Graphene hollow nano fiber and preparation method thereof

A hollow nano, graphene technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of long radial diffusion distance of ions, unfavorable application performance, etc., and achieve volumetric energy density The effect of improvement, reduction of preparation cost, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

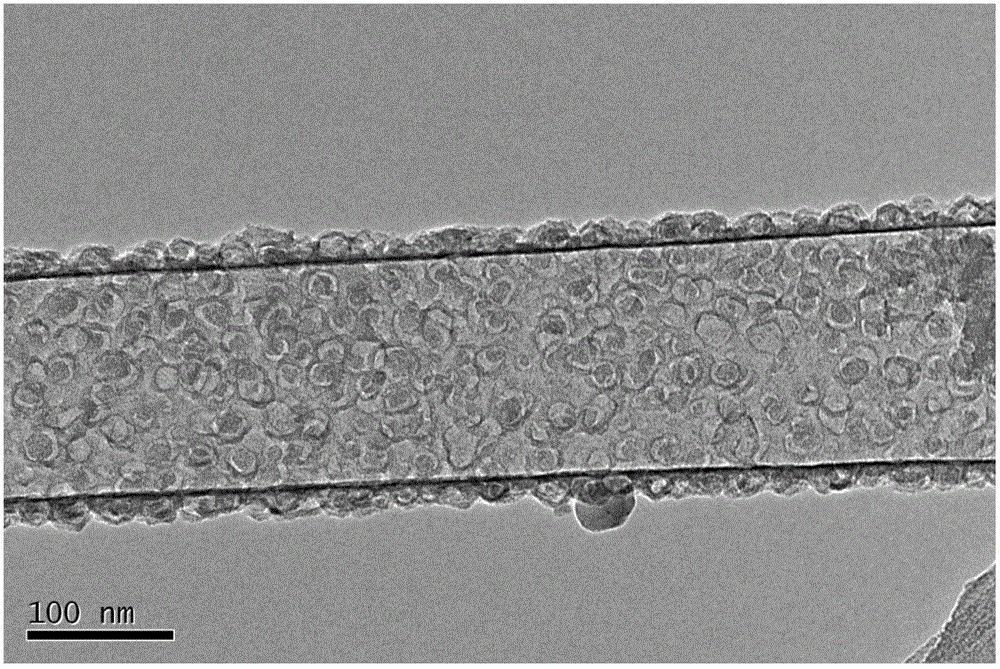

[0032] Zinc carbonate fiber template with a diameter of 6nm and an aspect ratio of 1000:1. Put it in the reactor, raise the temperature to 600°C under the atmosphere of argon as the carrier, and then pass the process gas (a mixture of hydrogen, argon and CO, the volume ratio is 0.5:0.5:1) at the same temperature break down. After reacting for 1 hour, the graphene hollow nanofiber product was directly obtained. Turn off the carbon source, keep the flow and ratio of hydrogen and argon carrier gas constant, and cool down to room temperature. The inner diameter of the obtained product is 6nm, the outer diameter is 7nm, the aspect ratio is 1000:1, and the specific surface area is 2600m 2 / g.

Embodiment 2

[0034] Using zinc sulfate fiber template, its diameter is 698nm, aspect ratio is 20:1. It is placed in a reactor, and after the temperature is raised to 1000 ° C under the atmosphere of nitrogen as the carrier, the process gas (hydrogen, nitrogen and methane, CO 2 The mixed gas, the volume ratio is 0.5:0.5:3:3) decomposes at the same temperature. After 2 hours of reaction, the graphene hollow nanofiber product is directly obtained, the carbon source is turned off, the flow rate and ratio of the hydrogen-nitrogen carrier gas are kept constant, and the temperature is lowered to room temperature. The inner diameter of the obtained product is 698nm, the outer diameter is 700nm, the aspect ratio is 20:1, and the specific surface area is 2300m 2 / g.

Embodiment 3

[0036] Zinc hydroxide fiber template with a diameter of 6nm and an aspect ratio of 2000:1. Put it in the reactor, raise the temperature to 400°C under the atmosphere of hydrogen as the carrier, and then pass in the mixed gas of process gas (hydrogen, acetylene, methanol, the volume ratio is 1:10) to decompose at the same temperature. After reacting for 0.01 hour, the graphene hollow nanofiber product is directly obtained, the carbon source is turned off, the flow rate of the hydrogen carrier gas is kept constant, and the temperature is lowered to room temperature. The inner diameter of the obtained product is 6nm, the outer diameter is 7nm, the aspect ratio is 2000:1, and the specific surface area is 300m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com