Regeneration method of inactivated SCR denitration catalyst

A denitration catalyst and catalyst technology, which are applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems that denitration activity cannot meet the national nitrogen oxide emission standard for a long time, poisoning active components, and complex flue gas components. , to save drying time, improve physical structure, and facilitate regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

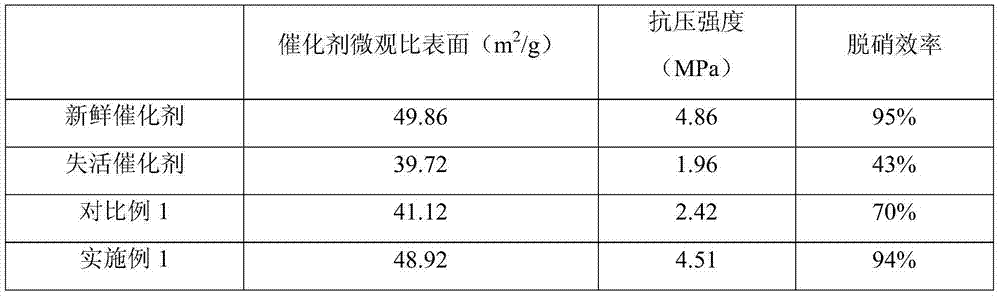

Embodiment 1

[0029] Regenerate a commercial denitrification catalyst that has been in operation for 26,000 hours in a power plant, a regeneration method for a deactivated SCR denitrification catalyst, the specific steps are as follows:

[0030] 1) Using 2.5Mpa oil-free dry compressed air, the flow rate is 0.5m 3 / s Purge the deactivated monomer catalyst for 1 hour to remove the dust with weak adhesion on the surface of the catalyst;

[0031] 2) the catalyst that will be placed in concentration through step 1) is that the strong alkali weak acid salt sodium carbonate of 1.0mol / L, the tensio-active agent flat add O concentration is 0.3wt%, penetrant JFC concentration is 0.5wt% and removes In the mixed solution composed of ionized water, supplemented by ultrasonic immersion for 20min, the power is 500W;

[0032] 3) Place the catalyst treated in step 2) in an organic acid solution: the concentration of formic acid is 0.8mol / L, the concentration of surfactant Pingping O is 0.3%wt, the concentr...

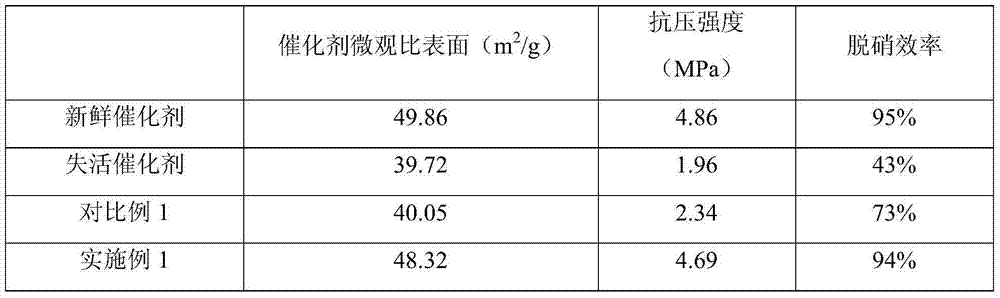

Embodiment 2

[0043] Regenerate a commercial denitrification catalyst that has been in operation for 25,000 hours in a power plant, a method for regeneration of a deactivated SCR denitrification catalyst, the specific steps are as follows:

[0044] 1) Use 3Mpa oil-free dry compressed air with a flow rate of 0.8m 3 / s purge the deactivated monomer catalyst for 1.5h to remove the dust with weak adhesion on the surface of the catalyst;

[0045] 2) Place the catalyst treated in step 1) into a strong base and weak salt sodium acetate with a concentration of 1.6mol / L, the concentration of the surfactant Pingping O is 0.3wt%, and the concentration of the penetrant JFC is 0.5wt% In the mixed solution composed of deionized water, supplemented by ultrasonic immersion for 40min, the power is 200W;

[0046] 3) placing the catalyst treated in step 2) in an organic acid solution with a concentration of acetic acid of 0.8mol / L, the concentration of the surfactant Pingping O is 0.3%wt, the concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com