Low-noise lubricating grease and preparing method thereof

A grease and low-noise technology, applied in the field of low-noise grease and its preparation, can solve the problem of long time for stable vibration value of grease, uneven dispersion of different thickener components, and poor mechanical stability of grease, etc. problem, to achieve the effect of fast reaction rate, improved anti-oxidation performance, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

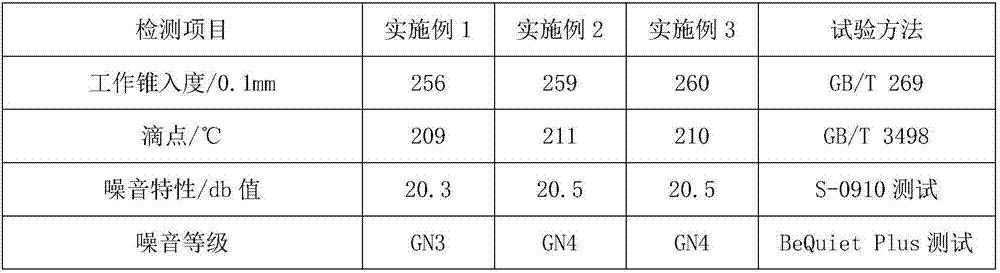

Examples

preparation example Construction

[0070] A preparation method of low-noise lubricating grease, comprising three steps of preparing polyurea lubricating grease, preparing lithium-based lubricating grease, and mixing; the specific steps are as follows:

[0071] 1) Preparation of polyurea grease:

[0072] Mix the base oil well, half of the mixed base oil is used to dissolve isocyanate, and the other half is used to dissolve organic amine; after all the base oil is dissolved, remove impurities through high-precision filtration, and slowly introduce it into the saponification kettle for polymerization reaction; before the reaction, add Anti-rust agent; react at 80-100°C for 1-1.5 hours; spare;

[0073] 2) Preparation of lithium-based grease;

[0074] Mix the base oil well, 2 / 3 of the mixed base oil is used to dissolve the polymer acid, and the dissolved solution is filtered through high-precision filtration to remove insoluble matter; heat, add lithium hydroxide when the temperature reaches 80-85°C, and directly h...

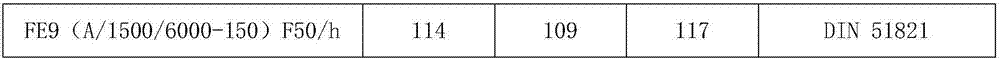

Embodiment 1

[0082] A low-noise lubricating grease described in this embodiment is composed of the following components: lithium-based grease: 300kg; polyurea grease: 620kg; polyol ester: 60kg; pentaerythritol succinate: 15kg; Thiocarbamate: 5kg;

[0083] in:

[0084] The composition of lithium-based grease is as follows: paraffin base oil: 91.77kg; polyalphaolefin (PAO): 170.43kg; lauryl hydroxystearic acid: 33kg; lithium hydroxide oily suspension: 4.8kg;

[0085] The composition of polyurea grease is: paraffin base oil: 202.93kg; polyalphaolefin (PAO): 376.87kg; 4.4`-diphenylmethane diisocyanate: 17.4kg; octadecylamine: 9.4kg; cyclohexylamine: 10.3kg; Sorbitan monooleate: 3.1kg;

[0086] In the present embodiment, the preparation method of a kind of low-noise lubricating grease is as follows:

[0087] (1) Preparation of polyurea grease: mix paraffin base oil and polyalphaolefin to make base oil, use 1 / 2 base oil to dissolve 4.4`-diphenylmethane diisocyanate, and the remaining 1 / 2 base...

Embodiment 2

[0091] A low-noise grease described in this embodiment is composed of the following components: lithium-based grease: 400kg; polyurea grease: 550kg; pentaerythritol: 45kg; 2.6-di-tert-butyl mixed phenol: 5kg;

[0092] in:

[0093] The components of lithium-based grease are: paraffin base oil: 177kg; polyalphaolefin (PAO): 177kg; lauryl hydroxystearic acid: 40kg; lithium hydroxide oily suspension: 6kg;

[0094] The components of polyurea grease are: paraffin base oil: 253kg; polyalphaolefin (PAO): 253kg; 4.4`-diphenylmethane diisocyanate: 18.04kg; octadecylamine: 9.74kg; cyclohexylamine: 10.72kg ; Benzotriazole: 5.5kg;

[0095] A kind of low-noise lubricating grease preparation method described in the present embodiment is as follows:

[0096] (1) Preparation of polyurea grease: mix paraffin base oil and polyalphaolefin to make base oil, of which 1 / 2 base oil is used to dissolve 4.4`-diphenylmethane diisocyanate, and the remaining 1 / 2 base oil Used to dissolve octadecylamine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com