Metal-silver-supported titanium dioxide photocatalyst and preparation method thereof

A titanium dioxide and photocatalyst technology, applied in the field of composite material preparation, can solve the problems of difficult operation, cumbersome method, difficult to achieve uniform loading of precious metals, etc., and achieve the effects of uniform loading and high photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

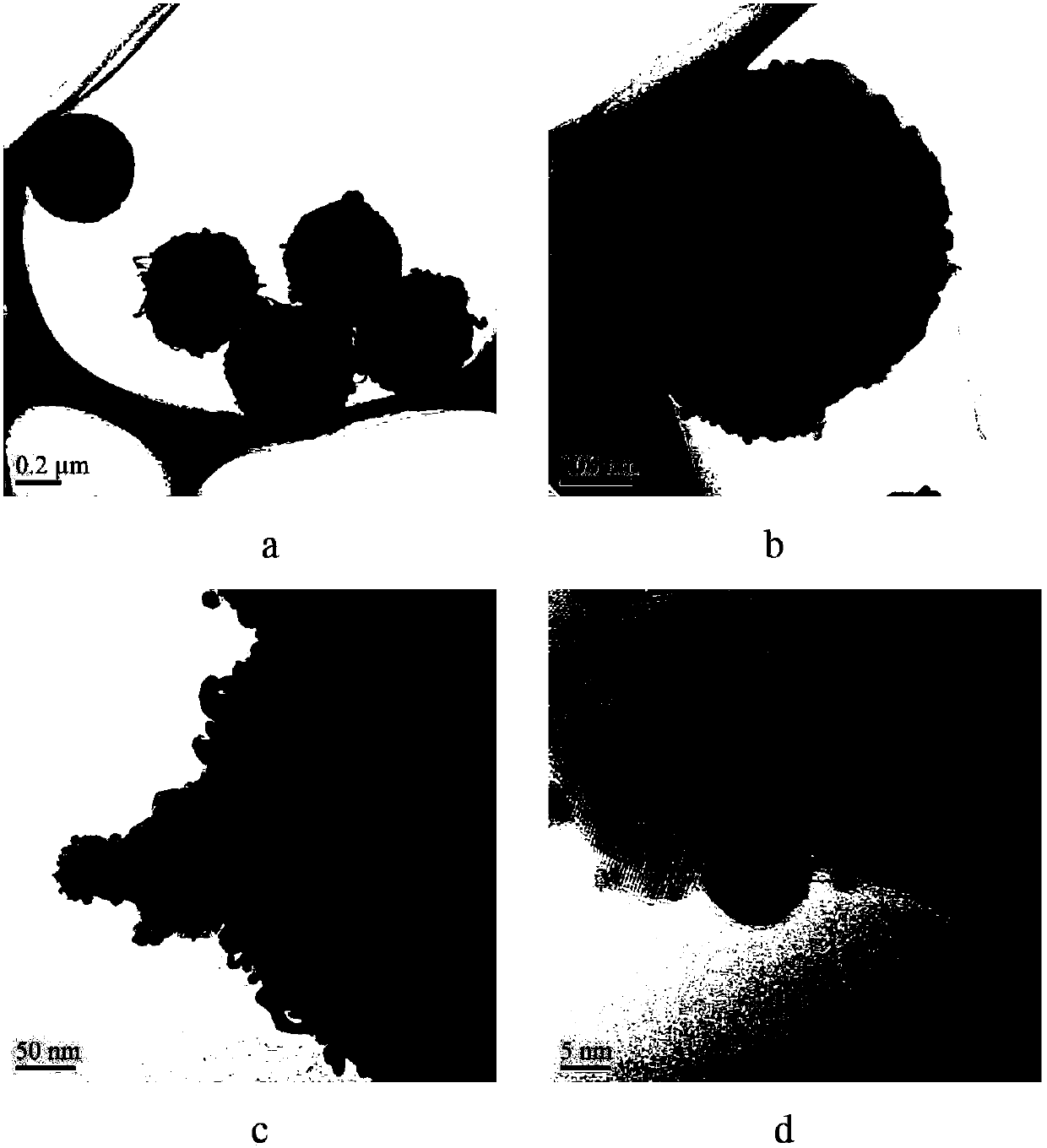

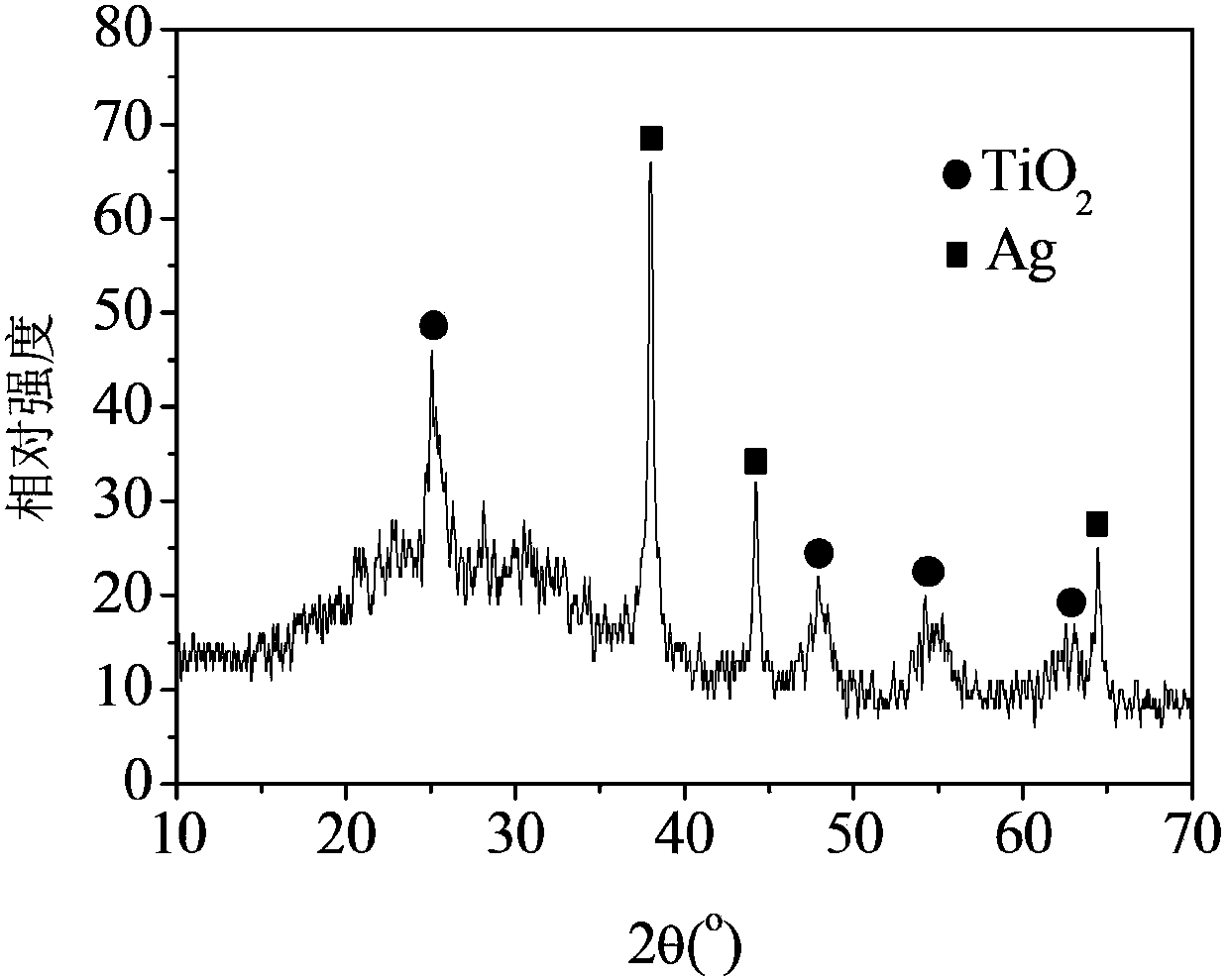

[0030] Add 1.0 mL of 0.1 mmol / L KCl solution into 300 mL of absolute ethanol, stir magnetically for 20 min, slowly drop in 5.4 mL of butyl titanate, stir vigorously for 10 min, age for 2 h, centrifuge and dehydrate with absolute ethanol Ionized water was washed sequentially to obtain a pure white powder. Disperse the pure white powder obtained above in 50mL of absolute ethanol, ultrasonically disperse for 20min, and add 10mL of AgNO with a concentration of 0.1g / 100mL to it. 3 The solution was magnetically stirred at a constant temperature at 35° C. for a certain period of time until the solution was evaporated to dryness, and a tan powder was obtained. The brown powder obtained above was calcined in an air atmosphere in a muffle furnace. The temperature rise system is 2°C / min before 300°C, 1°C / min from 300°C to 500°C, and kept at 500°C for 2 hours, and then naturally cooled to room temperature to obtain silver-loaded nano-titanium dioxide light. catalyst. figure 1 It is the...

Embodiment 2

[0032] Add 1.3 mL of KCl solution with a concentration of 0.8 mmol / L to 300 mL of absolute ethanol, stir magnetically for 20 min, slowly drop in 5.4 mL of butyl titanate, stir vigorously for 10 min, age for 1 h, centrifuge and dehydrate with absolute ethanol Ionized water was washed sequentially to obtain a pure white powder. Disperse the pure white powder obtained above in 40mL of absolute ethanol, ultrasonically disperse for 20min, and add 12mL of AgNO with a concentration of 1.3g / 100mL to it. 3 The solution was magnetically stirred at a constant temperature at 40° C. for a certain period of time until the solution was evaporated to dryness, and a tan powder was obtained. The brown powder obtained above was calcined in an air atmosphere in a muffle furnace. The temperature rise system is 2°C / min before 300°C, 1°C / min from 300°C to 500°C, and kept at 500°C for 2 hours, and then naturally cooled to room temperature to obtain silver-loaded nano-titanium dioxide light. catalys...

Embodiment 3

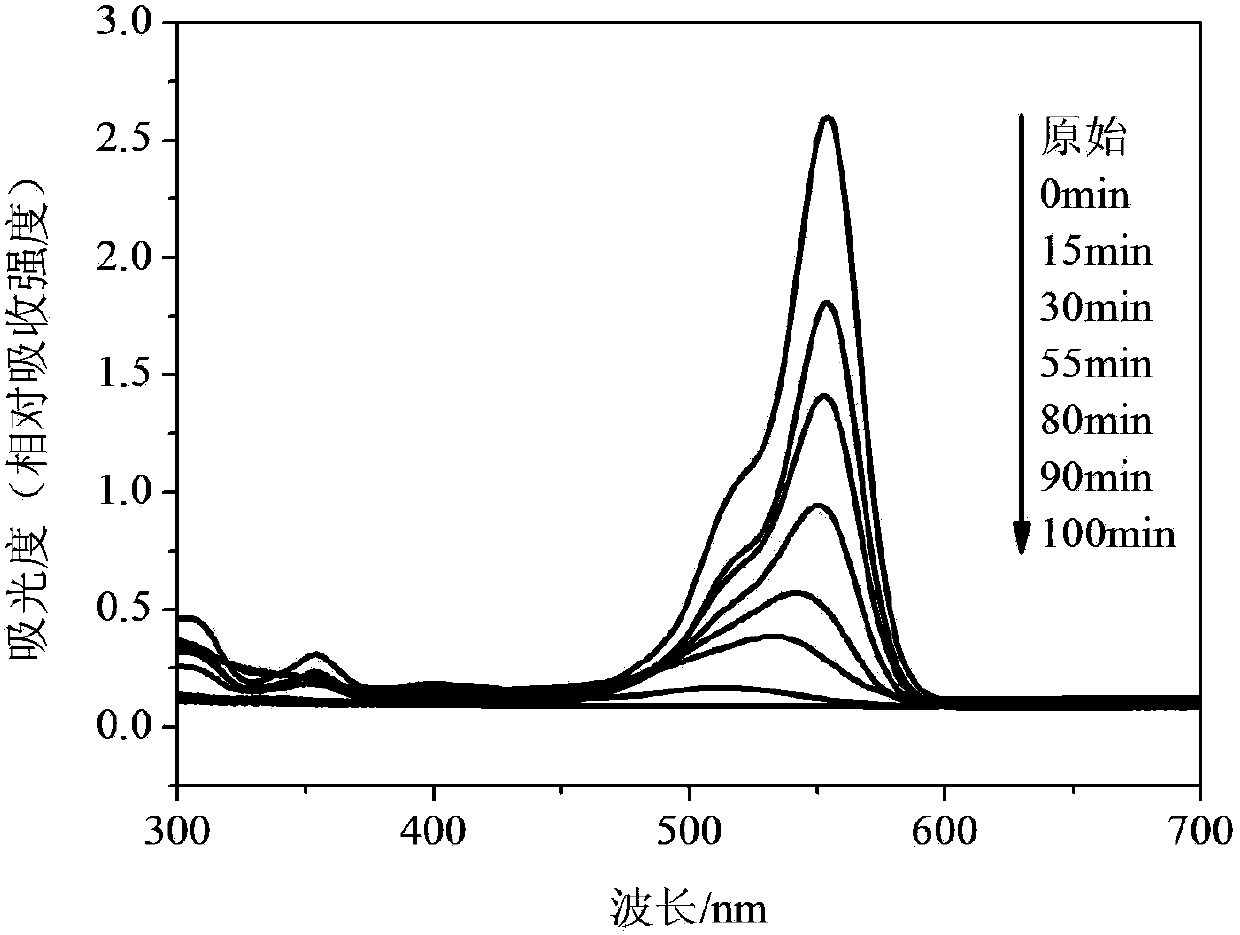

[0034] Add 1.5mL of 0.5mmol / L KCl solution into 300mL of absolute ethanol, stir magnetically for 20min, slowly drop in 5.4mL of butyl titanate, stir vigorously for 10min, age for 3h, centrifuge and dehydrate with absolute ethanol Ionized water was washed sequentially to obtain a pure white powder. Disperse the pure white powder obtained above in 45mL of absolute ethanol, ultrasonically disperse for 20min, and add 14mL of AgNO with a concentration of 0.8g / 100mL to it. 3 The solution was magnetically stirred at a constant temperature at 30° C. for a certain period of time until the solution was evaporated to dryness, and a tan powder was obtained. The brown powder obtained above was calcined in an air atmosphere in a muffle furnace. The temperature rise system is 2°C / min before 300°C, 1°C / min from 300°C to 500°C, and kept at 500°C for 2 hours, and then naturally cooled to room temperature to obtain silver-loaded nano-titanium dioxide light. catalyst. image 3 It is the degrad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com