Preparation method of graphene aerogel and graphene-carbon nanotube aerogel

A graphene aerogel and carbon nanotube technology, which is applied in the field of aerogels, can solve the problems of environmental hazards, low electrical conductivity, and affect the performance of graphene aerogels, so as to achieve no pollution in energy consumption and acceptable appearance. control, the effect of excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

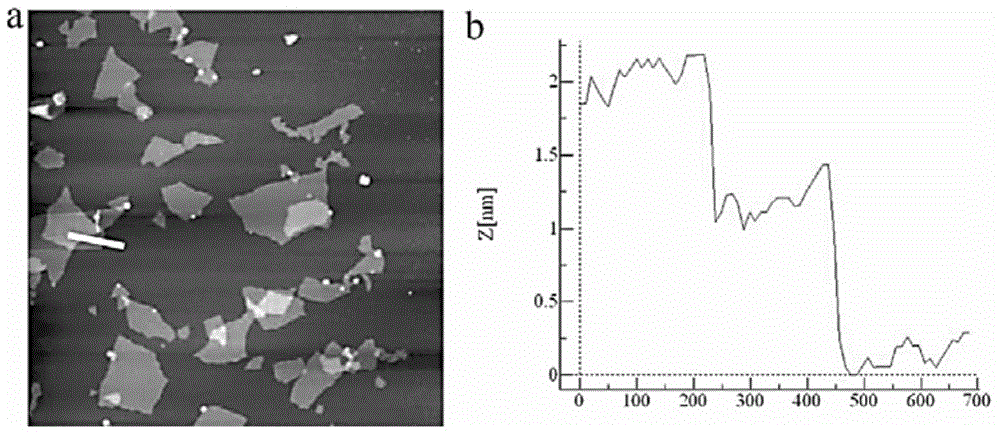

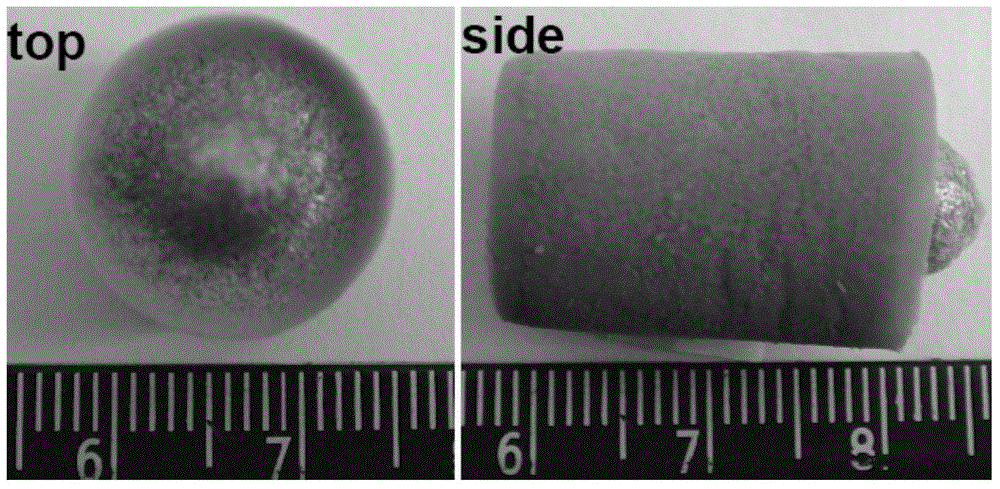

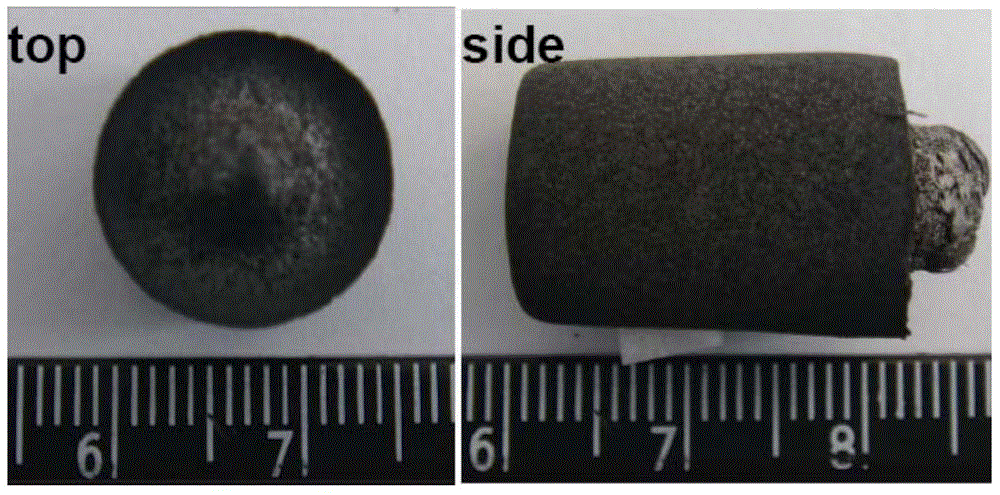

Image

Examples

Embodiment 1

[0035] The present embodiment prepares graphene airgel, specifically comprises the following steps:

[0036] (1) Graphene oxide is added to deionized water, ultrasonically dispersed until uniformly mixed, and a graphene oxide aqueous solution having a mass concentration of 4.0 mg / ml is obtained;

[0037] (2) the graphene oxide aqueous solution prepared in step (1) is carried out to supercritical drying, and graphene oxide airgel is obtained;

[0038] (3) After mixing the graphene oxide airgel prepared in step (2) with magnesium powder, place it in a reactor for magnesia thermal reaction. After the reaction is finished, soak the reaction product in an acidic aqueous solution, and then freeze After drying, the graphene airgel is obtained.

[0039] The graphene oxide described in step (1) is prepared by Hummers chemical method.

[0040]The specific process of preparing graphene oxide by Hummers chemical method: put a 500mL reaction bottle in an ice bath, add an appropriate amou...

Embodiment 2

[0053] The preparation of graphene-carbon nanotube airgel in this embodiment specifically includes the following steps:

[0054] (1) Graphene oxide is added to deionized water, and ultrasonically dispersed until uniformly mixed to obtain a graphene oxide aqueous solution with a mass concentration of 0.5 mg / ml;

[0055] (2) The mass ratio of carbon nanotubes and graphene oxide in step (1) is 5: 1, carbon nanotubes are added in the graphene oxide aqueous solution that step (1) makes, and ultrasonic dispersion is until mixed evenly, Prepare a mixed solution of graphene oxide and carbon nanotubes;

[0056] (3) freeze-drying the mixed solution of graphene oxide and carbon nanotubes prepared in step (2) to obtain graphene oxide-carbon nanotube airgel;

[0057] (4) After the graphene oxide-carbon nanotube aerogel prepared in step (3) is mixed with magnesium powder, place it in a reactor for magnesia thermal reaction, and after the reaction finishes, soak the reaction product in an a...

Embodiment 3

[0066] The preparation of graphene-carbon nanotube airgel in this embodiment specifically includes the following steps:

[0067] (1) Graphene oxide is added to deionized water, and ultrasonically dispersed until uniformly mixed to obtain a graphene oxide aqueous solution with a mass concentration of 8 mg / ml;

[0068] (2) The mass ratio of carbon nanotubes and graphene oxide in step (1) is 5: 1, carbon nanotubes are added in the graphene oxide aqueous solution that step (1) makes, and ultrasonic dispersion is until mixed evenly, Prepare the mixed solution of graphene oxide and carbon nanotubes:

[0069] (3) supercritically drying the mixed solution of graphene oxide and carbon nanotubes prepared in step (2) to obtain graphene oxide-carbon nanotube airgel;

[0070] (4) After the graphene oxide-carbon nanotube aerogel prepared in step (3) is mixed with magnesium powder, place it in a reactor for magnesia thermal reaction, and after the reaction finishes, soak the reaction produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com