High-performance oxygen evolution CoO@Co-NC/C composite catalyst as well as preparation method and application thereof

A composite catalyst, high-performance technology, applied in the field of electrocatalysis, can solve the problems of low activity and electrical conductivity, and achieve the effects of simple preparation method, improved activity and stability, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of CoO@Co-NC / Ketjen Black (KB)

[0032] The synthesis method adopts two-stage high-temperature treatment, and the specific process is as follows: Weigh 1mmol cobalt acetate tetrahydrate, 5g urea and 0.25g Ketjen black, add 50mL deionized water, dissolve or disperse by ultrasonication for 30min, and evaporate and dry at 80°C dry moisture. The obtained precursor mixture was heated from room temperature to 550 °C in a nitrogen protective gas at a heating rate of 5 °C / min and kept for 2 h; then continued to be heated at a rate of 5 °C / min to 700 °C and kept for 2 h. Naturally cooled to room temperature and taken out to obtain Co@CoO-NC / KB.

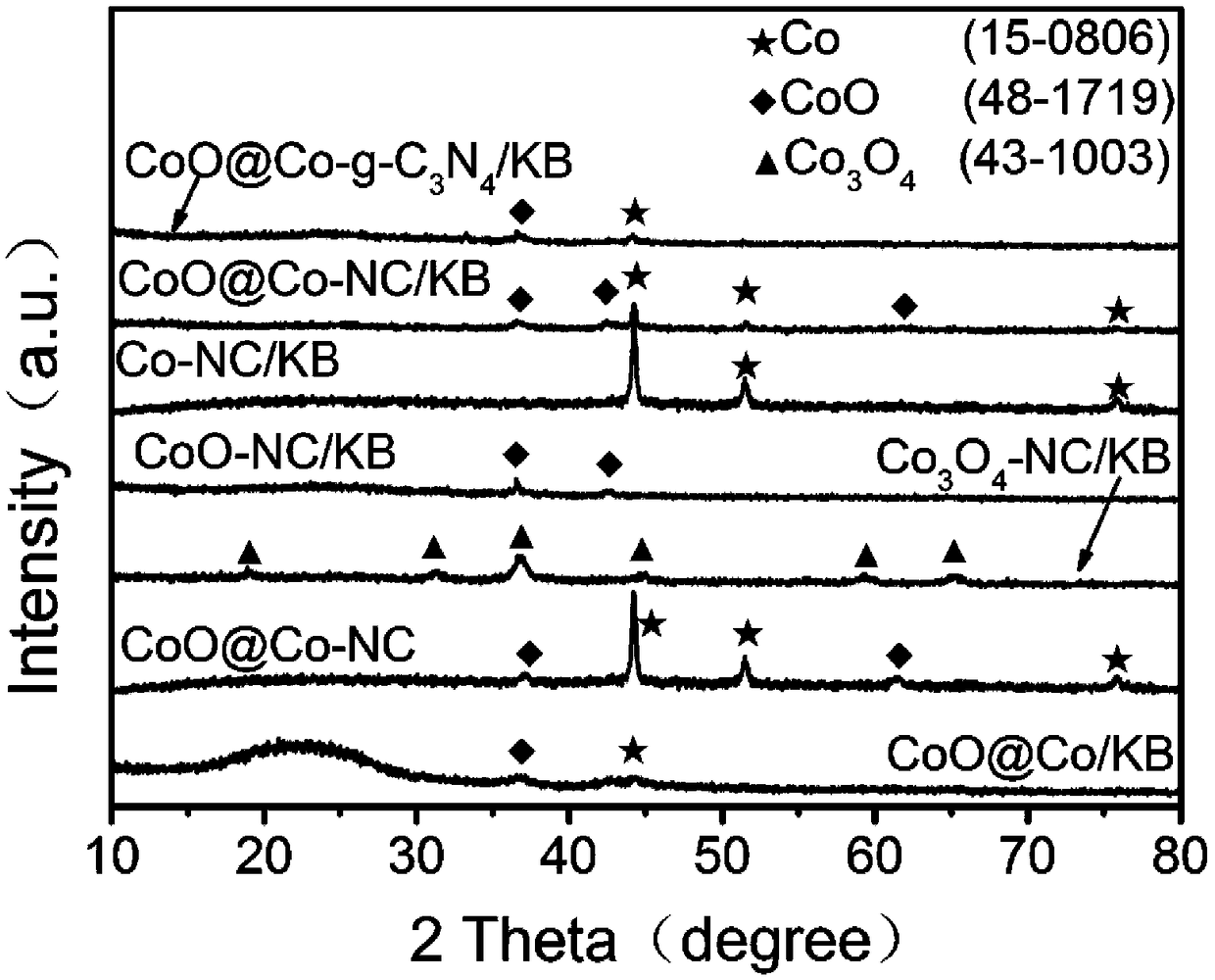

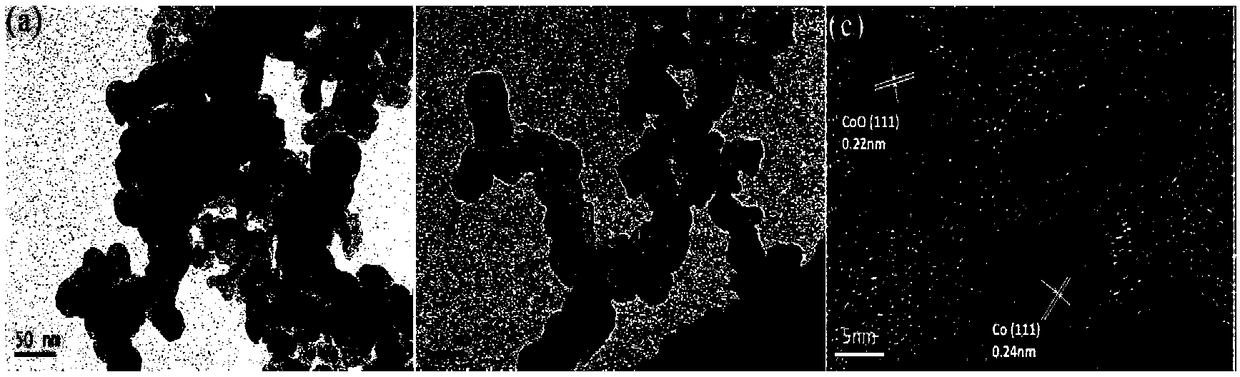

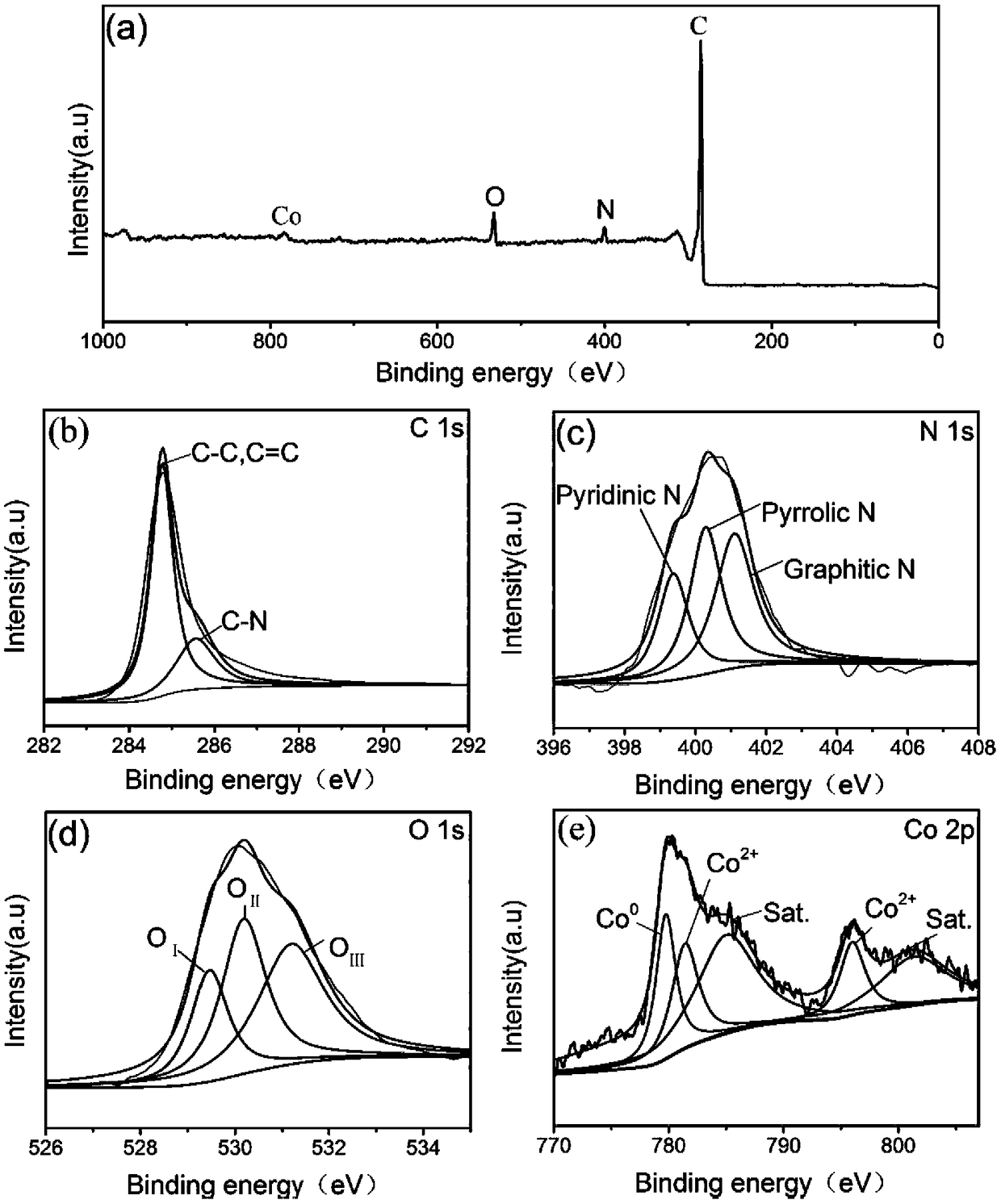

[0033] X-ray diffractometer (XRD, D8ADVANCE, Cu-Kα, ) to conduct phase analysis of the product; through transmission electron microscopy (JEOL-2010, 200kV) to conduct transmission electron microscopy (TEM) and high-resolution transmission electron microscopy (HRTEM) to characterize the product’s morphology; elements on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting current density | aaaaa | aaaaa |

| Limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com