Patents

Literature

101results about How to "Achieve resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wastewater evaporation concentration process and device system

InactiveCN102070272AAvoid easy cloggingGuaranteed uptimeMultistage water/sewage treatmentAlkali metal chloridesProcess systemsSludge

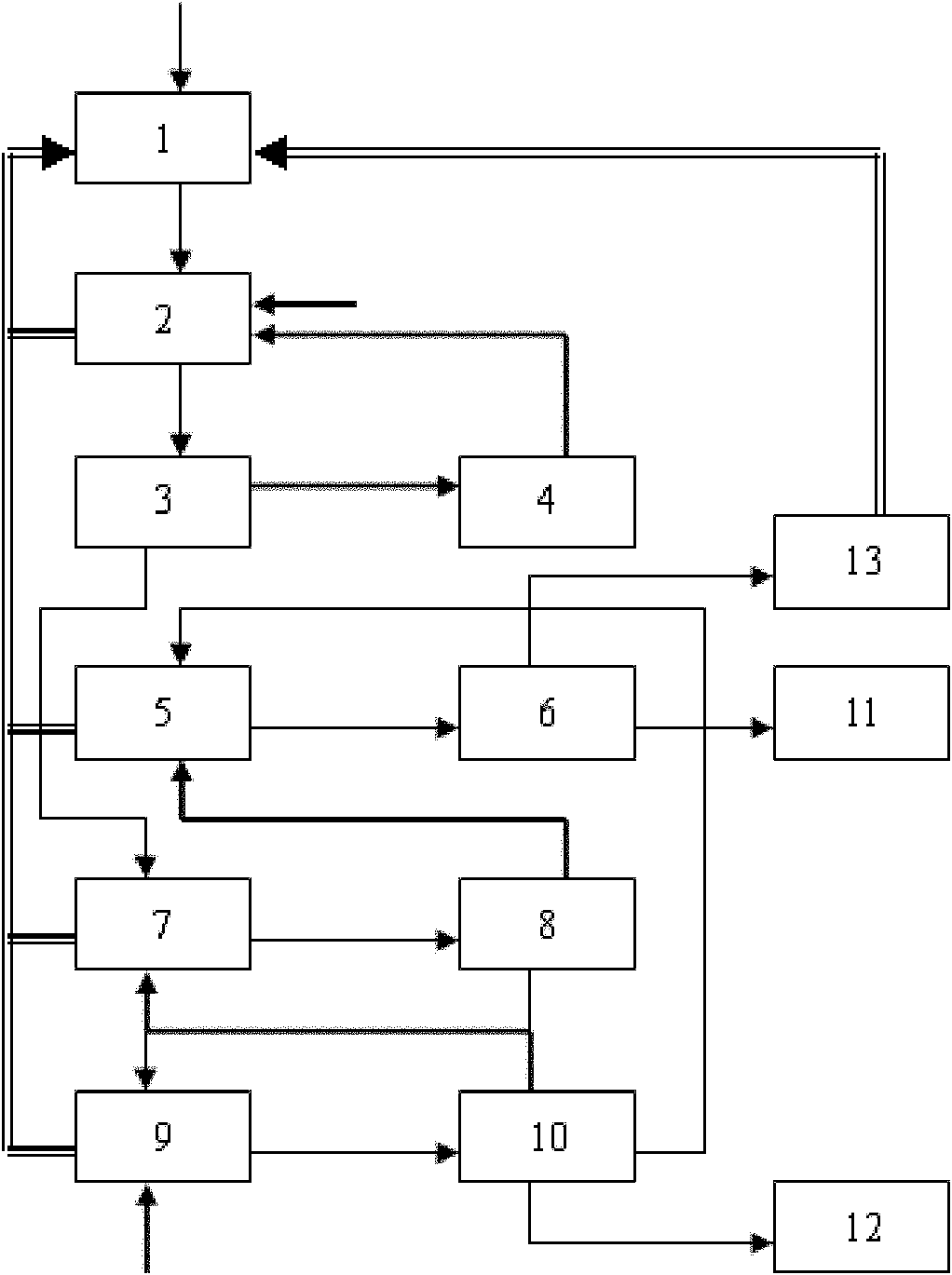

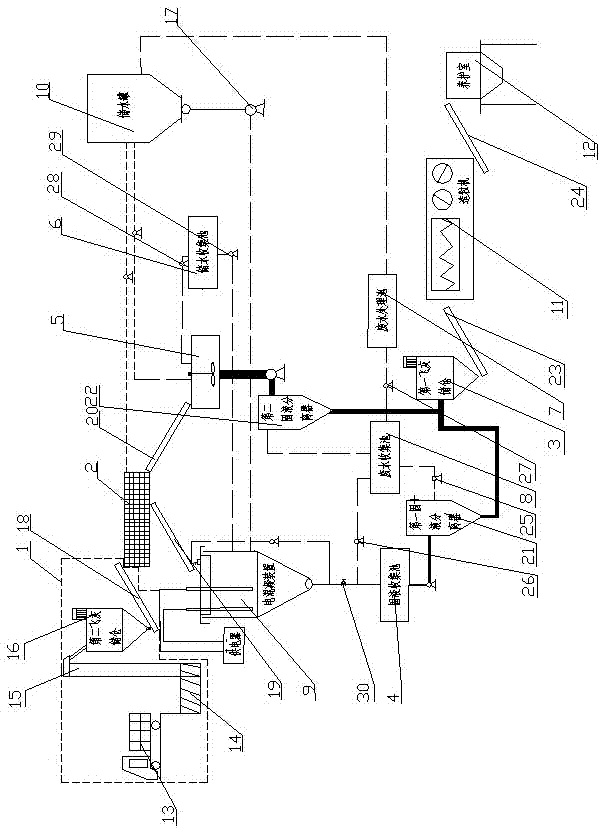

The invention discloses a wastewater evaporation concentration process and a wastewater evaporation concentration device system. The process comprises the following steps of: delivering softened wastewater to be treated to a mechanical vapor recompression (MVR) system to perform evaporation and concentration, compressing the generated secondary steam and then delivering the compressed steam to an evaporator to recycle, delivering the concentrate to a triple-effect mixed flow forced circulating evaporation crystallization system to perform evaporation and crystallization, performing solid-liquid centrifugal separation on the crystallized concentrate and crystal grains, returning the separated mother solution to a stock solution tank or continuously performing evaporation and crystallization, and reclaiming the separated crystal, wherein the secondary steam generated by evaporation and crystallization is recycled for the evaporation crystallization system. After the wastewater is evaporated and concentrated by adopting the process of mechanical vapor recompression circulating evaporation and triple-effect mixed flow forced circulating evaporation crystallization, the wastewater does not need to be discharged to the ground water area, and the wastewater is discharged in a form of steam or closed and embedded in a form of sludge or the like, so the purpose of zero discharge of the wastewater can be fulfilled; and the process system has high heat efficiency, low energy consumption, energy conservation, great reduction in running cost, low temperature difference, low corrosion, difficult scale formation and long equipment service life.

Owner:华电水务工程有限公司 +1

Wastewater evaporating process and device system

ActiveCN102060408AAvoid shockAvoid easy cloggingMultistage water/sewage treatmentProcess systemsTriple effect

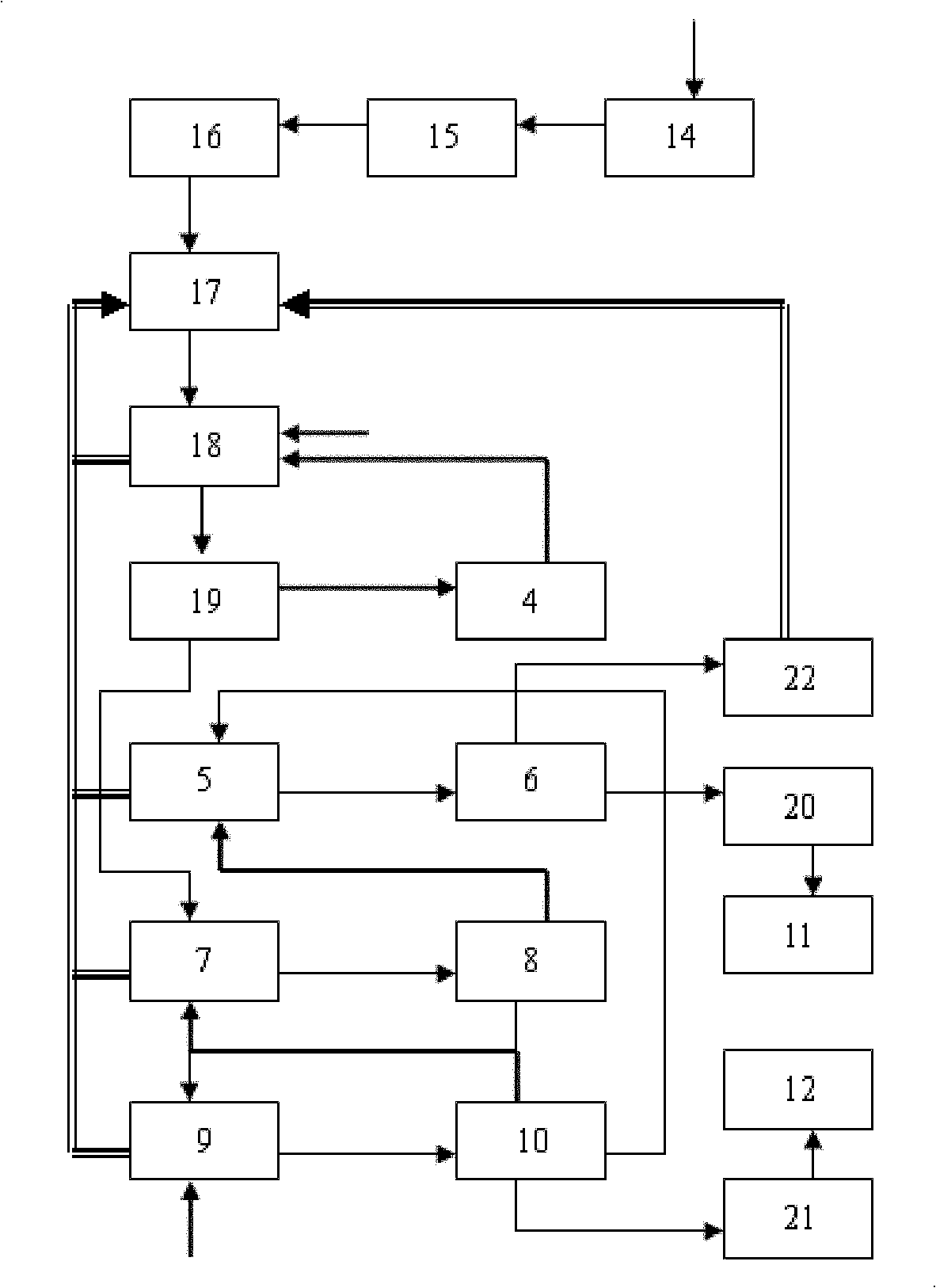

The invention discloses a wastewater evaporating process and device system. The wastewater evaporating process comprises the following steps: the wastewater to be treated firstly enters a pretreatment softening system for softening treatment and secondly enters a mechanical vapor recompression (MVR) system for evaporation concentration; the generated secondary steam is compressed and enters an evaporator for recycling; the concentrated solution enters a triple effect flow-mixing forced circulation evaporation and crystallization system for evaporation and crystallization; the generated secondary steam is reused by the evaporation and crystallization system; the concentrated solution and crystalline grains obtained through crystallization are subject to solid-liquid centrifugal separation; the separated mother solution is sent back to a raw liquor tank or evaporated continuously for crystallization; and the separated crystals enter a centrifugal drying and packaging system for weighting and packaging. After the process disclosed by the invention is adopted to soften, evaporate and crystallize wastewater and dry and package the obtained crystals, wastewater is not discharged to the water bodies of the surface of earth and the aim of zero wastewater discharge can be realized; the process system is low-carbon and environmentally friendly; the material can be recycled, the thermal efficiency is high, the energy consumption is low, the energy can be saved, the operating cost can be greatly reduced, the range of temperature is small, the corrosion is low and the service life of the equipment is long, and the scaling has small possibility of occurrence.

Owner:华电水务工程有限公司 +1

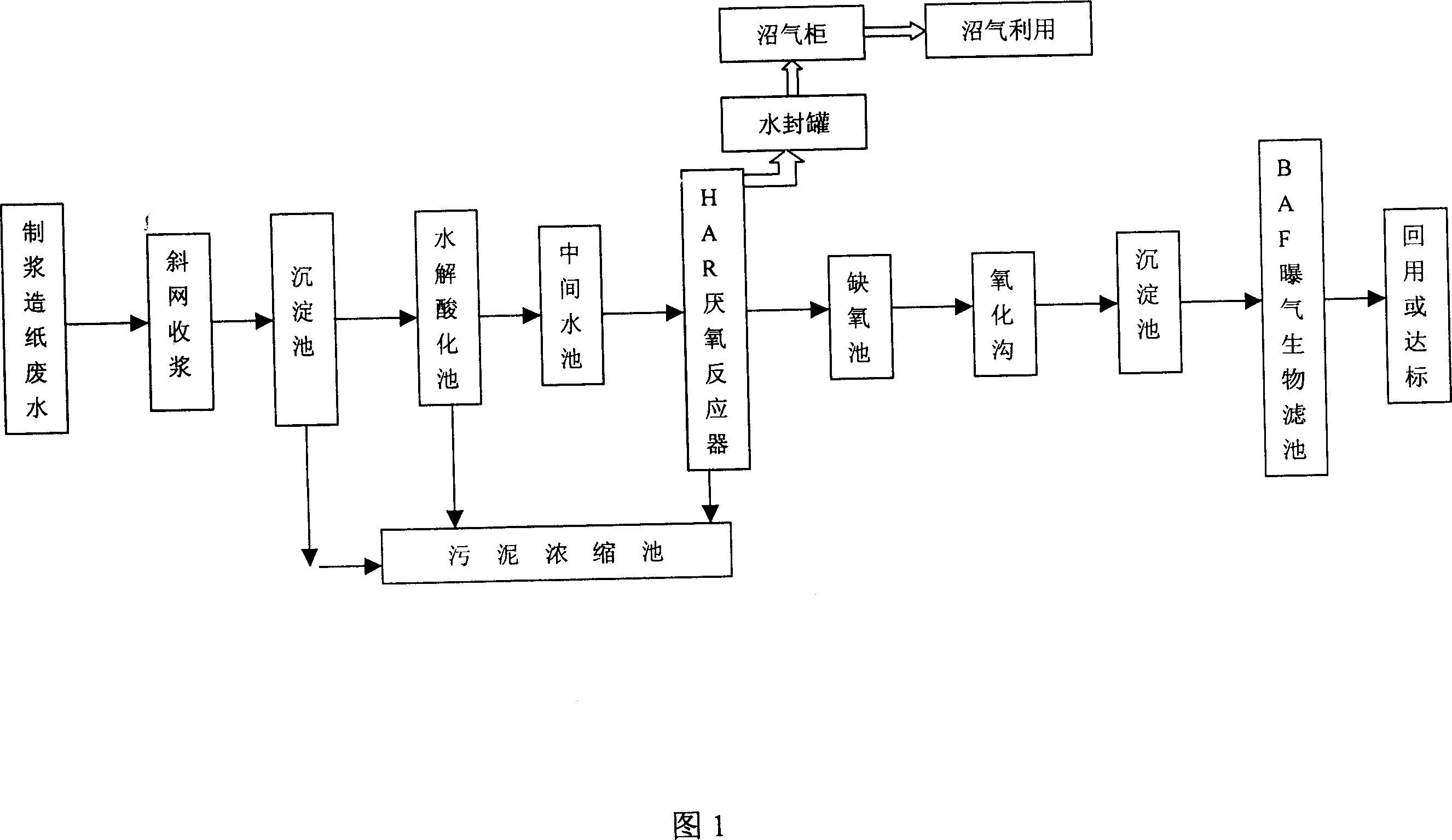

Paper-making effluent purifying treatment process

InactiveCN1931749AAchieve resource utilizationTo achieve the purpose of resource utilizationTreatment using aerobic processesWaste based fuelMedicineWastewater

The present invention is paper-making effluent purifying treatment process including hydrolyzing acidification, anaerobic biological treatment, anoxia treatment, aerobic biological treatment and aerobic biofilter treatment mainly. The present invention has low treating cost, low power consumption, capacity of generating energy source with produced methane, high treating efficiency, high COD and SS eliminating rate, and other advantages.

Owner:山东贵和显星纸业有限公司

Multifunctional seedling cultivation substrate

ActiveCN103392575AControl leggyImprove root vitalityCultivating equipmentsSoilless cultivationBiotechnologyGrowth retardant

The invention discloses a multifunctional seedling cultivation substrate which comprises the components of EM fermented maize straws, perlite, vermiculite and prohexadione calcium, wherein the volume ratio of the EM fermented maize straws, the perlite and the vermiculite is 6: 3: 1, and the amount of the prohexadione calcium is 10-20g / m<3>. The multifunctional seedling cultivation substrate can control excessive growth of seedlings and can effectively prevent side effects of sprayed conventional growth inhibitors, and cultivated seedlings are superior to existing conventional seedling cultivation substrates in root activity, strong seedling index, yield and other aspects. Meanwhile, using amount of grass carbon is reduced, grass carbon resource saving is facilitated, and the purposes of resource utilization of agricultural wastes and environment pollution reduction are achieved.

Owner:SHANDONG SHOUGUANG VEGETABLE IND GRP

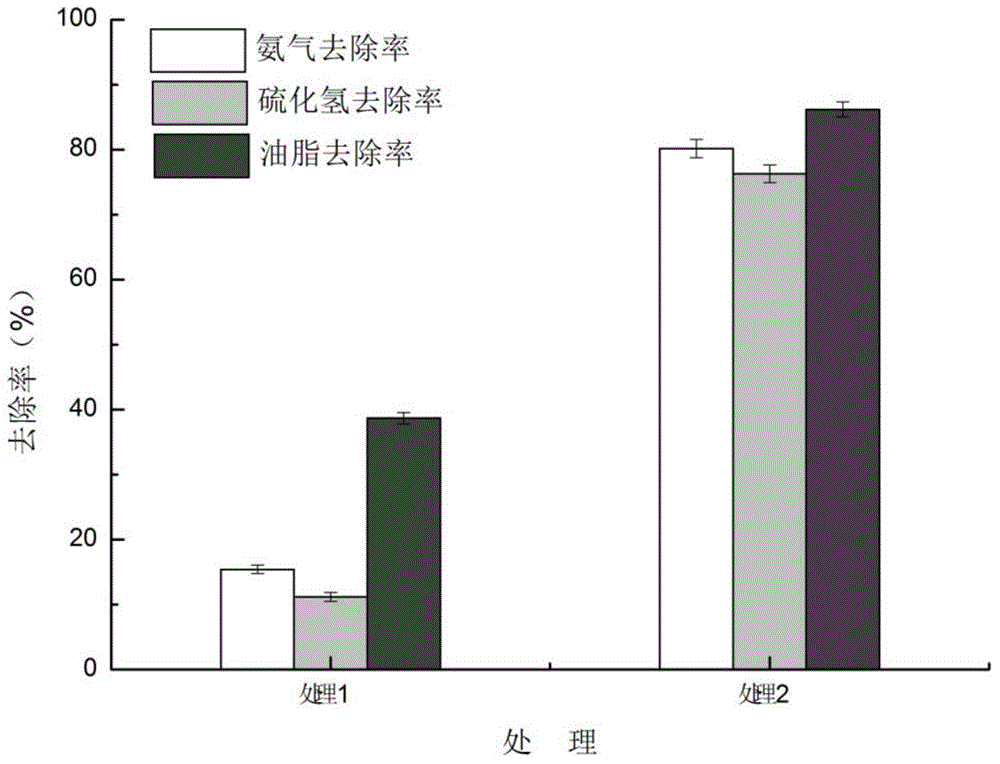

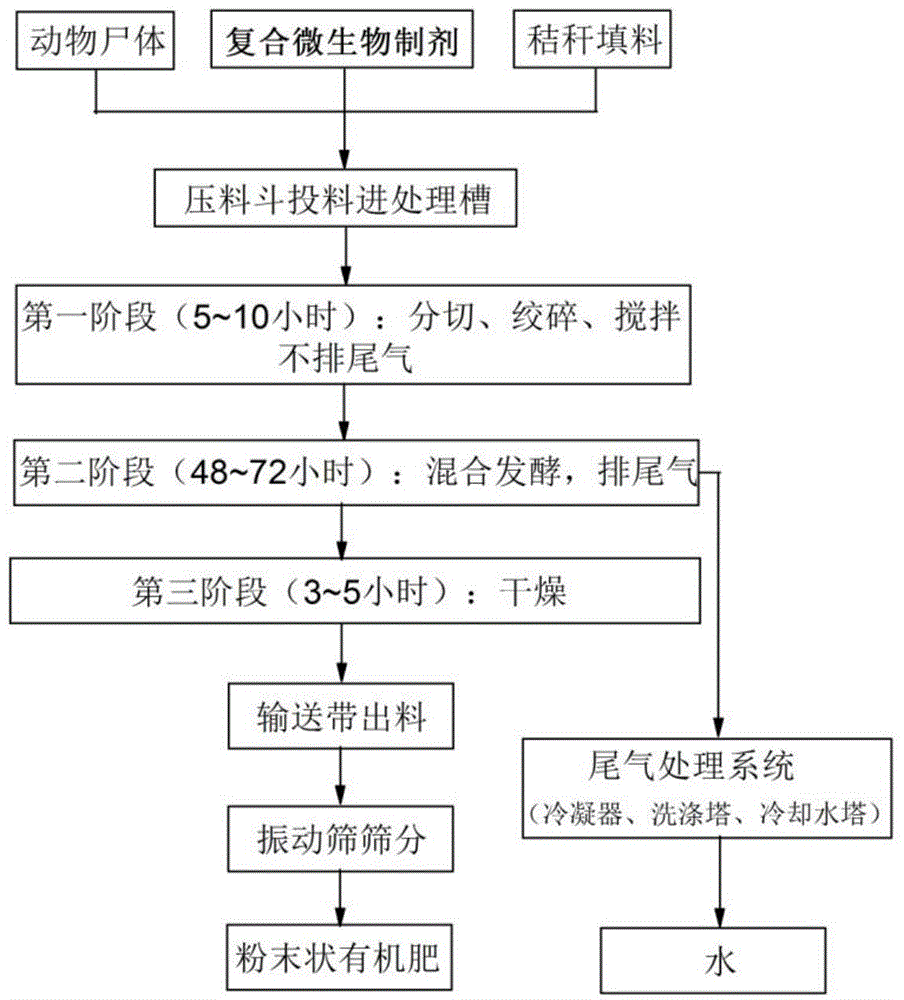

Compound microorganism preparation, preparing method and application of compound microorganism preparation to processing animal carcasses

ActiveCN104894007AEfficient decompositionQuick breakdownBio-organic fraction processingBacteriaBiotechnologyCellulose

The invention discloses a compound microorganism preparation. The compound microorganism preparation comprises thermophilic fat bacillus, pseudomonas aeruginosa, streptococcus thermophilus, bacillus megatherium and bacillus flexus. The invention further discloses a preparing method of the compound microorganism preparation and application of the compound microorganism preparation to processing animal carcasses. Compared with the prior art, the compound microorganism preparation has the beneficial effects that macromolecular compounds, such as fat and celluloses in the animal carcasses and straw auxiliary materials, which are difficult to decompose can be efficiently and rapidly decomposed through the compound microorganism preparation, and the animal carcasses are converted into organic fertilizers with the low fat content; and the compound microorganism preparation further has the efficient deodorization function, the release amount of NH3 and H2S in the processing procedure can be effectively reduced, the stink concentration is reduced, and odorless processing is achieved. Finally, the animal carcasses are efficiently and safely processed into the organic fertilizers in an environmental protection manner, and resource utilization of the animal carcasses is achieved.

Owner:ANHUI QINGMING ENVIRONMENTAL PROTECTION TECH CO LTD

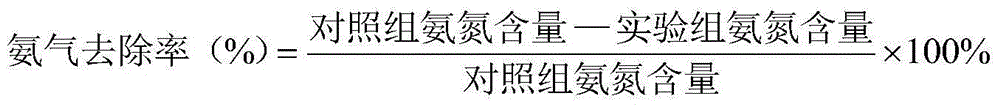

Domestic garbage treatment method and its special fermentation room

InactiveCN1840511AGuaranteed reducedAchieving zero emissionsClimate change adaptationOrganic fertiliser preparationLitterSewage

The related treatment method for domestic garbage comprises: adding 0.5-1.0% aerobic microbe into the fermentation room; breaking, air separating, and collecting exudate for standby; taking first fermentation for 15-25day to let water content in compost material as 30-40%, and collecting exudate for standby; adding aerobic microbe again and former exudates to keep water content as 45-55%for second static fermentation for 25-35day. This invention has well effect with low cost.

Owner:CHINA AGRI UNIV

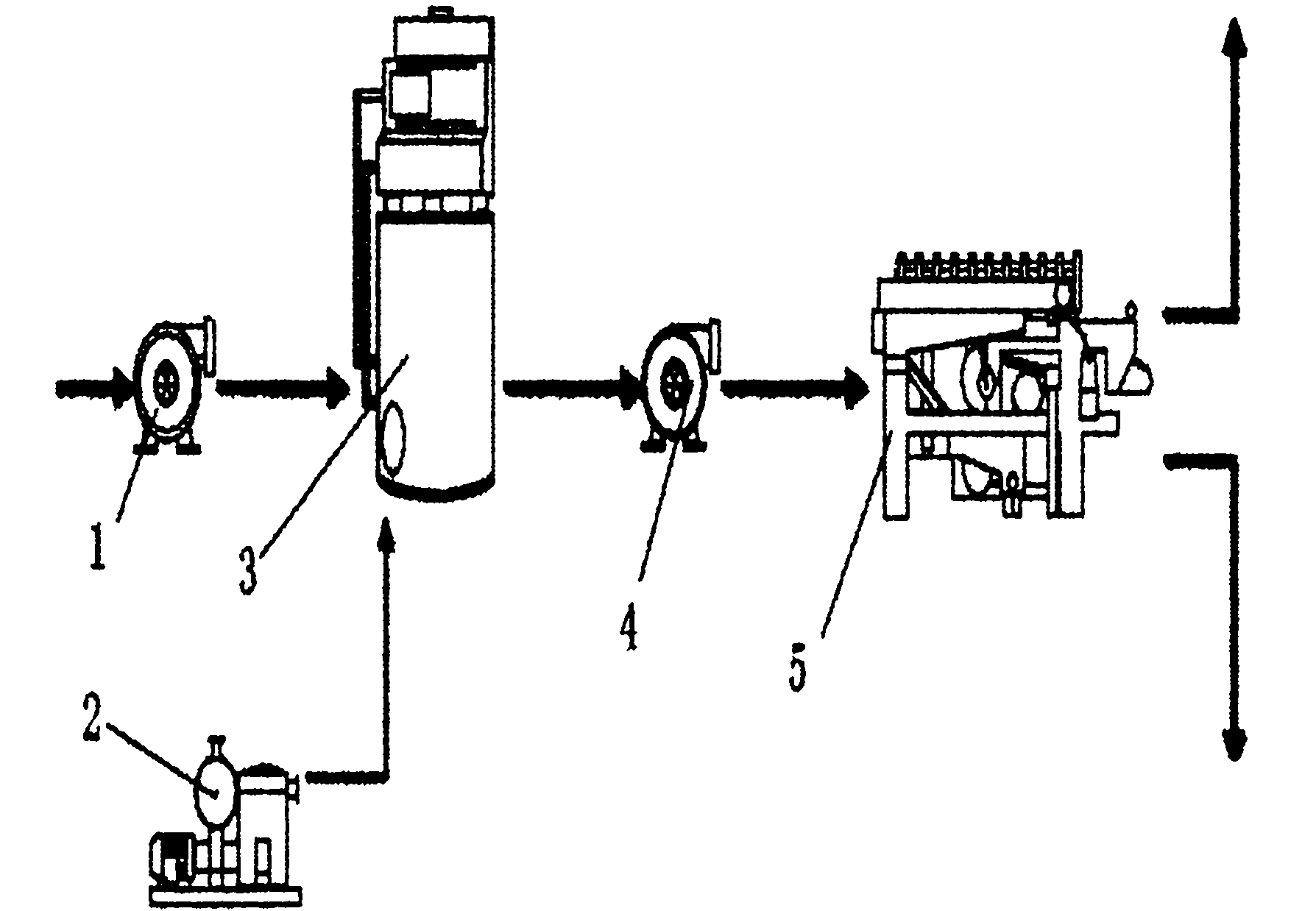

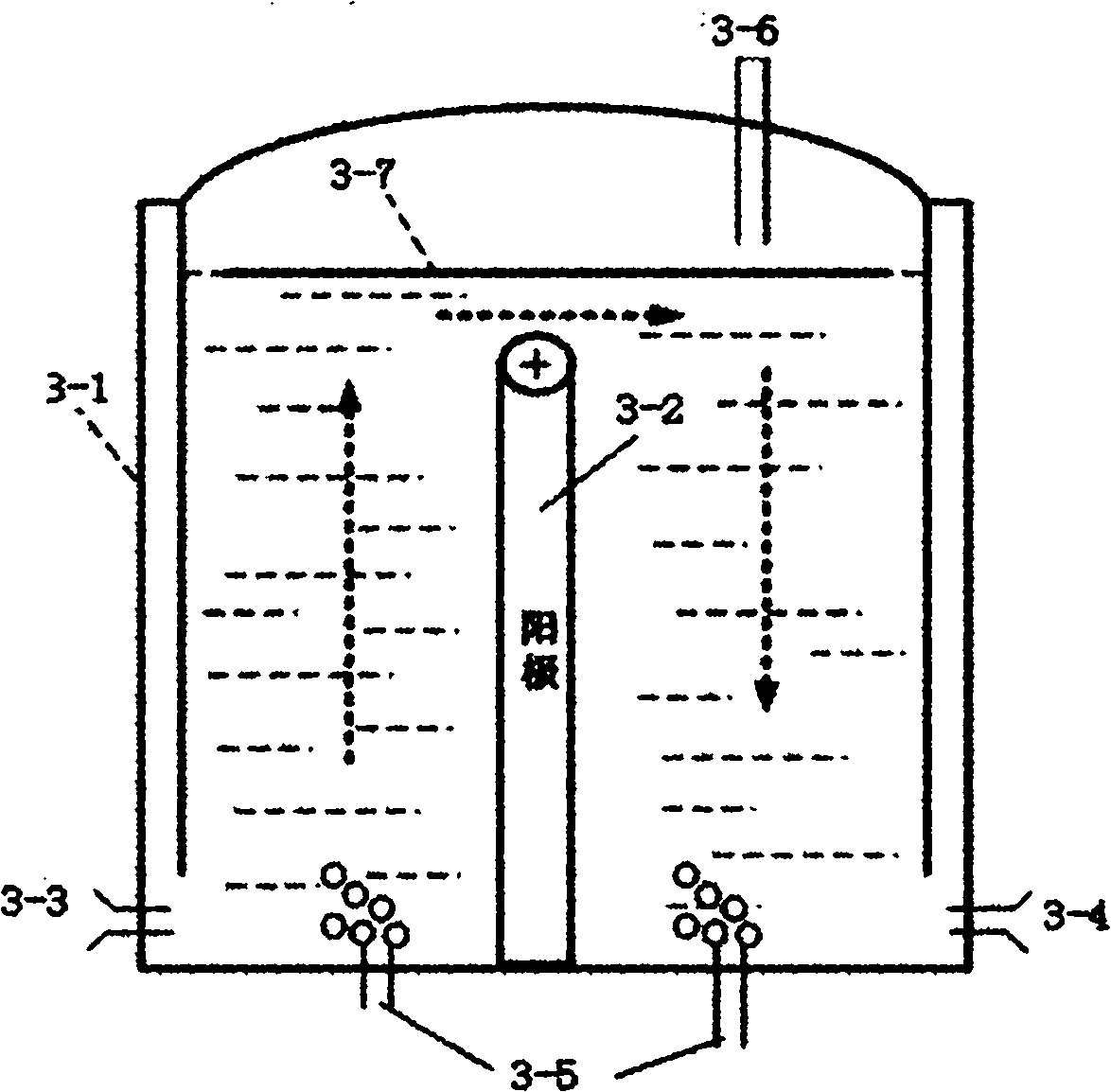

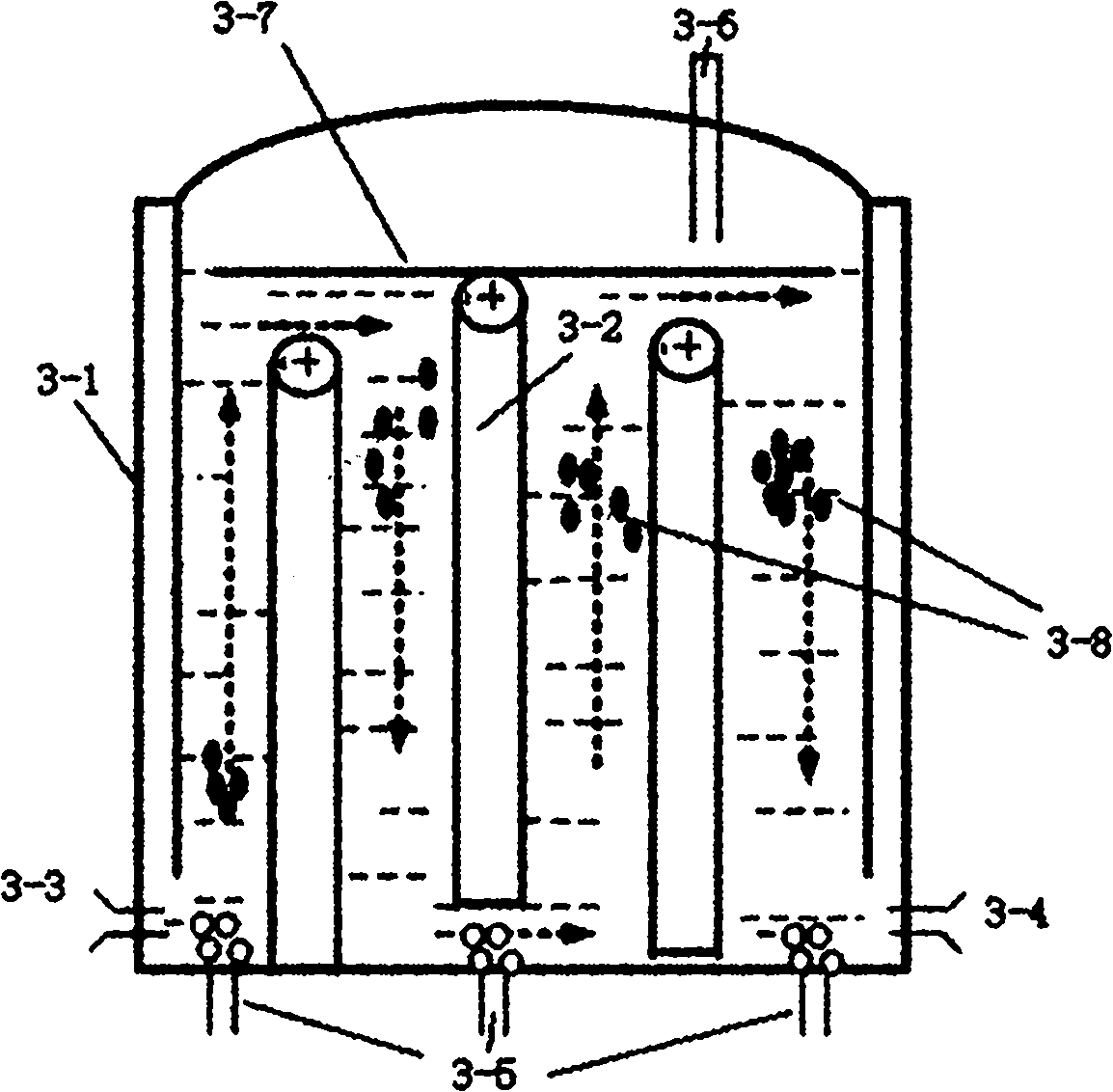

Method and device for treating oily sludge

InactiveCN102001806AImprove qualityQuickly break down complex structuresSludge treatment by oxidationElectrochemical responseMicro bubble

The invention relates to a method and a device for treating oily sludge. Under the action of an applied electric field and by adopting an electrochemical oxidation method, the oil-in-water and water-in-oil structure of emulsified oil is quickly broken, and the oily sludge serving as an electrolyte releases oil drops; oil is quickly taken by a large number of micro bubbles to the liquid level to be recycled under the action of applied air flotation; oily sludge flocs are subjected to electrochemical reaction on the surface to produce various active free radicals which have high activity and oxidability and mainly comprise hydroxyl, and organic pollutants are degraded to be converted into water and carbon dioxide; the active free radicals can destroy a microbial cell structure and kill sulfate reducing bacteria and saprophytic bacteria through a series of oxidation chain reactions; the sludge is powerfully dehydrated, so that the water quality of dehydrated water meets the water quality standard of oil field reinjection, and the sludge can be recycled; and a mud cake is nontoxic and harmless and can be used for soil improvement, fertilizers, building materials and the like.

Owner:朱同德 +1

Heavy metal passivator for simultaneous passivation of farmland soil cadmium, lead and zinc and preparation method

ActiveCN105295943AReduced mobilityHarm reductionAgriculture tools and machinesOrganic fertilisersActivated carbonSlag

The present invention relates to a heavy metal passivator for simultaneous passivation of farmland soil cadmium, lead and zinc, the heavy metal passivator comprises the following components and raw materials by weight: 15 to 25% of weathered coal, 15 to 30% of calcined powder, 15 to 25% of iron pyrite slag, 10 to 15% of activated carbon and 10-15% of calcium magnesium phosphate; the weathered coal and the activated carbon and the calcined powder and the iron pyrite slag are first mixed, stirred evenly, then mixed with the calcium magnesium phosphate, and fully stirred for evenly mixing to obtain the heavy metal passivator for simultaneous passivation of farmland soil cadmium, lead and zinc. The heavy metal passivator for simultaneous passivation of farmland soil cadmium, lead and zinc can make heavy metal pollutants stable in a long term so as to reduce heavy metal mobility and weaken heavy metal hazards in soil, and can effectively passivate and stabilize heavy metals in the soil, material dosing sequence can be quickly combined with the heavy metals, the reaction is more fully, and the heavy metal stabilizing effect is better.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

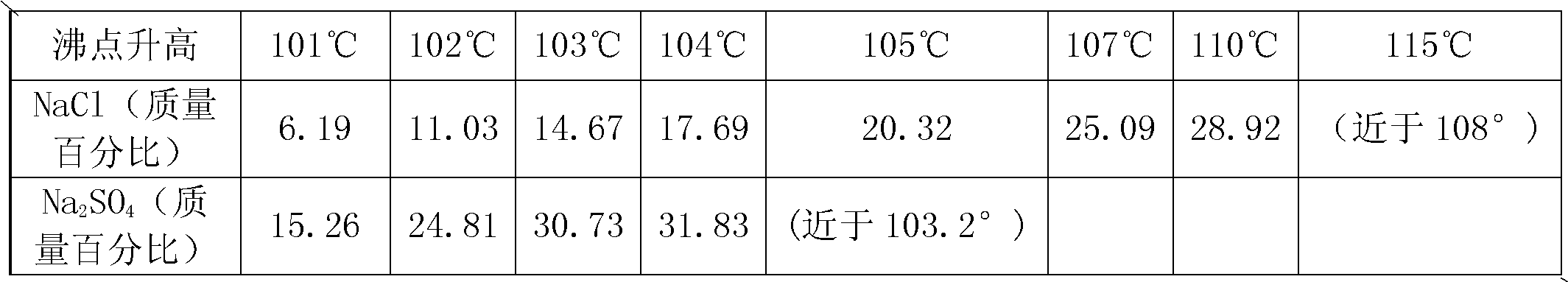

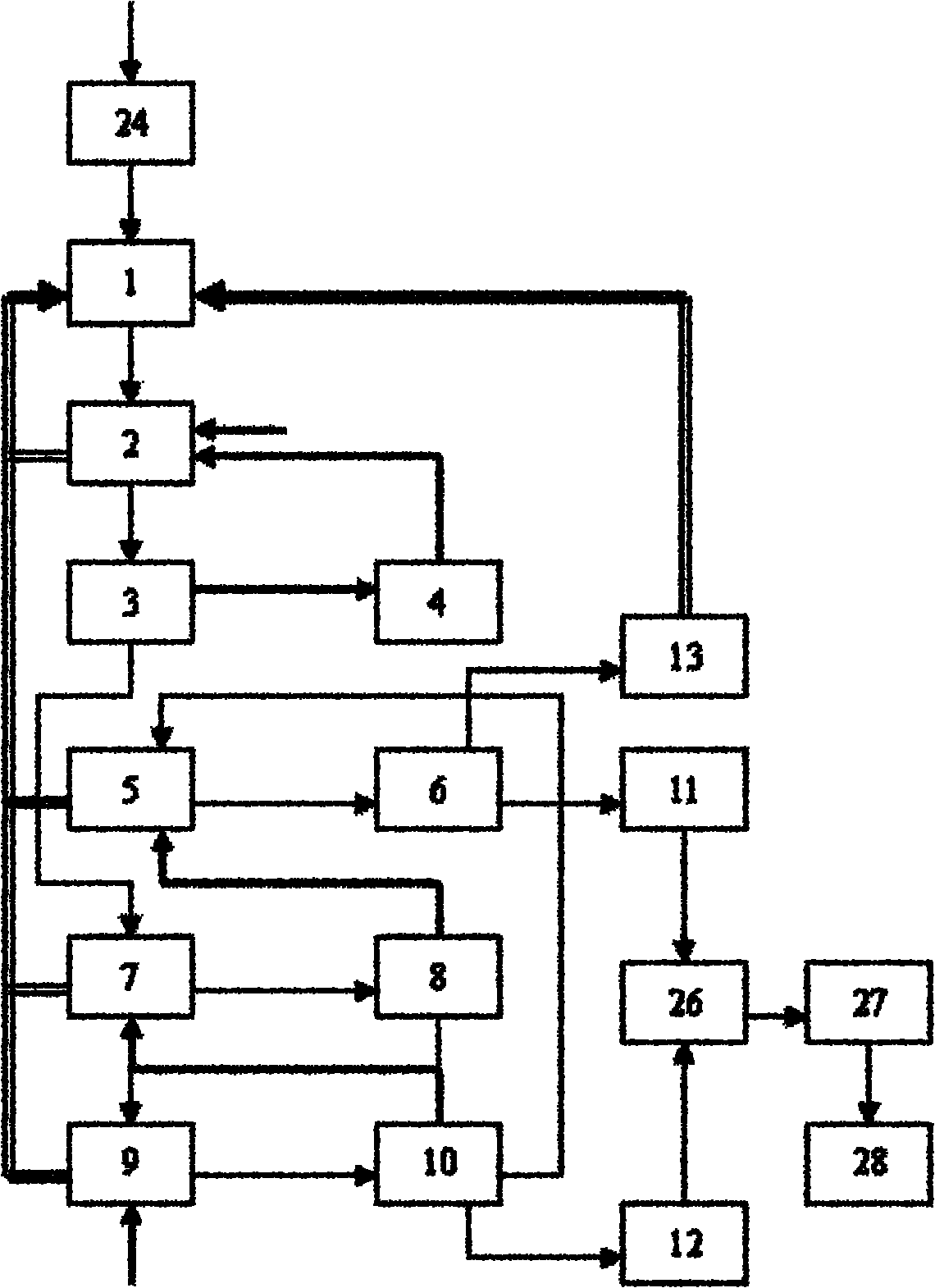

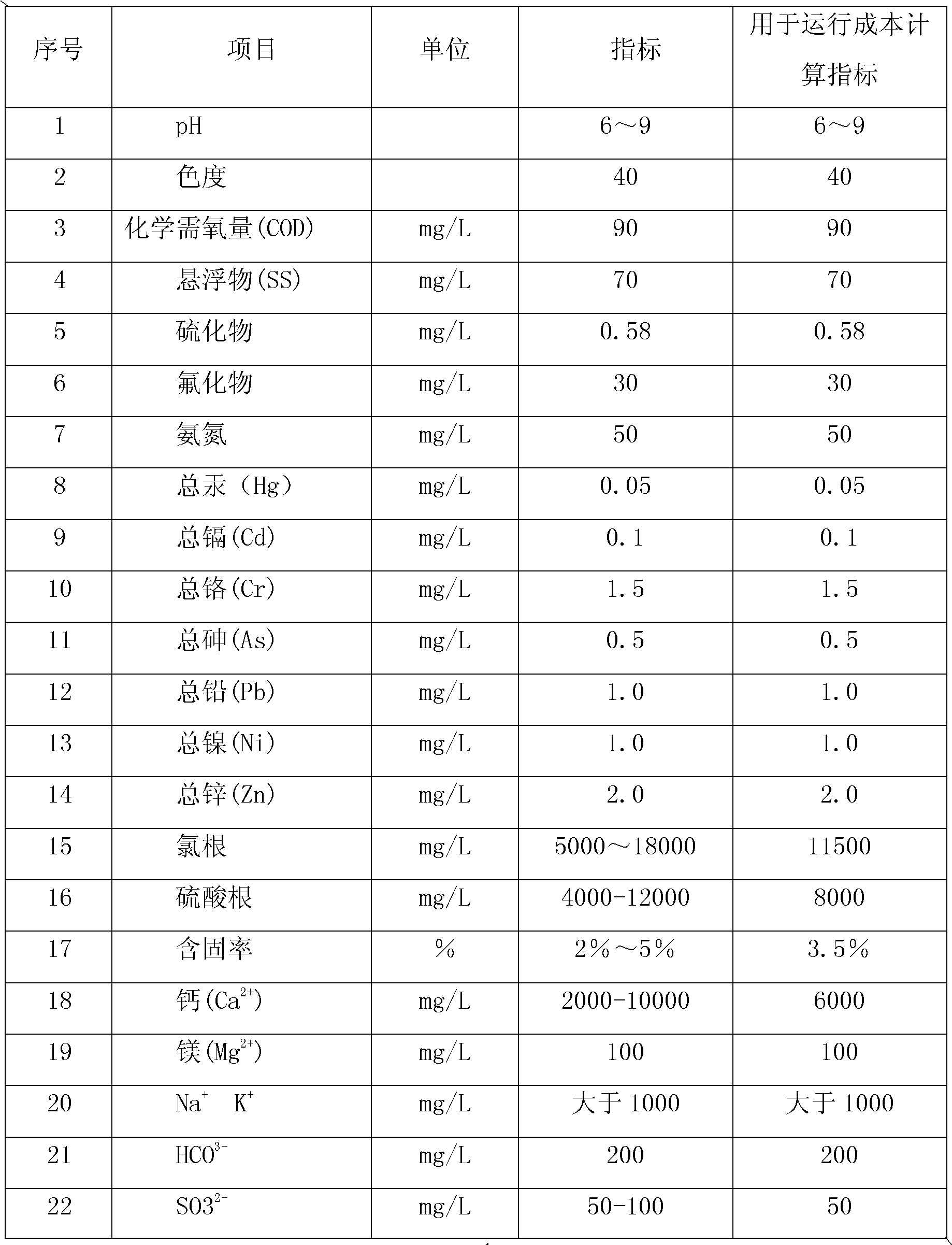

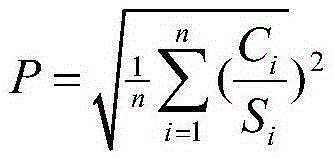

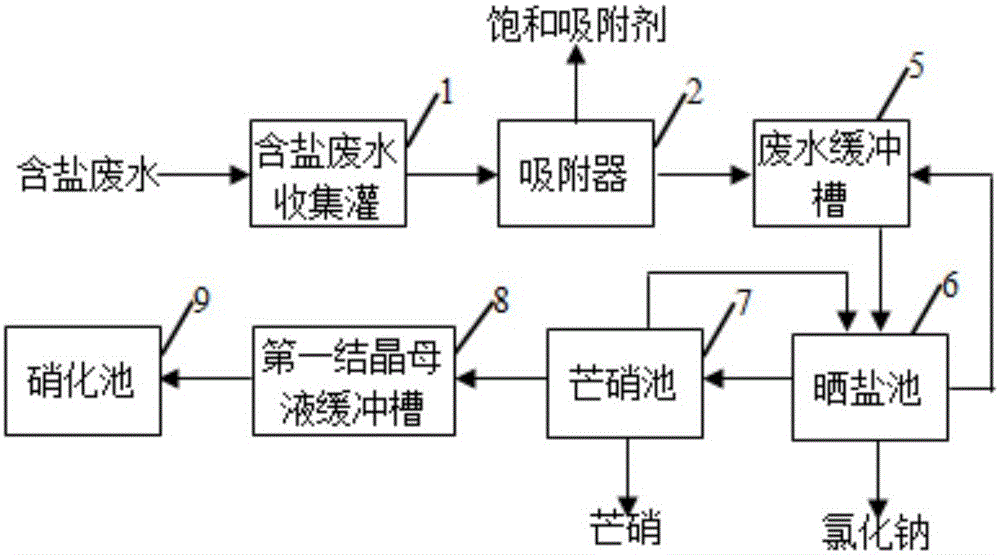

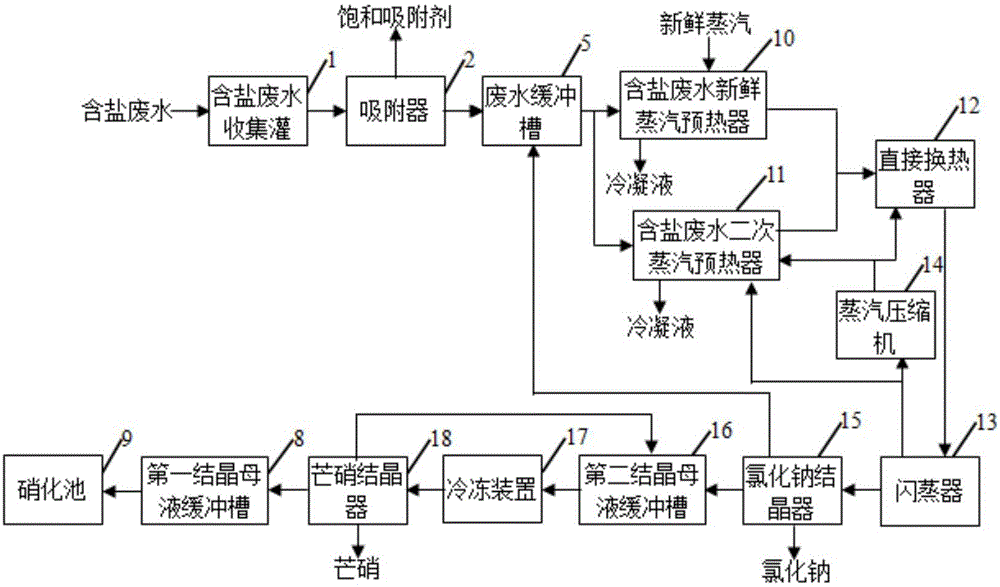

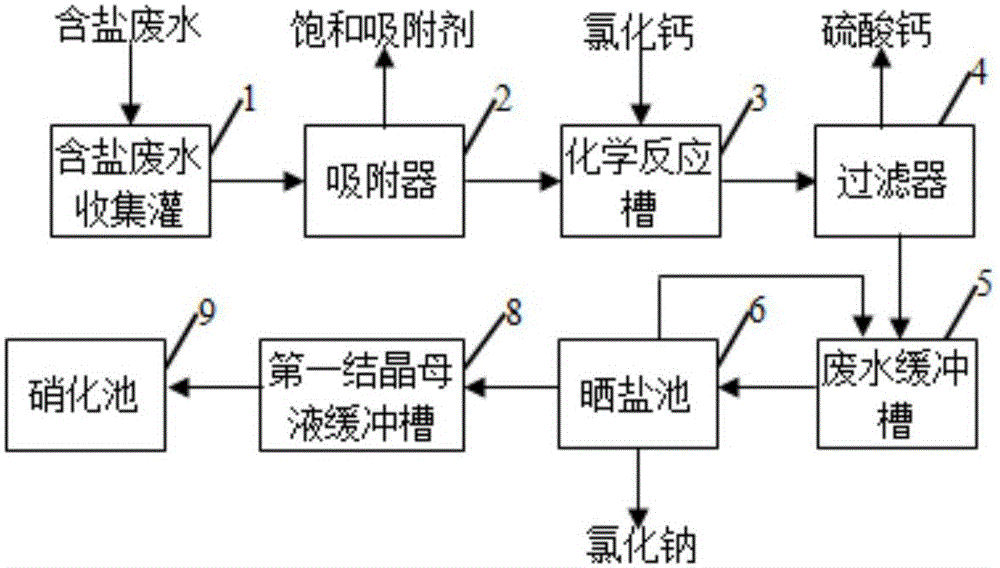

Purification treatment and pure-salt recovery process for strong-salt wastewater in coal chemical industry

ActiveCN105084651ARemove and reduce chromaRemove and reduce turbidityGeneral water supply conservationEnergy inputSulfate radicalsReverse osmosis

Provided is a purification treatment and pure-salt recovery process for strong-salt wastewater in the coal chemical industry. According to the purification treatment and pure-salt recovery process, a working procedure of absorption treatment is additionally conducted on organic matter macromolecules and heavy metals contained in high-concentration salt water after a wastewater reuse multistage reverse osmosis treatment process is carried out; working procedures of evaporation, freezing and desalination are additionally carried out to achieve the purposes of effective utilization of natural energy and industrial low-grade waste heat resources and effective removal of salt-containing wastewater after the working procedure of absorption treatment; a working procedure of chemical separation is added between the working procedure of absorption treatment and the working procedure of desalination to completely convert sulfate radical ions in the salt-containing wastewater into chloride ions and collect and reuse obtained solid, and a nitrate-rich mother solution subjected to crystallization and desalination is returned to a biochemical treatment stage for denitrification treatment. By means of the purification treatment and pure-salt recovery process, salt contained in the salt-containing wastewater is effectively separated out, meanwhile nitrate is returned for biochemical treatment, and secondary steam condensate is evaporated for recycle, so that the whole process achieves the purposes of zero discharge and effective resource utilization.

Owner:山西诺凯化工技术有限公司 +1

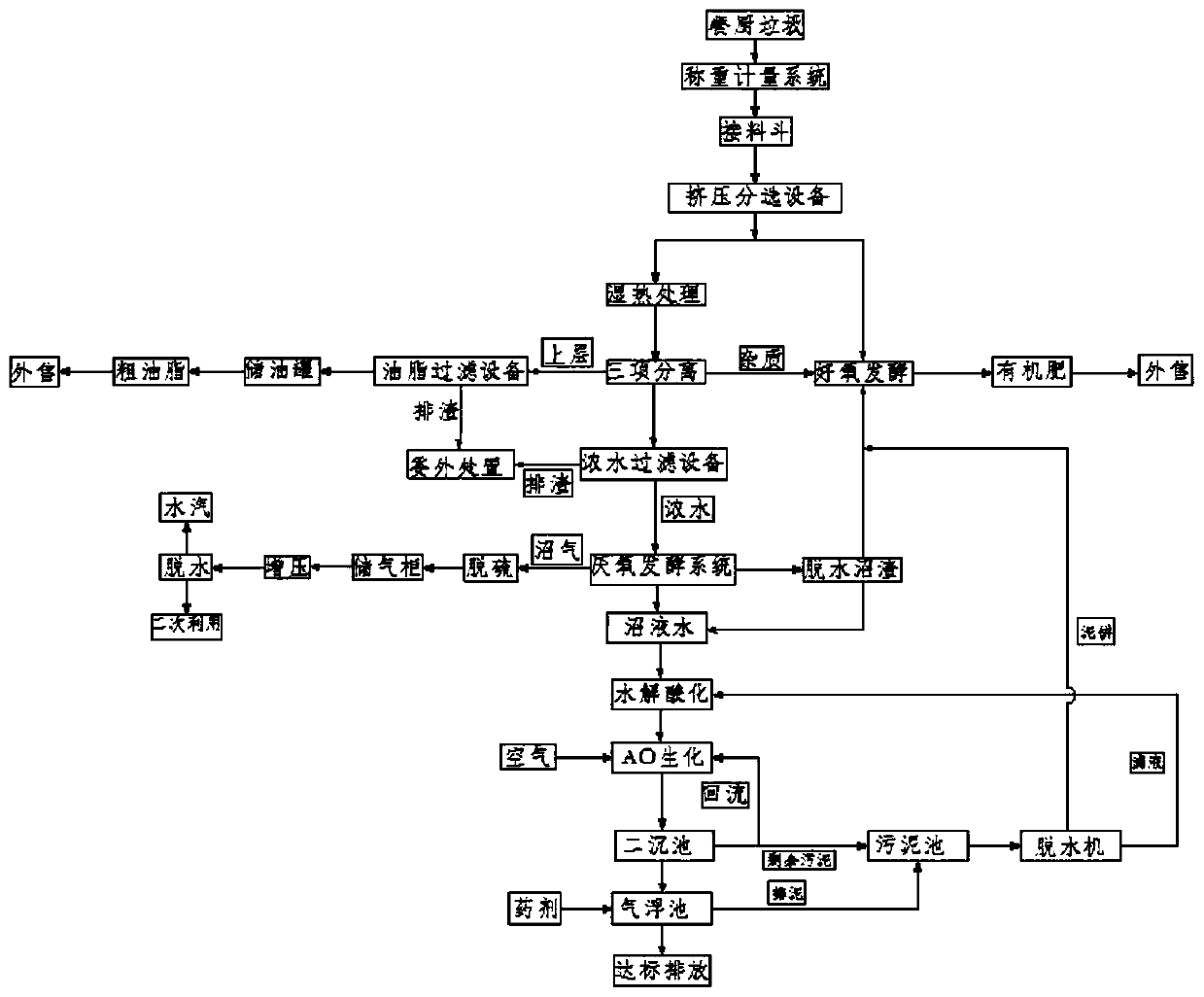

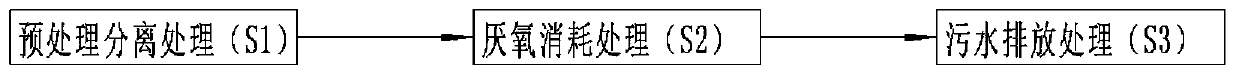

Integrated treatment method for kitchen waste

InactiveCN110883049AThe process method is novel and practicalHigh recovery rateSolid waste disposalTransportation and packagingBiogasPre treatment

The invention relates to an integrated treatment method for kitchen waste. By a pretreatment system, an anaerobic consumption system and a sewage treatment system, harmless treatment of the kitchen waste is realized; through resource utilization, integrated governance of the kitchen waste is realized, and grease, organic fertilizers and methane with economic efficiency can be produced; and sewageand odor generated are treated effectively and do not bring secondary pollution to the environment. The technological method is novel and practical; and a recovery rate is high.

Owner:苏州腾康环保科技有限公司

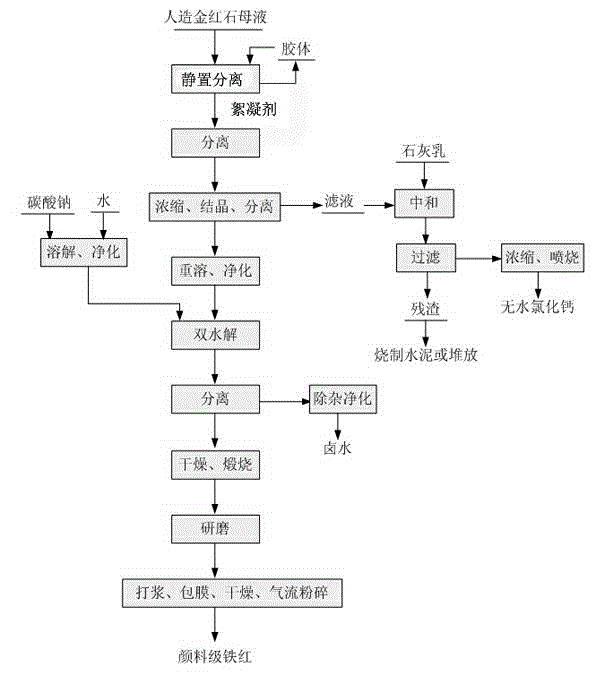

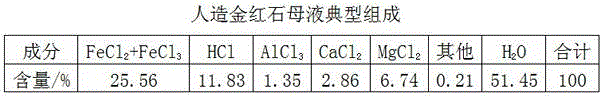

Novel method for recycling synthetic rutile mother liquor

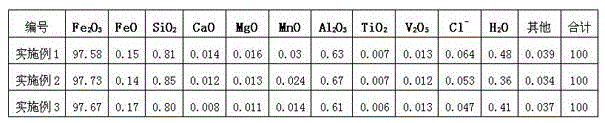

ActiveCN104528834AQuality assuranceAvoid technical difficulties of separationInorganic pigment treatmentFerric oxidesRutileImpurity

The invention discloses a novel method for recycling synthetic rutile mother liquor. The method comprises the following steps: treating TiO2 colloid, mechanical impurities and a part of residual metal ions in the mother liquor, concentrating and crystallizing the pretreated mother liquor to obtain a ferrous crystal, re-dissolving the ferrous crystal in deionized water, adding iron powder to reduce, and adsorbing with modified activated carbon to obtain the purified solution of ferrous oxide; preparing the solution of sodium carbonate, adding a certain amount of a heavy-metal precipitating agent, and adding activated charcoal to purify; carrying out coprecipitation reaction on the purified solution of ferrous oxide and the purified solution of sodium carbonate under a certain condition, and introducing air to oxidize at the same time; filtering the product of reaction after reaction, and separating to obtain a filter cake; calcining the filter cake at a certain temperature, cooling, and grinding to obtain primary iron oxide red; and coating the primary iron oxide red, and pulverizing by gas flow to finally obtain the finished iron oxide red. By adopting the method provided by the invention, high-quality rutile mother liquor can be obtained, and the problem of poor economic benefit of the existing technology for treating synthetic rutile mother liquor can be solved.

Owner:YIBIN TIANYUAN GRP CO LTD +1

Method for preparing sulphoaluminate cement by using fluorine-containing sludge

The invention provides a method for preparing sulphoaluminate cement by using fluorine-containing sludge, and belongs to the technical field of environmental engineering. The method comprises the following steps that 1, solidifying and desiccating fluorine-containing sludge; and 2, producing sulphoaluminate cement, wherein (1) preparation of raw materials: preparing the sulphoaluminate cement by using the following raw materials in percentage by weight: over 45 percent of CaO, 25 to 35 percent of Al2O3, less than 15 percent of SiO2, over 10 percent of gypsum and 1 to 3 percent of fluorine-containing sludge; (2) burning of chamotte: calcining the raw materials in a rotary kiln at the temperature of between 1,300 and 1,400 DEG C; and (3) preparation of cement: mixing 75 to 80 percent of the chamotte and 20 to 25 percent of the fluorine-containing sludge and grinding the chamotte and the fluorine-containing sludge until a specified specific surface area is reached. According to the method, the aims of innocent, stabilized and recycling use of sludge are achieved by adding the fluorine-containing sludge into the sulphoaluminate cement and burning the mixture of fluorine-containing sludge and the sulphoaluminate cement, so not only energy is saved, but also environment is protected and mankind is benefited.

Owner:苏州伟宇天诚环保科技有限公司

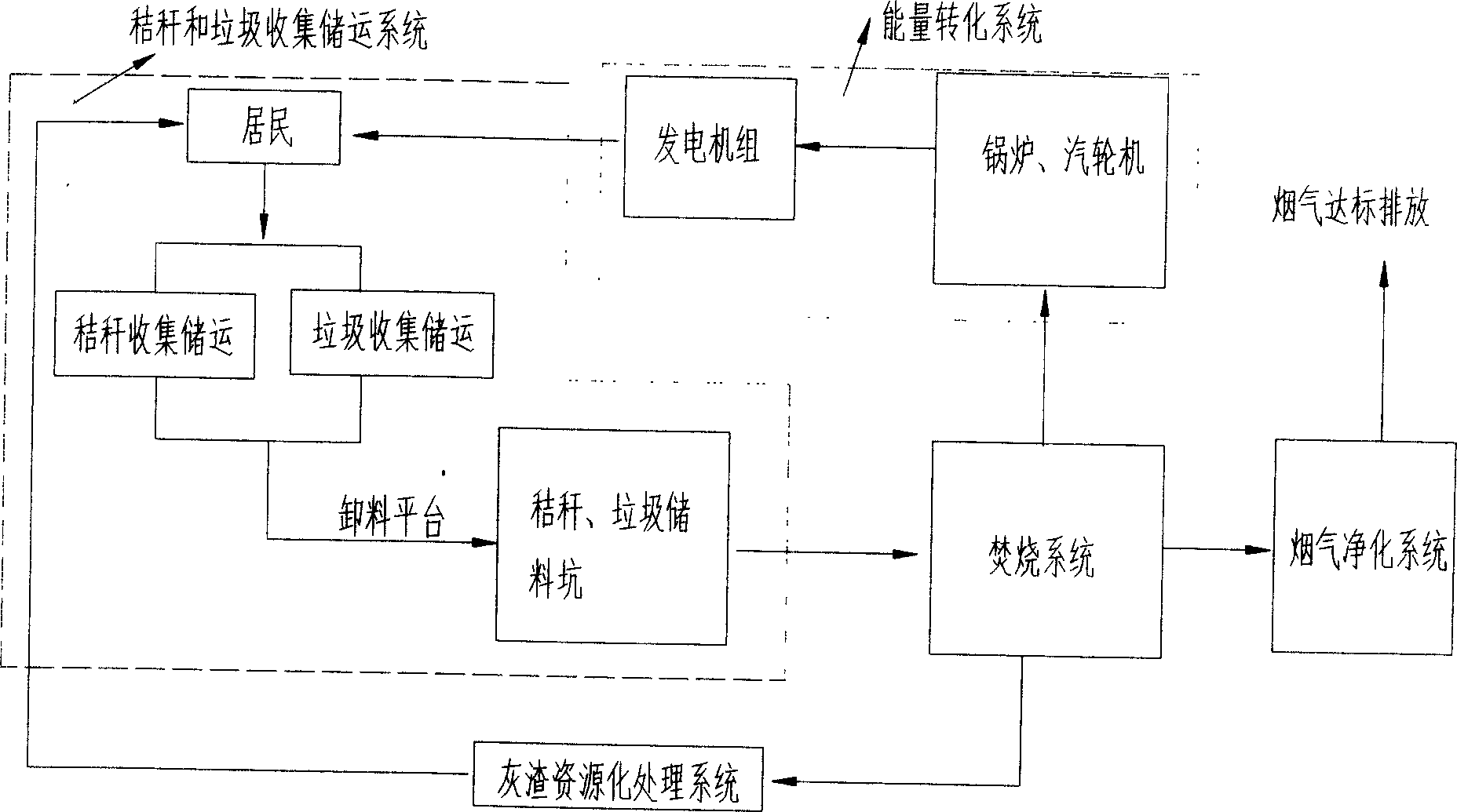

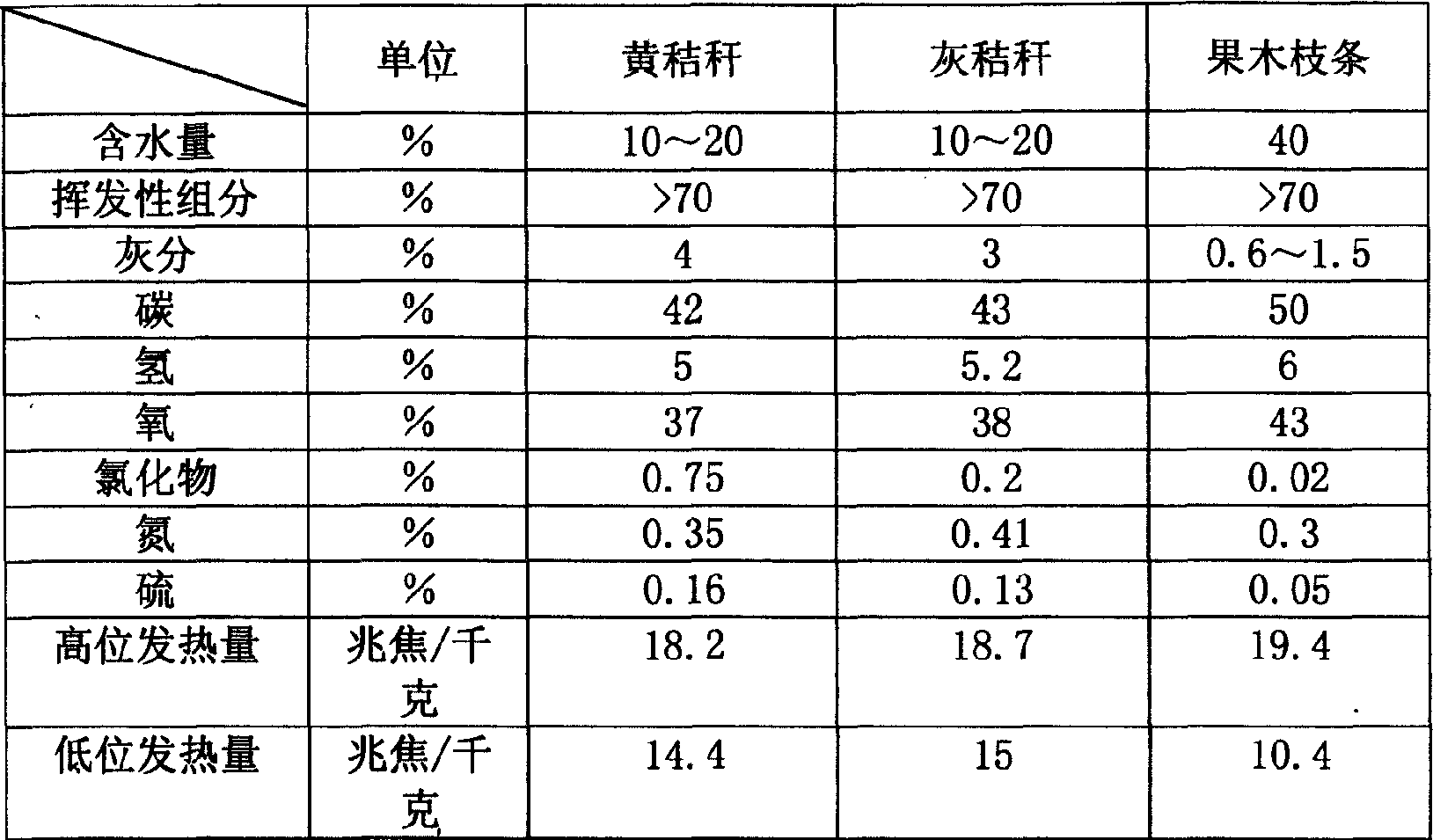

Method for electric generating utilizing stalks mixed burned with city life refuses

The invention relates a method of generating by using mixed combustion of stalks and municipal house refuse. The heat energy produced by the mixed combustion of the stalks and the municipal house refuse in the refuse burner is coverted into the generating energy by a boiler, a turbine and a generator, so as to supply the power for cities. The proportion of the stalks and the house refuse in their mixed combustion must be adjusted continually according to the differences of refuse water ratio and dust composition. When the combustion temperature in the burner is in the range of 870-1200 deg. C, the combustion can be fully burned and the combustion product can be discharged up to the standard.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION

Purifying system and method for mother of pearl in lake water-resource nutrient-enriched water body

InactiveCN1778716AAchieve resource utilizationLess quantityClimate change adaptationPisciculture and aquariaChlorophyll aWater source

A freshwater mussel purifying system in lake nutritive water body and its purification are disclosed. The purifying system consists of pile, float ball, nylon rope and mesh basket. It is characterized building lake pile freshwater mussel purifying system with corresponding time, determining optimum chlorophyll alpha and suspend unit elimination quantity from freshwater mussel, determining living things for freshwater mussel, building a freshwater mussel purifying system engineering in lake water source enriched water body, checking and managing regularly, maintaining complete of engineering structure, collecting mature freshwater mussel regularly, and supplementing young freshwater mussel in engineering area.

Owner:FRESHWATER FISHERIES RES INSITUTE OF JIANGSUPROVINCE

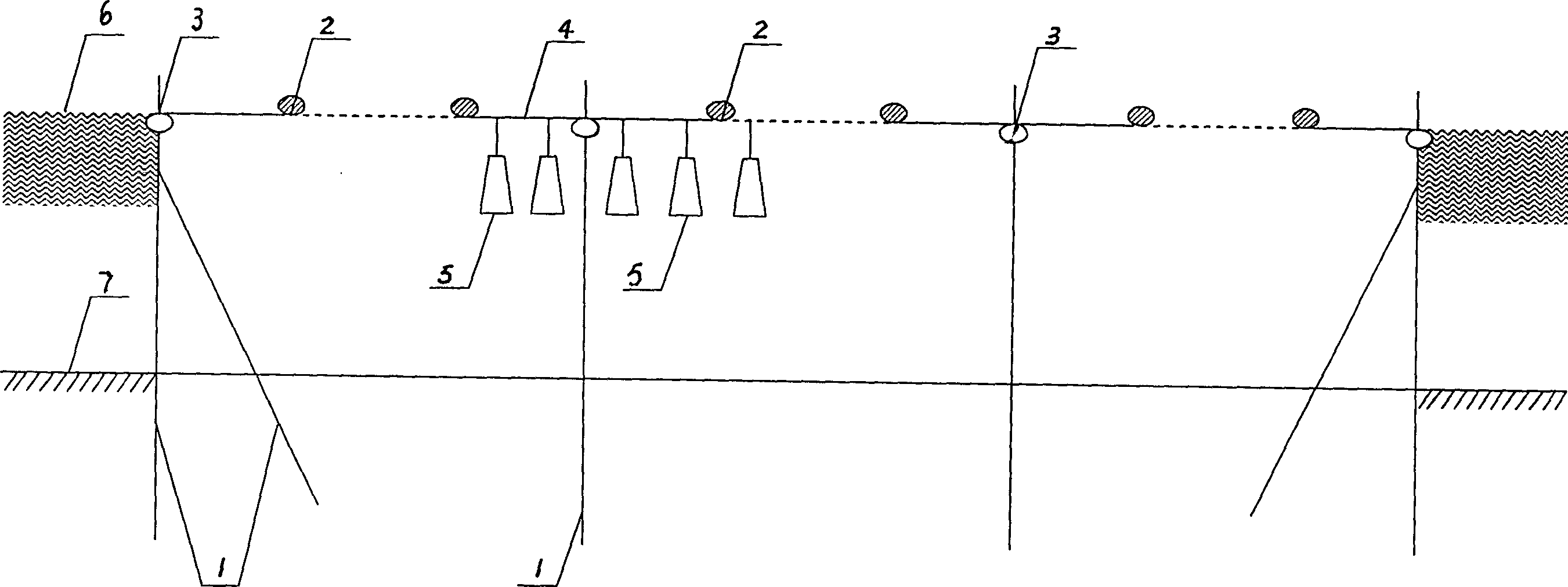

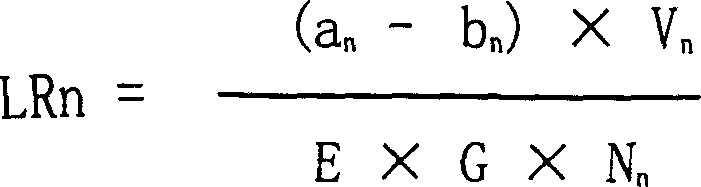

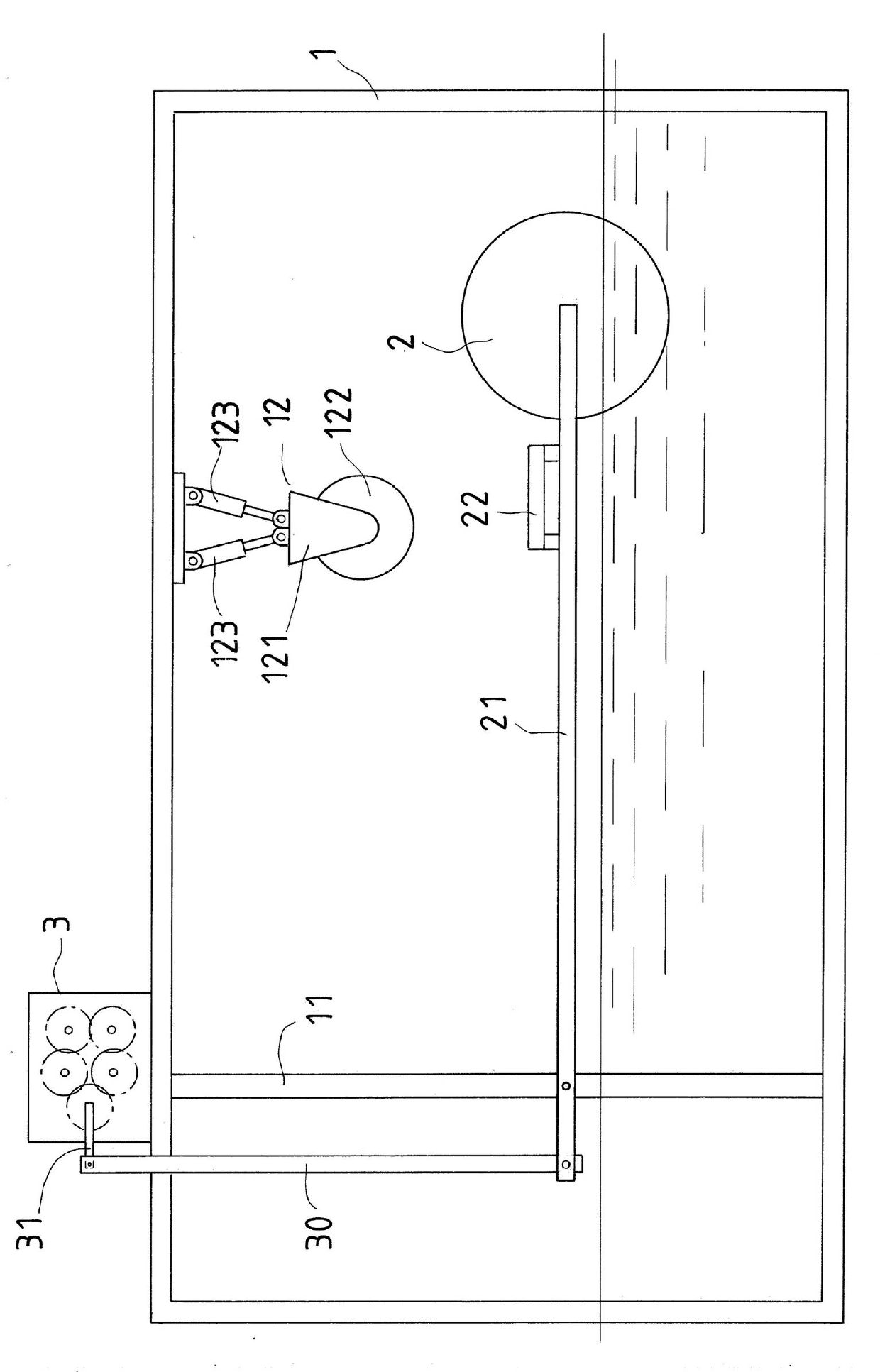

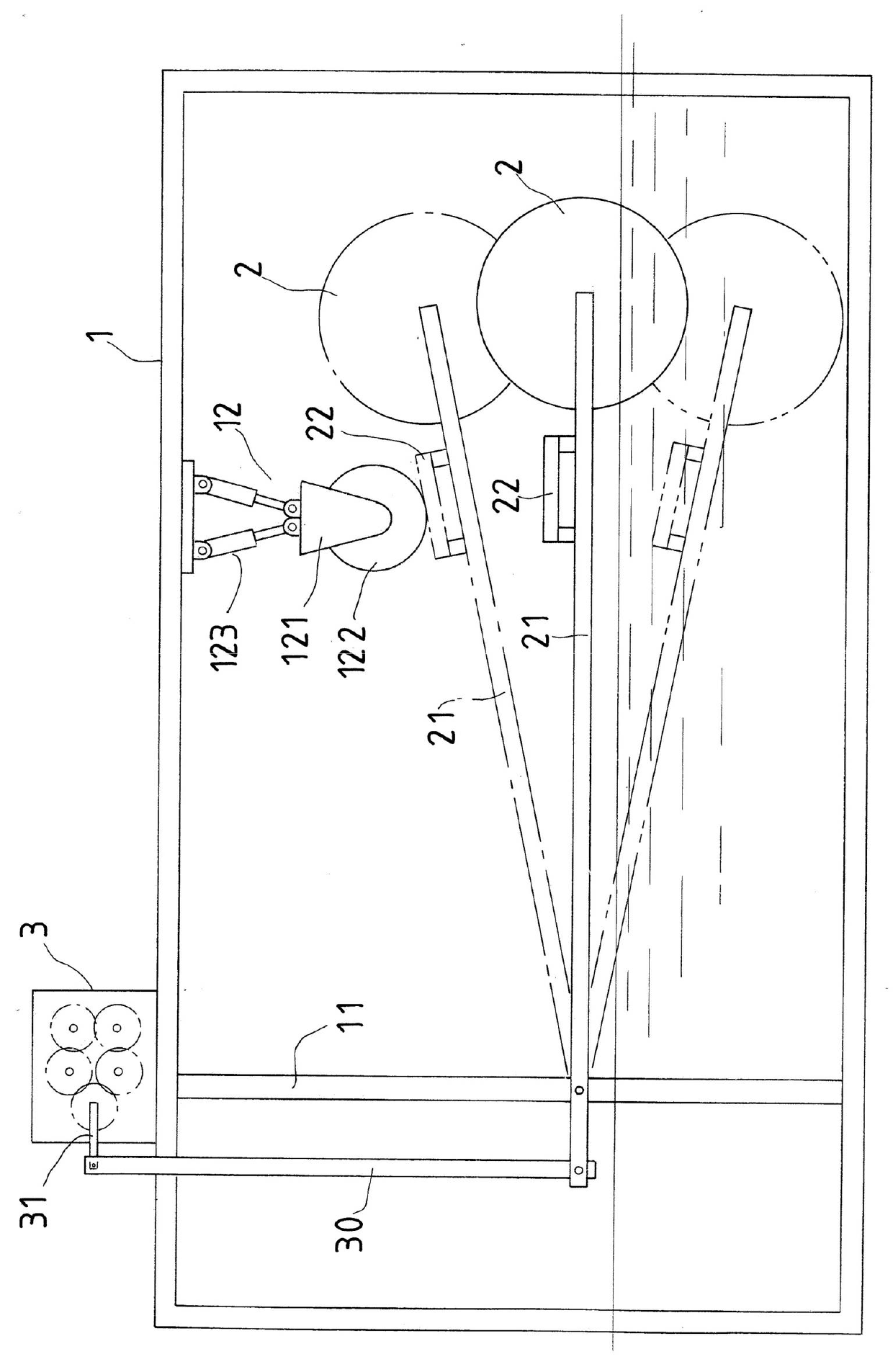

Wave power generation device

InactiveCN102635487AGuaranteed continuous power supplySimple structureMachines/enginesEngine componentsSeawaterElectric generator

The invention relates to a wave power generation device, which mainly makes use of buoyancy of seawater and thrust of waves to drive buoys to swing vertically, so as to produce driving force, and then the vertically swung driving force is converted into one-way output power through a reverse mechanism, the power is transferred and amplified by a speed increaser and is further transferred to a power wheel by an output end; while two ends of a rotary shaft of the power wheel are provided with flywheels, and a rotating wheel for transferring power is arranged on a rotary shaft so as to transmit the power to a power generator. The wave power generation device adopts a simple and convenient structure to realize conversion of natural resources, and convert the thrust brought by the natural resources into power, thus, the resources can be utilized continuously, the structure is simple, and the implementation cost is low. In addition, the rotating wheel is arranged on the rotary shaft of the wave power generation device to correspondingly transmit the excessive power to an air compressor, the air compressor drives an air motor by storing air to aid transmission power wheels, thus, power can be generated during slack tide of waves, and continuous power supply by the wave power generation device can be ensured.

Owner:杨辉雄

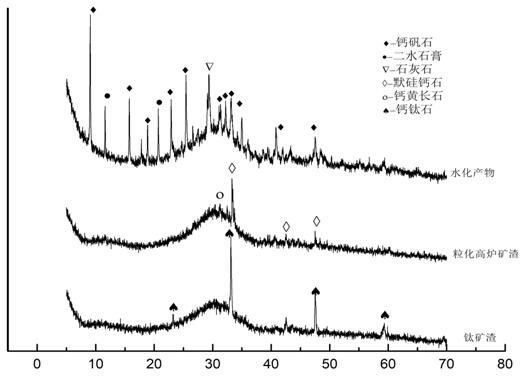

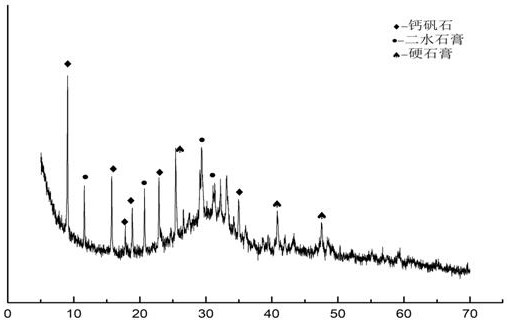

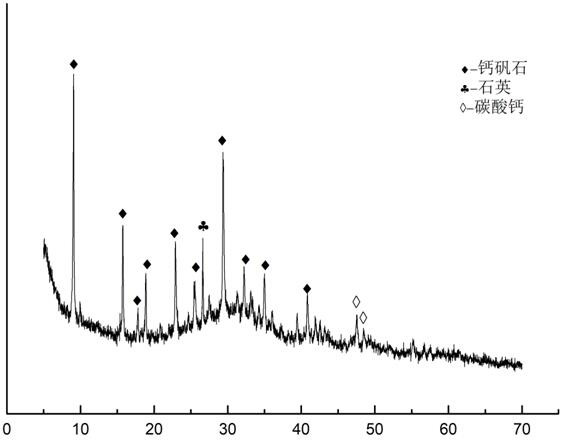

Titanium slag-based solid waste cementing material and preparation method thereof

The invention discloses a titanium slag-based solid waste cementing material and a preparation method thereof. The titanium slag-based solid waste cementing material comprises the following raw materials by weight: 70-80% of a titanium slag-based material, 15-25% of gypsum, and 2.5-7.5% of cement clinker. The preparation method is simple, and the used materials are subjected to separate or mixed grinding according to different types of grindability differences, and then are mixed and stirred. In the raw materials, the titanium-containing slag-based material is used as a main component and is matched with the cement clinker and the gypsum to form the gel material, so that effective comprehensive utilization of a large amount of high-titanium-containing slag and industrial byproduct gypsum resources produced by iron and steel enterprises in Panzhihua, Leshan sand bay and the like in the southwest region can be realized, most of conventional engineering applications can be met, and the material can also be used in a construction environment with rich tunnel terrestrial heat.

Owner:JIAHUA SPECIAL CEMENT

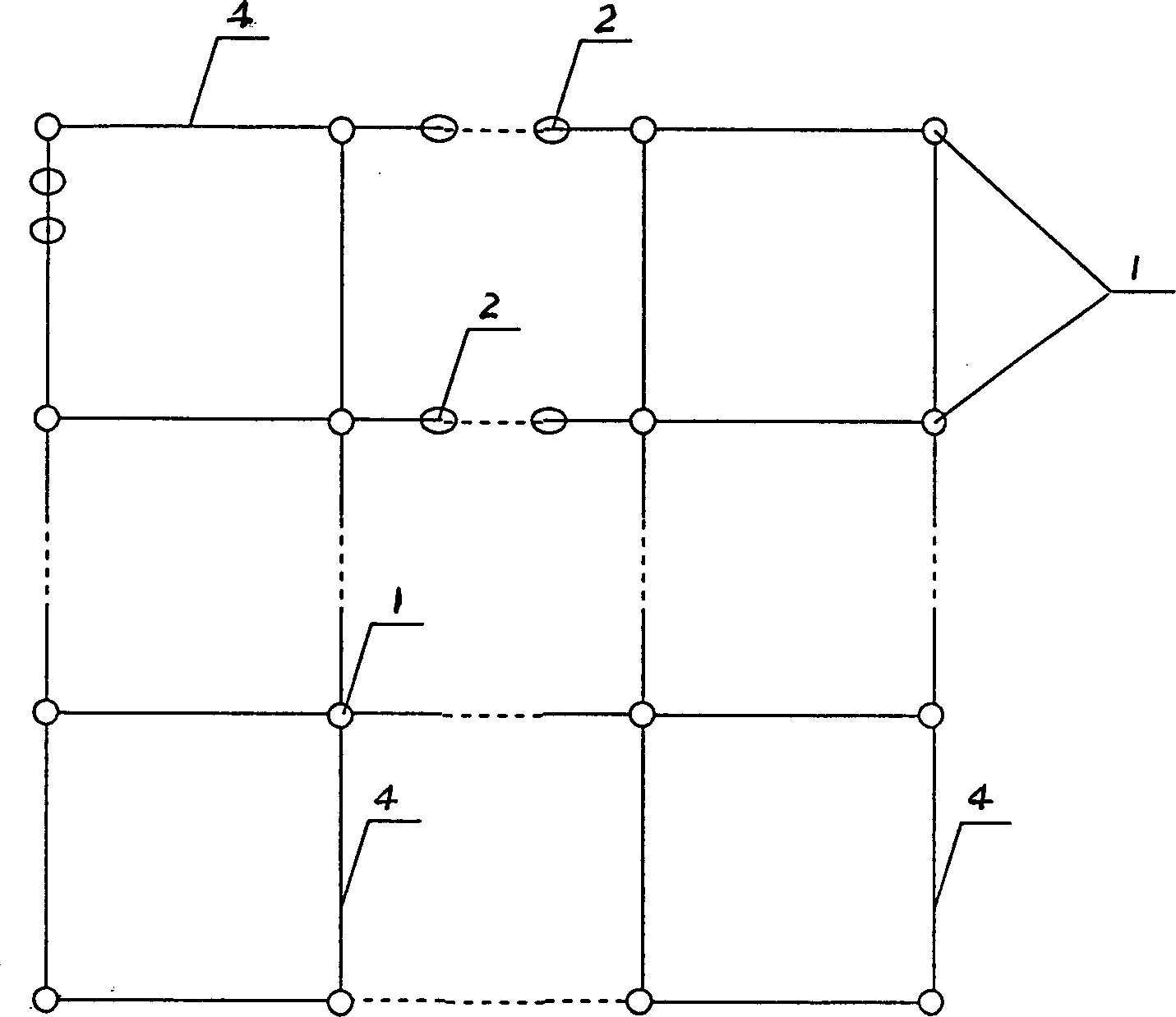

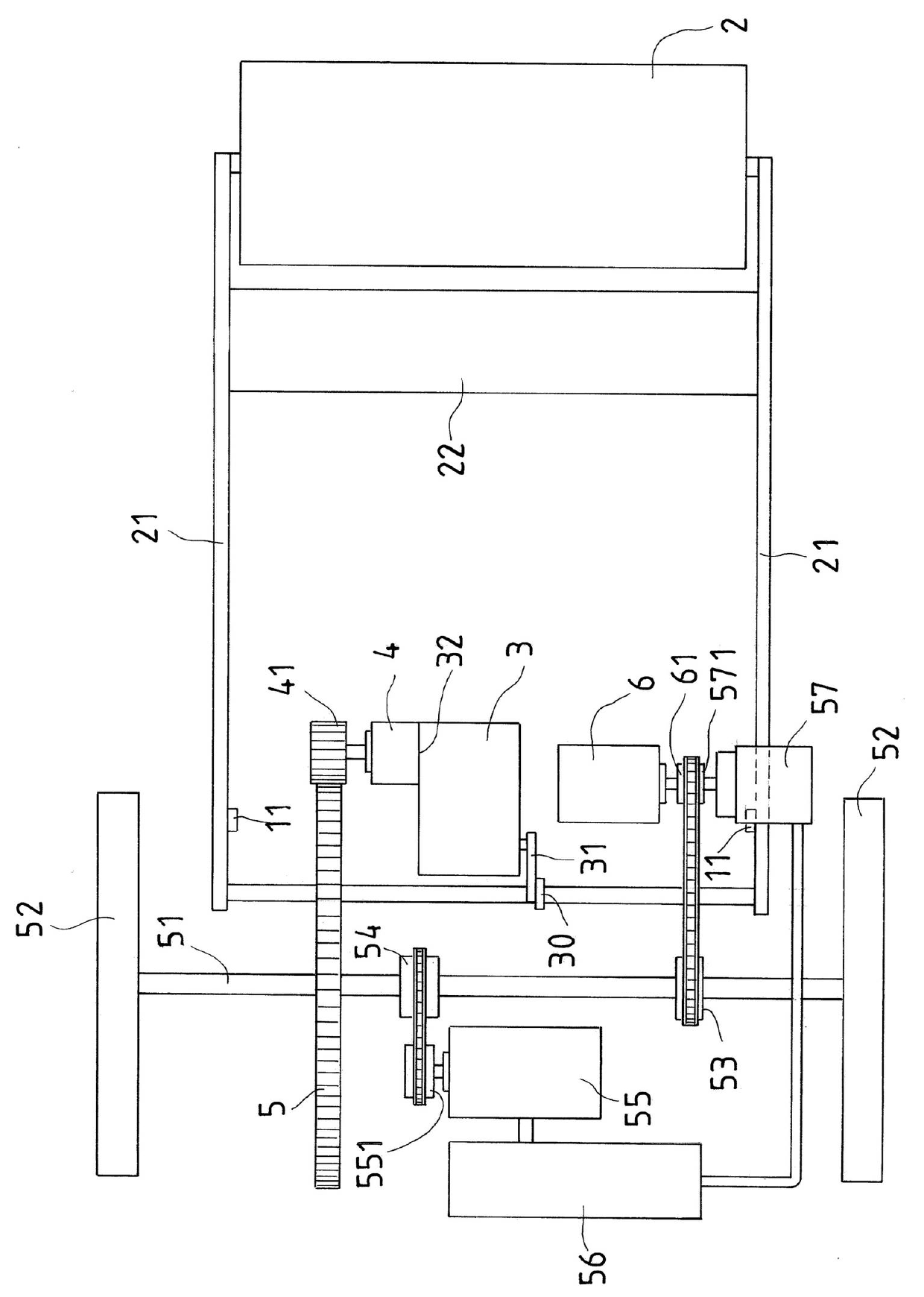

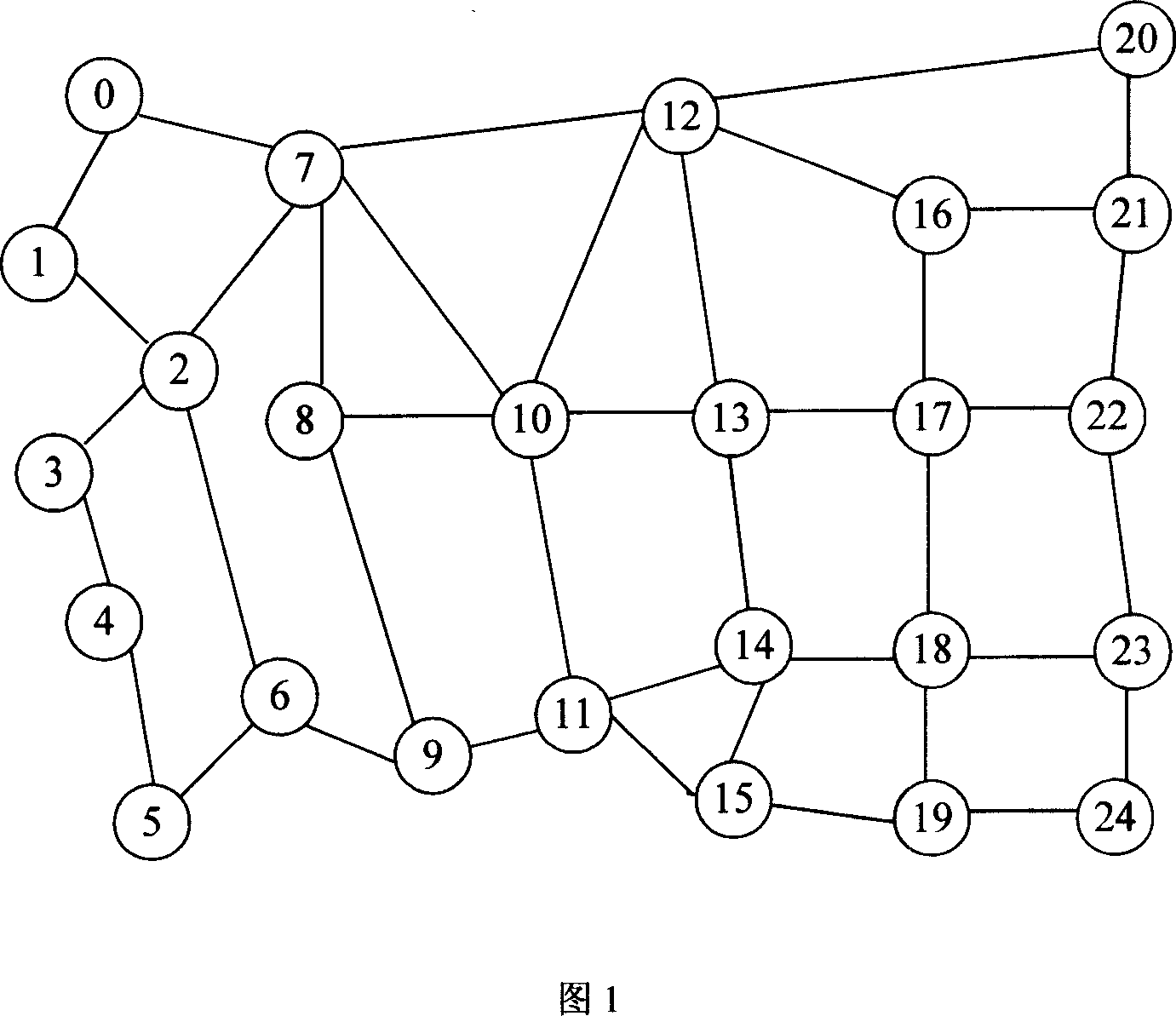

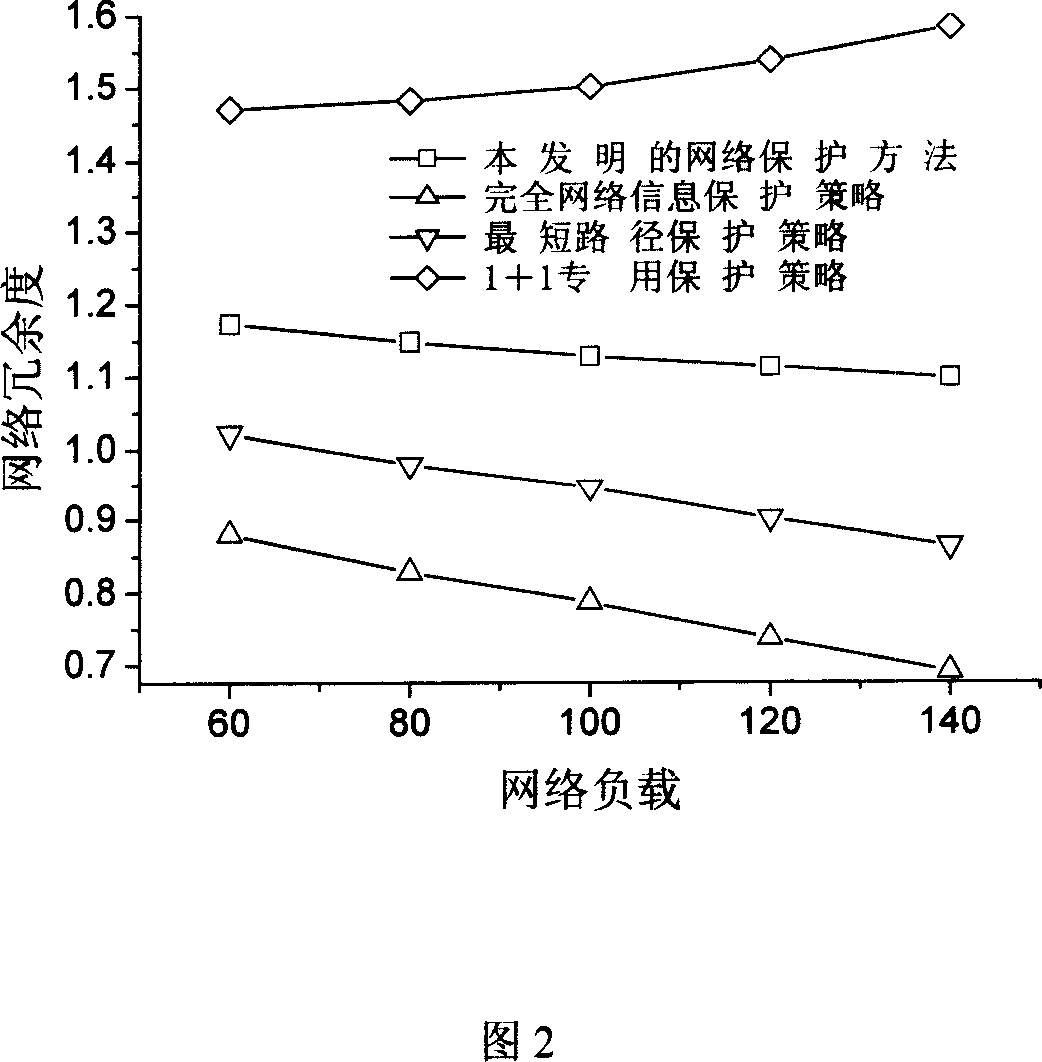

Preset network protection method capable of sharing bandwidth

InactiveCN1921409ASimplify network operationsEasy to operateError preventionData switching networksPath protectionUtilization factor

The invention relates to a preformed network protective method which can share bandwidth. Wherein, it comprises: first using traditional shortest path algorism to build one working path to each new service; then projecting present all preformed protective paths to the logic chain between source-host nodes; then based on the jump number of each protective path, the preformed bandwidth, and the bandwidth of new service request, fixing the cost of each logic chain, then using traditional shortest path algorism to build one shortest protective path for new service. When the network is accident, the fail service can be switched to preformed protective path, to quickly protect and return. The invention has the return-protect speed as 1+1 special protective method, while its network resource utilization rate reaches share path protective method.

Owner:SHANGHAI JIAO TONG UNIV

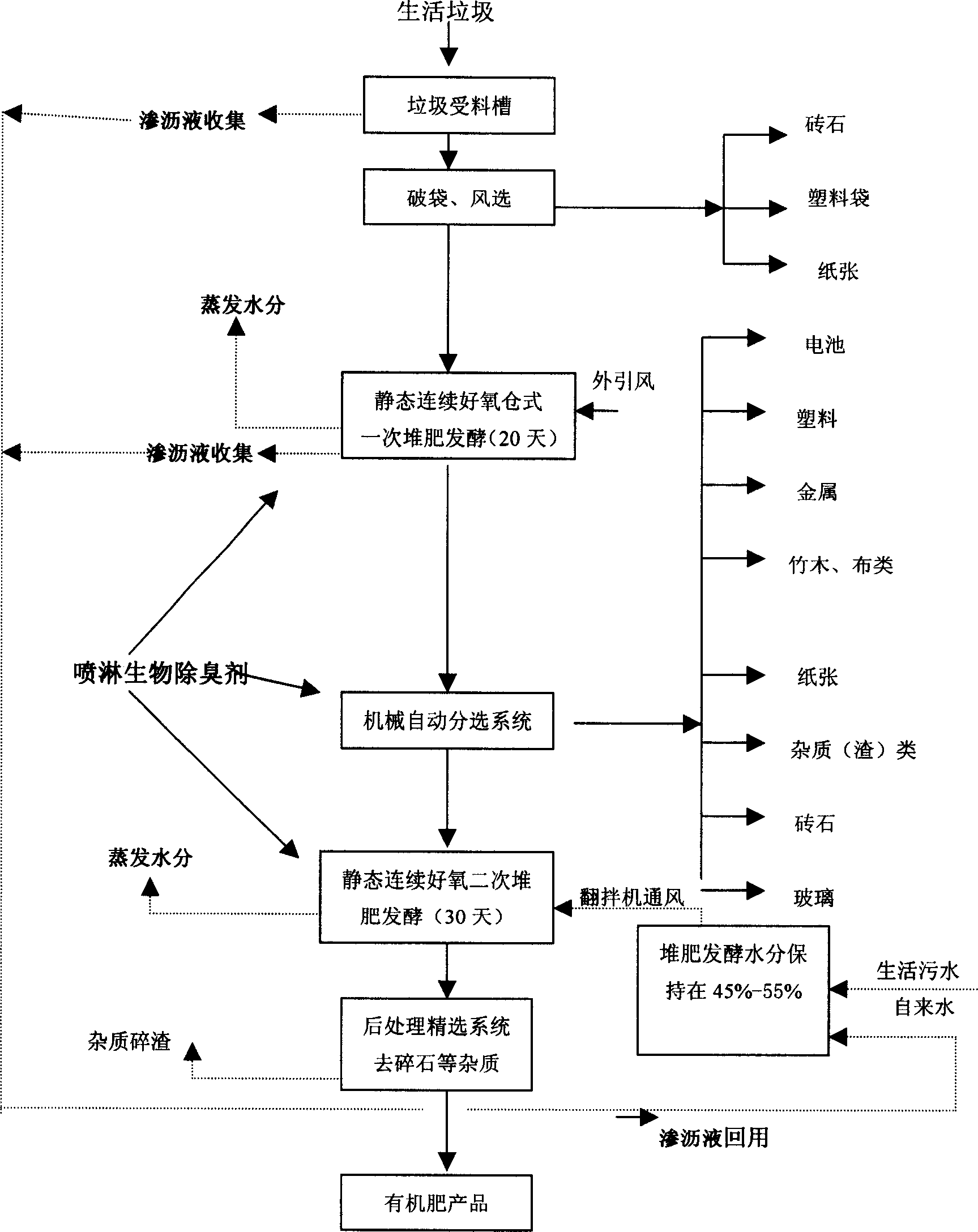

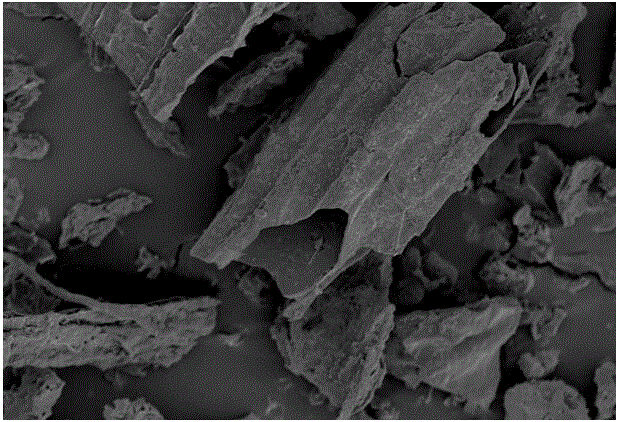

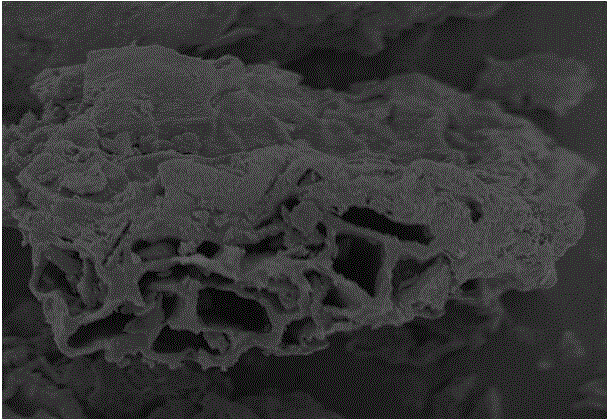

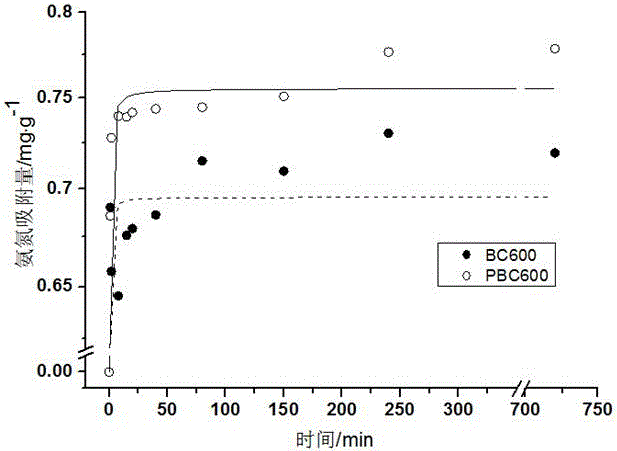

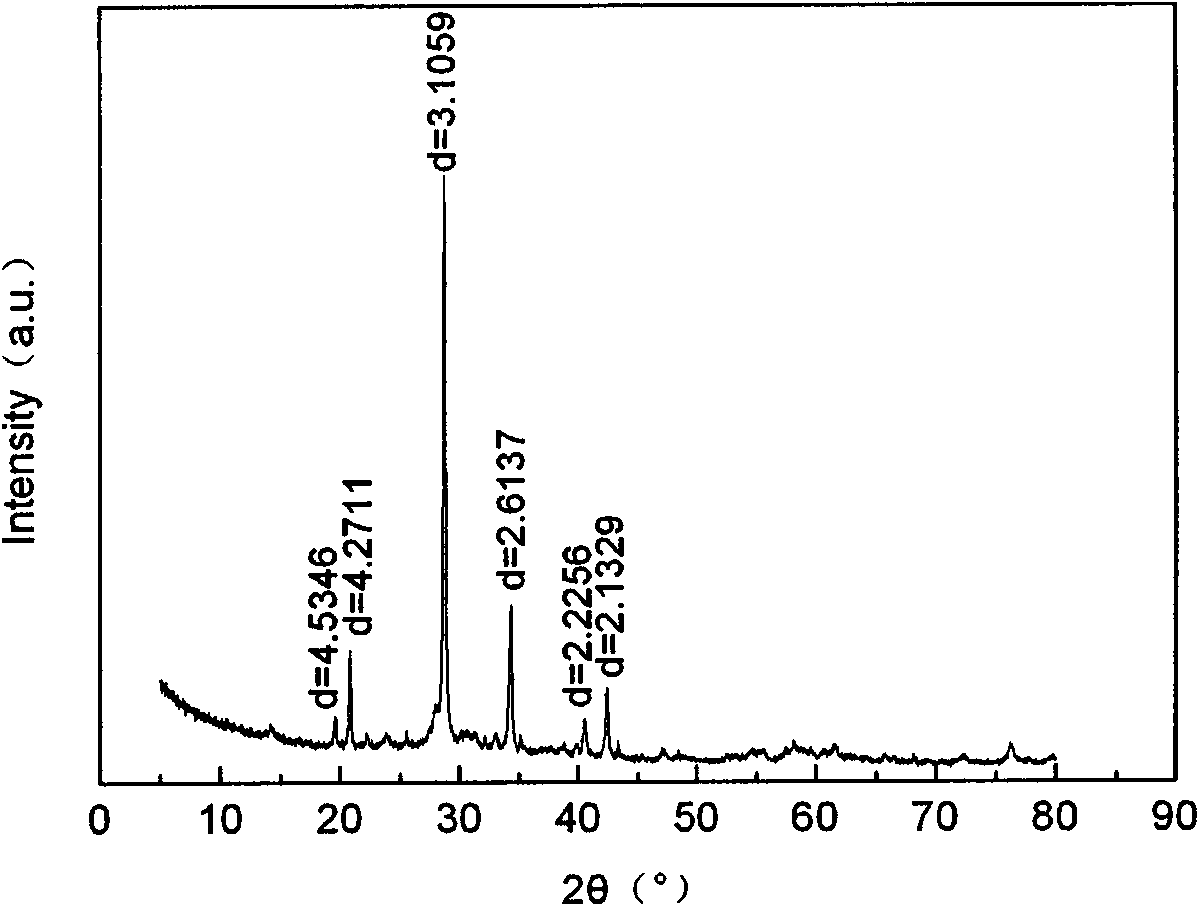

Preparation method of modified biochar with improved ammonia nitrogen removal ability

InactiveCN106345407AReduce secondary pollutionAchieve resource utilizationOther chemical processesWater contaminantsFiltrationSewage

The invention discloses a preparation method of modified biochar with improved ammonia nitrogen removal ability. The preparation method includes the specific steps of collecting biomass, subjecting the biomass to air drying, crushing and high-temperature pyrolysis under the protection of inert gas to obtain biochar, pulverizing the biochar prior to sieving, mixing the sieved pulverized biochar with water evenly prior to sterilization, and subjecting the sterilized biochar to circulating freezing and defreezing, suction filtration, drying and grinding so as to obtain the modified biochar. The preparation method has the advantages that the biochar is modified physically, so that the ability of the biochar to adsorb ammonia nitrogen in a water body is improved effectively, the modified biochar can be used for treatment of ammonia-nitrogen-containing wastewater, and biological and efficient utilization of the biomass is achieved.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing phacellite by using coal ash as raw material

InactiveCN101602511AUniform chemical compositionImprove thermal stabilityAluminium silicatesSolid waste disposalResource utilizationPotassium hydroxide

The invention discloses a method for preparing phacellite by using coal ash as a raw material, which comprises the following steps: 1) drying the coal ash, and carrying out gradient magnetic separation of dry method; 2) mixing the magnetically-separated coal ash and potassium hydroxide according to a mass ratio of 1:0.1-0.3, adding the mixture into a crucible of a muffle furnace, heating the mixture, and baking the mixture at a constant temperature; 3) adding acid into a baked product of the coal ash according to a solid-liquid ratio of 1:1-5, dissolving the baked product in the acid for 1 to 2 hours, adding a chelating agent into the mixture according to a solid-liquid ratio of 1:0.1-0.5 during acid dissolution, and continually stirring the mixture; 4) after the acid dissolution is finished, filtering, washing and drying the filter residue to obtain a coal ash pretreatment sample; and 5) adding potassium hydroxide solution into the coal ash pretreatment sample according to a solid-liquid ratio of 1:2-5, adding the mixture into a stainless steel reaction kettle, heating the mixture to carry out hydrothermal reaction, and filtering, washing and drying a reaction product to obtain a phacellite product. The method overcomes the defects of the prior art such as high cost, uneven chemical components of the product and the like, achieves resource utilization of the solid waste coal ash, and has environmental and economic double benefits.

Owner:ZHEJIANG UNIV

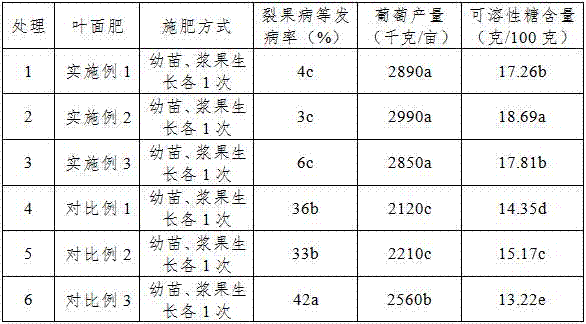

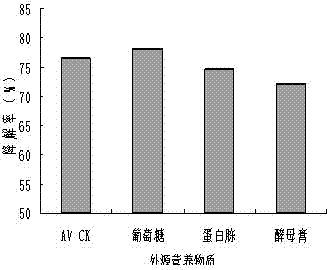

Preparation method of grape special purpose seaweed fertilizer

InactiveCN106915987AAchieve resource utilizationReduce manufacturing costBioloigcal waste fertilisersNitrogenous fertilisersHigh concentrationPretreatment method

The invention discloses a preparation method of grape special purpose seaweed fertilizer. The preparation method utilizes sodium alginate production enterprise by-product kelp slag as a raw material, builds a raw material pretreatment method and develops a bio-refining technology for two-step catalytic conversion of kelp slag based on an enzyme. Through the establishment of substrate and enzyme feeding strategy, substrate inhibition is reduced, high concentration substrate system enzyme efficient catalytic conversion is realized, high concentration seaweed fertilizer is prepared, recycling use of kelp processing wastes and protection of the environment are realized, a kelp industry chain is extended and the kelp processing technology and seaweed fertilizer production level are improved. The preparation method innovates a seaweed fertilizer preparation mode, utilizes kelp production enterprise by-products as raw materials, realizes waste recycling, improves seaweed resource utilization efficiency, protects the environment, reduces a seaweed fertilizer production cost, improves a yield of grapes after application, has strong practicability and can be easily industrialized. The seaweed fertilizer is a pure natural product, does not product pollution, can be degraded, satisfies industrial demands and is environmentally friendly.

Owner:NANCHANG UNIV

Waste incineration fly ash treatment system based on reduction

ActiveCN105436192AAchieve stabilizationThe effect is obviousTransportation and packagingSolid waste disposalElectricityElectrocoagulation

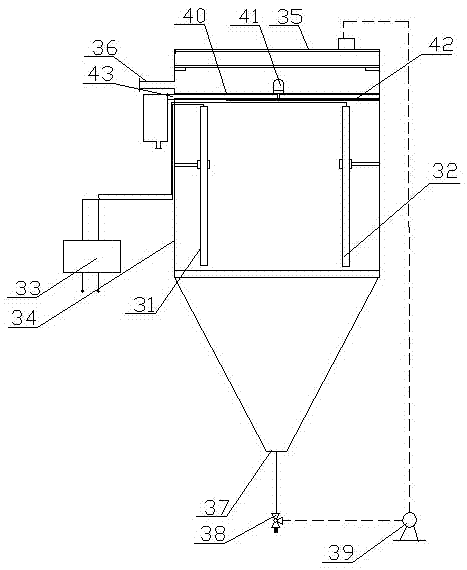

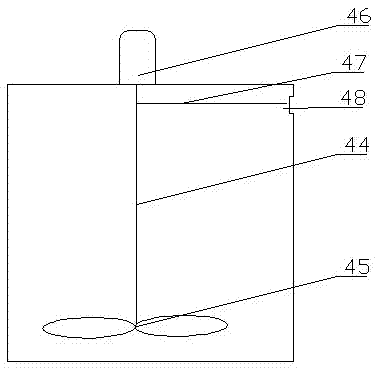

The invention discloses a waste incineration fly ash treatment system based on reduction, and relates to the field of environmental-friendly technology and equipment. The waste incineration fly ash treatment system based on reduction comprises a waste incineration fly ash storage and transportation device, a screening device, a first solid-liquid separator, a second solid-liquid separator, a washing tank, an electrocoagulation treatment device, a wastewater collecting tank and a water storage tank, wherein the water storage tank is connected to the electrocoagulation treatment device and the washing tank; the waste incineration fly ash storage and transportation device is connected to the screening device; the screening device is respectively connected to the washing tank and the electrocoagulation treatment device; the electrocoagulation treatment device is connected to a solid-liquid collecting tank; the solid-liquid collecting tank is connected to the first solid-liquid separator; the first solid-liquid separator is connected to a first fly ash storage bin; the washing tank is connected to the second solid-liquid separator; and the second solid-liquid separator is connected to the first fly ash storage bin. The waste incineration fly ash treatment system based on reduction can be used for dividing a waste incineration fly ash zone into a zone body rich in heavy metal and a zone body with low heavy metal content according to the grain size, and the heavy metal and the chlorine salt in the zone bodies are removed by virtue of different methods.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Process for extracting calcium chloride from waste incineration fly ash

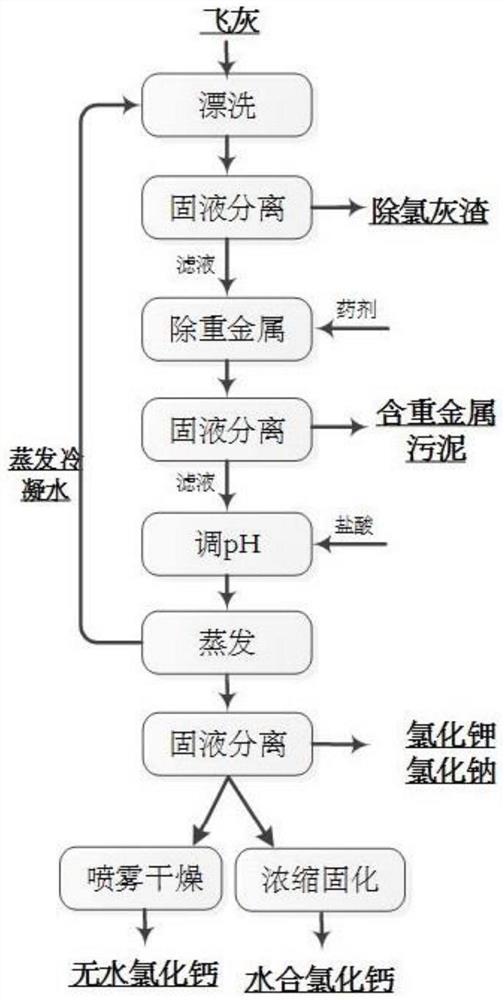

PendingCN112374521AReduce processing costsReduce operating costsCalcium/strontium/barium chloridesAlkali metal chloridesEnvironmental chemistryChloride sodium

The invention relates to a process for extracting calcium chloride from waste incineration fly ash, and belongs to the technical field of chemical engineering. The process comprises the following steps: 1) washing waste incineration fly ash by using evaporation condensate water, and carrying out solid-liquid separation to obtain dechlorinated ash residues and washing water; 2) adding a heavy metalremoval agent into the washing water, and removing heavy metal precipitates through solid-liquid separation; 3) adding hydrochloric acid to adjust the pH value, and then feeding into a subsequent evaporation process; 4) carrying out evaporating concentration on the solution, and carrying out solid-liquid separation on the concentrated solution to obtain sodium chloride, potassium chloride solid salt and a calcium chloride solution; and 5) concentrating, cooling and crystallizing the calcium chloride solution to obtain a hydrated calcium chloride product, or directly drying the calcium chloride solution to obtain an anhydrous calcium chloride product. According to the process, sodium chloride, potassium chloride and calcium chloride are recycled in a multi-time solid-liquid separation andevaporation concentration mode, and heavy metals are removed, so that the environmental protection property is good.

Owner:河北金坦化工装备有限公司

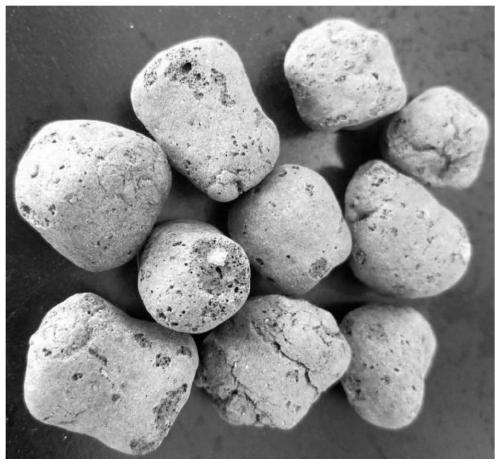

Method for preparing flower ceramic particles with urban water supply sludge

InactiveCN103723999AReduce consumptionAchieve resource utilizationCeramic materials productionCeramicwareUrban water supplyDry weight

A method for preparing flower ceramic particles with urban water supply sludge belongs to the field of environmental technology, and relates to the resource utilization of solid waste. Materials accounted by dry weight rate, including 30-50 percent of water supply sludge, 10-30 percent of coal slurry, 20-30 percent of flint clay, 5-7 percent of Chinese chestnut shell, 8-10 percent of waste glass and the like, are dried, grinded, mixed and uniformly agitated to be prepared into spheres 6-15 mm in particle diameter. The spheres are subjected to pre-heating torrefaction and cooling so as to form the high performance flower ceramic particles. The ceramic particles prepared by the method are light and have loose and porous surfaces, can absorb a considerable amount of water, and has proper ability to keep nutritious substances. Compared with soilless substrates such as sand and wood chips, the flow ceramic particles have the characteristics of cleanness, neatness, attractiveness in shape, lightness, no pollution, cleanable performance, durability, higher stability in chemical property and the like.

Owner:BEIJING UNIV OF TECH

Seedling raising method of Capsicum annuum L. var. conoides (Mill.) Irish

InactiveCN108401809AAchieve recyclingImprove germination rateBio-organic fraction processingSeed and root treatmentCapsicum annuumConoides

The invention provides a seedling raising method of Capsicum annuum L. var. conoides (Mill.) Irish. The method comprises the following steps: seed treatment and germination, seedling raising preparation, seedling raising management and transplant cultivation. According to the planting method, the germination rate and the survival rate are improved though disinfection and germination treatment of Capsicum annuum L. var. conoides (Mill.) Irish seeds, and through special seedling substrate seedling raising and strict seedling raising management; and the purposes of biomass recycling and seedling-raising cost reducing are realized through rational utilization of crop straws.

Owner:宜州市怀远镇诚信辣椒种植专业合作社

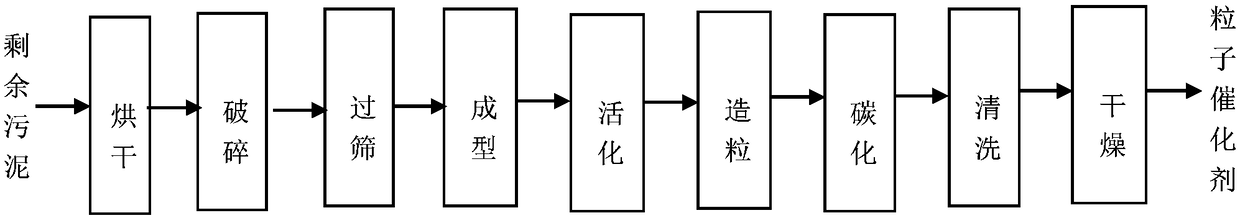

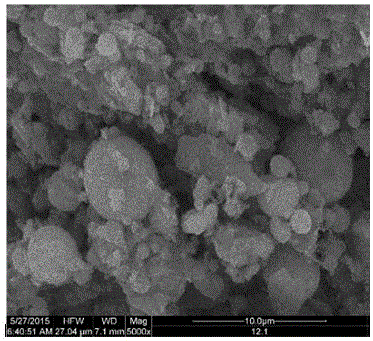

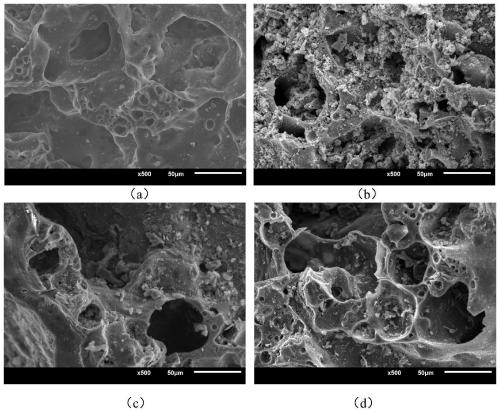

Method of preparing sludge-based Fe-Zn three-dimensional particle catalyst by residual sludge

ActiveCN108722425ASimple preparation processEasy to operateWater contaminantsCatalyst activation/preparationResource utilizationSludge

The invention discloses a method of preparing a sludge-based Fe-Zn three-dimensional particle catalyst by residual sludge. The sludge-based Fe-Zn three-dimensional particle catalyst is prepared, by taking residual sludge of a sewage treatment plant caused by flocculation adjustment of polyferric sulfate as material, by the steps of drying, crushing, screening, forming, activating, granulating, carbonizing, cleaning and drying the dehydrated residual sludge. The prepared catalyst fills an effective space between positive and negative electrodes of a three-dimensional electrode reactor for catalyzing electrocatalytic oxidation of the sewage. By taking sludge carbon as a framework, the Fe-Zn structure sludge-based catalyst is prepared by means of ferrum in a polyferric flocculant and zinc inan activator zinc chloride. The preparation process is simple in flow and easy to operate. By following a principle of sustainable development, waste is turned into wealth, pollutants are catalytically degraded efficiently, double purposes of resource utilization of the sludge and efficient removal of degradation-resistant waste water are achieved, and the method has good environmental benefit andeconomical benefit.

Owner:EAST CHINA NORMAL UNIV

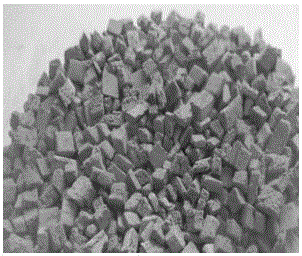

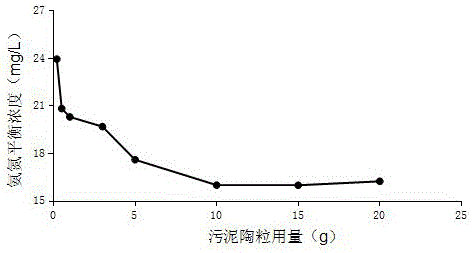

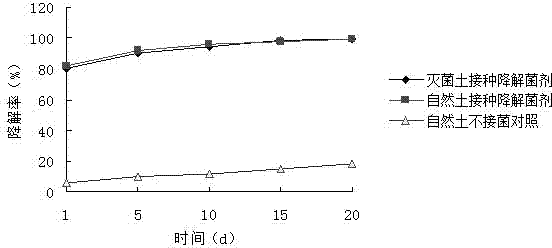

Preparation method of sludge ceramsite used for medium and low concentration ammonia nitrogen wastewater treatment

InactiveCN105819891ASolve disposal problemsAchieve resource utilizationCeramic materials productionCeramicwareSludgePre treatment

The invention provides a preparation method of sludge ceramsite used for medium and low concentration ammonia nitrogen wastewater treatment. The preparation method comprises the following steps: immersing fly ash in a 3-6% NaOH solution at 20-30DEG C for 3-4d, washing the immersed fly ash with deionized water, and drying the washed fly ash at 100-110DEG C; drying excess sludge and clay at 100-110DEG C; drying above three raw materials, crushing the dried three raw materials, and sieving the crushed three raw materials for later use; fully mixing, by mass, 30-60% of the preprocessed fly ash, 30-60% of the preprocessed excess sludge and 10% of the preprocessed clay to obtain a dry material; adding a proper amount of deionized water to the dry material, uniformly stirring to prepare a 1-3mm blank, placing the blank in a tray, and drying the tray in a 110DEG C oven until the surface of the blank has no water; putting the dried blank in a muffle furnace, heating the blank to 350-500DEG C, preheating the blank for 10-40min, heating the blank to 800-1100DEG C, sintering the blank for 10-25min, cooling the obtained product in the furnace to 180-200DEG C, and taking out the cooled product to obtain the sludge ceramsite. The sludge ceramsite prepared in the invention has the advantages of low price, economical property, high efficiency, environmental protection, and suitableness for treatment of medium and low concentration ammonia nitrogen wastewaters.

Owner:WUHAN UNIV

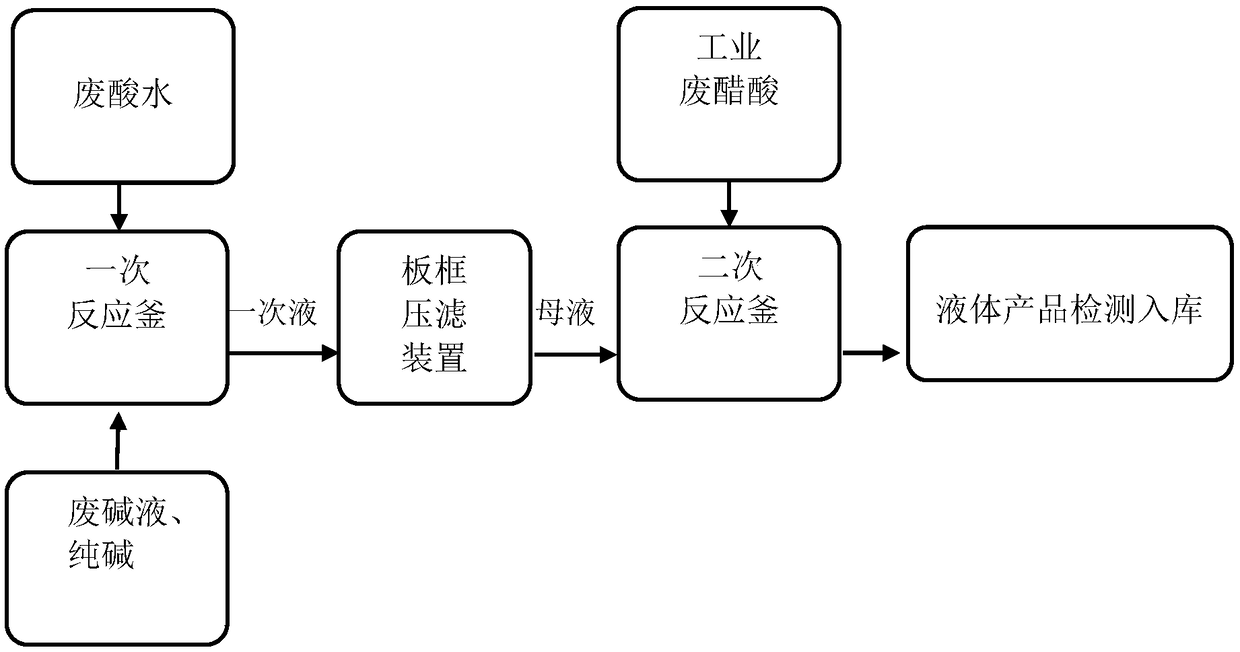

Process for preparing sodium acetate solution

ActiveCN108892611ALow costImprove qualityOrganic compound preparationCarboxylic acid salt preparationSodium acetateProcess equipment

The invention discloses a process for preparing a sodium acetate solution. According to the method, on the premise of not increasing a great quantity of process equipment, waste acid water generated in a decompressed concentrating process in the process of producing ferric chloride with steel pickling waste liquor, waste base liquid generated in a tail gas absorption tower and industrial waste acetic acid react to produce the sodium acetate solution, so that resource utilization is realized. The preparation method is simple and practical, is easy to operate, is low in equipment investment, andis suitable for industrial production. The sodium acetate product has high quality, can be used as an additional carbon source of a sewage treatment plant, and can be used for effectively solving thesafety problem that methyl alcohol is easily combusted and exploded as being used as a current carbon source in the sewage treatment plant. The waste acid water generated in a decompressed concentration process, the waste base liquid generated in a tail gas absorption tower and industrial waste acetic acid are utilized, so that the production cost is greatly reduced, waste is turned to be usefuland is used for treating waste materials, and the environment-friendly concept of energy conservation, emission reduction and cycling economy can be achieved.

Owner:蓝保(厦门)水处理科技有限公司

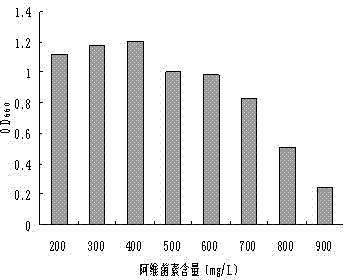

Avermectin pesticide residual degrading bacterium, and microbial inoculum produced thereby

InactiveCN102732455AEasy to useLow costBacteriaContaminated soil reclamationAbamectinLaboratory culture

The invention discloses an avermectin pesticide residual degrading bacterium and a microbial inoculum produced thereby, and relates to separation and screening of Bacillus stearothermophilus AZ11, a microbial inoculum produced through fermenting the Bacillus stearothermophilus AZ11, and an application of the microbial inoculum. Above bacterial strain is preserved in China General Microbiological Culture Collection Center, and has a preservation number of CGMCC NO.6119. The avermectin pesticide residual degrading microbial inoculum produced through fermenting the bacterial strain AZ11 can be widely applied to the restoration of soil and water subjected to avermectin pesticide residual pollution, can also be applied to the degradation of avermectin residuals in avermectin fermentation waste residues or other organic fertilizer raw materials, and can be directly sprayed on surfaces of soil or plants in the agricultural production to effectively degrade avermectin pesticide residuals, so the use is convenient and the cost is low; and the microbial inoculum can also be directly applied to the fermenting production process of the avermectin waste residues to realize the harmless resource utilization of waste residue fermentation products.

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI +1

Formula for producing green tea beverage by using apple secondary juice steam condensate

InactiveCN102422933AImprove the level of processing comprehensive utilization technologyPromote cleaner productionTea extractionWater savingAntioxidant

The present invention discloses a formula for producing a green tea beverage by using an apple secondary juice steam condensate. The formula is characterized in that: the formula comprises, by weight, 0.7-0.8% of green tea / leaf, 0.01-0.03% of citric acid, 3-4% of white granulated sugar, 0.002-0.005% of a composite pigment, 0.02-0.03% of an antioxidant, and 95.1-96.5% of a secondary juice steam water, wherein the sum of the percentages of the raw materials in the formula is 100%. With the present invention, purposes of resource utilization and water saving can be achieved, and the comprehensive utilization technology level in the fruit processing industry can be improved.

Owner:陕西省轻工业研究设计院

Modification method of sludge ceramsite for enhancing formaldehyde adsorption performance

InactiveCN110156440AAchieve resource utilizationEasy to operateOther chemical processesSilicon compoundsActivated sludgeManganese

The invention discloses a modification method of sludge ceramsite for enhancing formaldehyde adsorption performance. The method comprises the following steps: mixing activated sludge difficult to treat in a sewage treatment plant with clay, conducting calcining at high temperature to prepare sludge ceramsite, and crushing and sieving calcined sludge ceramsite to prepare dry sludge ceramsite; adding the dry sludge ceramsite into a potassium permanganate solution, dipping the dry sludge ceramsite in a drying oven, conducting standing and filtering, then putting filtered material into the dryingoven for drying, and then transferring the material to a muffle furnace for roasting to obtain manganese-loaded modified ceramsite. The modified sludge ceramsite loaded with heavy metal manganese improves the adsorption capacity of formaldehyde and has good capacity of removing indoor formaldehyde gas.

Owner:SOUTHWEST UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com