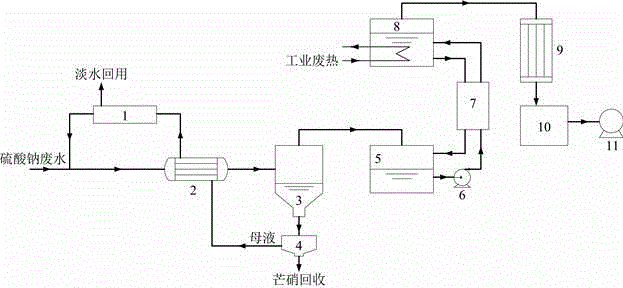

Zero-emission resource recycling method of high-salt sodium sulfate wastewater

A high-salt wastewater containing sodium sulfate technology, applied in chemical instruments and methods, alkali metal sulfite/sulfite, inorganic chemistry, etc., can solve the problems of large thermal resistance and high energy consumption, and achieve energy saving, Easy to operate, avoid the effect of crystallization on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Example: Sulfuric acid containing sodium sulfate and high-salt wastewater treatment project. Under the condition that the temperature of the lithium bromide solution in the absorber is 20~30℃ and the mass fraction is 53%~57%, the temperature is lower than 30℃ and the concentration of sulfuric acid is 200g / L. Sodium wastewater, after passing through the preheater together with the concentrated mother liquor, evaporates and concentrates and crystallizes in the crystallizer at a temperature below 10°C to obtain the product Glauber's salt. The concentration of the concentrated mother liquor obtained after the mother liquor is separated by membrane is higher than 150g / L , It produces fresh water with conductivity less than 200μS / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com