Method for preparing high-purity ammonium salts from high-impurity ammonium salt waste liquor

A technology of pure ammonium salt and ammonium salt, which is applied in the direction of ammonium salt preparation, chemical instruments and methods, metallurgical wastewater treatment, etc., can solve the problems of high cost and complicated treatment process, and achieve high recovery rate, low cost and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

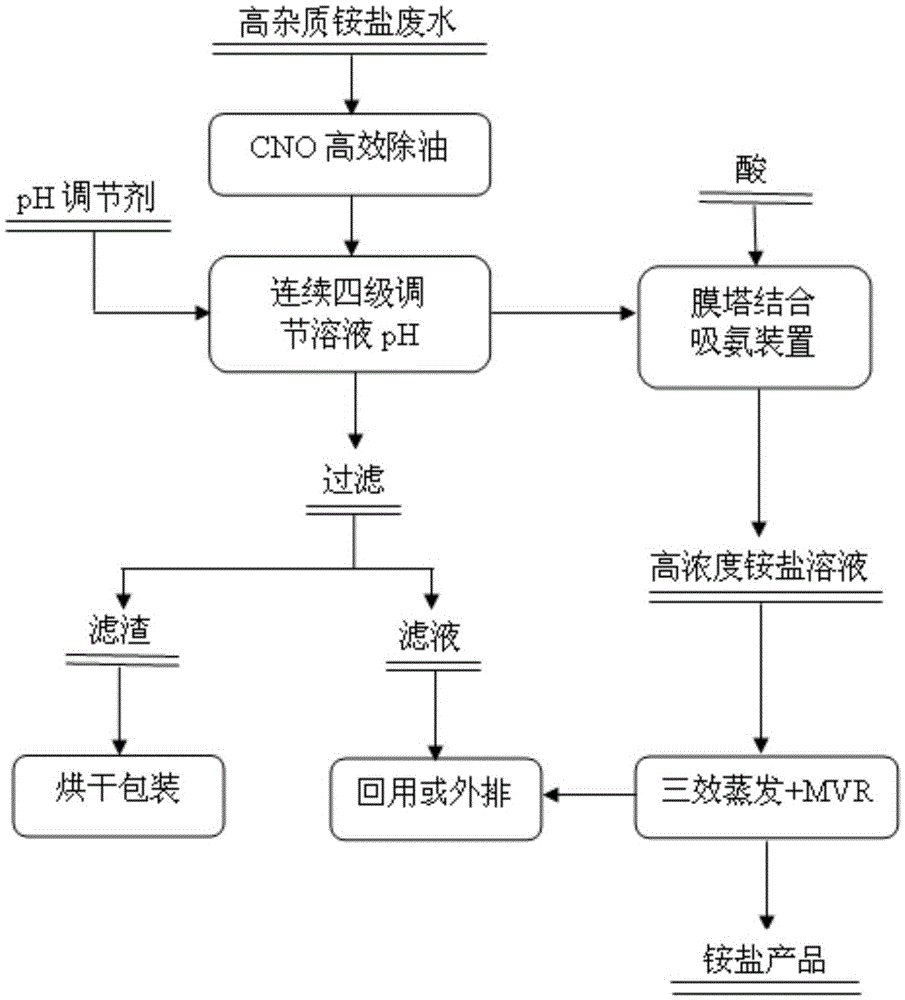

Method used

Image

Examples

Embodiment 1

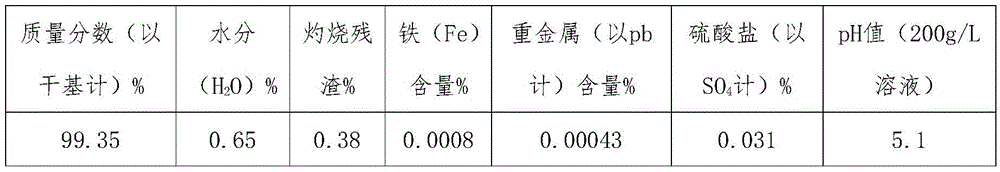

[0032] Contains NH 4 + The high-impurity ammonium chloride wastewater with a concentration of 8g / L is deoiled to less than 1ppm by a CNO high-efficiency degreaser. Quicklime, adjust the final pH of the solution to 11, and the overflow velocity is 20m 3 / h, starting from the second-stage reaction tank to start heating and ventilation in sequence, the wind speed is 200m 3 / h, the temperature is 85°C, and the ammonia nitrogen at the overflow of the fourth-stage reaction tank is less than 8mg / L, then filter it, and use the membrane method ammonia recovery technology to recover NH in the absorption tower 3 , using secondary countercurrent 5% dilute hydrochloric acid to spray to prepare a high-concentration ammonium chloride solution. Finally enter the three-effect evaporator for concentration and crystallization. The primary steam temperature is above 95°C. MVR is used to provide the secondary heat source for the three-effect booster. The secondary steam temperature is above 90°...

Embodiment 2

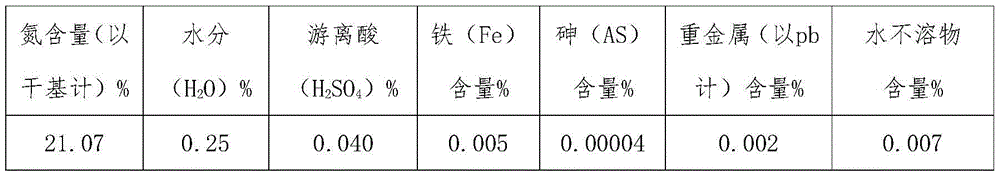

[0036] Contains NH 4 + The high-impurity ammonium sulfate wastewater with a concentration of 24g / L is deoiled by a CNO high-efficiency degreaser to below 1ppm. After degreasing, the liquid enters a continuous four-stage pH adjustment reaction tank, and slaked lime is added to the first-stage reaction tank under stirring conditions. , adjust the final pH of the solution to 12, and the overflow velocity to 25m 3 / h, starting from the second-stage reaction tank to start heating and ventilation in sequence, the wind speed is 250m 3 / h, the temperature is 85°C, and the ammonia nitrogen at the overflow of the fourth-stage reaction tank is less than 8mg / L, then filter it, and use the membrane method ammonia recovery technology to recover NH in the absorption tower 3 , using secondary countercurrent 8% dilute sulfuric acid to spray to prepare a high-concentration ammonium sulfate solution. Finally, enter the three-effect evaporator for concentration and crystallization. The tempera...

Embodiment 3

[0040] Contains NH 4 + The high-impurity ammonium nitrate wastewater with a concentration of 25g / L is deoiled to below 1ppm by a CNO high-efficiency degreaser. After degreasing, the liquid enters a continuous four-stage pH adjustment reaction tank, and quicklime is added to the first-stage reaction tank under stirring conditions. , adjust the final pH of the solution to 12, and the overflow velocity to 35m 3 / h, starting from the second-stage reaction tank to start heating and ventilation in sequence, the wind speed is 400m 3 / h, the temperature is 85°C, and the ammonia nitrogen at the overflow of the fourth-stage reaction tank is less than 8mg / L, then filter it, and use the membrane method ammonia recovery technology to recover NH in the absorption tower 3 , using secondary countercurrent 8% dilute nitric acid spraying to prepare a high-concentration ammonium nitrate solution. Finally enter the three-effect evaporator for concentration and crystallization. The temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com