Method and device for treating oily sludge

A sludge generation device technology, which is applied in the field of resourceful and harmless oily sludge treatment, can solve the problem that the storage tank is not a scientific and effective treatment method, and the oily sludge cannot be effectively treated, and the atmosphere and surrounding soil are recycled again. Pollution and other problems, to achieve the effect of rapid electrochemical reaction, strong reproducibility, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

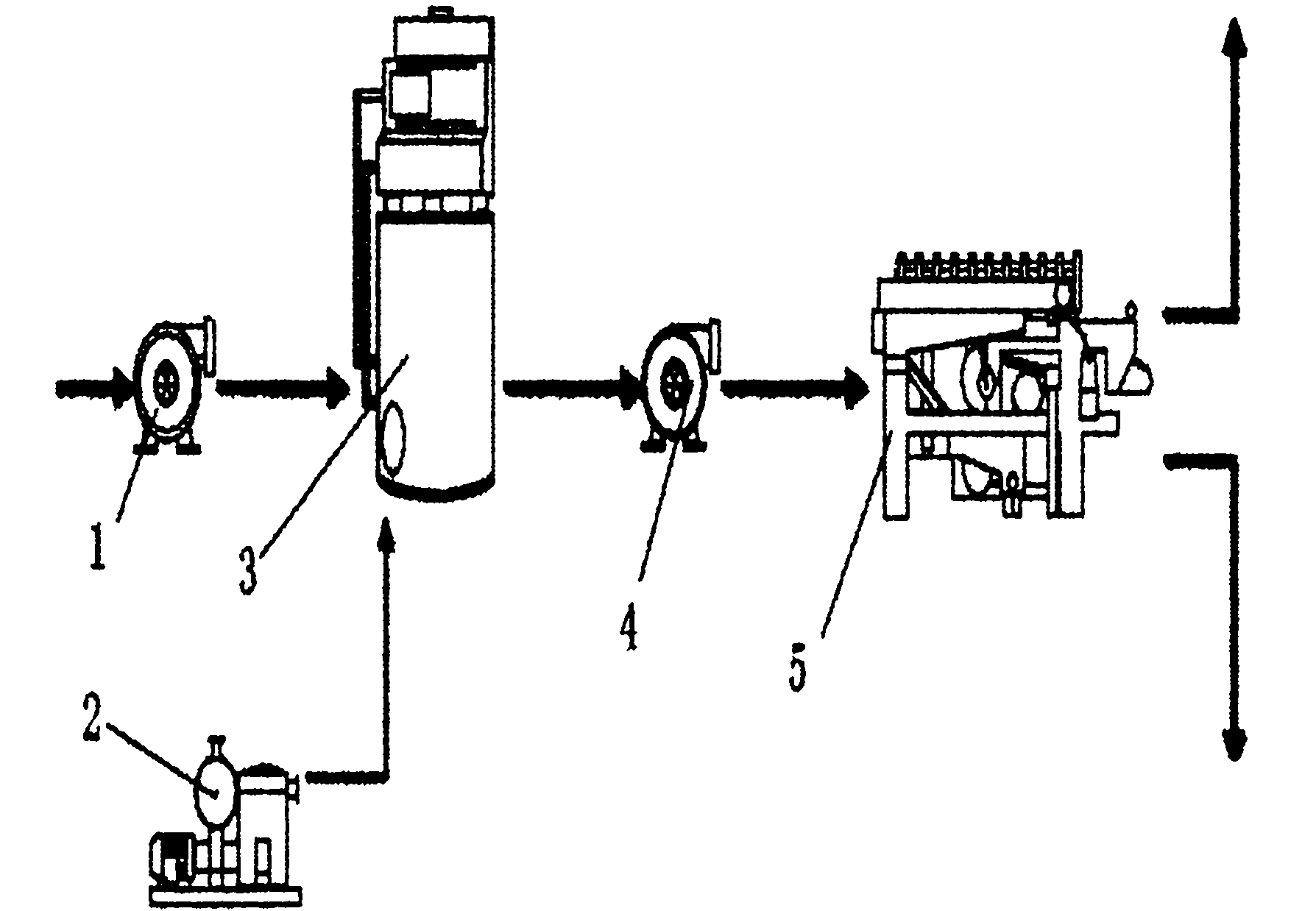

Method used

Image

Examples

Embodiment 1

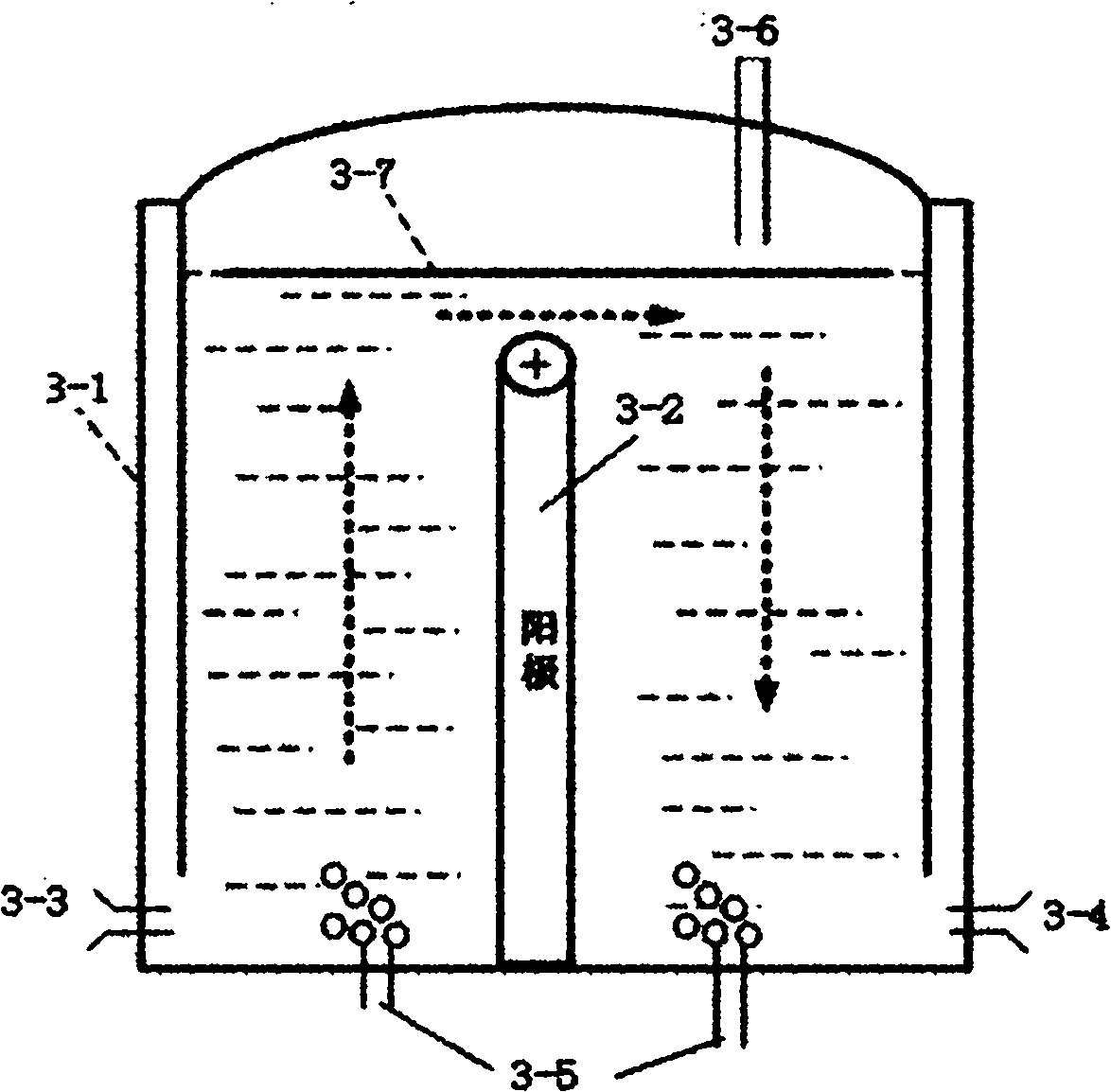

[0035] To treat oily sludge with a water content of 82% in a sewage station in an oil field, the electrochemical reactor uses figure 2Structure, voltage 60v, current 1000A, the residence time of oily sludge in the electrochemical reactor is 30 minutes, the outlet sampling measurement shows that the oil removal rate is 72%, the removal rate of organic pollutants and volatile solids is 84%, sulfate-reducing bacteria And the removal rate of saprophytic bacteria is 95%; the extracted water is sampled and measured after filtration, the COD is 153mg / L, the oil content is 17.6mg / L, the suspended solid SS is 34mg / L, the sulfate reducing bacteria and saprophytic bacteria are 0, reaching the reinjection water Standards and efflux secondary standards.

Embodiment 2

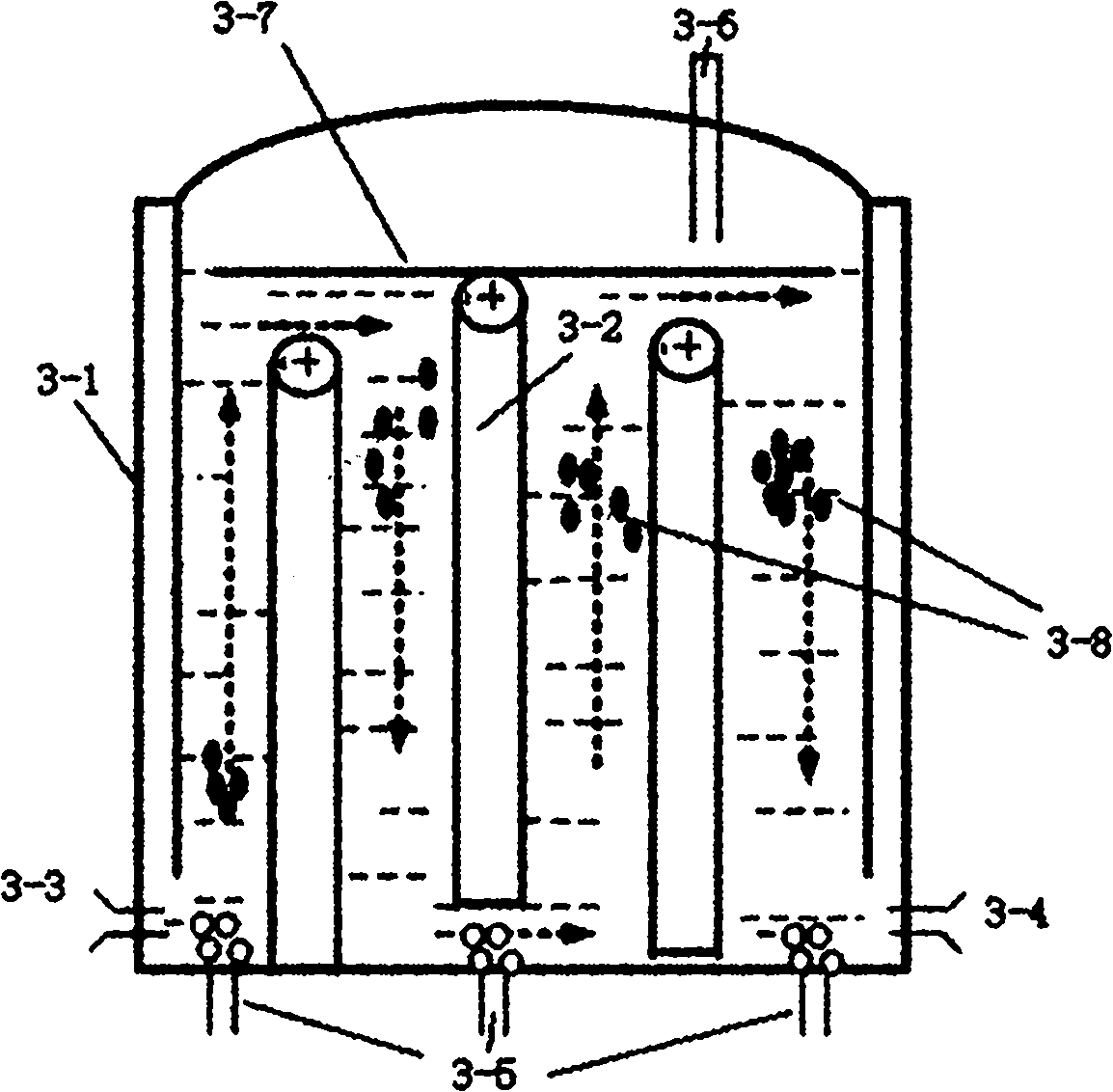

[0037] To treat oily sludge with a water content of 82% in a certain sewage station in an oil field, the electrochemical reactor adopts such image 3 Structure, voltage 60v, current 1000A, the catalyst added is mixed and sintered with shell carbon fiber, barium oxide and titanium oxide according to the mass ratio of 40:20:40. The residence time of oily sludge in the electrochemical reactor is 20 minutes, and the outlet sampling measurement shows that the oil removal rate is 90%, the removal rate of organic pollutants and volatile solids is 89%, and the removal rate of sulfate-reducing bacteria and saprophytic bacteria is 100%; The extracted water was sampled and measured after filtration. The COD was 126mg / L, the oil content was 14.9mg / L, the suspended matter SS was 35mg / L, and the sulfate-reducing bacteria and saprophytic bacteria were 0, meeting the reinjection water standard and the second-level discharge standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com