Patents

Literature

31results about How to "Morphological influence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

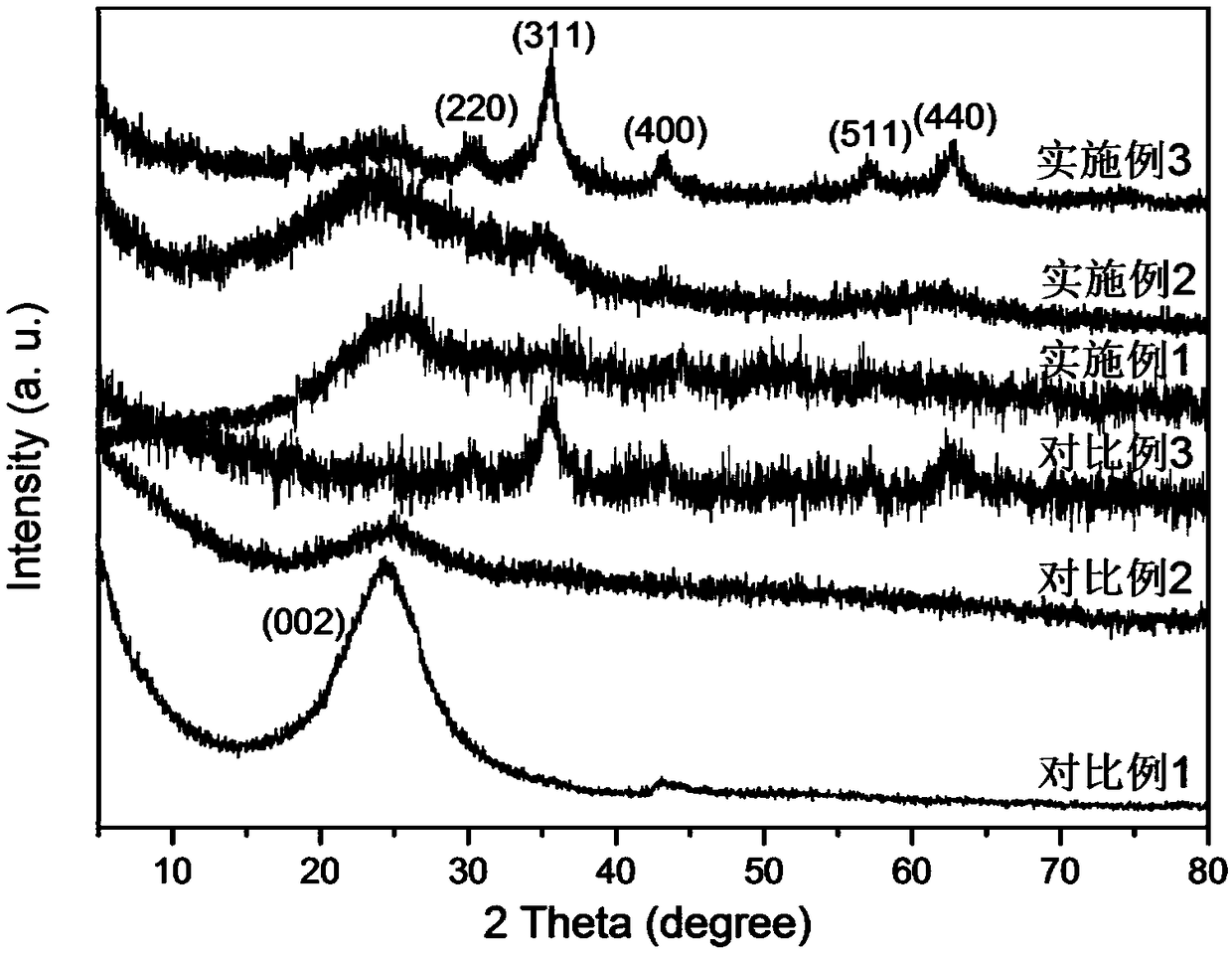

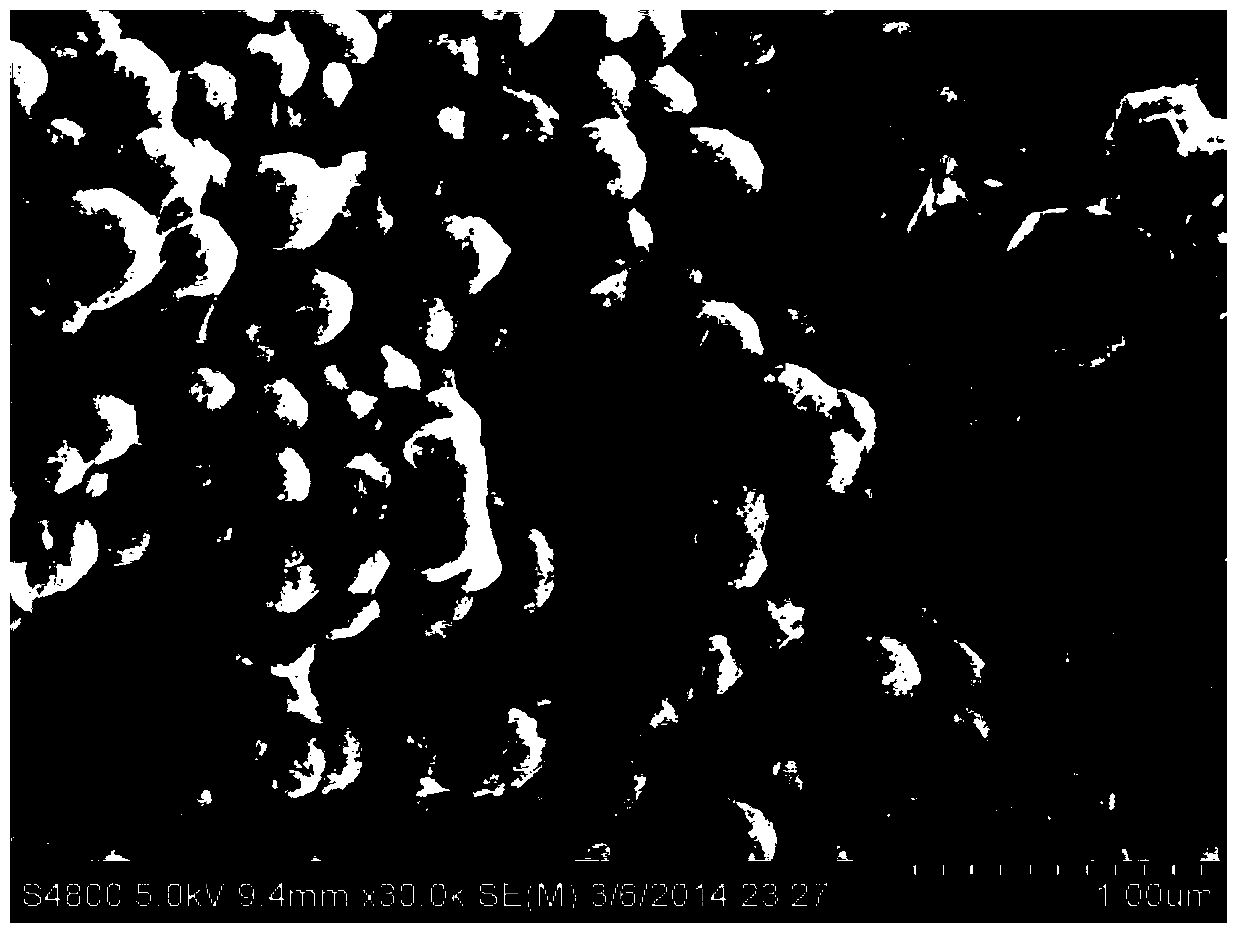

Preparation method of graphene aerogel and graphene-carbon nanotube aerogel

The invention relates to a preparation method of graphene aerogel and graphene-carbon nanotube aerogel. According to the method, graphene oxide or a mixture of graphene oxide and carbon nanotube is subjected to drying treatment; graphene oxide is reduced through a magnesium thermal reaction; the material is soaked in an acidic water solution; and impurities are removed, and the material is dried, such that graphene aerogel or graphene-carbon nanotube aerogel is obtained. Compared with prior arts, the method provided by the invention has the advantages of simple process, and is green and environment-friendly. Magnesium powder is adopted as a reducing agent. Compared to reducing agents such as hydrazine hydrate, sodium borohydride, formaldehyde, carbohydrate compounds, ascorbic acid and hydroiodic acid, magnesium powder has higher reducibility, such that the graphene aerogel or graphene-carbon nanotube aerogel with high carbon-oxygen ratio can be prepared. The electrical conductivity of the graphene aerogel or graphene-carbon nanotube aerogel can reach 10<4>s / cm. The graphene aerogel or graphene-carbon nanotube aerogel has large specific surface area, and is non-toxic and harmless. The graphene aerogel or graphene-carbon nanotube aerogel can be widely applied.

Owner:TONGJI UNIV

Method for reducing sulphur content of ternary precursor

ActiveCN110817975AReduce adsorptionReduce sulfur contentCell electrodesSecondary cellsSulfate radicalsPhysical chemistry

The invention discloses a method for reducing the sulphur content of a ternary precursor. Sulfate is used as a ternary salt raw material, and the ternary salt raw material, an alkaline solution and acomplexing agent are added to a reaction kettle for co-precipitation to prepare the ternary precursor, after co- precipitation reaction is carried out for 5-15 hours, pure water is added continuouslyor intermittently to the reaction kettle to replace clear liquid in the reaction kettle, and meanwhile, the alkaline solution and the complexing agent are added to keep a reaction system stable. The problem that the sulphur content in the ternary precursor exceeds the standard due to the fact that the sulfate is adsorbed on the surface of a crystal during the growth of the crystal and then wrappedinside the crystal is solved, the sulphur content of the prepared ternary precursor after one-time washing is less than 530 ppm, and during the subsequent water washing process, water resources are effectively saved; and the impurity content is reduced, the jolt ramming density of the ternary precursor is increased, and the morphology of the ternary precursor is not affected.

Owner:宜宾光原锂电材料有限公司

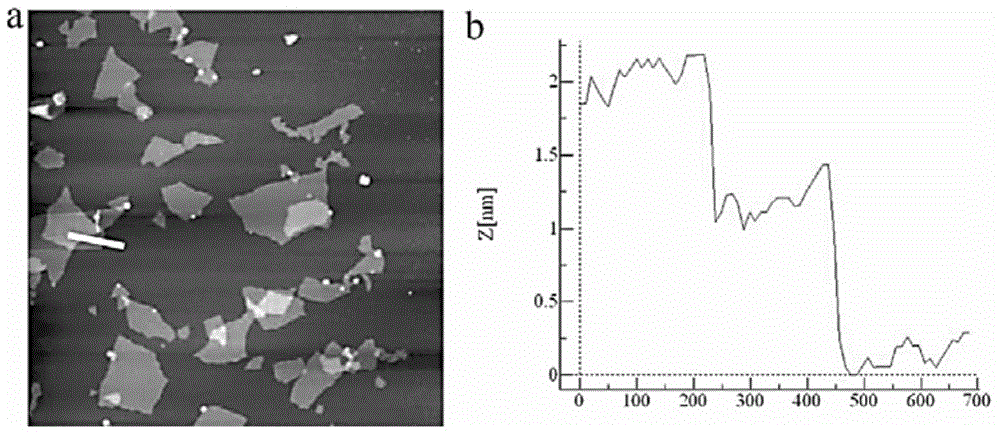

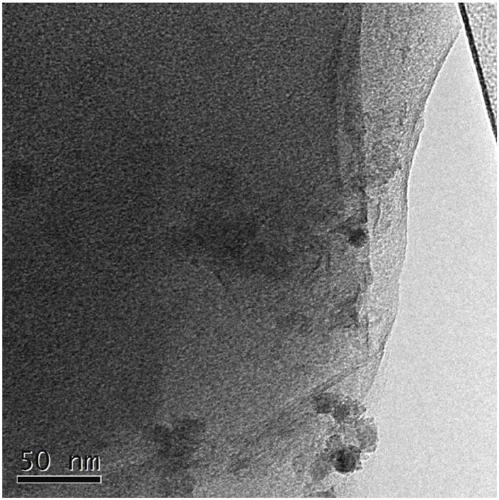

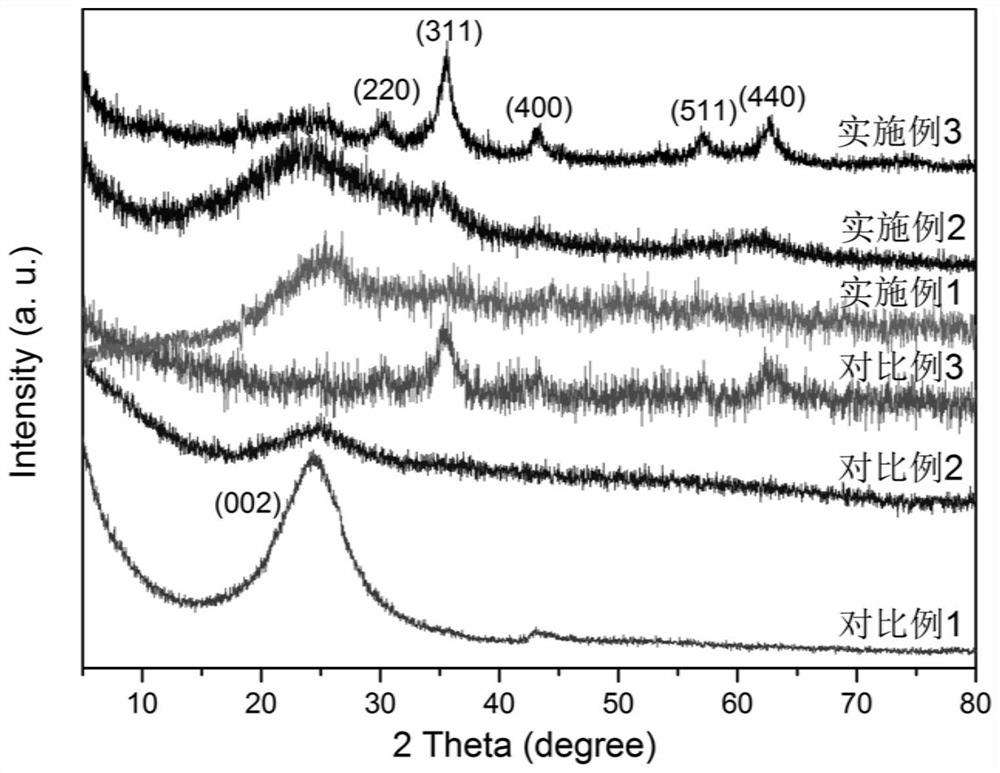

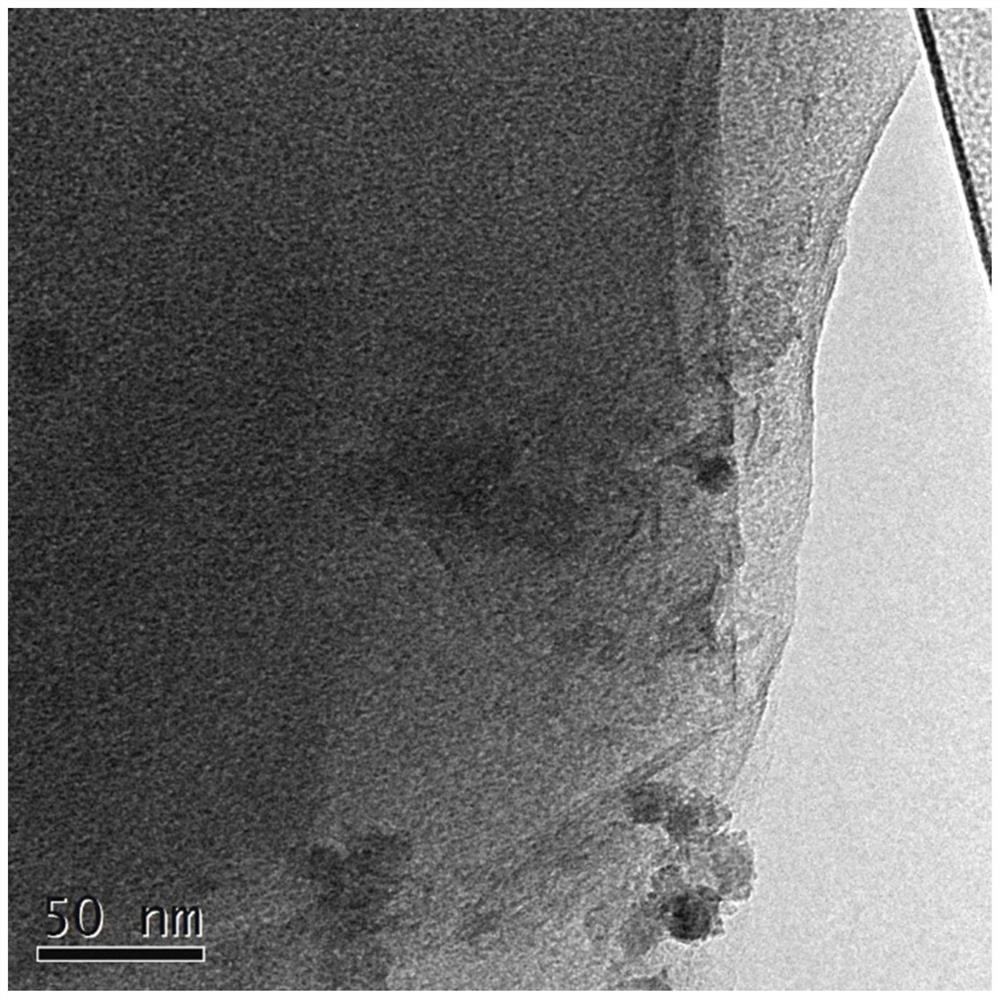

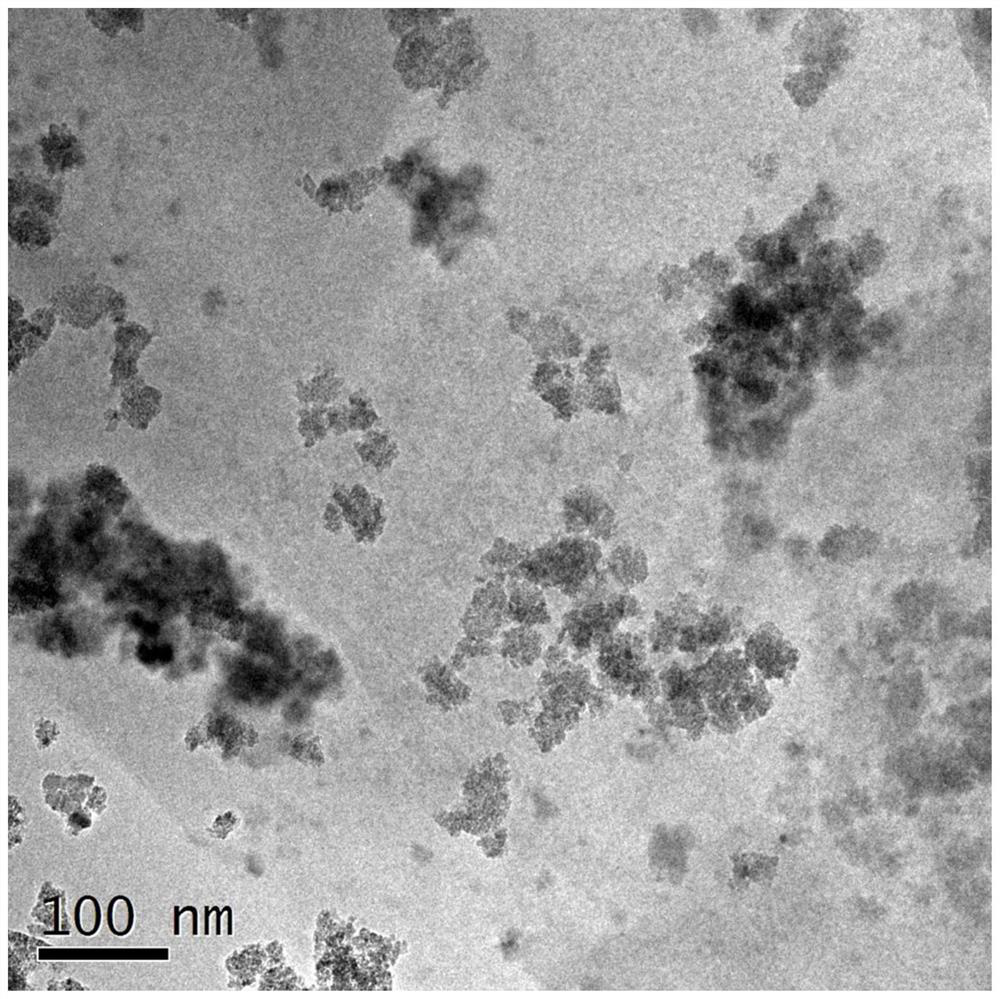

Preparation method and application of graphene/cobalt-nickel-manganese ferrite nano-composite material

ActiveCN109021919AImprove performanceShort synthesis timeOther chemical processesMagnetic/electric field screeningFerrite nanoparticlesCobalt

The invention discloses a preparation method and application of a graphene / cobalt-nickel-manganese ferrite nano-composite material. The preparation method comprises: adding a solution containing an iron source, a cobalt source, a nickel source and a manganese source into a dispersion containing graphene oxide drop by drop to obtain a mixed solution, adjusting pH of the mixed solution to greater than or equal to 8, adding a reducing agent into the mixed solution to obtain a precursor solution, transferring the precursor solution into a reactor, and carrying out microwave synthesis to obtain thegraphene / cobalt-nickel-manganese ferrite nano-composite material. The graphene / cobalt-nickel-manganese ferrite nano-composite material is composed of layered graphene and spherical cobalt-nickel-manganese ferrite nanoparticles. The spherical cobalt-nickel-manganese ferrite nanoparticles are uniformly dispersed on the layered graphene surface and between the layers. The graphene / cobalt-nickel-manganese ferrite nano-composite material has the characteristics of strong absorption intensity, effective absorption frequency bandwidth, thin thickness and light weight.

Owner:CENT SOUTH UNIV

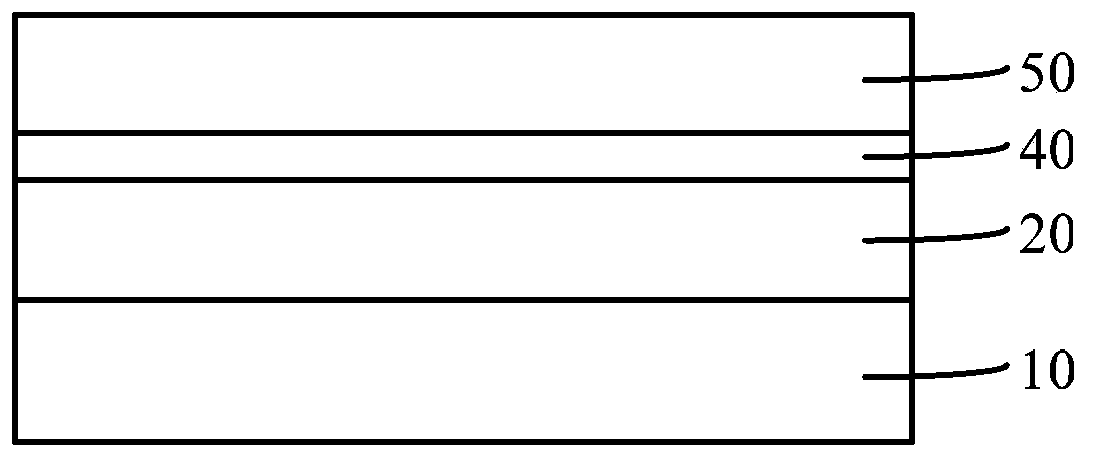

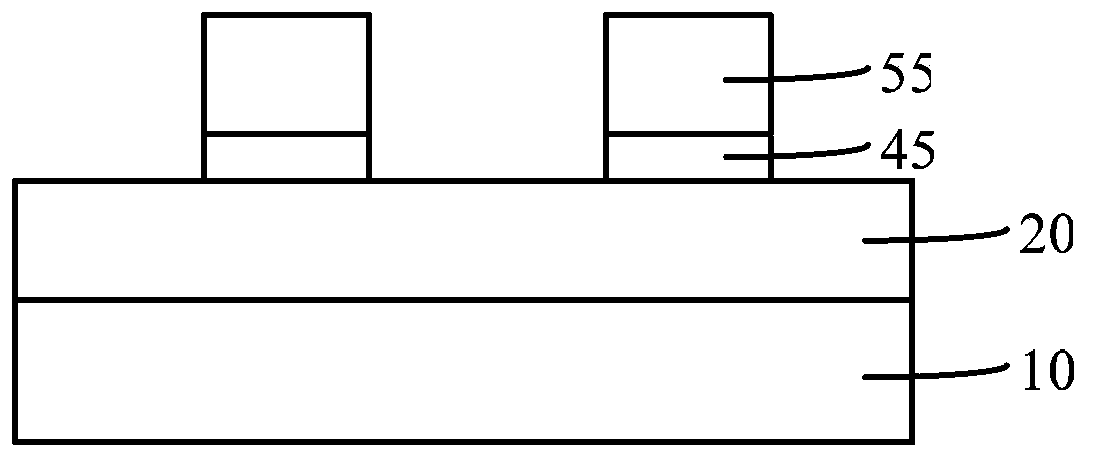

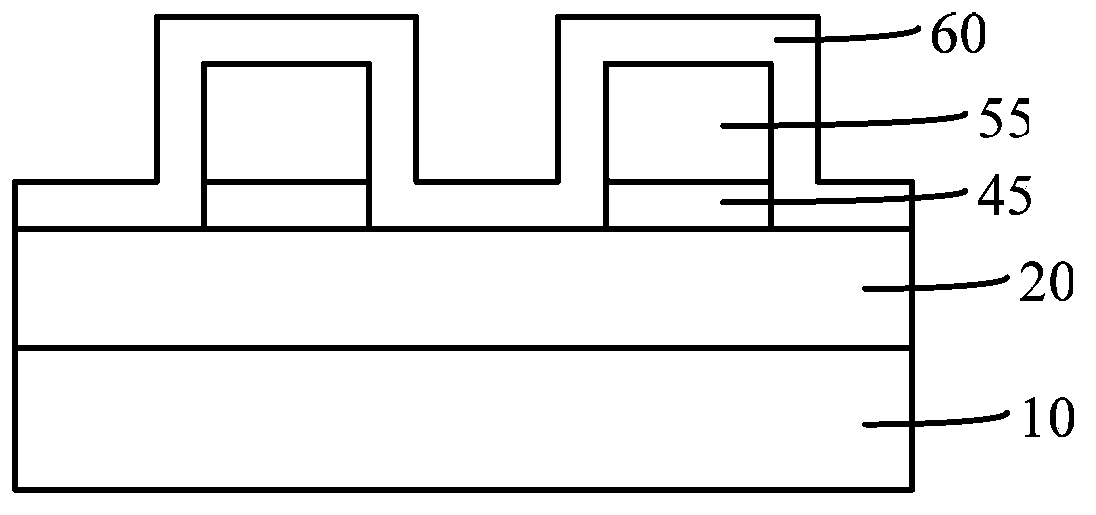

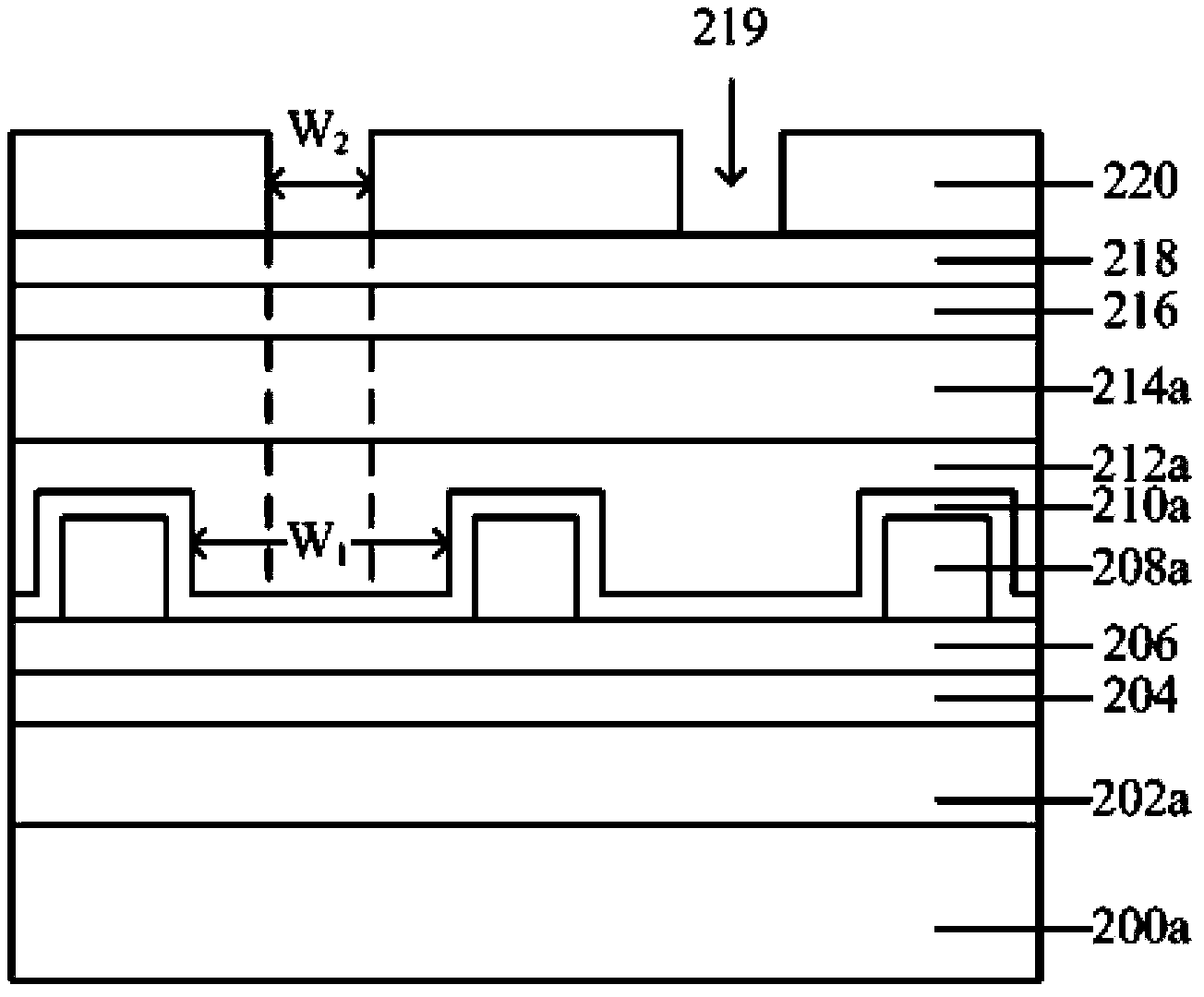

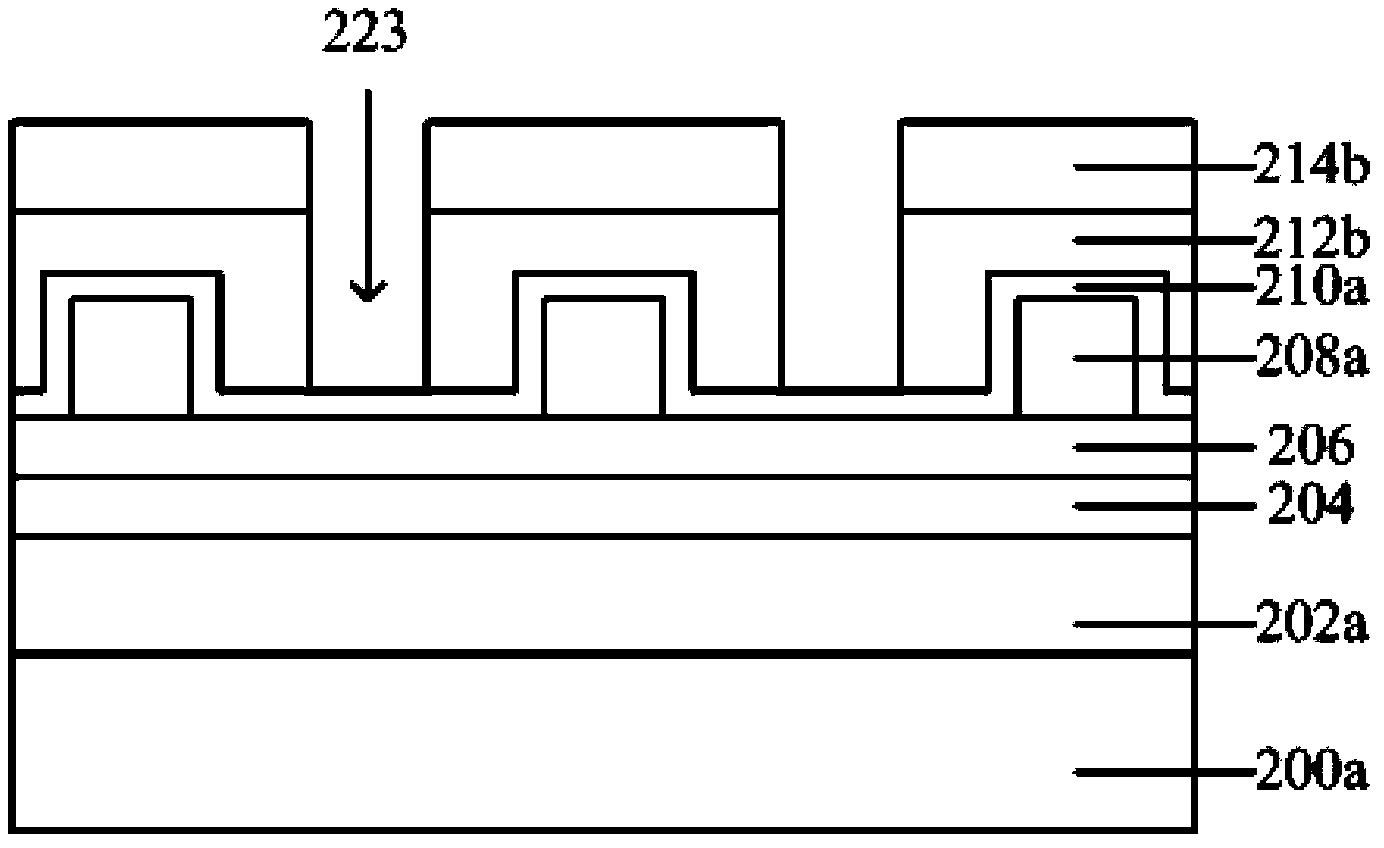

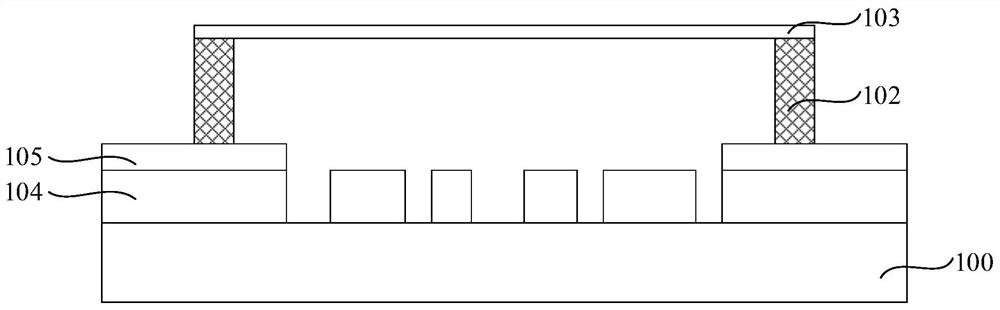

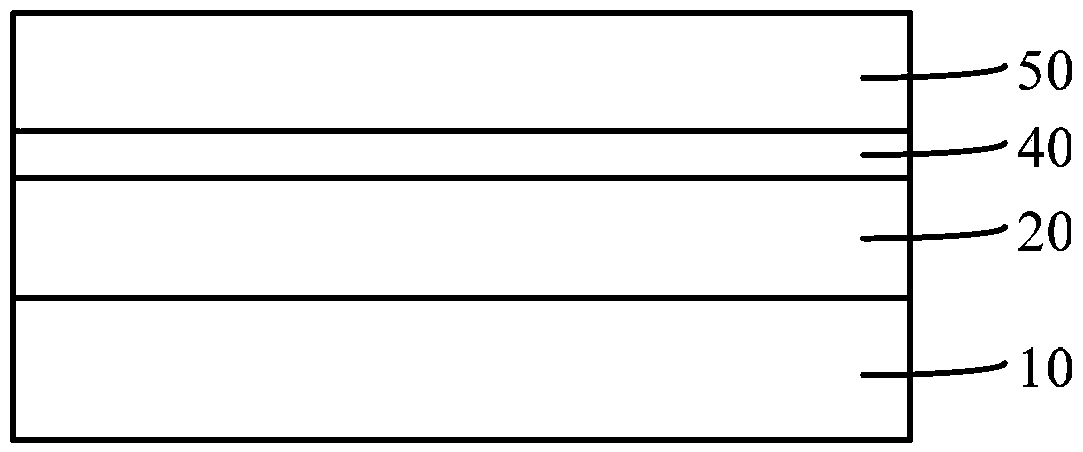

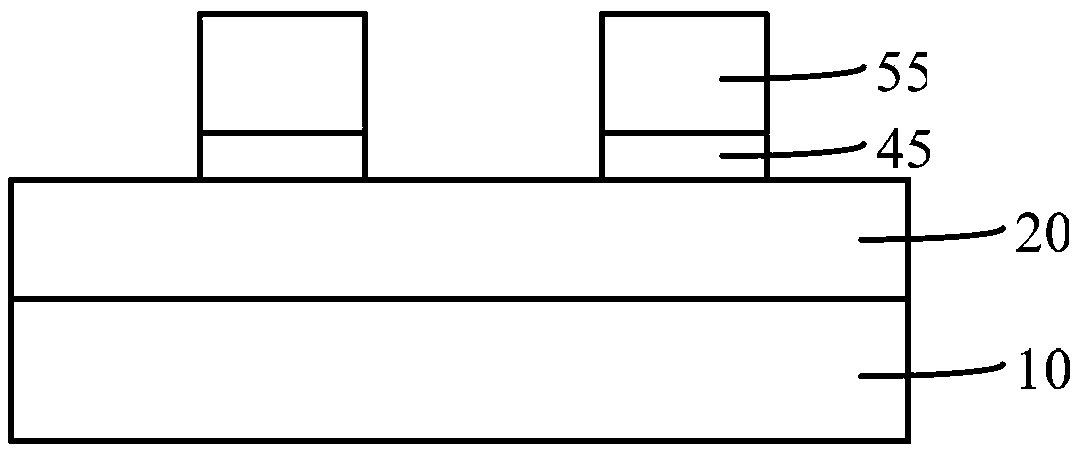

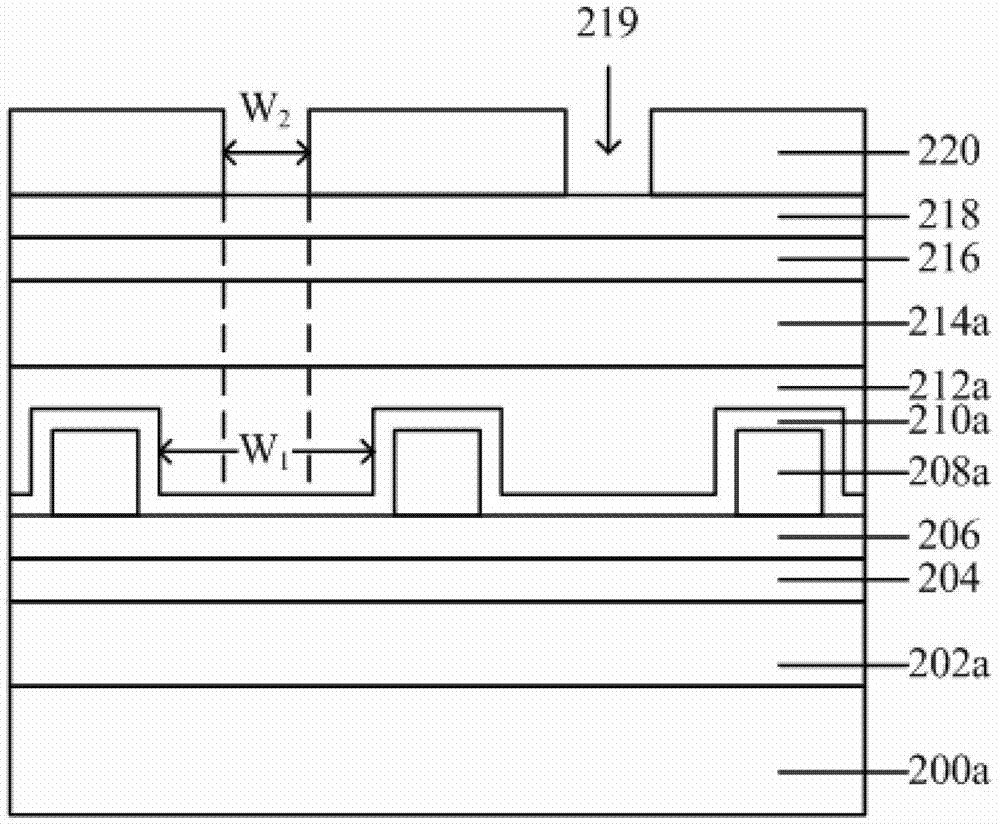

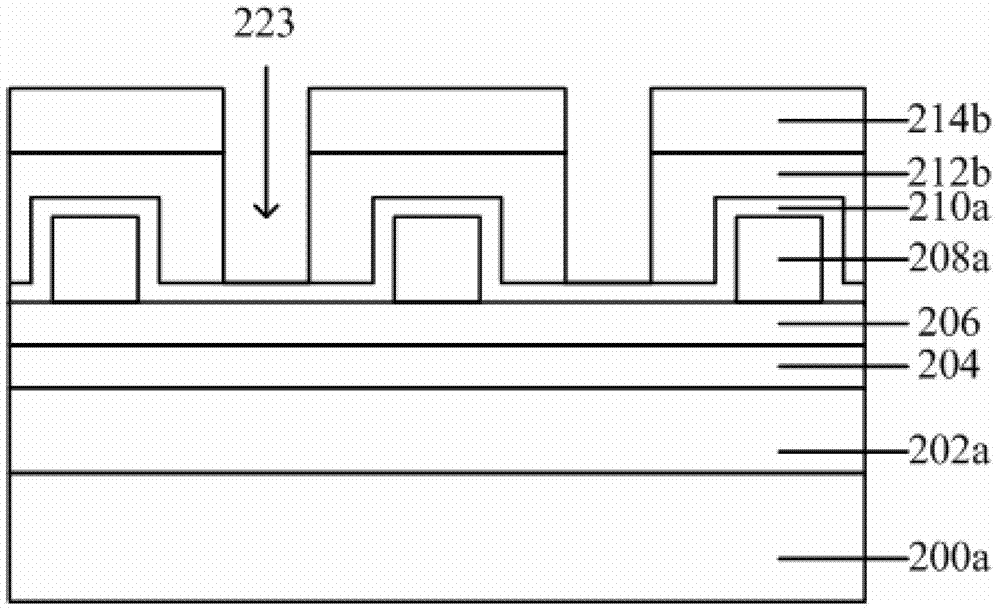

Self-alignment duplex patterning method

ActiveCN103681293AMorphological influenceGood sidewall morphologySemiconductor/solid-state device manufacturingPhotoresistMaterials science

The invention provides a self-alignment duplex patterning method. The method comprises the following steps: providing a material layer to be etched, forming a sacrificial photoresist layer on the material layer to be etched, curing photoresist at the top and side wall of the sacrificial photoresist layer to form a cured photoresist casing, performing back-etching on the cured photoresist casing at the top of the sacrificial photoresist layer until an uncured inner sacrificial photoresist layer is exposed, forming a first mask pattern on the cured photoresist casing on the side wall of the inner sacrificial photoresist layer, and removing the uncured inner sacrificial photoresist layer. As a hard mask layer is not required to form, the process procedures are reduced, and the impact of the stress generated by the hard mask layer on the profile of the sacrificial photoresist layer is eliminated. Besides, the first mask pattern is formed by removing the top of the cured photoresist casing, the side wall of the sacrificial photoresist layer formed by the photolithographic process is smooth and perpendicular to the surface of the material layer to be etched, and the side wall of the finally-formed etched pattern has a better profile.

Owner:SEMICON MFG INT (SHANGHAI) CORP

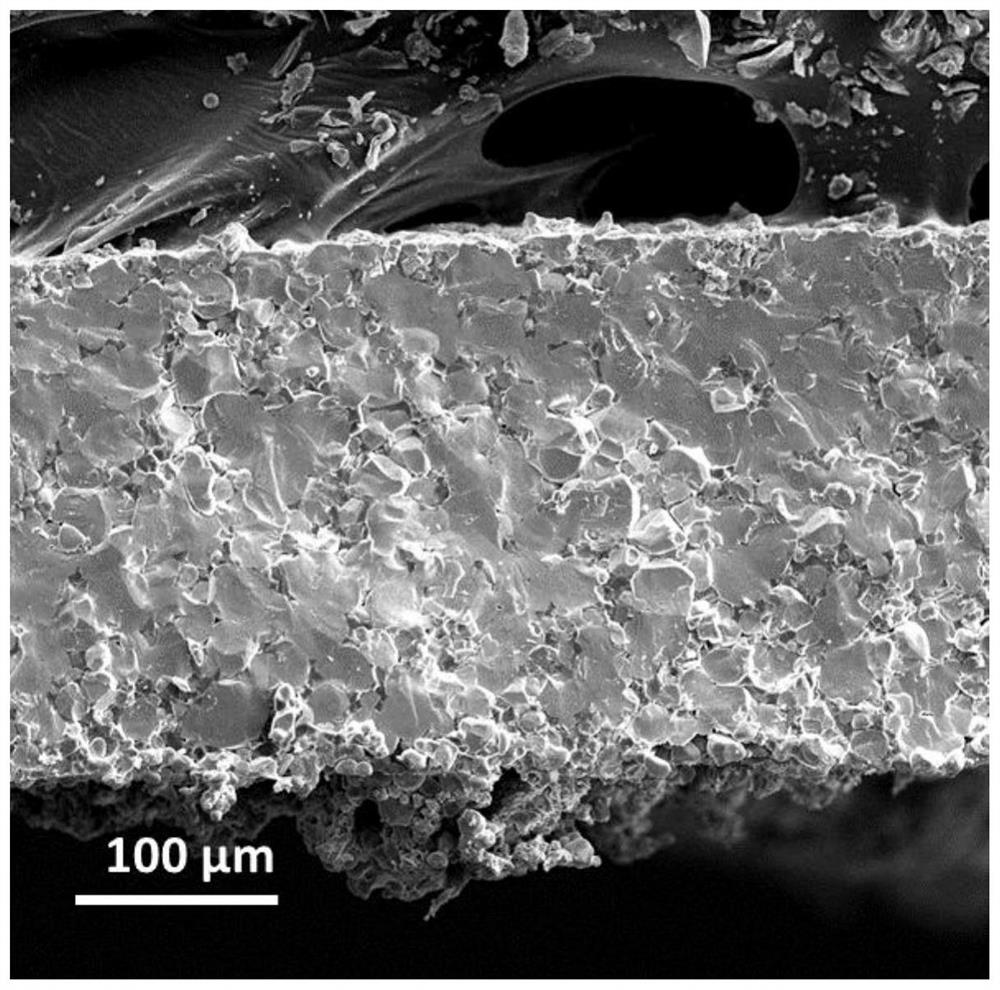

Low-impedance interface processing method of solid-state lithium battery positive electrode and positive electrode structure

ActiveCN109768215AImprove securityAvoid punctureNon-aqueous electrolyte accumulator electrodesSolid state electrolyteEngineering

The invention discloses a low-impedance interface processing method of a solid-state lithium battery positive electrode and a positive electrode structure. By the method, impedance of two interfaces between active material particle in a positive electrode plate and solid-state electrolyte particle and between the positive electrode plate and an electrolyte piece can be effectively reduced, so thatthe capacity of active positive electrode particle in the solid-state lithium battery can be effectively developed. The dual-layer structure ceramic piece comprising a solid-state electrolyte layer and a positive electrode layer and fabricated by the method is excellent in performance and has favorable application prospect in the field of solid-state lithium batteries.

Owner:杭州阳名新能源设备科技有限公司

Semiconductor device forming method

ActiveCN104124137AReduce process difficulty and production costLow costSemiconductor/solid-state device manufacturingEngineeringMask layer

A semiconductor device forming method includes providing a semiconductor substrate, forming a first mask layer on the semiconductor substrate, forming a first groove penetrating the first mask layer for a part of thickness, filling the first groove with a first hard mask layer, forming a second groove penetrating the first hard mask layer for the thickness of the first hard mask layer; utilizing the first hard mask layer as a mask to etch the first mask layer and the semiconductor substrate till a through hole or a groove is formed in the semiconductor substrate. By means of the semiconductor device forming method, only one etching process is required in formation of the through hole or the groove through a double graph technology, double graph forming process difficulty and manufacture cost are reduced, and the semiconductor device forming cost is further reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

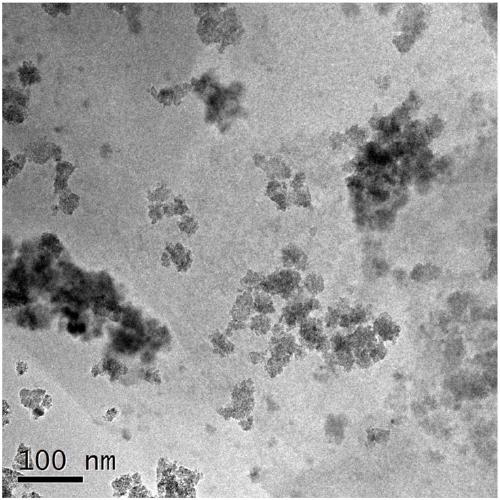

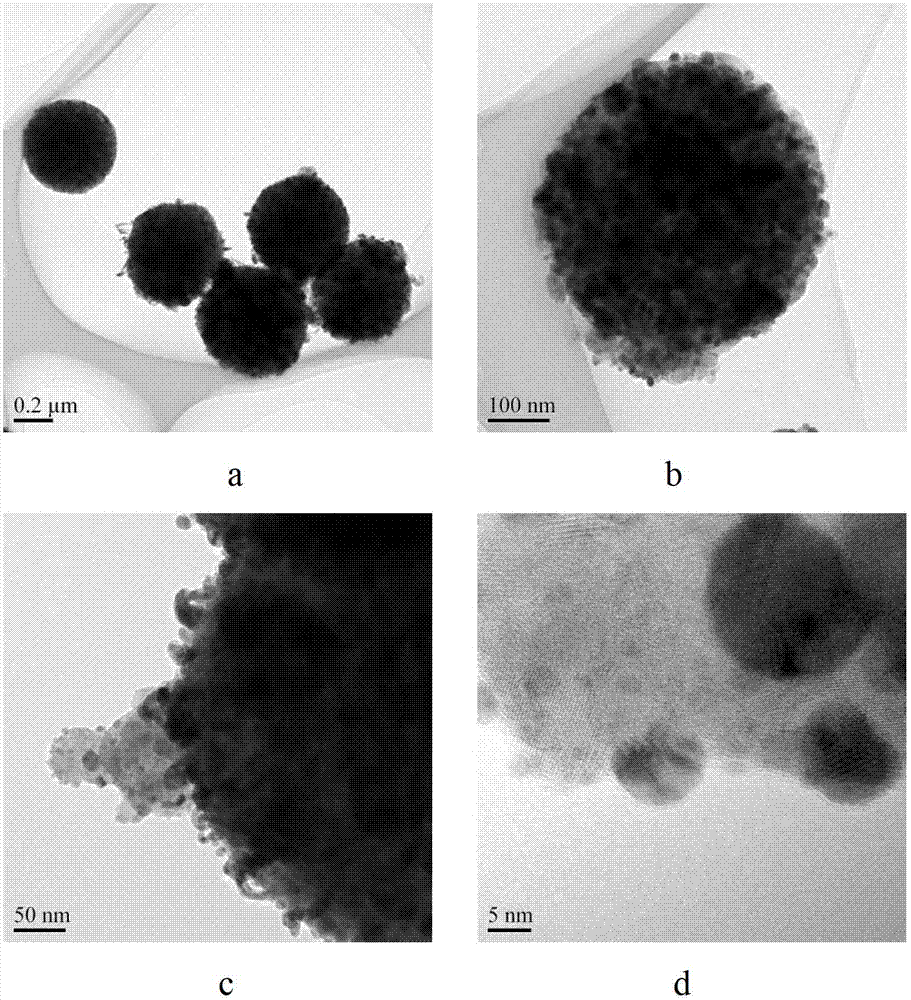

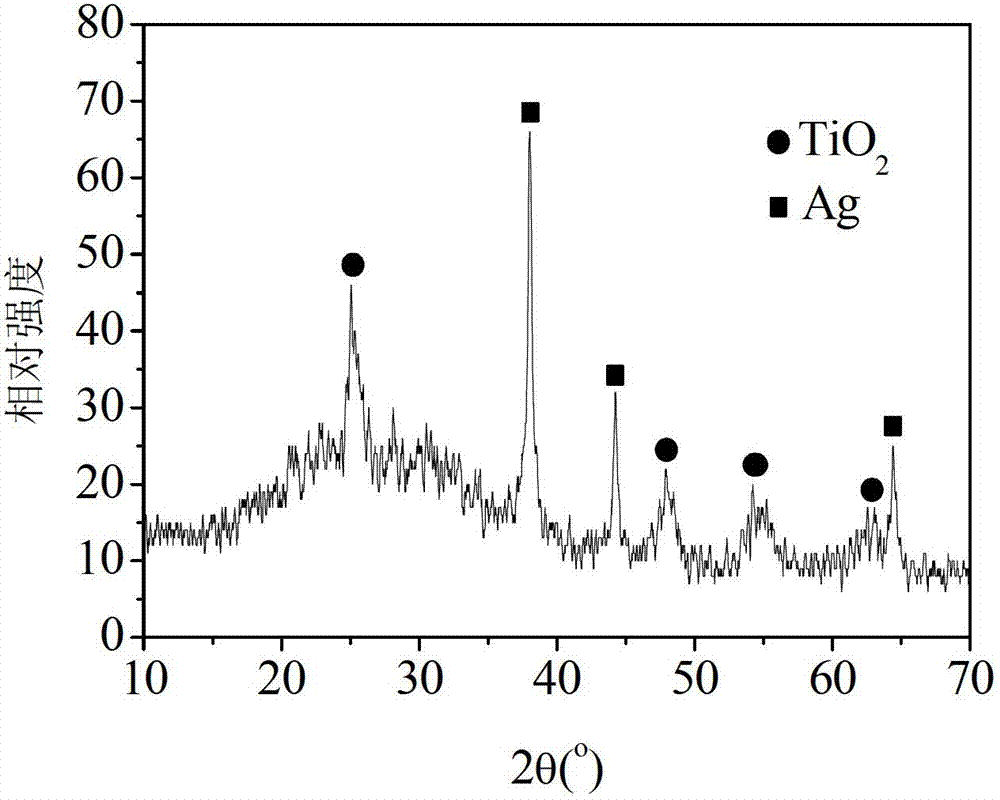

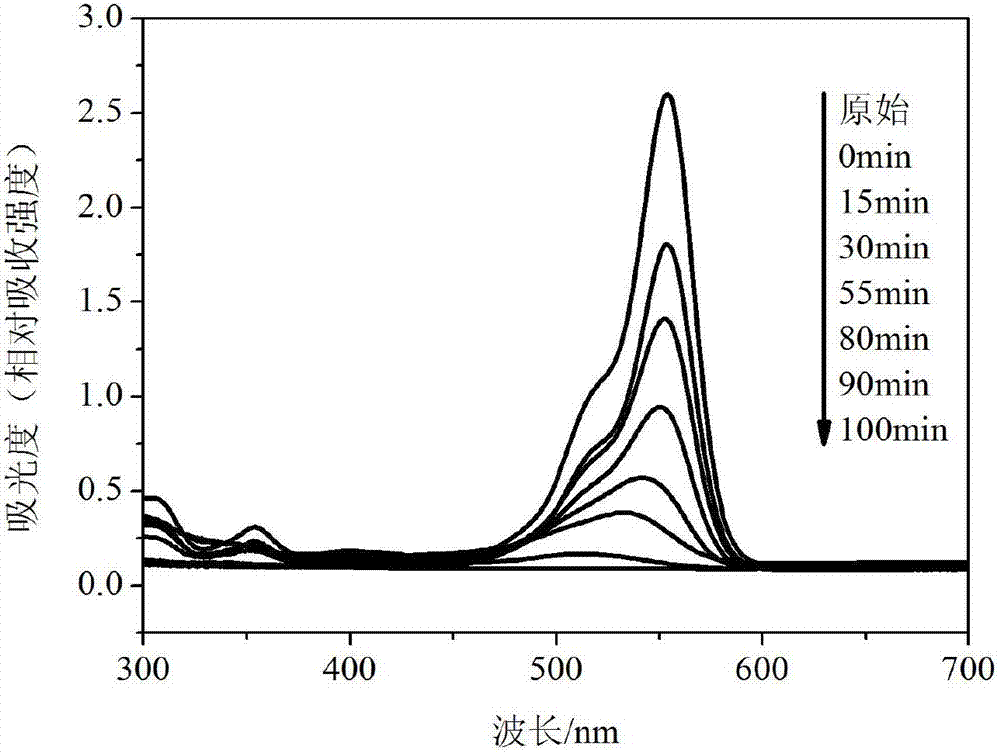

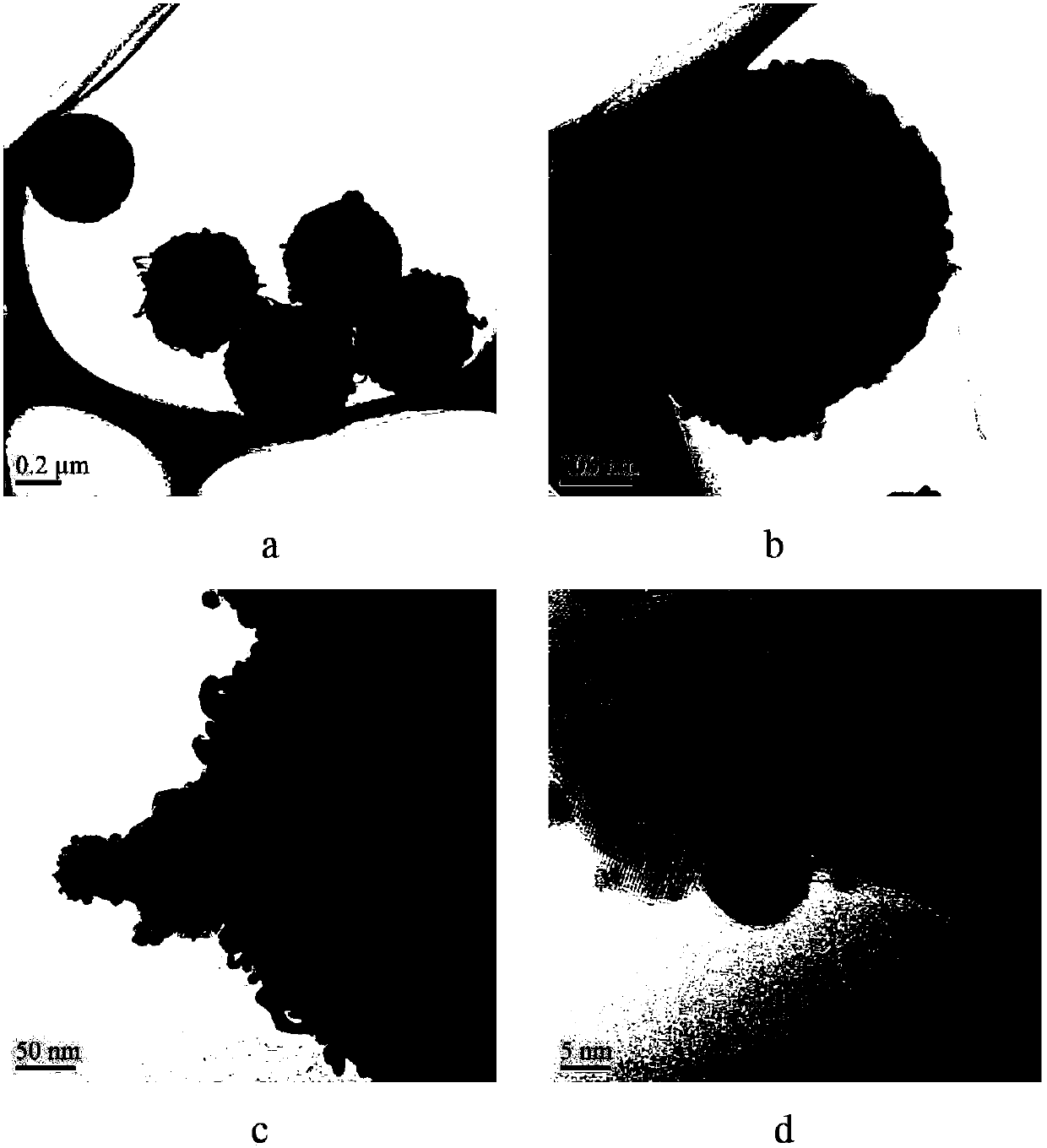

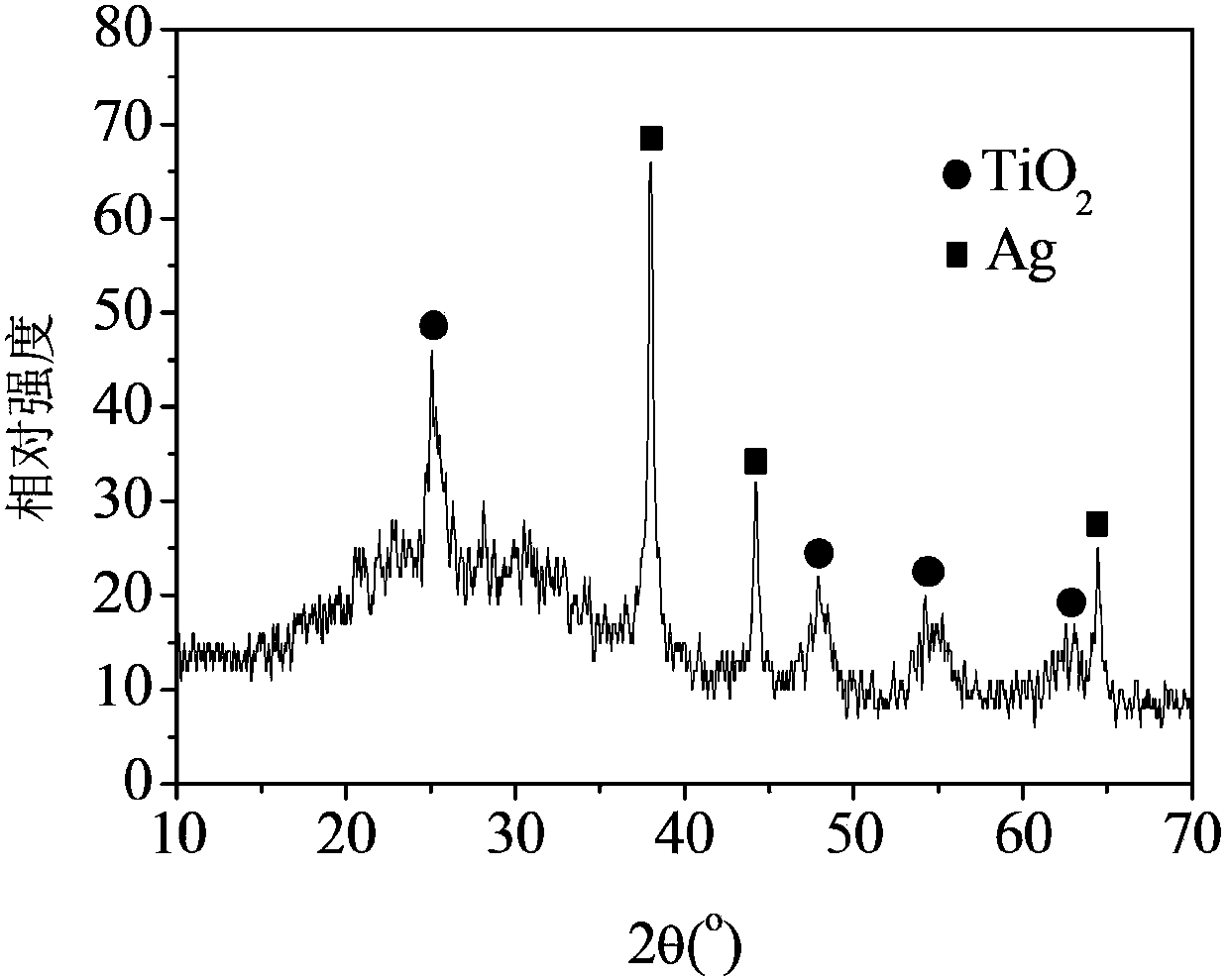

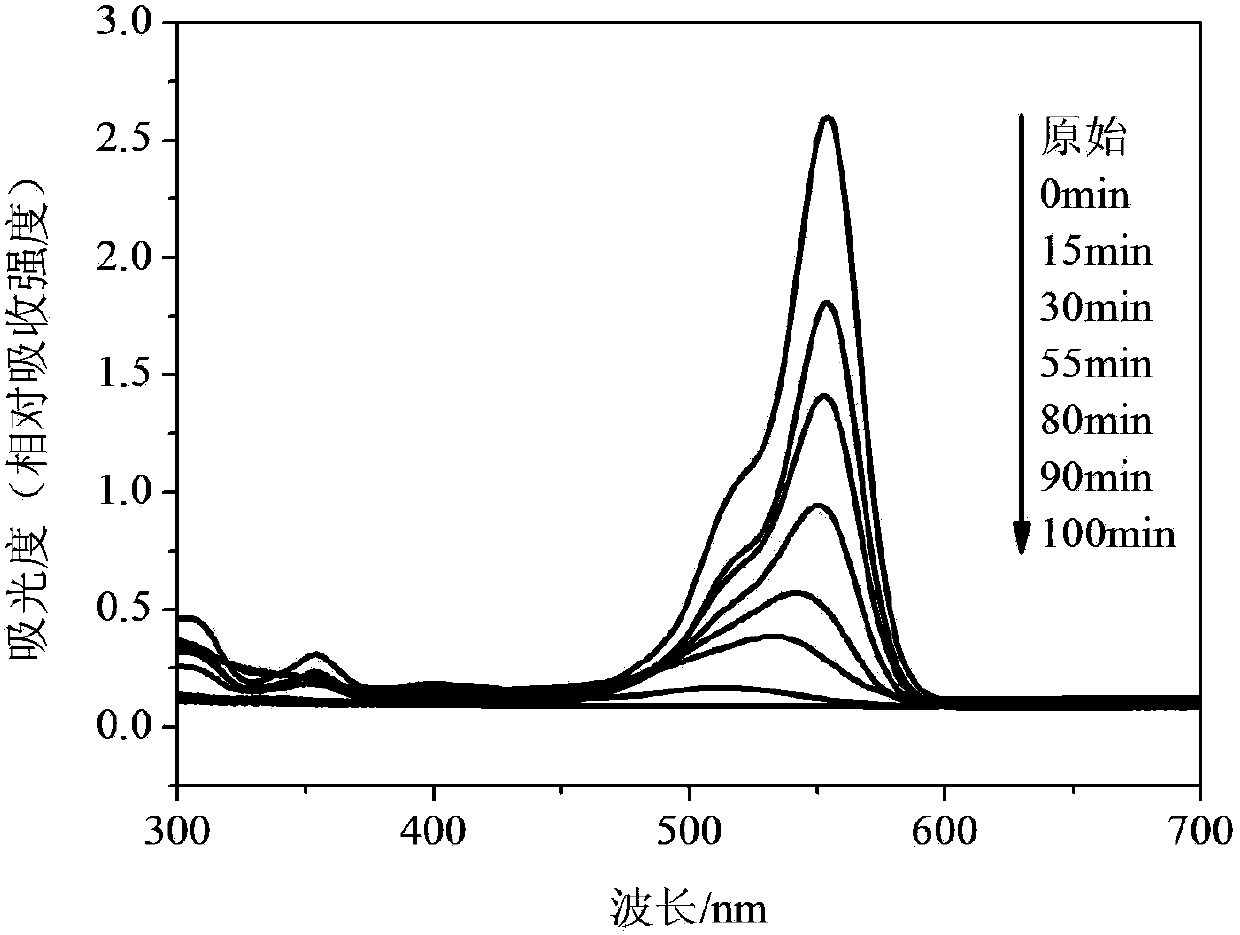

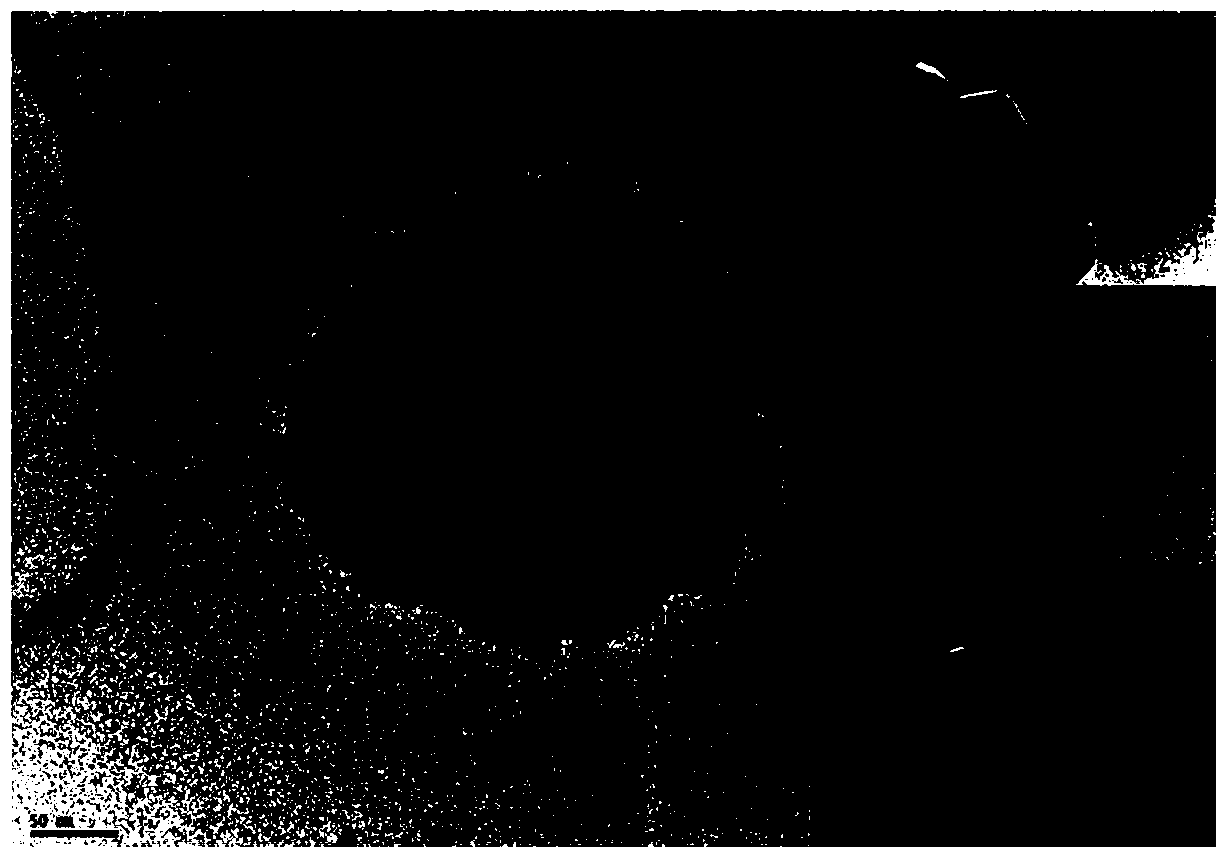

Metal-silver-supported titanium dioxide photocatalyst and preparation method thereof

InactiveCN102764649ALoad balancingImprove photocatalytic efficiencyMetal/metal-oxides/metal-hydroxide catalystsAmount of substanceOperational safety

The invention discloses a metal-silver-supported titanium dioxide photocatalyst and a preparation method thereof. The photocatalyst material is composed of metal-silver-supported titanium dioxide microspheres, wherein the diameter of the titanium dioxide microspheres is 300-500nm; the supported metal silver is dispersed in the titanium dioxide microspheres in a bulk phase homogenization manner; the diameter of the metal silver particles is 5-15nm; and the photocatalyst material has very high photocatalysis efficiency for simulated organic pollutant rhodamine B in water body under the irradiation of ultraviolet and visible light. The preparation method is simple in process, safe to operate and low in cost; and all the used reagents are cheap and accessible, and are free of substances poisonous / harmful to human body or environment.

Owner:SHAANXI UNIV OF SCI & TECH

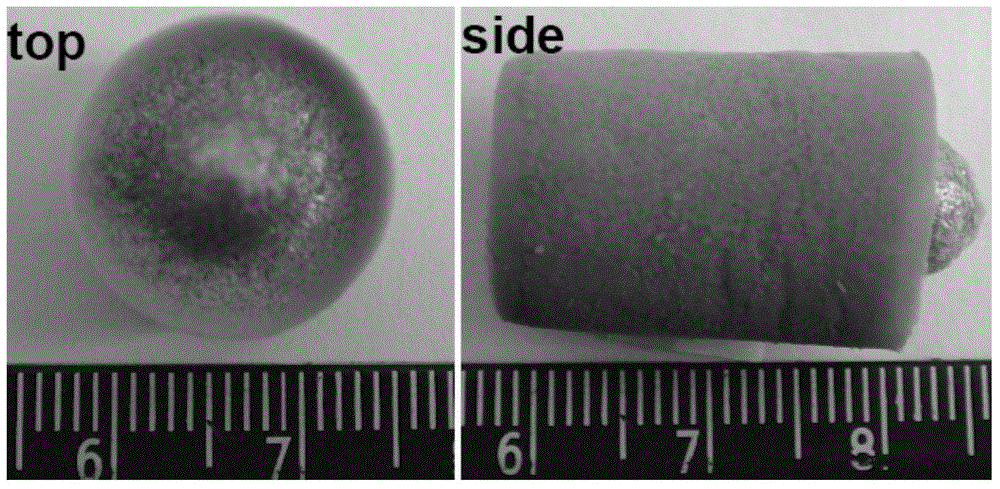

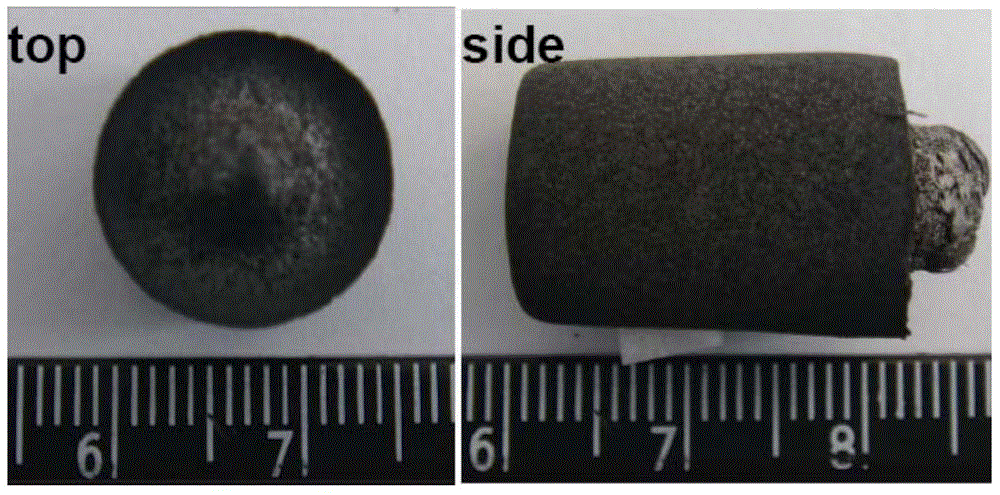

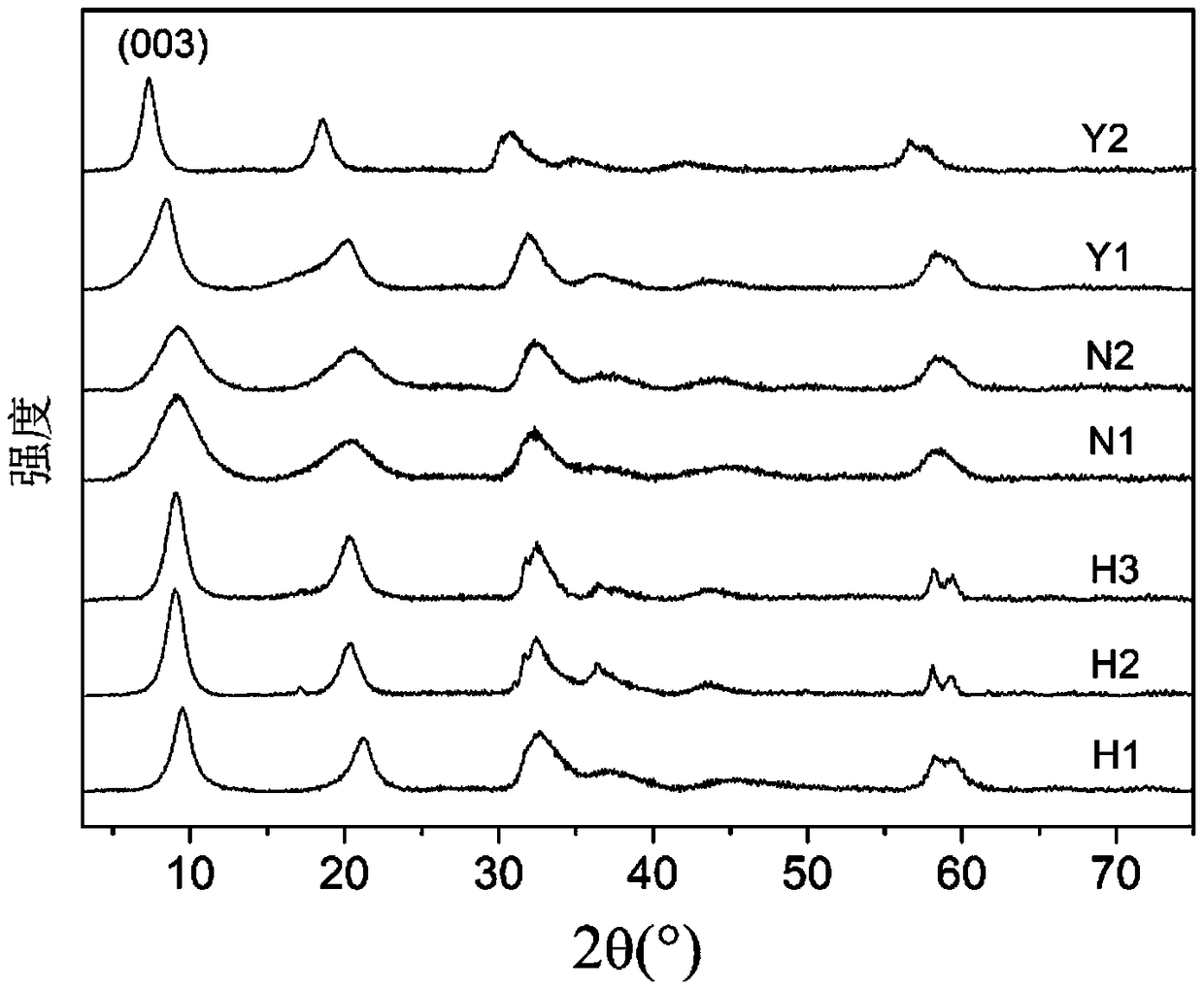

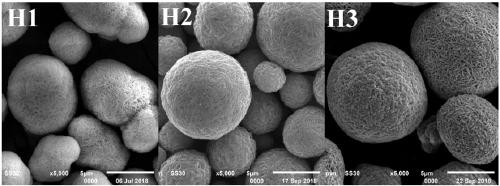

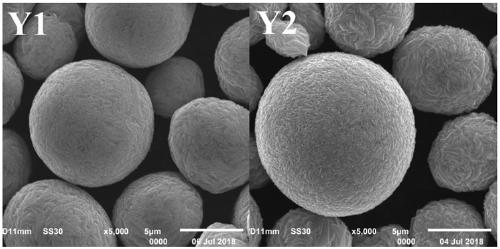

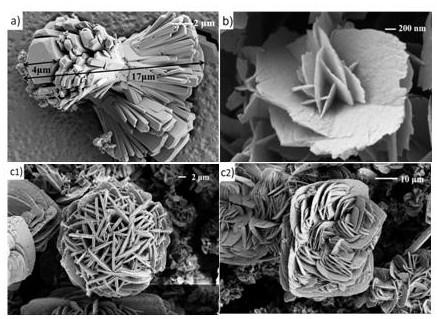

Spherical Co (II) Co (III) hydrotalcite like material and preparation method thereof

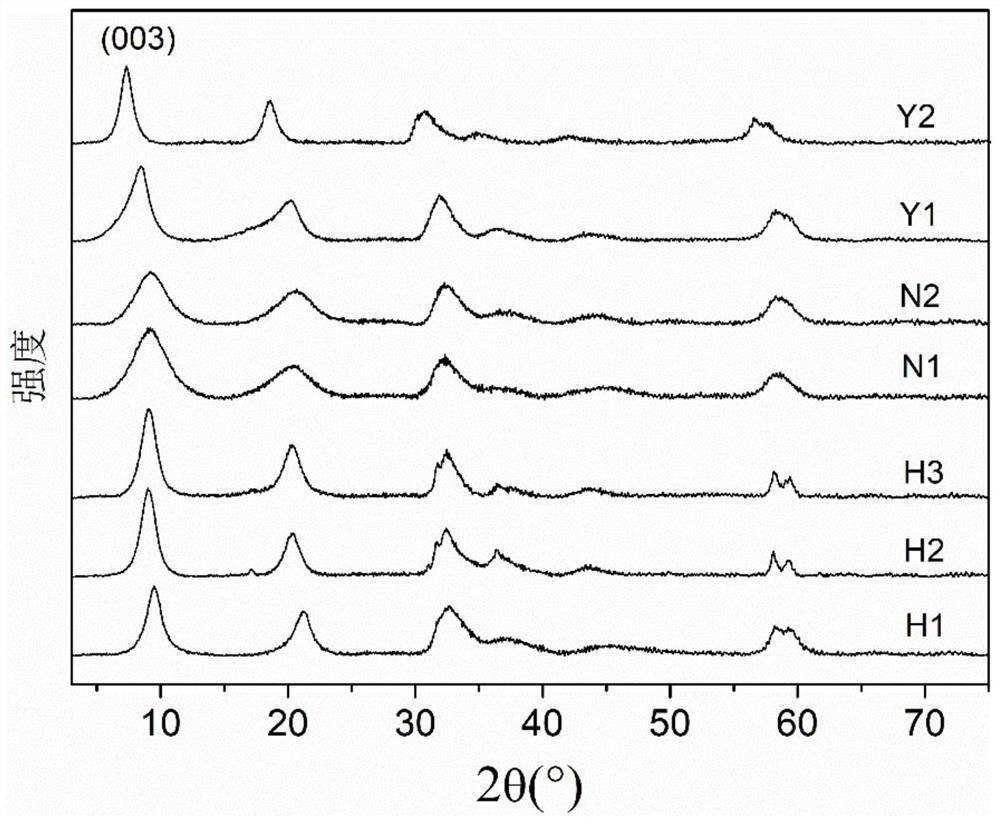

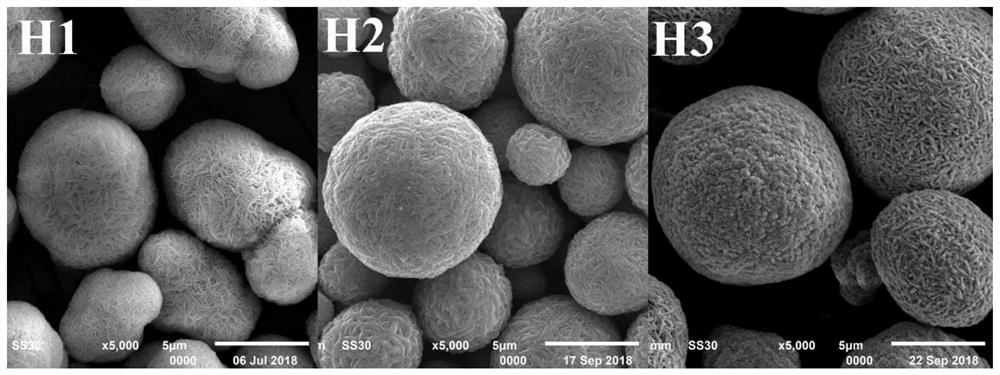

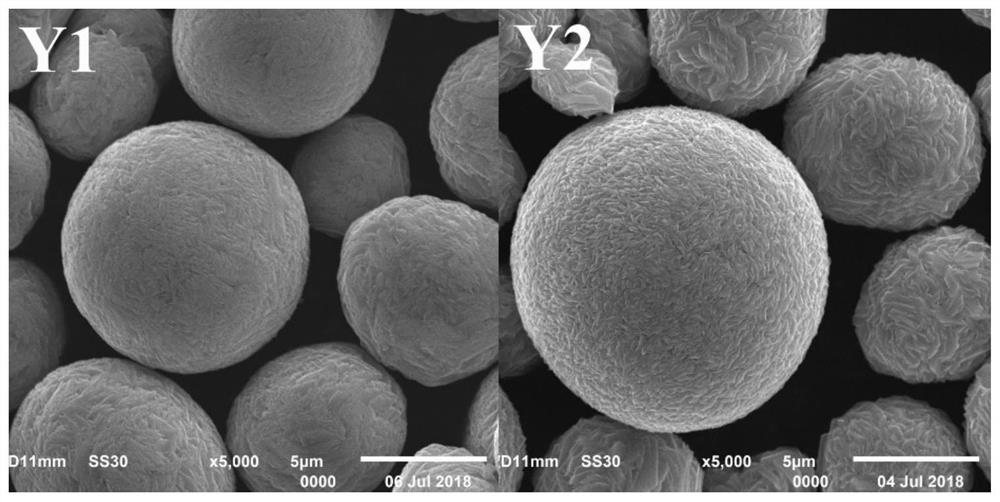

ActiveCN109502656AHigh crystallinityImprove orderCobalt oxides/hydroxidesNitrogen gasSodium hydroxide

The invention relates to a spherical Co (II) Co (III) hydrotalcite like material and a preparation method thereof, which are characterized in that the hydrotalcite like material is a layered dihydroxyl metal hydroxide formed by a divalent cobalt hydroxide and a trivalent cobalt hydroxide; interlayer object anions are organic acid radicals; particles have a spherical morphology. Mixed solution of cobalt salt and ammonium salt is used as a raw material A, mixed solution of organic acid sodium and an oxidizing agent is used as an additive B, and solution of the raw material A and the additive B is added into sodium hydroxide base solution by adopting a coprecipitation method; nitrogen gas is filled into a reaction kettle, violent stirring is carried out, and the temperature of the reaction kettle is controlled within a range of 35 DEG C to 65 DEG C; a sizing agent is centrifuged or filtered to obtain a filter cake, the filter cake is flushed with water until the filter cake is neutral, and vacuum drying is carried out to obtain the spherical Co (II) Co (III) hydrotalcite like material. According to the invention, effective control on a valence state of metal cobalt in a coprecipitation system is implemented, the hydrotalcite like material prepared hereby is single in crystal form and high in regularity, and the product is excellent in sphericity degree and relatively compact in sphere surface.

Owner:兰州金通储能动力新材料有限公司

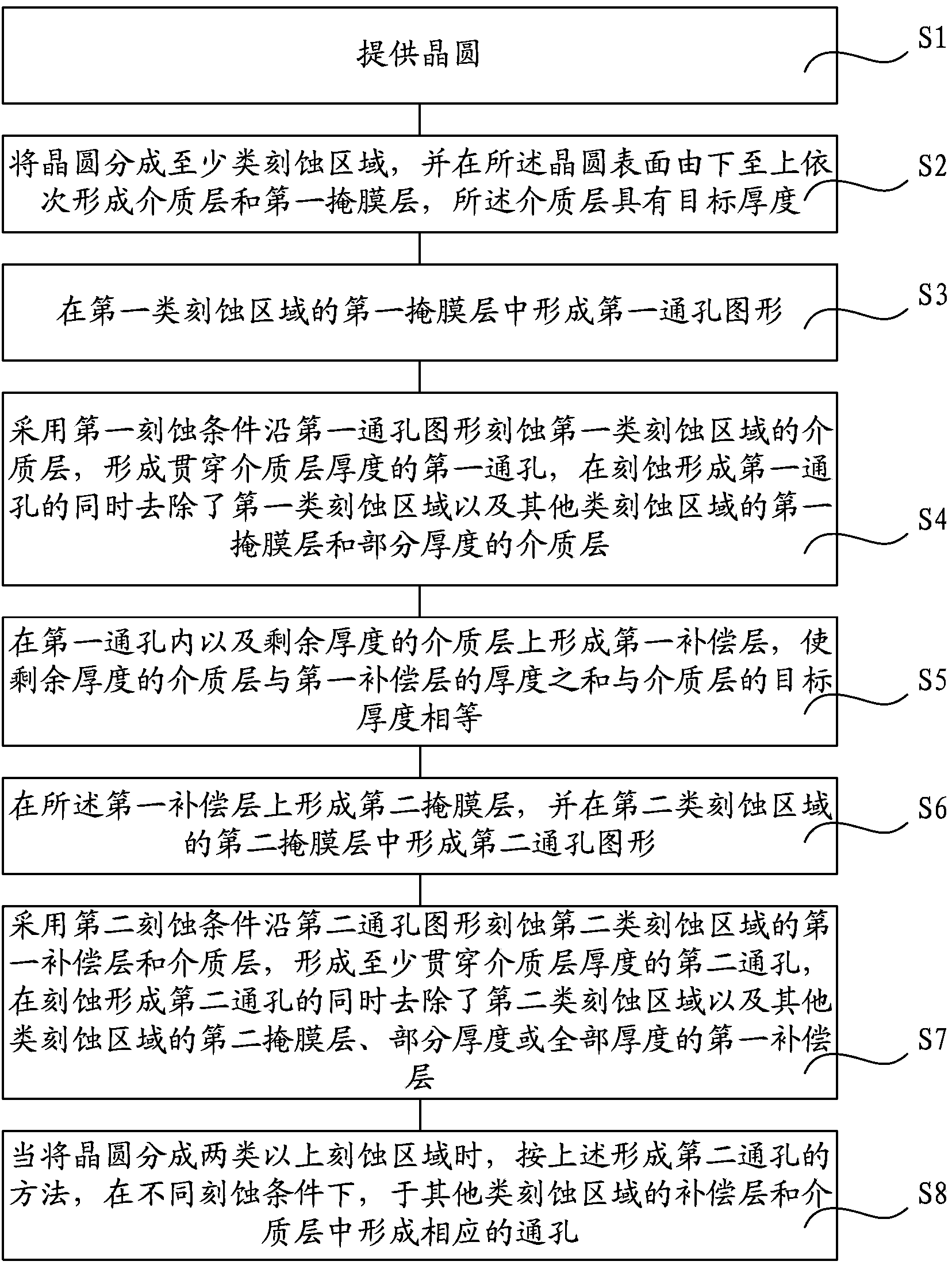

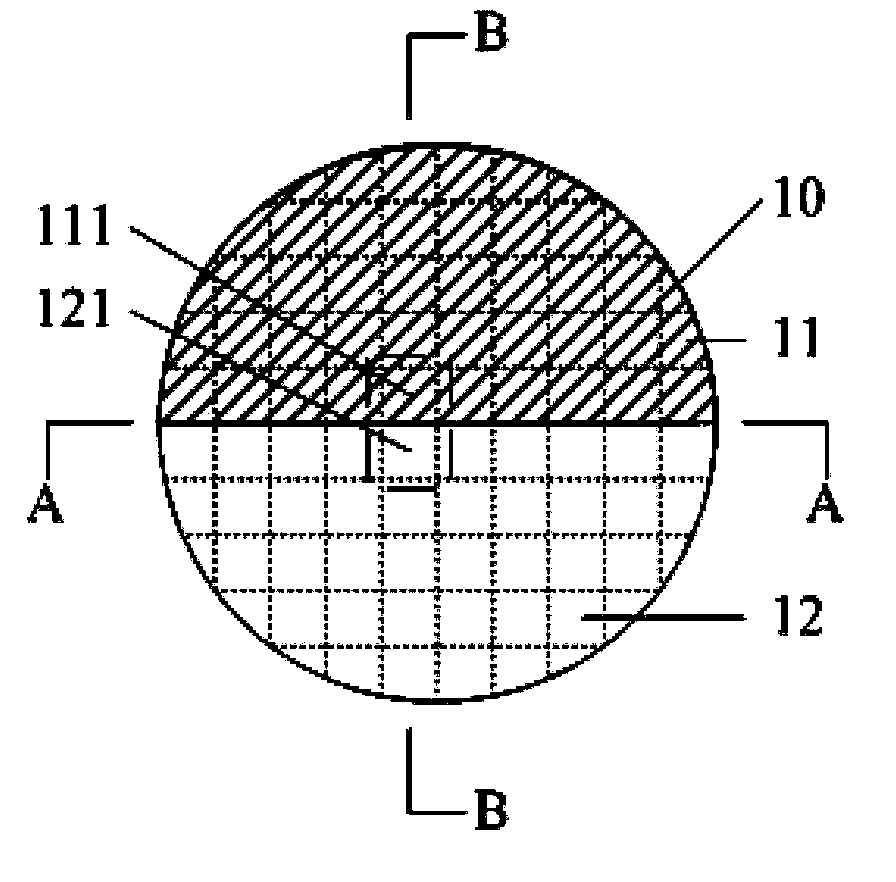

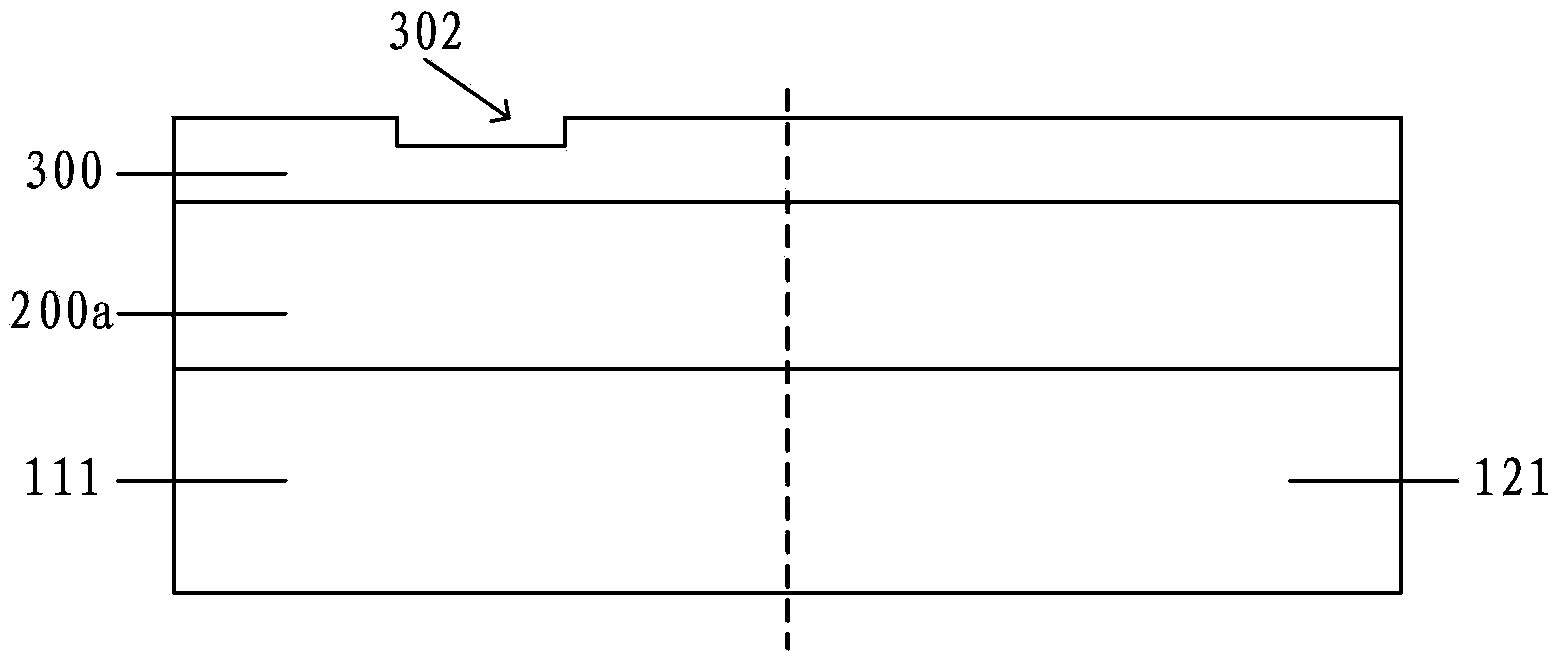

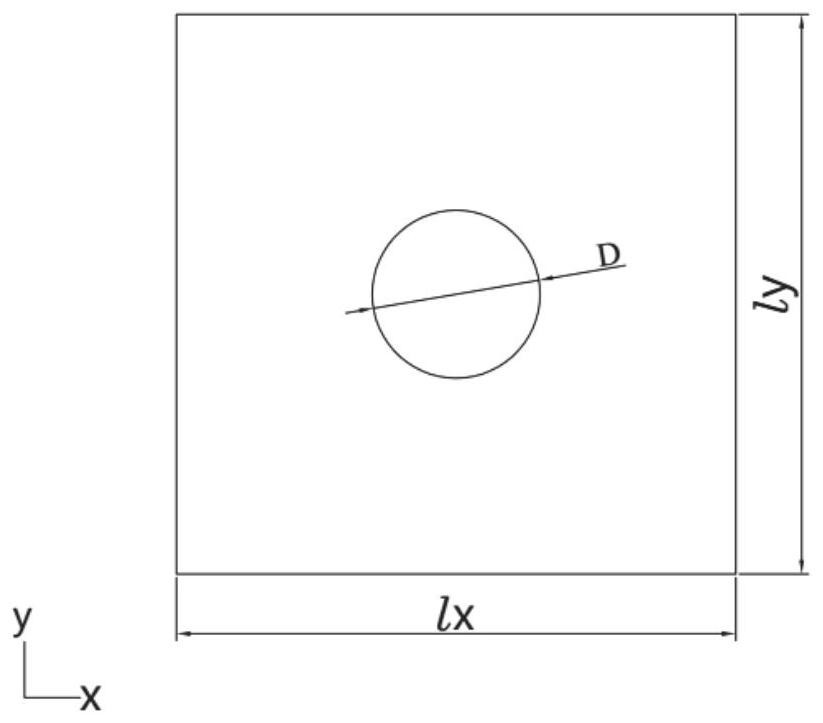

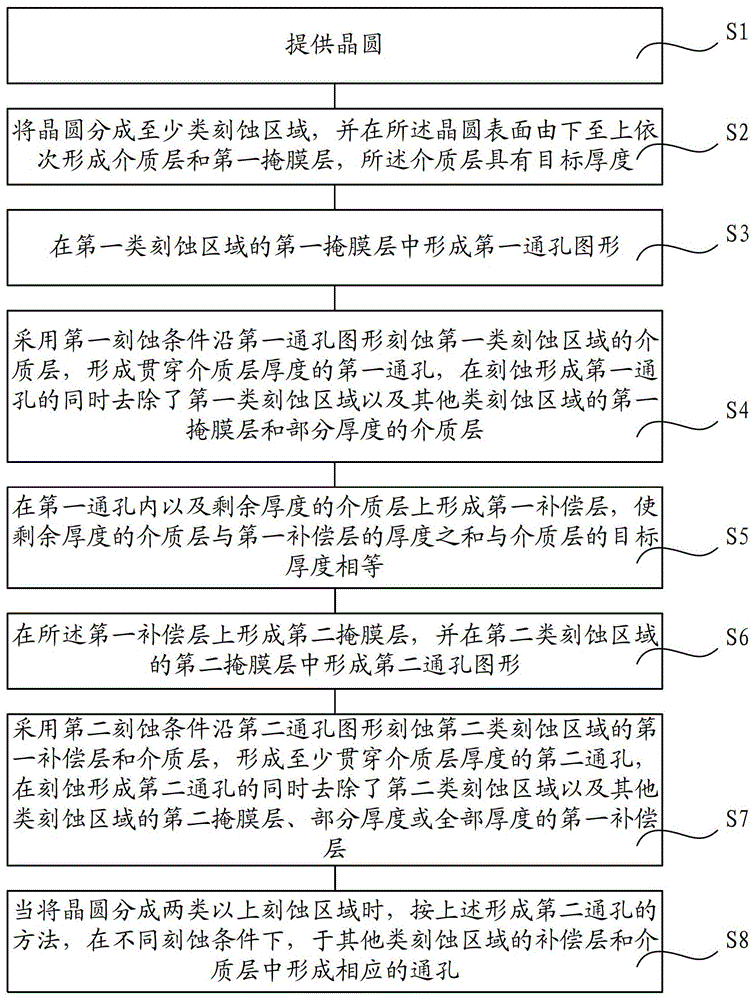

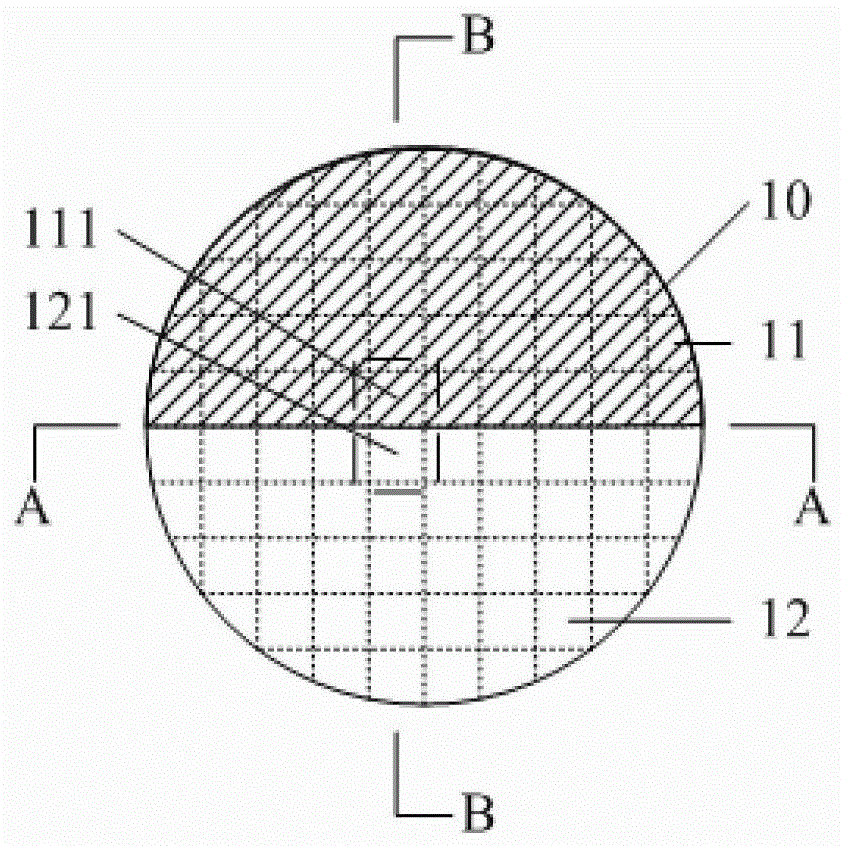

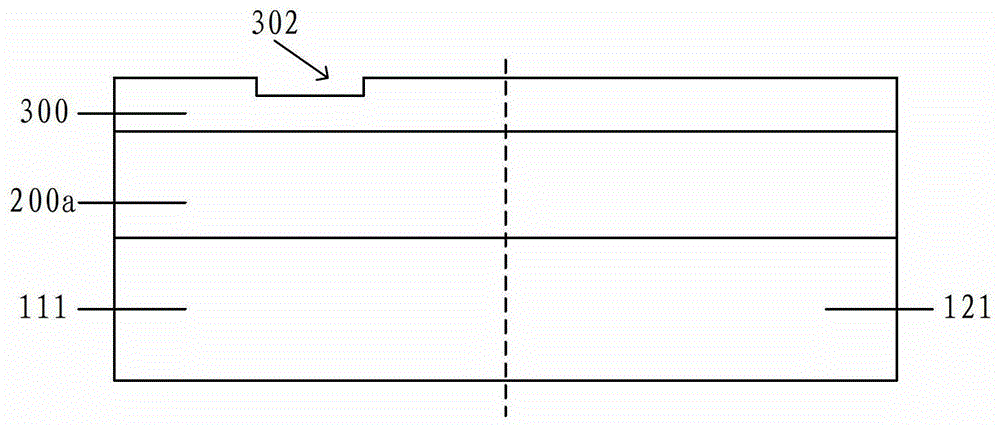

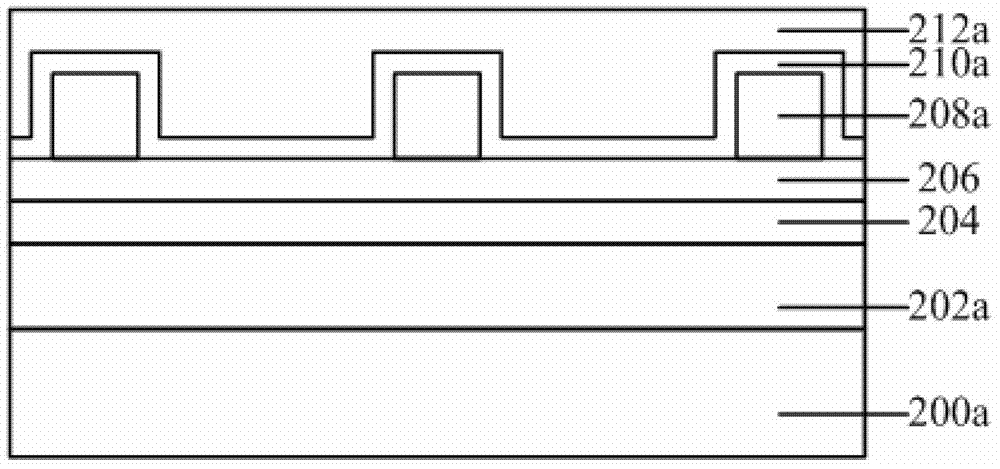

Method for collecting etching conditions

ActiveCN103855075AIncrease profitAvoid wastingSemiconductor/solid-state device testing/measurementSolid-state devicesDielectric layerMaterials science

A method for collecting etching conditions includes the steps that wafers are divided into at least two kinds of etching areas, dielectric layers with the target thickness are formed on the wafers, after through holes are formed in the dielectric layers of the etching areas of the first kind, compensation layers are formed in the through holes and on the rest of the dielectric layers, accordingly the sum of the thickness of the compensation layers and the thickness of the rest of the dielectric layers is equal to the target thickness of the dielectric layers before the first through holes are formed, furthermore, on the premise that shapes and appearances of the through holes are not influenced, the same wafer can be etched for many times, the utilization rate of the wafers is improved, the wafers are saved, and collection cost of the etching conditions is reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

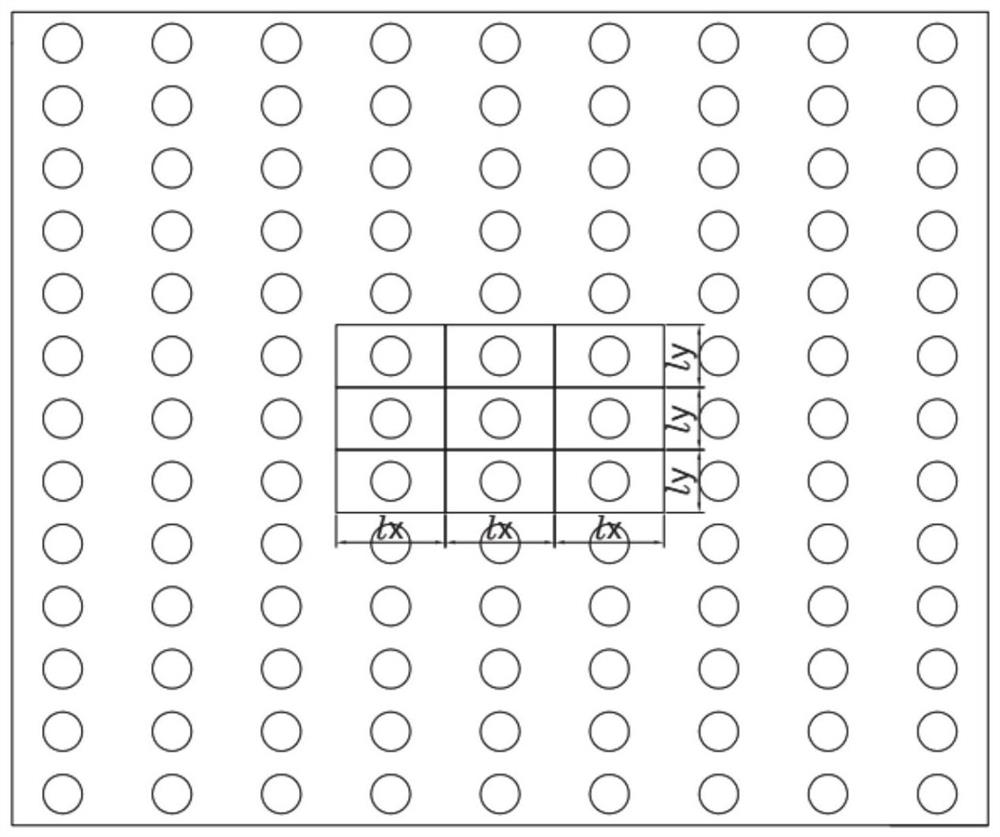

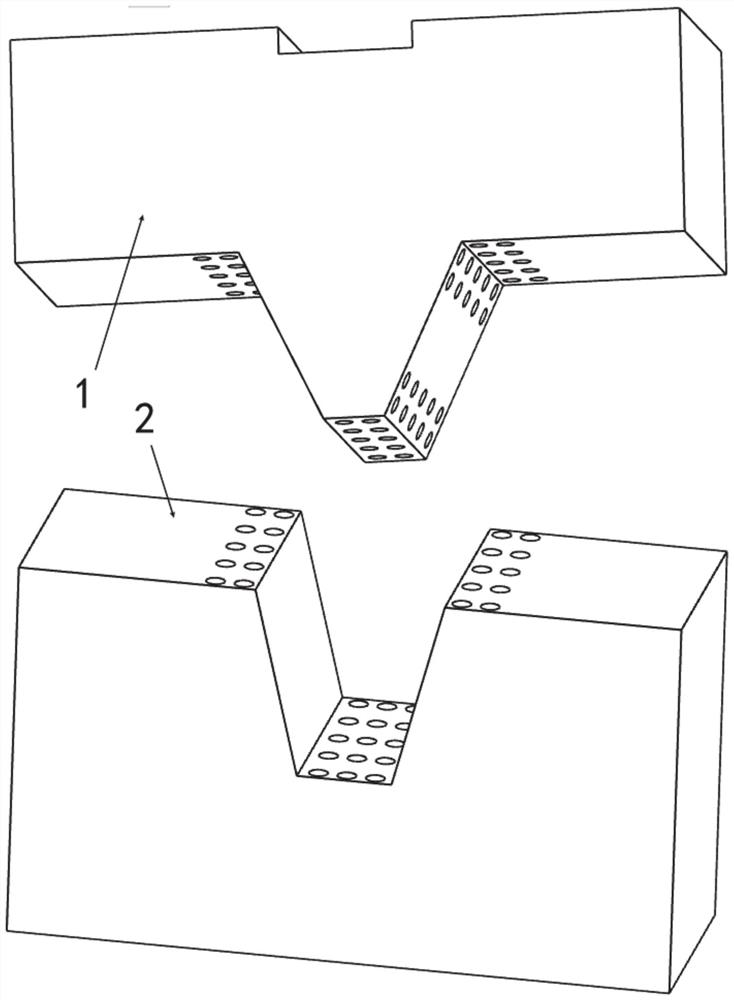

Bending die with self-lubricating pits and preparation method

PendingCN113458256AExtended service lifeEasy to useShaping toolsLaser beam welding apparatusMetallurgyLubrication

The invention provides a bending die with self-lubricating pits and a preparation method, and relates to the field of bending dies. The bending die comprises a male die and a female die which are matched with each other, wherein a plurality of pit textures arranged in a specific mode are arranged on the working faces of the male die and the female die, and the pit textures are used for containing a solid lubricant to form self-lubrication; the pit textures are distributed on the bending part and / or the cambered surface part of the working surface and avoid the ridge lines of the working surfaces; a micro-pit texture is machined on the surface of the bending die and can store a lubricating agent and abrasive dust generated in the working process, and the lubricating agent can continuously feed oil in the working process of the bending die, so that the effect of reducing friction is achieved; in addition, the abrasive dust is stored in the micro-pit texture, and three-body abrasion caused by the fact that the abrasive dust stays on the working face is avoided, and the anti-friction and anti-wear performance of the bending die is comprehensively improved.

Owner:SHANDONG UNIV

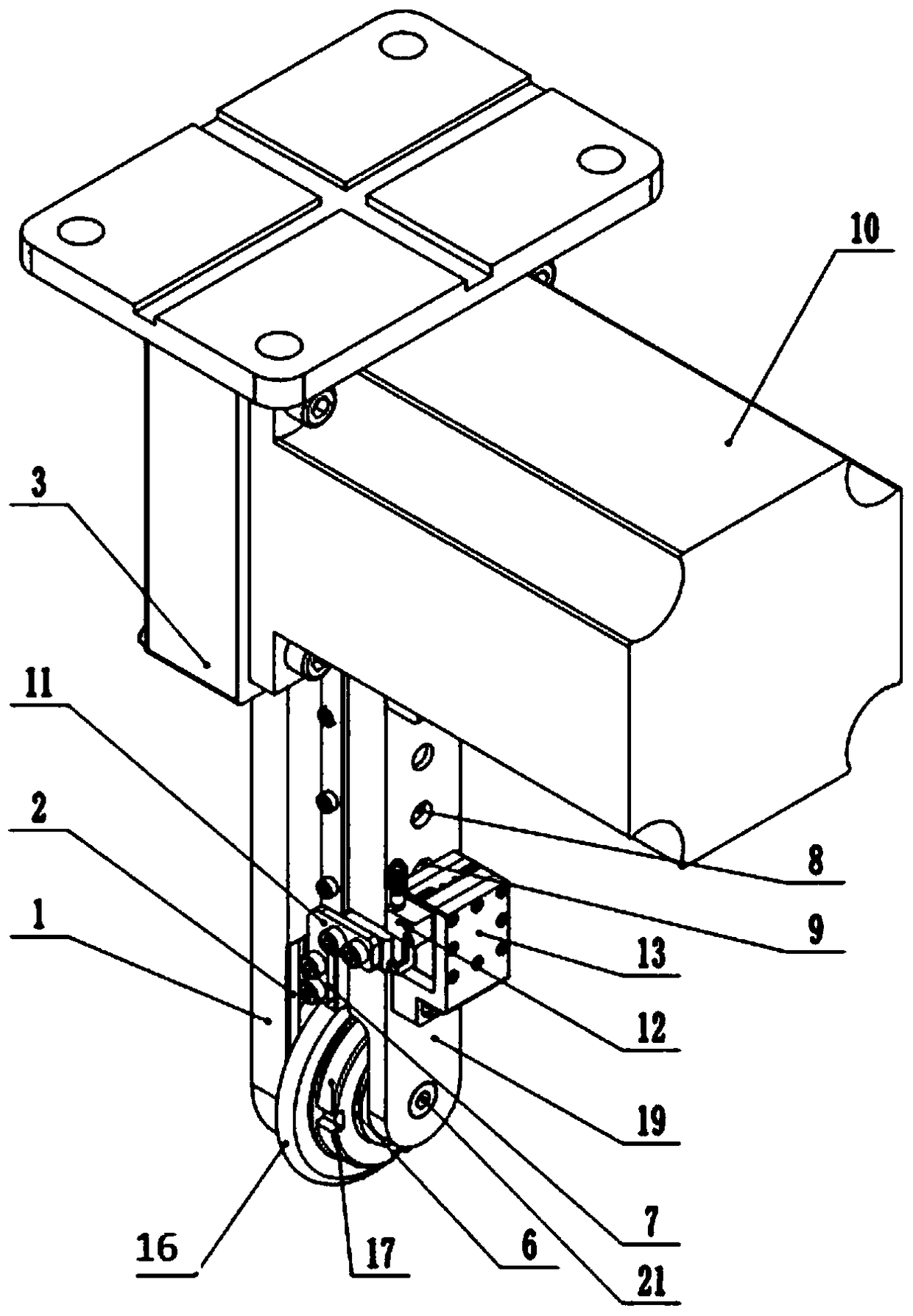

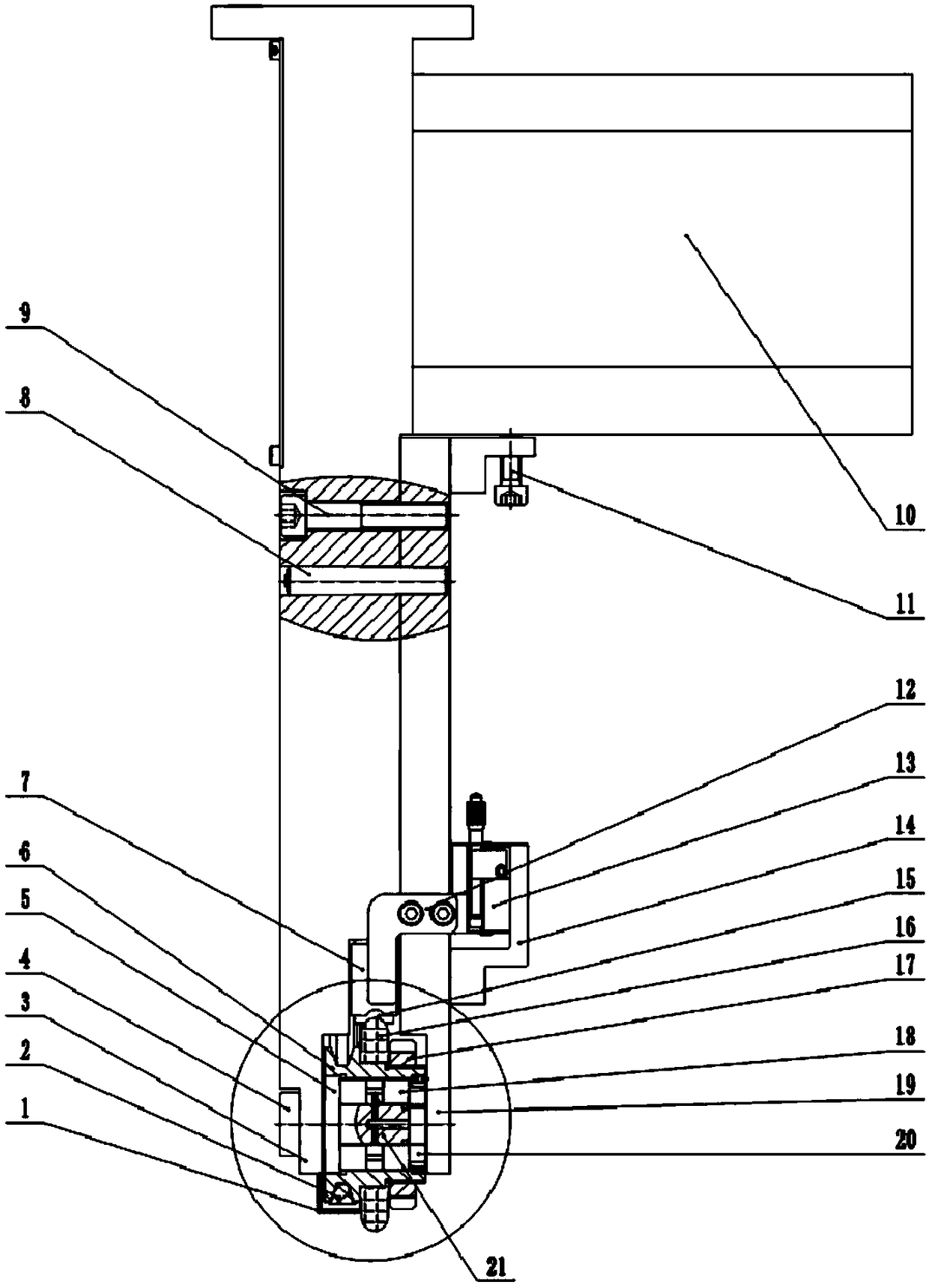

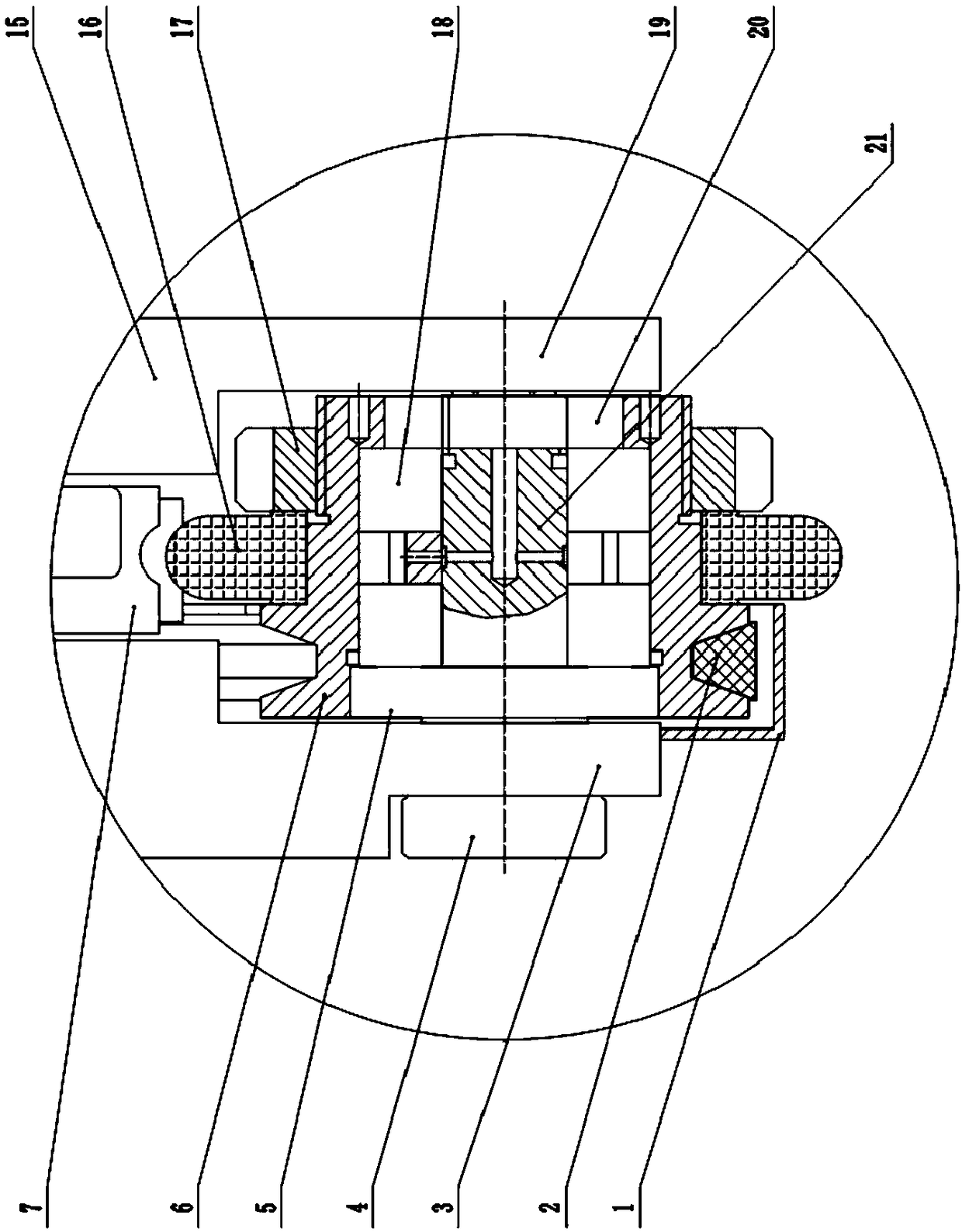

Grinding head with online electrolytic dressing function

ActiveCN109202706ASolve severe blockage problemsMaintain grinding abilityAbrasive surface conditioning devicesGrinding/polishing safety devicesBrushless motorsElectrolysis

The invention discloses a grinding head with an online electrolytic dressing function. The grinding head comprises a motion system, an electrolysis system and a supporting mechanism; the motion systemcomprises a DC brushless motor, a transmission V belt wheel set and a grinding wheel shaft system assembly; the electrolysis system comprises a copper shoe, a copper shoe frame, a fine adjustment mechanism and a fixing frame; and the supporting mechanism comprises a rack support plate, a pressure plate, a connecting screw and a positioning taper pin. According to the grinding head, through the electrolytic action, metal abrasive dust clogging in a grinding wheel is removed, the problem of serious blockage of the grinding wheel when pure metal with large machining plasticity is machined through electrolytic grinding is solved, the grinding condition is improved, the grinding ability of the grinding wheel is kept, the shape and appearance of the grinding wheel cannot be influenced because agrinding wheel material is not removed, and it is further guaranteed that processed products have high processing precision. According to the grinding head, the electrode fine adjustment mechanism isdesigned, a differential ball slide table is adopted for adjusting a gap between the grinding wheel and a copper shoe electrode with high precision, and the best an optimal electrolysis effect is obtained.

Owner:DALIAN UNIV OF TECH

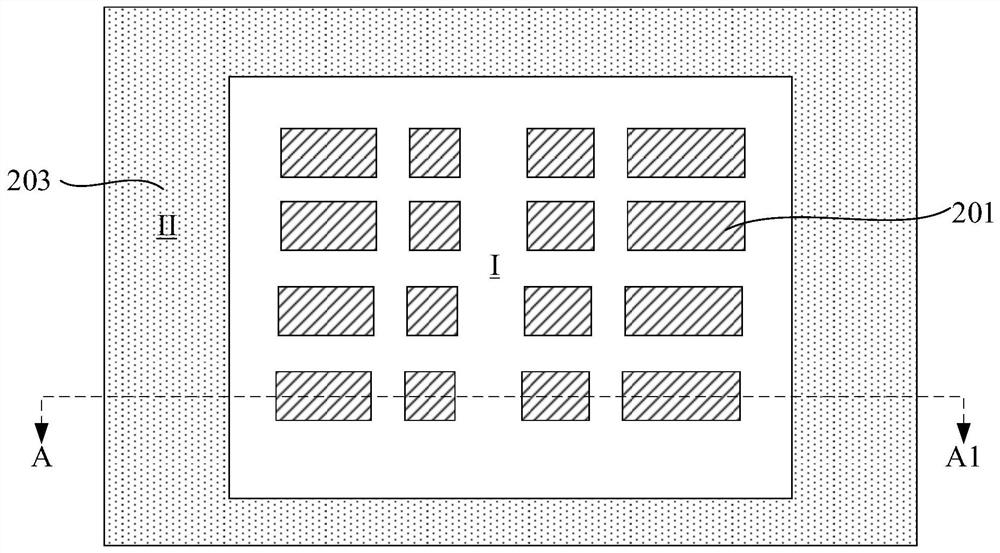

Mask plate and manufacturing method thereof

PendingCN111983888AImprove structural performanceExtended service lifeOriginals for photomechanical treatmentEngineeringMechanical engineering

The embodiment of the invention relates to a mask plate and a manufacturing method thereof. The mask plate comprises: a substrate; a pattern layer which is located on the substrate, wherein the pattern layer comprises a pattern area and a peripheral area surrounding the pattern area; a light-transmitting cover plate which is arranged on the peripheral area, wherein a mask cavity is defined by thelight-transmitting cover plate, the substrate and the peripheral area, and the pattern area is located in the mask cavity. The quality of the mask plate can be remarkably improved, and the service life of the mask plate is prolonged.

Owner:CHANGXIN MEMORY TECH INC

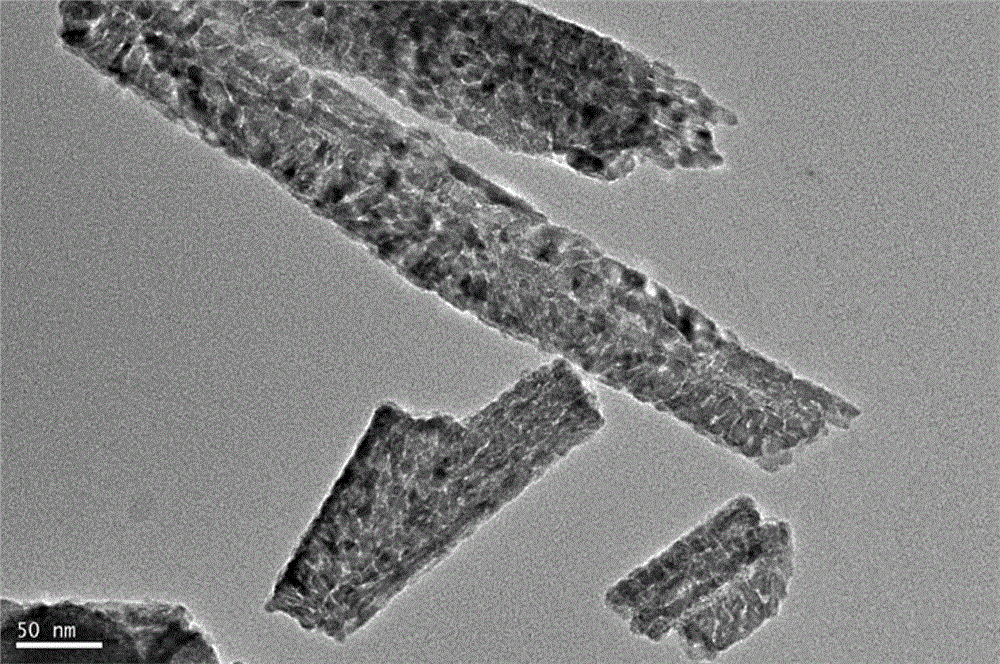

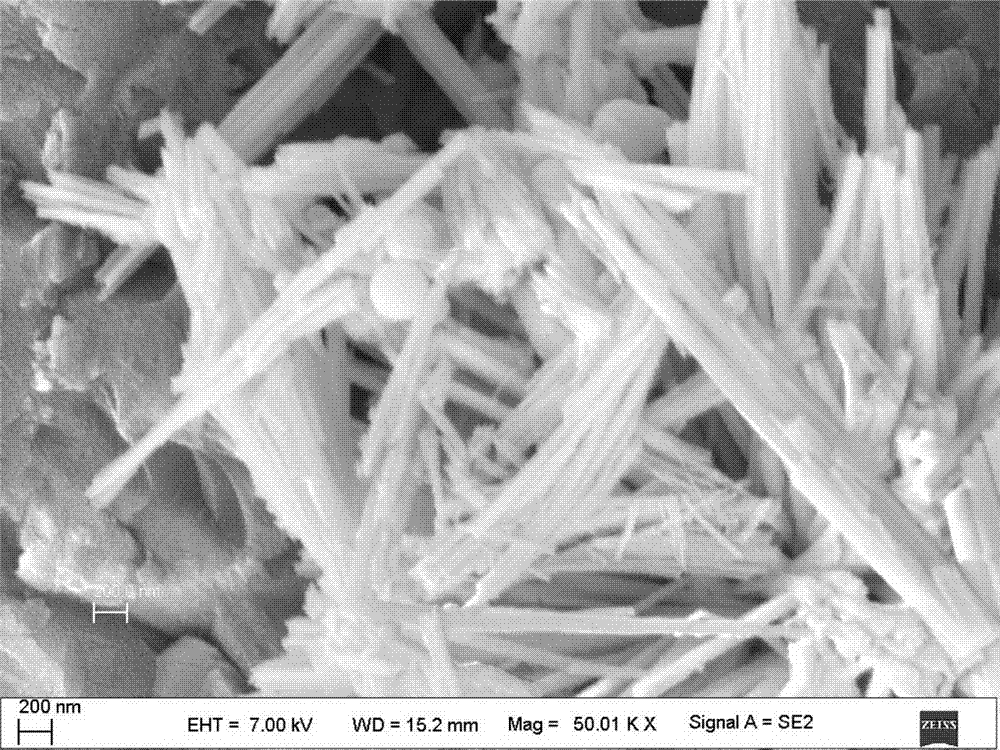

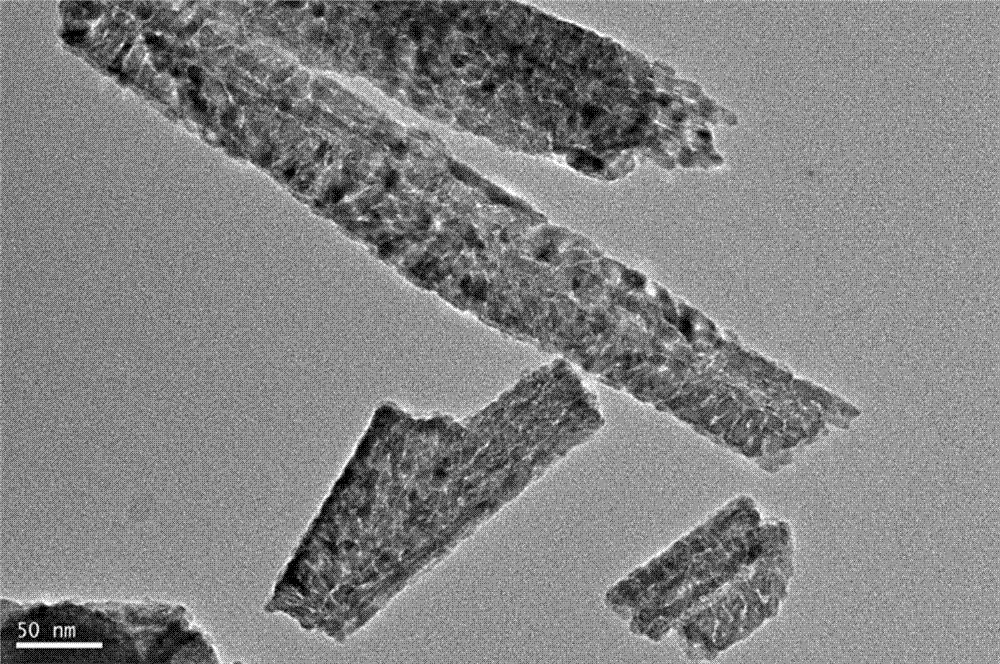

Method for doping Co3O4 nanowire with Sn

InactiveCN104016422AEasy to operateImprove conductivityMaterial nanotechnologyCobalt oxides/hydroxidesChemistryOleic Acid Triglyceride

The invention discloses a method for doping a Co3O4 nanowire with Sn. The method comprises the following steps: adding the Co3O4 nanowire, oleylamine and oleic acid into an organic solvent, heating to 80-100 DEG C, then, adding SnCl2, and reacting for 1-3 hours to obtain a Sn-doped Co3O4 nanowire. The method disclosed by the invention is used for successfully doping the Sn element into Co3O4, is simple to operate, almost free of influence on Co3O4 morphology, and capable of remarkably improving conductivity of Co3O4 after doping Sn.

Owner:NORTHWEST NORMAL UNIVERSITY

Metal-silver-supported titanium dioxide photocatalyst and preparation method thereof

InactiveCN102764649BAvoid uneven loadParticle size controllableMetal/metal-oxides/metal-hydroxide catalystsMicrosphereOperational safety

The invention discloses a metal-silver-supported titanium dioxide photocatalyst and a preparation method thereof. The photocatalyst material is composed of metal-silver-supported titanium dioxide microspheres, wherein the diameter of the titanium dioxide microspheres is 300-500nm; the supported metal silver is dispersed in the titanium dioxide microspheres in a bulk phase homogenization manner; the diameter of the metal silver particles is 5-15nm; and the photocatalyst material has very high photocatalysis efficiency for simulated organic pollutant rhodamine B in water body under the irradiation of ultraviolet and visible light. The preparation method is simple in process, safe to operate and low in cost; and all the used reagents are cheap and accessible, and are free of substances poisonous / harmful to human body or environment.

Owner:SHAANXI UNIV OF SCI & TECH

A method for reducing sulfur content of ternary precursor

ActiveCN110817975BReduce adsorptionReduce sulfur contentCell electrodesSecondary cellsSulfate radicalsPhysical chemistry

The invention discloses a method for reducing the sulphur content of a ternary precursor. Sulfate is used as a ternary salt raw material, and the ternary salt raw material, an alkaline solution and acomplexing agent are added to a reaction kettle for co-precipitation to prepare the ternary precursor, after co- precipitation reaction is carried out for 5-15 hours, pure water is added continuouslyor intermittently to the reaction kettle to replace clear liquid in the reaction kettle, and meanwhile, the alkaline solution and the complexing agent are added to keep a reaction system stable. The problem that the sulphur content in the ternary precursor exceeds the standard due to the fact that the sulfate is adsorbed on the surface of a crystal during the growth of the crystal and then wrappedinside the crystal is solved, the sulphur content of the prepared ternary precursor after one-time washing is less than 530 ppm, and during the subsequent water washing process, water resources are effectively saved; and the impurity content is reduced, the jolt ramming density of the ternary precursor is increased, and the morphology of the ternary precursor is not affected.

Owner:宜宾光原锂电材料有限公司

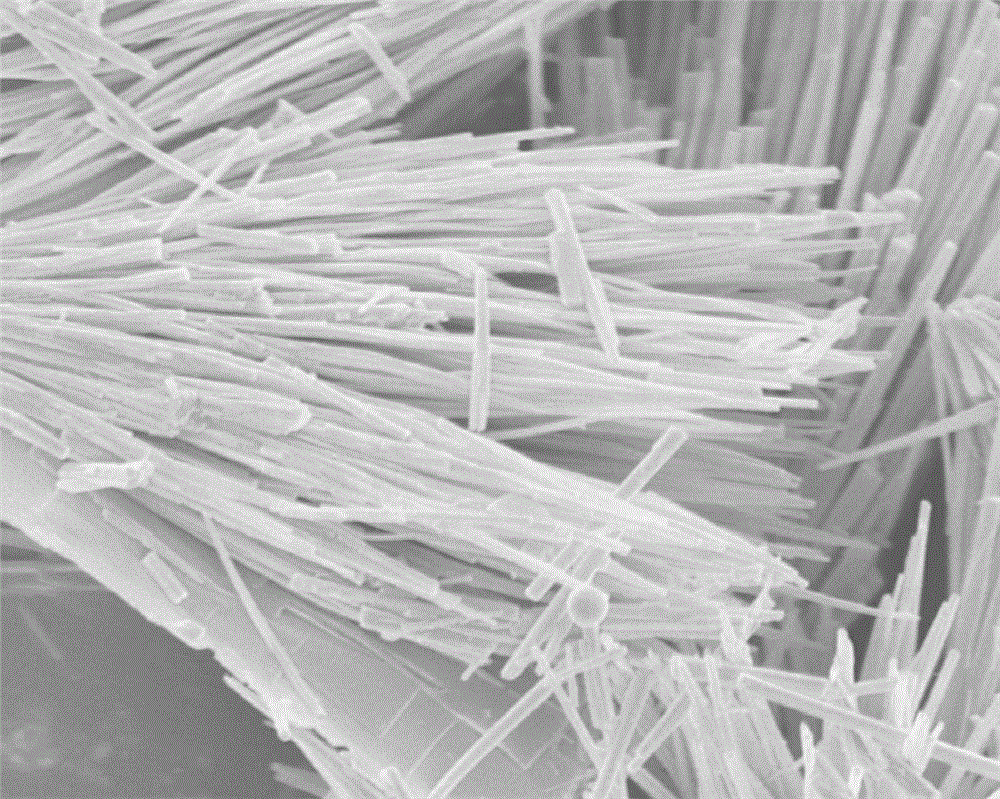

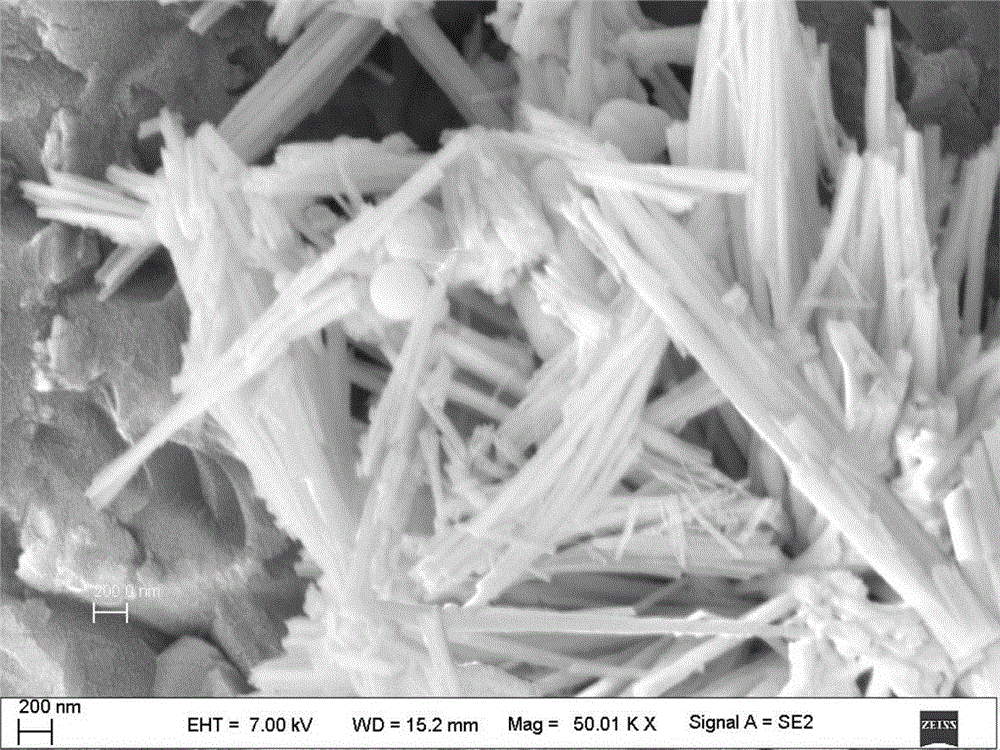

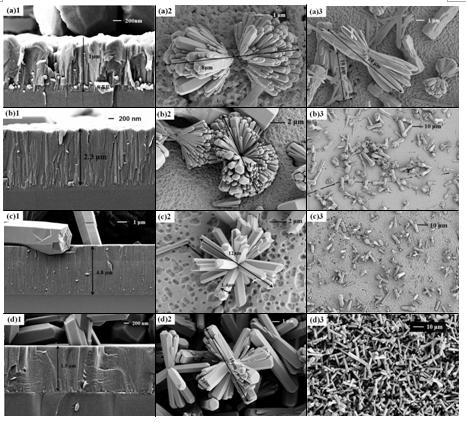

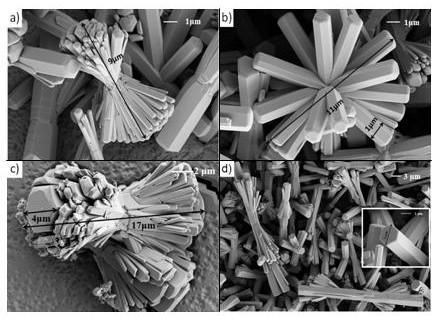

Preparation method of novel zinc oxide material

InactiveCN111252805AIncrease the lengthMorphological influencePolycrystalline material growthFrom normal temperature solutionsMeth-Hexamethylenetetramine

The invention discloses a preparation method of a novel zinc oxide material, which comprises the following steps: taking a sapphire substrate as a growth substrate, and cleaning the growth substrate;selecting ZnO as a target material, introducing oxygen flow by adopting a pulse laser deposition technology, controlling growth for a period of time at a specific temperature, and naturally cooling toroom temperature after the growth is finished, so as to obtain a ZnO seed crystal layer; weighing a certain amount of zinc acetate (Zn(CH3COO)2.2H2O) and hexamethylenetetramine (HMTA) according to aconcentration ratio of 1: 1, and fully dissolving the zinc acetate (Zn(CH3COO)2.2H2O) and hexamethylenetetramine (HMTA) to prepare a reaction solution; putting the ZnO seed crystal layer substrate into a polytetrafluoroethylene reaction kettle, pouring the prepared reaction liquid, sealing the reaction kettle, putting the reaction kettle into a constant-temperature drying box, and setting certainreaction time and reaction temperature to enable the ZnO seed crystal layer substrate to grow in the aqueous solution; and observing the shape of the ZnO nano material by controlling different precursor concentrations, reaction time and temperatures. The precursor concentration, the reaction time and the temperature in the method can obviously influence the growth process of the zinc oxide nanorod.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

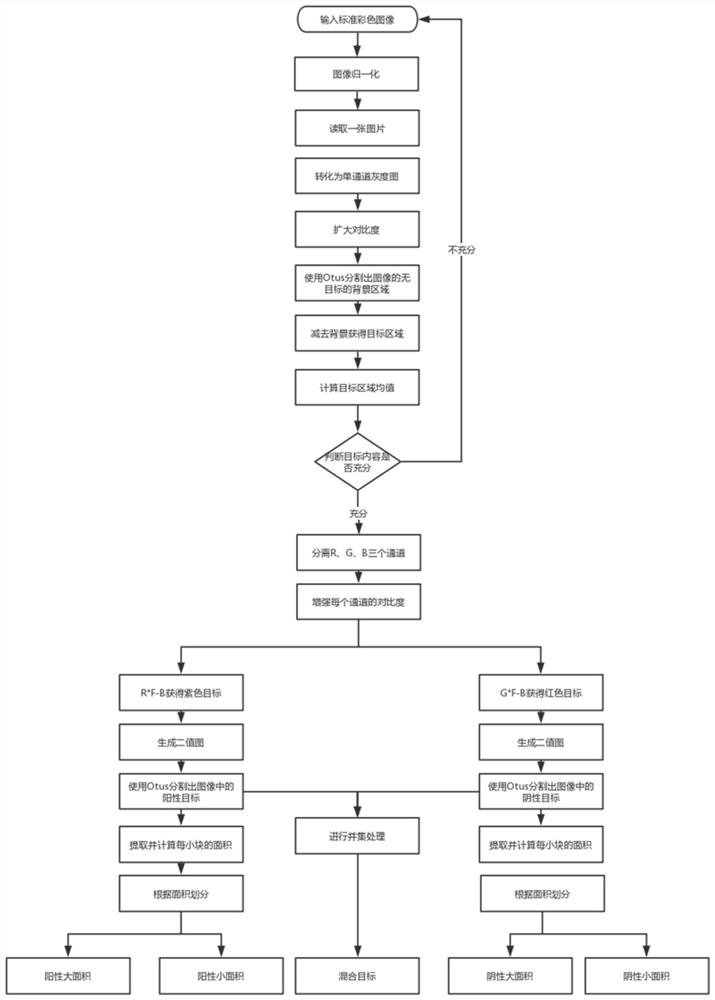

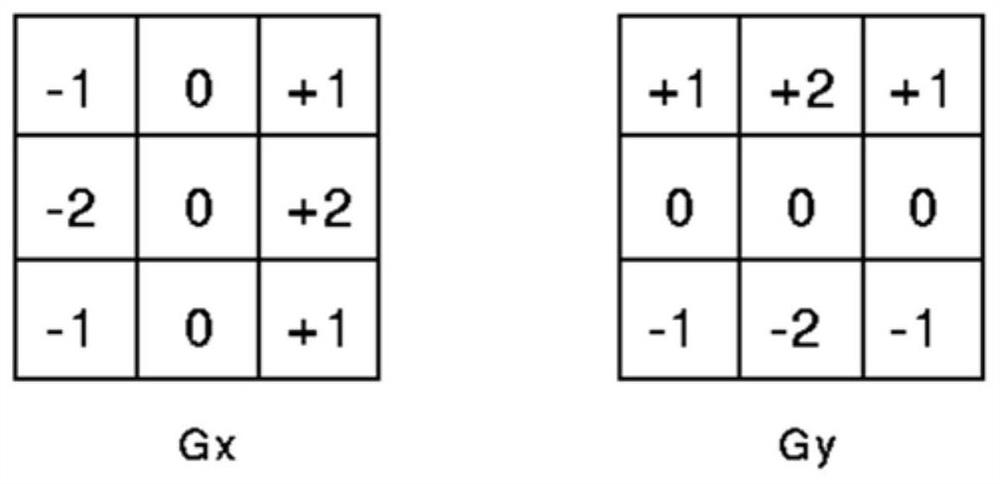

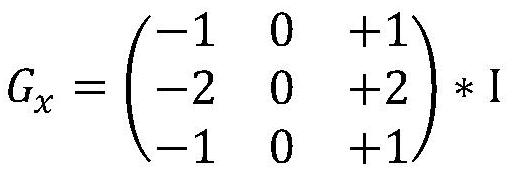

Gram staining leucorrhea smear color microscopic image segmentation method and system

PendingCN113205533ATroubleshoot preprocessing issuesPreserve morphological characteristicsImage enhancementImage analysisColor imageMicroscopic image

The invention provides a Gram staining leucorrhea smear color microscopic image segmentation method and system, and relates to the technical field of digital image processing, and the method comprises the steps: collecting and inputting a Gram staining leucorrhea standard smear; carrying out downsampling and normalization on the collected cell image to obtain a standard size image; converting the standard size image into a single-channel grayscale image; processing the single-channel grayscale image, and excluding a target-free image; separating R, G and B channels in the color image, and performing normalization processing; obtaining and calculating an intersection part of the positive target area and the negative target area, and taking a union set as a mixed negative and positive target; cutting an area in which the negative and positive targets are mixed to form all independent negative and positive targets; and obtaining and classifying area information of each independent target, carrying out targeted form recognition, and counting the number to output a recognition result. According to the invention, possibility can be provided for subsequent cellular morphology recognition, and the preprocessing problem of an input image in target recognition is solved.

Owner:JIANGSU BIOPERFECTUS TECH CO LTD

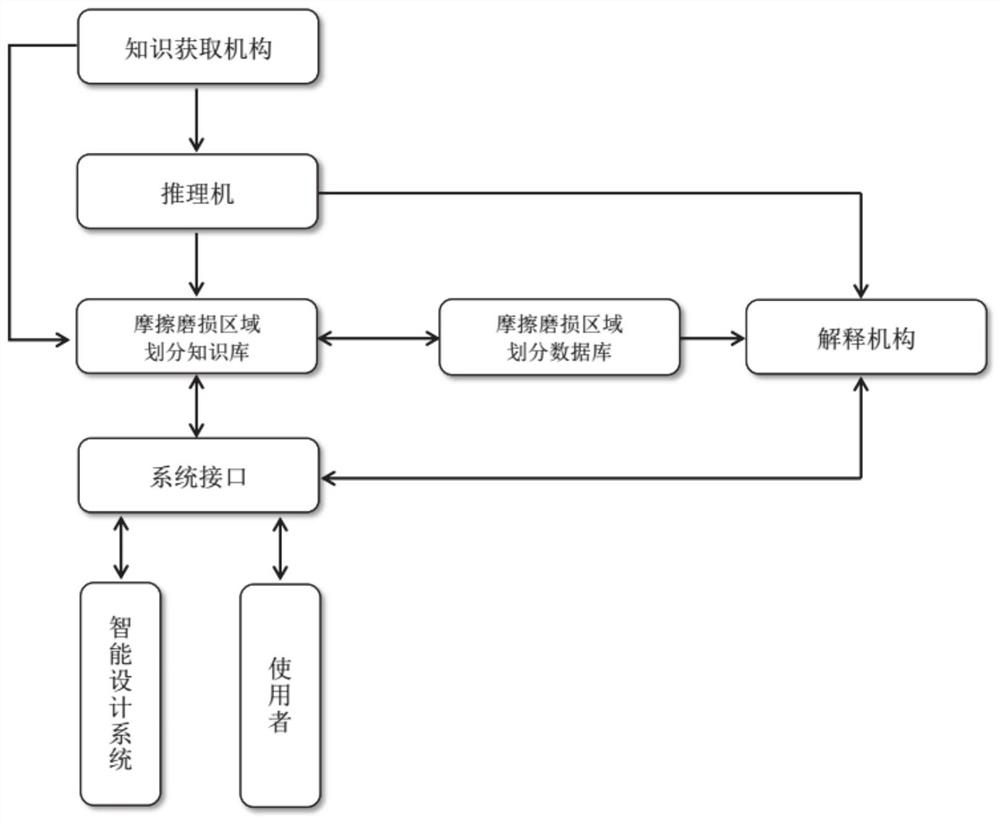

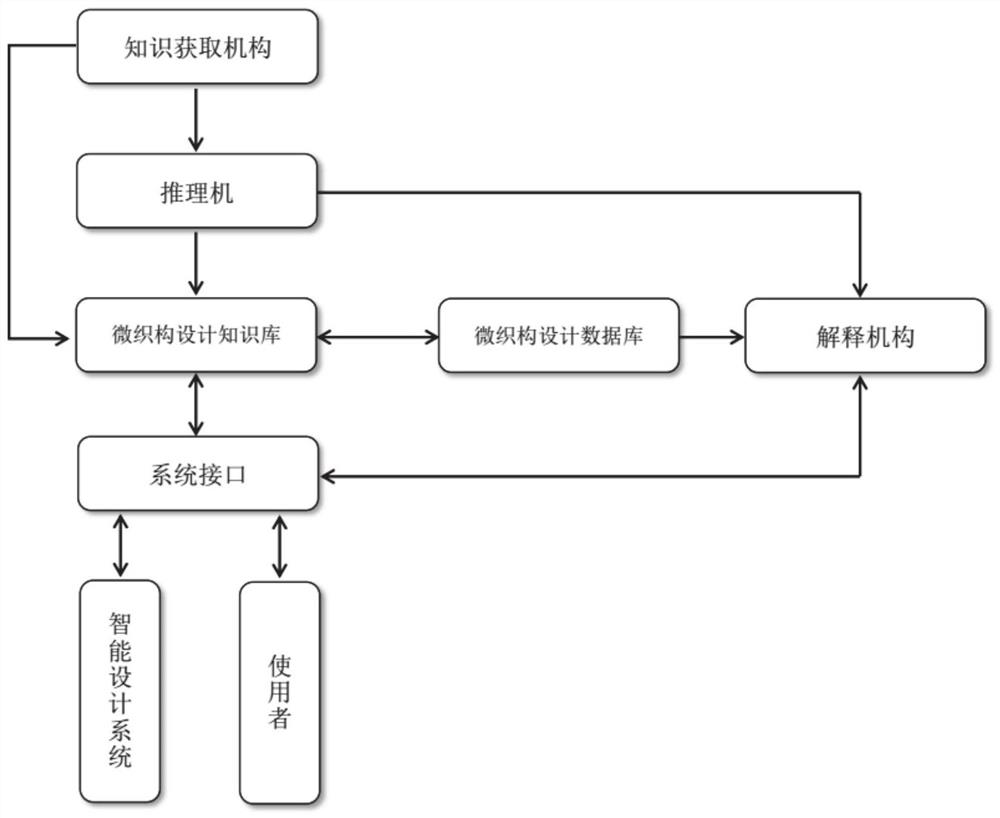

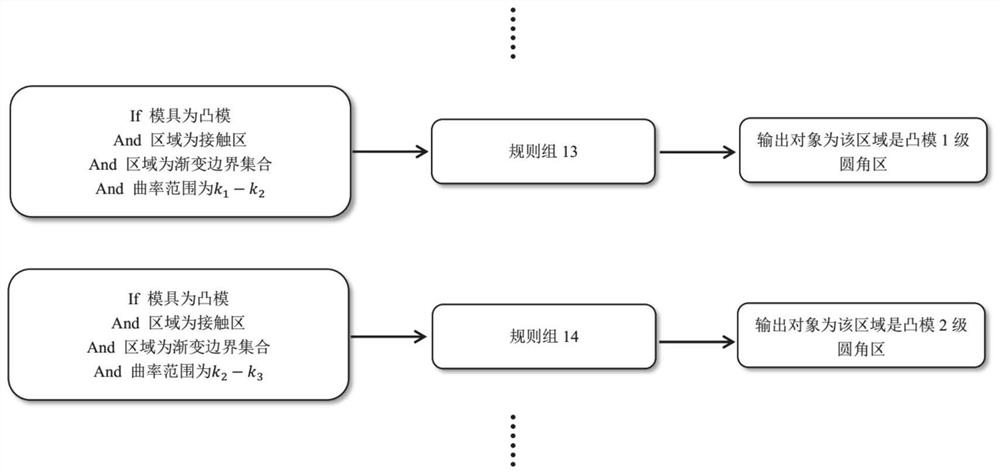

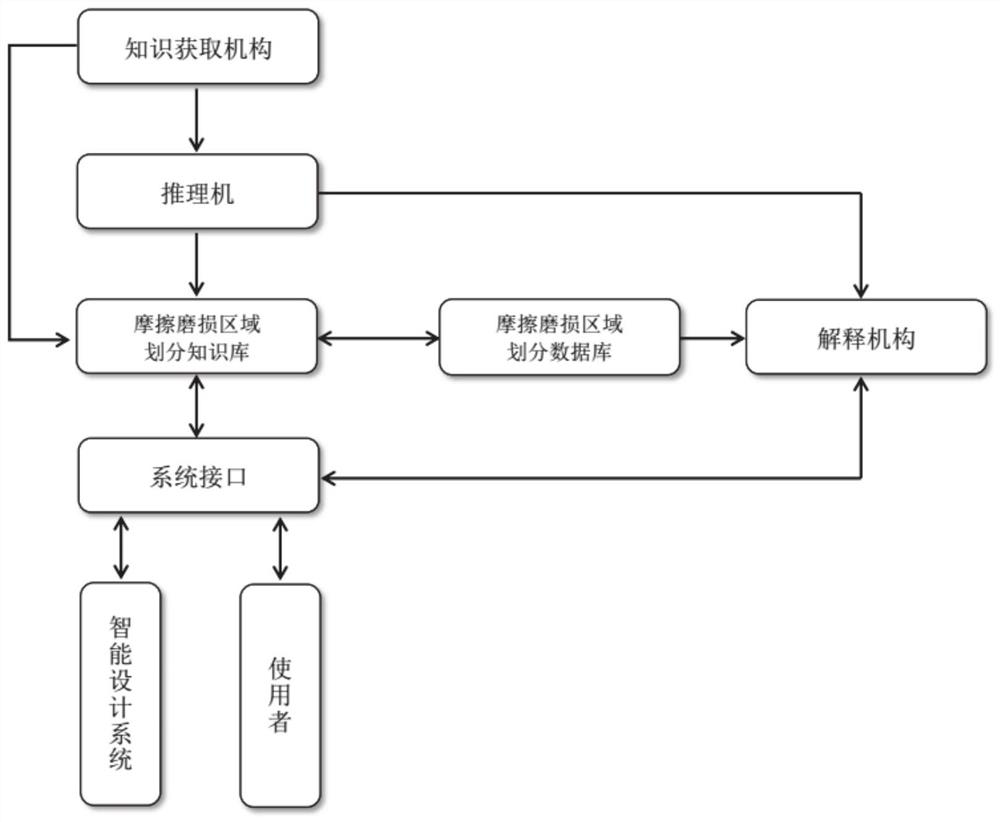

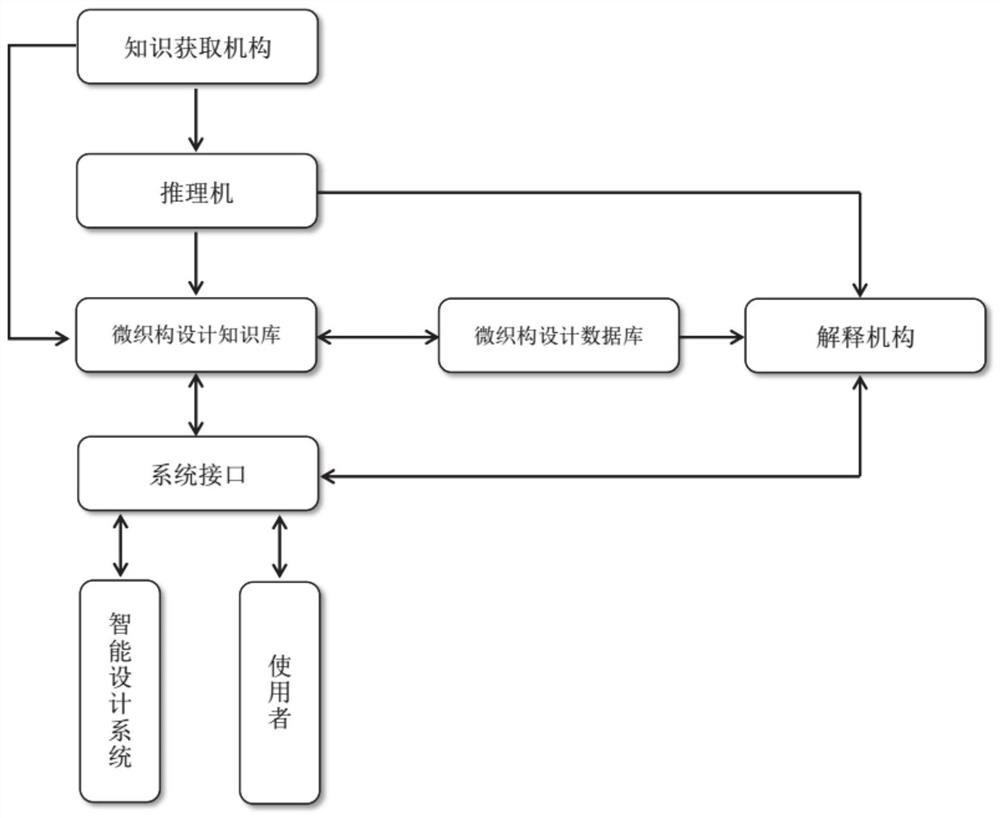

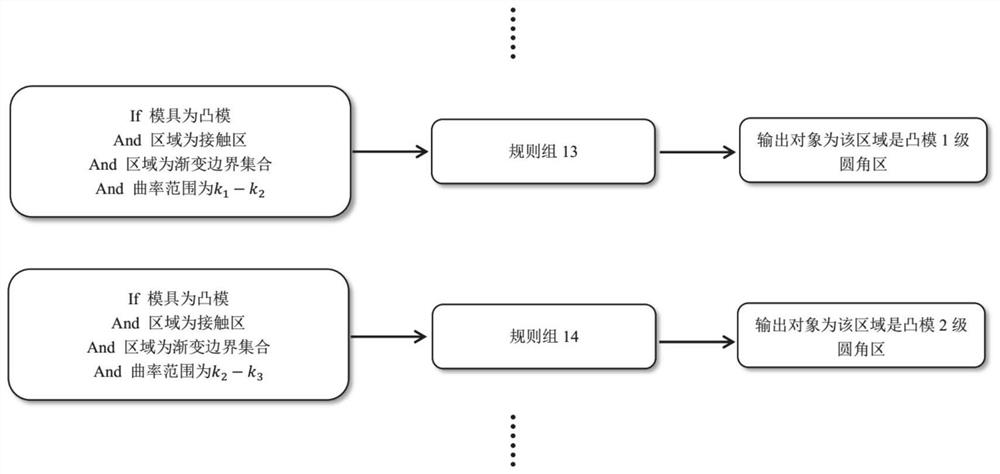

Machining method and design system for surface microtexture of stamping die

ActiveCN113468663AReduce frictionReduce the maximum thinning rateGeometric CADSustainable transportationPoint cloudEngineering

The invention discloses a processing method and a design system for a surface microstructure of a stamping die. The processing method comprises the following steps: acquiring three-dimensional point cloud data of the stamping die; according to the three-dimensional point cloud data, obtaining three-dimensional morphology characteristic parameters of the surface of the stamping die through calculation; carrying out boundary feature division according to the three-dimensional morphology feature parameters, and determining the stamping die surface boundary feature division parameters; according to the boundary feature division parameters and the three-dimensional shape feature parameters, acquiring friction wear area division parameters; acquiring die stamping simulation data, carrying out orthogonal polynomial regression design on the stamping die performance parameters and the micro-texture design parameters, and determining the corresponding relation between the performance parameters and the micro-texture parameters; according to the friction wear area division parameters, combining the corresponding relation between the performance parameters and the microstructure parameters to obtain stamping die surface microstructure machining design parameters; and machining the microstructure on the surface of the stamping die according to the microstructure machining design parameters. The surface friction characteristic and material flowing of the stamping die machined through the method are actively optimized.

Owner:SHANDONG UNIV

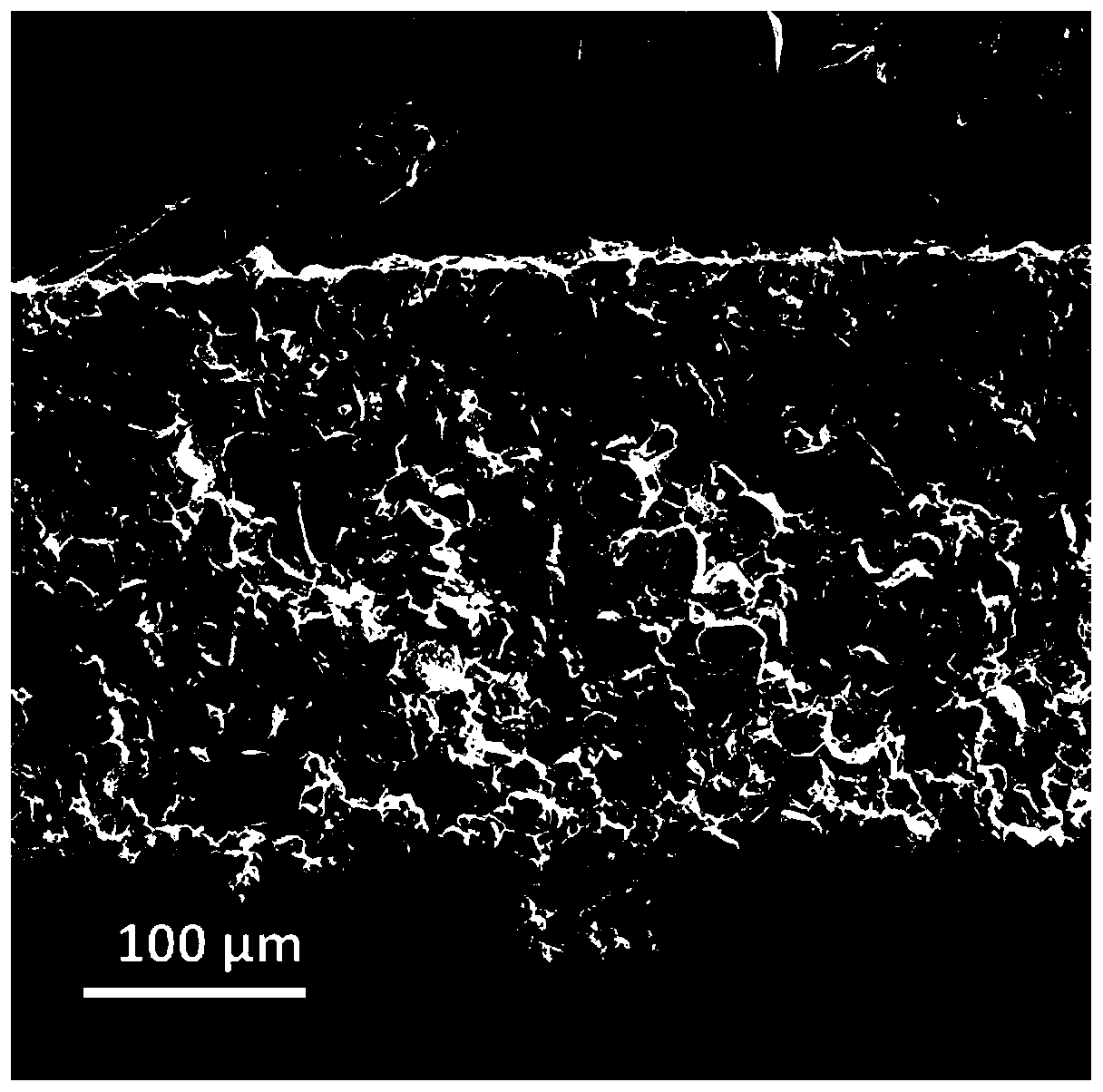

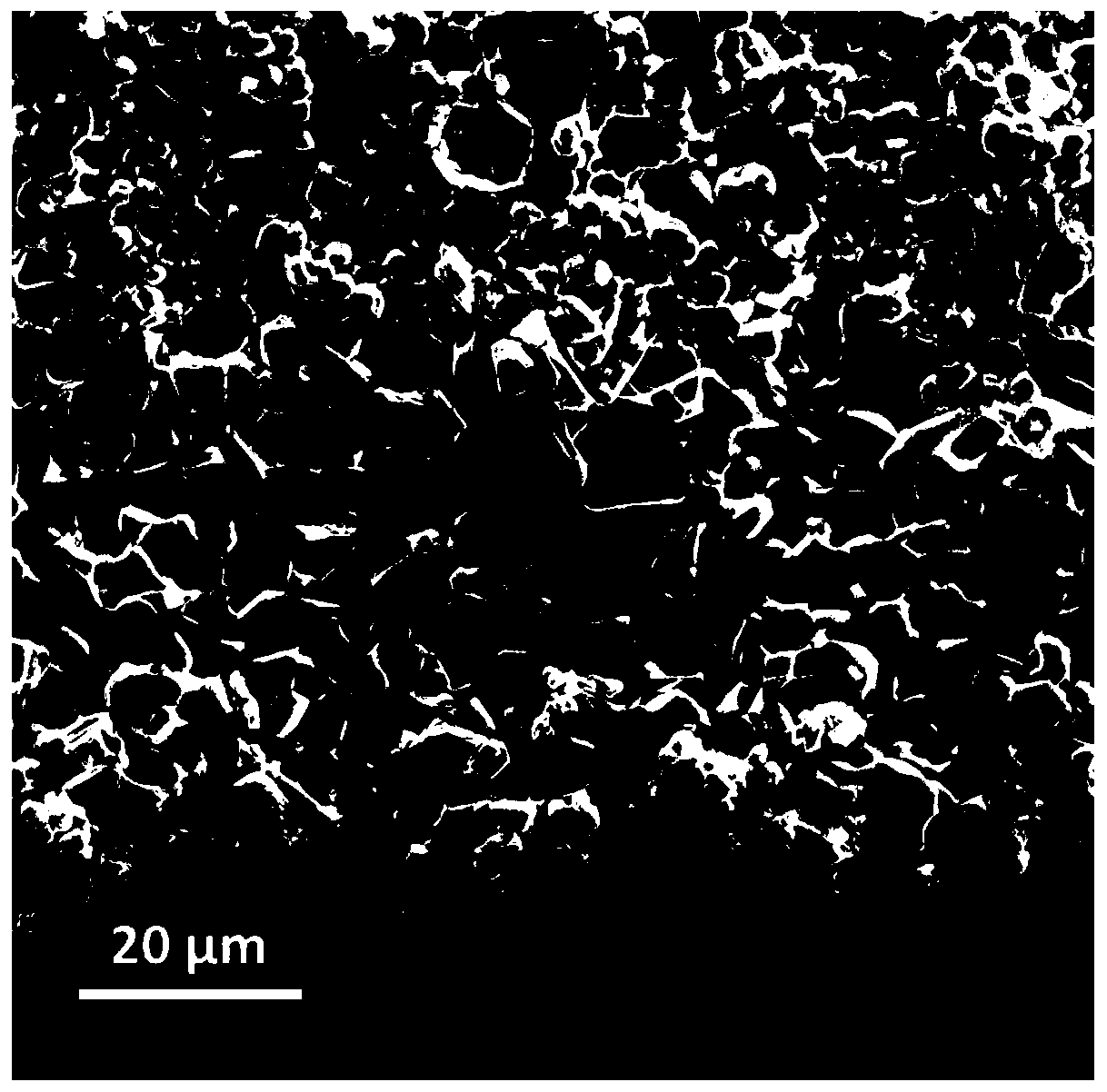

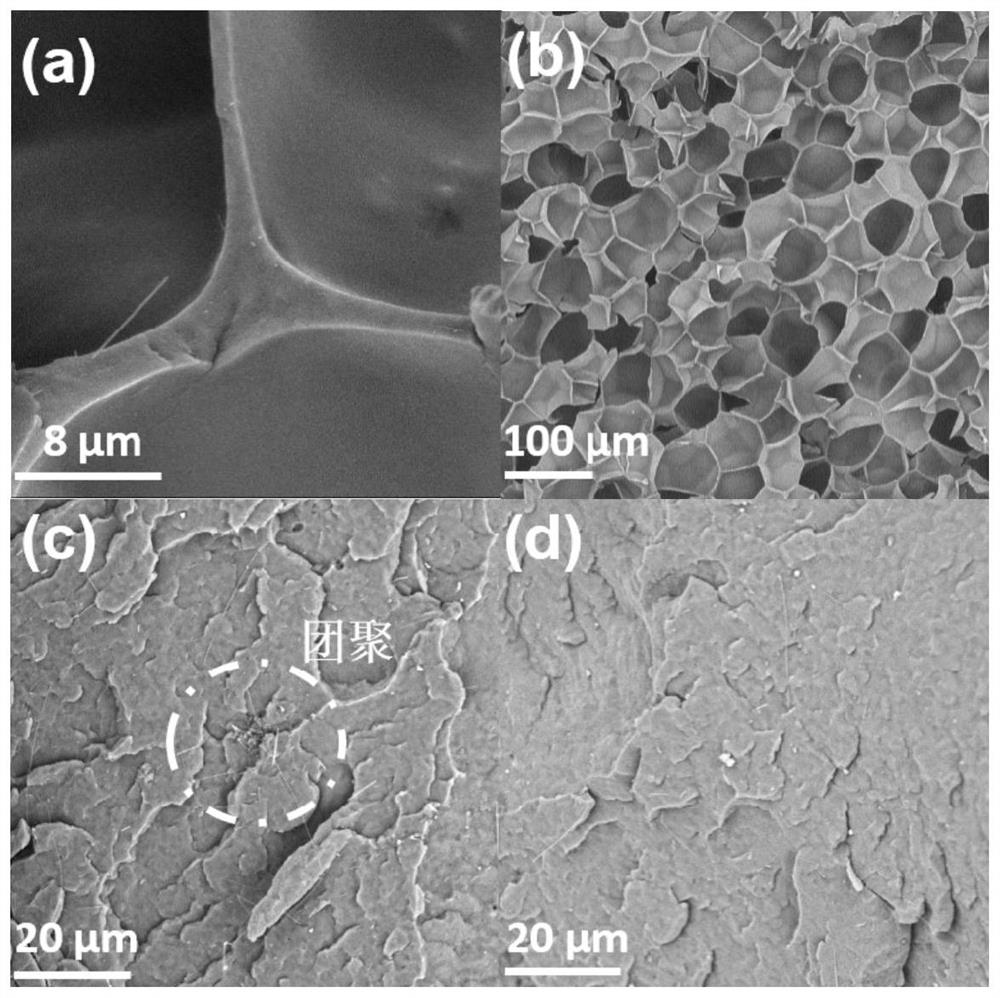

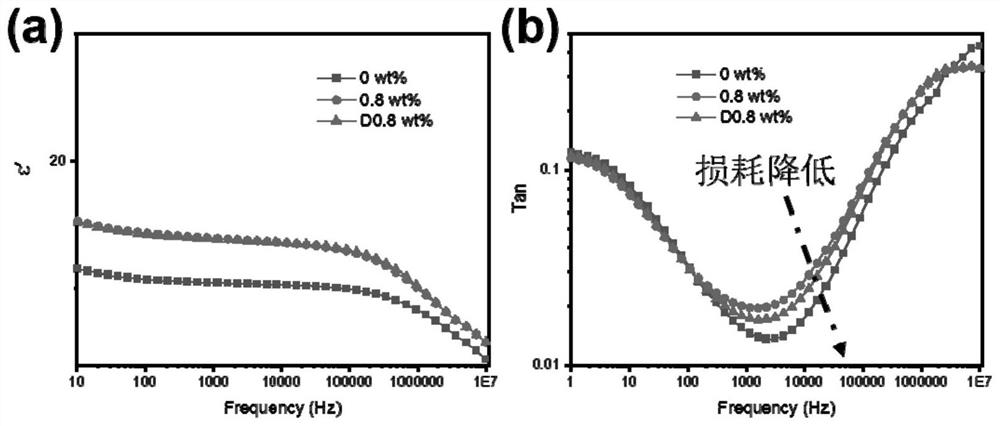

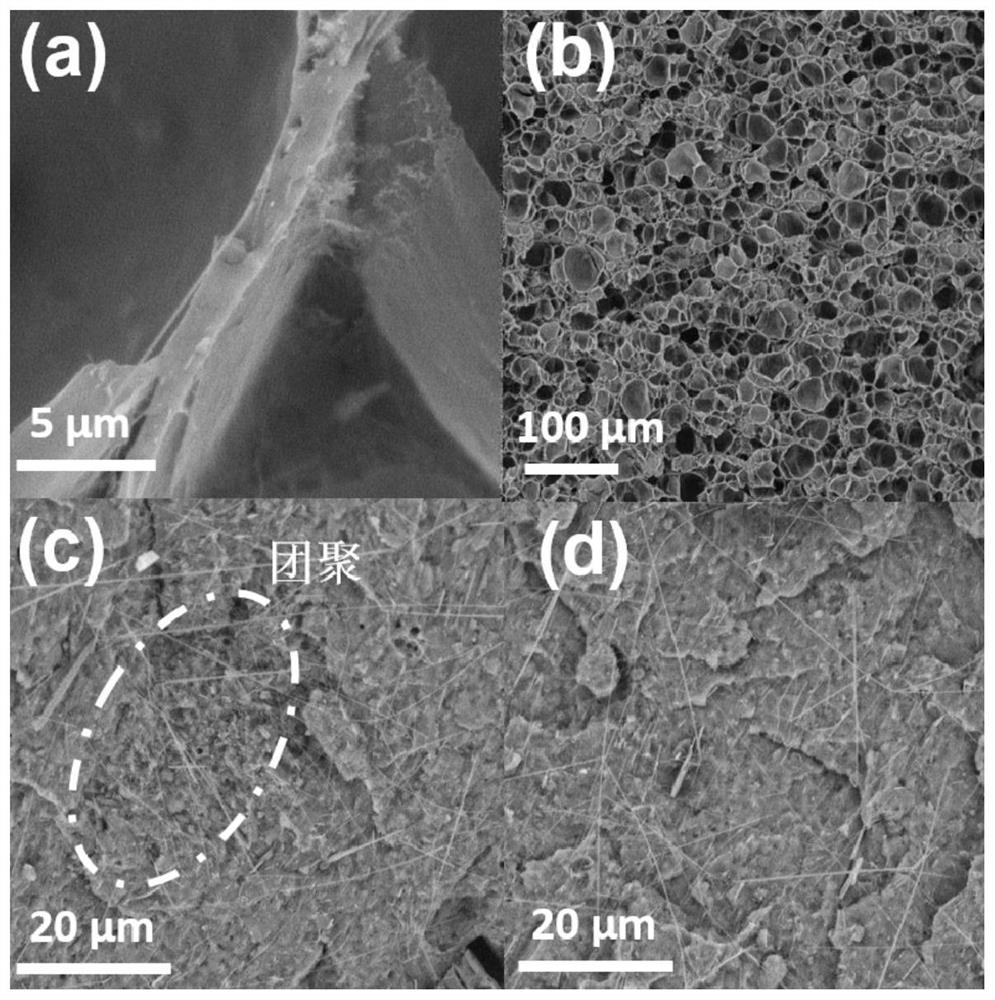

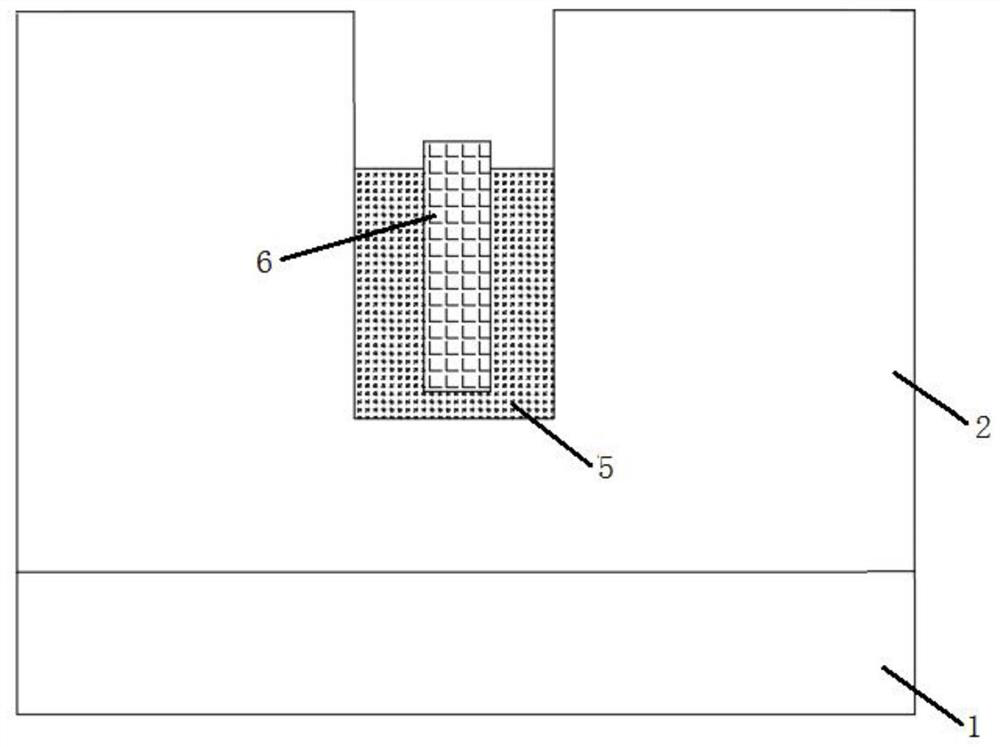

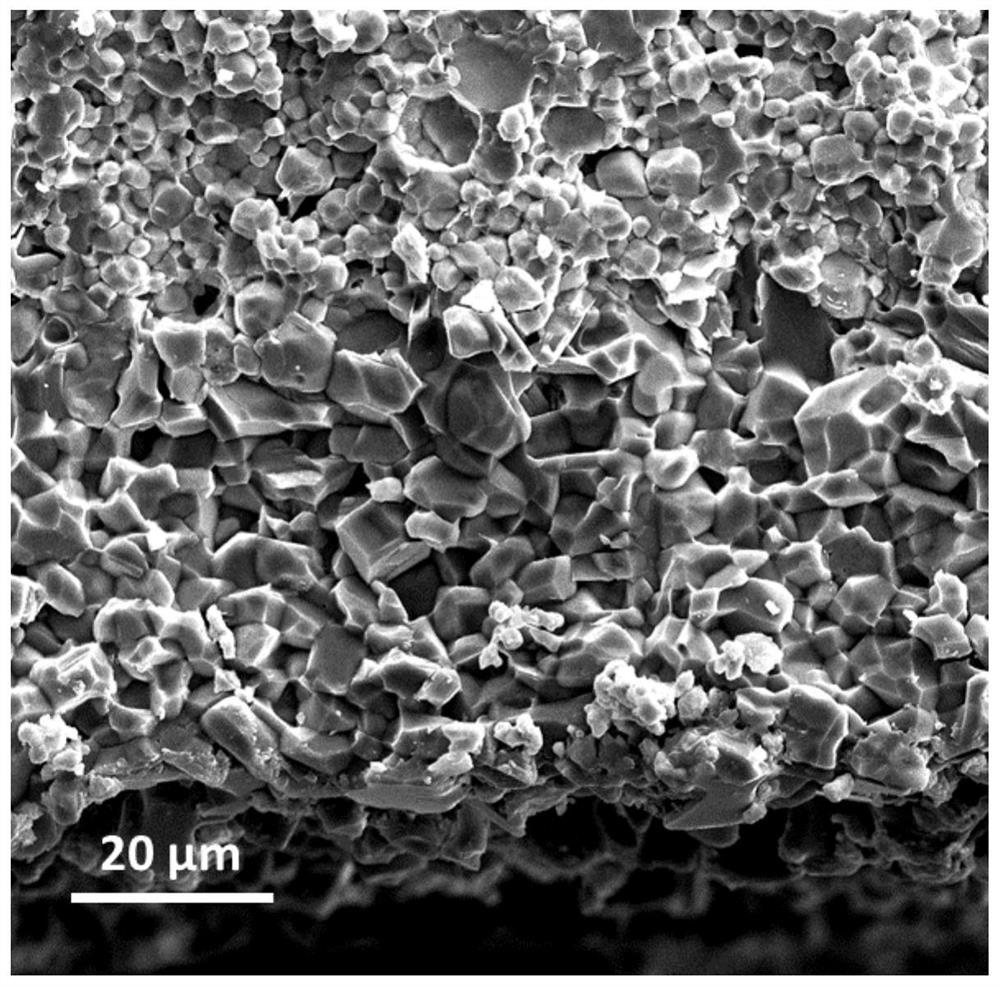

Method for promoting dispersion of nanofiller by utilizing stretching effect of pore wall of polymer foam material

The invention provides a method for promoting dispersion of nanofiller by utilizing a polymer foam material pore wall stretching effect, which comprises the following steps: carrying out hot press molding on a polymer / nanofiller premix to form a green body, placing the green body in a high-pressure cavity, introducing gas serving as a foaming agent into the high-pressure cavity to swell and permeate the green body, and carrying out high-pressure foaming on the green body; then foaming to form a honeycomb-shaped foam hole structure, in the foaming process, dispersing the nano-filler in the blank is mutually due to the stretching effect of the foam hole wall growth process, breaking the agglomeration structure of the nano-filler, and the obtaining foam material with the nano-filler dispersed and distributed on the foam hole wall; and performing hot pressing to remove a foam structure in the foam material to obtain the polymer nano composite material in which the nano filler is uniformly dispersed in the matrix. According to the invention, the dispersion of the nanofiller in the matrix can be promoted on the basis of not destroying the morphology of the nanofiller, not reducing the performance of the nanofiller, simplifying the operation and increasing the environmental protection property, and the performance of the polymer nanocomposite is effectively improved.

Owner:SICHUAN UNIV

A processing method and design system for surface micro-texture of stamping die

ActiveCN113468663BReduce frictionReduce the maximum thinning rateGeometric CADSustainable transportationPoint cloudProcess engineering

The invention discloses a processing method and a design system for the surface micro-texture of a stamping die. The three-dimensional point cloud data of the stamping die is obtained; the three-dimensional shape characteristic parameters of the stamping die surface are calculated according to the three-dimensional point cloud data; the three-dimensional shape characteristic parameters are obtained according to the three-dimensional shape characteristic parameters Carry out boundary feature division and determine the parameters of the stamping die surface boundary feature division; obtain the friction and wear area division parameters according to the boundary feature division parameters and three-dimensional shape characteristic parameters; obtain the die stamping simulation data, and analyze the stamping die performance parameters and micro texture design parameters Carry out orthogonal polynomial regression design to determine the corresponding relationship between performance parameters and micro-texture parameters; divide the parameters according to the friction and wear area, and combine the corresponding relationship between performance parameters and micro-texture parameters to obtain the stamping die surface micro-texture processing design parameters ; Process the micro-texture on the surface of the stamping die according to the micro-texture processing design parameters. The surface friction characteristics and material flow of the stamping die processed by the invention are actively optimized.

Owner:SHANDONG UNIV

A method of co3o4 nanowire doping sn

InactiveCN104016422BTopography has no effectMorphological influenceMaterial nanotechnologyCobalt oxides/hydroxidesNanowireOrganic solvent

Owner:NORTHWEST NORMAL UNIVERSITY

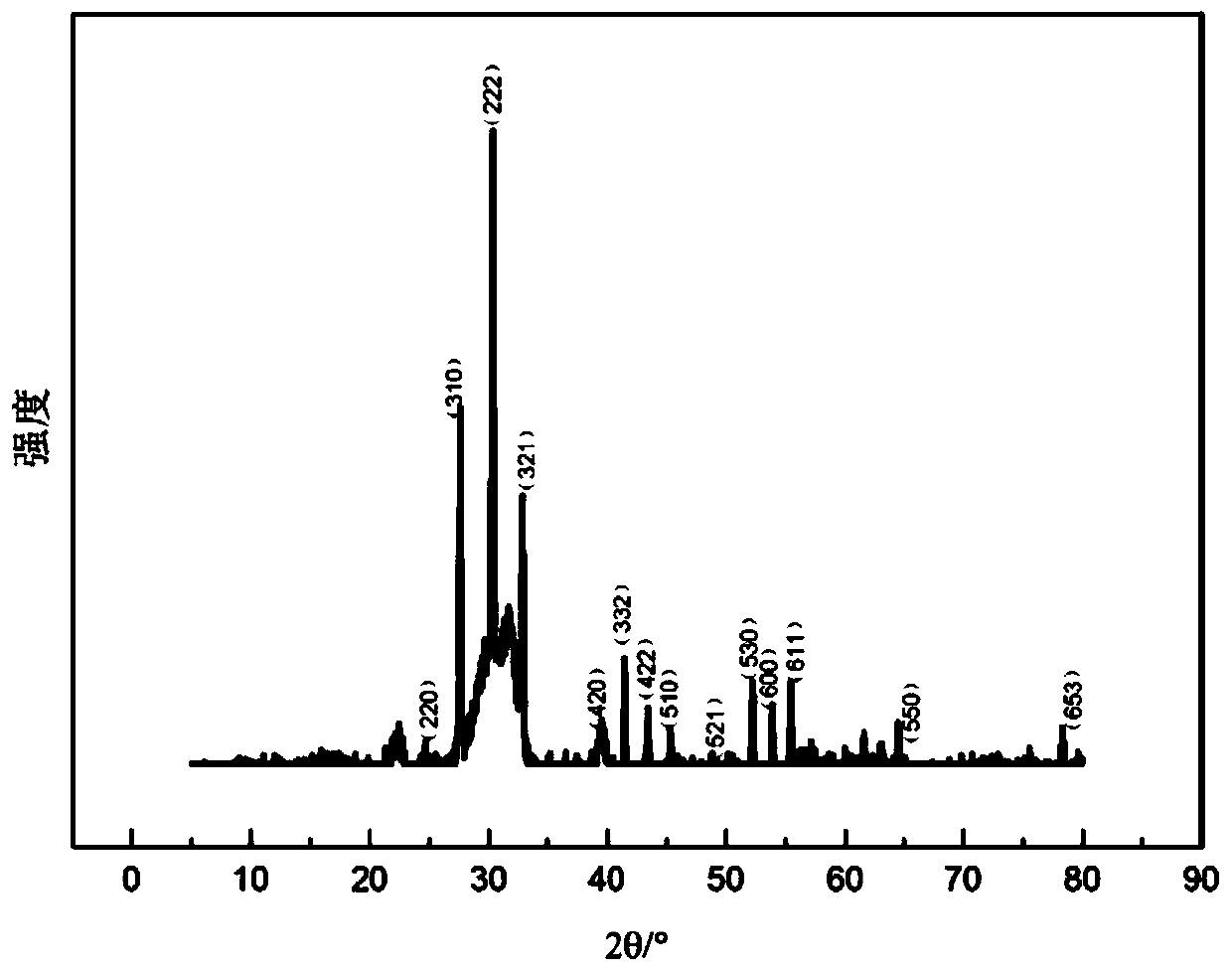

Preparation method and product of Bi12TiO20 micro-spheres

InactiveCN104211115ASimple preparation processThe preparation process is simple and controllableMaterial nanotechnologyBismuth compoundsPotassium hydroxideSurface modification

The invention discloses a preparation method and products of Bi12TiO20 micro-spheres. The preparation method comprises the following steps: by using a titanium oxyhydroxide precipitate which is obtained by hydrolyzing tetrabutyl titanate by virtue of an ammonia-water solution as a titanium source, fully dispersing the titanium oxyhydroxide precipitate in an ammonium bismuth citrate aqueous solution; then, adding a certain potassium hydroxide as a mineralizer; fully stirring and oscillating; transferring to a reaction kettle; sealing; and carrying out hydrothermal treatment at 150-300 DEG C for 6-48 hours to finally obtain the Bi12TiO20 micro-spheres with the diameters of 2-4 mu m, wherein each micro-sphere is self-assembled by smaller nano-particles. According to the preparation method of the Bi12TiO20 micro-spheres, by using the ammonium bismuth citrate as a bismuth source for the first time, the Bi12TiO20 micro-spheres which are self-assembled by the nano-particles by means of precise regulation of reaction conditions without additionally adding a surface modifier. The preparation method disclosed by the invention is simple and controllable in preparation process.

Owner:ZHEJIANG UNIV

Self-Aligned Dual Patterning Method

ActiveCN103681293BMorphological influenceGood sidewall morphologySemiconductor/solid-state device manufacturingPhotoresistMaterials science

The invention provides a self-alignment duplex patterning method. The method comprises the following steps: providing a material layer to be etched, forming a sacrificial photoresist layer on the material layer to be etched, curing photoresist at the top and side wall of the sacrificial photoresist layer to form a cured photoresist casing, performing back-etching on the cured photoresist casing at the top of the sacrificial photoresist layer until an uncured inner sacrificial photoresist layer is exposed, forming a first mask pattern on the cured photoresist casing on the side wall of the inner sacrificial photoresist layer, and removing the uncured inner sacrificial photoresist layer. As a hard mask layer is not required to form, the process procedures are reduced, and the impact of the stress generated by the hard mask layer on the profile of the sacrificial photoresist layer is eliminated. Besides, the first mask pattern is formed by removing the top of the cured photoresist casing, the side wall of the sacrificial photoresist layer formed by the photolithographic process is smooth and perpendicular to the surface of the material layer to be etched, and the side wall of the finally-formed etched pattern has a better profile.

Owner:SEMICON MFG INT (SHANGHAI) CORP

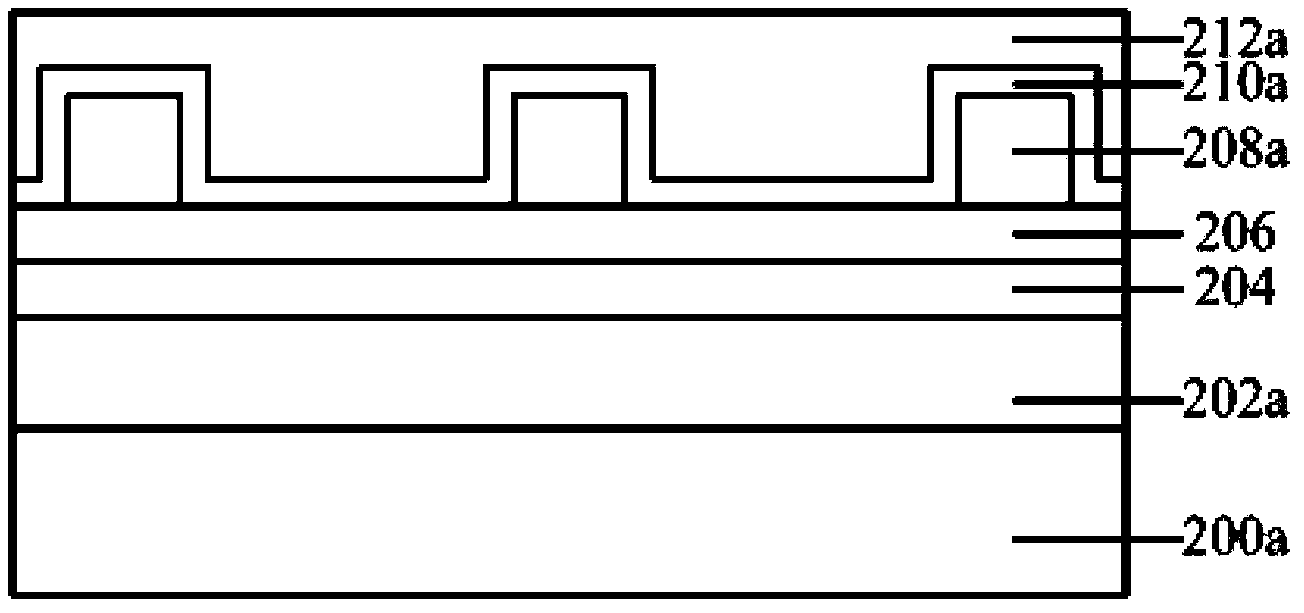

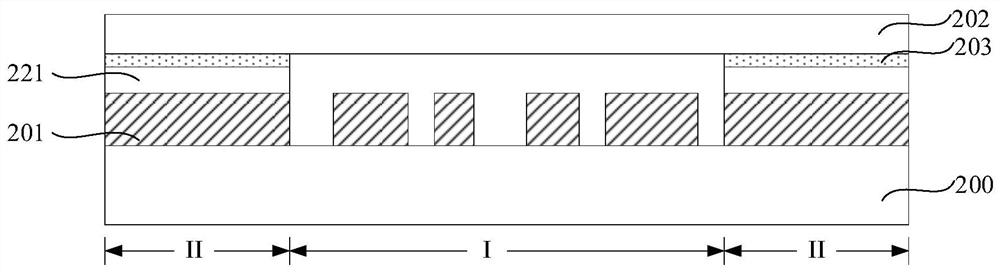

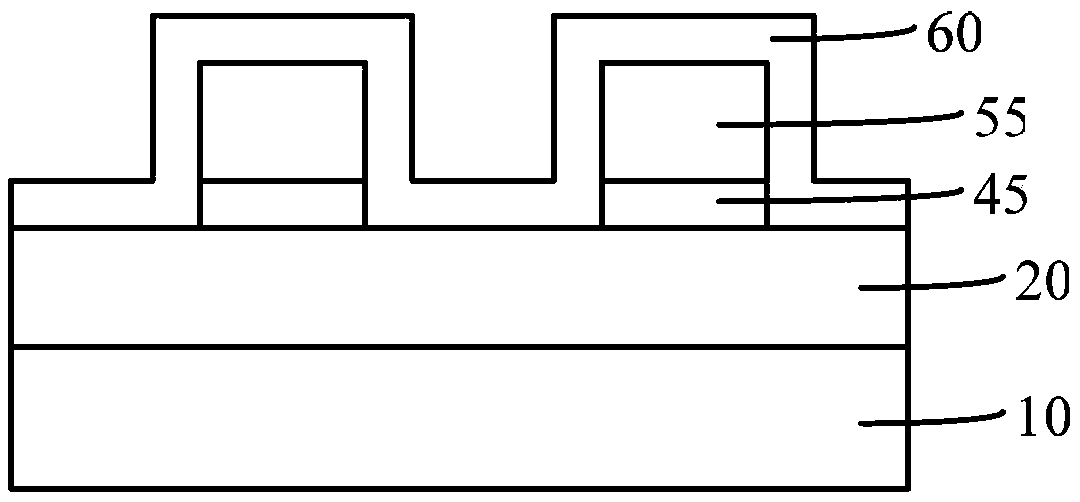

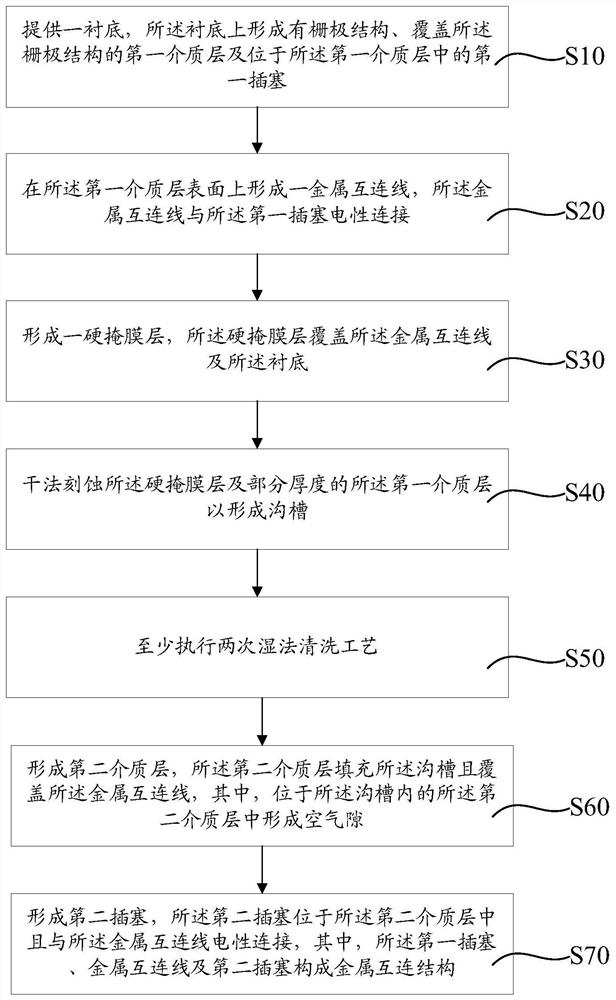

Method of forming metal interconnect structure

ActiveCN110148583BBalance stressMorphological influenceSolid-state devicesSemiconductor/solid-state device manufacturingEngineering physicsDielectric layer

The present invention provides a method for forming a metal interconnection structure, comprising: first providing a substrate on which a gate structure, a first dielectric layer and a first plug are formed, and then forming a metal interconnection line and hard mask layer, then etch the hard mask layer and a partial thickness of the first dielectric layer to form grooves, and perform at least two wet cleaning processes on the surface of the grooves and the metal interconnection lines, and then deposit second dielectric layer, so that an air gap is formed in the second dielectric layer in the trench, and finally a second plug is formed in the second dielectric layer, wherein the first plug, the metal interconnection line and the second plug form a metal interconnection structure. Before forming the second dielectric layer, multiple wet cleaning processes are performed on the surface of the groove and the metal interconnection to remove high polymer impurities, so that the gap between the metal interconnection and the subsequently formed second dielectric layer is The stress between them is more balanced, thereby avoiding the risk of the second plug protruding and breaking due to extrusion.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Collection method of etching conditions

ActiveCN103855075BIncrease profitAvoid wastingSemiconductor/solid-state device testing/measurementSolid-state devicesDielectric layerMaterials science

Owner:SEMICON MFG INT (SHANGHAI) CORP

Method for forming semiconductor device

ActiveCN104124137BLow costReduce processing difficultySemiconductor/solid-state device manufacturingEngineeringSemiconductor

A semiconductor device forming method includes providing a semiconductor substrate, forming a first mask layer on the semiconductor substrate, forming a first groove penetrating the first mask layer for a part of thickness, filling the first groove with a first hard mask layer, forming a second groove penetrating the first hard mask layer for the thickness of the first hard mask layer; utilizing the first hard mask layer as a mask to etch the first mask layer and the semiconductor substrate till a through hole or a groove is formed in the semiconductor substrate. By means of the semiconductor device forming method, only one etching process is required in formation of the through hole or the groove through a double graph technology, double graph forming process difficulty and manufacture cost are reduced, and the semiconductor device forming cost is further reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP

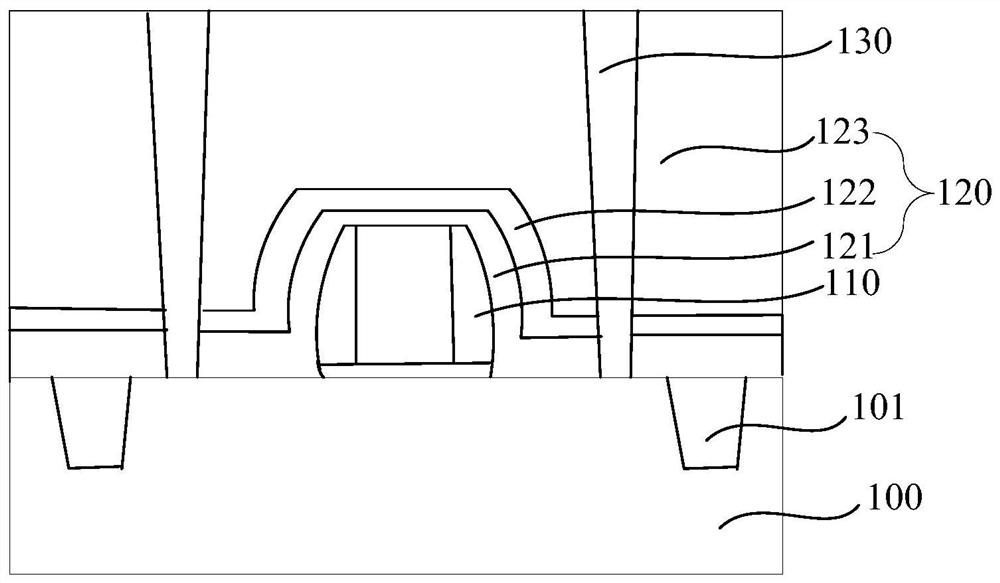

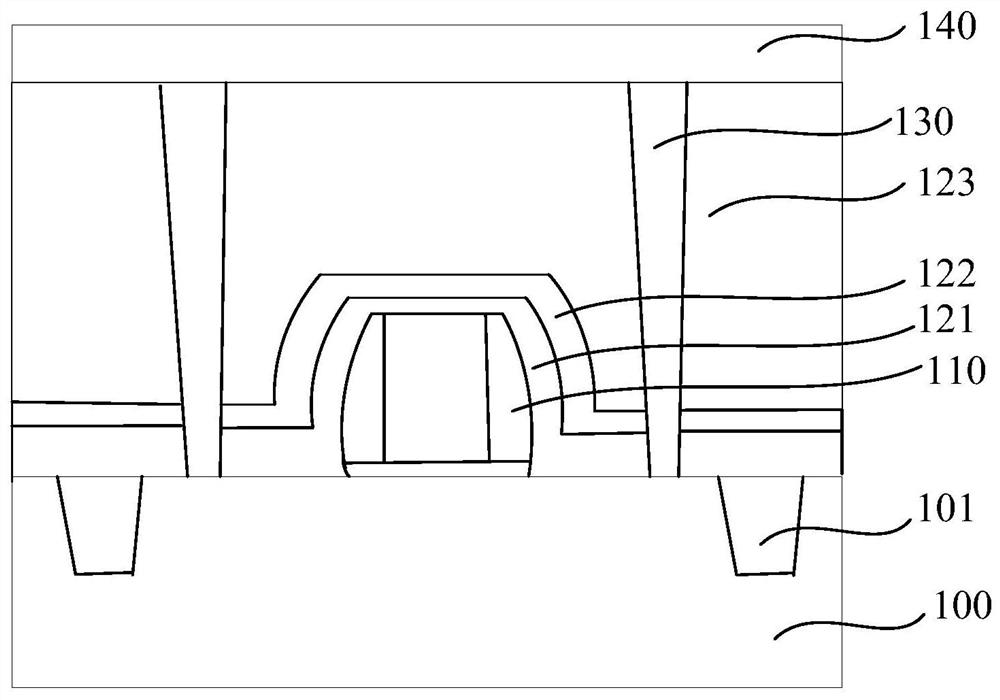

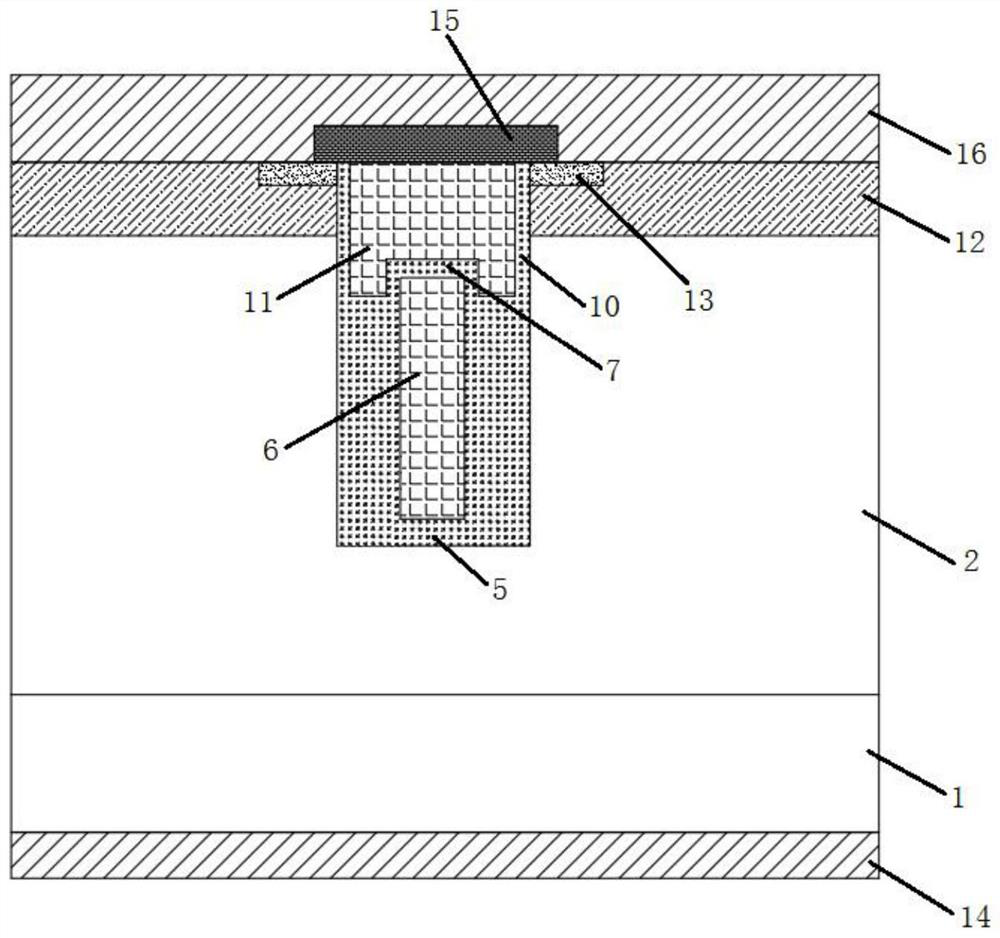

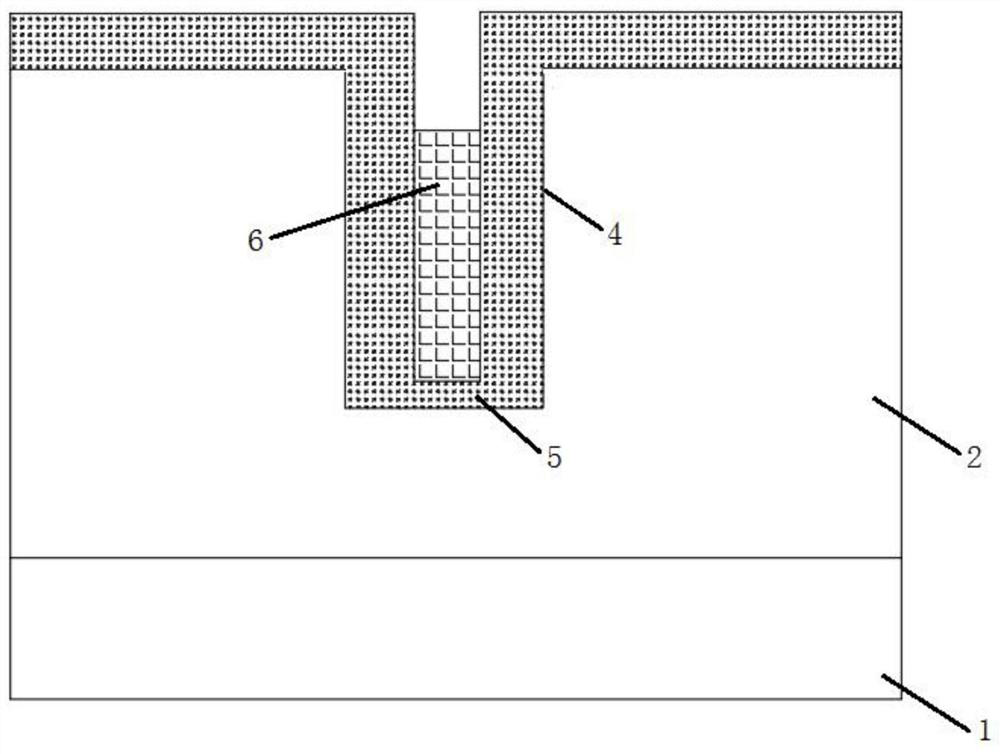

A kind of manufacturing method of split gate mosfet

ActiveCN111403289BPrecise thickness controlDoes not affect shapeSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETHigh density

The invention discloses a method for fabricating a split gate MOSFET, comprising: step 1, forming an epitaxial layer on a substrate; step 2, depositing a first oxide layer on a first main surface; step 3, forming a trench; Fourth, remove the first oxide layer; step five, form a second oxide layer in the trench; step six, form a separation gate polysilicon in the trench; step seven, form an isolation oxide layer between polysilicon; step eight, in the trench forming a nitride layer; step 9, forming sacrificial polysilicon in the trench; step 10, removing the nitride layer above the sacrificial polysilicon to form a mask structure; step 11, using the mask structure as an etching mask to remove the inter-polysilicon isolating the second oxide layer above the oxide layer; step 12, removing the nitride layer to lift off the sacrificial polysilicon. In the present invention, the isolation oxide layer between polysilicons that meets the technological requirements can be formed at one time through the high-density plasma chemical vapor deposition method or the low-temperature wet oxidation method.

Owner:捷捷微电(南通)科技有限公司

A kind of preparation method and application of graphene/cobalt nickel manganese ferrite nanocomposite material

ActiveCN109021919BImprove performanceShort synthesis timeOther chemical processesMagnetic/electric field screeningFerrite nanoparticlesIron oxide

The invention discloses a preparation method and application of a graphene / cobalt-nickel-manganese ferrite nanocomposite material. Add the solution containing iron source, cobalt source, nickel source, and manganese source dropwise into the dispersion liquid containing graphene oxide to obtain a mixed solution, adjust the pH of the mixed solution to ≥ 8, and then add a reducing agent to obtain a precursor solution. The solid solution is transferred into a reaction kettle for microwave synthesis reaction, and the obtained reaction product is graphene / cobalt nickel manganese ferrite nanocomposite material. Gained graphene / cobalt-nickel-manganese ferrite nanocomposite material is made of layered graphene and spherical cobalt-nickel-manganese ferrite nanoparticles, and the spherical cobalt-nickel-manganese ferrite nanoparticles are uniformly dispersed in the layered graphene surface and interlayer. The graphene / cobalt-nickel-manganese ferrite nanocomposite material has the characteristics of strong absorption strength, effective wave absorption frequency band, thin thickness and light weight.

Owner:CENT SOUTH UNIV

A kind of spherical co(ii)co(iii) hydrotalcite material and preparation method thereof

ActiveCN109502656BMorphological influenceImprove surface densityCobalt oxides/hydroxidesSingle crystalSlurry

A spherical Co(II)Co(III) hydrotalcite material and a preparation method thereof, characterized in that: the hydrotalcite material is a layered double hydroxyl group formed by divalent cobalt hydroxide and trivalent cobalt hydroxide Metal hydroxide, interlayer guest anions are organic acid radicals, particle morphology is spherical. The mixed solution of cobalt salt and ammonium salt is used as raw material A, the mixed solution of sodium organic acid and oxidizing agent is used as additive B, and the solution of raw material A and additive B is added to the sodium hydroxide bottom liquid by co-precipitation method; Inject nitrogen, stir vigorously, and control the temperature of the reaction kettle at 35°C~65°C; centrifuge or filter the slurry to obtain a filter cake, rinse with water until the filter cake is neutral, and dry in vacuum to obtain spherical Co(Ⅱ)Co(Ⅲ) Hydrotalcite-like materials. The invention realizes the effective control of the metal cobalt valence state in the co-precipitation system, and the hydrotalcite-like crystal thus prepared has a single crystal form, high regularity, good sphericity of the product, and relatively compact surface of the sphere.

Owner:兰州金通储能动力新材料有限公司

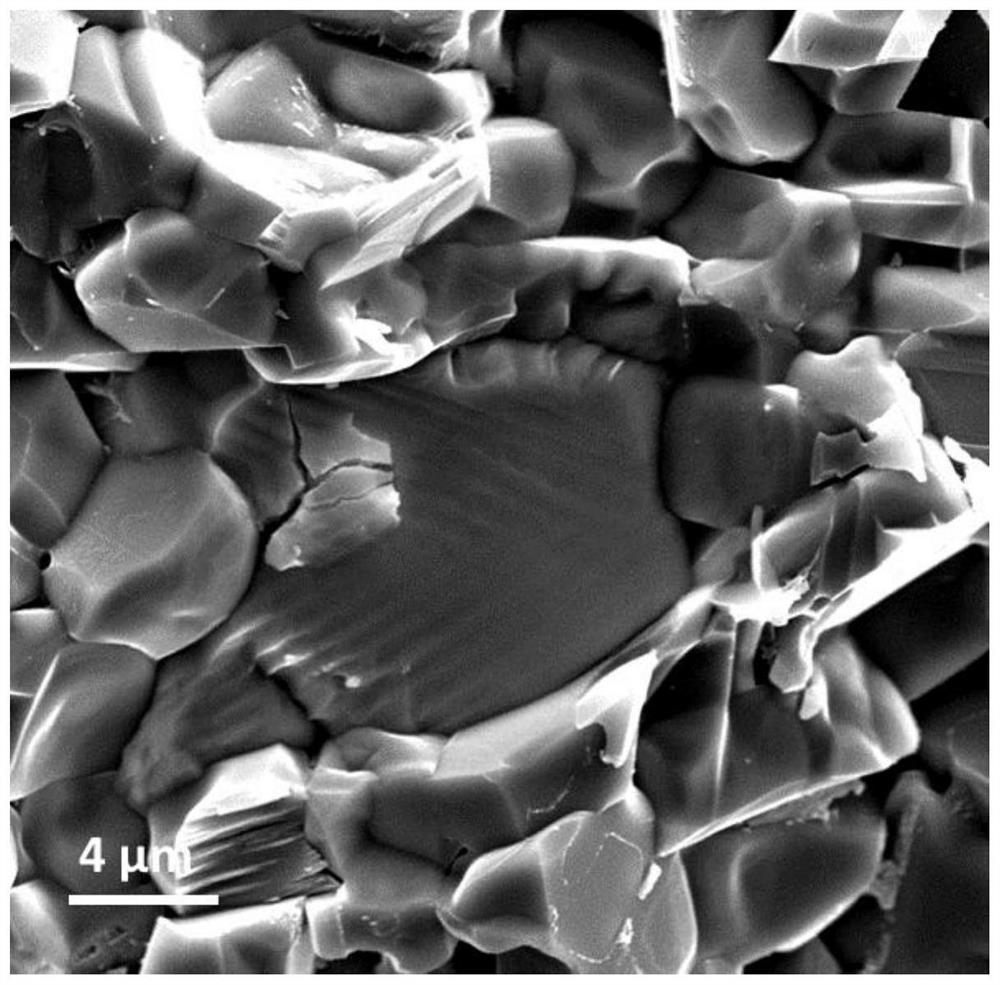

A method for treating the low-impedance interface of the positive electrode of a solid-state lithium battery and the structure of the positive electrode

ActiveCN109768215BSuppressed interdiffusionIncrease contactNon-aqueous electrolyte accumulator electrodesSolid state electrolyteLithium battery

The invention discloses a method for treating the low-impedance interface of the positive electrode of a solid-state lithium battery and a positive electrode structure. Through the method, the two interfaces between the active material particles in the positive electrode sheet and the solid electrolyte particles and between the positive electrode sheet and the electrolyte sheet can be effectively reduced at the same time. Impedance, so that the capacity of the active positive electrode particles in the solid-state lithium battery can be effectively utilized. The double-layer structure ceramic sheet comprising a solid electrolyte layer and a positive electrode layer prepared by the method of the invention has excellent performance, and has good application prospects in the field of solid-state lithium batteries.

Owner:杭州阳名新能源设备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com