direction, the upper horizontal plate 221, The lower horizontal plate 222 and the vertical plate 220 extend in the same direction; in the transverse section, the upper horizontal plate 221 and the lower horizontal plate 222 extend horizontally, and the vertical plate 210 extends vertically. Such as image 3 As shown, the two sides of each vertical plate 210 are respectively fixed to one side of the upper horizontal plate 221 and the lower horizontal plate 222, so that the upper horizontal plate 221, the lower horizontal plate 222 and the two vertical plates 210 form joint arms. Such as image 3 As shown, the two sides of the vertical plate 210 are also provided with flanges 213, and the two flanges ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com