Manganese oxide-graphite phase carbon nitride composite photocatalytic material and preparation method thereof

A graphitic carbon nitride, composite photocatalysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve wide application prospects, good thermal and chemical stability, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

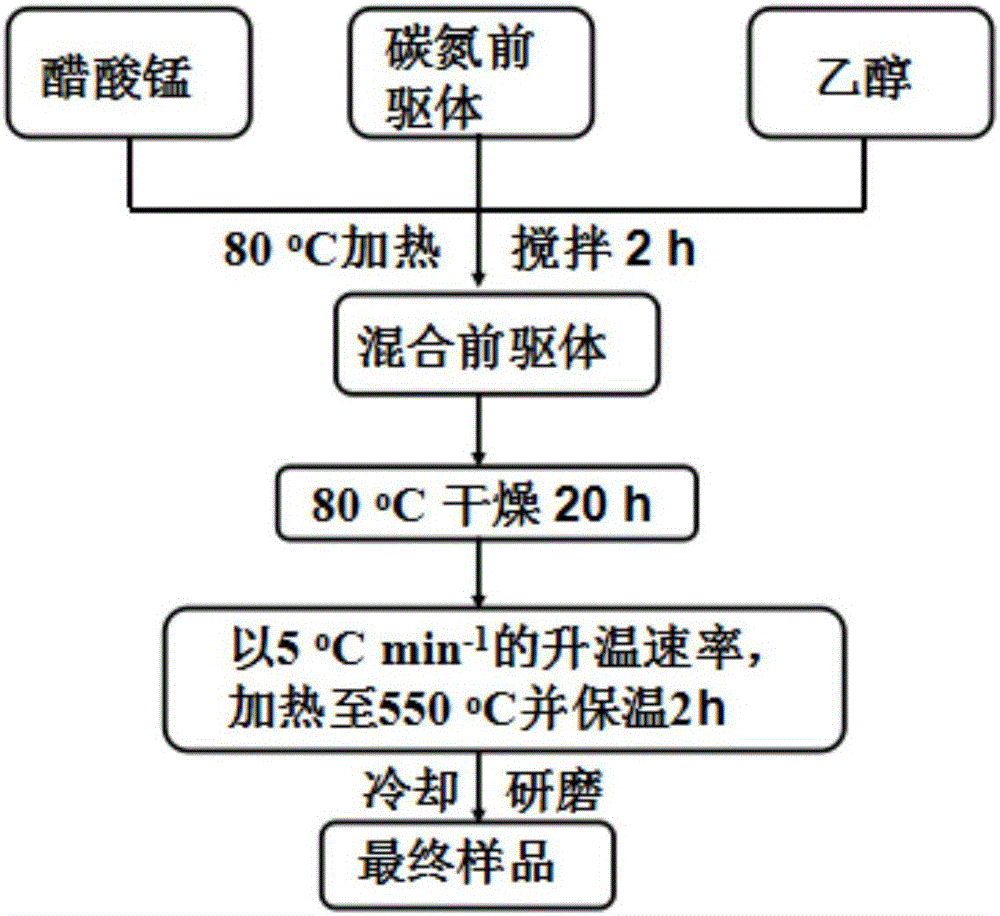

[0031] Preparation of 0.3mol% CM photocatalyst: Take 0.006g manganese acetate and disperse it in 10mL ethanol solution. After the pink manganese acetate crystals are completely dissolved in ethanol, add 2 g of melamine powder to the solution. Next, the above mixture was stirred at 80° C. for 2 hours with a magnetic stirrer to obtain a slurry. The slurry samples were then dried in an oven at 80°C for 20 hours. Finally, the sample was transferred to a muffle furnace at 5 °C min -1 heating rate, heated to 550 ° C and kept for 2 hours. After the sample had cooled to room temperature, the resulting product was transferred to an agate mortar and ground into a fine powder.

[0032] Its XRD pattern is as follows Figure 4 As shown in a, obvious g-C can be seen in the XRD pattern 3 N 4 The characteristic diffraction peaks of , indicating that at this temperature, a completely crystallized g-C 3 N 4 . MnO x Nanoparticles did not enter g-C 3 N 4 Lattice, only loaded on g-C 3...

Embodiment 2

[0034] Preparation of 0.9mol% CM photocatalyst: Take 0.018g manganese acetate and disperse it in 20mL ethanol solution. After the pink manganese acetate crystals are completely dissolved in ethanol, add 2 g of melamine powder to the solution. Next, the above mixture was stirred at 80° C. for 2 hours with a magnetic stirrer to obtain a slurry. The slurry samples were then dried in an oven at 100°C for 20 hours. Finally, the sample was transferred to a muffle furnace at 5 °C min -1 heating rate, heated to 550 ° C and kept for 2 hours. After the sample had cooled to room temperature, the resulting product was transferred to an agate mortar and ground into a fine powder.

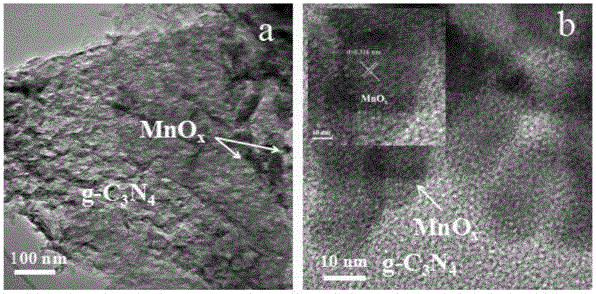

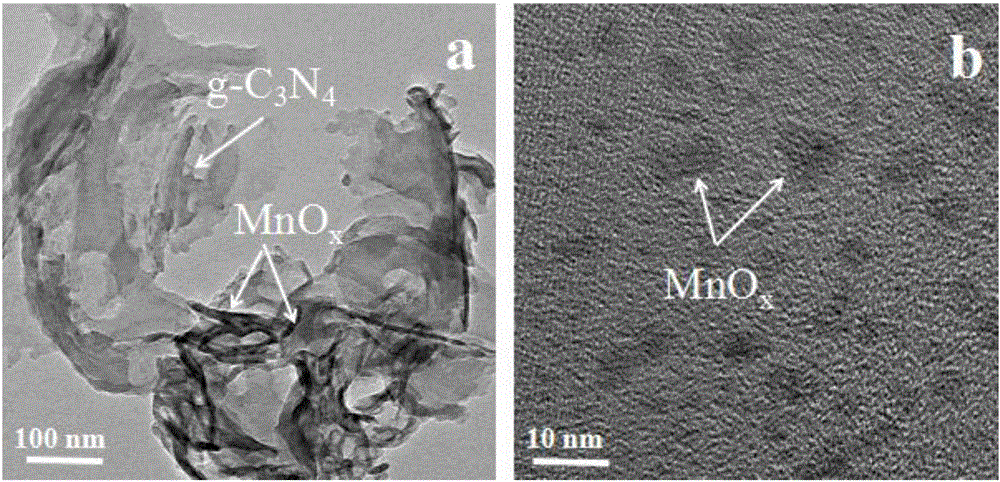

[0035] Its TEM picture is as follows figure 2 shown by figure 2 a Observable, g-C 3 N 4 It is a porous two-dimensional layered structure, MnO x Nanoparticles loaded on g-C 3 N 4 On the surface, the combination between the two is relatively tight. where MnO x The nanoparticle size is around 10-15 na...

Embodiment 3

[0037] Preparation of 0.3mol% CM photocatalyst: Disperse 0.002g manganese acetate into 10mL deionized water. After the pink manganese acetate crystals are completely dissolved in water, add 10 g of urea powder to the solution. Next, the above mixture was stirred at 80°C for 2 hours with a magnetic stirrer. The samples were then dried in an oven at 80°C for 20 hours. Finally, the sample was transferred to a muffle furnace at 5 °C min -1 heating rate, heated to 550 ° C and kept for 2 hours. After the sample had cooled to room temperature, the resulting product was transferred to an agate mortar and ground into a fine powder. The hydrogen production rate is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com