Patents

Literature

54 results about "Salt sodium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inorganic hydrated salt expanded graphite composite phase-changing heat storage material and preparation method thereof

The invention relates to an inorganic hydrated salt expanded graphite composite phase-changing heat storage material. In the preparation method thereof, 85-89 mass parts of inorganic hydrated salt sodium acetate trihydrate as a heat storage matrix, 5.5-6.5 mass parts of disodium hydrogenphosphate as a nucleating agent, 2.5-3.5 mass parts of carboxymethyl cellulose as a thickening agent, and 3-4.5 mass parts of expanded graphite is blended in an inorganic hydrated salt mixture as a material with a high thermal conductivity. Due to the use of the expanded graphite, the material not only maintains excellent properties of natural flake graphite such as good thermal conductivity, no toxicity and the like, but also has adsorbability which the natural flake graphite does not have. The invention solves the problems of sub-cooling degree, phase stratification and low thermal conductivity during the heat storage process. The composite phase-changing material has a low sub-cooling degree after the phase changing performance is improved, the solution thereof is uniform without sedimentation and stratification during the solid-liquid phase change, the performance is stable, the repeatability of good, and the phase-changing heat storage can be enhanced through improving the thermal conductivity of the material.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

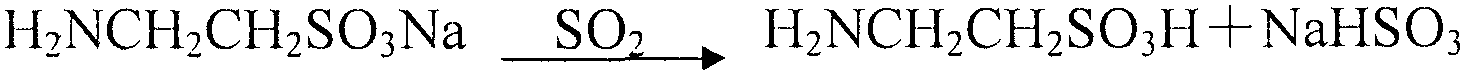

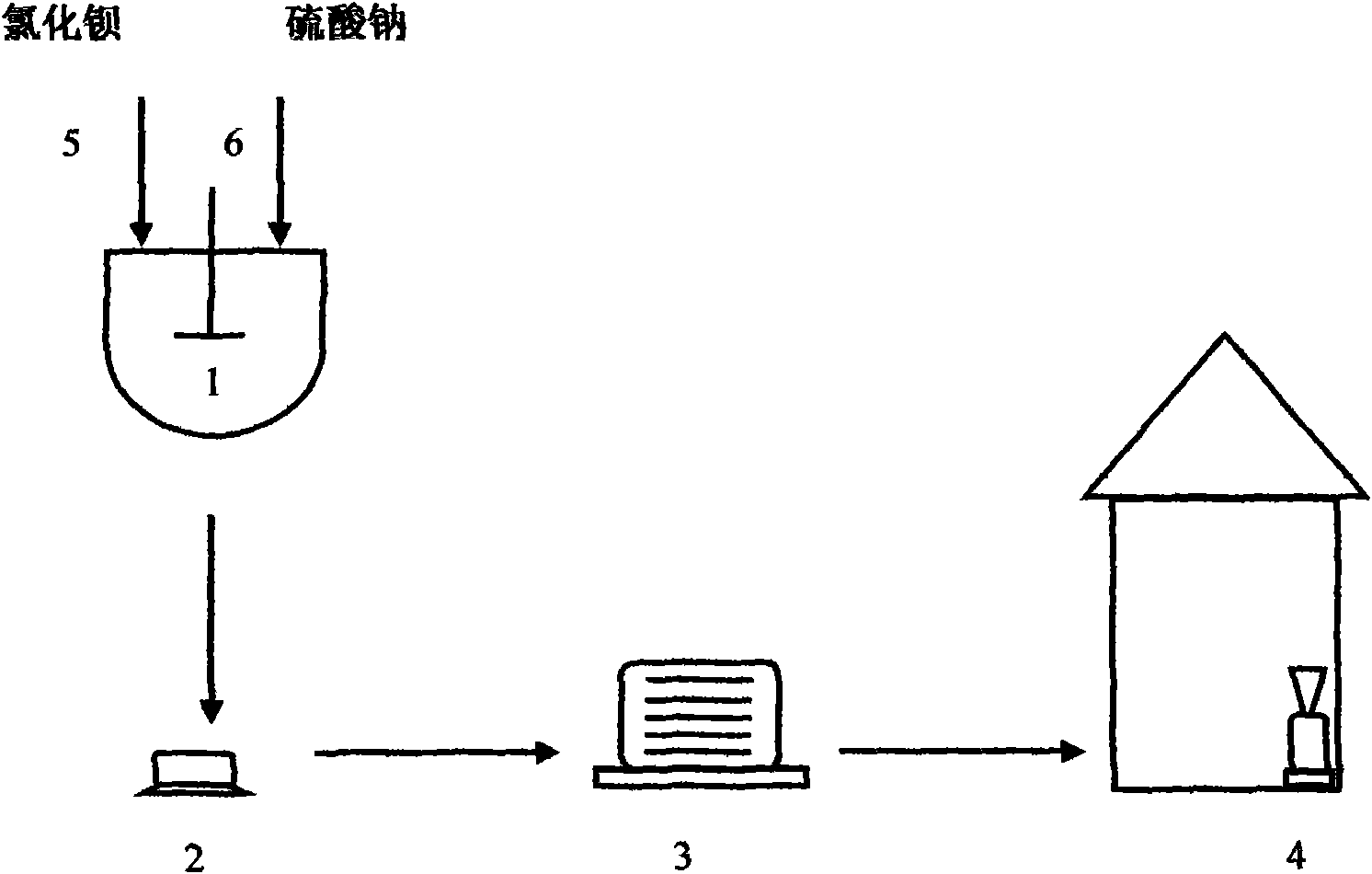

Preparation method for taurine

ActiveCN103382170ASolve pollutionAvoid it happening againOrganic compound preparationSulfonic acids salts preparationSalt sodiumEthylene oxide

Owner:QIANGJIANG YONGAN PHARMA

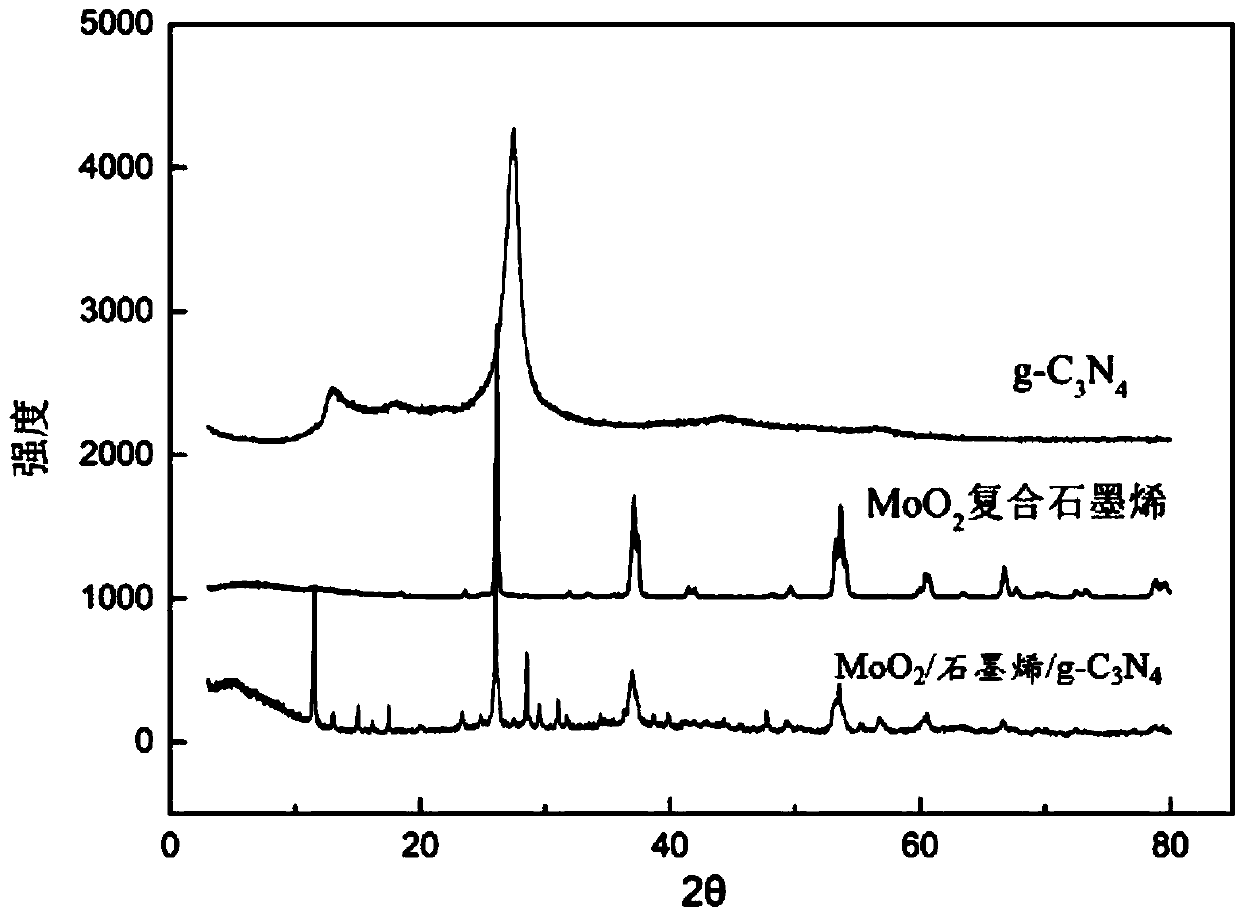

Preparation method for supercapacitor material MoO2/graphene/g-C3N4

ActiveCN107845508ALow costBest configurationMaterial nanotechnologyHybrid capacitor electrodesVacuum dryingCalcination

The invention discloses a preparation method for a supercapacitor material MoO2 / graphene / g-C3N4, and belongs to the technical field of composite material preparation. The method comprises the following steps: 1), scattering oxidized graphene into deionized water, employing a cell pulverizer for smashing, adding mixed solution composed of a molybdenum salt precursor and an end-capping reagent, carrying out the stirring of the mixed solution, enabling the mixed solution to be uniform, and obtaining an oxidized graphene-molybdenum salt-sodium salt mixed solution system; 2), adjusting pH value andthen carrying out the hydro-thermal reaction in a reaction still; 3), employing water and ethyl alcohol for cleaning, carrying out the low-temperature vacuum drying, and obtaining an MoO2 composite oxidized graphene material; 4), mechanically mixing the MoO2 composite oxidized graphene material with a carbon and nitrogen precursor, carrying out the high-temperature calcination of the mixture under the protective atmosphere of high temperature argon gas, cooling the mixture to the room temperature, and then obtaining the MoO2 / graphene / g-C3N4 composite material. The method is simple and feasible, and is low in cost. The specific capacity of an obtained composite material supercapacitor is remarkably enlarged, and the composite material supercapacitor is good in cyclic charging and discharging stability.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

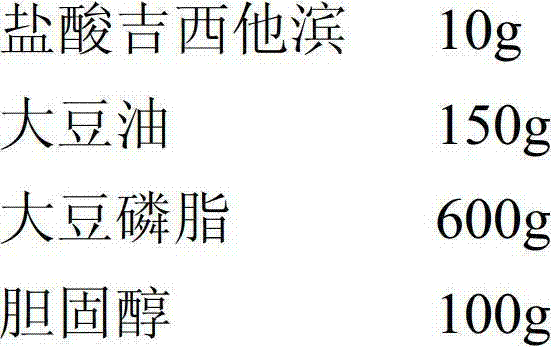

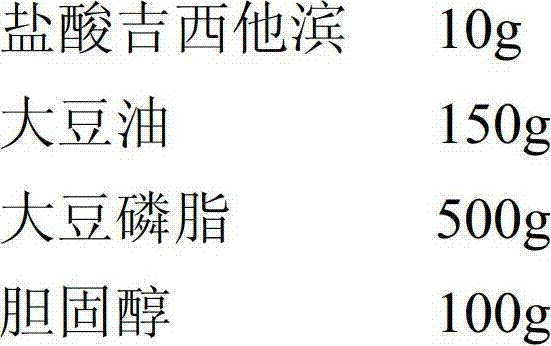

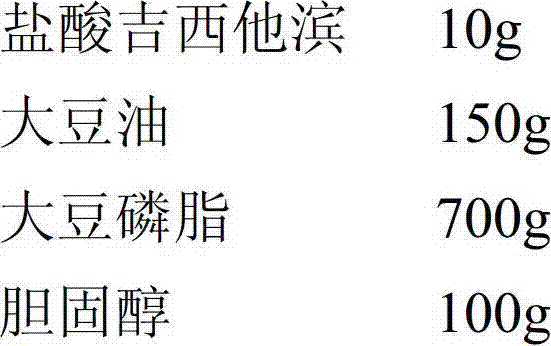

Gemcitabine or salt liposome thereof, and preparation method and application thereof

ActiveCN102784107AHigh encapsulation efficiencyImprove stabilityOrganic active ingredientsAntineoplastic agentsSide effectSalt sodium

The present invention relates to a gemcitabine or a salt sodium liposome thereof, and a preparation method and application thereof. The liposome comprises gemcitabine or the salt thereof, injection oil, phospholipid and cholesterol in a mass ratio of 1:1-20:50-70:5-30. The injection has good encapsulation efficiency, better stability, and lower side effect.

Owner:JIANGSU HANSOH PHARMA CO LTD

Practical nickel-free sealing agent for aluminum alloy anodic oxidation

InactiveCN103668387ANon-toxicGood sealingSurface reaction electrolytic coatingCobalt acetateEcological environment

The invention provides a practical nickel-free sealing agent for aluminum alloy anodic oxidation, which is prepared by compounding primary salt sodium acetate, secondary salt cobalt acetate and a penetrant sorbitol in combination with an assistant. The physical state is powder or water. The practical nickel-free sealing agent for aluminum alloy anodic oxidation, provided by the invention, is affordable and non-toxic to the ecological environment, and realizes an equivalent effect as nickel salt sealing; the sealing effect on an organic dyed film (red or yellow) is better than that of a nickel salt sealing agent.

Owner:台山市科美化学工业有限公司

Process for preparing high-purity methylsulfonic acid

The invention discloses a process for preparing high-purity methylsulfonic acid. The process comprises the following steps: generating methylsulfonic sodium in a mixed reactor by the reaction of a sodium sulfite solution and monochloro methane at the temperature of 70-110 DEG C, then adding concentrated hydrochloric acid after dewatering, and generating a methylsulfonic acid solution and a corresponding sodium chloride salt precipitate; distilling off a hydrochloric acid solution from filtrate obtained after filtering sodium chloride salt, then distilling off acid water by depressurization, decompressing and distilling to obtain the methylsulfonic acid with high yield and high purity. The filtered salt sodium chloride can be used as a raw material for industrial electroanalysis, all the water which is distilled out is recovered as an assistant material, and the recovered hydrochloric acid solution is recovered for circular mechanical application. The invention has no pungent odor, no generation of waste water and waste residues, single reaction, easy acquirement of raw materials, simple operation and low cost, is suitable for industrialized scale production and is an environment-friendly industrialized process for preparing the high-purity methylsulfonic acid.

Owner:衢州中科精细化学有限公司

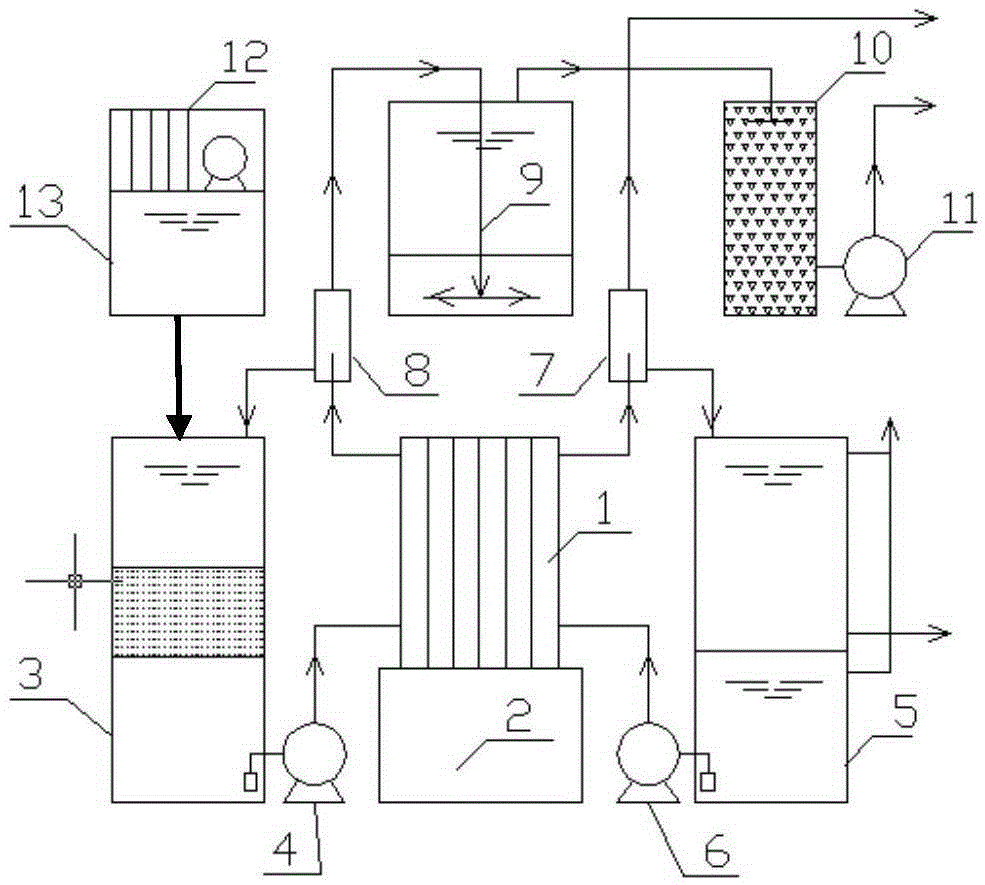

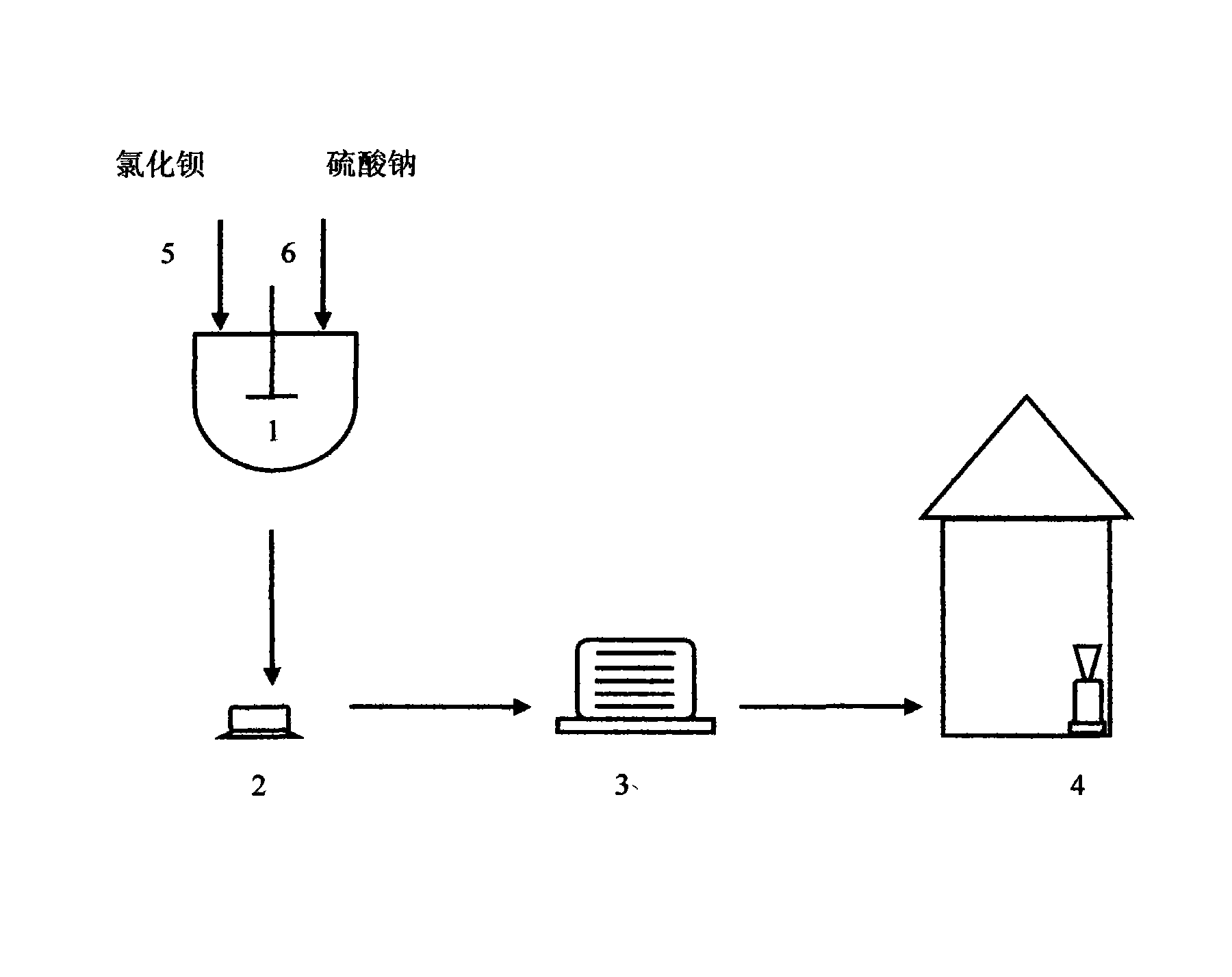

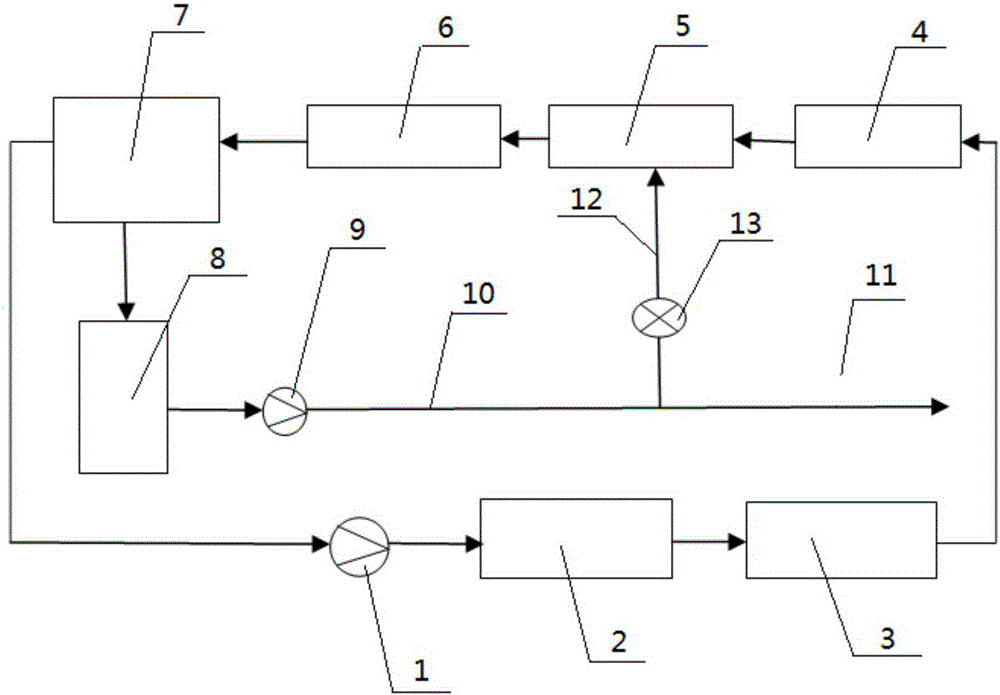

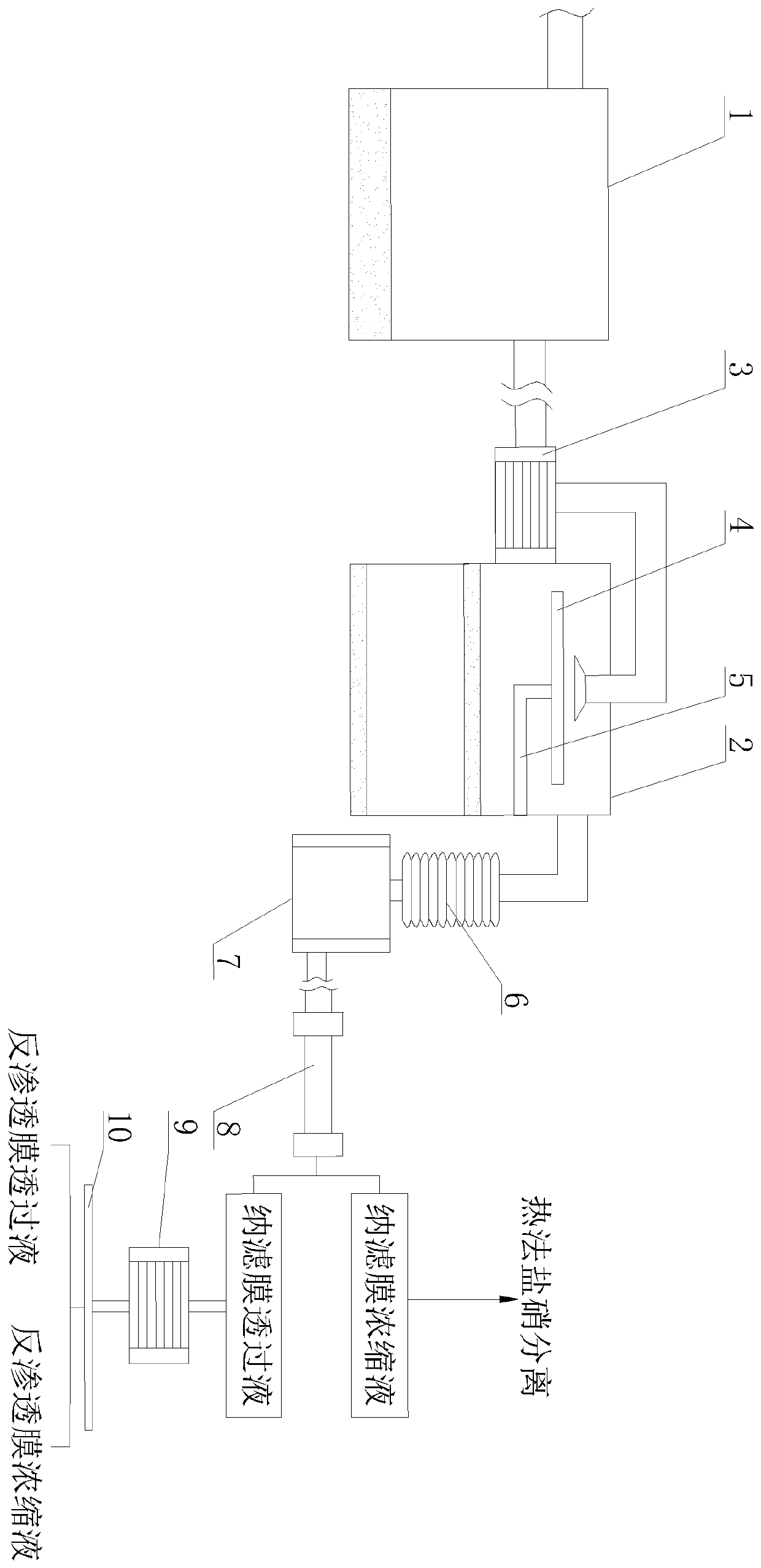

Portable electrolytic salt sodium hypochlorite generator suitable for various kinds of disinfection in disaster areas

The invention discloses a portable electrolytic salt sodium hypochlorite generator suitable for various kinds of disinfection in disaster areas. An ion membrane electrolysis cell is arranged and provided with a switching power supply. The ion membrane electrolysis cell is connected with a salt liquor metering pump, an alkaline liquor metering pump, a hydrogen separator and a chlorine separator. A soluble salt tank is connected with the salt liquor metering pump and the chlorine separator. An alkaline liquor tank is connected with the alkaline liquor metering pump and the hydrogen separator. A chlorine absorber is connected with the chlorine separator and an activated carbon tank. The activated carbon tank is connected with a vacuum pump. A reverse osmosis water purifier is arranged on a pure water tank. The pure water tank is connected with the ion membrane electrolysis cell. A bipolar type electrode structure is adopted in the electrolysis cell, so that the size of the electrolysis cell and the size of the switching power supply are reduced; the quality of salt liquor and alkaline liquor in the electrolysis cell is guaranteed through the reverse osmosis water purifier; and safe backflow of light salt brine is guaranteed through the soluble salt tank, safe backflow of high-concentration alkaline liquor is guaranteed through the alkaline liquor tank, and by means of the activated carbon tank and the vacuum pump, the chlorine separation efficiency and the absorption effect are ensured, and chlorine leakage is avoided.

Owner:CHINA IRRIGATION & DRAINAGE DEV CENT

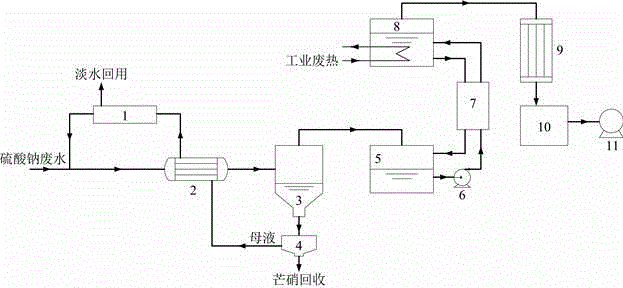

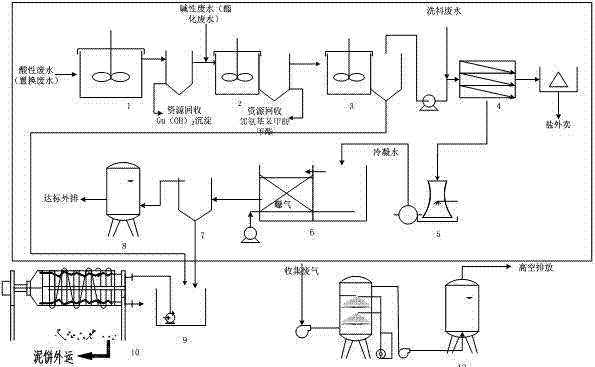

Zero-emission resource recycling method of high-salt sodium sulfate wastewater

InactiveCN104628208AReduce energy consumptionAvoid the deficiency of crystallization wallWater contaminantsMultistage water/sewage treatmentGas phaseLithium bromide

The invention discloses a zero-emission resource recycling method of high-salt sodium sulfate wastewater. The method comprises the following steps: 1) removing noncondensable gas from a gas phase space, gasifying water in sodium sulfate wastewater through pressure difference, enabling the gasified water to flow to the surface of lithium bromide solution through a gas phase channel, and evaporating, cooling, concentrating and crystallizing the high-salt sodium sulfate wastewater; 2) separating mirabilite and mother liquid from crystal mush, carrying out heat exchange and concentration on the mother liquid to obtain concentrated mother liquid and fresh water; feeding the concentrated mother liquid and new sodium sulfate wastewater together into a crystallizer and then repeating the steps 1) and 2); and 3) pumping the diluted lithium bromide solution into an evaporator, heating for evaporating to form concentrated lithium bromide solution, and returning the concentrated lithium bromide solution back into an absorber. According to the method disclosed by the invention, evaporation and crystallization are completed at a low temperature, no low-temperature clod source or septate heat exchange equipment, and therefore the energy consumption is lowered. By the method, mirabilite which is the crystallization product and fresh water can be recycled; furthermore, the aim of zero-emission resource recycling of high-salt sodium sulfate wastewater is achieved and the whole process is easy to operate.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

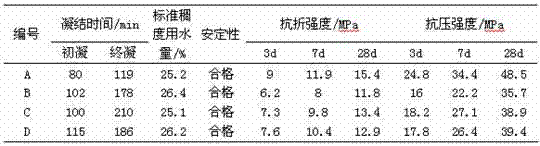

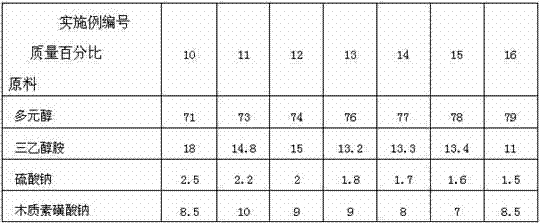

Activated basalt powder used as cement admixture and preparation method thereof

InactiveCN102503191AImprove grindabilityShorten grinding timeGrain treatmentsInorganic saltsSalt sodium

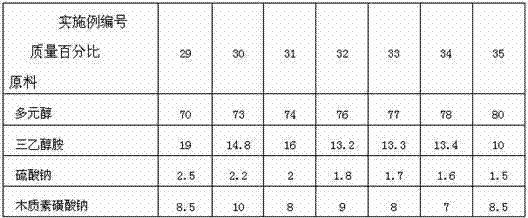

The invention discloses activated basalt powder used as a cement admixture. The activated basalt powder is characterized in that the activated basalt powder is mainly composed of basalt powder with weight of screen residue with fineness being 80 mu m not more than 0.5 and specific surface area of 380-600 m<2> / kg, and a grinding aid accounting for 0.15-1wt% of the basalt powder can also be added, wherein the grinding aid comprises the following raw material components in percentage by mass: 70-80% of polyol, 10-20% of triethanolamine, 1.5-2.6% of inorganic salt sodium sulfate, and 7-10% of organic salt sodium lignosulfonate. The activated basalt powder is prepared by mechanical activation and chemical activation, mechanical activation or chemical activation, mechanical activation and other modes. Used as the cement admixture, the prepared product can improve cement performances, adjust cement grade and lower cement production cost; and used as a concrete admixture, the prepared product can lower product cost of unit-volume concrete, improve the mechanical performances and durability of concrete.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Annealing and pickling method for duplex stainless steel

ActiveCN108977874AReduce usageProtection securityFurnace typesCleaning using toolsSalt sodiumElectrolysis

The invention discloses an annealing and pickling method for duplex stainless steel. The method comprises the following steps that the duplex stainless steel subjected to cold rolling through a twenty-high roll mill is uncoiled, degreased, annealed in a continuous annealing furnace, pickled, leveled and coiled so as to obtain a finished product, wherein in the annealing step in the continuous annealing furnace, the annealing temperature is 800-1200 DEG C, the pickling step comprises the processes of primary sodium sulfate electrolysis, primary grinding and scrubbing, secondary sodium sulfate electrolysis, secondary grinding and scrubbing and mixed acid pickling, and scale is removed through the pickling step. The method has the advantages that the pickling step after annealing of the duplex stainless steel comprises the processes of twice neutral salt sodium sulfate electrolysis, twice grinding and scrubbing and mixed acid pickling, so that the scale on the surface of strip steel is removed, the concentration of HF used is low, the operation time is short, the production cost is saved, the safety of workers is protected, and the environment is protected.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

High-salt non-degradable saccharin industrial wastewater and gas treatment method and device

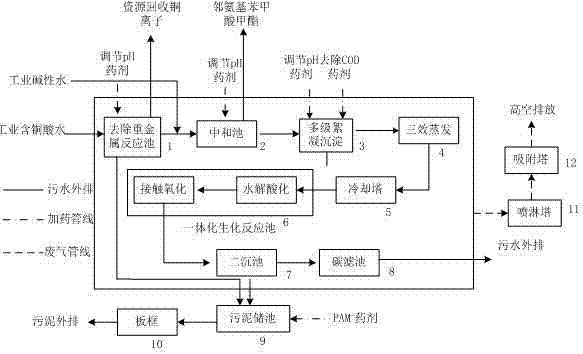

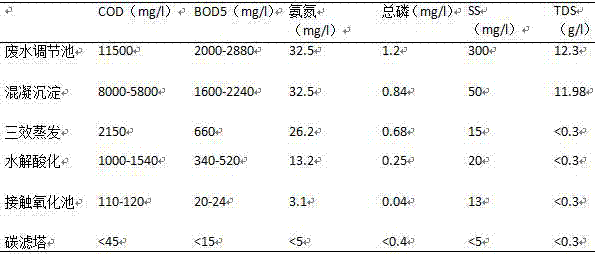

InactiveCN107055927AEfficient handlingEfficient resourcesOrganic compound preparationTreatment involving filtrationSodium sulfateToxic industrial waste

The invention provides a high-salt non-degradable saccharin industrial wastewater and gas treatment method and device. The high-salt non-degradable saccharin industrial wastewater and gas treatment method comprises the following steps: (1) performing copper extraction on acid wastewater containing copper ions; (2) performing acid-base neutralization on the supernate of wastewater from which copper is extracted and alkali wastewater to separate out methyl anthranilate; (3) performing flocculation and sedimentation on the supernate in the step (2) by use of a multi-stage flocculating precipitant; (4) performing evaporative crystallization on wastewater obtained in the step (3) to remove mixed salt sodium sulfate and sodium chloride; (5) performing integrated biotreatment on condensed water evaporated in the step (4) to be standard; and (6) capping all ponds, collecting waste gas, performing alkaline spraying, enabling the collected gas to pass through an active carbon adsorption tower, and performing high-altitude discharge. By use of the coupling and synergistic effect of different unit technologies, organic matters, granular suspended solids, high-price ions, other soluble inorganic salt and the like in high-salt industrial waste gas are removed, deep treatment and standard emission of the high-salt industrial wastewater are realized, and social, economical and environmental benefits are remarkably improved.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN +1

Method for purifying polysulfide silane coupling agent byproduct salt

ActiveCN103787373AHigh puritySolve environmental problemsSulfate/bisulfate preparationAlkali metal halide purificationSulfate radicalsEthylic acid

The invention aims at providing a method for purifying a polysulfide silane coupling agent byproduct salt. The method comprises the following steps: A, oxidizing sulfur ions, namely, feeding the byproduct saline of a polysulfide silane coupling agent into a reaction device, and adding a hydrogen peroxide solution in the stirring state to completely convert sulfur ions in the byproduct silane into sulfate radicals; and B, performing a hot saltpeter removal method, namely, filtering to remove impurities in the treated silane, performing multiple-effect evaporation on the obtained clear liquid so as to obtain byproducts sodium chloride and sodium sulfate. Whether the oxidation desulphuration ions are completely reacted can be detected by using a lead acetate test paper detection method or a copper chloride color change method. By adopting the method, sulfur ions can be completely converted into sulfate radicals, a sulfate product can be separated from sodium chloride by using the hot saltpeter removal method, and sodium chloride with high purity can be obtained. The problems of environment friendliness and purification treatment on the byproduct salt sodium chloride are solved.

Owner:南京曙光精细化工有限公司

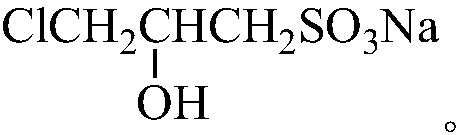

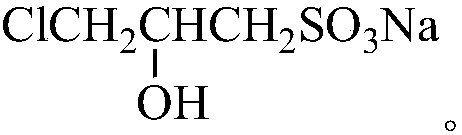

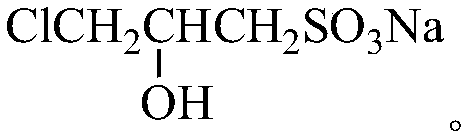

Amide quaternary ammonium salt sodium hydroxypropyl sulfonate asphalt emulsifier and preparation method thereof

ActiveCN107903194AImprove hydrophilicityEnhanced charge strengthSulfonic acids salts preparationBuilding insulationsSolventMethanol

The invention discloses an amide quaternary ammonium salt sodium hydroxypropyl sulfonate asphalt emulsifier and a preparation method thereof. The asphalt emulsifier is prepared from coconut oil acyl propyl dimethyl tertiary amine, alcohol solvent, acrylic acid, epoxy chloropropane and sodium hydrogen sulfite according to a molar ratio of 1mol:(4.00-9.00)mol):(1.00-1.10)mol:(1.0-1.15)mol:(1.05-1.25)mol, wherein the alcohol solvent is alcohol, methanol or isopropanol. The asphalt emulsifier is easy-to-obtain in synthesis raw materials, low in production cost, simple in process and needless of high-temperature reaction and can emulsify asphalt different in type, emulsified asphalt prepared by using the asphalt emulsifier is exquisite, uniform and high in storage stability, and cationic emulsified asphalt can be prepared.

Owner:山东圳谷新材料科技有限公司

Method for coproducing sodium chloride by using micro barium sulphate prepared by barium chloride

InactiveCN101580264AThe method is simple and clearIncrease profitCalcium/strontium/barium sulfatesAlkali metal chloridesBarium dichlorideSalt sodium

The invention discloses a method for coproducing sodium chloride by using micro barium sulphate prepared by barium chloride, which is technically characterized in that: reacting the barium chloride and sodium sulphate according to certain proportion to obtain micro barium sulphate and sodium chloride after filtration; filtering the micro barium sulphate and sodium chloride to obtain filter cake, washing, drying, grinding, and packaging into micro barium sulphate products; and distilling the filtrate under reduced pressure to obtain industrial salt sodium chloride products. The method is simple and concise, and particularly uses low-grade barium chloride and sodium sulphate to produce high-grade precipitated barium sulphate, the production technology and equipment are simple, the productivity is extremely high, and the profit is high.

Owner:王嘉兴

Method for preparing nano-barium sulfate coproducing sodium chloride

InactiveCN101638241AThe method is simple and clearIncrease profitCalcium/strontium/barium sulfatesAlkali metal chloridesSalt sodiumBarium dichloride

The invention discloses a method for preparing nano-barium sulfate coproducing sodium chloride. The method is technically characterized in that barium chloride and sodium sulfate undergo reaction according to a certain proportion and then filtration so as to obtain precipitated barium sulfate and sodium chloride. A filter cake obtained from the filtration is washed, dried, crushed and then packaged into a nano-barium sulfate product. The filtrate obtained from the filtration undergoes reduced pressure distillation so as to obtain an industrial salt sodium chloride product. The method is simple, fast and clear and particularly suitable for the production of high-grade precipitated barium sulfate by utilizing low-grade barium chloride and sodium sulfate. The method has simple production process and apparatus and achieves extremely high yield and great profit.

Owner:王嘉兴

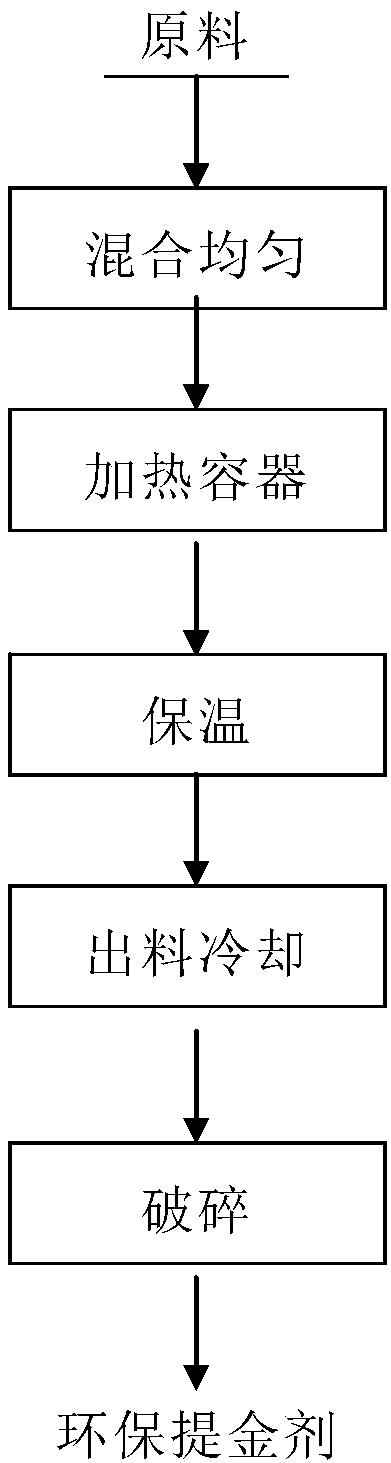

Environmentally-friendly gold extracting agent and preparation method thereof

PendingCN111304456AReduce manufacturing costSimple production methodProcess efficiency improvementSalt sodiumProcess engineering

The invention relates to an environmentally-friendly gold extracting agent and a preparation method thereof, belonging to the technical field of gold production. The environmentally-friendly gold extracting agent comprises sodium carbonate, urea, and yellow prussiate of soda. The preparation method comprises the following steps of: uniformly mixing the raw materials according to a certain proportion, heating the mixture to 800-850 DEG C in a closed container, keeping for a certain period of time, then pouring the mixture into an open container, and naturally cooling the mixture to obtain the environmentally-friendly gold extracting agent. The environmentally-friendly gold extracting agent can completely replace sodium cyanide and is suitable for the recovery and utilization of gold in gold-bearing oxidized ore and gold-bearing tailings. Compared with other agents, the environmentally-friendly gold extracting agent has the characteristics of low production cost, simple production method, strong applicability, environmental protection, good economic benefits and the like.

Owner:有研资源环境技术研究院(北京)有限公司

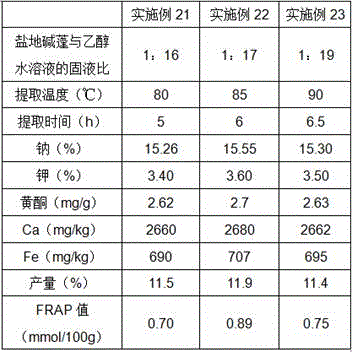

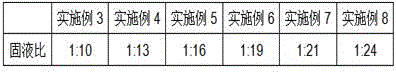

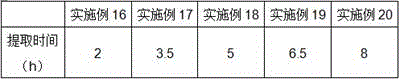

Plant salt and method for extracting plant salt from suaeda salsa by hot extraction technology via synergy of ultrasonic waves and microwaves

InactiveCN105876746AIncrease productionHas antioxidant activityFood scienceSalt sodiumOrganic chemistry

The invention provides a plant salt. The content of sodium in the plant salt is 15.26-15.55%, and the content of potassium in the plant salt is 3.4-3.6%. The invention further provides a method for extracting the plant salt from suaeda salsa through a hot extraction technology via the synergy of ultrasonic waves and microwaves. The method comprises the following steps of selecting raw materials and assisting hot extraction through synergy of the ultrasonic waves and the microwaves. The plant salt disclosed by the invention has the beneficial effects that the content of the sodium in the extracted plant salt is 15.26-15.55%, the content of the potassium is 3.4-3.6%, the content of Ca is 2660-2680 mg / kg, the content of Fe is 690-707 mg / kg, and the yield of the extracted plant salt is high and is 11.4-11.9%; the extracted plant salt has antioxidative activity, the content of flavone is 2.62-2.7 mg / g, and the whole antioxidative activity FRAP value is 0.7-0.89 mmol / 100g.

Owner:王胜

Intermittent electrolytic salt sodium hypochlorite generator suitable for small water supply projects in rural areas

The invention discloses an intermittent electrolytic salt sodium hypochlorite generator suitable for small water supply projects in rural areas. An electrolytic tank is arranged. An electrolysis electrode is fixed to the low end in the electrolytic tank. A cooling pipe is fixed to the upper portion of the electrolytic tank. An alternating current power supply switch, a direct current switching power supply and a direct current inverse-electrode switch are connected in series through a cable to be then connected with the electrolysis electrode. A reverse osmosis water purifier is communicated with the electrolytic tank through a pipe. The arranged cooling pipe starts cooling after electrolysis is carried out for 3-4 h, it can be effectively guaranteed that an electrolyte is stable and does not exceed 25 DEG C, and the later electrolysis condition is improved; purified water is used for preparing a salt solution so that the electrode can be effectively prevented from scaling; the same material and coating are adopted in the negative pole and the positive pole of the electrolysis electrode, the direct current inverse-electrode switch is used for alternate inverse-electrode electrolysis, and therefore scale on the electrode can be effectively removed; and the disinfectant dosage needed by the water supply projects for 1-5 days can be met when a sodium chlorate solution is produced each time. In addition, the intermittent electrolytic salt sodium hypochlorite generator is simple in structure and easy and convenient to operate and manage, and the disinfection needs of the small water supply projects in the rural areas can be met.

Owner:CHINA IRRIGATION & DRAINAGE DEV CENT

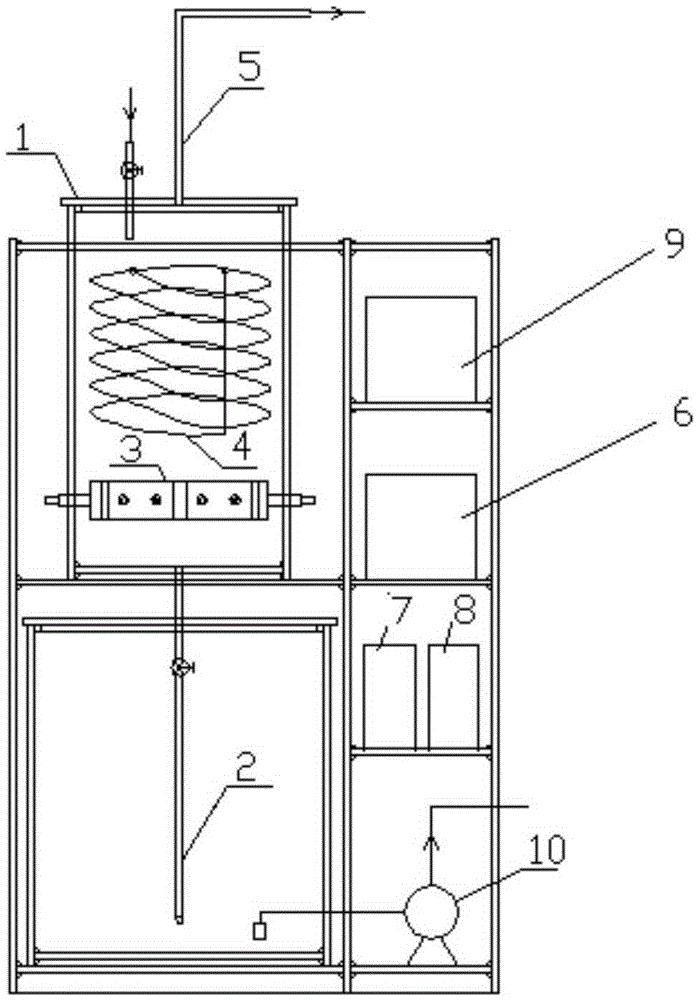

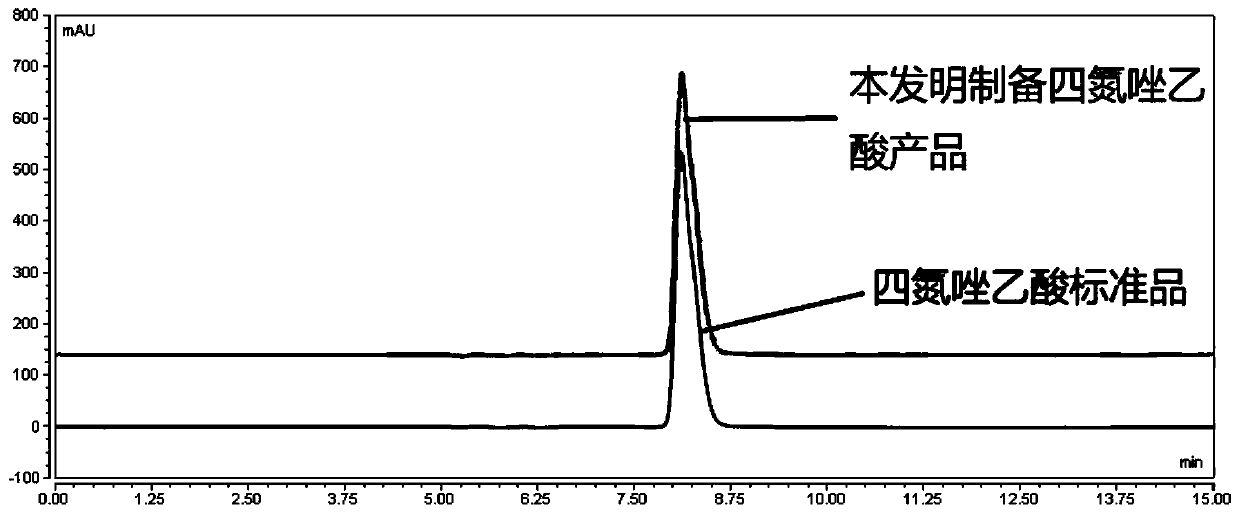

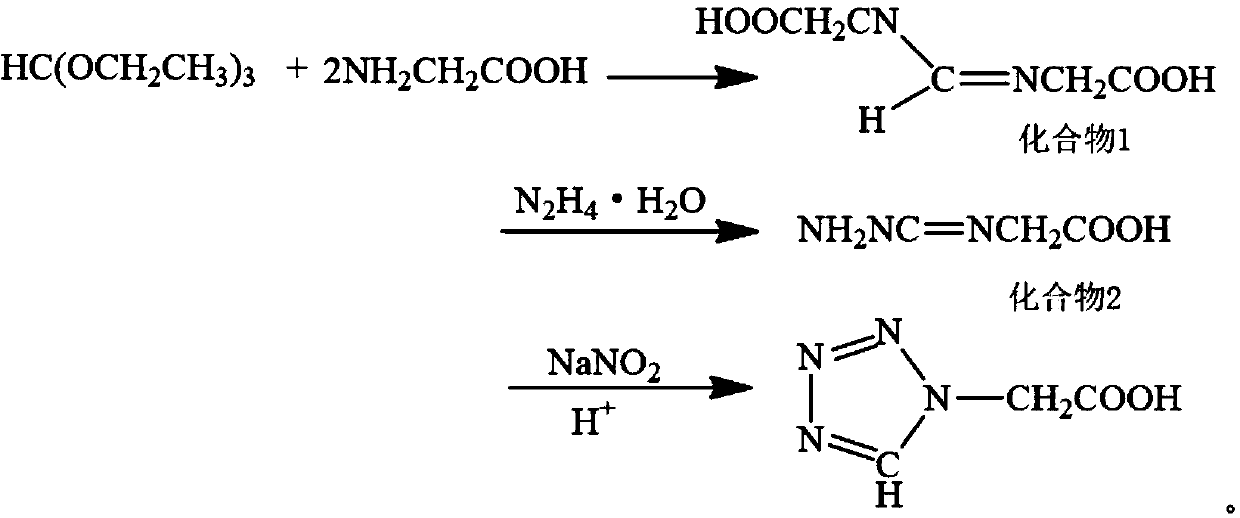

Method for synthesis of tetrazolylacetic acid using hydrazine hydrate method

Owner:CHEM TECH ACAD OF SHANDONG PROVINCE

Equipment and method for slowing down salt-sodium sulfate co-production sodium sulfate flash tank scaling

ActiveCN105174291AModerate amountReduce generationAlkali metal chloridesAlkali metal sulfites/sulfatesSalt sodiumSulfate

The invention provides equipment and method for slowing down salt-sodium sulfate co-production sodium sulfate flash tank scaling. The tank includes a circulation part, wherein the circulation part consists of a circulation pump, a preheater, a sodium sulfate evaporation tank, a sodium sulfate flash tank and a salt evaporation tank that are connected in order. The solid salt slurry flowing out of the salt evaporation tank is led to a salt slurry bucket, the effluent liquid is connected to the inlet of the circulation pump, the outlet of the salt slurry bucket is provided with a salt slurry pump, and the salt slurry pump conveys the salt slurry to a centrifuge through a salt slurry pump outlet pipe, and then salt can be collected. The equipment is characterized in that: the salt slurry pump outlet pipe is provided with a section of a reflux branch pipe communicated with the sodium sulfate flash tank, and the reflux branch pipe is equipped with a flow control valve. The equipment and method provided by the invention are beneficial to precipitation growth and flash operation of crystals in the sodium sulfate flash tank, can slow down the production of salt scale and prolong the operation period, and have very strong practicability.

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD

Method for purifying polysulfide silane coupling agent by-product brine

ActiveCN103787373BReduce processingHigh puritySulfate/bisulfate preparationAlkali metal halide purificationSulfate radicalsSilanes

The invention aims at providing a method for purifying a polysulfide silane coupling agent byproduct salt. The method comprises the following steps: A, oxidizing sulfur ions, namely, feeding the byproduct saline of a polysulfide silane coupling agent into a reaction device, and adding a hydrogen peroxide solution in the stirring state to completely convert sulfur ions in the byproduct silane into sulfate radicals; and B, performing a hot saltpeter removal method, namely, filtering to remove impurities in the treated silane, performing multiple-effect evaporation on the obtained clear liquid so as to obtain byproducts sodium chloride and sodium sulfate. Whether the oxidation desulphuration ions are completely reacted can be detected by using a lead acetate test paper detection method or a copper chloride color change method. By adopting the method, sulfur ions can be completely converted into sulfate radicals, a sulfate product can be separated from sodium chloride by using the hot saltpeter removal method, and sodium chloride with high purity can be obtained. The problems of environment friendliness and purification treatment on the byproduct salt sodium chloride are solved.

Owner:南京曙光新材料有限公司

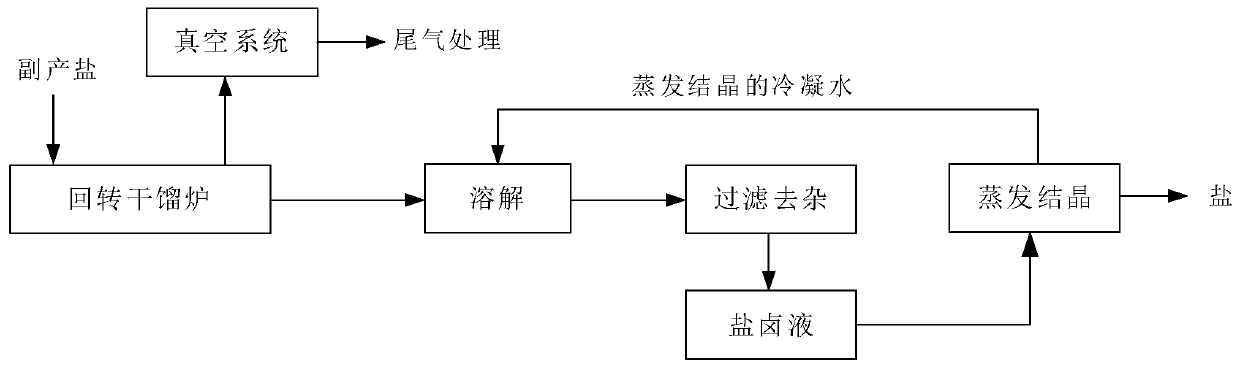

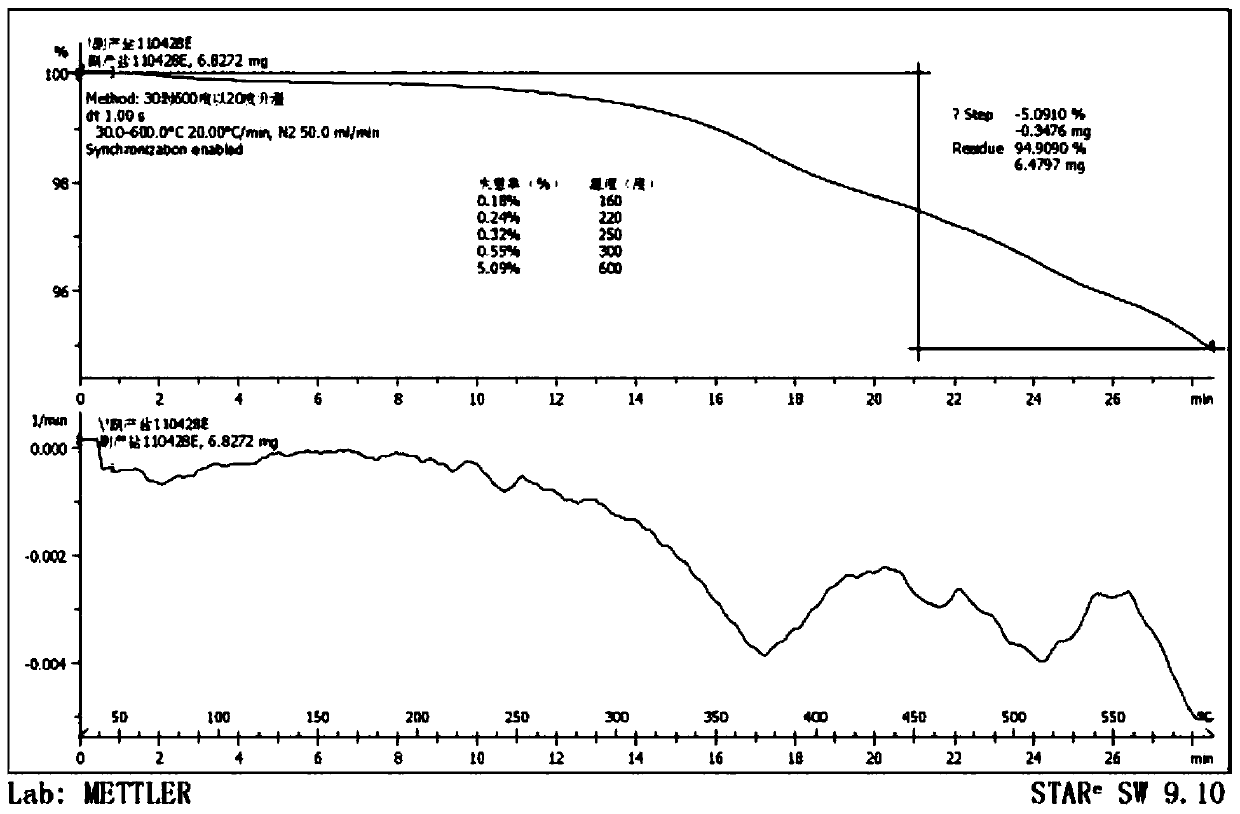

Recovery method of polyphenylene sulfide byproduct salt

The invention relates to a recovery method of polyphenylene sulfide byproduct salt, in particular to recovery treatment of byproduct salt sodium chloride in industrial production of polyphenylene sulfide resin, and belongs to the technical field of three-waste treatment. The technical problem to be solved by the invention is to provide a simple-process recovery method of polyphenylene sulfide byproduct salt, which comprises the following steps: putting polyphenylene sulfide byproduct salt in vacuum, keeping at 300-500 DEG C for 1.5-3 hours, adding water to dissolve the salt, and filtering by using a microporous filter to obtain a sodium chloride solution. According to the method, a vacuum dry distillation method is adopted, little tail gas is generated, the generated tail gas is easy to collect, advanced oxidation deodorization is conveniently adopted, environment-unfriendly emission is reduced, the produced sodium chloride solution is low in SS, NH3-N and COD and colorless, and pure salt can be obtained by evaporating and crystallizing the sodium chloride solution. The method is short in process, simple to operate and low in equipment requirement, and has the characteristics of low cost and low temperature.

Owner:四川明道和化学新材料有限公司

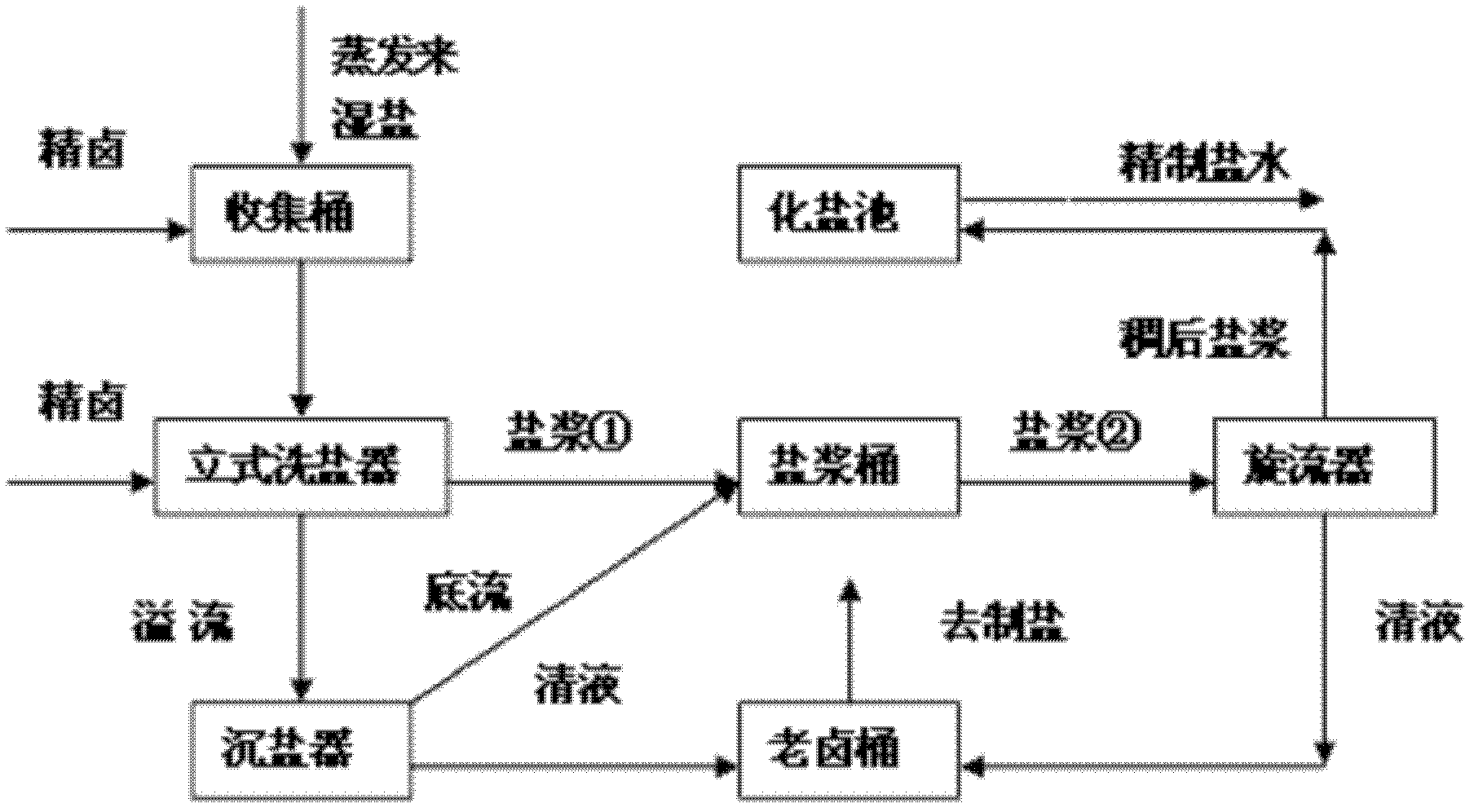

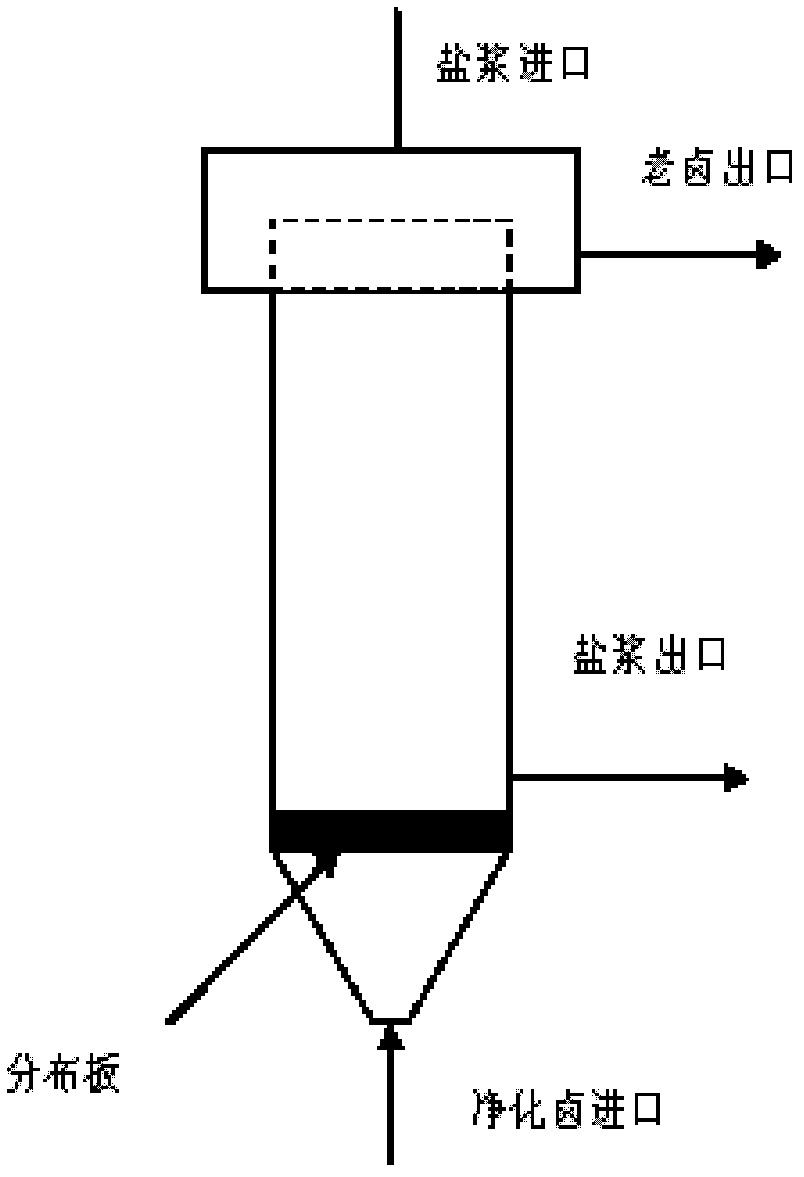

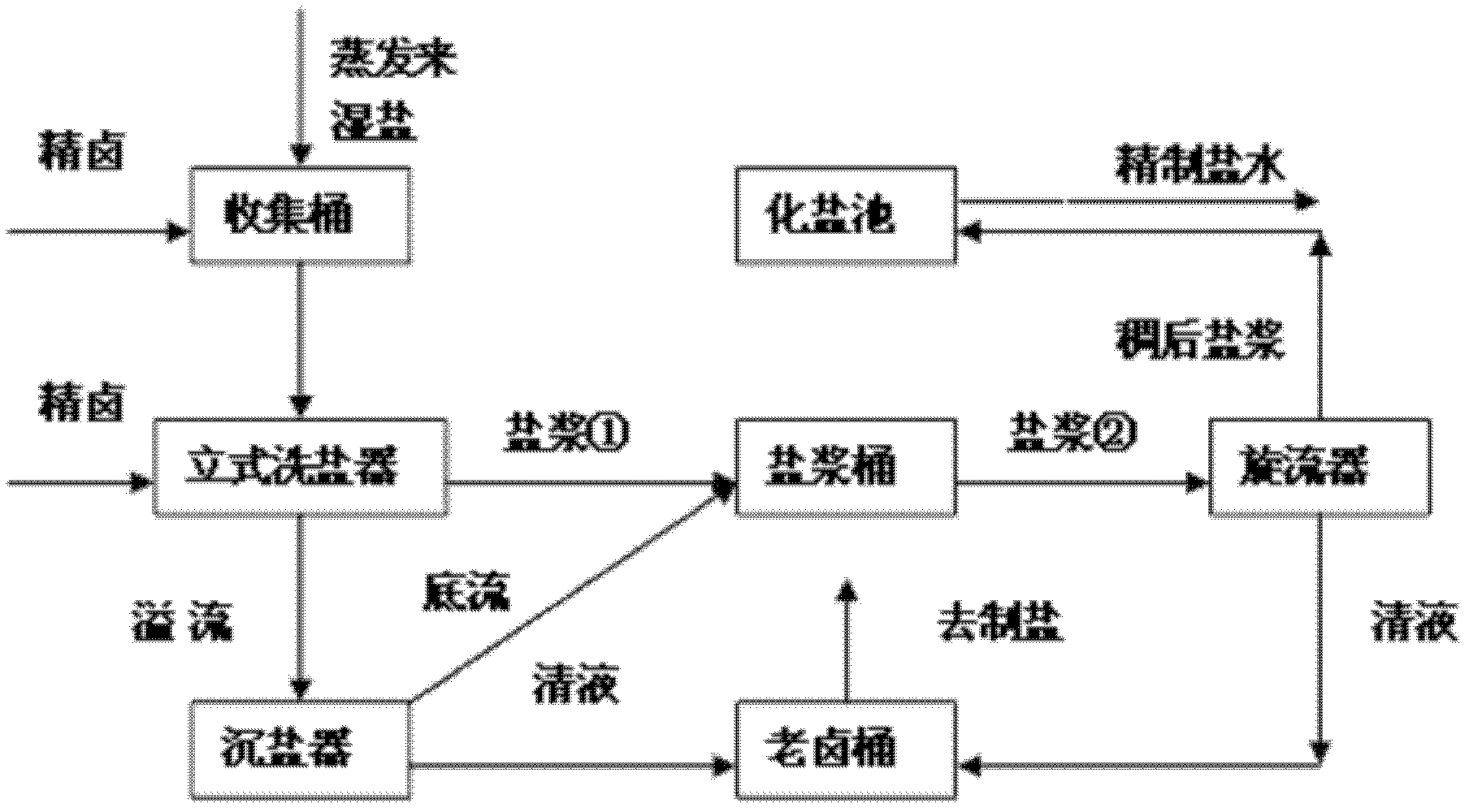

A method for producing caustic soda by purifying brine

The invention relates to a method for producing caustic soda by using purified brine. The steps include: adding a collection barrel, a vertical salt washer, a salt sinker, an old brine barrel and a cyclone to the recovery salt pipeline precipitated in the caustic soda evaporation process, and the salt slurry in the caustic soda evaporation process is collected by the collection barrel and then enters the The vertical salt washer, after cooling down, remelting and flotation with the purified brine entering from the lower part, the salt slurry is discharged from the discharge valve at the lower part of the vertical salt washer to the salt slurry tank, and the cleaned liquid is discharged from the vertical washing The overflow port of the salt tank overflows to the salt sinker, and the brine slurry in the salt sinker is discharged into the salt slurry tank, and the clear liquid rich in sodium sulfate flows back to the old brine tank, and is pumped to the salt and nitric acid cogeneration system. The salt slurry in the salt slurry tank is pumped to the cyclone by the salt slurry, and the clear liquid at the top of the cyclone flows back to the old brine tank, and the salt slurry thickened by the cyclone is transported to the salt tank for brine refining. Beneficial effects of the invention: 1. The high-nitrate mother liquor is recycled, which is environmentally friendly; 2. The power consumption and steam consumption are reduced, resources are saved, and production costs are reduced.

Owner:HUBEI SHUANGHUAN SCIENCE AND TECHNOLOGY STOCK CO LTD

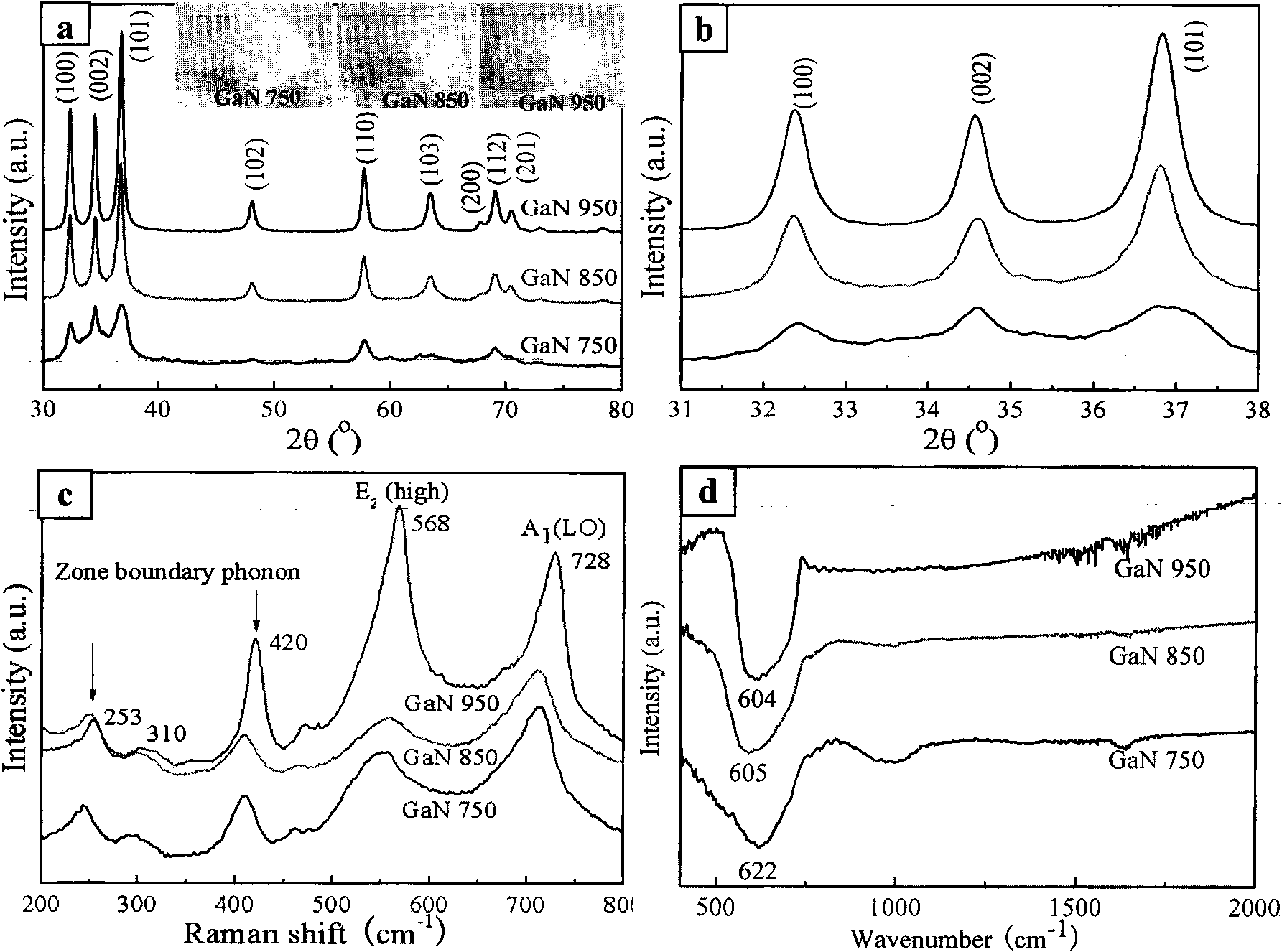

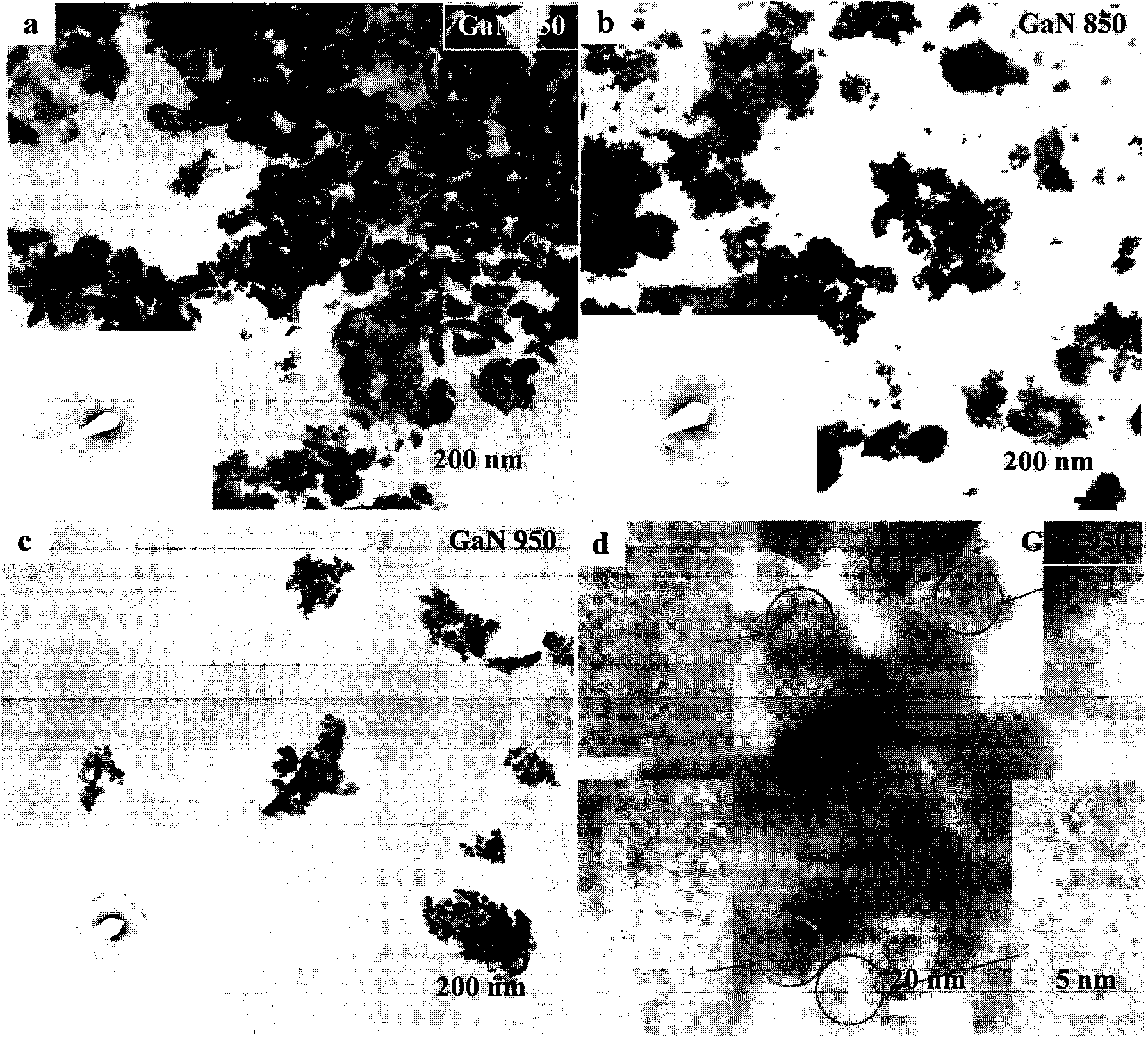

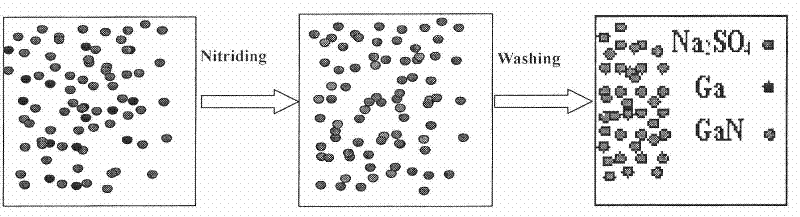

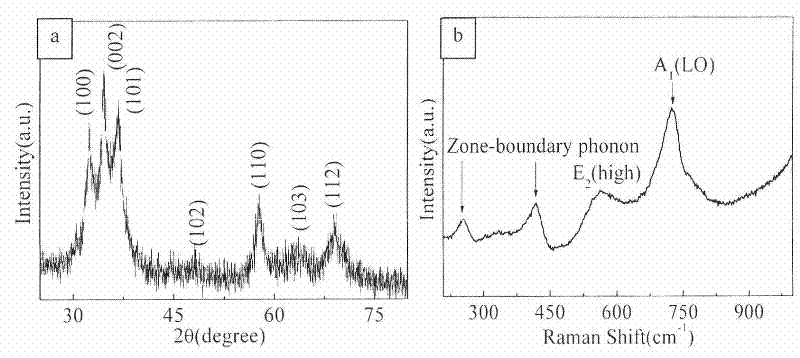

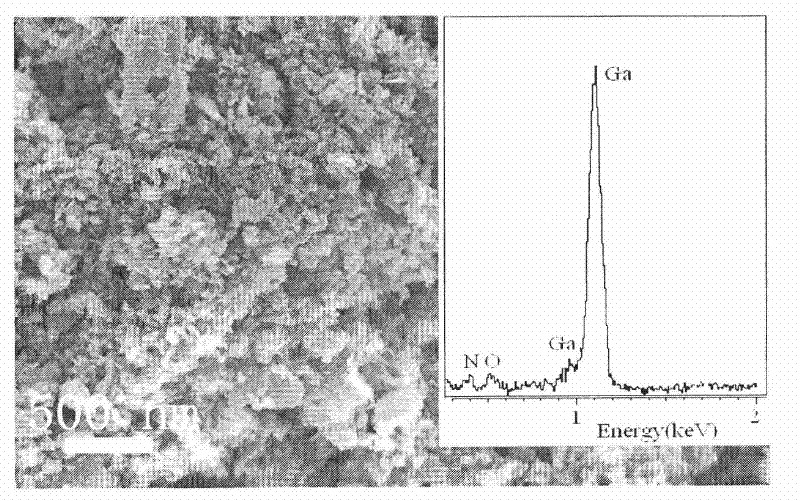

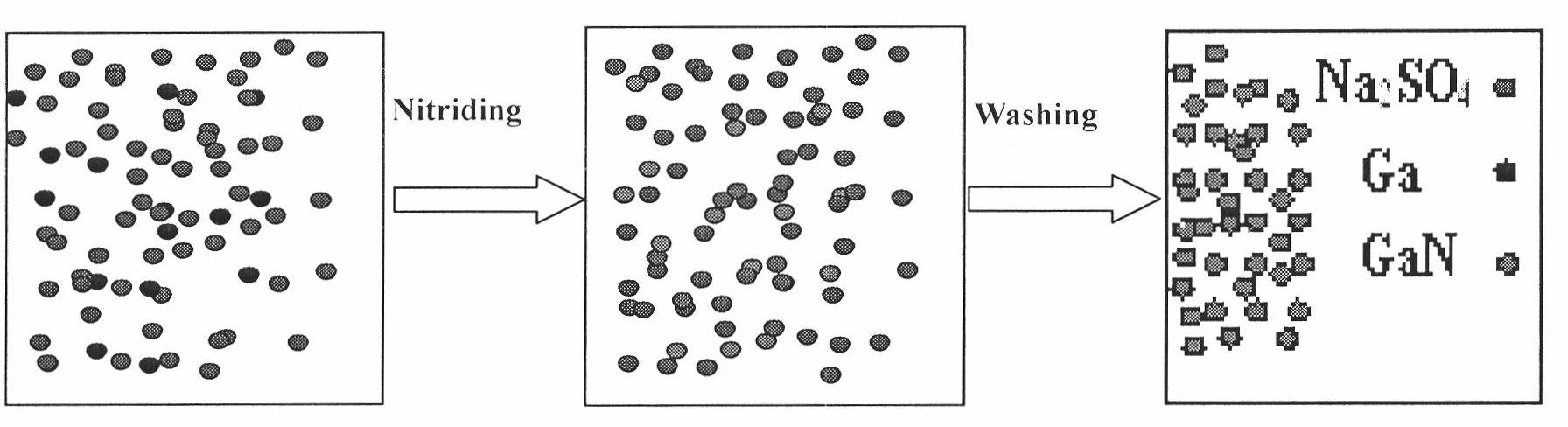

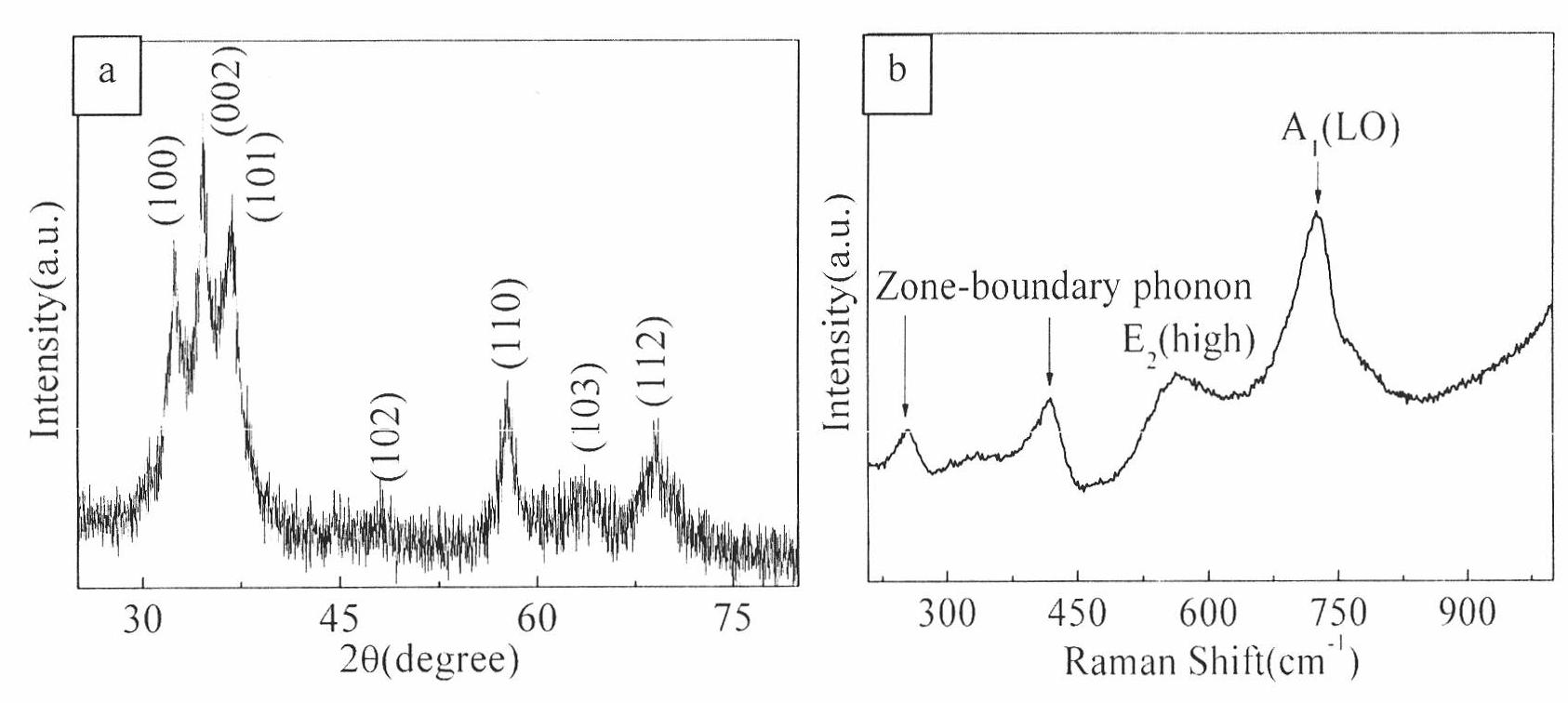

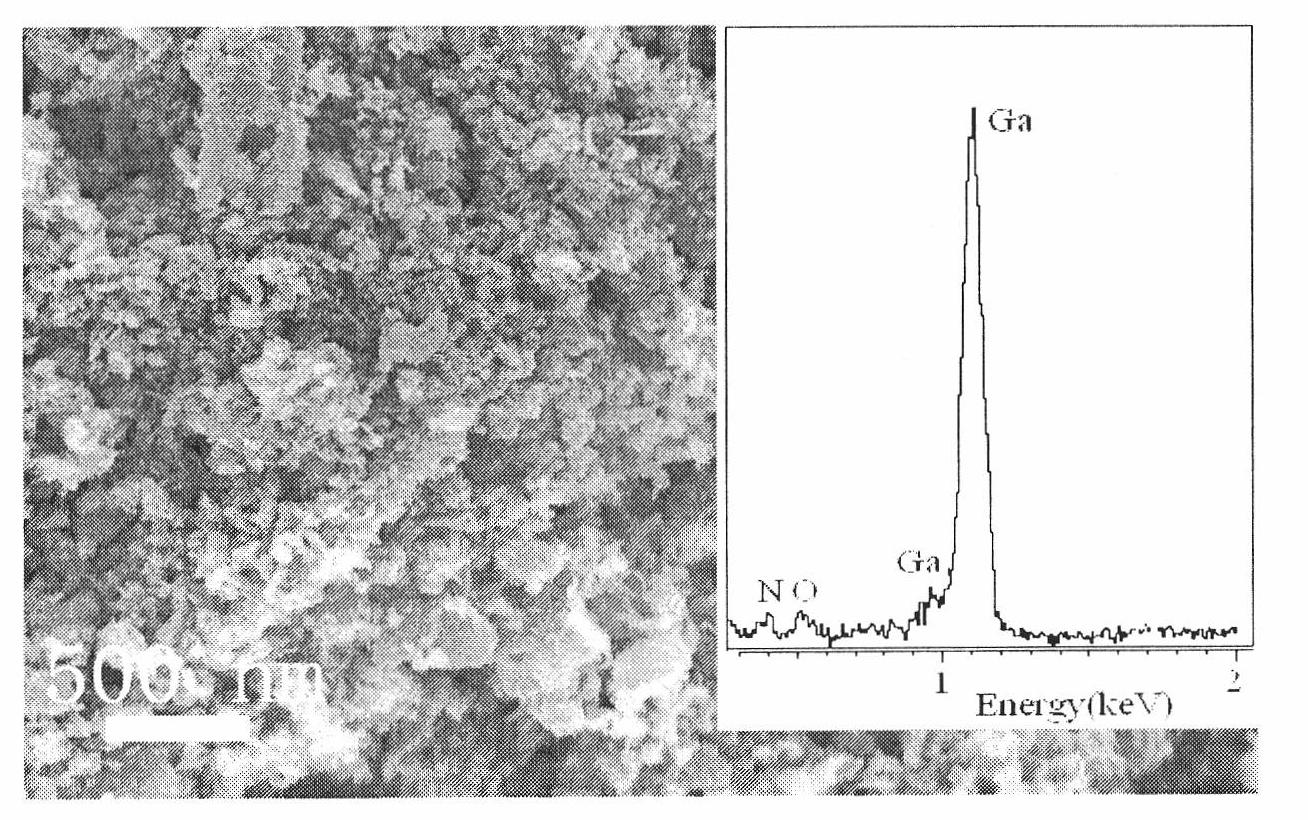

Method for preparing high-quality gallium nitride nano powder

InactiveCN104276547AMaterial nanotechnologyNitrogen-metal/silicon/boron binary compoundsSalt sodiumSodium phosphates

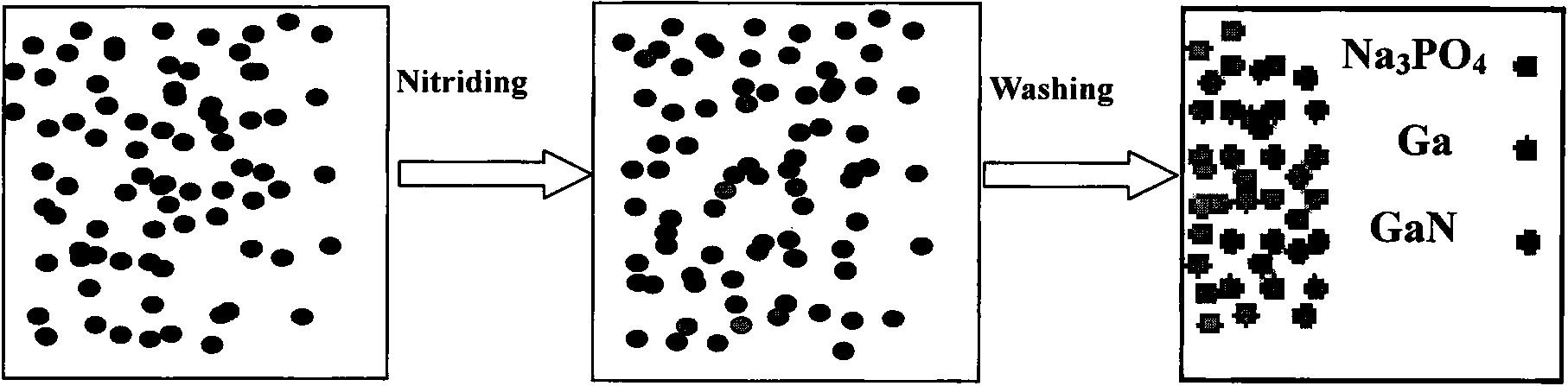

The invention discloses a method for preparing high-quality gallium nitride nano powder. The method comprises the following steps: fully mixing and grinding metal Ga and soluble salt sodium phosphate according to the mass ratio of 1 to (2-10) at certain temperature, and then nitriding the mixture with ammonia gas at 750-1050 DEG C for 2-4 hours; repeatedly washing the nitrided mixture to wash off sodium phosphate by using distilled water to finally obtain pure high-quality gallium nitride nano powder, wherein the diameters of the particles are 10-30nm. Particularly, the obtained product is gallium nitride powder with high crystallinity in a hexagonal phase structure when nitriding is performed at over 850 DEG C. The method has positive effects of being simple, convenient, economical and environment-friendly, and can be used for preparing the high-quality gallium nitride nano powder on a large scale.

Owner:SHANGRAO NORMAL UNIV

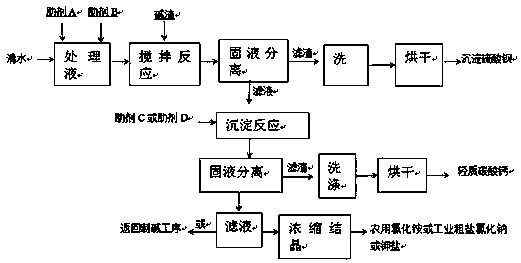

A method for comprehensive recovery and utilization of soda ash waste residue

ActiveCN107555462BComprehensive recyclingSimple process flowCalcium/strontium/barium carbonatesCalcium/strontium/barium sulfatesSalt sodiumWastewater

The invention discloses a comprehensive waste soda ash residue recycling method. The comprehensive waste soda ash residue recycling method comprises the following steps: preparing a treatment solution; mixing a waste soda ash residue and the treatment solution for a stirring reaction; performing solid-liquid separation for recycling precipitated barium sulfate; recycling light calcium carbonate; recycling agricultural-grade ammonium chloride, industrial crude salt sodium chloride or potassium salt. By the comprehensive waste soda ash residue recycling method, the waste soda ash residue is comprehensively recycled, so that zero discharge of the waste residue and waste water during soda ash production is achieved; an alkali residue treatment technology is simple in flow path, low in investment, quick in effect, low in treatment cost and considerable in benefits.

Owner:赵阳臣

Method synthesizing nanocrystalline by assistance of soluble salt

The invention relates to a method synthesizing nanocrystalline by the assistance of soluble salt. Soluble salt sodium sulfate Na2SO4 and soft metal are fully grinded or ball milled according to the proportion of 1 to 6-30 at a certain temperature or normal temperature and then the mixture of the soft metal and the sodium sulfate Na2SO4 is nitrided with ammonia or oxygenized with oxygen at 600 to 800 degrees centigrade for 2 to 4 hours. The nitrided or oxygenized mixture is flushed repeatedly with distilled water to wash away the sodium sulfate and obtain pure nanocrystalline powder. The method is simple, convenient, economical and environment-friendly, can be used to prepare the nanocrystalline massively and at the same time provides a universal thinking for synthesizing low melting pointsoft metal compound nanocrystalline in large quantity.

Owner:SHANGRAO NORMAL UNIV

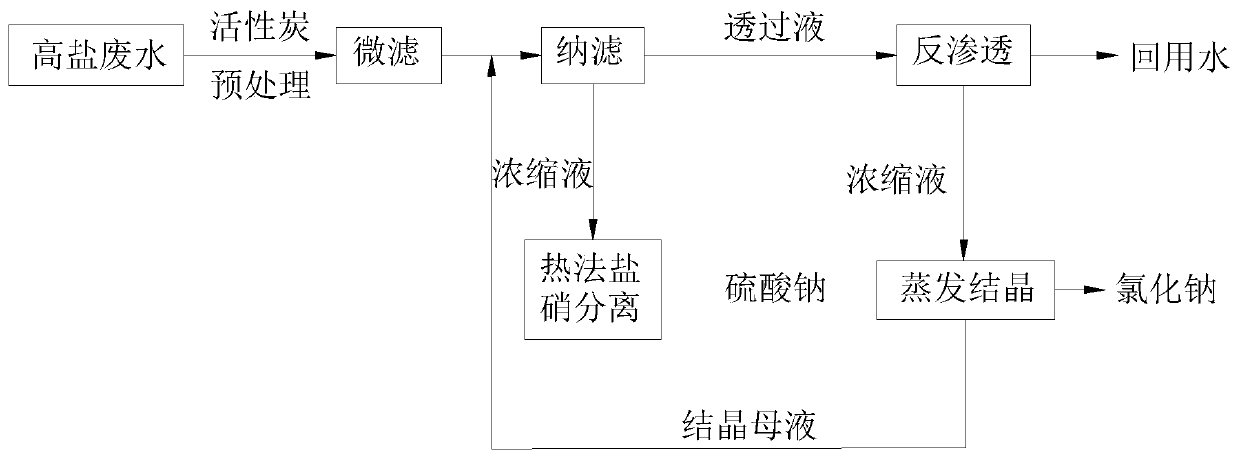

Method for separating sodium chloride and sodium sulfate in high-salinity wastewater in coastal industrial zone

InactiveCN110217928AHigh purityEfficient removalGeneral water supply conservationAlkali metal sulfite/sulfate purificationVibrating membraneSodium sulfate

The invention discloses a method for separating sodium chloride and sodium sulfate in high-salinity wastewater in a coastal industrial zone. In the method, divalent salt and a part of organic mattersare separated from monovalent salt by utilizing characteristics of a nanofiltration membrane; thermal salt-sodium sulfate separation is performed to obtain sodium sulfate solid having high purity; a vibrating membrane is adopted as the nanofiltration membrane which has an advantage that the vibrating membrane can treat wastewater having extremely high salt concentrations; then a reverse osmosis system is adopted to effectively remove the monovalent salt, and sodium chloride solid having good purity is obtained after evaporative crystallization; nanofiltration is used for pretreatment of reverse osmosis, thus reducing the salinity of seawater entering a reverse osmosis membrane module, and creating conditions for improving the seawater desalination recovery rate. The method is reasonable inprocess, capable of recovering resources, economical, efficient, and stable to operate, can make up shortcomings of the existing high-salinity wastewater inorganic salt separating technology, and achieves the objective of 'zero emission of solid and liquid' for high-salinity concentrate treatment.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

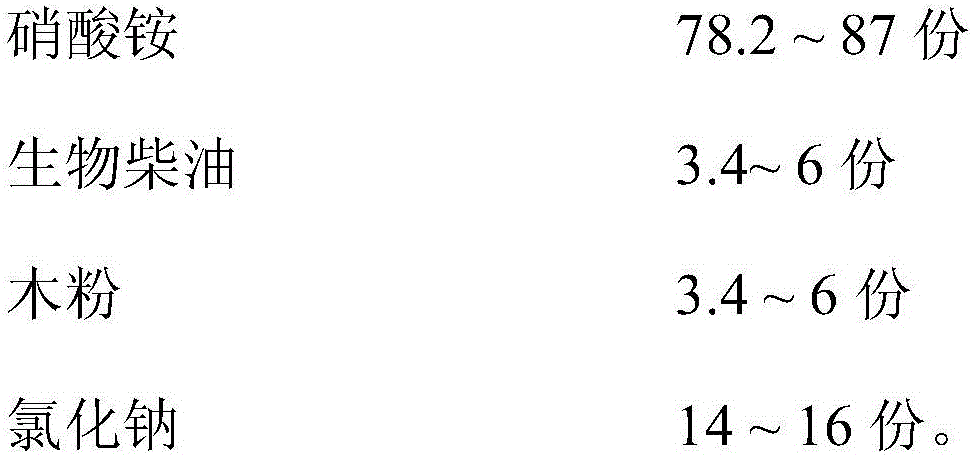

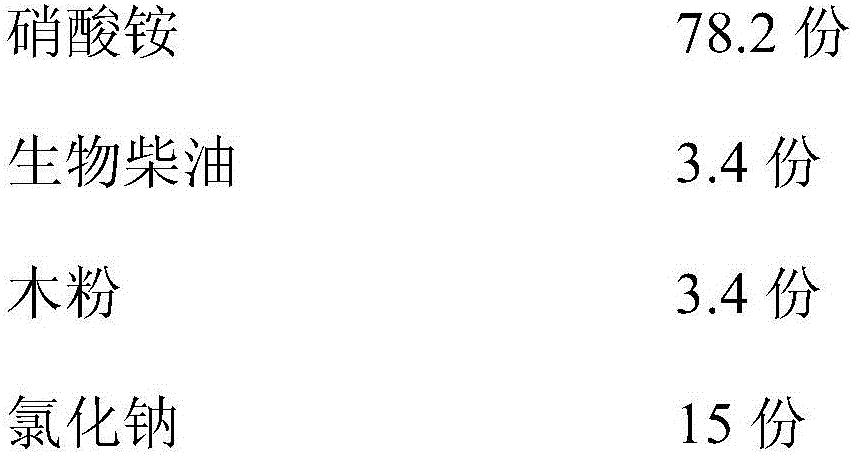

Ammonium nitrate-fuel oil explosive and preparation method thereof

InactiveCN106380360AReduce sulfur contentLow open flash pointExplosive ingredient compoundingBiodieselSalt sodium

The invention discloses an ammonium nitrate-fuel oil explosive and a preparation method thereof. The explosive is characterized by comprising the following components in parts by weight: 78.2 to 94 parts of ammonium nitrate and 2 to 8.3 parts of biodiesel. The explosive also comprises salt sodium chloride and wood powder. The invention further provides a preparation method of the explosive. The provided ammonium nitrate-fuel oil explosive has the characteristics of low cost, environment-friendliness, and safety.

Owner:SUZHOU FENGBEI BIOTECH CO LTD

Method for recovering propionyl triketone and sodium chloride from clethodim decarboxylation wastewater

PendingCN114735879ARealize resourcesEfficient separationFatty/oily/floating substances removal devicesOrganic chemistrySalt sodiumEnvironmental engineering

The invention relates to a method for recovering propionyl triketone and sodium chloride from clethodim decarboxylation wastewater, which comprises the following steps: adding a separating agent into the clethodim decarboxylation wastewater, and standing for layering to obtain an upper layer which is a separation phase and a lower layer which is a water phase; wherein the separating agent comprises a complexing agent, a cosolvent and a diluent; adding an alkaline solution into the separation phase, and standing for layering to obtain an upper layer which is a regenerated separating agent and a lower layer which is a sodium propionyltriketone solution; carrying out adsorption treatment on the water phase to obtain treated effluent; and evaporating the treated effluent to obtain evaporated effluent and sodium chloride. According to the method, toxic pollutants in the wastewater can be effectively recycled, the quality of subsequent evaporation salt is improved, propionyltriketone is recycled, the byproduct salt sodium chloride is obtained, wastewater recycling is achieved, and the method has the advantages of being easy to operate, high in pollutant removal rate and the like.

Owner:BEIJING HUIYU LEBANG ENVIRONMENT PROTECTION TECH CO LTD +1

Method synthesizing nanocrystalline by assistance of soluble salt

The invention relates to a method synthesizing nanocrystalline by the assistance of soluble salt. Soluble salt sodium sulfate Na2SO4 and soft metal are fully grinded or ball milled according to the proportion of 1 to 6-30 at a certain temperature or normal temperature and then the mixture of the soft metal and the sodium sulfate Na2SO4 is nitrided with ammonia or oxygenized with oxygen at 600 to 800 degrees centigrade for 2 to 4 hours. The nitrided or oxygenized mixture is flushed repeatedly with distilled water to wash away the sodium sulfate and obtain pure nanocrystalline powder. The method is simple, convenient, economical and environment-friendly, can be used to prepare the nanocrystalline massively and at the same time provides a universal thinking for synthesizing low melting point soft metal compound nanocrystalline in large quantity.

Owner:SHANGRAO NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com