Patents

Literature

728results about How to "Simple filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

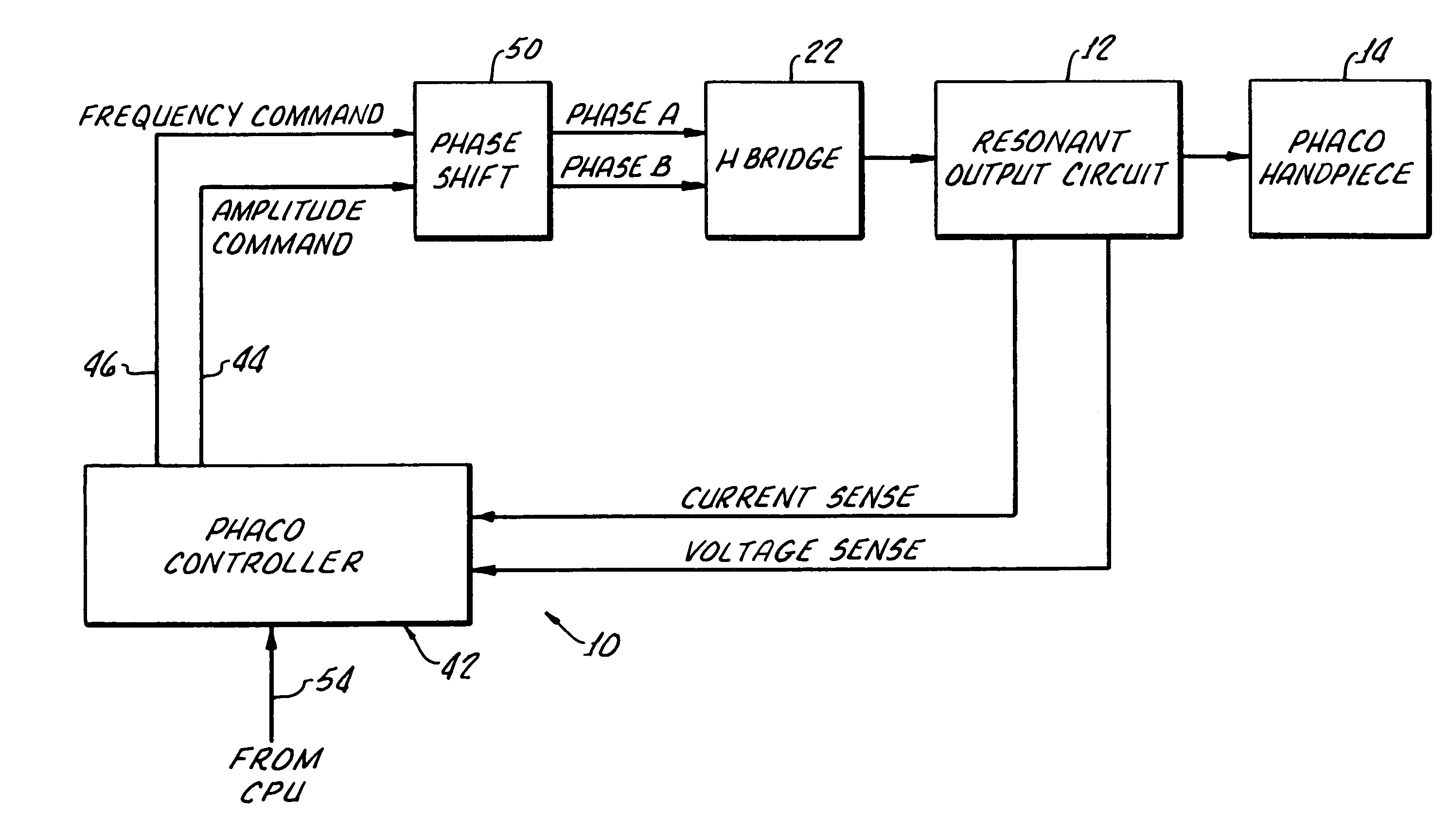

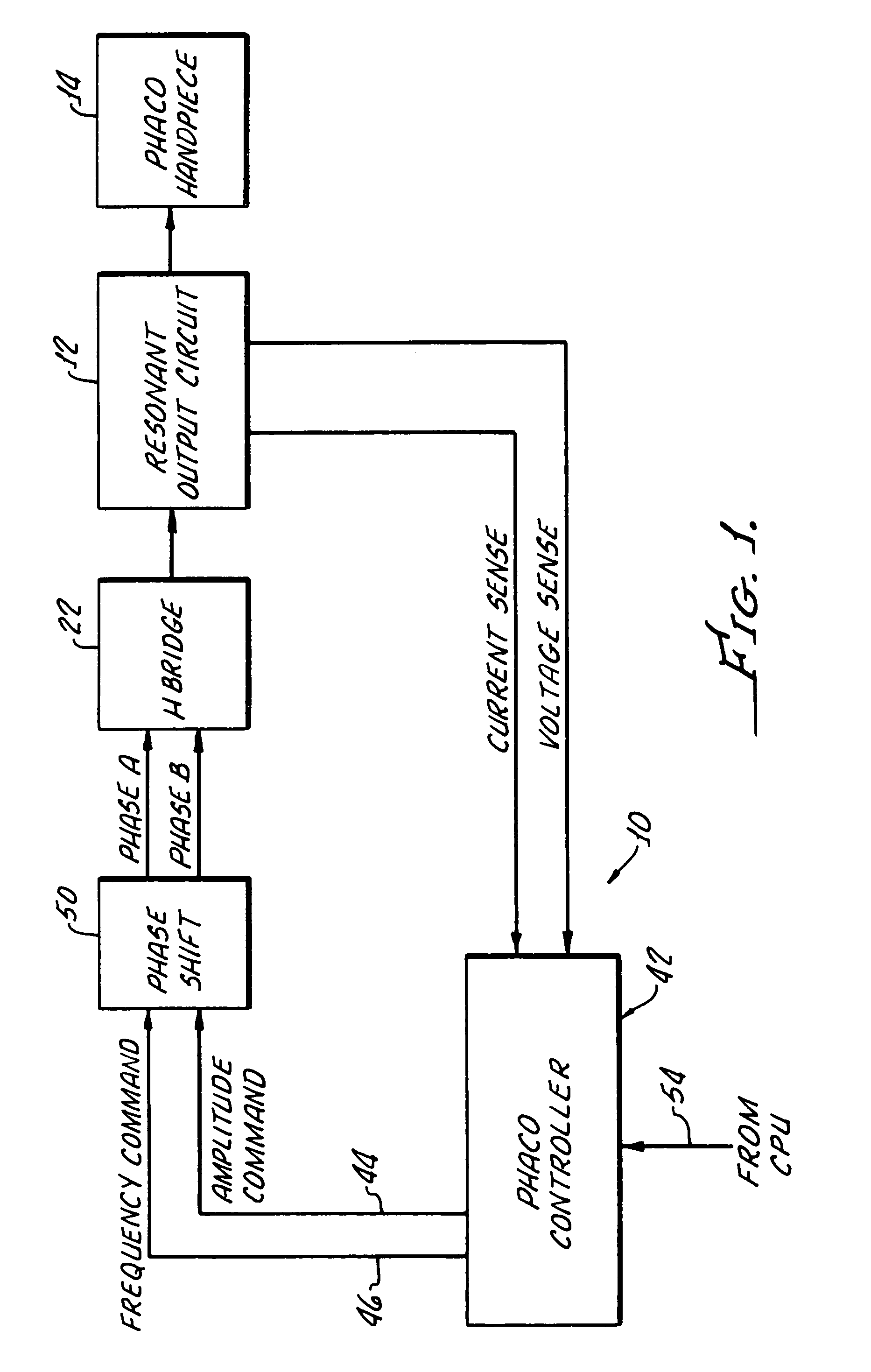

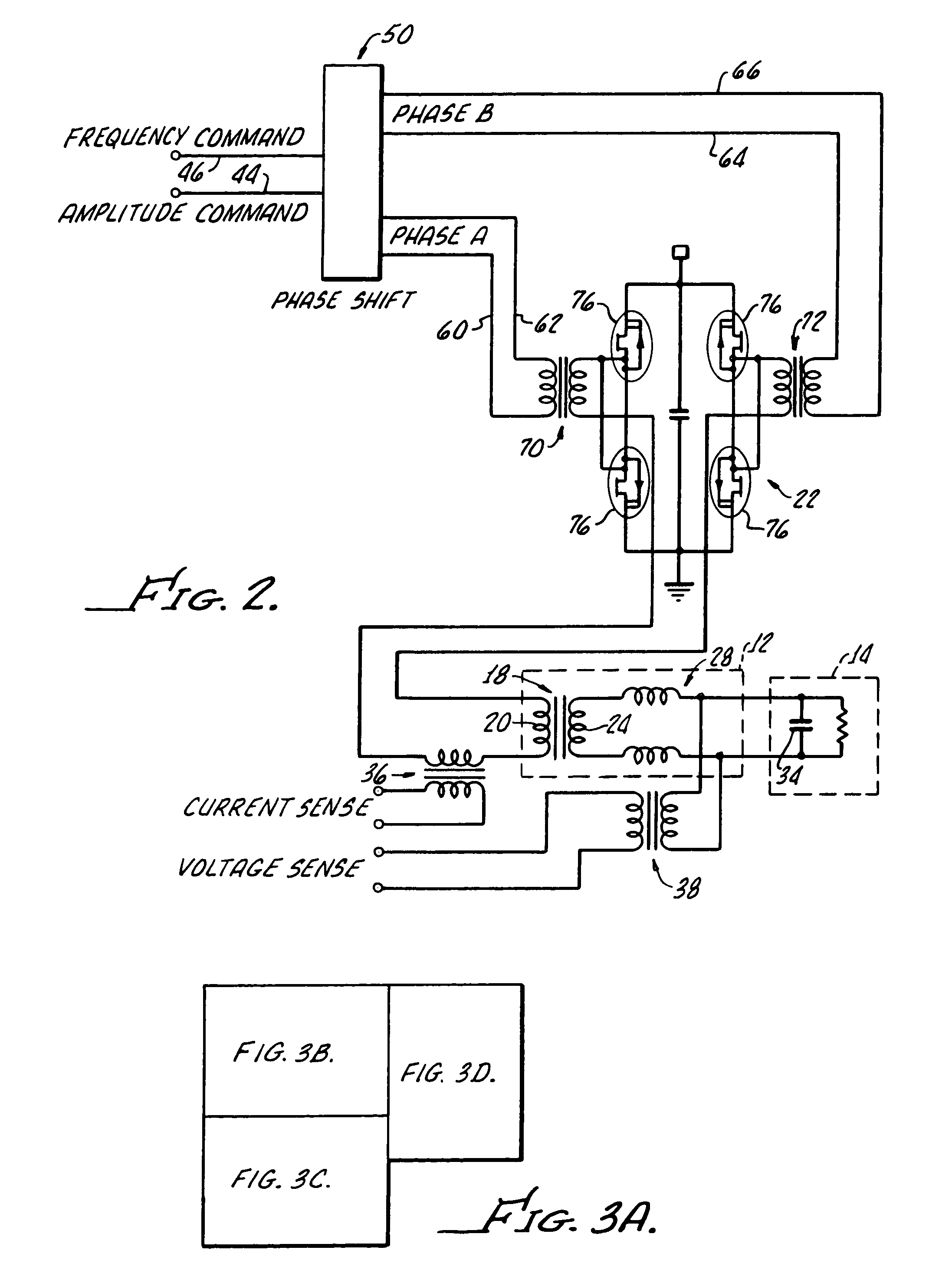

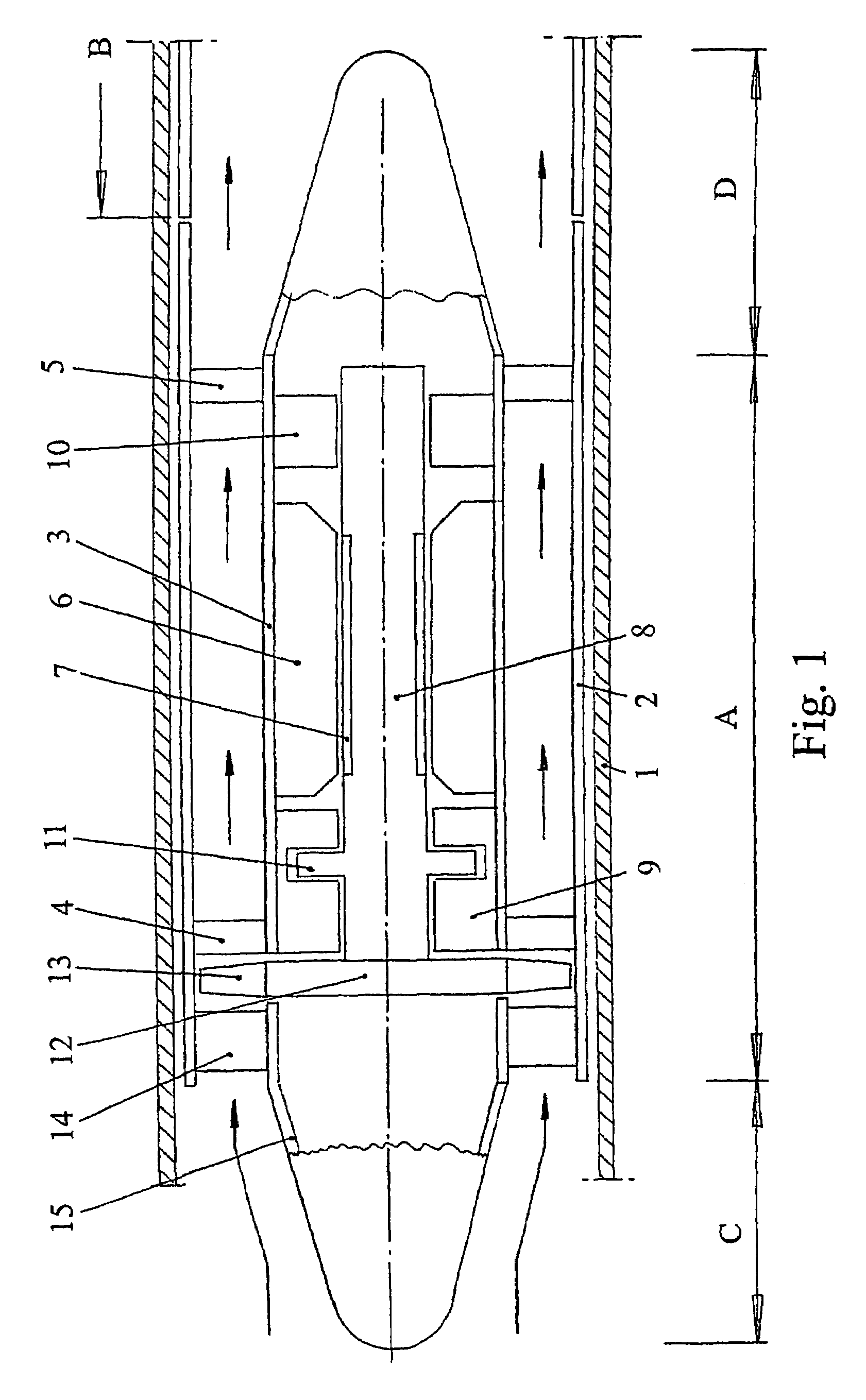

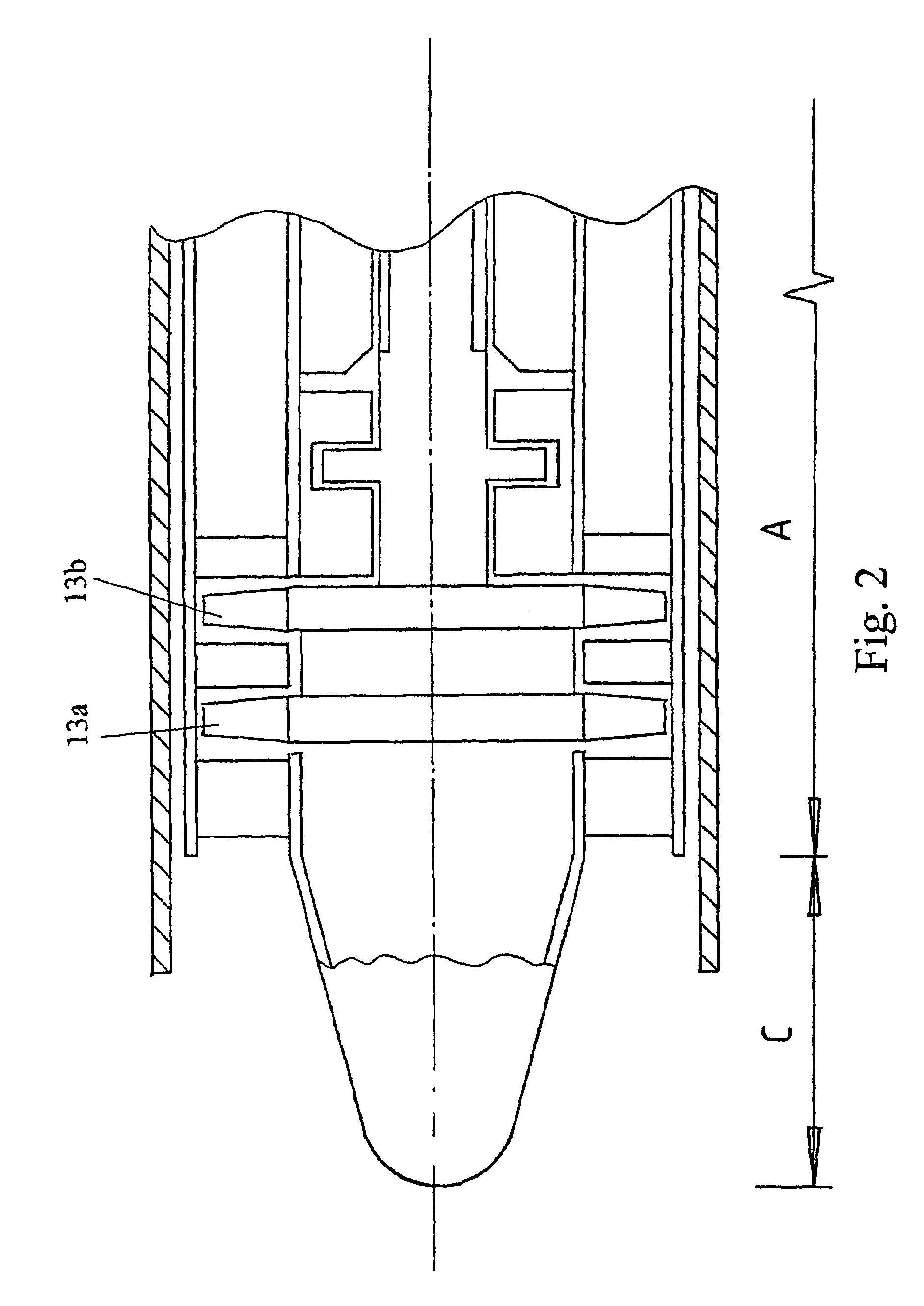

Resonant converter tuning for maintaining substantially constant phaco handpiece power under increased load

ActiveUS6997935B2Simple filterReduced transistor switching loss lossEye surgerySurgeryPhacoemulsificationTransducer

A phacoemulsification system includes a phacoemulsification handpiece including a cutting tip ultrasonically vibrated by an ultrasonic transducer. A power supply is provided for driving the ultrasonic transducer at a resonant frequency of the transducer and cutting tip and varying power to the transducer, in response to loading of the cutting tip, by phase shifting drive signals to the resonant converter which supplies power to the transducer.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

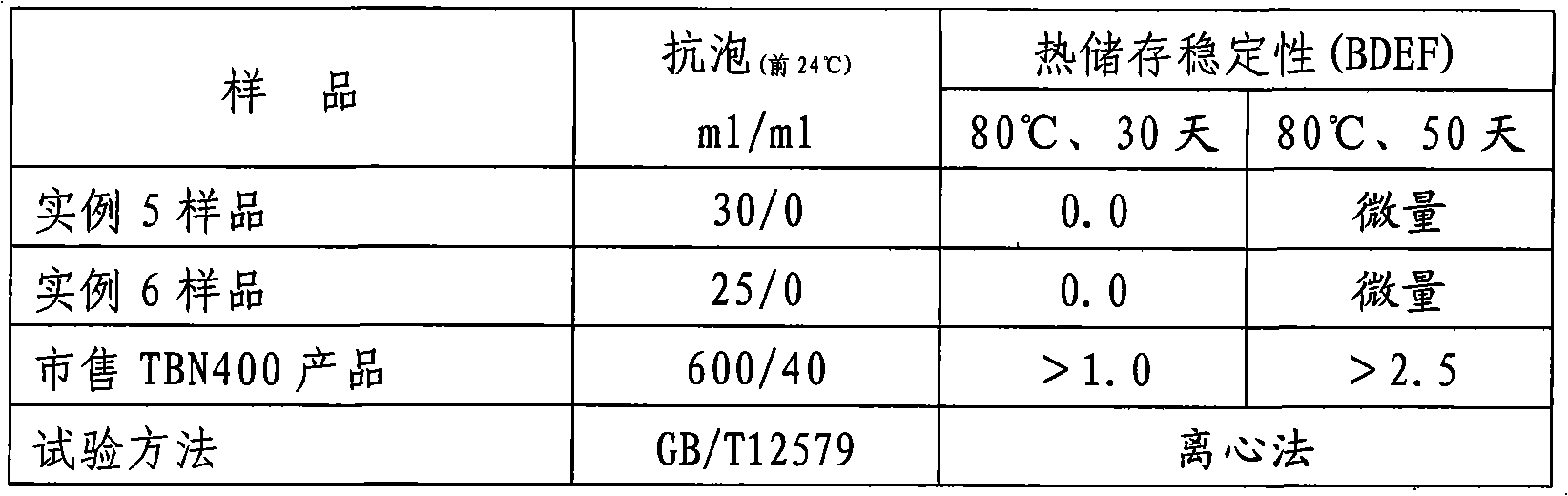

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

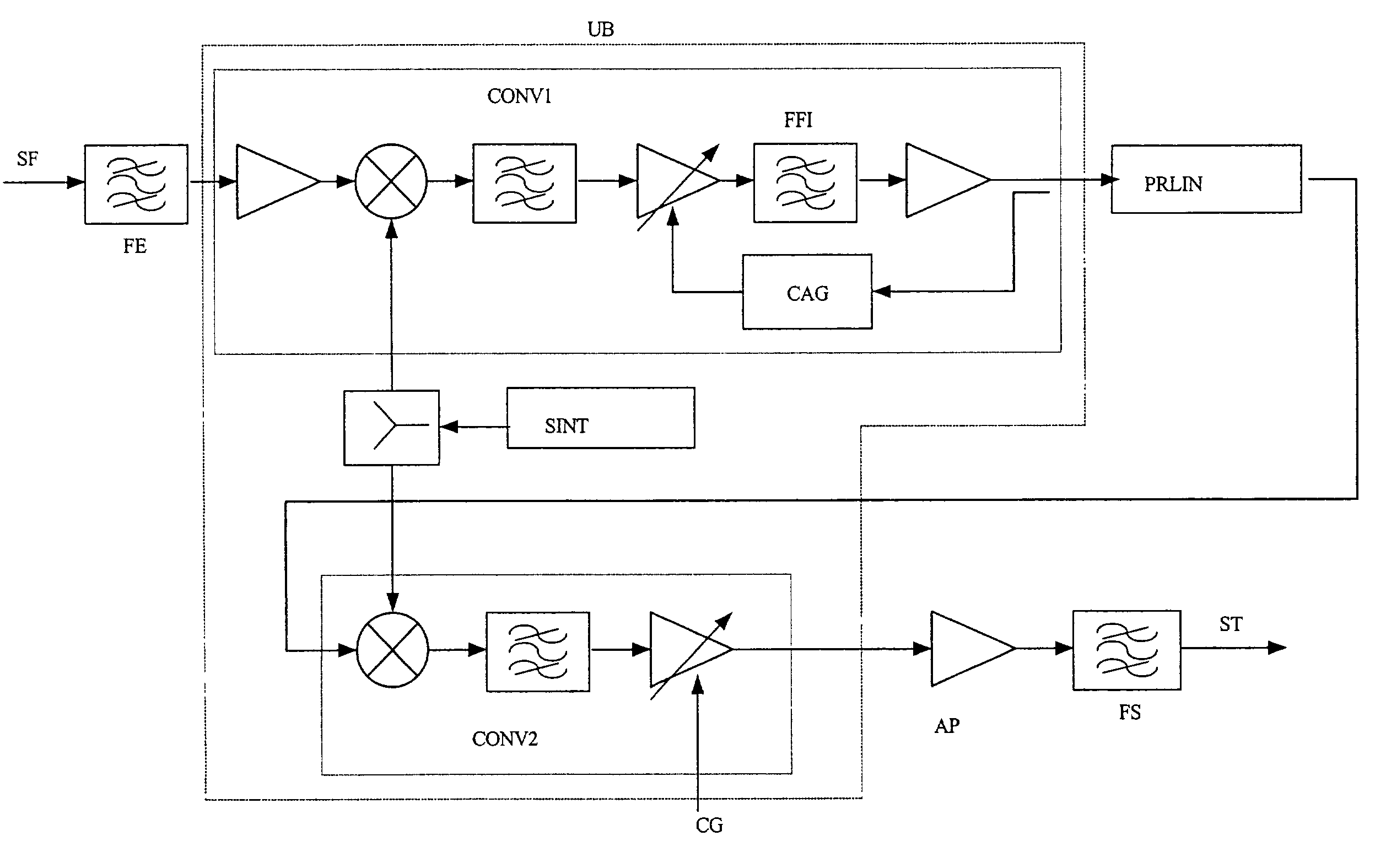

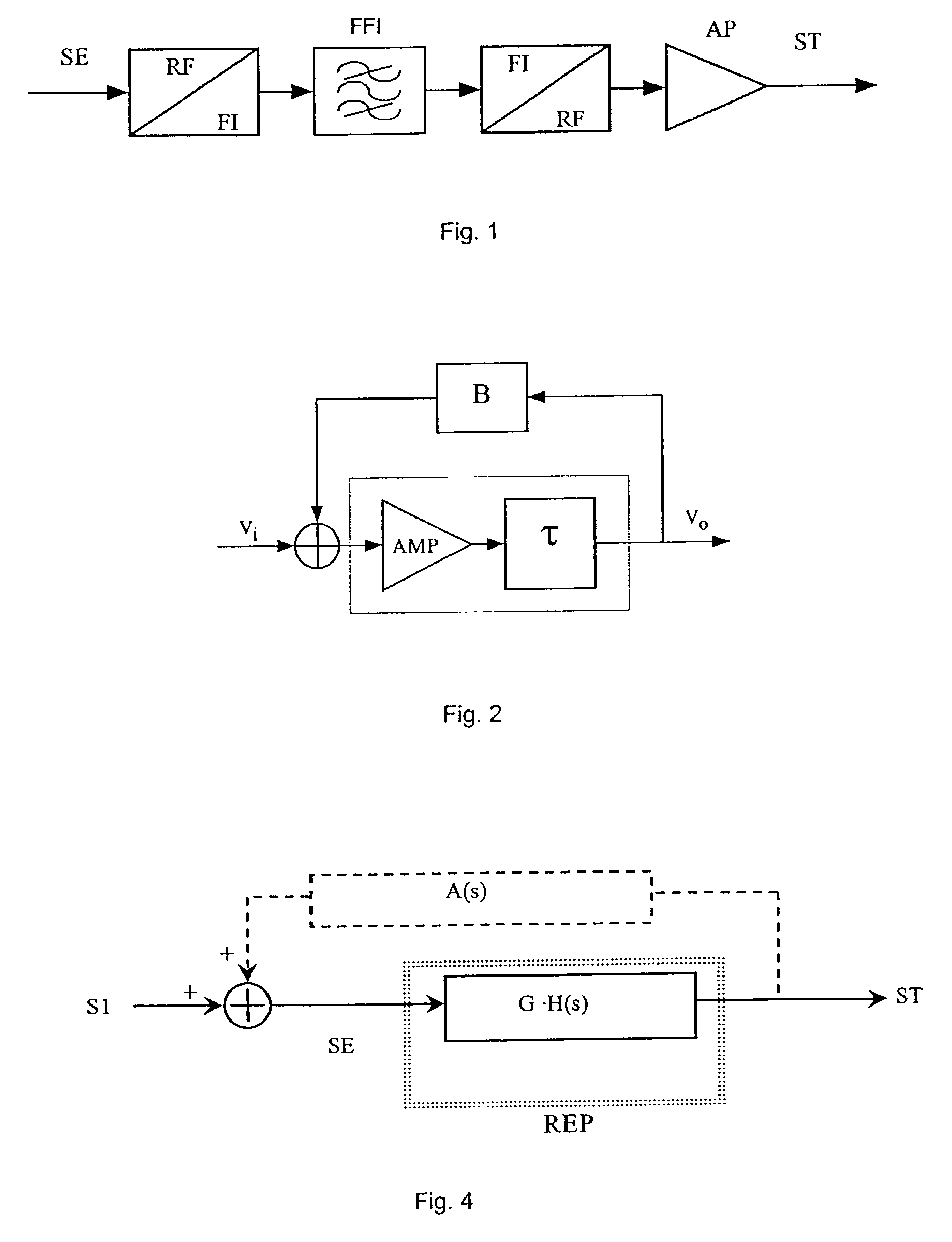

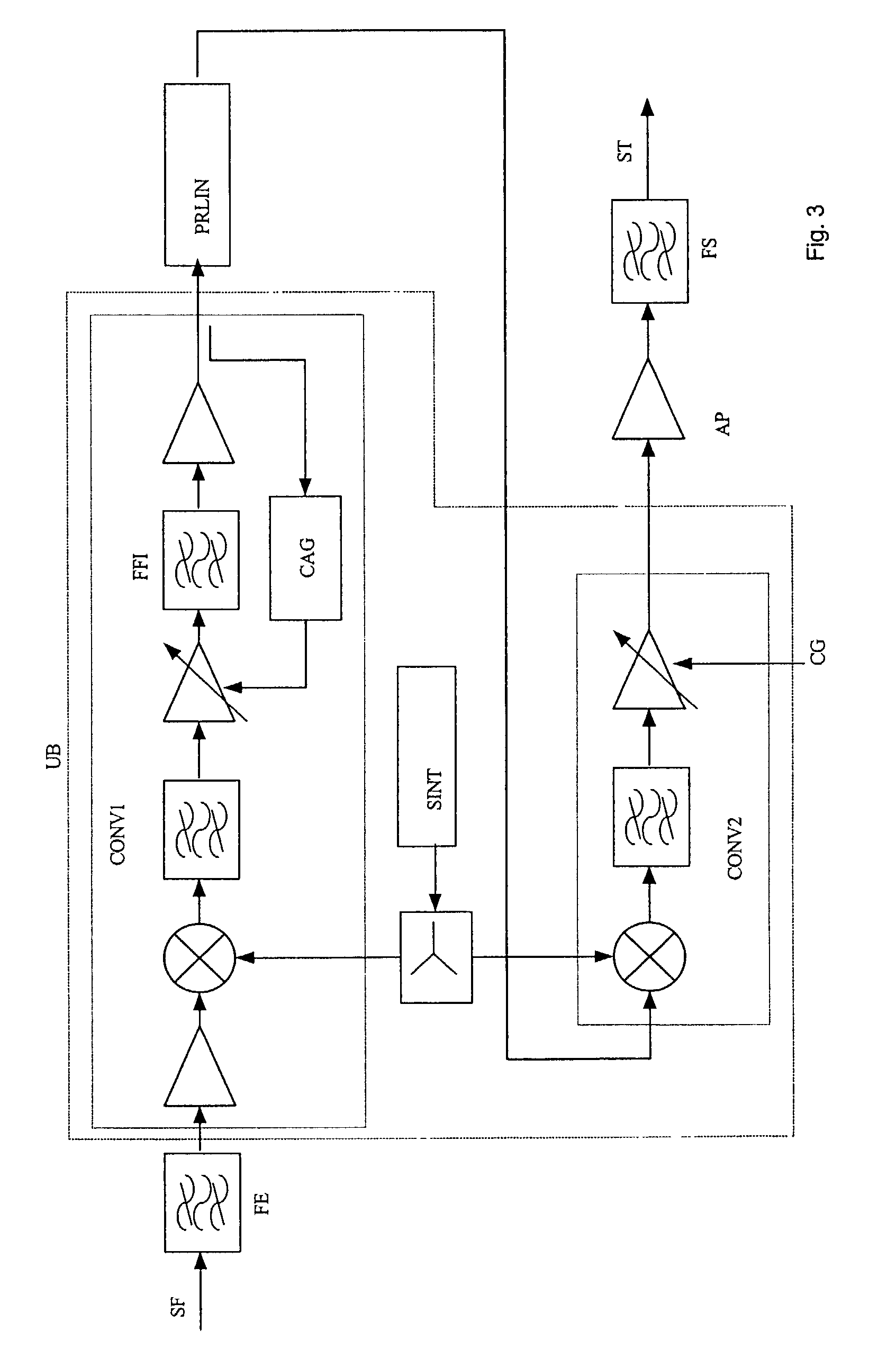

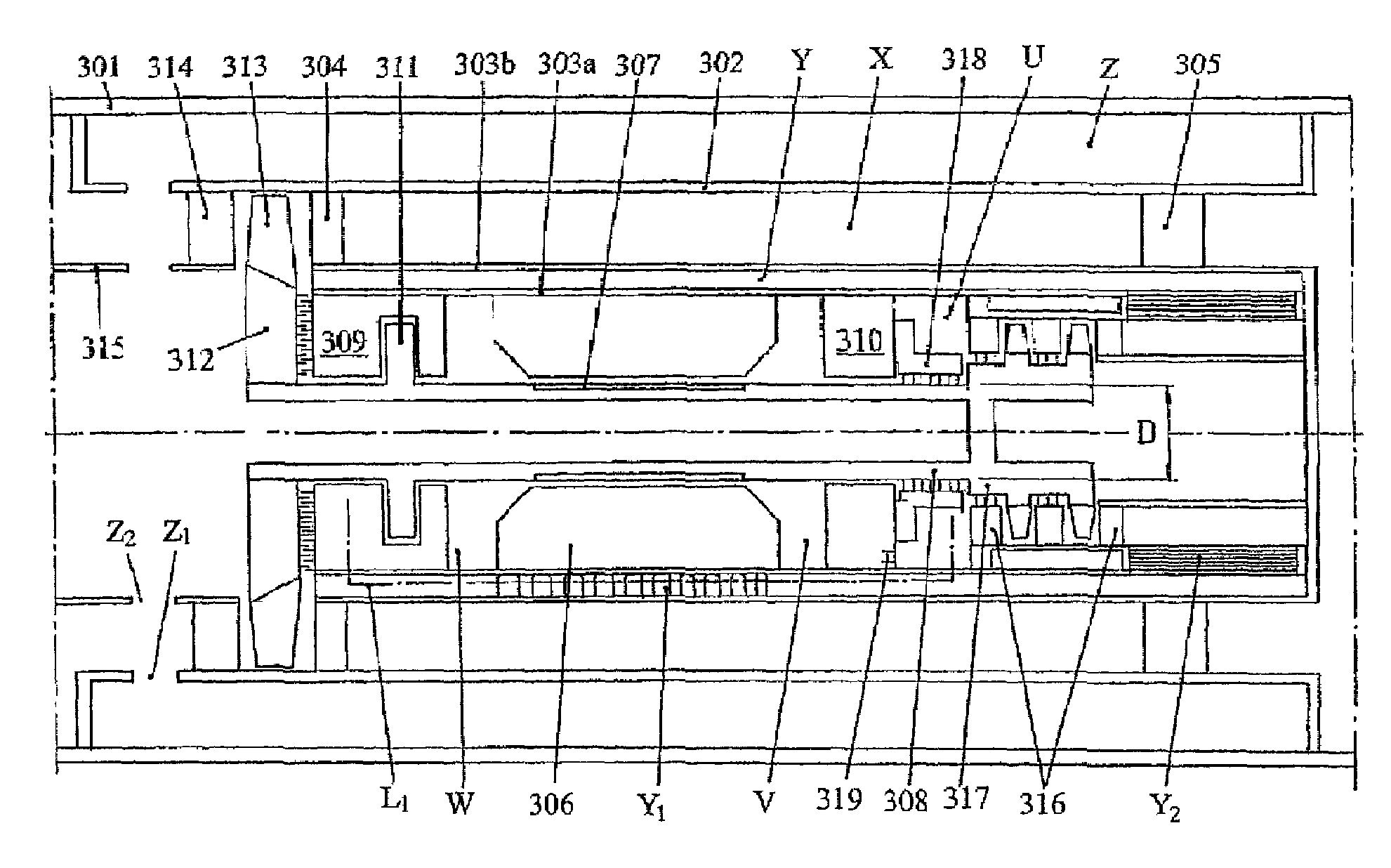

Process for re-transmitting single frequency signals and a single frequency signal repeater

InactiveUS7043203B2Limit resultSimple filterEcho effect reductionModulated-carrier systemsAutomatic controlCoupling

The invention discloses a process for re-transmitting single frequency signals and a single frequency signal repeater, where coupling occurs between the transmitting antenna and the receiving antenna, and where the process is of the type used in a single frequency signal repeater and comprises the steps of: [a] receiving a first radio frequency signal having a particular receiving power, [b] optionally converting said first radio frequency signal into a process signal, [c] filtering, amplification and automatically controlling the gain of said signal, [d] canceling said coupling between said transmitting antenna and said receiving antenna, [e] reconverting, as the case may be, said process signal into a second radio frequency signal, [f] amplifying the power of said second radio frequency signal, [g] output filtering, and [g] transmission.

Owner:MIER COMMUNICACIONES SA

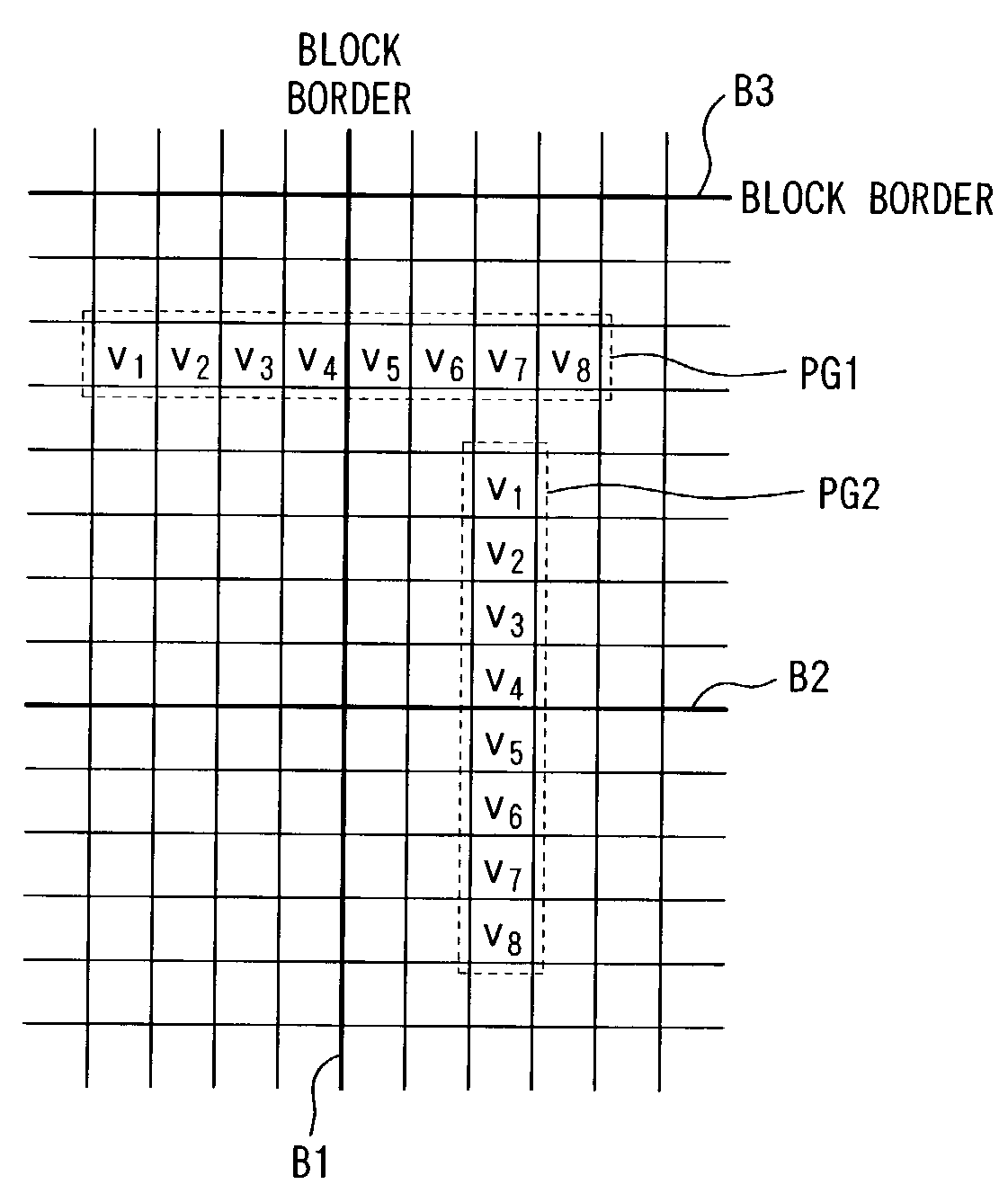

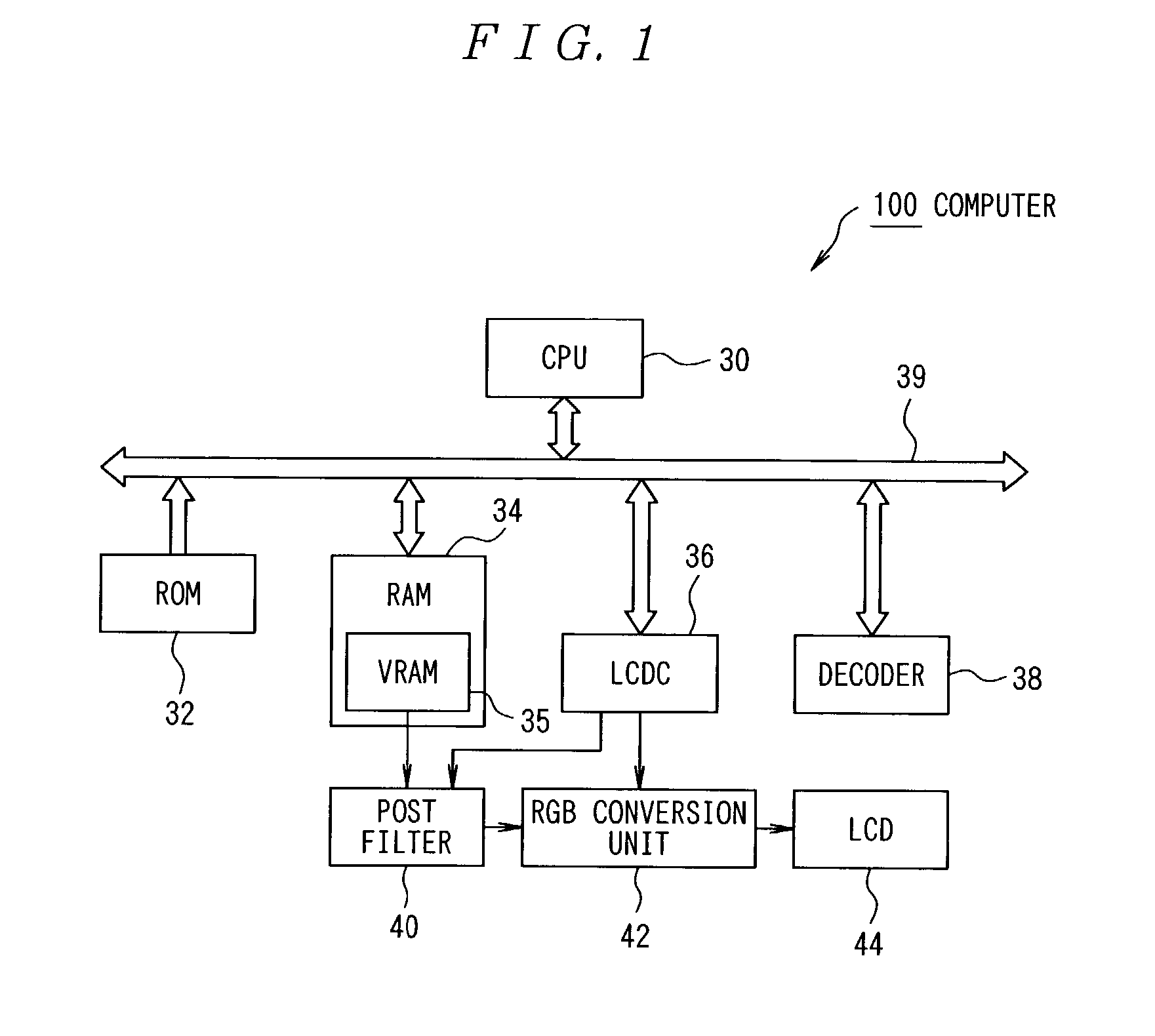

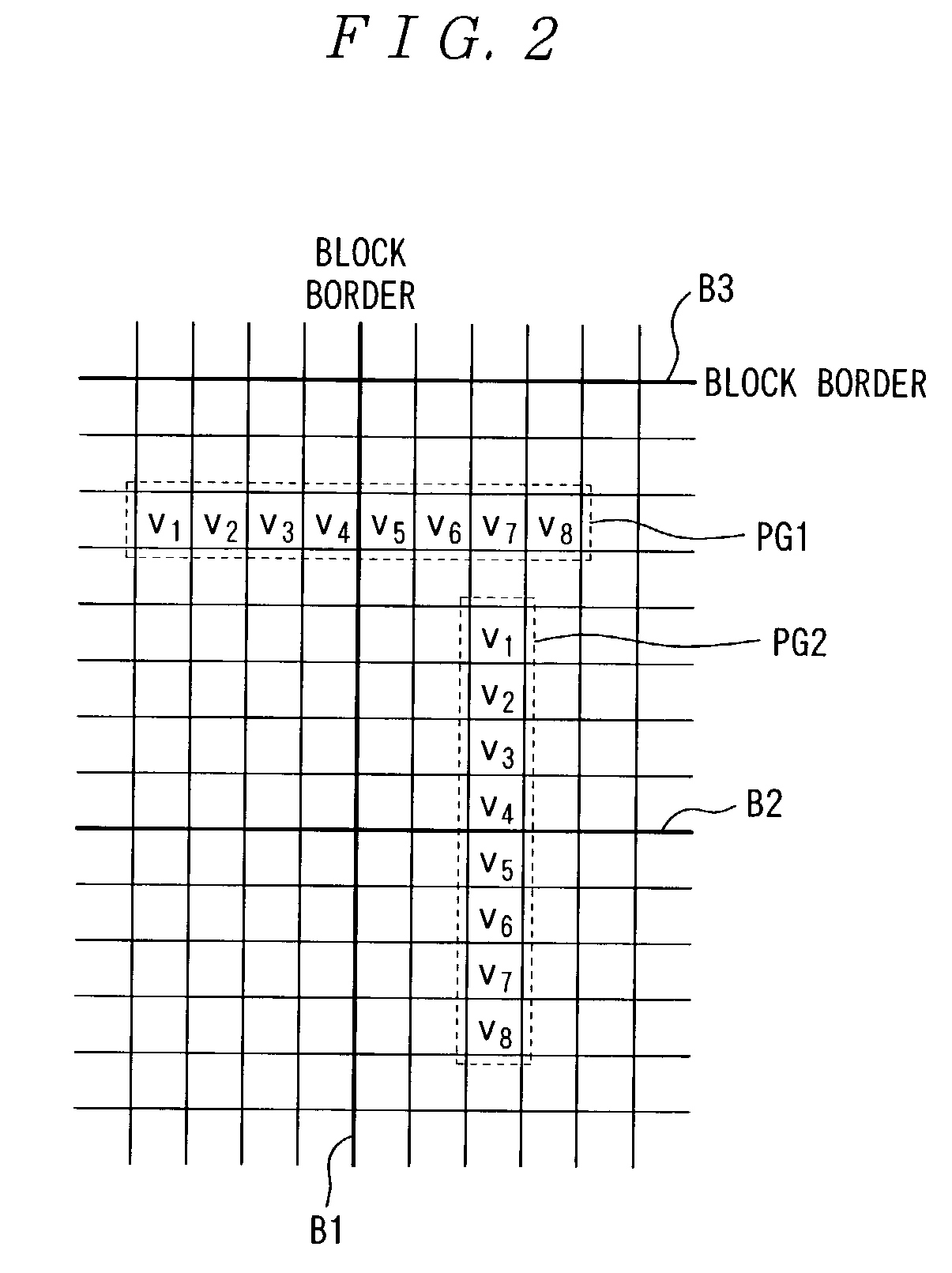

Deblocking and deringing apparatus, program and method

InactiveUS7215823B2Simple filterIncrease speedImage enhancementImage analysisDeblocking filterComputer vision

An image processor is provided which simplifies filter processing and increases the speed when an image is decoded, and is suitable for realizing effective screen effect.In deblocking filter processing, as to a pixel array intersecting a boundary between adjacent blocks, pixel values v2′ to v7′ after filtering are computed by filter arithmetic equations as shown belowv2′=(v2+v5) / 2+(v2−v5) / 4v3′=(v3+v5) / 2+(v3−v5) / 8v4′=(v4+v5) / 2v5′=(v5+v4) / 2+(v5−v4) / 8v6′=(v6+v4) / 2+(v6−v4) / 4v7′=(v7−(v7−v4) / 8.

Owner:SEIKO EPSON CORP

Method for manufacturing dendrobium officinale fresh juice stock solution

InactiveCN102008654ANot easy to clarifyNot easy to filterMetabolism disorderAlcoholic beverage preparationFlavorAdditive ingredient

The invention discloses a manufacturing method for extracting and processing fresh juice stock solution by using dendrobium officinale as a raw material. The method furthest protect the color, flavor, nutrition and effective ingredients of dendrobium officinale fresh juice by surface sterilization of the collected fresh dendrobium officinale and technology of juicing, enzymolysis, vacuum degasification, micro-filtration, ultra-filtration, sterile filling, high-temperature instantaneous sterilization and the like, and meanwhile, the product is favorable for storing and realizing industrialized production. The dendrobium officinale is processed into the dendrobium officinale fresh juice stock solution which is easy to store, convenient to carry, simple to administrate, good in mouthfeel and easy to absorb and has health-care nutritional components and medicinal functions; the fresh juice stock solution does not contain any additive; and the content of the fresh juice stock solution reaches over 99 percent. The dendrobium officinale fresh juice stock solution can be administrated separately, also can be added into mineral water to form health-care beverage, also can be dissolved into wine to form nourishing health-care wine, and can be added into high-grade dishes to form nourishing dishes for eating.

Owner:杨军

Momordica grosvenori extractive with at least 40 percent grosvenor momordica glycoside and preparation method thereof

InactiveCN101200753AReduce the amount of feedShorten the production cycleFermentationFood preparationSocial benefitsEnzymatic hydrolysis

The invention provides a milk white fructus momordicae extract, fructus momordicae glycoside V and fructus momordicae glycoside of which are respectively larger than or equal to 40 percent and 98 percent. The invention also discloses a preparation method of the extract. Using fresh fructus momordicae as the raw material, the invention is obtained through the water extraction, the concentration, the enzymatic hydrolysis, the macroporous adsorption resin refining, the ion exchange resin decoloration, the concentration and the spray drying. The invention is characterized in that the process parameters of the steps which are suitable for the industrial production are found, the yield and the quality of the fructus momordicae extraction are all obviously improved, and obvious economic benefits and social benefits are obtained.

Owner:GUILIN HUITONG BIOTECH

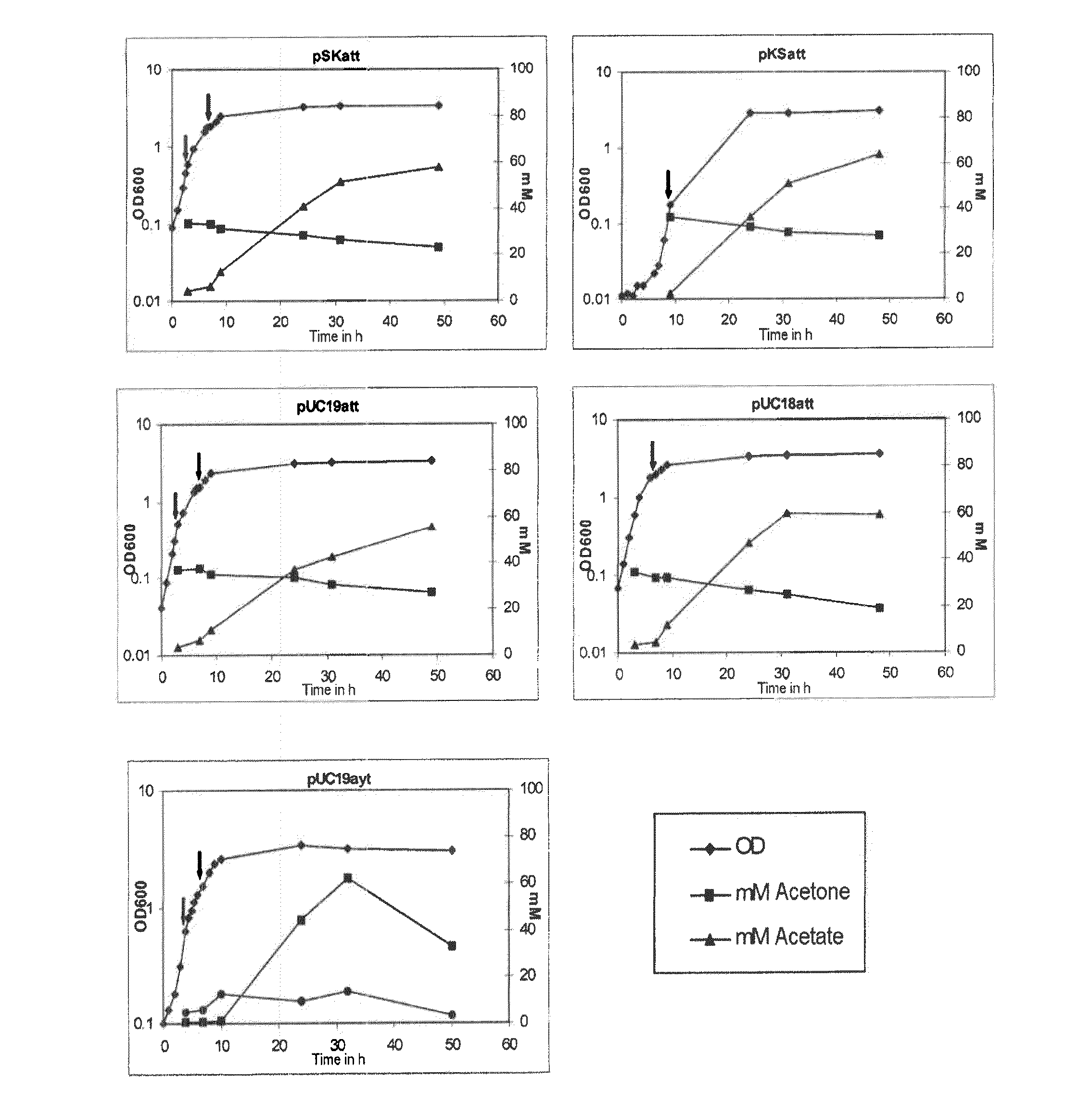

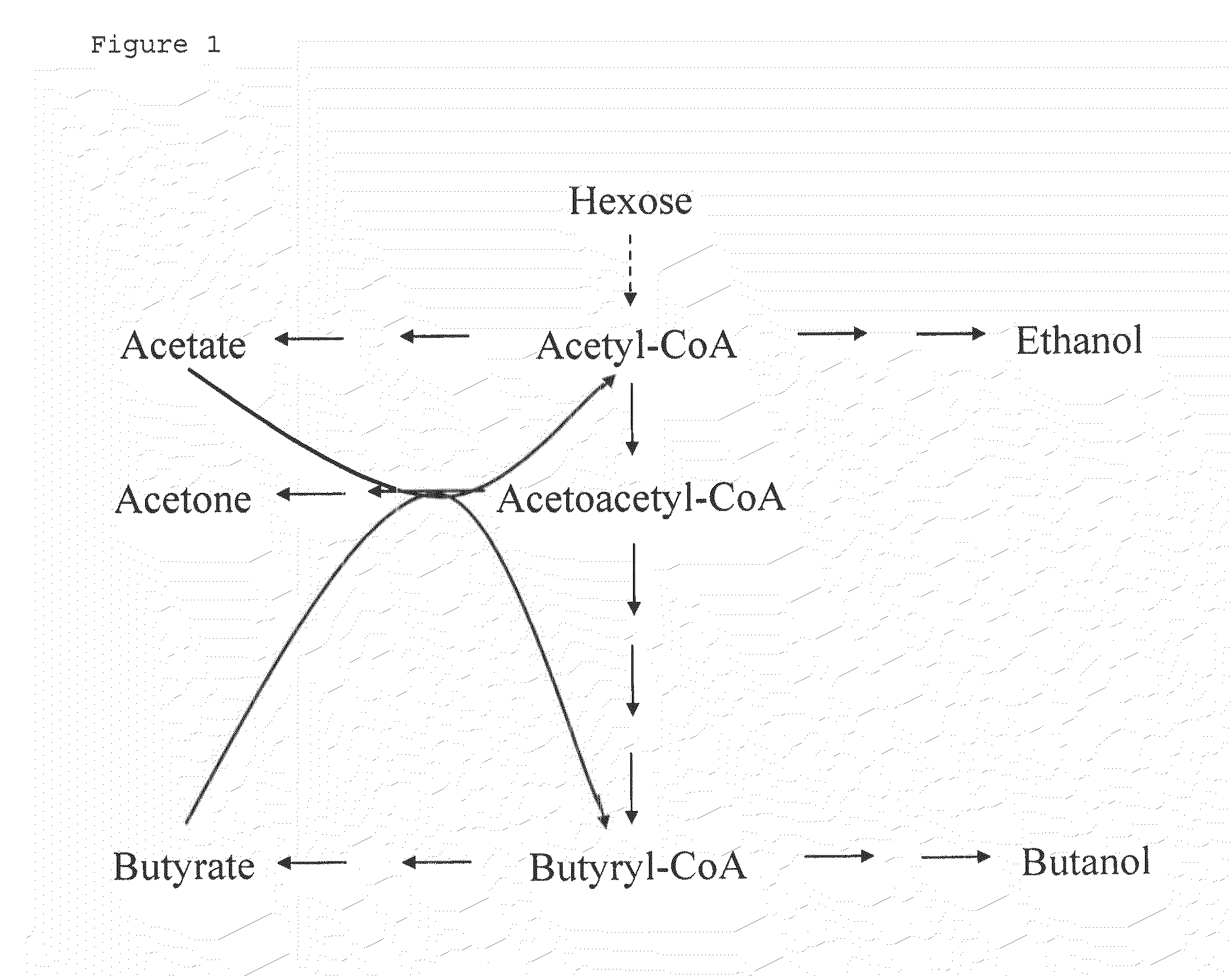

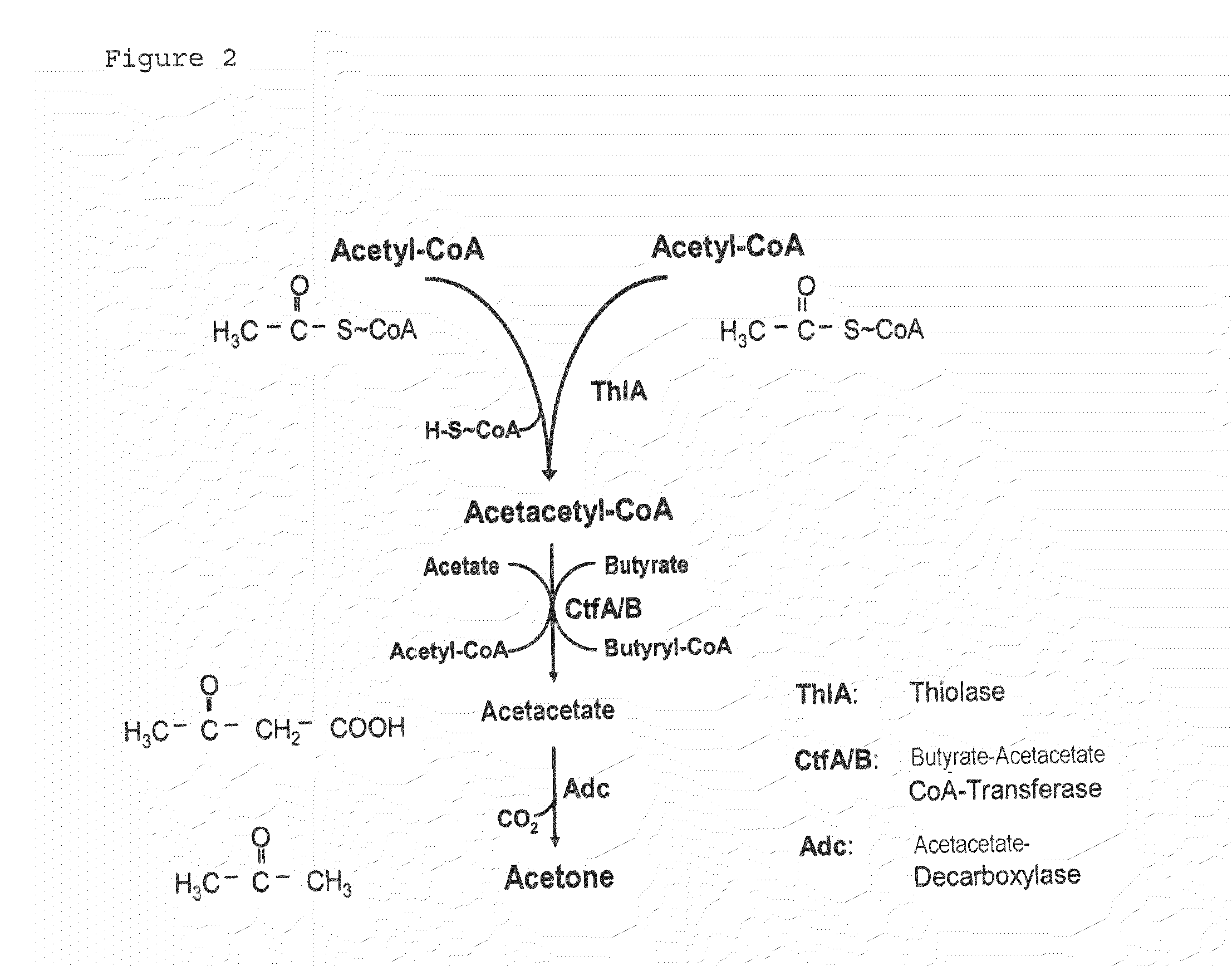

Fermentative production of acetone from renewable resources by means of novel metabolic pathway

ActiveUS20100261237A1YieldHigh yieldSugar derivativesHydrolasesAcyl Coenzyme A SynthetasesAcyl-CoA synthetase

The invention describes a process for preparing acetone starting from acetyl-coenzyme A comprising process steps A. enzymatic conversion of acetyl-CoA into acetoacetyl-CoA B. enzymatic conversion of acetoacetyl-CoA into acetoacetate and CoA and C. decarboxylation of acetoacetate to acetone and CO2, which is characterized in that the coenzyme A is not transferred in process step B to an acceptor molecule. In addition, process step B is surprisingly catalysed by enzymes of the classes of acyl-CoA thioesterase, acyl-CoA synthetase or acyl-CoA thiokinase.A completely novel metabolic pathway is concerned, because the enzymatic hydrolysis of acetoacetyl-CoA without simultaneous transfer of CoA to a receptor molecule has never previously been described for any microbial enzyme.

Owner:EVONIK OPERATIONS GMBH

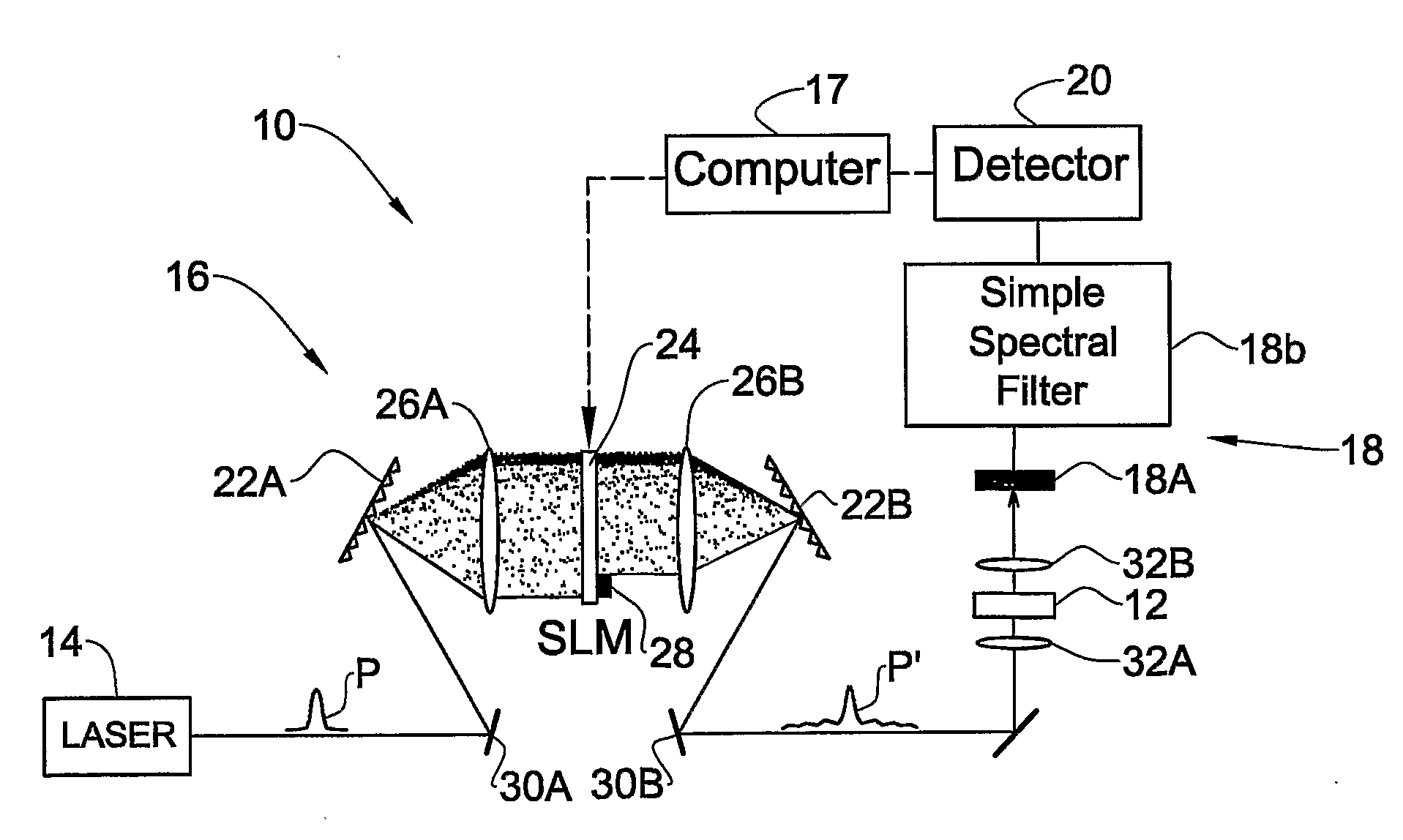

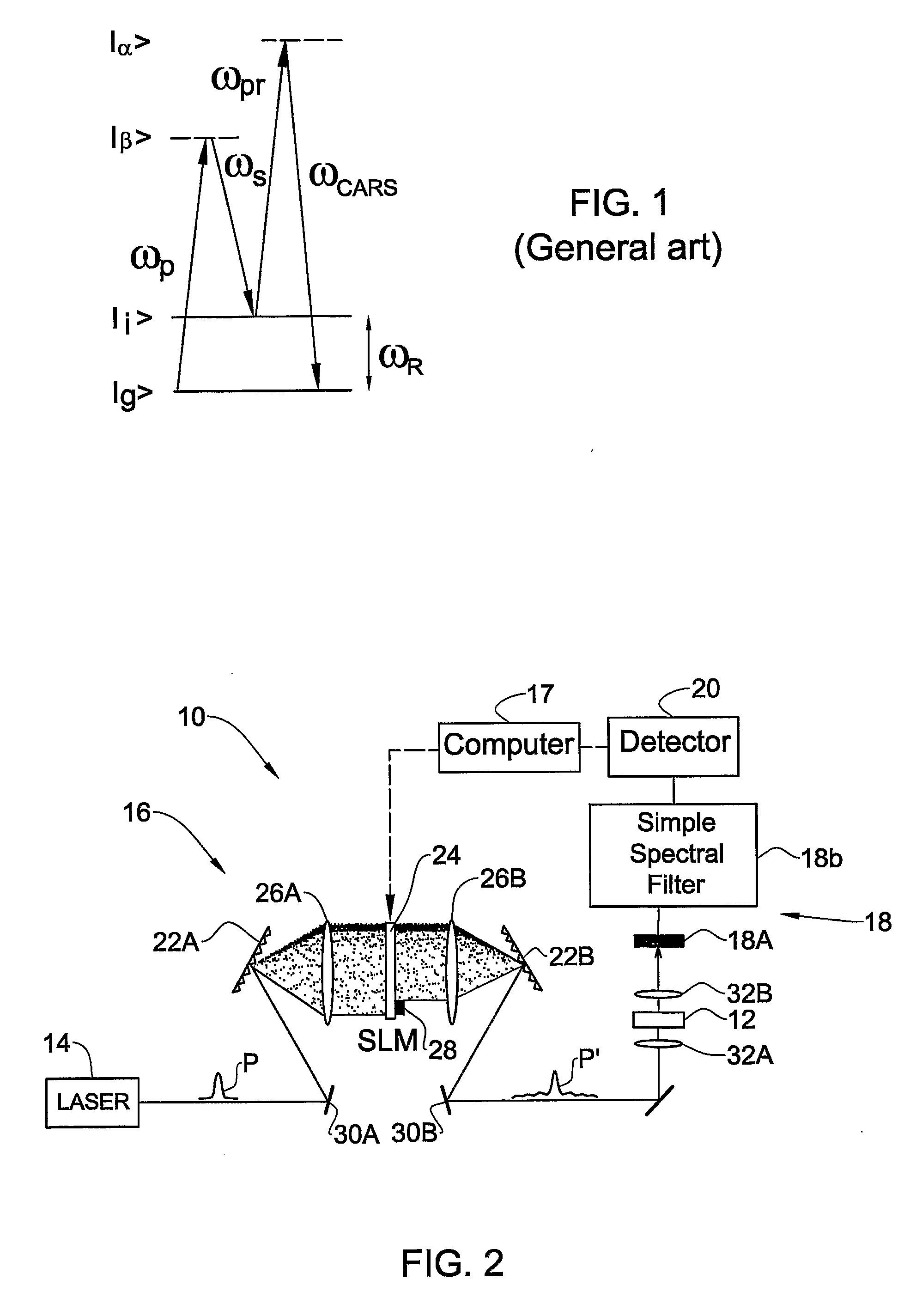

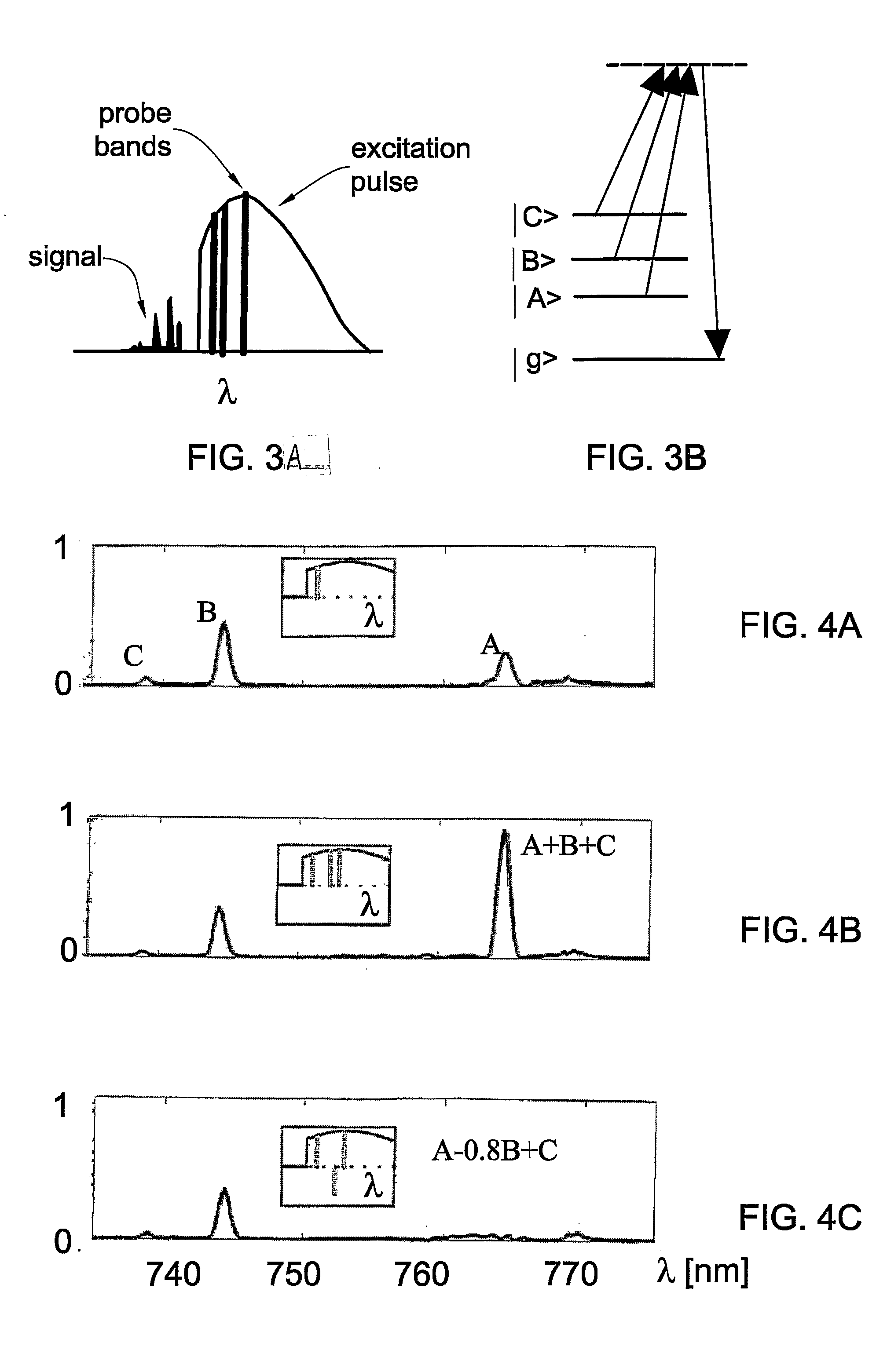

Coherently Controlled Nonlinear Raman Spectroscopy

InactiveUS20080309931A1Spectroscopic fingerprintEffective segmentationRadiation pyrometryRaman scatteringLength waveRaman scattering

A method and system (10) are presented for producing exciting radiation (P′) to be used in producing an output coherent anti-stokes Raman scattering (CARS) signal of a medium (12). An input spectral phase coherent optical pulse (P), carrying a pump, a Stokes and a probe photon, is optically processed by adjusting spectral phase and polarization of wavelength components of the input pulse to produce a unitary optical exciting pulse (P′) that carries the pump photon, the Stokes photon and multiple probe photons and is capable of inducing interference between contributions from at least some of vibrational levels in the CARS signal.

Owner:YEDA RES & DEV CO LTD

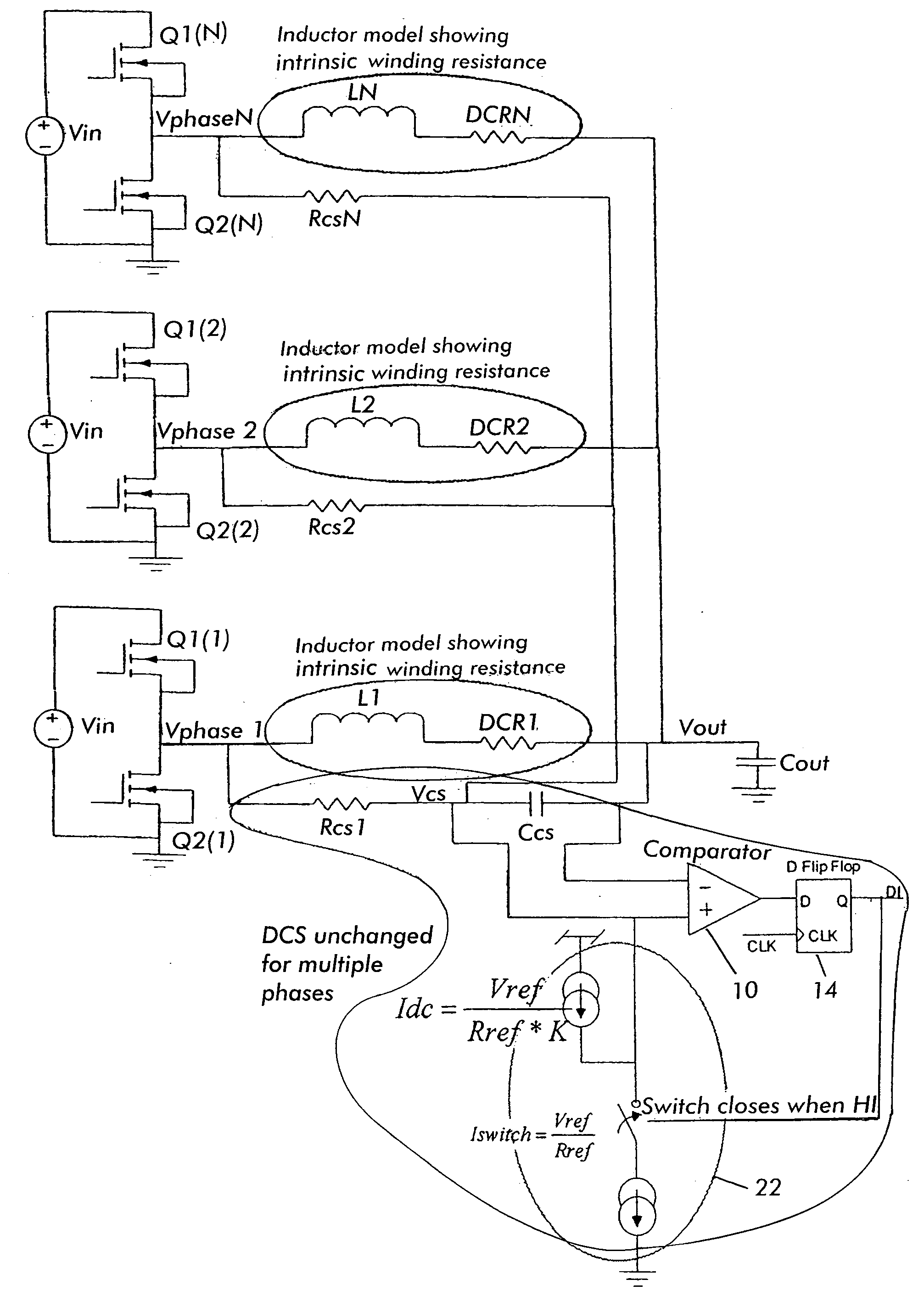

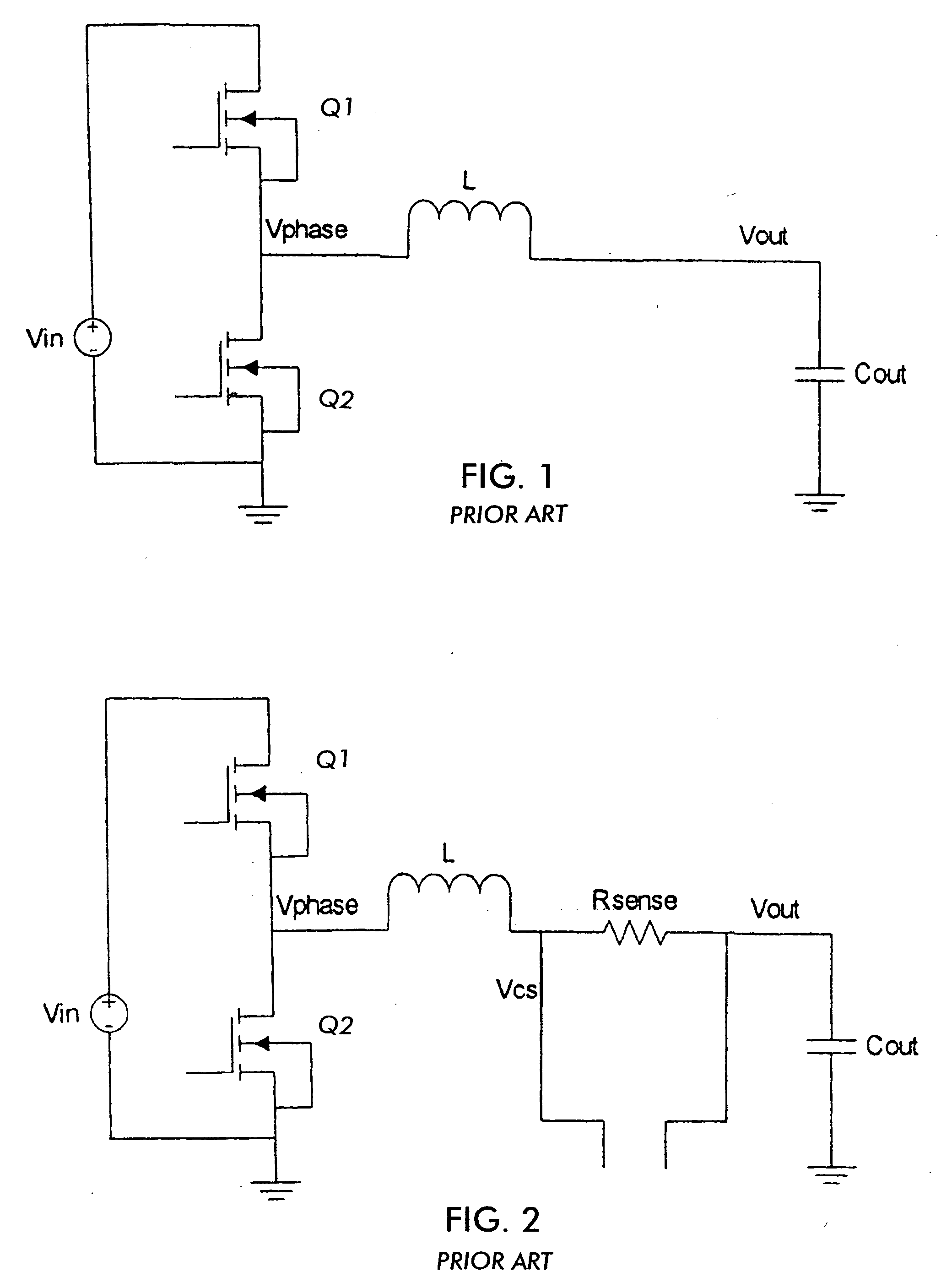

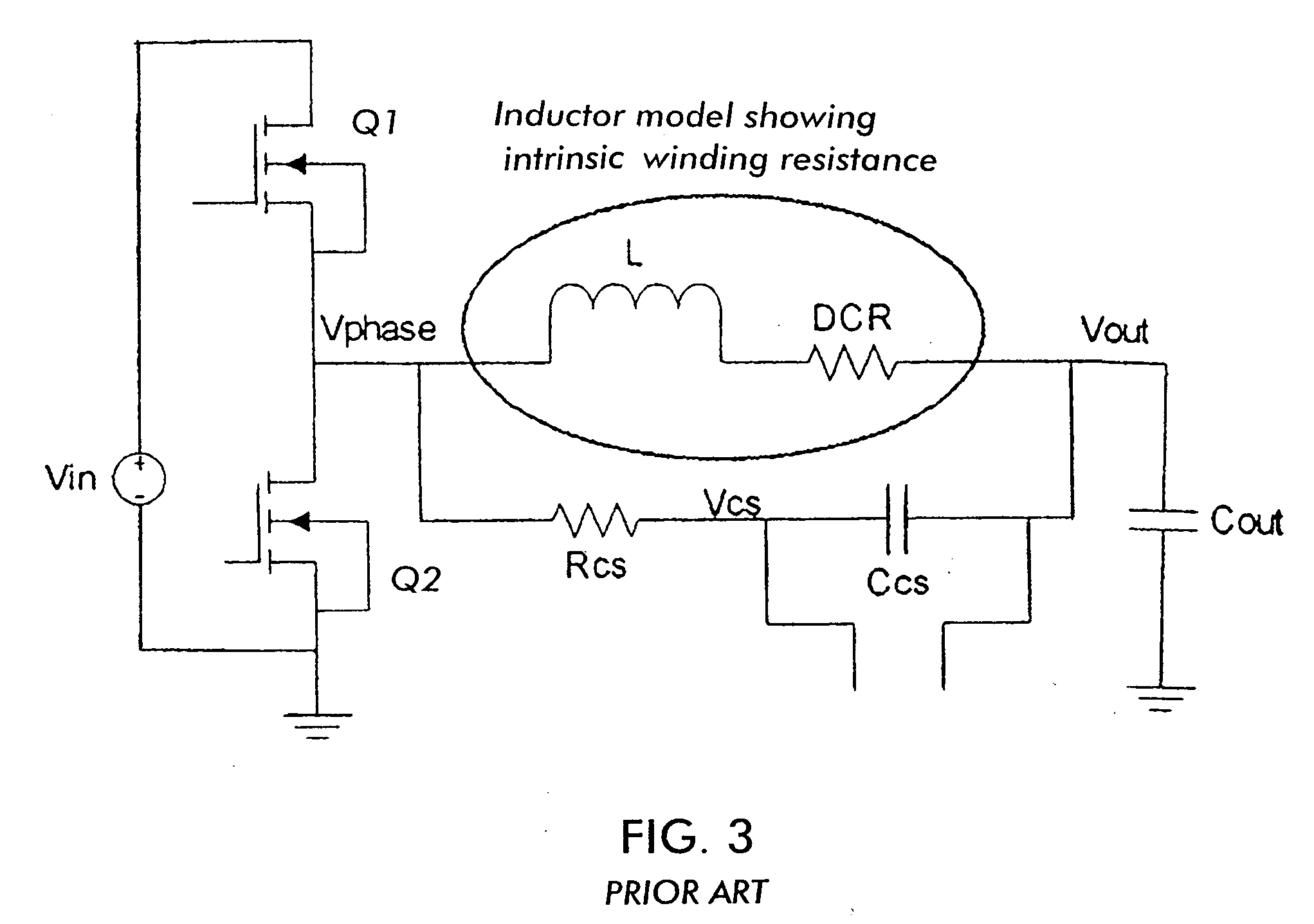

Digital current sense

InactiveUS20080203997A1Simple filterEfficient power electronics conversionCurrent/voltage measurementComparators circuitsInductor

A circuit for measuring a current in an output inductor of at least one switching power supply having high- and low-side switches connected at a switching node, the output inductor having input and output terminals, the input terminal being connected to the switching node. The circuit including a sensing circuit for detecting a direction of current through the inductor, the sensing circuit generating a sense voltage related to the direction of current; a comparator circuit having an output terminal and input terminals coupled to the sensing circuit and receiving the sense voltage, the comparator circuit providing a comparison output of the sense voltage and an output voltage of the output inductor; and a switched current source circuit controlled by the comparison output for providing a reference current to the sensing circuit, the comparison output turning the switched current source circuit ON and OFF depending on the comparison output and having a duty cycle, whereby the average current flowing through the switched current source circuit is substantially equal to the average current in the sensing circuit and proportional to the duty cycle, the duty cycle being proportional to the inductor current.

Owner:INFINEON TECH AMERICAS

Prepn of catalyst material containing nano molecular sieve

InactiveCN1432433ANot easy to gatherImprove catalytic performanceMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveSlurry

The preparation process of catalyst material containing nano molecular sieve includes: mixing acid silicon and / or alumina sol with pH 1-4 and containing SiO2 and / or Al2O3 10-50 wt% and molecular sieve slurry with pH 9-14 and containing nanometer molecular sieve 10-50 wt% in the weight ratio between SiO2 and / or Al2O3 to molecular sieve of 0.2-2; forming the mixture of pH 7-9.5 into gel; and dryingand crushing or shaping the gel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for converting alcohols and ethers into aromatic hydrocarbons as well as preparation method and use method thereof

ActiveCN103007985ASmall particle sizeEasy to spreadMolecular sieve catalystsHydrocarbon from oxygen organic compoundsHydrogenAlcohol

The invention discloses a catalyst for converting alcohols and ethers into aromatic hydrocarbons, as well as a preparation method and a use method of the catalyst, and belongs to the technical field of chemical engineering. The preparation method comprises the steps as follows: at first, taking a template agent, kaolin, sodium hydroxide and water as raw materials for preparing a hydrogen type nanoscale ZSM-5 molecular sieve, and then directly preparing the catalyst; or based on the hydrogen type nanoscale ZSM-5 molecular sieve, preparing the two-component, three-component or four-component catalyst with metal and / or a structure enhancer and / or a stabilizing additive. The catalyst comprises the following components in percentage by mass: 30-100% of the needle-like nanoscale ZSM-5 molecular sieve, 0-10% of the metal, 0-50% of the structure enhancer and 0-10% of the stabilizing additive. The invention further provides a method for enabling the catalyst to be used for converting alcohols and ethers into aromatic hydrocarbons. The catalyst is small in particle size, high in catalytic efficiency and low in use cost; the preparation method is simple and efficient; and the use method is reasonable and efficient.

Owner:TSINGHUA UNIV

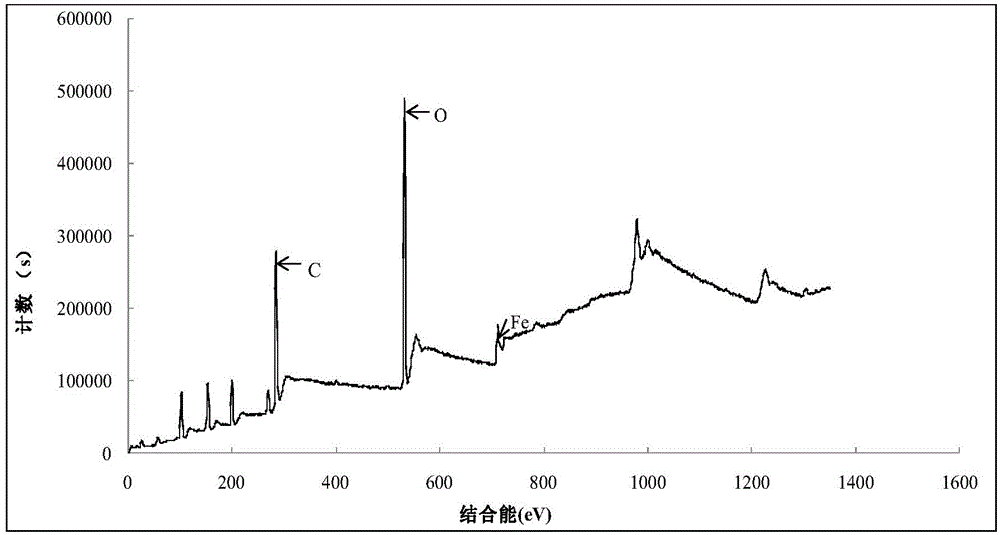

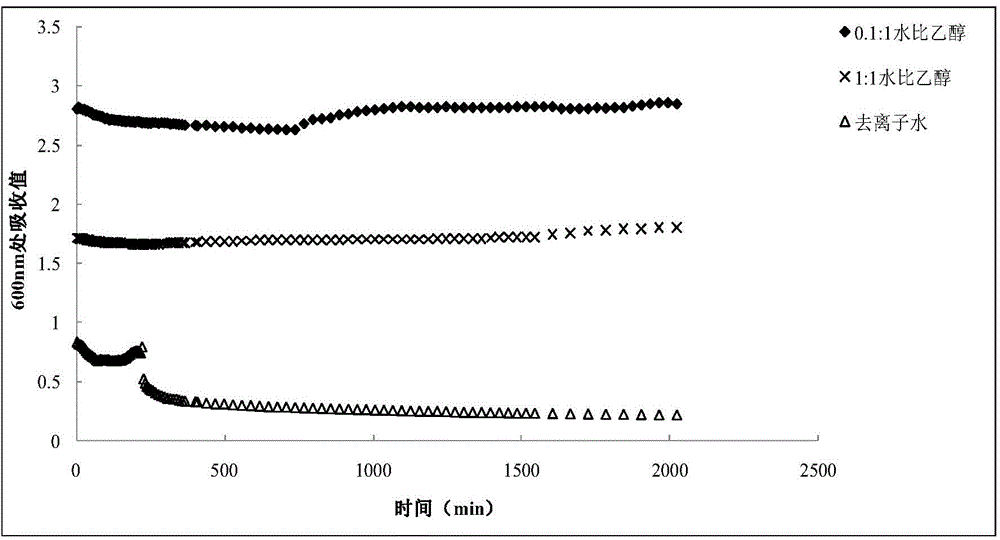

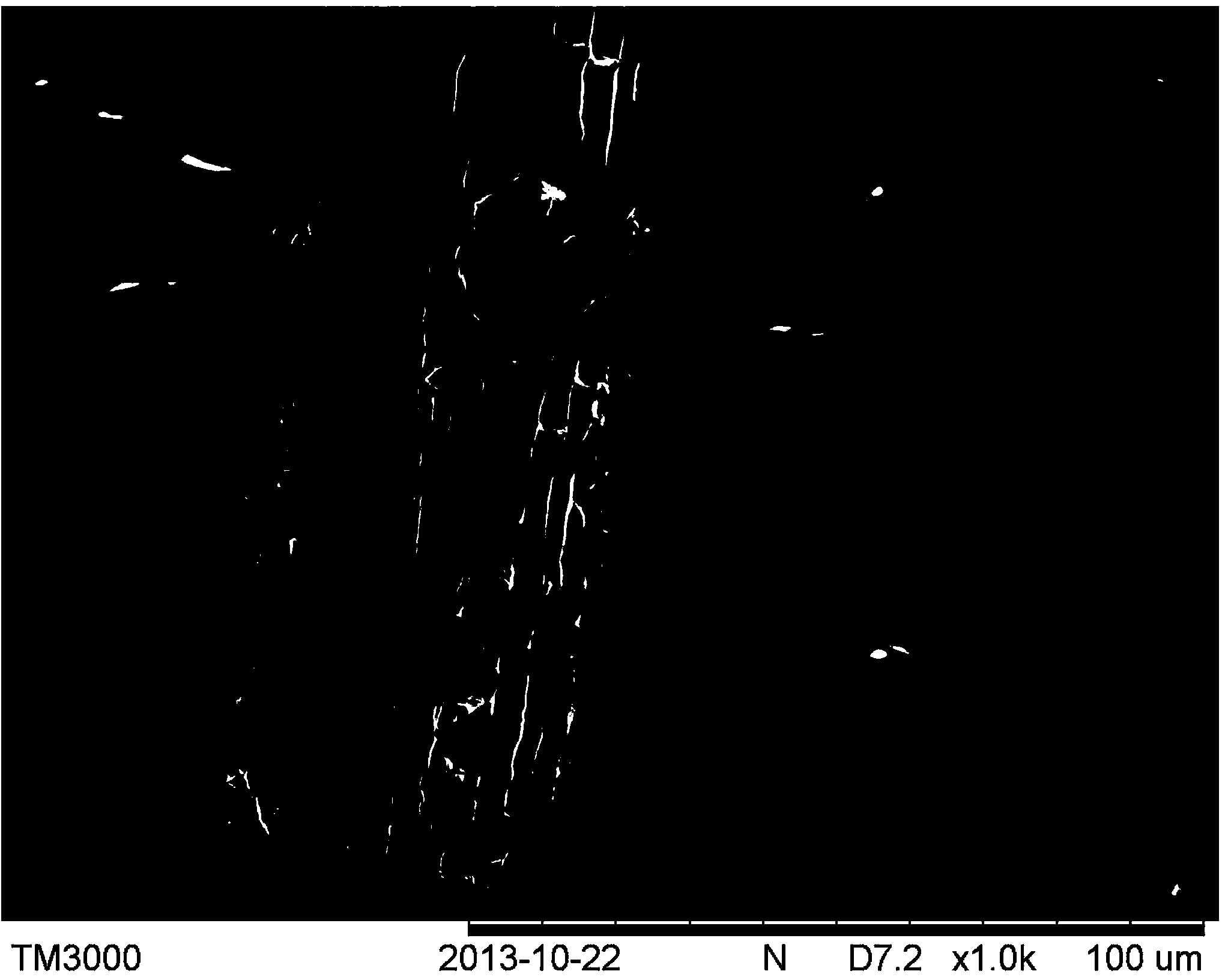

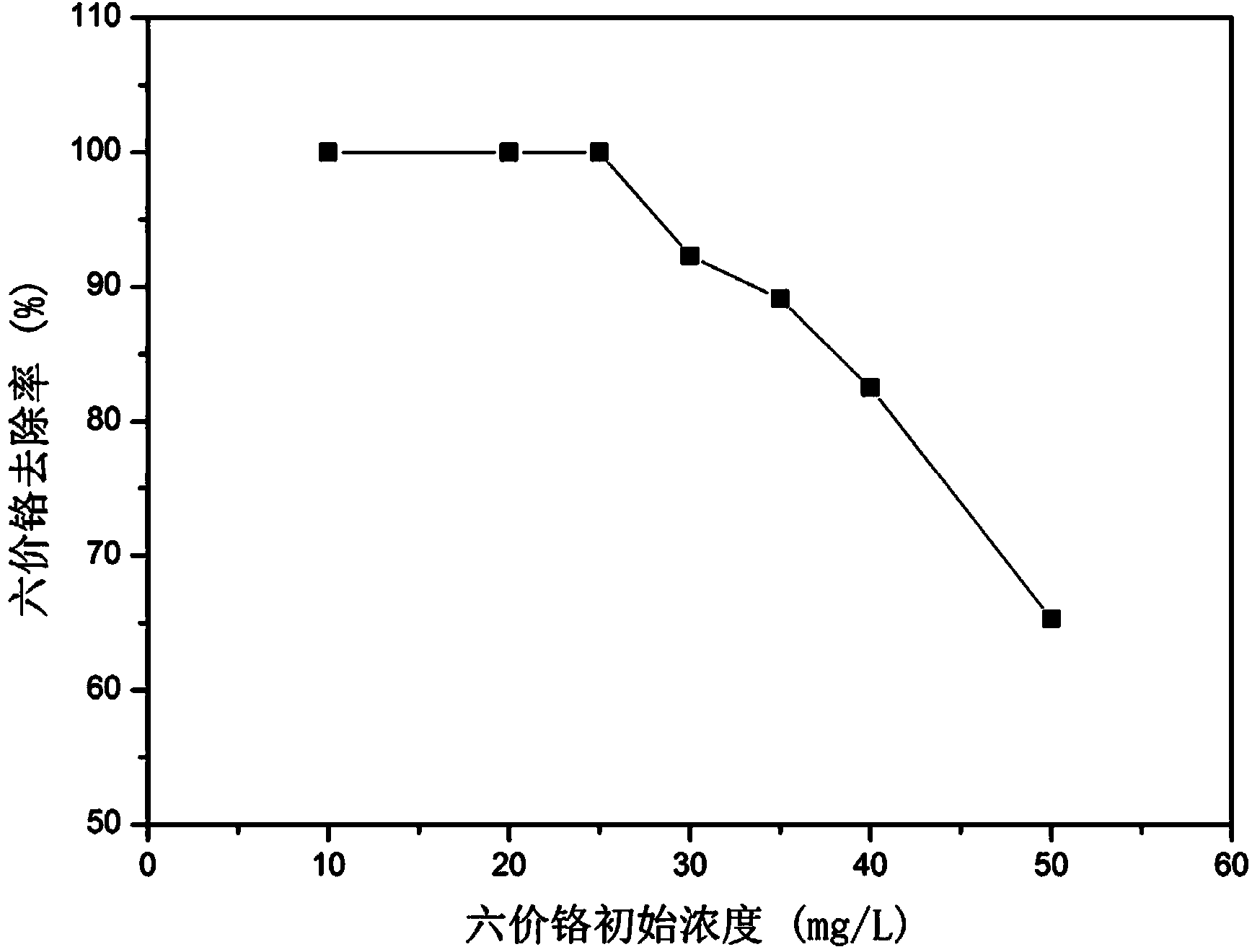

Method for preparing NZVI (nano-scale zero-valent iron) suspension from green tea as well as application of suspension

InactiveCN104857934ALarge specific surface areaImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionDissolutionSewage

The invention discloses a method for preparing NZVI (nano-scale zero-valent iron) from green tea as well as an application of a suspension of the NZVI. The method comprises technological steps as follows: A, preparing a green tea dissolution solution; B, preparing a ferric trichloride solution; C, preparing the GT-NZVI (green tea-NZVI) suspension. The prepared GT-NZVI has the advantages of good suspension stability, simple preparation technology, low cost, environment-friendliness, good stability, high penetrability in an aquifer and capability of quickly and thoroughly removing hexavalent chromium in sewage and underground water.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

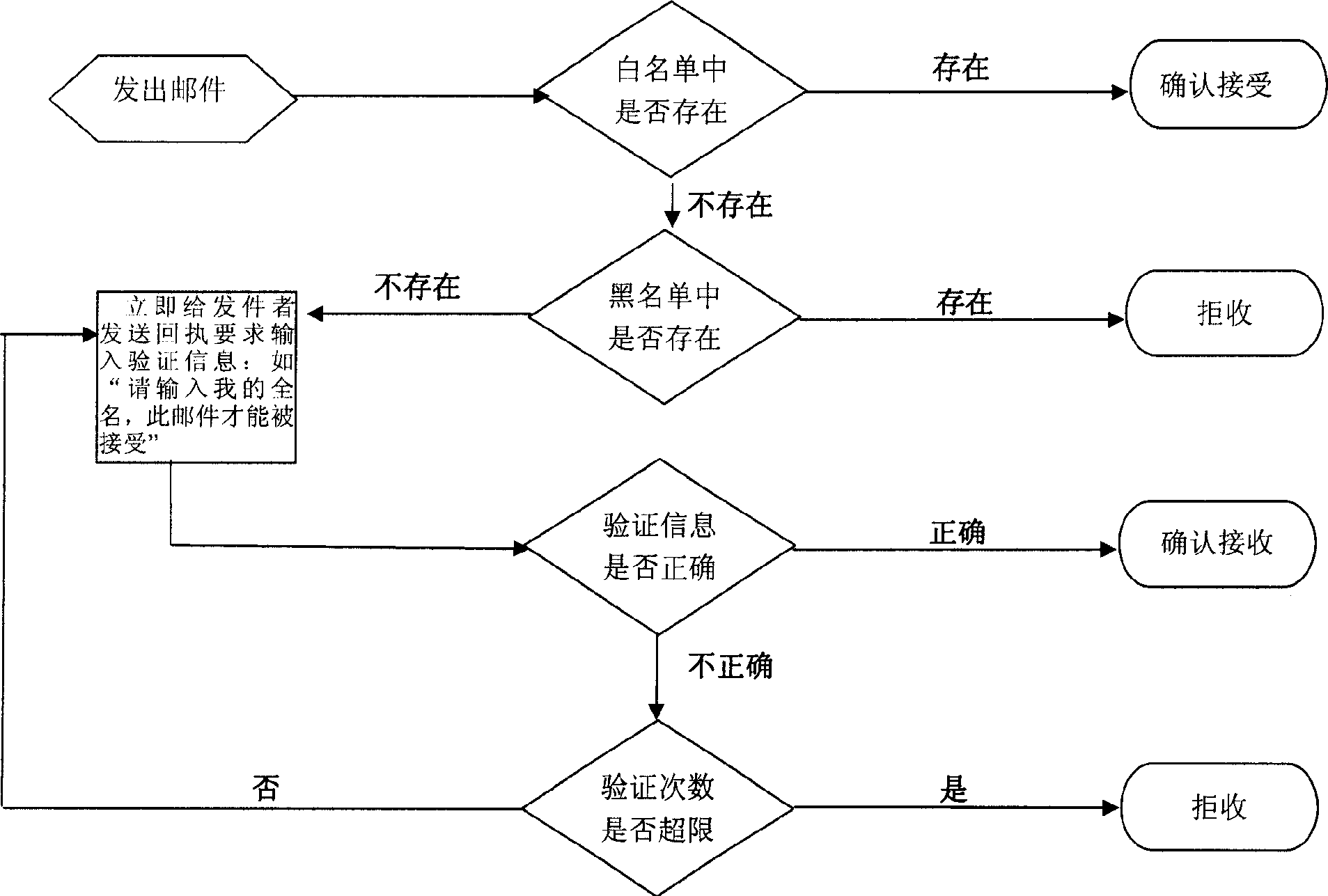

Method for against refuse E-mail

ActiveCN1707492ASimple filterImplement automatic classificationOffice automationPlatform integrity maintainanceEmail addressSpamming

The present invention relates to technology of resisting spamming and provides one reliable method of resisting spamming capable of rejecting most of the spamming. The method includes the following steps: comparing the e-mail sending address with the addresses in the white list and receiving e-mail with sending address in the white list; comparing the e-mail sending address with the addresses in the black list and reject e-mail with sending address in the black list; verifying the sender's defined verification information provided in the request of the acceptor for the e-mail with sending address not in the white list nor the black list; and receiving the e-mail with correct verification information or rejecting e-mail with incorrect verification information.

Owner:TENCENT TECH (SHENZHEN) CO LTD

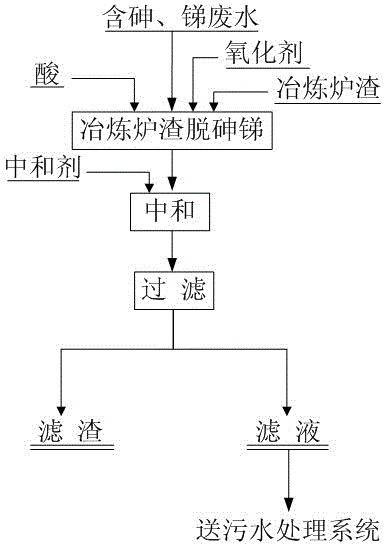

Method for removing arsenic and antimony in industrial wastewater by using smelting furnace slag

InactiveCN103553197AShort reaction timeSave precipitantSolid waste disposalWaste water treatment from metallurgical processArsenateMagnesium

The invention relates to a method for removing arsenic and antimony in industrial wastewater by using smelting furnace slag. The method comprises the following steps: adding acid to the industrial wastewater containing more than 10mg / L of As and more than 10mg / L of Sb so as to adjust the acidity, and controlling the pH to 0.5-4; adding the smelting furnace slag and an oxidizing agent, enabling the smelting furnace slag to chemically react with or physically adsorb As<3+> and Sb<3+> in the wastewater under acidity and oxidation atmospheres, controlling the temperature at 40-100 DEG C, and carrying out heat preservation reaction for 1-3 hours; adding a neutralizing agent for neutralization, and controlling the pH to 6-9; filtering a solution so as to obtain filtrate and filter residues, if the As contained in the filtrate is less than 0.3mg / L and Sb contained in the filtrate is less than 0.5mg / L, meeting the residue removal standards, feeding the filtrate to a wastewater treatment system for further purifying other impurities, if the As contained in the filtrate is more than 0.3mg / L and the Sb contained in the filtrate is more than 0.5mg / L, repeating the steps till meeting the residue removal standards, and sending the filtrate residues to a filter residue yard for storage. The method has the advantages that the smelting furnace slag is used for replacing a precipitant so as to remove impurities, the arsenic and the antimony in the wastewater are rapidly and efficiently removed within 1 to 3 hours, the removal rate is close to 100%, the method is high in efficiency and low in cost, and the filter residues have good crystal structures, are easy to clarify and filter and contain arsenate and antimonite formed by iron, calcium, magnesium, aluminium, pentavalent arsenic and pentavalent antimony and have stable chemical property.

Owner:HONGHE COLLEGE

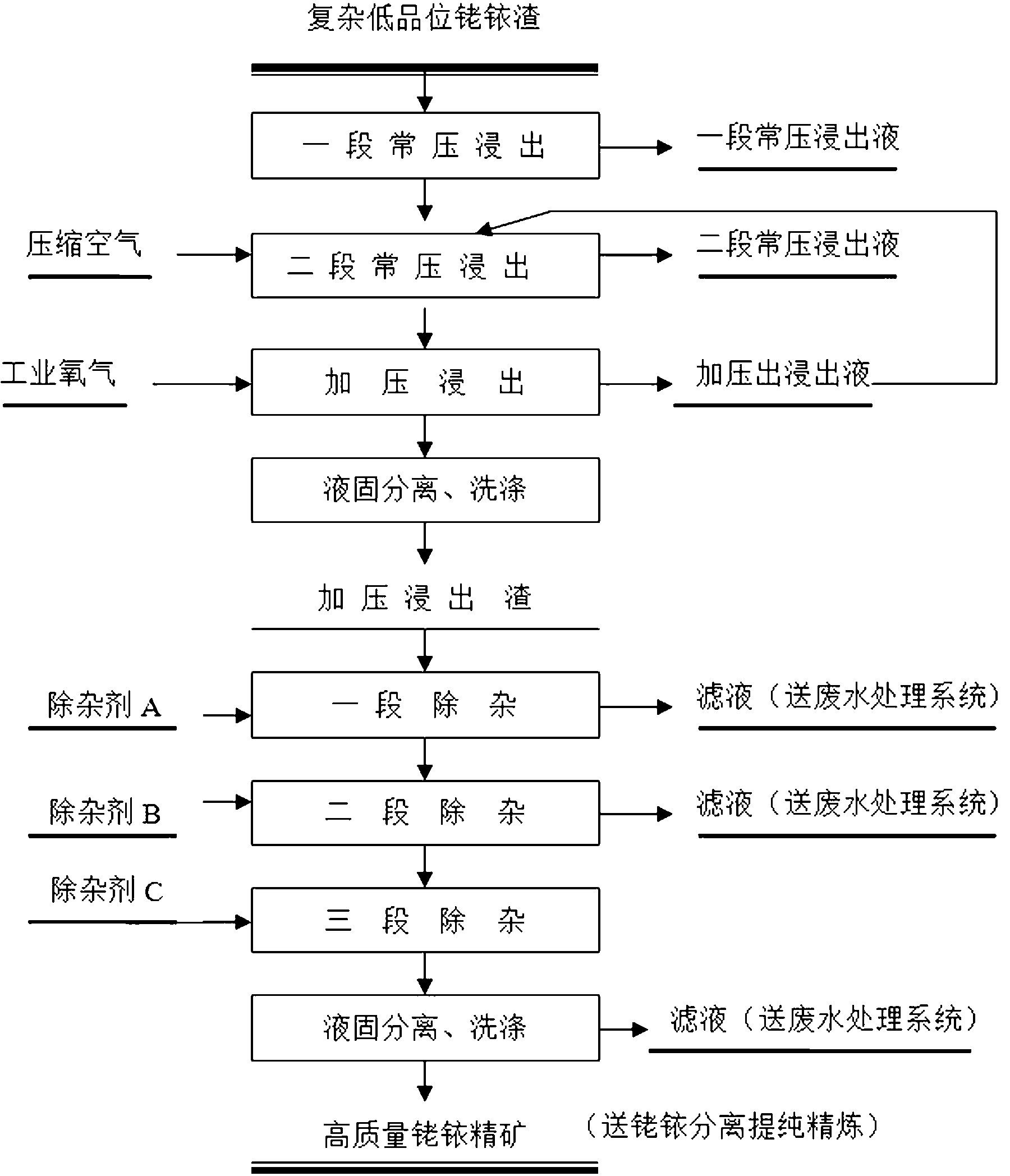

Method for efficiently enriching gold and platinum group metals from complex low-grade rhodium iridium residues

ActiveCN103320620AHigh recovery rateEliminate Scatter LossProcess efficiency improvementIridiumToxic material

The invention relates to a method for efficiently enriching gold and platinum group metals from complex low-grade rhodium iridium residues and belongs to the field of wet metallurgy of rare and precious metals. The method comprises the following steps that: primary normal pressure leaching, secondary normal pressure leaching and pressurization leaching are performed by using a low-concentration pure sulfuric acid solution, wherein an oxidizing agent is not introduced or added into the primary normal pressure leaching, air in the secondary normal pressure leaching serves as an oxidizing and leaching agent, industrial oxygen serves as an oxidizing and leaching agent in the pressurization leaching; the high-grade high-quality rhodium iridium concentrate is obtained by employing a three-step impurity removal process. The method is simple in process and environment-friendly, toxic waste gas, waste residues and the like are not generated in the process, a toxic agent is not used, the enrichment ratio and recovery rate of rare and precious metals such as rhodium and iridium are high, the grade of the precious metals in the enriched residue is 15 percent, the recovery rate of the precious metals is over 98 percent, and the method is conveniently linked with rhodium and iridium separating and refining.

Owner:JINCHUAN GROUP LIMITED

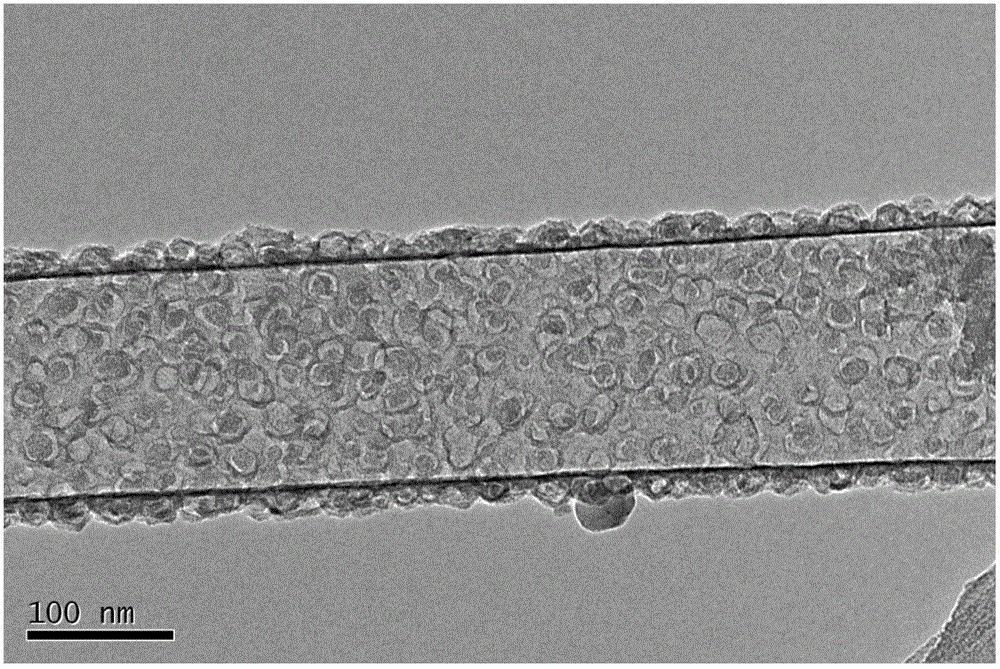

Graphene hollow nano fiber and preparation method thereof

The invention relates to a graphene hollow nano fiber and a preparation method thereof. The external diameter of the graphene hollow nano fiber is 7-700nm, the internal diameter is 6-698nm, the length-diameter ratio is 20:1-2000:1, and the specific area is 300-2600 m<2> / g. The preparation method comprises the following steps: by using an inorganic fiber as a template, heating to 400-1000 DEG C in a carrier gas, introducing a carbon source, and decomposing at the same temperature to directly form the graphene hollow fiber or form a carbon-inorganic template composition fiber; and cooling the composition fiber, treating with acid or alkali, filtering, washing and drying. The preparation method is simple; and the product has the advantages of high purity, complete structure and high mechanical strength, and is suitable to be used as a separation or adsorbing material, an electrode material for electrochemical energy storage or a conducting agent.

Owner:TSINGHUA UNIV

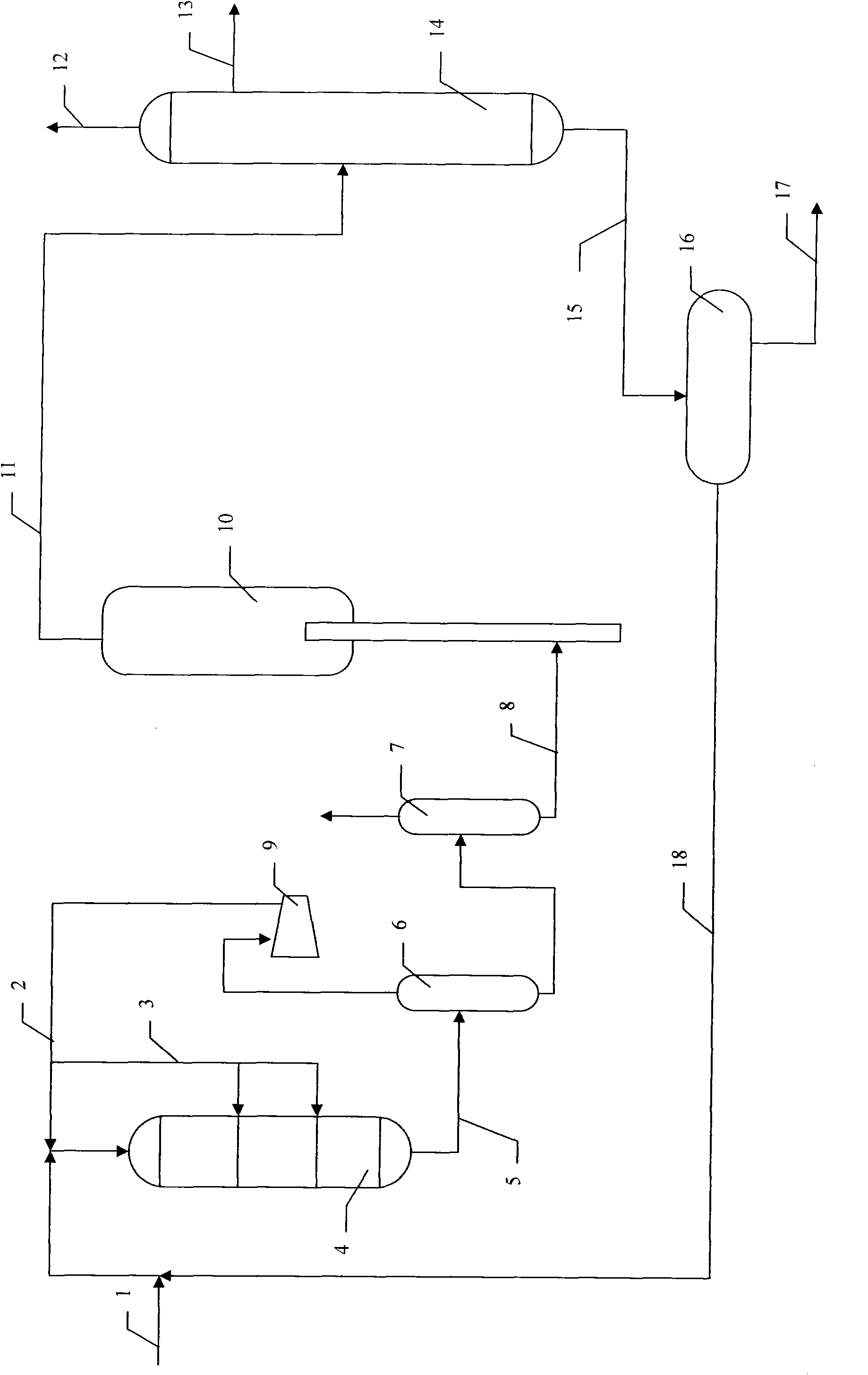

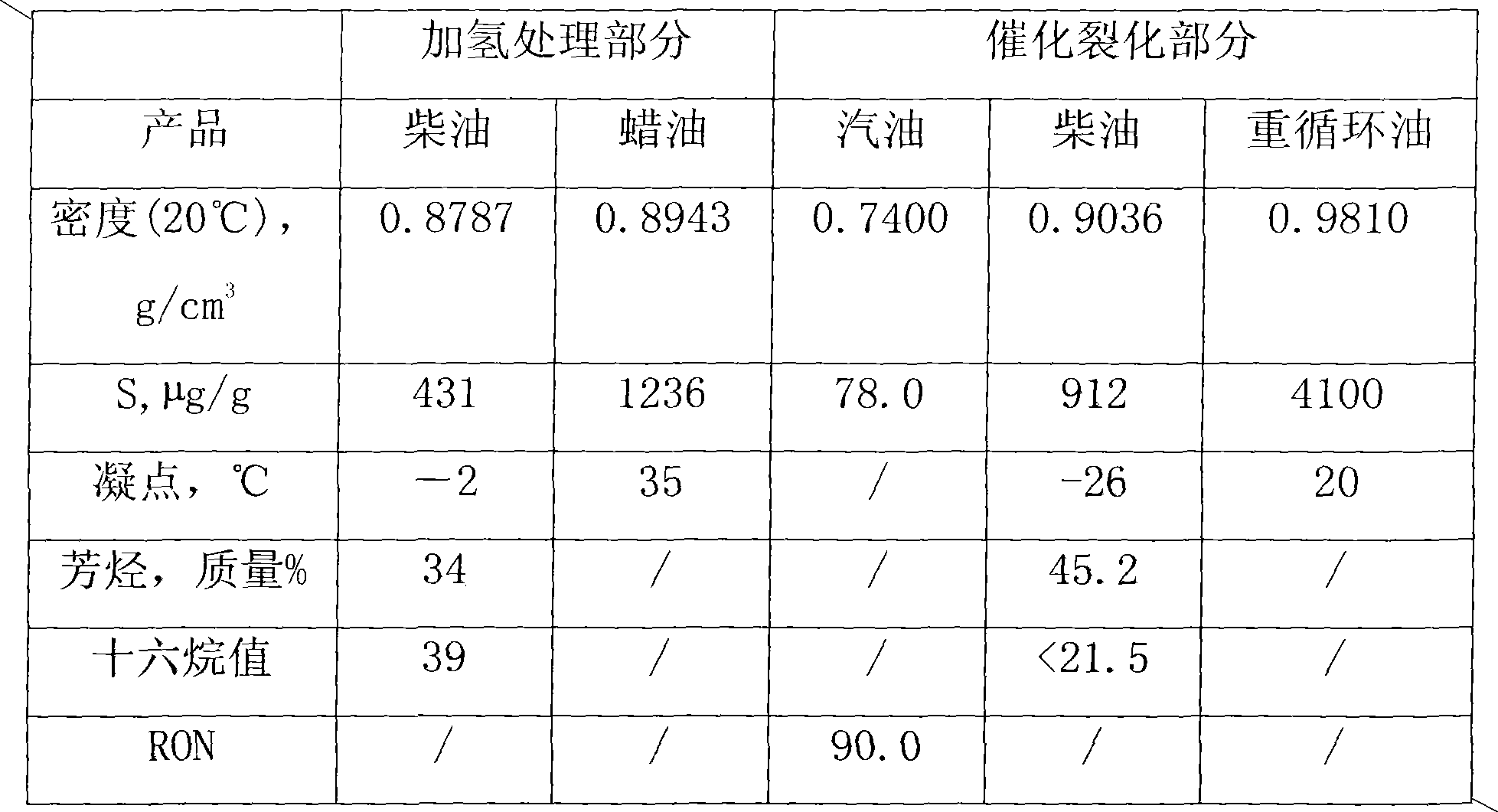

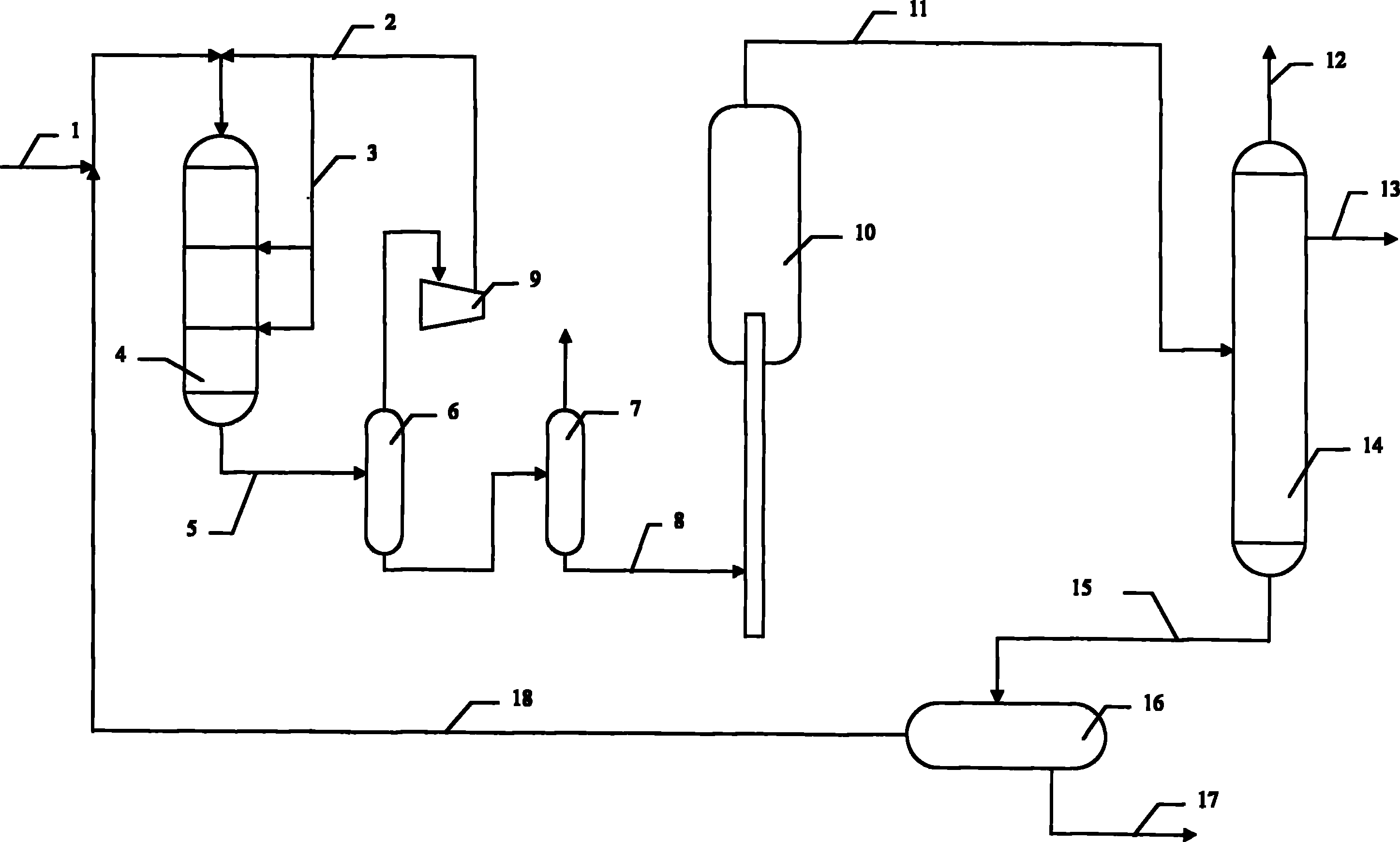

Wax oil hydrogenated treatment and catalytic cracking combined method

ActiveCN101875856AGuarantee normal productionSolve the problem that it is difficult to separate the catalyst solid powderTreatment with hydrotreatment processesGas phaseCombined method

The invention discloses a wax oil hydrogenated treatment and catalytic cracking combined method, which comprises the following steps of: performing hydrogenated reaction on hydrogenated treatment raw materials in the presence of hydrogen and hydrogenated treatment catalyst, performing gas-liquid separation on the hydrogenated reaction effluent, circulating the gas phase for the hydrogenated reaction, directly feeding the liquid phase into a catalytic cracking device without fractionation, and mixing dry gas and liquefied gas separated from the catalytic cracking reaction effluent, catalytic cracking heavy fraction formed by catalytically cracking gasoline and the hydrogenated treatment raw materials to perform hydrogenated reaction. Compared with the prior art, the method can produce maximum gasoline, meanwhile saves equipment investment, makes full use of reaction heat energy and reduces the production energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

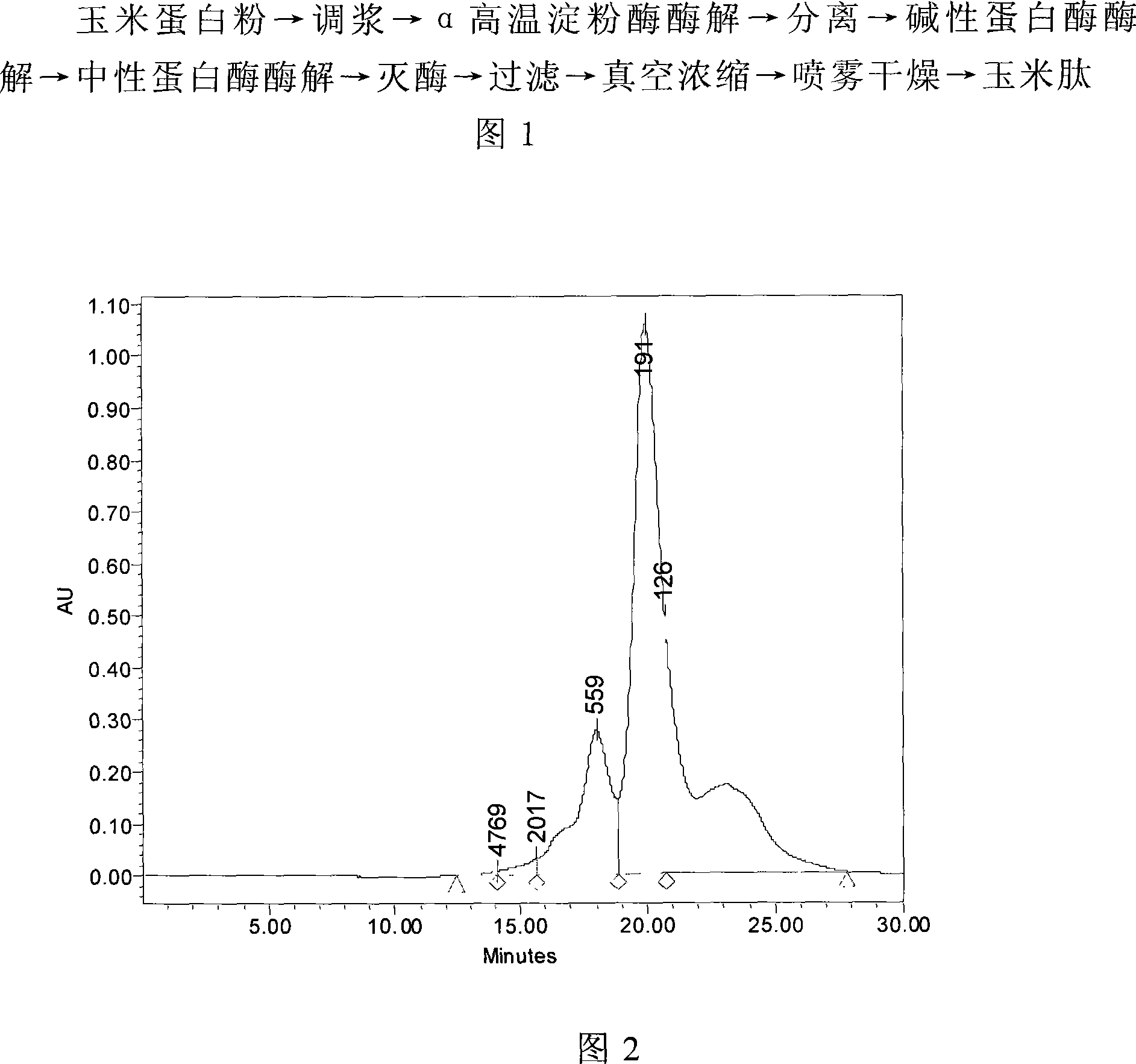

Industrial production method of corn protein polypeptide from corn protein powder by enzymatical process

ActiveCN101096696AHigh peptide yieldComplete enzymatic hydrolysisFermentationBiotechnologyClinical nutrition

The invention discloses a unique extracting method of maize albumen powder from maize, which comprises the following steps: using composite proteinase to enzymolyze zein; separating; hyperfiltering; condensing; spraying; drying; obtaining the white powder shaped product. The invention simplifies the technique and shortens the manufacturing period with good taste and small molecular weight of hybrid peptide, which can be clinical nutrition, hygienic food, sports food and cosmetics.

Owner:中食都庆(山东)生物技术有限公司

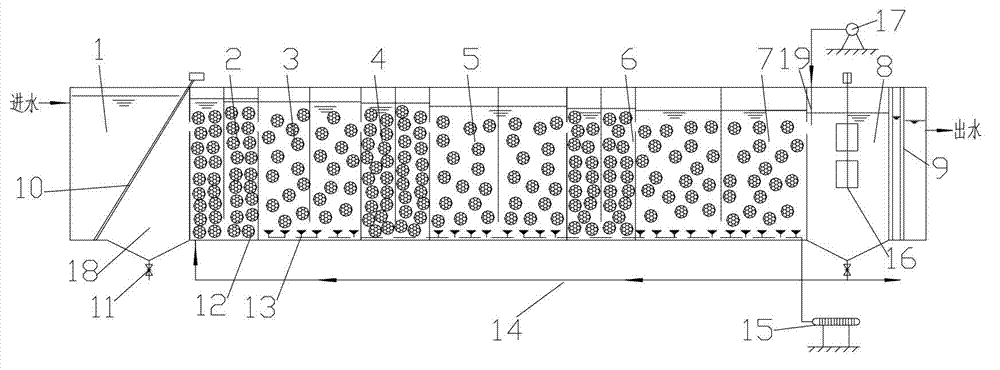

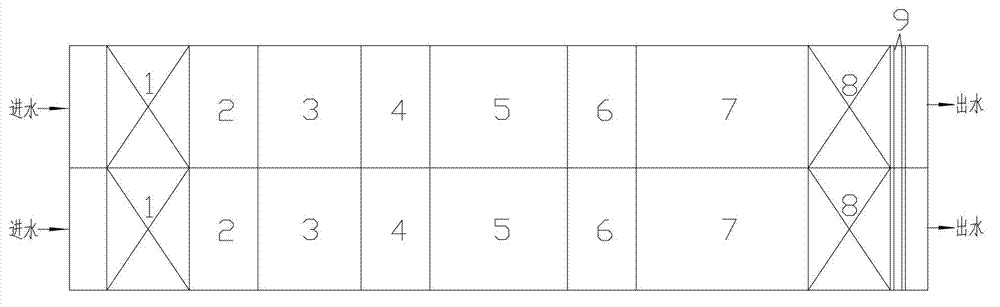

Integrated sewage treatment device with high efficiency and low consumption and treatment method

The invention relates to an integrated sewage treatment device with high efficiency and low consumption and a treatment method, and belongs to the field of sewage treatment. The integrated sewage treatment device comprises a pretreatment unit, a multi-oxidation-deoxidation environment coupling biological reaction pond unit and a deep treatment unit sequentially connected. The multi-oxidation-deoxidation environment coupling biological reaction pond unit adopts a three-stage anoxia-aerobiotic alternating reaction pond filled with a circular composite glass ball porous microbial carrier. The deep treatment unit comprises a filter cloth dynamic film biological reaction pond and first and second dynamic films. Sewage is treated through the devices sequentially. The device provided by the invention cannot only remove carbon containing organic matters, but also has good nitrogen and phosphorus removal capacity.

Owner:BEIJING UNIV OF TECH

Downhole compressor

ActiveUS7338262B2Suitable for useImprove cooling effectCircumferential flow pumpsPositive displacement pump componentsImpellerEngineering

Owner:CORAC ENERGY TECH

Red date ine and its brewing method

InactiveCN1935974AEasy to filterImprove product qualityAlcoholic beverage preparationSulfur dioxideChemistry

The invention relates to red date wine and brewing method. The red date wine is light rose red or red, transparent, has pure red date sweet smell and bouquet. The alcohol content is 6-12%(20 degree centigrade V / V), total sugar 3-100g / L, titration acid 5-8g / L, dissociating sulfur dioxide <=50mg / L. The method includes full fruit dipping and clean juice fermenting processes. Pectinase would not be added in to improve the quality of the product. After main fermenting, aging for 4-6 months, the wine would be prepared. The invention has great meaning for sustainable development and society evolving for red date producing area.

Owner:HEBEI AGRICULTURAL UNIV.

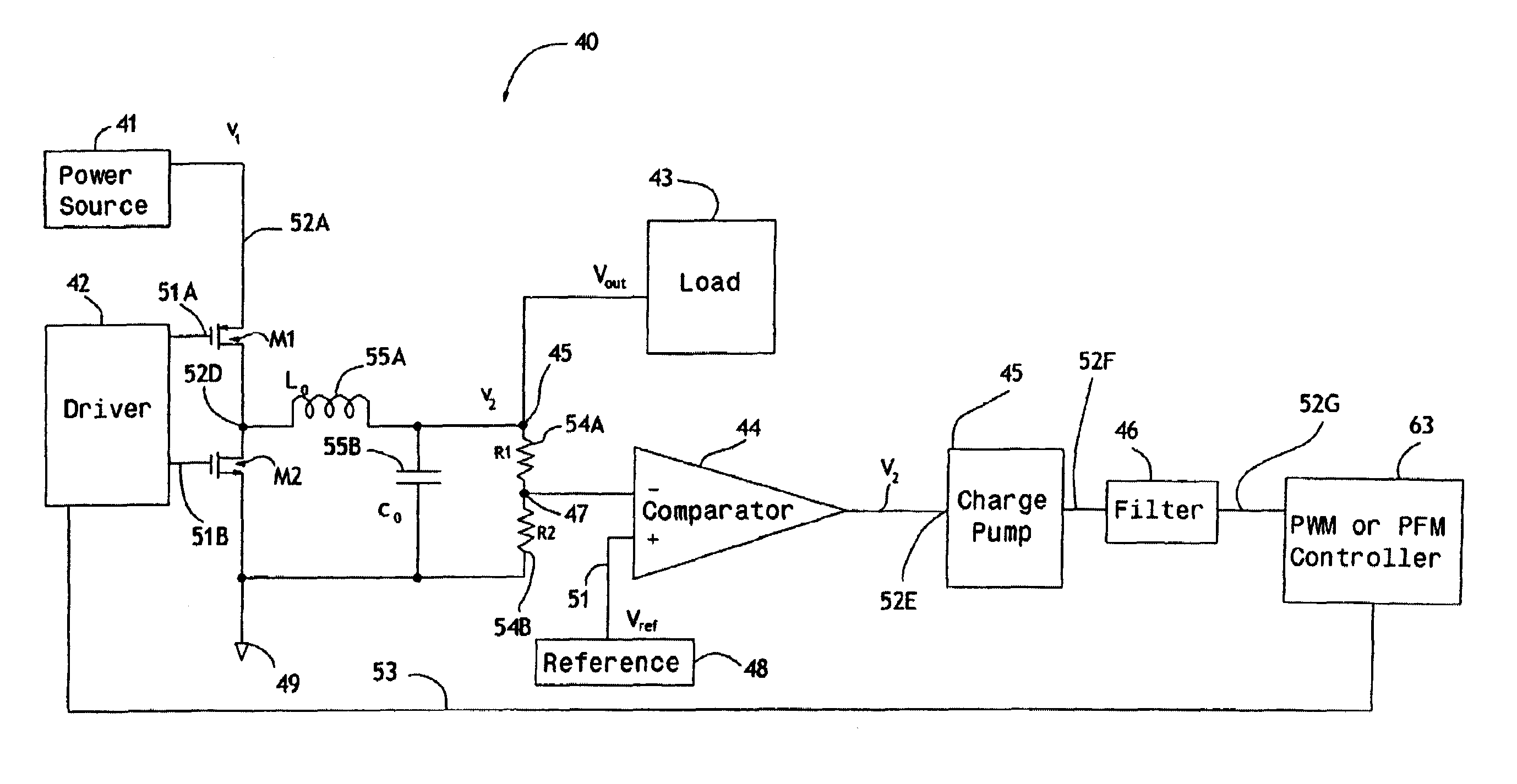

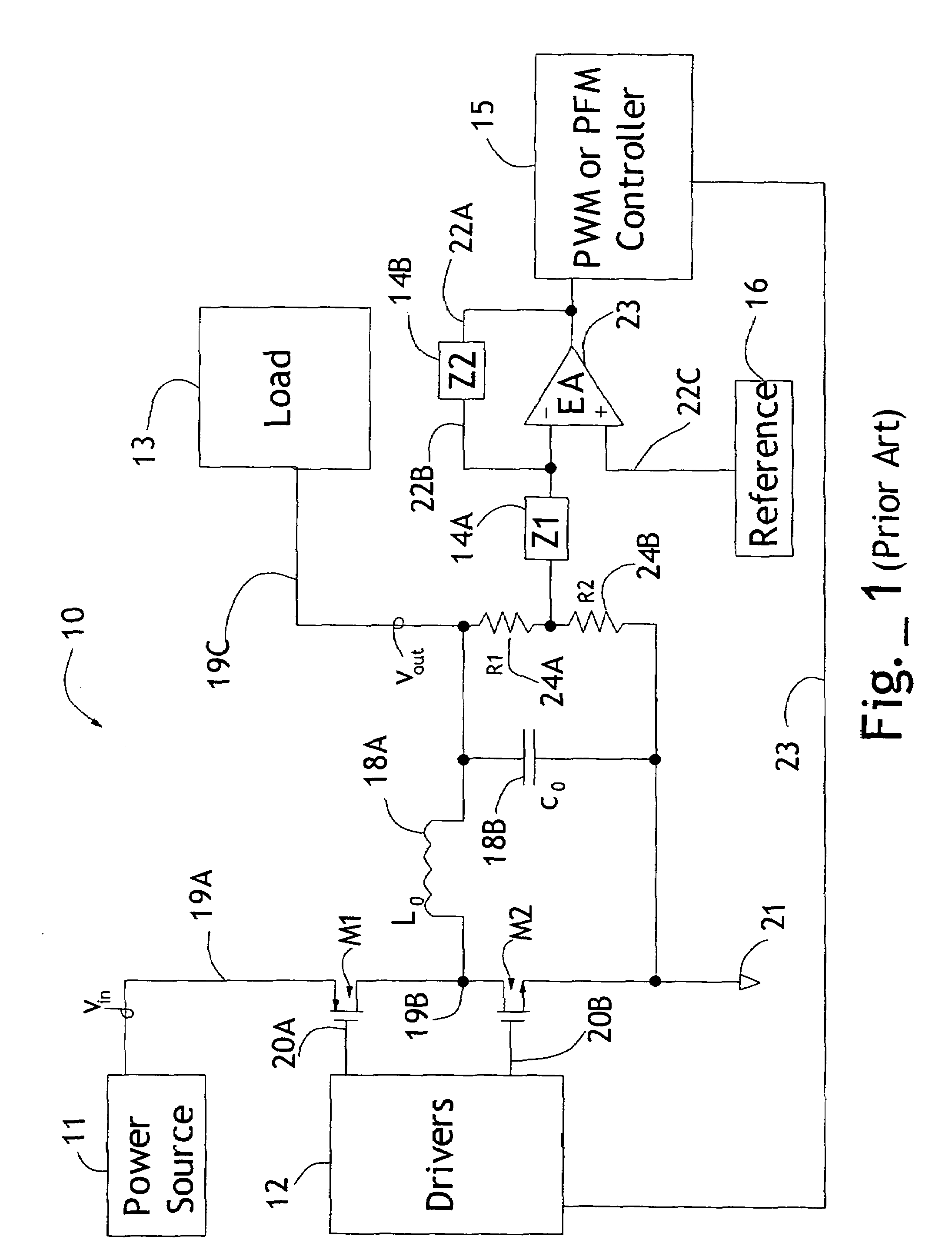

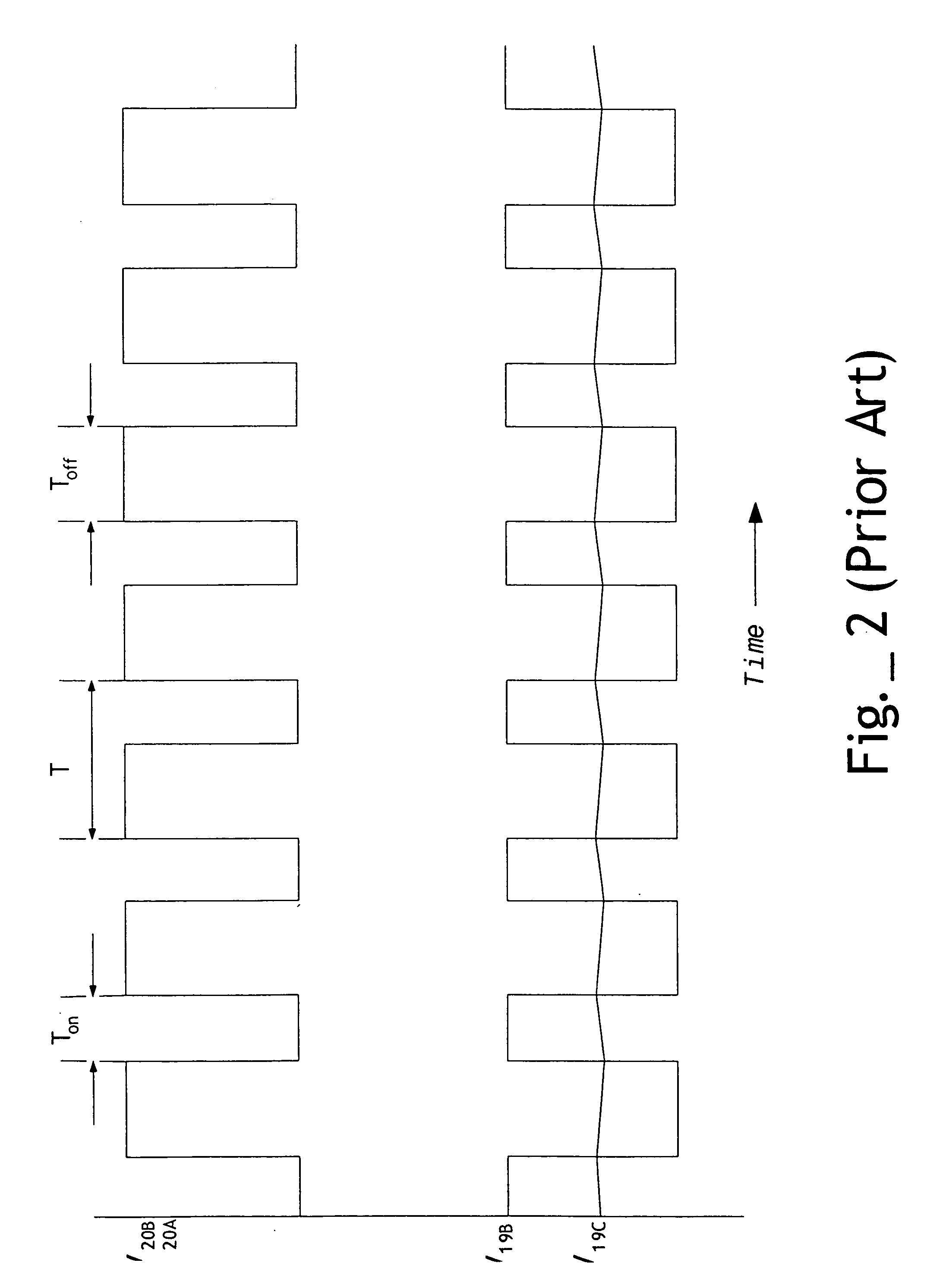

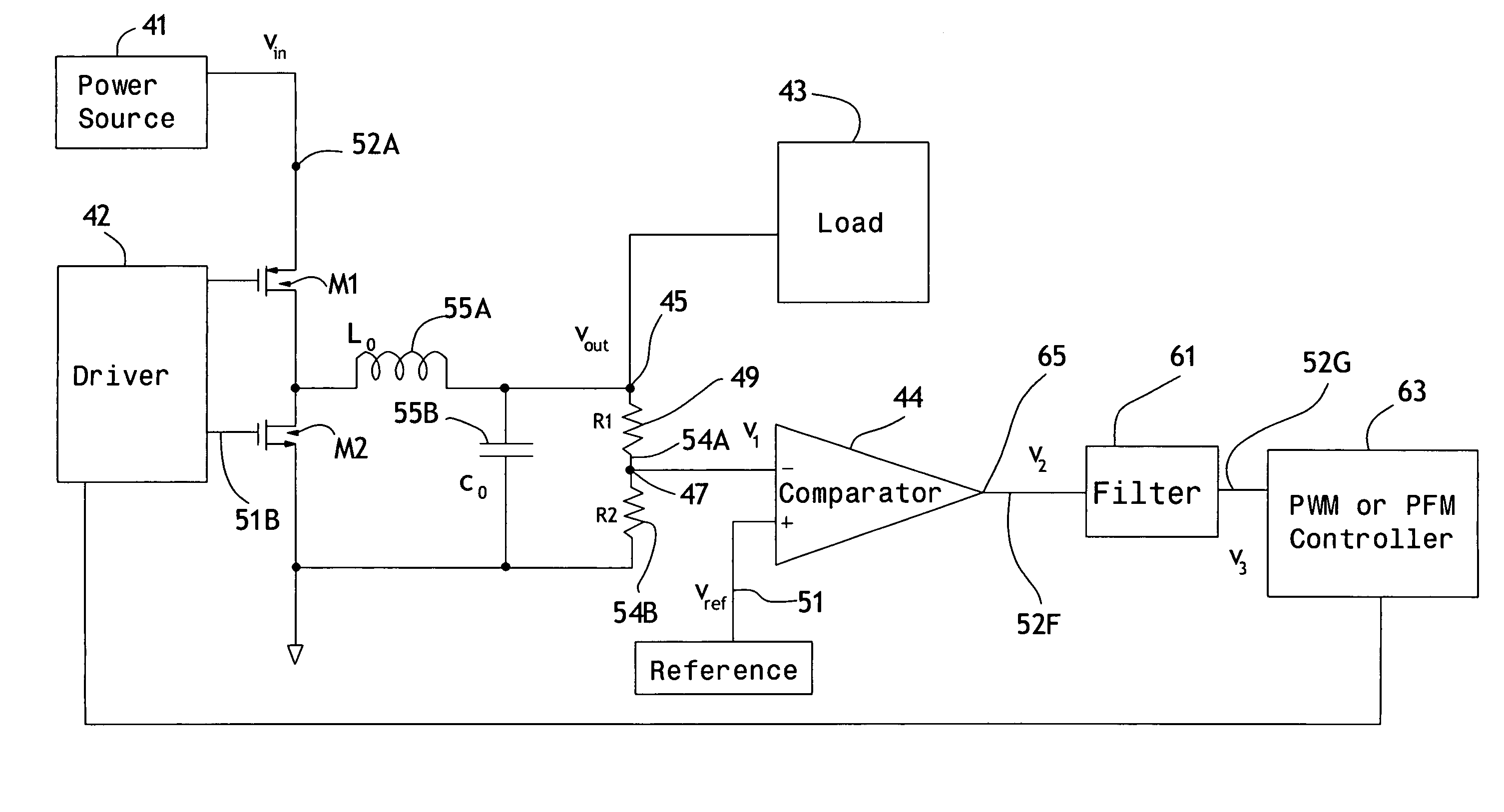

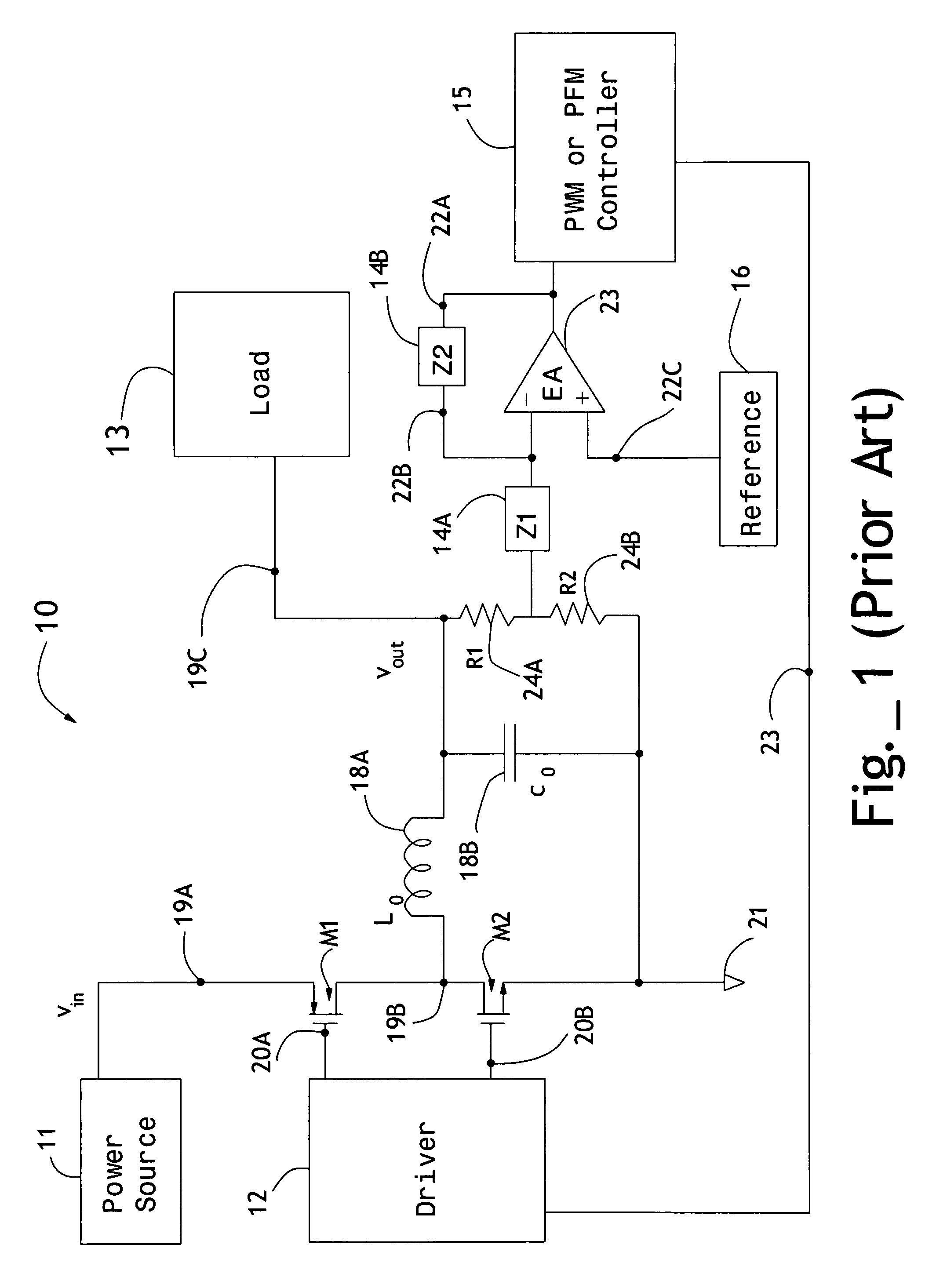

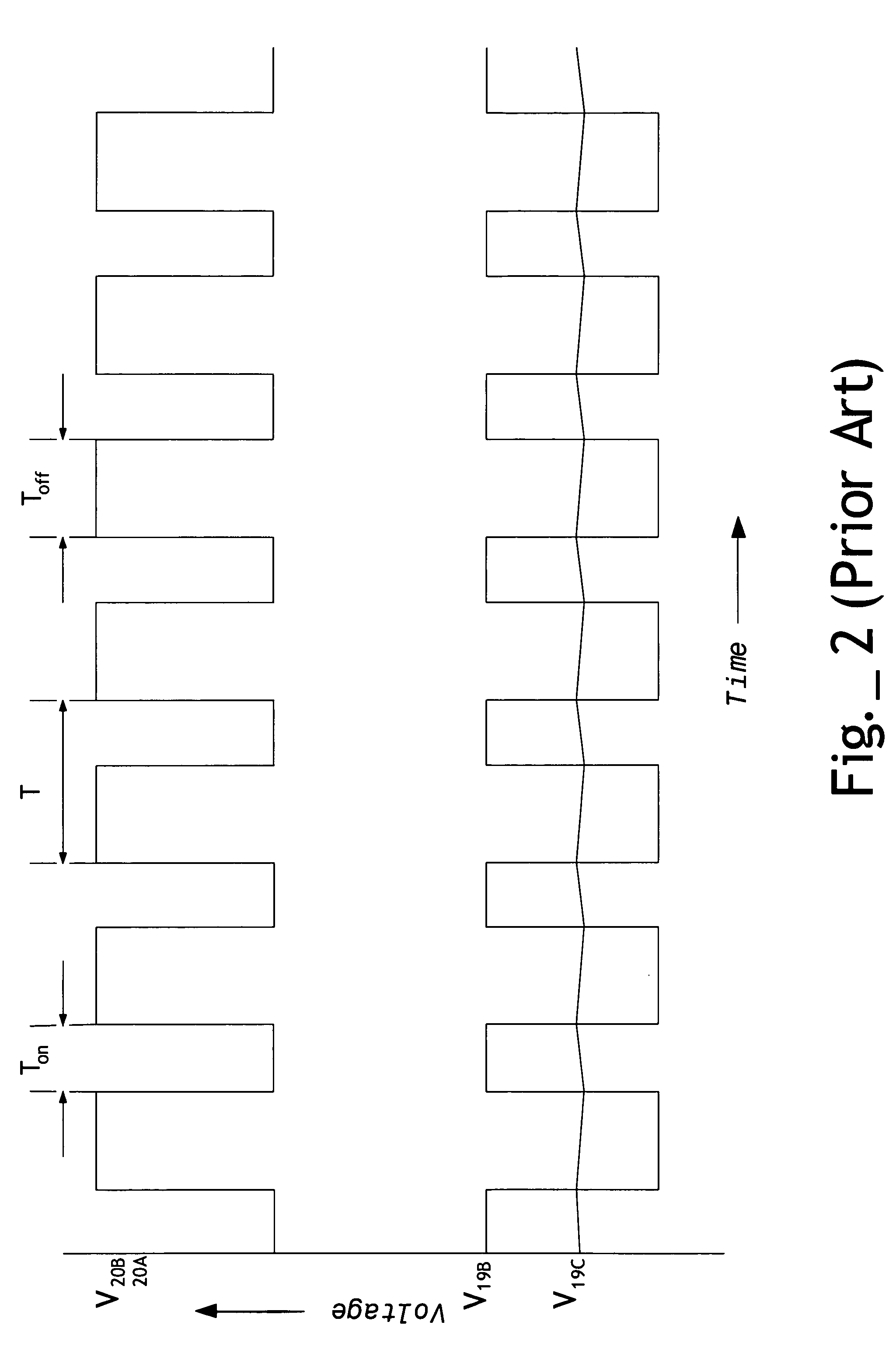

Control loop for switching power converters

InactiveUS7265523B2Linearize nonlinear responseImprove stabilityDc-dc conversionElectric variable regulationControl theoryComparator

A control loop for a clocked switching power converter where the loop features a comparator (44) and a filter (61) in series to linearize the nonlinear response of the comparator (44). The filter (61) has poles and zeros offsetting the poles and zeros of a bridge rectifier (M1 and M2).

Owner:AIVAKA

Extract technology of semi-manganese oxide ore

The invention provides a new method for extracting a semi-manganese oxide ore to prepare a manganese sulfate solution, belonging to the technical field of manganese ore extraction. The method comprises the following steps: crushing the semi-manganese oxide ore; adding cassava alcohol waste water in a reactor, then adding the semi-manganese oxide ore and sulfuric acid, and adjusting the ore pulp liquid-to-solid ratio to be 3:1-5:1 with water; and stirring at 70-98 DEG C for reaction for 1-6h to obtain the reaction lixivium, wherein the leaching rate of manganese is more than 90%. In the invention, the trade waste, i.e. cassava alcohol waste water is taken as a reducing agent, so that the method changes waste into treasures, has double benefits of environmental protection and economy, and has mild process condition and simple edulcoration process.

Owner:GUANGXI UNIV

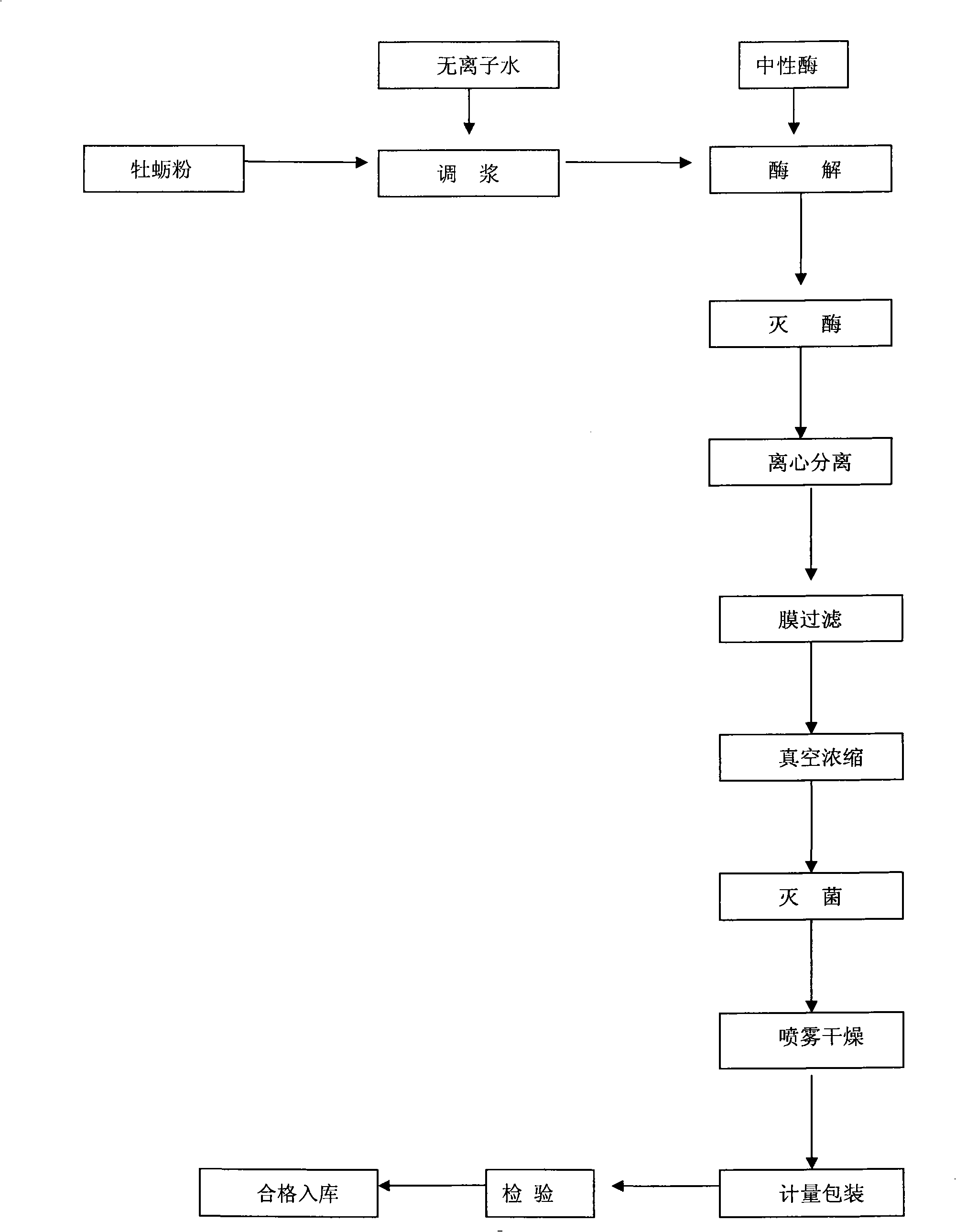

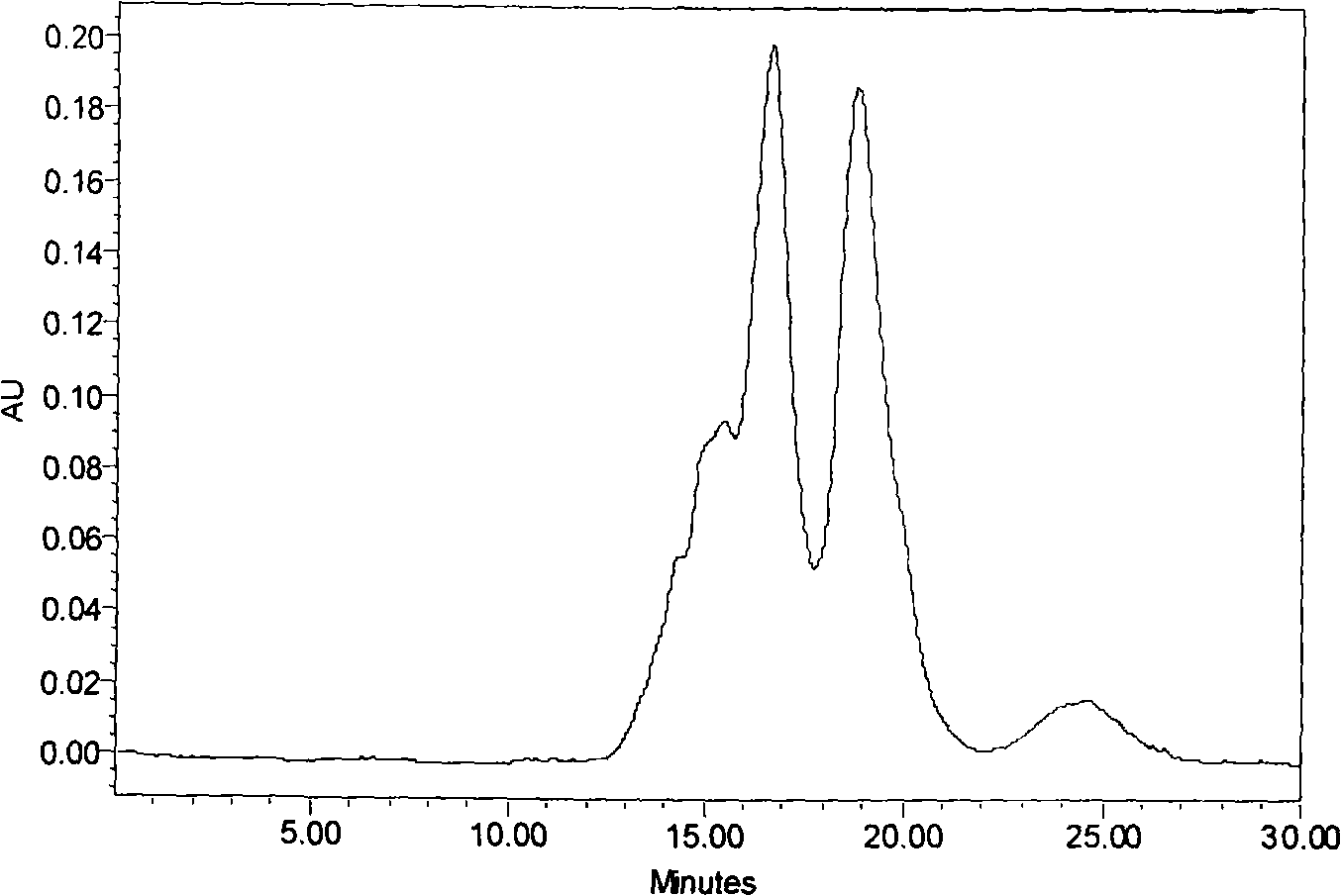

Industrial production method for making peptide of oyster from oyster powder by enzyme method

ActiveCN101263860AHigh peptide yieldHigh technology contentAnimal proteins working-upFood preparationNeutral proteaseEmulsion

The invention discloses an industrial production method for preparing oyster bioactive peptides from oyster powder through enzymatic method, which is characterized in that: the special of the production method lies in comprising the following steps: (1) inputting the oyster powder of 1kg, adding deionized water, carrying out shear through the emulsion shearing machine on the bottom of a tank after finishing feeding and reflowing into the tank; (2) regulating the PH of the feed liquid to 7.0 to 7.5, warming up to 48 to 52 DEG C, adding neutral protease of 10 to 20g and beginning enzymolysis for 6 hours; (3) warming up to 80 DEG C and carrying out killing enzyme for 10 minutes; (4) filtering with ceramic membrane, carrying out spray drying and passing through 60 mesh sieve for the feed liquid when the concentration of vacuum concentration is 20% and packaging with compound bag. The industrial production method has the advantages that: the technology is simple; the generating period is short; the produced oyster bioactive peptides are white, not fishy smell and good taste; and the molecular weight of the contained mixing peptide is small.

Owner:中食都庆(山东)生物技术有限公司

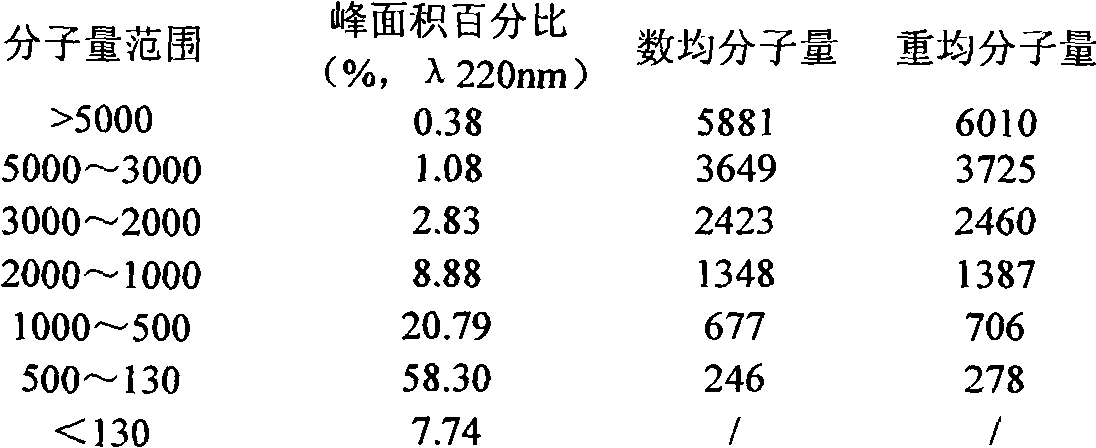

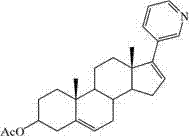

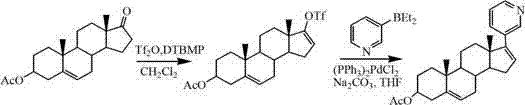

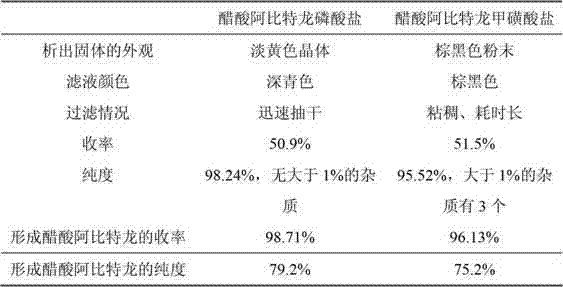

Purifying method for abiraterone acetate

Owner:LUNAN PHARMA GROUP CORPORATION

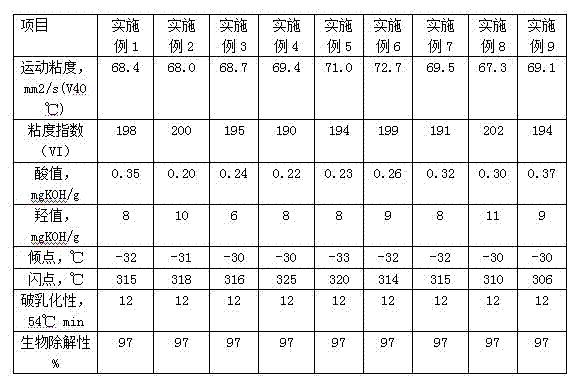

Method for producing pentaerythritol oleate under catalysis of granular solid superacid

InactiveCN102875374ANo pollutionHigh yieldOrganic compound preparationCarboxylic acid esters separation/purificationPentaerythritolAcid catalyzed

The invention discloses a method for producing pentaerythritol oleate under catalysis of granular solid superacid, and relates to a method for synthesizing ester base oil in biodegradable lubricating oil. The method comprises the following steps of: mixing pentaerythritol and oleic acid in a mass ratio of 1:(7.2-9.5), adding the granular solid superacid, and reacting at the temperature of between 140 and 240DEG C for 4 to 10 hours in the vacuum degree of 100-1,000Pa; filtering by using a 200-12,500 mesh filter screen or filter plate; and heating crude grease to the temperature of between 160 and 280DEG C, removing unreacted acid or alcohol, keeping the vacuum degree of the system ranging from 1 to 500Pa, and distilling under reduced pressure for 40 to 120 minutes to obtain the pentaerythritol oleate. The pentaerythritol oleate produced by the method has excellent low temperature fluidity, lubricity, viscosity-temperature characteristics, oxidation safety, cleanness and good biodegradability, and the method is an environment-friendly and high-efficiency production method having advantages of simple treatment, short production period, high esterification rate and high product yield.

Owner:SICHUAN SIPO CHEMICAL CO LTD

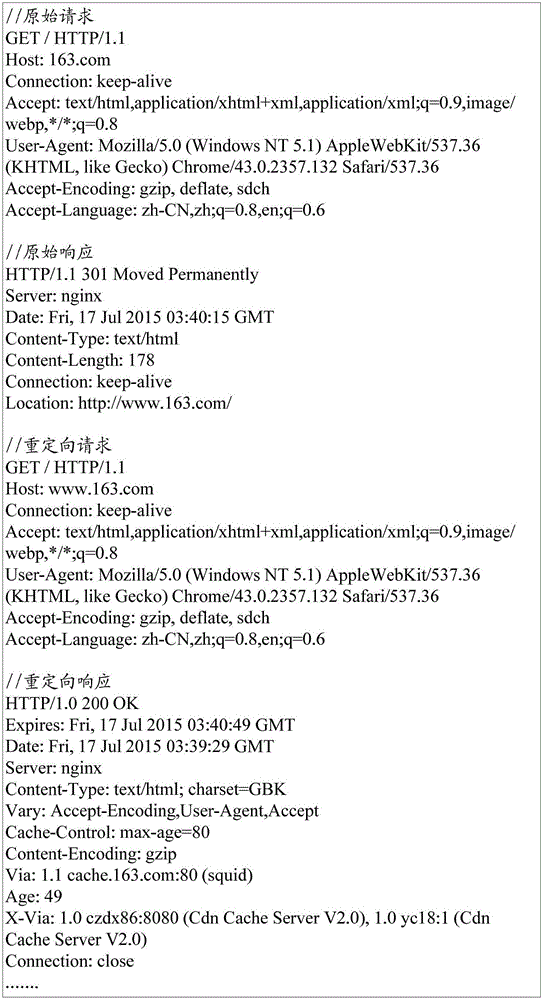

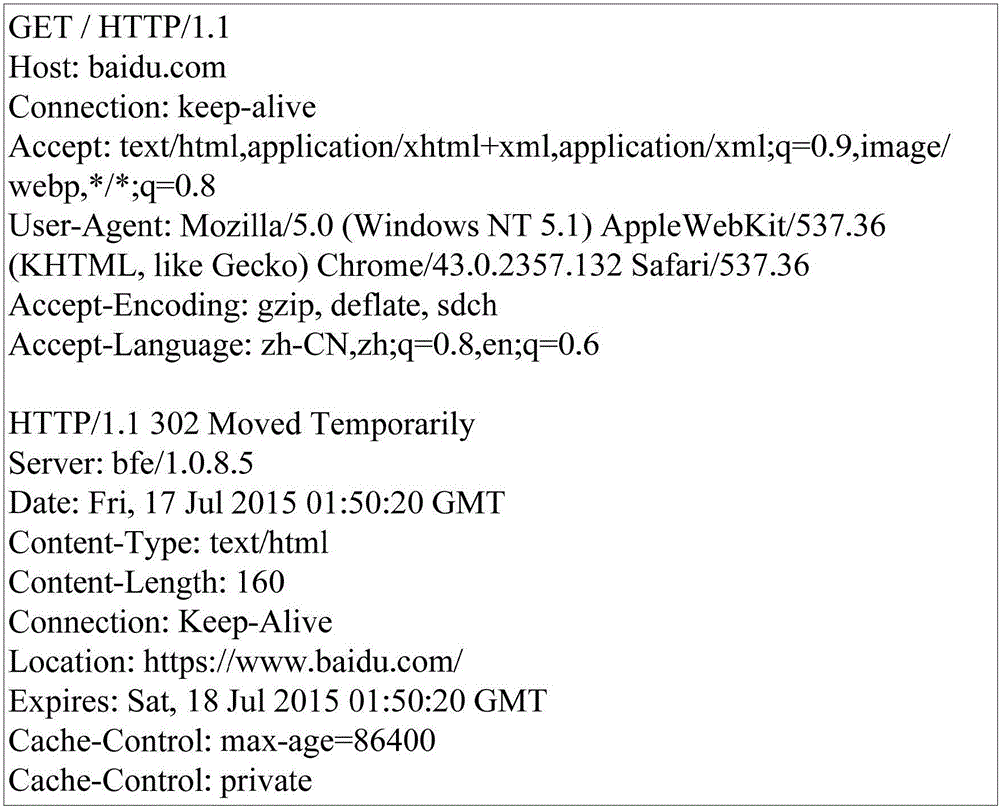

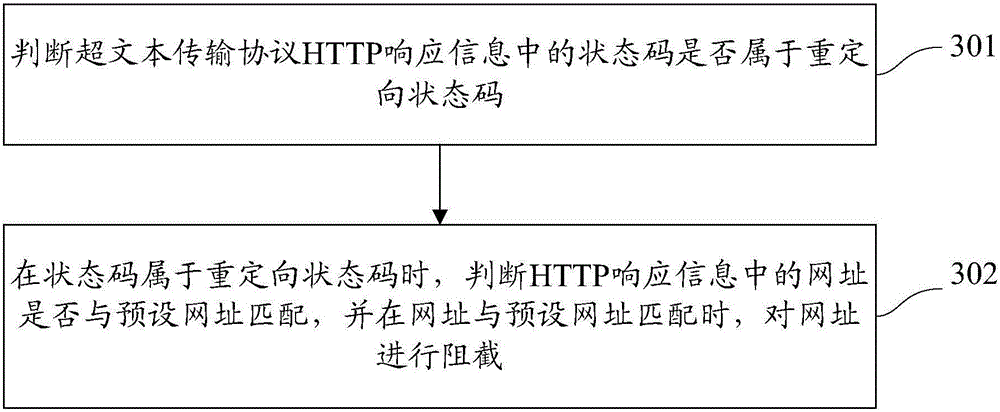

URL filtering method and device

The invention discloses a uniform resource locator (URL) filtering method. The URL filtering method comprises the steps: judging whether a status code of hypertext transfer protocol (HTTP) response information belongs to a redirection status code; if the status code belongs to the redirection status code, judging whether a URL of the HTTP response information matches a preset URL; and if the URL matches the preset URL, blocking the URL. The invention further discloses a URL filtering device.

Owner:BEIJINGNETENTSEC

Production method of water-soluble licoflavone

InactiveCN102140144ASimple methodSimple and fast operationCosmetic preparationsToilet preparationsSolubilityCyclodextrin

The invention relates to a preparation method of water-soluble licoflavone, in particular to a novel method for embedding cyclodextrin into licoflavone. By adopting the method disclosed by the invention, the solubility of licoflavone in water is enhanced, and the application range of licoflavone in whitening and speckle-removing functional cosmetics is expanded.

Owner:SHANGHAI OLI ENTERPRISES CO LTD

Method for removing heavy metal ions out of water

ActiveCN103910437AAchieve separationSimple operating conditionsWater contaminantsBiological water/sewage treatmentCadmium CationAdsorption effect

The invention belongs to the field of the environmental pollution control method and specifically relates to a method for removing heavy metal ions out of water. The method comprises the steps of mixing penicillium simplicissimum spores and a heavy metal ion solution to obtain a mixed solution, next, adding charcoal dust to the mixed solution, and then carrying out culturing and separation processes, thus completing the adsorption and removal of heavy metal ions out of the water. The method is characterized in that an immobilized object and an immobilization carrier are exchanged, the penicillium simplicissimum mycelia are taken as the carrier to immobilize the charcoal dust, the reducing adsorption action of the charcoal and the penicillium simplicissimum on hexavalent chromium (Cr<6+>) in water and the adsorption effect of the charcoal and the penicillium simplicissimum on heavy metal ions such as cadmium (Cd<2+>), lead (Pb<2+>) and copper (Cu<2+>) in water are achieved simultaneously, and therefore, charcoal dust with the heavy metal ions is easy to separate; the method is simple in operation condition, easy to implement, low in cost and high in removal rate, and does not cause secondary pollution.

Owner:HUNAN UNIV

Control loop for switching power converters

InactiveUS7940033B2Improve stabilityImprove performanceDc-dc conversionElectric variable regulationTransverterClock rate

A pulse regulation loop for a clocked switching power converter where the loop is around a bridge converter. The loop features a comparator, a charge pump and a filter in series, feeding a pulse modulator controlling the clock duty cycle of the bridge. Ripple in the bridge converter output is feed to the comparator which causes the charge pump to inject or remove charge from the filter at the clock rate providing control over the modulator that establishes converter efficiency. The charge pump is of the PLL type, having switches responsive to voltage output from the comparator, evaluating the converter ripple relative to a reference voltage.

Owner:AIVAKA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com