Patents

Literature

151 results about "Lithium soap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium soap is a soap consisting of a lithium salt of a fatty acid. Sodium-based and potassium-based soaps are used as cleaning agents in domestic and industrial applications, whereas lithium soaps are used as components of lithium grease (white lithium).

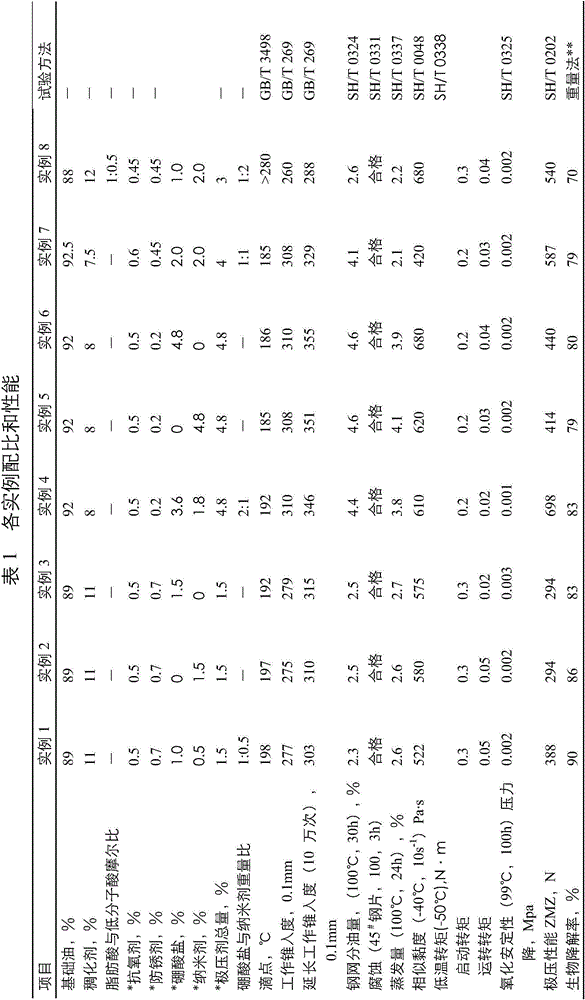

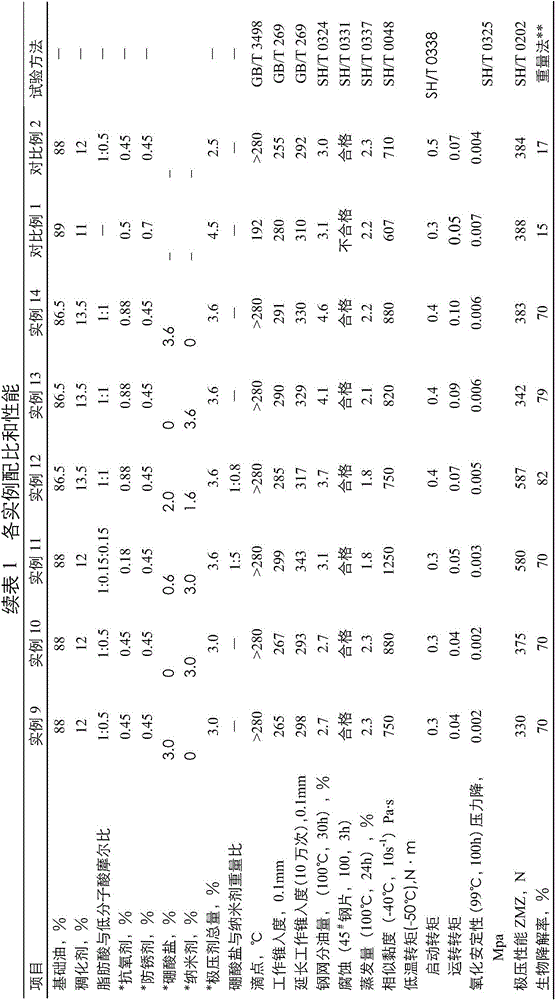

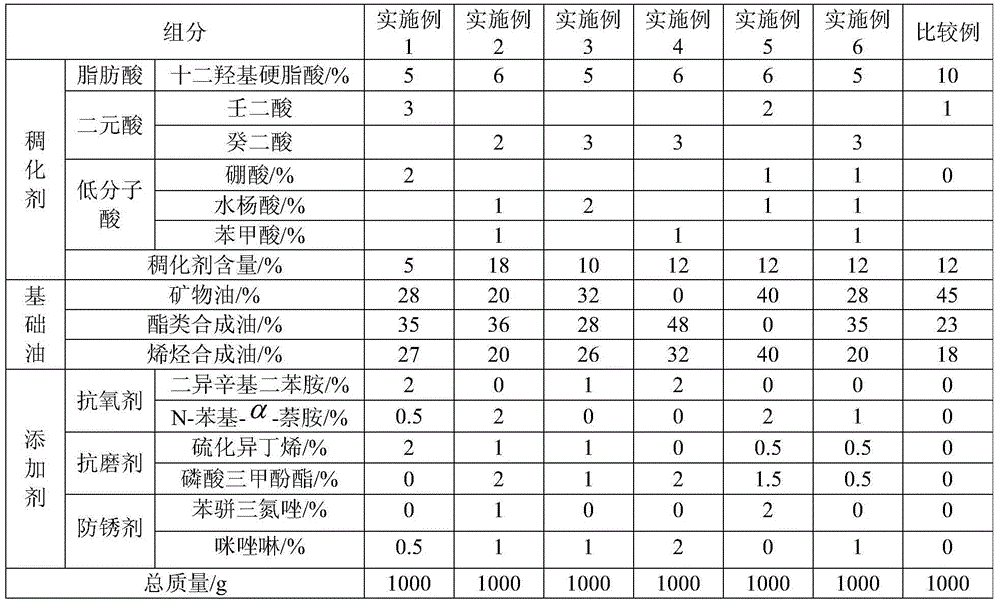

Environmentally friendly lubricating grease composition and preparation method thereof

InactiveCN104804842APromote degradationGood high and low temperature characteristicsLubricant compositionLithium soapAntioxidant

An environmentally friendly lubricating grease composition comprises base grease composed of base oil and a thickener, and an additive, wherein the base oil is selected form synthetic oil base oil, the thickener is a lithium soap or composite lithium soap thickener, and the additive at least contains an extreme pressure anti-wear agent selected from borate and a nanometer extreme pressure agent, an antioxidant and an antirust agent. The above lubricating grease has the advantages of good biodegradability, good high and low temperature characteristics, good extreme pressure anti-wear performances, and low starting torque and running torque, and is suitable for being used in railway switch machines.

Owner:CHINA PETROLEUM & CHEM CORP +1

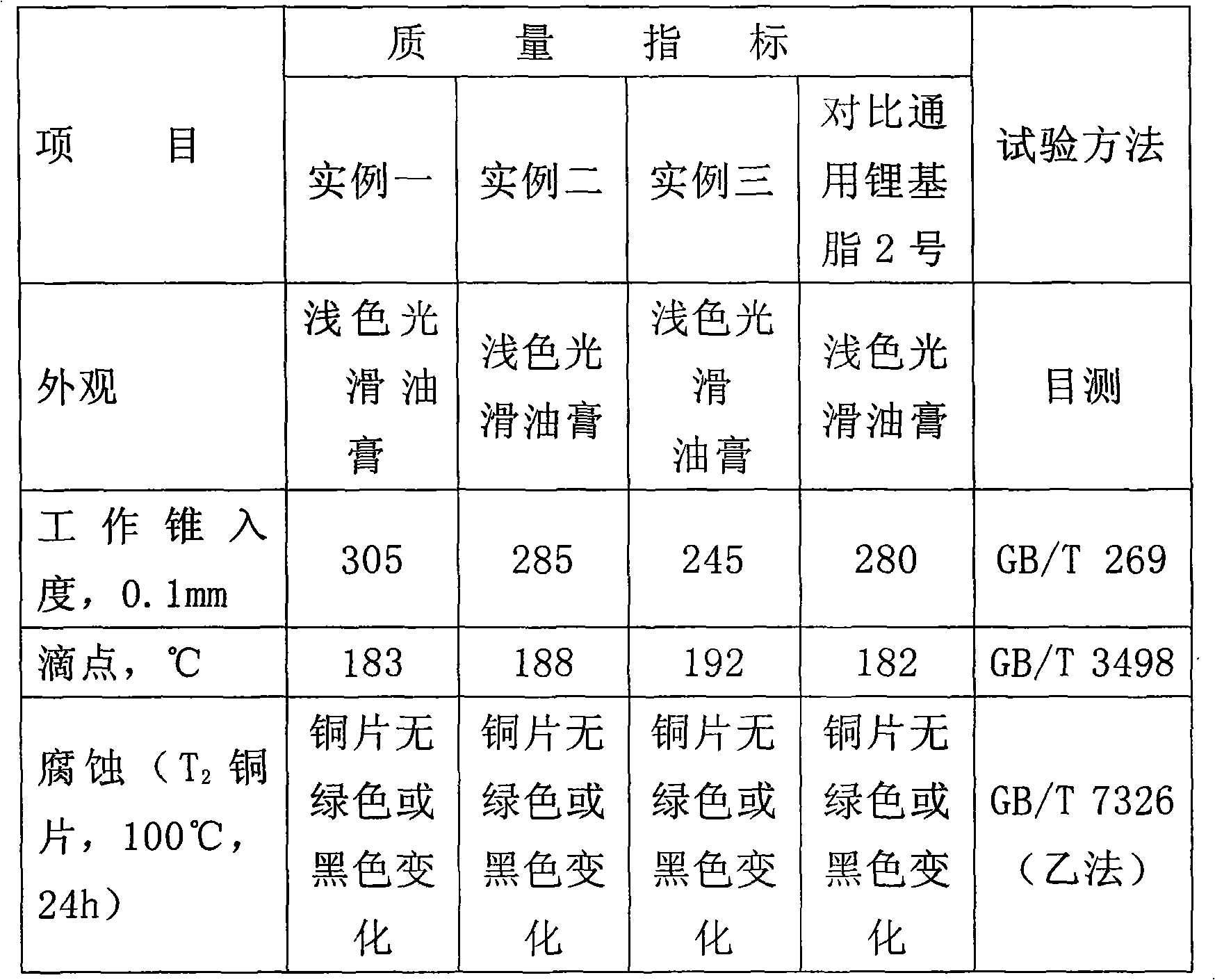

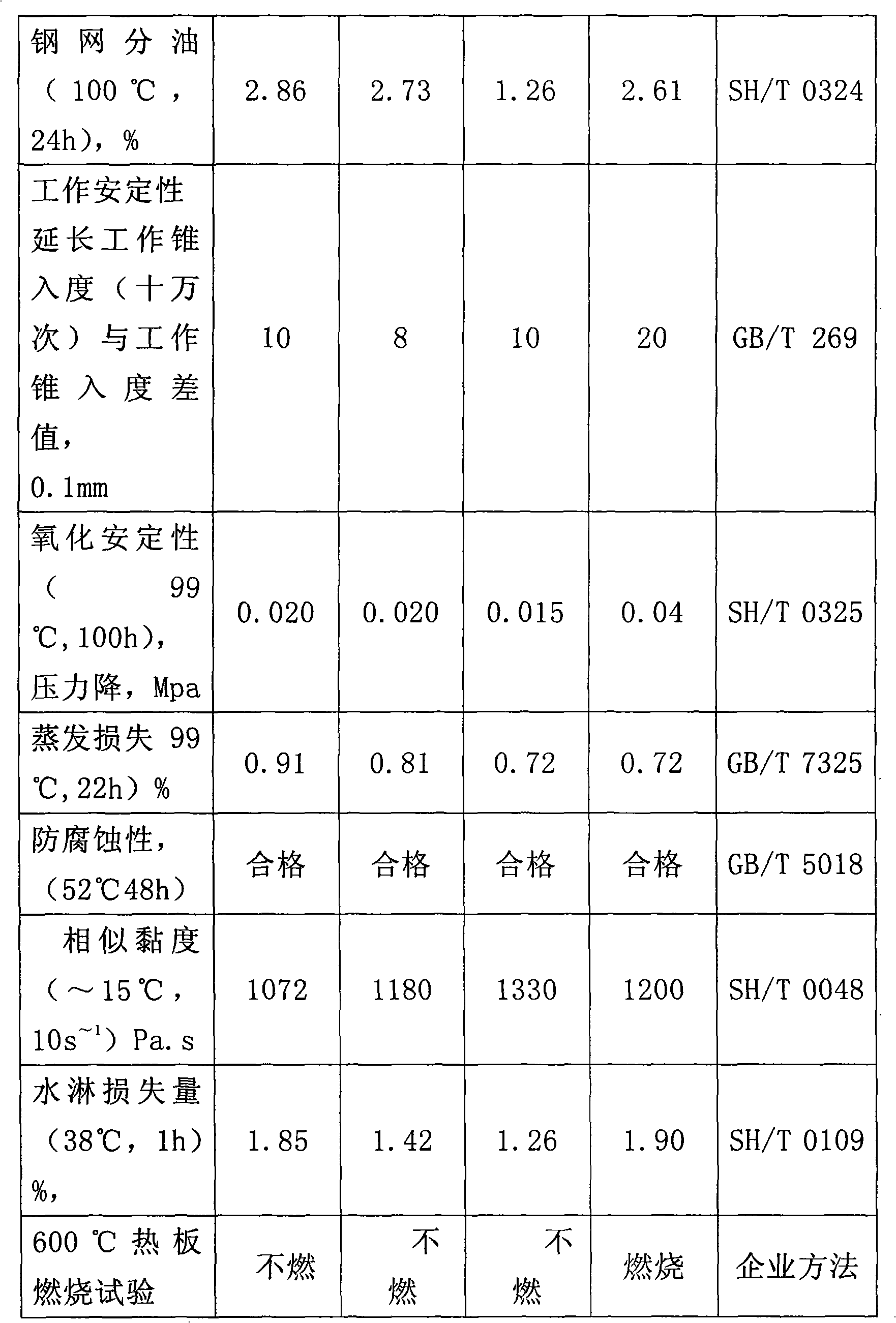

Flame-retarded lubricating grease and preparation method thereof

ActiveCN101619261AImprove performanceImprove flame retardant performanceThickenersAdditivesLithium soapAntioxidant

The invention relates to flame-retarded lubricating grease and a preparation method thereof. The preparation method comprises the following technical steps: firstly, putting base oil and an inorganic thickening agent in an open reaction kettle for stirring and mixing, adding a dispersant after heating and heating again to take the mixture out of the kettle for use; secondly, mixing fatty acid calcium soap with the base oil, adding fatty acid lithium soap after heating, keeping heat, dehydrating and refining; finally, removing the materials to a middle kettle, lowering the temperature by cooling, stirring the materials with lubricating grease prepared by the inorganic thickening agent, adding an antioxidant, a flame retardant and an anti-rusting agent for homogenization and filtering to obtain finished products. The lubricating grease not only keeps various excellent properties of original general lithium grease, but also specially enhances the incombustible flame retardance of a 600 DGE C hot plate. Assessment of the properties of the flame-retarded lubricating grease shows that the flame-retarded grease lubricant has excellent mechanical stability, water resistance, lubricating property, anti-rusting property and flame retardance, long service life and low cost, and can replace general lithium grease used in coal mine, subway, metallurgy and other industries at present.

Owner:无锡中石油润滑脂有限责任公司

Composite lithium base lubricant and its preparing method

ActiveCN1616612AGood mechanical stabilityGood colloidal stabilityBase-materialsLithium soapLithium hydroxide

The composite lithium-base lubricating grease consists of the following components: high alkality calcium sulfonate with calcium carbonate existing in calcite crystal and dispersed colloid particle form in 20-60 wt%; thickener comprising composite lithium soap in 3-15 wt%; and lubricating base oil in the rest amount. The preparation process of the lubricating grease includes mixing and heating Newtonian fluid high alkality calcium sulfonate, converting agent and base oil until thickening; adding C12-C24 fatty acid and auxiliary acid and producing saponification with lithium hydroxide aqua; heating to dewater and cooling to form grease. The composite lithium-base lubricating grease of the present invention has excellent mechanical stability, colloid stability, water resistance, rust resistance and high temperature use performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

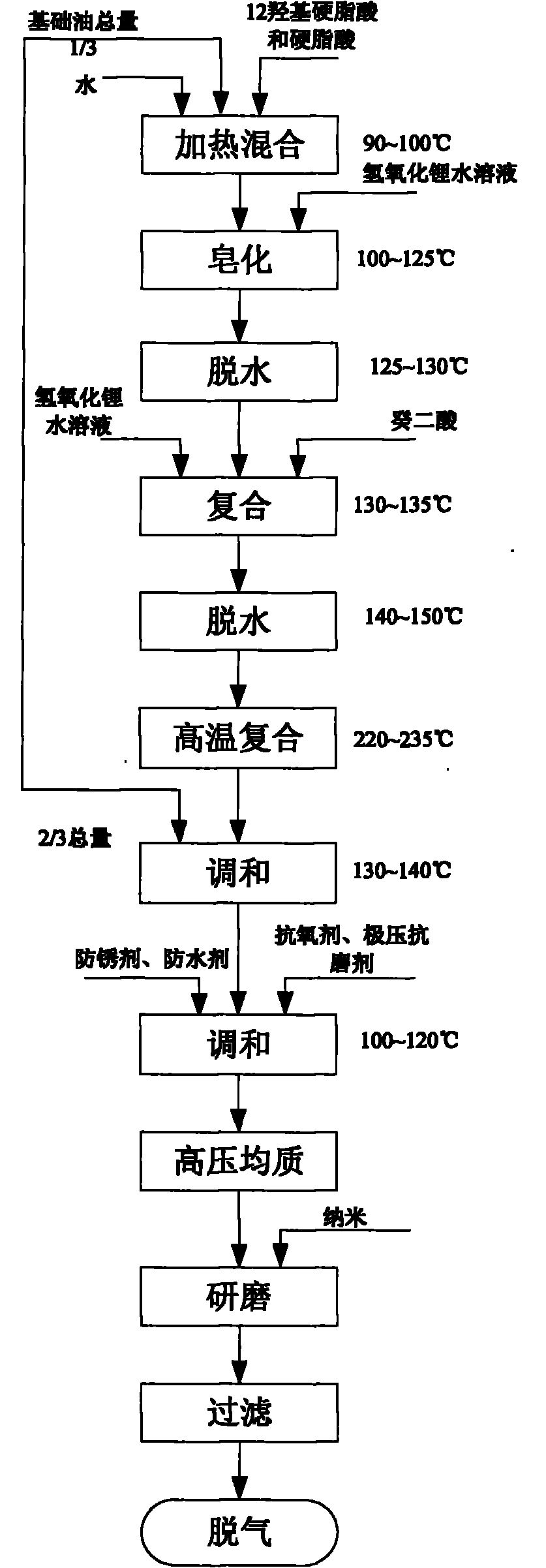

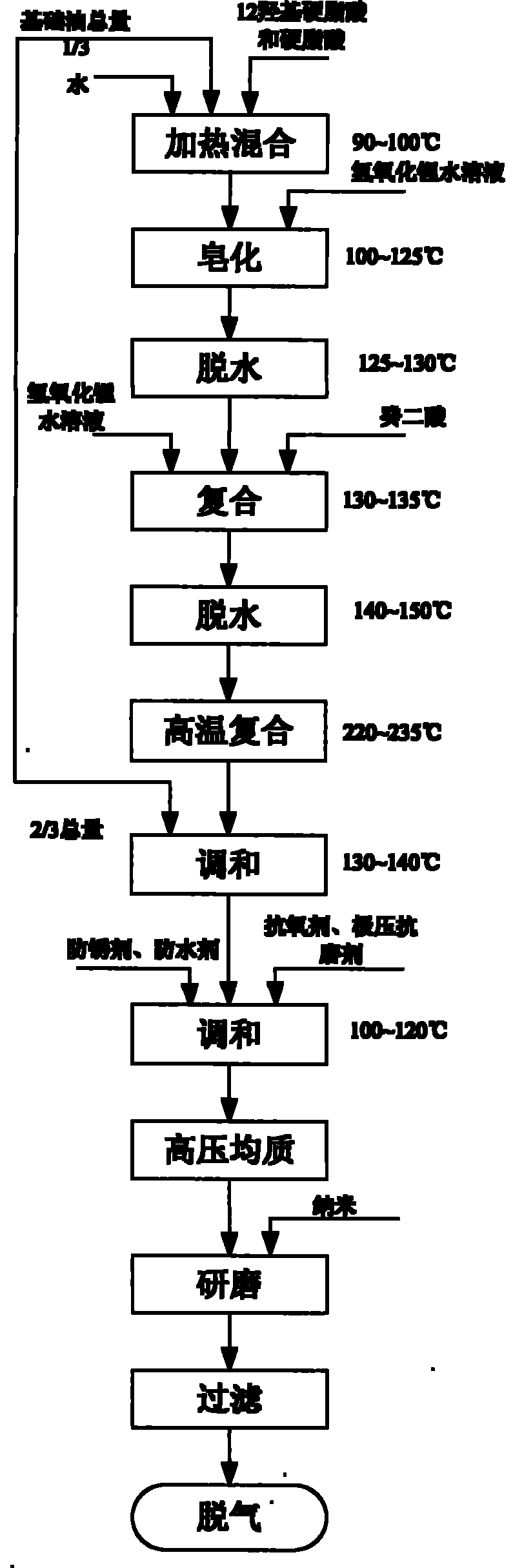

Hub bearing lubricating grease and preparation method thereof

InactiveCN102140382AGood extreme pressure and anti-wear propertiesImprove adhesionLubricant compositionLithium soapHigh resistance

The invention discloses a hub bearing lubricating grease and a preparation method thereof. In the lubricating grease, composite lithium soap is taken as a thickening agent, an antirusting agent, an antioxidant, an extreme-pressure anti-wear agent and a waterproofing agent are added, and a nanometer additive and the like are added according to different proportions. The lubricating grease is prepared by the processes including saponifying, dehydrating, blending, shearing, homogenizing, grinding, filtering, degassing and the like. A lubricating grease composition has the advantages of high dropping point, high wear resistance, high extreme pressure resistance, high high-low temperature performance and the like, has high water resistance and rust resistance, and is suitable for lubricating the automobile bush bearings under harsh working conditions.

Owner:SOUTH CHINA UNIV OF TECH

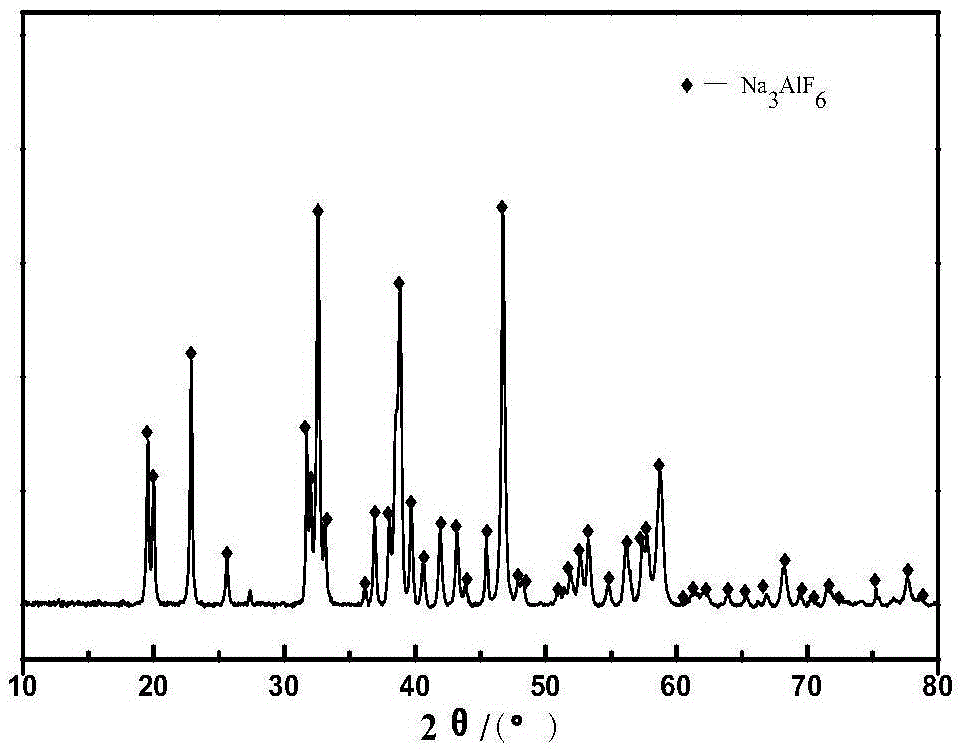

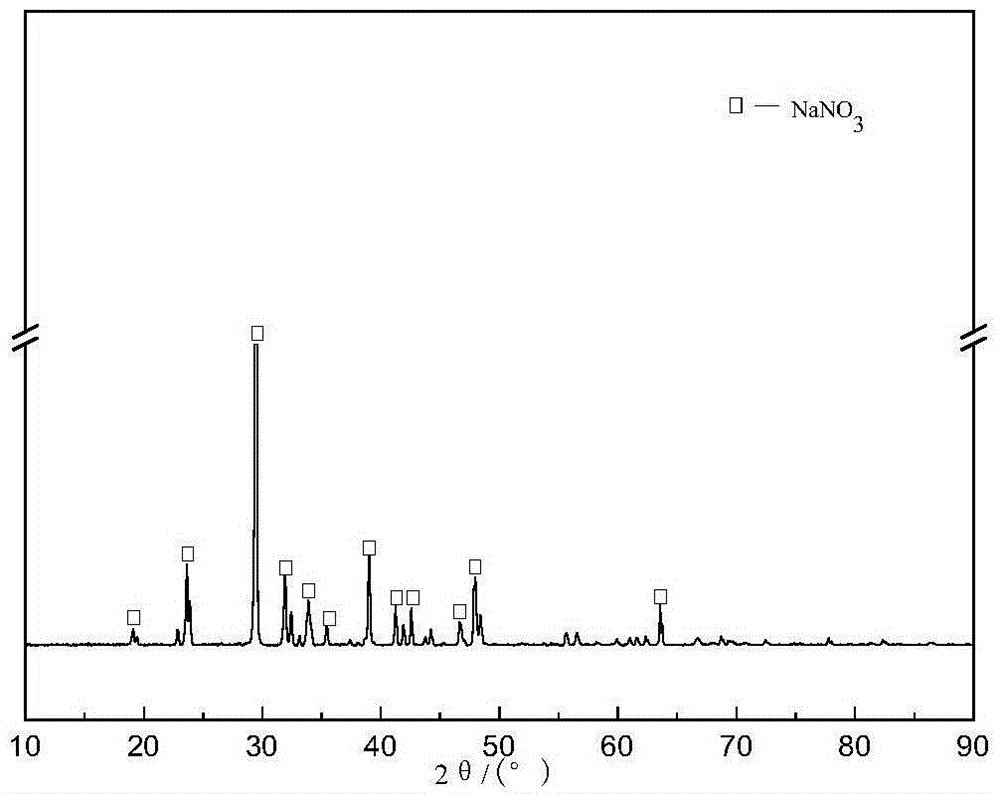

Method for extracting lithium salt from aluminum electrolyte by utilizing fluoride roasting and acid leaching

ActiveCN105543504AReduce energy consumptionEfficient extractionProcess efficiency improvementLithium soapLithium carbonate

The invention discloses a method for extracting lithium salt from aluminum electrolyte by utilizing fluoride roasting and acid leaching, and belongs to the technical field of inorganic chemistry. The method comprises the following steps: step 1: mixing materials; and step 2: carrying out fluoride roasting; and step (3): (1) carrying out acid leaching and filtering to obtain primary filtrate and primary filtered substances; (2) respectively treating the primary filtrate and the primary filtered substances to obtain secondary filtrate and secondary filtered substances; (3) respectively treating the secondary filtrate and the secondary filtered substances to obtain tertiary filtrate and tertiary filtered substances; and (4) respectively treating the tertiary filtrate and the tertiary filtered substances. According to the method disclosed by the invention, an element lithium in the electrolyte can be effectively extracted, so that energy consumption for electrolytic aluminum production is reduced; lithium carbonate chemical raw materials with a high additional value are recycled, and the used raw materials are common raw materials in the chemical field, so that the comprehensive average extraction cost is relatively low; various substances can be separated out, and the obtained substances are relatively high in purity; and the lithium element influence problem is solved for the aluminum electrolysis industry, benefits are increased, and the comprehensive level of the aluminum electrolysis industry in China is improved.

Owner:NORTHEASTERN UNIV

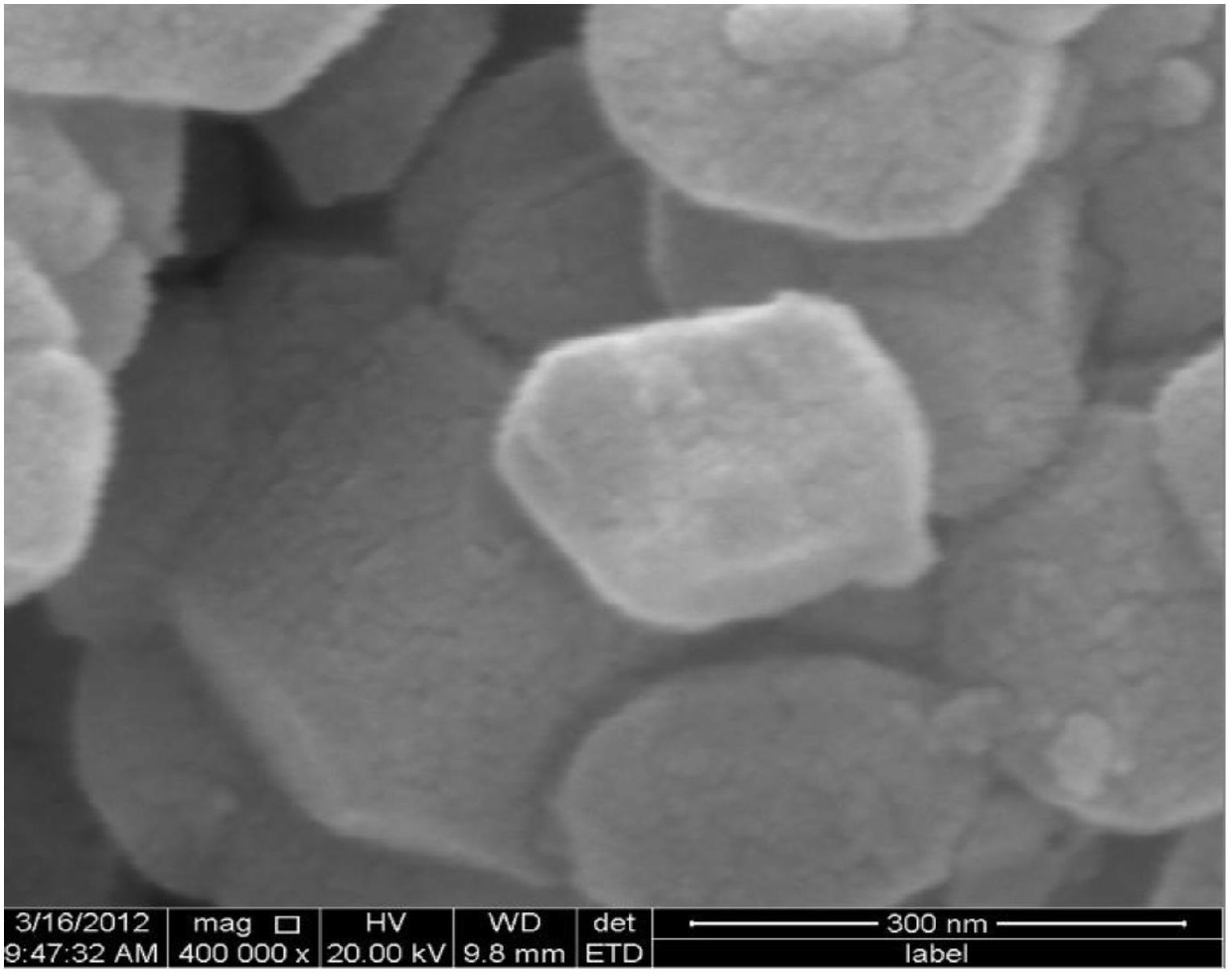

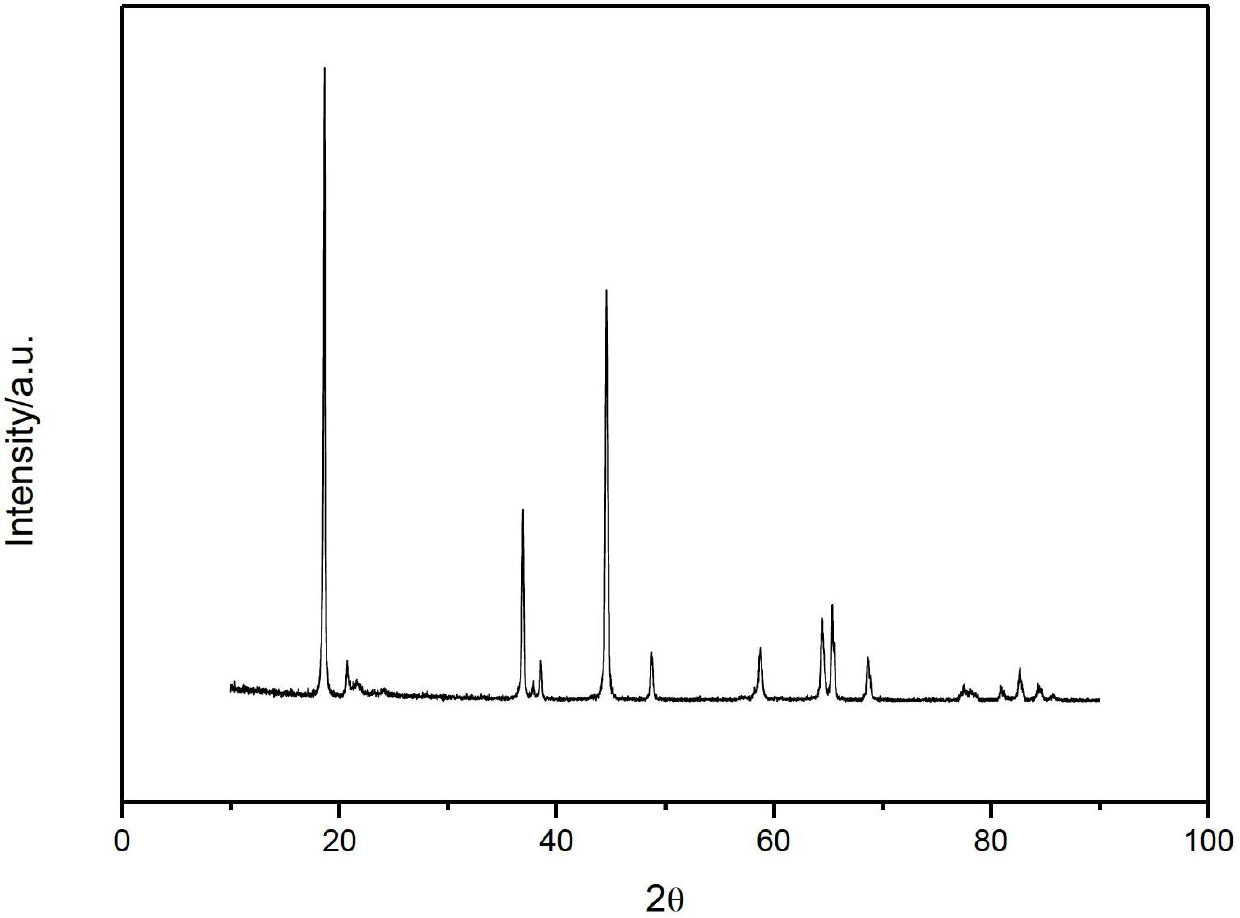

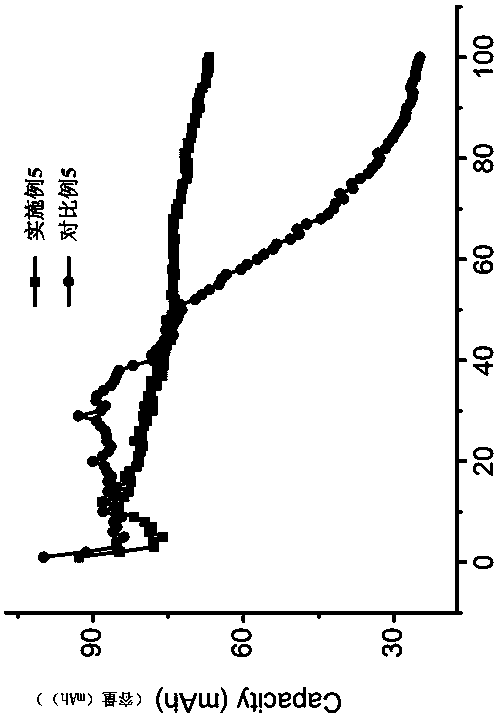

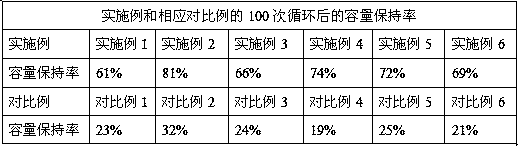

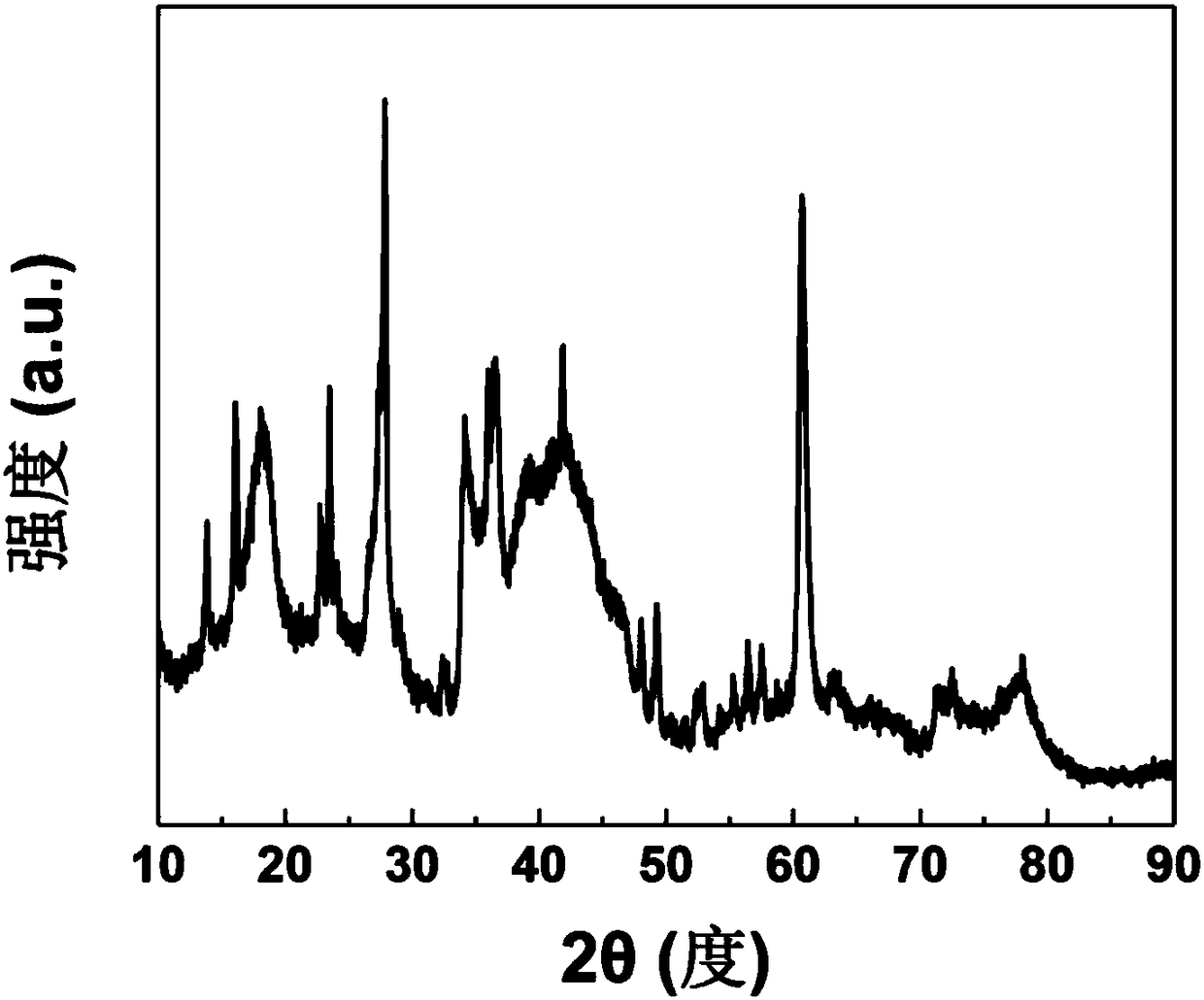

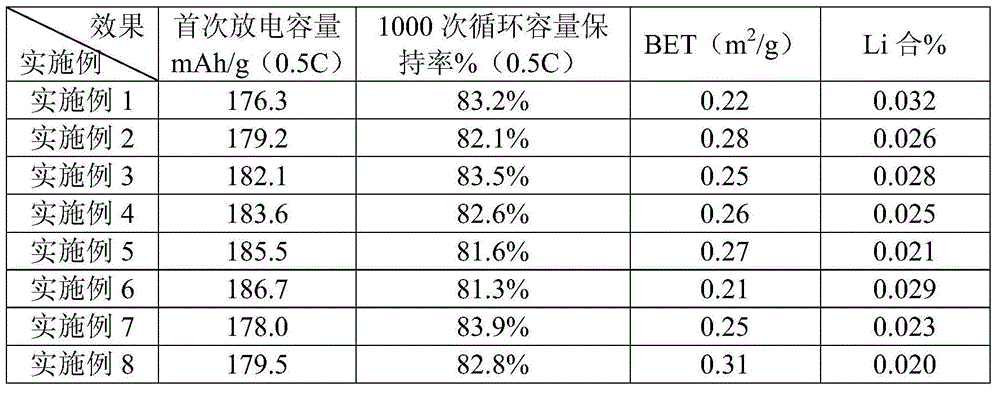

Lithium ion battery cathode multicomponent material and preparation method thereof

InactiveCN104319386AImprove cycle performanceImprove securityCell electrodesSecondary cellsLithium soapManganate

The invention relates to a preparation method of a lithium ion battery cathode multicomponent composite material Lia(NixCoyMnz)NbO2 / M, and a preparation method of a precursor of the multicomponent material. The lithium ion battery cathode multicomponent composite material belongs to a nickel cobalt lithium manganate series cathode material, and can be expressed by a chemical formula Lia(NixCoyMnz)NbO2 / M. The preparation method comprises the following steps: measuring to prepare a standard mixed solution; under the protection of an inert atmosphere, adding a proper amount of a complexing agent and a precipitating agent into the mixed solution, adjusting the pH value to reach the end point of the reaction, filtering, washing and drying to obtain a spherical multicomponent precursor containing doped elements; grinding a lithium source and multicomponent precursor obtained in the step (2) in a ball mill; and placing the mixture obtained in the step (3) in a high temperature kiln to obtain a first sintering, so as to obtain the multicomponent material. The invention thorough mixing of precursor and lithium salt improves reaction activity, and strictly controls the temperature in the process of sintering, so as to obtain the multicomponent cathode material with regular morphology and uniform particle size.

Owner:QINGDAO QIANYUN HIGH TECH NEW MATERIAL

Lubricating grease for hubs of heavy trucks and preparation method for lubricating grease

ActiveCN102618368AStable structureImprove water resistanceLubricant compositionLithium soapHeat resistance

The invention discloses lubricating grease for hubs of heavy trucks. The lubricating grease consists of base oil, thickening agent and additive, the thickening agent is composite lithium soap thickener, and the additive consists of borate oiling agent, compound viscosity index improver, purification dispersant, amine-type antioxidant, sulfur-phosphorous-type antioxidant and sulfonate antirusting agent. The special lubricating grease for hubs of trucks which is obtained by means of circular shearing treatment is excellent in heat resistance, adhesion, mechanical stability, water resistance, extreme pressure abrasion resistance and the like, and can meet requirements on lubrication and protection for bearings of the hubs of the trucks under harsh conditions.

Owner:杭州得润宝油脂股份有限公司

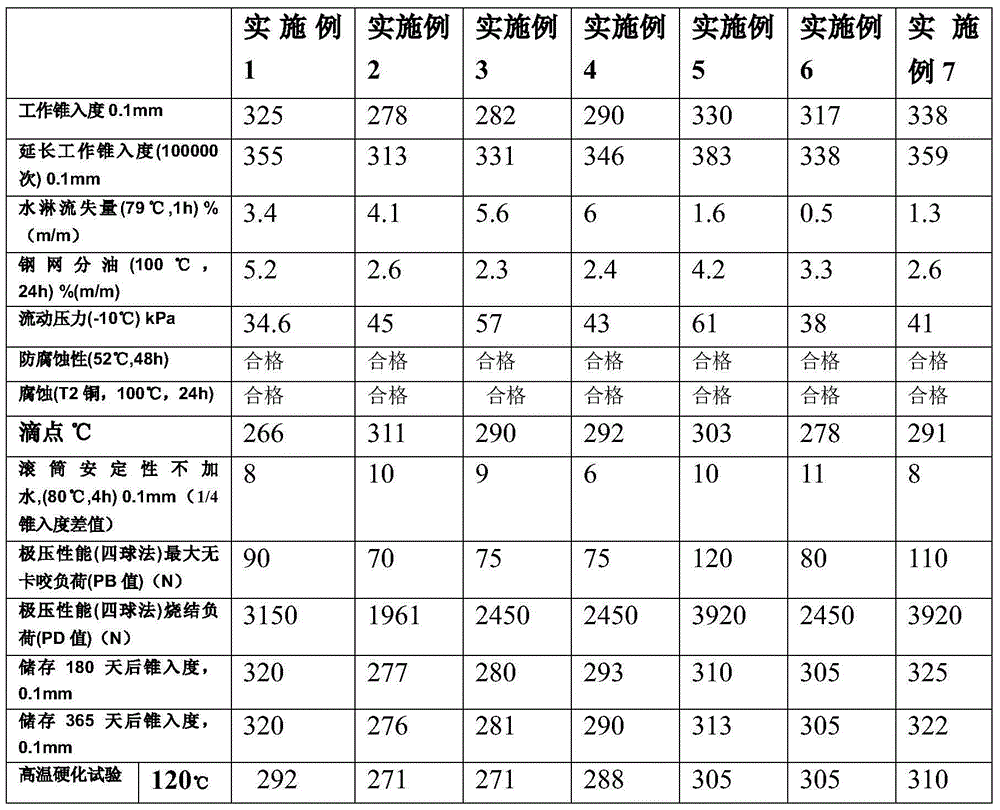

Lithium-calcium complex lubricating grease composition and preparation method

InactiveCN104449983AGood mechanical stabilityGood colloidal stabilityLubricant compositionLithium soapLong chain fatty acid

The invention relates to a lithium-calcium complex lubricating grease composition and a preparation method. The lubricating grease comprises the following components: (1) 60%-87% of base oil; (2) 10%-38% of a thickening agent; and (3) 1.5%-11% of an additive, wherein the thickening agent disclosed by the invention is a lithium-calcium complex thickening agent, comprises one or more long-chain fatty acid lithium soap and one or more micromolecular acid calcium soap, and is obtained from the reactants of acid and lithium hydroxide and calcium hydroxide. The lithium-calcium complex lubricating grease prepared by the method has good mechanical stability, colloid stability, water resistance and good extreme pressure antiwear property; and above all, the hardening phenomenon is not generated under room-temperature long-term storage and high-temperature (120 DEG C) conditions on the basis that excellent performances of the original lithium-calcium complex lubricating grease are reserved.

Owner:CHINA PETROLEUM & CHEM CORP

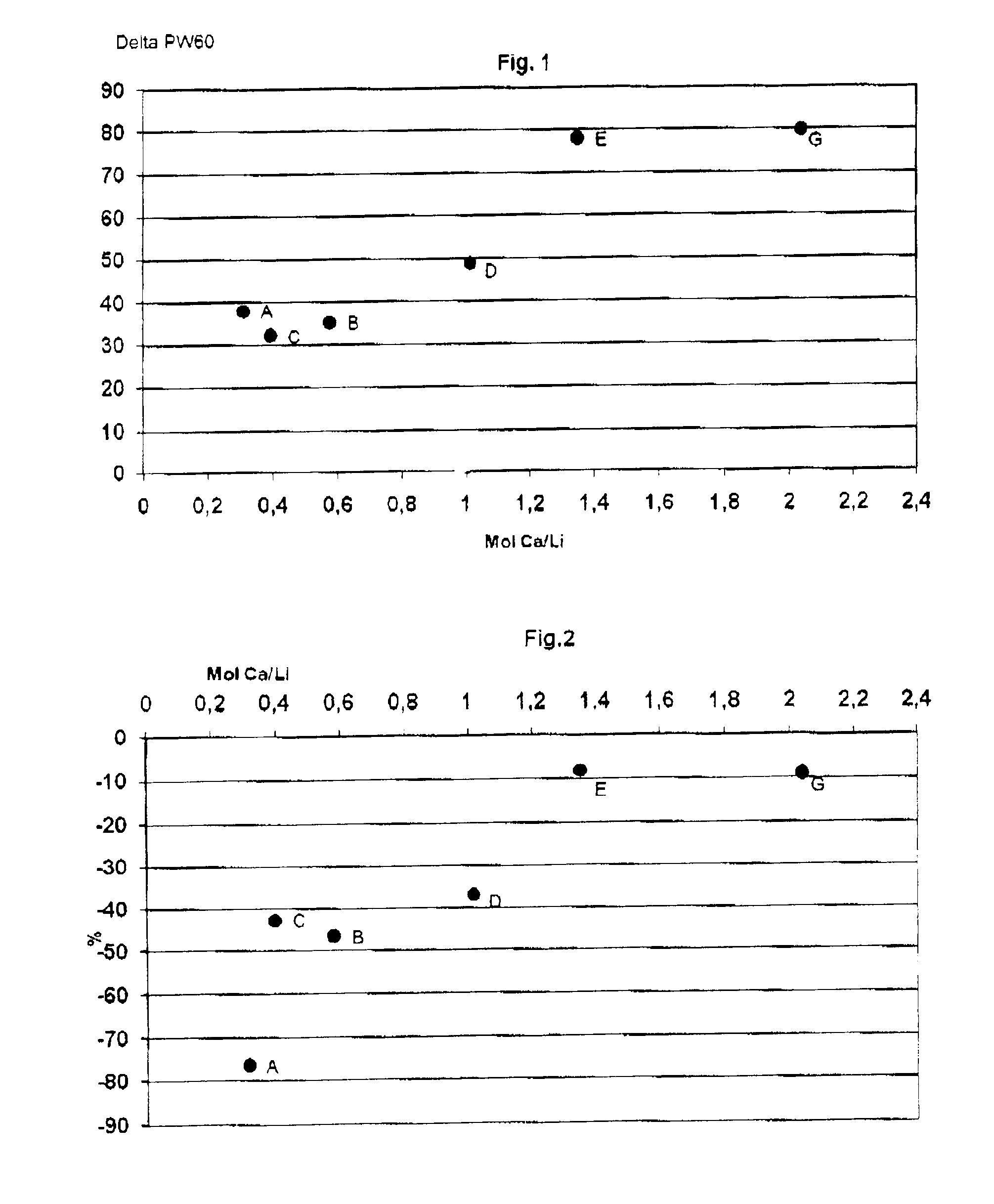

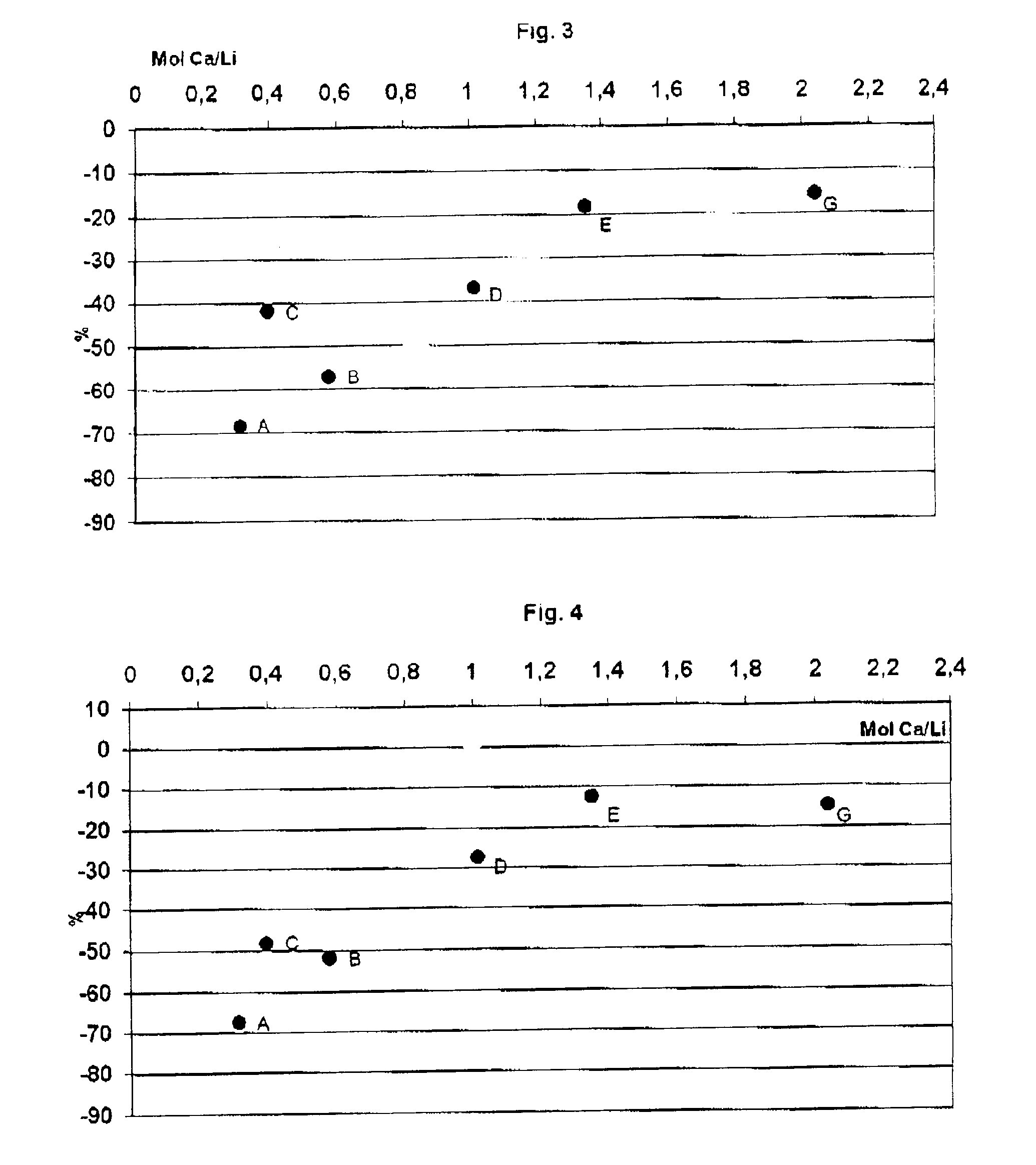

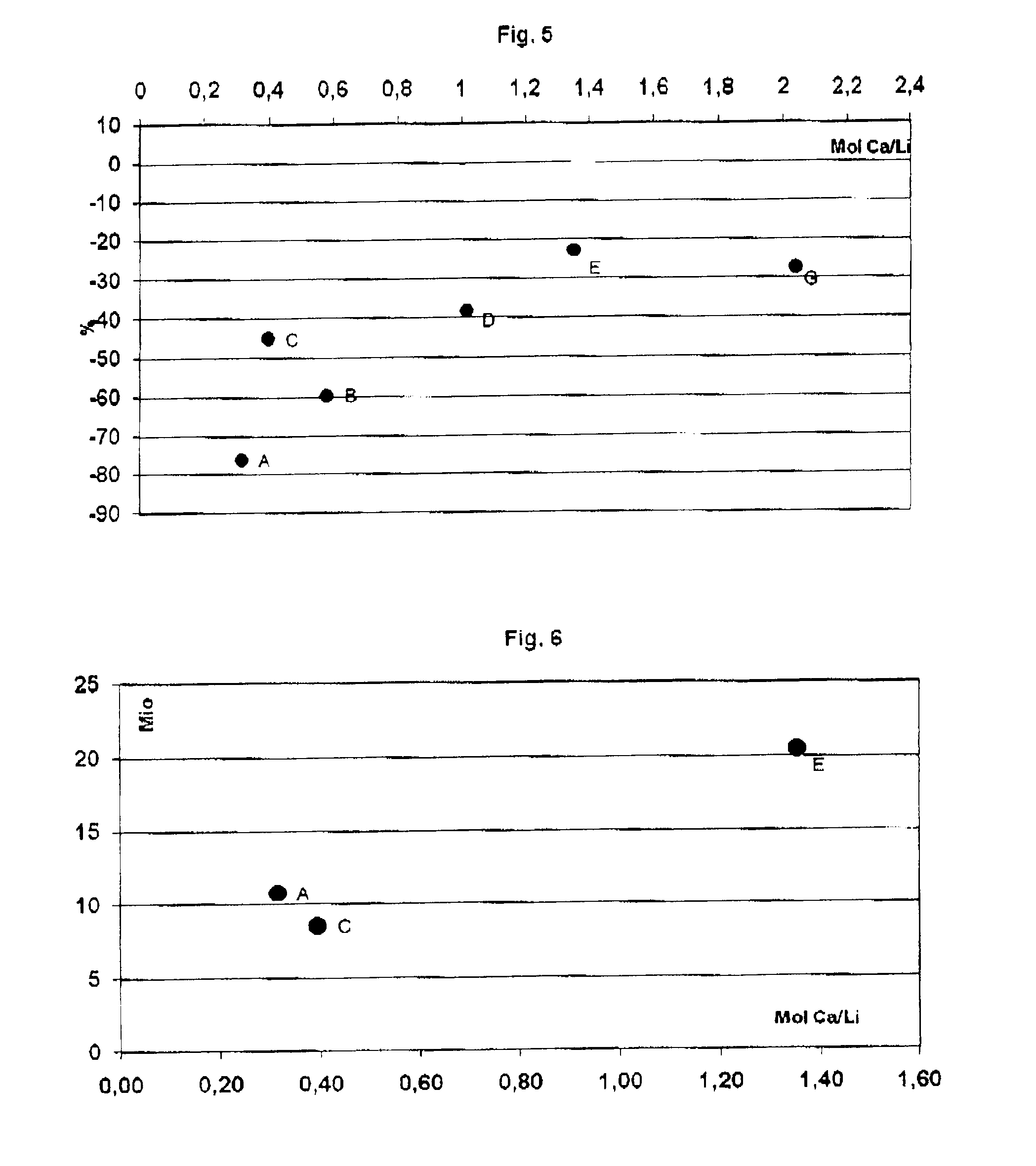

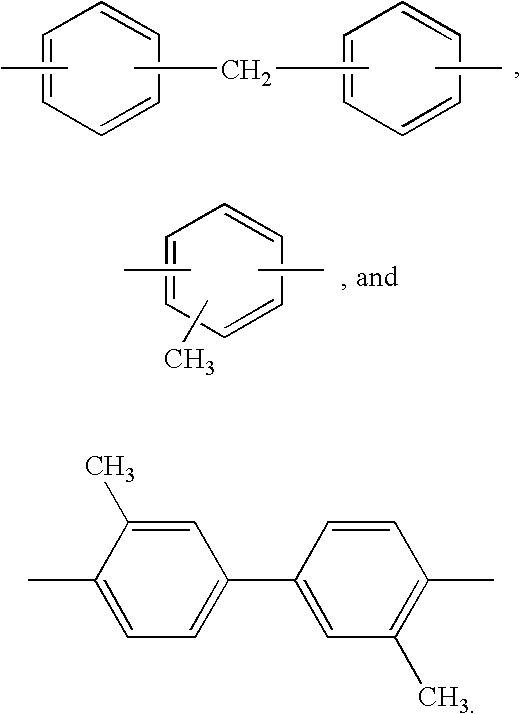

Calcium/Lithium Complex Greases and Encapsulated Constant Velocity Joint Containing the Grease and Method for their Production

ActiveUS20100048436A1Loss of efficiency and lifetime in joint shaftsThickenersAdditivesLithium soapHigh calcium

Embodiments of the invention include compositions of calcium / lithium complex greases containing calcium / lithium soaps having a high calcium fraction and complexing agents, encapsulated constant velocity shafts containing such lubricating greases and the use of the lubricating greases in encapsulated shafts of constant velocity shafts.

Owner:FUCHS PETROLUB SE

Grease composition for precision equipment and timepiece containing the same

ActiveUS20050014658A1Suffer from difficultyAppropriate slip torqueSynchronous motors for clocksLiquid carbonaceous fuelsLithium soapEngineering

A grease composition for a precision instrument comprising a lithium soap grease or a urea grease, and an anti-wear agent, wherein the lithium soap grease and the urea grease are each a grease having no hydroxyl group in a molecule, and the anti-wear agent is contained in an amount of 0.1 to 20% by weight based on the total amount of the grease composition. By the use of the grease composition for a sliding mechanism of a precision instrument such as a watch, an appropriate slip torque can be obtained, and the precision instrument such as a watch can operate stably.

Owner:CITIZEN WATCH CO LTD

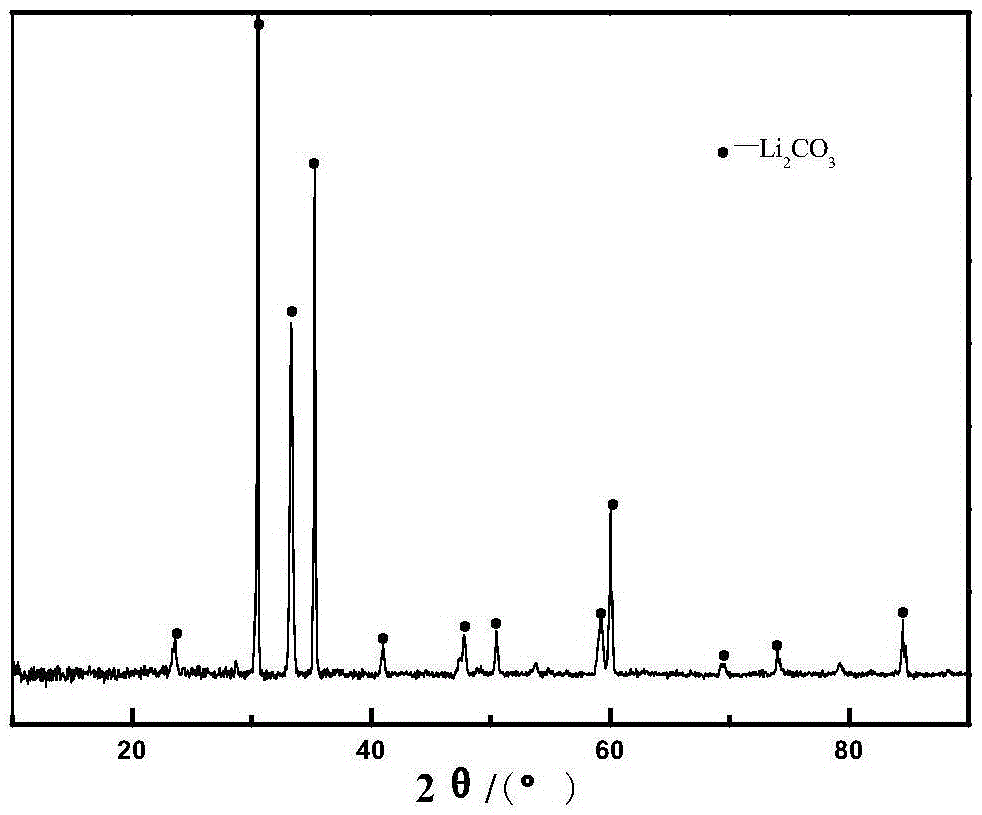

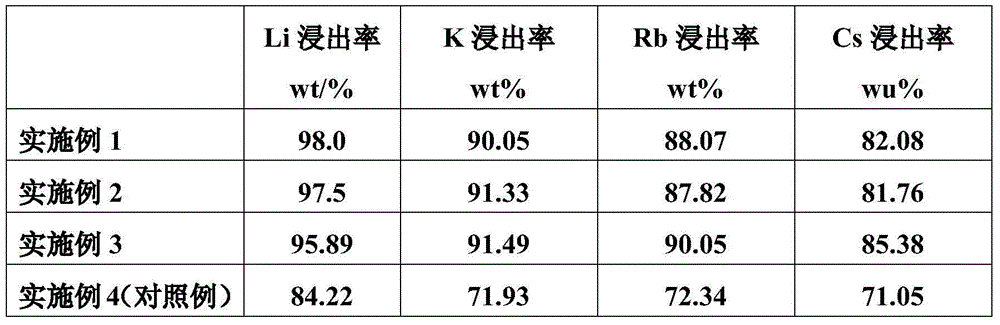

Method of extracting lithium salt from lepidolite

InactiveCN104313349AAvoid generatingReduce pollutionProcess efficiency improvementLithium soapRubidium

The invention discloses a method of extracting a lithium salt from lepidolite. The method comprises the following steps: roasting lepidolite mineral aggregates with CaO and Ca(CH3COO)2 in a plasma generator after ball-milling and mixing; reacting roasted materials with a dilute sulfuric acid solution and (NH4)2SO4 under a pressurized state, controlling an acid leaching temperature to 85-100 DEG C to obtain a solid-liquid mixture, cooling and freezing the solid-liquid mixture to separate potassium, rubidium, cesium and alum, filtering, adding alkali and removing impurities and depositing lithium to prepare the lithium salt. The method disclosed by the invention is capable of completely removing fluorine in the raw materials, reducing the equipment damages and environmental pollution caused by fluorine gas generation in a raw material roasting stage, improving the extraction and utilization efficiency of rare metal raw materials in the lepidolite raw material, lowering the energy consumption, shortening the reaction time and reducing the consumption of acid-base raw materials. The method disclosed by the invention is mild in condition, stable in operation process, short in production period, high in equipment efficiency, capable of realizing comprehensive utilization of resources, low in production cost and beneficial to realizing industrial production of extracting the lithium salt from the lepidolite.

Owner:李宇龙 +1

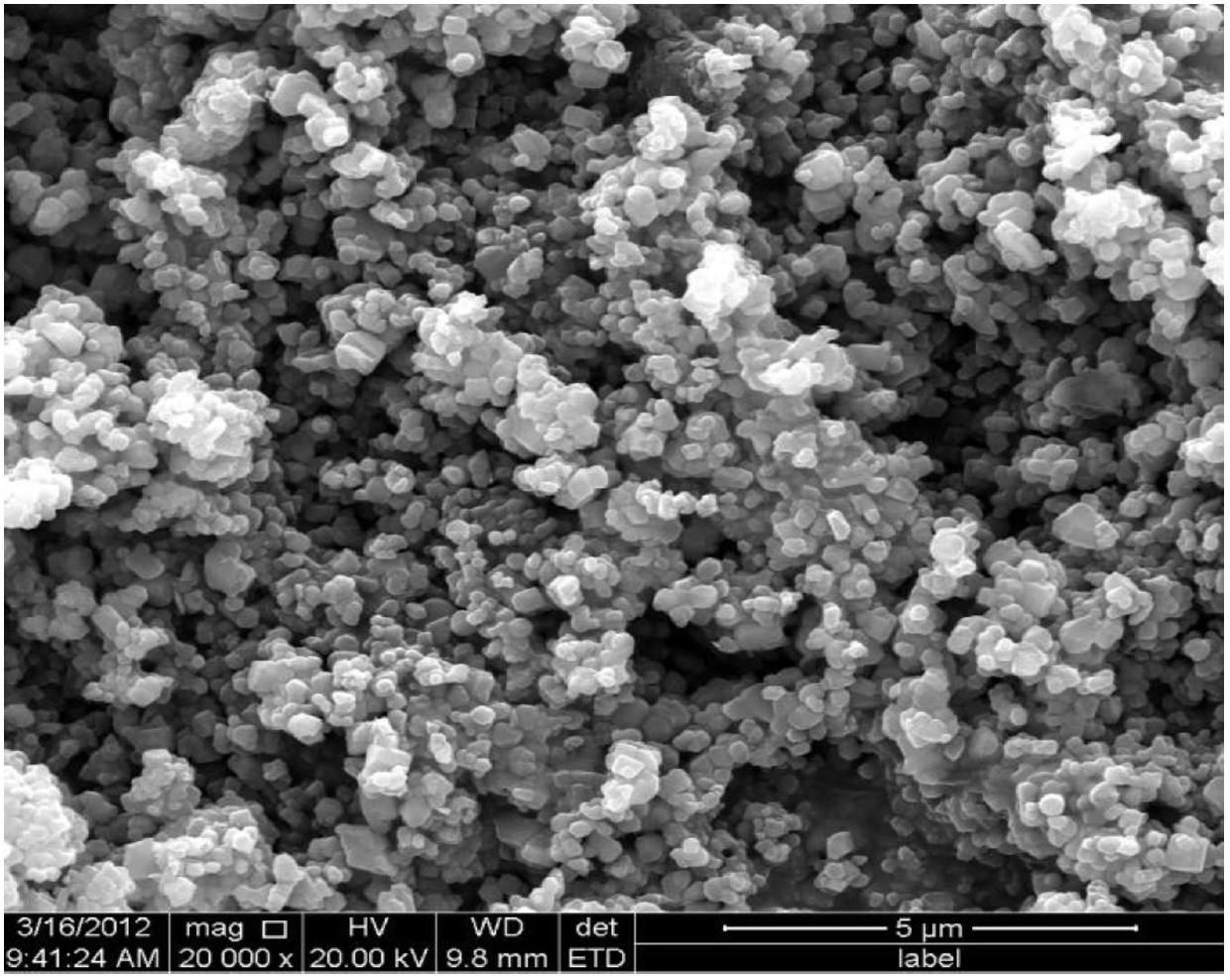

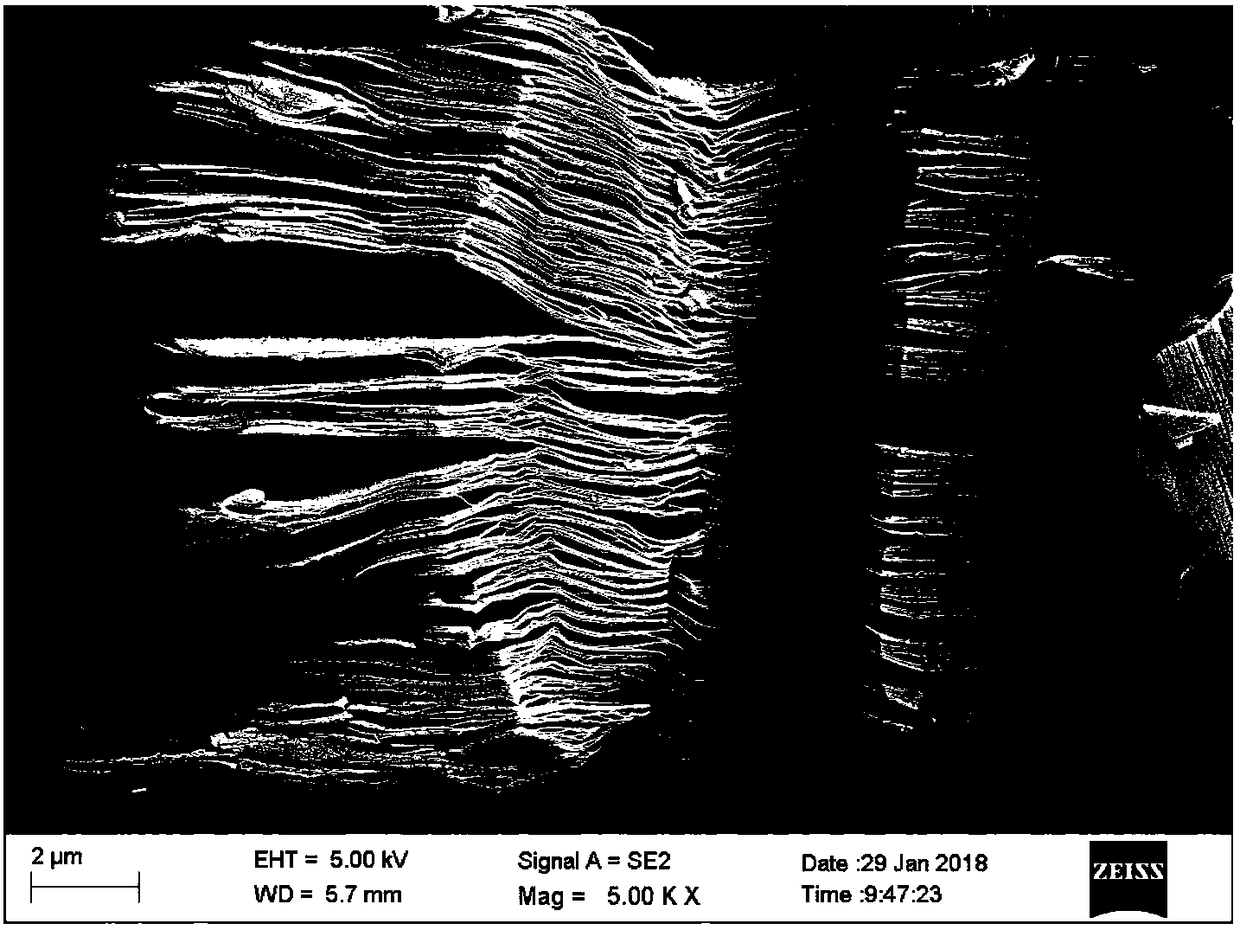

Preparation method of lithium manganese base-enriched ternary composite anode material

InactiveCN102655232ALarge specific surface areaUniform particle size distributionCell electrodesLithium soapGranularity

The invention relates to a preparation method of lithium manganese base-enriched ternary composite anode material, belonging to the field of green energy resource material. The method comprises the following steps of: stirring to make the mixture dissolve so as to obtain mixed solution; putting precipitator in the water to dissolve in a stirring way, so that precipitator solution can be obtained; mixing the mixed solution with the precipitator solution to obtain reaction liquid, adjusting the pH value of the reaction liquid into 7.0-12.0, stirring for reaction, aging, filtering to obtain precipitate, and washing the precipitate by detergent; cooling the washed precipitate into the temperature which is less than or equal to -10 DEG C, and freezing for the time which is more than or equal to 1h, and drying under the vacuum degree which is less than or equal to 10.0Pa, so that a precursor can be obtained; and mixing the precursor with the lithium salt to carry out thermal treatment, so that the lithium manganese base-enriched ternary composite anode material can be obtained. The material prepared by the method is small in granularity, even in particle size distribution, and high in activity, so that the first irreversible capacity can be reduced, and the cycle performance of the lithium ion secondary battery taking the material as the anode material can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

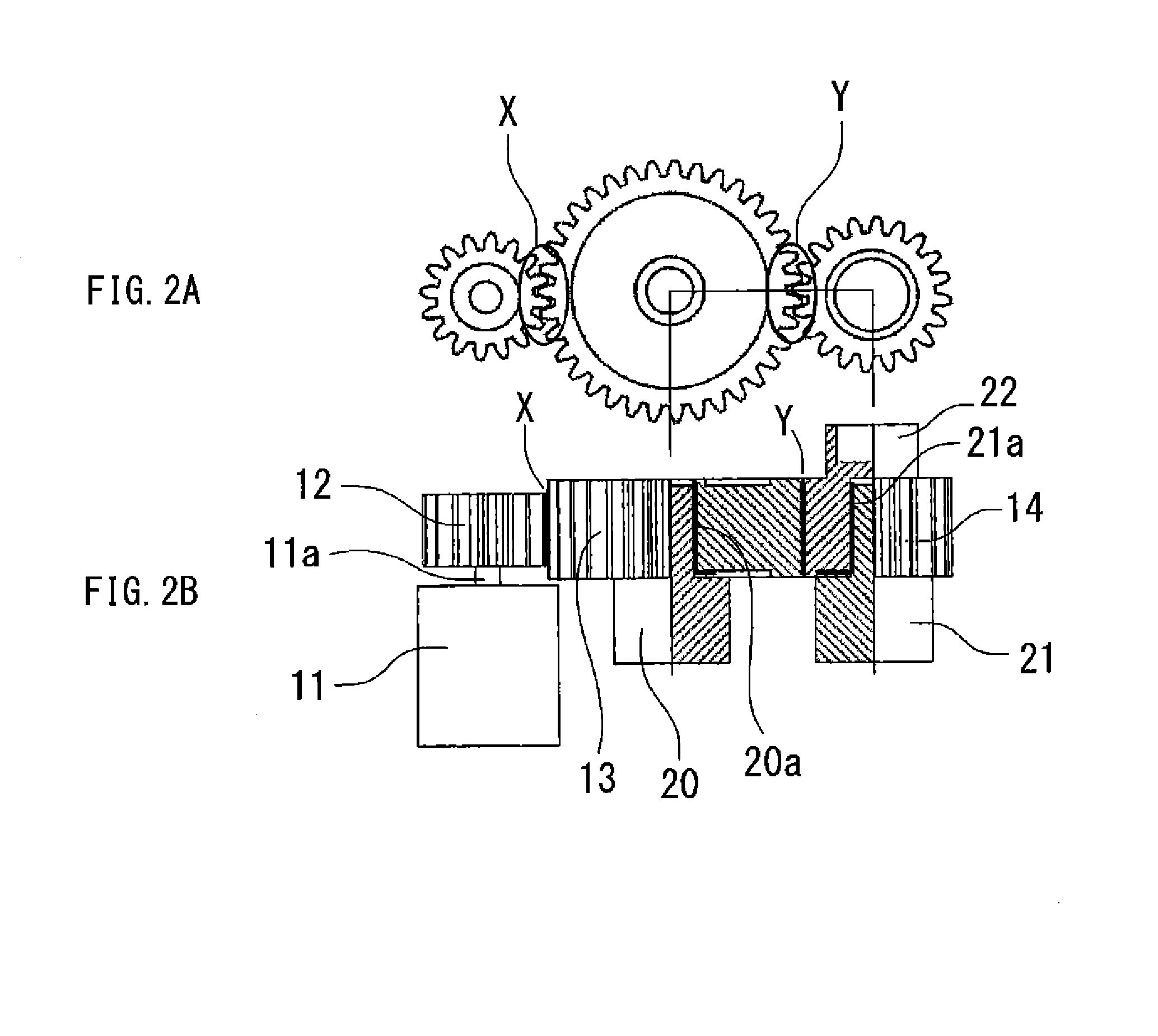

Resin gear device with resin lubricating grease composition

ActiveUS20140239760A1Solution to short lifeReduce the differenceGear lubrication/coolingBearing componentsLithium soapRotational axis

An actuator includes a stepping motor; a multi-stage gear device including a first stage gear attached to a rotation shaft of the motor, wherein a gear of each stage engages with a gear of a next stage; and a base member on which the multi-stage gear device and the stepping motor are mounted, wherein in the multi-stage gear device, a grease composition for resin is applied to a bearing part of the gear, and to an engaging part between the gears, and the grease composition for resin includes: (a) a base oil including a poly-alpha-olefin oil with a kinematic viscosity at 100° C. of 4 to 6 mm2 / s; (b) a thickening agent which is lithium soap; (c) a viscosity increasing agent; (d) a solid lubricant; and (e) an anti-wear agent, and wherein the NLGI consistency number of the composition is 00, 0, 1, or 2.

Owner:MINEBEAMITSUMI INC

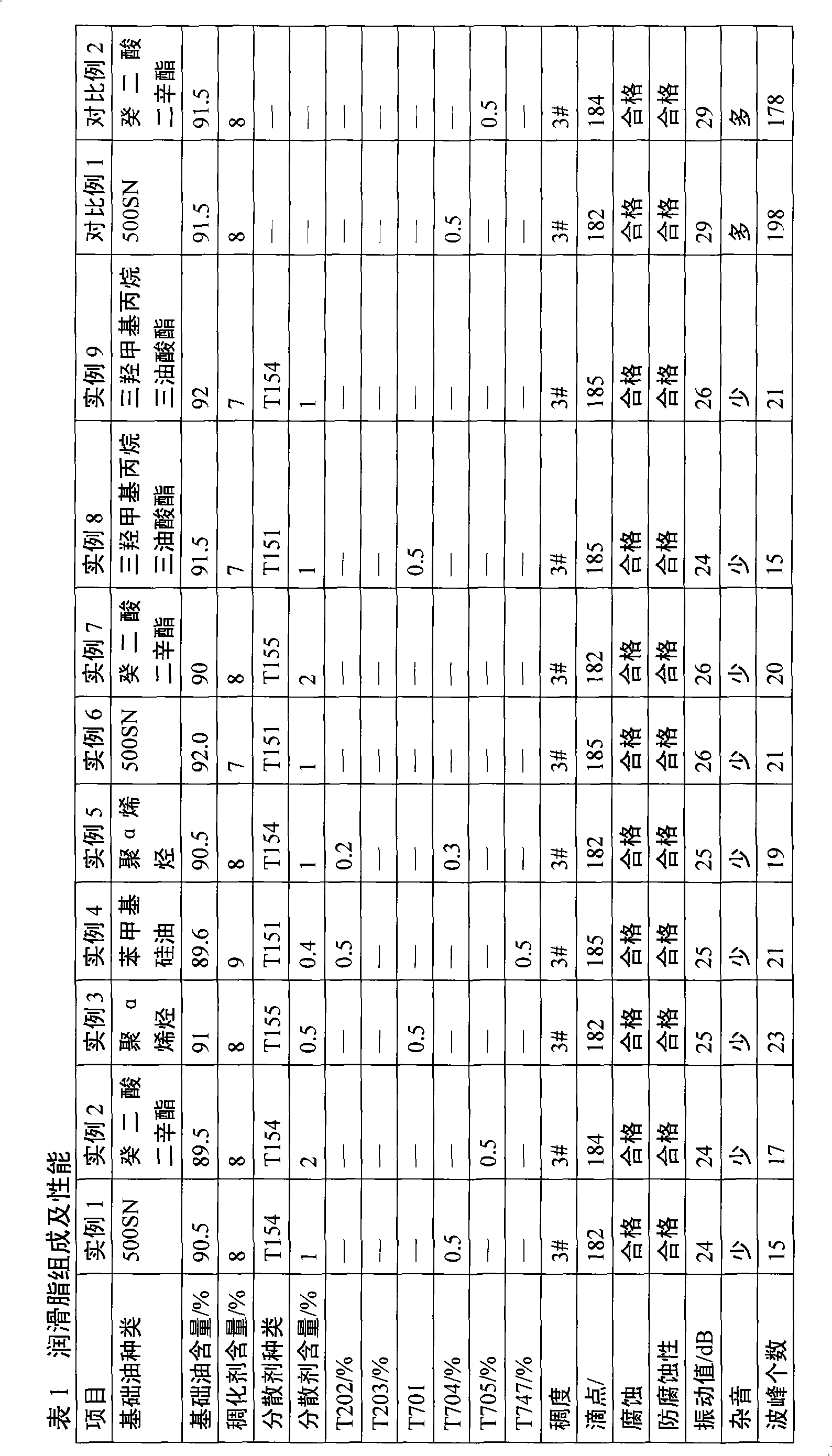

Low-noise lithium-based lubricating grease composition and preparation method thereof

The invention relates to a lithium-based lubricating grease composition. Based on the total weigh of lubricating grease, the lithium-based lubricating grease composition comprises the following components: (1) 75 to 94 percent of base oil; (2) 5 to 15 percent of lithium soap thickening agent; and (3) 0.1 to 4 percent of alkenyl diimide dispersing agent. The lubricating grease composition has excellent bearing vibrating performance, can be applied to medium and small-sized sealing bearings and is applicable to lubrication of motor bearings of official automated equipment and household appliances.

Owner:CHINA PETROLEUM & CHEM CORP +1

Lubricating grease composition

The invention provides a lubricating grease composition. The lubricating grease composition comprises a base oil, a thickening agent and an additive, wherein the thickening agent comprises a compound barium soap and a compound lithium soap; the additive comprises a sulfur-phosphorous additive and a thiodiazolyl compound; and based on the total weight of the lubricating grease composition, the content of the barium compound soap is 1.5 to 7.5 weight percent, the content of the lithium compound soap is 5 to 15 weight percent, the content of the sulfur-phosphorous additive is 0.1 to 5 weight percent, the content of the thiodiazolyl compound is 0.1 to 3 weight percent and the content of the base oil is 70 to 93.3 weight percent. Under a condition of low compound barium content, the lubricating grease composition of the invention has high oxidation stability, high temperature resistance and high extreme-pressure abrasion resistance, so the lubricating grease composite can be used as lubricating grease for high-speed bearings.

Owner:CHINA PETROLEUM & CHEM CORP +1

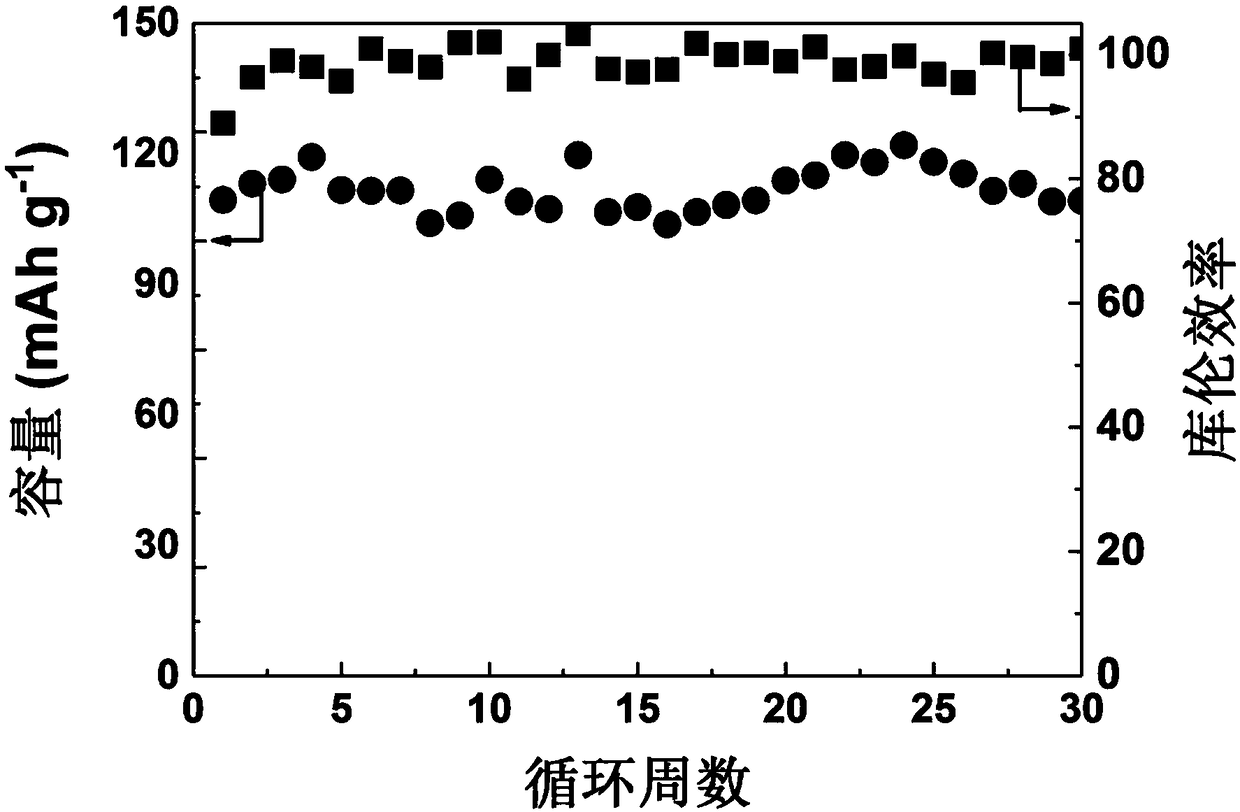

A lithium metal battery electrolyte and a lithium metal battery and a lithium sulfur battery

InactiveCN109216769AIncrease lithium ion contentImprove conductivityLi-accumulatorsOrganic electrolytesLithium soapLithium metal

In order to improve the cycle performance of the battery, A lithium metal battery electrolyte and a lithium metal battery and a lithium sulfur battery are disclose, A lithium metal battery electrolyteincluding solvents and lithium salts, the lithium salt comprises a lithium salt I, lithium salt II, lithium salt III, The mass percentages of each component in the electrolyte are: 40 to 85 percent of solvent, 10 to 50 percent of lithium salt I, 0.1 to 3 percent of lithium salt II, 0.1 to 10 percent of lithium salt III, wherein the solvent is an arbitrary combination of an organic heterocyclic compound containing an oxygen group element on a ring, the lithium salt I is lithium bis-trifluoromethanesulfonimide (LiTFSI), the lithium salt II is lithium nitrate (LiNO3), and the lithium salt III isone or a combination of one or several of a lithium salt containing boron and a lithium salt containing phosphorus; A lithium metal battery comprise a positive electrode, a lithium-containing negative electrode, a separator and that electrolyte; A lithium-sulfur battery comprise a sulfur-containing positive electrode, a lithium-containing negative electrode, a membrane and that electrolyte; The invention belongs to the field of lithium ion batteries and improves the cycling performance of lithium sulfur batteries.

Owner:ZHUHAI COSMX BATTERY CO LTD

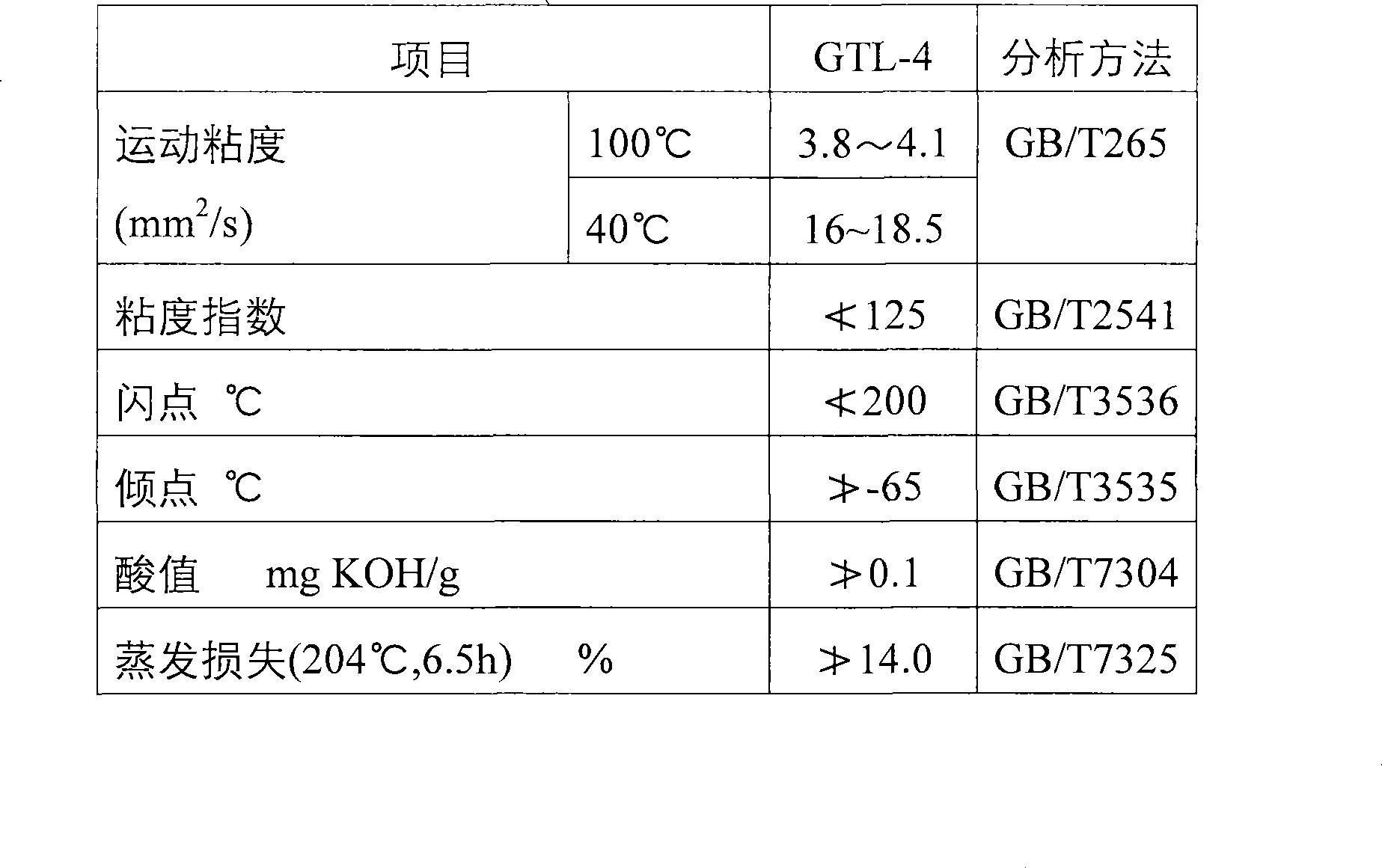

Consistent grease for meter, gear and driving screw of airplane

The invention relates to lubricating grease for aircraft instruments, gears and drive screws, which comprises the following compositions based on the total weight of the lubricating grease: (a) 3 to 20 weight percent of lithium soap thickening agent; (b) 0.1 to 5.0 weight percent of phosphate ester; (c) 0.01 to 3.0 weight percent of antioxidant; (d) 0.1 to 5.0 weight percent of composite antirust agent; and (e) the balance being GTL syntholube basic oil. The lubricating grease has superior high and low temperature performance, oxidation stability, low votatility, colloid stability, mechanical stability, extreme pressure antiwear property and compatibility with rubber seal, and is suitable for general lubrication of the aircraft instruments, the gears and the drive screws at a temperature of between 73 DEG C below zero and 120 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP +1

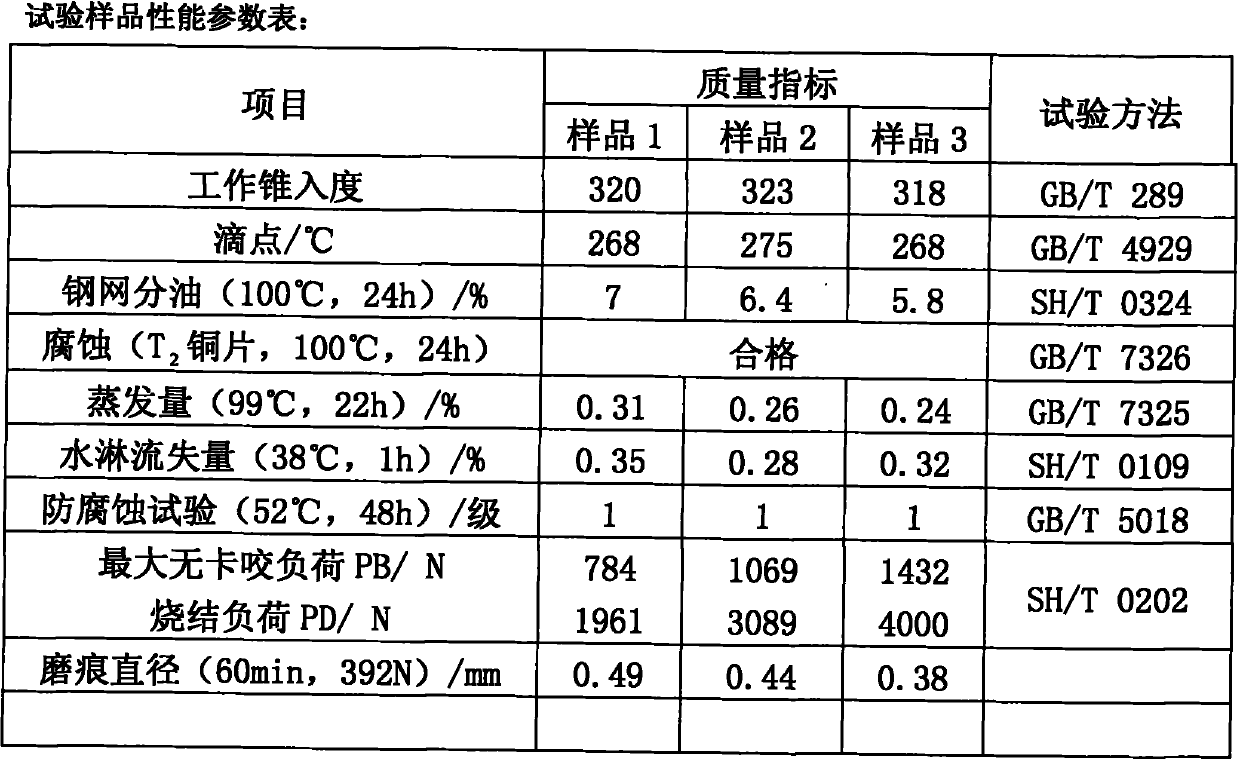

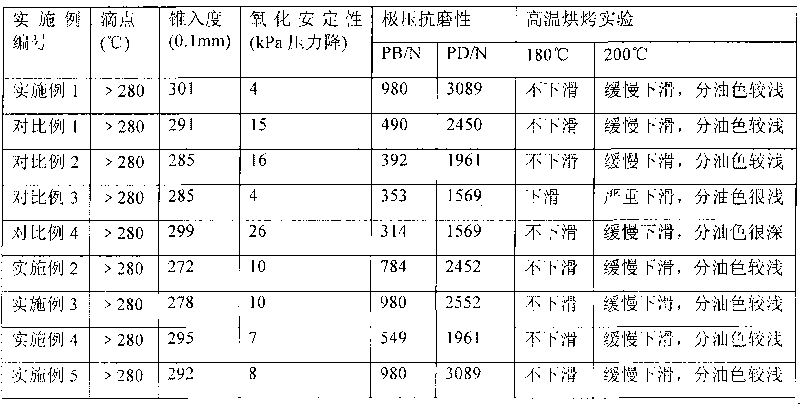

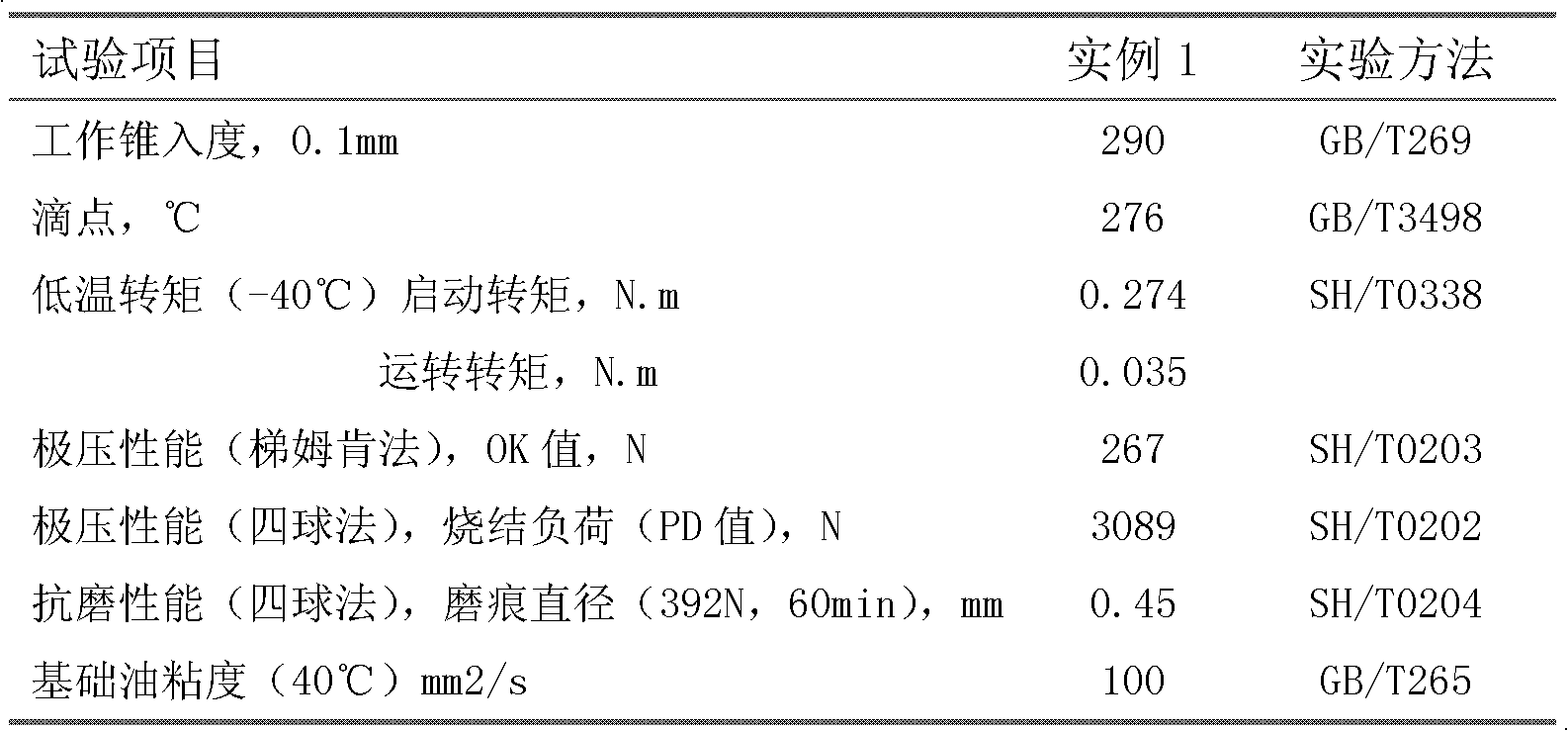

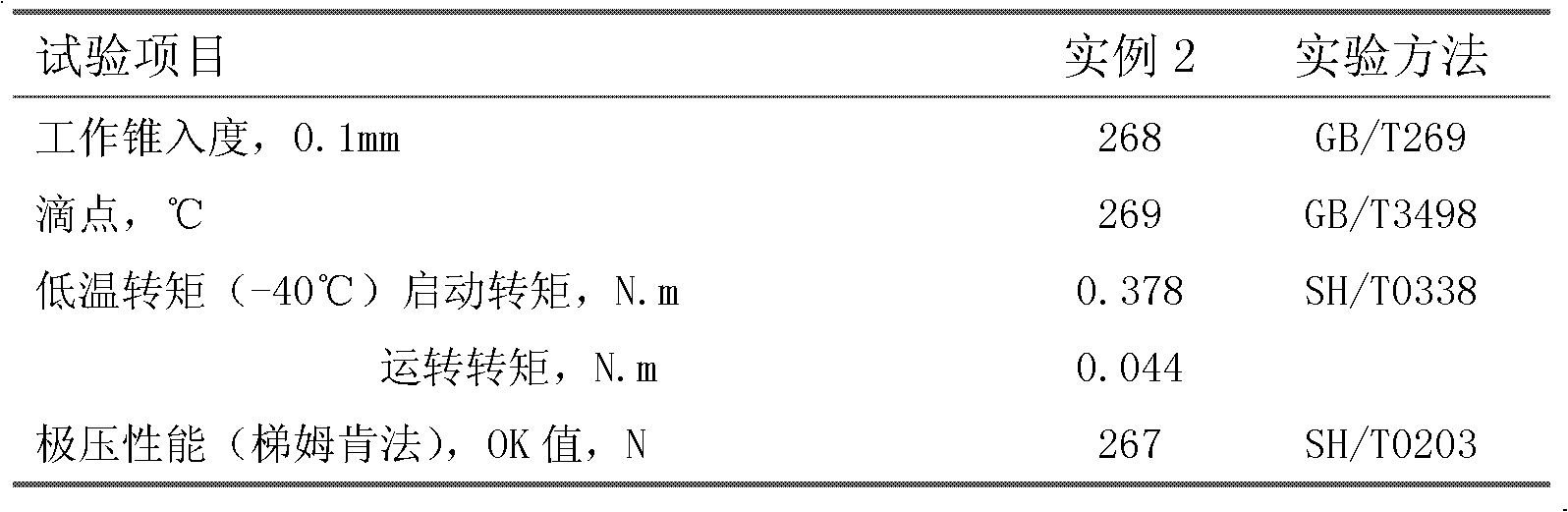

Wide temperature range and high extreme pressure composite lithium lubricating grease composition

ActiveCN102250671AGood high and low temperature performanceGood extreme pressure and anti-wear propertiesAdditivesLithium soapAntioxidant

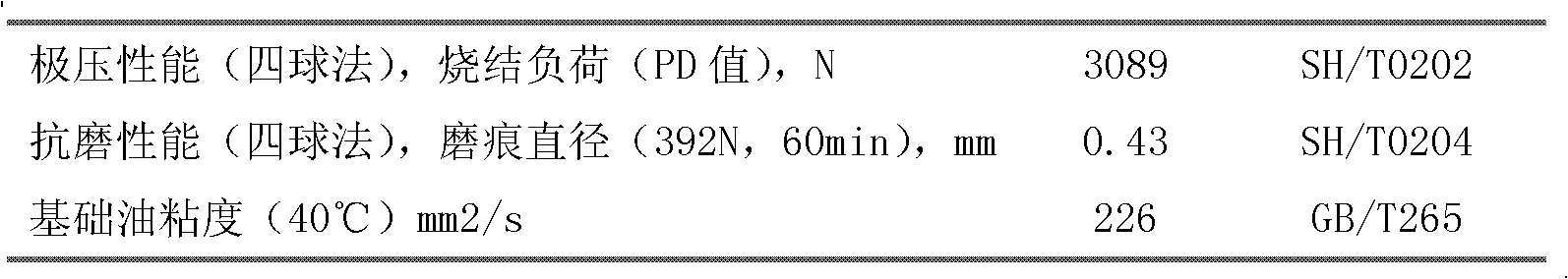

The invention relates to a wide temperature range and high extreme pressure composite lithium lubricating grease composition. The composite lithium-based lubricating grease composition provided by the invention is prepared from poly-alpha-olefin synthetic oil and ester oil as base oils and two-component composite lithium soap as a thickening agent, and an antioxidant, an anticorrosion and antirust agent and an extreme-pressure anti-wear additive are added. Due to the appropriate proportion of raw materials, the lubricating grease has excellent high and low temperature performance, the dropping point is greater than 260 DEG C, and the low-temperature (-40 DEG C) torque is not higher than 0.98 N.m during starting and is not higher than 0.50 N.m during running; the lubricating grease also has excellent extreme-pressure anti-wear properties, the sintering capacity is not lower than 3089 N, the Timken 0K value is up to 267 N, and the anti-wear performance (tested by a four-ball machine method) is not greater than 0.60 mm. Therefore, the lubricating grease provided by the invention can be used for lubricating high-load equipment within a wide temperature range.

Owner:CHINA PETROLEUM & CHEM CORP

Composite solid electrolyte and preparation method thereof

ActiveCN108281702ALow costLow toxicitySolid electrolytesLi-accumulatorsLithium soapSolid state electrolyte

The invention relates to composite solid electrolyte and a preparation method thereof. The composite solid electrolyte is prepared from the following components: inorganic solid electrolyte, polyphosphazene electrolyte, inorganic small molecules and lithium salt. The preparation method comprises the following steps: (1) dissolving the inorganic solid electrolyte, the polyphosphazene electrolyte, the inorganic small molecules and the lithium salt in an organic solvent according to a ratio, and pouring into a polytetrafluoroethylene mold, thus obtaining a uniform mixture; and (2) removing the solvent in the mixture in step (1) in a volatilization manner at the room temperature, drying, or directly removing the solvent in the mixture in the step (1) in a drying manner, thus obtaining the composite solid electrolyte. Compared with the prior art, the composite solid electrolyte prepared by the method is good in mechanical performance, high in electric conductivity, excellent in film formingperformance, capable of solving the problems that the existing solid electrolyte is poor in mechanical performance and low in electric conductivity, and has good application prospect.

Owner:SHANDONG UNIV

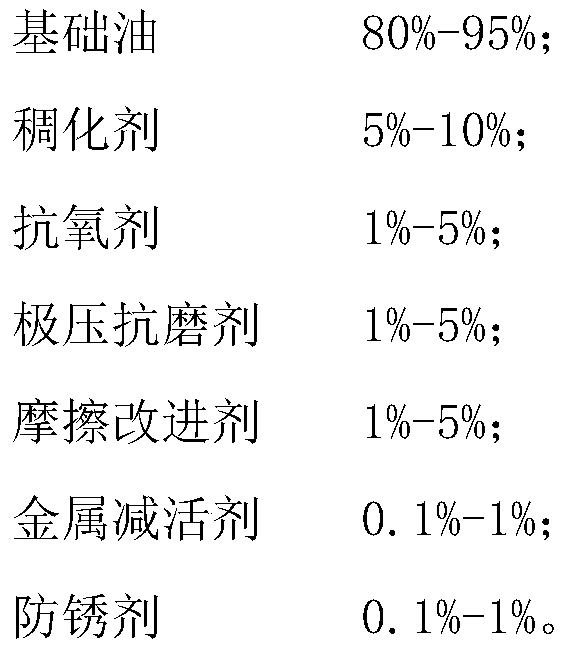

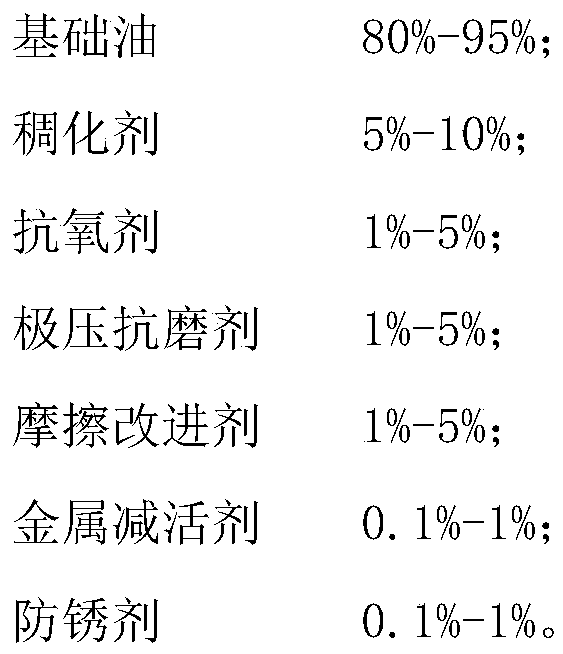

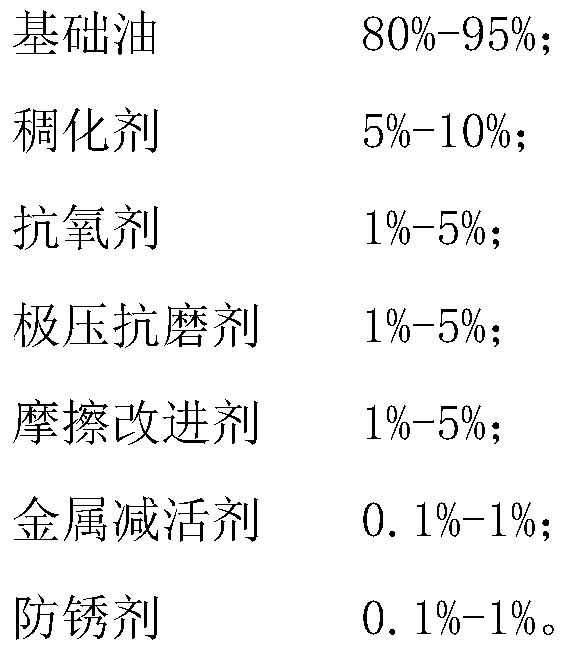

Long-life industrial robot RV reducer lubricating grease and preparation method thereof

InactiveCN109810768AIncrease frictionImprove Oxidation StabilityLubricant compositionLithium soapLithium hydroxide

The invention provides long-life industrial robot RV reducer lubricating grease and a preparation method thereof. According to the long-life industrial robot RV reducer lubricating grease, synthetic oil is used as base oil, fatty acid lithium soap is used as a thickening agent, an antioxidant, an anti-wear reagent at extreme pressure, a friction modifier, a metal deactivating agent and an antirusting agent are added and the long-life industrial robot RV reducer lubricating grease is prepared through modulation by a special technology, and the thickening agent is a thickening agent generated from the reaction of fatty acid and lithium hydroxide; and the antirusting agent is one type or multiple types of sulfonate, hydroxyl and salts of the hydroxyl, organic amine, esters, organic phosphoricacid and salts of the organic phosphoric acid and a heterocyclic compound. The long-life industrial robot RV reducer lubricating grease has excellent mechanical stability and oxidation stability, excellent abrasion resistance, low-temperature resistance and protection performance. Lubricating requirements of an industrial robot RV reducer are met. According to the preparation method of the long-life industrial robot RV reducer lubricating grease, a certain amount of antioxidant addition agents are added before high-temperature refining to effectively prevent high-temperature oxidation, and the service life of the lubricating grease is prolonged; and petroleum calcium sulfonate is added, and the tribology performance is effectively improved.

Owner:辽宁海华科技股份有限公司

Preparation method of lithium ion battery cathode material NCA with high specific energy

The invention discloses a preparation method of a lithium ion battery cathode material NCA with high specific energy. The method comprises the following steps: (1) nickel salt, cobalt salt and aluminium salt are mixed, a NaOH solution is added, ternary system hydroxide deposition is produced by a controlled crystallization method, filtering and washing are carried out, and drying is carried out; (2) in an atmosphere oven, air or oxygen is pumped in, calcination is carried out, and ternary composite oxide is obtained; (3) the oxide and the lithium salt are mixed, a reactant is sintered in two stages in air flow or oxygen flow, and the reactant is cooled in furnace; (4) an oxalic acid solution is used for cleaning, centrifugal drying as well as drying and sintering are carried out in order to obtain a composite oxide, crushing and grading are carried out, the oxide is sieved by a 300 mesh sieve, and the ternary system composite oxide LixNi1-y-zCoyAlzO2 is obtained, wherein x is more than or equal to 1 and less than or equal to 1.15, y is more than or equal to 0.05 and less than or equal to 0.15, and z is more than or equal to 0 and less than or equal to 0.05. The preparation method has a low requirement for synthesis devices, the operation is simple, and the sintering process does not have special requirements. The synthesized material has a stable structure and is environmentally friendly.

Owner:HENAN KELONG NEW ENERGY CO LTD

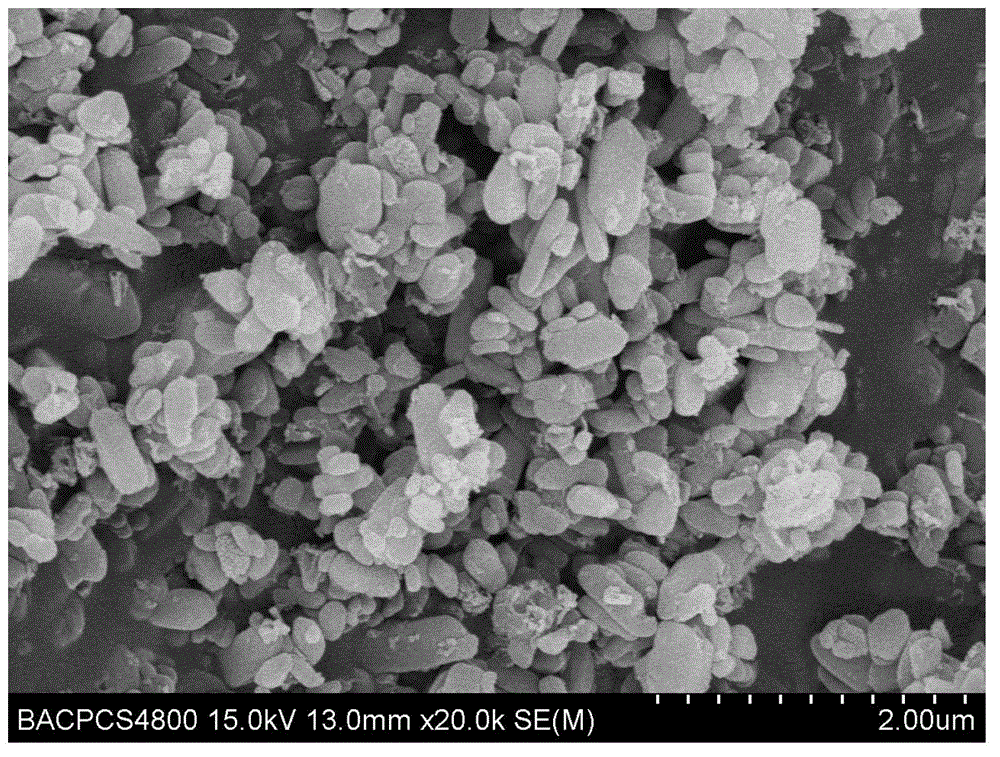

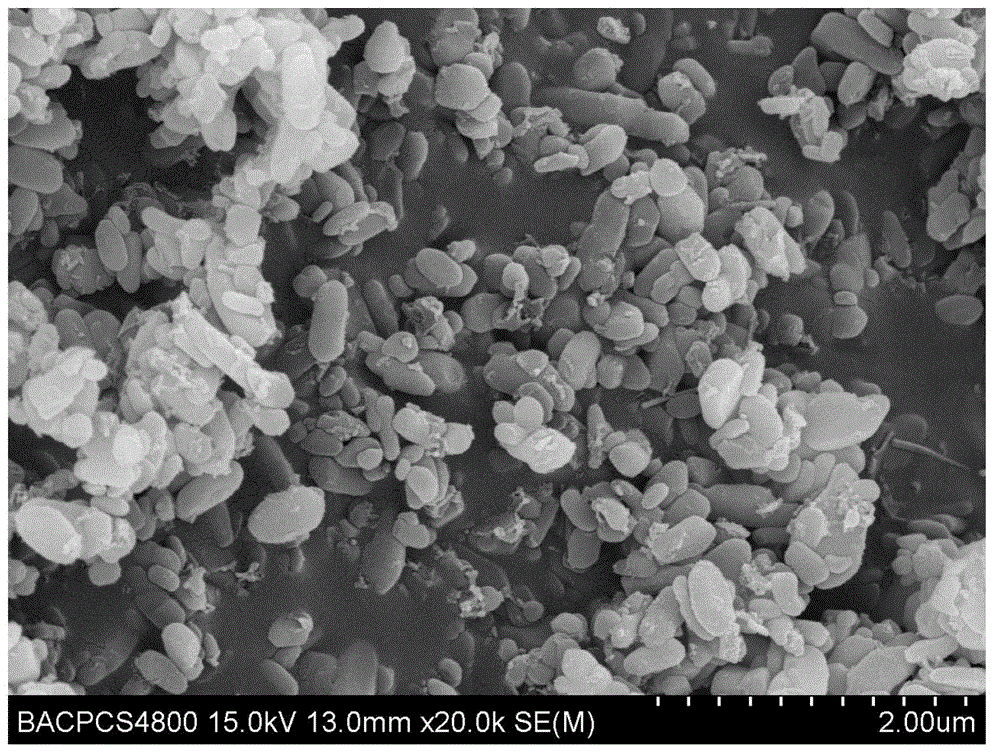

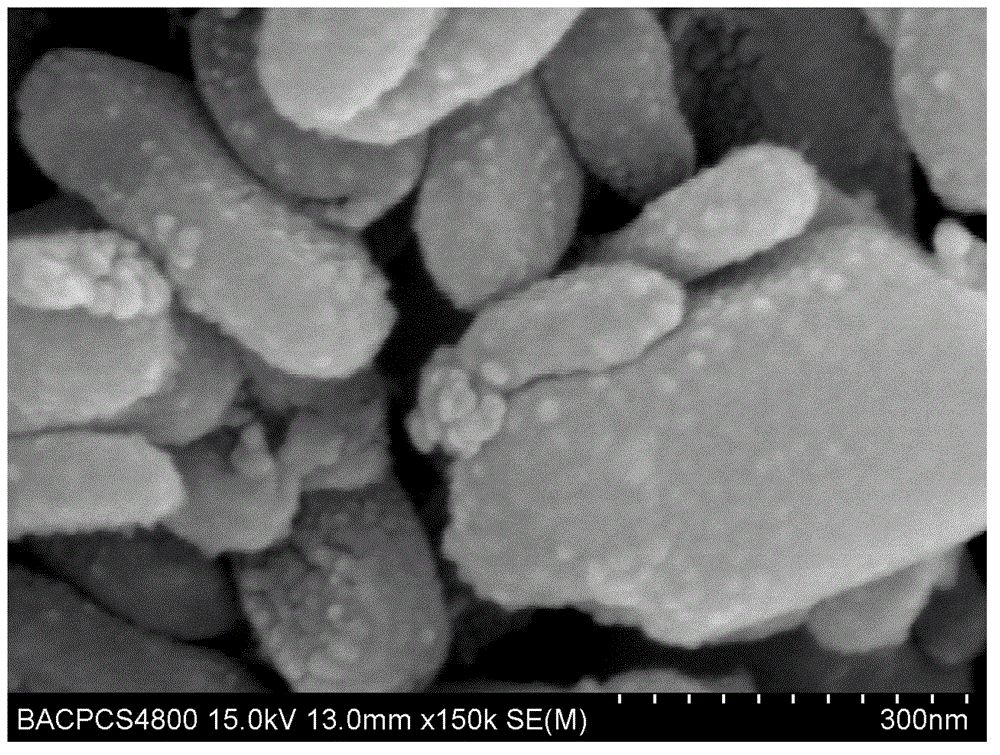

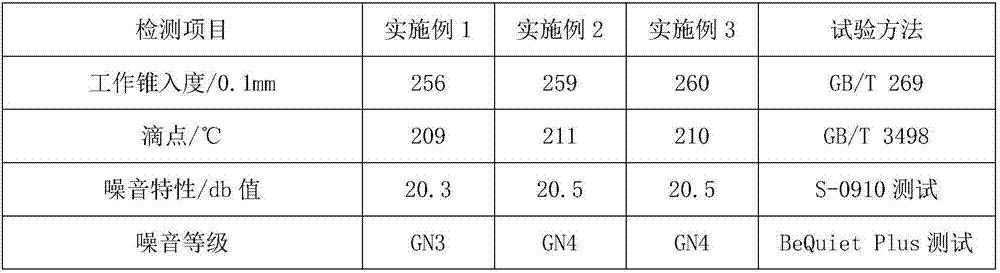

Low-noise bearing lubricating grease and preparation method thereof

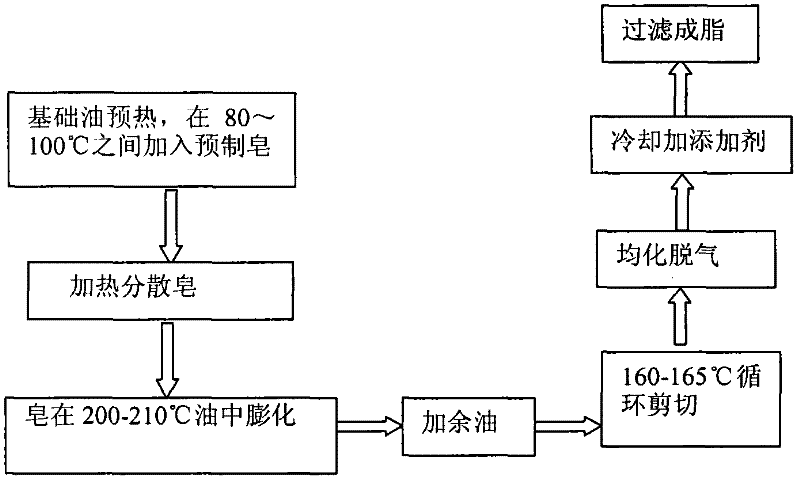

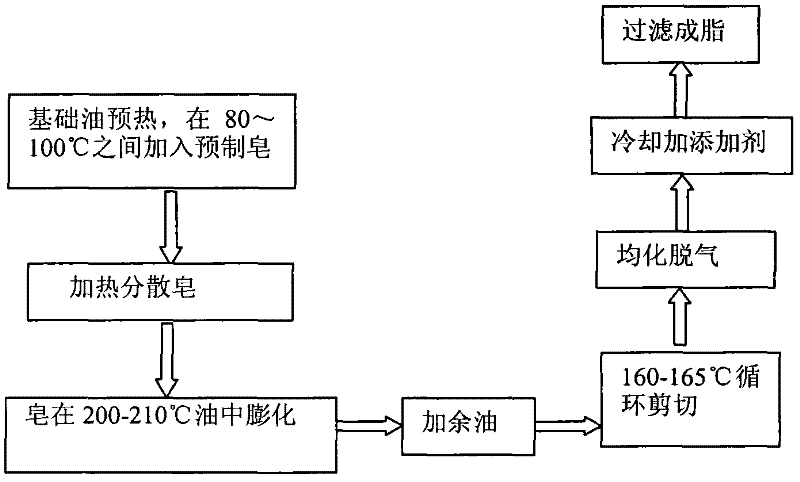

The invention discloses low-noise bearing lubricating grease and a preparation method thereof. The preparation method comprises the following steps of: performing saponification reaction of hydroxyl fatty acid having 12 to 24 carbon atoms and lithium hydroxide in a ratio, dehydrating and drying the generated fatty acid lithium, and grinding into pre-prepared soap powder; preheating base oil which is formed by mixing naphthenic mineral oil and ester synthetic oil and accounts for 2 / 3 of the total quantity, adding pre-prepared lithium soap when the temperature is between 80 and 100 DEG C, heating for dispersing, heating to the temperature of between 200 and 210 DEG C, and bulking at the constant temperature for 20 to 30 minutes; adding the residual 1 / 3 base oil, cooling naturally to the temperature of between 160 and 165 DEG C, shearing circularly at the constant temperature for 30 minutes, cooling to the temperature of between 120 and 130 DEG C, and adding an additive; and homogenizing, degassing, filtering accurately, and packaging to obtain the lubricating grease. According to the low-noise bearing lubricating grease, the conventional method for saponifying directly to form the pre-prepared soap is changed, namely a fiber structure of the lubricating grease is controlled by circular temperature-control shearing, so that the noise reduction performance of the lubricating grease in bearings reaches the international advanced level on the premise of keeping the current performance.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

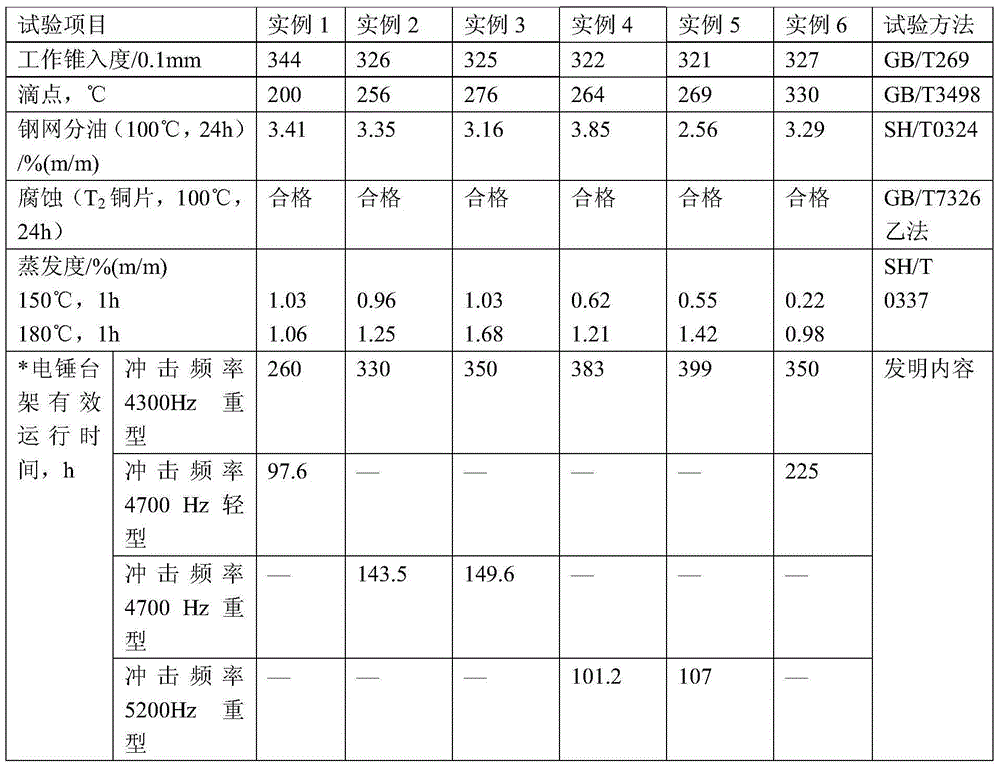

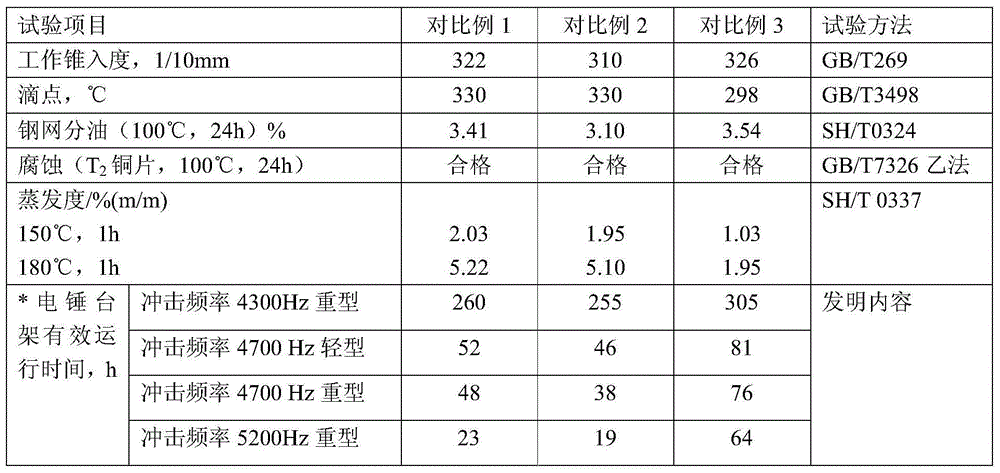

A lubricating grease composition used for cylinders of electric tools and a preparing method thereof

ActiveCN105586121ALow evaporation loss performanceImprove extreme pressure and anti-wear performanceAdditivesBase-materialsLithium soapAntioxidant

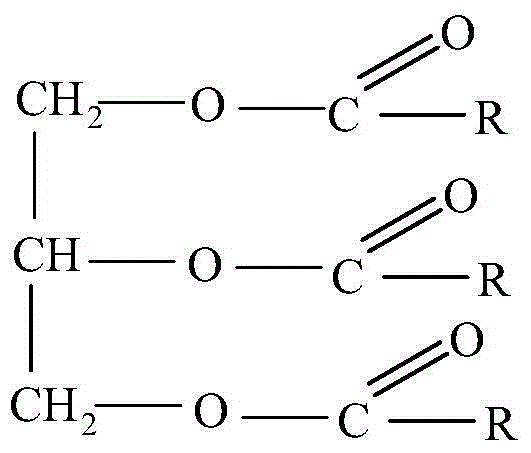

A lubricating grease composition used for cylinders of electric tools is provided. The composition comprises base oil, a thickening agent and functional additives, wherein the base oil is one of or a mixture of at least two substances selected from HVI hydrogenated base oil, metallocene PAO, trimethylolpropane trioleate, alkyl silicone oil or methylphenyl silicone oil, the thickening agent is one of or a mixture of at least two substances selected from lithium soap, composite aluminum soap or polyurea, the functional additives are an extreme pressure antiwear agent, an antioxidant or a rubber compatibility modifier or a mixture thereof, the extreme pressure antiwear agent comprises an organic molybdenum salt and a heavy-load diesel engine oil complexing agent, and the rubber compatibility modifier is dimethyl silicone oil or / and alkyl silicone oil. The lubricating grease prepared with the composition is excellent in impact load resistance, free of loss at high temperature, long in service lifetime and low in high-temperature evaporation loss and can be widely used for cylinders of various electric hammers and electric picks.

Owner:杭州得润宝油脂股份有限公司

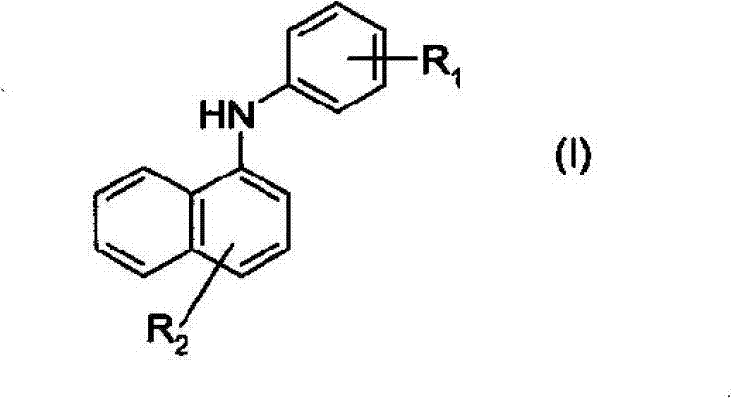

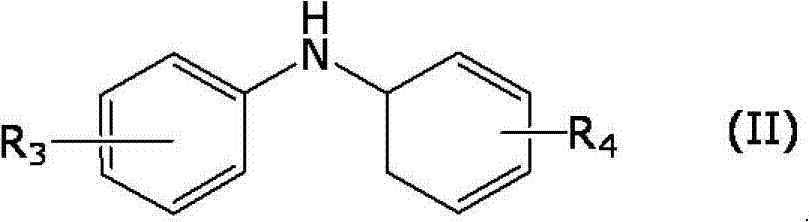

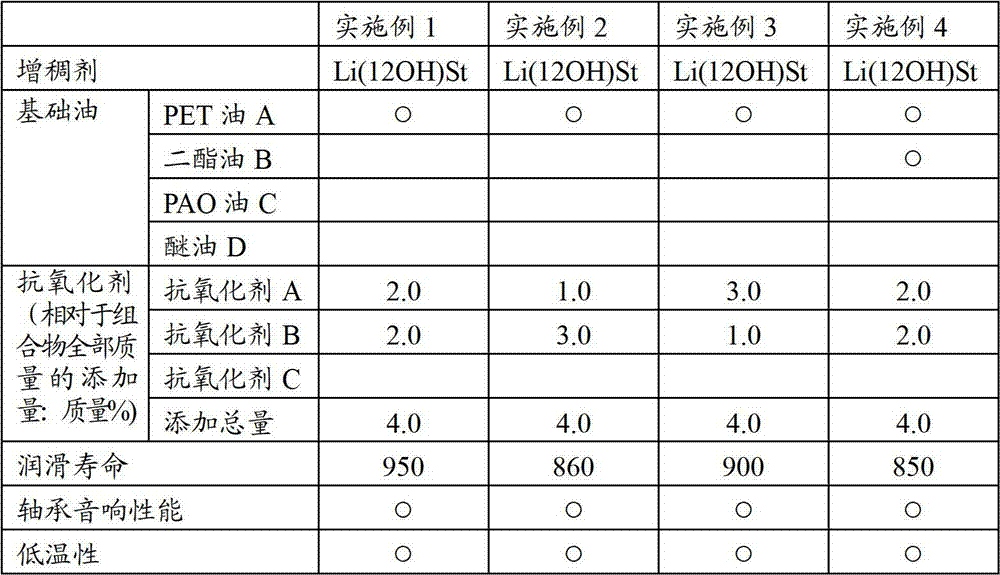

Lubricating grease composition

ActiveCN102994196AImprove performanceSolution to short lifeLubricant compositionLithium soapPentaerythritol

The invention provides a lubricating grease composition used in rolling bearings, which is wider in temperature application range, excellent in bearing sound performance and long in service life. The lubricating grease composition is characterized in that synthetic oil containing pentaerythritol ester oil is adopted as the base oil of the lubricating grease composition and lithium soap is adopted as the thickener of the lubricating grease composition. Meanwhile, the composition also comprises the following two antioxidants in the mass ratio thereof to be 1:3-3:1, namely (a) 1-naphthyl amine antioxidant and (b) diphenylamine antioxidant.

Owner:KYODO YUSHI CO LTD

Lubricating grease composition for water pump bearing of automobile and preparation method thereof

InactiveCN104450117ADrop point highGood mechanical stabilityLubricant compositionOrganic sulfide compoundLithium soap

The invention provides a lubricating grease composition for a water pump bearing of an automobile and a preparation method thereof. The lubricating grease composition is prepared from the following components in percentage by weight: (1) 5-18% of a thickening agent which is compound lithium soap; (2) 75-90% of base oil; and (3) 2-7% of an additive which comprises (a) 1-2.5% of an amine antioxidant; (b) 1-3% of an organic sulfide and / or organic phosphide antiwear agent; and (c) 0.5-2% of a triazole and / or tetrahydroglyoxaline antirust agent. The lubricating grease produced by the composition has a relatively high dropping point and good mechanical stability, thereby facilitating use of the lubricating grease under a high-temperature environment while ensuring non-drainage so as to play a good sealing effect. The composition has good wear-resisting and carrying capacities. Through an experiment on a four-ball method wear tester, the maximum non-seizure load PB and the sintering load PD are relatively high, and wear of the lubricated part can be effectively reduced. Meanwhile, the service life of the bearing is long-acting. The composition is suitable for being used on the water pump bearing of the automobile.

Owner:CHINA PETROLEUM & CHEM CORP

Lubricating grease for changing anti-rust effect

InactiveCN102453593AHigh kinematic viscosityImprove rust resistanceLubricant compositionLithium soapMetallurgy

The invention relates to lubricating grease for changing the anti-rust effect. The lubricating grease comprises lithium soap thickening agents, base oil, antioxidants, anti-rust agents and viscosifiers and solves the problems that steel and iron are easy to rust under special conditions, and thus equipment can not be used and the resources are wasted. The lubricating grease has the beneficial effect the anti-rust effect of the lubricating grease is improved through improving the kinematic viscosity of the base oil and adding the proper antioxidants, anti-rust agents and viscosifiers to the lubricating grease. Through the damp heat test and the salt spray test in the lubricating analysis evaluation, the anti-rust effect in the evaluation results is greatly improved through being compared with the anti-rust effect of the ordinary lubricating grease. After the actual use, the equipment can still maintain a good state under the influence of external oxygen, water and acid media.

Owner:WUXI FEITIAN GREASE

Method for preparing ferrous phosphate-based lithium salt

The invention relates to a method for preparing a lithium iron phosphate material through a solvothermal method, in particular to a method for preparing a ferrous phosphate-based lithium salt. The method is characterized by comprising the following steps of: (1) preparing primary nano-grade lithium iron phosphate particles; (2) atomizing to form secondary particles; and (3) sintering lithium iron phosphate: sintering the obtained secondary lithium iron phosphate particles, baking in a nitrogen atmosphere or a mixed atmosphere of nitrogen and hydrogen in the volume ratio of (1-5):(95-99) at the high temperature of 400-800 DEG C for 6-25 hours, and cooling. The method for preparing the ferrous phosphate-based lithium salt provided by the invention has the advantages of rich raw material source, low price, simple and practicable synthesizing process, safety, reliability, low production cost, high yield and freeness from environmental pollution; and a product has high electrochemical performance. A high-boiling-point solvent is adopted partially instead of water, so that preparation of nano-grade lithium iron phosphate through a normal-pressure low-temperature hydrothermal method is realized.

Owner:IRICO

Grease copositions

InactiveUS20150315509A1Drop point highAppropriate consistencyGroup 3/13 element organic compoundsThickenersLithium soapCarboxylic acid

A grease composition comprising base oil and as thickener calcium complex soap and lithium soap is disclosed. A higher fatty acid, an aromatic monocarboxylic acid and a lower fatty acid are used as carboxylic acids constituting the calcium complex soap and lithium soap. The grease composition has a high dropping point and excellent shear stability, and exhibits thermal stability and long bearing life.

Owner:SHELL OIL CO

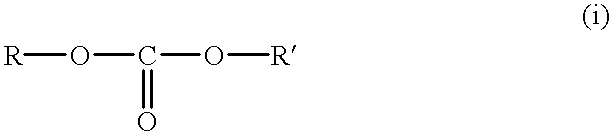

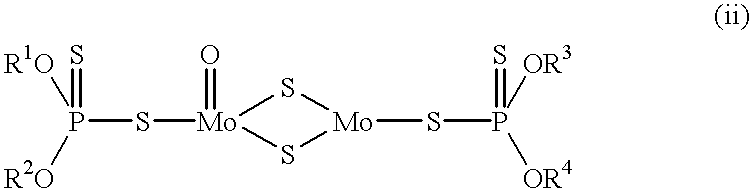

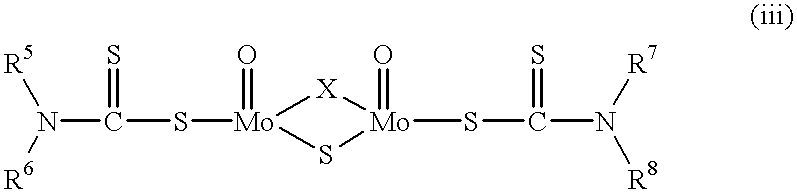

Rolling device for information apparatus

A rolling device is made up of a plurality of rolling bodies provided between an outer member having a first contact face with each of the plurality of rolling bodies and an inner member having a second contact face with each of the plurality of rolling bodies wherein the plurality of rolling bodies individually are able to roll relative to the first and second faces. A grease composition is sealedly filled in between the outer member and the inner member and contains a carbonate compound serving as a base oil, a lithium soap serving as a thickener, and at least one organomolybdenum compound selected from the group consisting of a molybdenum dithiophosphate and a molybdenum dithiocarbamate.

Owner:MINEBEA CO LTD

Low-noise lubricating grease and preparing method thereof

The invention relates to low-noise lubricating grease and a preparing method thereof. The low-noise lubricating grease is prepared from, by weight, 25-50 parts of lithium base lubricating grease, 50-75 parts of polyurea lubricating grease, 6-10 parts of second dispersant and 0.3-1.0 part of antioxidant; the preparing method comprises the steps of preparation of the polyurea lubricating grease, preparation of the lithium base lubricating grease and mixing. According to the low-noise lubricating grease, a mixture of the lithium soap lubricating grease and the polyurea lubricating grease is used as a raw material, then the second dispersant and the antioxidant are added into the mixture, and the high-temperature mixing technology is adopted to prepare the low-noise lubricating grease with even components; the low-noise lubricating grease has great low-noise performance and can effectively cover up abnormal noise generated by vibration of bearings, and a stable bearing vibration value can be obtained within 1-2 seconds; meanwhile the low-noise lubricating grease has good mechanical stable performance and long lubricating life, and the maximum service temperature can reach 150 DEG C.

Owner:辽宁海华科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com