Patents

Literature

86results about How to "Put an end to the phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

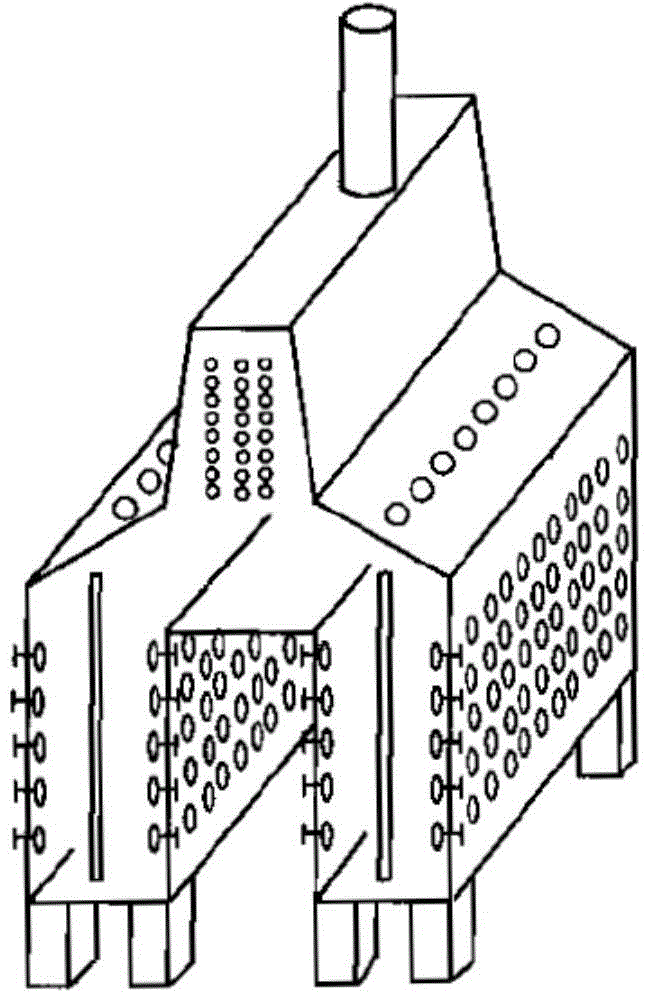

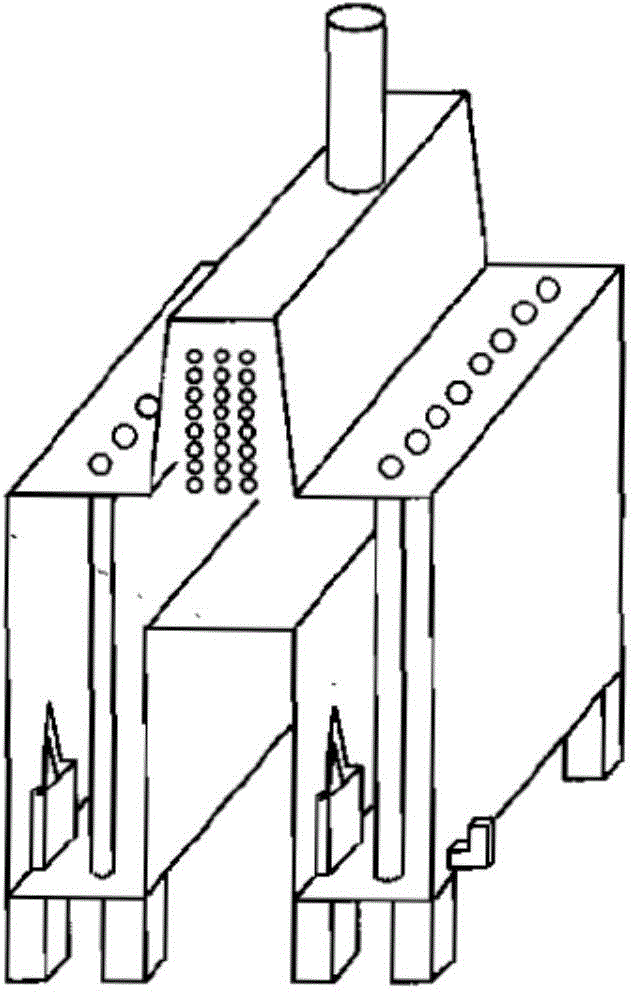

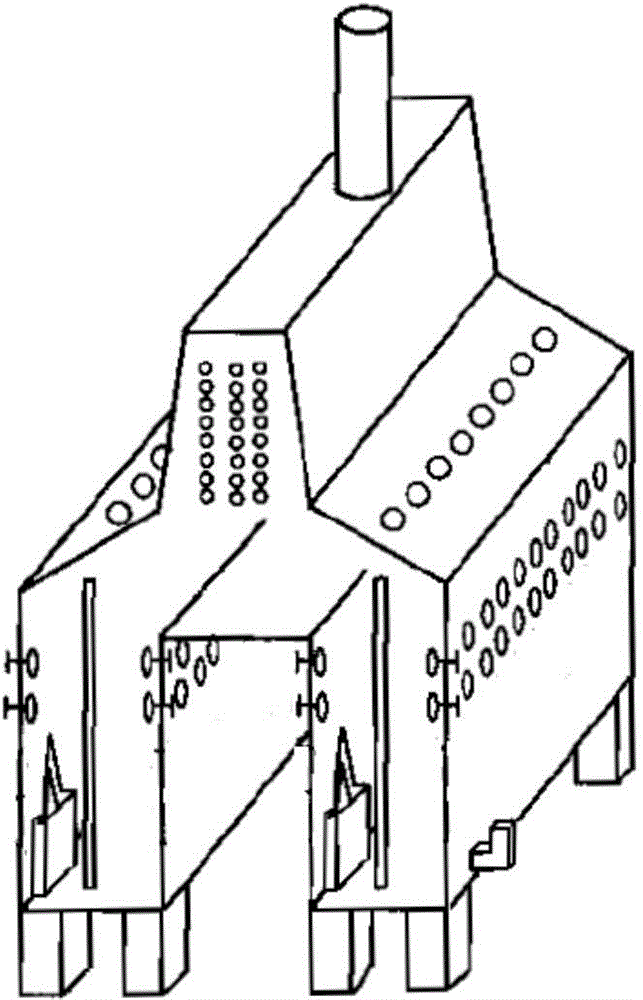

Wastewater evaporation concentration process and device system

InactiveCN102070272AAvoid easy cloggingGuaranteed uptimeMultistage water/sewage treatmentAlkali metal chloridesProcess systemsSludge

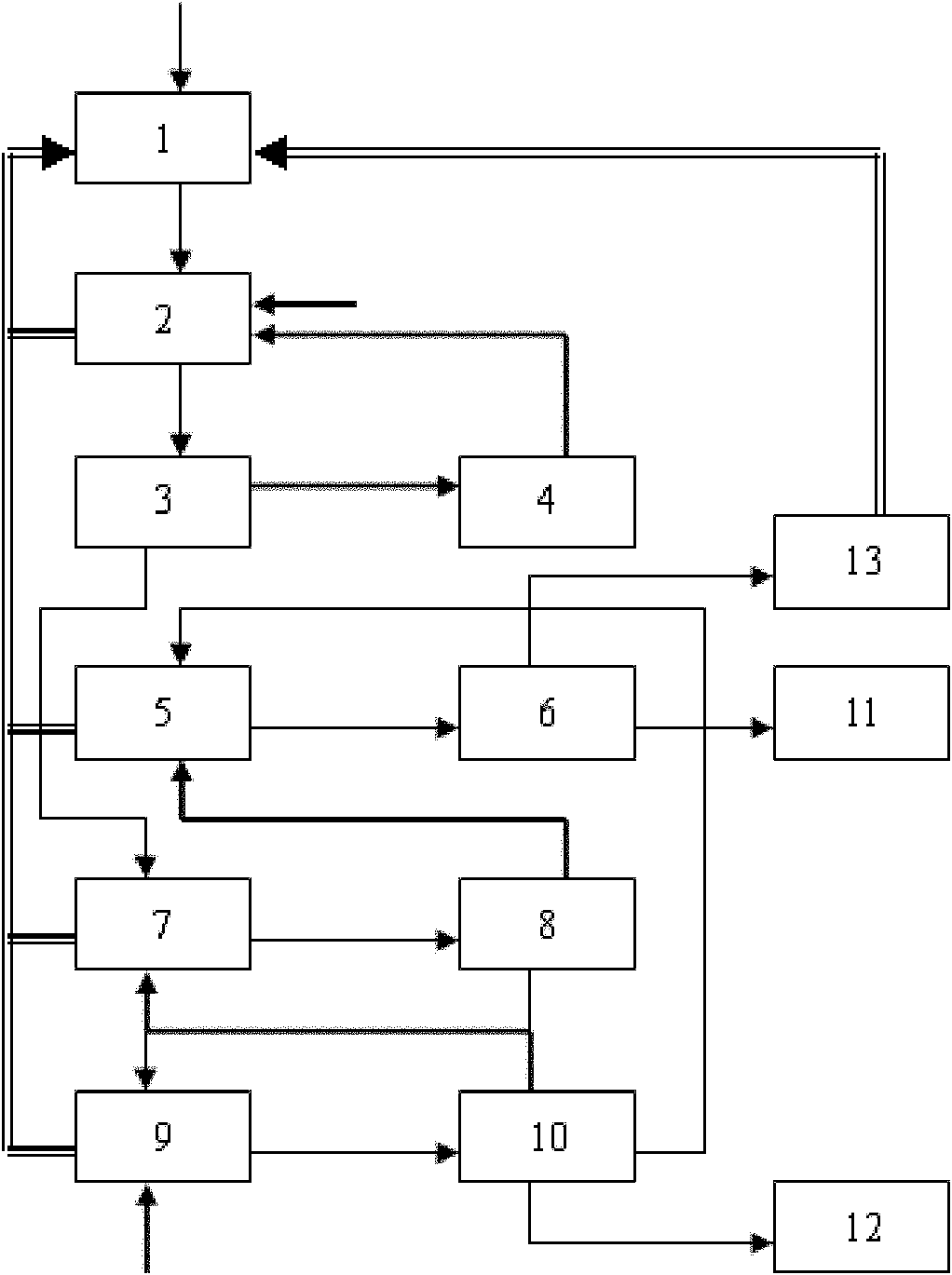

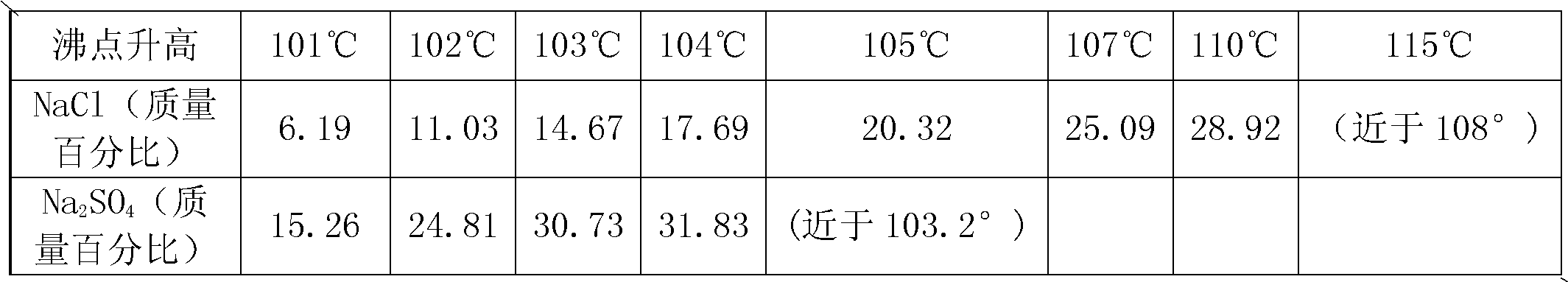

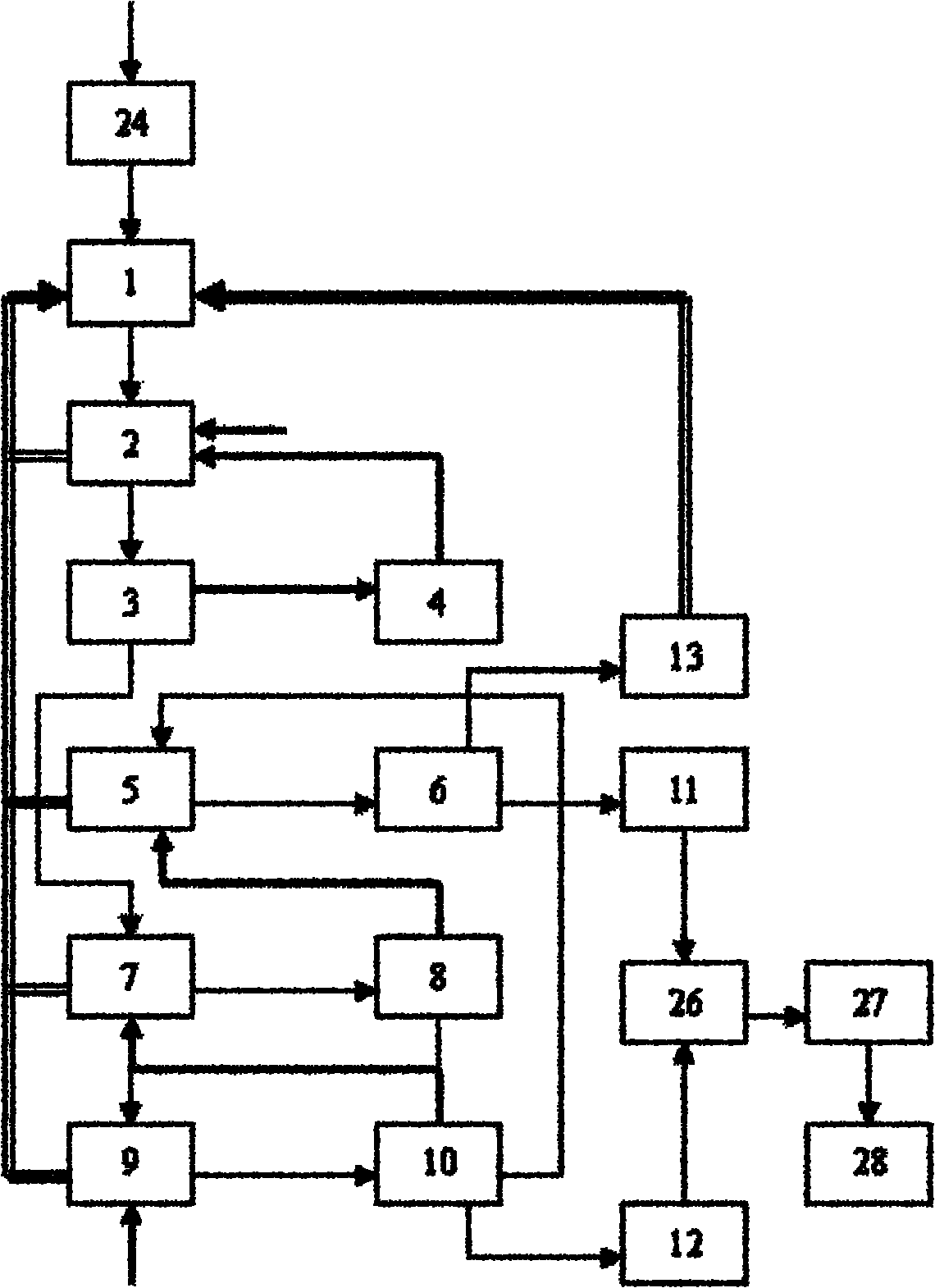

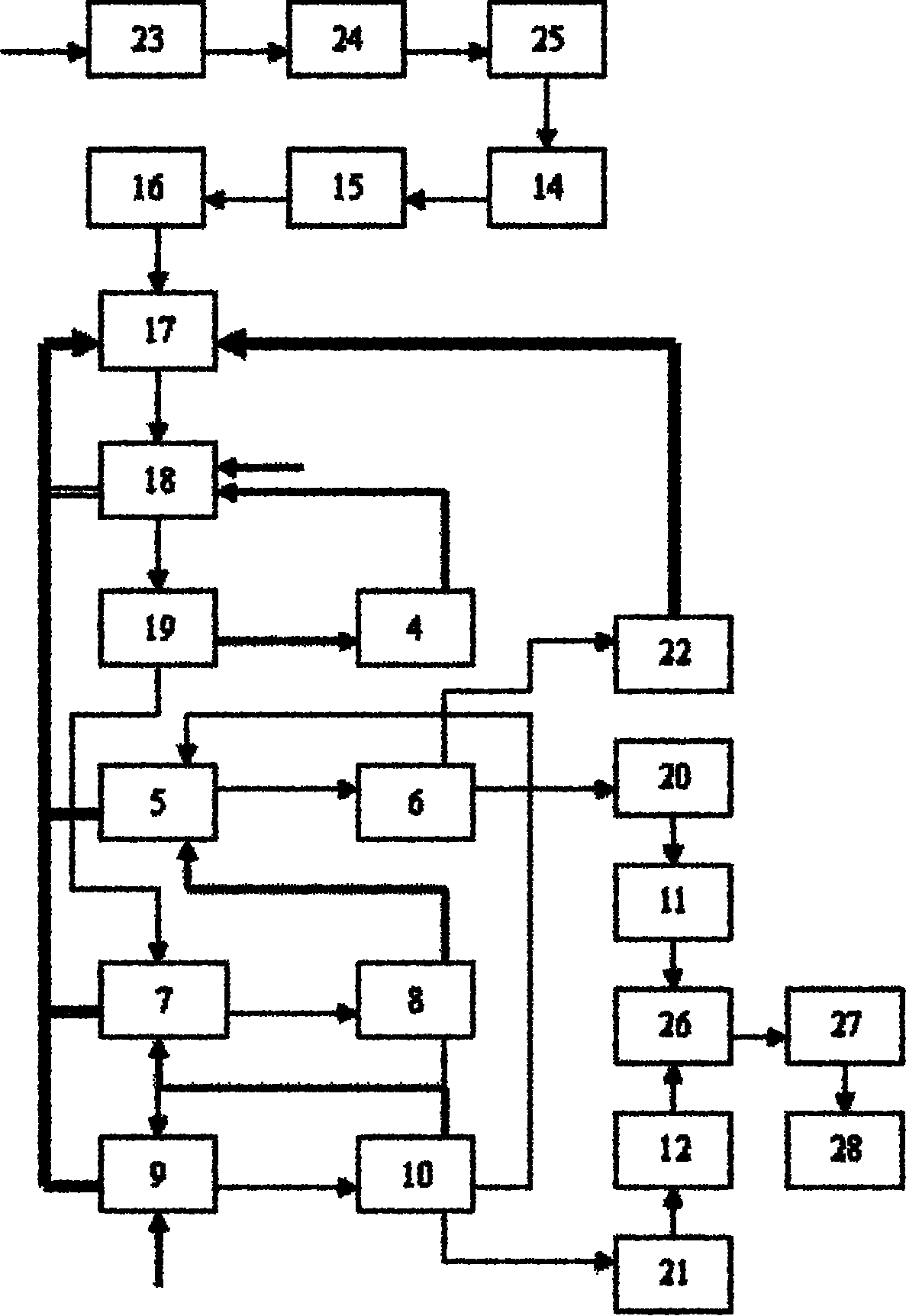

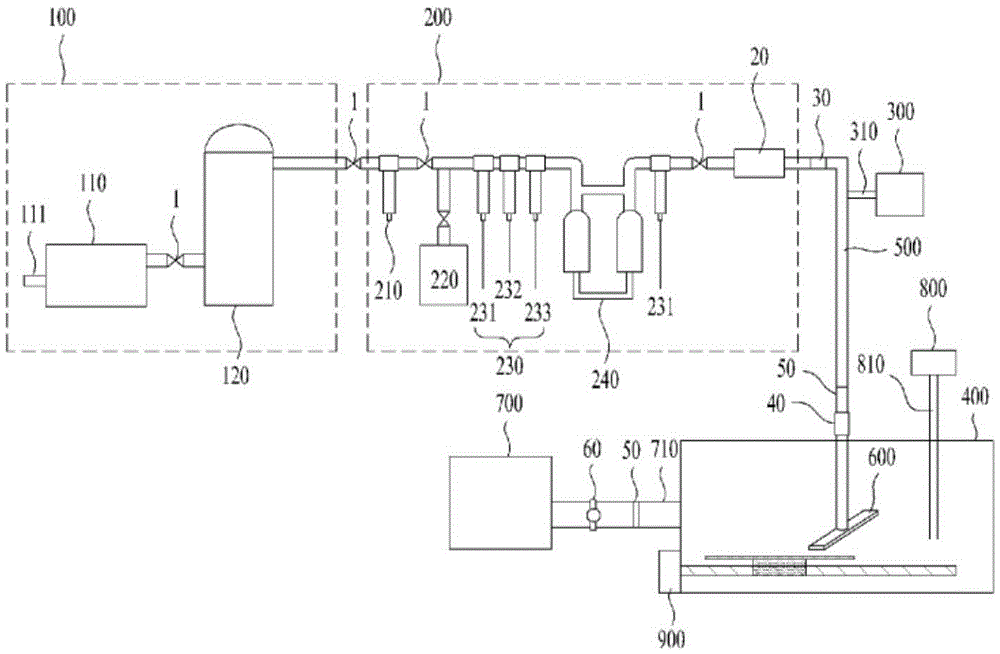

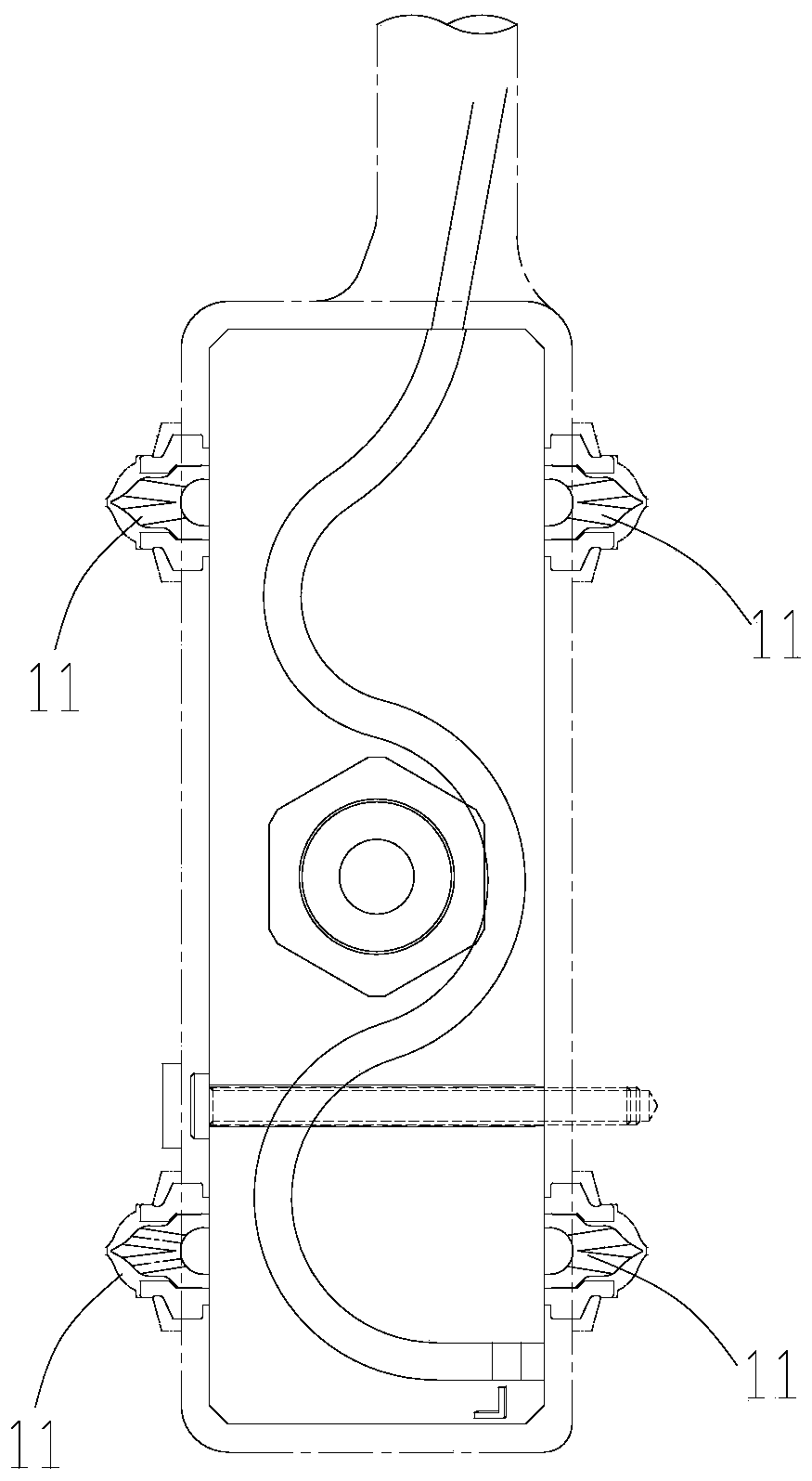

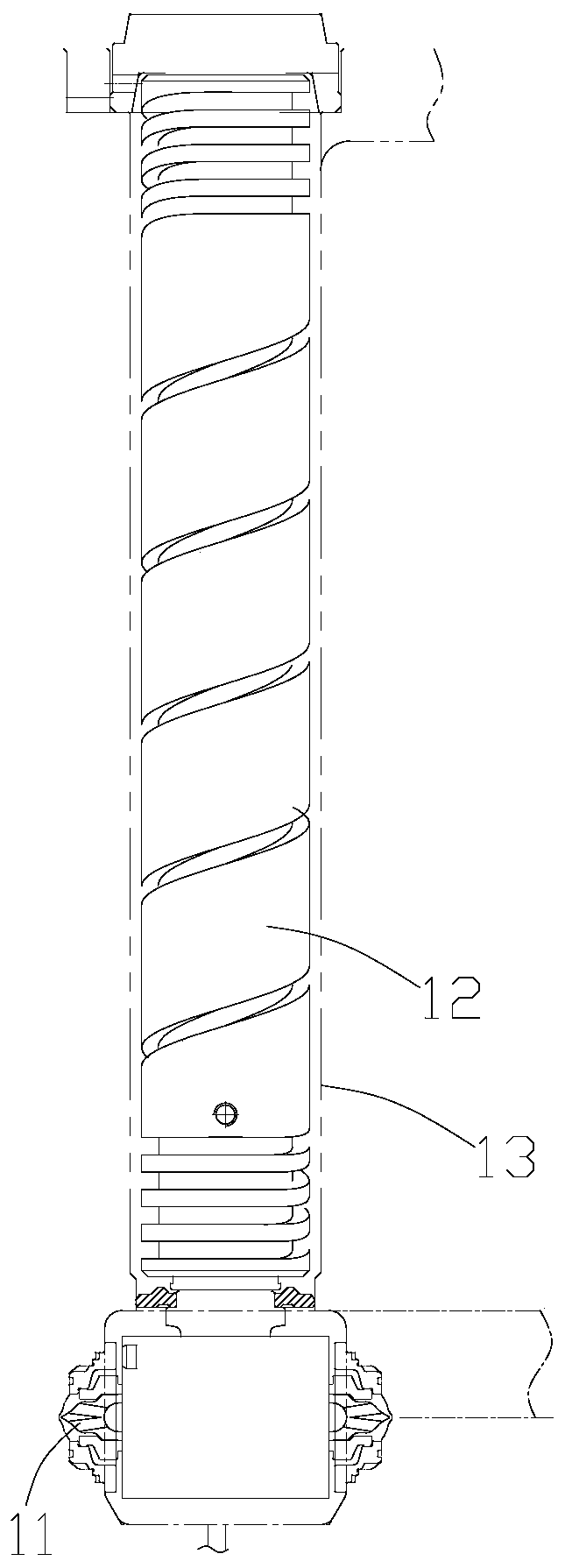

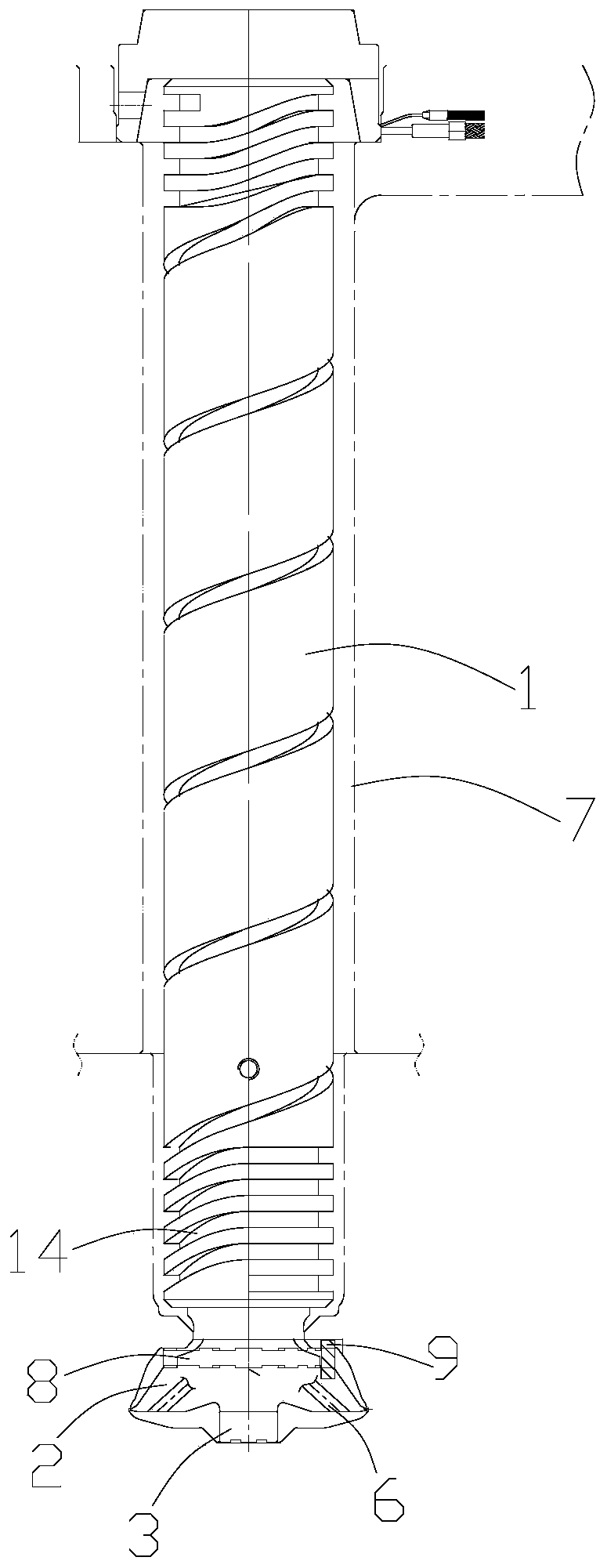

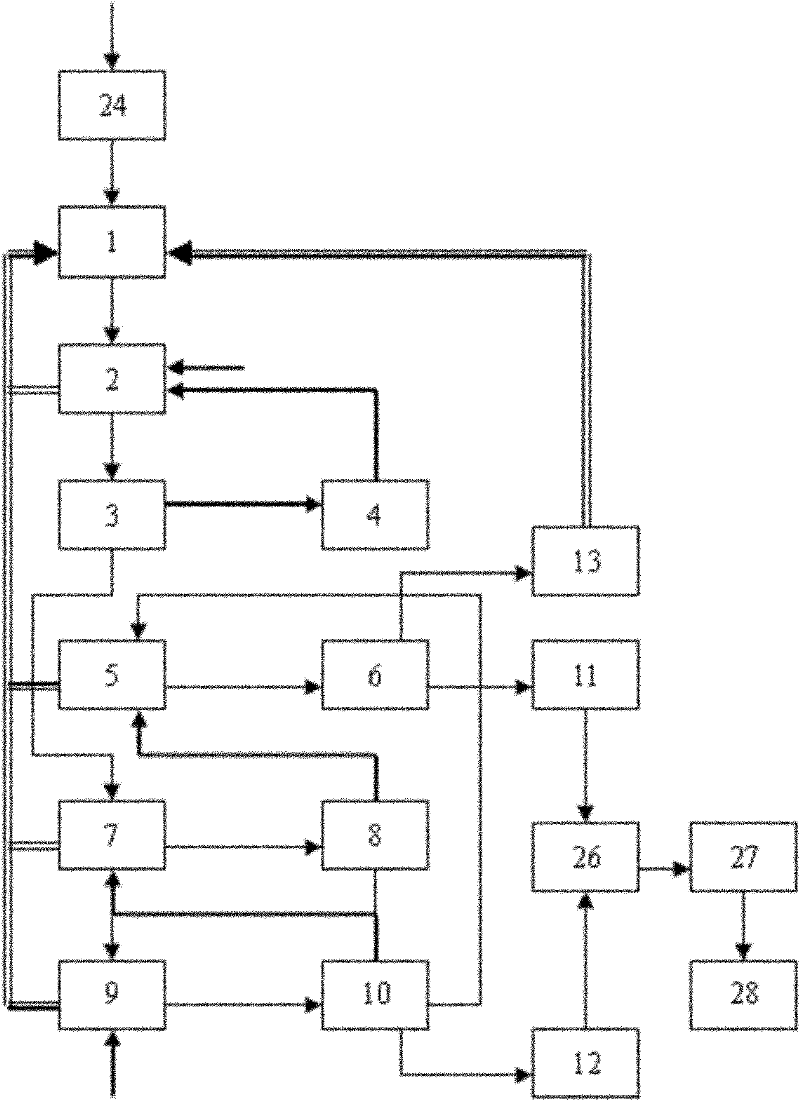

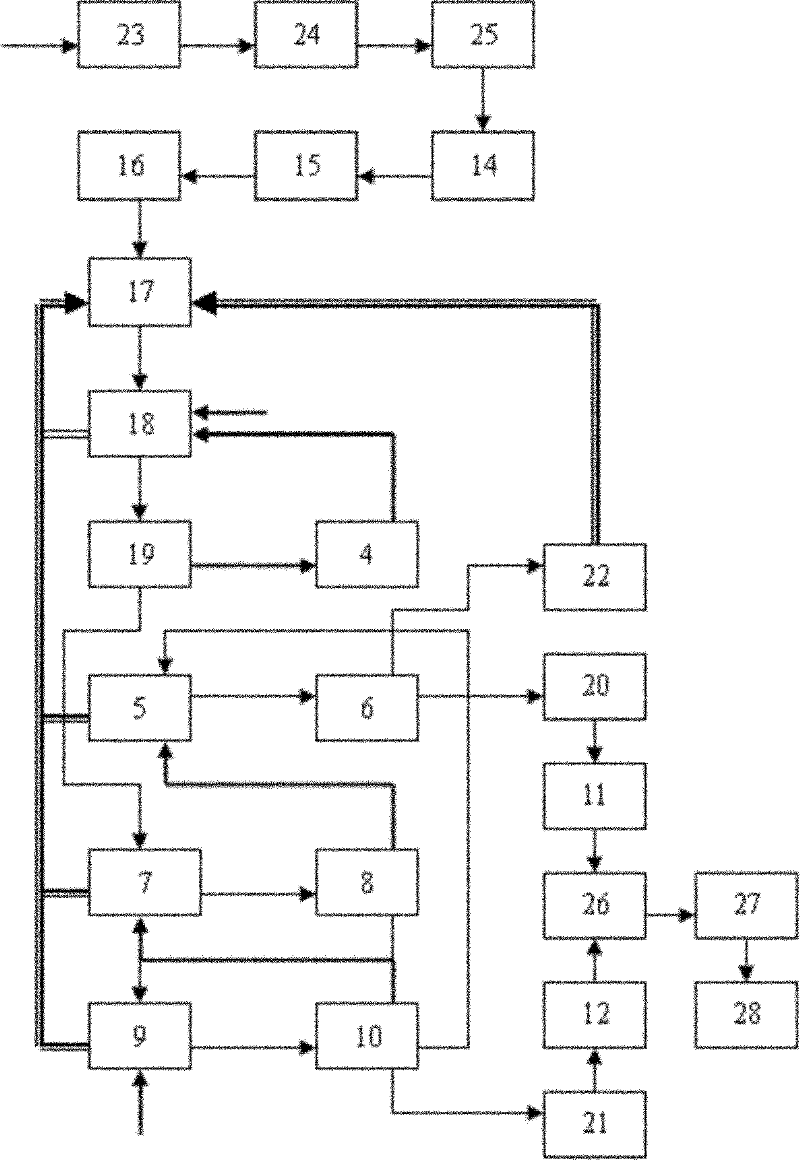

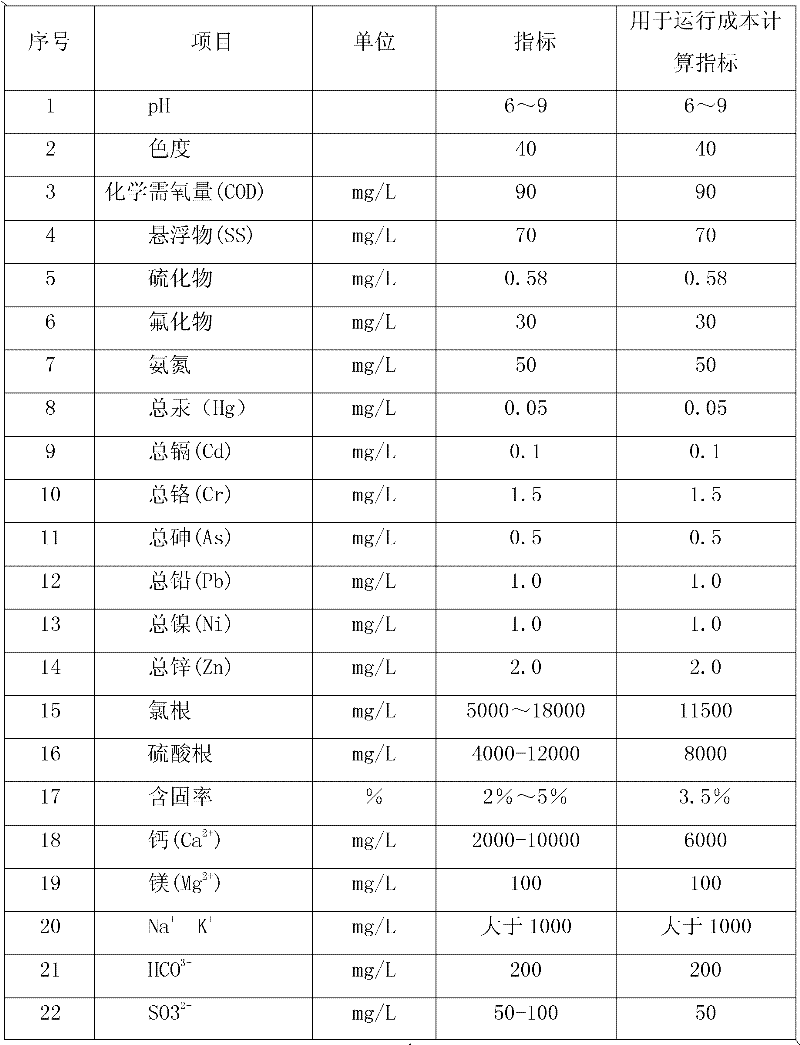

The invention discloses a wastewater evaporation concentration process and a wastewater evaporation concentration device system. The process comprises the following steps of: delivering softened wastewater to be treated to a mechanical vapor recompression (MVR) system to perform evaporation and concentration, compressing the generated secondary steam and then delivering the compressed steam to an evaporator to recycle, delivering the concentrate to a triple-effect mixed flow forced circulating evaporation crystallization system to perform evaporation and crystallization, performing solid-liquid centrifugal separation on the crystallized concentrate and crystal grains, returning the separated mother solution to a stock solution tank or continuously performing evaporation and crystallization, and reclaiming the separated crystal, wherein the secondary steam generated by evaporation and crystallization is recycled for the evaporation crystallization system. After the wastewater is evaporated and concentrated by adopting the process of mechanical vapor recompression circulating evaporation and triple-effect mixed flow forced circulating evaporation crystallization, the wastewater does not need to be discharged to the ground water area, and the wastewater is discharged in a form of steam or closed and embedded in a form of sludge or the like, so the purpose of zero discharge of the wastewater can be fulfilled; and the process system has high heat efficiency, low energy consumption, energy conservation, great reduction in running cost, low temperature difference, low corrosion, difficult scale formation and long equipment service life.

Owner:华电水务工程有限公司 +1

Wastewater evaporating process and device system

ActiveCN102060408AAvoid shockAvoid easy cloggingMultistage water/sewage treatmentProcess systemsTriple effect

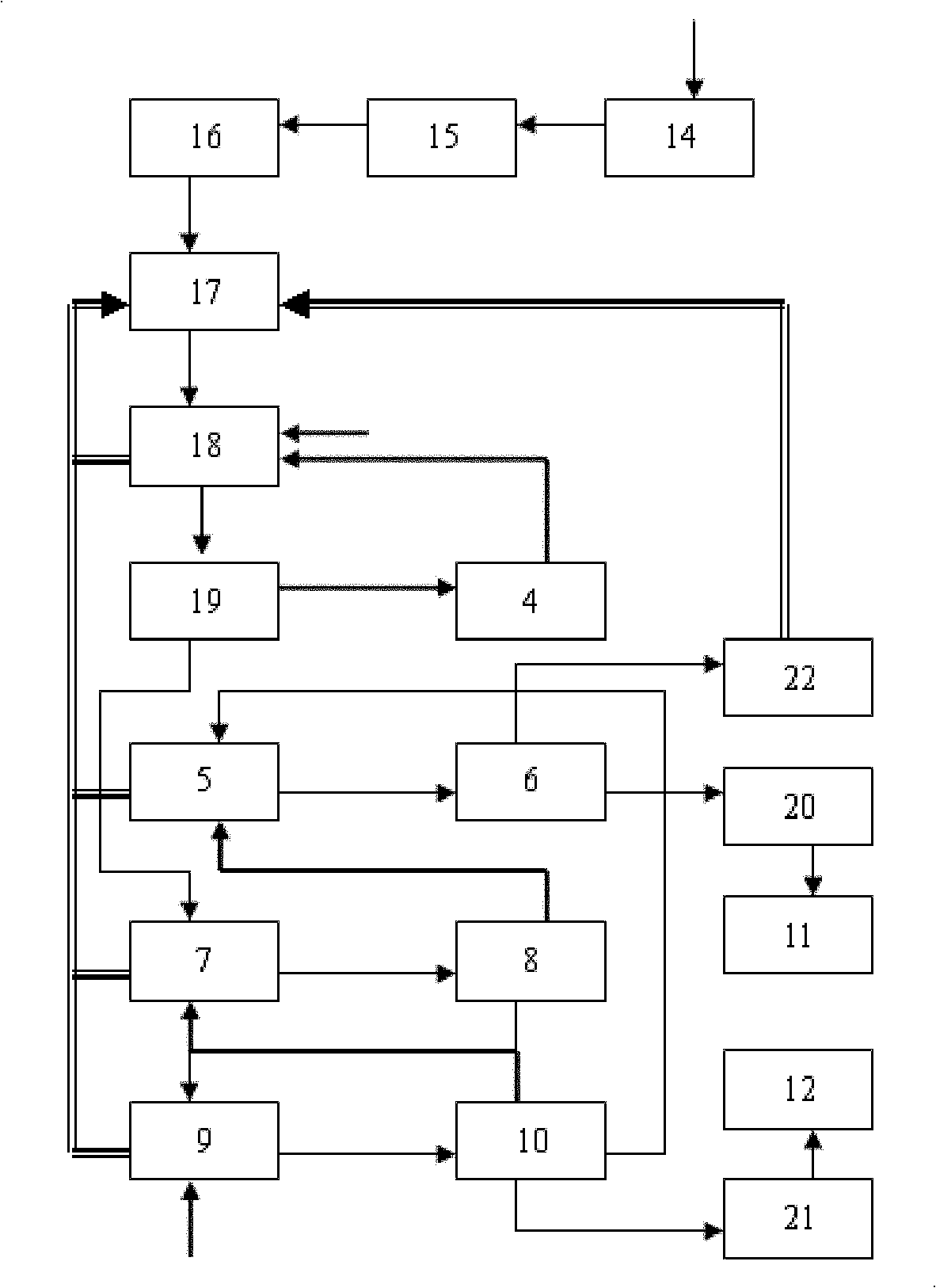

The invention discloses a wastewater evaporating process and device system. The wastewater evaporating process comprises the following steps: the wastewater to be treated firstly enters a pretreatment softening system for softening treatment and secondly enters a mechanical vapor recompression (MVR) system for evaporation concentration; the generated secondary steam is compressed and enters an evaporator for recycling; the concentrated solution enters a triple effect flow-mixing forced circulation evaporation and crystallization system for evaporation and crystallization; the generated secondary steam is reused by the evaporation and crystallization system; the concentrated solution and crystalline grains obtained through crystallization are subject to solid-liquid centrifugal separation; the separated mother solution is sent back to a raw liquor tank or evaporated continuously for crystallization; and the separated crystals enter a centrifugal drying and packaging system for weighting and packaging. After the process disclosed by the invention is adopted to soften, evaporate and crystallize wastewater and dry and package the obtained crystals, wastewater is not discharged to the water bodies of the surface of earth and the aim of zero wastewater discharge can be realized; the process system is low-carbon and environmentally friendly; the material can be recycled, the thermal efficiency is high, the energy consumption is low, the energy can be saved, the operating cost can be greatly reduced, the range of temperature is small, the corrosion is low and the service life of the equipment is long, and the scaling has small possibility of occurrence.

Owner:华电水务工程有限公司 +1

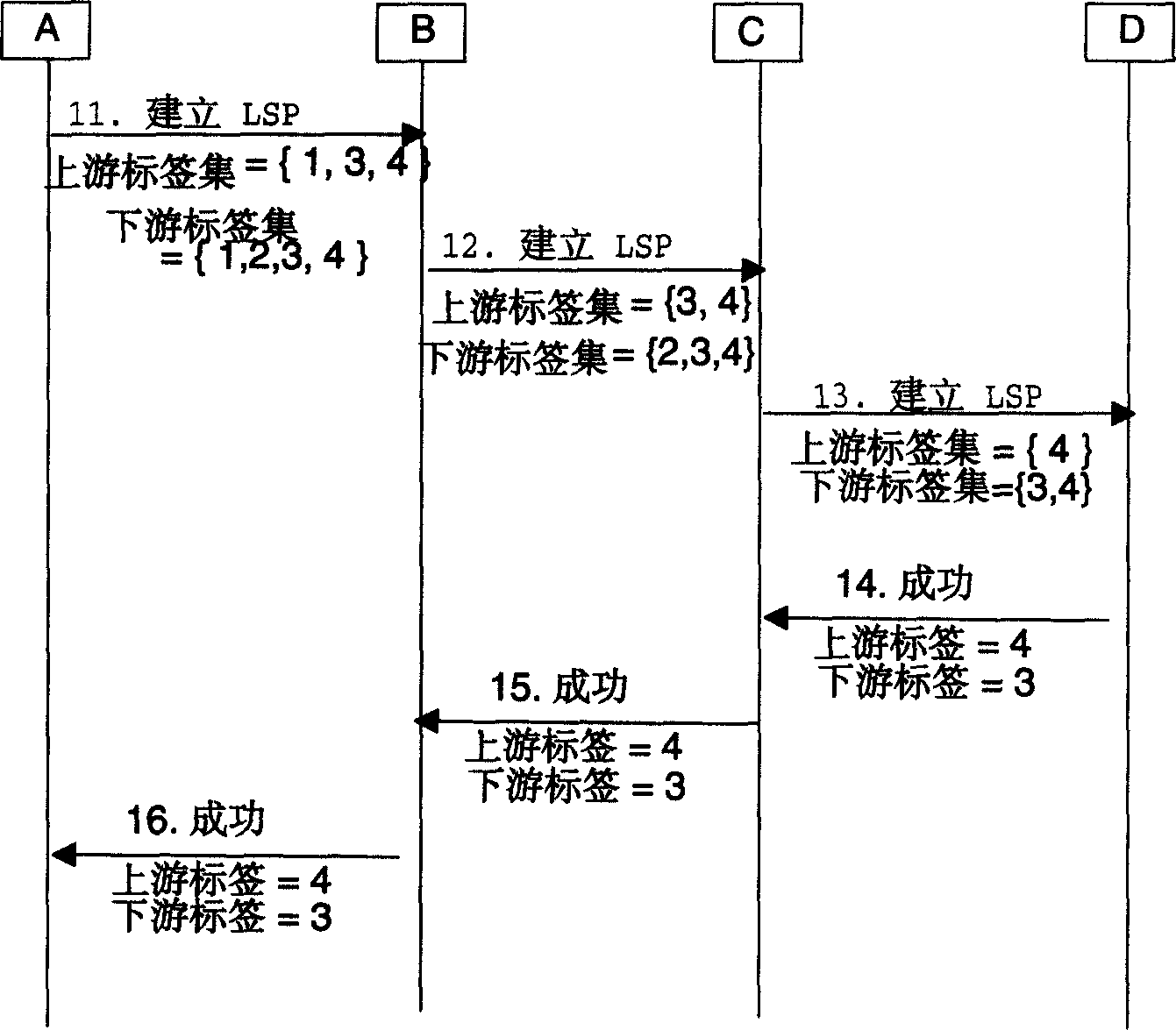

Method for constructing bidirectional lable swap path in optical network

InactiveCN1510874ASpeed up buildPut an end to the phenomenonMultiplex system selection arrangementsData switching by path configurationResource informationLabel switching

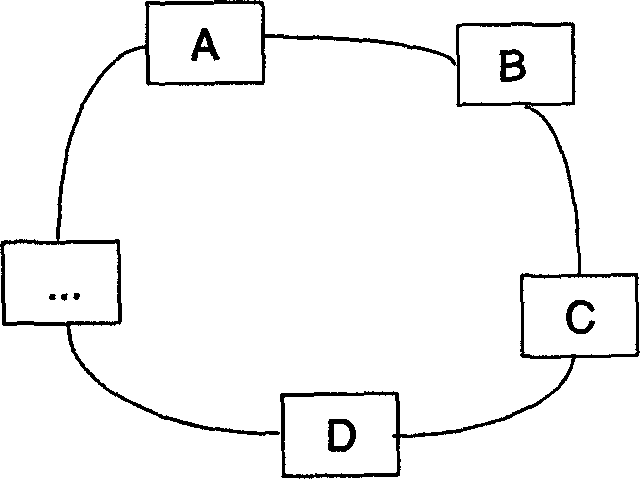

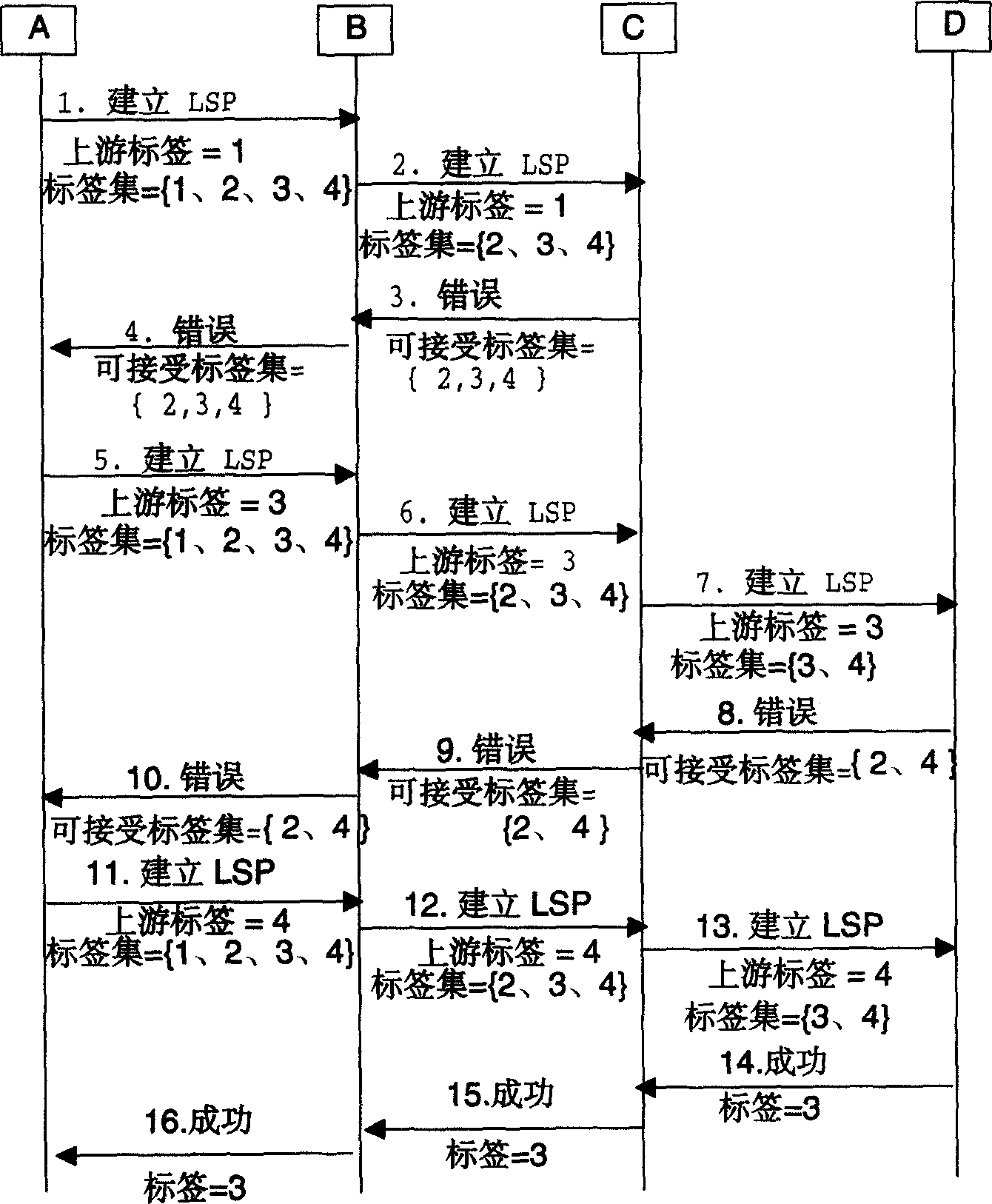

A method for building up bidirection label switched path, this method starts from initial node of bidirection label switched path (LSP), sends the bidirection LSP establishment request to descendant node node-by-node and obtains the tally set of the up and down stream of present node according to available resource information of present chain section and the up and down stream tally set provided by up stream node, until final node; if the establishment request of bidirection LSP is sent to final node and the received available up and down stream tally set are not all empty, the final node selects available up and down stream label from received available tally set, then start from next node of bidirection LSP, send bidirection LSP establishment response and the up and down stream label selected by down stream node to previous node node-by-node, until initial node; this method can complete the establishment of bidirection LSP within a signalling turn back..

Owner:HUAWEI TECH CO LTD

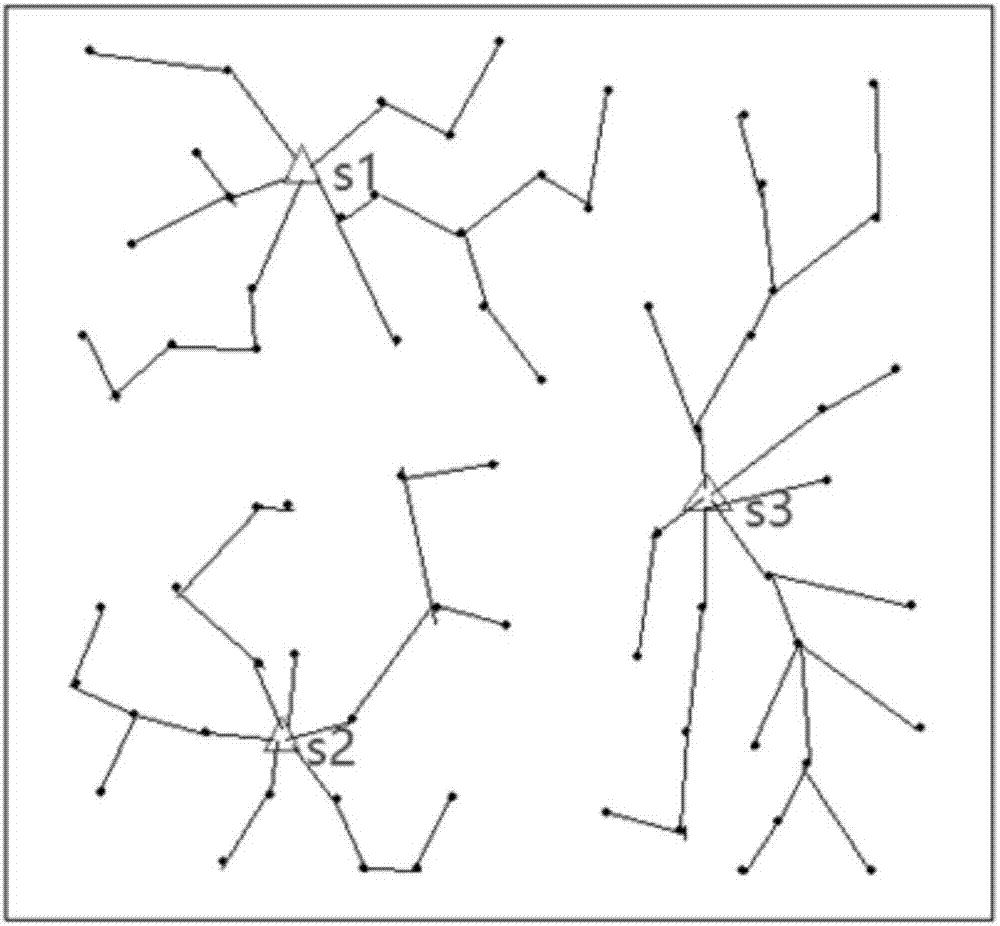

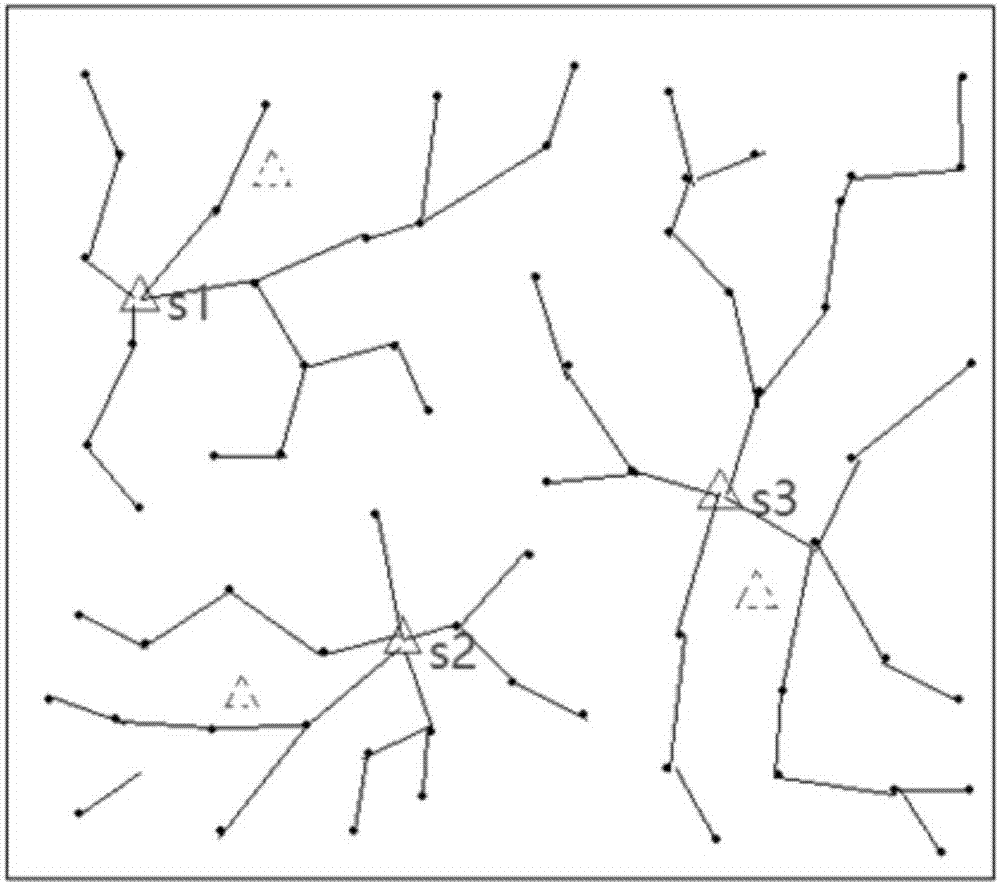

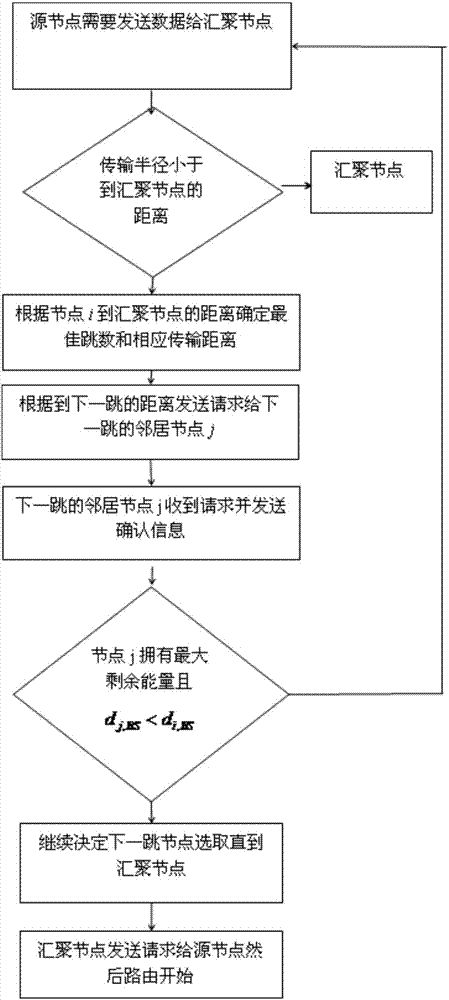

Routing protocol with high-efficient energy based on multiple mobile aggregation nodes

ActiveCN107295569AAdjust and balance energy expenditureAdjust and balance consumptionPower managementNetwork traffic/resource managementEnergy basedWireless sensor networking

The invention provides a routing protocol with high-efficient energy based on multiple mobile aggregation nodes. A plurality of mobile aggregation nodes are deployed in a perception area of a wireless sensor network, and each mobile aggregation node is a cluster head and is used to form a plurality of clusters. Each mobile aggregation node can carry out autonomous movement and can communicate with each other. A current sensor node firstly determines a distance between the node itself and the mobile aggregation node, and if the distance is less than a transmission radius, the current sensor node directly communicates with the mobile aggregation node. Otherwise, a maximum optimal hop count of the current sensor node to the mobile aggregation node and a maximum distance between the current sensor node and a next hop of a sensor node are calculated so as to find an optimum next hop of the sensor node. In the invention, defects of an energy cavity phenomenon and uneven distribution of cluster heads are avoided, a network flow load is mitigated and a life cycle of a wireless sensor network is greatly prolonged.

Owner:YANGZHOU UNIV

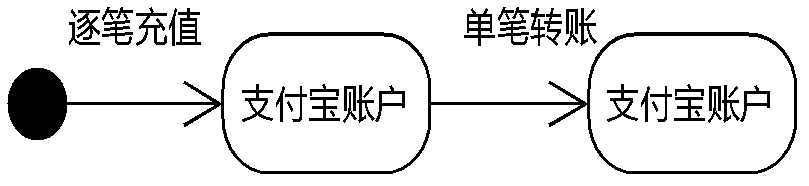

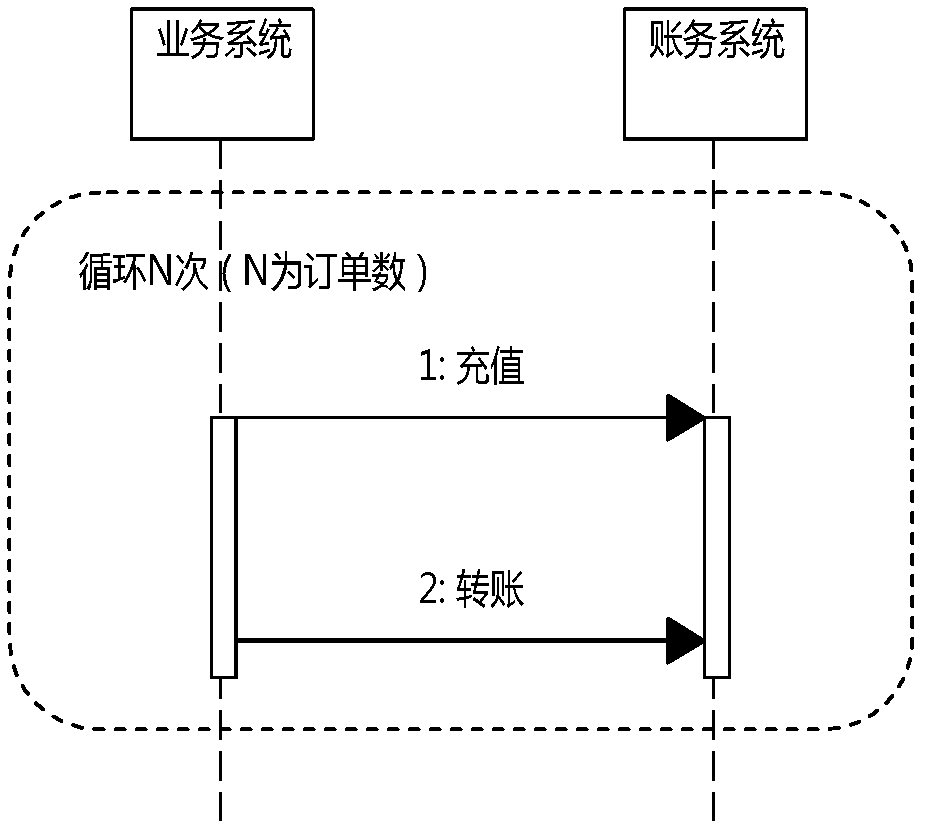

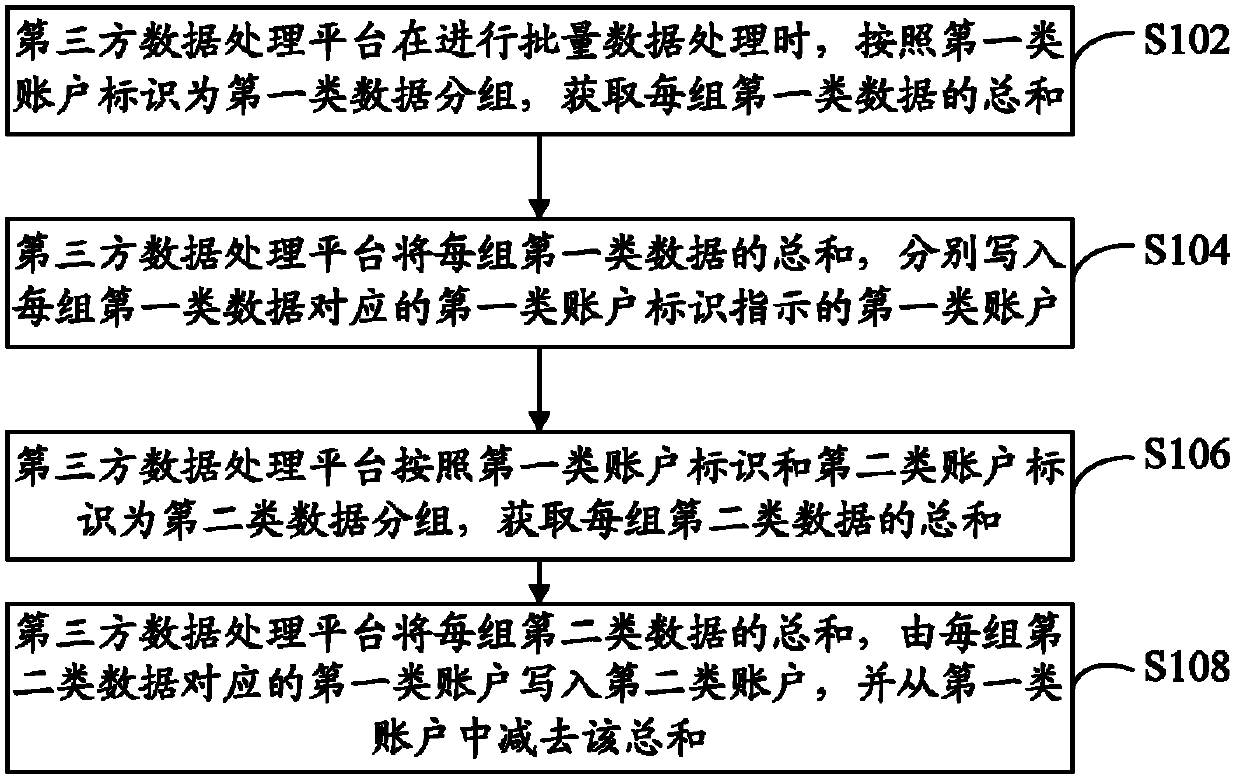

Data processing method and device

InactiveCN103325032APut an end to the phenomenonImprove throughputPayments involving neutral partyData miningThroughput

The invention provides a data processing method and device. The data processing method includes the steps that when a third data processing platform carries out batch data processing, a first kind of data are grouped according to a first kind of account identifications, and the sum of the first kind of data of each set is obtained; the sum of the first kind of data of each set is written into a first kind of accounts corresponding to the first kind of data of each set and indicated by a first kind of account identifications; the third data processing platform groups a second kind of data according to the first kind of account identifications and a second kind of account identifications, and the sum of the second kind of data of each set is obtained; the sum of the second kind of data of each set is written into a second kind of accounts through the first kind of accounts corresponding to the second kind of data of each set, and the sums are subtracted from the first kind of accounts. According to the data processing method and device, system efficiency is improved, and the system throughput rate is improved.

Owner:ALIBABA GRP HLDG LTD

Process for treating and reclaiming polymer-contained sewage

InactiveCN1381410AViscosity unchangedPut an end to the phenomenonMultistage water/sewage treatmentDisinfectantSewage

A process for deeply treating and reclaiming polymer-contained sewage incldues such steps as loading the said sewage in regulation pool, adding disinfectant; adsorbing 20-30% of suspended substance and bacteria, stage-1 membrane filtering to remove over 99% of suspended substance and bacteria, and filtrate out 80% of Ca2+ and Mg+2 ions, stage-2 membrane filtering to filtrate out 90% of Ca2+, Mg2+, K+ and Na+ ions, storing cleaned water 80%-85% in water tank, and using 15%-20% of concentrated liquid back for preparing polymer solution. Its advantages are high recovery rate of wate (72-81%), and no drainage.

Owner:大庆东昊投资有限公司

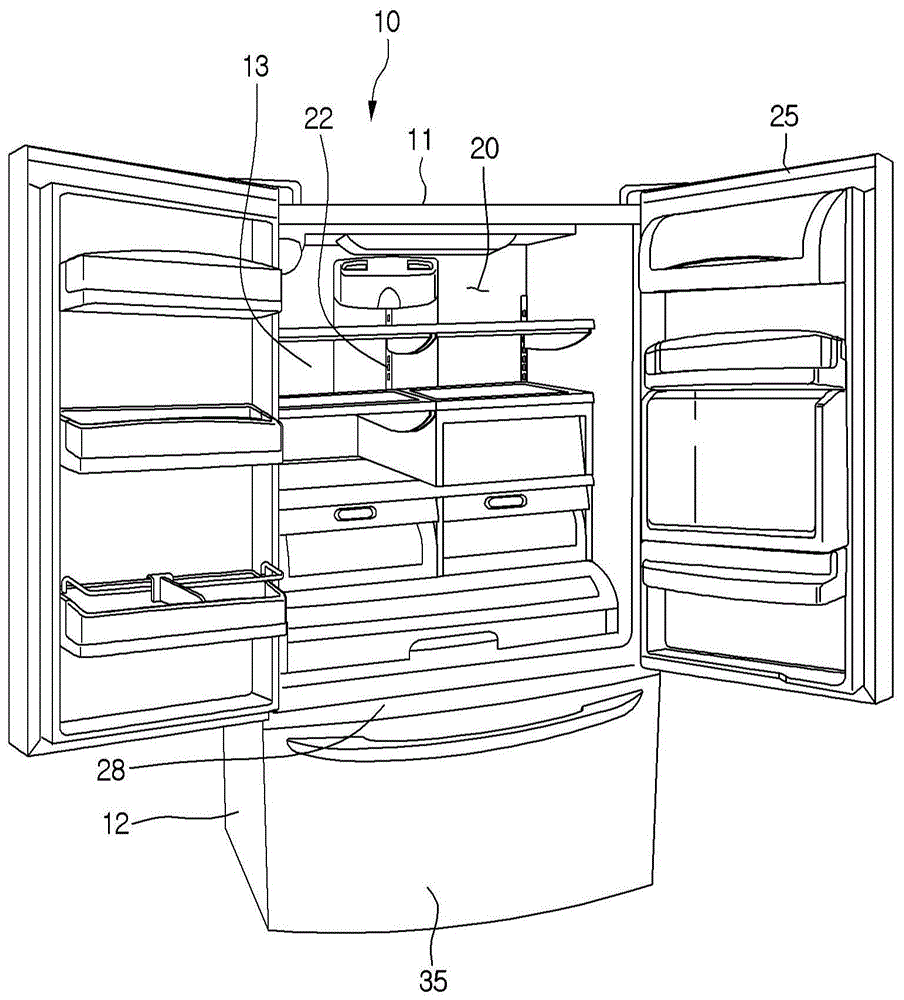

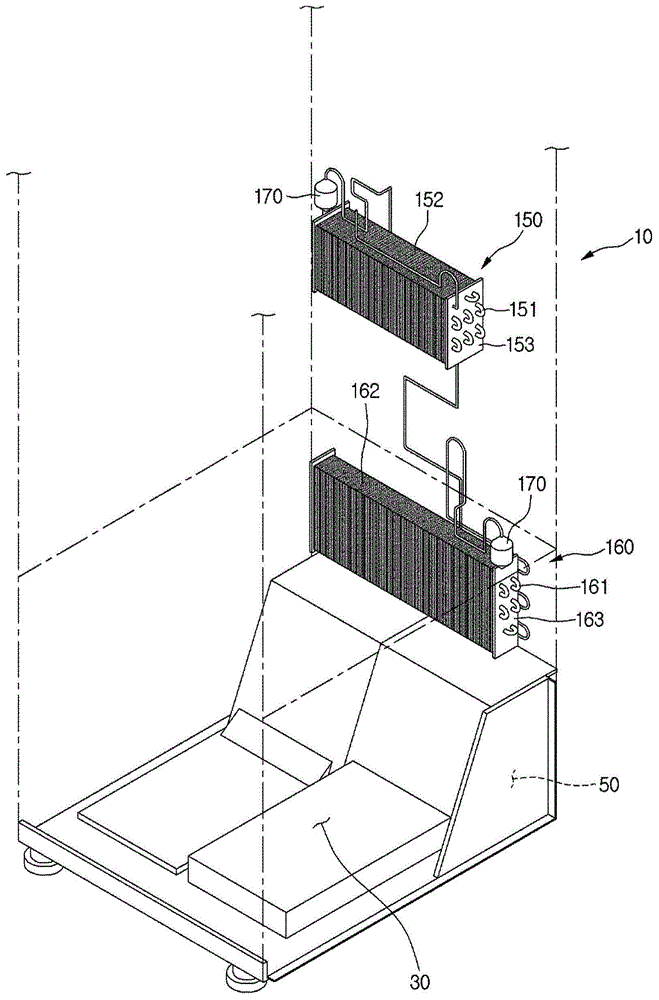

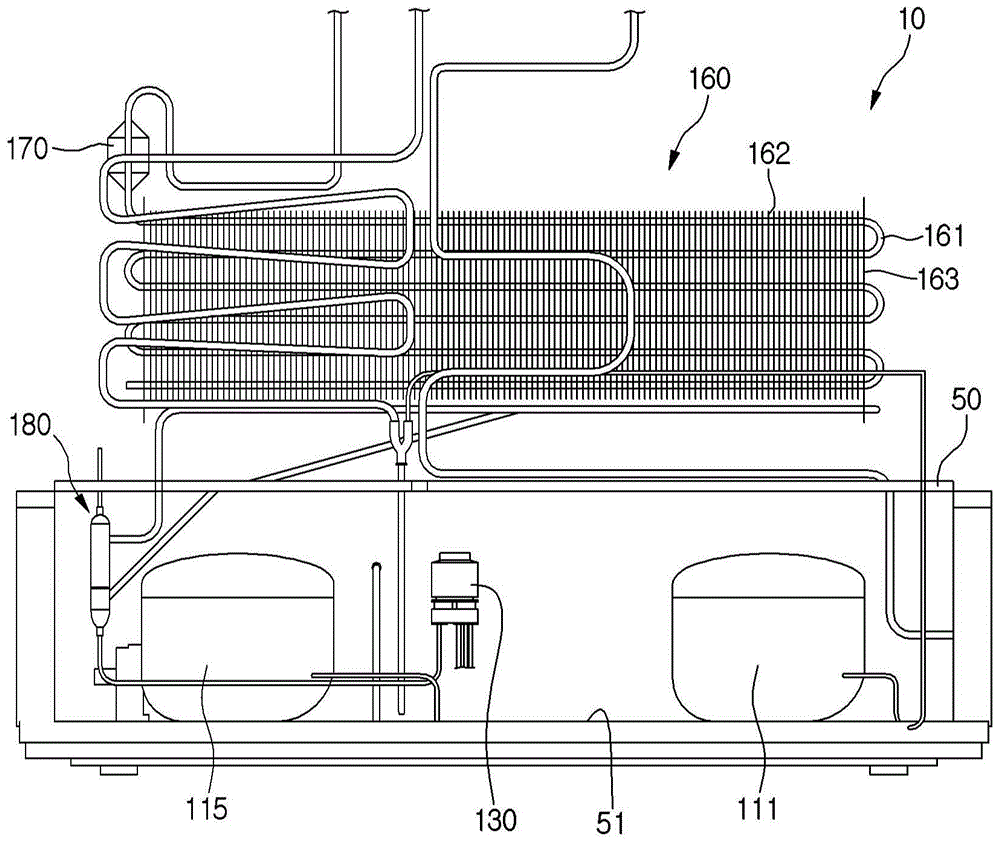

Refrigerator and control method

ActiveCN104613696AEffective simultaneous coolingMinimize temperature deviationCompression machines with non-reversible cycleDomestic refrigeratorsEngineeringRefrigerant

Provided is a refrigerator (10) and a method for controlling the same. The refrigerator (10) includes a compressor (111, 115) compressing a refrigerant, a condenser (120) condensing the refrigerant compressed in the compressor (111, 115), a refrigerant tube (100) guiding the refrigerant condensed in the condenser (120), a flow adjustment part (130) coupled to the refrigerant tube (100) to divide the refrigerant into a plurality of refrigerant passages (101, 103, 105), a plurality of expansion devices (141, 143, 145) respectivley disposed in the plurality of refrigerant passages (101, 103, 105) to decompress the refrigerant condensed in the condenser (120), a plurality of evaporators (150, 160) evaporating the refrigerant decompressed in the plurality of expansion devices (141, 143, 145), and a supercooling heat exchanger (500) disposed at an outlet-side of the condenser (120) to supercool the refrigerant. The refrigerant supercooled in the supercooling heat exchanger (500) is introduced into the flow adjustment part (130).

Owner:LG ELECTRONICS INC

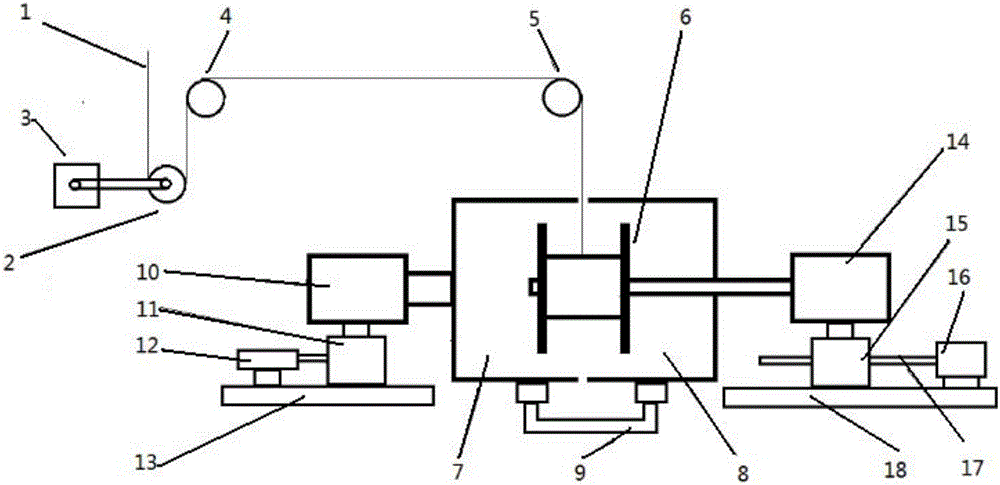

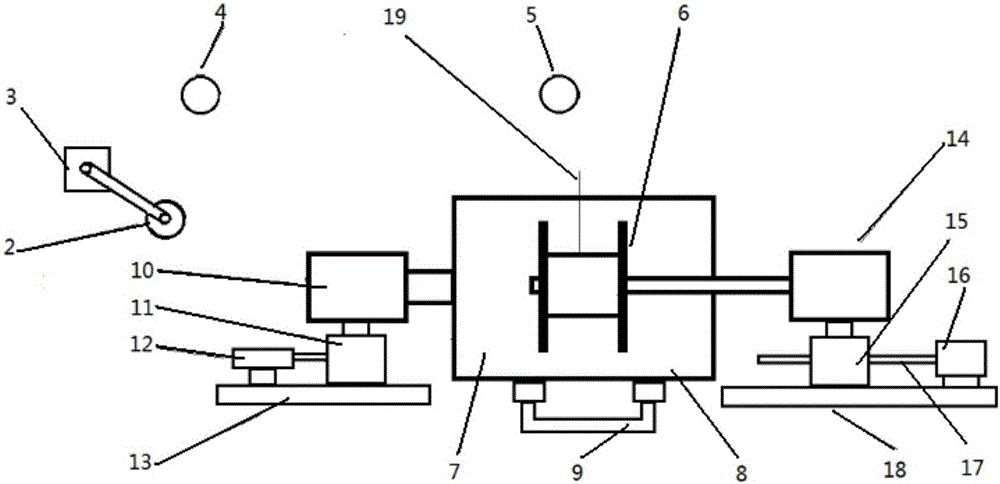

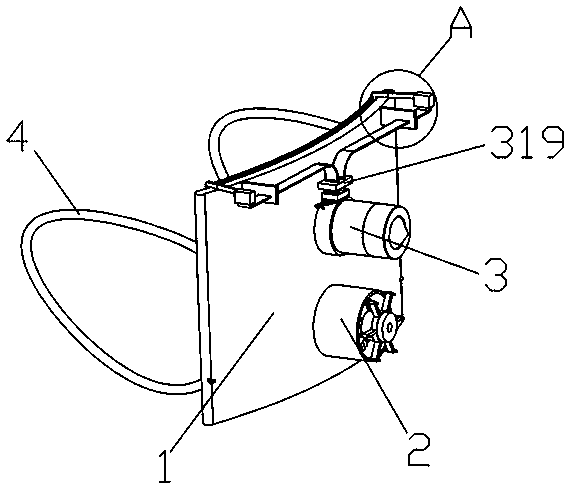

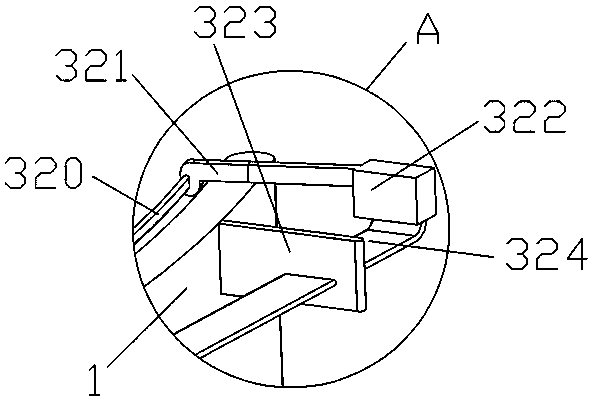

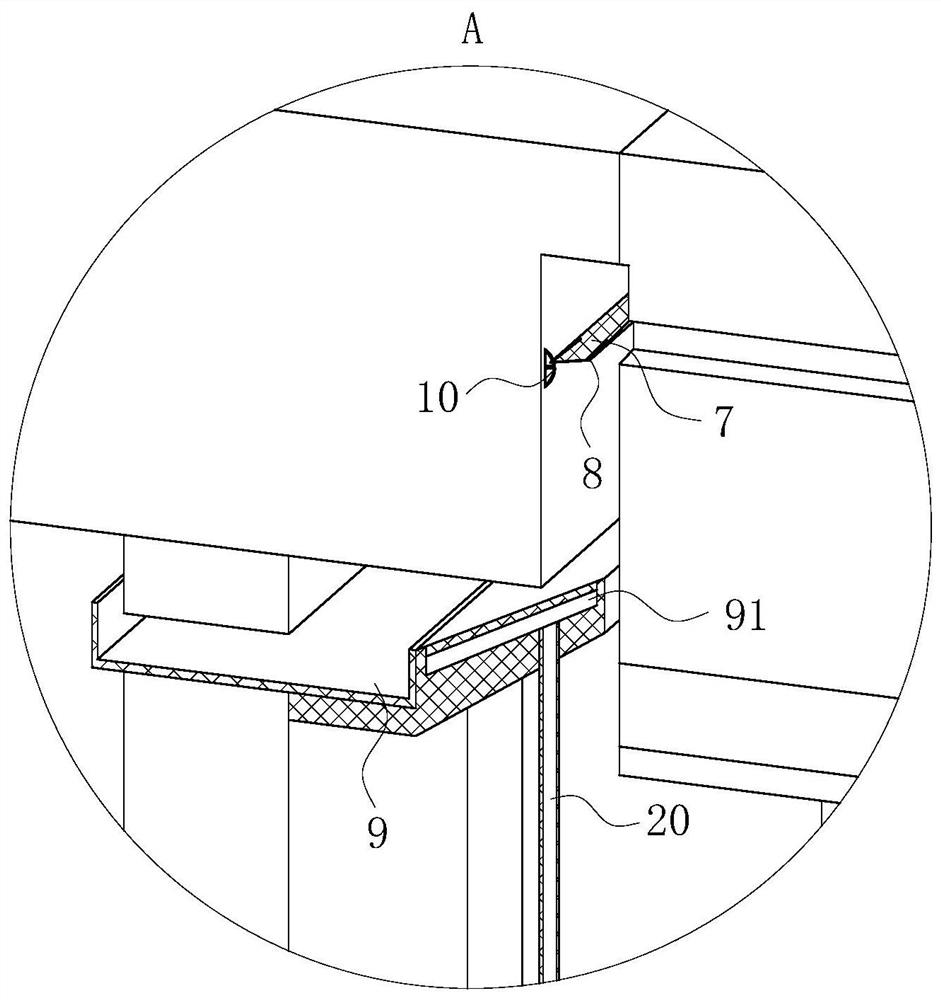

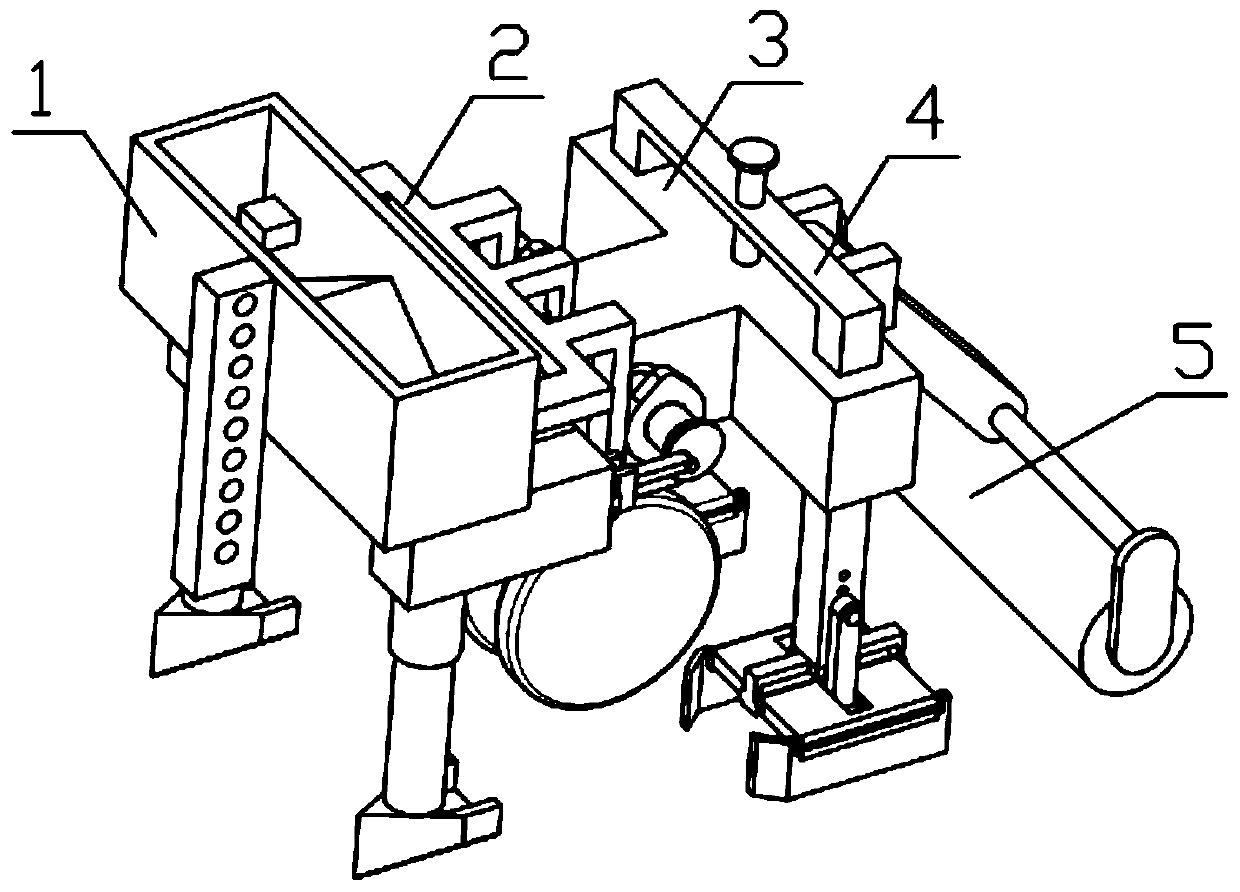

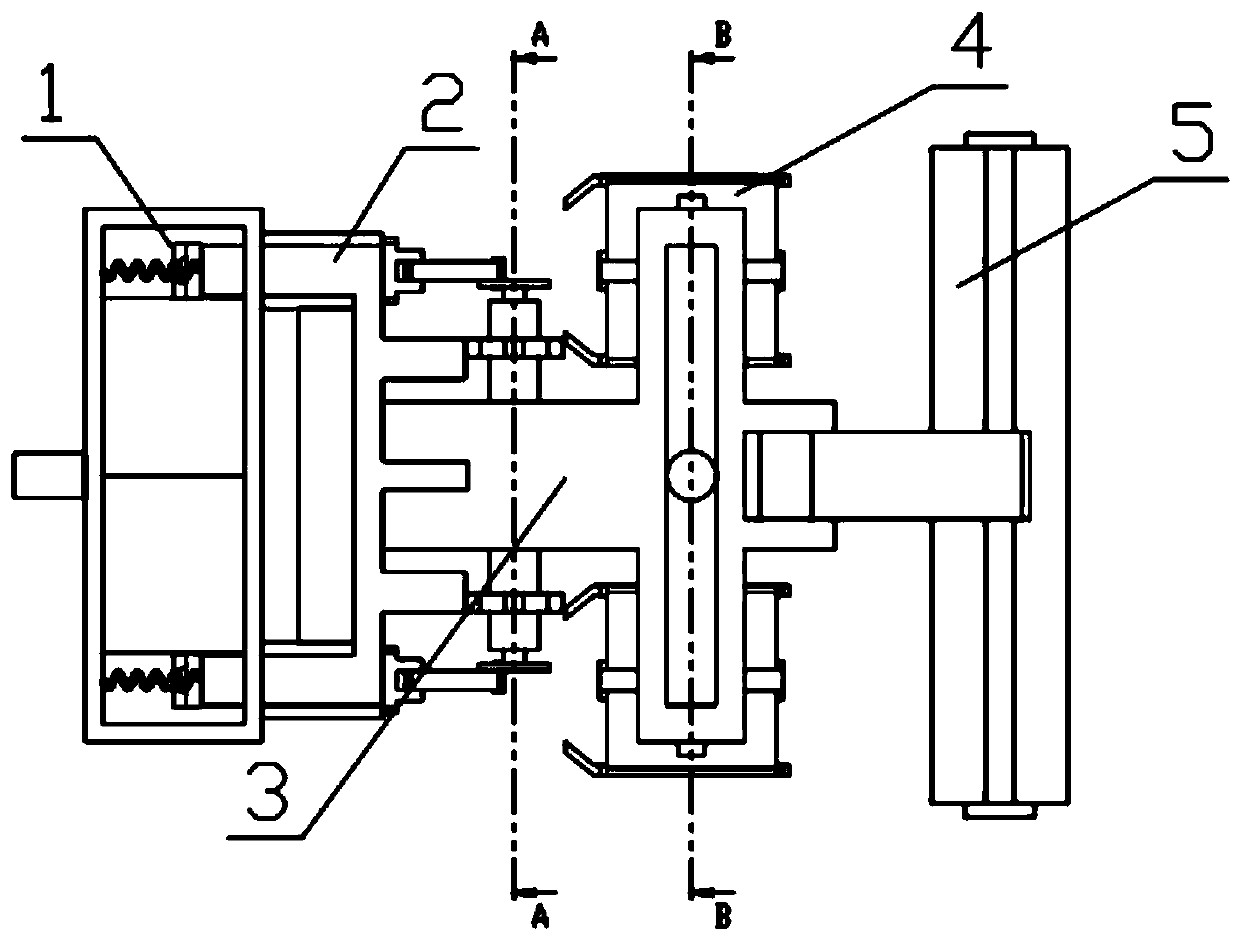

Optical fiber screening, rewinding and whip preventing device

InactiveCN105819277AQuality assuranceImplement anti-whiplash functionFilament handlingMotor driveEngineering

The invention discloses an optical fiber screening, rewinding and whip preventing device. The device comprises a dancing wheel, a lead, a wire arranging wheel and an optical fiber wire collecting disc; the optical fiber wire collecting disc is coated with a first protective cover and a second protective cover; optical fibers enter the optical fiber wire collecting disc from a gap between the first protective cover and the second protective cover; a first motor drives the first protective cover to rotate; meanwhile, a transmission device drives the second protective cover to synchronously rotate; a second motor drives the optical fiber wire collecting disc to rotate; and when the optical fibers are broken, an air pressure rod pushes a first base to move on a first guide rail, and the first protective cover is pushed to the second protective cover, so that the first protective cover and the second protective cover tightly clamp the broken ends of the optical fibers. When the optical fibers are broken in screening and rewinding caused by the strength problem of the optical fibers or the equipment problem, the broken ends of the optical fibers can be clamped through the device to prevent from continuously whipping the optical fibers on the surface of the optical fiber wire collecting disc in a high-speed state so as to prevent influence on the quality of the optical fibers.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH

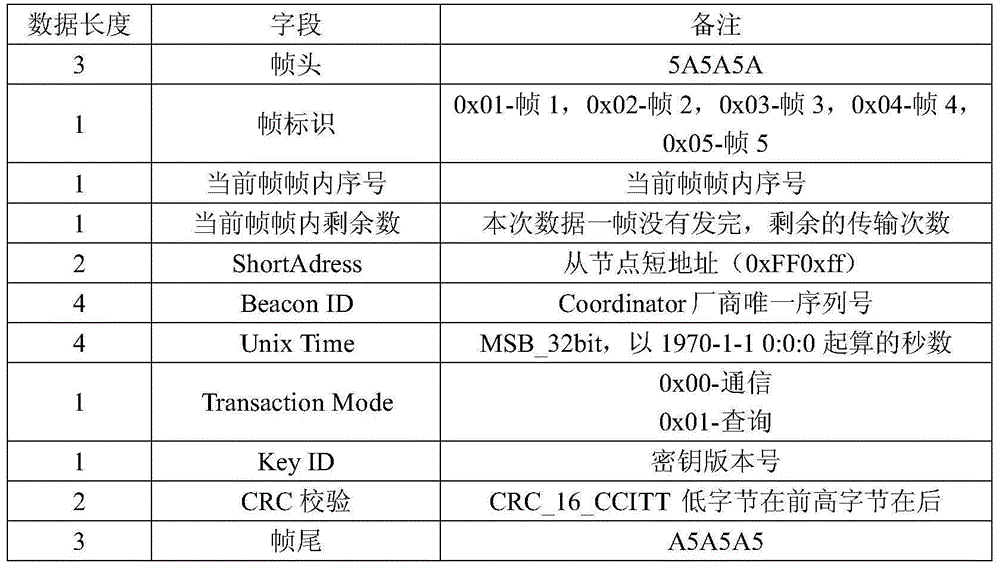

Multi-source data transmission system based on Zigbee network

ActiveCN105162734AImprove adaptabilityReduce complexityWireless commuication servicesData switching networksTransport systemData domain

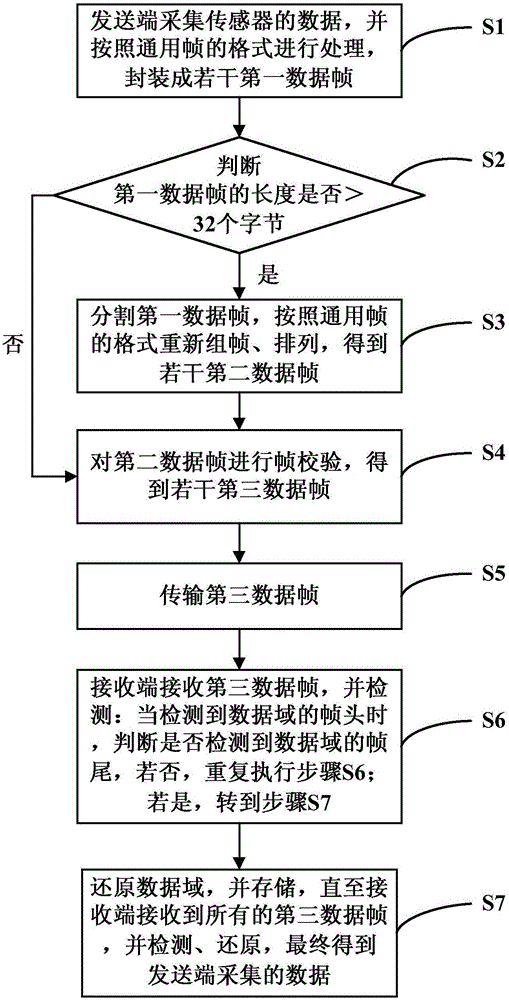

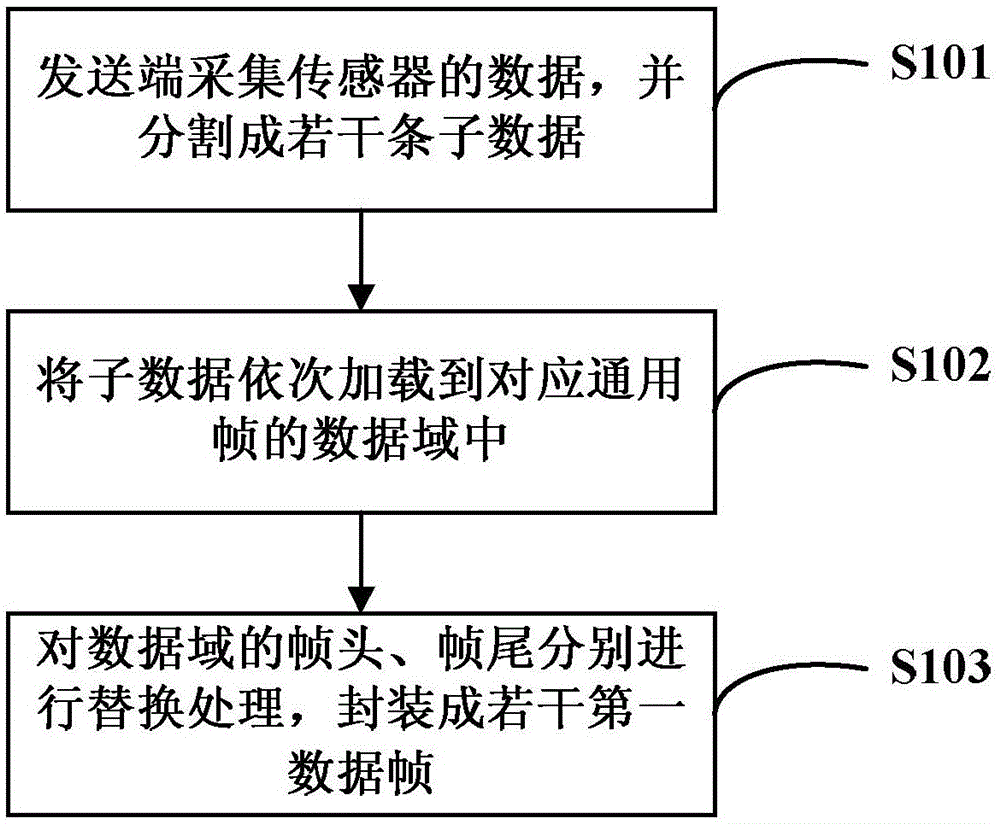

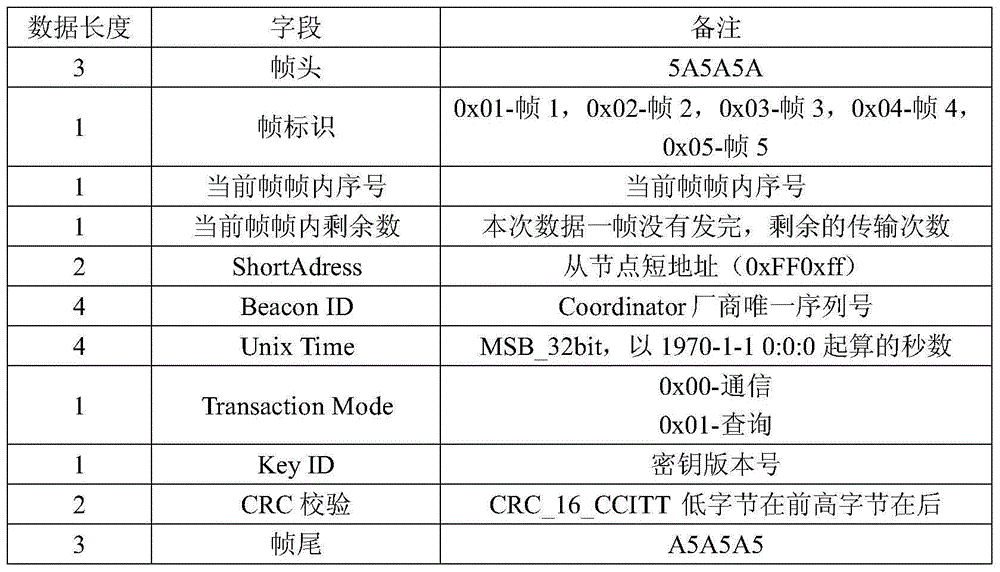

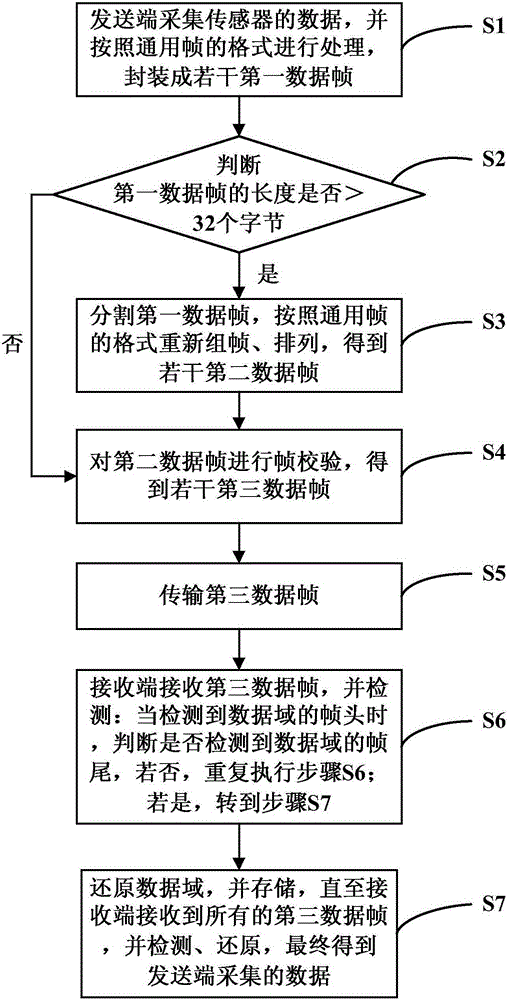

The invention discloses a multi-source data transmission system based on a Zigbee network and relates to the field of wireless data transmission. A sending end of the system collects data of a sensor and processes the data according to a format of a general frame for packaging the data into a plurality of data frames; judges whether the length of each data frame is greater than 32 bits or not, divides, re-framing and arranging the data frames whose lengths are greater than 32 bits and performs frame verification of the data frames whose lengths are smaller than or equal to 32 bits; and transmits the data frames subjected to frame verification. A receiving end receives and detects the data frames; judges whether the frame footer of a data domain is detected or not, repeats receiving detection if no frame footer is detected, restores the data subjected to replacement treatment and stores if the frame footer is detected until all the data frames are received, detected and restored. Finally, the data collected by the sending end is acquired. According to the invention, uniform transmission of multi-source sensor information is realized, adaptability to the multi-source sensor is improved and complexity in data analysis of a rear-end server is reduced.

Owner:武汉森岩科技有限公司

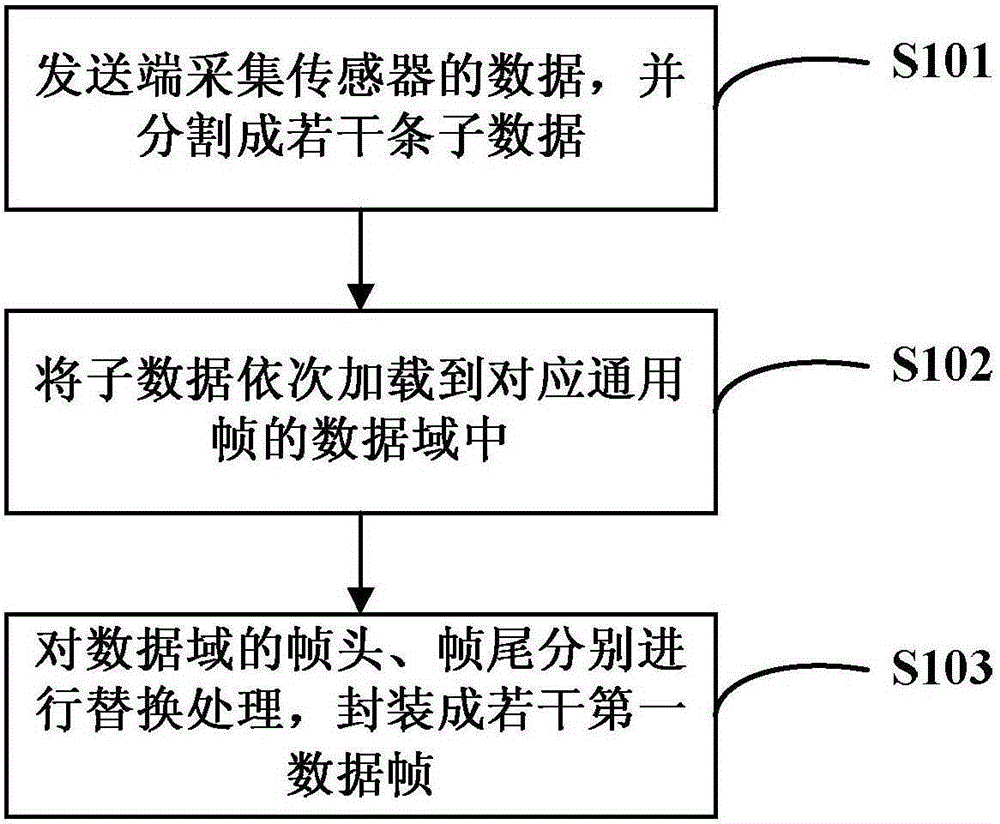

Multi-source data transmission method based on Zigbee network

ActiveCN105187332AImprove adaptabilityReduce complexityWireless commuication servicesData switching networksData domainBack end server

The invention discloses a multi-source data transmission method based on a Zigbee network, and relates to the field of wireless data transmission. A sending end of the system collects data of a sensor, processes the data according to a format of a universal frame, packages the data into multiple data frames, judges whether the length of each data frame is larger than 32 bytes, if so, divides, re-frames and arranges the data frames, carries out frame verification on the data frames with lengths not greater than 32 bytes in sequence, and transmits the data frames after the frame verification operation; and a receiving end receives and detects the data frames: when detecting the frame header of a data domain, judges whether detecting the frame tail of the data domain, if not, repeats the receiving and detecting operations, if so, restores the replaced data, stores the restored replaced data until receiving all data frames, and detects and restores the data to obtain the data collected by the sending end at last. The multi-source data transmission method disclosed by the invention is used for achieving uniform transmission of multi-source sensor information, improving the adaptability of the multi-source sensor and reducing the data analysis complexity of a back end server.

Owner:武汉森岩科技有限公司

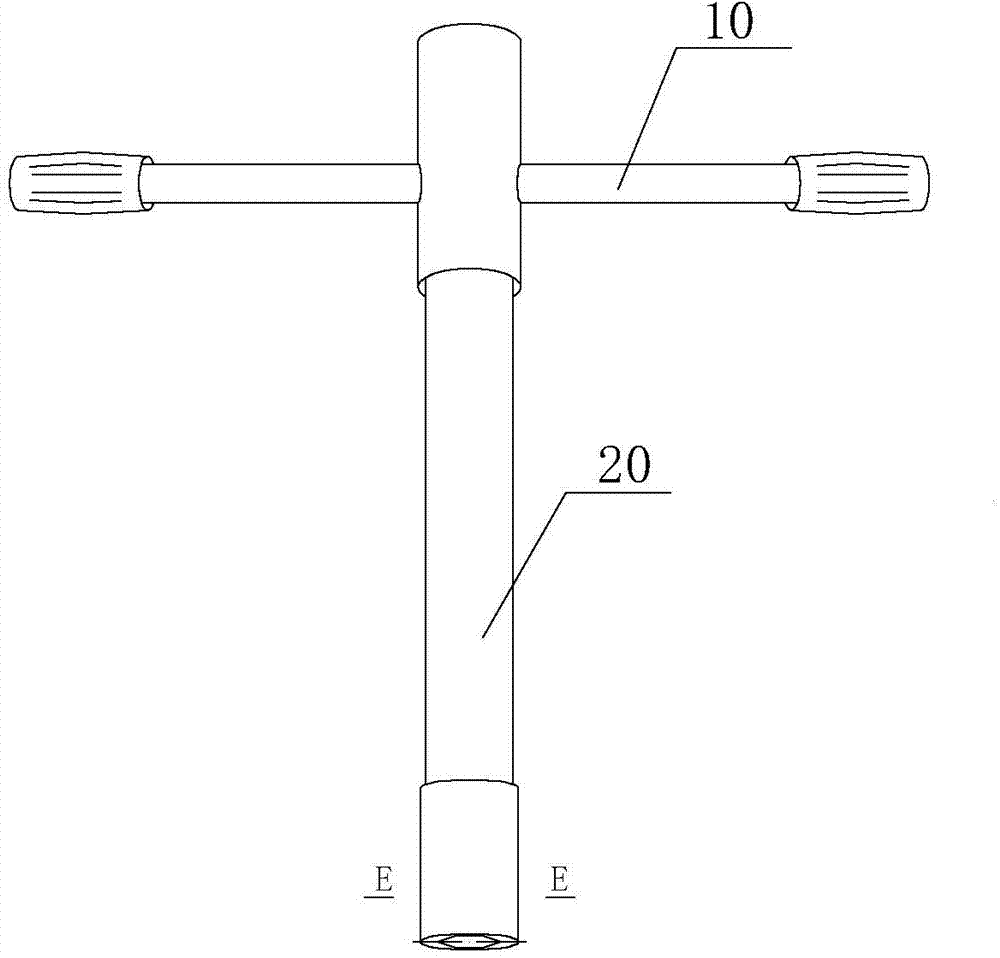

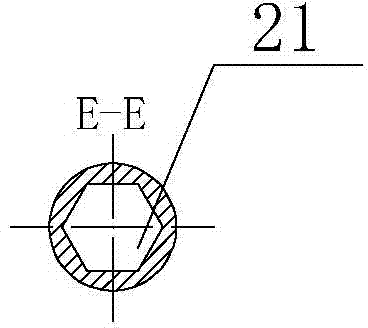

Portable operating handle for 10 kV switch cabinet

InactiveCN104124619APut an end to the phenomenonAvoid the risk of being lost in the stationWing handlesWing knobsEngineeringElectrical and Electronics engineering

The invention discloses a portable operating handle for a 10 kV switch cabinet. The portable operating handle for the 10 kV switch cabinet comprises an operating handle, a connecting piece and switch sleeve heads, one end of the connecting piece is provided with a through hole penetrating the operating handle, and the other end of the connecting piece is provided with an inner hexagonal groove; one end of every switch sleeve head is provided with a hexagonal cylinder matching with the inner hexagonal groove. The portable operating handle for the 10 kV switch cabinet has the advantages that the plurality of switch sleeve heads can all be connected with the operating handle, thereby effectively solving the problem that a plurality of switch sleeve heads are matched with a plurality of operating handle; is small in structural size and convenient to carry, thereby avoiding the risk of loss of tools inside a station, guaranteeing timely first-aid repair of devices and further guaranteeing normal power utilization of residents.

Owner:STATE GRID CORP OF CHINA +1

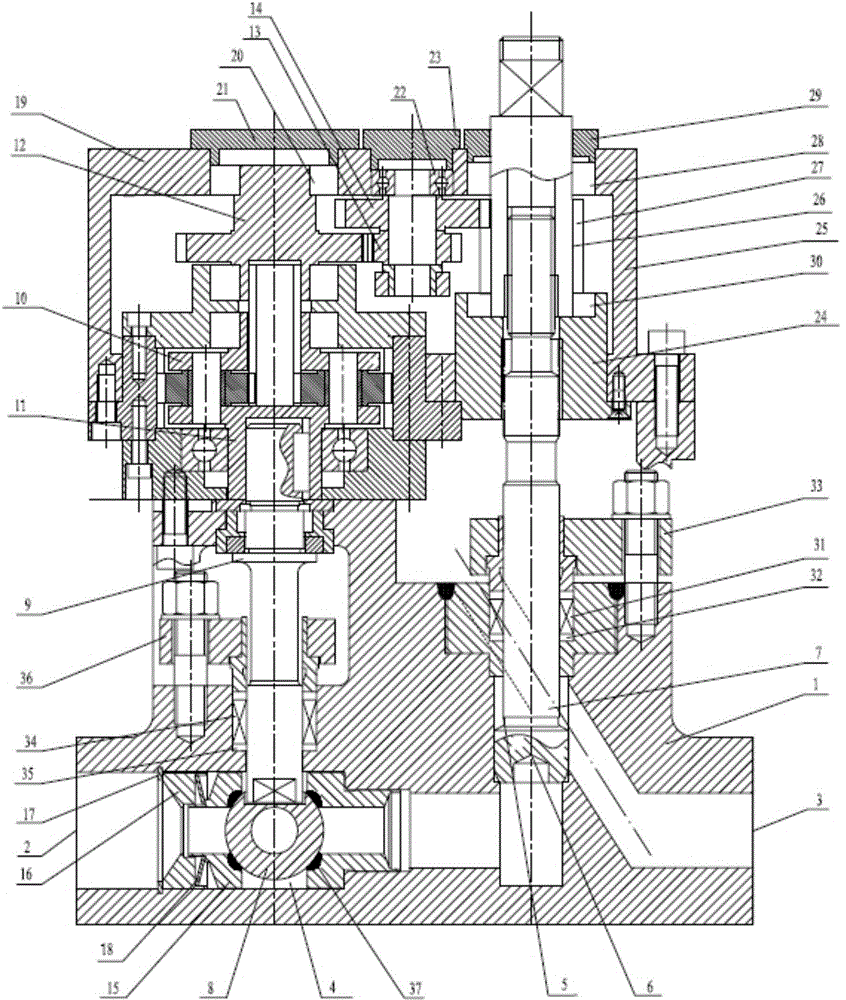

Combined valve

InactiveCN104482253ASolve bad working conditionsSolve the requestSpindle sealingsPlug valvesEngineeringVALVE PORT

The invention provides a combined valve. The combined valve can be free of leakage for a long time under severe working conditions. The combined valve comprises a combined valve body, wherein a medium inlet and a ball valve cavity communicated with the medium inlet are formed in one side of the combined valve body, a medium outlet and a stop valve cavity communicated with the medium outlet are formed in the other side of the combined valve body, the ball valve cavity is communicated with the stop valve cavity, a stop valve element arranged in the stop valve cavity a is connected with stop valve rod, a handle is connected to one end of the stop valve rod, a ball valve ball body arranged in the ball valve cavity is connected with a ball valve rod, the ball valve rod is connected with an output shaft at one end of a speed reduction mechanism, the other end of the speed reduction mechanism is connected with a driving gear for driving the speed reduction mechanism to rotate, the driving gear is meshed with a transition gear, and the stop valve rod drives the transition gear to rotate. The combined valve is integrally designed, has few leakage points, and is more reliable in pipeline installation, and more convenient to operate.

Owner:BEIJING OTE CONTROL VALVE

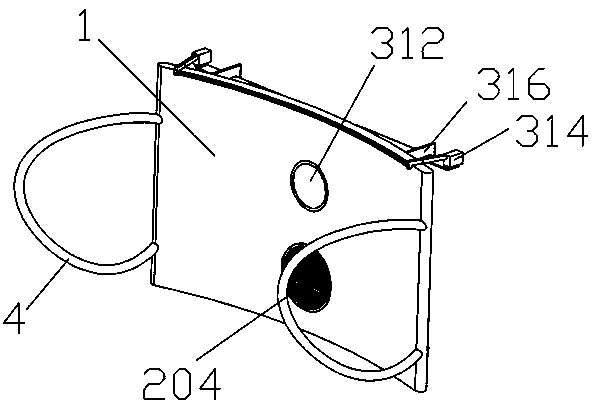

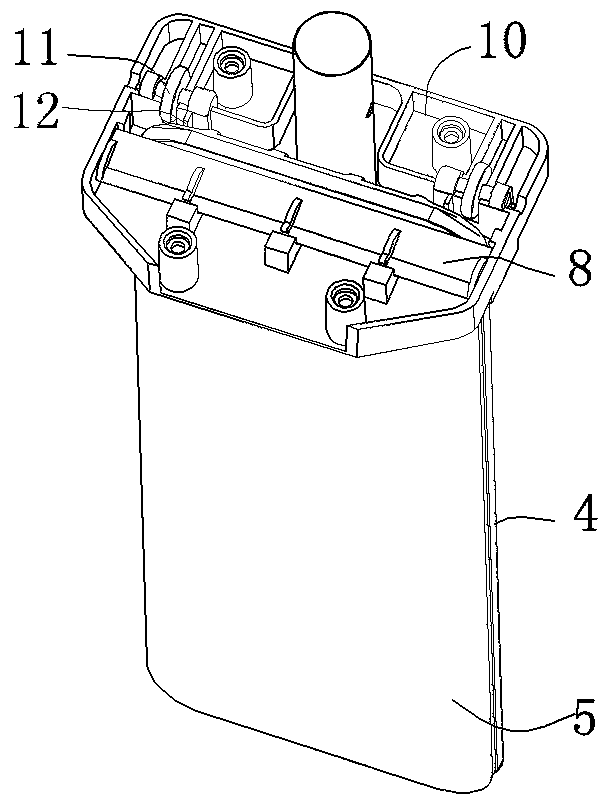

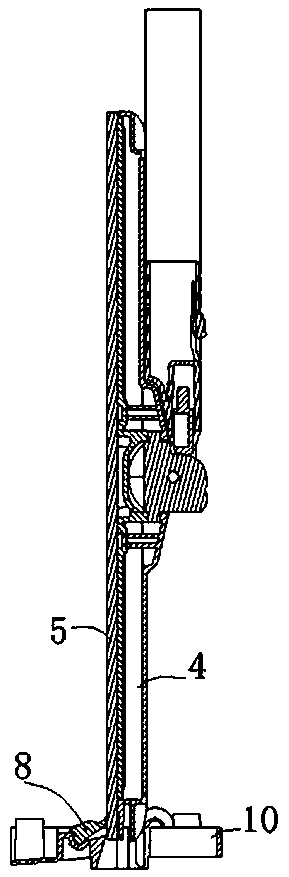

Medical mask capable of preventing eyeglasses from being atomized

The present invention discloses a medical mask capable of preventing eyeglasses from being atomized. The medical mask comprises a protection panel, an expiration module, an anti-atomization module andwearing ropes, the wearing ropes are fixedly connected to the front side and the rear side of the protection panel, the anti-atomization module is arranged on the upper side of the middle of the front face of the protection panel, and the expiration module is arranged on the lower side of the middle of the front face of the protection panel. According to the invention, the anti-atomization moduleis arranged, the sucked air can be heated, when the outside air is cold, proper air can be provided and sucked into the abdomen, and through the arrangement of a refrigeration diode, the refrigeration surface of the refrigeration diode can cool the cold guide strip, so that air around the cold guide strip can be cooled, hot air exhaled by a human body can be cooled when passing through the cold guide strip, and the phenomenon of glasses atomization caused by mask wearing is avoided.

Owner:丁锬

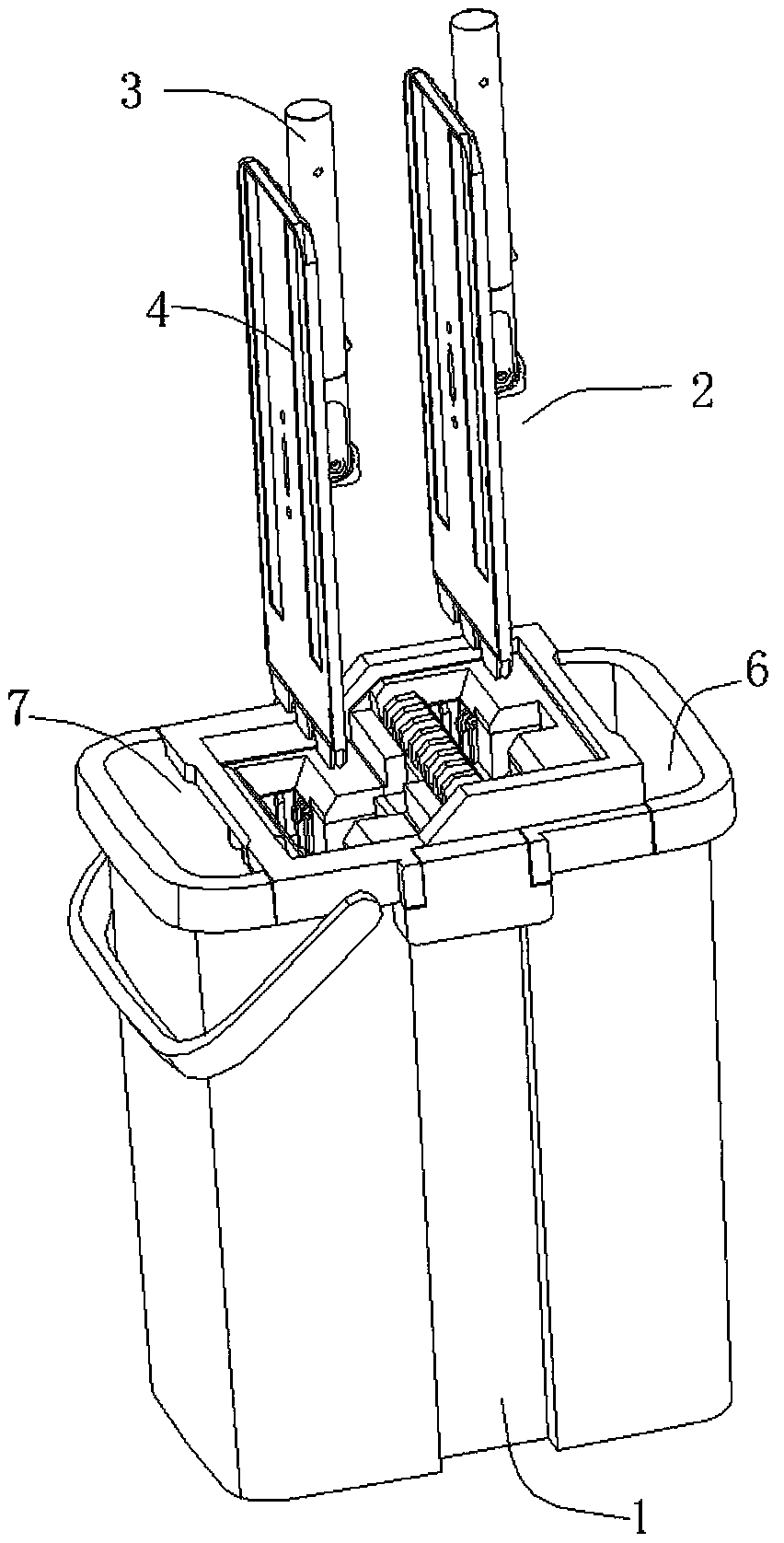

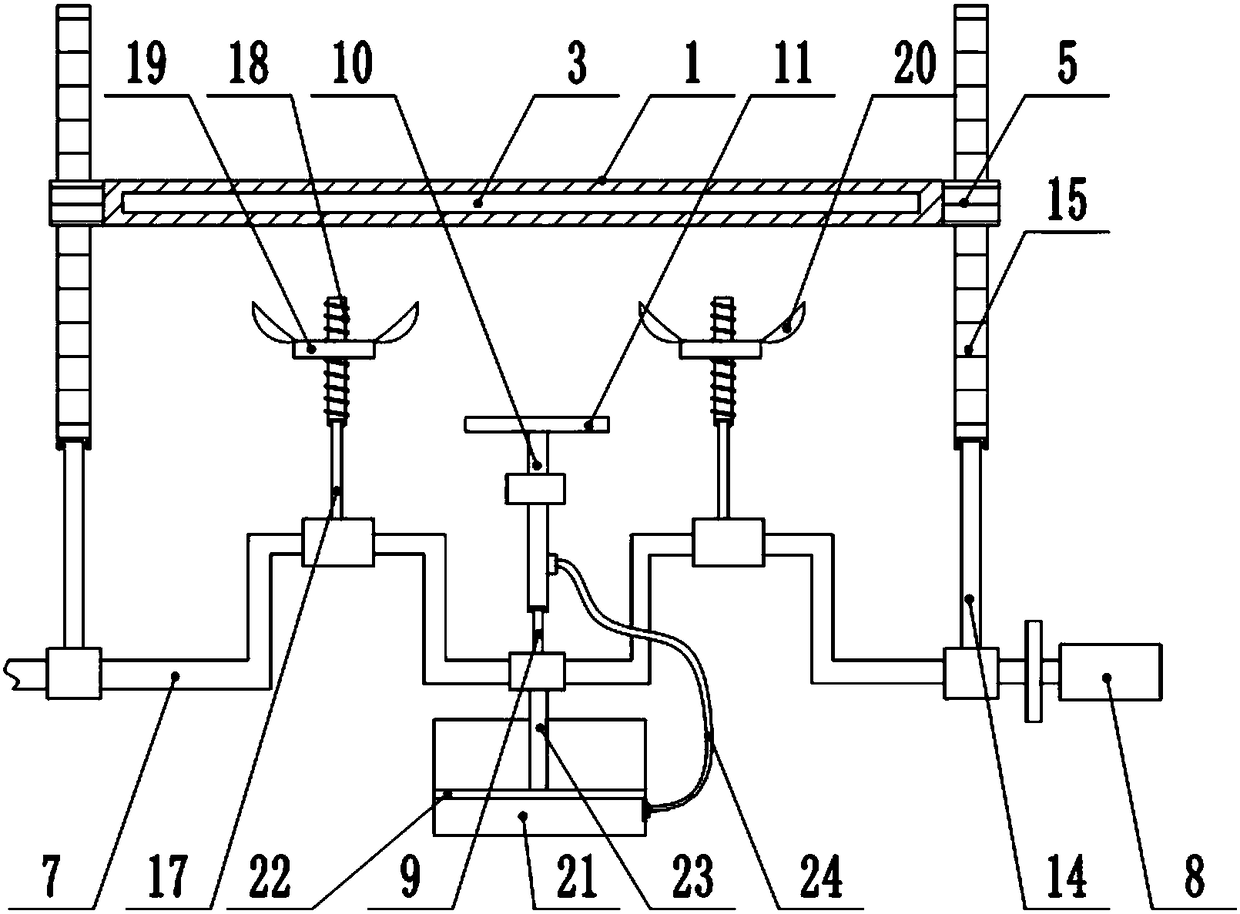

Plate mop water squeezing using method and plate mop cleaning tool thereof

ActiveCN109730601AAvoid pollutionPut an end to the phenomenonCarpet cleanersFloor cleanersEngineering

The invention discloses a plate mop water squeezing using method and a plate mop cleaning tool thereof. The plate mop cleaning tool capable of being upright comprises a mop bucket and a plate mop, wherein the plate mop comprises a mop rod and a plate mop head; the plate mop head is movably connected onto the mop rod; a wiping object is arranged on the plate mop head; the mop bucket comprises an independent water squeezing area and an independent cleaning area; after the plate mop is used up, the plate mop is upright in the mop bucket; a rubbing plate is rotationally arranged on the mop bucket;and due to rotation of the rubbing plate, the size of a squeezing opening can be changed. The size of the squeezing opening can be changed by virtue of the rotation of the rubbing plate, so that therubbing plate produces a high appropriate squeezing force to the wiping object when the plate mop head is pressed downwards, and when the plate mop head is upwards pulled, a phenomenon that the mop bucket is lifted when the plate mop is lifted upwards is avoided. The plate mop head is clamped by the squeezing opening, so that the plate mop can be upright in the mop bucket after used up. The spaceis saved, and the wiping object on the plate mop head is avoided from being polluted.

Owner:CIXI BOSHENG PLASTIC PROD

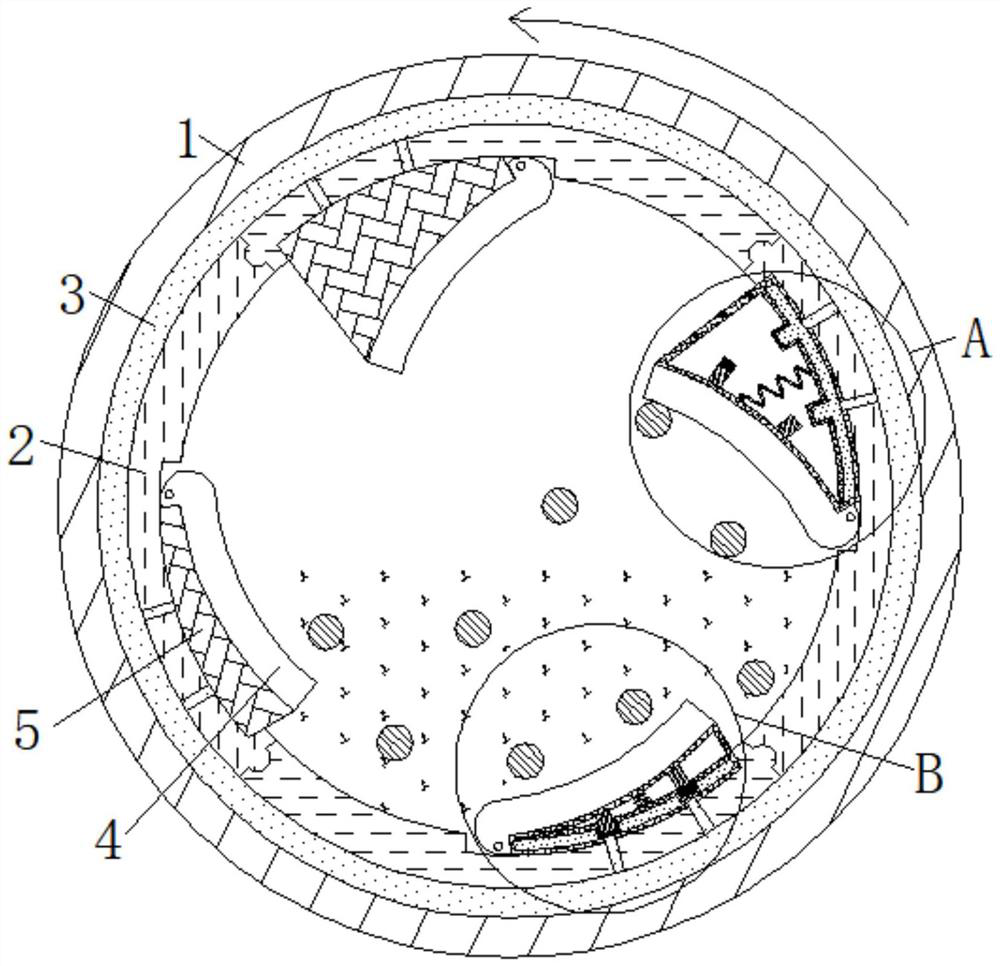

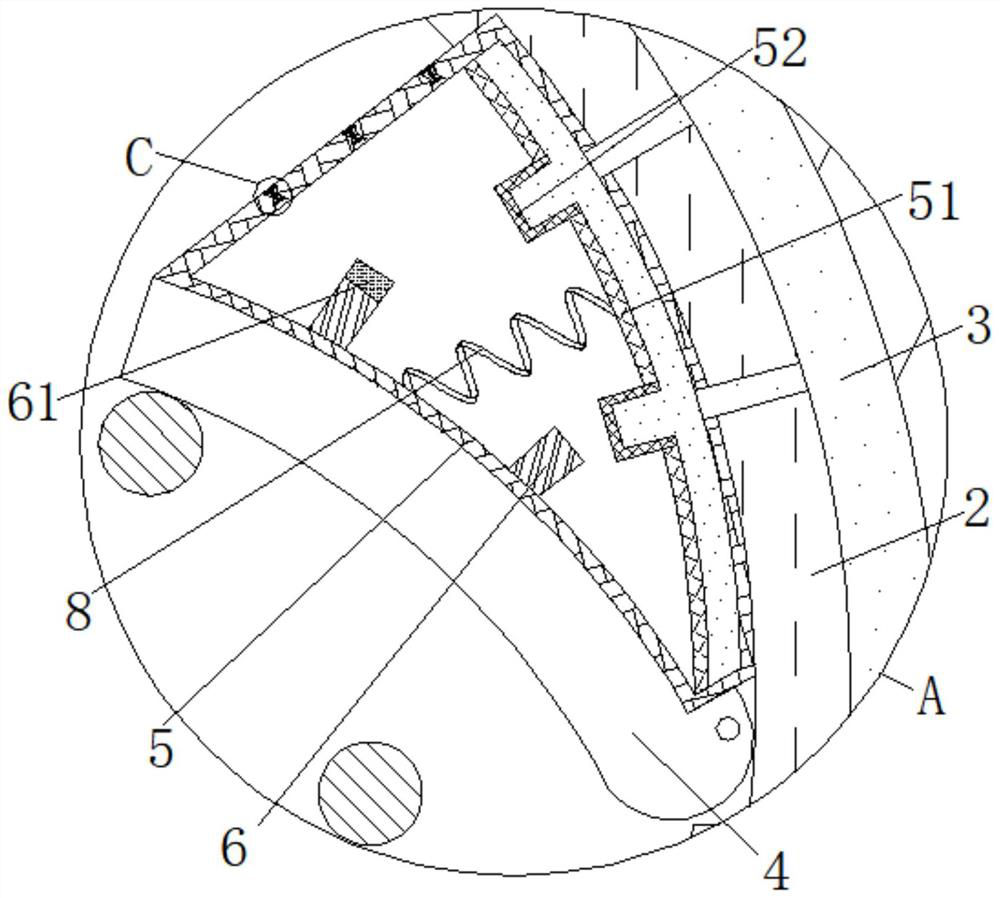

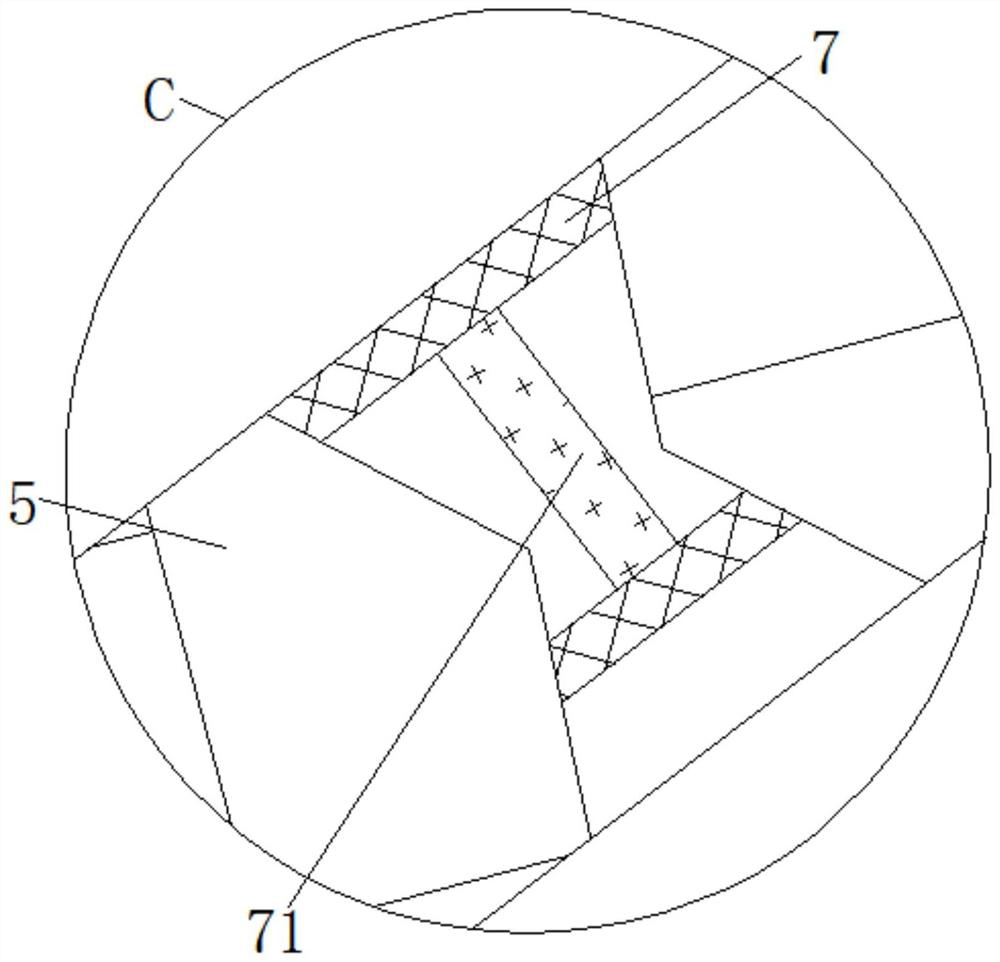

Ball mill for cement production

ActiveCN113649134AAvoid breakage damageGrind fullyCement productionGrain treatmentsWater storageStructural engineering

The invention relates to the technical field of grinding equipment, and discloses a ball mill for cement production. The ball mill comprises a cylinder; the two ends of the interior of the cylinder are fixedly connected with a lining assembly; the lining assembly is composed of four lining plates; the lining plates are arranged around the cylinder; the two lining plates are clamped with each other; a water storage cavity is arranged between the cylinder and the lining plates; and grooves are arranged in the lining plates, and movable plates are hinged to the inner walls, located at one ends of the grooves, of the lining plates. The movable plates and limiting bags are arranged in the lining plates, so that the movable plates rotate outwards due to gravity in the ascending stage, the movement path of a grinding ball is changed due to the external force of the movable plates during centrifugal operation, the throwing movement is formed, the grinding ball is effectively made to fully grind materials, and the grinding efficiency of the grinding ball is improved, and meanwhile, the lining plates and the movable plates are connected through the limiting bags, so that an effective supporting and protecting effect is provided for rotation of the movable plates, and the phenomenon that the grinding ball is clamped between the movable plates and the lining plates is avoided.

Owner:重庆市新嘉南建材有限责任公司

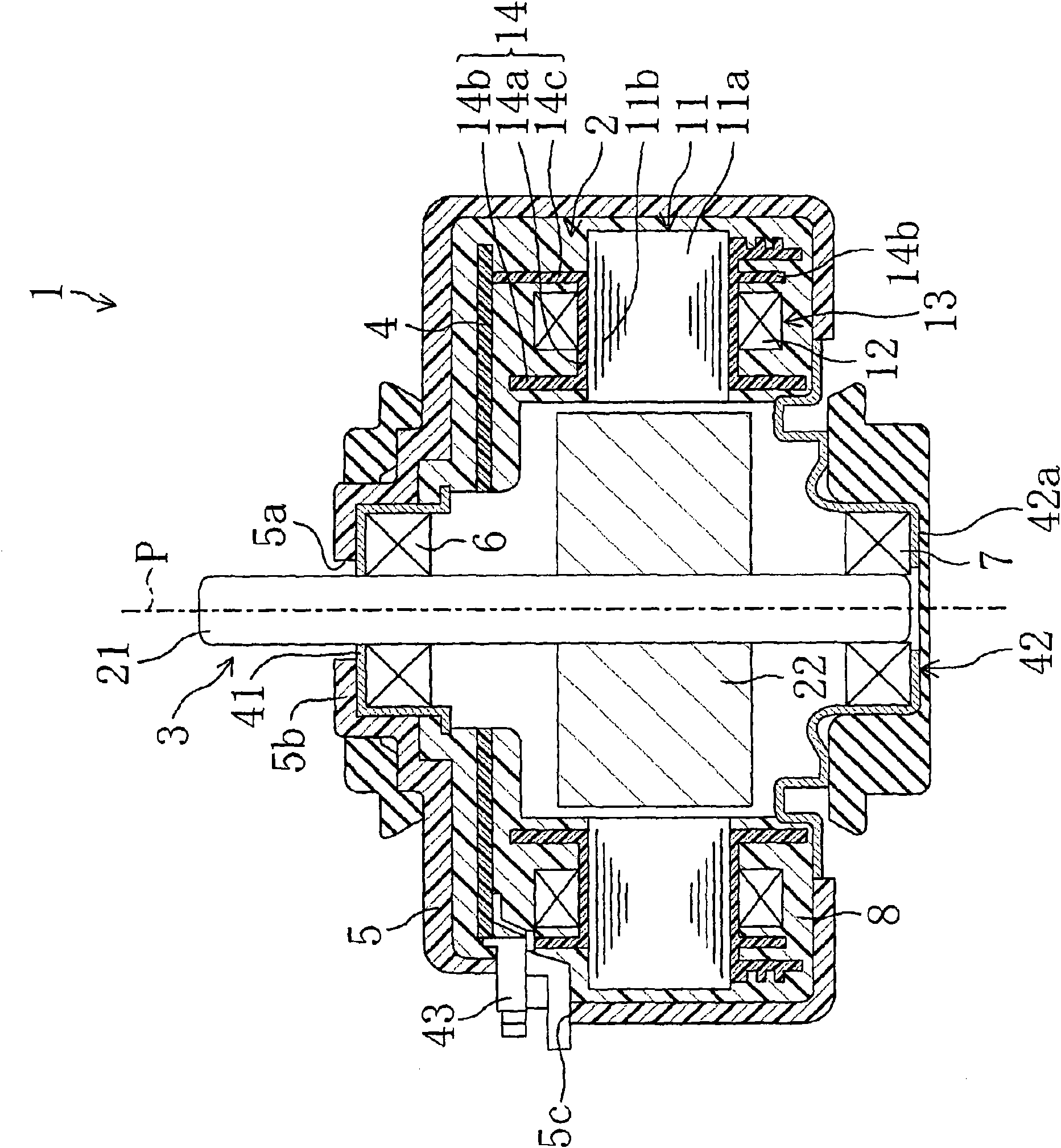

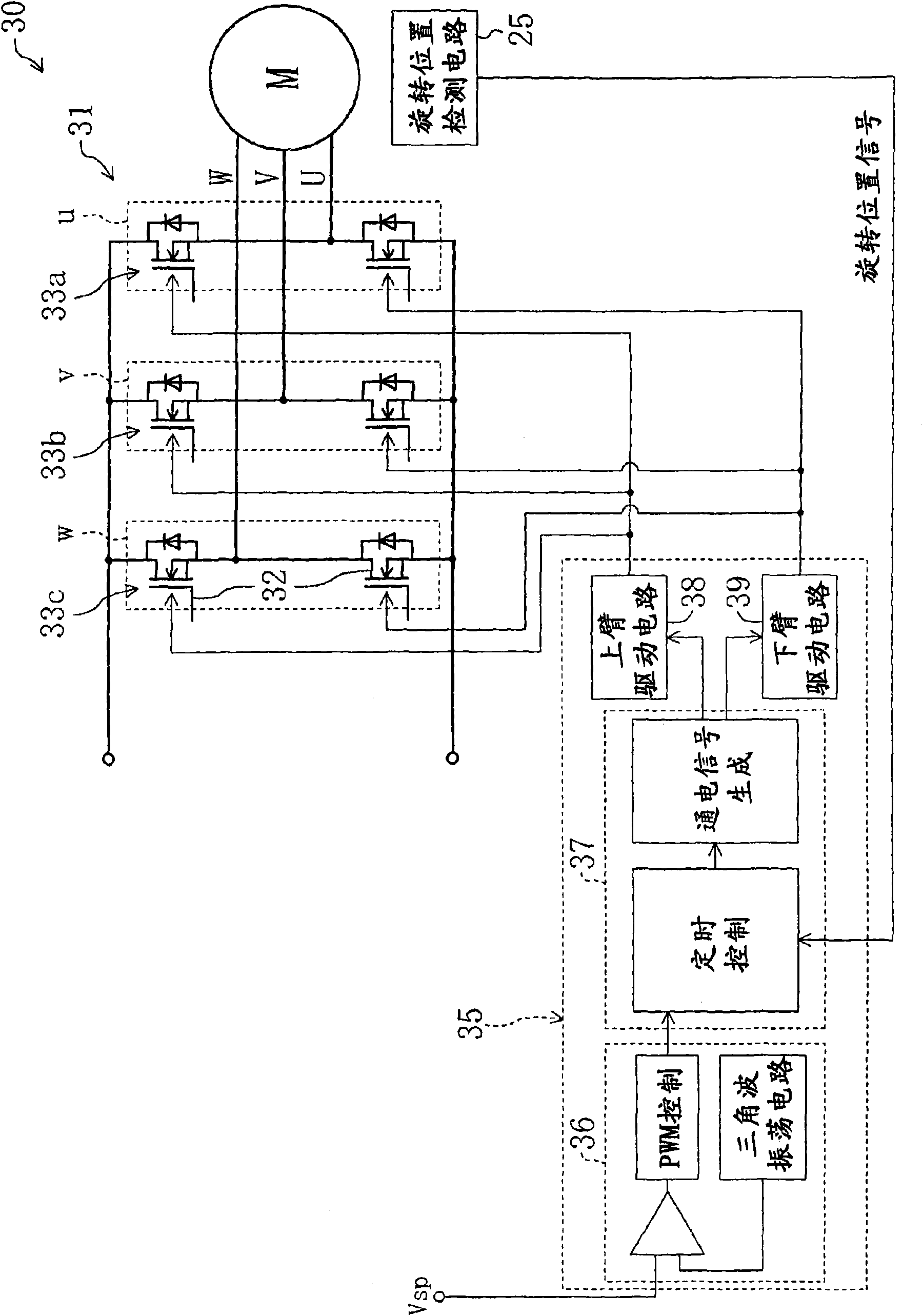

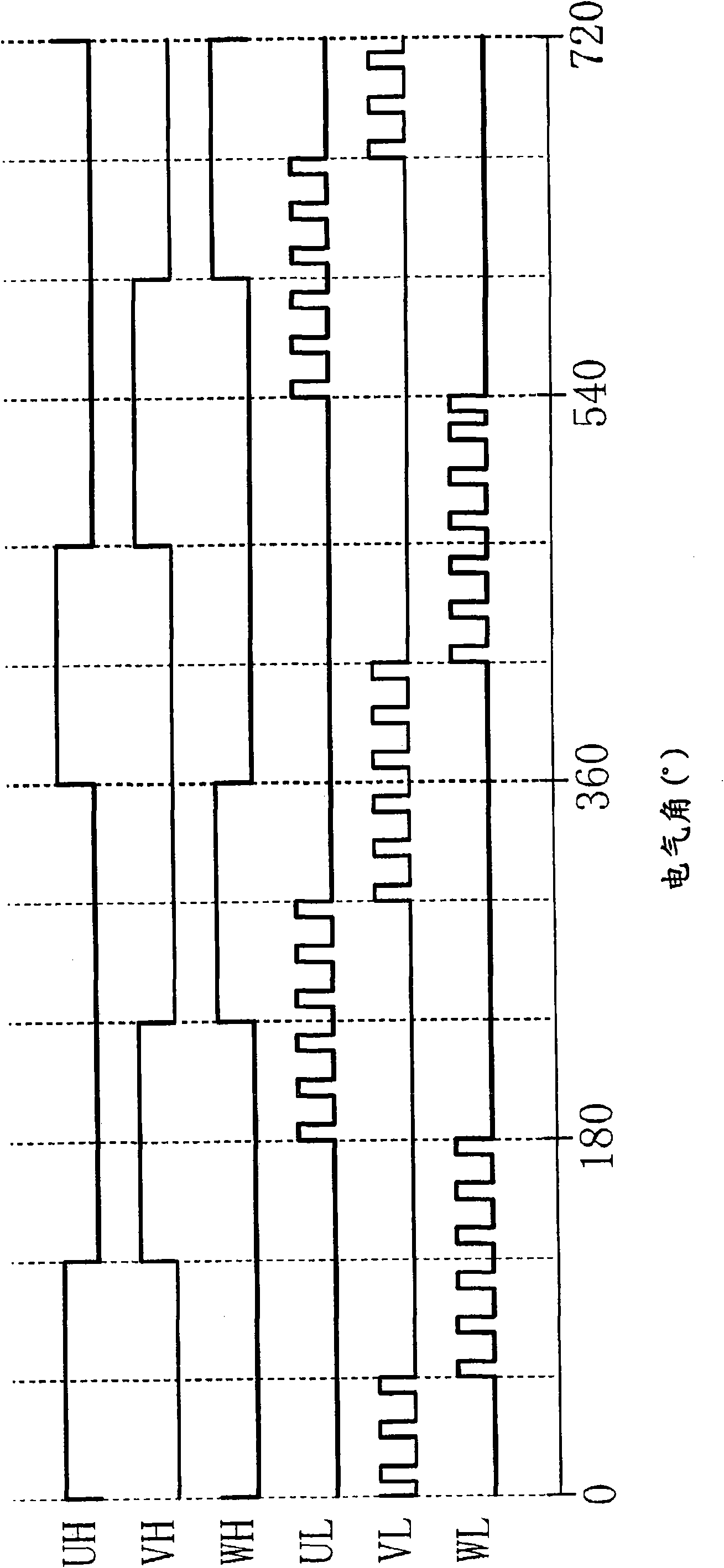

Electric motor

InactiveCN101594016APut an end to the phenomenonPhenomenon that prevents heat conduction to switching elementsWindingsElectricitySemiconductor chip

The invention provides an electric motor. On outside in axial cord direction of a stator that formed by windings with a plurality of phases annularly around the axial cord, in the way that extends in the axial cord intersecting direction, in the electric motor provided with cardinal plate having a semiconductor chip with a switching element, on-off action of the switching element will not be restricted because of heat generated in the windings of the stator. A semiconductor chip (u, v, w) having a switching element (32) is arranged on the cardinal plate (4) to make at least part of the windings (13) have no phases with electricity following on-off action of the switching element (32) and at least one overlap of the gaps between the windings (13) and the neighboring windings (13).

Owner:NIDEC SHIBAURA CORP

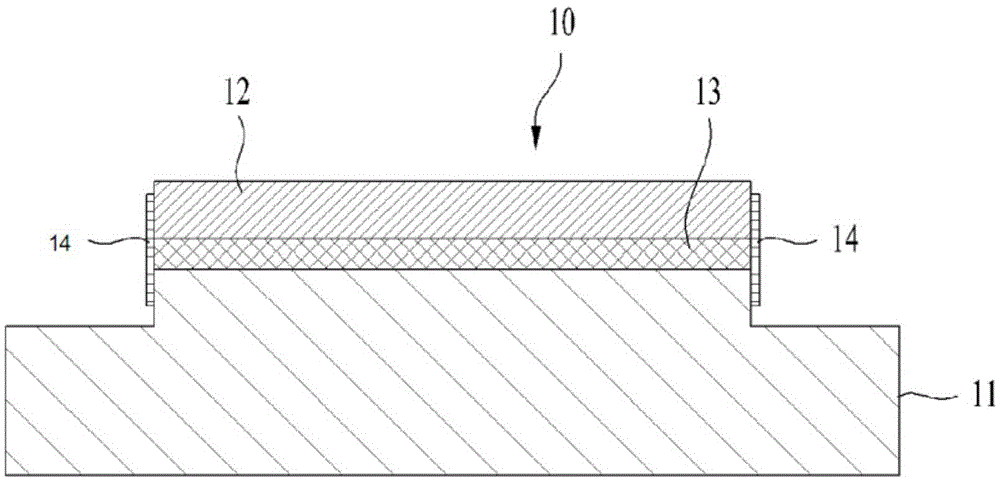

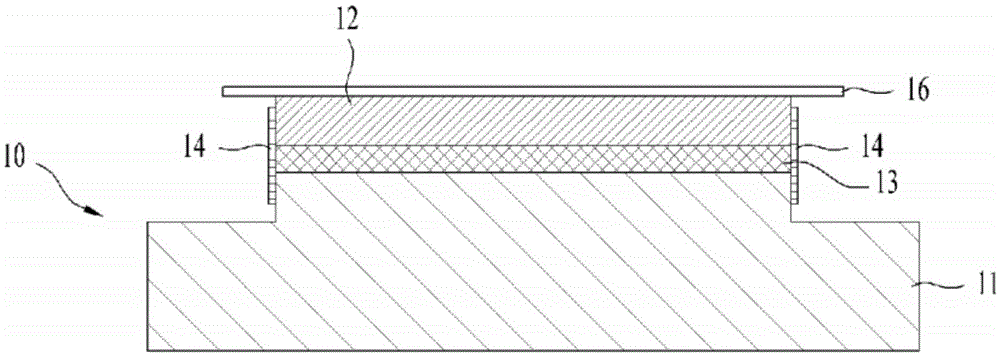

Electrostatic chuck and method for manufacturing electrostatic chuck

InactiveCN105531810AInhibit sheddingWith anti-corrosion coatingPretreated surfacesSemiconductor/solid-state device manufacturingVacuum stateChemistry

The present invention provides an electrostatic chuck comprising: a base material; an adsorption part for adsorbing a wafer by using electrostatic force; an adhesive layer for adhering the adsorption part to the base material; and an adhesive layer anti-corrosion coating layer provided to cover an exposed surface of the adhesive layer, wherein the adhesive layer anti-corrosion coating layer has no pores or cracks since the adhesive layer anti-corrosion coating layer is made by using a method of spraying and coating, at conditions of 0-50 DEG C and a vacuum state, ceramic powder which is continuously supplied at a constant quantity so as to carry gas of which a fixed flow rate is controlled, and a method for manufacturing an electrostatic chuck, comprising the steps of: (a) forming an adhesive layer for adhering an adsorption part for adsorbing a wafer to a base material by using electrostatic force; and (b) forming an adhesive layer anti-corrosion coating layer which covers an exposed surface of the adhesive layer and has no pores or cracks by being made by using a method of spraying and coating, at conditions of 0-50 DEG C and a vacuum state, ceramic powder which is continuously supplied at a constant quantity so as to carry gas of which a fixed flow rate is controlled.

Owner:PINVIS CO LTD +2

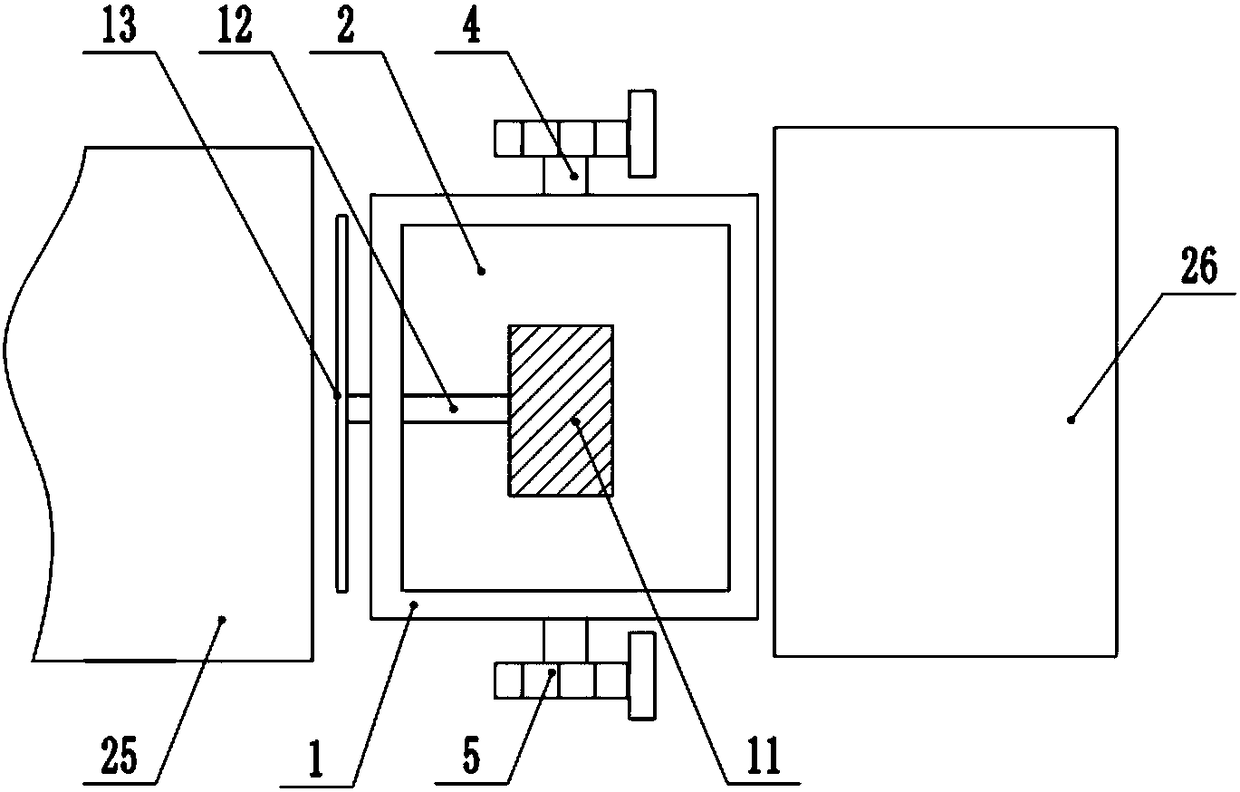

Multipoint lateral glue feeding hot nozzle structure and hot runner system

The invention discloses a multipoint lateral glue feeding hot nozzle structure, which comprises a hot nozzle body and a nozzle core, wherein the nozzle core is arranged on one end of the hot nozzle body and is of a horn shape; a plurality of nozzle tips are arranged in the circumferential direction of the nozzle core; the bottom of each nozzle tip is independently provided with a glue inlet; and alateral glue inlet is arranged between any two adjacent nozzle tips. The invention also discloses a hot runner system, which comprises a mould, a hot nozzle open frame and the above multipoint lateral glue feeding hot nozzle structure, wherein the mould comprises a front mould and a rear mould, and the front mould and the rear mould are mutually matched; the hot nozzle open frame is arranged on the front mould; a cavity is formed in the hot nozzle open frame; and the multipoint lateral glue feeding hot nozzle structure is arranged in the cavity and comprises the hot nozzle body and the nozzlecore, and the hot nozzle body, the nozzle core and the hot nozzle open frame are matched. The invention has a simple structure, material cost can be lowered, the volume of the mould is reduced, and the invention is favorable for improving the appearance sense of beauty of a product.

Owner:SHENZHEN MOLD TIP TECH CO LTD

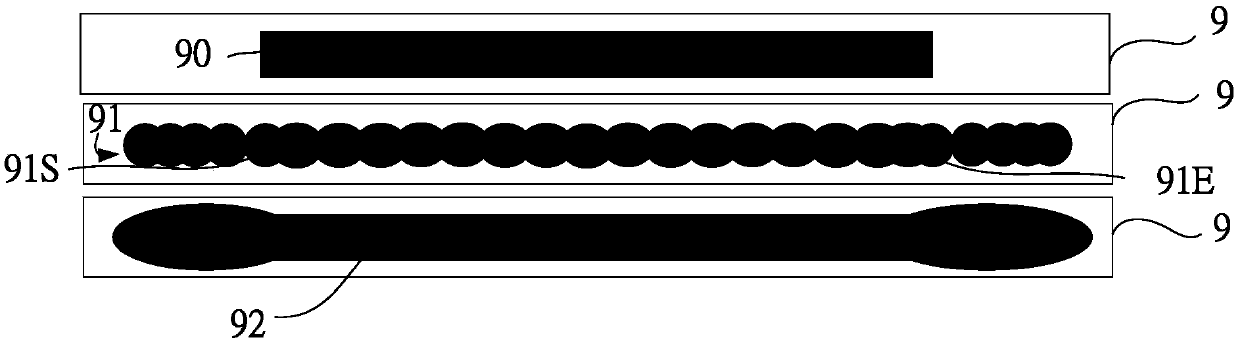

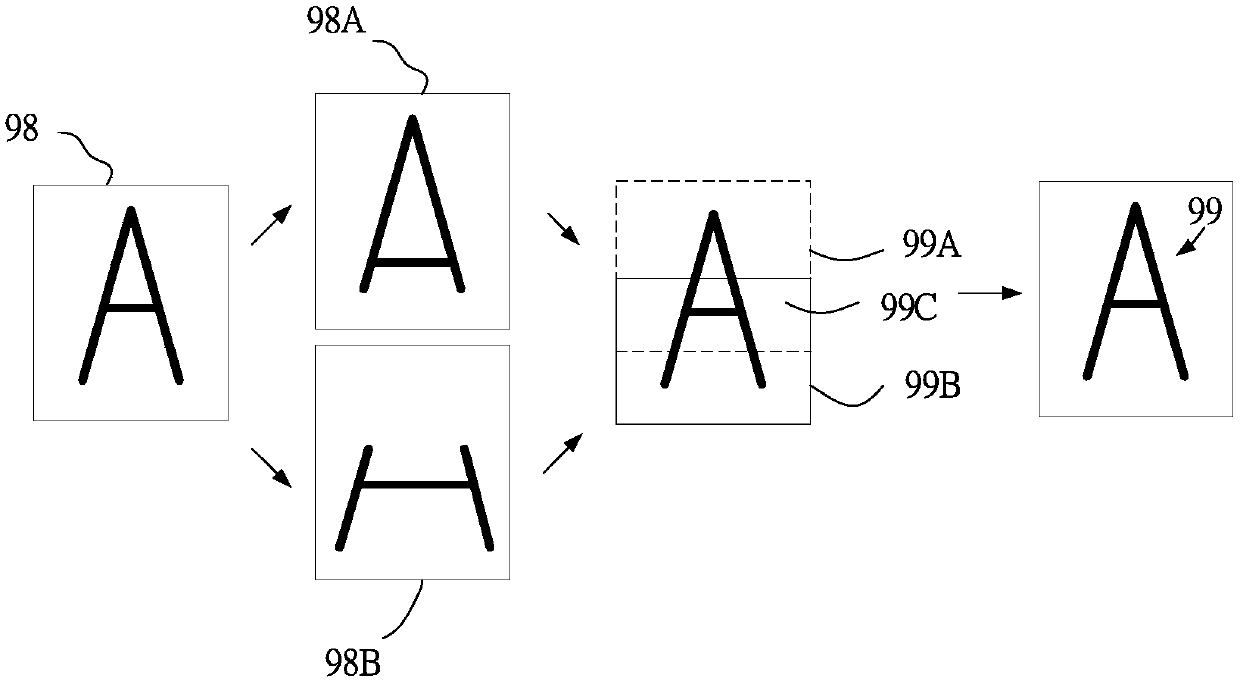

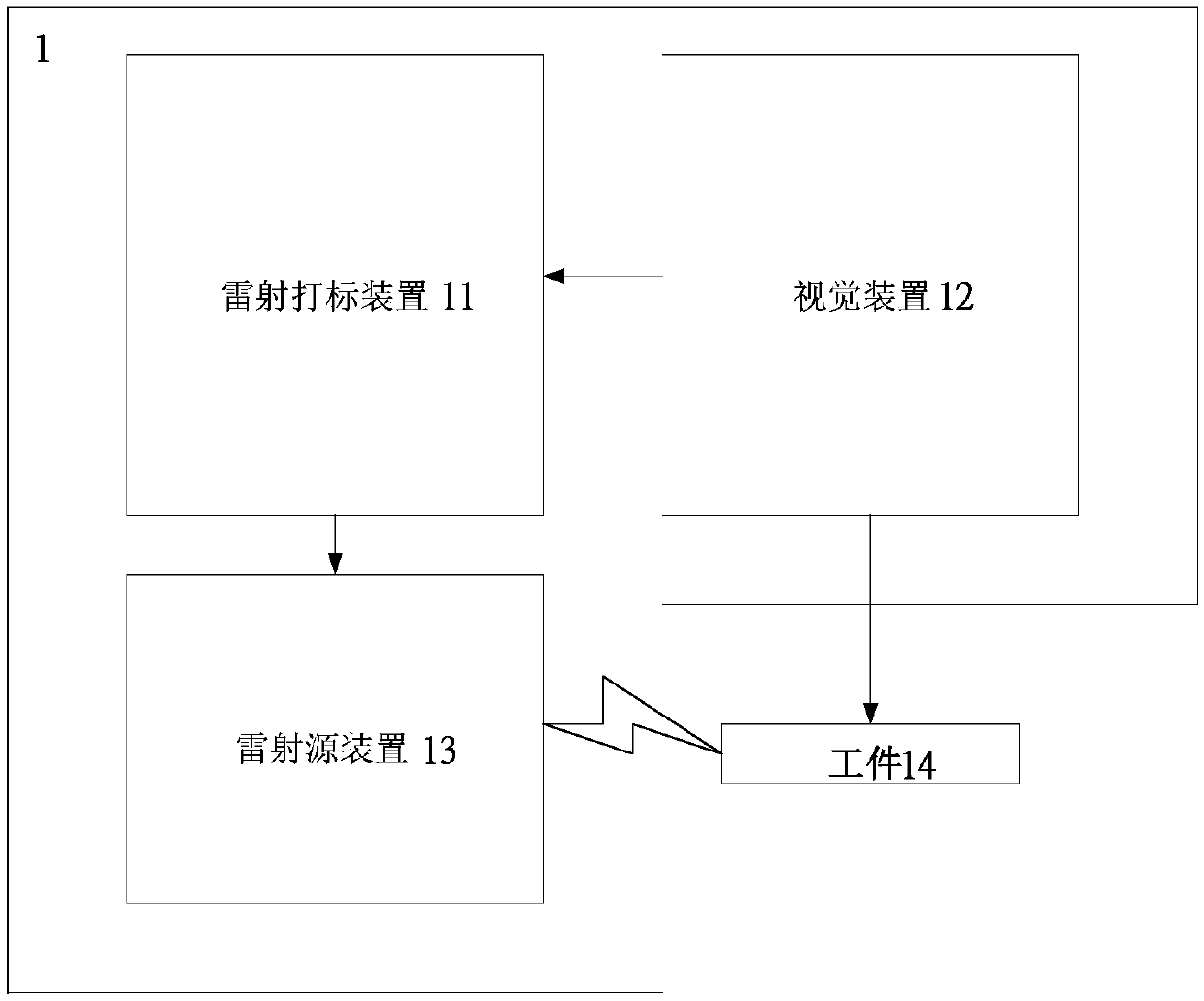

Laser marking partitioning joint device and method thereof

The invention relates to a laser marking partitioning joint device and method. The laser marking partitioning joint device comprises a laser marking device, a laser source device and a visual device,the laser marking device drives a laser source device, and the laser marking device comprises: a user interface for drawing graphics and import request data; an arithmetic module for outputting readable data according to graphics and request data; a galvanometer module for driving the laser source device; and a controller module for receiving readable data and data transmitted by the galvanometermodule, and carrying out interpolation on the readable data and the data transmitted by the galvanometer module to obtain the default value of connection graph parameters; the laser source device receives the default value of the connection graph parameters and marks the carrying out partition marking on a workpiece; and the visual device has an image capturing module and an image comparison module. The image capturing module captures the partition marking image on the workpiece, and the image comparison module carries comparison and returns the image discrimination result to the user interface. The partition marking is used to correct the partition marking image, and the visual device determines whether the partition marking image is good or bad.

Owner:新代科技(苏州)有限公司

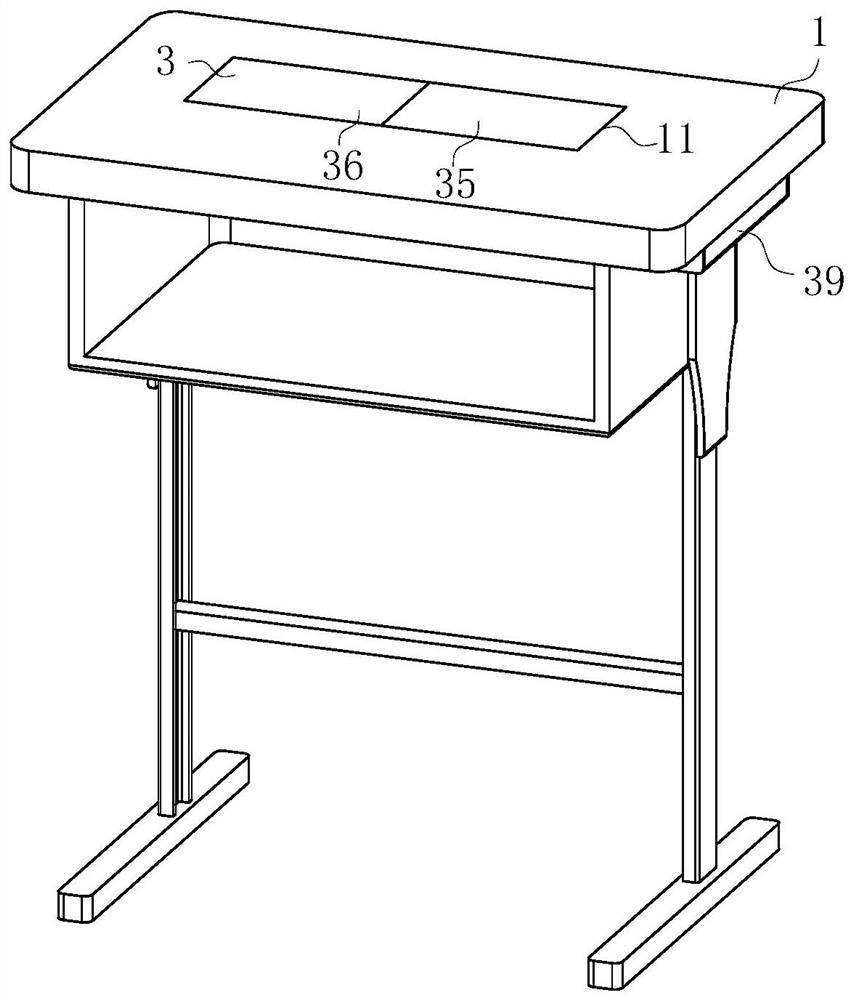

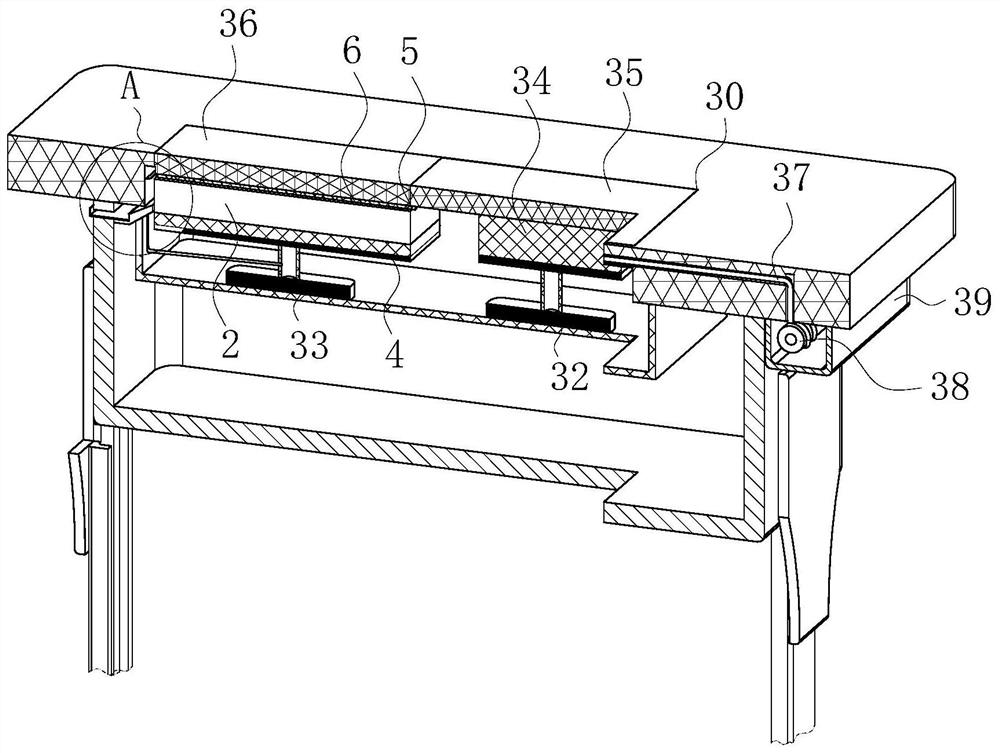

Teaching device based on big data

ActiveCN112102673AFacilitate efficient teaching workImprove safe useSchool benchesElectrical appliancesPhysicsEngineering

The invention belongs to the technical field of teaching devices, and particularly relates to a teaching device based on big data. The teaching device comprises a cloud server and a teaching operationmodule, wherein the teaching operation module comprises a tablet computer mounted on a desk; a sliding cavity is formed in the upper surface of the desk, and a fixed box is fixedly mounted at the bottom end of the sliding cavity; two electromagnetic supporting blocks are fixedly arranged in the fixed box, and elastic supporting pipes are arranged above the two electromagnetic supporting blocks; magnets are mounted above the two elastic supporting pipes, and insulating base plates are arranged on the upper surfaces of the magnets; a sealing sliding plate is arranged above the tablet computer in a sliding manner; elastic pull ropes are connected to two sides of one end of the sealing sliding plate, and the elastic pull ropes are wound on a winding drum; two sides of the other end of the sealing sliding plate are connected to the sliding cavity through springs; and the winding drum is rotationally arranged in a fixed drum, and the fixed drum is fixedly arranged on the side surface of thedesk. The teaching device facilitates students to learn more intuitively and efficiently, and meanwhile facilitates a teacher to carry out efficient teaching homework.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Device for picking out wastes and removing dust of upper module and lower module of capsule filling machine

InactiveCN105055170AReduce energy consumption and costsGood effectCapsule deliverySteel tubeDevice Panel

The invention discloses a device for picking out wastes and removing dust of an upper module and a lower module of a capsule filling machine. The device comprises a device panel (1), wherein the upper portion of the device panel (1) is inserted in a poriferous stainless steel tube (2); a brush is wound on the outside of the poriferous stainless steel tube (2); one side of the bottom of the device panel (1) is connected with a synchronous transmission shaft (11) of the capsule filling machine; and the other side of the bottom of the device panel (1) is connected with a compressed air pipe (6). Residual materials in the upper module and the lower module of the capsule filling machine can be removed effectively, particularly, viscose materials containing polysaccharides and viscose materials containing extracts can be removed, the problem that the modules are adhered to the materials is solved, the quality of products is improved effectively, the use ratio of hollow capsules can be above 95%, frequency of adhesion of capsules on the modules is reduced, loss of powder is also reduced, and production cost is saved.

Owner:NANJING ZHONGKE PHARMA +1

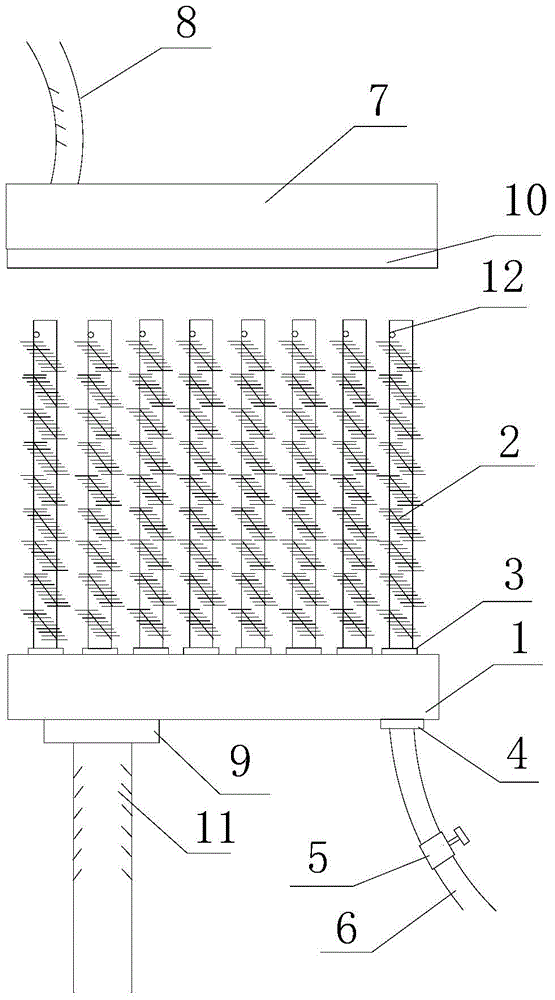

Soybean seeding device

InactiveCN110663315AHas the effect of blockingAvoid breakingPlantingSeed depositing seeder partsAgricultural engineeringBiology

The invention relates to an agricultural seeding device, in particular to a soybean seeding device. The soybean seeding device comprises a material storage and discharging mechanism, a discharging control mechanism, a connection shell, a closing mechanism and a compacting mechanism. The soybean seeding device has advantages that seed damage is avoided, seeds can be discharged completely without residues, continuous seed discharging and intermittent seed discharging can be both realized, and a soil closing function, an adjustment function and a soil compacting function are achieved. The discharging control mechanism is movably mounted in a groove of the material storage and discharging mechanism and positioned in an inner groove of the connection shell; the closing mechanism is movably mounted in through holes of the connection shell; the compacting mechanism is movably mounted on the connection shell.

Owner:田玉龙

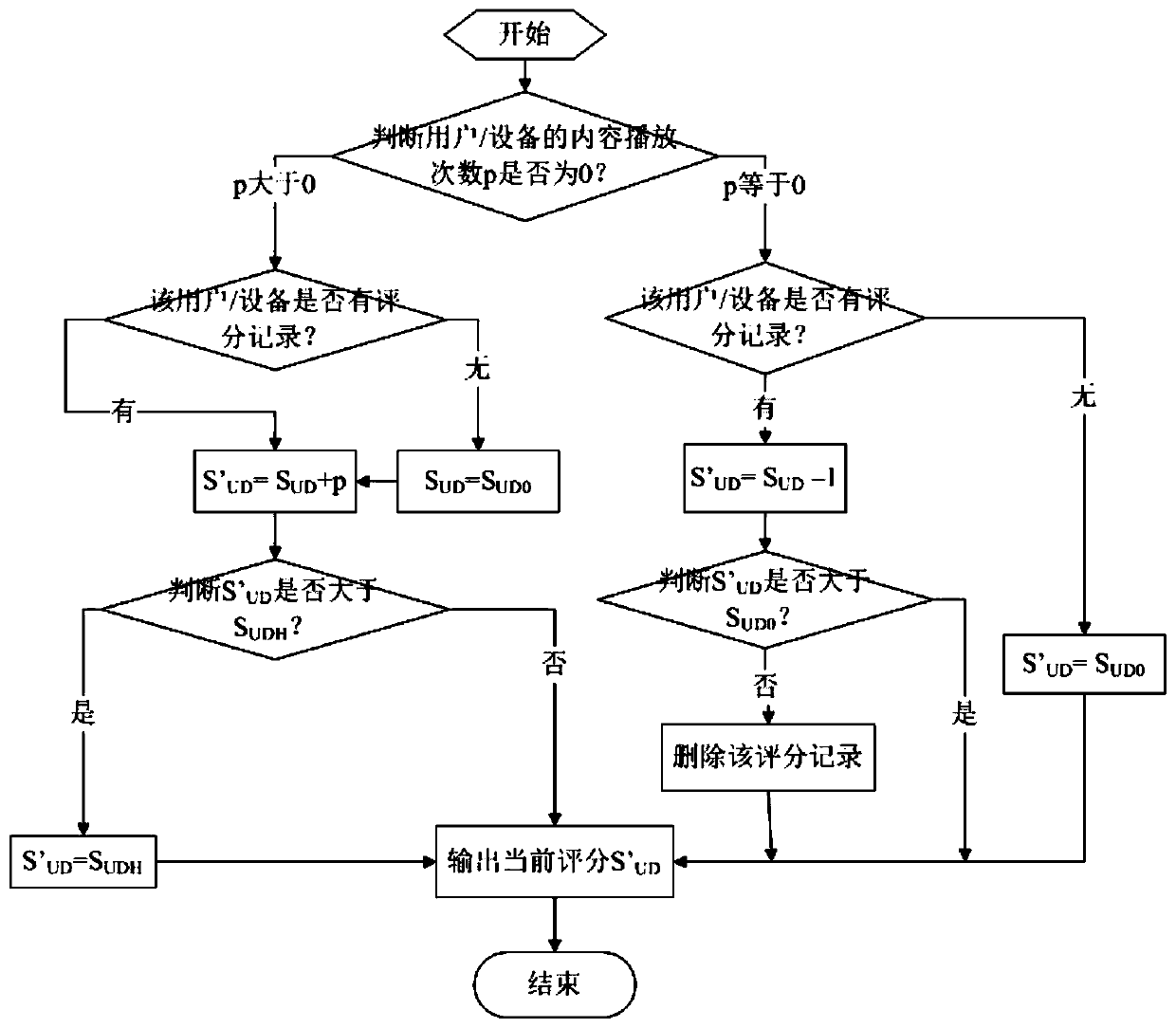

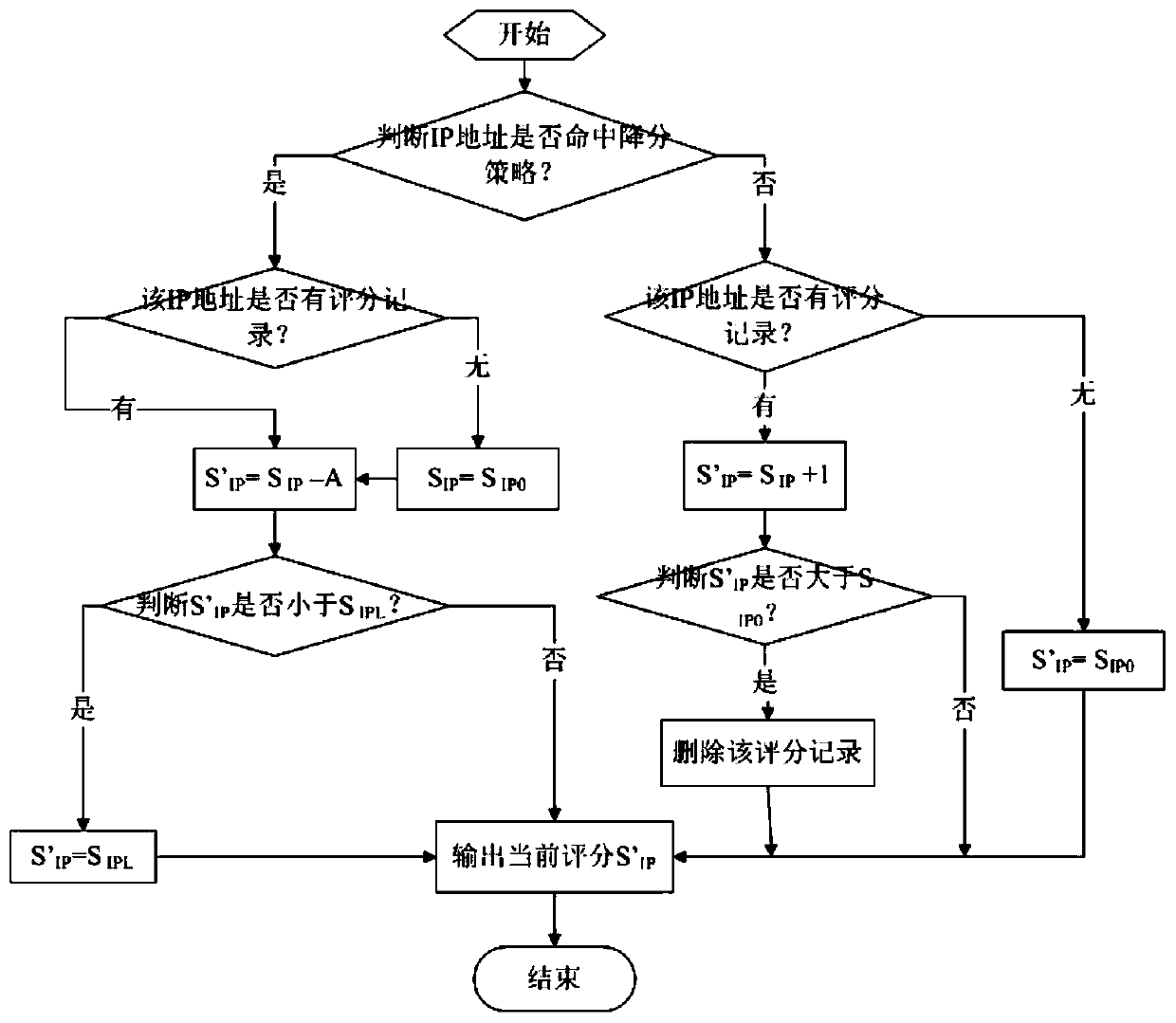

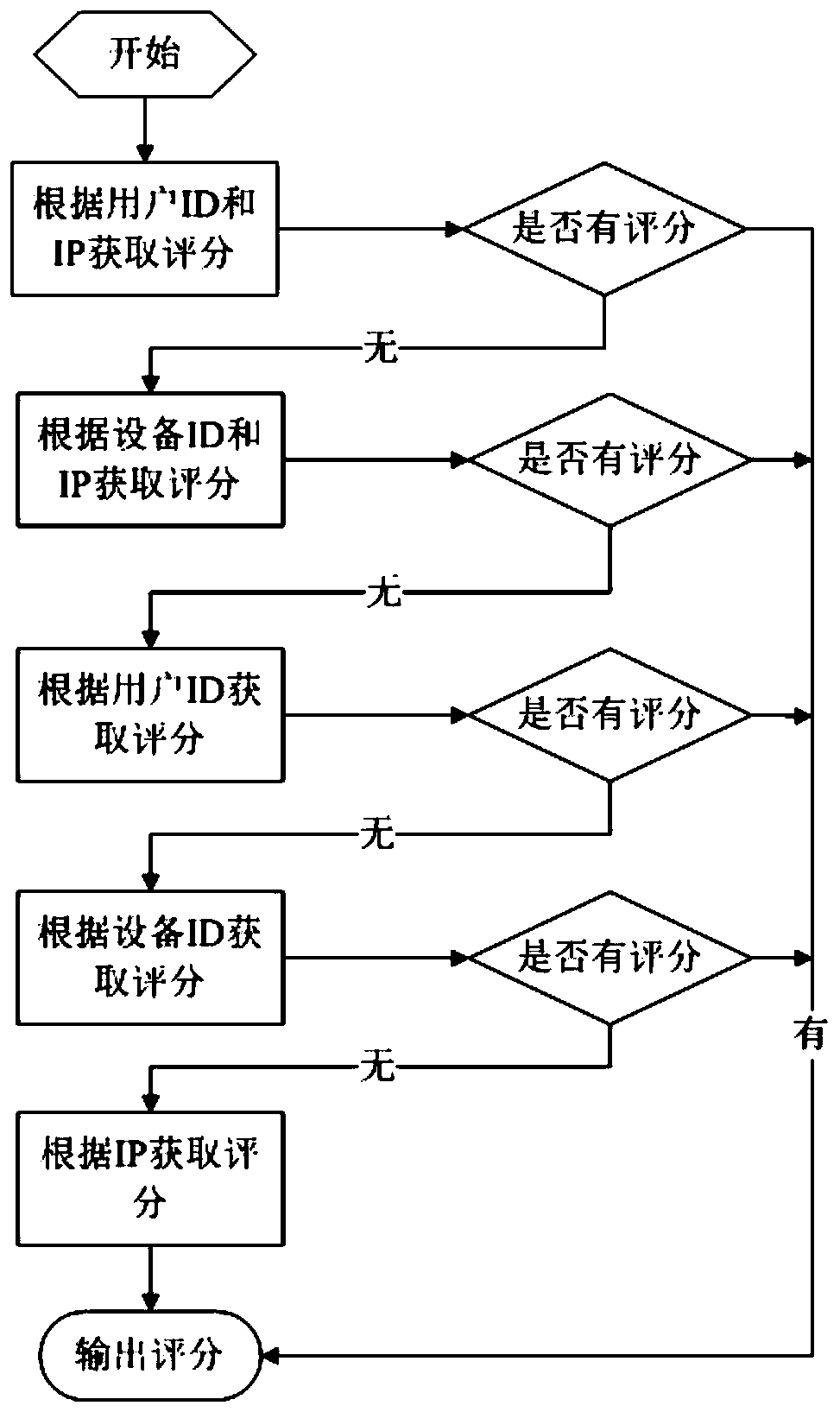

Client risk identification method and system

ActiveCN110572700ARatings are authenticReduce computing pressureSelective content distributionRisk levelAccess frequency

The invention discloses a client risk identification method and system, and relates to the technical field of video back-end development. According to the client risk identification method, when the client requests to access the server interface each time, risk level identification is carried out for one time; scores of the clients are obtained according to different types of the clients; the risklevel and the allowed access frequency of the client are determined according to the score, so that the frequency of interface access request of the client is limited, the computing pressure of the server is reduced, the computing resources of the server are saved, and the phenomenon of maliciously requesting the interface of the server is avoided. According to the risk identification method, scoring is carried out according to different types of clients, and dynamic adjustment is carried out according to an actual service scene when scoring is carried out on the clients of the same type, sothat scoring of the clients is more real and credible, and the accuracy of malicious interface access request judgment is improved.

Owner:HUNAN HAPPLY SUNSHINE INTERACTIVE ENTERTAINMENT MEDIA CO LTD

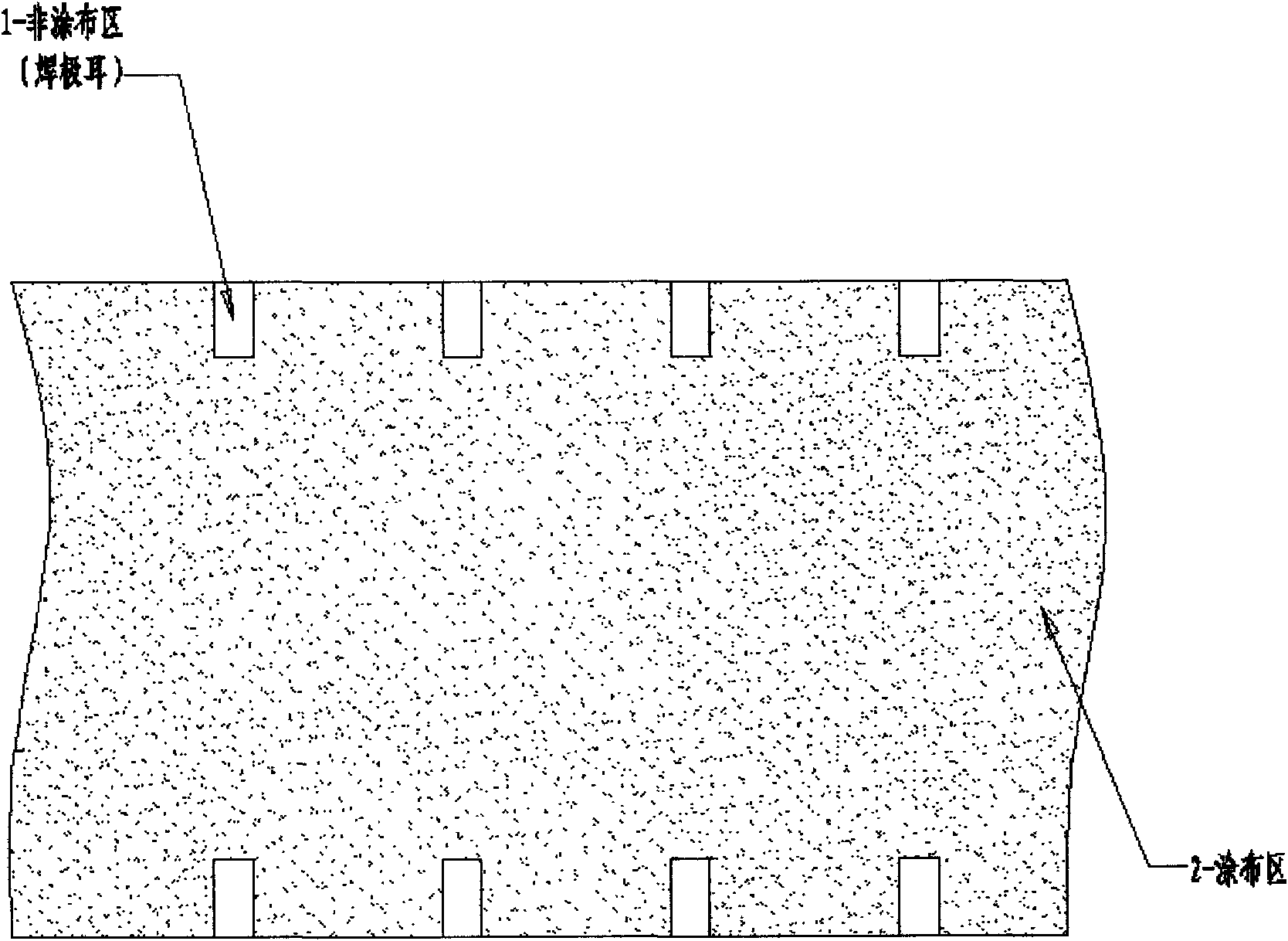

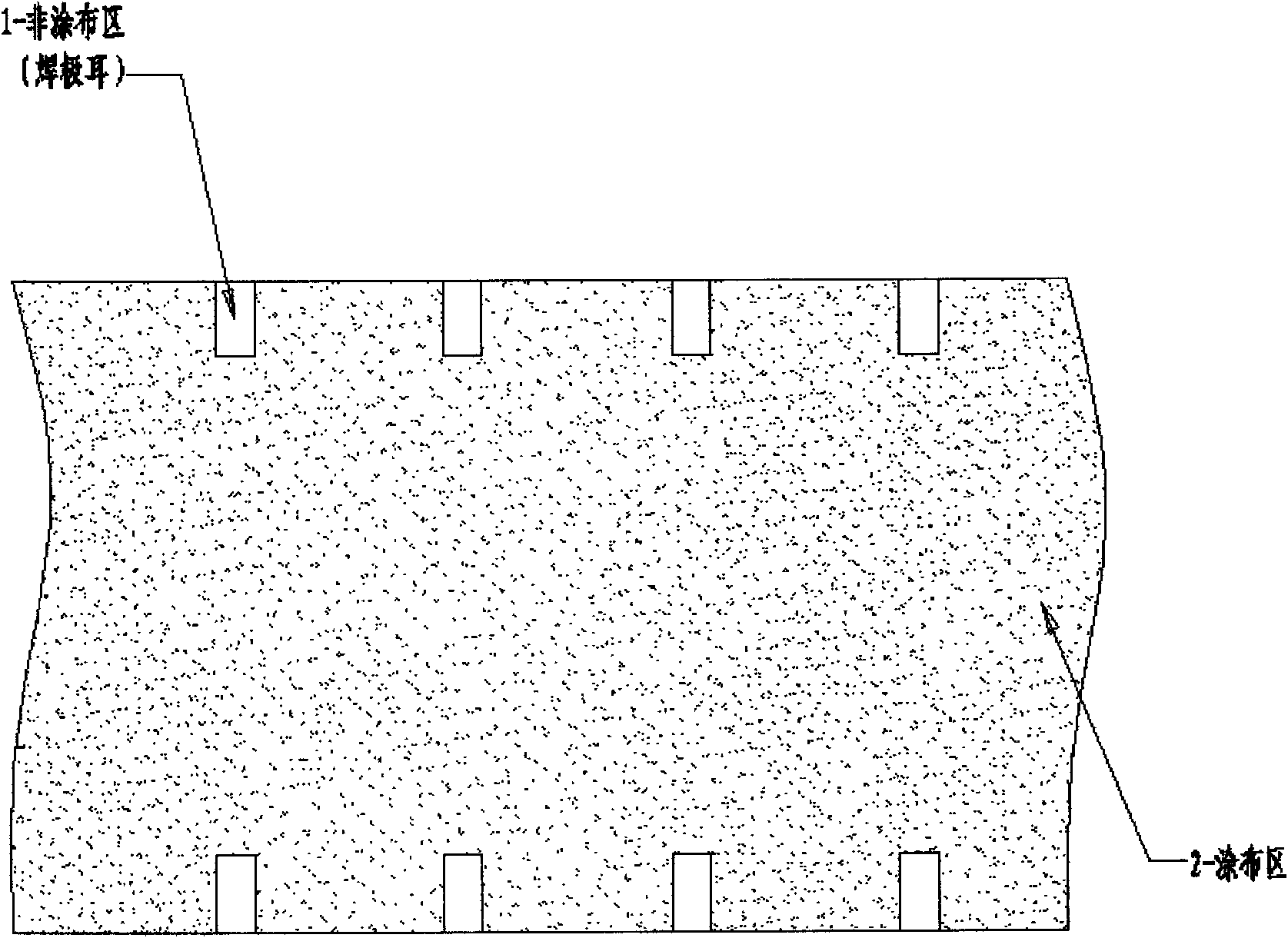

Coating process for notch type lithium ion battery

InactiveCN102205307AReduce widthLarge capacityLiquid surface applicatorsCoatingsElectrical batteryPole piece

The invention discloses a coating process for a lithium ion battery and particularly relates to a coating process for a notch type lithium ion battery. The notch type lithium ion battery comprises a coating area and a non-coating area. When a pole piece is coated, some areas of the pole piece are not coated and the uncoated areas are used for welding with pole ears. By using the coating process, the capacity of the lithium ion battery is increased, the product quality is promoted, the process is simplified, the production cost is lowered, and the process is safe, reliable and pollution-free.

Owner:梁文明

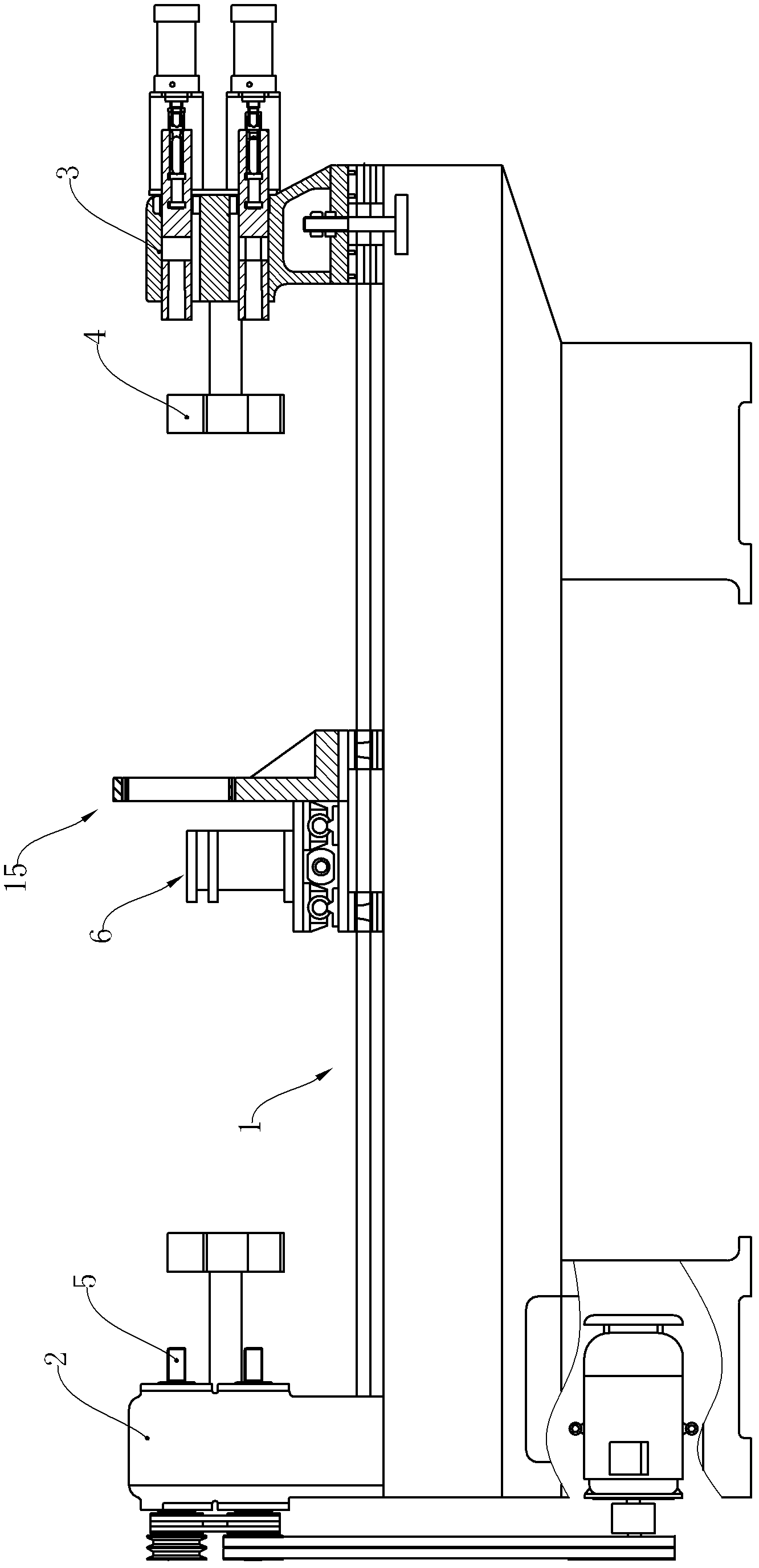

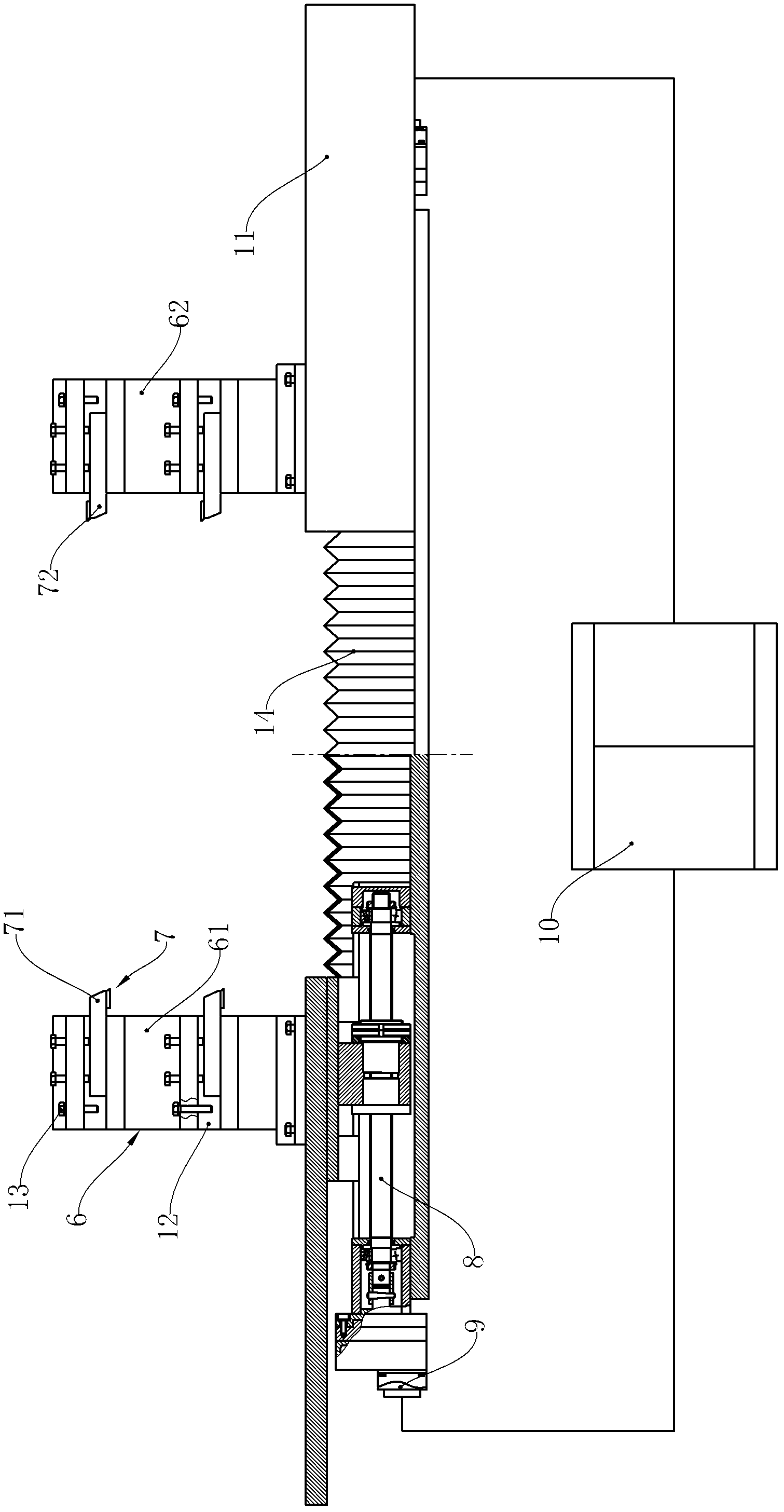

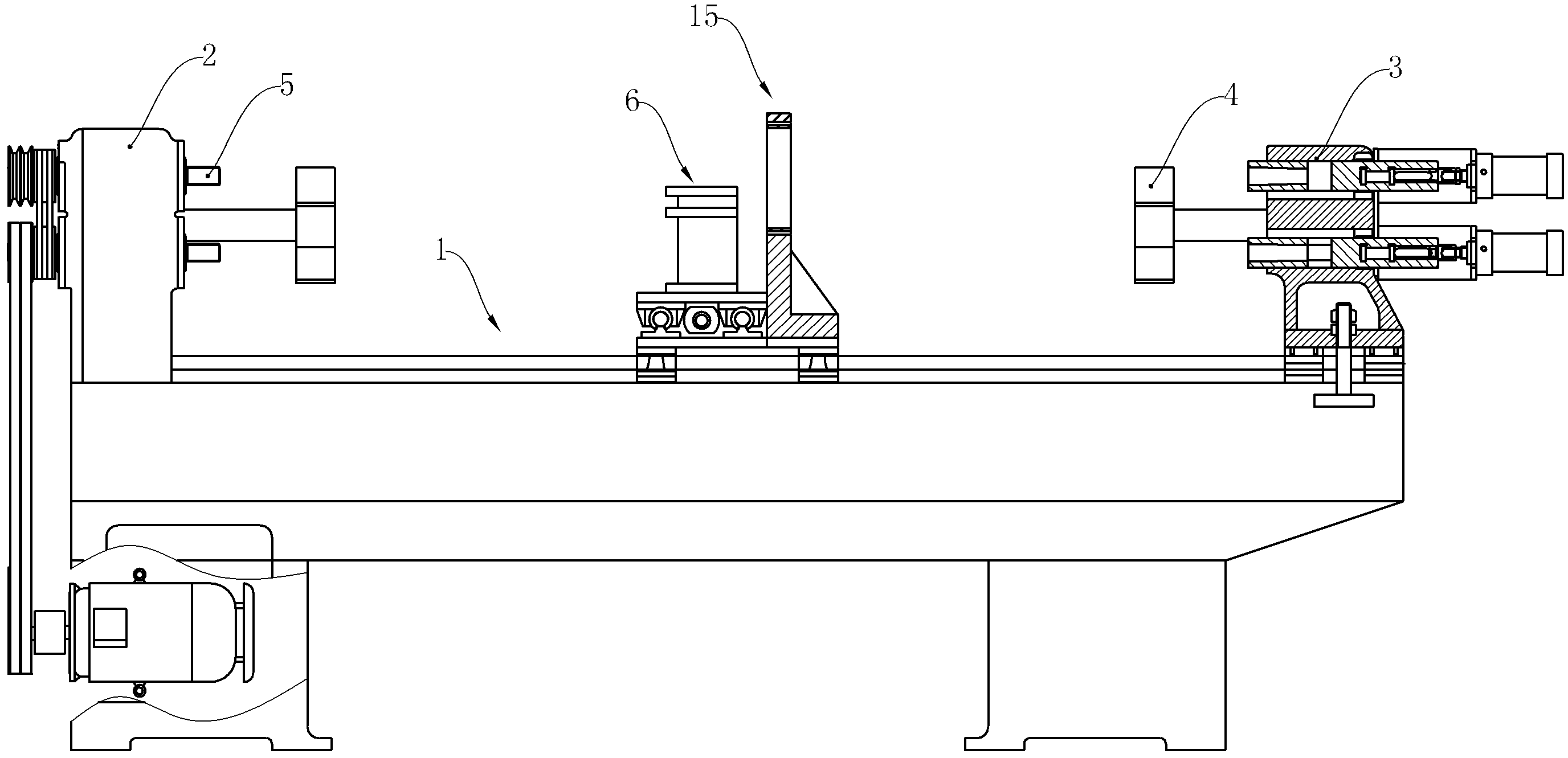

Numerical control woodworking machine tool and method for finely processing wood product thereby

InactiveCN102626936AAvoid irreparable flawsImprove the finishWood-turning machinesEyelidReciprocating motion

The invention discloses a numerical control woodworking machine tool which comprises a body provided with a feeding unit as well as a roughing turning tool table and a fine turning tool table, wherein the roughing turning tool table and the fine turning tool table are arranged face to face and are both equipped with a piece of power equipment for driving them to undergo a linear and reciprocating motion perpendicular to axis of the body. The two pieces of power equipment are connected with their corresponding control modules which are provided with an interpolation arithmetic unit, wherein the interpolation arithmetic unit of the fine turning tool table is used for controlling a machining contrail that a fine turning tool automatically tracks a roughing turning tool in real time. The invention further provides a method for finely processing a wood product by using the numerical control woodworking machine tool to overcome a double-fold eyelid. The numerical control woodworking machine tool and the method for finely processing wood product thereby provided by the invention can significantly improve processing efficiency of wood products, and overcome a double-fold eyelid phenomenon in wood product processing by using the numerical control woodworking machine tool, thus solving a technical problem existing long in the field.

Owner:山东华野机械科技有限公司

Printing equipment

InactiveCN108407442AFast dryingSpeed up the air flowRotary pressesMetal working apparatusCrankshaftComputer engineering

The invention relates to the field of printing devices, and discloses printing equipment. The printing equipment comprises a machine frame and a fixing frame, wherein a through groove which penetratesthrough the fixing frame is formed in the fixing frame, and a through hole is formed in the side wall of the fixing frame; cross shafts are fixedly connected to the two ends of the fixing frame, thecross shafts are coaxially and fixedly connected with gears, and a crankshaft is arranged below the fixing frame; a main journal of the crankshaft is rotationally connected with a first connecting rod, the other end of the first connecting rod is rotationally connected with a printing tube, the printing tube is slidably connected to the machine frame, and the top of the printing tube is connectedwith a printing plate; the printing tube is further connected with a cutting knife, push rods are rotationally arranged on the portions, on the two sides of the printing tube, of the main journal correspondingly, the other ends of the push rods are rotationally connected with racks, the racks are slidably connected to the machine frame, and the racks can be meshed with the gears, and second connecting rods are rotationally connected to the portions, at the two ends of the printing tube, of the main journal; the other ends of the second connecting rods are rotationally connected with screw rods, the screw rods are in threaded connection with nuts, and the top ends of the nuts are hinged to rotating blades. According to the device, automatically turning over a paper board during printing isrealized.

Owner:重庆川之舟印务设计有限公司

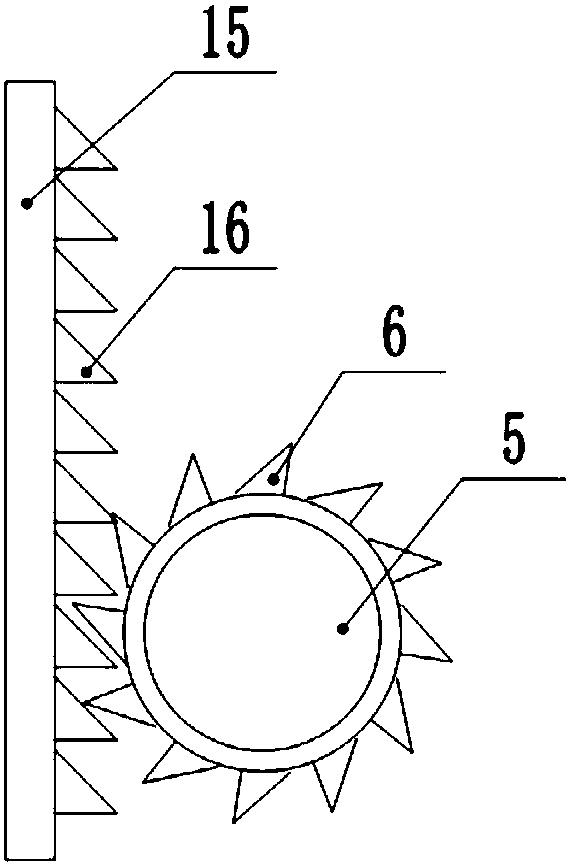

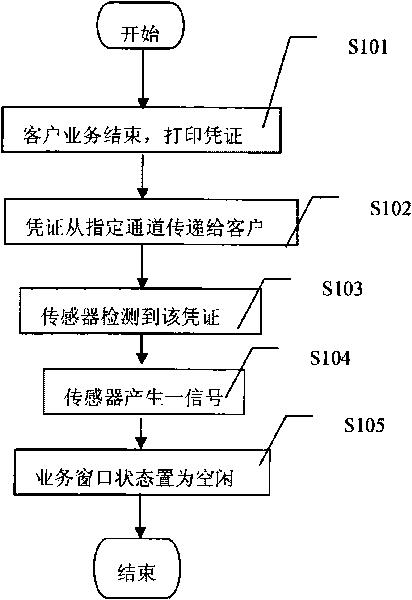

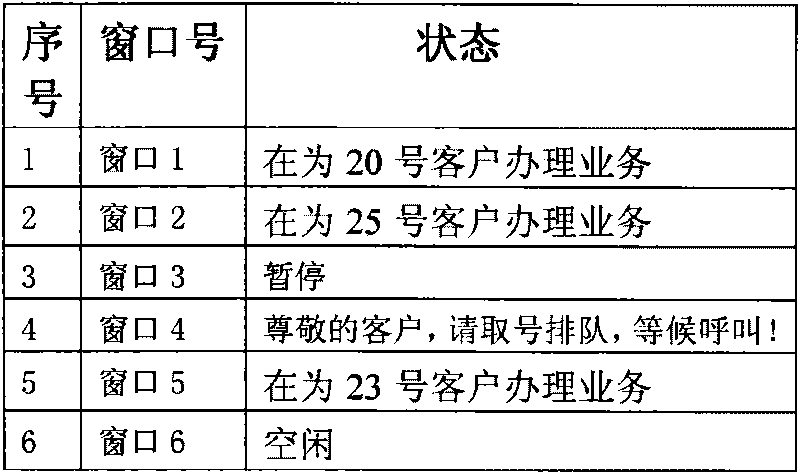

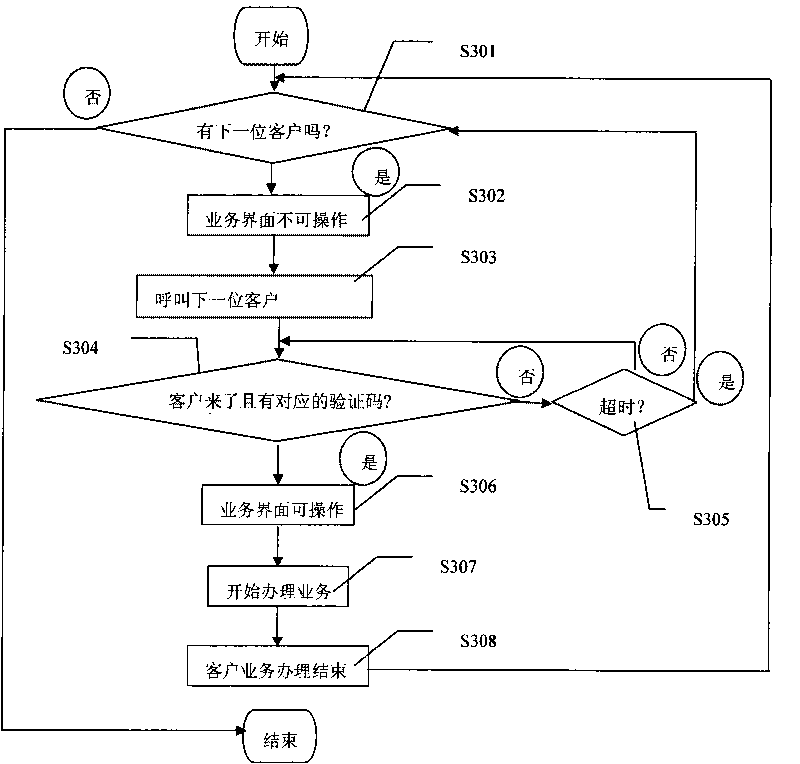

Method for queueing to prevent queue jumping

InactiveCN101739743APrevention of queue jumpingPut an end to the phenomenonChecking apparatusService personnelDistributed computing

The invention relates to a method for queueing to prevent the queue jumping, aiming at solving the problem that the client transacting the services sieves a chance to jump the queue to transact the services. After one of the clients holding the queue numbers to transact the services finishes transacting the services and a detecting device detects that a service transacting window is in the idle state, if the next client is called by the calling service and the client who is not the next client to be called in turn by the calling service comes to the service transacting counter to transact the services, the client can be detected by the detecting device as the client who jumps the queue and can be warned, thus the service personnel can not transact the services for the client who jumps the queue and the clients can transact the services according to the sequence of the queue numbers, which reflects the principles of justness, fairness and openness and is good for building a harmonious society.

Owner:郑志豪 +1

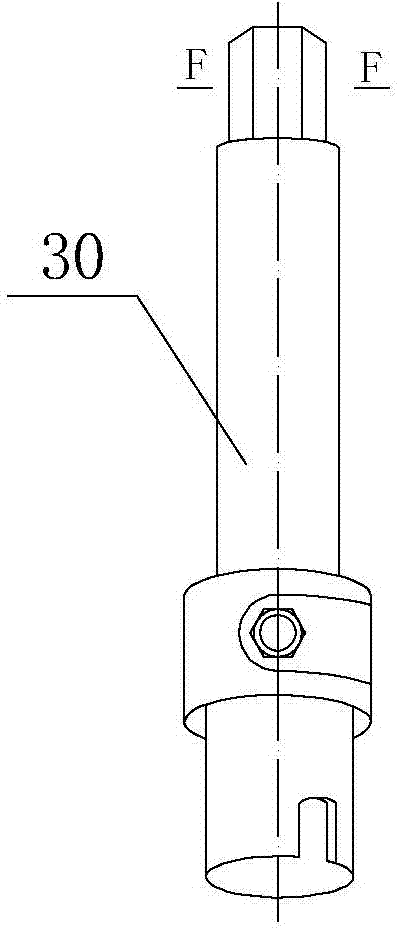

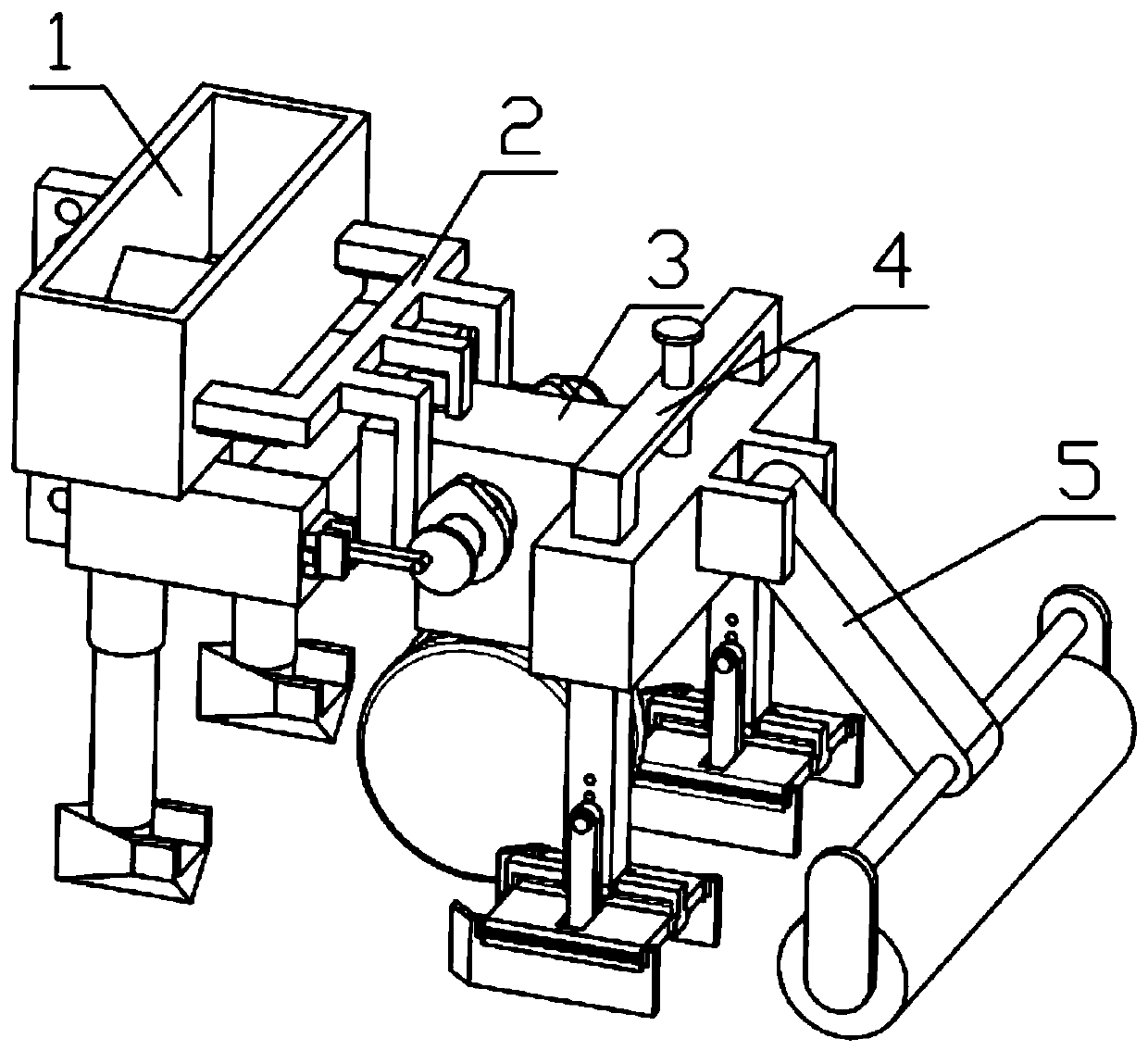

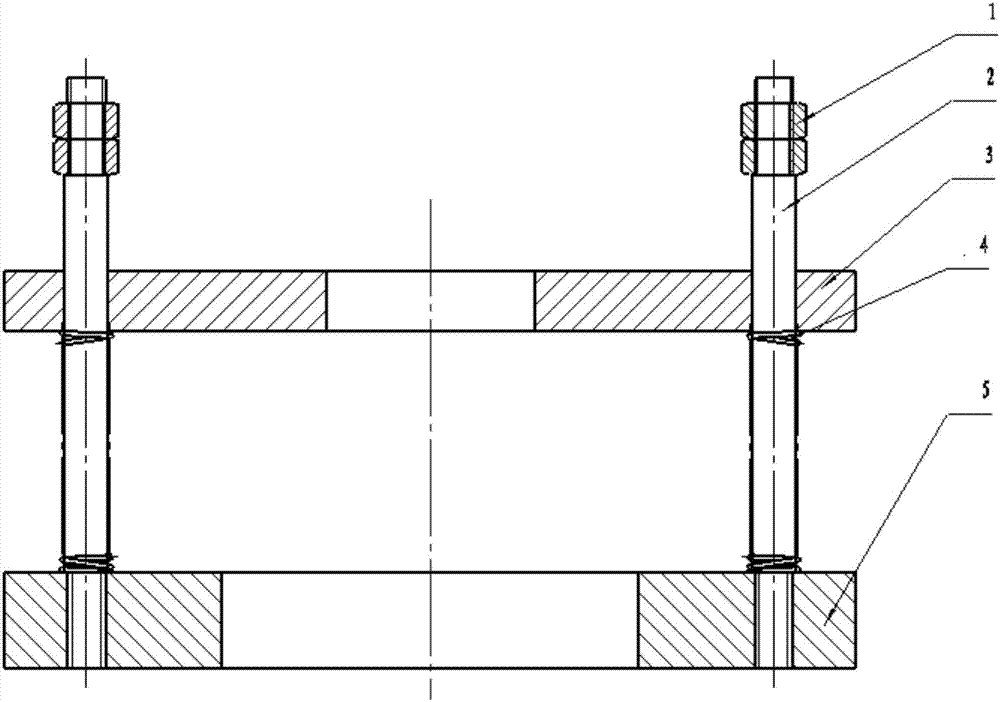

Die discharging structure for avoiding punch wrapping during warm forging reverse extrusion

InactiveCN107186153APut an end to the phenomenonIncrease productivityForging/hammering/pressing machinesEngineeringForge

The invention discloses a die discharging structure for avoiding punch wrapping during warm forging reverse extrusion. The die discharging structure is characterized by comprising discharging rods and a discharging plate arranged on the discharging rods in a sleeving mode, and the discharging plate can freely move on the discharging rods and is fixed at the upper ends of the discharging rods by nuts. The die discharging structure for avoiding punch wrapping during warm forging reverse extrusion is simple, the phenomenon that a warm forging reverse extrusion forge piece wraps a punch is effectively avoided, and the production efficiency is improved.

Owner:JIANGSU SUNWAY PRECISION FORGING

Wastewater evaporating process and device system

ActiveCN102060408BReduce energy consumptionAchieve resource utilizationSolution crystallizationMultistage water/sewage treatmentProcess systemsTriple effect

The invention discloses a wastewater evaporating process and device system. The wastewater evaporating process comprises the following steps: the wastewater to be treated firstly enters a pretreatment softening system for softening treatment and secondly enters a mechanical vapor recompression (MVR) system for evaporation concentration; the generated secondary steam is compressed and enters an evaporator for recycling; the concentrated solution enters a triple effect flow-mixing forced circulation evaporation and crystallization system for evaporation and crystallization; the generated secondary steam is reused by the evaporation and crystallization system; the concentrated solution and crystalline grains obtained through crystallization are subject to solid-liquid centrifugal separation;the separated mother solution is sent back to a raw liquor tank or evaporated continuously for crystallization; and the separated crystals enter a centrifugal drying and packaging system for weighting and packaging. After the process disclosed by the invention is adopted to soften, evaporate and crystallize wastewater and dry and package the obtained crystals, wastewater is not discharged to the water bodies of the surface of earth and the aim of zero wastewater discharge can be realized; the process system is low-carbon and environmentally friendly; the material can be recycled, the thermal efficiency is high, the energy consumption is low, the energy can be saved, the operating cost can be greatly reduced, the range of temperature is small, the corrosion is low and the service life of the equipment is long, and the scaling has small possibility of occurrence.

Owner:华电水务工程有限公司 +1

Ethylene cracking furnace of double-section heat supply structure

ActiveCN104560114AReduce the amount usedReduce equipment investment costs and operation and maintenance costsThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingQuenchingEngineering

The invention provides an ethylene cracking furnace of a double-section heat supply structure. The ethylene cracking furnace comprises a radiation section (1), a convection section (5), a radiation coiled tube (4), a quenching boiler (6), a high-pressure steam pocket (7) and a draft fan (8), wherein the quenching boiler (6) is connected with the radiation coiled tube (4); the draft fan (8) is connected with the top of the convection section (5); and the high-pressure steam pocket (7) is connected with the quenching boiler (6). The ethylene cracking furnace is of the double-section combined heat supply structure that the radiation section (1) is internally provided with an upper heat supply section and a lower heat supply section. By adopting the ethylene cracking furnace of the double-section heat supply structure, the arrangement of a combustor and the design of a combustion tube line arrangement are simplified, the flame inside a hearth is prevented from coiling to touch furnace tubes, interference of flame is also prevented, uniform distribution of heat in the height direction inside the hearth in the radiation section is maintained, and meanwhile the emission of NOx is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com