Wastewater evaporation concentration process and device system

An evaporative concentration and evaporation system technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, inorganic chemistry, etc. It can solve the problems that affect the operation and service life of equipment, difficult to clean, and the quality of recycled water is not as good as crystal seeds. Laws and other issues to achieve the effect of ensuring long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

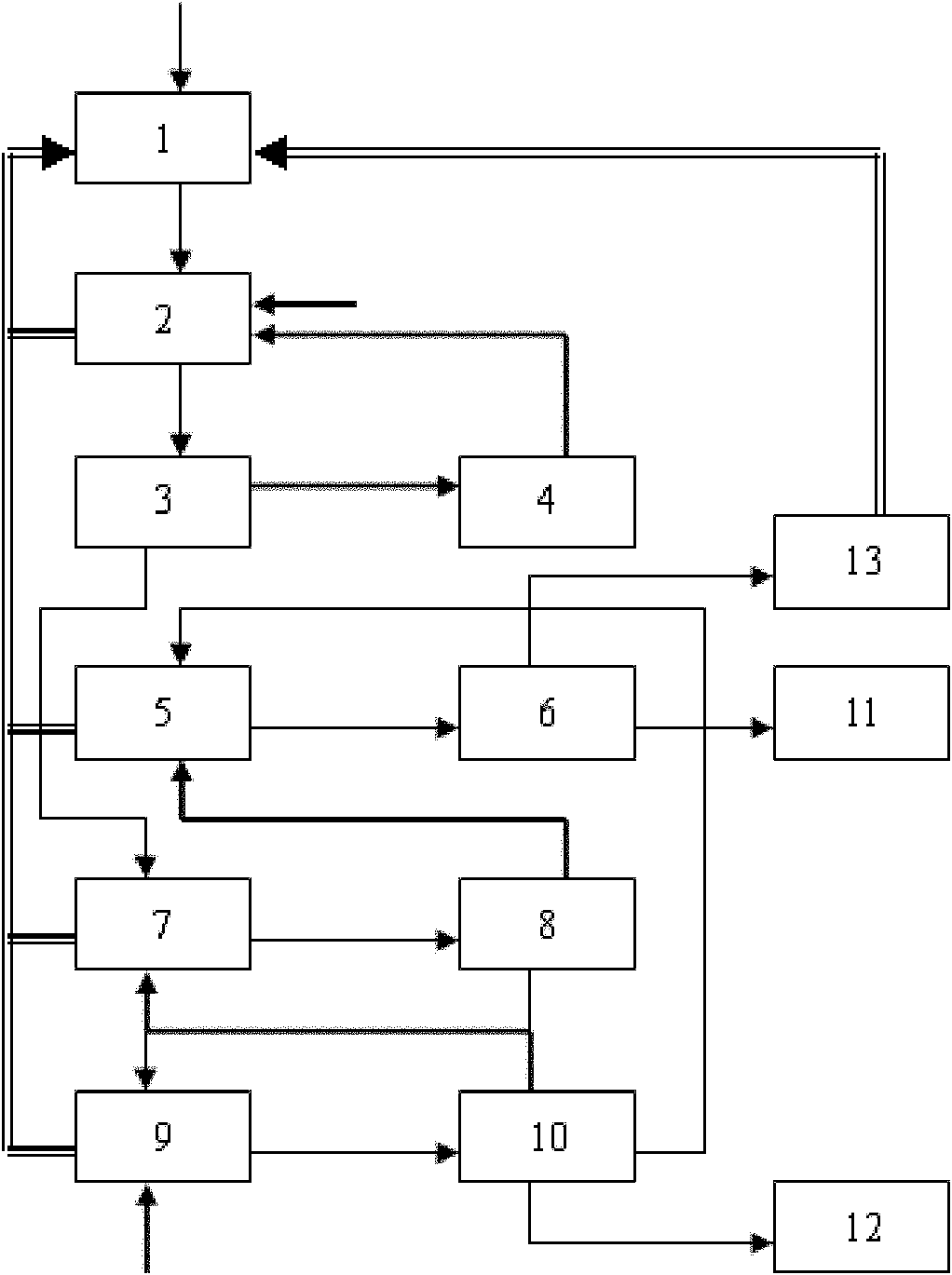

[0087] Embodiment 1 of the present invention: wastewater evaporation concentration process (see figure 1 ): The waste water to be treated is softened and stored in the adjustment tank, pumped into the buffer tank, and the scale inhibitor and defoamer are added to the buffer tank. The amount of scale inhibitor added is 25g / t, and the amount of defoamer added is 3g / t; waste water comes out of the buffer tank, and is pumped into the preheater 1 (preferably plate heat exchanger) of the MVR system by the feed pump, and exchanges heat with the steam condensate from the evaporator 2 and the forced circulation evaporation crystallization system; After the waste water is preheated, it enters the evaporator 2, and first injects fresh steam to pre-evaporate the waste water for about 100 to 200 minutes, reaching an evaporation temperature of 90°C (reducing the evaporation temperature can greatly inhibit the possibility of fouling, and reduce the evaporator due to fouling. Possibility of sca...

Embodiment 2

[0104] Embodiment 2 of the present invention: wastewater evaporation concentration process (see figure 1 ): After the wastewater to be treated is softened, first add scale inhibitor at 25g / t, add defoamer at 4g / t, put it into the preheater 1 of the MVR system for preheating, then enter the evaporator 2, inject fresh steam to The waste water is pre-evaporated, and the concentrated liquid and secondary steam produced enter the separator 3 for vapor-liquid separation, and the separated secondary steam is compressed by the steam compressor 4 and sent to the evaporator 2 for recycling; the separated concentrated liquid enters the third The high-efficiency forced circulation evaporation crystallization system conducts evaporation and crystallization in the mixed-flow evaporation method, and the concentrated solution passes through the second effect, first effect, and third-effect forced circulation evaporation crystallization system in turn, and the crystallized concentrated solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com