Patents

Literature

493 results about "Triple effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

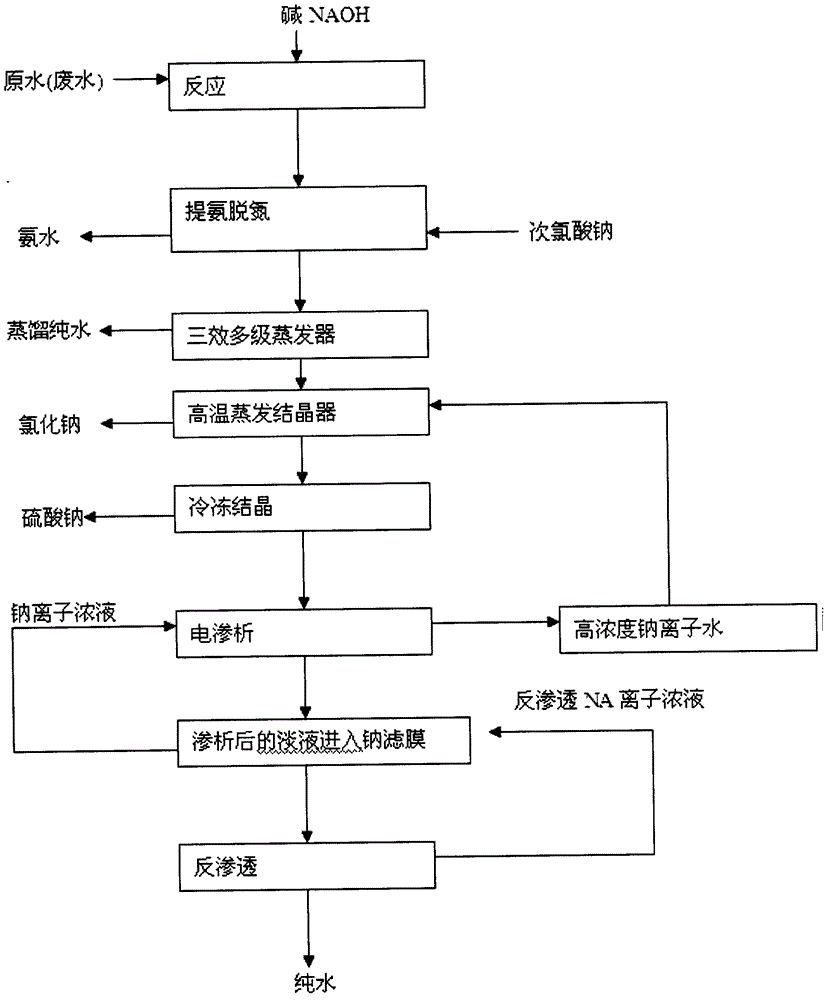

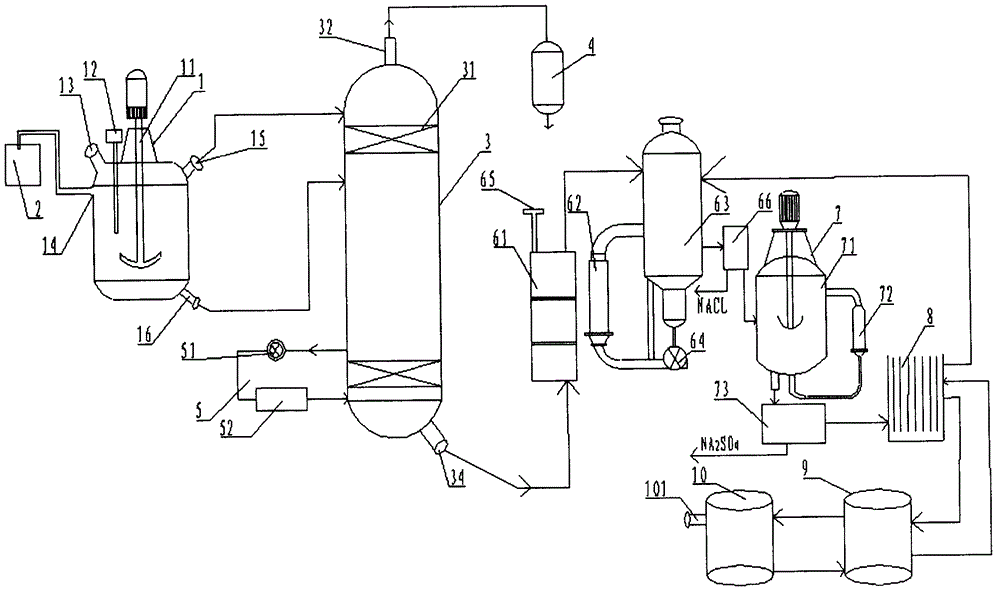

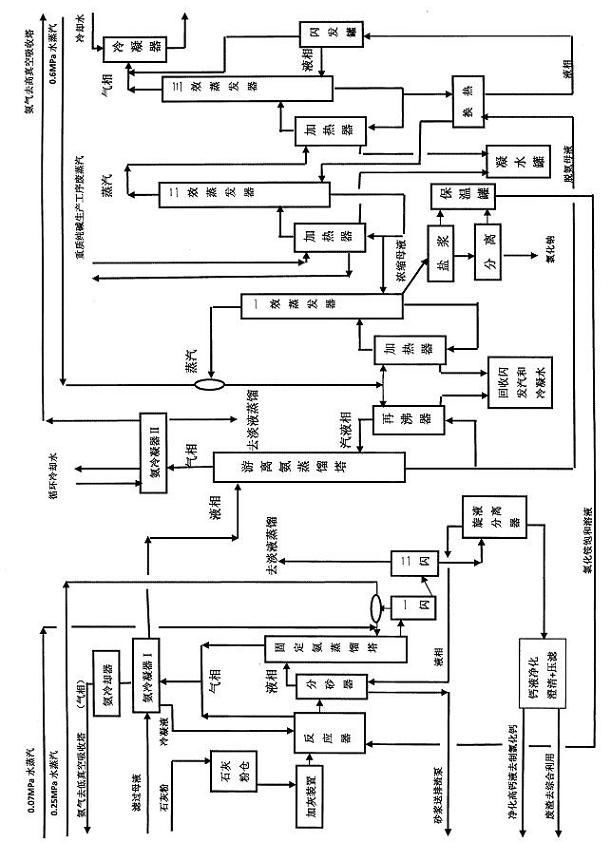

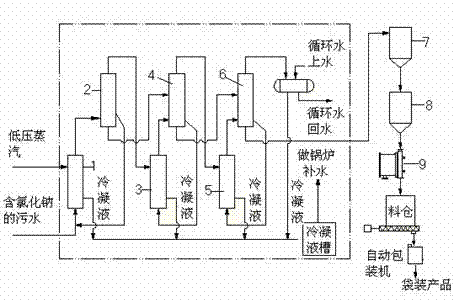

Method and device for utilizing sewage containing ammonia and sodium

ActiveCN104609633AReduce energy consumptionSave energyWater contaminantsMultistage water/sewage treatmentResource utilizationReverse osmosis

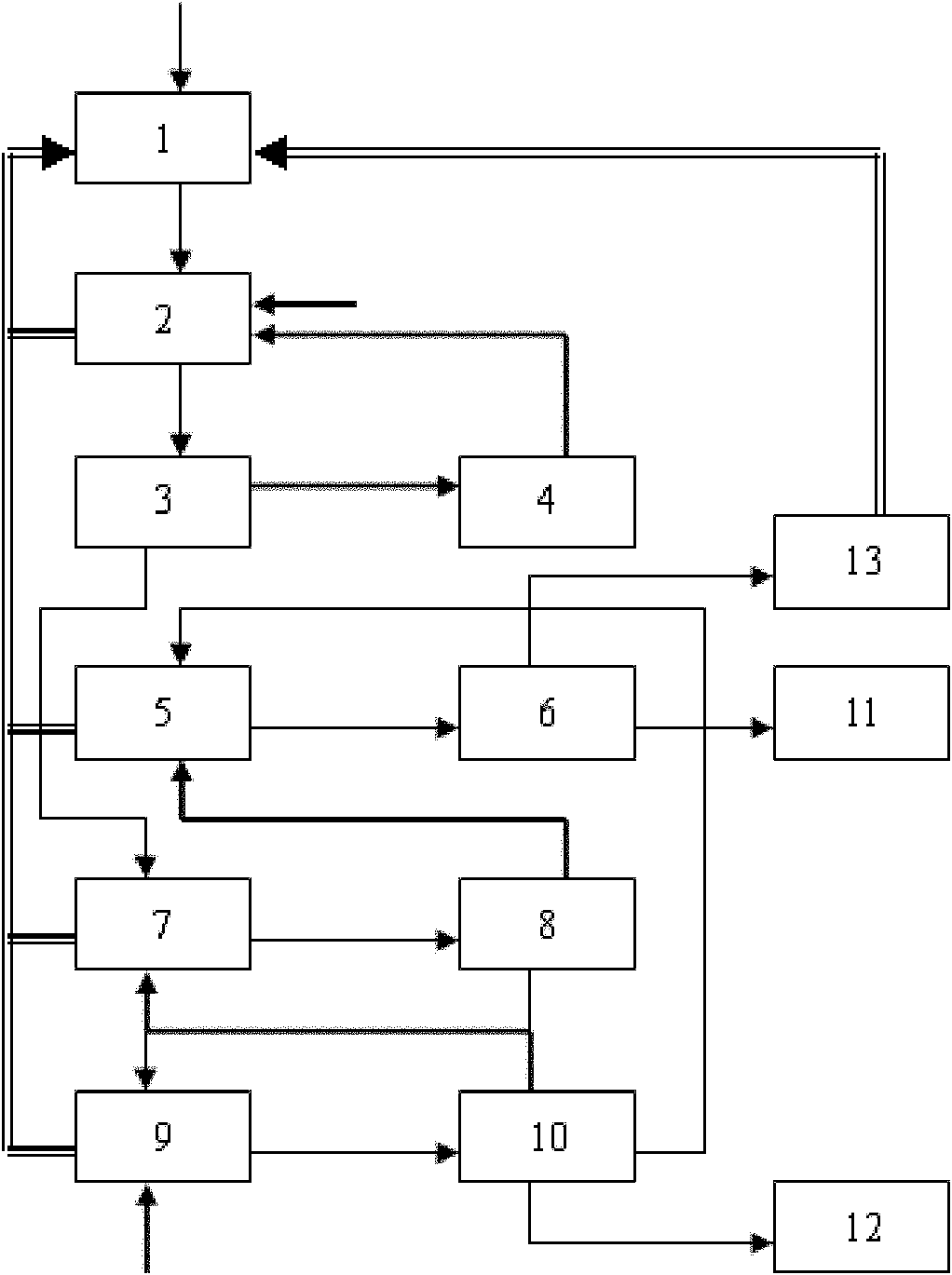

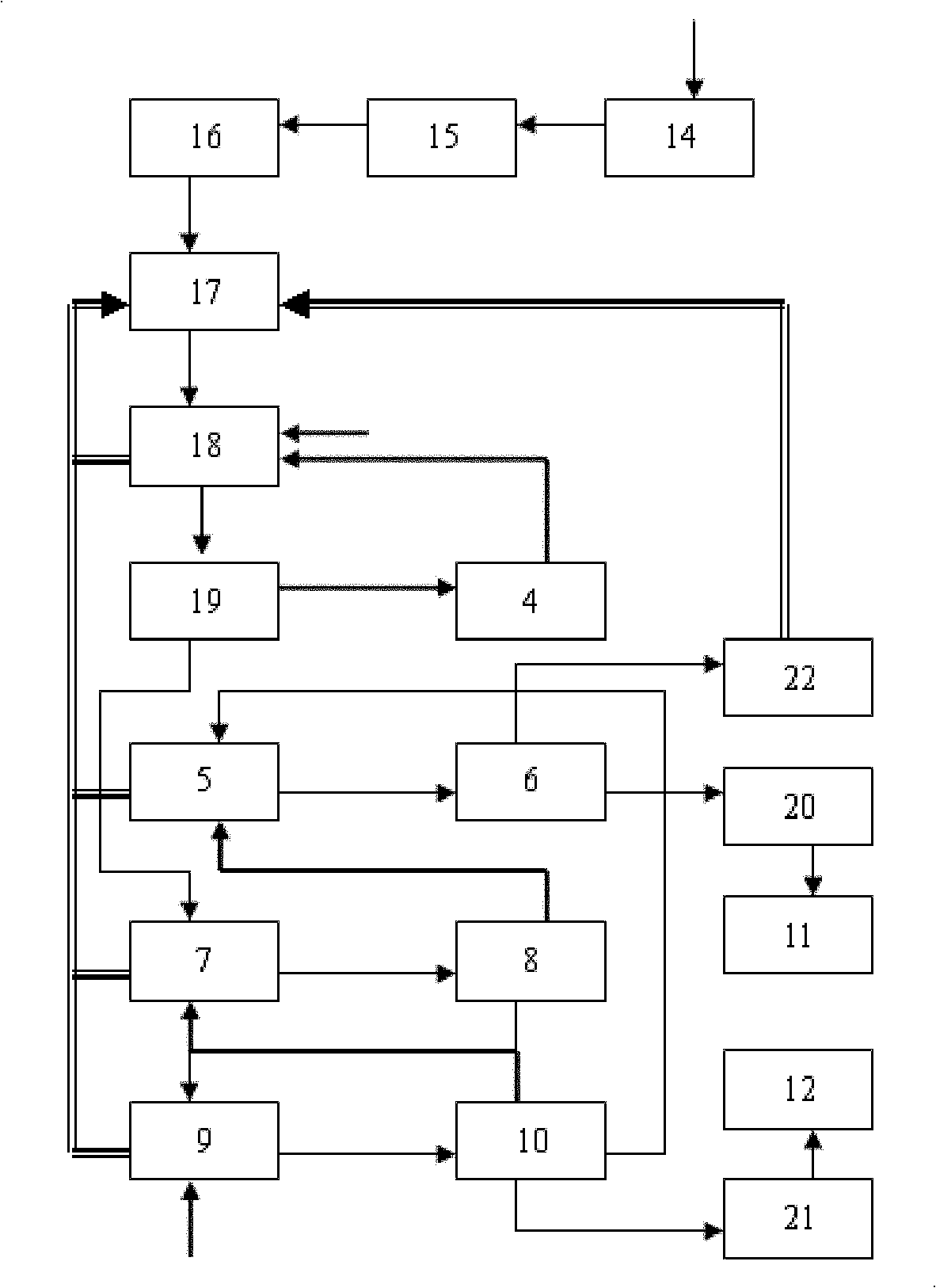

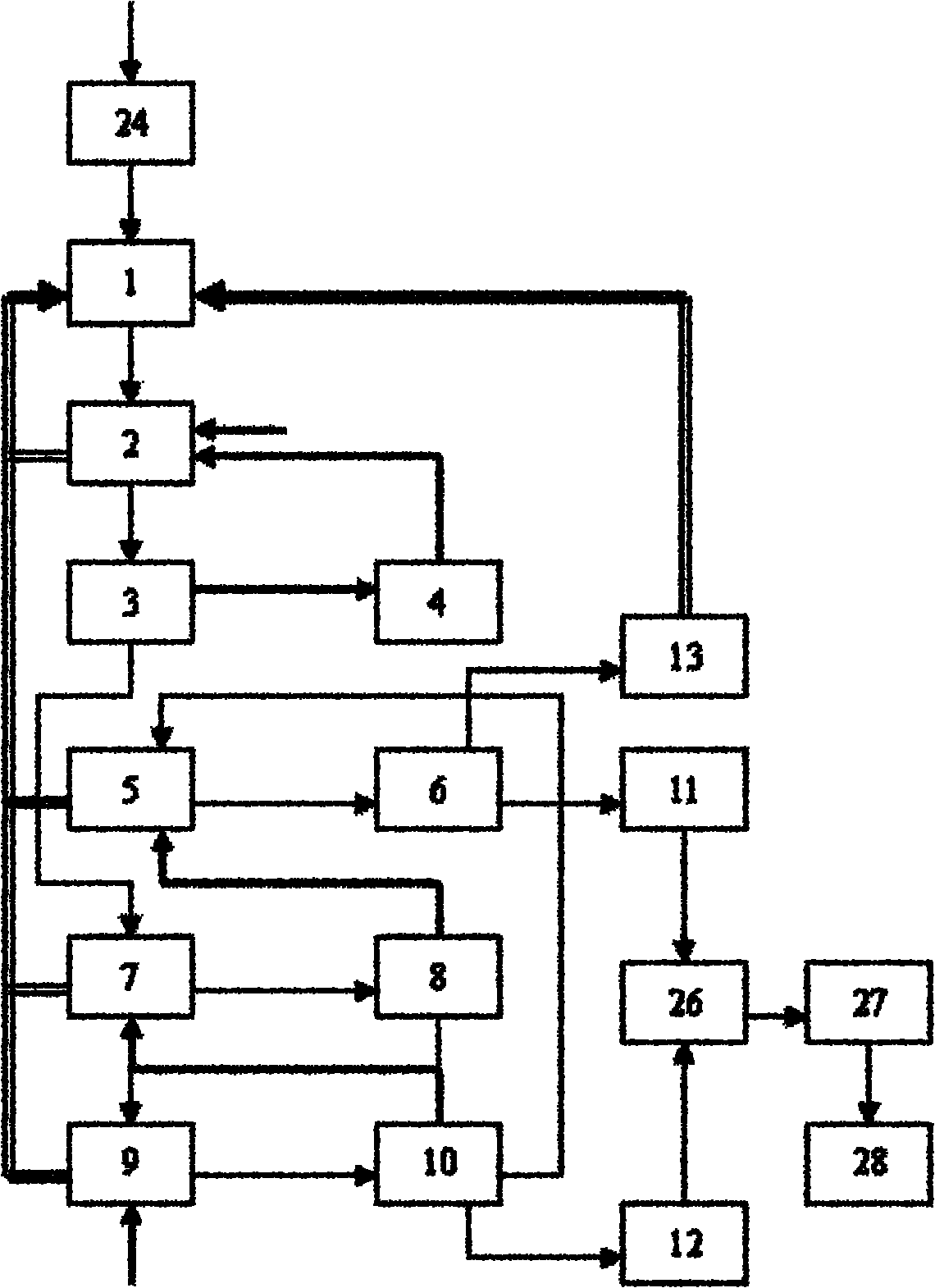

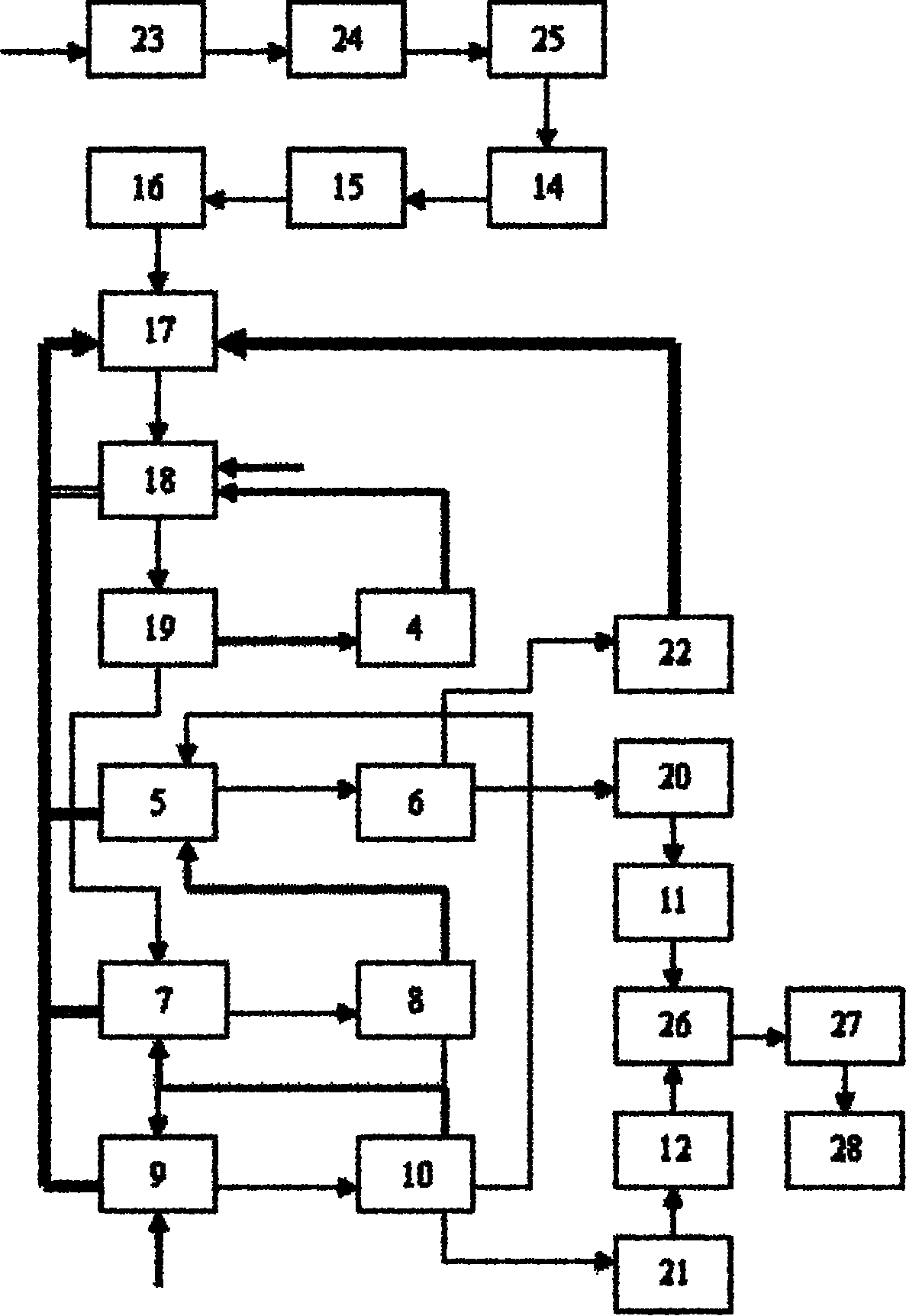

The invention discloses a method and device for utilizing sewage containing ammonia and sodium. The method comprises the steps of deamination reaction, denitrification reaction, gas-liquid separation, triple-effect multistage evaporation, evaprative crystallization and freezing crystallization, electrodialysis and sodium filteration membrane, and concentration of reverse osmosis membrane, so that distilled water and membrane deion pure water are recovered, and the resource utilization of sole sodium chloride and sodium sulfate is realized.

Owner:RUANSHI CHEM CHANGSHU

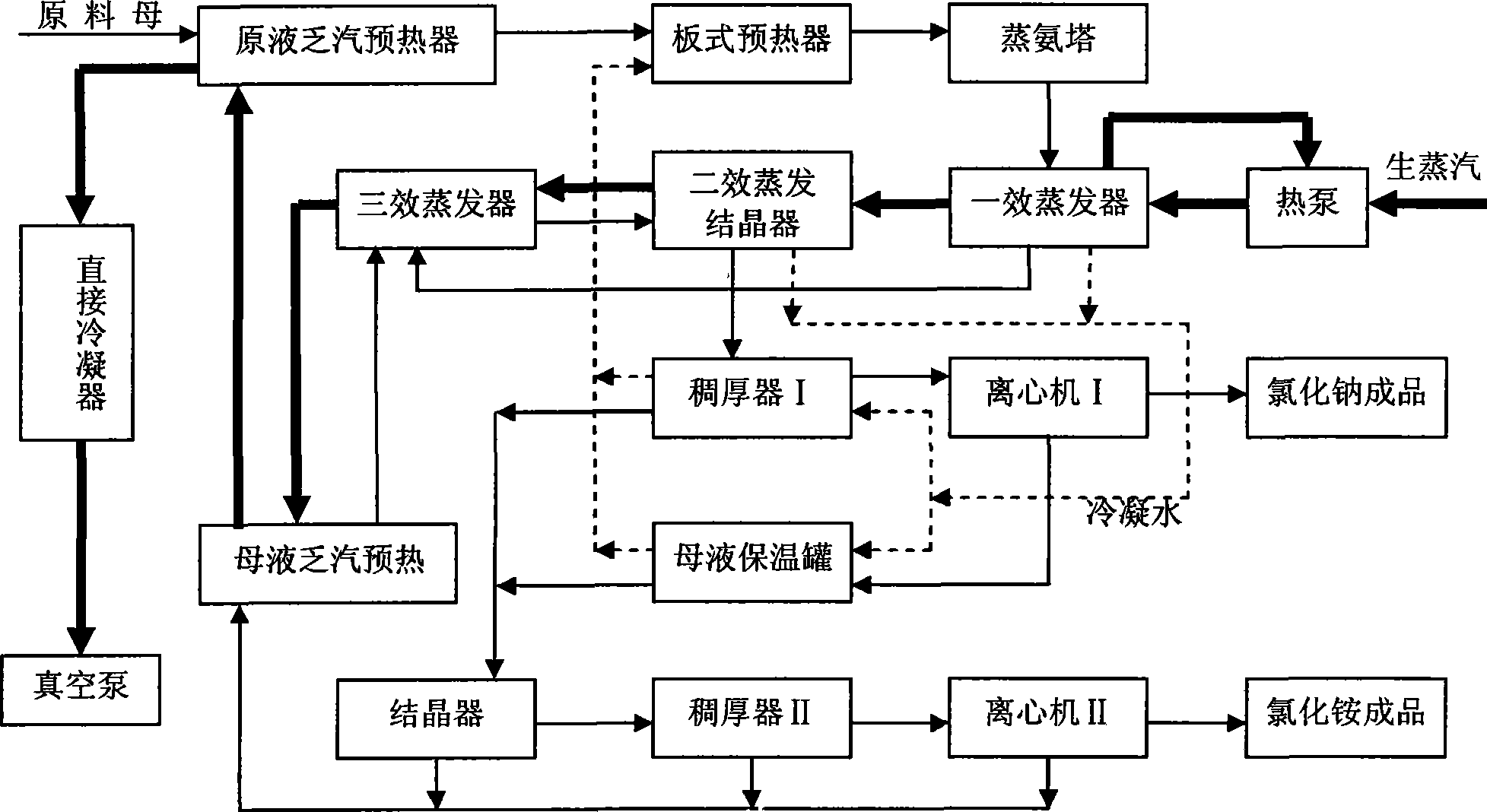

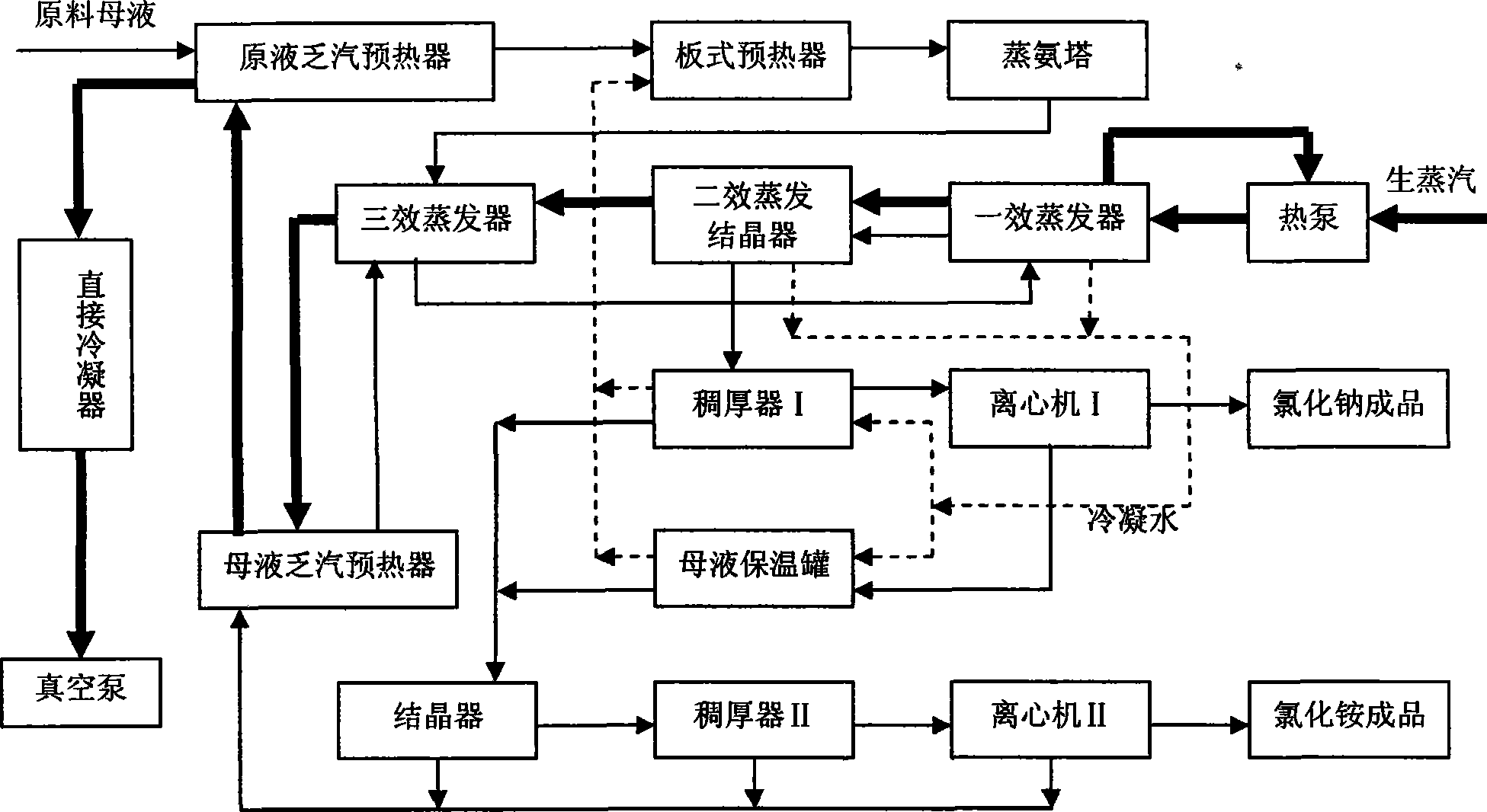

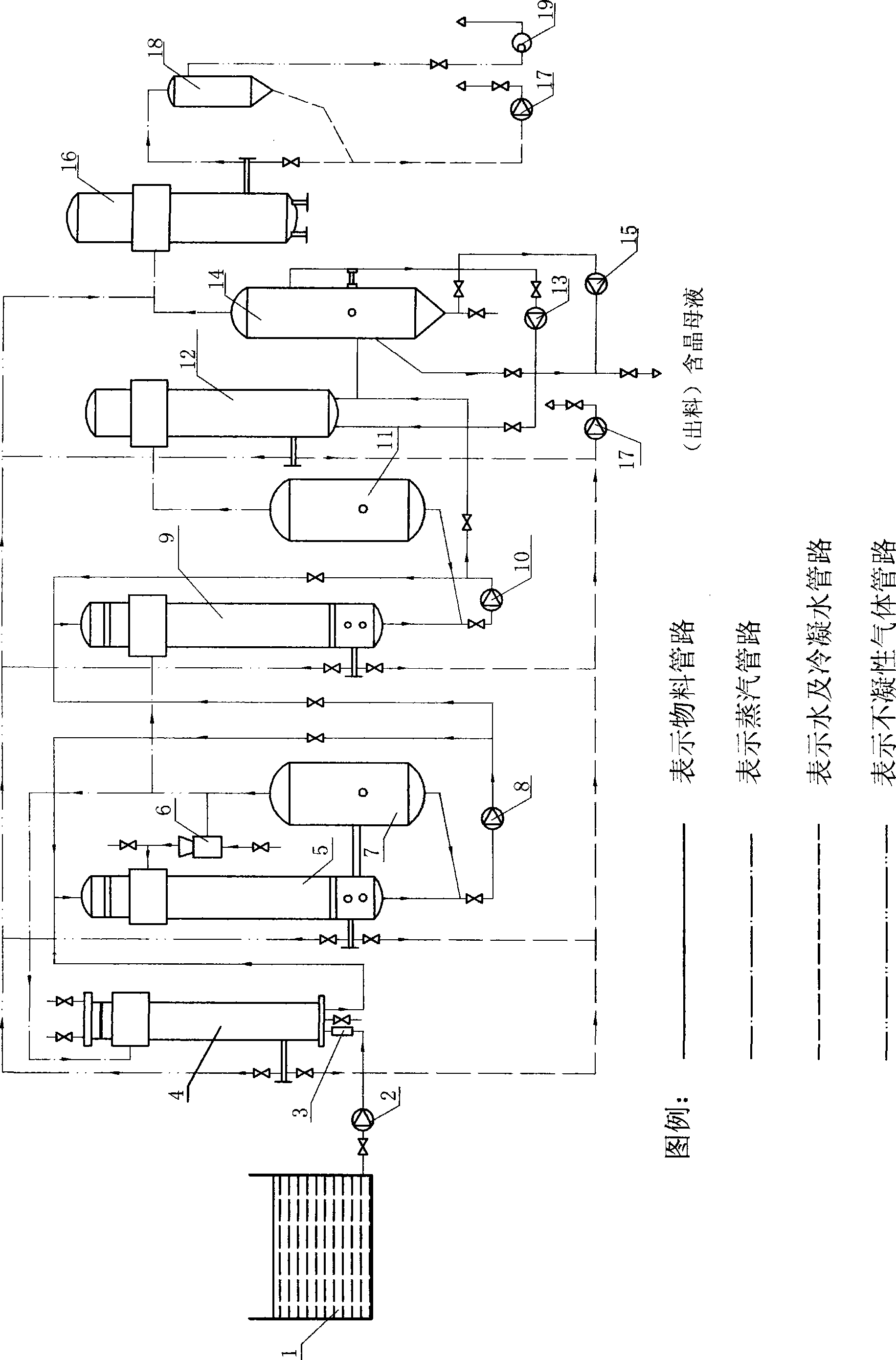

Process method for recovering ammonium chloride and sodium chloride from waste water containing ammonium chloride and sodium chloride

InactiveCN101544437AFully recycleReduce energy consumptionEnergy inputSolution crystallizationSodium bicarbonateDecomposition

The invention relates to a process method for recovering ammonium chloride and sodium chloride from waste water containing the ammonium chloride and the sodium chloride, which produces the ammonium chloride and the sodium chloride by using mother solution which is generated in a process for producing sodium bicarbonate by natural bittern double decomposition reaction and contains the ammonium chloride and the sodium chloride as raw materials. The method adopts ammonium still, evaporation, crystallization and separation process to treat, wherein the evaporation adopts multiple-effect, a heat pump and a vacuum evaporation process, and selects a falling film evaporator and a forced circulation type evaporator to perform triple-effect mixed-flow procedure, so that sodium chloride is crystallized and separated in the evaporation; and the ammonium chloride is crystallized and separated by cooling after the evaporation. The method effectively reduces the operation temperature of the equipment, can repeatedly use secondary steam and condensed water, reduces erosion of the ammonium chloride solution to the equipment, saves the energy, reduces the cost, improves the production efficiency, and reduces environmental pollution.

Owner:HEBEI UNIV OF TECH +1

Method for comprehensively treating high salt content organic industrial wastewater

ActiveCN101585620AUnique methodSimple processMultistage water/sewage treatmentWater/sewage treatment by neutralisationSocial benefitsIndustrial effluent

The present invention provides a method for comprehensively treating high salt content organic industrial wastewater, and relates to the field of the organic material preparing technique. The method of the invention mainly comprises the following steps: executing acid-alkali adjustment to the organic wastewater until pH=7-9, preheating to 30-60 DEG C; introducing the wastewater into a triple effect evaporator for executing triple effect evaporation, executing salting out to the evaporated wastewater which is condensed to a certain degree so that the solid and liquid are separated; separating the concentrated liquid for continuing the condensation; when the separated liquid satisfies a certain requirement, atomizing into an incinerator for incinerating and discharging according to the standard, and introducing the triple effect evaporation condensation water into a biochemical treating system. The method of the invention can totally dispose and remove the organic matter in the high salt content organic industrial wastewater so that the high salt content organic industrial wastewater can be charged according to the standard. The method of the invention has the advantages of unique method, simple technical process, easy operation, low operation cost, large treating capacity, low regeneration energy consumption, no easy forming of secondary pollution after abandon, better economic and social benefit, and wide application range. The method of the invention can be widely applied for the treating of the high salt content organic wastewaters of garbage penetrating fluid, dye intermediate wastewater, etc.

Owner:HEBEI JIANXIN CHEM IND CO LTD

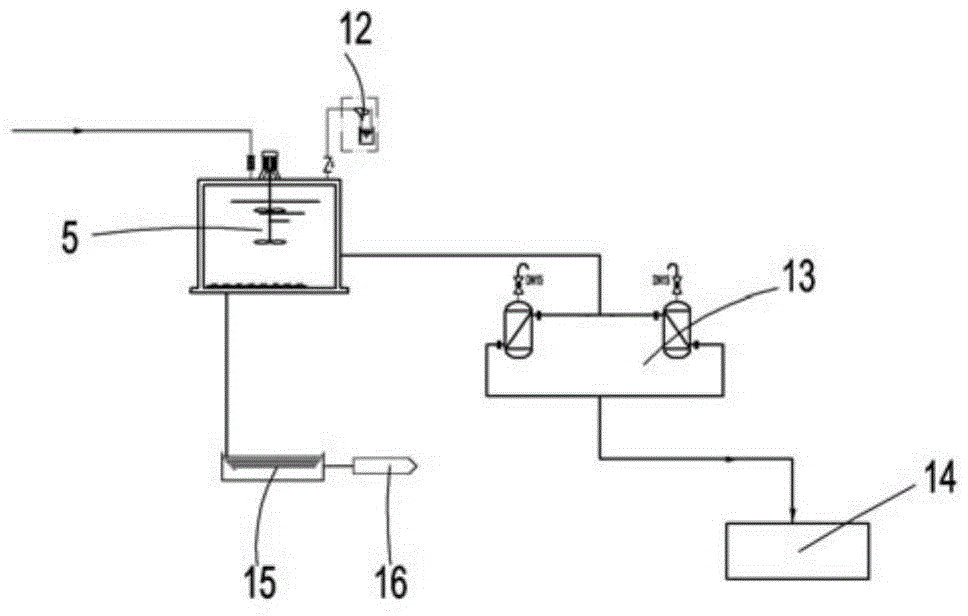

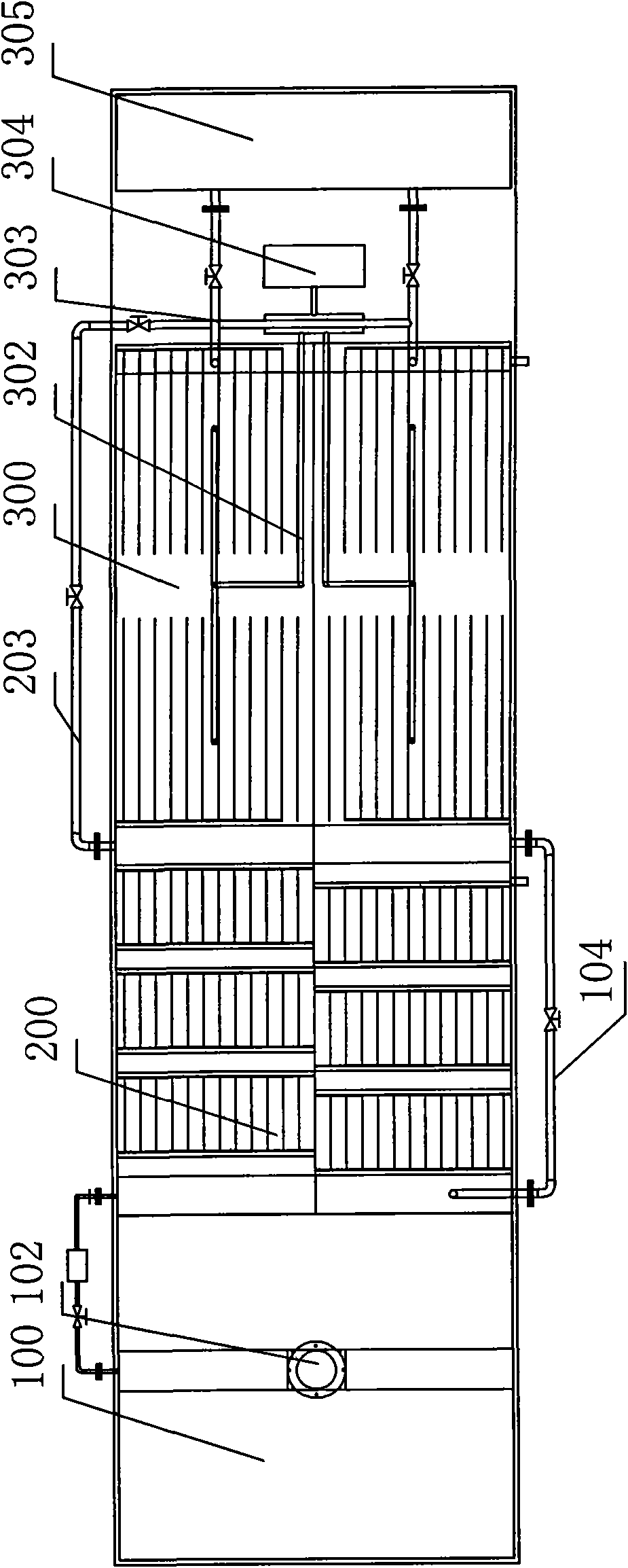

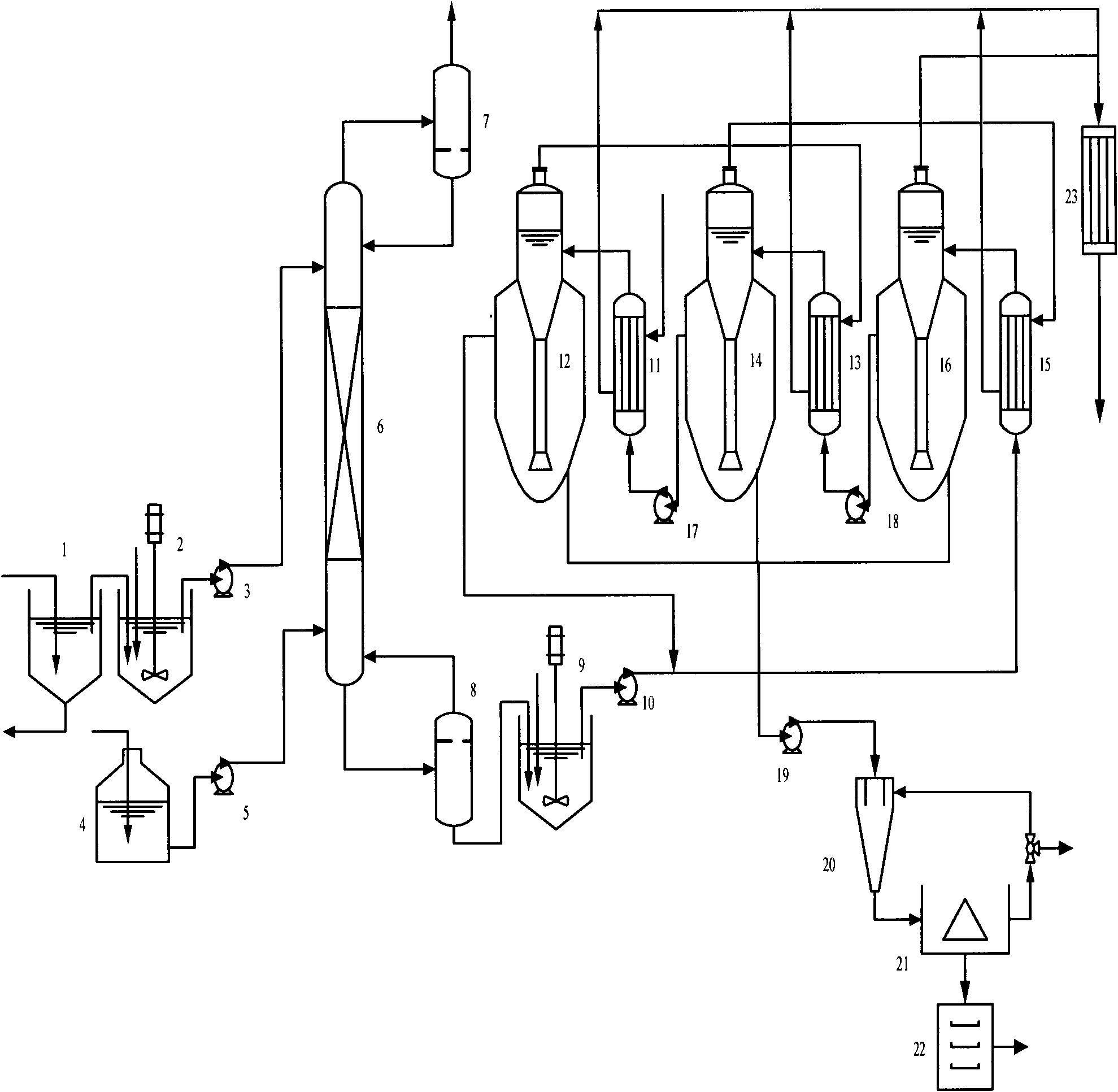

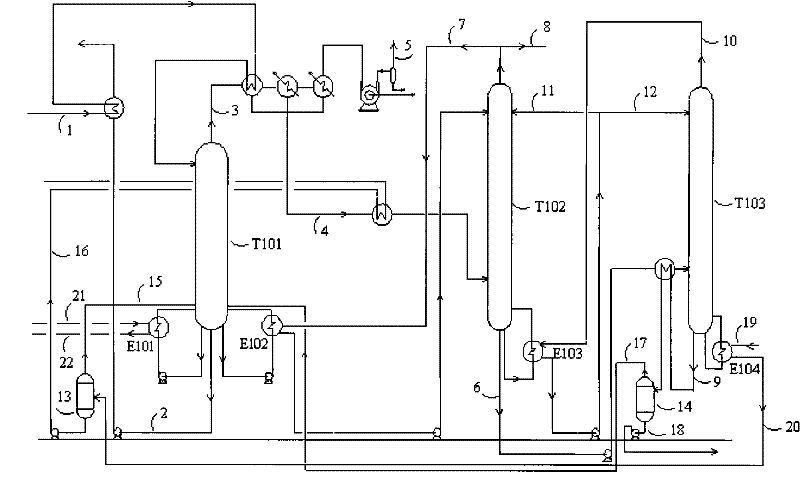

Wastewater evaporation concentration process and device system

InactiveCN102070272AAvoid easy cloggingGuaranteed uptimeMultistage water/sewage treatmentAlkali metal chloridesProcess systemsSludge

The invention discloses a wastewater evaporation concentration process and a wastewater evaporation concentration device system. The process comprises the following steps of: delivering softened wastewater to be treated to a mechanical vapor recompression (MVR) system to perform evaporation and concentration, compressing the generated secondary steam and then delivering the compressed steam to an evaporator to recycle, delivering the concentrate to a triple-effect mixed flow forced circulating evaporation crystallization system to perform evaporation and crystallization, performing solid-liquid centrifugal separation on the crystallized concentrate and crystal grains, returning the separated mother solution to a stock solution tank or continuously performing evaporation and crystallization, and reclaiming the separated crystal, wherein the secondary steam generated by evaporation and crystallization is recycled for the evaporation crystallization system. After the wastewater is evaporated and concentrated by adopting the process of mechanical vapor recompression circulating evaporation and triple-effect mixed flow forced circulating evaporation crystallization, the wastewater does not need to be discharged to the ground water area, and the wastewater is discharged in a form of steam or closed and embedded in a form of sludge or the like, so the purpose of zero discharge of the wastewater can be fulfilled; and the process system has high heat efficiency, low energy consumption, energy conservation, great reduction in running cost, low temperature difference, low corrosion, difficult scale formation and long equipment service life.

Owner:华电水务工程有限公司 +1

Wastewater evaporating process and device system

ActiveCN102060408AAvoid shockAvoid easy cloggingMultistage water/sewage treatmentProcess systemsTriple effect

The invention discloses a wastewater evaporating process and device system. The wastewater evaporating process comprises the following steps: the wastewater to be treated firstly enters a pretreatment softening system for softening treatment and secondly enters a mechanical vapor recompression (MVR) system for evaporation concentration; the generated secondary steam is compressed and enters an evaporator for recycling; the concentrated solution enters a triple effect flow-mixing forced circulation evaporation and crystallization system for evaporation and crystallization; the generated secondary steam is reused by the evaporation and crystallization system; the concentrated solution and crystalline grains obtained through crystallization are subject to solid-liquid centrifugal separation; the separated mother solution is sent back to a raw liquor tank or evaporated continuously for crystallization; and the separated crystals enter a centrifugal drying and packaging system for weighting and packaging. After the process disclosed by the invention is adopted to soften, evaporate and crystallize wastewater and dry and package the obtained crystals, wastewater is not discharged to the water bodies of the surface of earth and the aim of zero wastewater discharge can be realized; the process system is low-carbon and environmentally friendly; the material can be recycled, the thermal efficiency is high, the energy consumption is low, the energy can be saved, the operating cost can be greatly reduced, the range of temperature is small, the corrosion is low and the service life of the equipment is long, and the scaling has small possibility of occurrence.

Owner:华电水务工程有限公司 +1

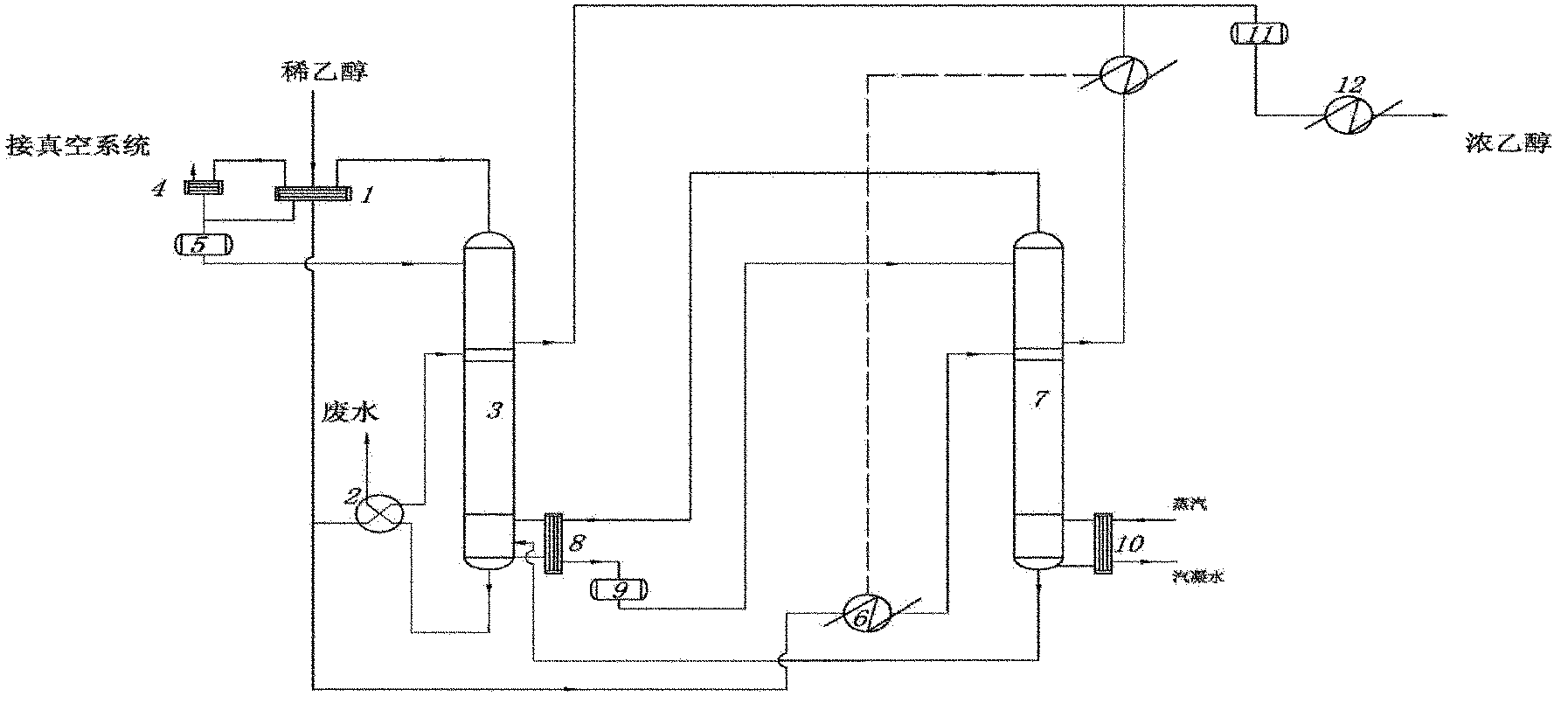

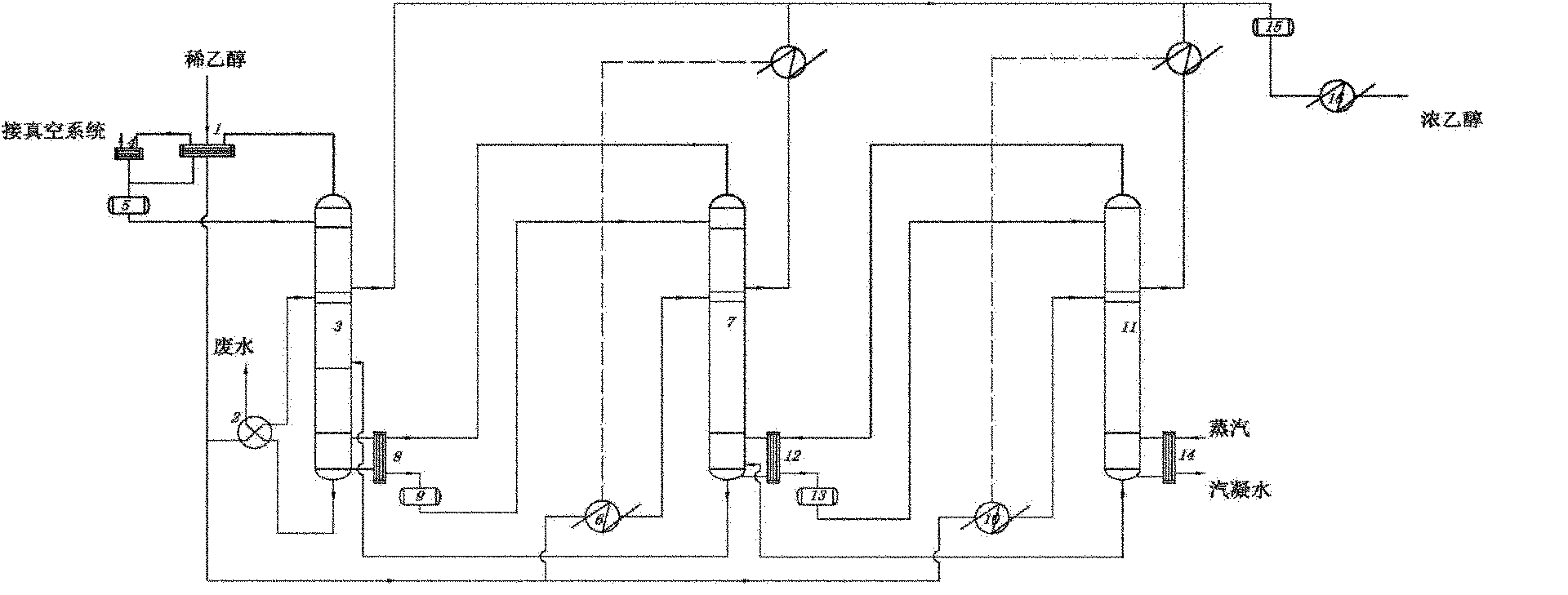

Low-pressure ethanol recovery device and method with triple effect rectification

ActiveCN102091429AReduce energy consumptionReduce lossesOrganic compound preparationHydroxy compound preparationRecovery methodReboiler

The invention discloses a low-pressure ethanol recovery device and method with triple effect rectification. The low-pressure ethanol recovery device with triple effect rectification comprises a first rectifying tower, a second rectifying tower, a third rectifying tower, a rectifying tower reboiler, a rectifying tower feed preheater, a condenser, a return tank, a dilute ethanol feed preheater, a temporary finished product storage tank and a finished product cooler. In the ethanol recovery method with triple effect rectification, by controlling the recovery of the finished ethanol in the second rectifying tower, the content of ethanol in tower bottom wastewater of the second rectifying tower is 5wt%-30wt%, the temperature of the tower bottom wastewater is 100-120 DEG C, and the working pressure of the third rectifying tower is 250-400kPa. The invention adopts the low-pressure triple effect rectification technique and reduces energy loss in the technical process, thus greatly reducing the energy consumption; and the operating pressure and temperature of the third rectifying tower are greatly reduced, and the requirements on the high temperature resistant and corrosion resistant properties of equipment are reduced, thereby reducing the equipment investment and the maintenance cost.

Owner:GUANGDONG ZHONGKE TIANYUAN NEW ENERGY SCI & TECH

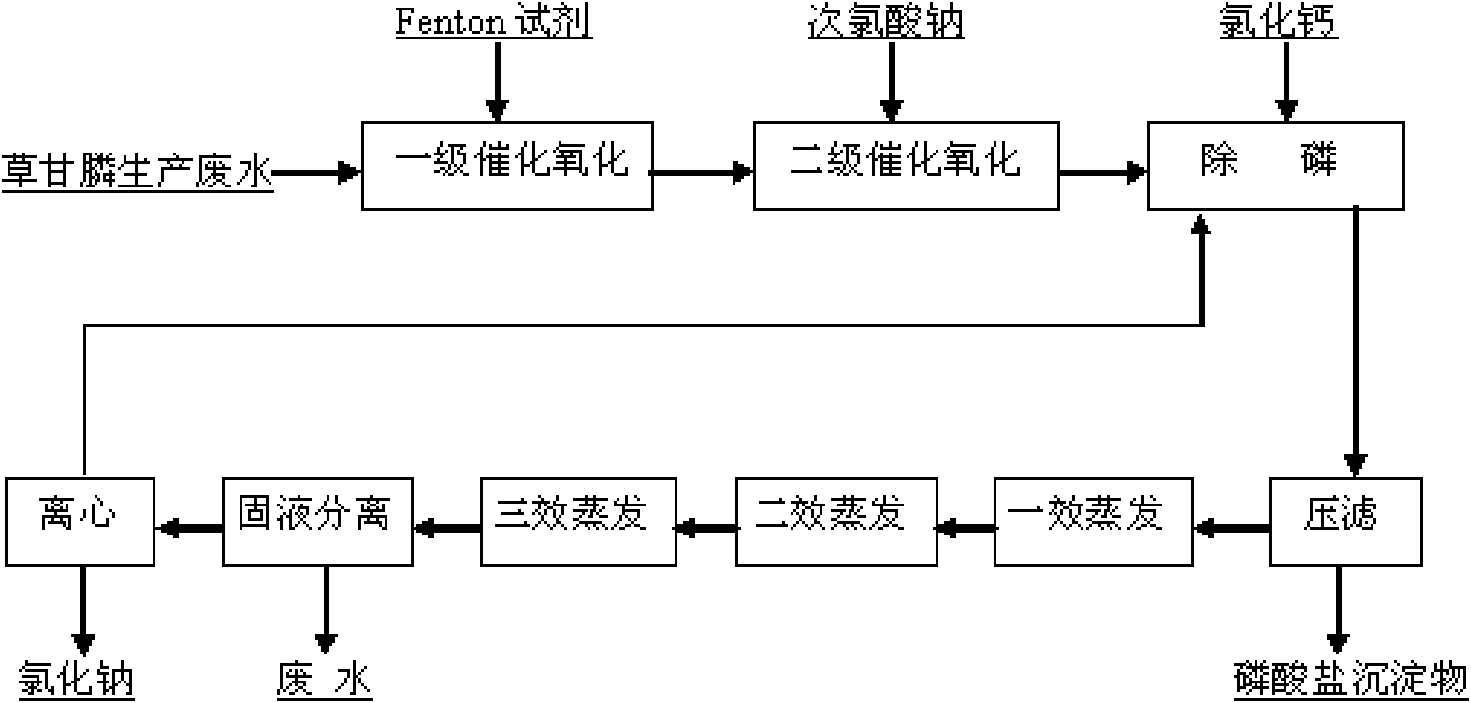

Pretreatment method for glyphosate industrial waste water

InactiveCN101671089AReduce potential threatsQuality improvementMultistage water/sewage treatmentNature of treatment waterSocial benefitsPretreatment method

A pretreatment method for glyphosate industrial waste water relates to the technical field of the treatment method for the industrial waste water from pesticides. The invention provides the pretreatment method for the glyphosate industrial waste water, which can remove glyphosate, sodium chloride and reduce COD cr value. The pretreatment method can effectively remove the vast majority of sodium chloride and glyphosate in the glyphosate industrial waste water by adopting steps such as adjusting Ph value, catalytic oxidation, calcification phosphorus removal, triple effect evaporation crystallized sodium chloride removal and the like, and greatly reduces COD cr value; the pretreated waste water can be discharged into a follow-up biochemical treatment system for biochemical treatment, thus causing waste water to be discharged after reaching standards, being beneficial to the protection of the environment and having good social benefits.

Owner:FUJIAN SANNONG GROUP

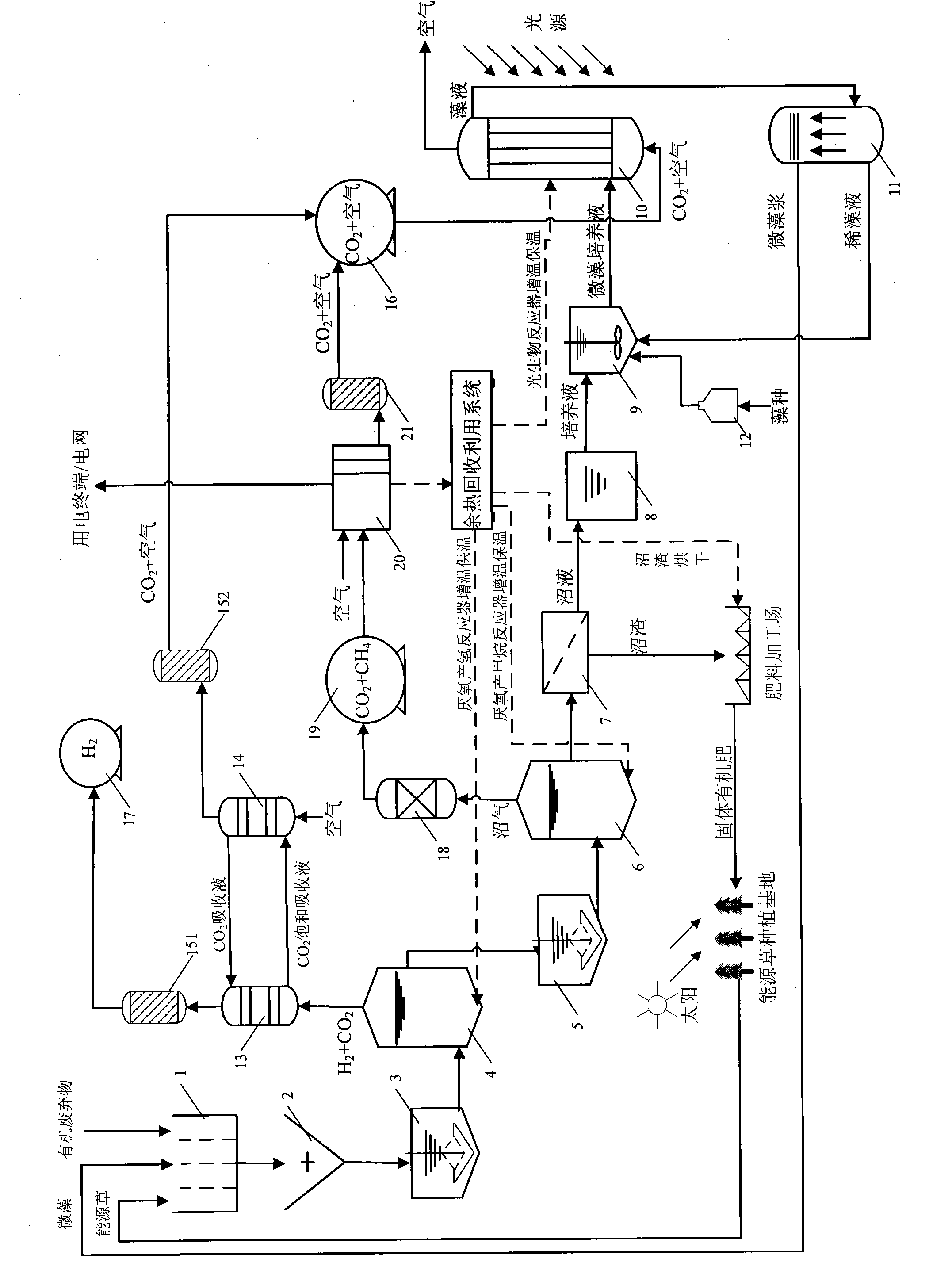

Energy utilization system of organic wastes with zero emission of carbon dioxide

ActiveCN101920258ARealize processingEliminate pollutionWaste processingSolid waste disposalSludgeCo2 absorption

The invention provides an energy utilization system of organic wastes with zero emission of carbon dioxide, which organically combines anaerobic fermentation hydrogen production, methane fermentation, CO2 absorption, microalgae fixation CO2, biogas liquid treatment and energy grass planting. The system is suitable for treating various types of organic wastes, can be applied to the treatment of agricultural organic wastes, industrial organic wastes, domestic organic wastes, slurry and the like, and the industries, such as new energy development. Through the application of the invention, the specific application demonstration of recycling economy can be carried out, clean energy is obtained while eliminating environmental pollution, no greenhouse gas emits in the process, and the triple effects of wastes treatment, production of clean and renewable energy sources and reduction of carbon dioxide emission can be realized.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

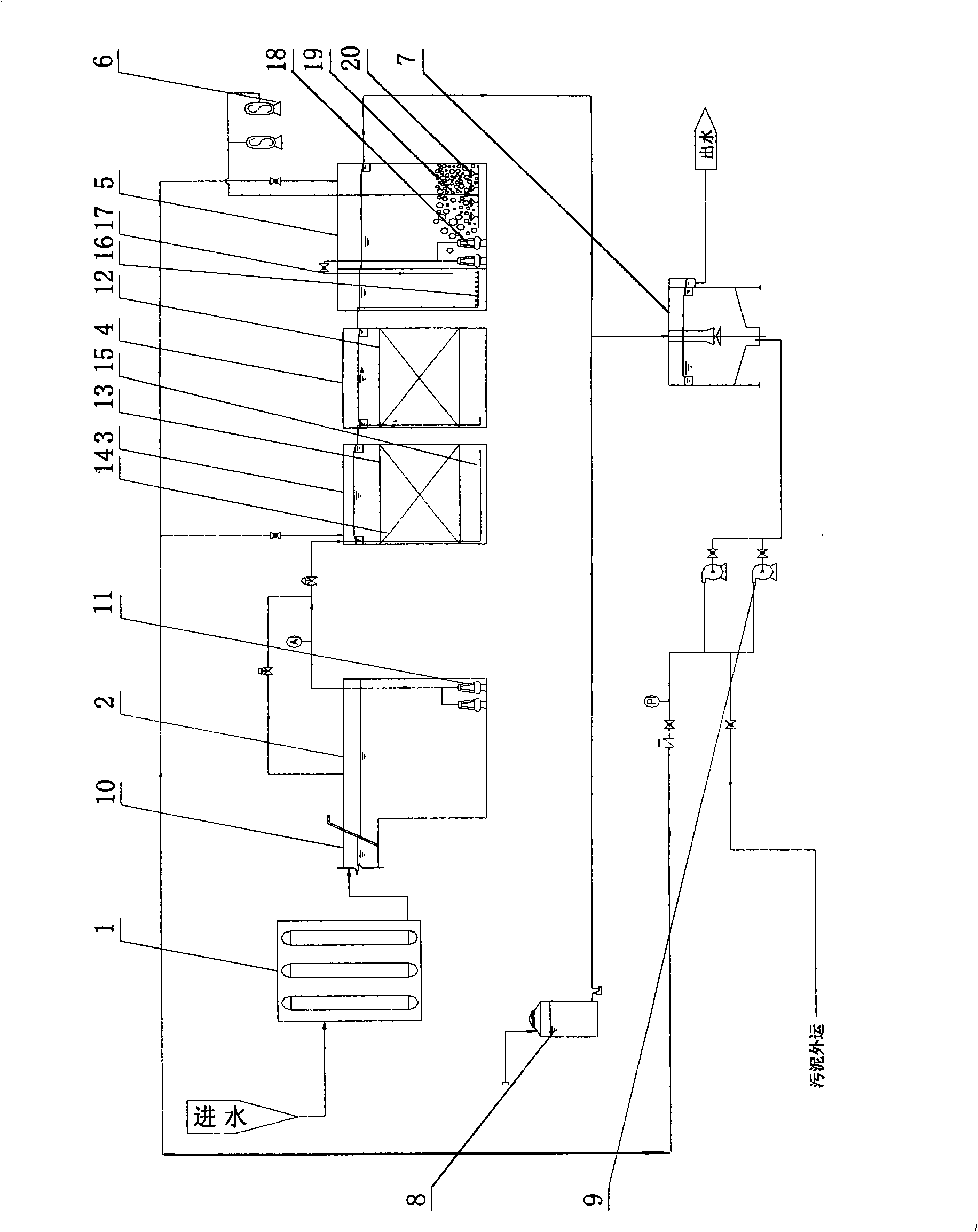

Method for processing high-toxicity high-concentration highly salt-containing organic waste water with biochemistry combination process of catalytic oxidation

InactiveCN101314510AGood effectIn line with environmental protection development ideasWater contaminantsWater/sewage treatment by electrochemical methodsComing outHigh concentration

The invention belongs to the water treatment technical field, in particular to a method for treating high-toxicity high-concentration high-salinity organic wastewater by a process of combining catalysis, oxidation and biochemistry. The method comprises the following specific steps that: wastewater enters a triple-effect distillation desalter; a pressure of the distillation desalter is controlled between 9 and 11 KG; a temperature of the distillation desalter is controlled between 85 and 95 DEG C; a water body is pretreated by a grating well and an adjusting tank and enters a micro electrolytic oxidation and oxidation tank by a lifting pump; the treated water automatically flows into a hydrolysis acidification tank, and the dwell time of water power is between 12 and 15 hours; the addition amount of combined type fillers is 50 to 70 percent of a usable capacity of the hydrolysis acidification tank; the treated water coming out from the hydrolysis acidification tank enters an oxygen compatible tank of an A / O tank; simultaneously, activated sludge is pumped into the oxygen compatible tank, and the dwell time of water power is between 5 and 8 hours; effluent water enters an aerobic tank by a circulating pipeline; the dwell time of water power in the aerobic tank is between 10 and 15 hours; the addition amount of suspended fillers is 30 to 40 percent of a volume of the aerobic tank; water treated by the A / O tank flows into a secondary sedimentation tank; the effluent water is discharged; and the residual sludge is discharged. The method applies the triple-effect distillation technology to the wastewater treatment technology and is organically combined with the subsequent catalysis oxidation technology and the biotreatment technology, thereby providing a brand-new development idea for the wastewater treatment of the type.

Owner:SHANGHAI CHEMAREA WATER TECH

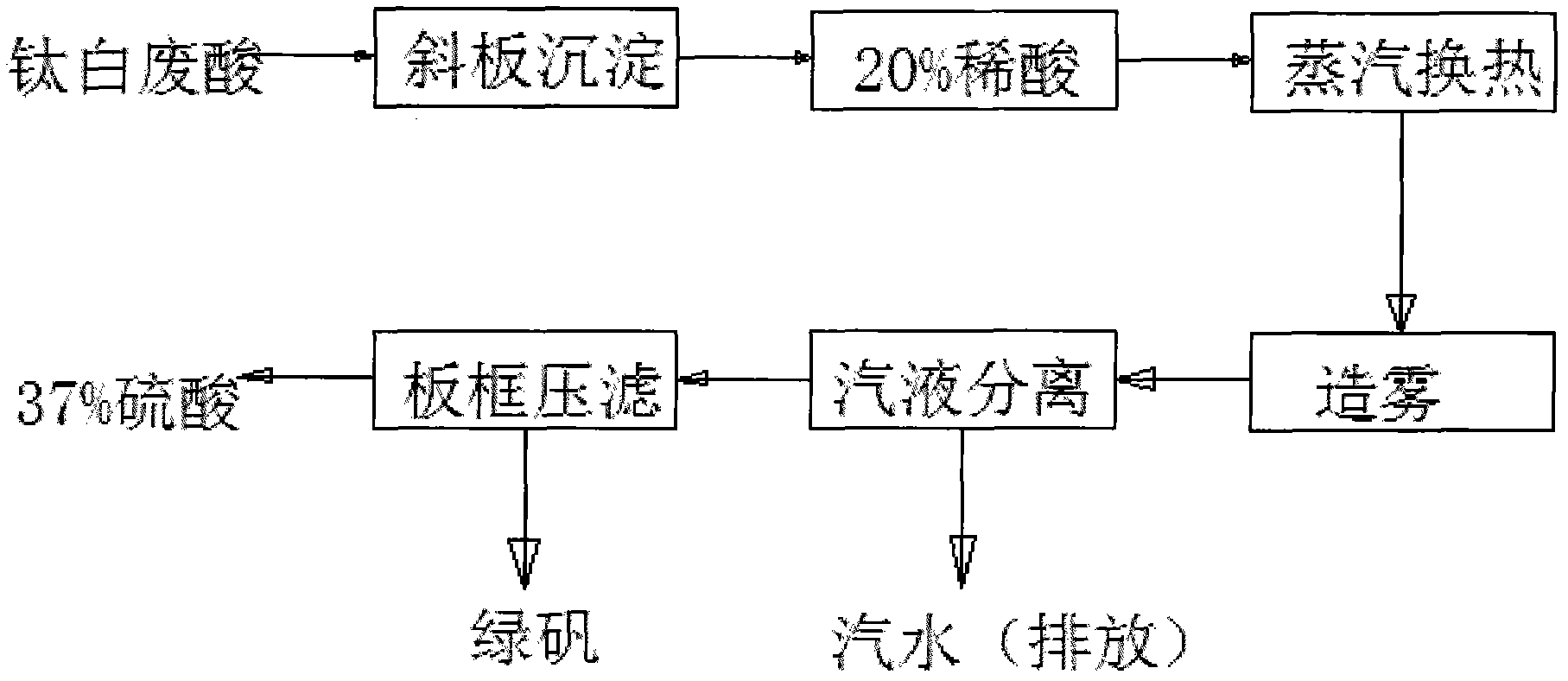

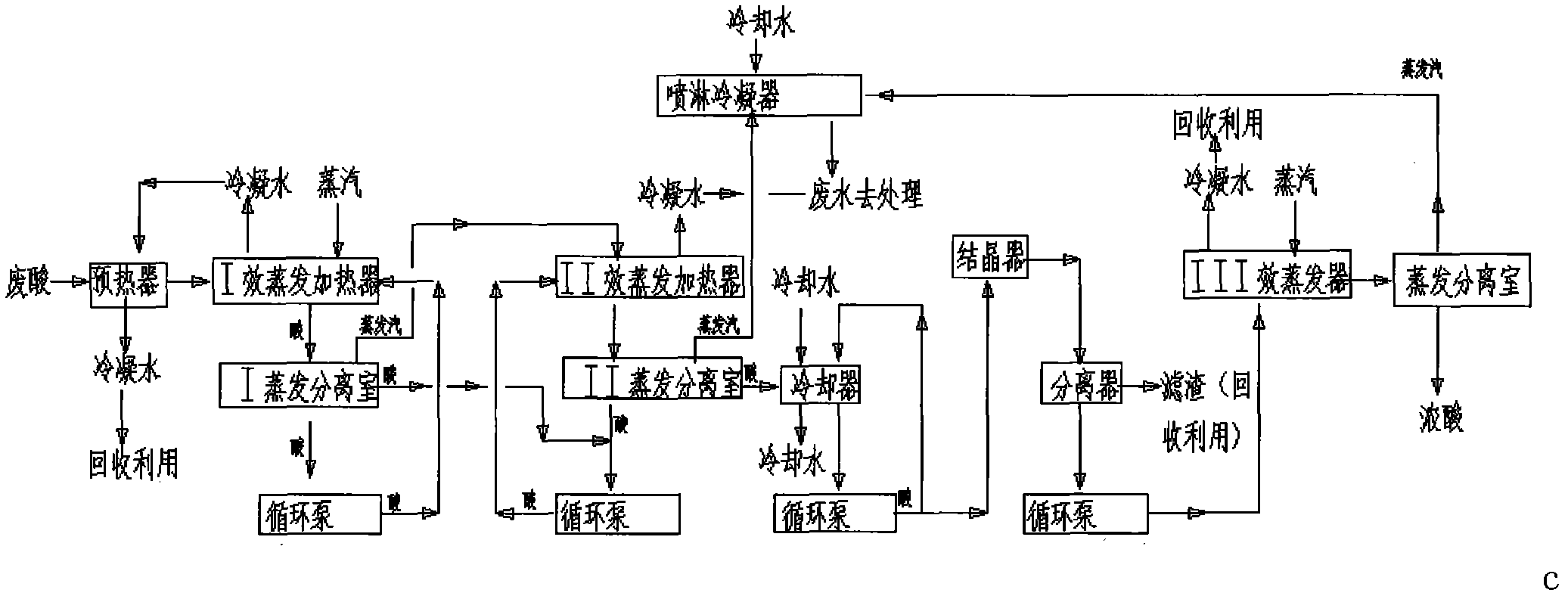

Waste acid concentration multistage treatment method

ActiveCN101935077ATake advantage ofReduce heat transfer areaMultistage water/sewage treatmentWater/sewage treatment by heatingSteam condensationSpray cooling

The invention relates to a waste acid concentration multistage treatment method which comprises the following steps of: heating 20-22% waste acid by a preheater, evaporating by a one-effect evaporation heater and a double-effect evaporation heater, cooling by a cooler and crystallizing by a crystallizer; heating by a triple-effect evaporation heater and separating by a separator to obtain 65% concentrated acid. The secondary steam part is used as a heat source part of the next stage heater and is condensed by spraying cooling water, wherein the one-effect evaporation heater and the double-effect evaporation heater are falling film graphite tube array evaporation heaters; the triple-effect evaporation heater is a floating head tube array graphite heat exchange. The water evaporation capability of the method is increased from 2.5 tons to 10 tons, and the stage number is 3 or more. A large amount of steam and cooling water is saved, and the pollution to the environment is reduced. The heat exchange area of equipment is reduced by 30%, and materials are saved and manufacturing cost is reduced correspondingly. The heat of steam is fully utilized, more than 35% of steam is saved, and more than 30% of cooling water can be saved. The condensed water part of the steam is used as the hear source part of the preheater and is recycled for other uses.

Owner:NANTONG JINGTONG GRAPHITE EQUIP

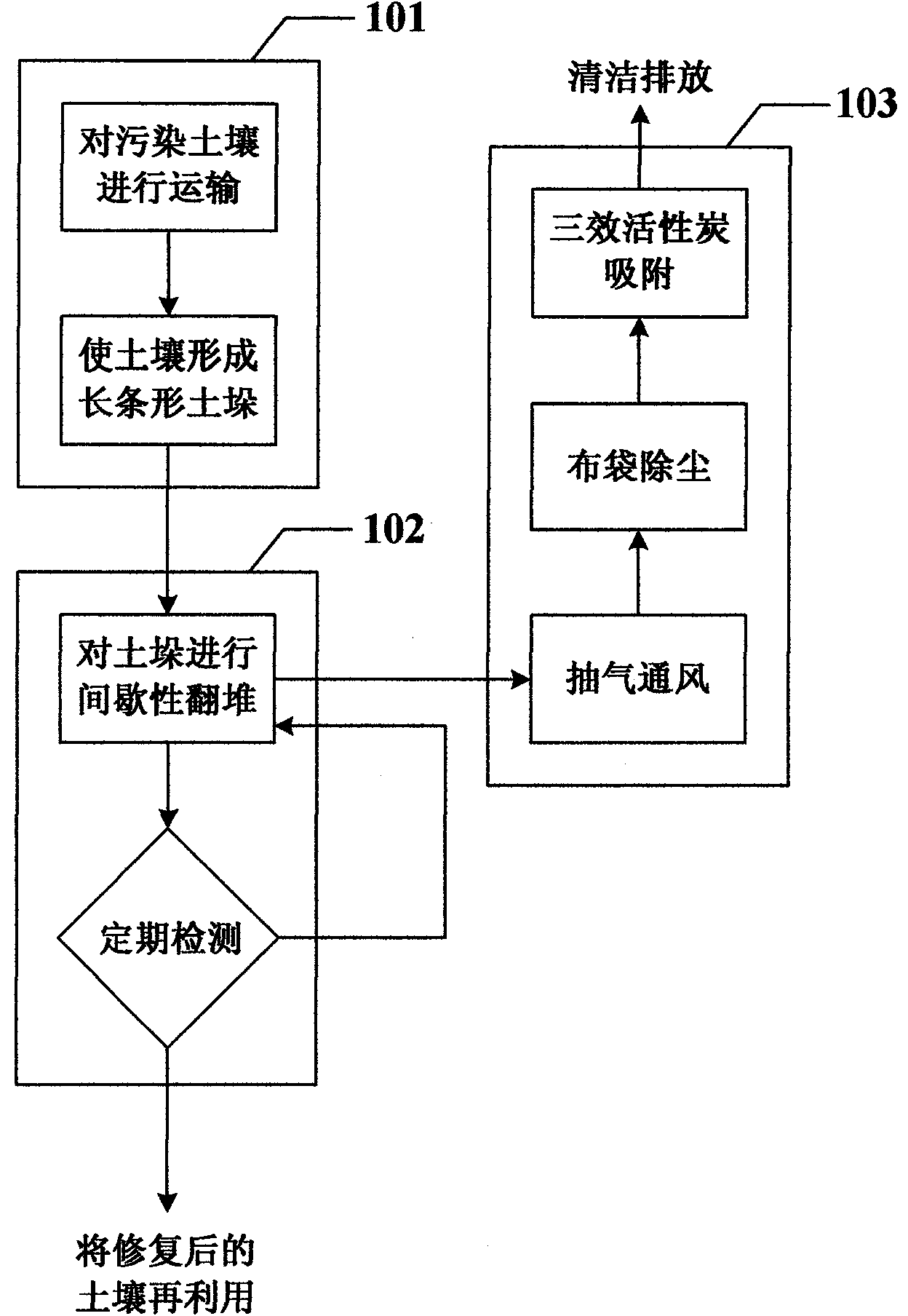

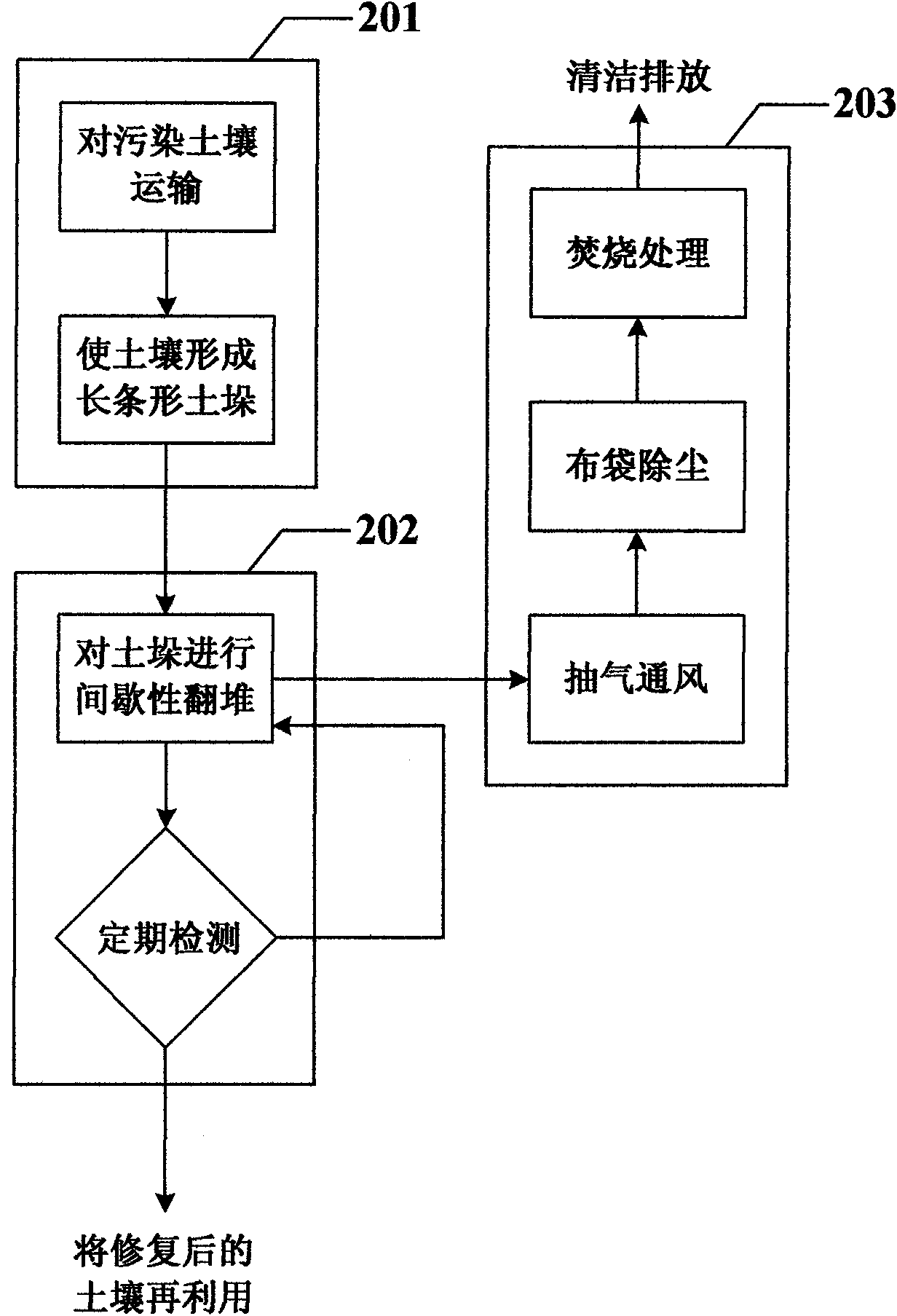

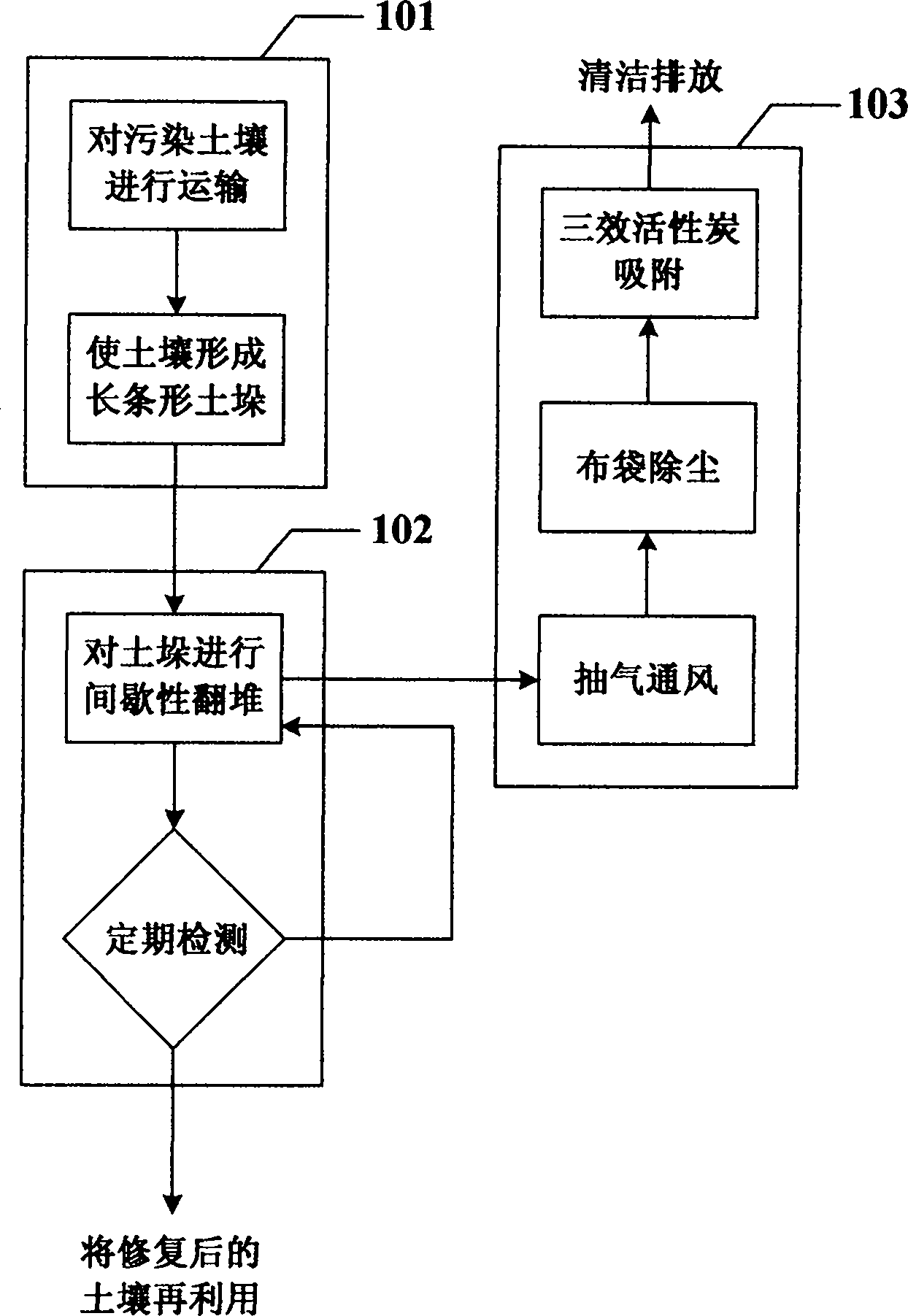

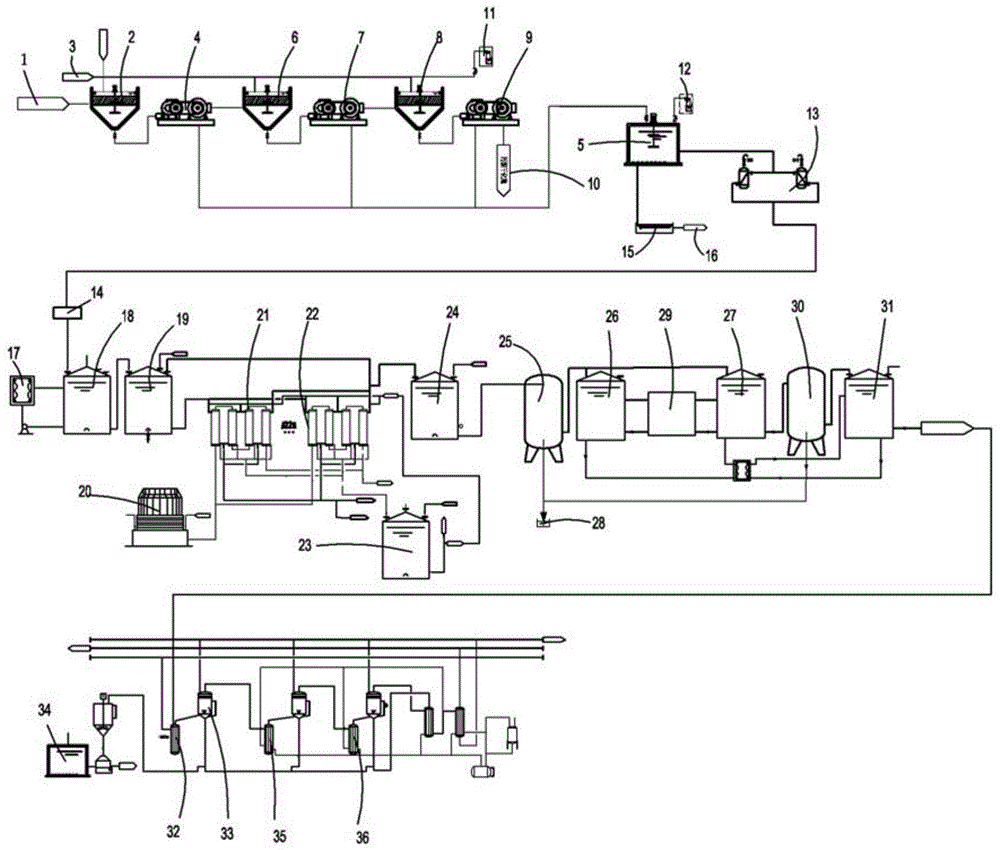

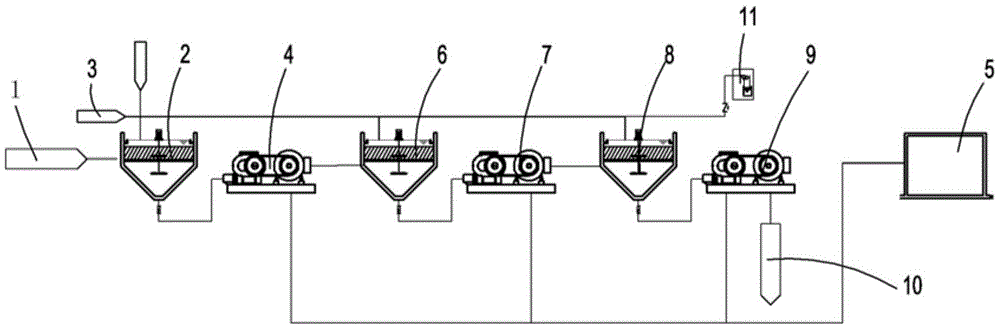

Low-temperature deabsorption repairing process used for polluted soil

ActiveCN102139277AAvoid secondary pollutionGuaranteed clean emissionsDispersed particle filtrationContaminated soil reclamationActivated carbonThree stage

The invention relates to a low-temperature deabsorption repairing process used for polluted soil, comprising three stages, namely polluted soil preparation stage, low-temperature deabsorption stage and tail gas treatment stage. In the polluted soil preparation stage, after being conveyed to a low-temperature deabsorption workshop, the polluted soil are processed into a plurality of elongated soilstacks by virtue of equipment; in the low-temperature deabsorption stage, the soil stacks are intermittently turned over by soil turning equipment to volatilize pollutants in the soil and the turned soil is detected regularly; and in the tail gas treatment stage, gas carrying the pollutants after volatilization are led out by a centrifugal exhaust fan, and the gas is dedusted by a cloth bag and absorbed by triple-effect activated carbon absorption so as to realize the clean discharge of the tail gas. In the invention, based on the characteristic that the pollutants in the soil are easy to volatilize at normal temperature, the soil is turned over to volatilize the pollutants; enforced drawing ventilation is carried out on air in an airtight workshop, the gas carrying the pollutants is dedusted and absorbed by activated carbon, and finally the pollutants in the soil are removed by deabsorption, thus effective repairing of the polluted soil is realized.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

Method for synergistic treatment and harmless cyclic utilization of refuse fly ash by using cement kiln

ActiveCN105478438AIncrease temperatureAvoid foulingSolid waste disposalSnow meltingMembrane distillation

The invention relates to a method for synergistic treatment and harmless cyclic utilization of refuse fly ash by using a cement kiln. The method for synergistic treatment and harmless cyclic utilization of refuse fly ash by using thecement kiln comprises a three-stage washing desalination technology, a technology of removing heavy metals by coagulation and sedimentation, a membrane distillation concentration technology, a technology of removing slight trace carnallite and a triple-effect evaporation crystallization technology, wherein the three-stage washing desalination technology can remove heavy metals and chloride ions in the fly ash, and the fly ash which contains water and dioxin and the fly ash which contains less than 1% of chlorine ions enter the cement kiln and are incinerated at the temperature of above 1400 DEG C to turn into cement raw materials, and the dioxin is split at the temperature of above 800 DEG C; the technology of removing the heavy metals by coagulation and sedimentation can remove multiple metal ions in the fly ash, and precipitates are dried in advance and then enter the cement kiln to be incinerated; the membrane distillation concentration technology can remove the rest of chloride ions in a solution, and generated distilled water can be recycled; the technology of removing the slight trace carnallite can remove the slight trace carnallite, and heat energy can be recycled; and the triple-effect evaporation crystallization technologyevaporates and separates high salt content concentrated liquid to obtain industrial salt which is used for a paper making technology, snow-melting agents and chloro-alkali industries.

Owner:HUZHOU SENNUO MEMBRANE TECH ENG

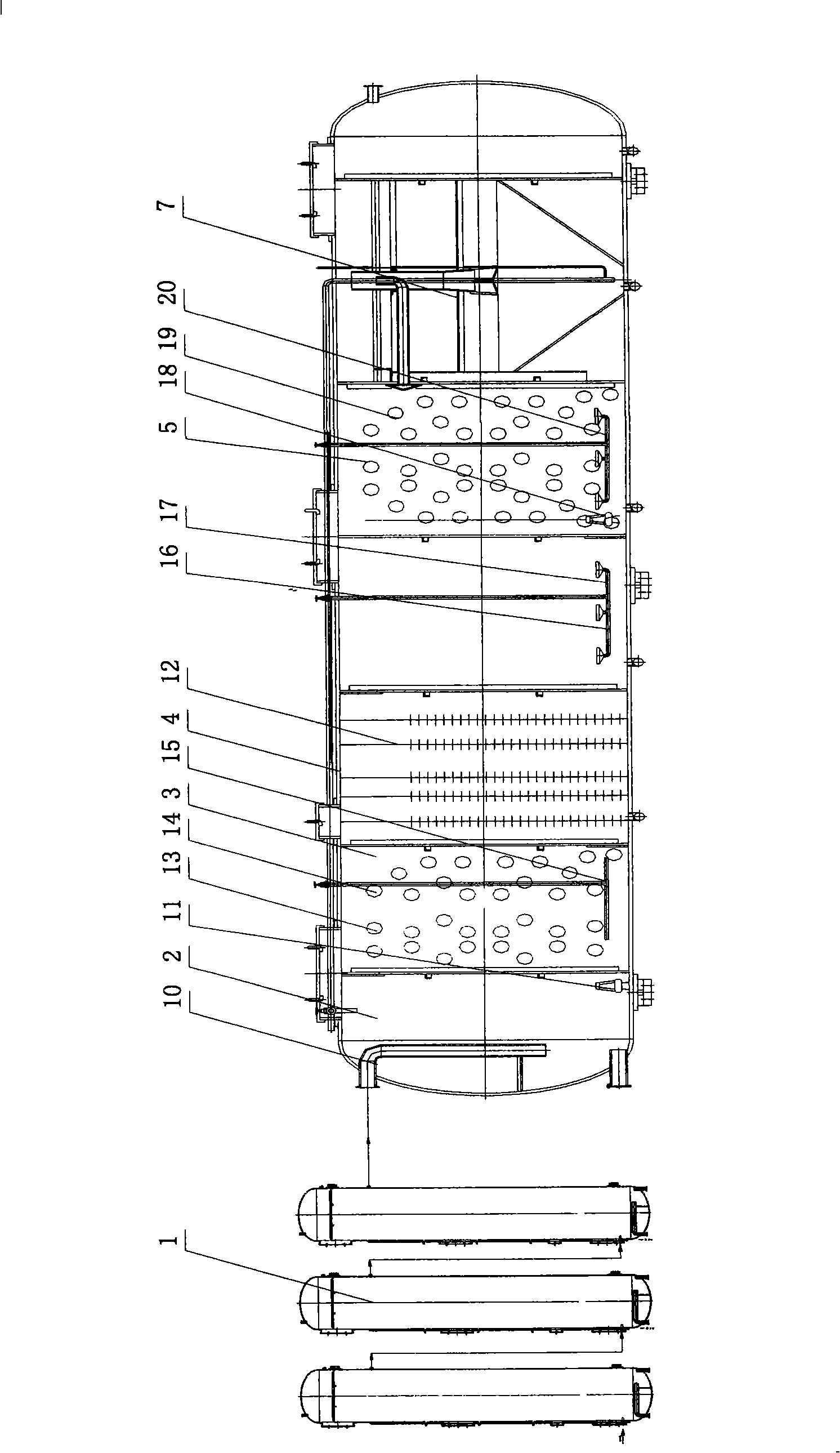

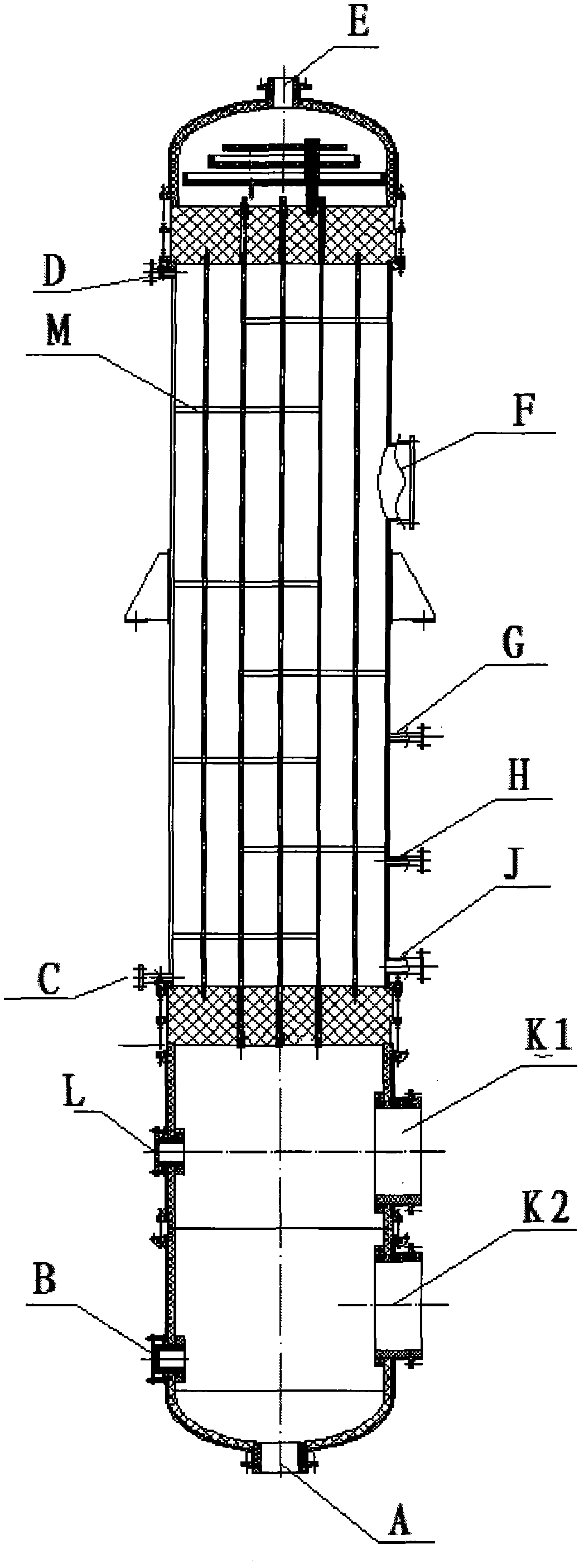

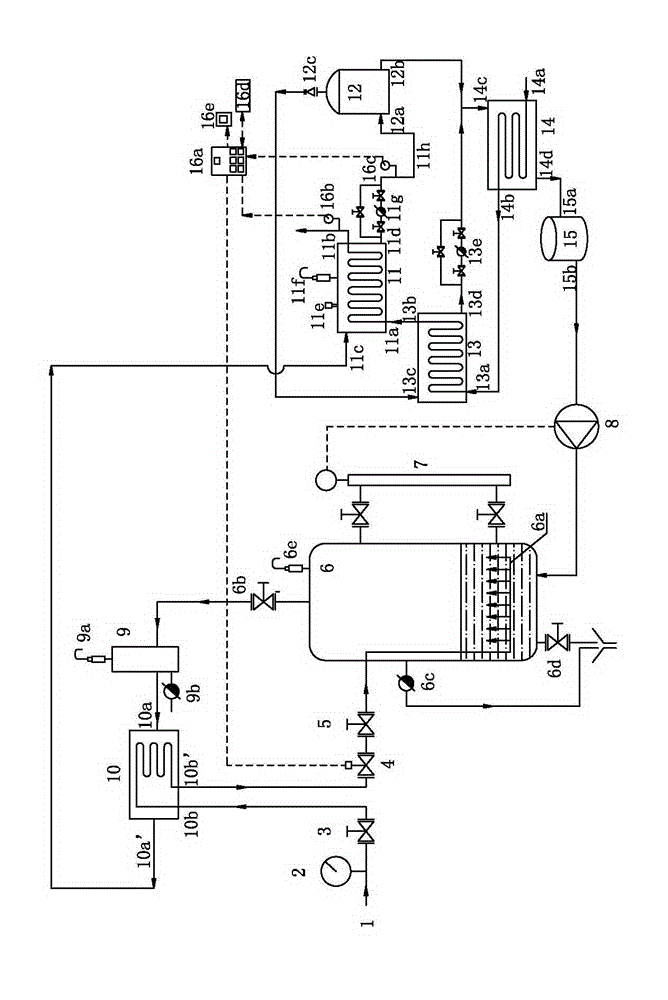

Production method and device for sodium gluconate energy-saving triple effect concentration and crystallization

InactiveCN101445449AIncrease production capacityImprove product qualityCarboxylic compound separation/purificationMoistureTriple effect

The invention discloses a production method and a device for sodium gluconate energy-saving triple effect concentration and crystallization. The continuity of sodium gluconate concentration and crystallization can be realized, that is, a raw material liquid enters a preheater continuously; the moisture can be evaporated after passing through 1st, 2nd and 3rd effect heating evaporators and 1st, 2nd and 3rd effect separators; the 2nd steam is separated continuously to heat and evaporate materials in the 1st, the 2nd and the 3rd effect heating evaporators; the crystal of sodium gluconate is separated out in the 3rd effect heating evaporator and pumped out continuously; therefore, the process of feeding, concentration and crystallization, and crystal separation at the same time is formed continuously, the 2nd steam is fully utilized, the steam consumption for evaporating moisture is 0.28 Tsteam / Twater, the crystallization rate achieves 65%, and materials can form a large amount of crystal in the 3rd effect heating evaporator. The invention can improve the productivity, reduce the steam consumption and improve the quality of products.

Owner:山东凯翔生物科技股份有限公司

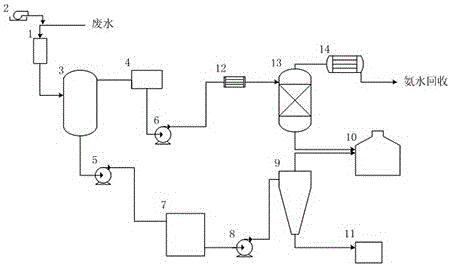

High-concentration ammonia nitrogen wastewater treatment system and treatment method

InactiveCN106186501ASolve wasteSave heatWater contaminantsMultistage water/sewage treatmentHigh concentrationHeat energy

The invention provides a high-concentration ammonia nitrogen wastewater treatment system and treatment method. The treatment system comprises a pretreating and regulating unit, a triple-effect evaporation unit, a rectifying and ammonia distilling unit and a film scraper evaporation unit; the pretreating and regulating unit is used for receiving high-concentration ammonia nitrogen wastewater and regulating the pH value of the high-concentration ammonia nitrogen wastewater to be alkaline; the triple-effect evaporation unit is used for evaporating the alkalized high-concentration ammonia nitrogen wastewater into desalted high-concentration ammonia-containing wastewater and low-ammonia-nitrogen high-salinity wastewater; the rectifying and ammonia distilling unit is used for conducting rectifying and ammonia distilling on the desalted high-concentration ammonia-containing wastewater to generate ammonium hydroxide and low-ammonia-nitrogen tail water capable of being biochemically treated; the film scraper evaporation unit is used for evaporating the low-ammonia-nitrogen high-salinity wastewater into low-ammonia-nitrogen tail water capable of being biochemically treated and high-concentration saline water. According to the wastewater treatment system, after the high-concentration ammonia nitrogen wastewater is subjected to efficient evaporation, rectifying and ammonia distilling and film scraper evaporation desalting, the ammonia recovery efficiency can reach 95% or above, ammonium hydroxide can be effectively recovered to increase the economic benefit, and inorganic salt components in the wastewater are removed; by adopting an efficient evaporation device, heat energy is effectively saved, and the energy utilization efficiency is improved.

Owner:上海凯工石油装备科技有限公司

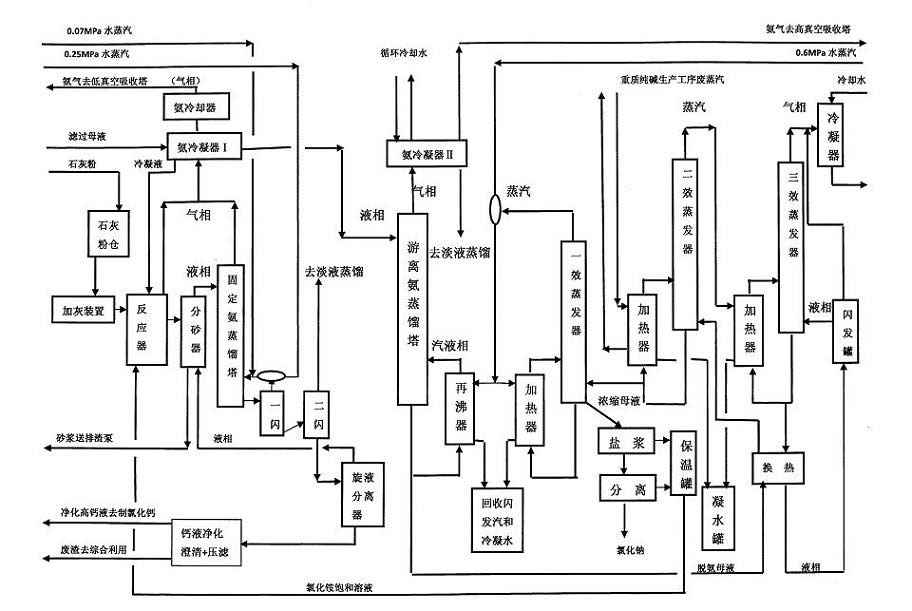

Process for preparing calcium chloride solution by utilizing ammonia soda filtration mother liquor

ActiveCN102145912AIncrease solute concentrationQuality improvementCalcium/strontium/barium chloridesEnergy inputFiltrationChloride

The invention discloses a process for preparing a calcium chloride solution by utilizing ammonia soda filtration mother liquor and relates to the field of the production method of calcium chloride. The process comprises the following steps: distilling the filtration mother liquor to obtain mother liquor without ammonia, performing triple effect evaporation and separation to the obtained mother liquor to obtain an ammonium chloride saturated solution, then using the ammonium chloride saturated solution to react with lime powder in a reactor and generate a calcium chloride solution, and finally purifying the calcium chloride solution to prepare the finished product-calcium chloride solution. By adopting the process, the soda-calcium production can be realized under the premise of ensuring the recovery and recycling of ammonia and carbon dioxide and the content of the calcium chloride solution is more than 30wt%.

Owner:大连大化工程设计有限公司 +1

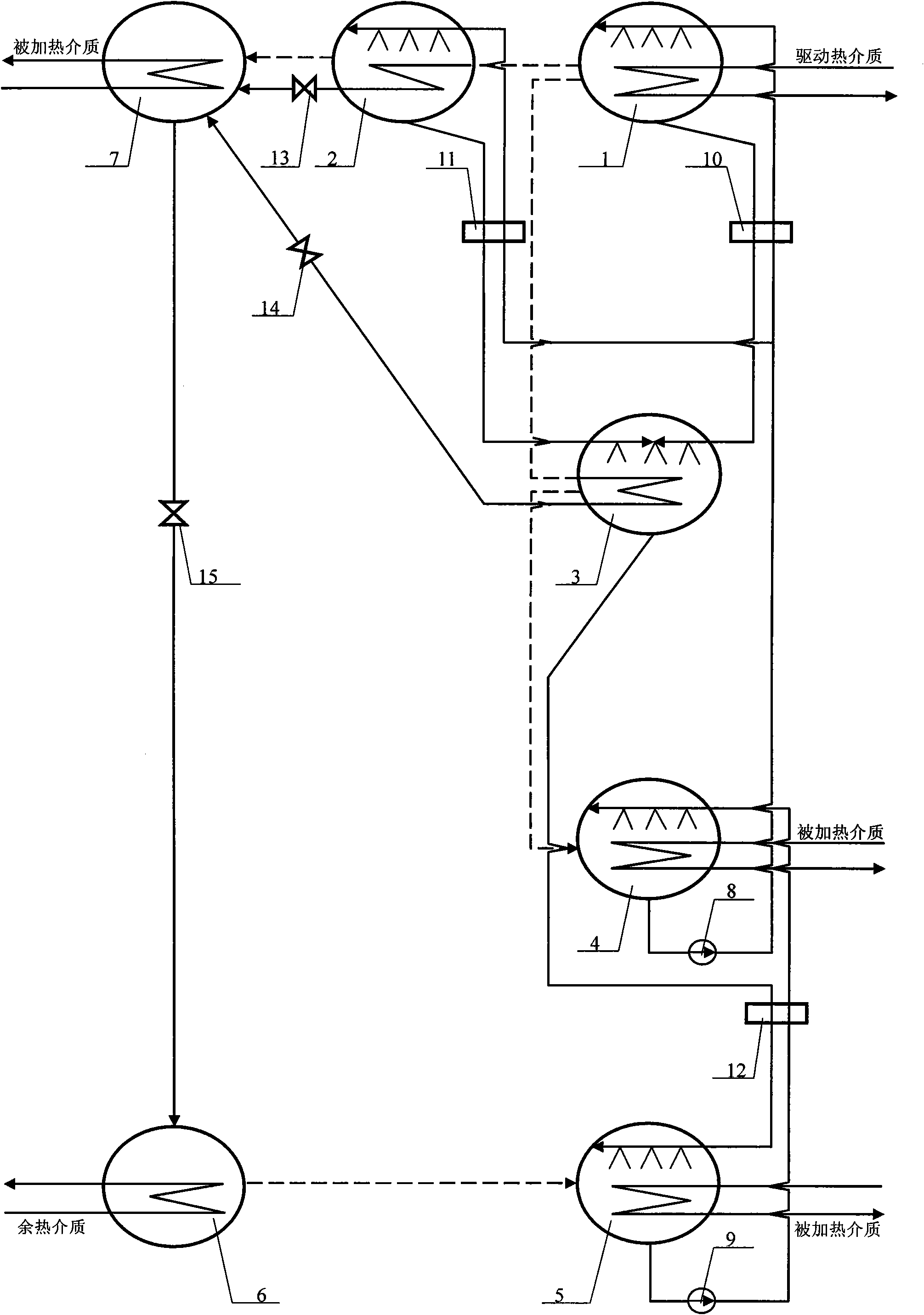

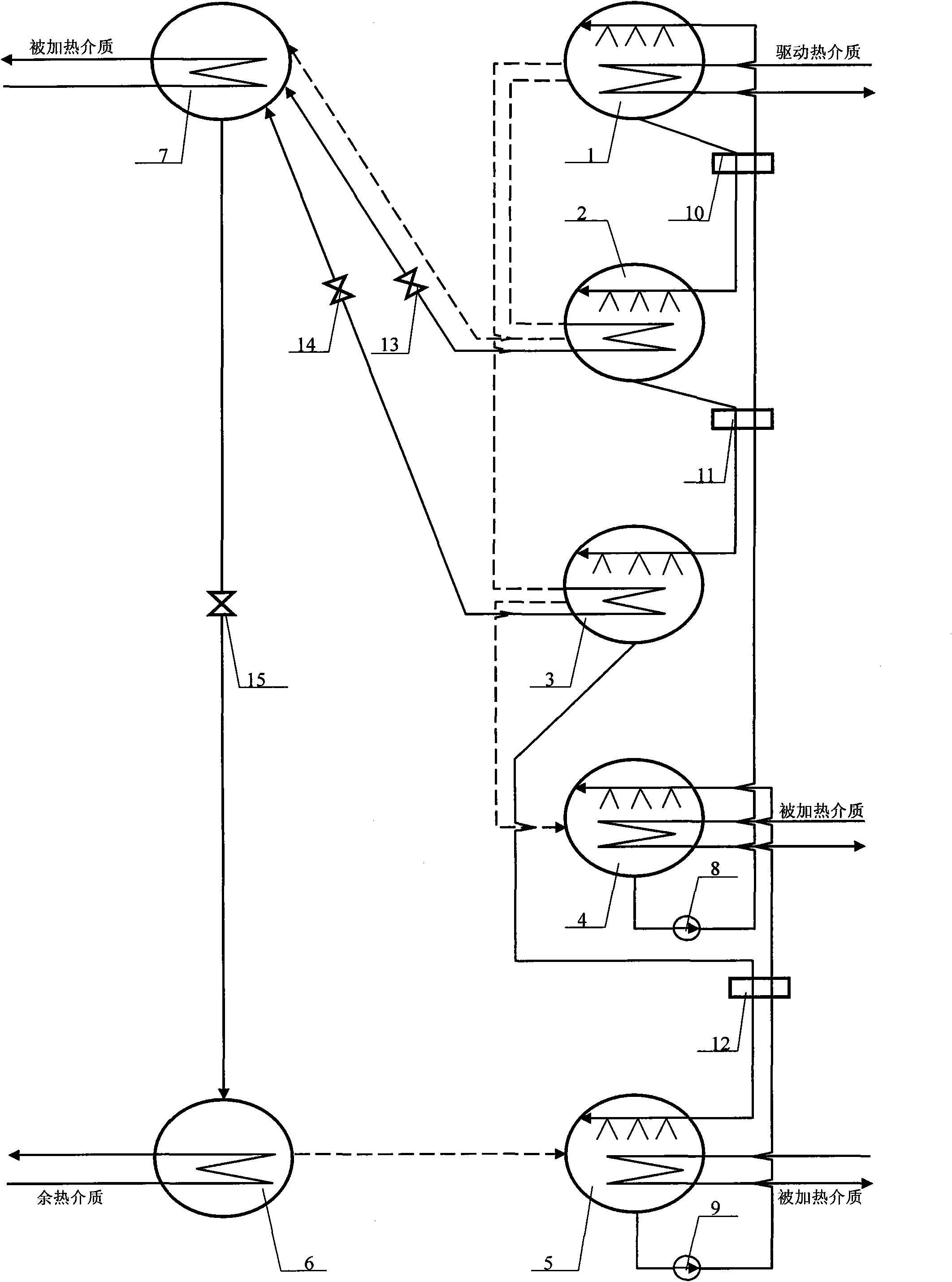

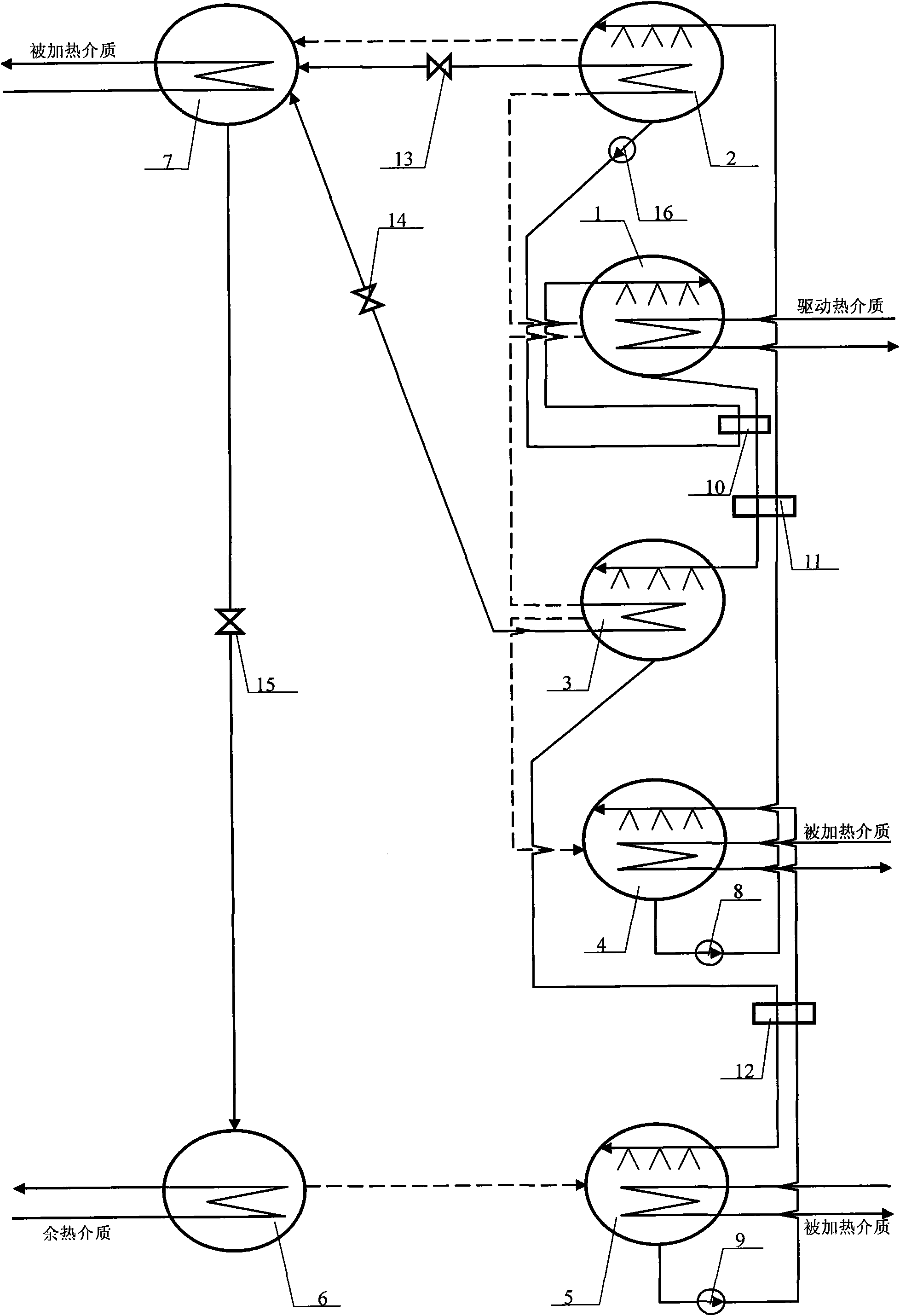

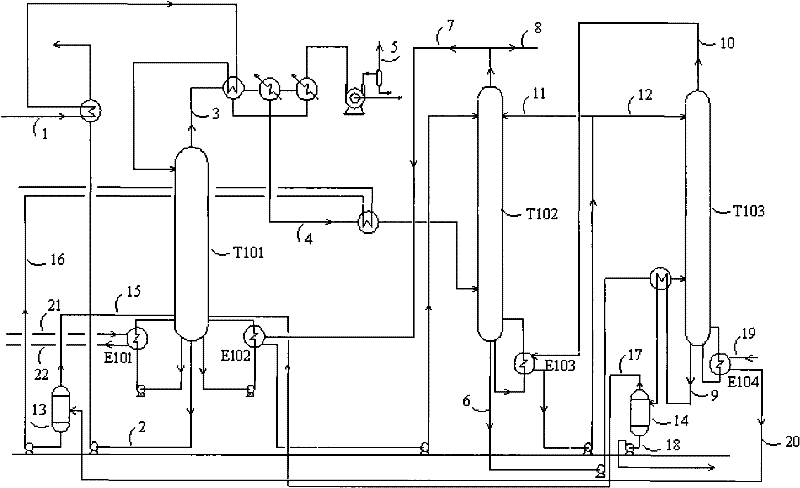

Double-effect and triple-effect first-type absorption heat pump with heat return end and heat supply end

ActiveCN102116538AAchieve convergenceEnergy efficient heating/coolingClimate change adaptationAbsorption heat pumpProcess engineering

The invention provides a double-effect and triple-effect first-type absorption heat pump with a heat return end and a heat supply end, which belongs to the technical field of absorption heat pumps. A second absorber is sequentially communicated with a second solution pump, a third solution heat exchanger, a first absorber, a first solution pump, a second solution heat exchanger, a first solution heat exchanger and a first generator, the first generator is further sequentially communicated with the first solution heat exchanger, a second generator, the second solution heat exchanger, a third generator, the third solution heat exchanger and a second absorber, the first generator is provided with a steam channel used for communicating with the second generator and the third generator, the second generator is communicated with a condenser via a first throttling valve, the third generator is communicated with the condenser via a second throttling valve, the second generator is provided with a steam channel used for communicating with the condenser, the third generator is provided with a steam channel used for communicating with the first absorber, the condenser is communicated with an evaporator via a third throttling valve, and the evaporator is provided with a steam channel used for communicating with the second absorber, so that the double-effect first-type absorption heat pump with the heat return end and the heat supply end is formed.

Owner:李华玉

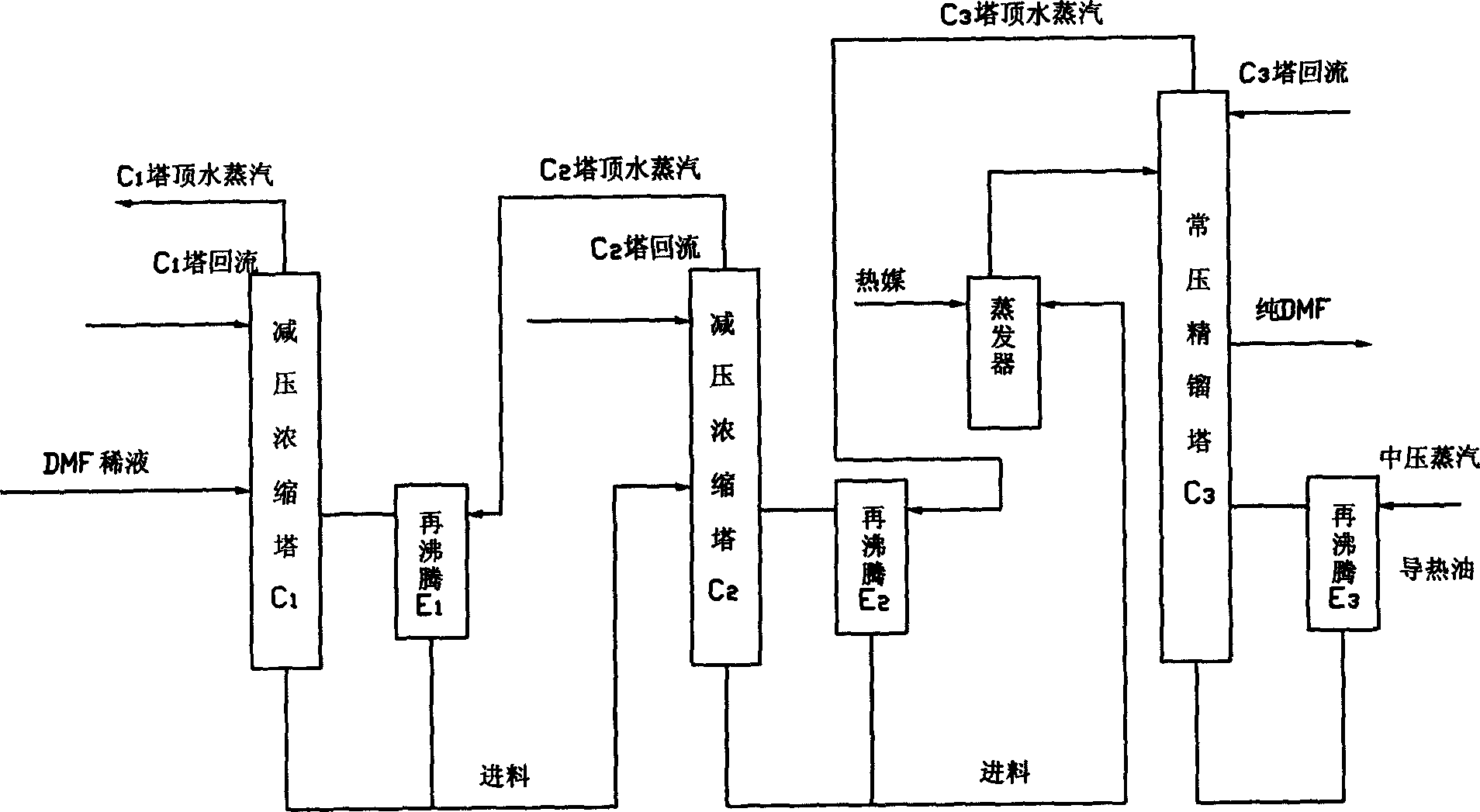

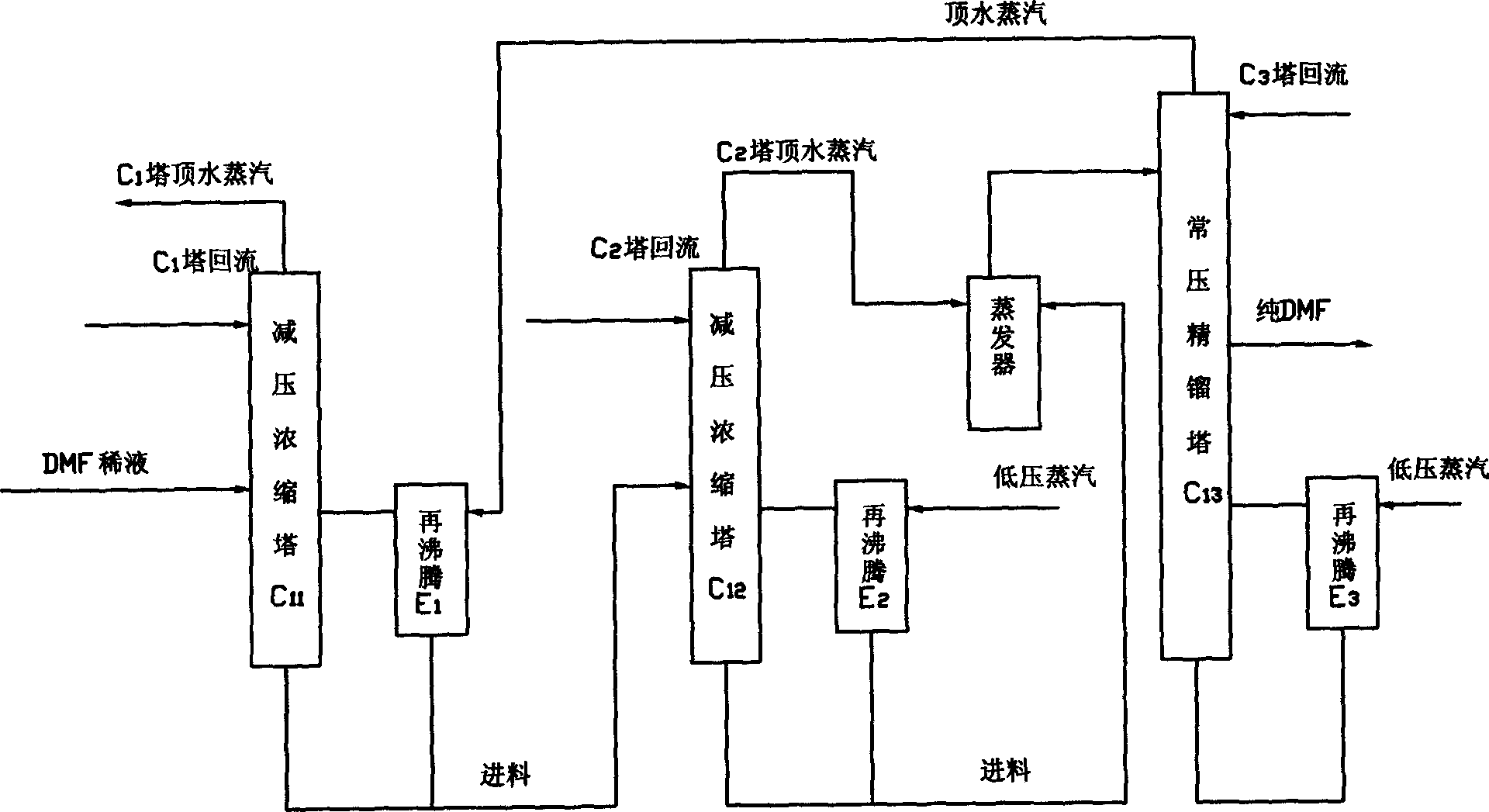

Dimethyl formylamine solution three-effect rectification recovery method for wet synthesis of leather

ActiveCN1891685AReduce consumptionAchieve consumptionCarboxylic acid amide separation/purificationThermal energyRecovery method

A triple-effect distillation and recovery method for wet synthetic leather dimethylformamide(DMF) solution includes: feeding, preheating, condensing and separating it by a concentration tower and a distillation tower to output it to complete the recovery process, in which, low-pressured steam is the heating media, using decompressed concentration for step I, atmospheric concentration for level II and vacuum distillation, the decompressed concentration processes in the packing tower, atmospheric concentration processes in the plate column, decompressed concentration processes in the combined packing and plate column. In the described cycle process, energy can be recycled between the steam in the top, heating at the bottom, feed preheating, preheating of finished condensation, distillation, reboilling processes.

Owner:ZHEJIANG HEXIN NEW MATERIAL CO LTD

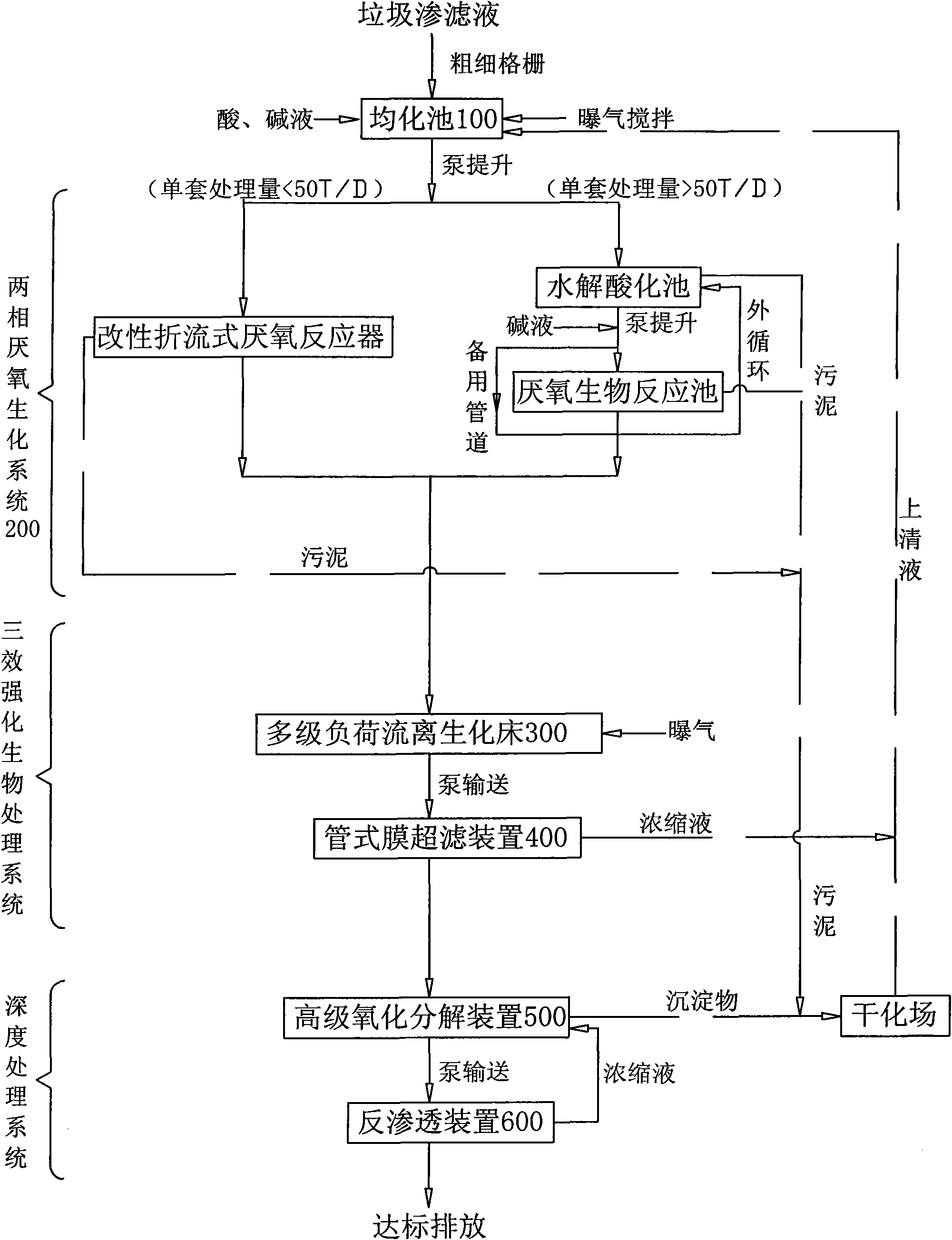

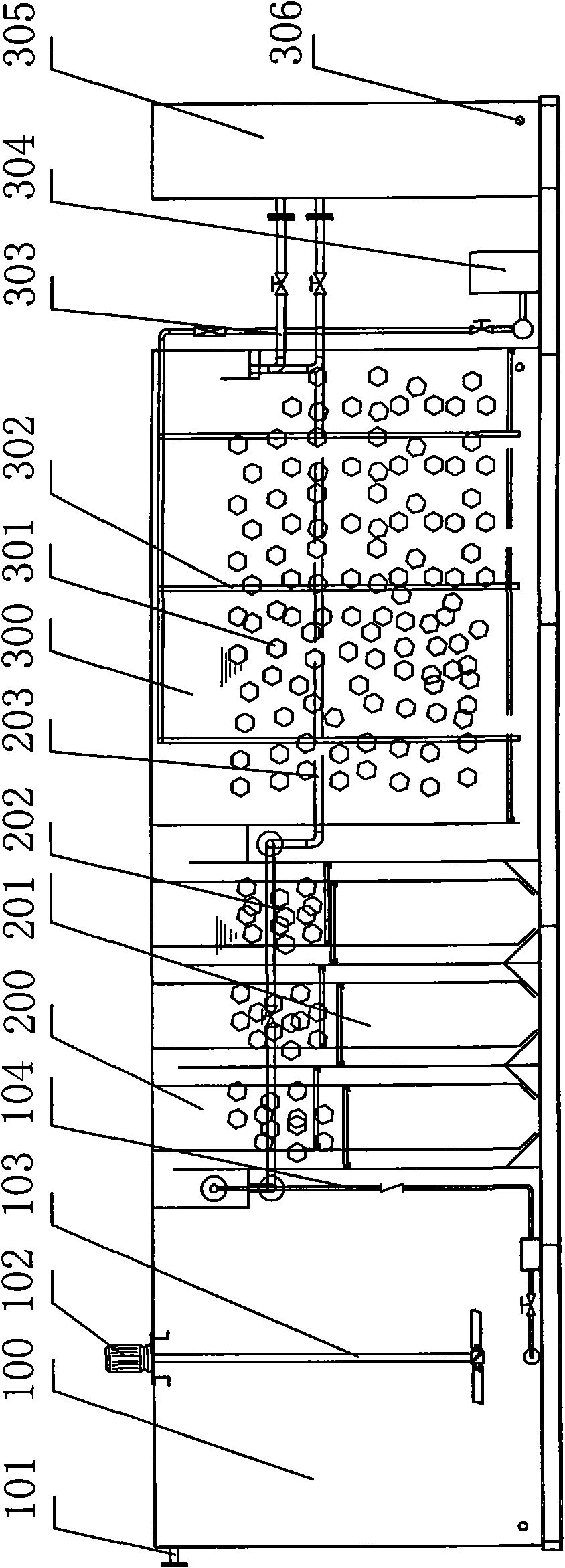

Garbage percolate treatment method

ActiveCN101967031AEfficient removalAchieving zero emissionsMultistage water/sewage treatmentSoil organic matterLitter

The invention relates to a garbage percolate treatment method. Garbage percolate is subjected to homogenization, a two-phase anaerobic biochemical system, a triple-effect enhanced biotreatment system and advanced treatment, a plurality of pollution elements can be removed with high efficiency by effectively aiming at the characteristics of high organic matter and ammonia nitrogen content in the garbage percolate in each step, and the effluent index is greatly superior to the standard in China. The garbage percolate treatment method has strong impact resistance capacity, can adapt to changes of water quality and water quantity of the garbage percolate in different seasons and different stages (a primary stage, a middle stage and an aged stage), prolongs the service life and the lifetime of the systems and reduces the treatment cost of the garbage percolate.

Owner:JIANGSU ZHAOSHENG ENVIRONMENTAL PROTECTION TECH CO LTD

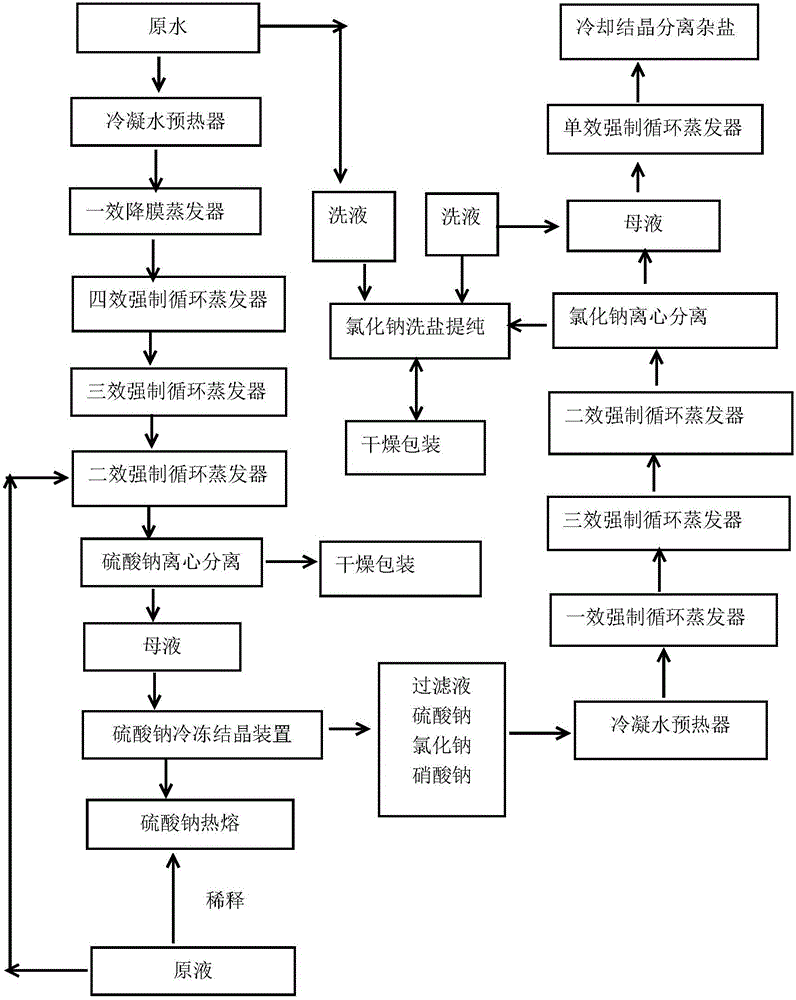

Desulfurization wastewater concentration, evaporation, crystallization and salt separation process

ActiveCN106007133AEfficient separationDissolution inhibitionWater/sewage treatment by centrifugal separationWater contaminantsWastewaterSingle effect

The invention discloses a desulfurization wastewater concentration, evaporation, crystallization, and salt separation process. The process comprises the steps as follows: introducing raw water into a quadruple-effect counter-flow forced circulation evaporator, treating sodium sulfate through evaporating, concentrating and crystalizing, separating sodium sulfate first, and freezing separated mother liquor, wherein most of sodium sulfate in the mother liquor is successfully separated; introducing the frozen mother liquor into a triple-effect evaporator after preheating, evaporating, concentrating and crystalizing sodium chloride, wherein the obtained crystal salt is used as an industrial raw material; introducing the mother liquor produced by a sodium chloride evaporator into a single-effect evaporator to obtain an abraum salt crystal. The process successfully separates the sodium sulfate in the desulfurization wastewater, and the sodium chloride is treated through evaporating, concentrating and crystalizing, the obtained sodium chloride crystal salt is used as the industrial raw material, the mother liquor produced by the sodium chloride evaporator enters the single-effect evaporator to obtain the abraum salt crystal, so that the sodium sulfate and the sodium chloride are effectively separated.

Owner:SUZHOU JOYFA ENVIRONMENTAL TECH CORP LTD

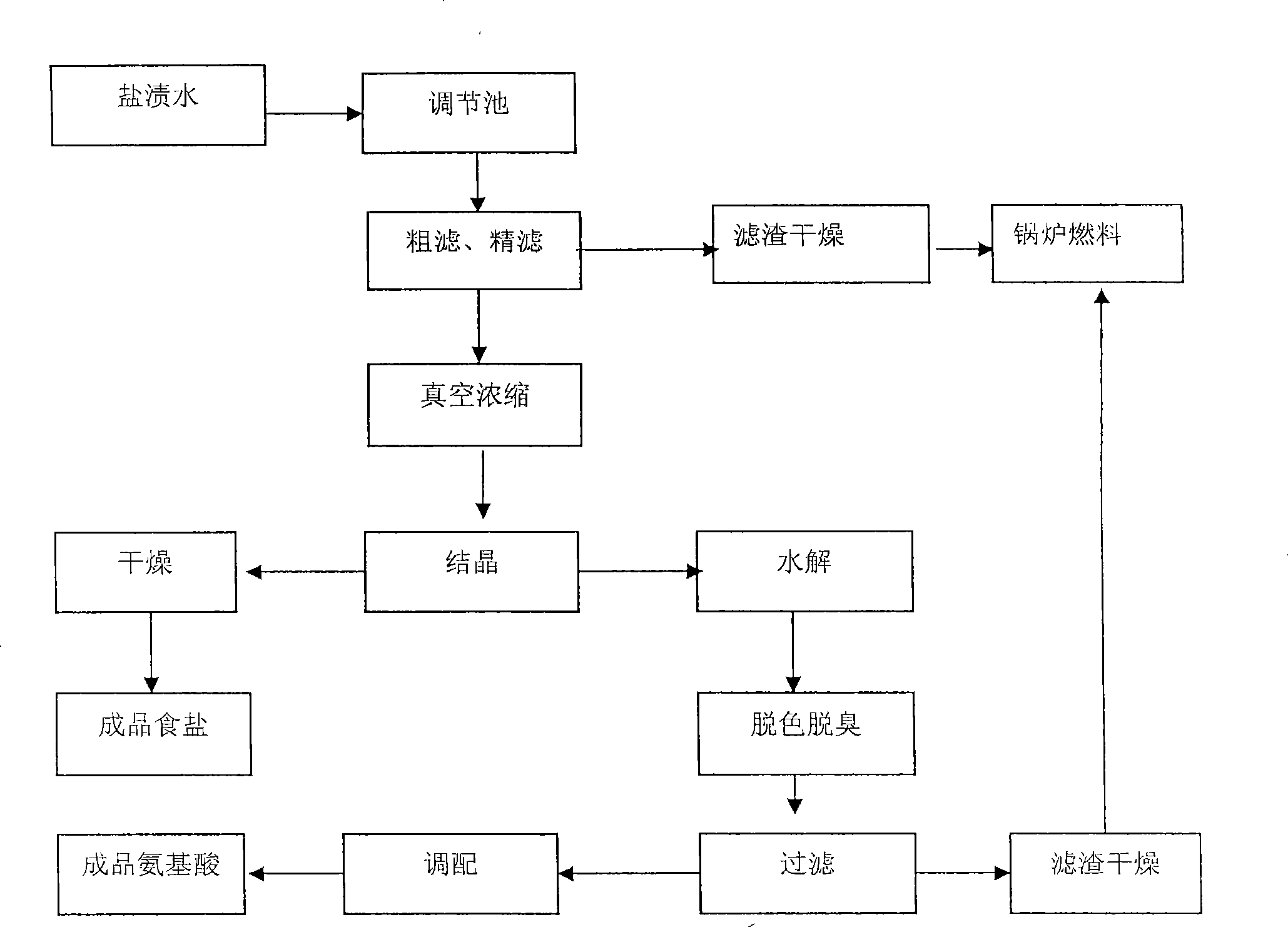

Salting pickled vegetable brine recovery technique

ActiveCN101391844AClimate change adaptationMultistage water/sewage treatmentSaline waterCentrifugation

The invention relates to a method for recycling and treating the salt water of pickled krault and is realized by the following steps: after the salt water is coarsely and then finely filtered, the residue is dried and used as boiler fuel, the filtrate enters into triple effect concentration, the saturated salt solution of the condensed juice is pumped into a crystallizer for crystallization, and salt is obtained after centrifugal separation, and the liquid after centrifugation is hydrolyzed, discolored, deodorized, filtered, prepared, filled and sterilized to obtain vegetable amino acid. The invention has simple operation and no regeneration of waste, the recycled residue can be used as the boiler fuel, the salt and the vegetable amino acid can be used as food and chemical fuel, thus eliminating the pollution of the salt water of pickled krault to environment.

Owner:吉香居食品股份有限公司

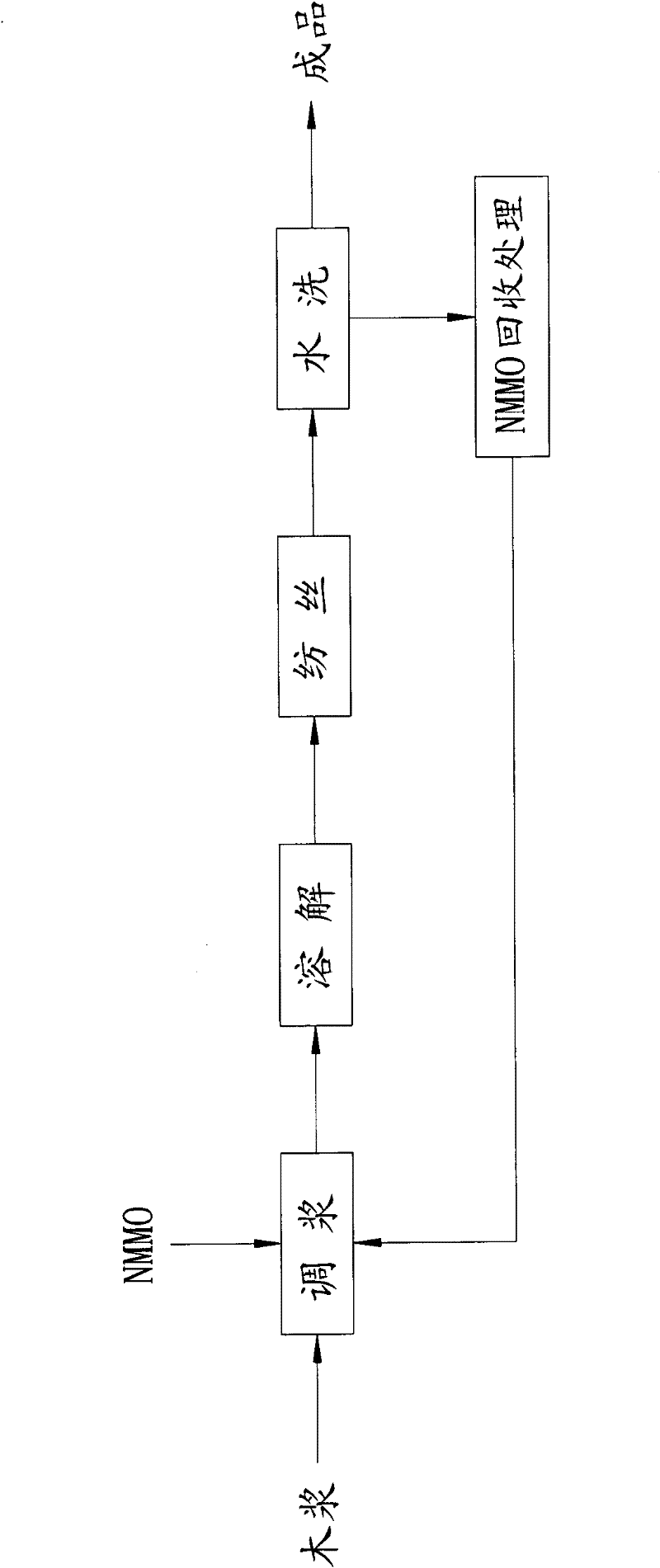

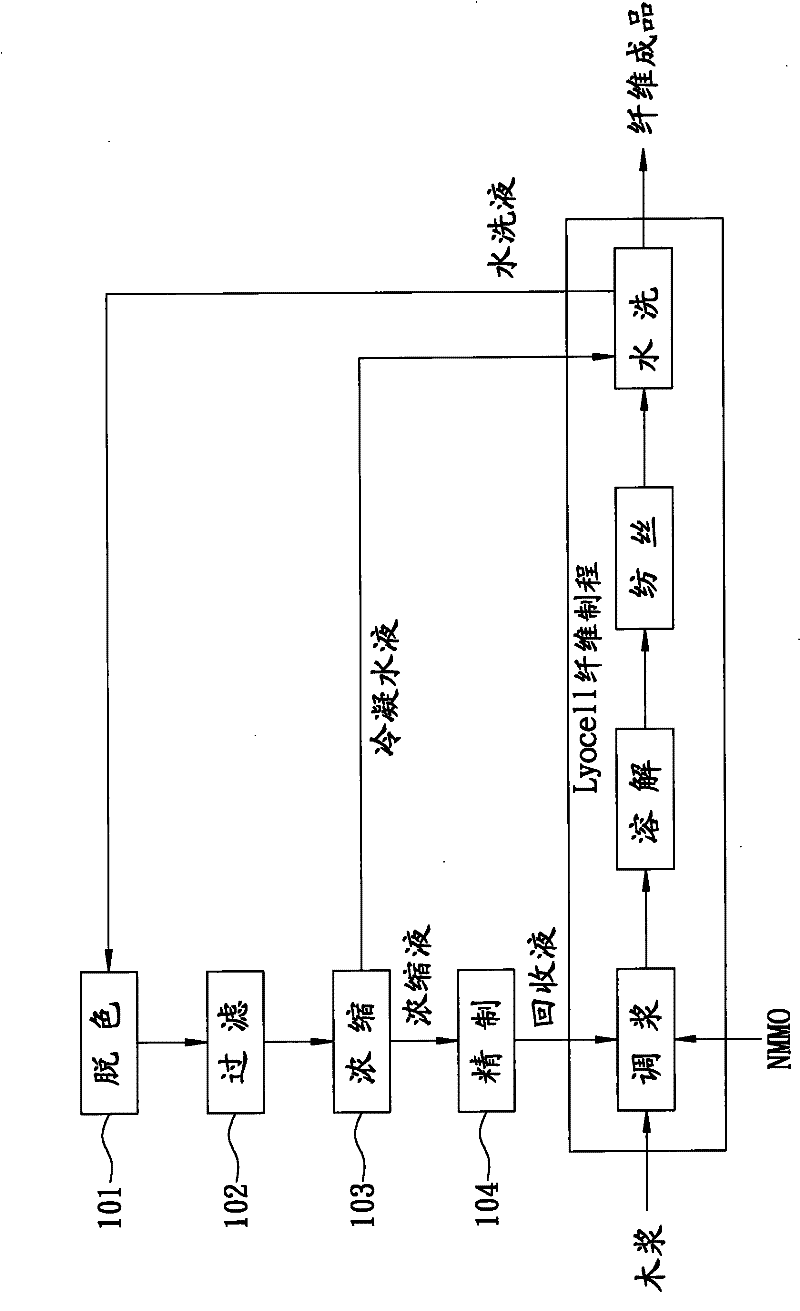

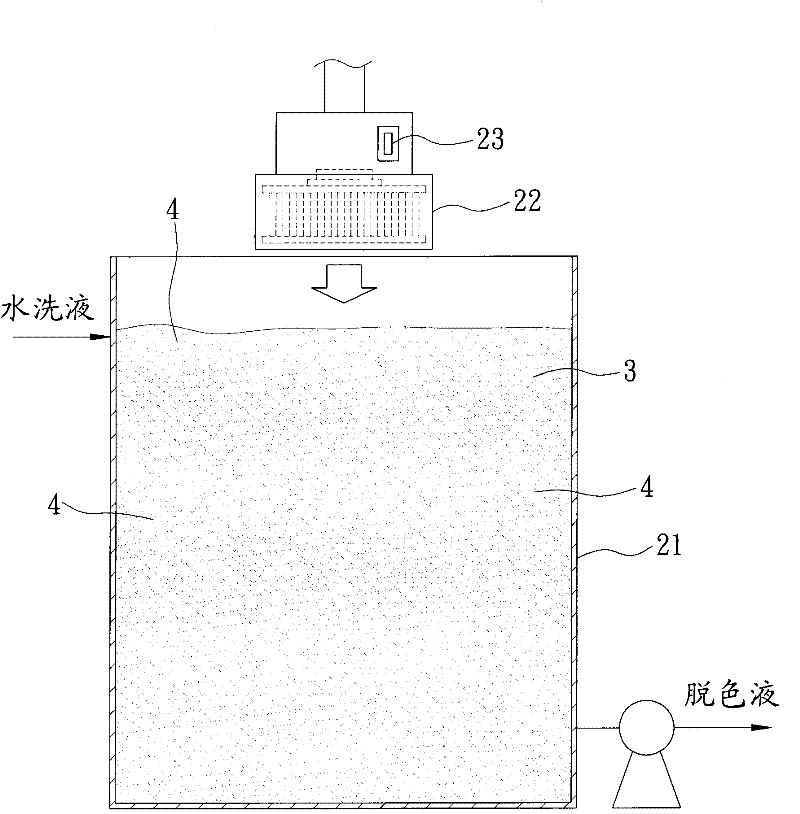

Solvent recovery method of Lyocell fibers

ActiveCN102234852AMeet the needs of useMeet environmental requirementsArtificial filament recoveryTextile/flexible product manufactureFiberRecovery method

The invention discloses a solvent recovery method of Lyocell fibers, comprising the following steps: processing collected Lyocell fibers into a washing liquor, introducing the washing liquor to a decolouring groove, using active carbon powder to decolor through suspension, then removing the active carbon and impurities from the decolored washing liquor by a two-stage filtration containing prefiltration and ultrafiltration, removing the water from the washing liquor by one of the following two methods: mechanical vapor recompression condensation method and triple effect evaporation vapor condensation method, so as to obtain a recovered solution with the solvent concentration which coincides with fiber processing. Because the recovery process is simple, the devices used in conjunction with the process are not complicate, easy to access, and suitable for using in the recovery of a large amount of low concentration washing liquor, so that the invention has competitive recovery cost, recovery efficiency and quality of the recovered solution, and has practicability and environmental nature.

Owner:骏隆翔(厦门)纤维科技有限公司

Method for extracting tea saponin from camellia seed meal

The invention relates to a method for extracting tea saponin from camellia seed meal, comprising the following steps of: crushing camellia seed meal into powder with the particle size of 100-200 meshes, packaging into cloth bags and sealing the openings; putting the cloth bags with the camellia seed meal into a batch extractor which is provided with a filter screen at the position of a conical opening of a conical tank bottom and connected with a condenser; injecting hydrous ethanol into the batch extractor according to the mass ratio of the camellia seed meal powder to the ethanol of 1:8-10, raising the temperature to 80-90 DEG C to enable the ethanol to back flow, extracting tea saponin in the states of stirring and ethanol reflux for 3-4h to obtain a tea saponin extract; pumping the extract out from the batch extractor, injecting into a concentration tank and carrying out the triple-effect concentration to obtain tea saponin rough products with the tea saponin yield of about 20 percent. With the method, the problem of plugging in the procedure of separating the tea saponin extract can be solved; and the method can improve the yield of the tea saponin, save the filter procedure and simplify the process.

Owner:JIANGNAN UNIV

Fume wet-type magnesia desulfated waste-liquid recovery method

ActiveCN101549210AReduce recycling costsImprove desulfurization efficiencySolution crystallizationDrying machines with non-progressive movementsRecovery methodLiquid waste

Owner:HEFEI GUOHUI ENVIRONMENTAL PROTECTION TECH

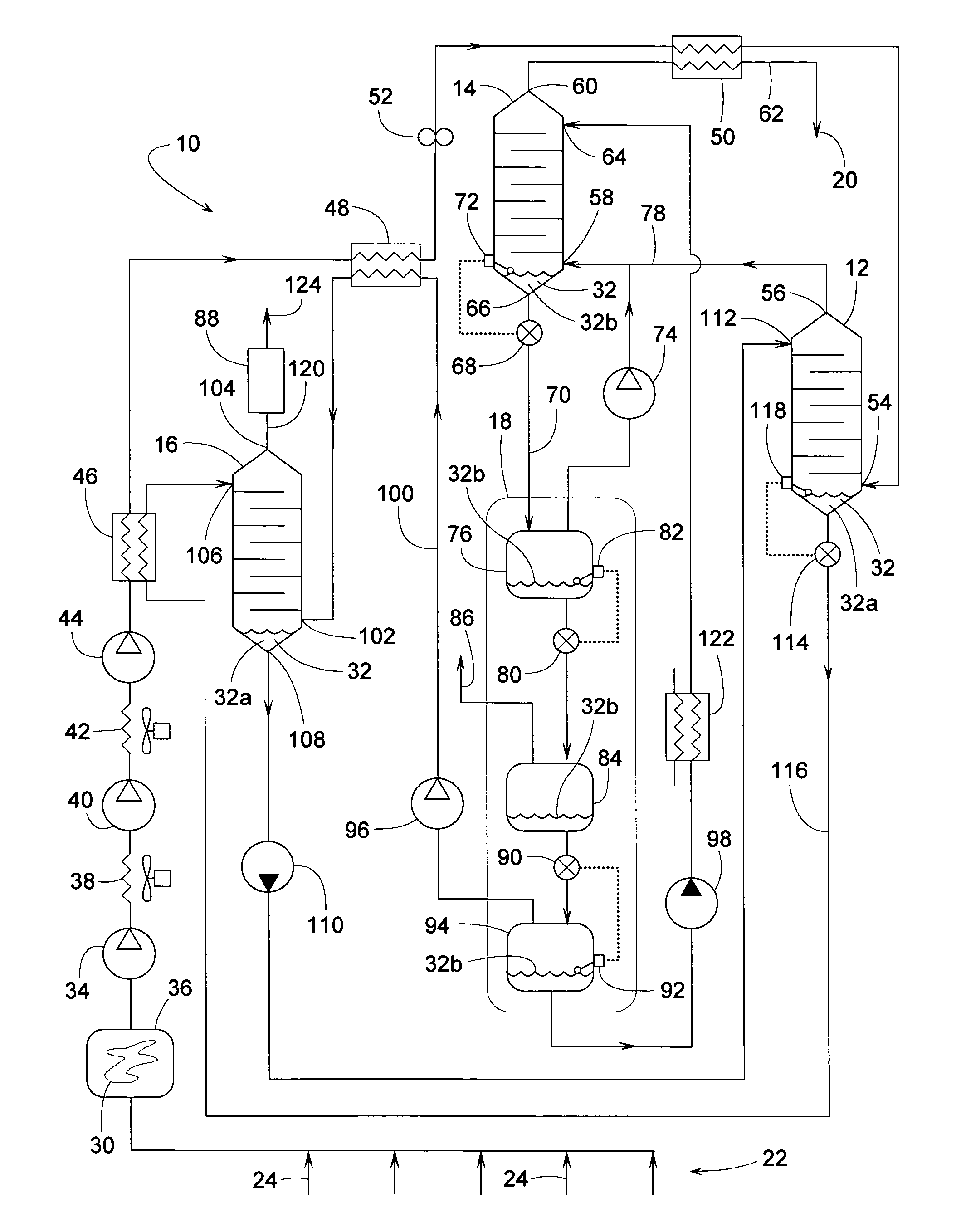

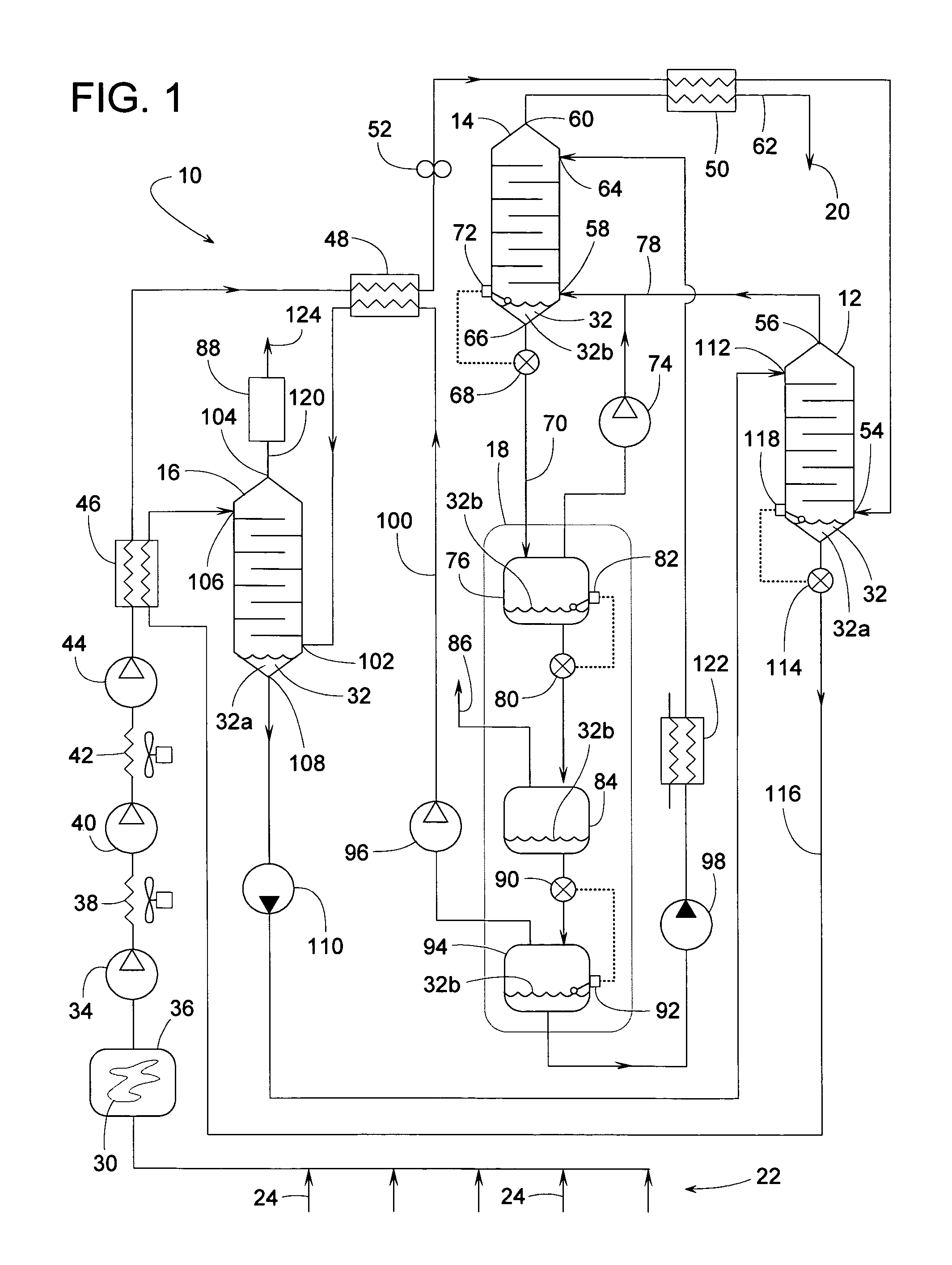

System and method for treating wastewater containing sodium chloride

InactiveCN102923893AAchieving zero emissionsReduce consumptionMultistage water/sewage treatmentWater/sewage treatment by heatingEnvironmental resistanceTriple effect

The invention relates to the technical field of wastewater treatment, in particular to a system and method for treating wastewater containing sodium chloride. The system for treating wastewater containing sodium chloride comprises a crystallization centrifugal separation system and is characterized in that the crystallization centrifugal separation system comprises a hydrocyclone, a thickener and a centrifugal machine which are sequentially connected, wherein the hydrocyclone is connected with a triple effect evaporation device used for concentrating wastewater containing the sodium chloride. The system has the beneficial effects of realizing zero emission of the wastewater, reducing negative effects of salt-containing wastewater emission on local surface water body and agricultural production, recycling a large quantity of steam condensate and sodium chloride, realizing win-win targets of economic benefit and environmental protection benefit, reducing consumption of live steam and lowering operation cost, and has a wider application prospect in the high-salinity wastewater treatment project.

Owner:山东沃蓝生物集团有限公司

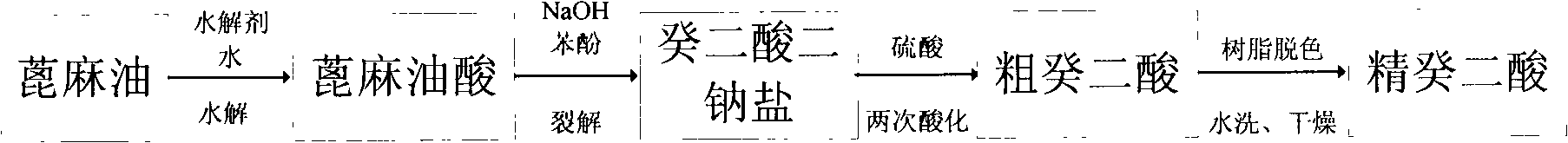

Process for changing phenolic nitrate effluent into useful material by extracting, evaporating, crystallizing and coupling

InactiveCN101654305ASolve bottlenecksSolve the miscibility problemEvaporationSolution crystallizationPhenolSodium sulfate

The invention discloses a process for changing phenolic nitrate effluent into useful material by extracting, evaporating, crystallizing and coupling, belonging to the field of changing waste water into useful materials. The process comprises the steps of pre-treating waste water, extracting phenol, performing triple effect evaporation and recycling sodium sulfate. Phenol is extracted with ricinoleic acid and is recycled, so the industrial usage of the phenol is decreased. The oil-water mutual solving problem is efficiently solved by utilizing the salting-out effect of the sodium sulfate highlycontained in the waste water. By adopting triple effect evaporation of counter-current operation under a basic condition, the phenol is efficiently prevented from secondarily returning into air, so the phenol contained in the treated waste water is less than 0.5mg / l and can be used as the scouring water for preparing process or can be directly discharged. The by-product sodium sulfate solid is efficiently recycled and the purity of the sodium sulfate is above 99.9%. The produced sodium sulfate makes up for the steam consumption during the evaporation process. Furthermore, the process has theadvantages of low treating cost, economic benefit and obvious environmental benefit.

Owner:TSINGHUA UNIV

Outer drying steam triple-effect heat exchange system

InactiveCN102878547AIncrease moisture contentReduce moisture contentSuperheating controlWater bathsDry heat

The invention relates to an outer drying steam triple-effect heat exchange system. A flow divider is arranged in the liquid phase space of a water-bath-type saturated steam generator, and a steam discharge pipeline of the flow dividier is sequentially provided with a steam water separator and a steam drying heat exchanger; overheated steam enters the flow divider through a pressure control valve; wet saturated steam from the saturated steam generator is heated into dry saturated steam by overheated steam; the dry saturated steam enters a main steam heat exchanger and becomes high-temperature condensation water after materials are heated for the third time; flash steam of the high-temperature condensation water heats the materials in the flash steam heat exchanger for the second time; condensed flash steam enters the condensation water heat exchanger; the condensation water in the high-temperature condensation water continuously releases sensible heat to heat the material for the first time; the condensation water after temperature reduction enters a water collecting tank, and is pumped into the saturated steam generator by a water supplying pump; and the aperture of the pressure control valve is regulated by a PLC (programmed logic controller) according to the material outlet temperature. The system achieves cascading utilization of steam heat energy, guarantees that the steam heat energy can be used up, and improves the energy efficiency.

Owner:YIHENG ENERGY SAVING TECH JIANGSU

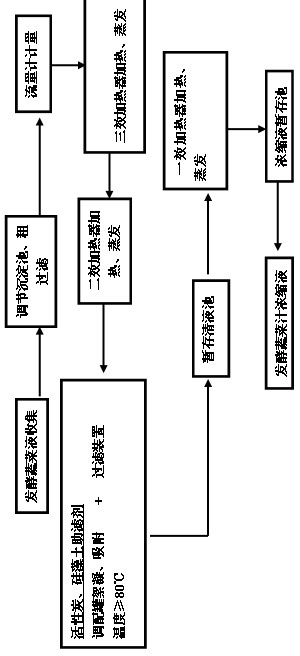

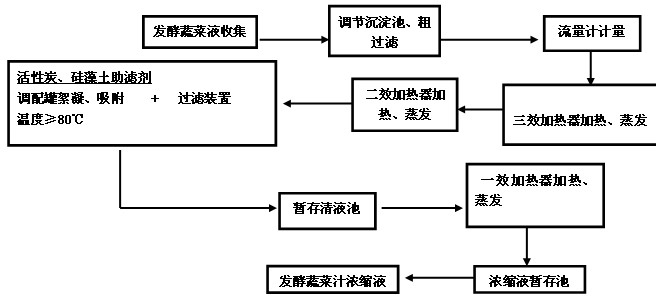

Preparation method of salted vegetable concentrated liquid

The invention discloses a preparation method of salted vegetable concentrated liquid, comprising the following steps of: collecting fermented and ripened salted vegetable fermentation liquid into a regulating settling tank, carrying out coarse filtration by a bottom filter screen of the regulating settling tank, and carrying out primary clarification on the salted vegetable fermentation liquid; feeding the coarsely filtered fermentation liquid into a triple-effect evaporation device, and heating and evaporating at the conditions that the vacuum degree is 0.08MPa and the boiling point is 50-55 DEG C; feeding the treated salted vegetable fermentation liquid into a double-effect evaporation device, and heating and evaporating at the conditions that the vacuum degree is 0.06MPa and the boiling point is 80-85 DEG C; feeding the treated salted vegetable fermentation liquid into an activated carbon and kieselguhr filtering device, and carrying out decoloration and foreign taste removal treatment on the salted vegetable fermentation liquid; and feeding the decolored clear liquid the foreign taste of which is removed into a single-effect evaporation device, and heating and evaporating at the conditions that the vacuum degree is 0.04MPa and the boiling point is 90-95 DEG C to prepare the required salted vegetable concentrated liquid. The invention has low production cost and realizes the recycle of the salted vegetable concentrated liquid.

Owner:吉香居食品股份有限公司

Triple-effect absorption system for recovering methane gas

ActiveUS7699914B1Efficient methodAvoid accumulationGas treatmentLiquid degasificationCombustionCo2 absorption

A method of using a triple-effect absorption system to recover methane from landfill gas contaminated with CO2 and trace contaminates such as chlorinated hydrocarbons and aromatics involves processing the landfill gas with three absorbers and a flash system. One absorber uses a solvent to absorb the trace contaminants from the landfill gas, the second absorber in conjunction with the flash system extracts CO2 from the gas, and just a first portion of that CO2 is used for stripping the trace contaminates from the solvent in the third absorber. The rest of the extracted CO2 is vented to atmosphere to prevent dampening the combustion of the trace contaminants absorbed by the first portion of CO2.

Owner:MORROW LUKE N +2

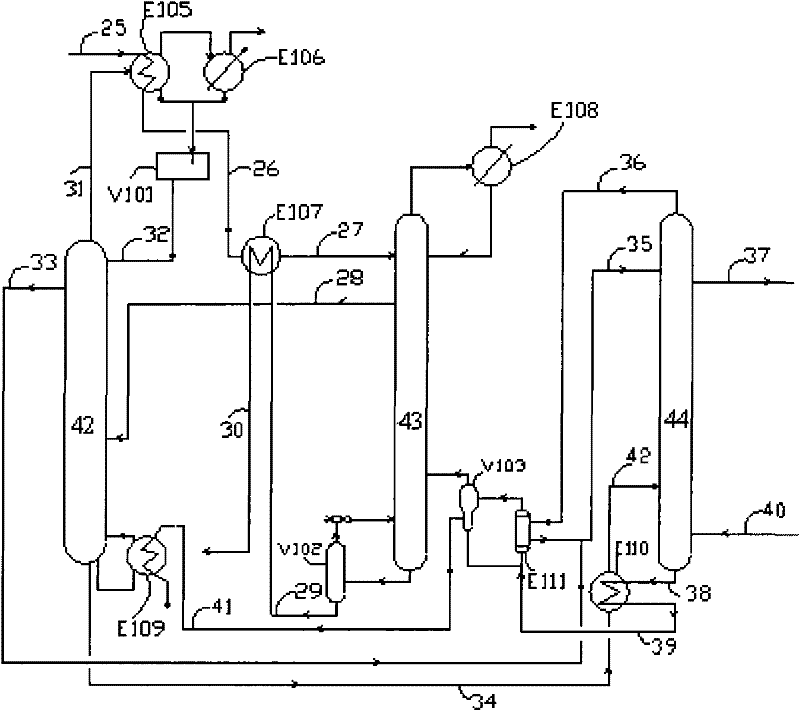

Method for preparing azeotropic ethanol through three-tower triple-effect differential pressure heat integration

ActiveCN102126920AImprove the heating effectRealize three-effect utilizationOrganic compound preparationHydroxy compound preparationMolecular sieveHigh energy

The invention relates to a method for preparing azeotropic ethanol through three-tower triple-effect differential pressure heat integration and mainly solves the problem of high energy consumption in the prior art. The method is realized in the following heating modes that: a first reboiler in the kettle of a rough distillation tower is heated by absolute ethanol gas 21 from a molecular sieve dehydration unit; a second reboiler in the kettle of the rough distillation tower is heated by a material fluid 7 from the top of a rectifying tower I; flash vapor 15 from a flash evaporation tank 13 andflash vapor 17 from a flash evaporation tank 14 enter the rough distillation tower to directly heat the rough distillation tower; a reboiler in the kettle of a rectifying tower is heated by a material fluid 10 from the top of a rectifying tower II; and a reboiler in the kettle of the rectifying tower II is heated by primary vapor 19 from the outside. By the technical scheme, the problem is preferably solved; and the method can be applied to an industrial production process for preparing the azeotropic ethanol through three-tower triple-effect differential pressure distillation.

Owner:CHINA PETROCHEMICAL CORP +1

Fruit tree yellowing disease preventing and treating method and special comprehensive preparation

ActiveCN103563692ACure jaundiceInhibit root rotPlant protectionFertilizer mixturesDiseaseGibberellin

The invention belongs to a fruit tree yellowing disease preventing and treating comprehensive preparation in fruit tree fertilizers. The preparation comprises (1) a foliage spray micro element fertilizer comprising the following components in percentage by weight: 18-22% of sequestration iron, 13-17% of magnesium, 13-17% of boron, 18-22% of zinc, 9-11% of silicon, 9-11% of selenium, 9-11% of kalium, 0.02% of endogenous hormone and 0.02% of gibberellin, total being 100%, and adding 500-700 times of water for foliage spray; (2) a root-irrigation conditioner comprising the following components in percentage by weight: 11-14% of sequestration iron, 45-55% of citric acid, 2-3% of soil conditioner, 30-40% of nitrogen, phosphorus and potash fertilizers which are same in amount, and trace of protease, total being 100%; and adding 40-60 times of water for the root-irrigation; and (3) a stem-coating nutritional agent comprising the following components in percentage by weight: 18-22% of sequestration iron, 0.1-0.3% of humic acid, 0.1-0.3% of fulvic acid, trace of aspartic acid and threonine and the balance of soft water penetrating agent, total being 100%; and adding 10-20 times of water for stem-coating. After kiwi fruit flowers, before a fruit expanding period (the first-ten and middle ten days of June), the foliage spray micro element fertilizer (the sequestration iron and multiple micro element nutrient solution) can be sprayed on leaves, meanwhile the conditioner (multiple nutrients and enzyme compounds and endogenous root-generating healing agents) is performed. A leaf fast green comprehensive preventing and treating preparation is coated on stems for the serious fruits. Triple effect is united as one, and the purpose of curing the yellowing disease is achieved.

Owner:吴新忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com