Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

230results about How to "Promotes electrochemical reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer perovskite/graphene composite material and preparation method thereof

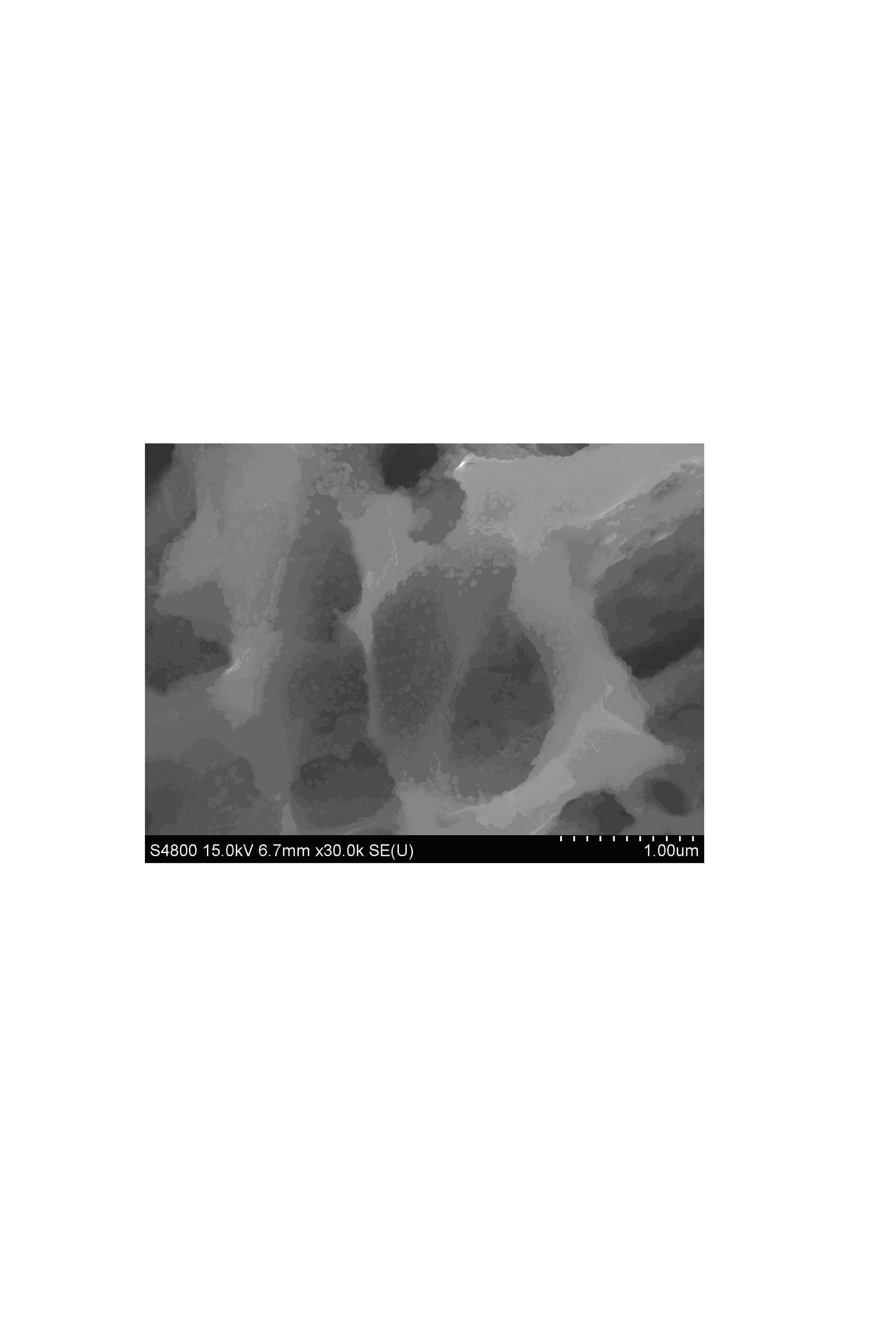

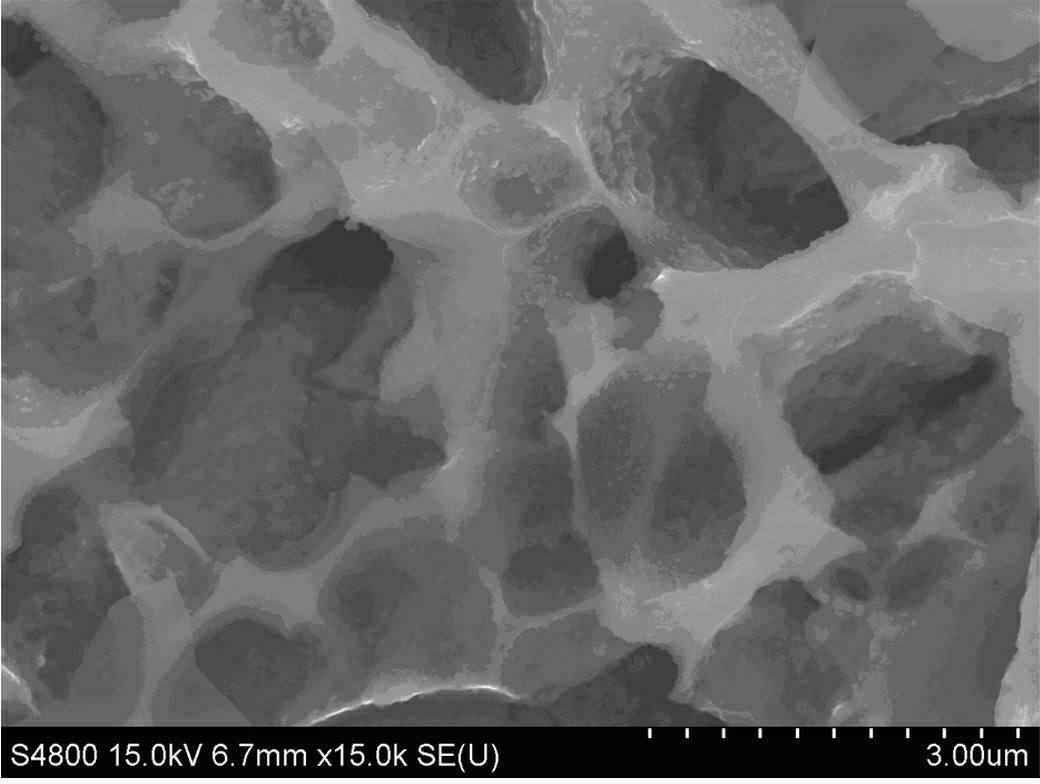

The invention relates to a nanometer perovskite / graphene composite material. The nanometer perovskite / graphene composite material is of a porous structure, the aperture of the nanometer perovskite / graphene composite material is about 0.5-1.5 microns, nanometer perovskite particles are distributed uniformly on a graphene film, and the average crystallite dimension of the composite material is about 10-20nm. A preparation method of the nanometer perovskite / graphene composite material comprises the following steps of: with graphite paper as an anode, a carbon rod as a cathode and concentrated sulfuric acid as an electrolyte, carrying out oxidation peeling to prepare a thin-layer graphene material, and then preparing graphene suspension from the thin-layer graphene material; adding nitrate and citric acid to the graphene suspension to enable the metal nitrate to be hydrolyzed to form sol, polymerizing the sol to form gel, finally drying and baking the gel to obtain the nanometer perovskite / graphene composite material. The preparation method disclosed by the invention has the advantages of simple process and low cost; and the nanometer perovskite / graphene composite material disclosed by the invention has good chemical uniformity; in addition, a reaction process is easy to control, and nanometer perovskite particles are more uniformly distributed on the graphene film and have smaller particle sizes, thus the nanometer perovskite / graphene composite material prepared by the method disclosed by the invention has excellent electro-catalysis performances and is suitable for being taken as an electro-catalysis material of a fuel cell.

Owner:YANSHAN UNIV

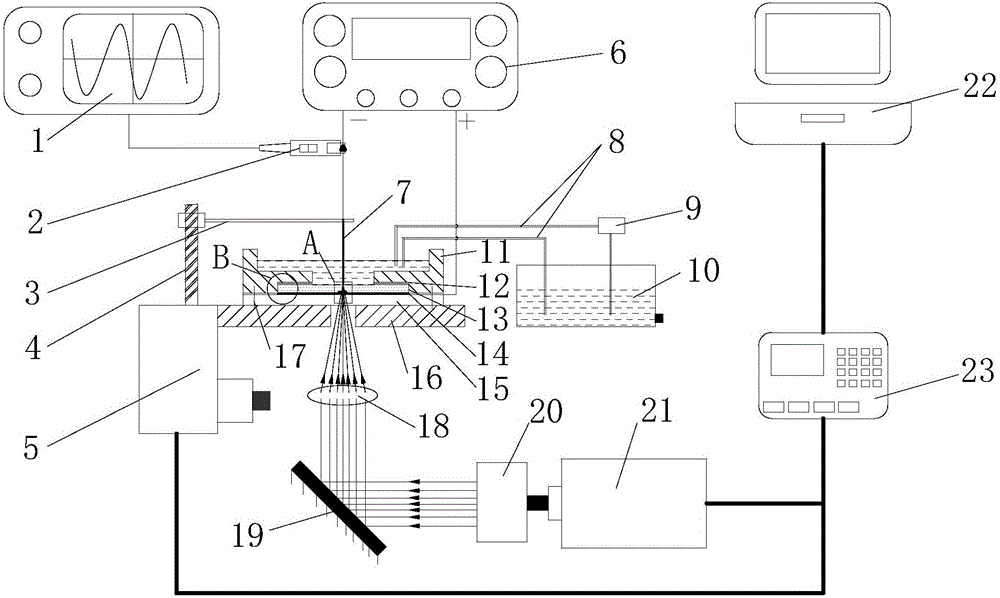

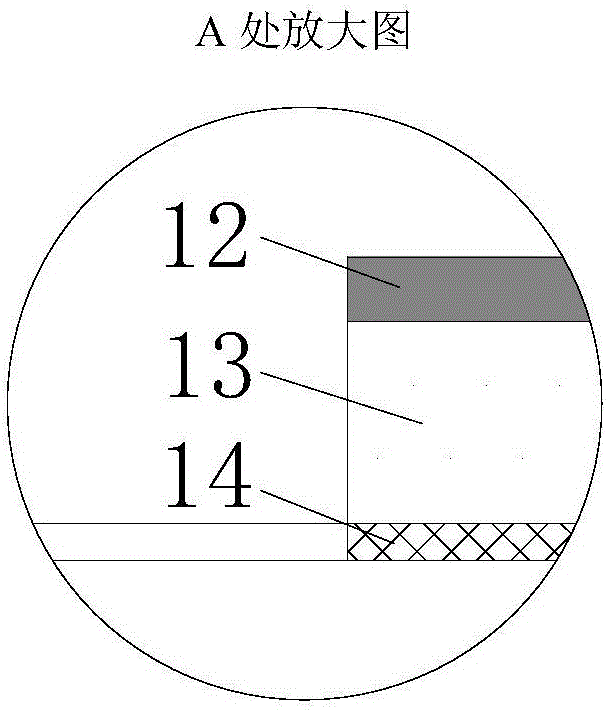

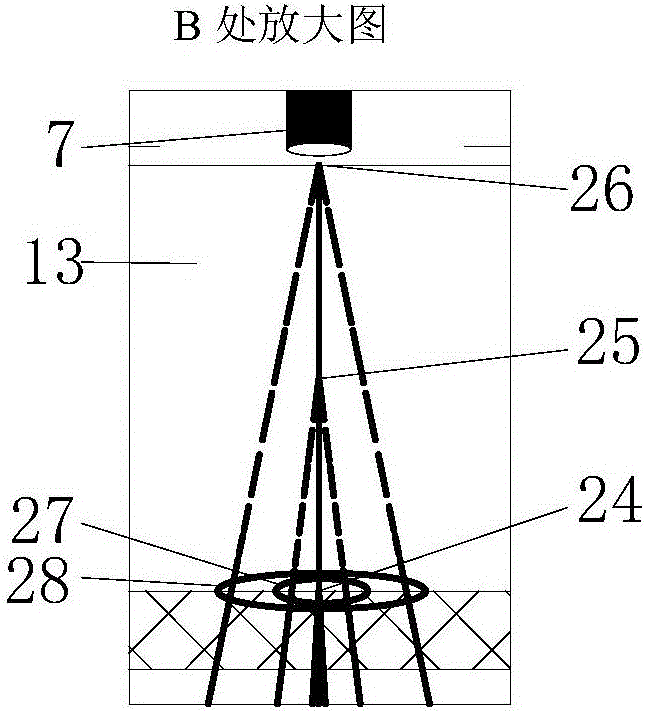

Method and device for coaxial combined machining with tubular electrode discharging and laser irradiation

ActiveCN106424987AImprove processing efficiencyImprove processing localityStress concentrationMaterial defect

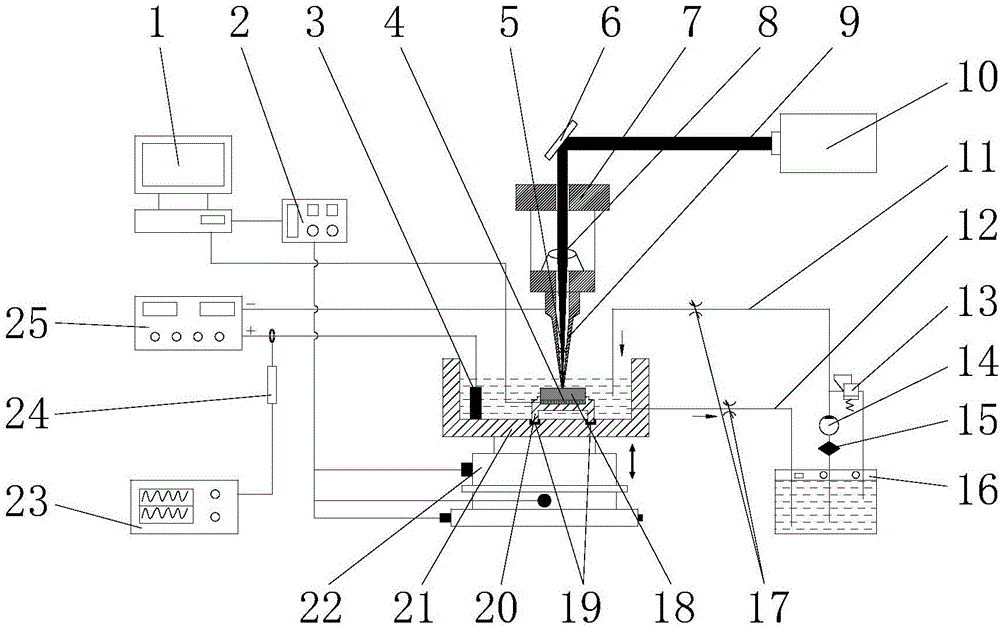

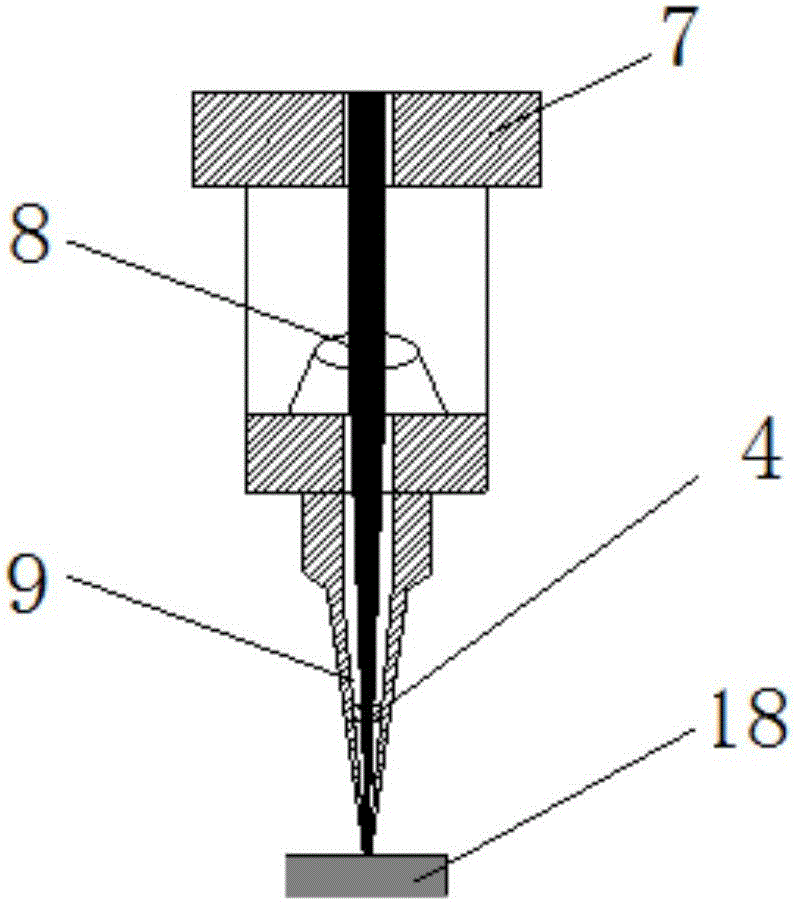

The invention provides a method and a device for coaxial combined machining with tubular electrode discharging and laser irradiation, and belongs to the field of non-traditional machining and combined machining. Micro-etching machining is performed on the surface of an insulating high-hardness brittle material by virtue of a coaxial action of cone-shaped tube electrode discharging and laser irradiation, recessive material defects and stress concentration generated by pulsed laser acting on the surface of a workpiece can attract spark discharge to always act on the current area, and meanwhile, the spark discharge changes the surface shape and physico-chemical property of the current area, then nonlinear absorption of the current area on laser energy is improved, a local field enhancement effect is generated, and pulsed laser focused irradiation can accelerate an electrochemical reaction to promote generation of a stable discharge gas film layer on the surface of a hollow tool electrode; and the interactive cooperation of two types of energy achieves fixed-area micro-etching of the insulating high-hardness brittle material, the machining efficiency is significantly improved, and the machining quality is improved.

Owner:JIANGSU UNIV

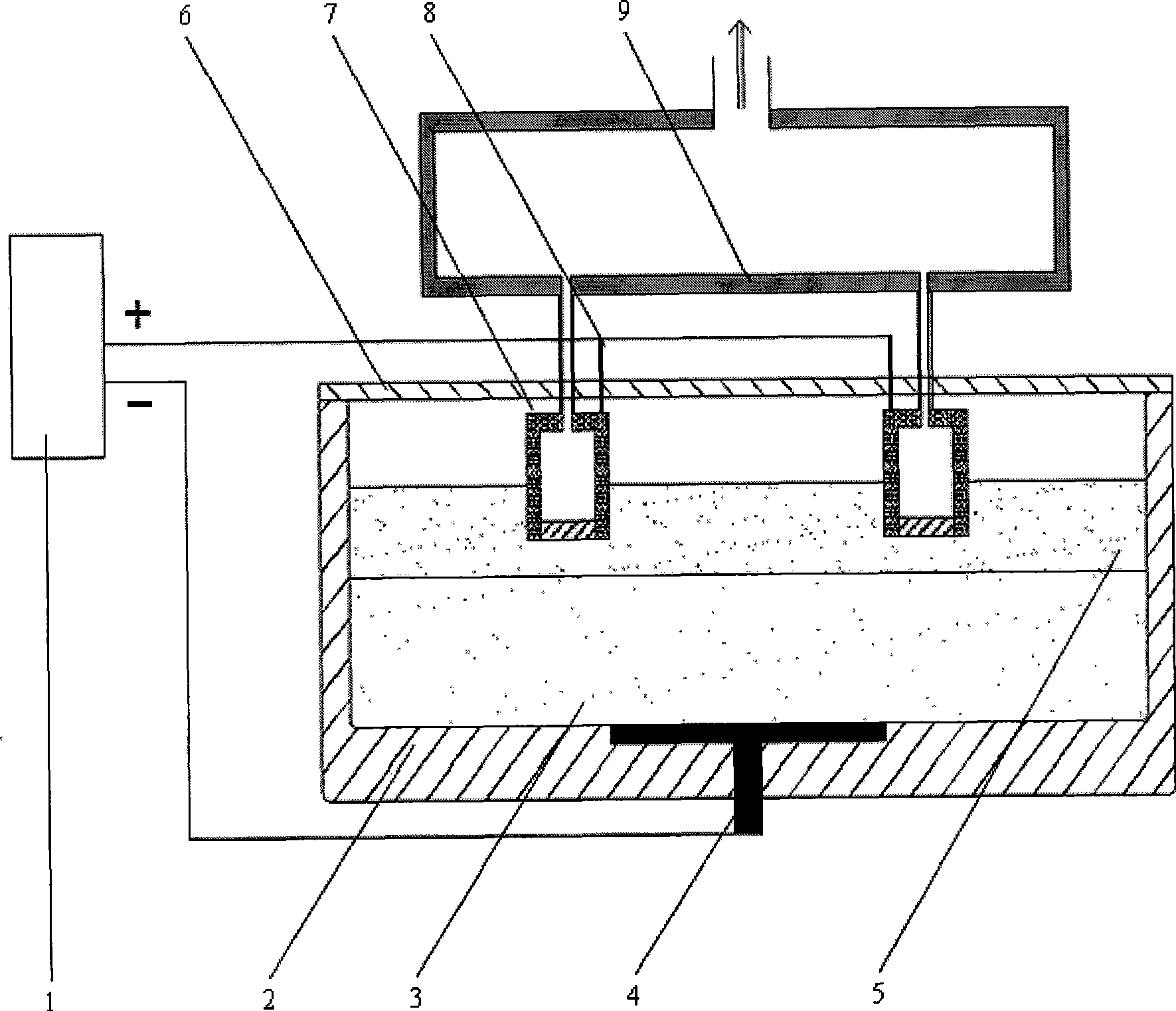

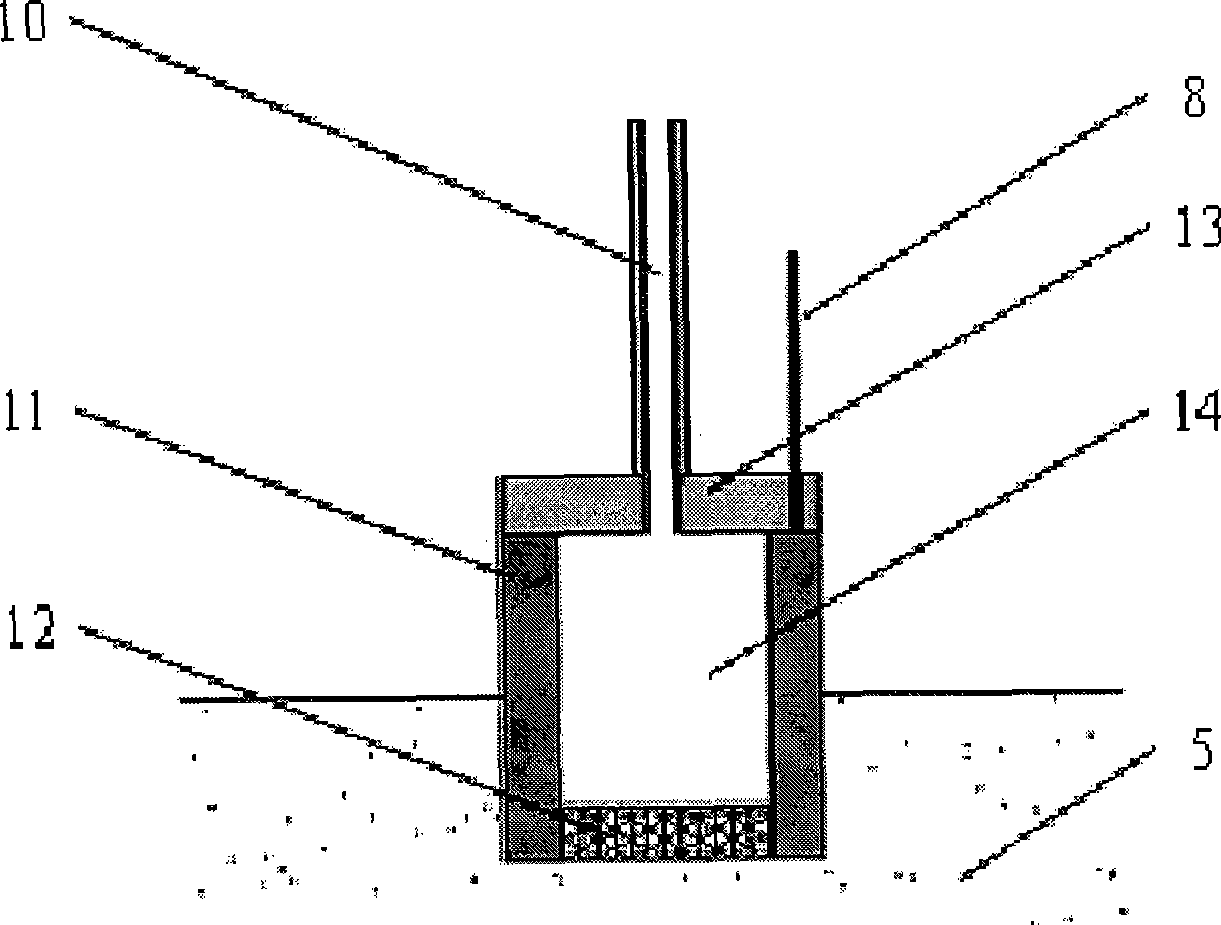

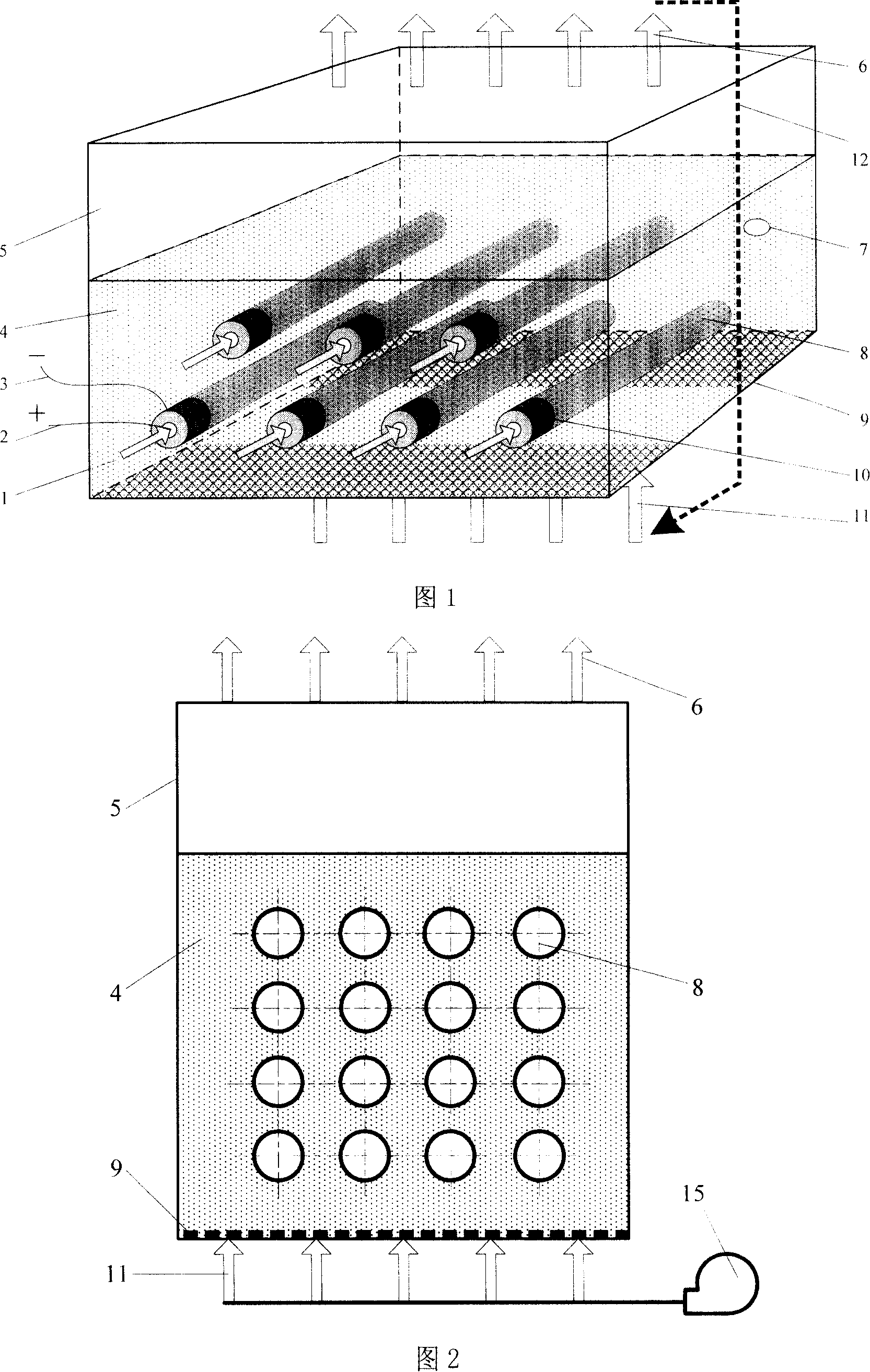

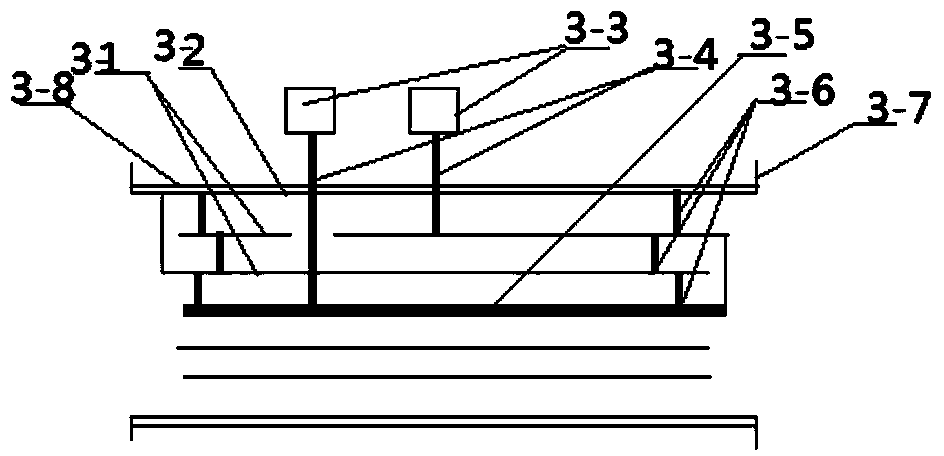

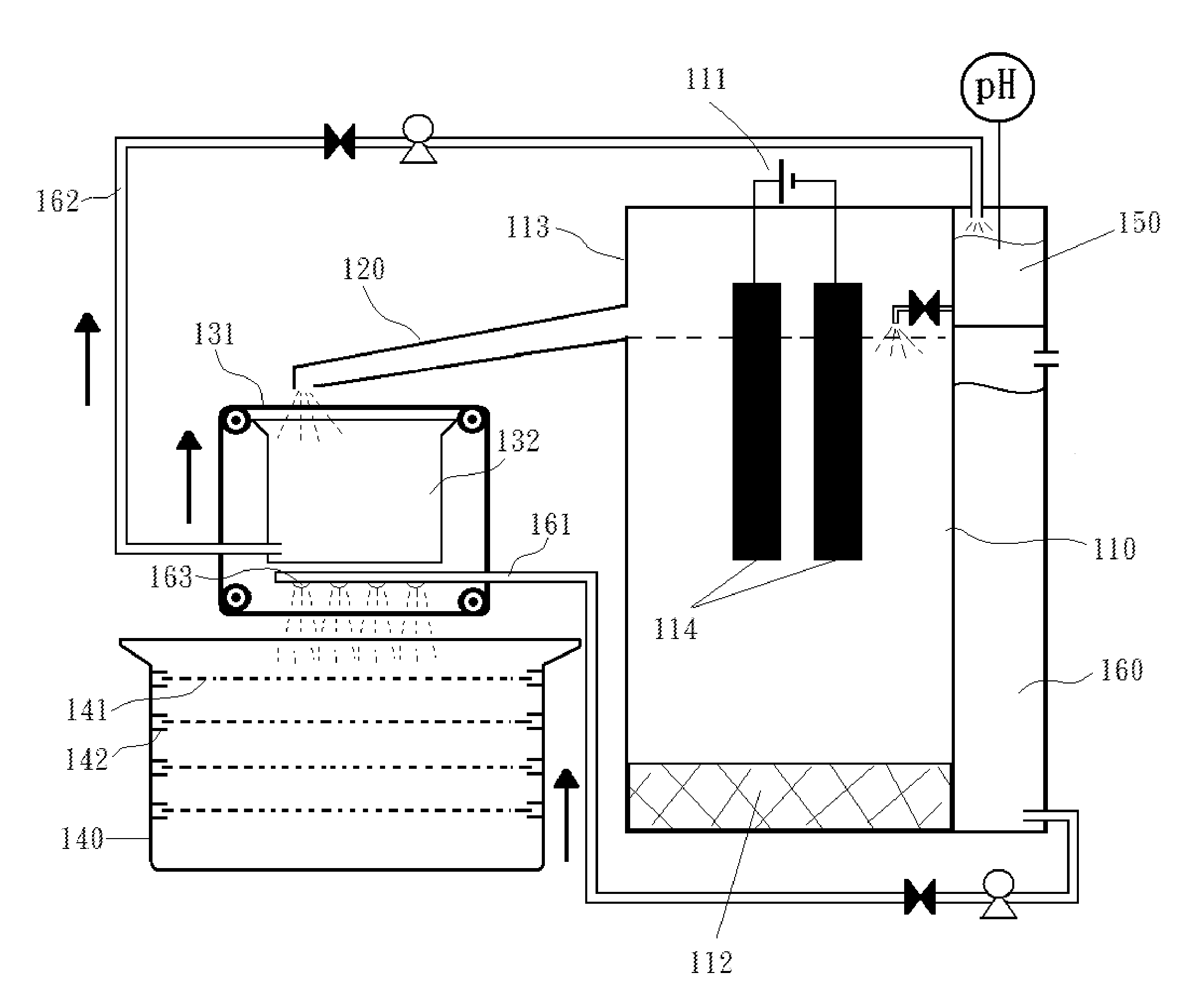

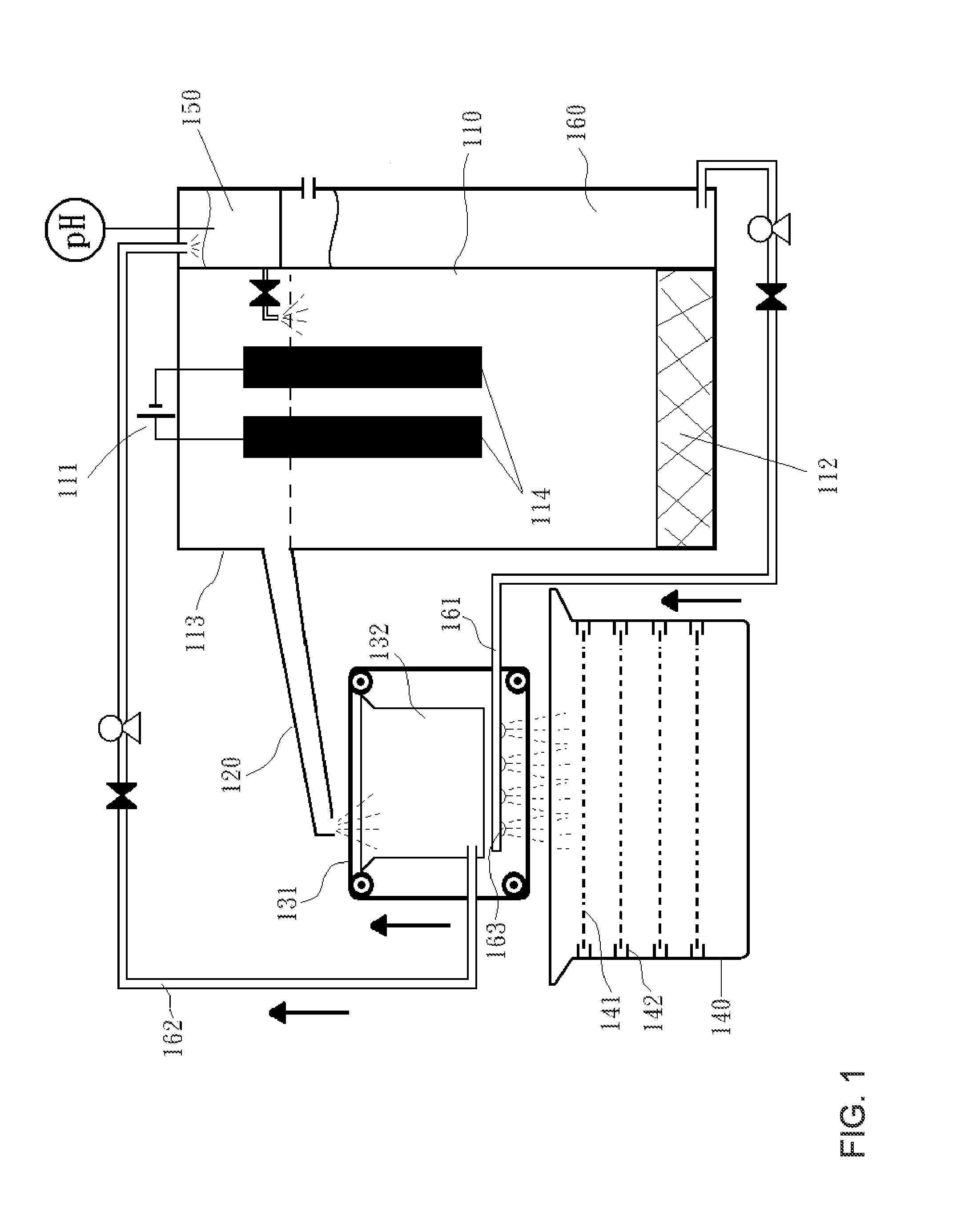

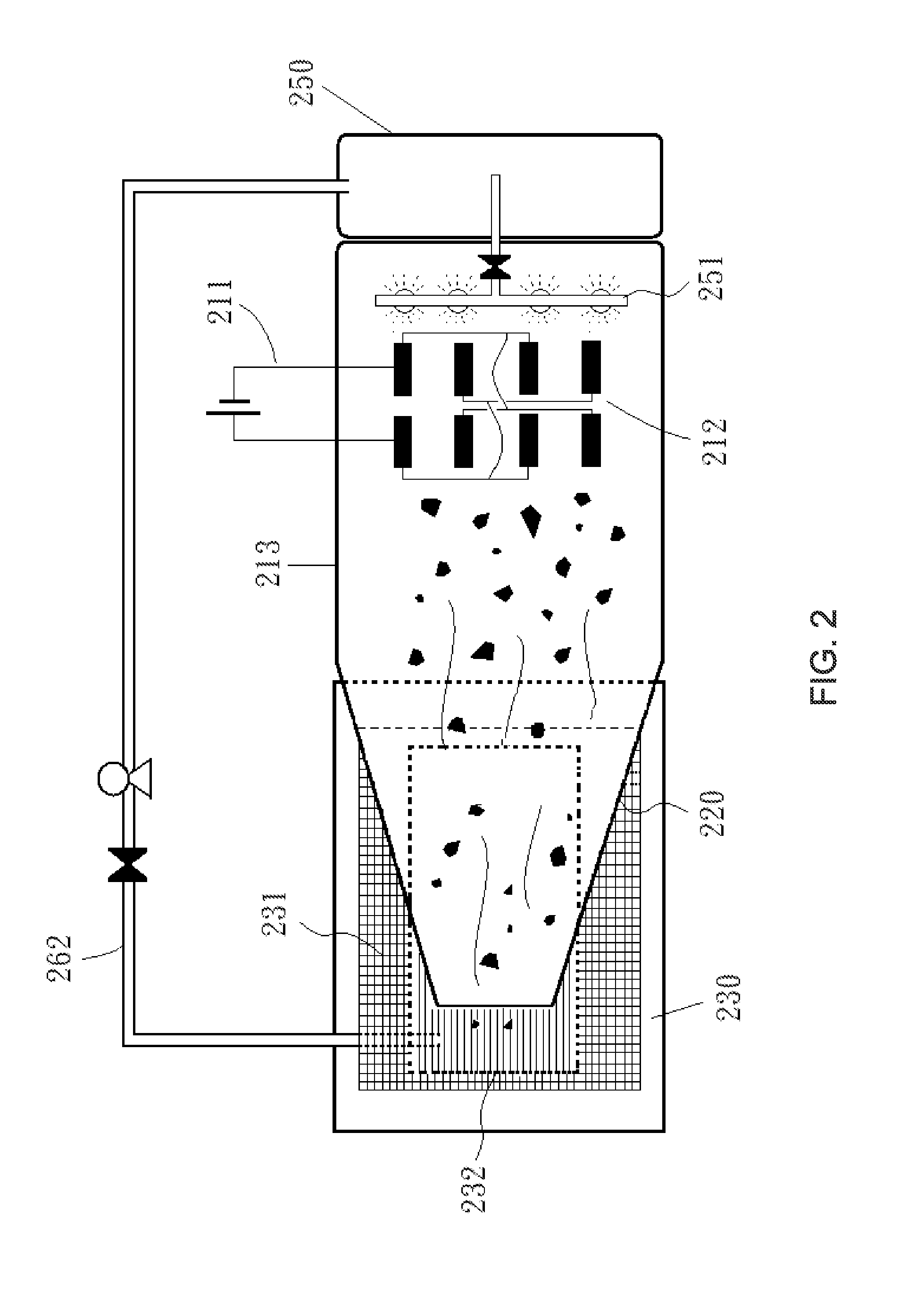

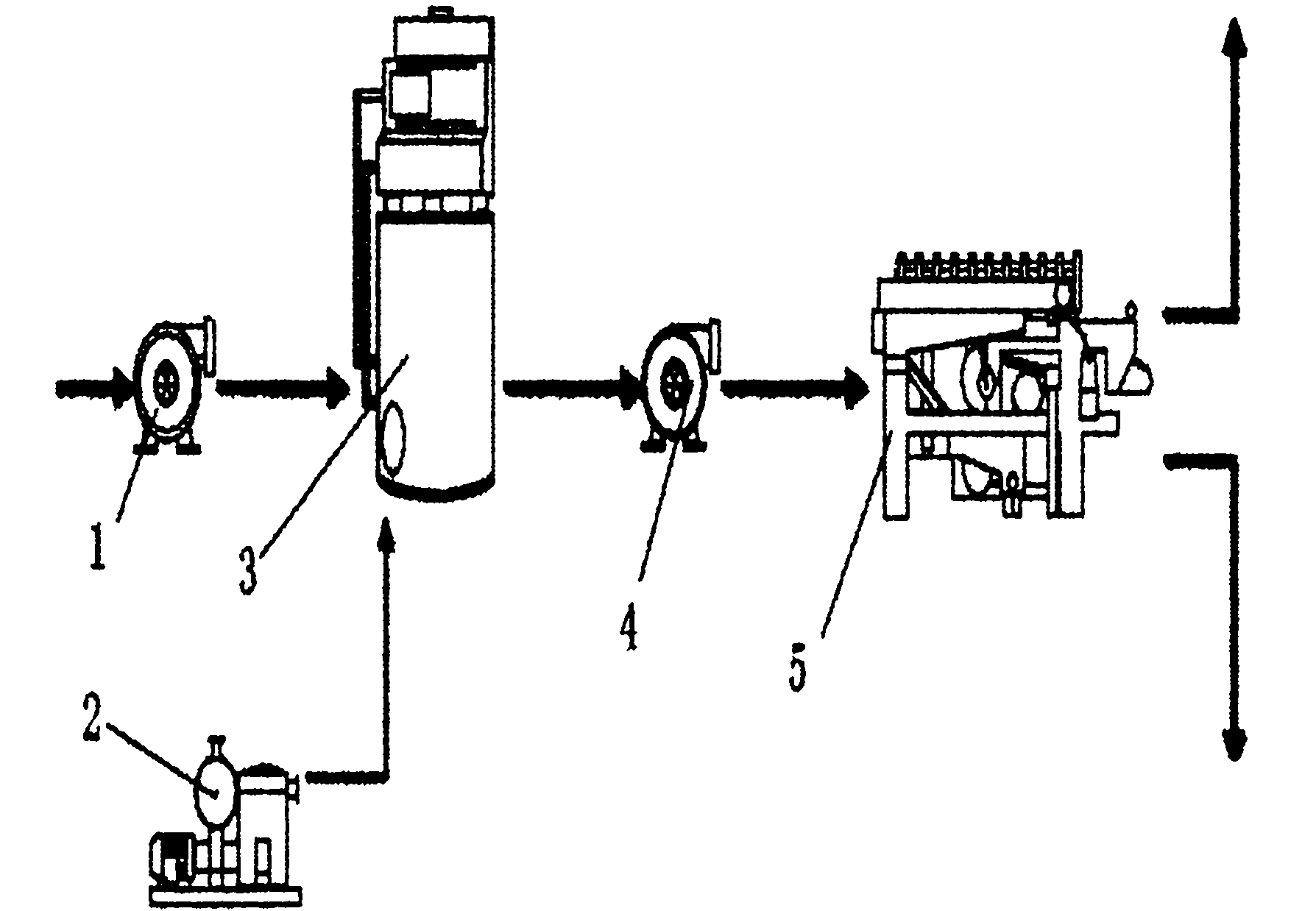

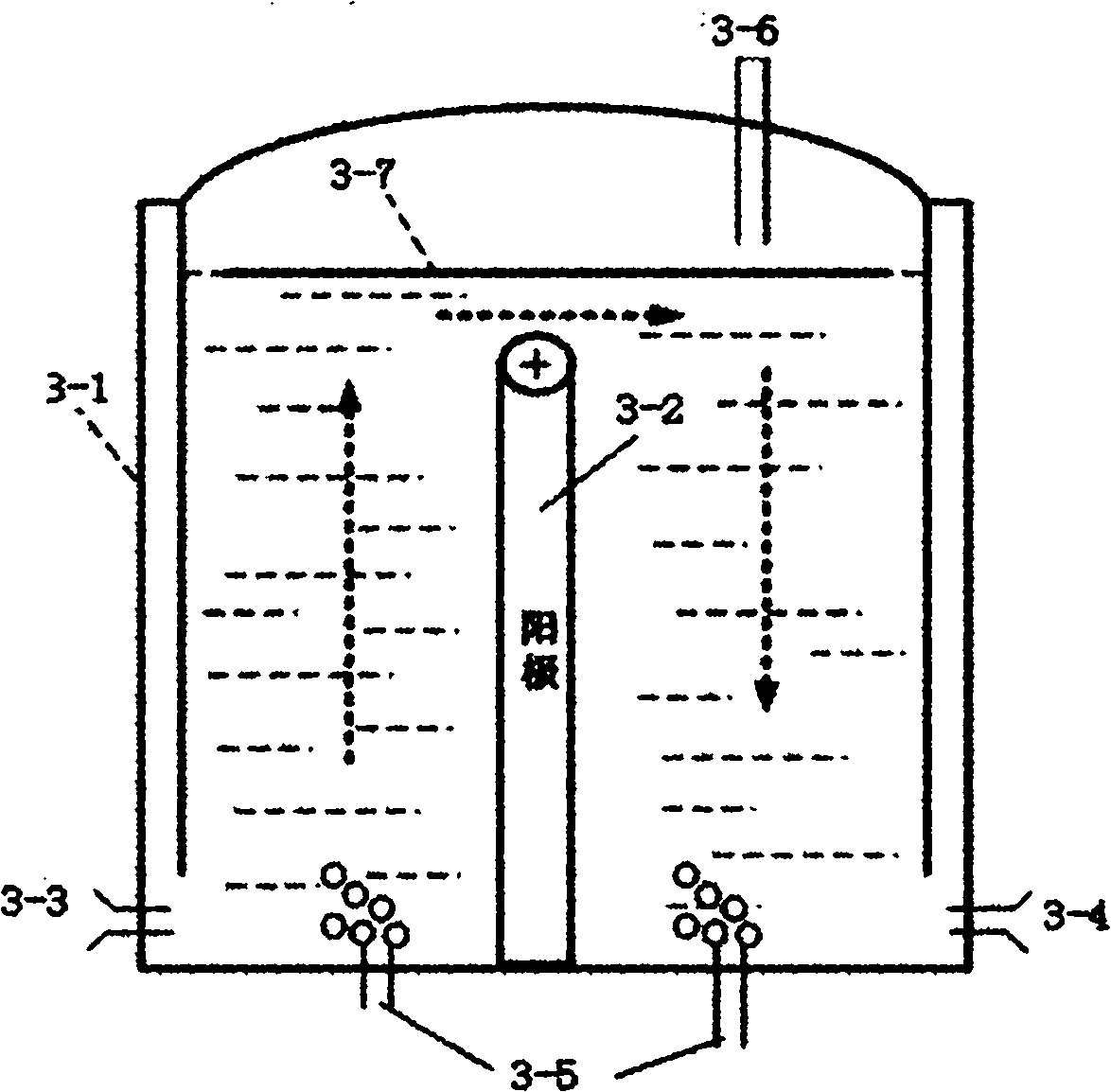

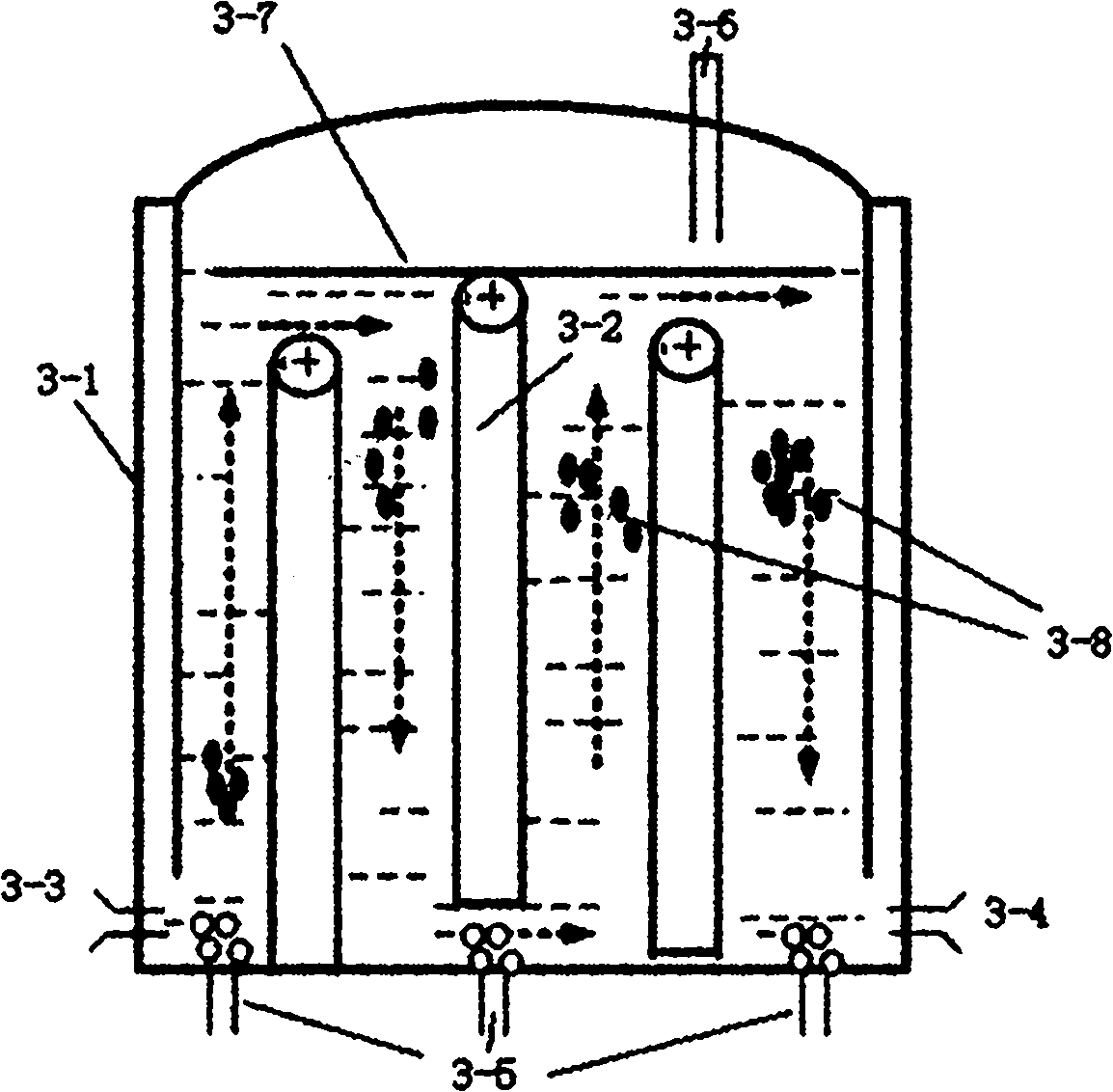

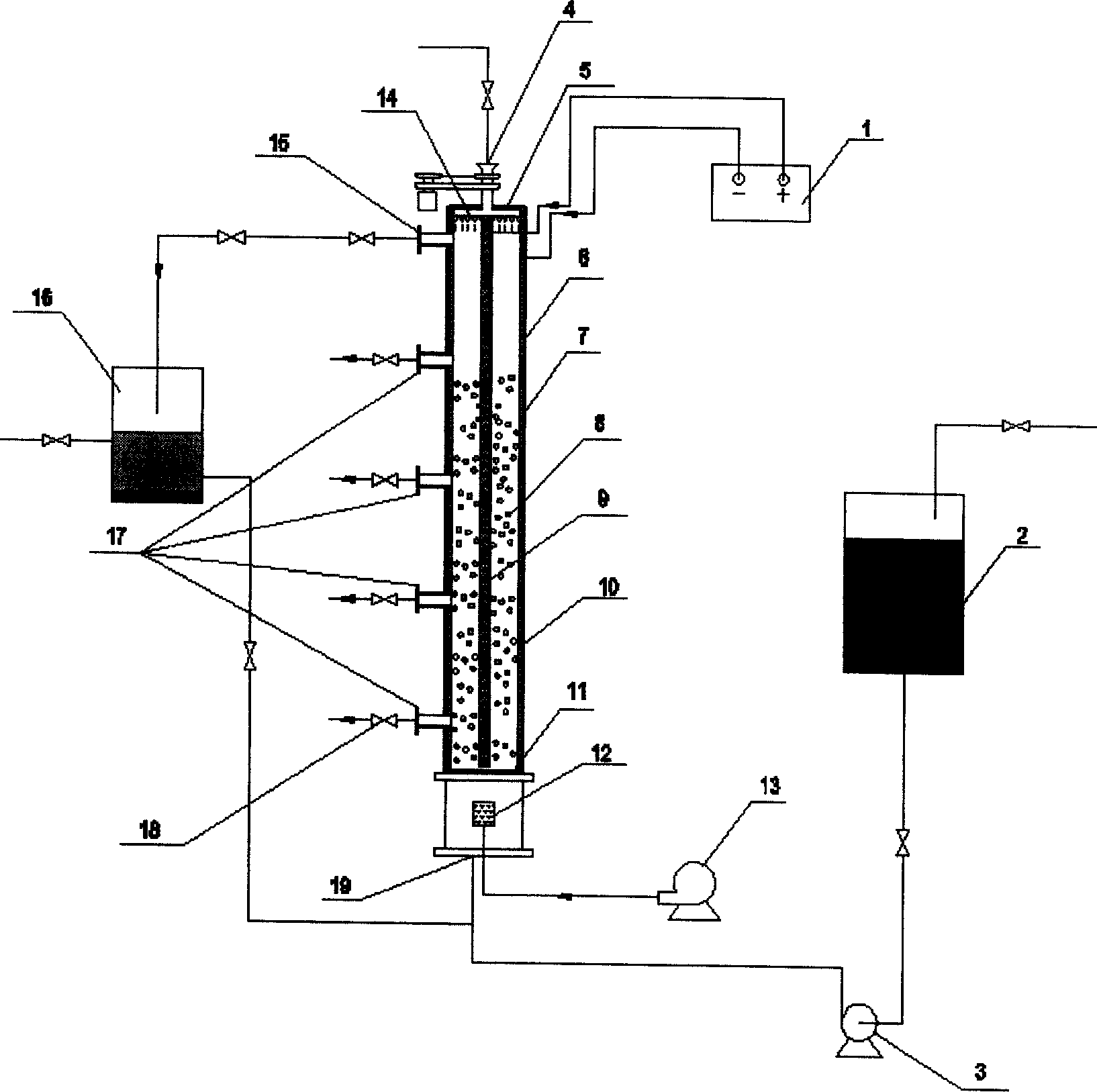

Device designed for continuous production of graphene flakes by electrochemical method

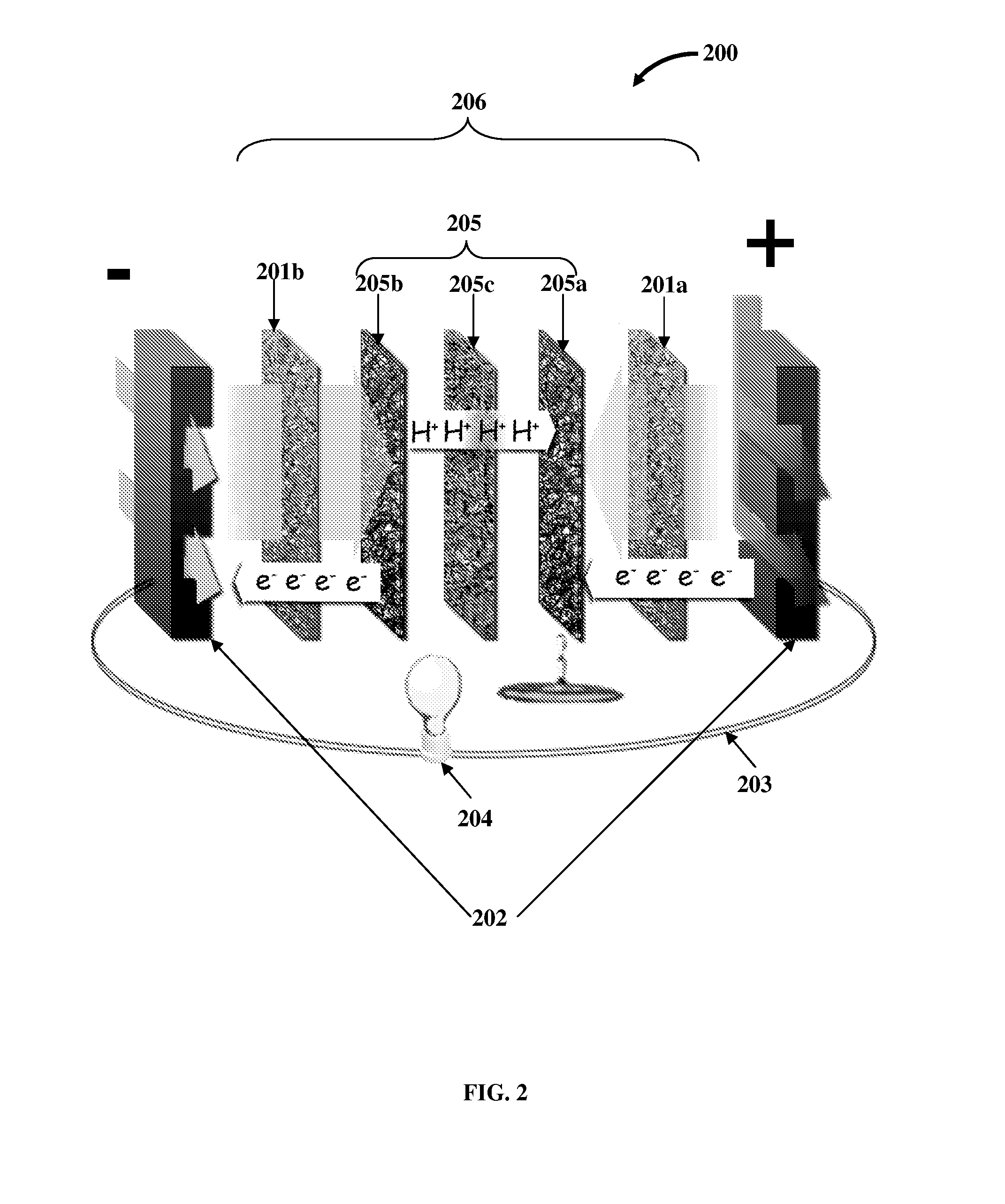

ActiveUS20140166475A1Improve efficiencyPromotes electrochemical reactionsCellsMaterial nanotechnologyHigh volume manufacturingFiltration

Disclosed is a device designed for a continuous production of graphene flakes by an electrochemical method. The device consists of an electrochemical unit for generating graphene flakes by an electrochemical exfoliation; a filtration unit for separating the graphene flakes from an electrolyte solution; a guiding path connected to the electrochemical unit and transports the graphene flakes and the electrolyte solution into the filtration unit; a grading collection unit for accepting the separated graphene flakes from the filtration unit and separating the graphene flakes by size. The device can achieve the effect of producing high-quality graphene flakes in mass production electrochemically, continuously and quickly.

Owner:NAT CHUNG SHAN INST SCI & TECH

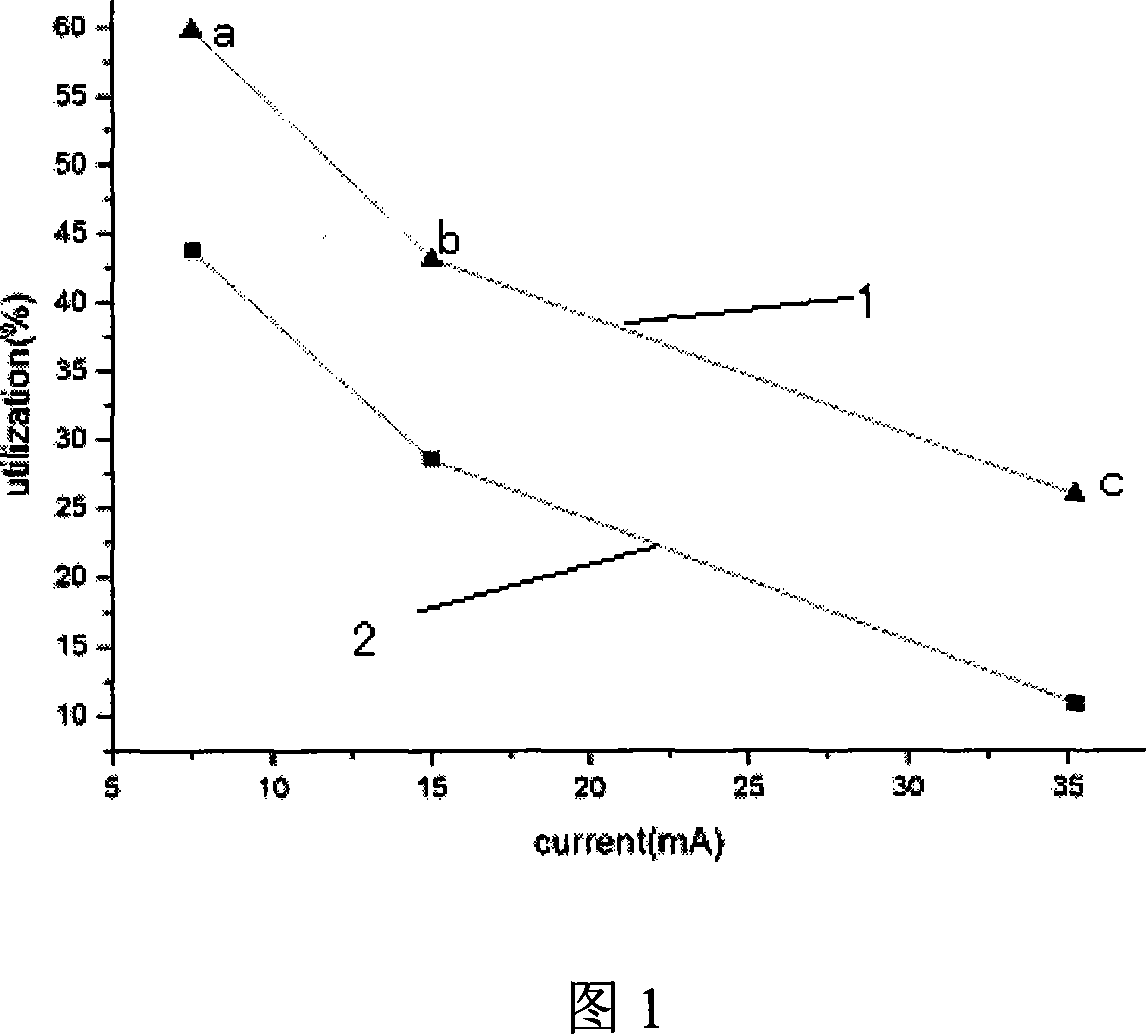

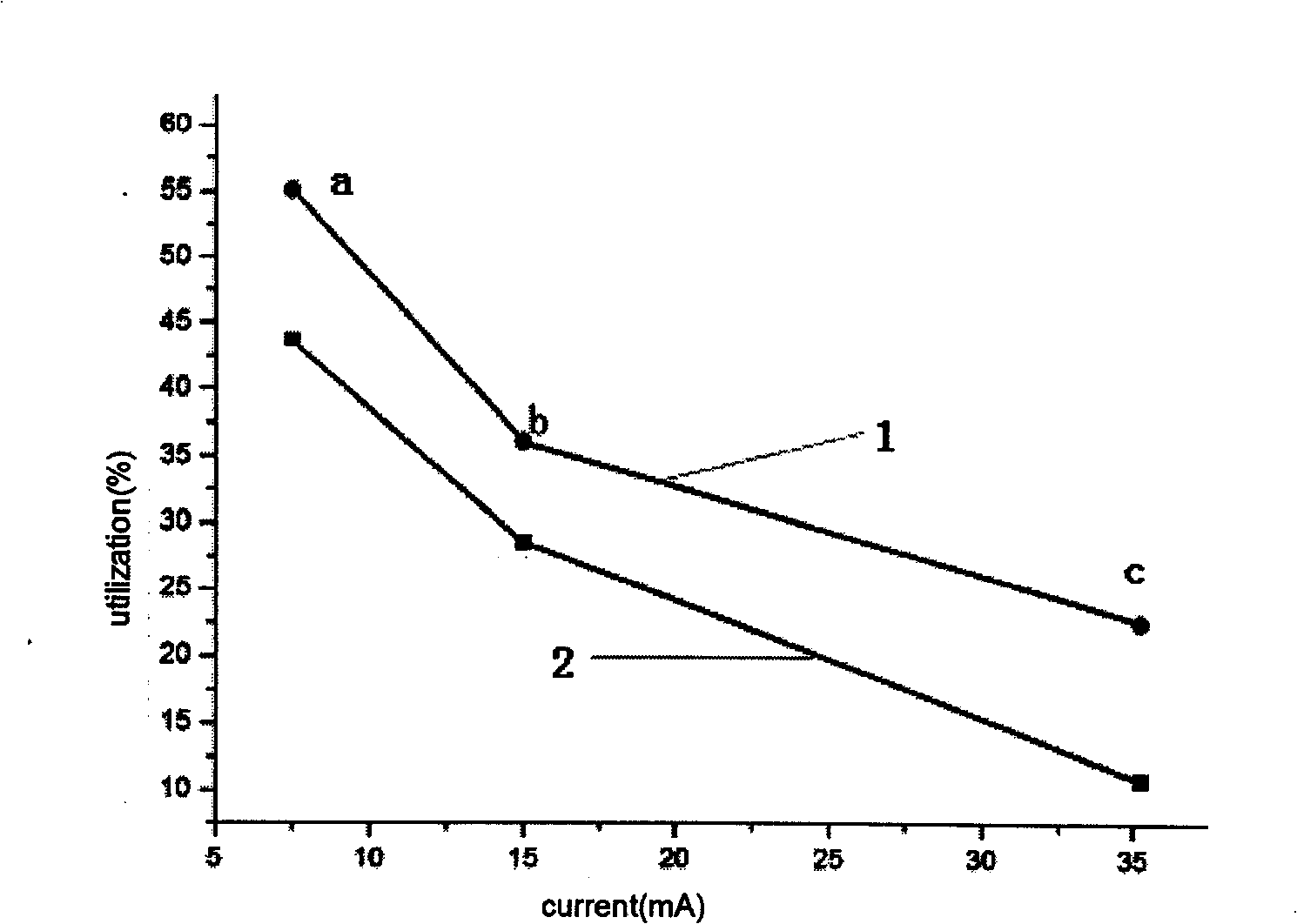

Anode material of lead accumulator and preparation method thereof

InactiveCN101320800AImprove discharge capacityLarge specific surface areaLead-acid accumulator electrodesFiberCarbon nanotube

The invention discloses lead storage battery positive pole material and a production method thereof, ingredients of the material and percent contents of the ingredients by weight are as follows: 0.2-2% of carbon nanometer tube, 0.2-2% of polyacrylonitrile short fiber, 60-90% of PbO2, the rest is lead powder. The carbon nanometer tube experiencing mixed-acid ultrasonic treatment is used as an additive for the lead storage battery positive pole, which can not only resist corrosion from the execrable electrochemical environment in the lead storage battery, increase specific surface area of the positive pole active substances, promote charging and discharging abilities of an electrode, improve the circulation performance, boost chemical efficiency, but advance the utilization rate of the active substances and discharging capacity of the lead storage battery. In case of 0.5c-10c of current, the utilization rate of the active substances in simulation batteries can be enhanced by 8%-15%. The invention has simple process and low cost as well as adapt to large-scale production and application.

Owner:ZHEJIANG UNIV

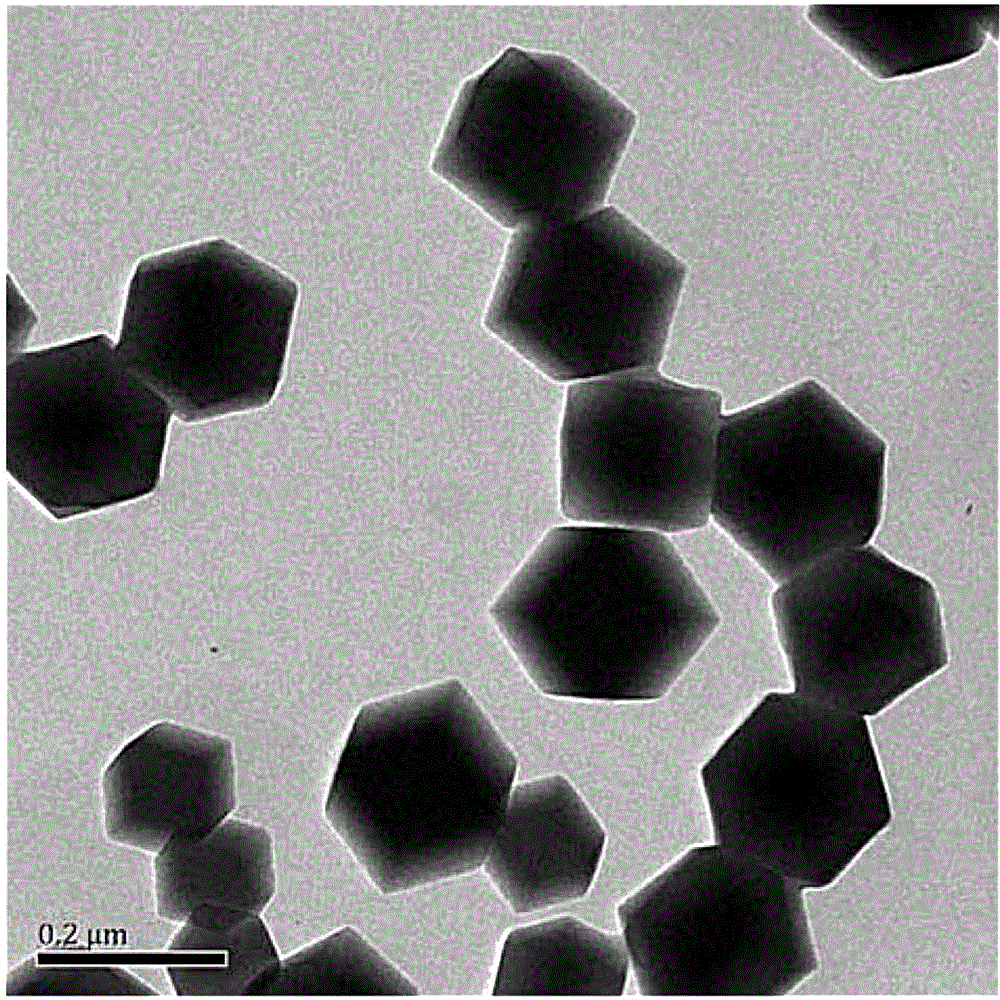

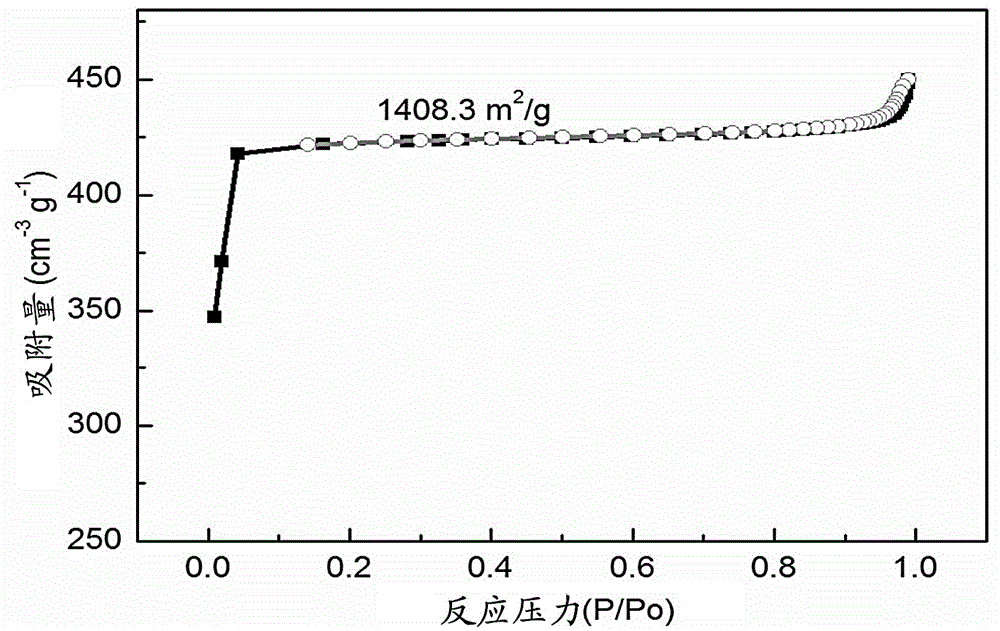

A method for preparing a doped carbon material supported alloy bifunctional electrocatalyst that have a hollow polyhedral nanocage microstructure

InactiveCN108963278AThe synthesis method is simple and safeImprove electrocatalytic performanceCell electrodesAlloySolvent

The invention discloses a preparation method of a dual-functional electrocatalyst with a hollow polyhedral nano-cage microstructure doped with carbon material loading alloy, belonging to the field ofzinc Air Battery Catalyst Technology. The technical scheme of the invention mainly comprises the following steps of: adding an alcohol solution of cobalt nitrate and 2-Polyhedral ZIF- 67 precursor Wassynthesized by the reaction of methimidazole with ethanol at room temperature., and then that ZIF-67 precursor and that nickel source are heat and refluxed in an alcohol solvent to obtain hollow polyhedral nanocage product, and the obtained product is solvothermally react with the magnesium source and the boron source to obtain the target product. The catalyst of the invention introduces nickel and magnesium, so that the synergistic action between different components enhances the catalytic activity of the composite material, and the introduction of heteroatom boron effectively optimizes theelectronic structure of the material and improves the electrocatalytic performance. The catalyst of the invention and the preparation method thereof are prepared from zinc. The catalyst for air battery has a wide application prospect.

Owner:HENAN NORMAL UNIV

Method and device for treating oily sludge

InactiveCN102001806AImprove qualityQuickly break down complex structuresSludge treatment by oxidationElectrochemical responseMicro bubble

The invention relates to a method and a device for treating oily sludge. Under the action of an applied electric field and by adopting an electrochemical oxidation method, the oil-in-water and water-in-oil structure of emulsified oil is quickly broken, and the oily sludge serving as an electrolyte releases oil drops; oil is quickly taken by a large number of micro bubbles to the liquid level to be recycled under the action of applied air flotation; oily sludge flocs are subjected to electrochemical reaction on the surface to produce various active free radicals which have high activity and oxidability and mainly comprise hydroxyl, and organic pollutants are degraded to be converted into water and carbon dioxide; the active free radicals can destroy a microbial cell structure and kill sulfate reducing bacteria and saprophytic bacteria through a series of oxidation chain reactions; the sludge is powerfully dehydrated, so that the water quality of dehydrated water meets the water quality standard of oil field reinjection, and the sludge can be recycled; and a mud cake is nontoxic and harmless and can be used for soil improvement, fertilizers, building materials and the like.

Owner:朱同德 +1

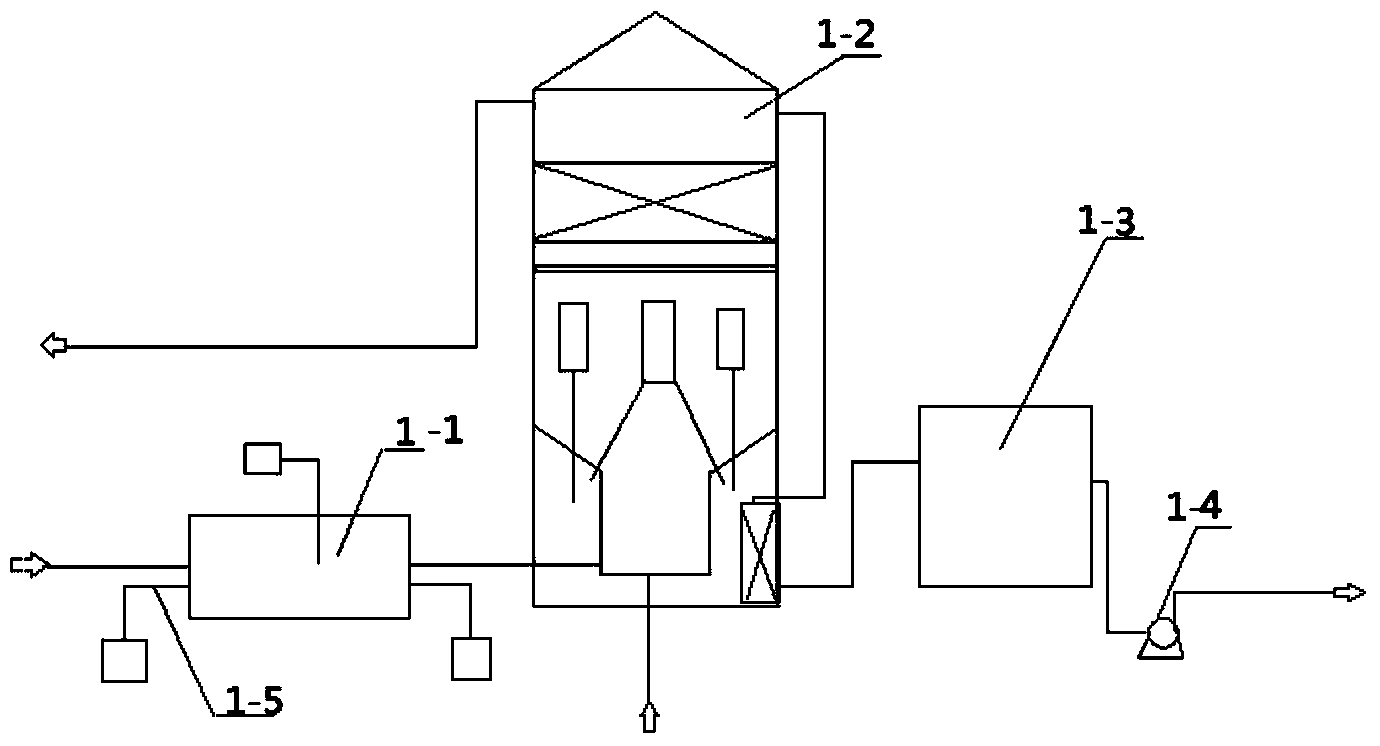

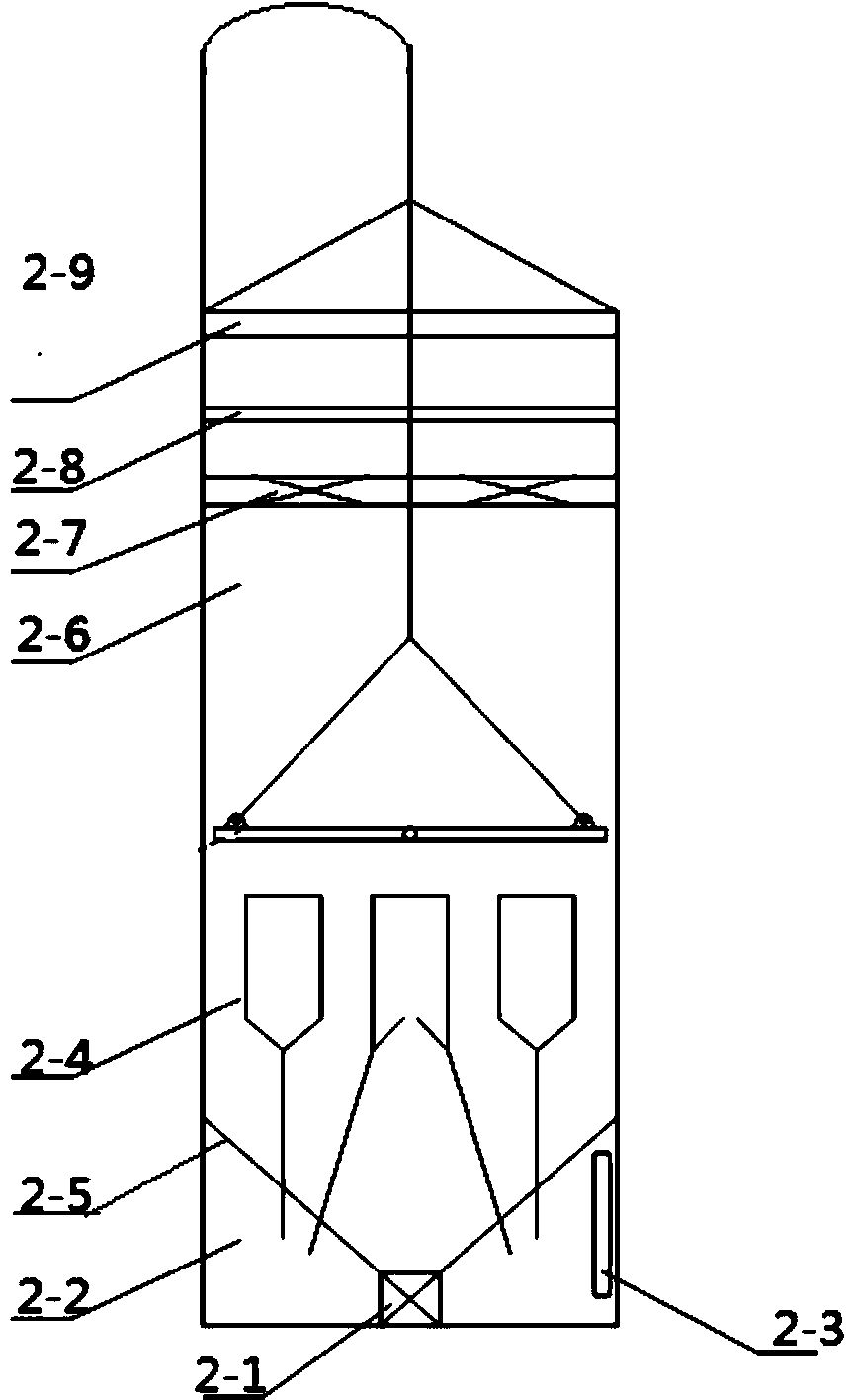

Electric biological processing device and method for waste water containing heavy metal ion and non-degradable organism

InactiveCN1749177AWide concentration rangeReduce outputWater/sewage treatment by magnetic/electric fieldsSustainable biological treatmentElectrochemical responseMicroorganism

The present invention relates to electric and biological processing apparatus and method for waste water containing heavy meal ion and non-degradable organism. The apparatus includes electric and biological reaction tower with top air outlet, bottom air distributor, liquid inlet in the upper part, liquid outlet in the lower part and connected with precipitator, tower wall and tower core constituting one electrode pair and insulating layer outside the tower wall. The present invention has the advantages of multi-dimensional electrode reinforced electric field to promote the electrochemical reaction and directional motion of heavy metal ion, and catalytic electrode / efficient functional microbe group with coupled reaction to degrade organic waste water. The present invention can treat waste water containing heavy meal ion and non-degradable organism effectively.

Owner:TIANJIN UNIV

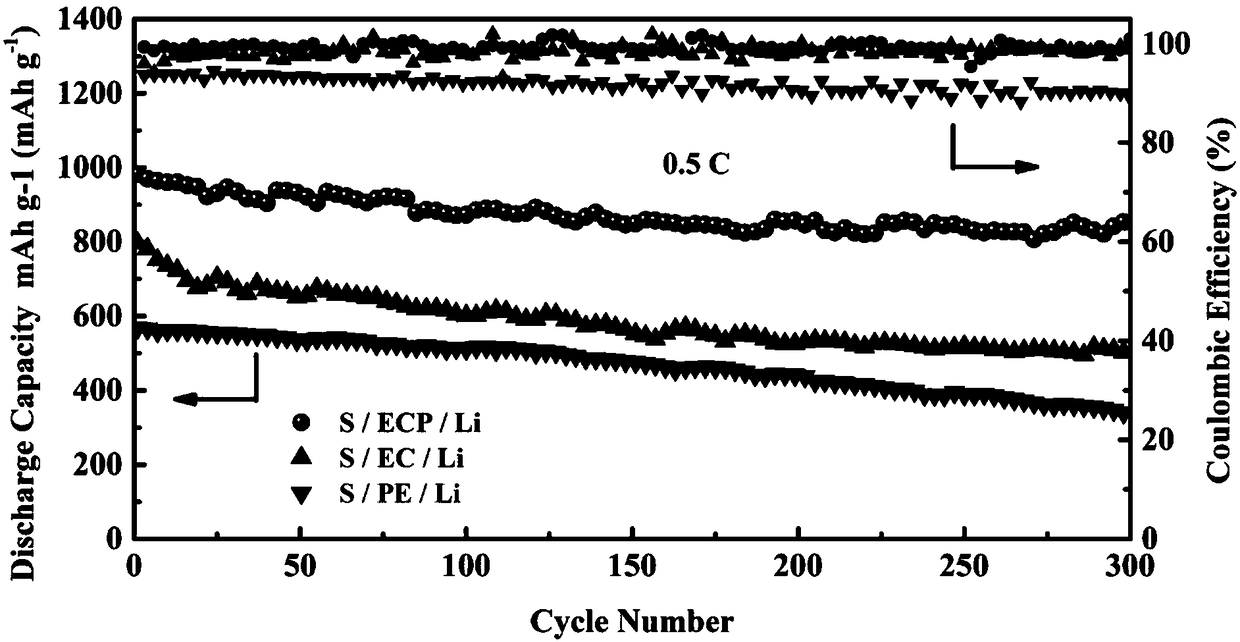

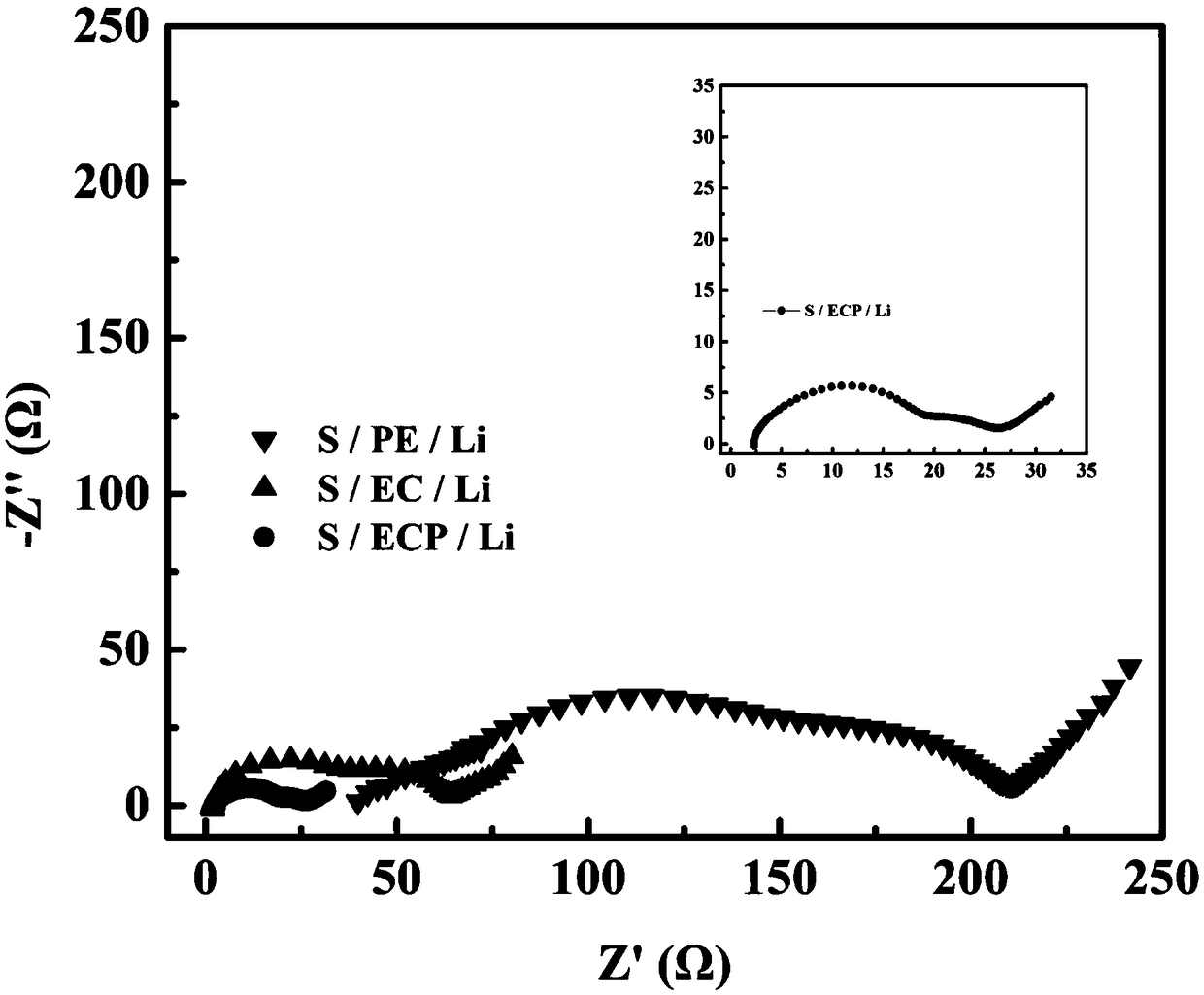

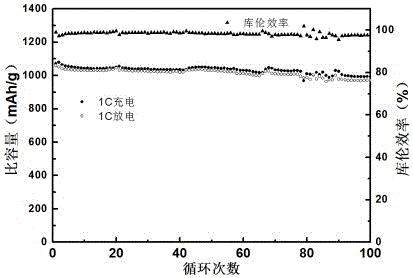

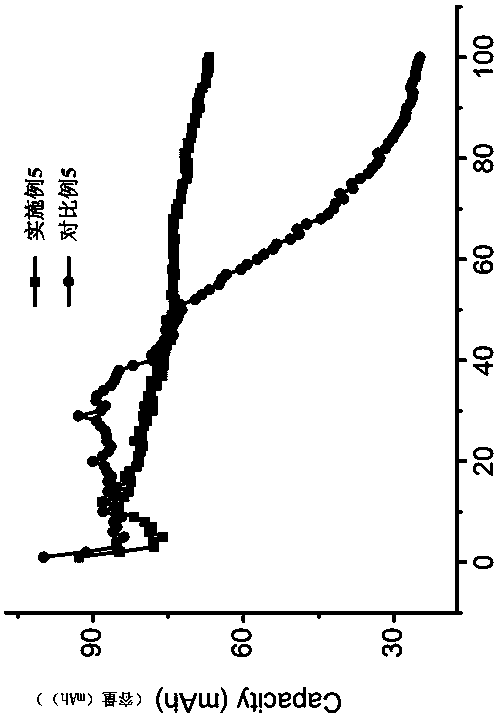

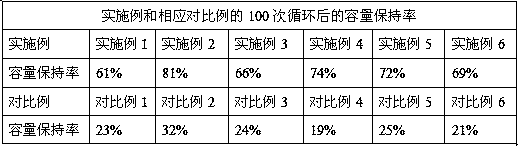

A functional separator for a lithium-sulfur battery, a preparation method thereof and an application thereof in lithium-sulfur battery

ActiveCN109103399AImprove adhesionImprove stabilitySecondary cellsCell component detailsCyclic processAdhesive

The invention relates to a functional separator for a lithium sulfur battery, and a preparation method and application thereof, belonging to the technical field of electrochemistry. The functional separator of the invention is composed of a polymer separator matrix and a functional modification layer applied one side surface of the polymer separator matrix, wherein the functional modification layer comprises a binder, a conductive carbon material and a dendritic branched macromolecule. The adhesive of the invention has good adhesion and high stability. The conductive carbon material has a veryhigh electron conduction rate, can improve the utilization rate of the active substance and greatly reduce the internal impedance of the battery. The dendritic branch macromolecule contains more organic functional groups, the dendritic branched macromolecule has chemisorption to the polysulfide generated in the sulfur positive electrode region during the cycle, and the carbon material has physical adsorption to the dissolve polysulfide, thereby effectively inhibiting the shuttle effect in the lithium-sulfur battery. Therefore, the lithium sulfur battery prepared using the functional separatordescribed in the present invention exhibits excellent cycle performance and rate performance.

Owner:WUHAN UNIV

Device and method for processing semiconductor material through backward multifocal lasers and electrochemistry in combined manner

InactiveCN106735866APromotes electrochemical reactionsIncrease potential differenceOther manufacturing equipments/toolsLaser beam welding apparatusElectrochemical responseCorrosion

The invention provides a device and method for processing a semiconductor material through backward multifocal lasers and electrochemistry in a combined manner. The energy, frequency and wavelength of the lasers are regulated, and a multifocal laser beam acts on the back face of a semiconductor sample; on one hand, when the lasers radiate the back face of the semiconductor sample, a large amount of light can be stimulated in the semiconductor sample to generate holes, the holes move to the position of the surface of the polished semiconductor sample to participate in the electrochemistry reaction, and material corrosion removal is achieved; and on the other hand, on the back face of the semiconductor sample, the multifocal lasers gradually conduct processing inwards. A work electrode is a cathode, the semiconductor sample is used as an anode, and when the potential between the two electrodes is high, spark discharge processing is conducted; and when the potential is low, electrochemistry erosion removal is conducted. The multifocal lasers and electrochemistry act on the semiconductor sample in the combined manner, the corrosion efficiency is improved, and the surface quality of through holes is improved. When the high-precision micro-through-holes are processed in the semiconductor material, the combination effect is good in action effect, and the device and the method are suitable for precise processing.

Owner:JIANGSU UNIV

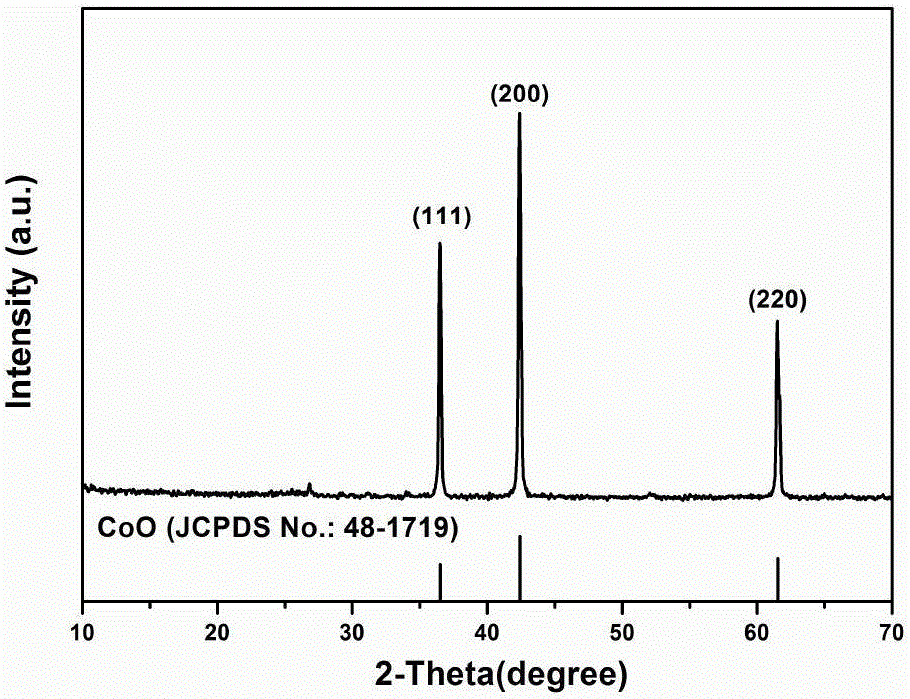

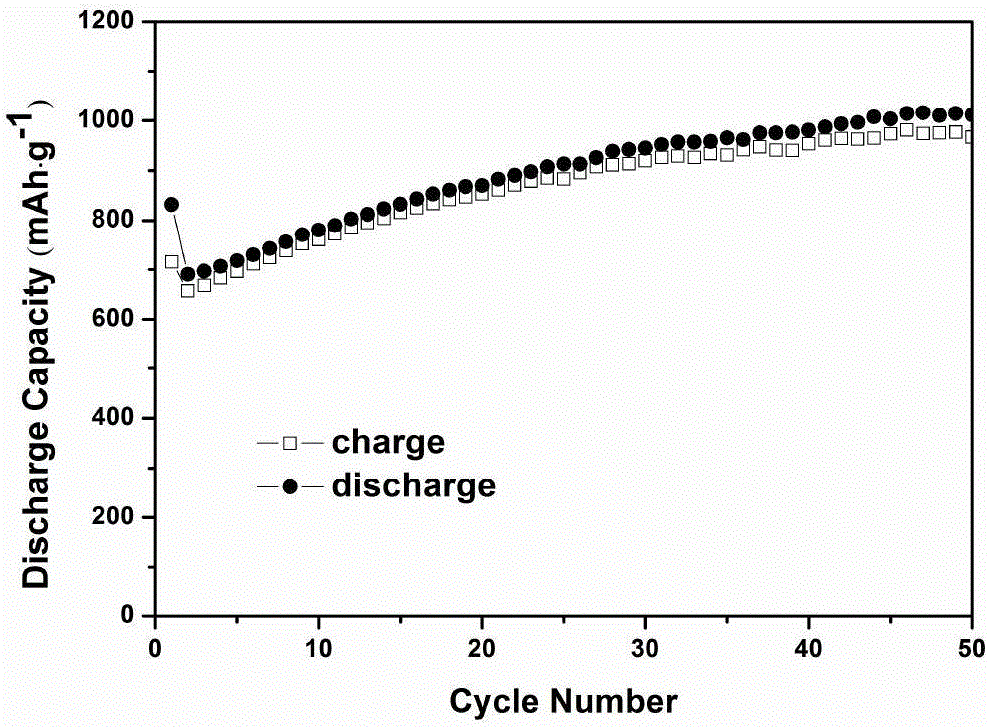

Method for preparing anode material of three-dimensional porous carbon skeleton/CoO composite structured lithium ion battery

ActiveCN105845915AImprove cycle performanceImproved magnification performanceCell electrodesSecondary cellsElectrochemical responseChemical reaction

The invention relates to a method for preparing an anode material of a three-dimensional porous carbon skeleton / CoO composite structured lithium ion battery. Parenchymatous tissue of plants is used as the biomass carbon material; the biomass carbon material is immersed through acid, such that a pre-carbonized precursor is obtained; then, the precursor and alkali are mixed and sufficiently grinded, and then thermally treated in a tube furnace, such that a three-dimensional porous carbon skeleton is obtained; the three-dimensional porous carbon skeleton is immersed in solution including cobalt salt; then, suction filtration and drying are carried out; and finally, the mixture is thermally treated in the tube furnace, such that a CoO loaded three-dimensional porous carbon skeleton composite is obtained. The composite is applied to the lithium ion battery, such that the lithium ion battery has good cycle performance and rate performance; the porous carbon skeleton, prepared by using the parenchymatous tissue of plants as the biomass carbon material, has a steady structure for supporting load of CoO; the porous carbon skeleton having different pore diameters can be obtained by controlling the addition amount of urea; due to the porous carbon skeleton, the CoO structure can be stabilized; simultaneously, the electrical conductivity of CoO is also improved; therefore, the electron transmission rate is increased; the electrochemical reaction is accelerated; and the rate performance is improved easily.

Owner:SHAANXI UNIV OF SCI & TECH

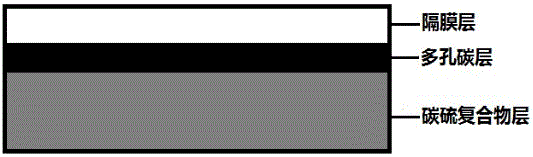

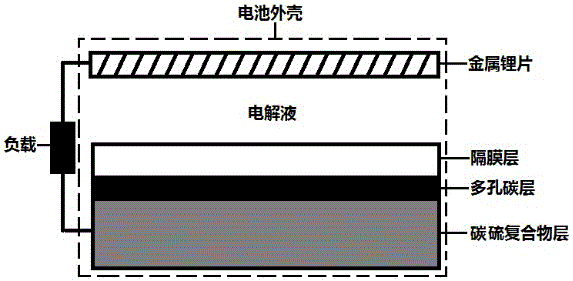

Composite positive electrode of lithium sulfur battery, preparation method of composite positive electrode and lithium sulfur battery

InactiveCN105742567ASimple preparation processReduce size and massCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsComposite materialElectrical battery

A composite positive electrode of a lithium sulfur battery is formed by combining a diaphragm layer, a porous carbon layer and a carbon sulfur compound, wherein the porous carbon layer is arranged on one side of the diaphragm layer, and the carbon sulfur compound is arranged on the porous carbon layer. The preparation method comprises the following steps of adding the porous carbon, a conductive agent and an adhesive into an organic solvent to prepare paste, applying the paste onto one side of a diaphragm, and forming a porous carbon layer compound on one surface of the diaphragm layer; and adding the carbon sulfur compound, the conductive agent and the adhesive into the organic solvent to prepare paste, and applying the paste onto the porous carbon layer in the compound to obtain the composite positive electrode of the lithium sulfur battery. The lithium sulfur battery disclosed by the invention comprises the composite positive electrode of the lithium sulfur battery, a negative electrode and an electrolyte. By the lithium sulfur battery, the interface resistance can be reduced, the ionic conductivity and electron conductivity are improved, and the energy density, the cycle performance and the rate performance of the lithium sulfur battery are effectively improved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

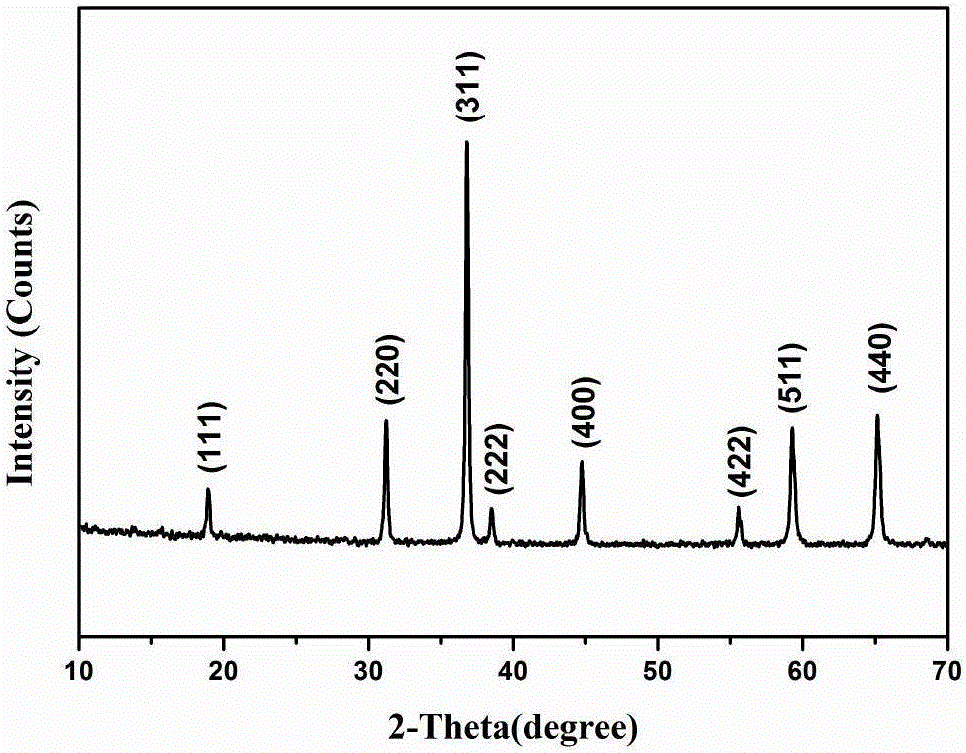

Preparation method of lithium ion battery anode material using biomass as carbon source and with C@Co3O4 core-shell structure

ActiveCN105826538AImprove cycle stabilityImproved magnification performanceCell electrodesSecondary cellsElectrochemistryHeat treated

Provided is a preparation method of a lithium ion battery anode material using biomass as a carbon source and with a C@Co3O4 core-shell structure .Edible fungus is utilized as biomass carbon, a carbon sphere precursor having surface activity is obtained through hydrothermal carbonization of concentrated sulfuric acid and then is heated and stirred in a solution containing cobalt salt to make the cobalt salt adsorbed on the surface, and then the lithium ion battery anode material with the C@Co3O4 core-shell structure is obtained through heat treatment .The electrical conductivity of the material is not only improved, the volume expansion effect of Co3O4 in the charging and discharging process is also relieved, and a Co3O4 structure is stabilized, so that the cycling stability and rate performance of a lithium ion battery are improved somewhat, and the lithium ion battery anode material having excellent electrochemical properties is obtained .

Owner:SHAANXI UNIV OF SCI & TECH

Additive for high-carbon lead-acid storage-battery polar plate

The invention discloses an additive for a high-carbon lead-acid storage-battery polar plate. The weight percentage of the additive is 0.01-10 percent of the content of lead powder in the formula of the polar plate corresponding to a storage battery, and the additive comprises precipitated SiO2 and / or gas-phase SiO2 or also comprises any one or two in CMC (Carboxyl methyl Cellulose) and PTFE (Polytetrafluoroethylene); because of the existence of the precipitated SiO2 or the gas-phase SiO2, the additive can interact with a sulphuric-acid electrolyte to form a three-dimensional netted structure in a system, and sulphuric acid and water are packaged in the three-dimensional netted structure, so that the electrolyte can be fully contacted with active substances; and meanwhile, the specific surface area of the precipitated SiO2 or the gas-phase SiO2 is higher, the porosity of the polar plate is improved, the surface utilization ratio of the active substances is improved, the capacity of the storage battery is improved, the cycling life of the storage battery is prolonged, and the additive is widely applicable to various high-carbon lead-acid storage-battery polar plates.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Flexible thin-film electrode and preparation method and application thereof

ActiveCN106602012AEasy to operateLow costHybrid capacitor electrodesCell electrodesThin film electrodePorous carbon

The invention provides a flexible thin-film electrode, which comprises an ultrathin porous carbon nitride nanosheet and a carbon nanotube, wherein manganese oxide is loaded on the ultrathin porous carbon nitride nanosheet as an electroactive material; due to the ultrathin porous carbon nitride nanosheet, the flexible thin-film electrode has a multi-channel structure; and the carbon nanotube is taken as a conductive support and is also taken as a mechanical support, so that the flexible thin-film electrode has a three-dimensional conductive network structure. The invention further provides a preparation method and an application of the flexible thin-film electrode. The method provided by the invention is simple in operation and low in cost. A thin film prepared by the method has the three-dimensional conductive network structure and the multi-channel structure, has good flexibility and excellent electrochemical property, and can be widely used for a high-efficiency energy storage device.

Owner:SHANGHAI JIAO TONG UNIV

A lithium metal battery electrolyte and a lithium metal battery and a lithium sulfur battery

InactiveCN109216769AIncrease lithium ion contentImprove conductivityLi-accumulatorsOrganic electrolytesLithium soapLithium metal

In order to improve the cycle performance of the battery, A lithium metal battery electrolyte and a lithium metal battery and a lithium sulfur battery are disclose, A lithium metal battery electrolyteincluding solvents and lithium salts, the lithium salt comprises a lithium salt I, lithium salt II, lithium salt III, The mass percentages of each component in the electrolyte are: 40 to 85 percent of solvent, 10 to 50 percent of lithium salt I, 0.1 to 3 percent of lithium salt II, 0.1 to 10 percent of lithium salt III, wherein the solvent is an arbitrary combination of an organic heterocyclic compound containing an oxygen group element on a ring, the lithium salt I is lithium bis-trifluoromethanesulfonimide (LiTFSI), the lithium salt II is lithium nitrate (LiNO3), and the lithium salt III isone or a combination of one or several of a lithium salt containing boron and a lithium salt containing phosphorus; A lithium metal battery comprise a positive electrode, a lithium-containing negative electrode, a separator and that electrolyte; A lithium-sulfur battery comprise a sulfur-containing positive electrode, a lithium-containing negative electrode, a membrane and that electrolyte; The invention belongs to the field of lithium ion batteries and improves the cycling performance of lithium sulfur batteries.

Owner:ZHUHAI COSMX BATTERY CO LTD

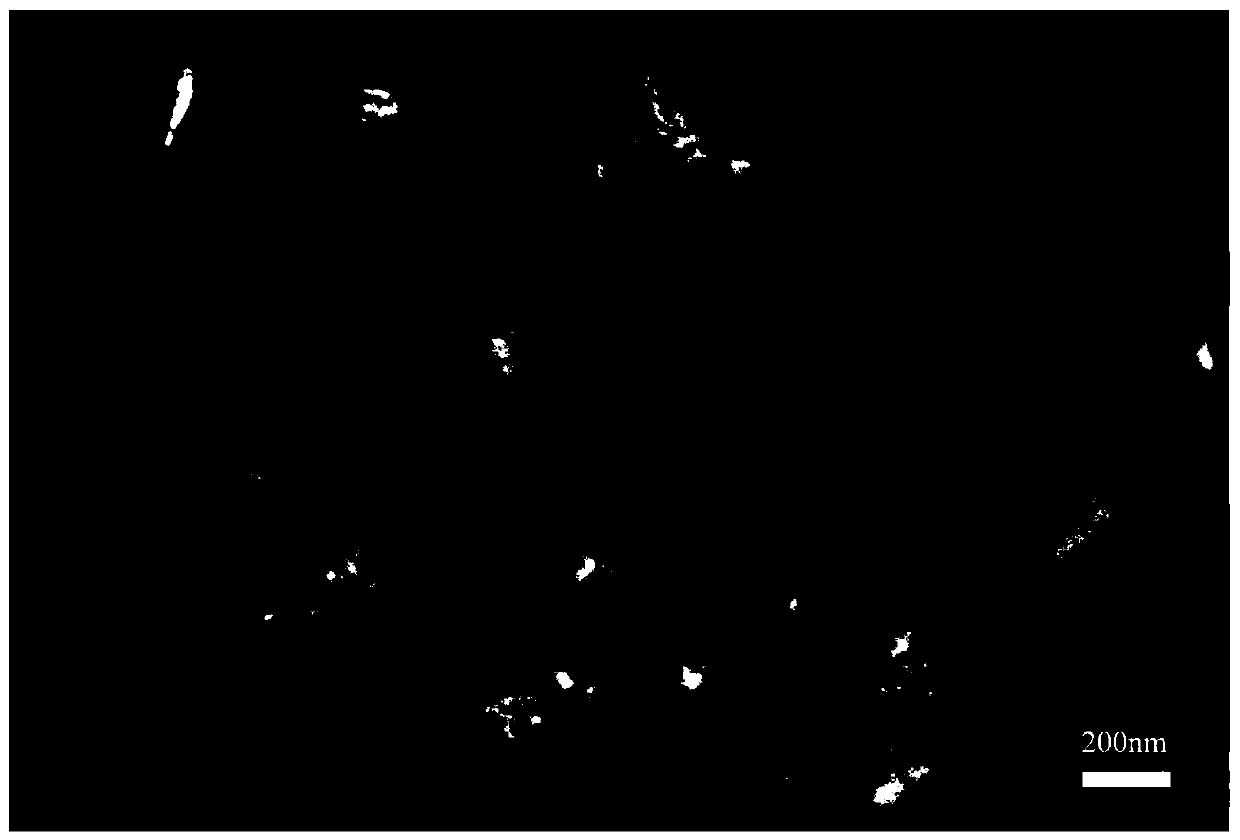

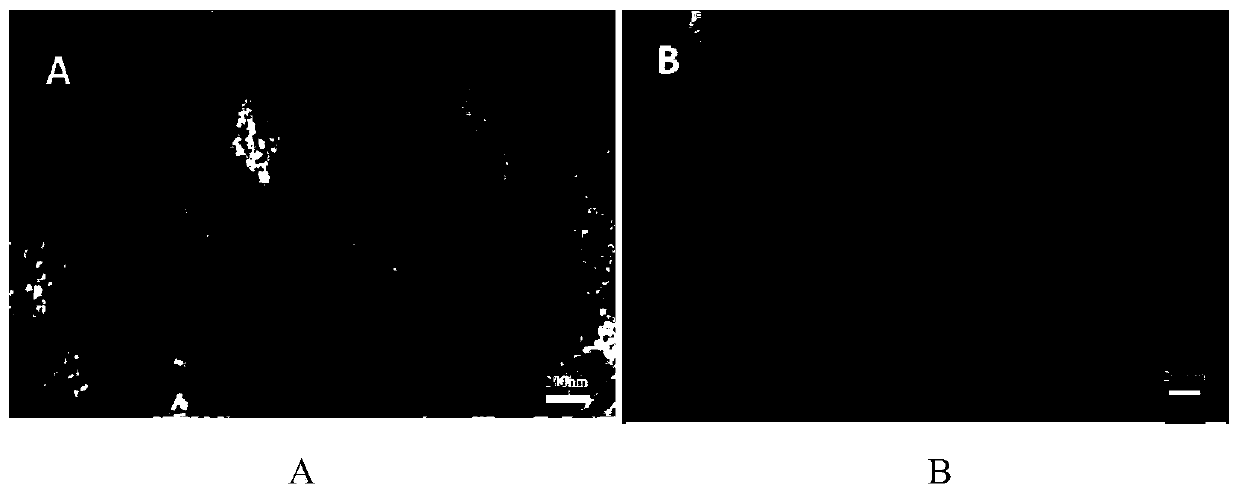

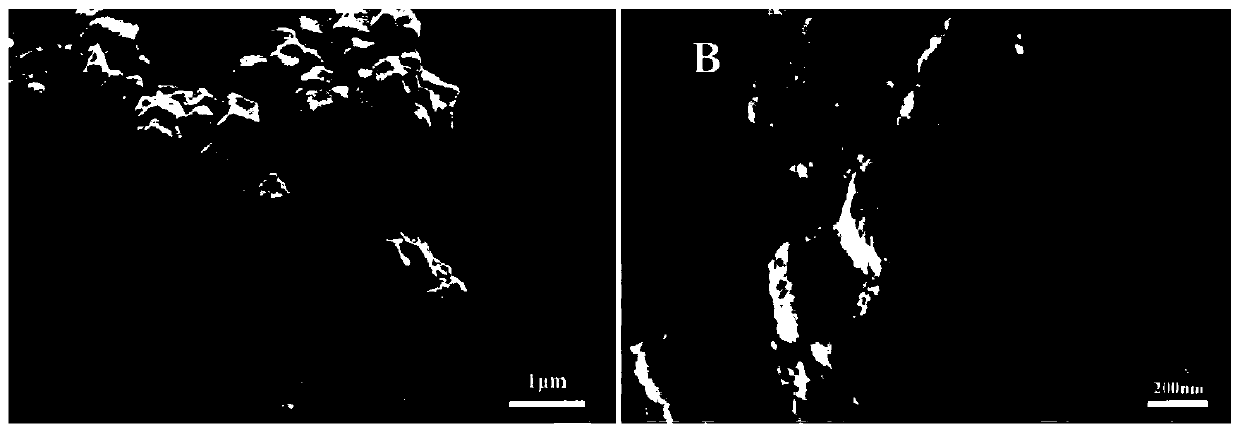

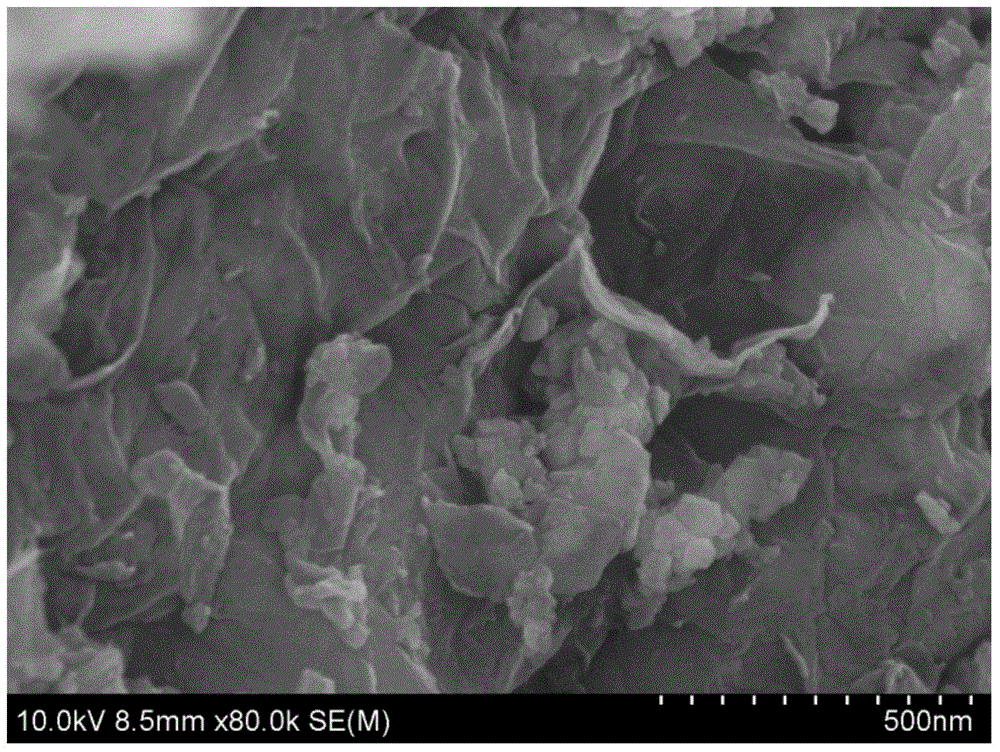

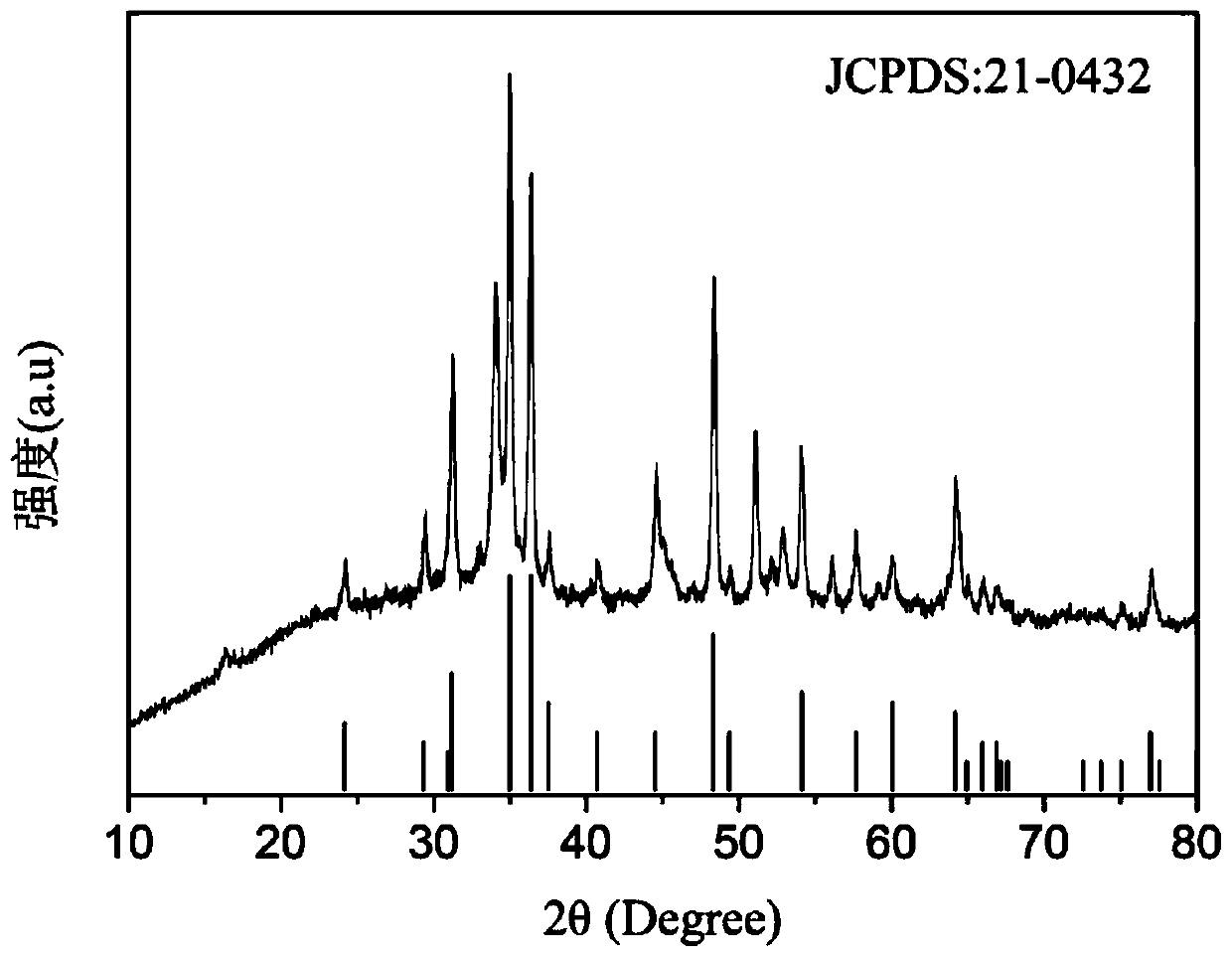

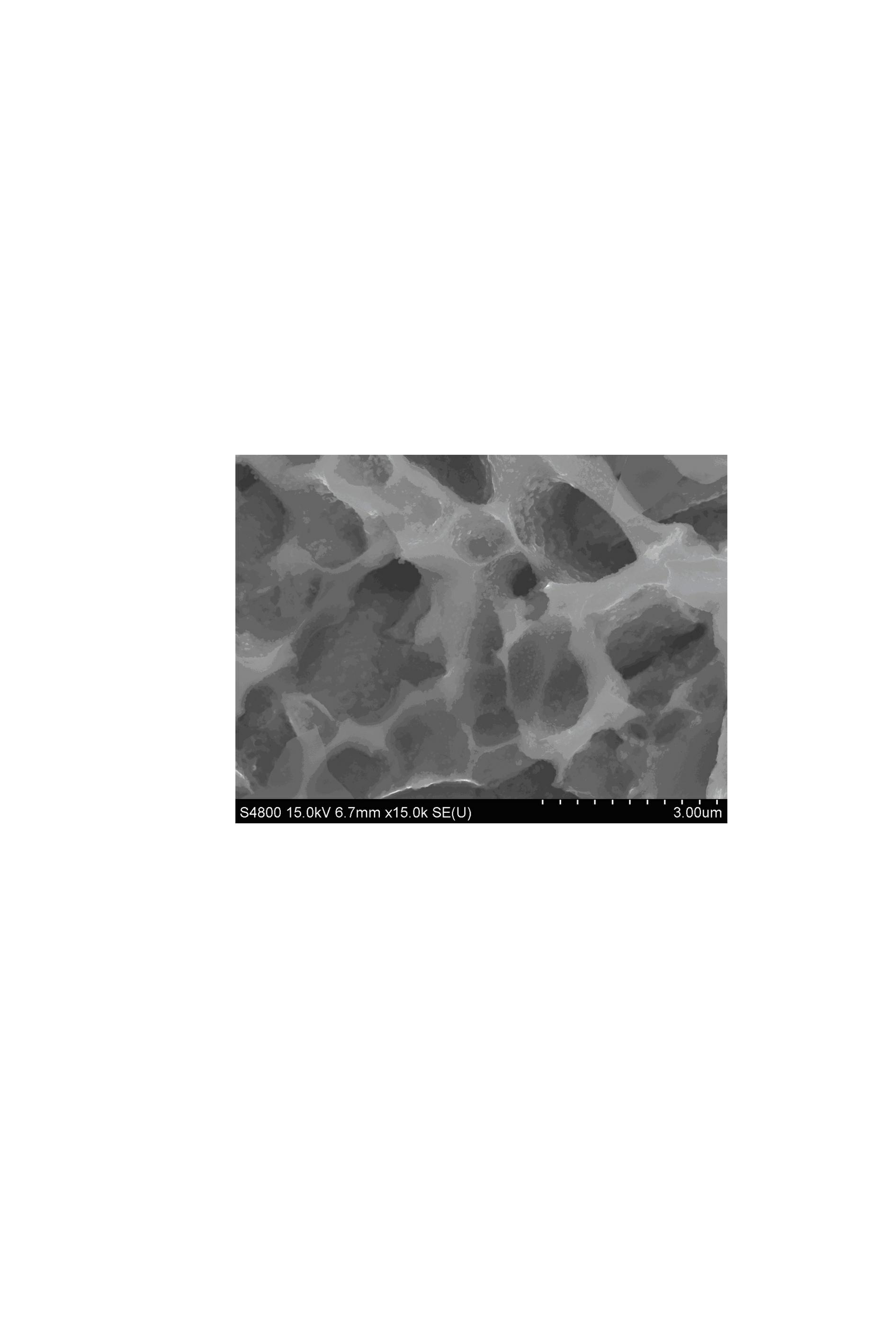

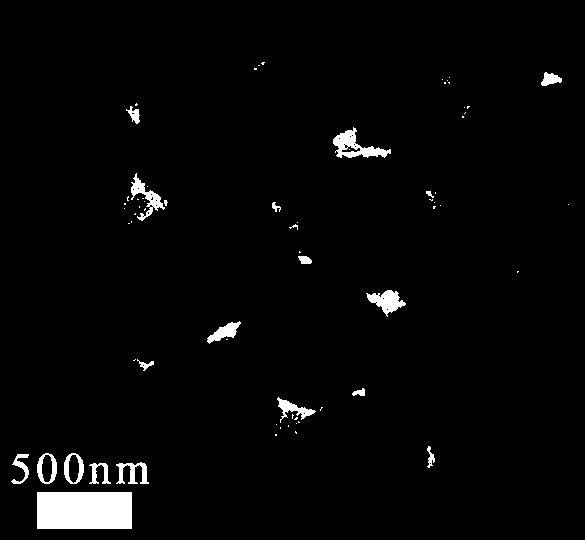

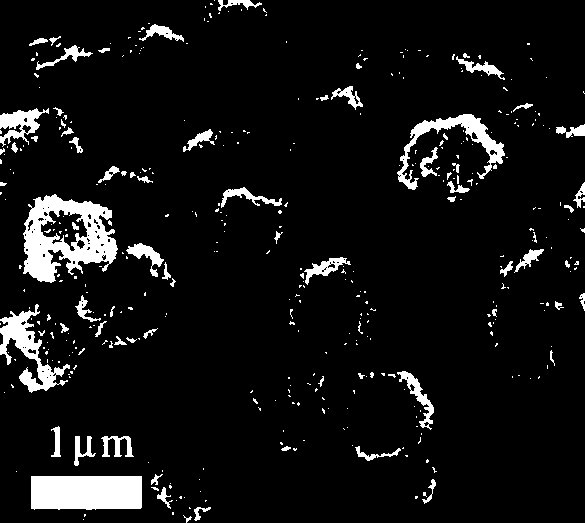

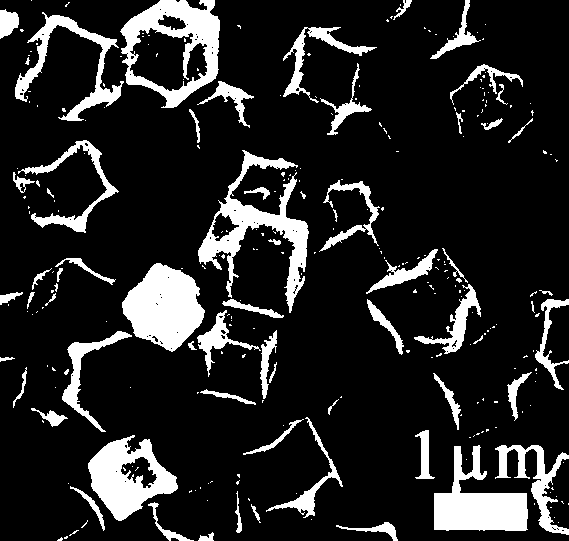

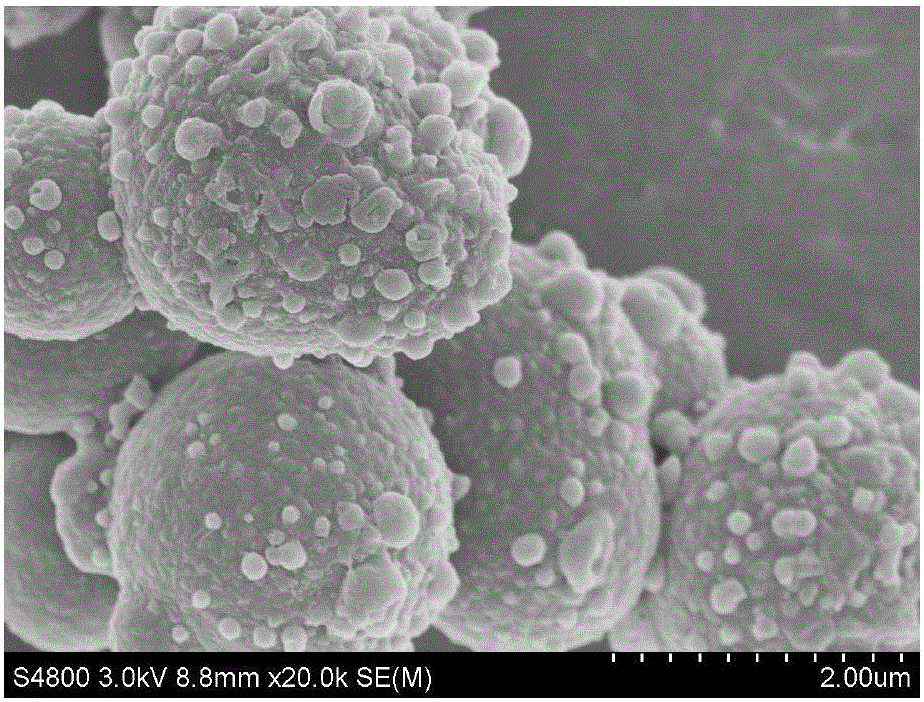

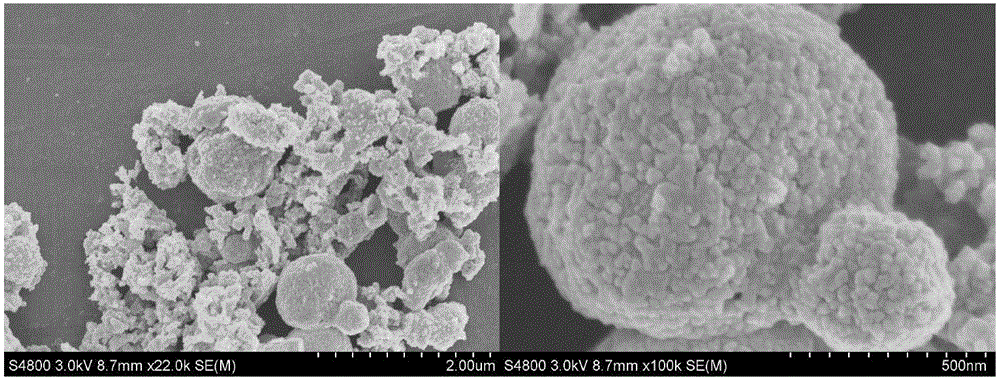

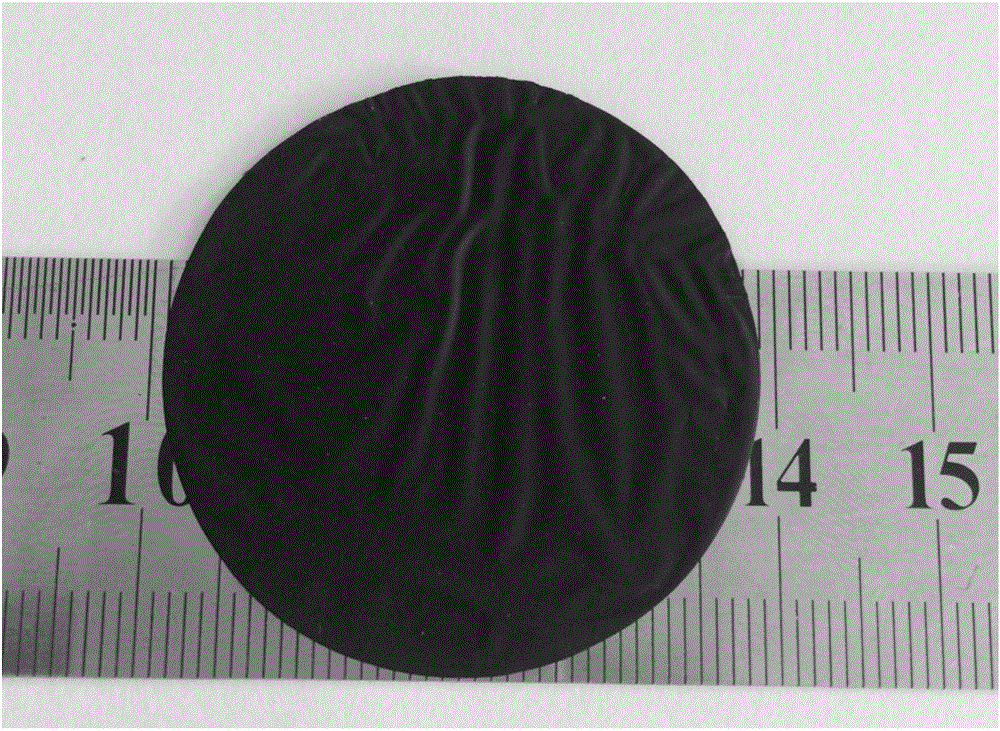

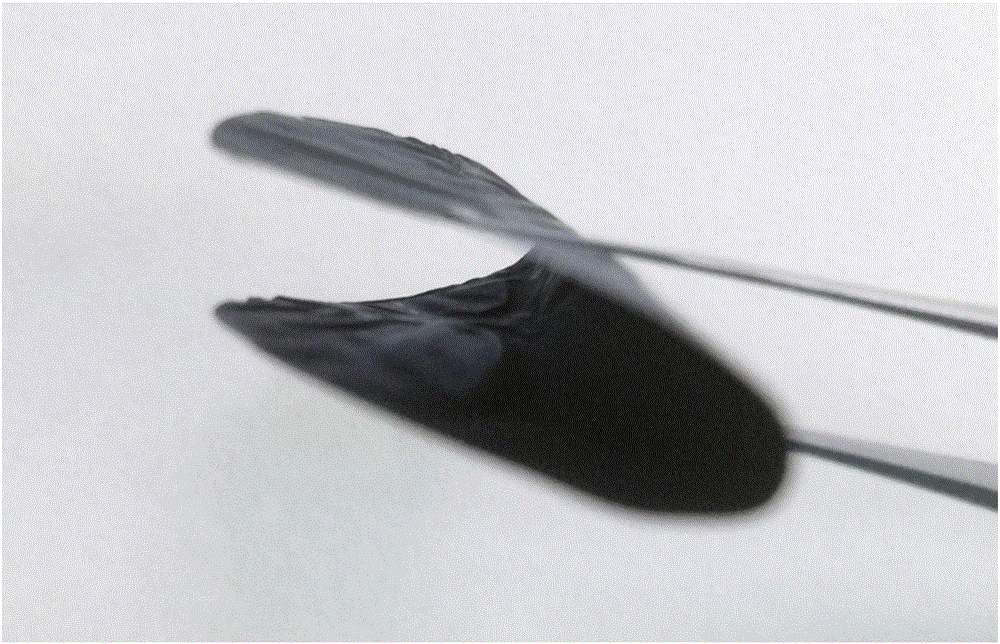

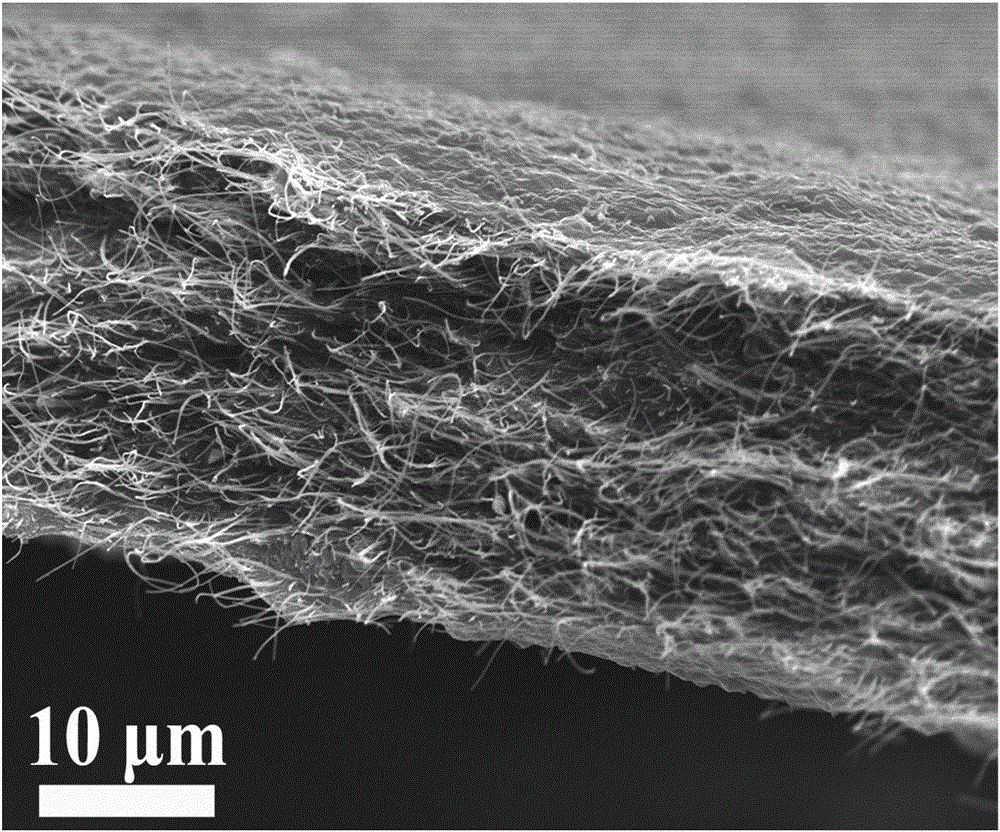

Preparation method and application of graphene-calix[4]arene-gold nano-particle ternary nano-composite materials

InactiveCN103521759ARealize functionPromotes electrochemical reactionsNanotechnologyMaterial electrochemical variablesElectrochemical responseWater dispersible

The invention discloses a preparation method and application of graphene-calix[4]arene-gold nano-particle ternary nano-composite materials. The preparation method comprises the steps of preparing water-dispersible graphene-calix[4]arene nano-composite materials and graphene-calix[4]arene-gold nano-particle nano-composite materials. The preparation method is simple and quick. Experiments show that a modified electrode of the graphene-calix[4]arene-gold nano-particle ternary nano-composite materials can promote electrochemical reaction of methylene blue in a cooperated mode, electrochemical detection of the methylene blue has wide linear range from 1.0*10<-8> to 2.5*10<-5> mol.L-1, and the low detection limit is 9*10-9 mol.L-1.

Owner:NANTONG VOCATIONAL COLLEGE

Slag nonpollution deoxygenation method capable of regulating anode oxygen partial pressure and device thereof

InactiveCN101457276AImprove pollutionAccelerated exclusionGas emission reductionOxygen ionsVacuum chamber

The invention relates to a pollution-free molten slag deoxidization method capable of adjusting anode oxygen partial pressure and a device thereof, and belongs to the technical field of metallurgical refining process. In the method, molten steel or molten metal is deoxidized and purified by the special device. In the method, the molten slag is taken as electrolyte, a deaeration cavity electrode inserted into the molten slag is taken as an anode, and the molten steel or the molten metal is taken as a cathode; the deaeration electrode is provided with an electrode cavity and is communicated with a vacuum chamber by a conduit; an applied DC power supply exerts direct current impulse voltage so that an electric field is formed between the molten steel or the molten metal and an oxygen electrode of the molten slag, and the conduction of oxygen ions in a molten slag system and mass transfer of dissolved oxygen in the molten steel are controlled by controlling a current value and a voltage value of the DC power supply as well as components of the molten slag. The oxygen is diffused from the molten slag to the electrode cavity and discharged by an air exhaust system by controlling the oxygen partial pressure of the electrode cavity.

Owner:SHANGHAI UNIV

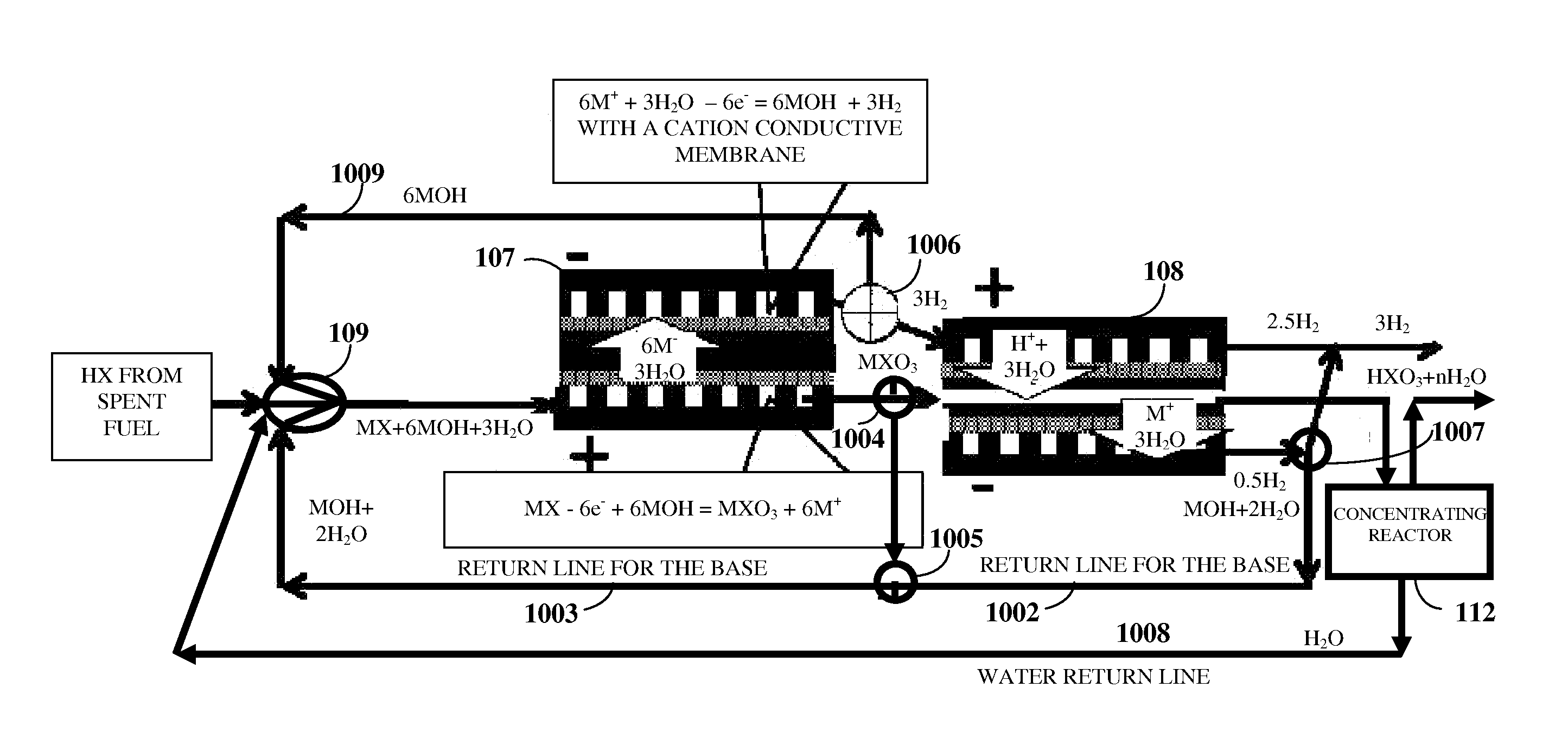

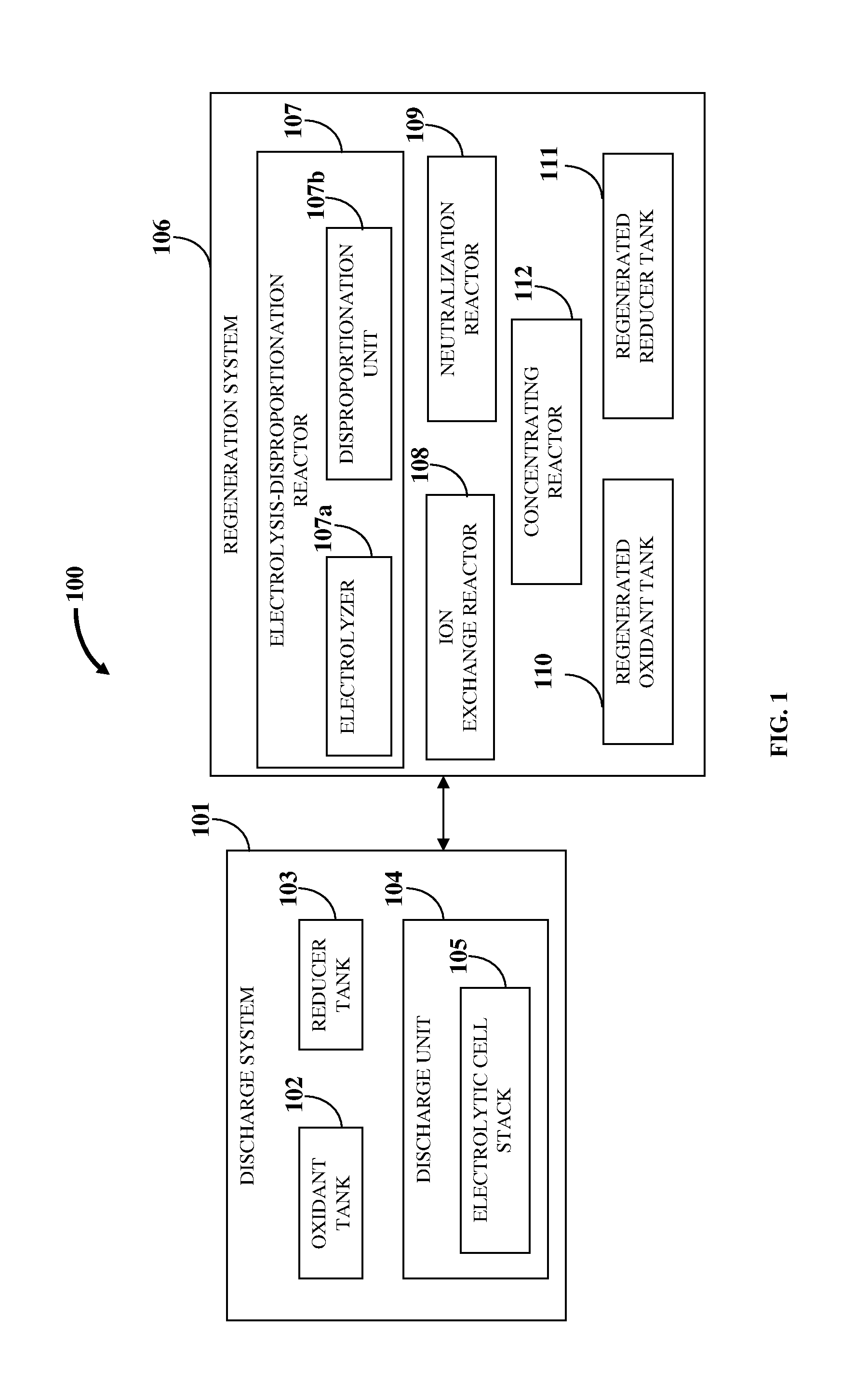

Flow Battery And Regeneration System

InactiveUS20140050999A1Improve energy efficiencyShort filling timeFuel cells groupingRegenerative fuel cellsElectrolysisIon exchange

Methods for generating electric power and a discharge fluid from an oxidant and a reducer using a discharge system, and regenerating an oxidant and / or the reducer from the discharge fluid using a regeneration system are provided. A discharge unit of the discharge system generates electric power and the discharge fluid by transferring electrons from a positive electrode of a 5-layer electrolyte-electrode assembly (5EEA) to an aqueous multi-electron oxidant (AMO) and from a reducer to a negative electrode of the 5EEA. The regeneration system neutralizes the discharge fluid to produce a salt form of the discharge fluid. The regeneration system electrolyzes the salt form of the discharge fluid into an intermediate oxidant in an electrolysis-disproportionation reactor and releases the reducer, while producing the AMO by disproportionating the intermediate oxidant. The regeneration system converts a salt form of the AMO into an acid form of the AMO in an ion exchange reactor.

Owner:FTORION

Anode material of lead-acid battery and its production method

InactiveCN101246961AImprove discharge capacityLarge specific surface areaLead-acid accumulator electrodesCarbon nanotubeElectrochemistry

The present invention discloses an anode material of lead-acid battery, the components and weight percentage content are: 0.2-2% of carbon nano-tube, 0.2-2% of polyacrylonitrile short fiber, 60-90% of PbO2, others is ceruse. Graphitized process carbon nano-tube as anode additive, not only resists rigor corruption of electrochemical circumstance in lead-acid battery, adds specific surface area of anode active material, enhance charge and discharge capability of electrode, improves circle capability, enhances formation efficiency, but also improve the utilization rate of active material and discharging capacity of lead-acid battery. In the conditions of 0.5c-10c current, the utilization rate of active material can be improved of 15-25%. The present invention has simple technique, low cost and is suitable for large-scare production and application.

Owner:ZHEJIANG UNIV

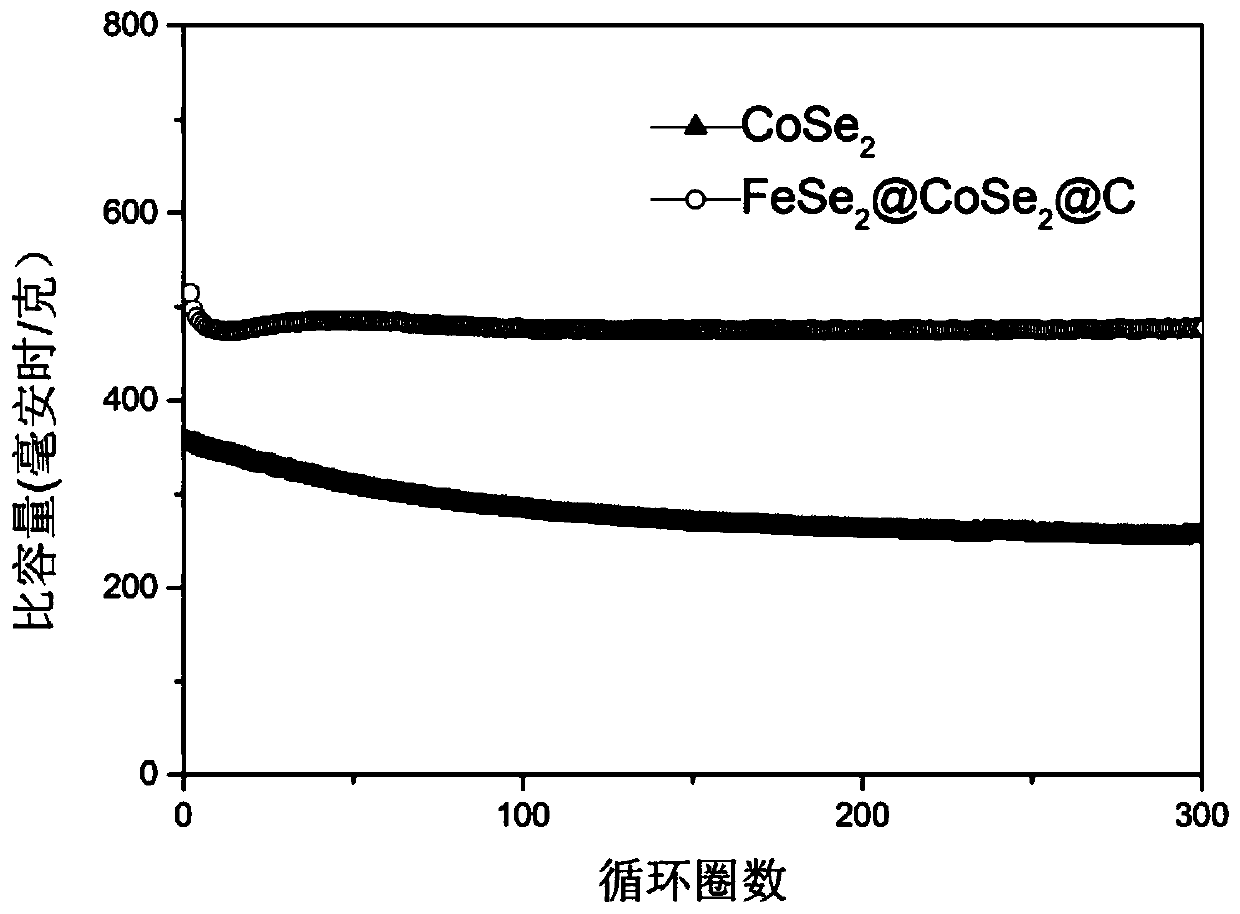

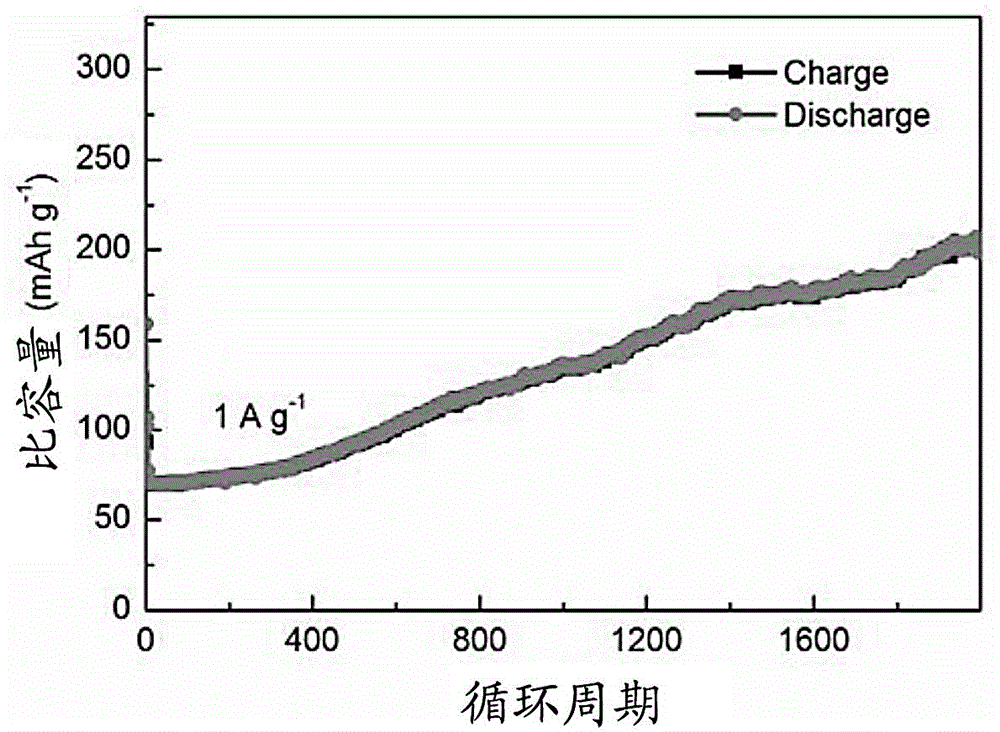

Preparation method of cobalt-iron bimetal selenide sodium ion battery negative electrode material

ActiveCN110943216APromotes electrochemical reactionsHigh specific capacitySecondary cellsNegative electrodesFerrocobaltPhysical chemistry

The invention relates to a preparation method of a cobalt-iron bimetal selenide sodium ion battery negative electrode material, which synthesizes a FeSe2 (at) CoSe2 heterostructure through a simple and convenient method so as to enhance the electrochemical properties of a sodium ion battery. The method comprises the following steps: firstly, synthesizing a precursor of ZIF-67, then growing a Fe metal layer on the surface through ion adsorption, and carrying out high-temperature selenylation calcination to obtain the core-shell structure material with a uniform heterogeneous interface. The ferrocobalt bimetal selenide material prepared by the method is used as a negative electrode material to be applied to the sodium-ion battery, so that the cycle performance of the sodium-ion battery is remarkably improved, the capacity of the battery is improved, the service life of the battery is prolonged, and the volume expansion in the charging and discharging process is effectively inhibited.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

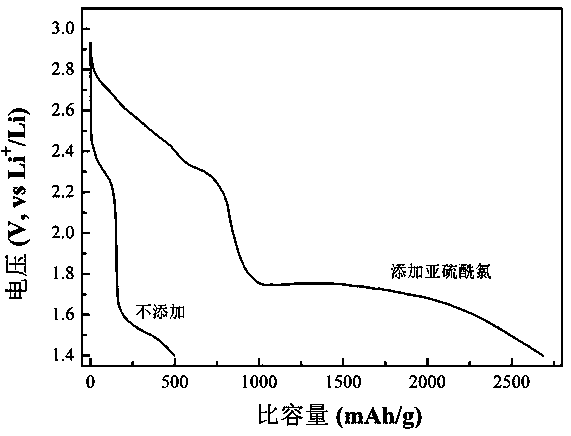

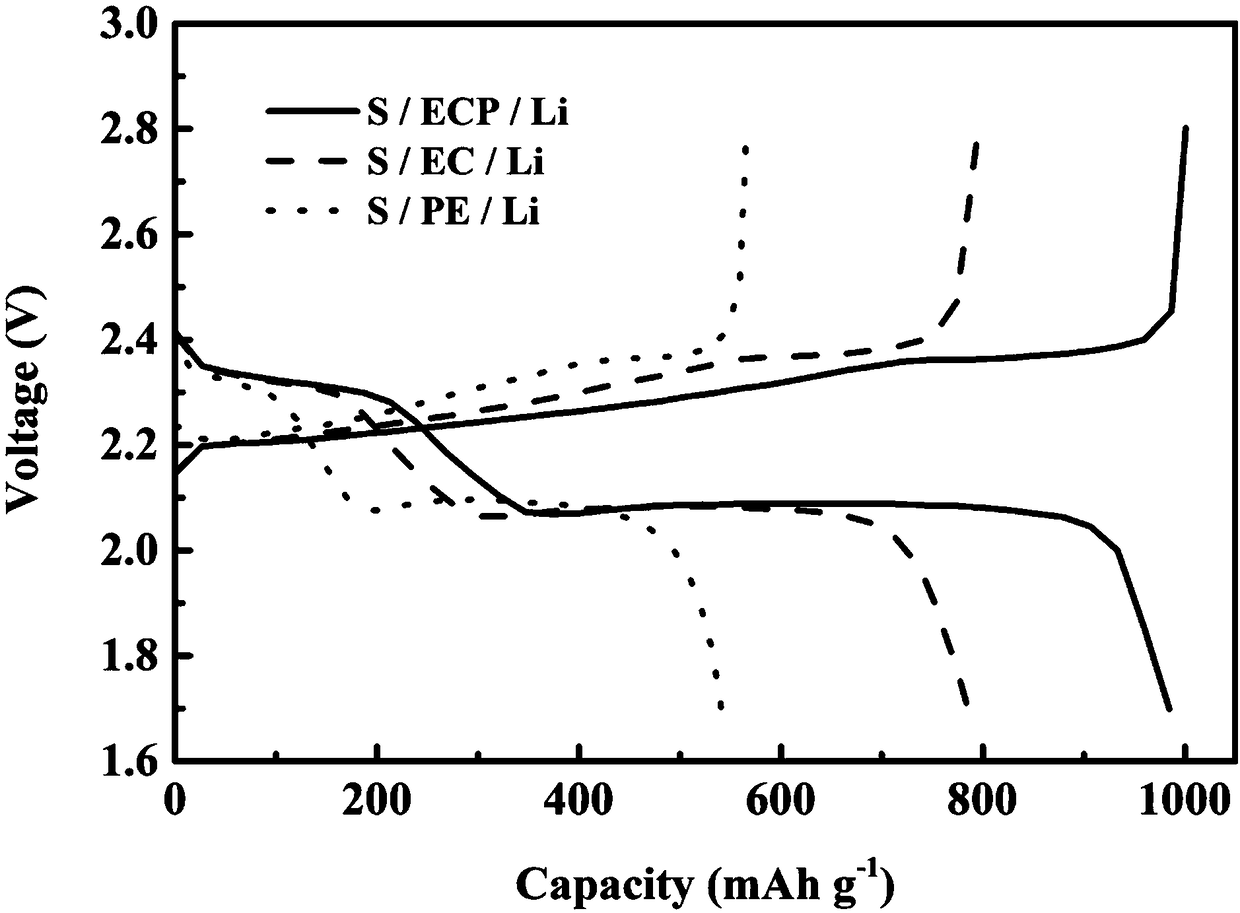

Electrolyte of lithium-sulfur battery

InactiveCN109301325ASimple and fast operationReduce manufacturing costLi-accumulatorsOrganic electrolytesOrganic solventLithium–sulfur battery

The invention relates to a novel electrolyte of a lithium-sulfur battery, which includes an organic solvent, a lithium salt, and an active additive being thionyl chloride (volume percentage being 0.5-10%); the concentration of the lithium salt is 0.1-2 mol / L; the organic solvent is carbonates. The electrolyte effectively generates an anode material protective film, thus improving stability of thestructure, significantly improving performance, security and energy density of the battery.

Owner:XUZHOU NORMAL UNIVERSITY

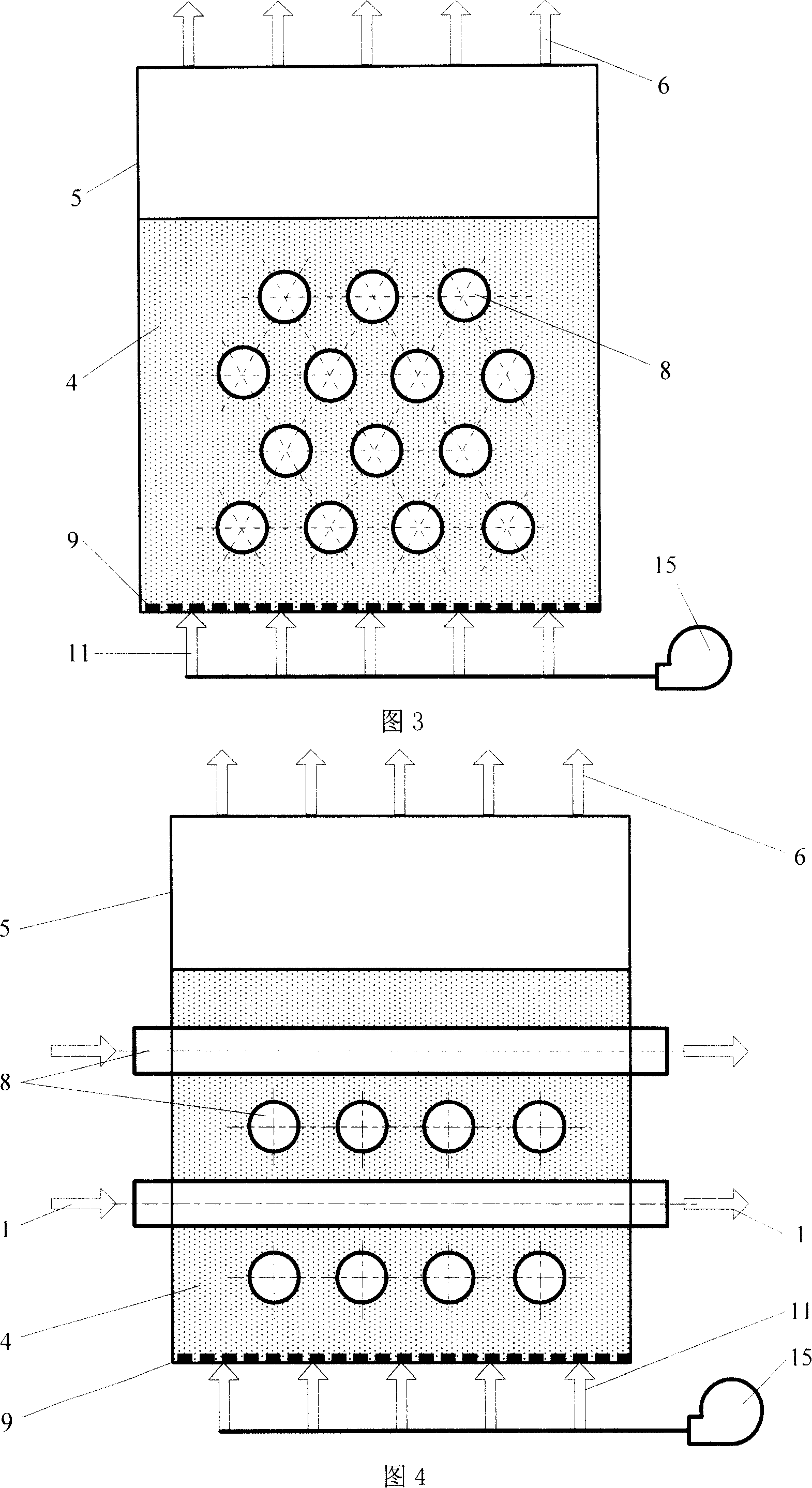

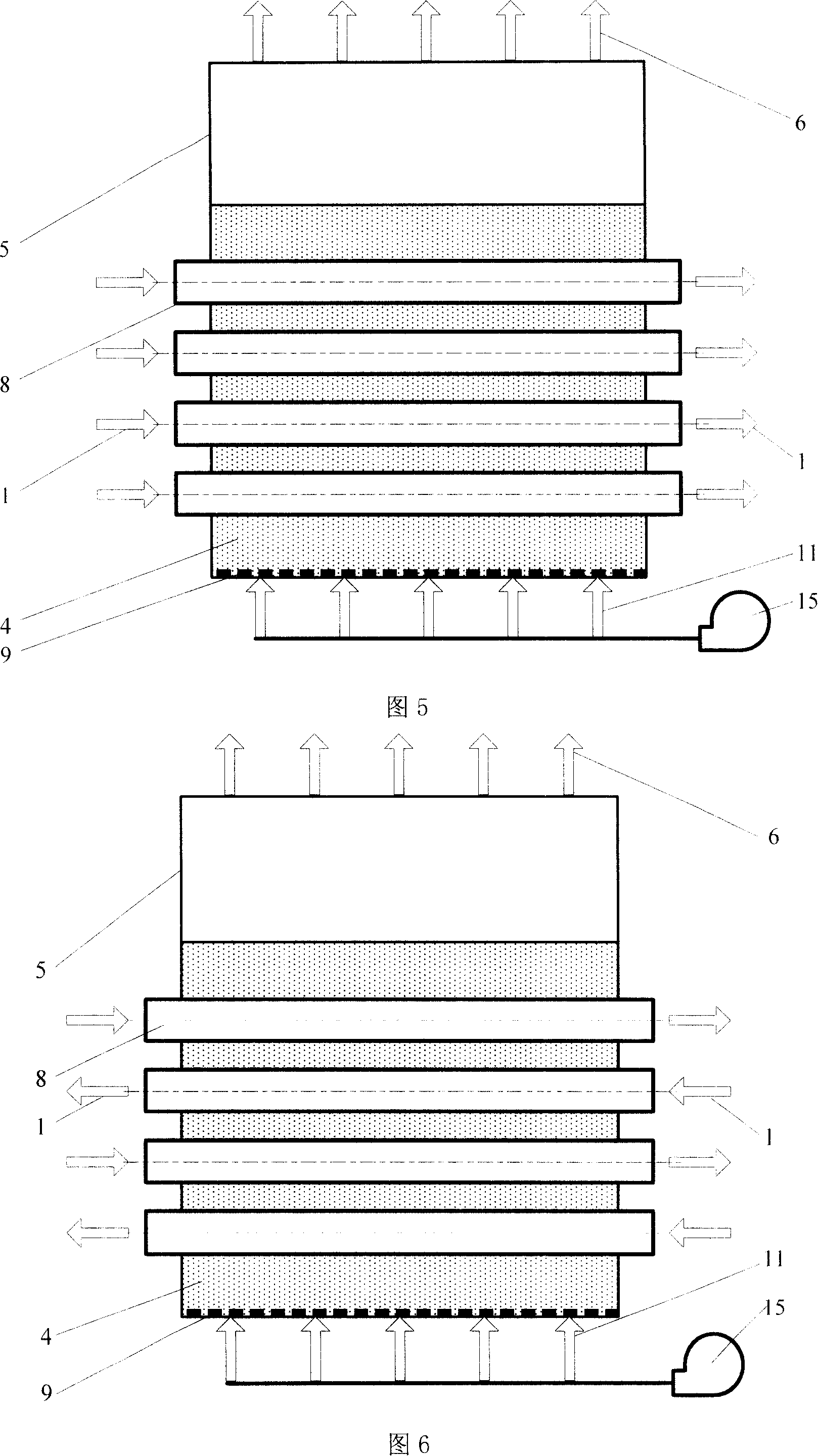

Buried tube type bubbling bed direct carbon fuel cell

ActiveCN1988229ASolving Feed ProblemsEasy to implementFuel cell auxillariesSolid electrolyte fuel cellsSolid carbonWorking temperature

This invention relates to a buried bubble bed direct carbon fuel cell including a bubble bed, tube solid oxide fuel cell monomers, an air distribution board and solid carbon fuel and wind feed device, in which, the monomers are arranged crossly, in sequence or in stagger to be plugged in the buble bed horizontally, the joint places of the monomers and the bed are sealed, the tube solid oxide electrolyte fuel battery is buried in the solid fuel to form a tube-buried structure, the wind feeding device sends gas into the bed via the distributing board to blow up solid carbon fuel particles, and the working temperature of the bed is 700-1000deg.C, the inside tube of the cell is output positive and the outside is output negative and the reacted anode gas is discharged from the top of the bed .

Owner:TSINGHUA UNIV

Oily sewage ultrasonic magneto-electric flocculation suspension filtering purifying process

ActiveCN103848534AReduce foulingReduce passivationFatty/oily/floating substances removal devicesMultistage water/sewage treatmentFlocculationBuffer tank

The invention relates to an oily sewage ultrasonic magneto-electric flocculation suspension filtering purifying process, and is an oily sewage medication-free purifying treatment process in combination of ultrasonic, a tubular magneto-electric flocculator and an air flotation suspended sludge filtering. The flocculation treatment is firstly performed on the oily sewage through the tubular magneto-electric flocculator, the ultrasonic device is acted on the magneto-electric flocculator, and then then treated oily sewage enters the suspended sludge filtering device, the purified water is extracted by using a lifting pump through a buffer tank. The ultrasonic, the magnetic treatment, the electric flocculation, the sterilization, the air flotation and the suspended sludge filtering are combined to prevent the electrode from scaling and passivating and prevent the device from scaling, the process is fast in filter layer formation, strong in adaptability, flexible and stable in operation, free from chemical agent in whole process, and suitable for various suspension-containing sewage treatment, and especially suitable for the oily sewage treatment.

Owner:北京碧海云新能源科技有限公司

Method for producing composite porous material containing metal-carbon-nitrogen

The invention discloses a method for producing a composite porous material containing metal-carbon-nitrogen. The method comprises the following steps: a compound containing metal M and an organic ligand compound raw material are mixed, or respectively dissolved in a solvent, wherein, the metal M is transition metal or a transition metal mixture from a periodic table of elements, the organic ligand compound at least contains nitrogen and carbon, the solvent at least comprises at least one of compounds containing a general formula of CxHyOmNnSz, wherein x, y, z, m and n are integer, x is greater than or equal to 0, y is greater than or equal to 0, m is greater than or equal to 0, n is greater than or equal to 0, z is greater than or equal to 0, and all of x, y, z, m and n cannot represent 0; the raw materials are added in the solvent and are uniformly mixed, or the raw materials are respectively dissolved in the solvent and the raw material solutions are uniformly mixed, after a synthesis reaction, the products are separated, washed, and dried to obtain the composite porous material containing metal-carbon-nitrogen. The composite porous material has high capacity, excellent multiplying power performance, excellent cycling stability, and good low-temperature performance.

Owner:XIAMEN UNIV

Hollow core-shell structure supercapacitor material Fe-Co-S/NF as well as preparation method and application thereof

ActiveCN110176360AEasy to controlMild reaction conditionsHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceSolvent

The invention relates to the technical field of supercapacitor materials, and in particular relates to a hollow core-shell structure supercapacitor material Fe-Co-S / NF as well as a preparation methodand an application thereof. The method comprises the following steps of 1) preparing a cobalt source, an organic ligand and a solvent into a reaction solution, and soaking nickel foam in the reactionsolution to react to obtain Co-MOF / NF; 2) enabling the Co-MOF / NF to be soaked in a ferrous sulfate water solution, after completing, then taking out Co-MOF / NF and performing drying to obtain LDH@Co-MOF / NF; and (3) enabling a sulfur source, the solvent and the LDH@Co-MOF / NF to be reacted in a sealing condition, and drying the reaction product after the reaction is ended, so as to obtain the product. According to the preparation method disclosed by the invention, the cobalt-based MOF grows on the foamed nickel to serve as a template for in-situ synthesis of a Fe-Co-S electrode material with ultra-high-performance; and when the electrode material is used for constructing a high-performance supercapacitor self-supporting electrode material, super-high mass specific capacitance is shown.

Owner:SHANDONG UNIV

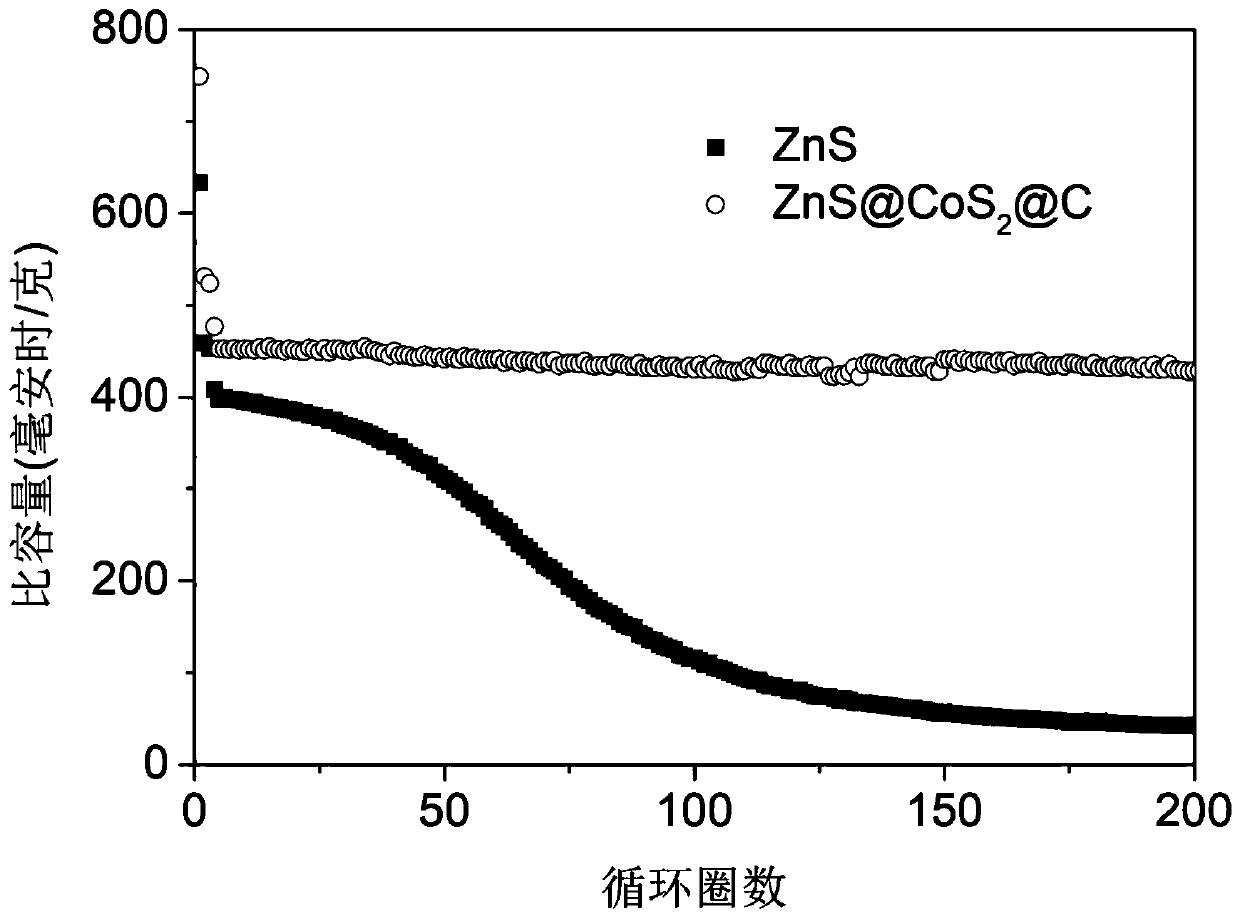

Preparation method of sodium ion battery negative electrode material of zinc-cobalt bimetal sulfide

ActiveCN110828785AImprove efficiencyImprove Coulombic efficiencyCell electrodesSecondary cellsElectrical batterySodium-ion battery

The invention belongs to the technical field of material chemistry, particularly discloses a preparation method of a sodium ion battery negative electrode material of zinc-cobalt bimetal sulfide, andsynthesizes a ZnS@CoS2@C heterostructure by a simple and convenient method so as to enhance electrochemical property of the sodium ion battery. The method comprises steps that ZnO precursor is synthesized; the ZnS@CoS2@C is obtained by growing a layer of Co-MOF structure on the surface through performing hydrothermal vulcanization and calcining in an Ar atmosphere, and the ZnS@CoS2@C has a uniformheterogeneous interface structure, so the ion diffusion kinetics is improved, electron conductivity is improved, and electrochemical performance of the sodium ion battery is further improved. Compared with pure ZnS, the ZnS@CoS2@C heterostructure is utilized as SIB of a negative electrode, so the specific capacity can be remarkably improved, and excellent cycling stability and rate performance are shown.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

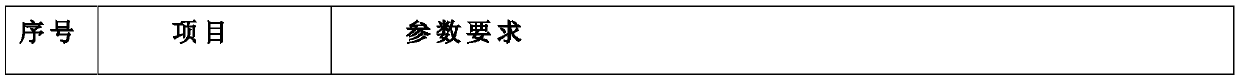

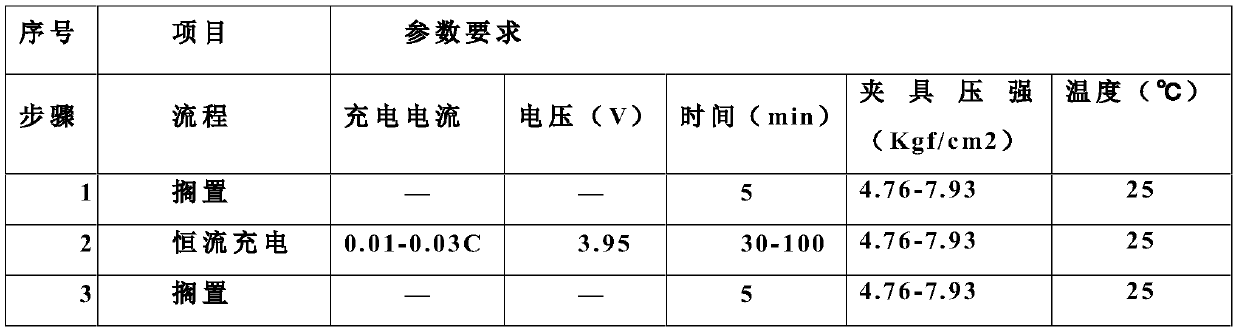

Formation method for flexibly-packaged power lithium-ion battery

ActiveCN109755680AImprove full wettabilityImprove wettabilityFinal product manufactureSecondary cells charging/dischargingElectrochemical responseCharge current

The invention protects a formation process for a high-energy-density flexibly-packaged power lithium-ion battery. The process comprises the steps that liquid is injected into a cell, the cell stands,pre-edge-sealing is performed, and the cell is vertically placed into a pressure fixture; the surface of the cell is pressurized, a certain temperature is set, primary charging is performed on the cell, and pressure, temperature and charging currents are set in a stepped mode; after charging is completed, primary second-sealing is performed, and meanwhile air is pumped while a certain vacuum degree is maintained; and standing, secondary pressurization, normal-temperature charging and secondary second-sealing are performed. According to the formation process, the high-temperature pressurizationformation process is adopted, and compared with normal-temperature normal-pressure formation, sufficient wettability of an electrolyte and an anode / cathode active material is improved, and an electrochemical reaction is benefited; in the last step of primary formation, formation pressure is raised, formation temperature is lowered, the uniformity, compactness and stability of an SEI film generated on the surface of a cathode are improved, generation of a thick interface film is avoided, and internal resistance is lowered; and capacity performance of the cell is enhanced.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

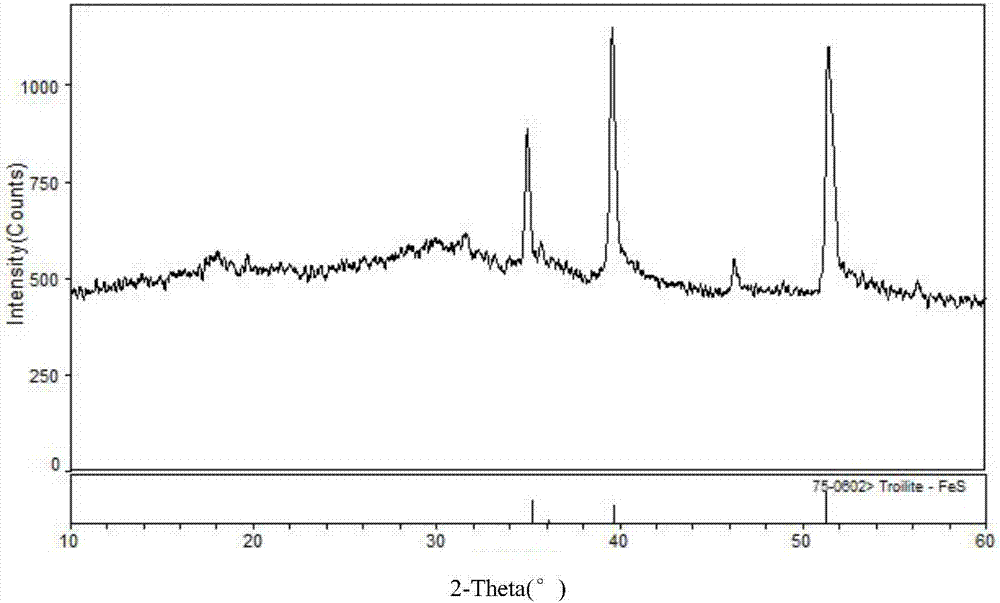

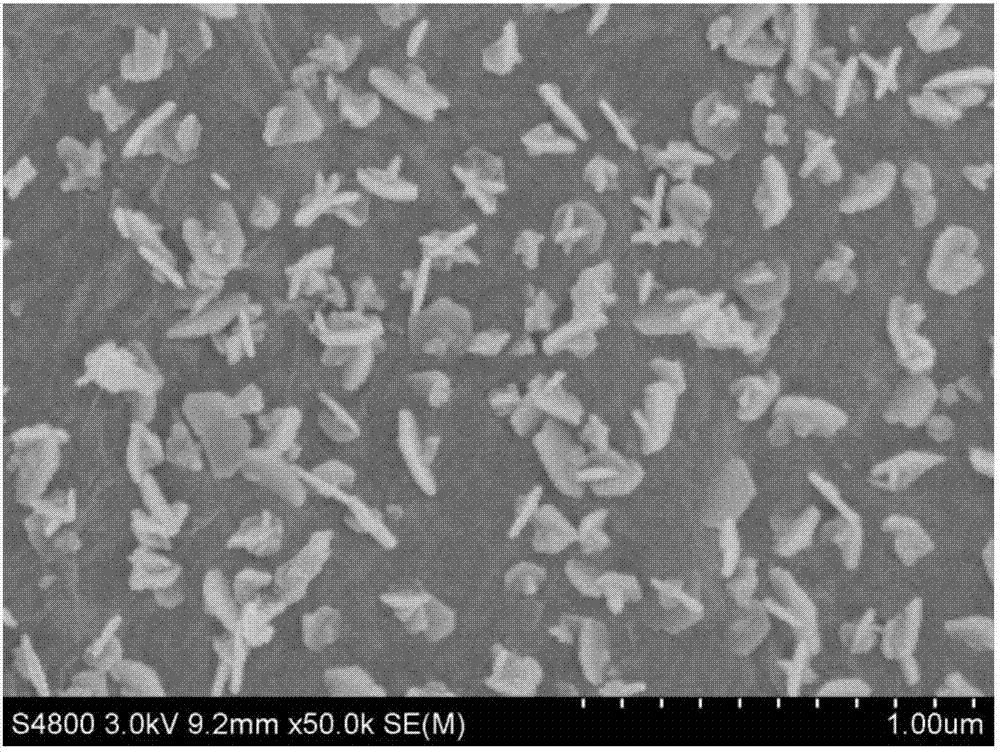

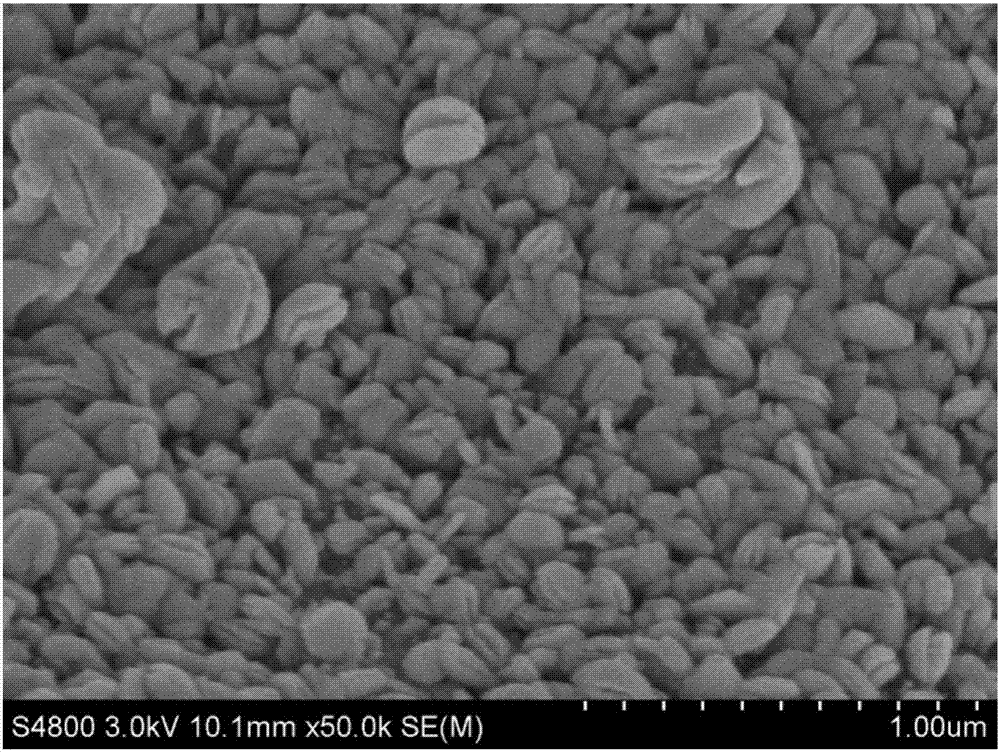

Preparation method of FeS/RGO nano composite sodium-ion battery negative electrode material

The invention discloses a preparation method of an FeS / RGO nano composite sodium-ion battery negative electrode material. The preparation method comprises the following steps: dissolving oxidized graphene into deionized water to prepare a solution, and carrying out ultrasonic treatment to obtain a turbid liquid in which the oxidized graphene is dispersed uniformly; adding ferric acetylacetonate into acetone, carrying out ultrasonic treatment until the ferric acetylacetonate is dissolved, and then adding the solution into the turbid liquid to obtain a mixed solution of ferric salt and the oxidized graphene; heating and evaporating the mixed solution of ferric salt and the oxidized graphene until the acetone is completely evaporated, and carrying out heating vulcanization after freeze drying. According to the preparation method, the oxidized graphene is creatively introduced into the battery negative electrode material, through the control in the heating vulcanization process, the crystallization behavior of transition metal sulfide is changed, namely generated ferric sulfide particles or sheets are stably anchored on the oxidized graphene layer through heating vulcanization to form a novel composite structure, volume expansion of sodium ions in insertion and extraction process is relieved, the pulverization of the material is inhibited, and the cycling stability is improved.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of porous metal doped lithium manganate/graphene lithium battery positive electrode material

InactiveCN105206799AImprove conductivityAvoid reunionMaterial nanotechnologyCell electrodesCvd grapheneMuffle furnace

The invention relates to a preparation method of a porous metal doped lithium manganate / graphene lithium battery positive electrode material. The method includes the steps that 1, a sol-gel method is adopted for preparing a precursor of porous LiM0.2Mn1.8O4, and the precursor is put into a muffle furnace to be calcined at constant temperature to obtain porous LiM0.2Mn1.8O4; 2, graphene oxide is taken and added into deionized water to prepare a graphene oxide solution with the mass concentration of 0.05-0.1 g / mL; 3, porous LiM0.2Mn1.8O4 is put into the graphene oxide solution, the mixture is subjected to magnetic stirring, ultrasonic dispersion and drying and then transferred into a tube furnace to be calcined at constant temperature, and the porous metal doped lithium manganate / graphene lithium battery positive electrode material is obtained. Compared with the prior art, the preparation method is simple, and the raw materials are easy to get; the prepared material is good in crystallinity and uniform in particle size, and the size is about 30 nm; serving as a lithium battery positive electrode material, the prepared material is good in electrochemical stability, high in specific discharge capacity and good in rate performance and cycle performance.

Owner:SHANGHAI JIAO TONG UNIV

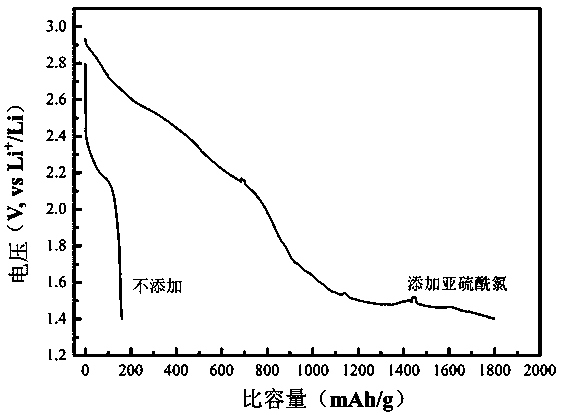

Sodium ion battery negative electrode material and preparation method thereof

ActiveCN109888237APlay a pivotal or even decisive roleSmall particle sizeCell electrodesSecondary cellsState of artPhysical chemistry

The invention belongs to the technical field of sodium ion batteries and particularly relates to a sodium ion battery negative electrode material and a preparation method thereof. The negative electrode material is an iron-based selenide FeSe2@C. The negative electrode material has a controllably synthesized hollow core-shell structure and stable morphology, high specific surface area can be provided for electrolyte contact, the diffusion length of sodium ions can be shortened, and the expansion of the material can be inhibited in the charging and discharging process. According to the materialand the method in the invention, volume expansion of the sodium ion battery negative electrode material prepared in the prior art in the charging and discharging process is overcome, the stability performance of the battery is effectively improved, and the cycling performance and the coulombic efficiency of the sodium ion battery are improved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method and application of graphene-calix[4]arene-gold nano-particle ternary nano-composite materials Preparation method and application of graphene-calix[4]arene-gold nano-particle ternary nano-composite materials](https://images-eureka.patsnap.com/patent_img/3627bf76-f827-4c6a-9888-b515798ffcdd/HSA0000096493770000011.PNG)

![Preparation method and application of graphene-calix[4]arene-gold nano-particle ternary nano-composite materials Preparation method and application of graphene-calix[4]arene-gold nano-particle ternary nano-composite materials](https://images-eureka.patsnap.com/patent_img/3627bf76-f827-4c6a-9888-b515798ffcdd/HSA0000096493770000012.PNG)

![Preparation method and application of graphene-calix[4]arene-gold nano-particle ternary nano-composite materials Preparation method and application of graphene-calix[4]arene-gold nano-particle ternary nano-composite materials](https://images-eureka.patsnap.com/patent_img/3627bf76-f827-4c6a-9888-b515798ffcdd/HSA0000096493770000013.PNG)