Fiber with multiple core-shell structures and preparation method thereof

A technology with a shell structure and multiple cores, which is applied in the field of fibers with multiple core-shell structures and its preparation, can solve the problems of difficult and difficult preparation methods, and achieve controllable morphology and structure, convenient operation, and designability and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

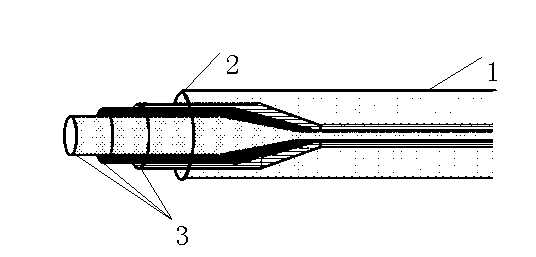

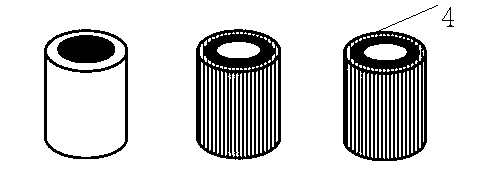

[0040] The present invention uses microfluidic technology to design and build a microfluidic chip according to the structure and function of multi-component fibers, and can prepare fibers 4 with multiple core-shell structures by adjusting the components and flow rates of each phase solution. Fiber 4 with multiple core-shell structures, each layer is distinguished by its material and function. The material of each fluid channel 3 is selectively used to wrap functional nanoparticles, drugs or cells, and can be applied in fields such as cell culture, drug sustained release, and tissue engineering. Compared with the traditional fiber preparation method, the method proposed by the invention has simple device, convenient operation, stronger designability and practicability of the fiber. Its specific preparation method comprises the following steps:

[0041] (1) Preparation steps of microfluidic chip:

[0042] Use the method of micromachining to prepare the channel network. The mat...

Embodiment 1

[0046] Example 1 Preparation of fiber 4 with two-layer core-shell structure:

[0047] 1. Preparation of microfluidic chip:

[0048] A circular PDMS channel network is prepared by micromachining. The channel network includes two coaxially nested fluid channels 3, two continuous phase channels 2, and a co-flow channel 1. The interior of each channel is treated with hydrophobicity. .

[0049] 2. Preparation of fiber:

[0050] (1) Configuration of each phase solution:

[0051] Fluid phase solution 1: Add monodisperse silica nanoparticles with a diameter of 180 nm to the aqueous solution of polyethylene glycol diacrylate, adjust the mass fraction of silicon dioxide to 40%, and the content of polyethylene glycol diacrylate The mass fraction is 10%, ultrasonically dispersed until the colloidal particle solution produces a bright color; add the initiator 2-hydroxyl-2-methylpropiophenone (1%, volume ratio) to the above solution, mix well, and seal the backup use.

[0052] Fluid ph...

Embodiment 2

[0056] Example 2 Preparation of fibers with a hollow structure of two layers of core-shell:

[0057] 1. Preparation of microfluidic chip:

[0058] Use an acetylene blowtorch or a microelectrode puller to draw three kinds of glass capillary tubes so that one end becomes a tapered tip, and polish it on sandpaper until the tip is smooth and the inner diameter of the tip of the single tube is 40 microns and 100 microns respectively , 200 microns, placed in alcohol for ultrasonic cleaning, and blown dry with nitrogen; using a glass plate as a substrate, insert a capillary with an inner diameter of 200 microns into a capillary with an inner diameter of 580 microns, adjust the tip to the central axis of the capillary, and follow the above steps Nest the 100-micron capillary in the 200-micron tube, the 40-micron capillary in the 100-micron tube, install the needle, and fix it with quick-drying adhesive.

[0059] 2. Preparation of fiber:

[0060] (1) Configuration of each phase solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com