Patents

Literature

96results about How to "Achieve zero emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

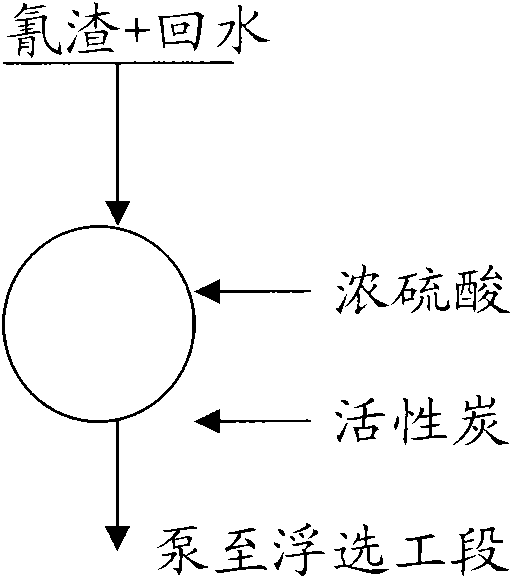

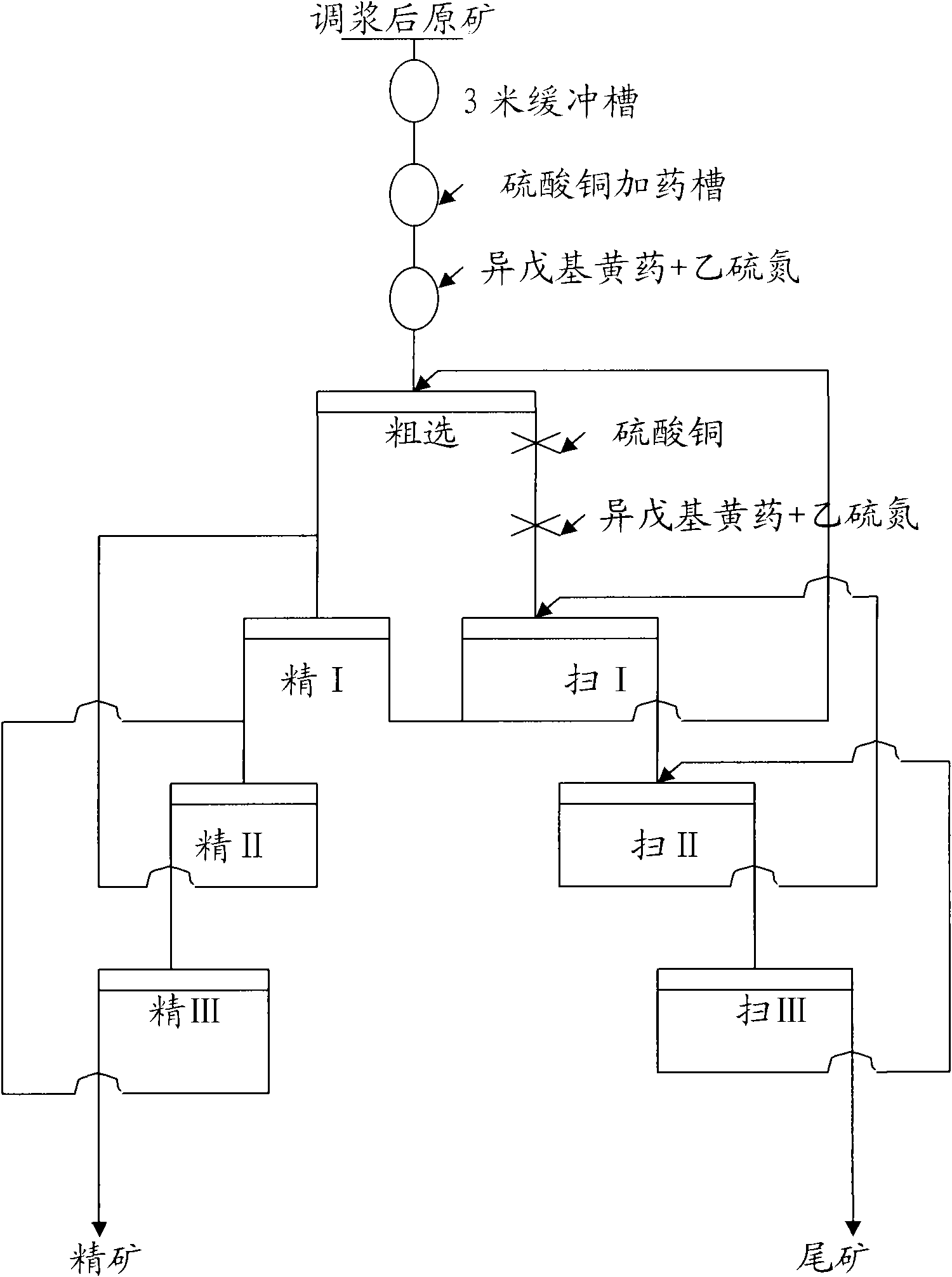

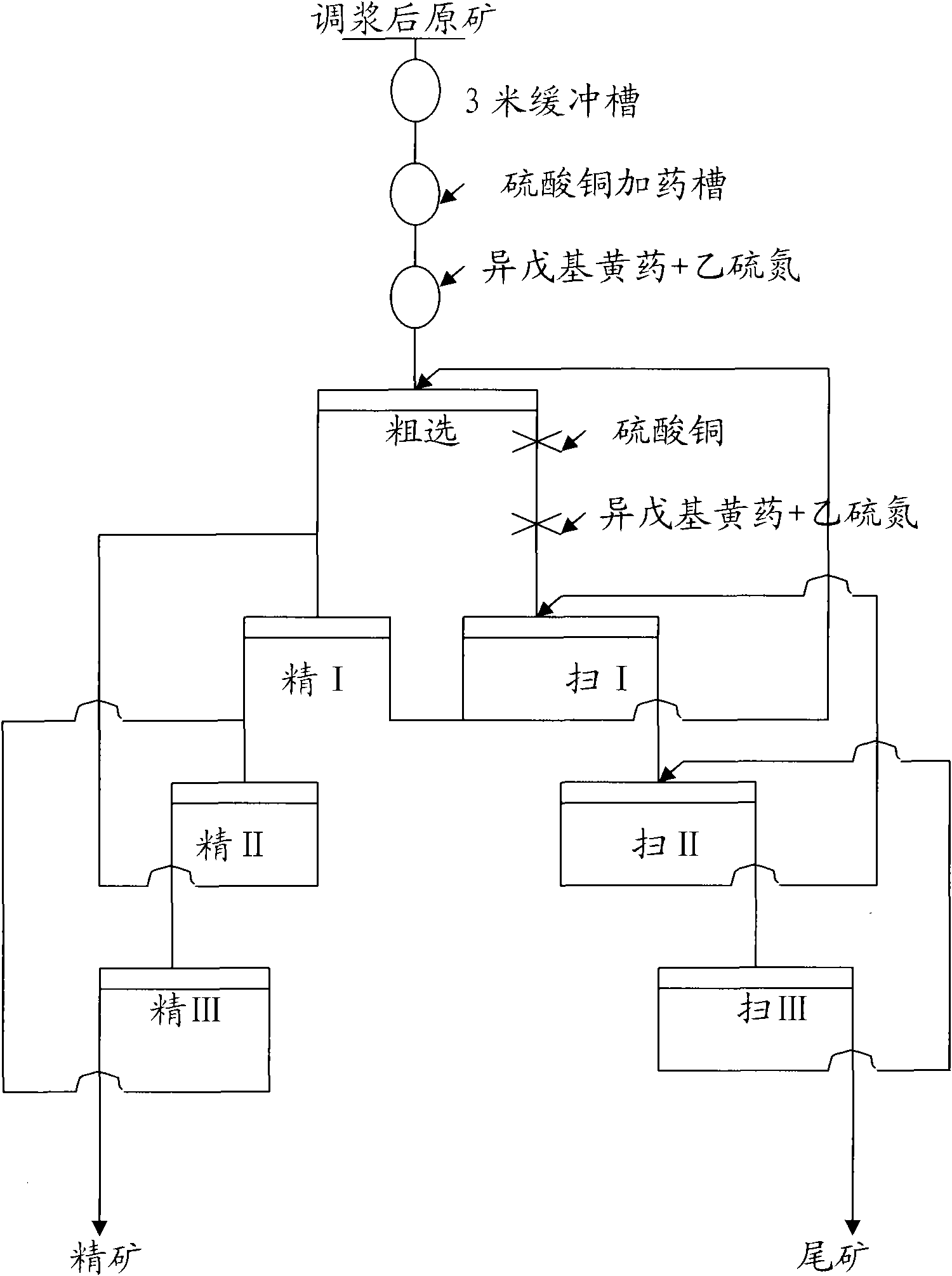

Method using mineral dressing backwater to float and to recover gold, silver, lead and zinc in cyanidation tailings of gold mine

The invention discloses a method using mineral dressing backwater to float and recover gold, silver, lead and zinc in cyanidation tailings of a gold mine. The method comprises the following working procedures: (1) pulp pre-processing stage: adding mineral dressing backwater in cyaniding tailings, adding concentrated sulfuric acid to stir for 5 minutes, reacting the concentrated sulfuric acid withthe pulp until smoke is completely generated, adding activated carbon to remove reagent for 55 minutes, and then pumping to a flotation workshop section; and (2) bulk flotation stage: pumping the pretreated pulp into a 3-meter stirring buffer slot, stirring for 30 minutes continuously, flowing into a medicine injecting slot 1 and a medicine injecting slot 2 by proper motion, sequentially adding copper sulfate and diethyldithiocarbamate, stirring fully, then entering a floatation unit to perform roughing on the pulp, further carrying out selection stage by stage on the rough concentrate obtained by roughing to obtain qualified lead and zinc bulk concentrate containing gold and silver, and further carrying out scavenging stage by stage on the roughed tailing to obtain floated tailing which is the sulphur concentrate. The invention realizes comprehensive utilization of mineral dressing tailings and zero exhaust of the tailings, thus realizing cleaner production of the mineral dressing process.

Owner:青岛黄金铅锌开发有限公司

Two-stage plasma gasifying, melting and cracking method and device of waste containing organic matters

ActiveCN102000691ANo emissionsComplete gasificationSolid waste disposalGlass furnace apparatusGeneration rateHigh energy

The invention relates to a treatment method of waste containing organic matters, in particular to two-stage plasma gasifying, melting and cracking method and device of the waste containing organic matters, belonging to the field of gasifying, melting and cracking techniques. In the invention, the serious defects of high energy consumption of the waste containing organic matters and more flying ash during the plasma arc melting and cracking are solved, thereby thoroughly utilizing the energy of the organic matters and maximizing the treating efficiency, thoroughly cracking the tar, reducing the generation rate of Dioxin, obtaining synthesis gas with high quality and high heat value as much as possible, providing guarantee for the subsequent gasification power generation, the hydrogen energy recovery or the production of green liquid fuel, simultaneously finishing one-step recovery of noble metals and direct utilization of glass bodies in the field of building materials, laying foundation for the large-scale commercial development and application of the energy of the waste containing organic matters, and thoroughly solving the possible pollutant discharging problem in the gasifying process of the organic matters, particularly the dangerous waste.

Owner:HOOTECH

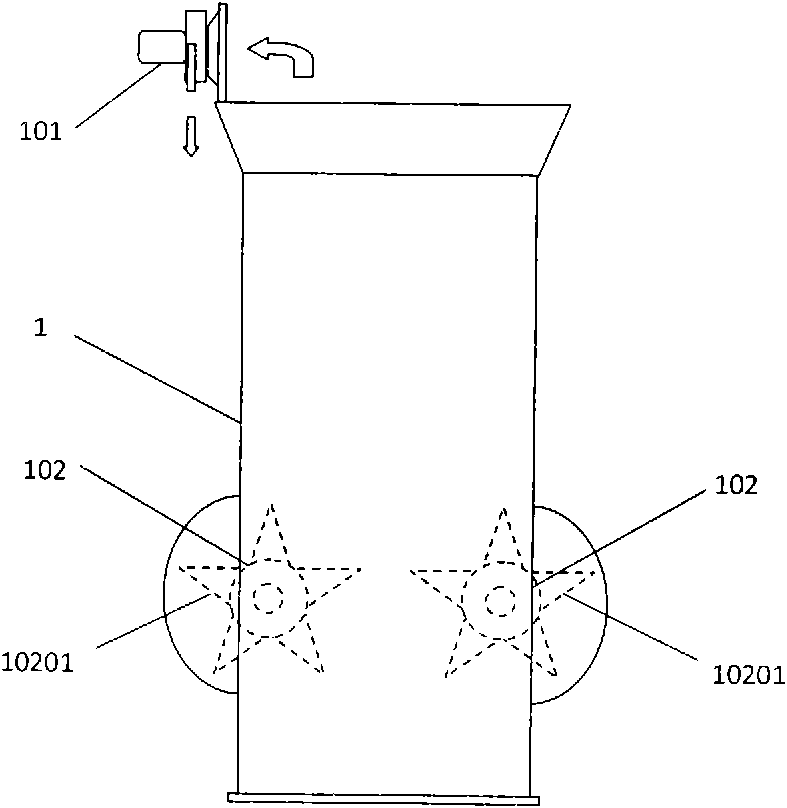

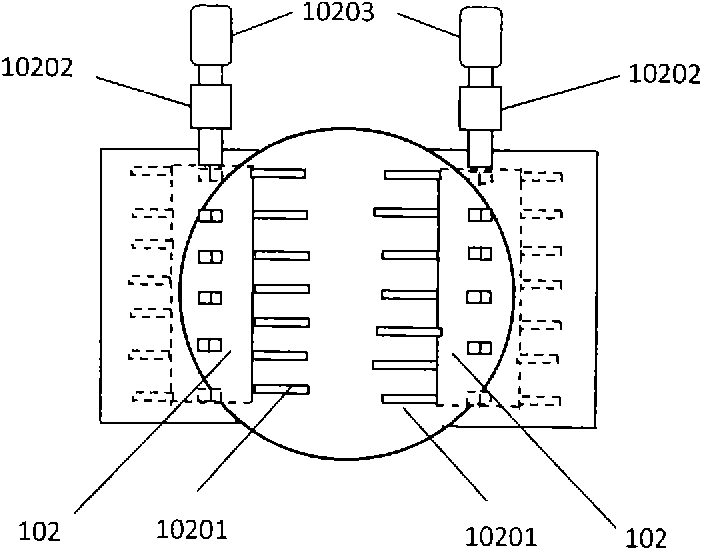

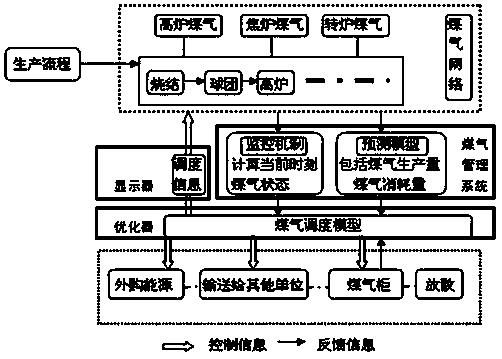

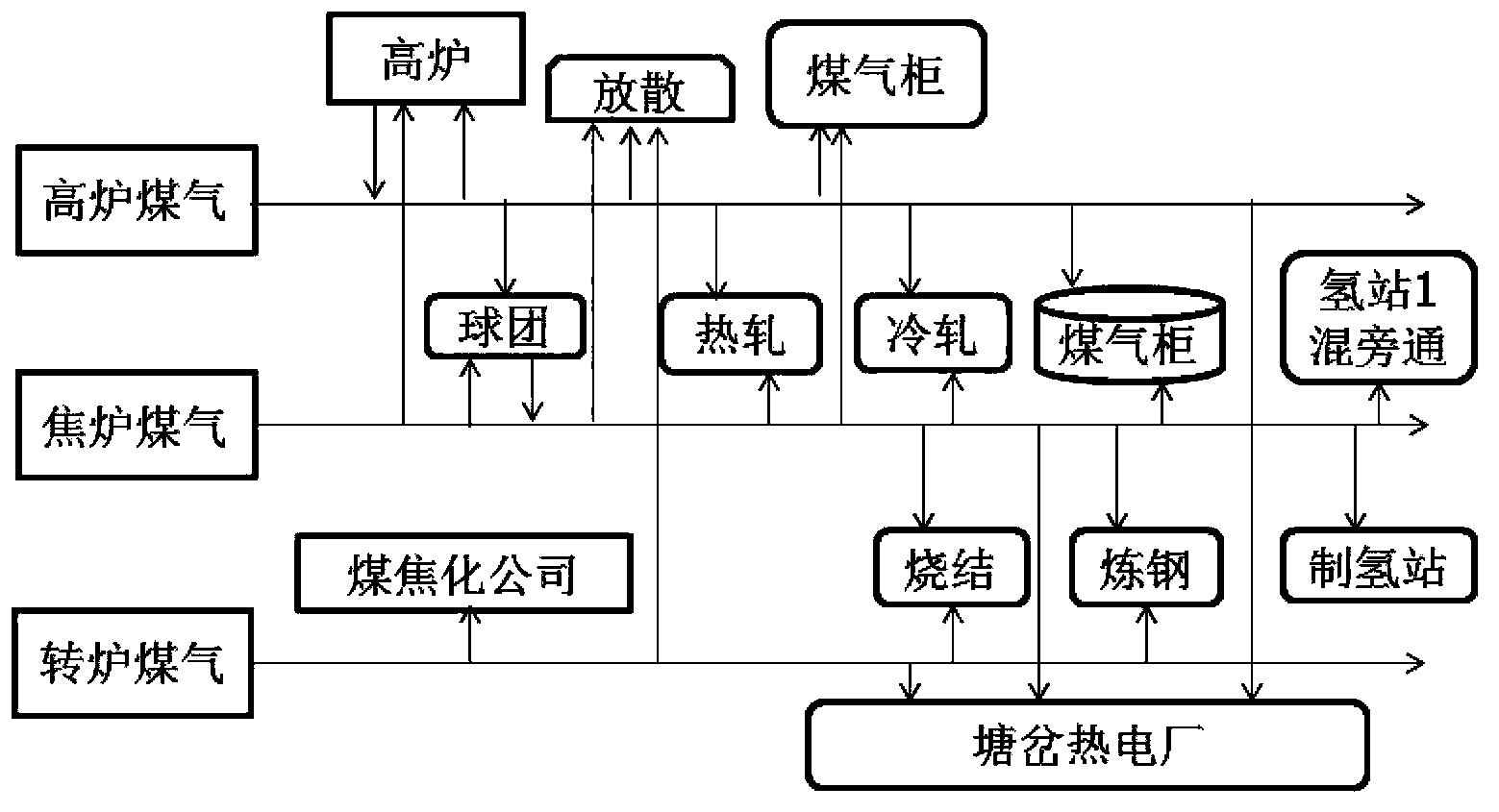

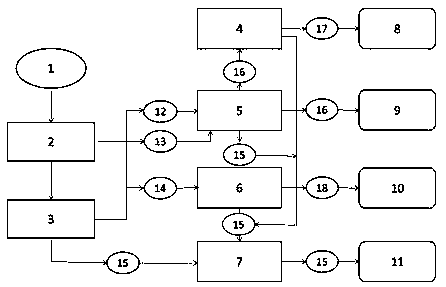

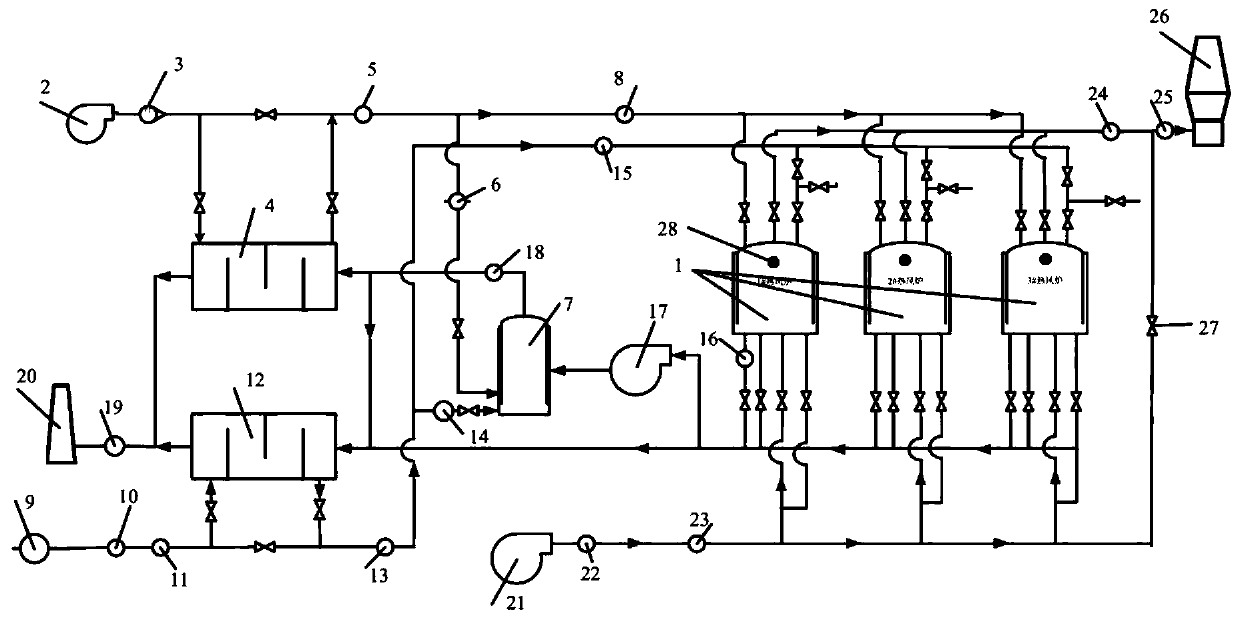

Gas optimization scheduling device of iron and steel enterprise

InactiveCN103439926AEmission reductionReduce purchasesEnergy industryTotal factory controlDisplay devicePurchasing

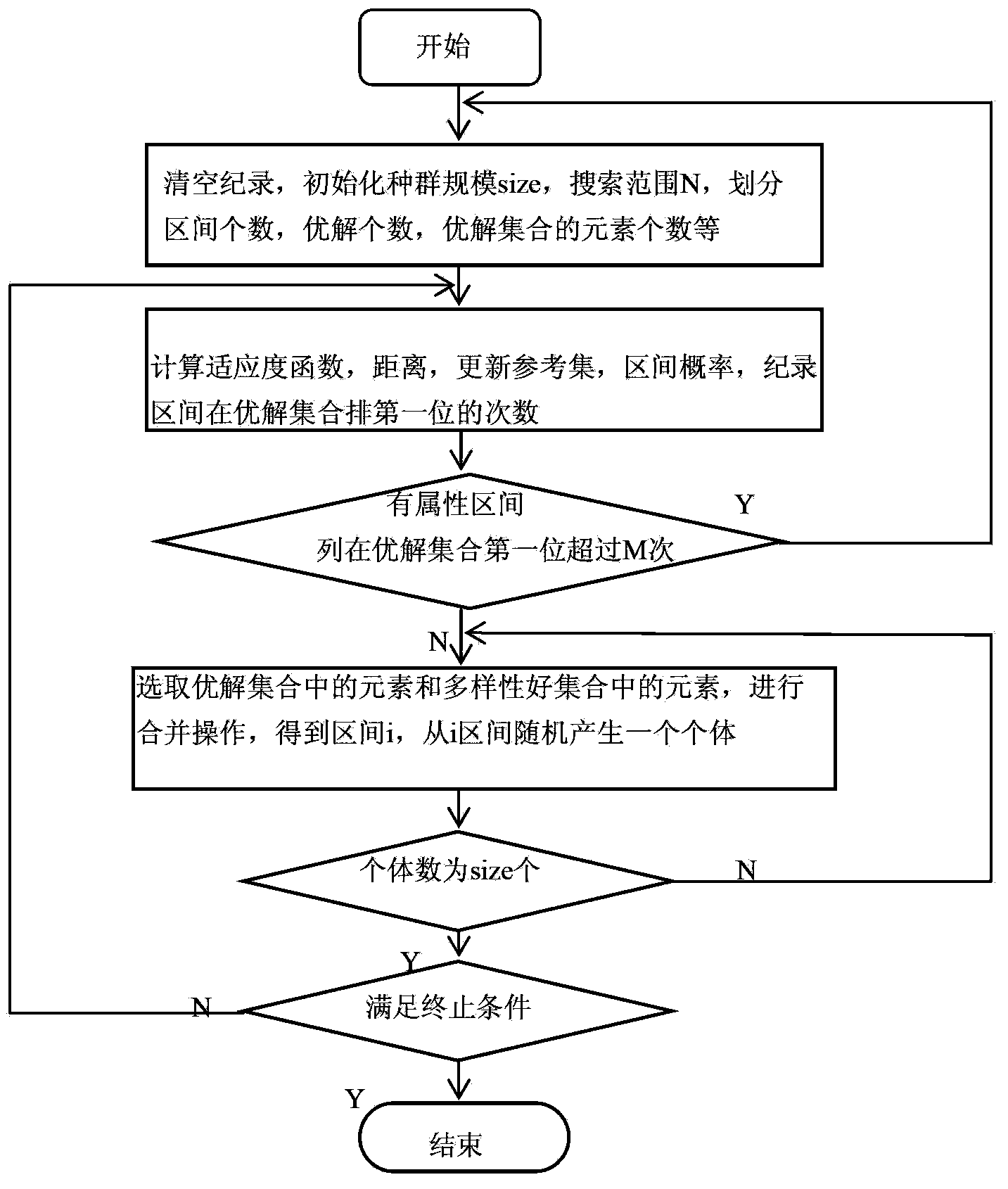

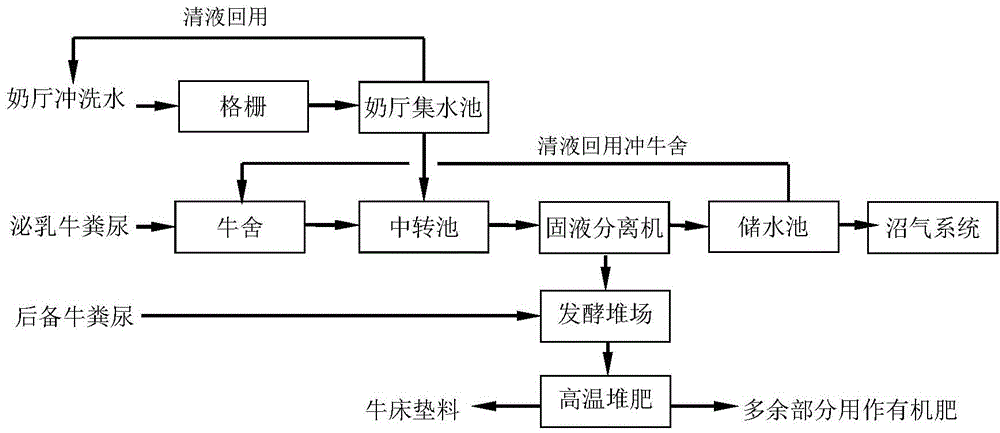

The invention relates to a gas optimization scheduling device of an iron and steel enterprise. The scheduling device is connected with an energy management system and comprises a gas managing device, an optimizing device and a display device, wherein the gas managing device, the optimizing device and the display device are sequentially connected. The gas managing device acquires gas consumption amount historical data, gas generation amount historical data and storage amount data of a gas cabinet in each procedure through the energy management system of the enterprise to predict the production amount and the consumption amount of gas at present or in future; on the basis of the predicted data, the optimizing device adopts improved distribution estimation algorithms to optimize distribution of the gas, and the optimization principle aims to make the scattering amount smallest and the purchasing amount largest; the display device displays the gas distribution scheme obtained by the optimizing device for reference of users, so that the gas can be reasonably distributed. Compared with the prior art, the gas optimization scheduling device has the advantages of reducing the scattering amount and the purchasing amount of the gas and the like.

Owner:TONGJI UNIV

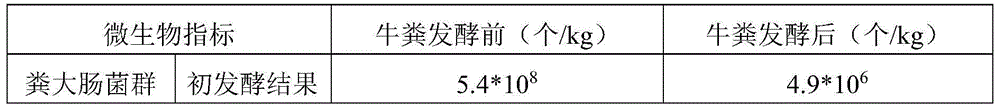

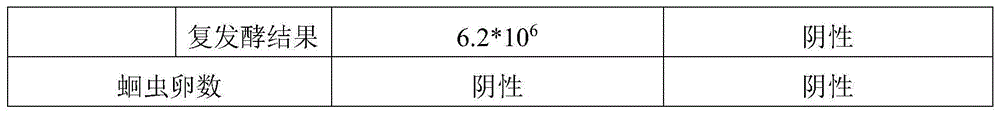

Method for producing environmentally friendly bedding material by using dairy cattle farm wastes

InactiveCN104557168AIncrease milk productionSimple processBio-organic fraction processingExcrement fertilisersWater contentEnvironmentally friendly

The invention relates to the fields of animal husbandry environment pollution treatment and waste recycling, and concretely relates to a method for producing an environmentally friendly bedding material by using dairy cattle farm wastes. The method for producing the environmentally friendly bedding material by using cattle farm wastes comprises the following steps: 1, carrying out solid-liquid separation to make the water content of dehydrated night soil of 70% or below; 2, stacking, and maintaining the water content of the night soil in a range of 55-70% in the stacking process; and 3, fermenting the stacked night soil, turning stacked night soil when the temperature in the stacked night soil reaches 55DEG C, carrying out heat insulation for 7d or above when the temperature in the stacked night soil reaches 70DEG C or above, and adjusting the water content of the night soil to 20-35% when the temperature in the stacked night soil decreases to 50DEG C or below in order to obtain the bedding material. The dairy cattle night soil is stacked and fermented, and is recycled as the bedding material, so zero discharge of the dairy cattle night soil is reached, and the comprehensive utilization of the dairy cattle night soil is realized.

Owner:INNER MONGOLIA YOURAN ANIMAL HUSBANDRY CO LTD

Method for disposing residues produced by fermentation of cephalosporin C through alkaline hydrolysis process

ActiveCN102488997ASimple equipment and processLow costClimate change adaptationBioloigcal waste fertilisersCephalosporin CChemistry

The invention relates to a method for disposing residues produced by fermentation of cephalosporin C through an alkaline hydrolysis process, which comprises the following steps: putting the disposing residues produced by the cephalosporin C in aqueous alkali so as to be heat and hydrolyzed, wherein the working pressure is 0.4-0.7 Mpa, the hydrolysis temperature is 150-220 DEG C, and the hydrolysis time is 1-3h; and filtering after hydrolysis, and respectively collecting filtrate and filter residues. The process and equipment provided by the invention are simple, has low cost, high efficiency, less pollution, and is easy to industrial production; and the obtained filtrate and filter residues realize full degradation of antibiotics and intermediate products thereof, so that higher ecological safety is realized.

Owner:天津市裕川环境科技有限公司

Method for producing aerated concrete building block by using fluorite tailings

The present invention provides a method for producing an aerated concrete building block by using fluorite tailings, wherein a main raw material ratio of fluorite tailings to lime to cement to industrial gypsum to aluminum powder is 60-80:10-20:10-15:2-5:0.006-0.007. The method comprises: carrying out particle size separation and an agent and slime treatment on fine grain fluorite tailings, and adding water to stir to prepare a slurry; adding lime, cement, industrial gypsum and aluminum powder to a material mixing stirrer according to a certain ratio, and completely stirring; casting the obtained material into a mold frame, carrying out gas evolution, and cutting; and carrying out steam curing through a steam curing kettle to produce the product. The produced aerated concrete building block has characteristics of good thermal insulation property, small specific gravity and white color, has a strength of higher than strength of fly ash building block, and is an aerated concrete building block having excellent performances. With the method, complete fluorite tailings utilization can be achieved, zero solid waste emission can be achieved, and reuse rate of water for production in concentrators can be improved.

Owner:ZHEJIANG WUYI SHENLONG FLOATATION

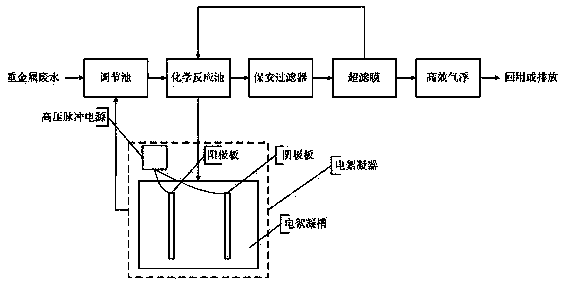

Method and device for deeply treating heavy metal wastewater

ActiveCN103539295AAchieve enrichmentAchieve purificationWater contaminantsWater/sewage treatment bu osmosis/dialysisChemical reactionUltrafiltration

The invention provides a method and device for deeply treating heavy metal wastewater. Heavy metal wastewater flows into a chemical reaction tank after being adjusted by medicating in an adjusting tank; a surfactant is added into the chemical reaction tank; particle size of heavy metals and micromolecule pollutants is increased through combined action of anionic and nonionic surfactants; after ultrafiltration separation, permeated liquor is exhausted or recycled by reaching standards through air flotation; concentrated liquor is electrically flocculated by adopting high-voltage pulses, and effluent reaches emission standards or is recycled for a production process. The heavy metal wastewater treated by the method disclosed by the invention has stable effluent water quality; meanwhile, power consumption is low and is only 1 / 5-1 / 20 that of a common electrolytic process.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

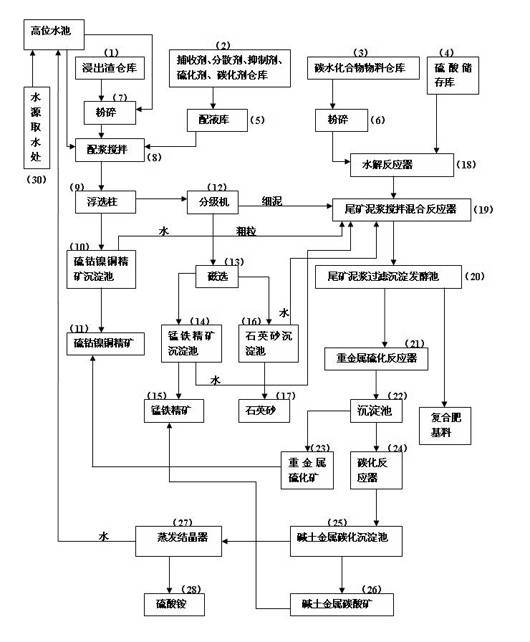

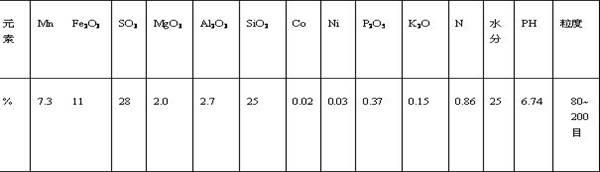

Method for comprehensively recycling leaching slag in production of electrolytic manganese metal and manganese dioxide

InactiveCN102660689AAchieve zero emissionsAmmonium sulfatesProcess efficiency improvementAlkaline earth metalElectrolysis

The invention relates to a method for comprehensively recycling leaching slag in production of electrolytic manganese metal and manganese dioxide, and the method comprises the following specific steps of: (1) recovering heavy metals and noble metals; (2) recovering manganese and iron; (3) treating tailing slurry and preparing a composite organic fertilizer; (4) separating trace heavy metals in the composite organic fertilizer; (5) recovering alkaline-earth metal; and (6) carrying out crystal separation on ammonium sulfate. The method can be used for recovering ferromanganese ore concentrate from the leaching slag in production of electrolytic manganese metal and manganese dioxide, thus obtaining the heavy metals such as cobalt, nickel, copper, silver, tin and the like, noble metal ore concentrate, quartz sand, ammonium sulfate, and compound fertilizer base material containing N, P, K, humic acid, trace elements and standard heavy metals; and therefore, a zero emission effect can be realized in the production of electrolytic manganese metal and manganese dioxide.

Owner:大新县信锰矿业有限公司

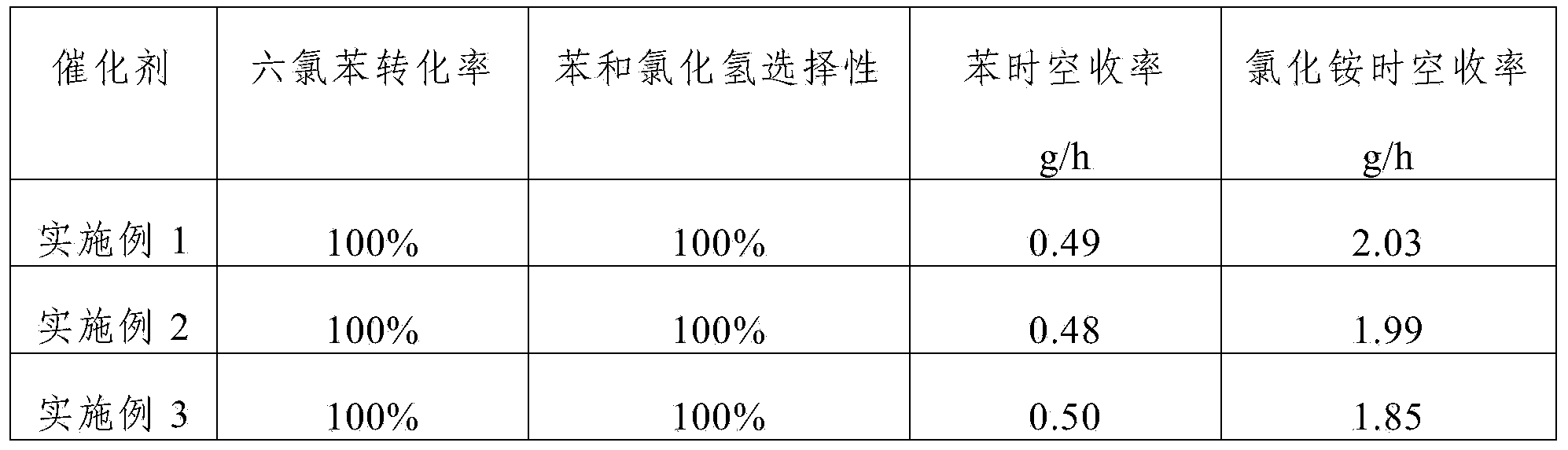

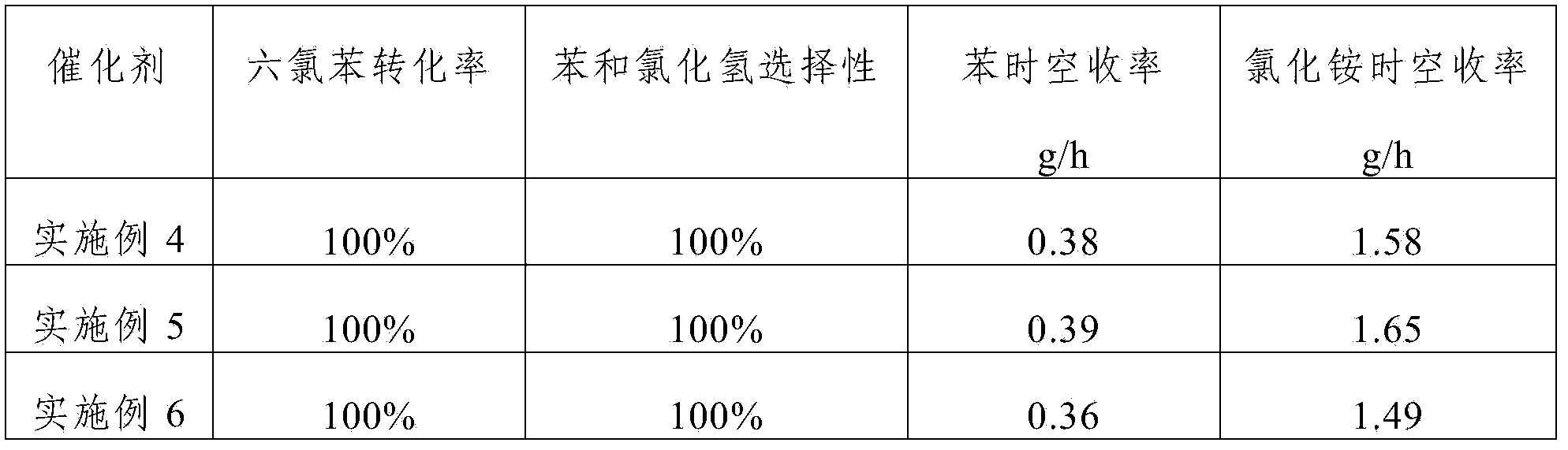

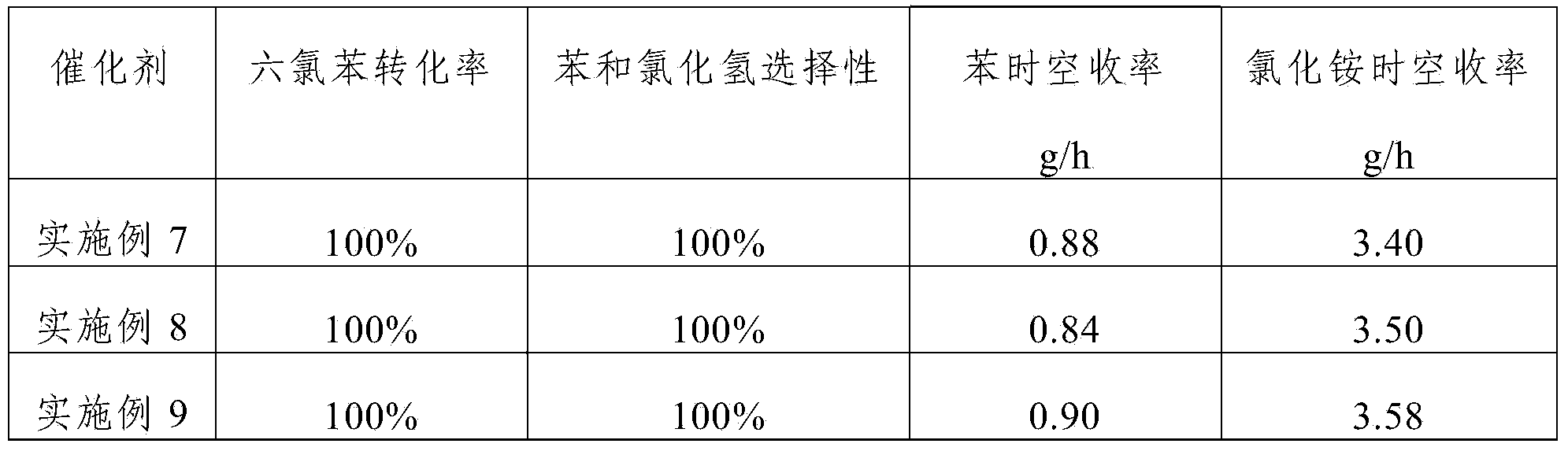

Method for catalytic degradation of hexachlorobenzene

ActiveCN103977744AHigh catalytic activityLarge amount of processingHydrocarbon from halogen organic compoundsAmmonium halidesSolventChemistry

The invention discloses a method for catalytic degradation of hexachlorobenzene. The method comprises the following steps: firstly, filling a catalyst into a fixed bed reactor, and carrying out reduction treatment on the catalyst; secondly, mixing hexachlorobenzene steam and preheated hydrogen uniformly to obtain a mixed gas, introducing the mixed gas into the fixed bed reactor after reduction treatment, and carrying out catalytic hydrodechlorination reaction on the catalyst, thereby obtaining the mixed gas of benzene steam, hydrogen chloride gas and unreacted hydrogen; and thirdly, feeding the mixed gas of benzene steam, hydrogen chloride gas and unreacted hydrogen into a condenser for condensing, converting benzene into liquid, then feeding the hydrogen chloride gas and unreacted hydrogen in the mixed gas into an absorption tower for absorbing hydrogen chloride by ammonia water, compressing the unreacted hydrogen by a compressor, and returning for recycling. A solvent is not required to be added in catalytic hydrogenation and degradation of hexachlorobenzene by the method provided by the invention, benzene and ammonium chloride are produced as byproducts, and zero emission of pollutants can be reached, and the method is an environmental-friendly technology for degrading hexachlorobenzene efficiently.

Owner:XIAN CATALYST NEW MATERIALS CO LTD +1

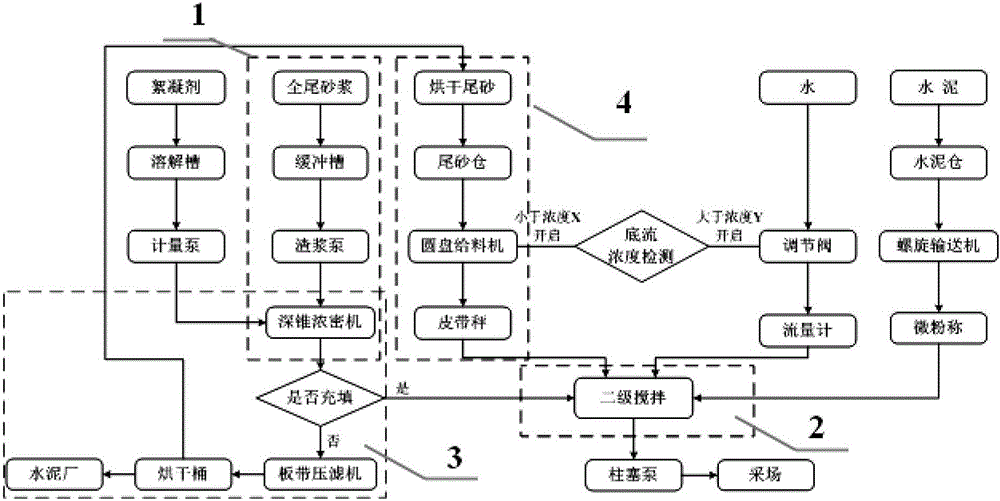

Preparation method of full-tailings paste

The invention provides a preparation method of a full-tailings paste and belongs to the technical field of mining. The method comprises the following steps: firstly thickening and concentrating full-tailings slurry of a concentration plant through a deep-cone thickener, introducing the full-tailings slurry into a paste stirring system when the full-tailings slurry needs to be packed after the full-tailings slurry is thickened to the designed concentration, introducing the full-tailings slurry into a full-tailings drying system, introducing one part of the dried full tailings into an automatic adding system of the dried full tailings to adjust the preparation concentration of the paste, and selling the other part of the dried full tailings into cement plants. The paste prepared by the method is stable in concentration, high in packing efficiency and high in utilization rate of the tailings; meanwhile, the full tailings can be sold to the cement plants for manufacturing cement; the waste is turned into wealth; the benefits of the mines are increased.

Owner:UNIV OF SCI & TECH BEIJING +1

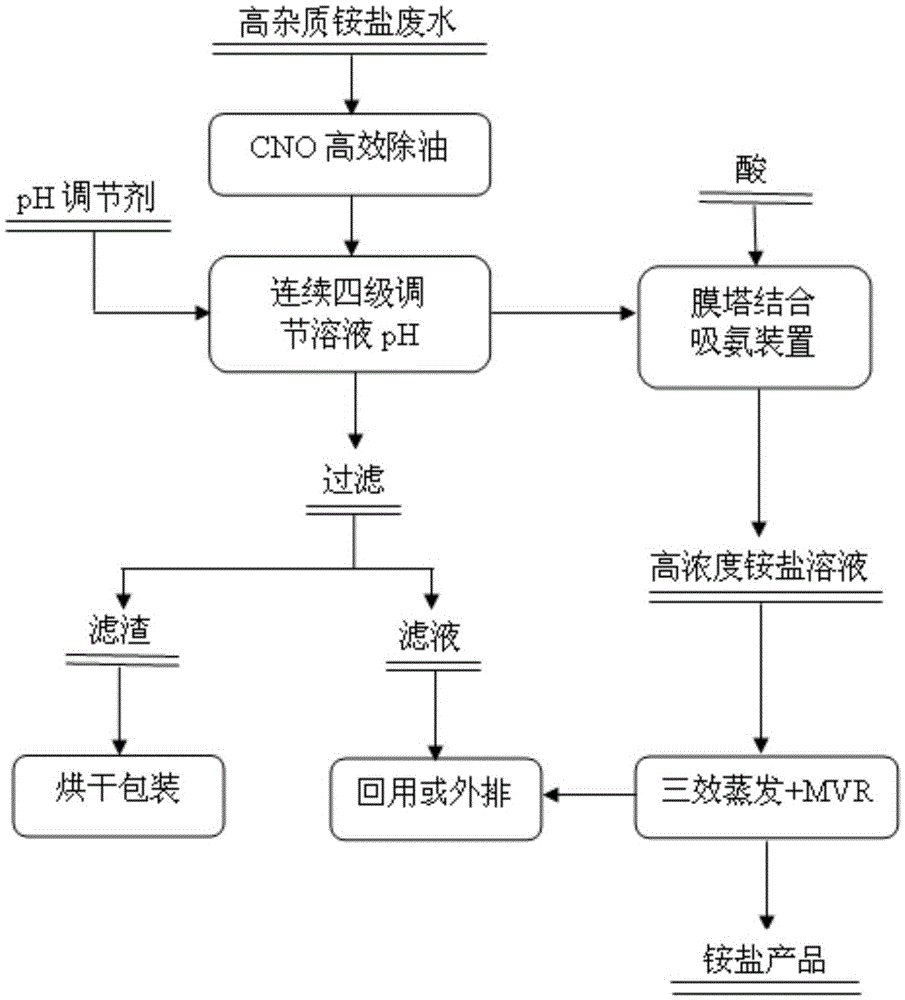

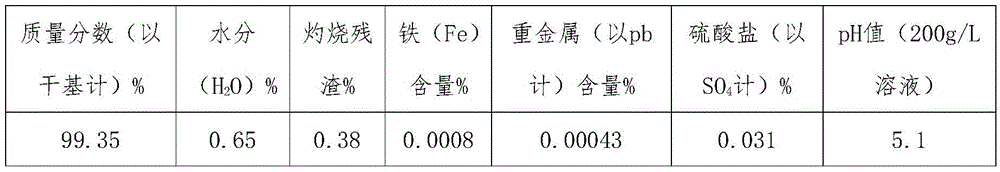

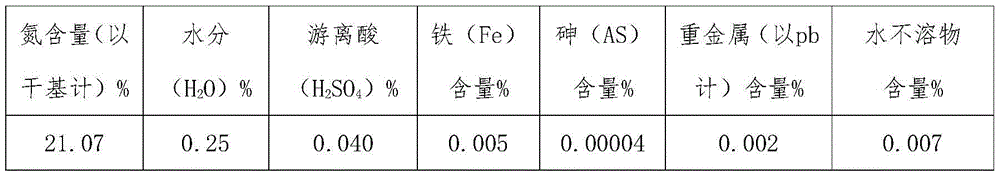

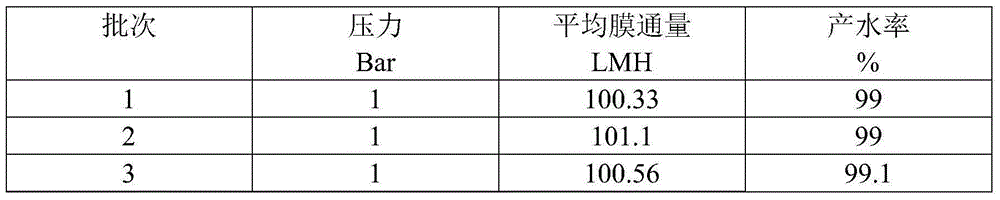

Method for preparing high-purity ammonium salts from high-impurity ammonium salt waste liquor

ActiveCN105480988ALow costEnergy savingFatty/oily/floating substances removal devicesWater contaminantsTriple effectHigh concentration

The invention relates to the field of sewage treatment, in particular to a technology for effectively treating high-impurity high-ammonia-nitrogen wastewater to recycle ammonium salts by combining multiple techniques. The ammonium salts comprise the ammonium chloride salt, the ammonium sulfate salt, the ammonium nitrate salt, the ammonium phosphate salt and the like, after efficient degreasing is performed on the high-impurity high-ammonia-nitrogen wastewater generated in the production process through a CNO degreaser, four stages of continuous overflow reaction equipment are adopted, a pH regulator is added in the first-stage reaction tank to regulate solutions, and corresponding high-concentration and high-purity ammonium salt solutions are generated in the second-stage reaction tank, the third-stage reaction tank and the fourth-stage reaction tank through treatment. The ammonium salt solutions are pumped into a triple effect evaporator, crystallized ammonium salts are separated out through a centrifugal machine and dried, the ammonium salt products are obtained, and condensate water and effluent ammonia nitrogen of the fourth-stage reaction tank are used for production or discharged out. The ammonium salt products produced through the technology are high in purity, and zero discharge of the ammonia-nitrogen wastewater is achieved. The technology has the advantages of being easy to operate, low in labor intensity, free of environmental pollution, capable of meeting the cleaner production standard and suitable for scale production.

Owner:赣州逸豪优美科实业有限公司

Method for extracting geniposide from gardenia yellow pigment waste liquor

ActiveCN103087129AIncrease profitAchieve zero emissionsSugar derivativesSugar derivatives preparationIsobutanolReverse osmosis

The invention discloses a method for extracting geniposide from gardenia yellow pigment waste liquor, which mainly comprises the following steps: concentrating gardenia yellow pigment waste liquor used as a raw material through a reverse osmosis membrane, extracting with isobutanol, decolorizing with active carbon, concentrating, performing crystallization purification twice, and finally drying. The invention can solve the waste problem that the gardenia effective component can not be economically and effectively recovered from the gardenia yellow pigment producing waste liquor in an environment-friendly way.

Owner:广西山云生化科技股份有限公司

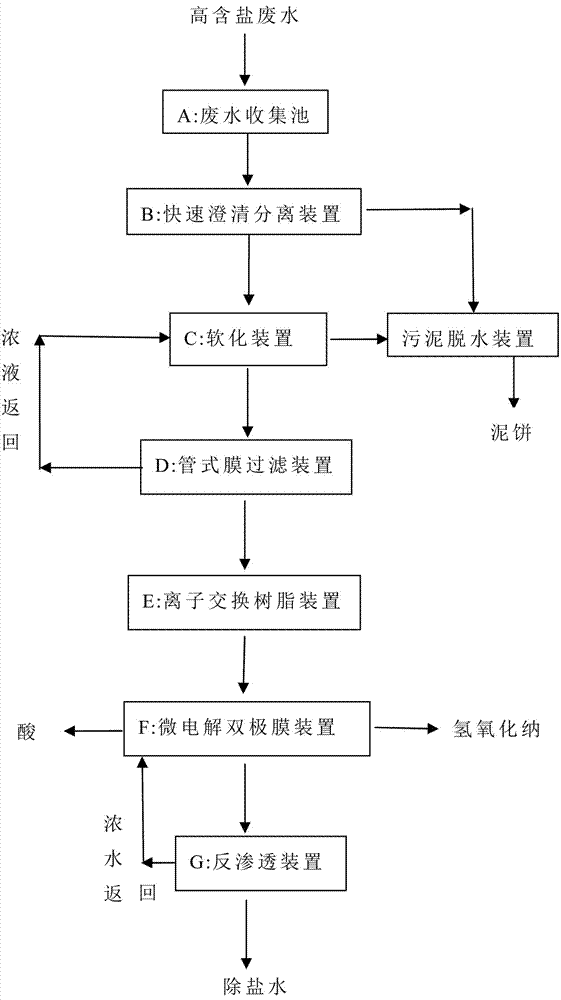

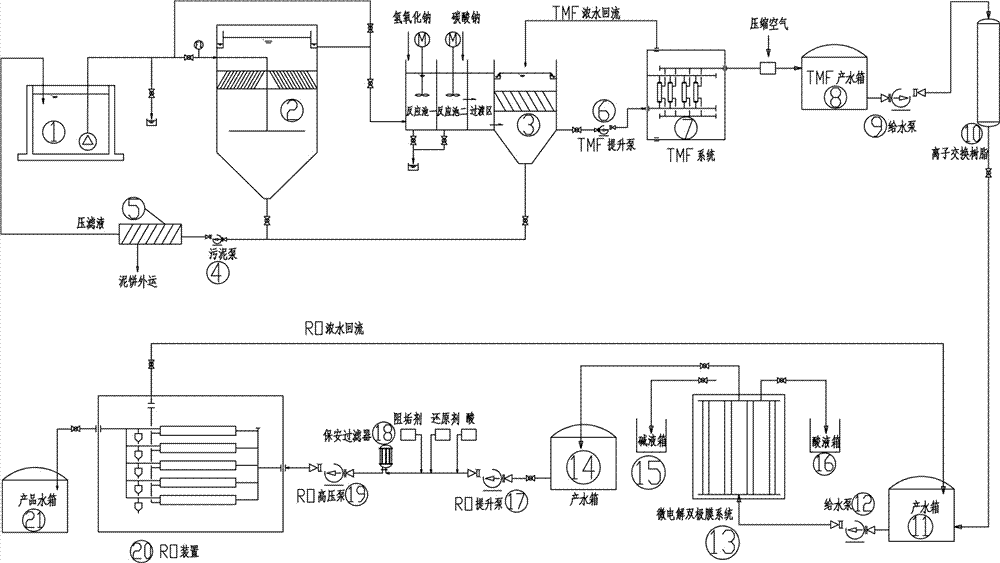

Zero-drainage technology and equipment for treatment of wastewater with high salt content

PendingCN107381885AUniform water qualityImprove qualityElectrolysis componentsGeneral water supply conservationElectrolysisFiltration membrane

The invention discloses a zero-drainage technology for treatment of wastewater with high salt content. The zero-drainage technology sequentially comprises the following steps of removing of suspension matters, reducing of hardness in wastewater, separating of solid and liquid by a tubular membrane, removing of residual hardness by ion exchange resin, freshening of concentrated salt water by a microelectrolysis bipolar membrane device, and removing of salt by a reverse osmosis device, so as to obtain desalted water and acid and sodium hydroxide commodities. The invention also discloses equipment. The equipment comprises a wastewater collecting tank, a quick clarifying and separating device, a primary softening device, a secondary softening device, a TMF (tubular micro-filtration membrane) concentrated water tank, a TMF lifting pump, a TMF system, a TMF water production tank, an exchange lifting pump, an ion exchange resin device, an intermediate water production tank, an electrolysis water supply pump, the microelectrolysis bipolar membrane device, and a product water tank. The zero-drainage technology and the system have the advantages that the suspension matters in the wastewater with high salt content can be quickly removed; the hardness in the wastewater is removed; the wastewater of concentrated salt water is freshened by the microelectrolysis bipolar membrane device; the acid and sodium hydroxide commodities are produced in the wastewater freshening process; the running cost is low, the wastewater with high salt content can reach zero-drainage effect, and the additional economic value is produced.

Owner:WUHAN SHANGYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

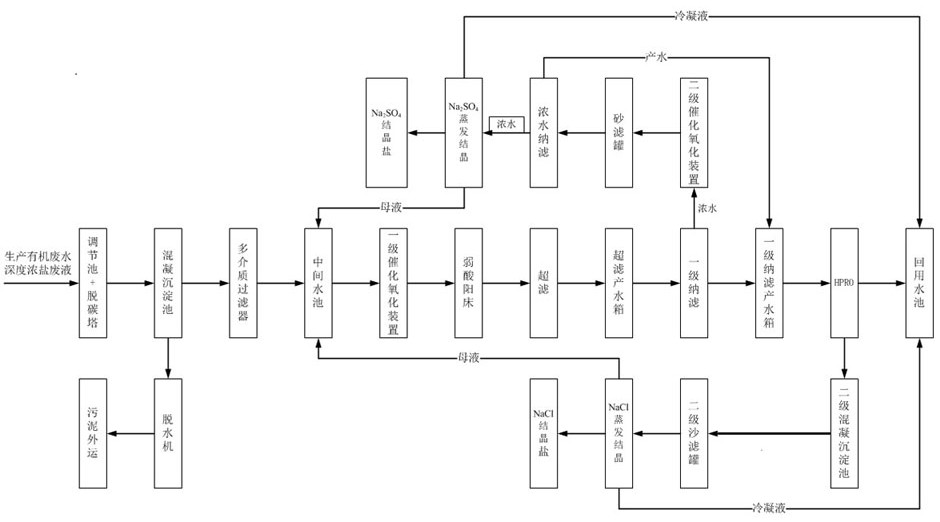

Salt-containing organic wastewater recycling and zero discharge process

PendingCN113636702AReduce environmental risksImprove resource utilizationWater contaminantsTreatment involving filtrationCatalytic oxidationSodium sulfate

The invention discloses a salt-containing organic wastewater recycling and zero discharge process, which comprises the following steps: adjusting and decarbonizing organic salt-containing waste liquid, feeding the organic salt-containing waste liquid into a coagulative precipitation tank, and feeding effluent into a multi-medium filter; mixing the effluent and subsequent separation mother liquor in an intermediate water tank, carrying out primary catalytic oxidation, entering a weak acid cation bed, removing impurities, and carrying out ultrafiltration; enabling water after ultrafiltration to enter a first-stage nanofiltration device to be subjected to quality-divided concentration; enabling that the concentrated water sequentially enters a secondary catalytic oxidation device and a sand filter tank to remove organic matters and residual impurities, and is conveyed to a concentrated water nanofiltration device and a sodium sulfate evaporative crystallization device; mixing the produced water, performing high-pressure reverse osmosis, sequentially feeding the water into a secondary coagulative precipitation tank and a sand filter tank to remove impurities in water, and feeding the water into a sodium chloride evaporative crystallization device; and producing sodium chloride and sodium sulfate in the purity higher than 98%. The mother liquor separated by evaporative crystallization flows back to a pre-process system, and the evaporation condensate is conveyed to a recycling water tank, so that the treatment and disposal of the mother liquor and a series of pollution problems are avoided, huge hazardous waste disposal cost is reduced, and the environmental pollution is reduced while the cost is reduced.

Owner:清创人和生态工程技术有限公司

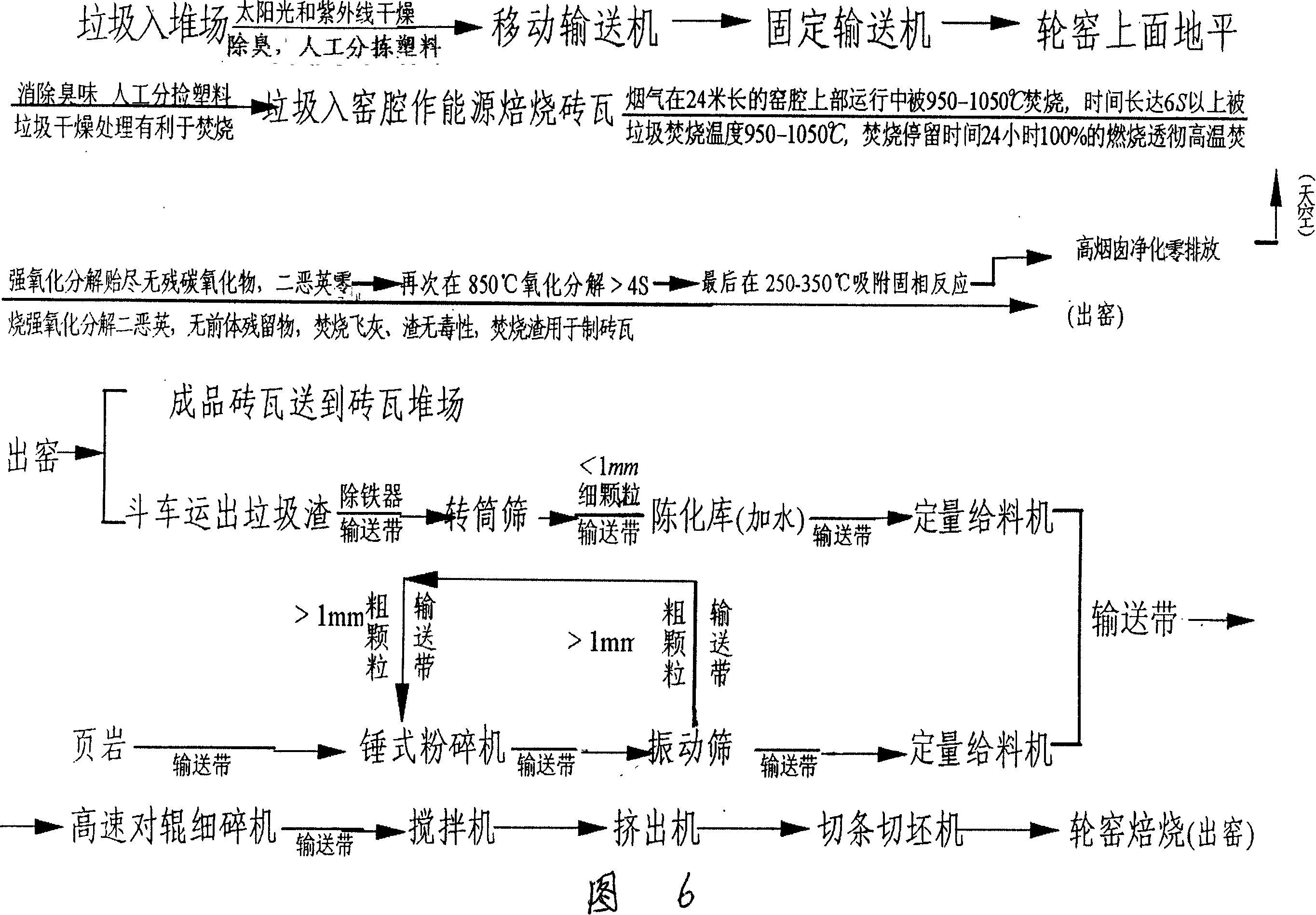

Novel without drainage of dioxin production technology for firing brick and tile and making brick and tile using with life garbage in city

InactiveCN101125336AGood economic benefitsCombustion processed successfullySolid waste disposalCircular economyOxide

The invention belongs to the field of circulating economy and environmental protection. The invention particularly relates to a new producing technique of dioxin zero release for using city life rubbish to make brick and tile by fire. At first, the rubbish is processed to dry status while selecting plastic and copper or iron made impurities; then the rubbish is thrown into brick and tile kiln to be fully burnt and later is used as regenerated resource for making bricks and tiles by fire. The rubbish burnt residues are used for making the bricks and tiles. During the burning process of the rubbish, the original residual toxic articles caused by burning the rubbish are eliminated by utilizing the unique structure of the kiln; in addition, the flying dust and toxic articles are fully burnt. The fume is decomposed by strong oxygenation and is burnt into oxycarbide without remnant for a long time and for many times when in running process, and the zero release of dioxin is achieved. The fume is purified by three layers of facilities inside a high chimney, and thus the normal temperature vapor released from the high chimney has zero release.

Owner:陈福暄

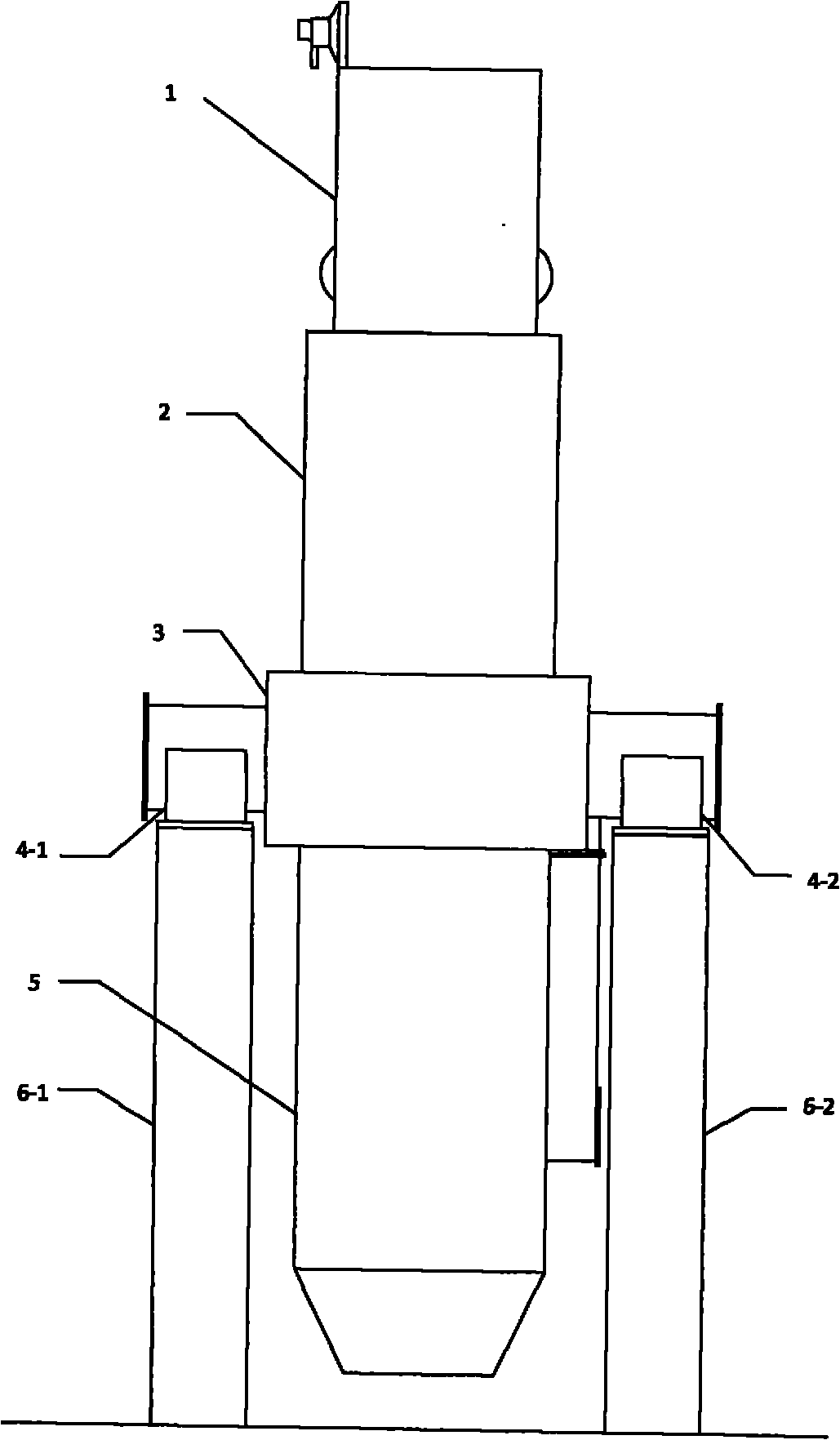

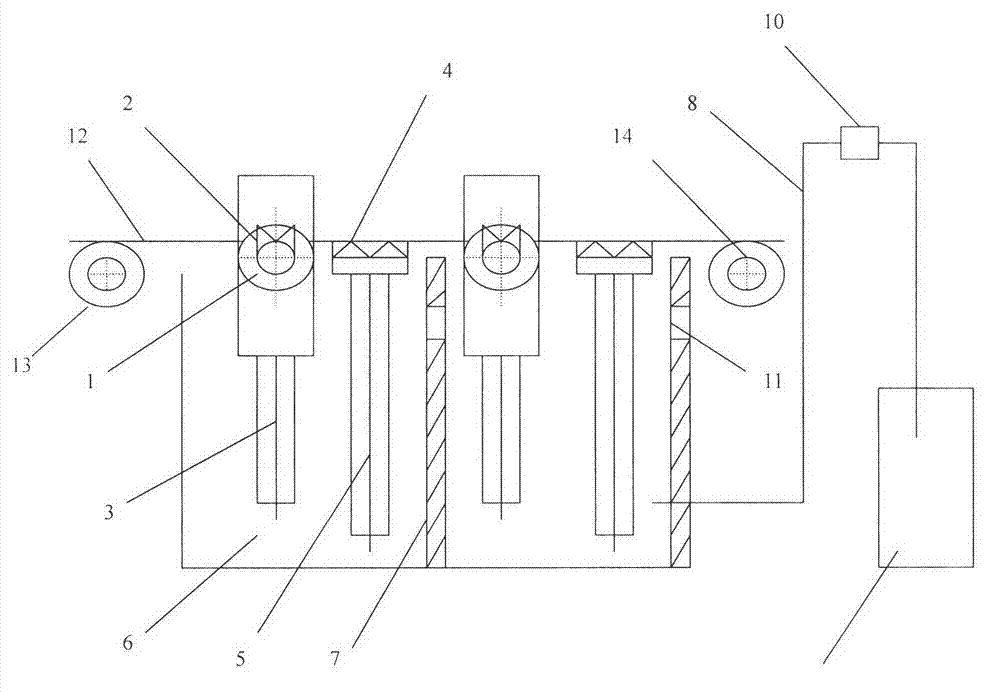

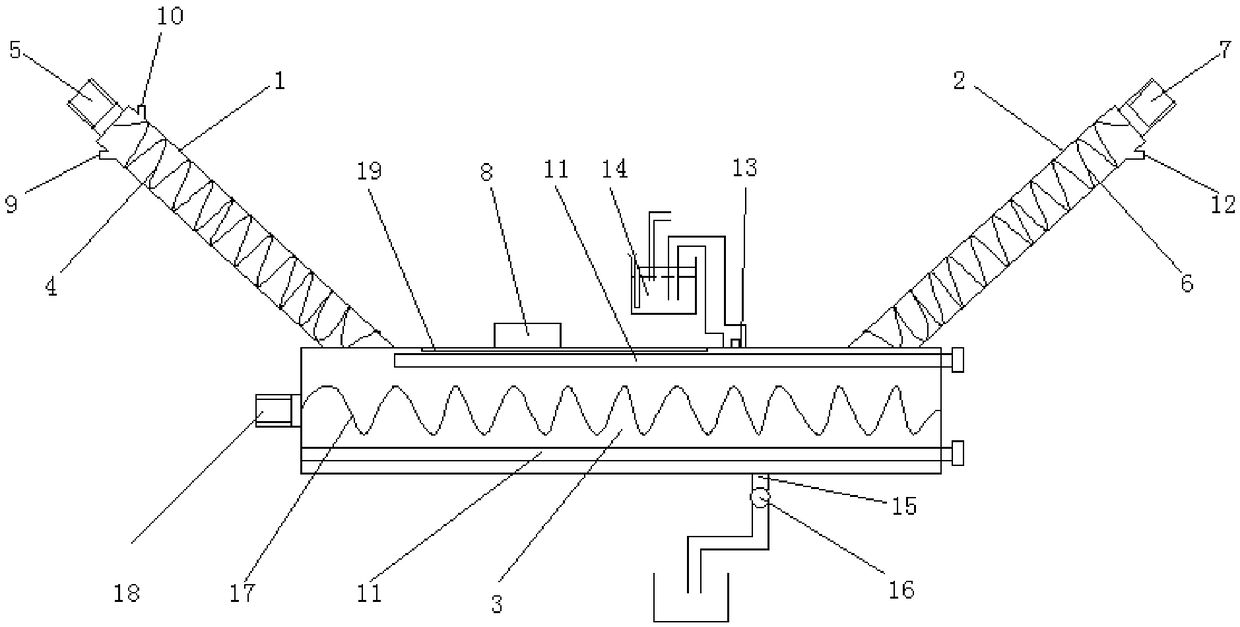

Backflow water washing equipment

The invention provides backflow water washing equipment which is low in cost and has a good using effect. According to the technical scheme, the equipment comprises a water spraying system, an air sucking system, a serial tank body and a circulating system, wherein the water spraying system mainly comprises water spraying plates (1) and lifting pumps (3), and each water spraying plate (1) is provided with a water spraying nozzle (2) of which the water spraying angle can be adjusted; the air sucking system mainly comprises air sucking plates (4) and air channels (5), and each air sucking plate (4) is provided with an air sucking hole; the serial tank body mainly comprises a plurality of washing tanks (6) formed by a plurality of clapboards (7), and water flowing openings (11) at different heights are formed in the clapboards (7); the circulating system mainly comprises a circulating pipe (8), a liquid sucking pump (10) and a plating tank (9); and the air sucking system and the water spraying system are fixed on the edges of the washing tanks (6) respectively. The equipment has a simple structure and is safe and reliable, and the force and the cleanliness of water washing are enhanced; and simultaneously, a serial circulating washing process is realized to achieve the effect of zero emission of washing fluid, so that the environment is greatly protected, and raw and auxiliary materials are greatly saved.

Owner:东营宏源机械设备有限公司

Clean production method of p-anisidine

ActiveCN106187786AEasy to operateReduce high-salt and high-COD wastewaterOrganic compound preparationAmino-hyroxy compound preparationChemistryP-Anisidine

The invention discloses a clean production method of p-anisidine. The clean production method comprises the following steps of (1) enabling nitrochlorobenzene, sodium hydroxide and methanol to be subjected to an etherification reaction so as to obtain etherification reaction liquid; (2) directly filtering the etherification reaction liquid obtained in the step (1) to obtain a filtrate and filter cakes, washing the filter cakes with the methanol, drying the washed filter cakes to obtain industrial-grade sodium chloride, and distilling the filtrate so as to obtain p-nitroanisole concentration liquid; and (3) under the condition that a hydrogenation catalyst exists, enabling the p-nitroanisole concentration liquid obtained in the step (2) to be subjected to a hydrogenation reduction reaction in the hydrogen atmosphere, and after the reaction is completed, performing after-treatment so as to obtain the p-anisidine. According to the clean production method, after the etherification reaction is finished, direction filtration is performed so that the sodium chloride is removed, then concentration treatment is performed on the etherification reaction liquid, the hydrogenation reaction is directly performed, the operation is simple and convenient, and the yield and the purity of the obtained product are high.

Owner:ZHEJIANG RUNTU INST

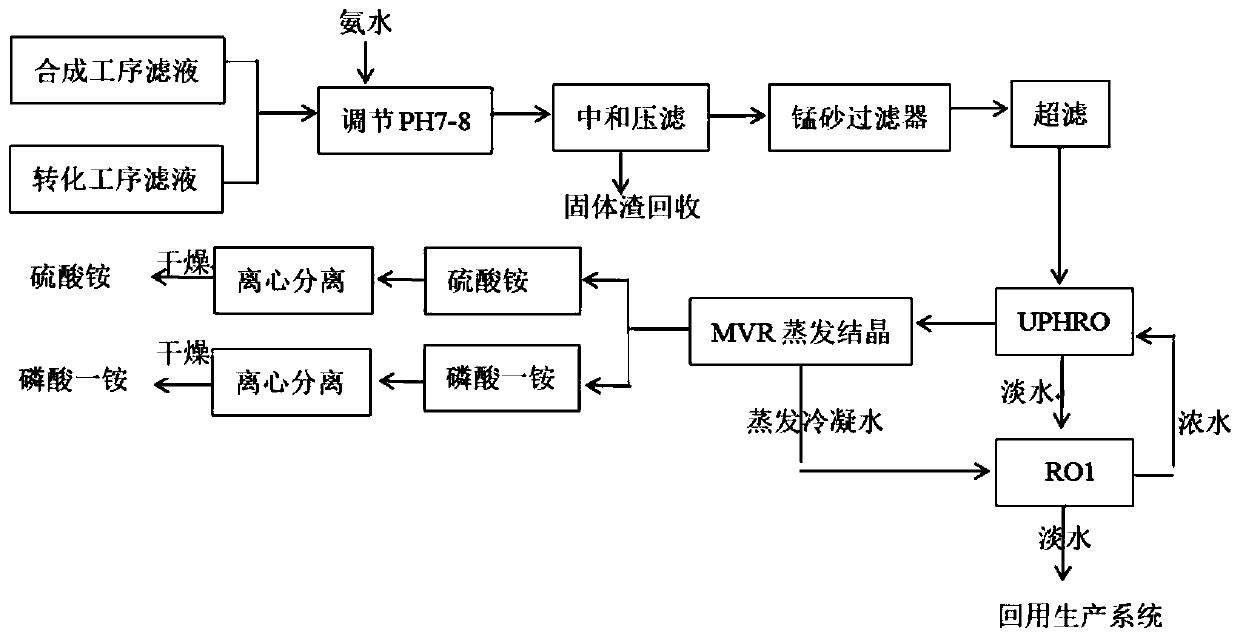

Method for resource utilization of wastewater in synthetic process of battery-grade iron phosphate

PendingCN110589788AMake up for expensesGood economic and environmental benefitsPhosphatesWater contaminantsAmmonium sulfateChemistry

The invention discloses a method for resource utilization of wastewater in the synthetic process of battery-grade iron phosphate. The method comprises the following steps: a, adding ammonia water to adjust the pH value of the wastewater generated in the synthetic process of the iron phosphate to 7-8 to obtain a solution; b, filtering the solution for multiple times to obtain a product, namely a filtrate without suspended solids; c, pumping the filtrate into an ultrahigh-pressure reverse osmosis device, and performing a reaction to obtain concentrated water A and fresh water A; d, introducing the concentrated water A into an MVR evaporative crystallization device, carrying out vacuum concentration evaporative crystallization to obtain an ammonium sulfate and monoammonium phosphate mixture and evaporation condensate water, and carrying out centrifugal separation on the ammonium sulfate and monoammonium phosphate mixture to respectively obtain ammonium sulfate and monoammonium phosphate;e, mixing the fresh water A and the evaporation condensate water, and pumping the mixed water into a primary reverse osmosis device to obtain concentrated water B and fresh water B; and f, pumping theconcentrated water B into an ultrahigh-pressure reverse osmosis device, and recovering the fresh water B. The method has the beneficial effect that the treatment cost of the wastewater can be saved.

Owner:襄阳泽东新能源发展有限公司

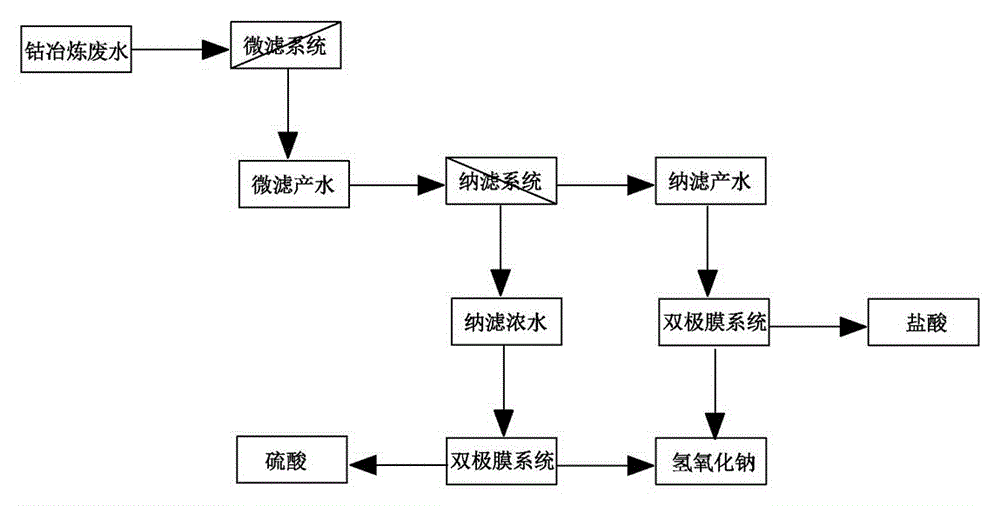

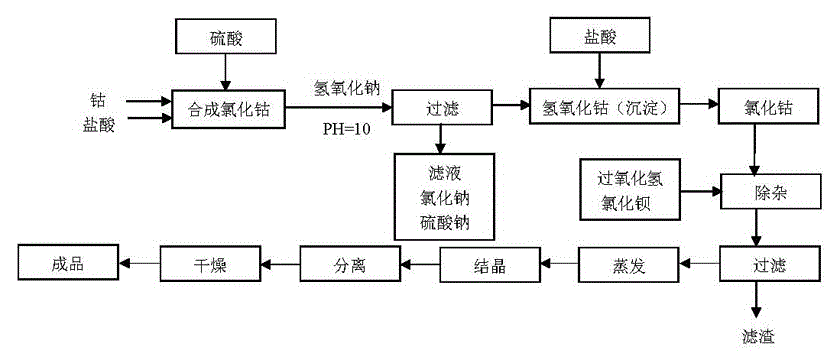

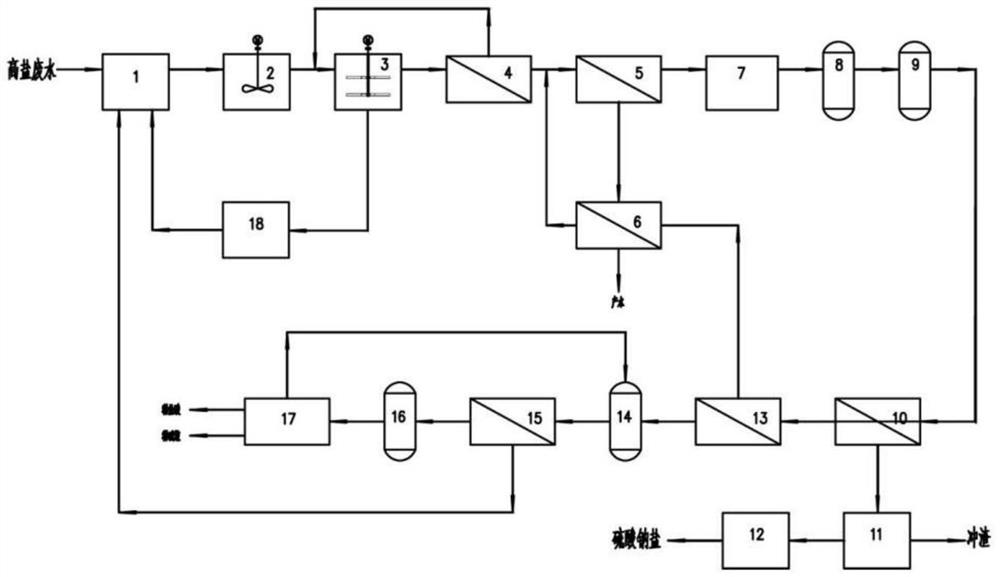

Process for preparing strong acid and strong alkali by separating cobalt smelting wastewater

InactiveCN105060405AAchieve zero emissionsChlorine/hydrogen-chlorideWaste water treatment from metallurgical processFiltrationStrong acids

The invention discloses a process for preparing strong acid and strong alkali by separating cobalt smelting wastewater. The process is characterized by comprising the following steps: S1, filtration by microfiltration: using a microfiltration system to treat cobalt smelting wastewater to remove a lot of suspended soils and particles and controlling the SS value being less than 1 to obtain microfiltration contributing water; S2, nanofiltration separation: feeding the treated microfiltration contributing water to a nanofiltration system to separate two types of salt to obtain nanofiltration concentrated water and nanofiltration contributing water, wherein the nanofiltration concentrated water is sodium sulfate and the nanofiltration contributing water is sodium chloride; S3, nanofiltration concentrated water treatment: feeding the nanofiltration concentrated water into a bipolar membrane system to be treated to prepare sodium hydroxide and sulfur acid; and S4, nanofiltration contributing water treatment: feeding the nanofiltration contributing water into the bipolar membrane system to be treated to obtain sodium hydroxide and hydrochloric acid. The process for preparing strong acid and strong alkali by separating cobalt smelting wastewater disclosed by the invention abandons high cost caused by evaporation, so that salt in the wastewater can be recycled in the process, and zero discharge of wastewater is achieved.

Owner:XIAMEN STARMEM TECH

Method for recycling meat ball and fish ball poaching liquid

The invention belongs to the field of wastewater utilization, and relates to a method for recycling poaching liquid used during meat ball and fish ball processing. The method includes thickening the meat ball and fish ball poaching liquid by using the liquid repeatedly so that the concentration of the liquid is increased to 4-7% from the original approximate concentration of 1%; then concentrating the thickened poaching liquid by a freeze concentration technology to finally obtain concentrated solution; and properly proportioning the concentrated solution, then manufacturing the concentrated solution into seasoned cans via canning and sterilizing procedures or processing the concentrated solution into powdery condiments by a drying process. By thickening the meat ball and fish ball poaching liquid, the usage of the poaching liquid can be reduced in a production process, and the content of soluble substances can be increased. The method has the advantages that the poaching liquid used in meat ball and fish ball processing enterprises is treated, environmental pollution caused by the meat ball and fish ball poaching liquid is reduced, the concentrated meat ball and fish ball poaching liquid can be manufactured into the condiments, and a commercial value is generated.

Owner:FUJIAN AGRI & FORESTRY UNIV

Process for preparing poly-ferric sulfate chloride by oxidation of oxyful

InactiveCN101519228AWith environmental protection chemicalAchieve zero emissionsIron sulfatesWater/sewage treatment by flocculation/precipitationChemical industryIron sulfate

The invention discloses a process for preparing poly-ferric sulfate chloride by oxidation of oxyful, which comprises the following steps: iron sulfate heptahydrate is stirred and added into a reaction tank, and industry by-product hydrochloric acid is added into the reaction tank; oxyful containing 30-35 percent of hydrogen peroxide (H2O2) is slowly and uniformly added into the reaction tank; 5 percent of natrium hydroxide (NaOH) solution is slowly and uniformly added into the reaction tank, and a poly-ferric sulfate chloride product which has 8-14 percent of degree of basification is produced; the poly-ferric sulfate chloride product in the reaction tank is put into a curing tank to be cured for 10 days, and the chemical index of the poly-ferric sulfate chloride product is adjusted to a required value. The invention has the advantages of environmentally-friendly and wide raw material source, small investment, quick return, chemical industry environmental protection and zero discharge of industrial waste. In addition, the invention adopts the oxyful for oxidation and is easy and convenient to operate and control.

Owner:赵 立民

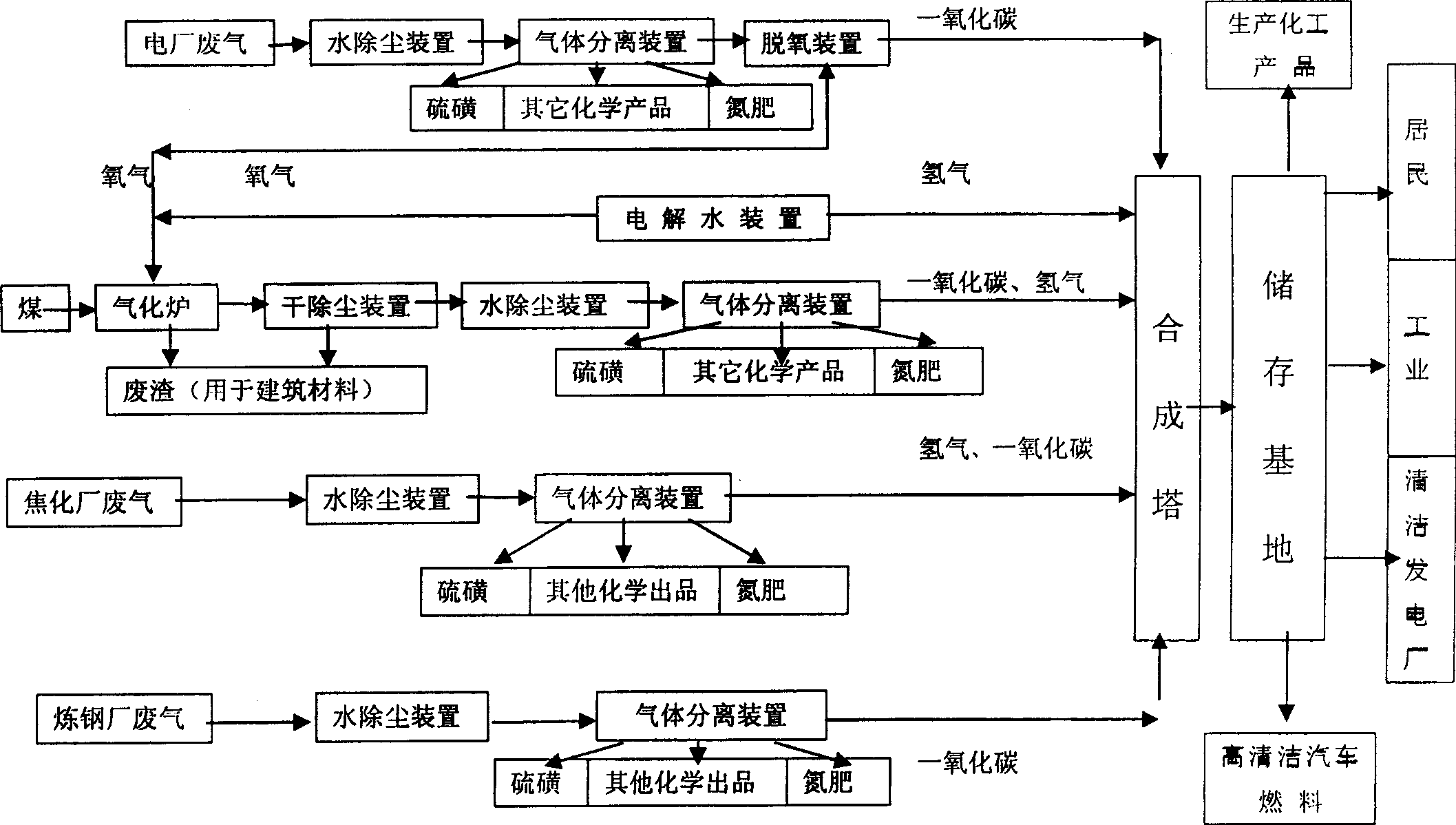

Process of co-producing high clean fuel by adding hydrogen to coal gasifying, power plant or other industrial waste gas

InactiveCN1782038ASave resourcesAchieve zero emissionsGaseous fuelsGas modification by gas mixingAutomatic controlEngineering

The present invention relates to process of coal gasifying and compounding CO2 from industrial waste gas with H2 to produce clean fuel. Normally, coal gas contains CO in about 65 % and H2 in about 30 %. Industrial waste CO2 is used in producing O2 and CO or compounding H2 to produce clean fuel for generating electricity or producing chemical products, etc. The present invention can save coal resource and reach zero exhaust of harmful gas. Or, coke oven gas may be used in preparing high H2 and low CO gas, and blast furnace gas may be used in preparing high CO and low H2 gas via compounding with H2. The gas materials entering the Linda low temperature synthesis tower or other tower has the proportion computer controlled in producing clean fuel.

Owner:马喜超

Catalyst for degrading hydrogen peroxide as well as preparation method and application of catalyst

ActiveCN104785254AHigh catalytic activity and stabilityMild reaction conditionsMetal/metal-oxides/metal-hydroxide catalystsSolventActivated carbon

The invention discloses a catalyst for degrading hydrogen peroxide. The catalyst comprises an activated carbon carrier, Pd, metal M1 and metal M2, wherein the Pd, the metal M1 and the metal M2 are loaded on the carbon carrier; the mass percentage content of the Pd in the catalyst is 0.3-1.5 percent, the mass percentage content of the metal M1 is 0.1-1 percent, and the mass percentage content of the metal M2 is 0.05-2 percent; the metal M1 is Pt, Ru or Sn; the metal M2 is K, Ag or Ce. In addition, the invention further discloses a preparation method of the catalyst and a method for catalyzing, hydrogenating and degrading the hydrogen peroxide by applying the catalyst. The catalyst disclosed by the invention has very high catalytic activity and stability and can safely and efficiently catalyze and degrade the hydrogen peroxide in a solvent, so that the hydrogen peroxide is converted into water and does not generate oxygen; the degradation rate of the hydrogen peroxide is larger than 99.5 percent. The catalyst disclosed by the invention has an important safety guarantee effect on chemical industrial solvent recycling and is very wide in market application prospect.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Process for co-producing electrical carbon through anaerobic and pyrolysis coupling of organic waste

InactiveCN109628498AHigh yieldAchieve zero emissionsInternal combustion piston enginesWaste processingCo2 removalVariable pressure

The invention discloses a process for co-producing electrical carbon through anaerobic and pyrolysis coupling of organic waste. Solid residuesobtained after anaerobic pretreatment are used as a raw material for pyrolysis, under the effect of methane bacteria, some organic molecules,for example, protein and fat, free around biomassmacromolecules in an anaerobic systemin the anaerobic fermentation process produce hydrolysis reaction with amorphous hemicellulose to generate marsh gas, the residual cellulose and lignin cannot be utilized by the anaerobic system and enter a pyrolysis reactor afterbeing dried, energy gases such as H2, CH4 and CO are prepared by utilizing a thermochemical method, accordingly theenergy gas yield is improved, and the vinegar grain reduction rate is improved. Gasesproduced by an anaerobic fermentation process and the pyrolysis reaction are subjected to variable-pressure adsorption and CO2 removal, pure energy gases are obtained and applied for power generationand gas supply, a by-product biochar can be applied to soil remediation, and heat utilization rate is improved through waste heat recovery. The system can achieve energy self-sufficiency.

Owner:江苏久力环境科技股份有限公司

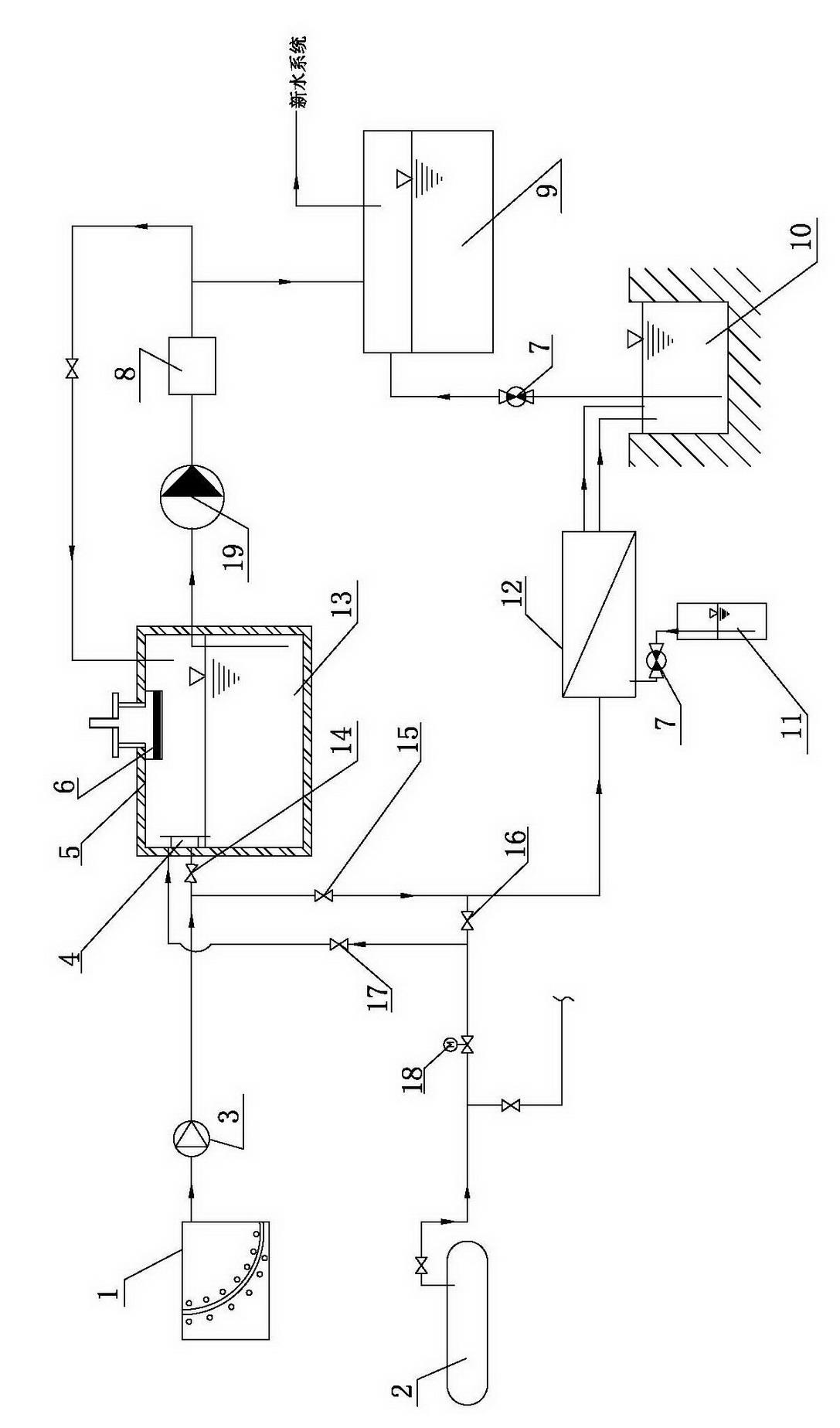

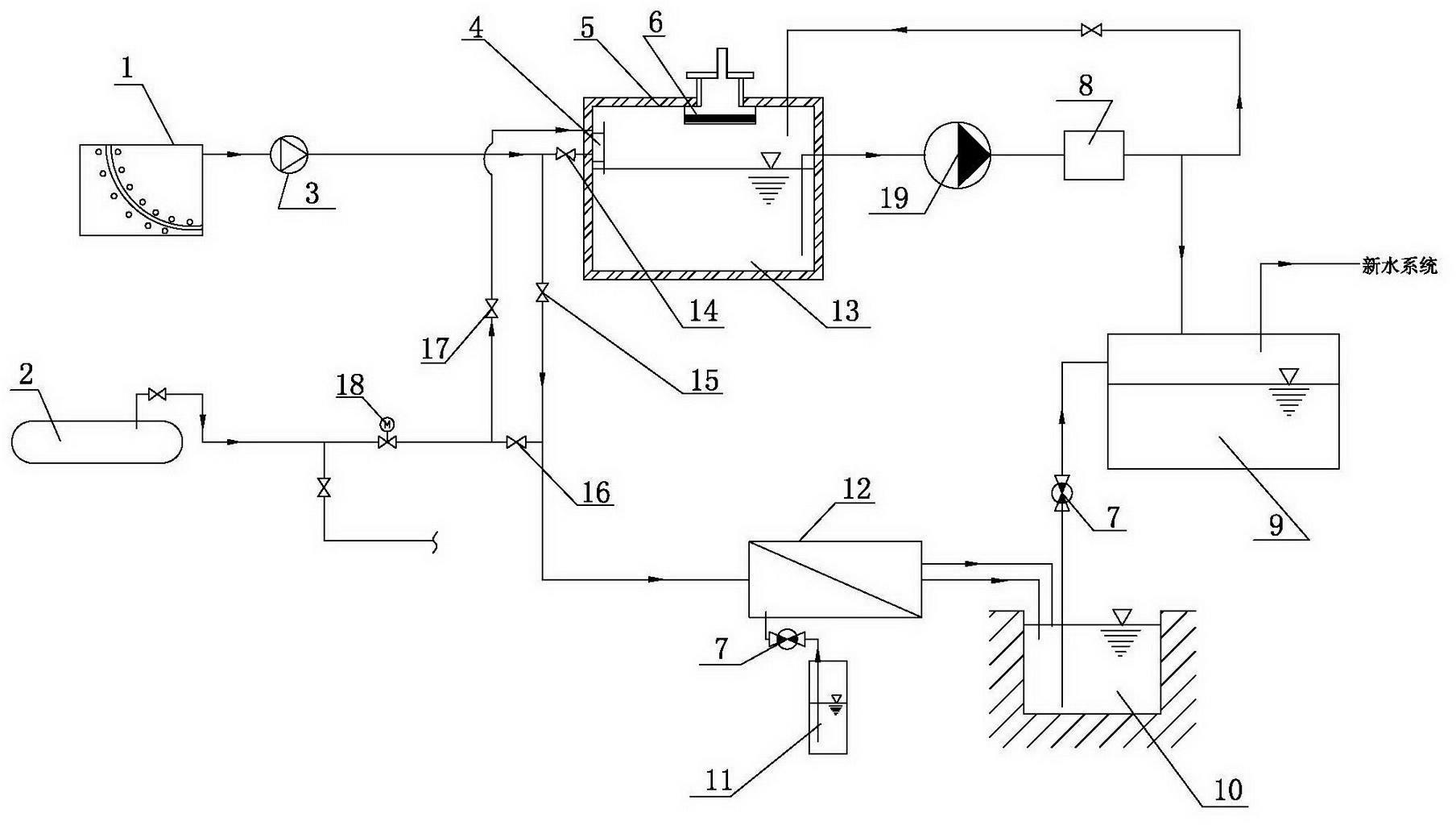

Zero-emission comprehensive utilizing technology for continuous-casting secondary-cooling vapor and converter vaporizing vapor

ActiveCN102538496ARealize energy savingAchieve zero emissionsManufacturing convertersIncreasing energy efficiencySocial benefitsWater storage

The invention discloses a zero-emission comprehensive utilizing technology for continuous-casting secondary-cooling vapor and converter vaporizing vapor. The zero-emission comprehensive utilizing technology for the continuous-casting secondary-cooling vapor and the converter vaporizing vapor comprises the following steps; 1, heating period: cooling the continuous-casting secondary-cooling vapor and the vaporized converter vapor, dewatering the continuous-casting secondary-cooling vapor and the vaporized converter vapor into hot water at 85-95 DEG C, collecting the hot water into a heat-preserving water tank for supplying a circulating heating medium to a heat supply network, and supplementing surplus water in the circulating heating medium into a fresh water system; and 2, non-heating period: cooling the continuous-casting secondary-cooling vapor and the vaporized converter vapor into liquid water, collecting the liquid water into a water storage pool, and supplementing the liquid water into the fresh water system. After adoption of the technology, the continuous-casting secondary-cooling vapor and the vaporized converter vapor are completely recycled, so that the zero emission isrealized; the influence of the emission of the continuous-casting secondary-cooling vapor and the vaporized converter vapor on the environment is avoided, and the energy brought by the emission is comprehensively utilized, so that aims of saving energy, reducing emission and lowering consumption are fulfilled; the economic, environmental and social benefits are outstanding; and the zero-emission comprehensive utilizing technology for the continuous-casting secondary-cooling vapor and the converter vaporizing vapor is worth of wide popularization.

Owner:抚顺新钢铁有限责任公司

Treatment system and method for resource utilization of ferrous metallurgy high-salinity wastewater

PendingCN113562924AImprove corrosion resistanceStrong resistance to microbial contaminationSludge treatment by de-watering/drying/thickeningWater softeningHazardous substanceReverse osmosis

The invention relates to a treatment system and method for resource utilization of ferrous metallurgy high-salinity wastewater. Impurities such as fluorides, silicon scales, heavy metals and suspended solids in the high-salinity wastewater are removed through an adjusting tank, a softening reaction tank, a concentration sedimentation tank and a tubular microfiltration device, and clear water treated by a primary RO device and a secondary RO device is recycled. Concentrated water generated by the primary RO device sequentially passes through an ozone catalytic oxidation device, an activated carbon adsorption device and aresin softening device, so that the hardness and COD in the concentrated water are sequentially reduced; effluent of the resin softening device enters a nanofiltration device, and concentrated water of the nanofiltration device enters a freezing crystallization device and an evaporative crystallization device to separate out sodium sulfate for sale. The water produced by the nanofiltration device respectively enters a high-pressure reverse osmosis device, a defluorination device, an electrodialysis device and a bipolar membrane electrodialysis device to generate diluted hydrochloric acid and diluted alkali lye. The method has the advantages that low-cost treatment is realized, various harmful substances in the high-salinity wastewater are removed step by step, and reasonable resource utilization of the wastewater and wastes is realized.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Method for high-precision forecasting of blast furnace hot blast stove gas consumption amount

ActiveCN110699502ARealize dynamic optimal schedulingAchieve zero emissionsSteel manufacturing process aspectsForecastingHot air ovenBusiness enterprise

The invention relates to a method for the high-precision forecasting of the blast furnace hot blast stove gas consumption amount. The purposes are to forecast the blast furnace hot blast stove gas consumption amount in the iron-making production process in advance and provide technical supports for implementation of steel enterprise dynamic gas optimal scheduling. Based on a blast furnace and hotblast stove production plan and an equipment maintenance plan, according to the hot blast stove burning and air supplying system, by referring to hot blast stove thermal balance test analysis report data, a single blast furnace gas consumption forecasting model under various working conditions of a blast furnace is established, wherein the working conditions of the blast furnace include the normalproduction working condition, the wind reduction working condition, the damping down working condition and the rewinding working condition; by means of the method, high-precision (larger than or equal to 95%) forecasting of the blast furnace hot blast stove gas consumption amount can be achieved, and a technological base is laid for enterprise gas dynamic optimized dispatching; and the method hasan important effect on enterprise gas zero emission.

Owner:鞍钢集团自动化有限公司

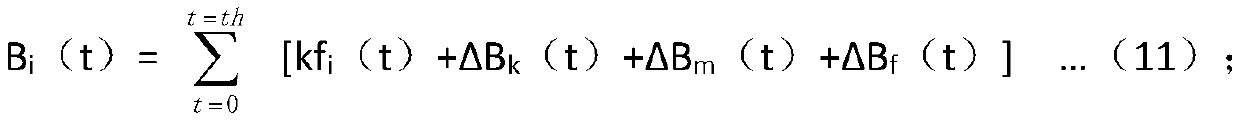

Cyclic utilization device and method for discarded aluminum plastic resources

InactiveCN109016233AImprove qualityAchieve zero emissionsPlastic recyclingIndustrial effluentSodium aluminate

The invention belongs to the technical field of aluminum plastic separation cyclic utilization and discloses a cyclic utilization device and a method for discarded aluminum plastic resources. The method comprises the following steps of firstly, classifying and sorting; secondly, smashing; thirdly, washing materials; fourthly, soaking and separating, wherein sodium hydroxide and an unsaturated sodium aluminate solution are added to a soaking and separating device so that soaking can be conducted, an aluminum foil layer reacts with sodium hydroxide, and plastic is separated out; or hydrochloricacid is added to the soaking and separating device so that reaction can conducted, aluminum chloride is prepared, and the plastic is separated; fifthly, washing the plastic; and sixthly, separating the plastic. According to the cyclic utilization method for the discarded aluminum plastic resources, through an inorganic solution soaking method and airtight type harmless treatment, automated cyclictreatment is carried out on waste water and exhaust gas generated in the production process; the discarded aluminum plastic resources are changed into agents which can be used for treating industrialwaste water and exhaust gas pollution; a large quantity of high-quality plastic is also acquired; zero emission of discarded aluminum plastic resource cyclic treatment is achieved; and the purposes oftreating waste with waste and changing waste into wealth are achieved.

Owner:赵安全

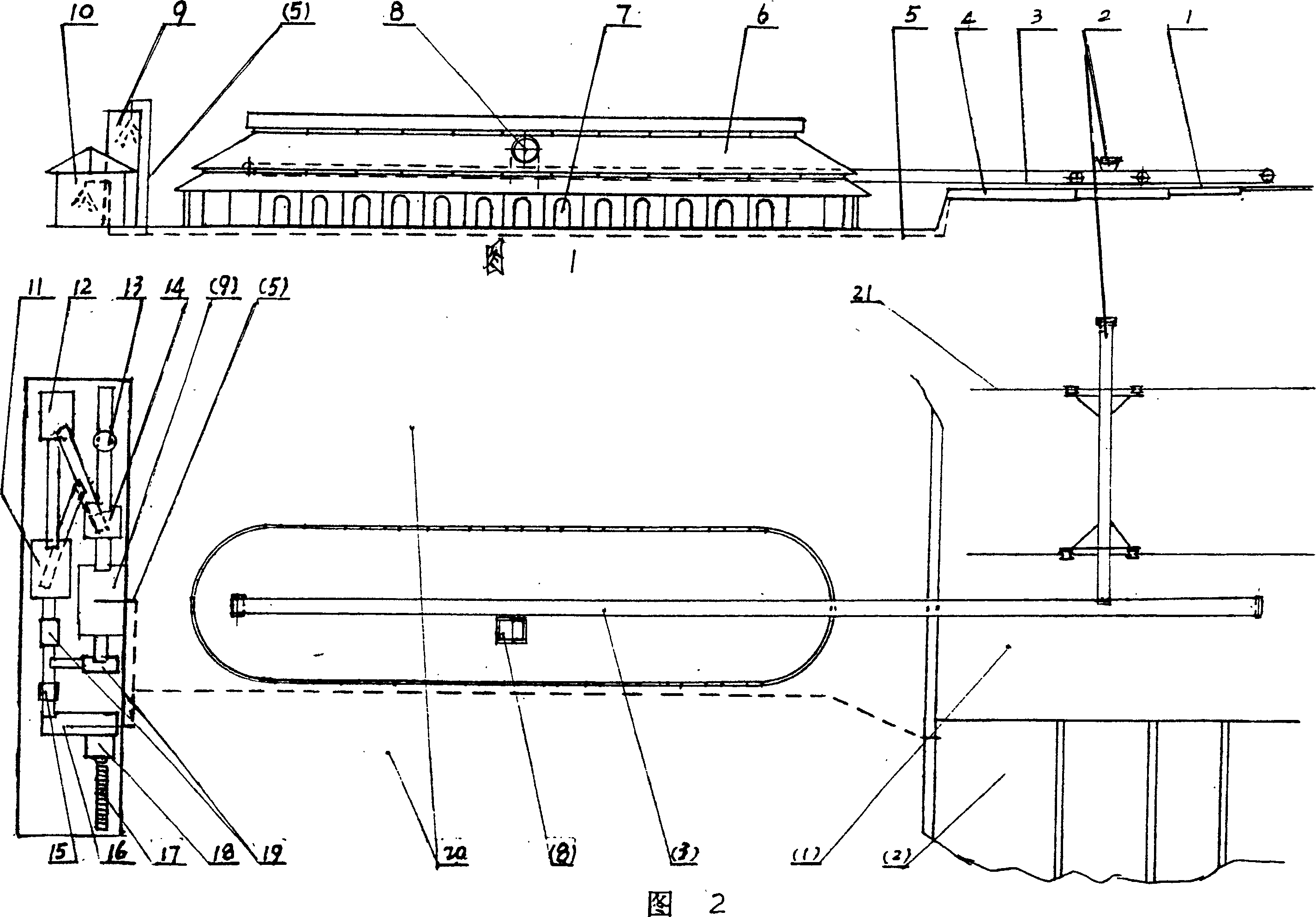

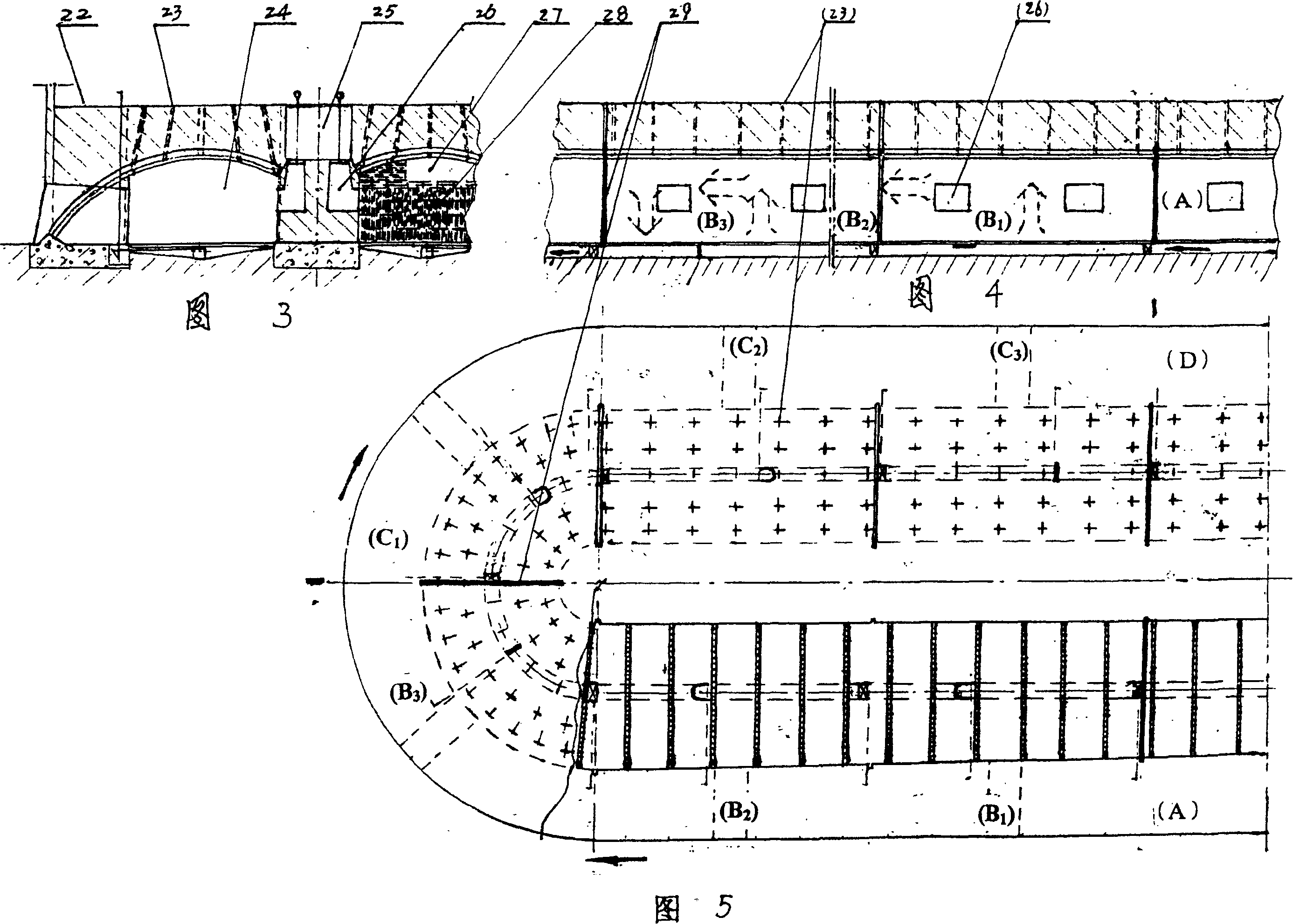

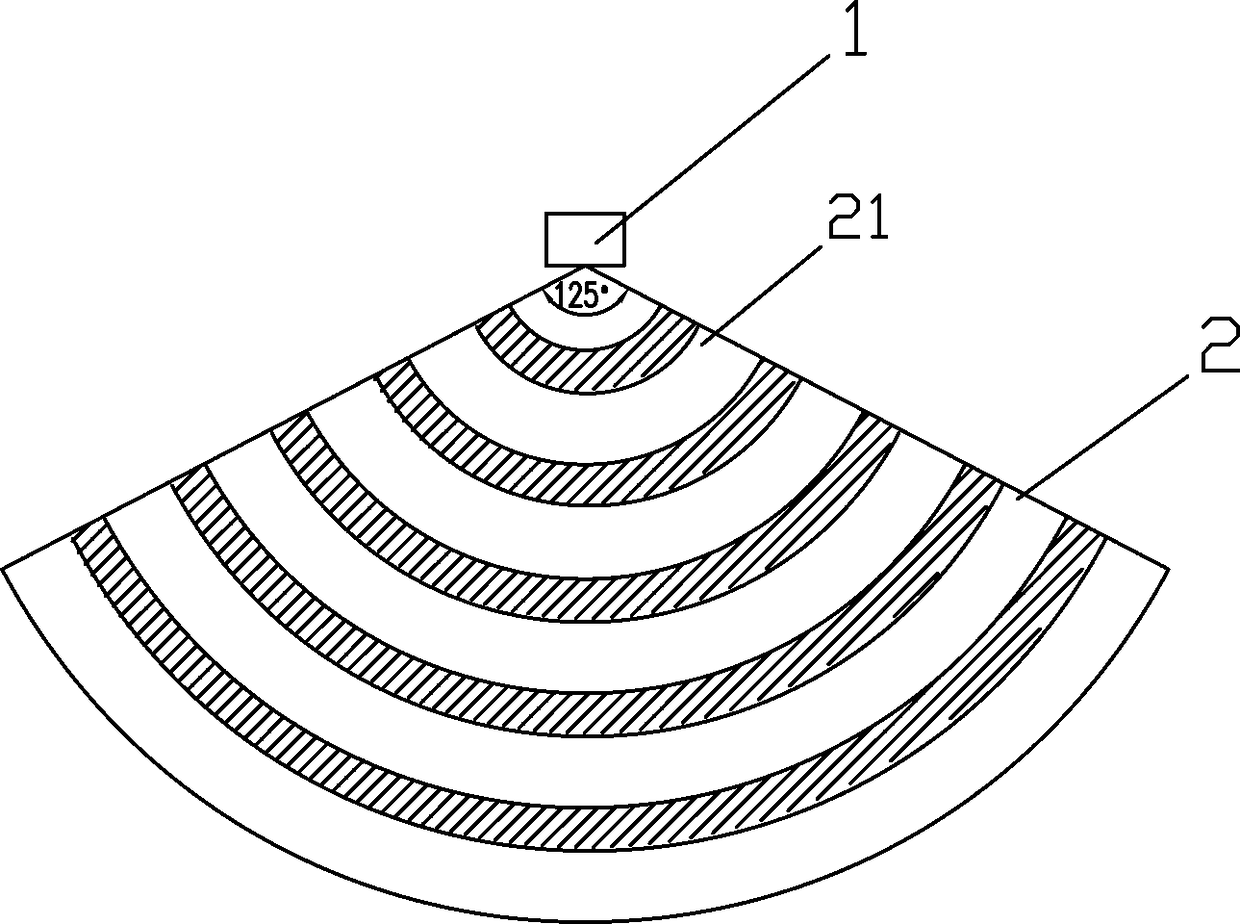

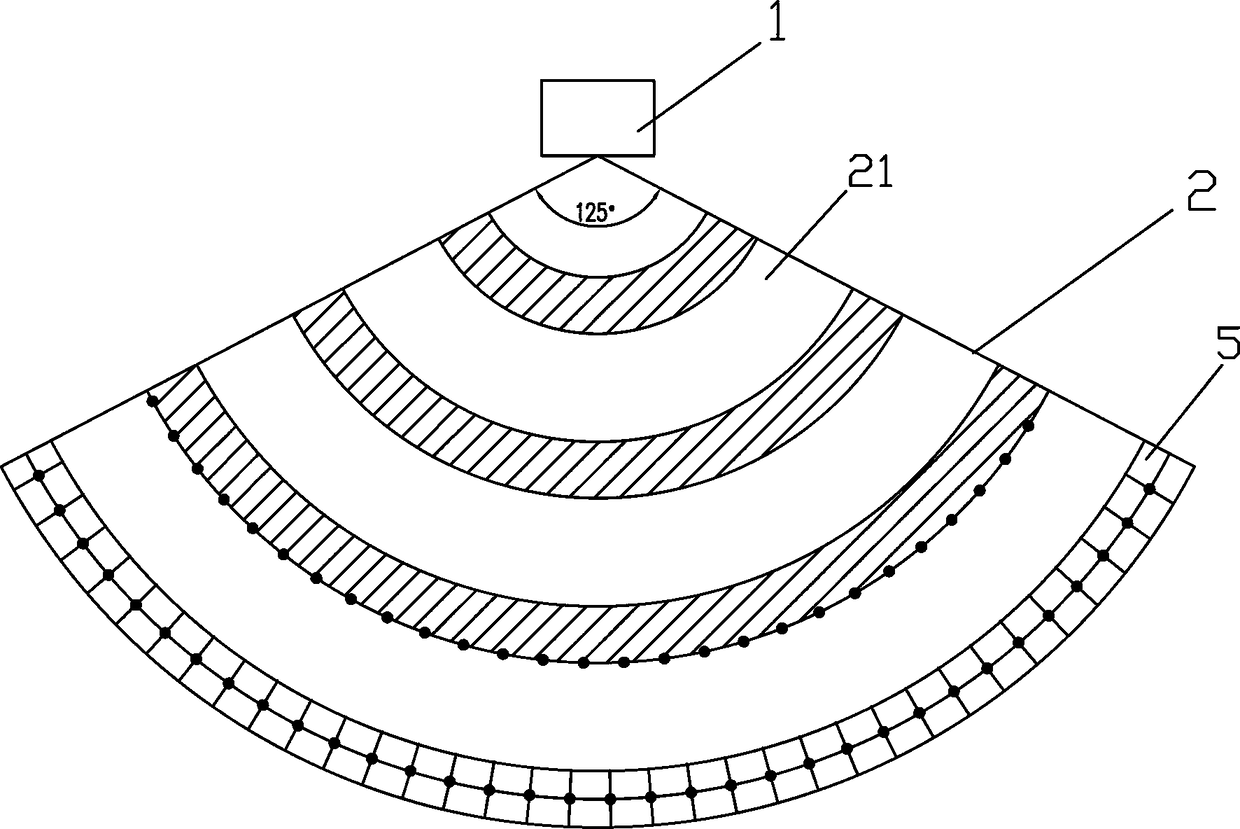

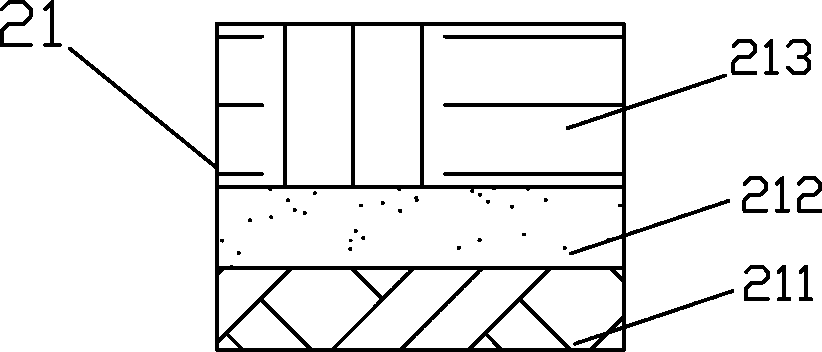

Outdoor theatre and construction method thereof

ActiveCN108775169AImprove stress resistanceImprove shear resistanceWatering devicesGrowth substratesPlant rootsEngineering

The invention provides an outdoor theatre and a construction method thereof. The outdoor theatre comprises a stage, an audience area, a drainage system and an irrigation system, wherein the audience area is distributed with the stage position serving as a center and comprises 3-12 layers of fan-shaped platforms arranged from inside to outside; the fan-shaped platforms are arranged on a rough place, the rough place comprises 3-12 layers of stepped slopes, and each fan-shaped platform comprises a base layer, a coarse sand layer and a soil planting layer from bottom to top in sequence; the drainage system comprises a main drain arranged in the base layers of the fan-shaped platforms, a plurality of underground percolation blind pipes are distributed in the base layers of the fan-shaped platforms in a fork-shaped vein manner, an overground open drain and a filter. The green theatre is good in soil permeability, high in trample resisting capability and good in buffer performance; lawn strength and crushing resistance are high, and the service life of a plant root layer is long; the irrigation is convenient, rainwater and residual irrigation water are recycled, and the purpose of urban zero emission is achieved.

Owner:SHANGHAI CHENSHAN BOTANICAL GARDEN +1

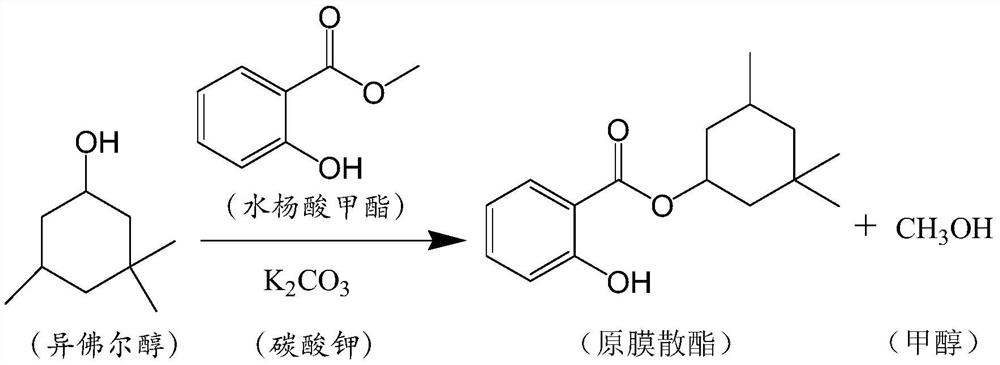

Method for preparing salicylate through green synthesis process

PendingCN112321434AReduce secondary recyclingEasy to separateOrganic compound preparationPreparation by ester-hydroxy reactionSalicylic acid esterTrans esterification

The invention discloses a method for preparing salicylate through a green synthesis process. The method comprises the following steps: carrying out ester exchange on salicylate compounds and isophorone which are used as raw materials under the catalysis of a potassium carbonate weak base catalyst, directly conducting filtering after the ester exchange is finished, directly applying the obtained weak base catalyst to the next batch of reaction, and directly rectifying and purifying the obtained filtrate to obtain the salicylate, thereby obtaining a finished homosalate product meeting requirements. After the process is used for improving an original process, the whole system does not generate waste water and waste residues any more, so corresponding cost for treating the waste water and thewaste residues is saved, raw material cost is correspondingly saved due to continuous application of the catalyst, the product has a cost advantage, and the current demand for a green and environment-friendly process is better met.

Owner:马鞍山科思化学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com