Patents

Literature

98 results about "Hydrogen carrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A hydrogen carrier is an organic macromolecule that transports atoms of hydrogen from one place to another inside a cell or from cell to cell for use in various metabolical processes. Examples include NADPH, NADH, and FADH. The main role of these is to transport hydrogen atom to electron transport chain which will change ADP to ATP by adding one phosphate during metabolic processes (e.g. photosynthesis and respiration).

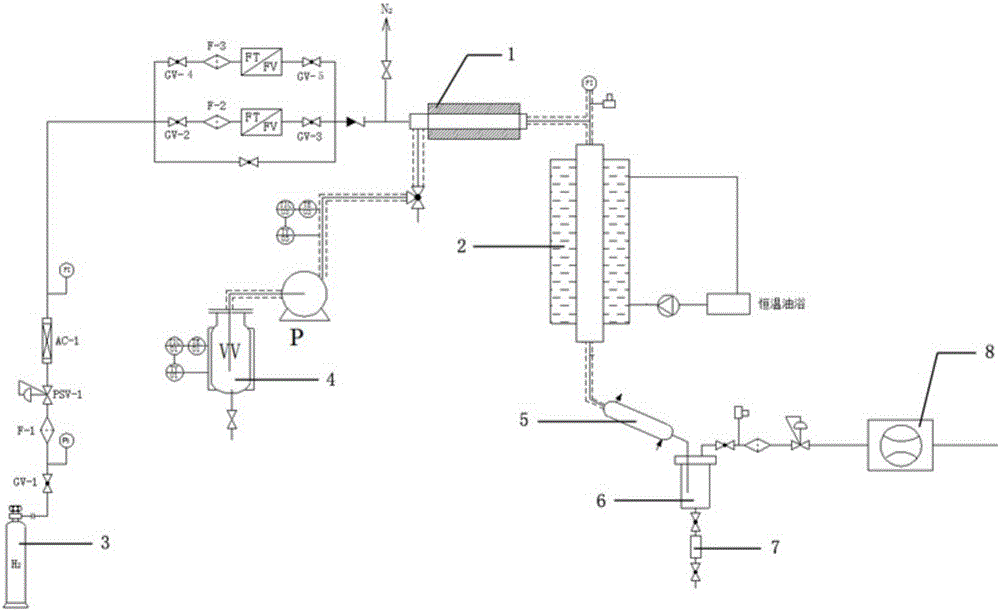

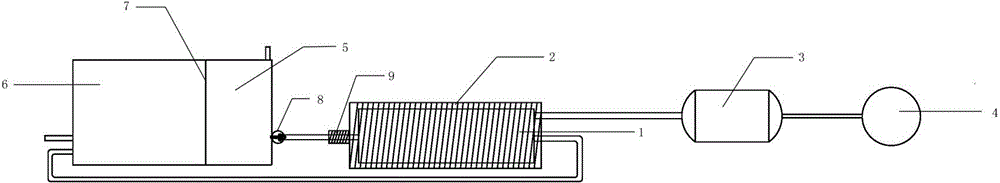

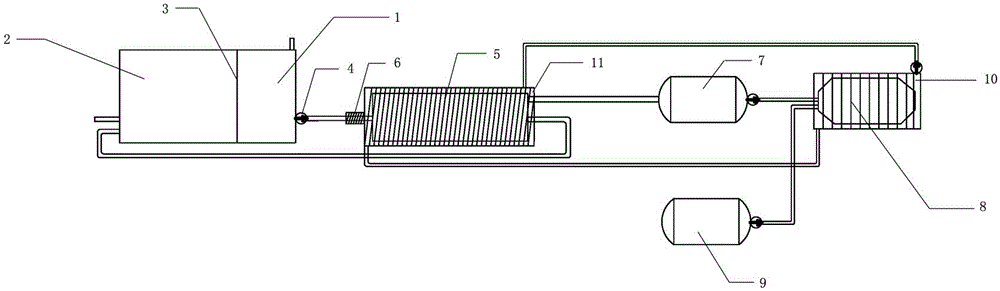

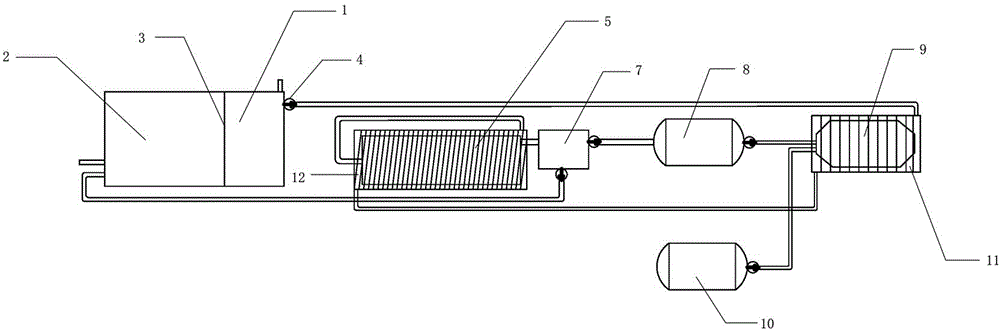

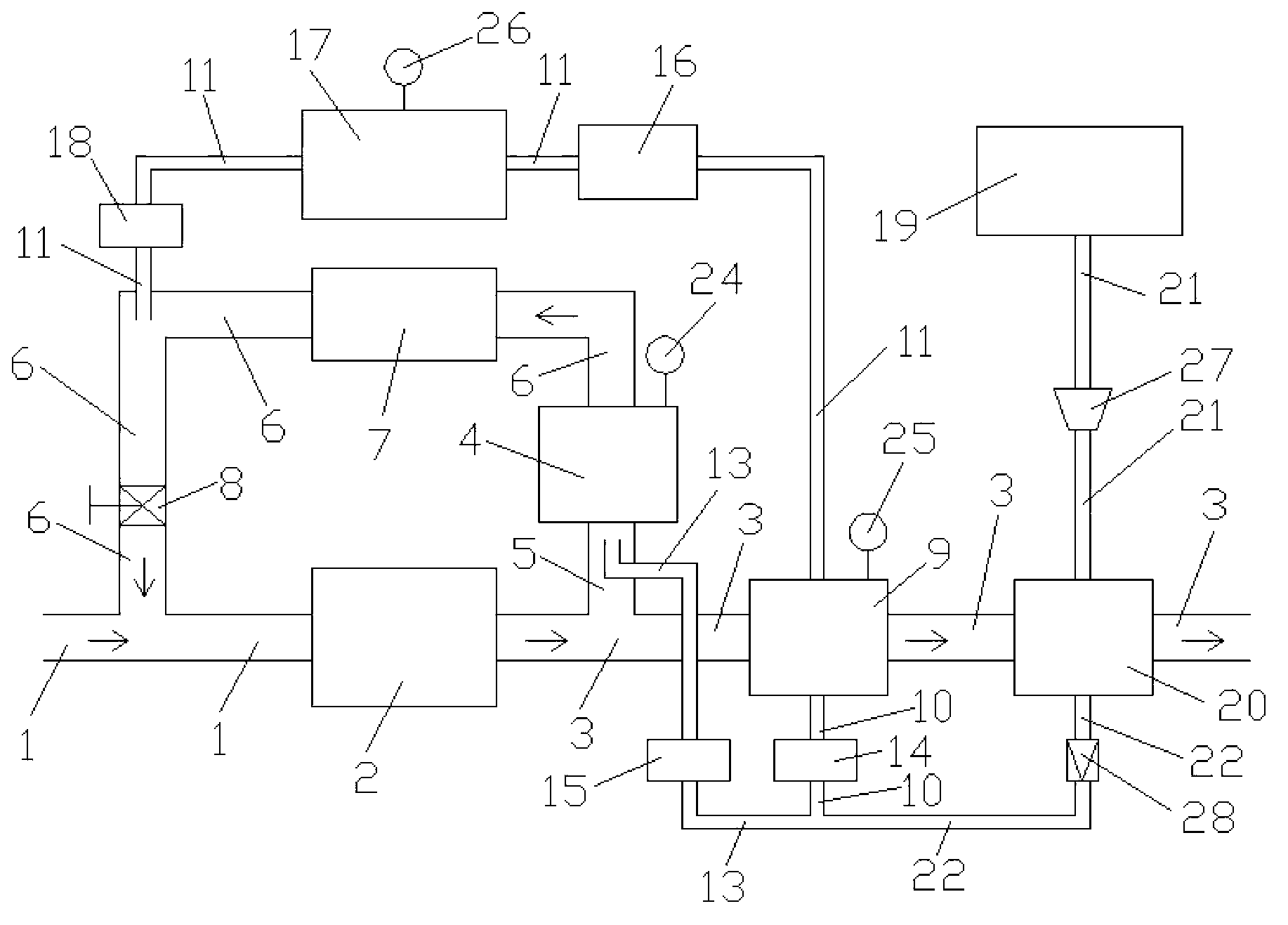

Continuous hydrogenation reaction system for liquid organic hydrogen storage carrier and hydrogenation reaction method

ActiveCN105060244AChange viscosityImprove responseHydrogenMetal/metal-oxides/metal-hydroxide catalystsTemperature controlHydrogenation reaction

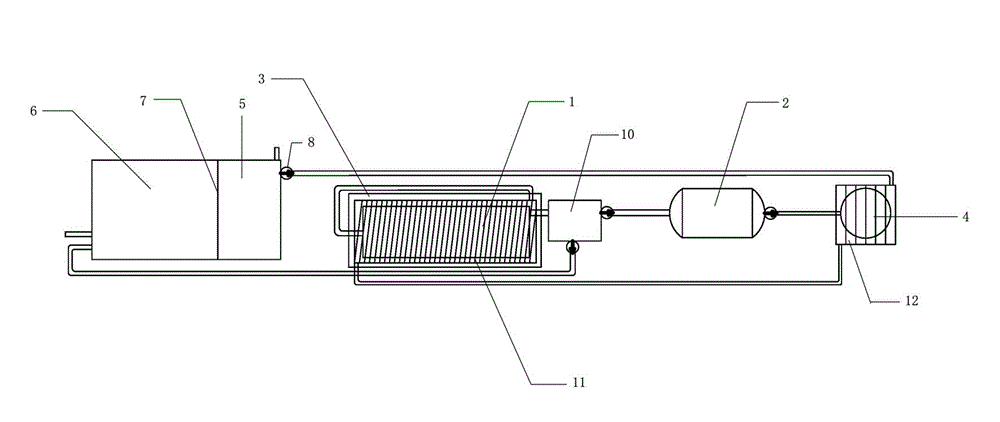

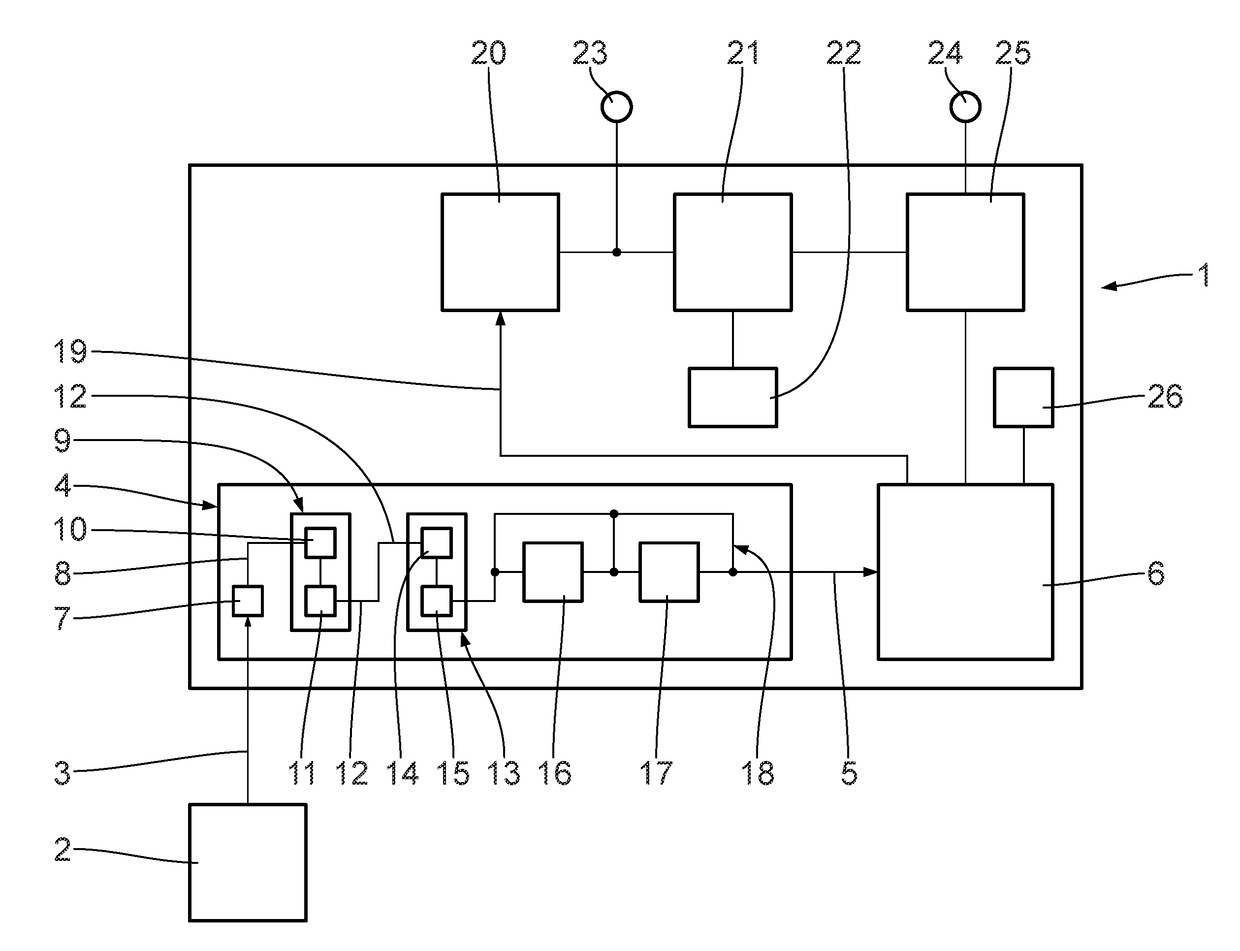

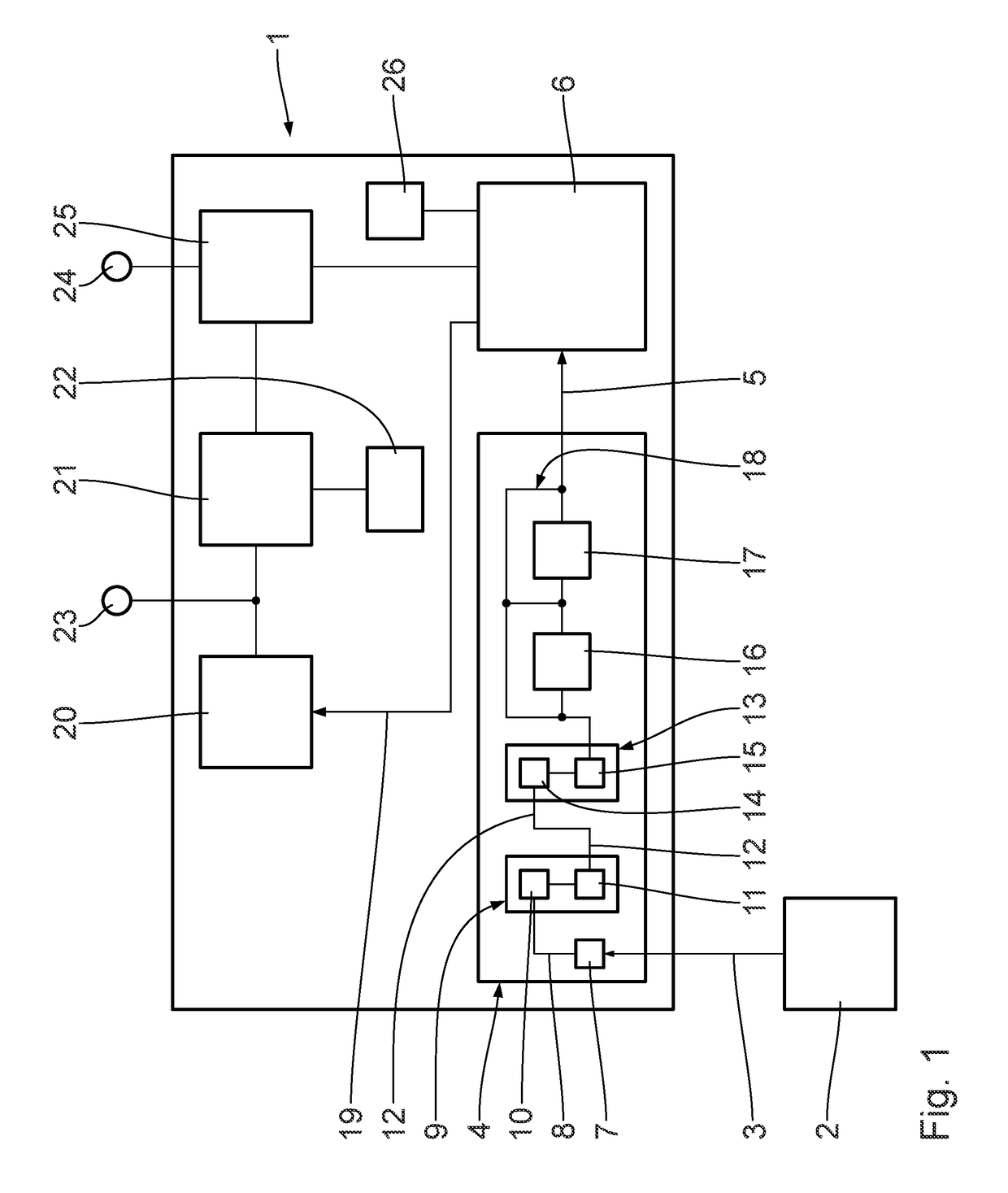

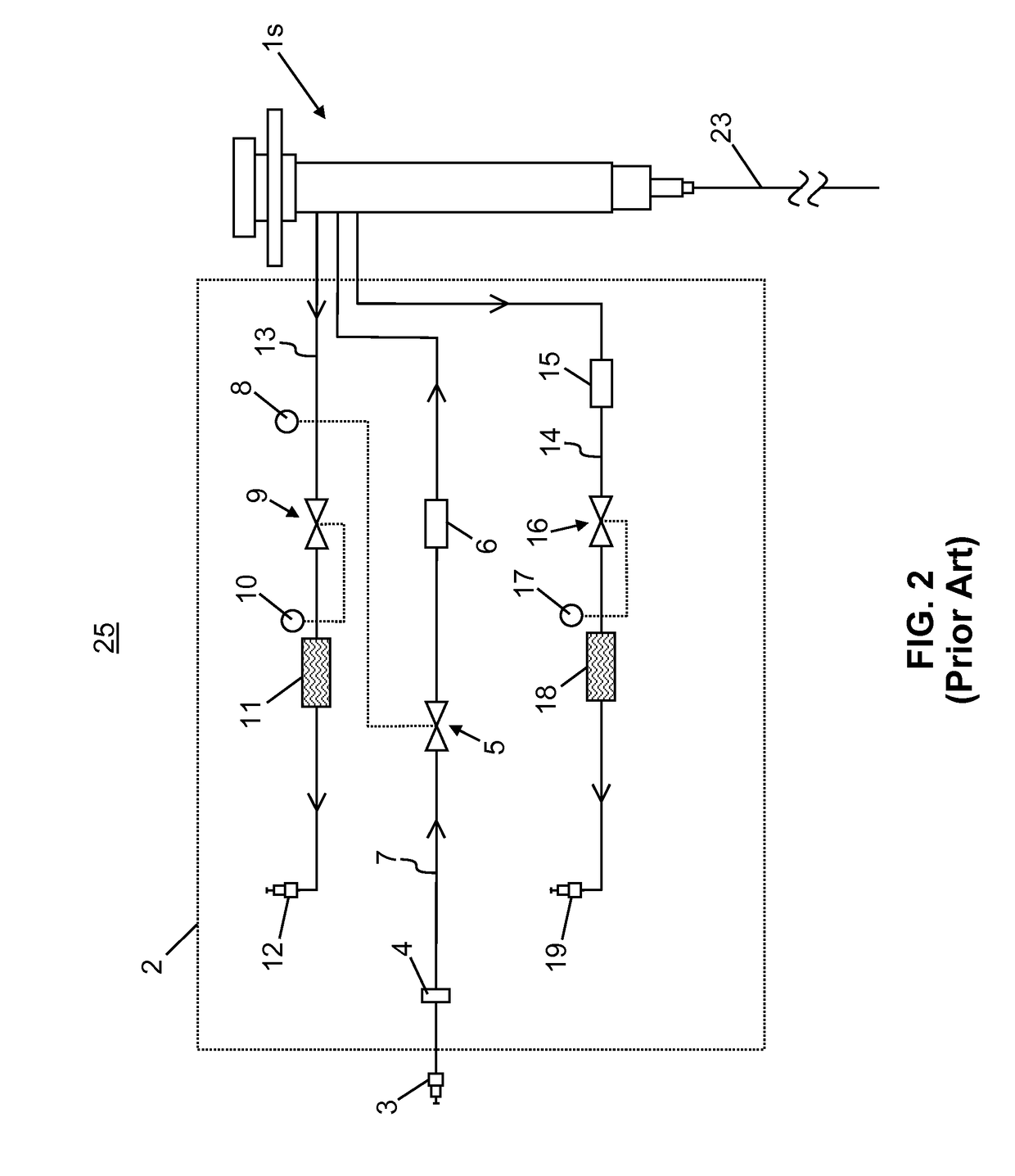

The invention discloses a continuous hydrogenation reaction system for a liquid organic hydrogen storage carrier and a hydrogenation reaction method. The system comprises a feeding system, preheaters, static bed reaction stills and separation devices. The feeding system is communicated with inlets of the preheaters through pipelines. Outlets of the preheaters are communicated with inlets of the static bed reaction stills through pipelines. Outlets of the static bed reaction stills are communicated with inlets of the separation devices through pipelines. The static bed reaction stills are filled with hydrogenation catalysts and inert materials. The interiors of the reaction stills are kept at the constant temperature through circulation heat conduction media in interlayers of the surfaces of the static bed reaction stills. According to the continuous hydrogenation reaction system, the single-tube type static bed reaction stills are mainly adopted, the single-tube type static bed reaction stills are filled with the hydrogenation catalysts and the inert materials, heat tracing and heating control systems are arranged in all the pipelines in the liquid feeding system to be used for conducting temperature-control heating on liquid flowing through the system, a plurality of sets of gas quality and flow controller systems are designed in the system, the preheaters in the system are designed to be gas-liquid blending type preheaters, and the hydrogenation effect of the liquid hydrogen storage carrier is improved beneficially.

Owner:WUHAN HYNERTECH CO LTD

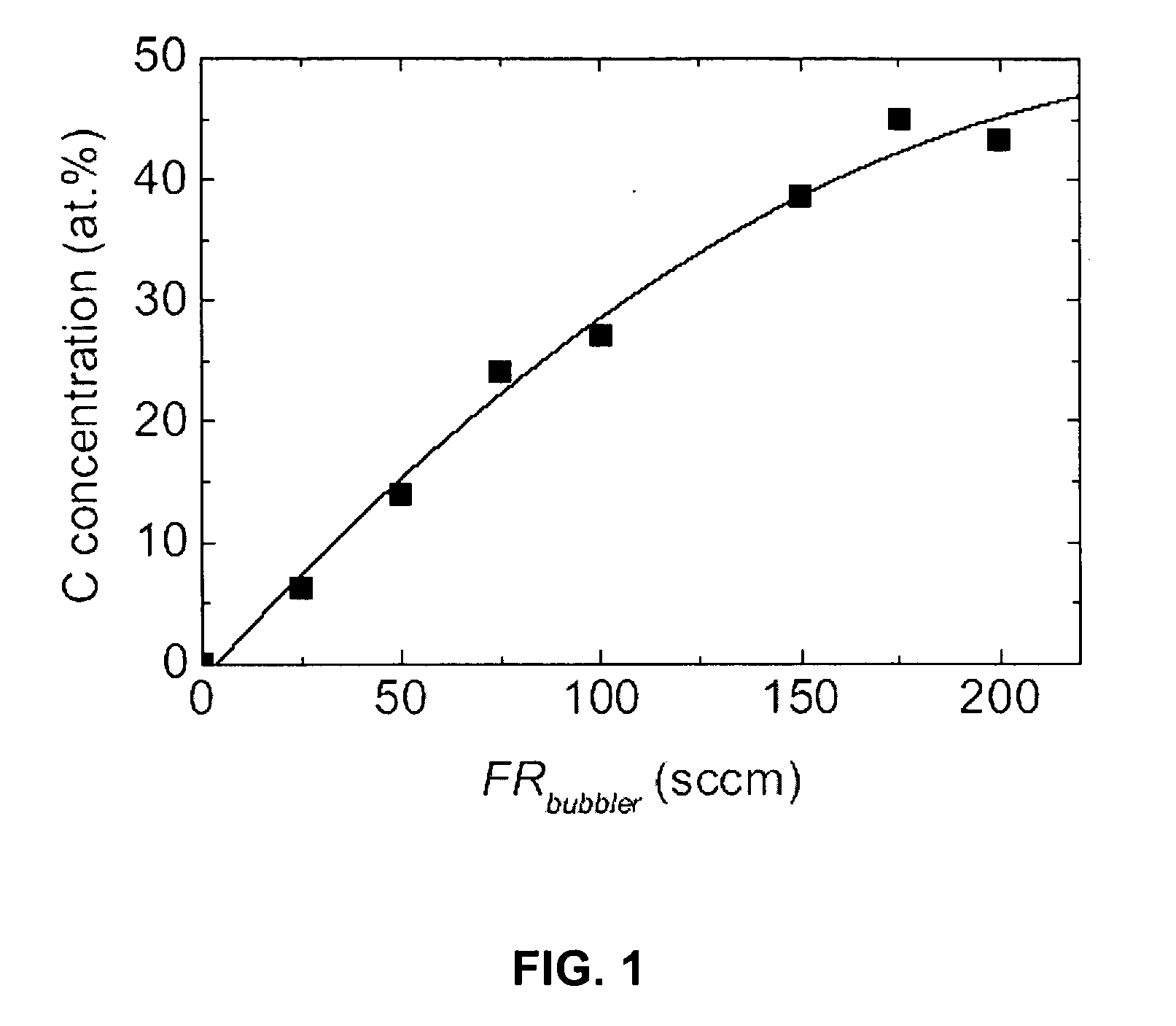

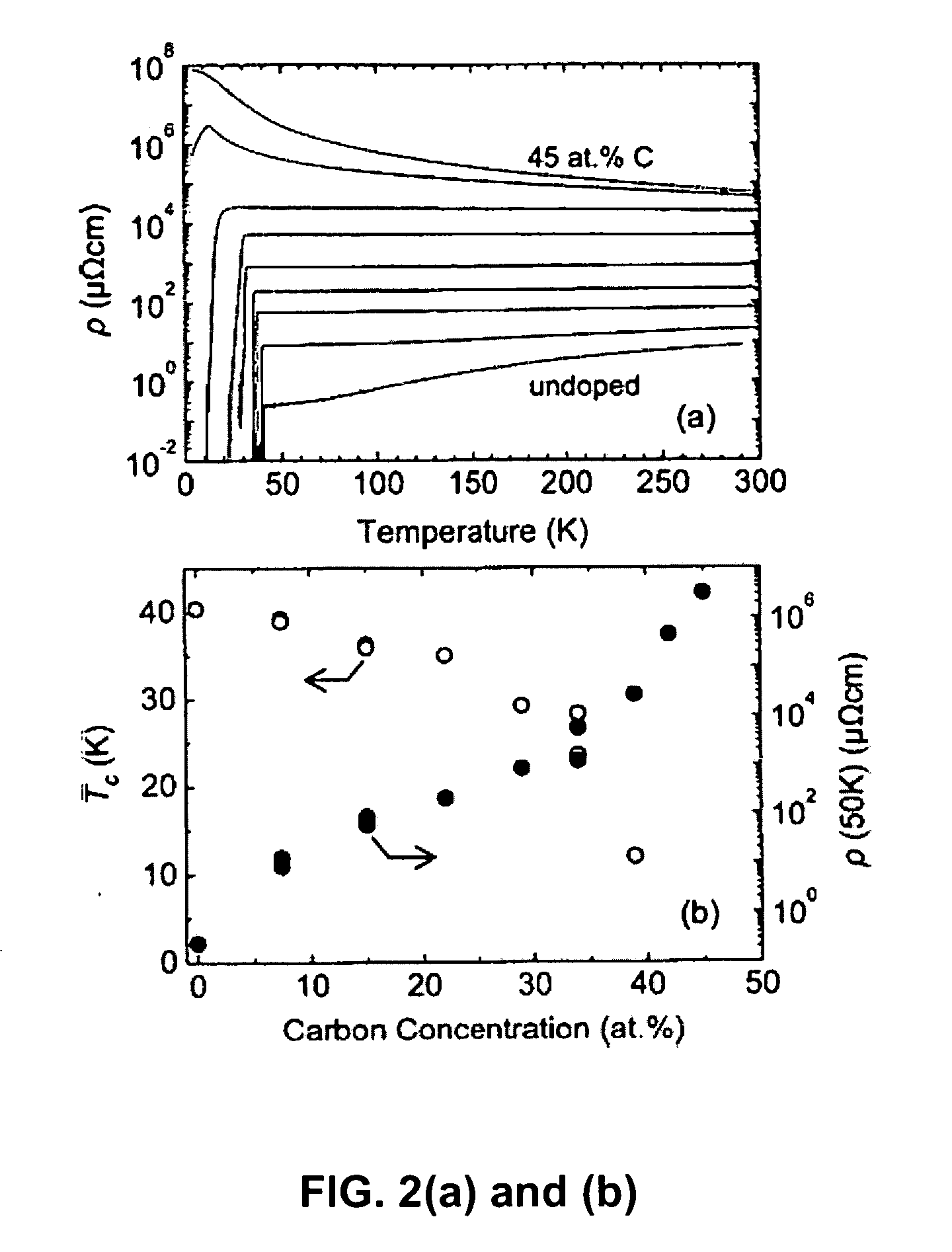

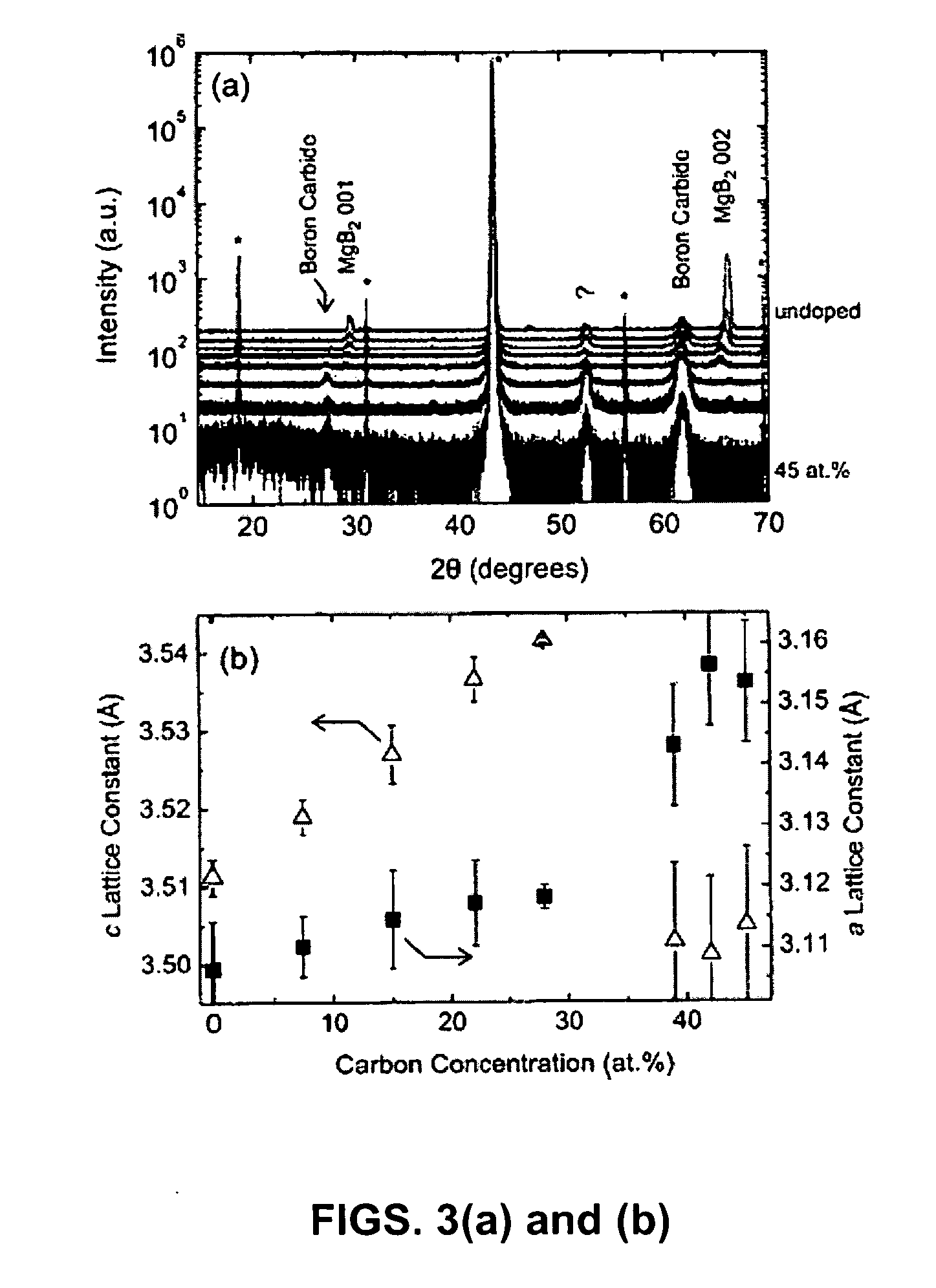

Method for producing doped, alloyed, and mixed-phase magnesium boride films

Conducting and superconducting doped, magnesium boride materials are formed by a process which combines physical vapor deposition with chemical vapor deposition by physically generating magnesium vapor in a deposition chamber and introducing a boron containing precursor and a dopant into the chamber which combines with the magnesium vapor to form the material. Embodiments include forming carbon-doped magnesium diboride film and powder with hybrid physical-chemical vapor deposition (HPCVD) by adding a carbon-containing metalorganic magnesium precursor, bis(methylcyclopentadienyl)magnesium, with a hydrogen carrier gas together with a borane precursor in a chamber having a source of magnesium vapor.

Owner:PENN STATE RES FOUND

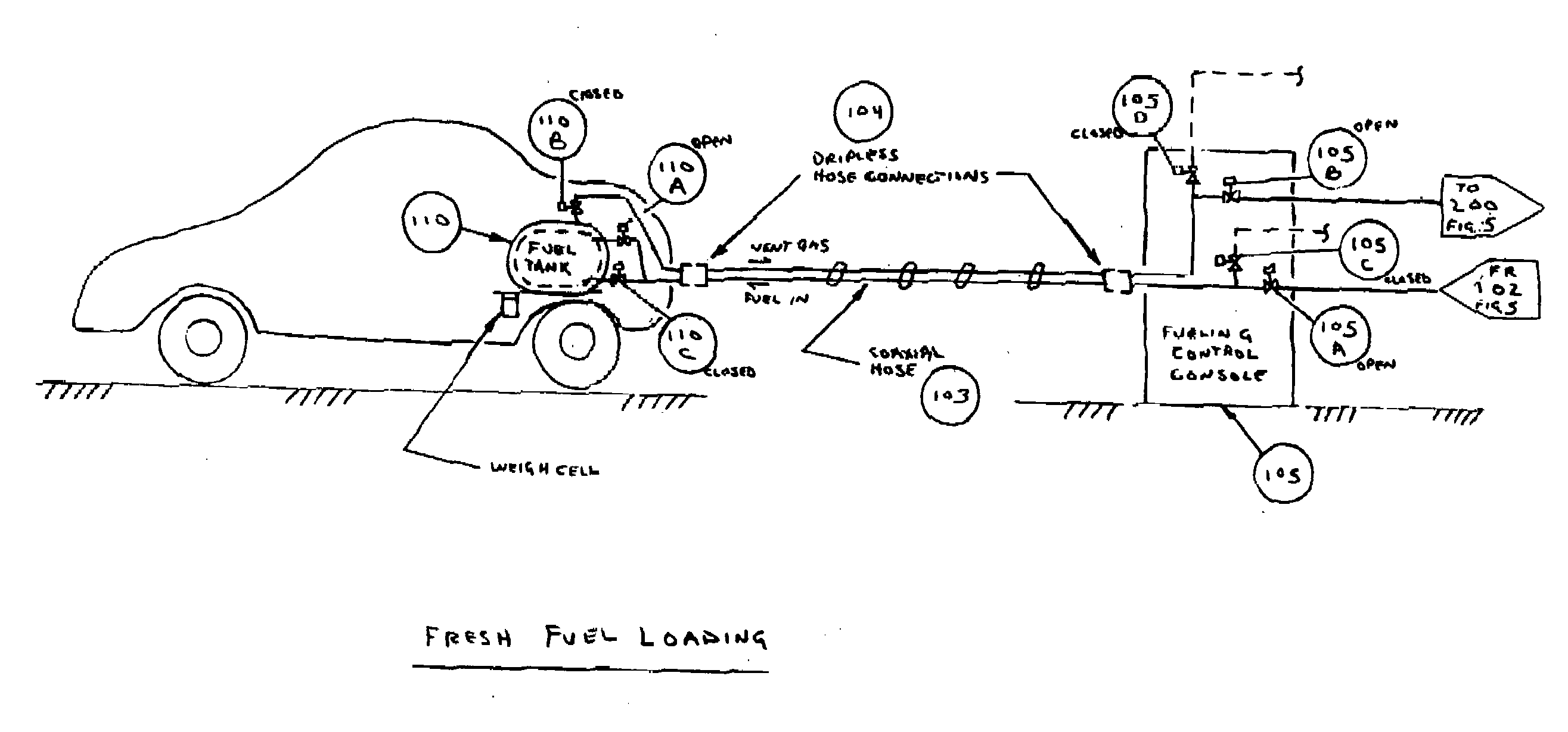

Hydrogen powered vehicle fueling via a pneumatic transfer of a solid state hydrogen carrier

InactiveUS20080138674A1Easy to handleReactant parameters controlRegenerative fuel cellsParticulatesHydrogen

Apparatus and methods are provided for fuelling a hydrogen-powered vehicle directly with a solid-state particulate carrier material those functions as a reversible hydrogen carrier. The material is delivered to the vehicle from a filling station via pneumatic transfer in a carrier fluid. Such as a hydrogen gas or an inert gas. Following removal of hydrogen from the carrier material to form an at least partially dehydrogenated carrier, a second re-fuelling mode of operation removed the hydrogen-depleted carrier from the vehicle's fuel storage vessel and pneumatically transfers it back to the filling station, where it can be subsequently rehydrogenated.

Owner:AIR PROD & CHEM INC

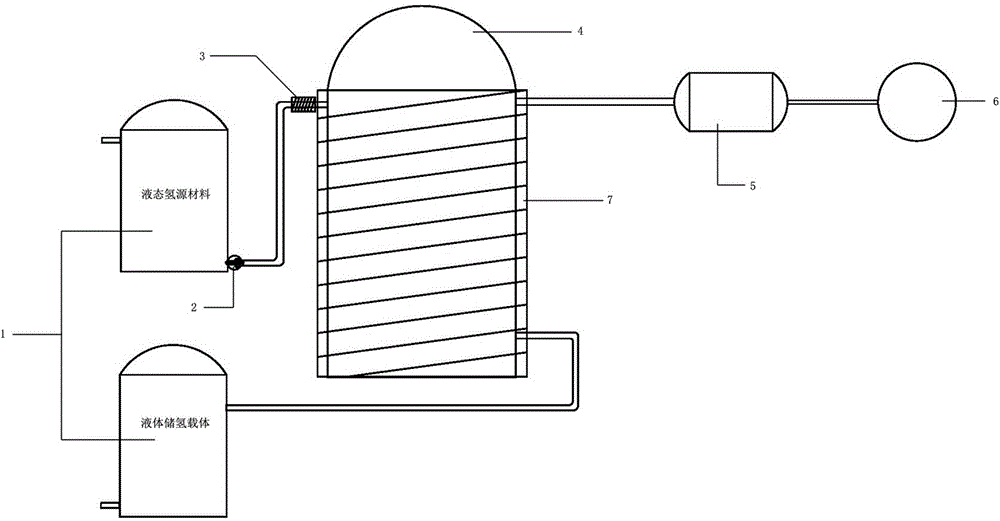

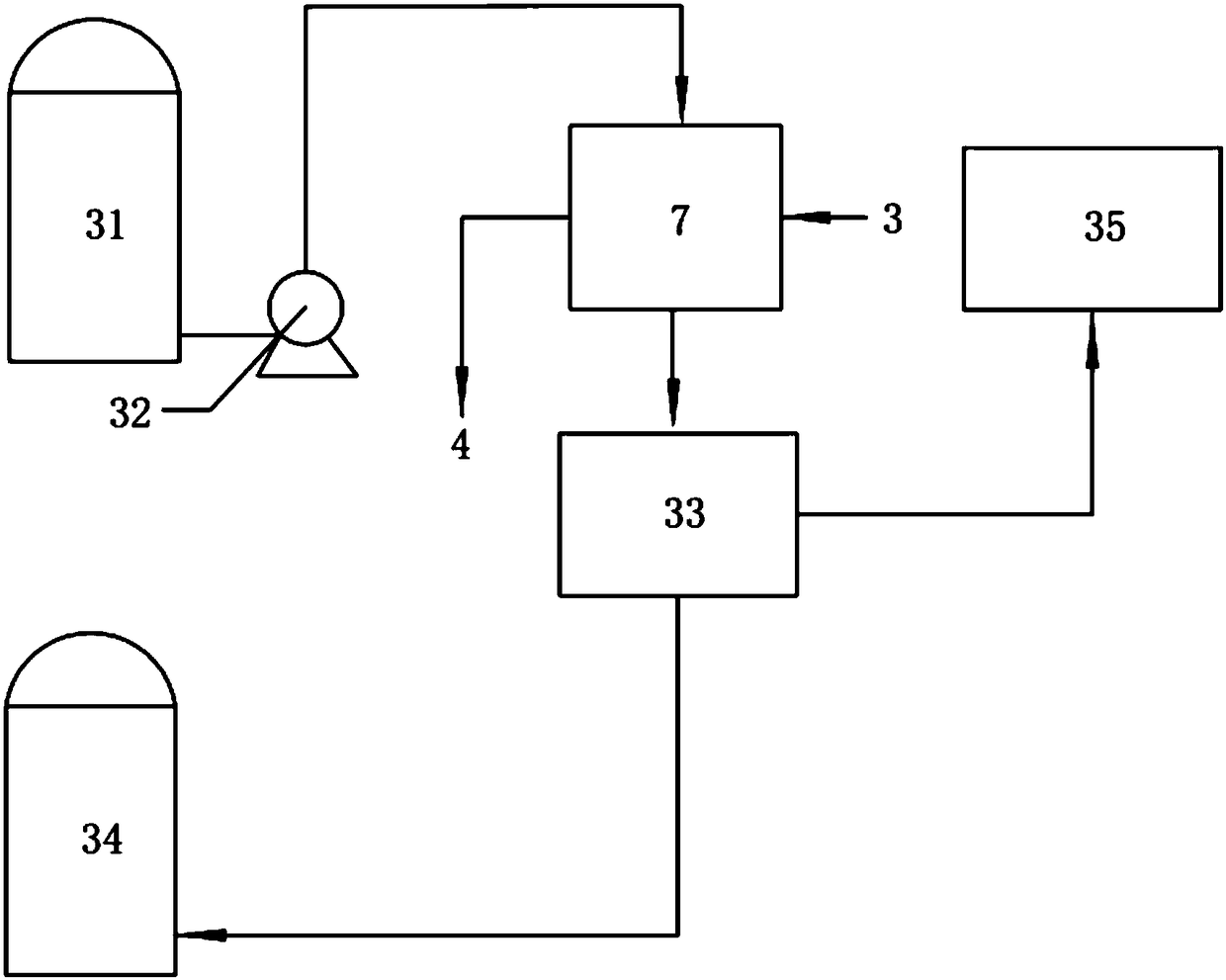

Liquid-state hydrogen source material hydrogen supply reaction system based on hydrogen fuel cell

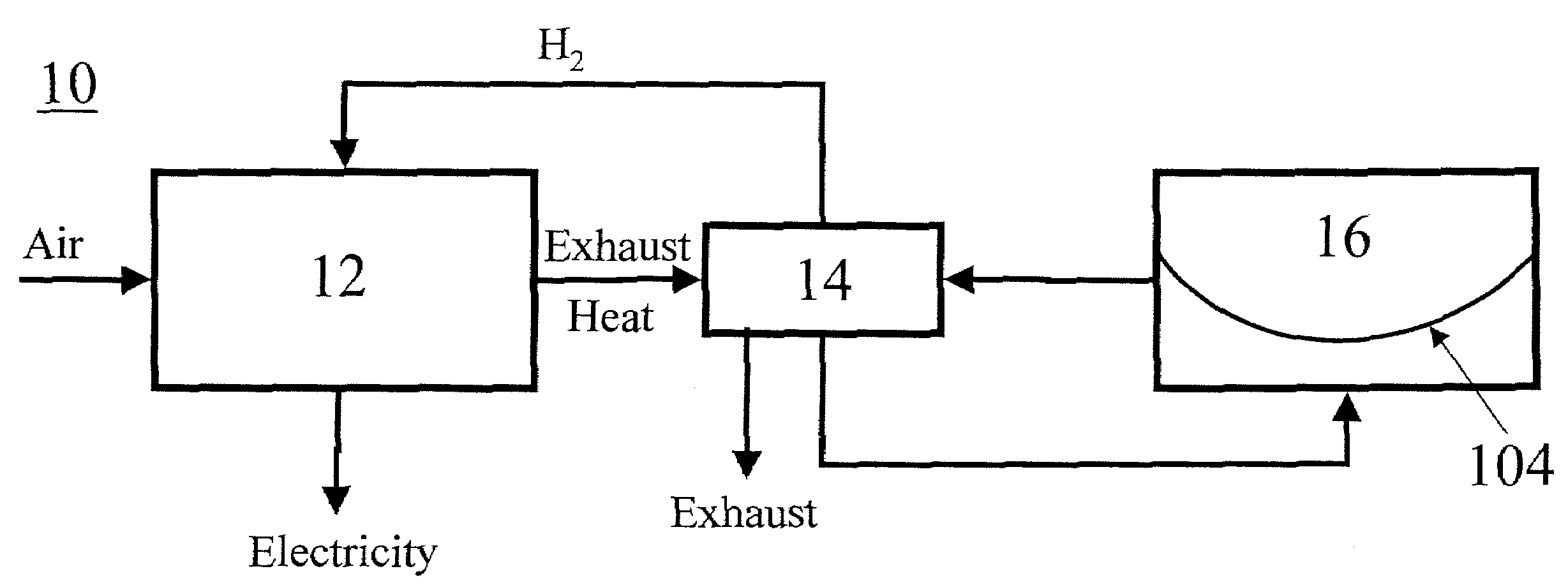

The present invention discloses a liquid-state hydrogen source material hydrogen supply reaction system based on a hydrogen fuel cell. The system comprises: a storage tank for storing a liquid-state hydrogen source material and a liquid-state hydrogen storage carrier, a reaction kettle for dehydrogenation of the liquid-state hydrogen source material, a buffer tank for storing hydrogen, a heating device for heating the reaction kettle, and a hydrogen fuel cell, wherein the liquid-state hydrogen source material is pumped into the reaction kettle through a pump, the liquid-state hydrogen storage carrier after the dehydrogenation reaction is conveyed to the storage tank, the hydrogen generated through the liquid-state hydrogen source material dehydrogenation reaction is conveyed to the buffer tank through the reaction kettle, and the hydrogen in the buffer tank is conveyed into the hydrogen fuel cell. According to the present invention, the normal temperature and normal pressure liquid-state hydrogen source material dehydrogenation reaction system based on the fuel cell is provided, and the integrated technology for combining the hydrogen released through the dehydrogenation reaction of the normal temperature and normal pressure liquid-state hydrogen source material under the mild condition and the hydrogen fuel cell is firstly provided.

Owner:WUHAN HYNERTECH CO LTD

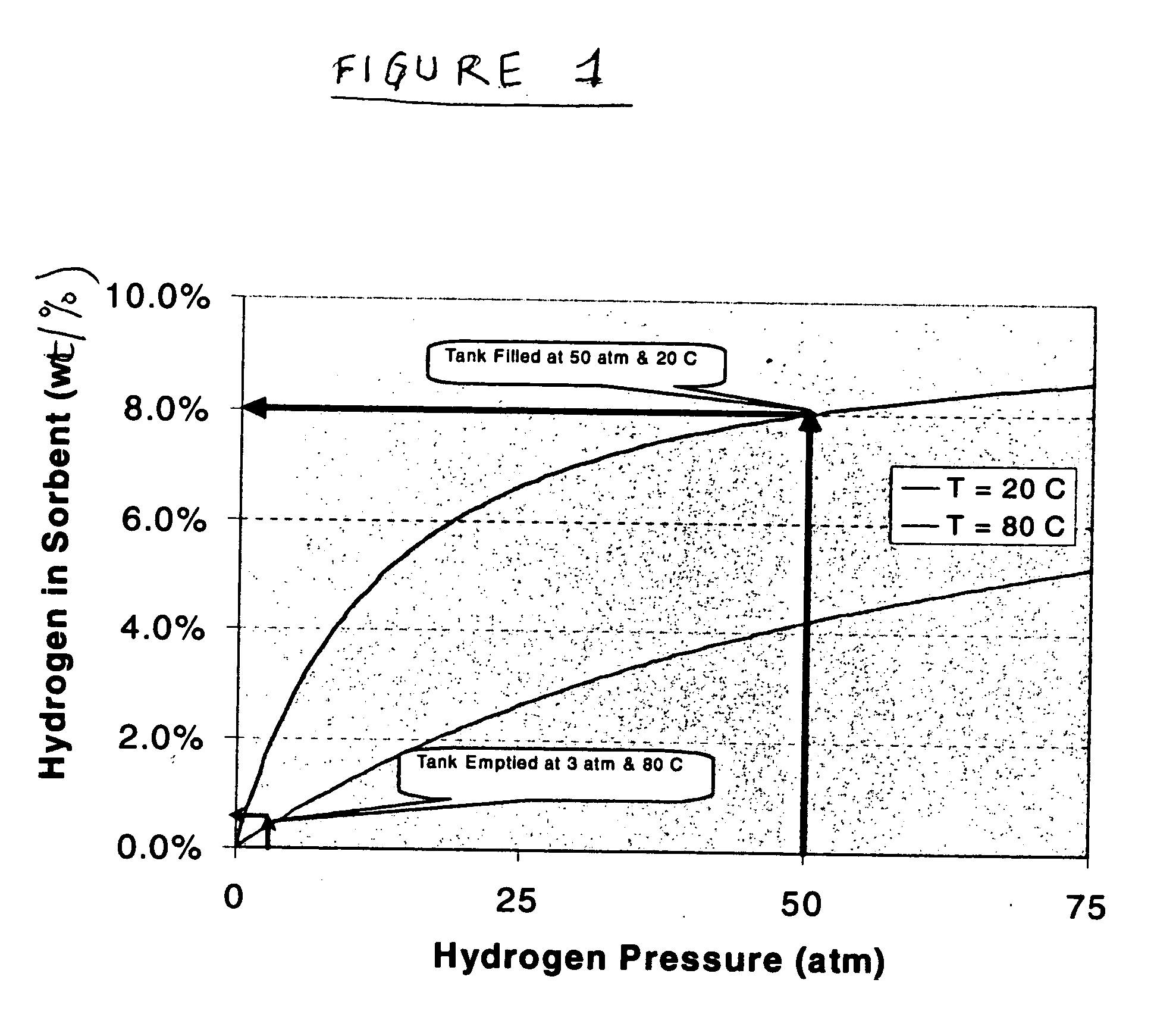

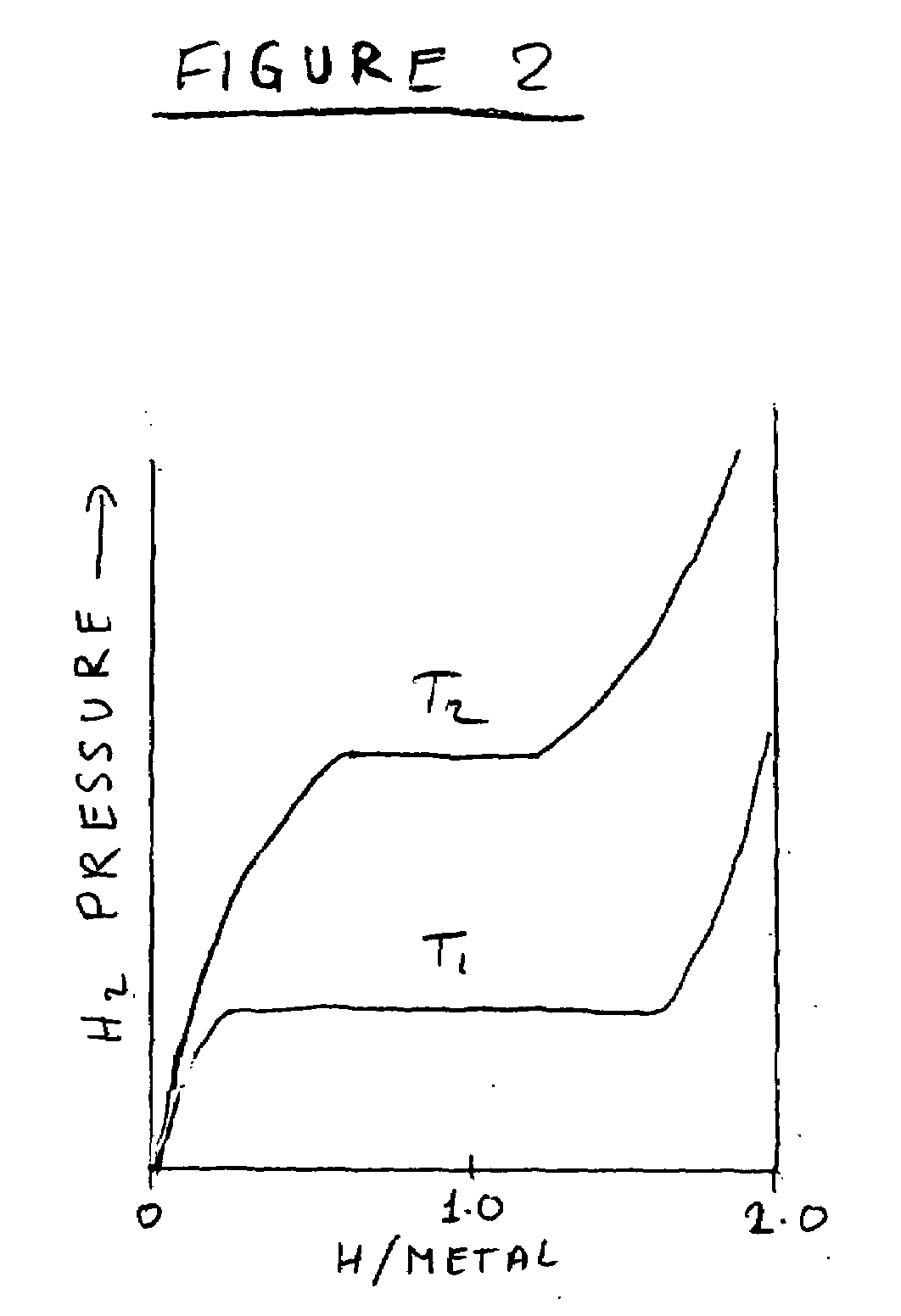

Hydrogen storage material and related system

Disclosed herein is a hydrogen storage material comprising a metal hydride and an organic hydrogen carrier. Also disclosed herein is a hydrogen storage / fuel cell system which employs the hydrogen storage material.

Owner:GENERAL ELECTRIC CO

Cascaded power plant process and method for providing reversibly usable hydrogen carriers in such a power plant process

Owner:SILICON FIRE AG

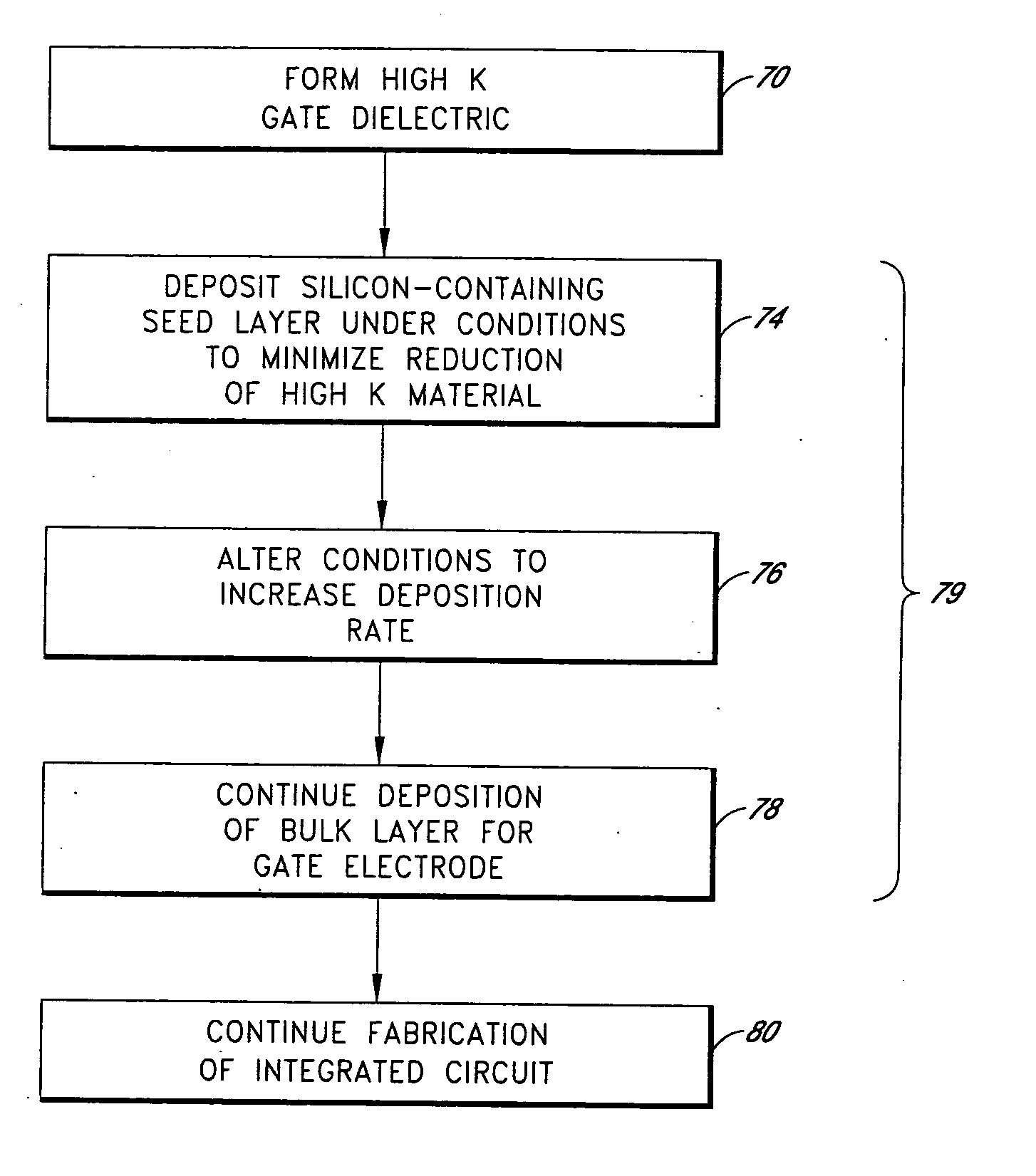

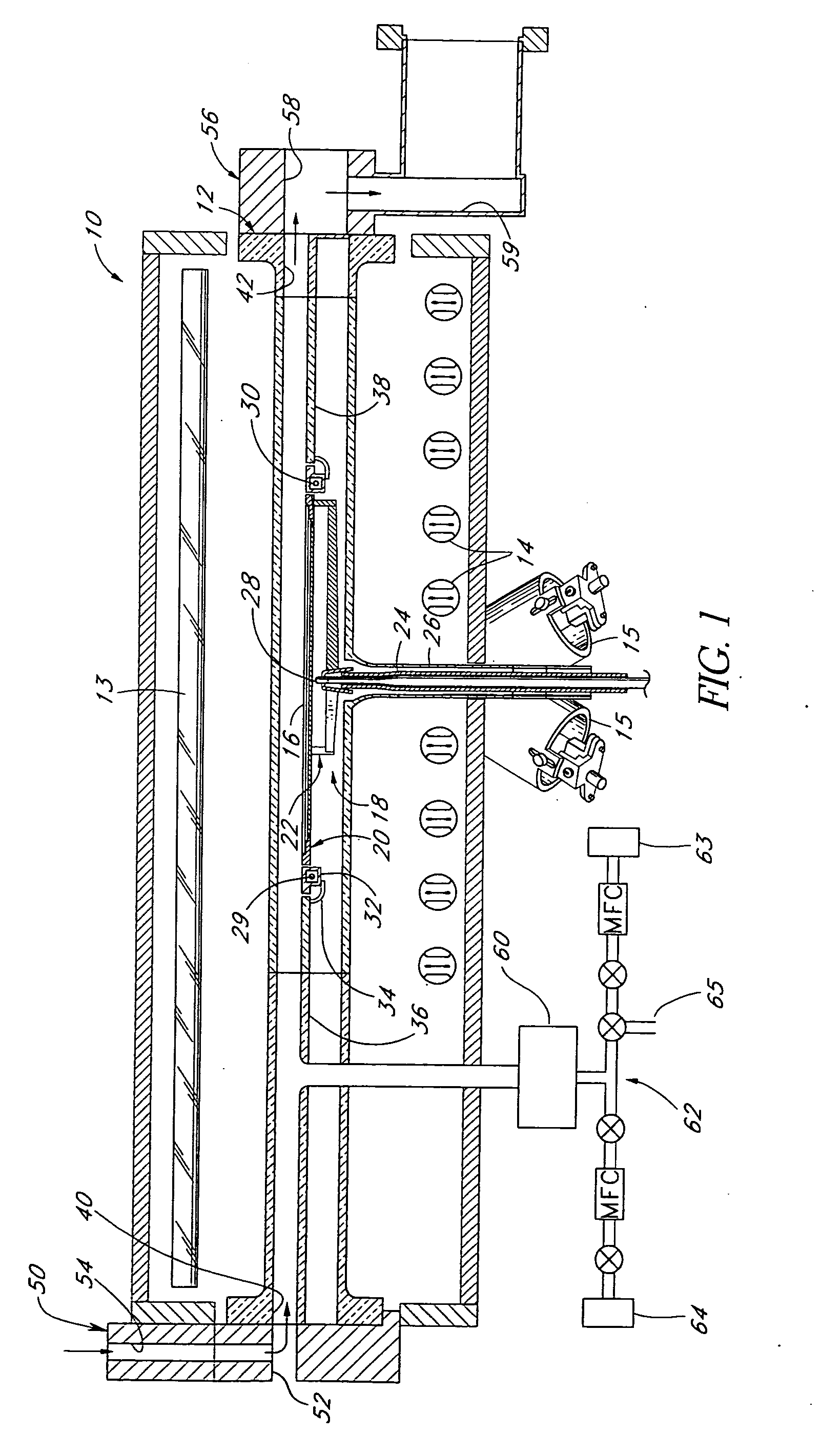

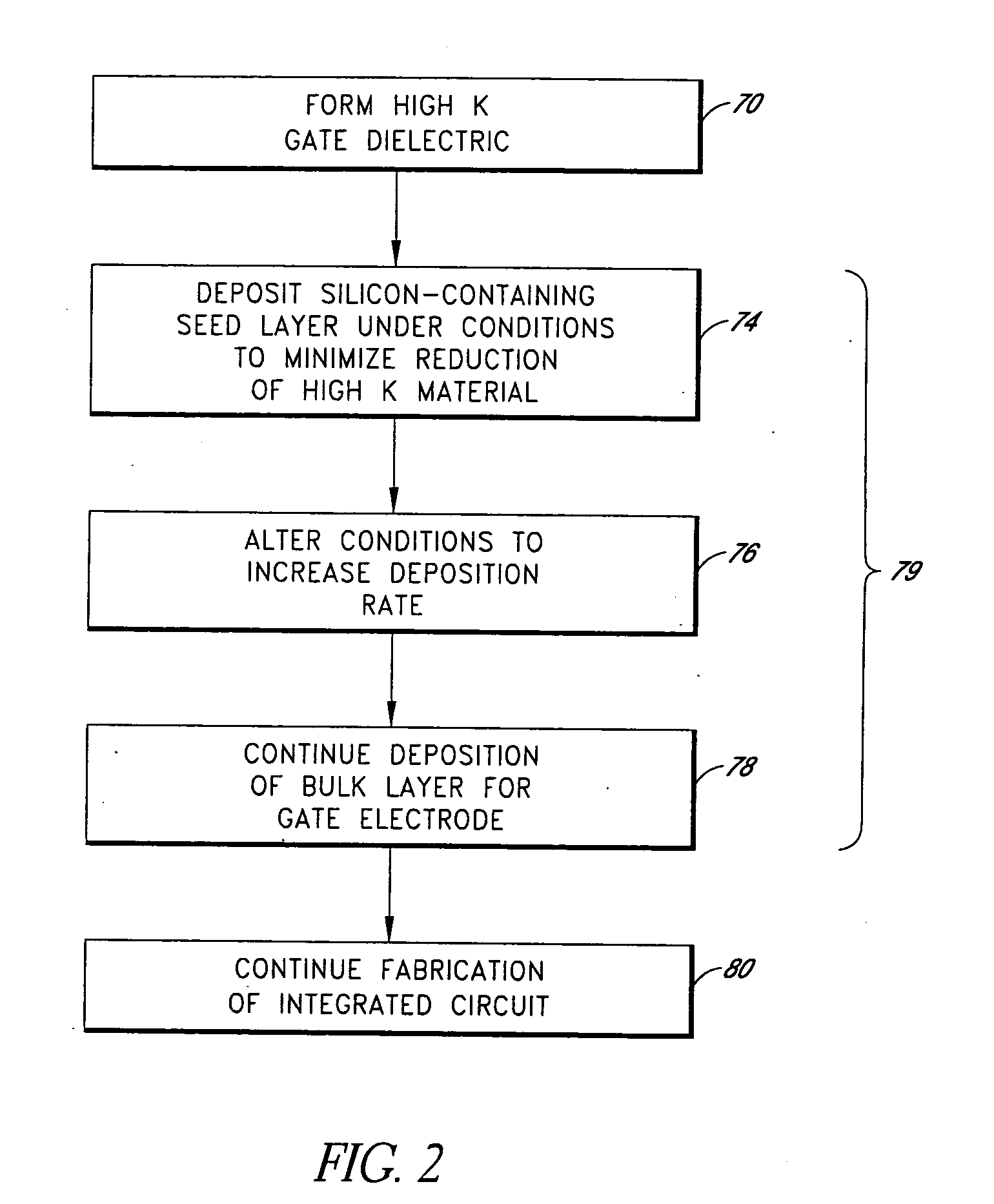

Integration of high k gate dielectric

ActiveUS20050233529A1Reduce decreaseMinimizing diffusion of hydrogenTransistorPolycrystalline material growthDiffusionGate dielectric

Methods are provided herein for forming electrode layers over high dielectric constant (“high k”) materials. In the illustrated embodiments, a high k gate dielectric, such as zirconium oxide, is protected from reduction during a subsequent deposition of silicon-containing gate electrode. In particular, a seed deposition phase includes conditions designed for minimizing hydrogen reduction of the gate dielectric, including low hydrogen content, low temperatures and / or low partial pressures of the silicon source gas. Conditions are preferably changed for higher deposition rates and deposition continues in a bulk phase. Desirably, though, hydrogen diffusion is still minimized by controlling the above-noted parameters. In one embodiment, high k dielectric reduction is minimized through omission of a hydrogen carrier gas. In another embodiment, higher order silanes, aid in reducing hydrogen content for a given deposition rate.

Owner:ASM IP HLDG BV

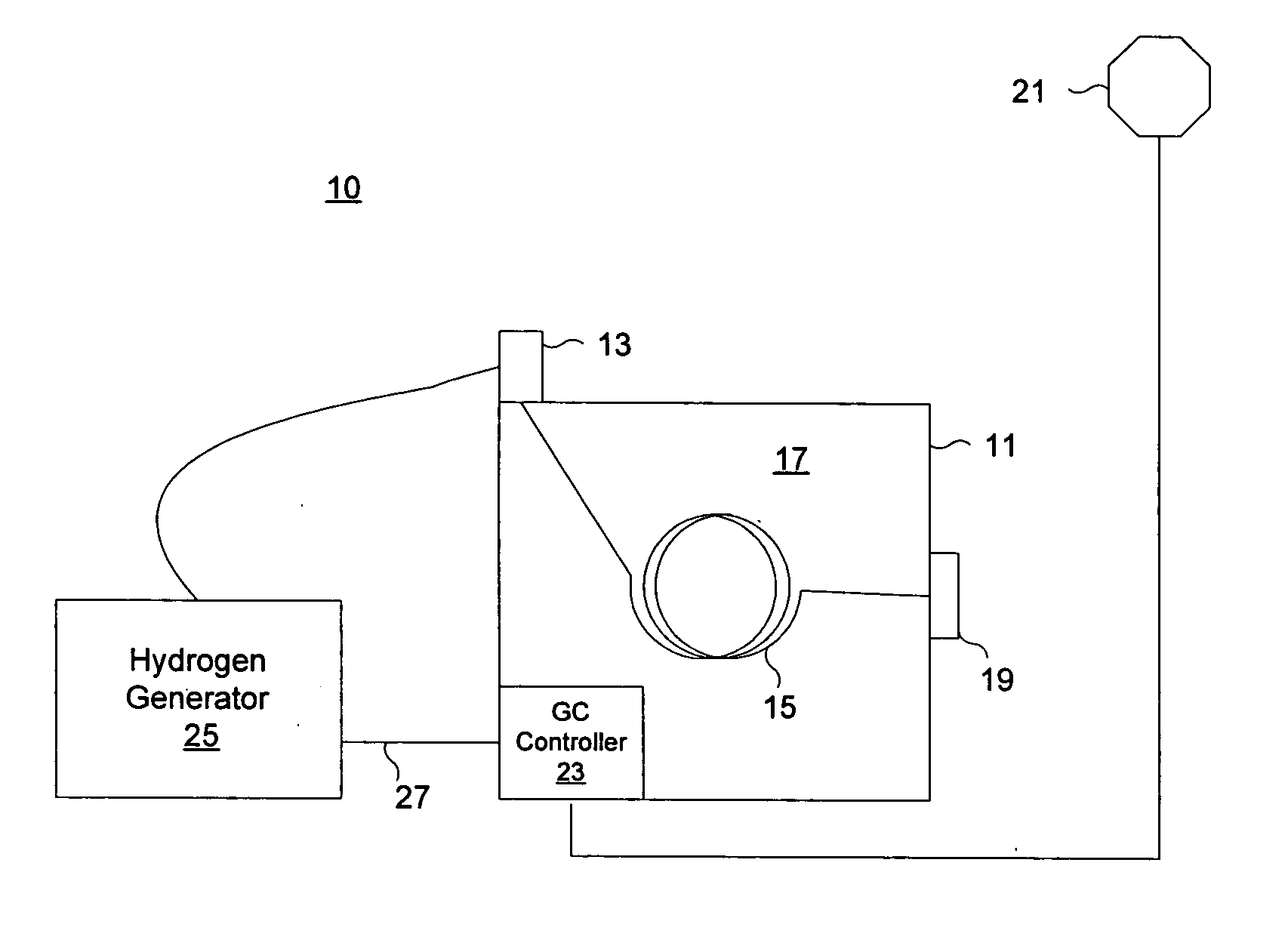

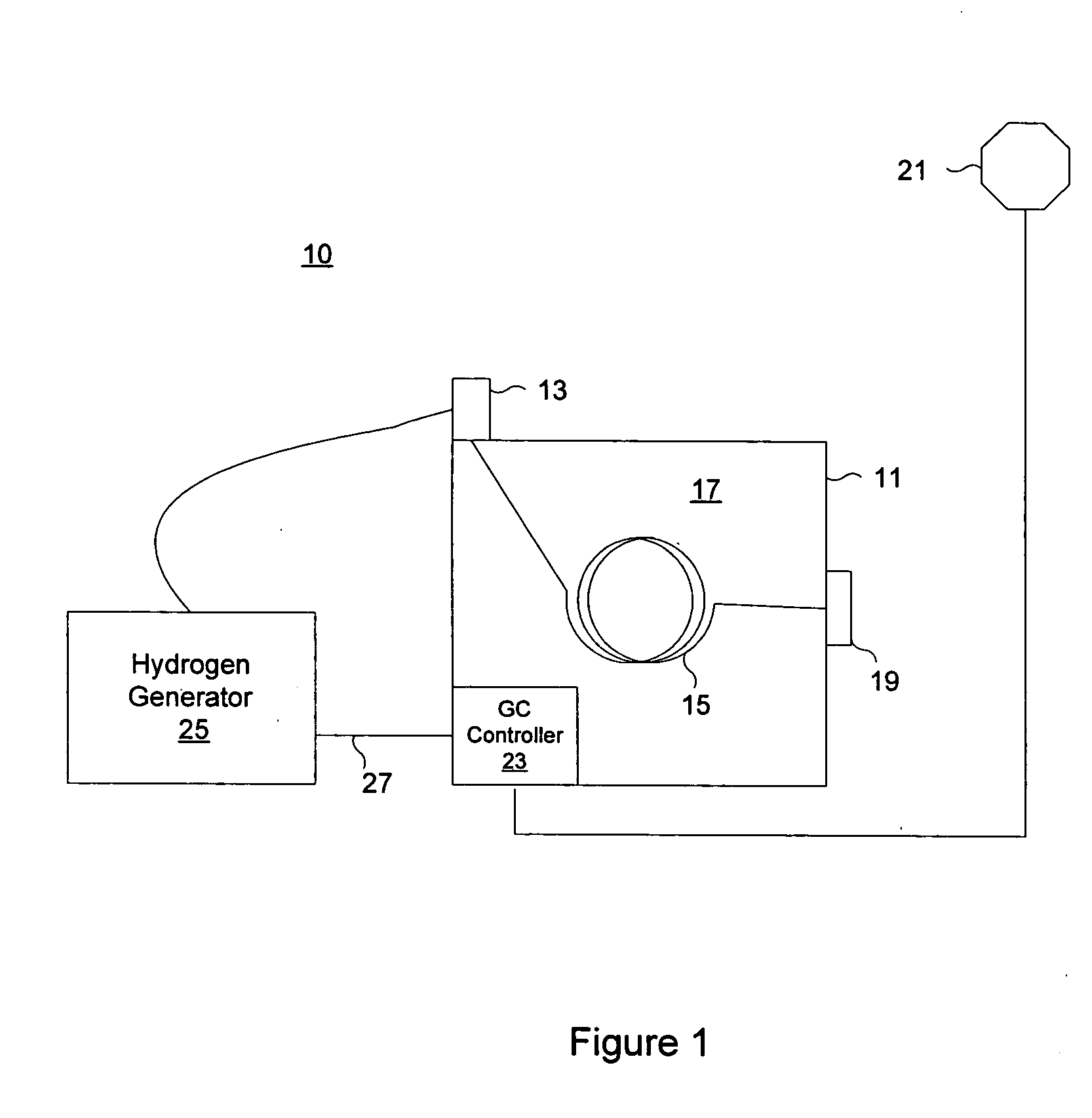

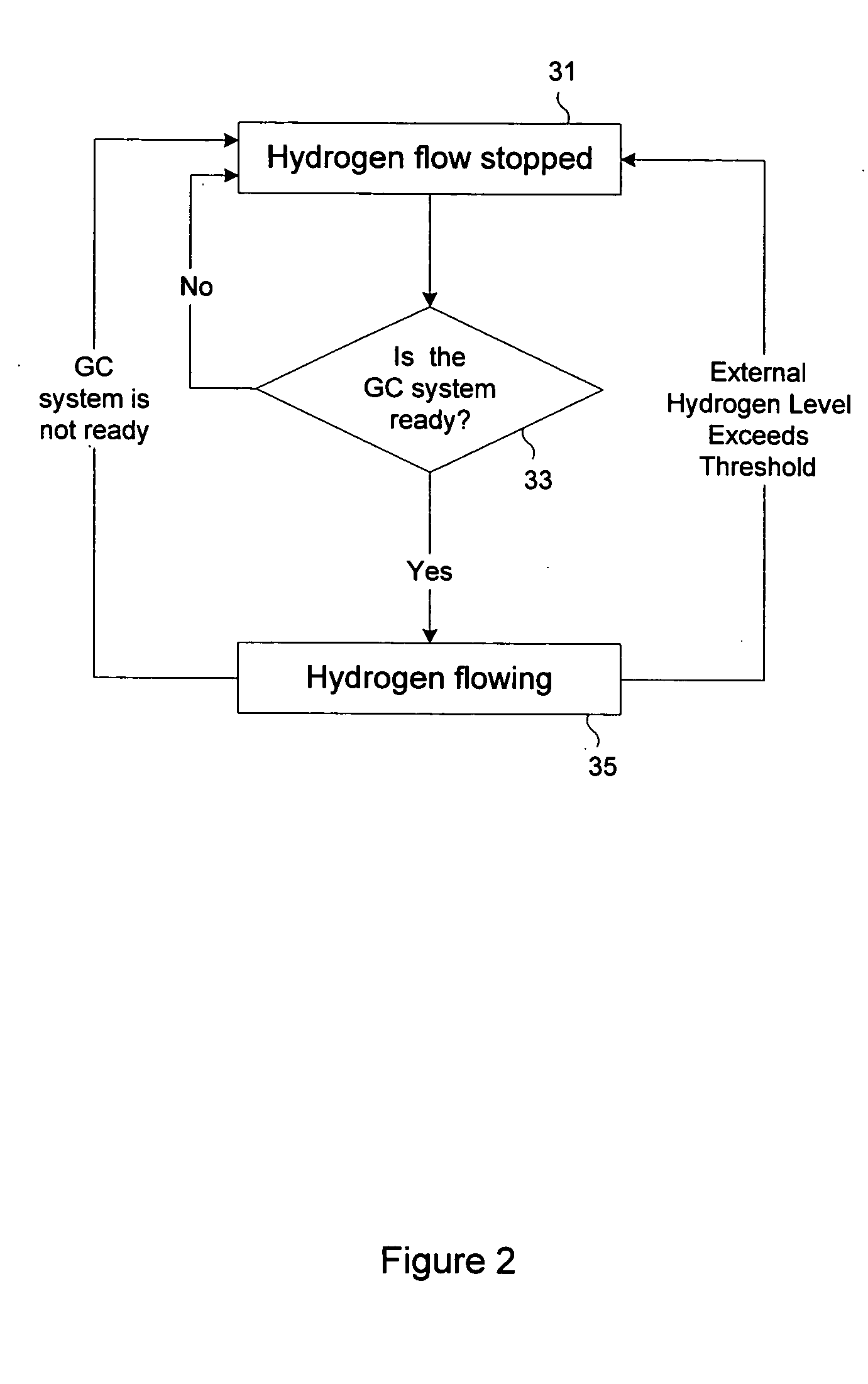

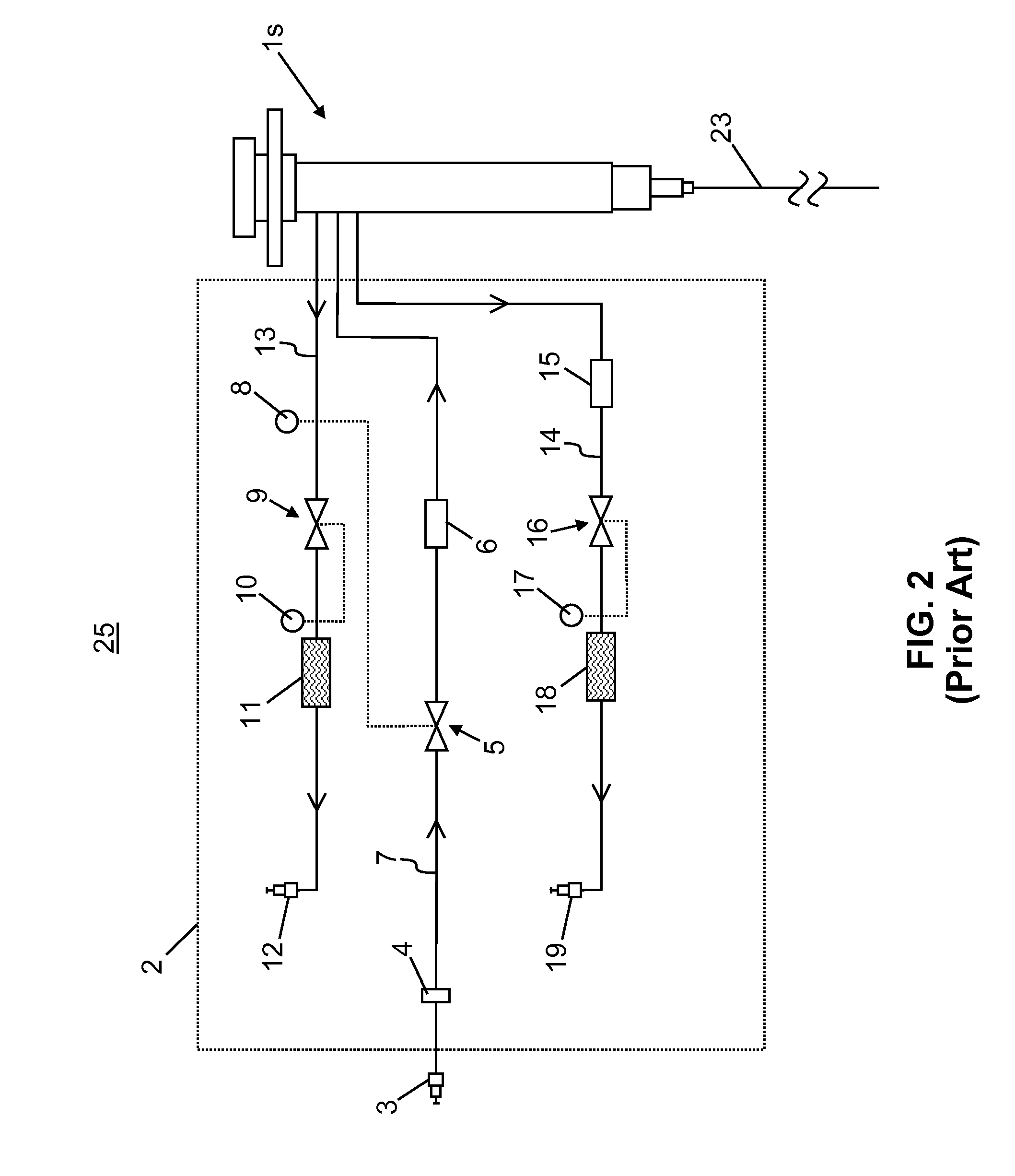

Interlocked hydrogen source for gas chromatography

InactiveUS20070224693A1Stop the flowComponent separationBiological testingHydrogenGas liquid chromatographic

A gas chromatograph uses hydrogen carrier gas supplied by a hydrogen source. At least one hydrogen sensor monitors the hydrogen level. The gas chromatograph communicates with the hydrogen source over a communication link. When the sensed hydrogen level exceeds a threshold, the gas chromatograph signals the hydrogen source to stop the flow of hydrogen.

Owner:AGILENT TECH INC

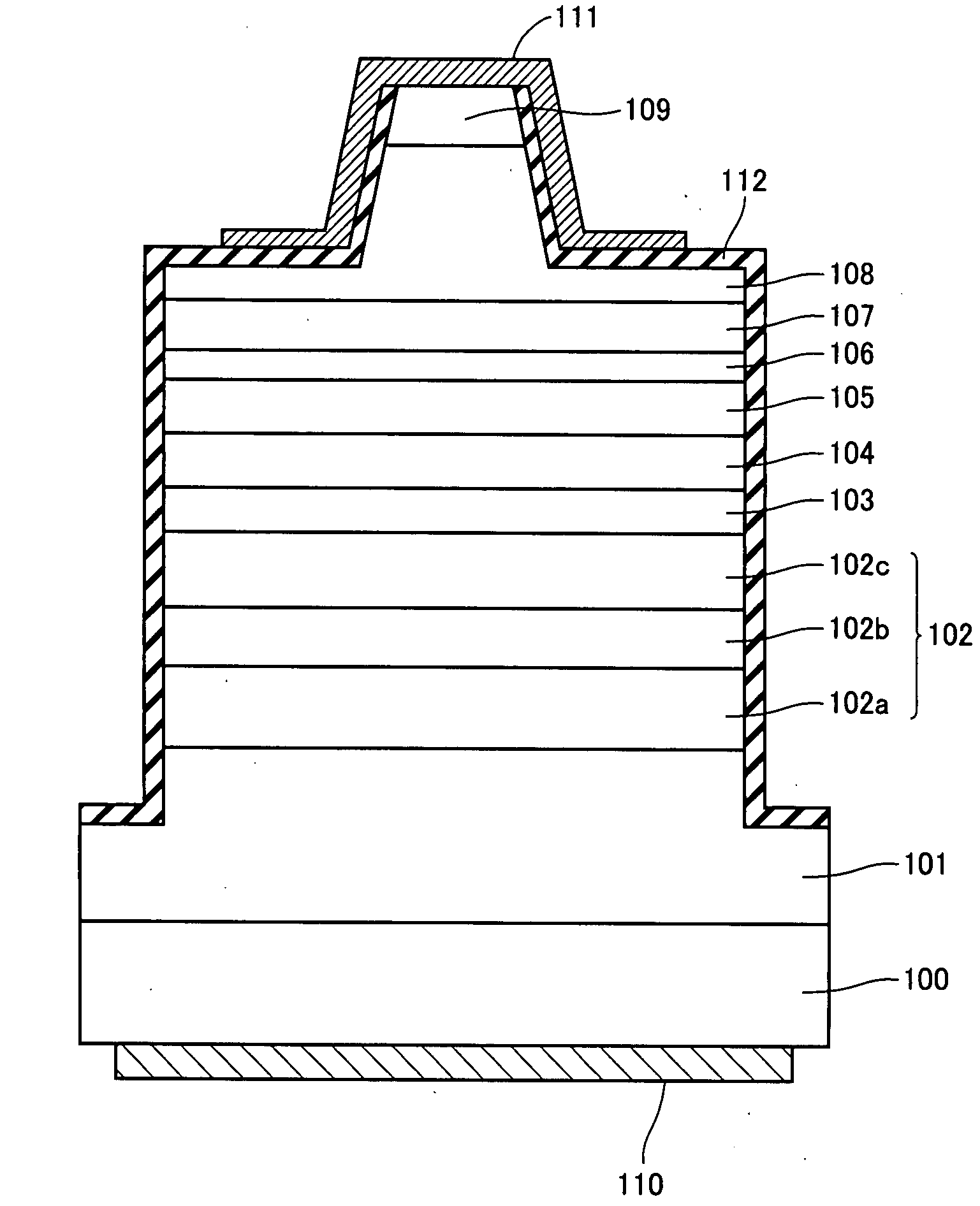

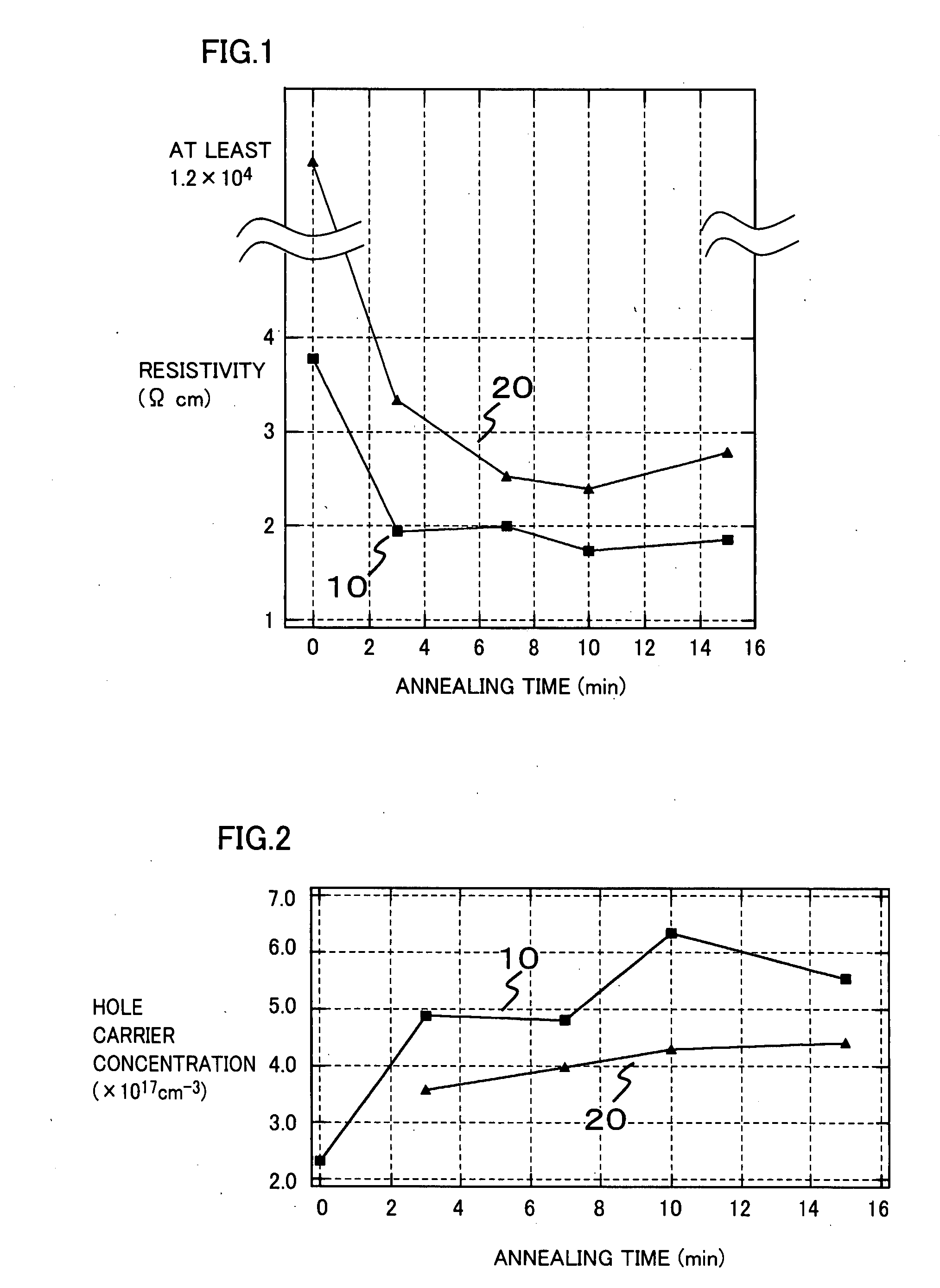

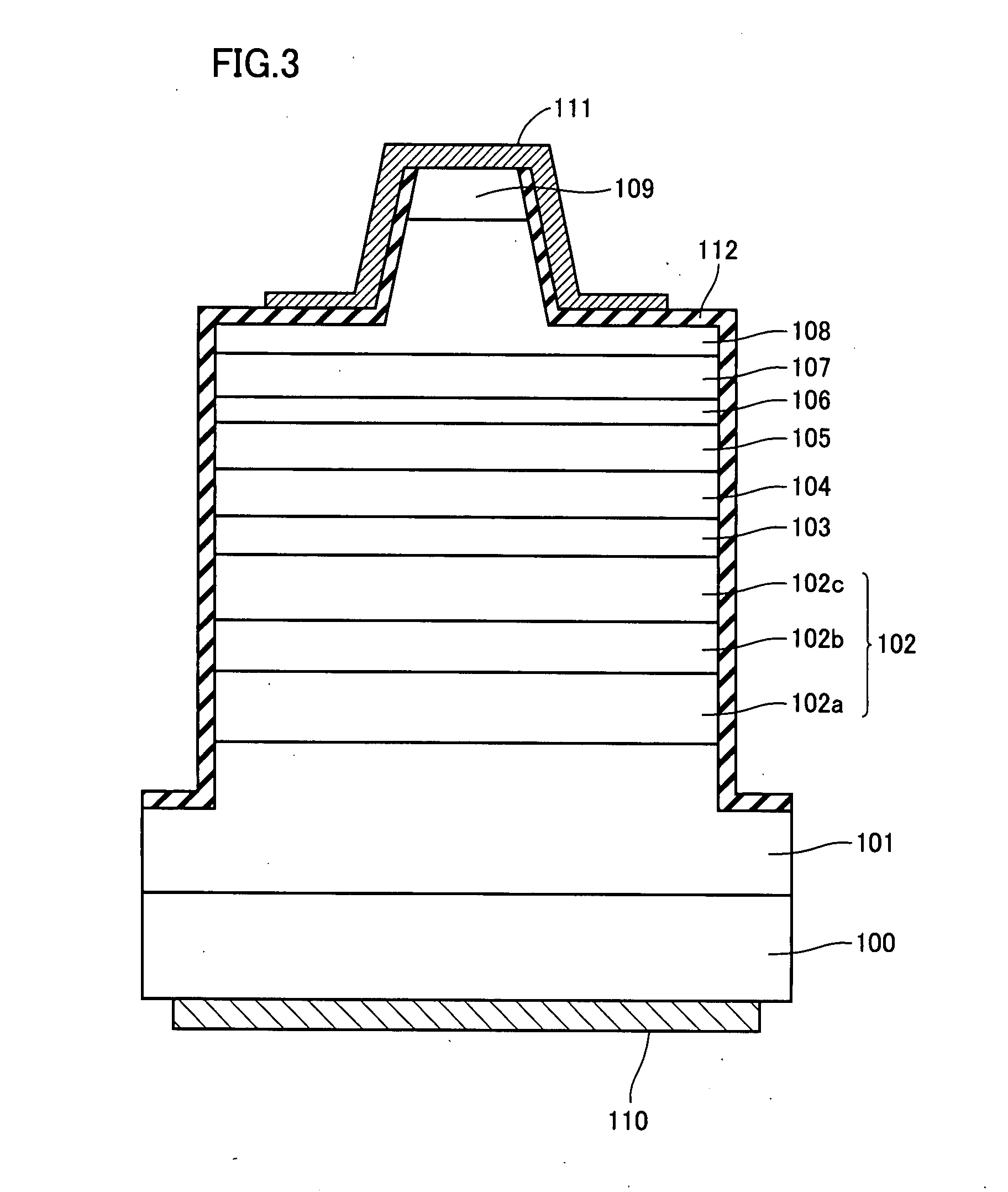

Method of manufacturing p-type nitride semiconductor and semiconductor device fabricated by the method

ActiveUS20090121320A1Low resistivityGood reproducibilityOptical wave guidanceSemiconductor/solid-state device manufacturingNitrogenChemical vapor deposition

The present invention includes a first step of forming a nitride semiconductor layer by metal organic chemical vapor deposition by using a first carrier gas containing a nitrogen carrier gas and a hydrogen carrier gas of a flow quantity larger than that of the nitrogen carrier gas to thereby supply a raw material containing Mg and a Group V raw material containing N, and a second step of lowering a temperature by using a second carrier gas to which a material containing N is added, and hence solves the problems.

Owner:SHARP FUKUYAMA LASER CO LTD

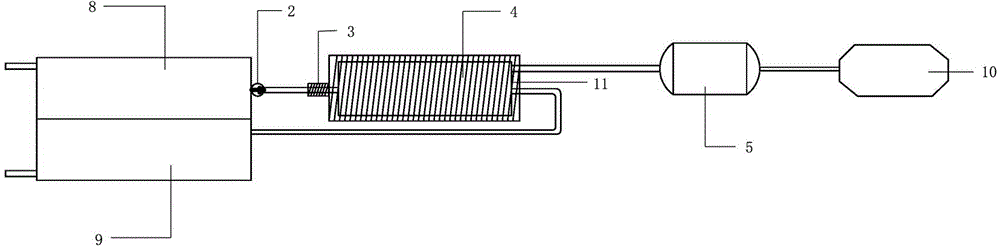

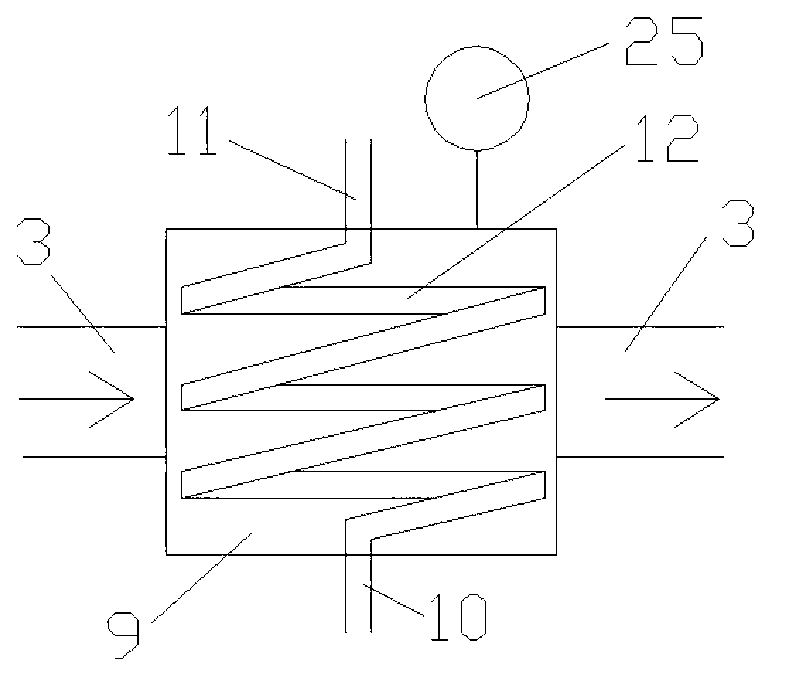

Hydrogen supply system for liquid hydrogen storage material for hydrogen internal combustion engine

ActiveCN104975988ASave spaceLow oxygenInternal combustion piston enginesFuel supply apparatusDehydrogenationLiquid hydrogen

The invention discloses a hydrogen supply system for a liquid hydrogen source material for a hydrogen internal combustion engine. The hydrogen supply system comprises a hydrogen storage tank used for storing the liquid hydrogen source material and a liquid hydrogen storage carrier, a reaction kettle used for dehydrogenating the liquid hydrogen source material, a buffering tank used for storing hydrogen, an oxygen storage tank used for storing oxygen, a heat exchange device used for transmitting heat generated by the hydrogen internal combustion engine to the reaction kettle, and a hydrogen storage device which is used for conveying the liquid hydrogen source material into the reaction kettle through a pump. The dehydrogenation reaction of the liquid hydrogen source material is conducted in the reaction kettle; hydrogen generated through the reaction is conveyed to the buffering tank; meanwhile, the liquid oxygen storage carrier generated after dehydrogenation is conveyed back to the hydrogen storage tank; the hydrogen in the buffering tank and the oxygen in the oxygen storage tank enter the hydrogen internal combustion engine according to a proportion. According to the dehydrogenation device for the normal-temperature and normal-pressure liquid hydrogen source material for a hydrogen internal combustion engine automobile, a hydrogen storage and hydrogen internal combustion engine integrated technology for enabling the hydrogen released by liquid hydrogen source material dehydrogenation at the normal temperature and the normal pressure to directly enter a hydrogen internal combustion engine system is put forwards for the first time, according to the technology, a common car can run for 500 kilometers with the hydrogen generated by 80 L of an organic carrier, and therefore the cost for large-scale utilization of hydrogen energy in the future is greatly reduced.

Owner:WUHAN HYNERTECH CO LTD

Liquid hydrogen source material dehydrogenation reaction system and application method thereof

The invention discloses a liquid hydrogen source material dehydrogenation reaction system and an application method thereof. The dehydrogenation system comprises a storage device used for storing a liquid hydrogen source material and a liquid hydrogen-storage carrier, a reaction kettle used for dehydrogenating the liquid hydrogen source material, a buffering tank used for storing hydrogen gas, and a heating device arranged outside the reaction kettle and used for heating the reaction kettle. According to the invention, the liquid hydrogen source material is delivered into the reaction kettle through a pump; the liquid hydrogen source material is dehydrogenated in the reaction kettle; produced hydrogen gas is delivered to the buffering tank; and residual liquid hydrogen-storage carrier is delivered back to the hydrogen storage tank. The normal-temperature normal-pressure liquid hydrogen source material dehydrogenation system provided by the invention is used for carrying out a dehydrogenation reaction upon the liquid hydrogen source material. The produced hydrogen gas is supplied for a fuel cell or an internal combustion engine. The hydrogen gas is converted into electrical energy or mechanical energy which can be applied in various industrial and civil fields such as automobiles, electrical power, energy storage, chemical engineering, pharmacy, and mobile devices.

Owner:WUHAN HYNERTECH CO LTD

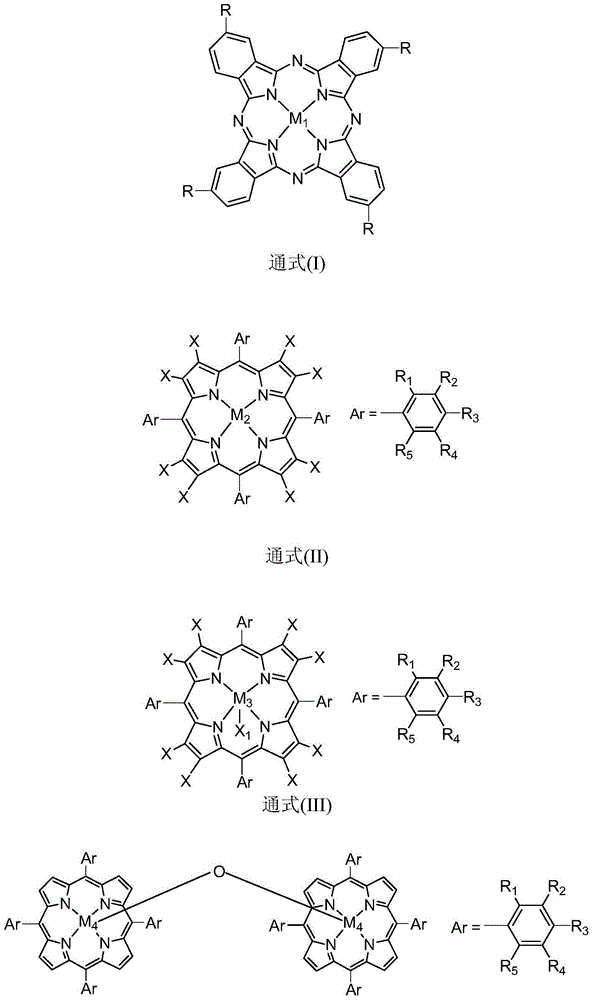

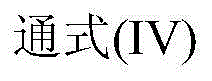

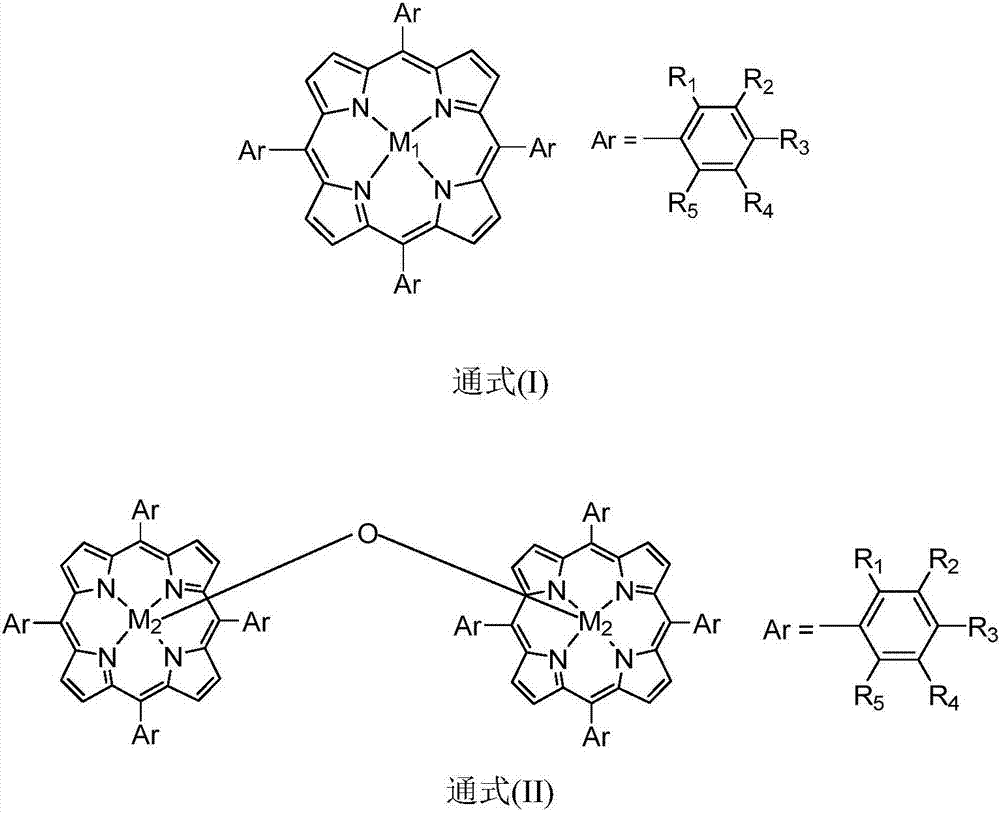

Method for preparing acetophenone by bionic catalytic oxidation of ethylbenzene

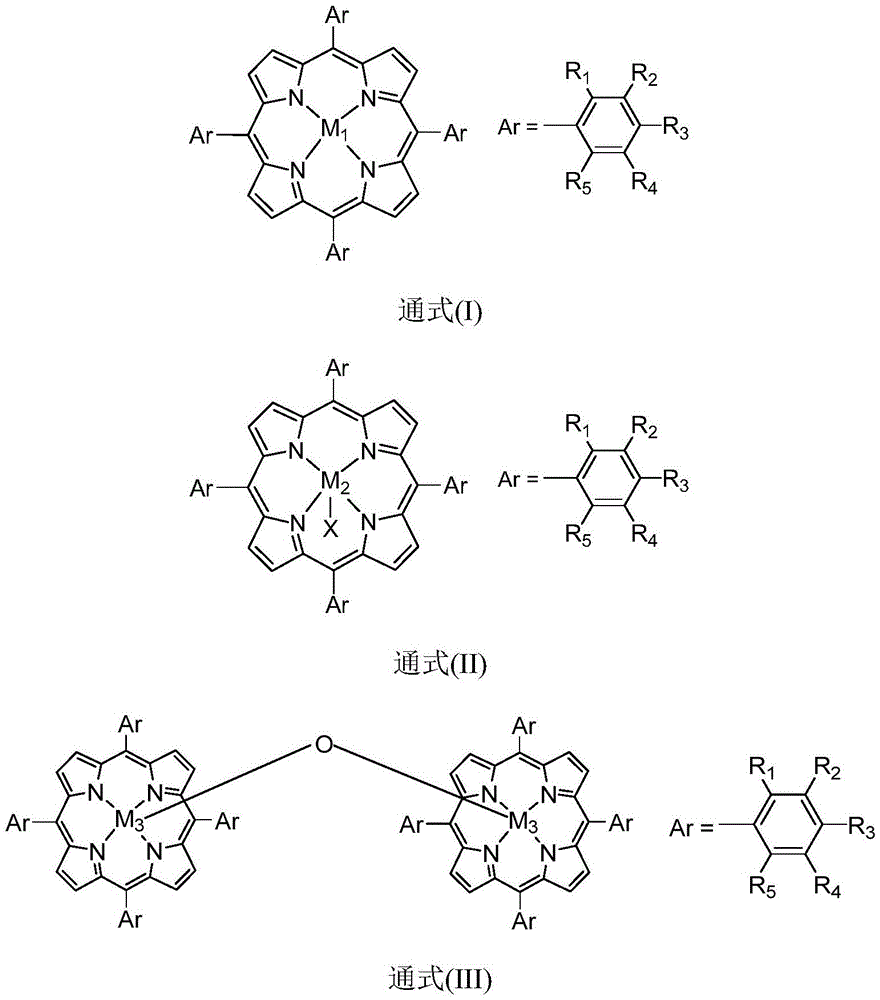

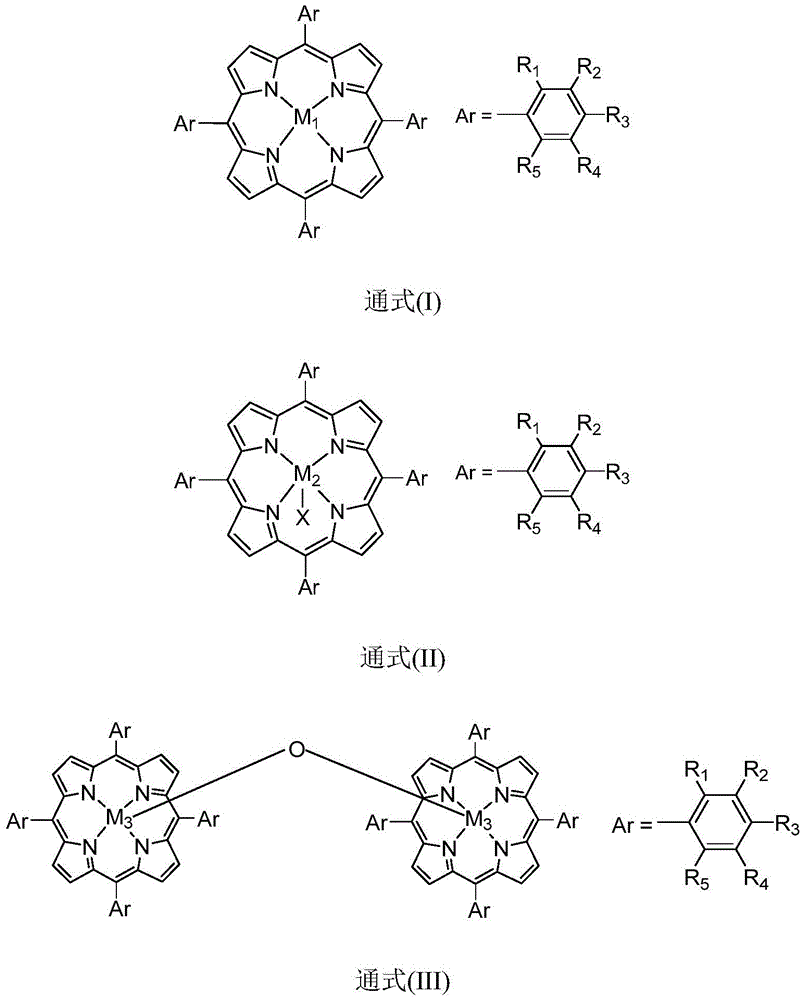

ActiveCN104628548AHigh selectivityAchieve separationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperaturePorphyrin

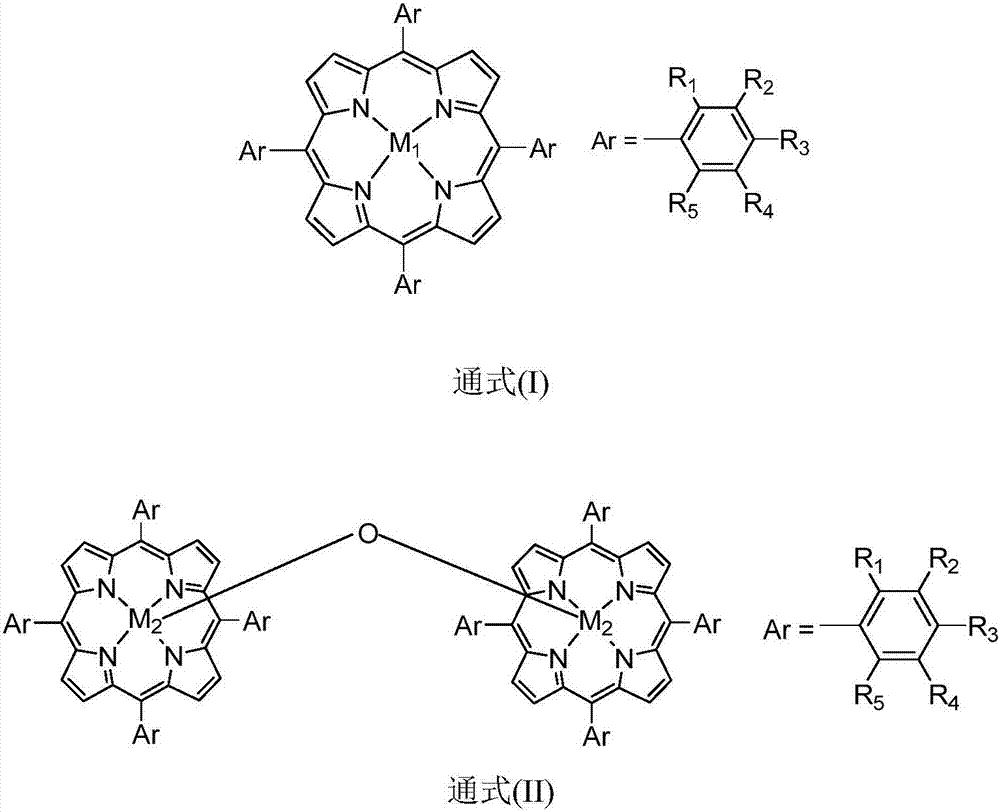

The invention discloses a method for preparing acetophenone by bionic catalytic oxidation of ethylbenzene, which comprises the following steps: by using ethylbenzene as a raw material, metal phthalocyanine or metalloporphyrin compound as a catalyst and oxygen gas as an oxygen source, adding certain amounts of solvent and hydrogen carrier, and carrying out catalytic oxidation reaction at 50-150 DEG C under the reaction pressure of 0.2-2.0 MPa to obtain the acetophenone. The method has the advantages of mild reaction conditions, favorable catalytic effect, high acetophenone selectivity, simple technique and the like.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

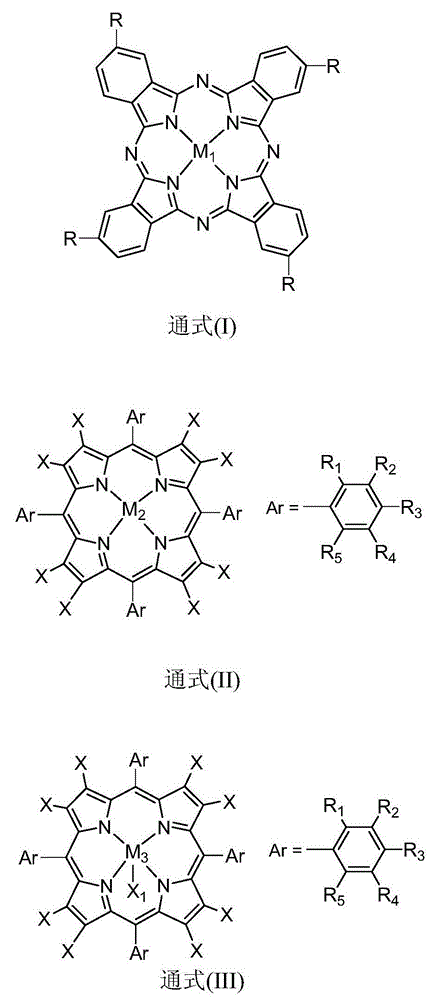

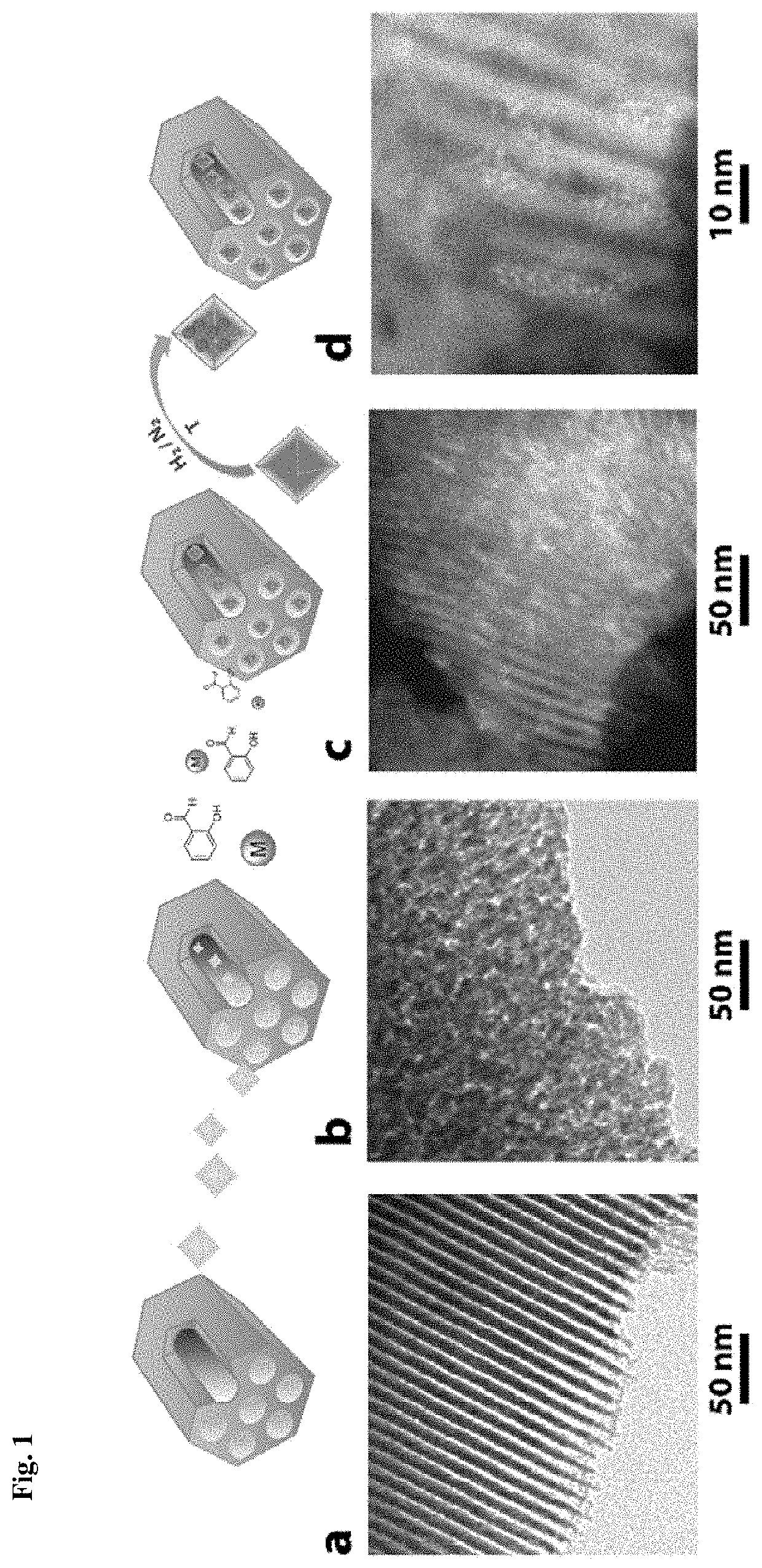

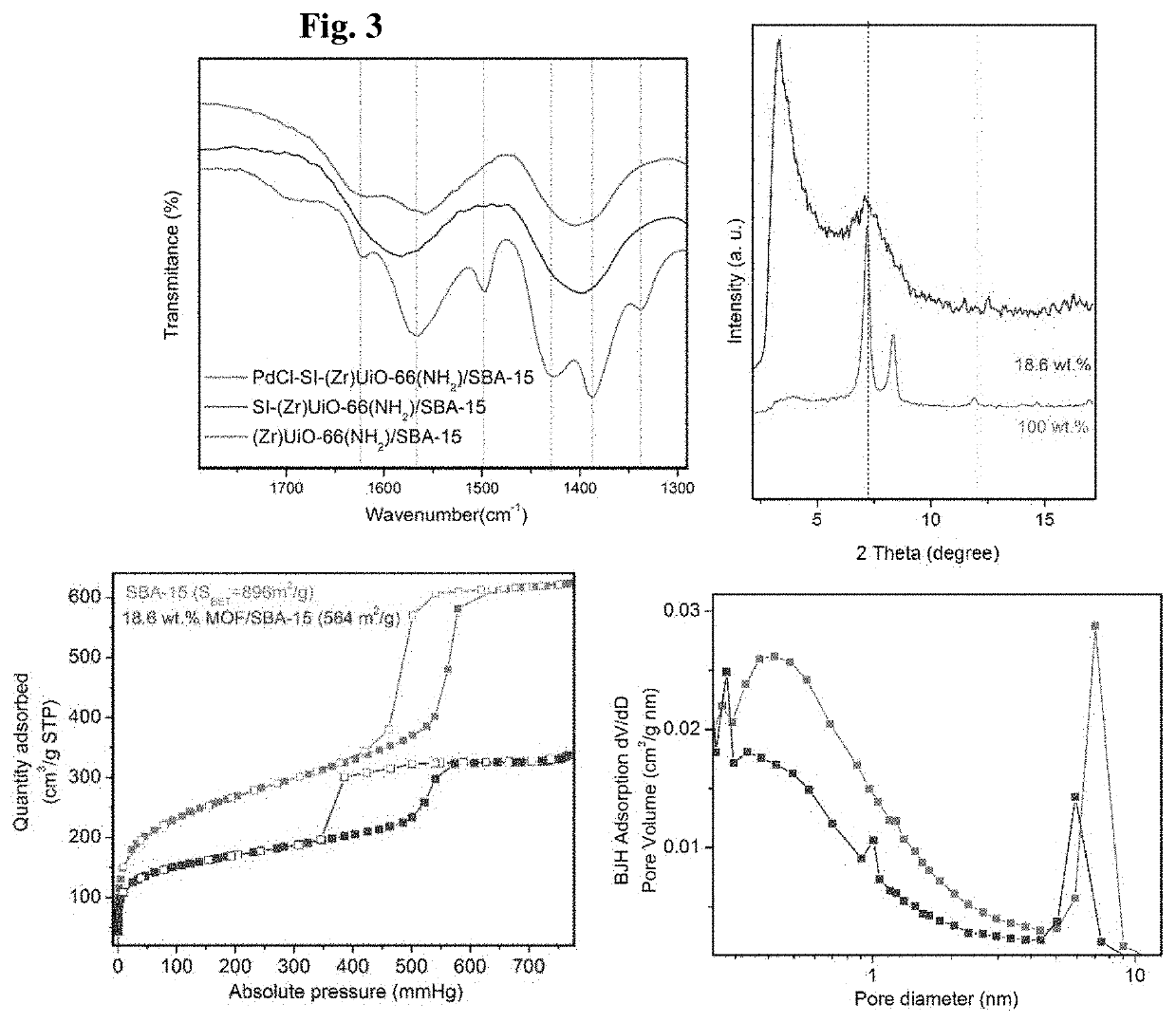

Method of making confined nanocatalysts within mesoporous materials and uses thereof

ActiveUS20210008529A1Group 5/15 element organic compoundsNickel organic compoundsNano catalystMetal-organic framework

The present disclosure provides methods of making confined nanocatalysts within mesoporous materials (MPMs). The methods utilize solid state growth of nanocrystalline metal organic frameworks (MOFs) followed by controlled transformation to generate nanocatalysts in situ within the mesoporous material. The disclosure also provides applications of the nanocatalysts to a wide variety of fields including, but not limited to, liquid organic hydrogen carriers, synthetic liquid fuel preparation, and nitrogen fixation.

Owner:RES TRIANGLE INST

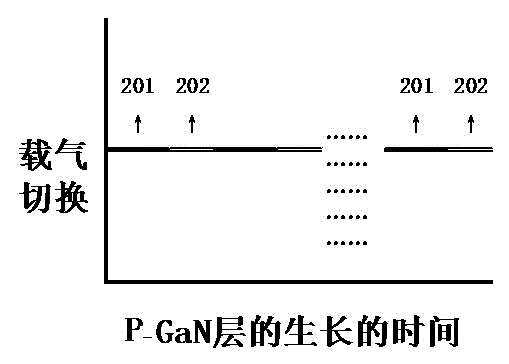

Epitaxial production method capable of effectively improving P-GaN hole injection layer quality

InactiveCN104319317AImprove qualityImprove activation efficiencySemiconductor devicesContact layerBiological activation

The invention discloses an epitaxial production method capable of effectively improving P-GaN hole injection layer quality. The epitaxial production method capable of effectively improving the P-GaN hole injection layer quality includes the step of sequentially growing a low temperature GaN buffer layer, an unintentional doped GaN layer, an n type electron injection layer, a multiple quantum well active area, a p-GaN hole injection layer and a p type heavy doped contact layer on a substrate, wherein the P-GaN hole injection layer is grown in alternate type nitrogen and hydrogen carrier gas switching environment, doping of magnesium atoms is performed in nitrogen environment, and activation energy of the magnesium atoms is reduced in hydrogen environment. The P-GaN hole injection layer grown in the alternate type carrier gas switching environment can effectively improve efficiency of merging the magnesium atoms into GaN crystal lattices, improves quality of the GaN crystal lattices, reduces work voltage and improves antistatic ability. Simultaneously, activation efficiency of the magnesium atoms is improved, a large quantity of hole carriers are provided, and luminance of LED (light emitting diode) devices is improved by reducing the activation energy of the magnesium atoms.

Owner:SUZHOU NANOJOIN PHOTONICS

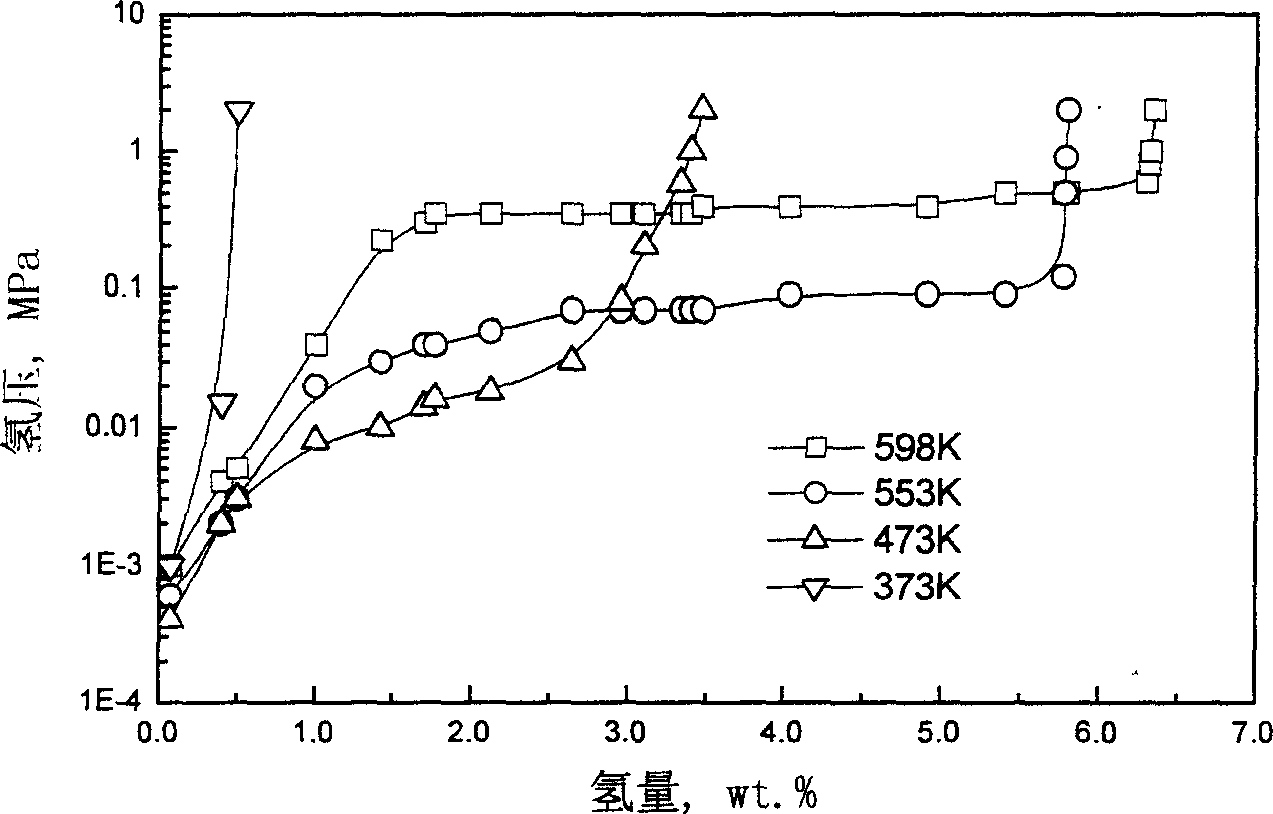

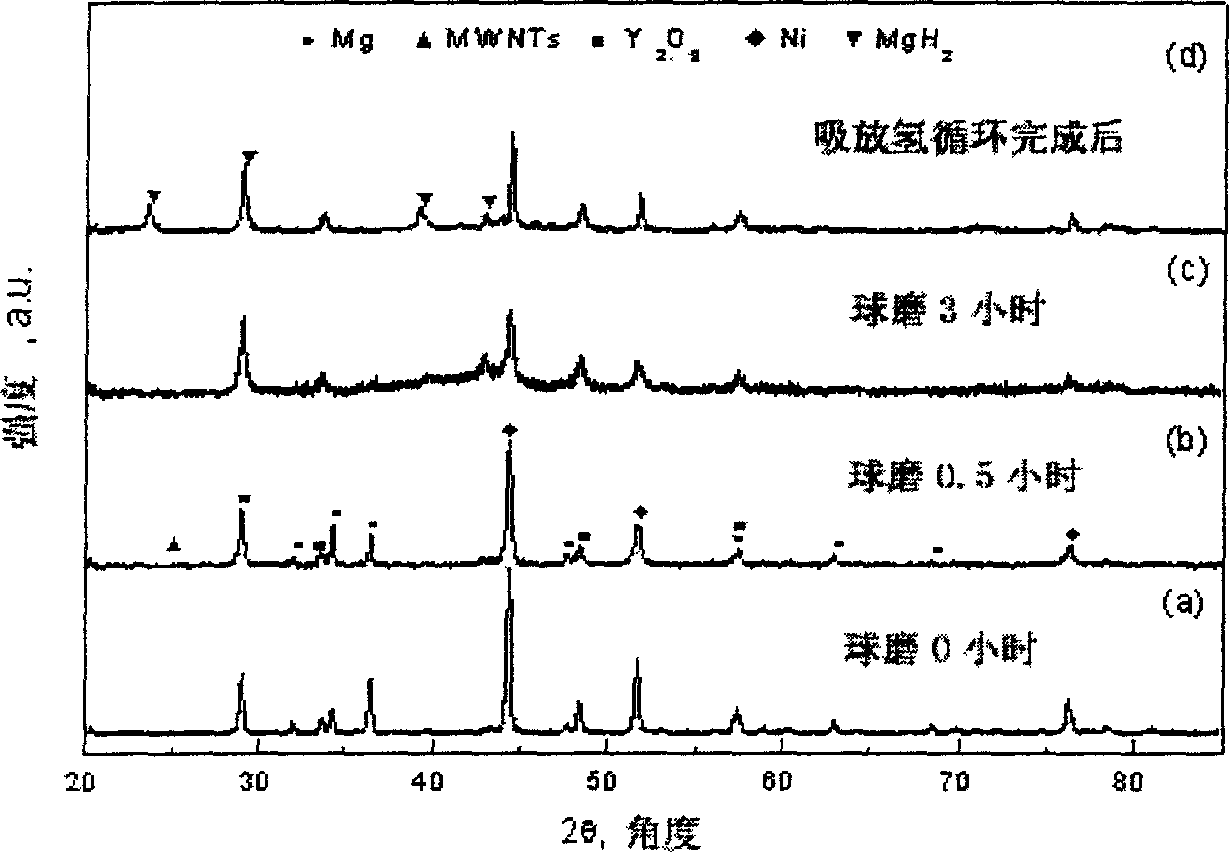

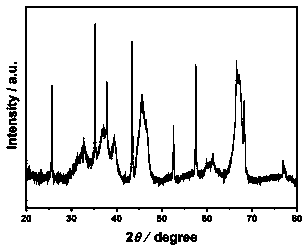

Magnesium and multi-wall nano carbon tube composite hydrogen storage material and process for preparing same

InactiveCN1699611AComposite fully and evenlyComposite uniformCell component detailsFuel cellsHydrogen atmosphere

The present invention relates to light nanometer composite hydrogen storage material, which comprises Mg and multi-wall nanometer carbon tube (MWNTs) and the composition expression is Mg / (x-wt%)MWNTs, here 0<xíœ50. The Mg nanometer crystal is hydrogenated to form large quantity of hydrogenation phase MgH2 of nanometer structure and catalysis phase of multi-wall nanometer carbon tube debris. These three phases tightly connect to each other, forming uniform dispersion distribution. The preparation method is: Mg powder is mixed with multi-wall nanometer carbon tube and then ball-ground in hydrogen atmosphere to undertake catalysis reaction. The method combines the preparation, activation and hydrogenation of composite material in one process. The invention has the advantages of high power of the storage and release of hydrogen, high velocity of the absorption and release of hydrogen, moderate operation temperature, low weight, low production cost, abound resources and safety in storage and transportation. It can be used for the mass production, storage and transportation of hydrogen, the hydrogen carrier of fuel cell, the purge and purification of hydrogen, and organic hydrogenation engineering.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

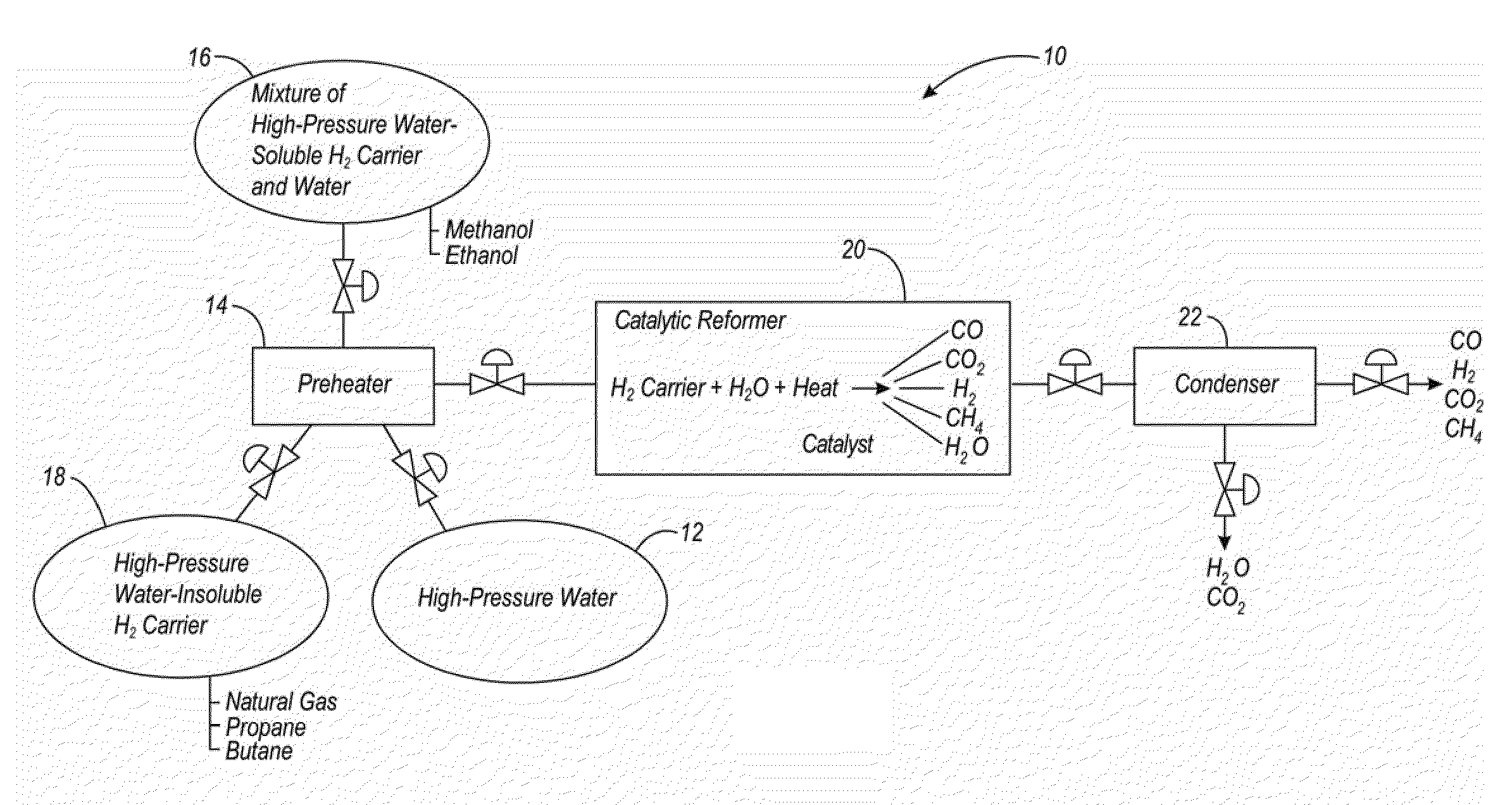

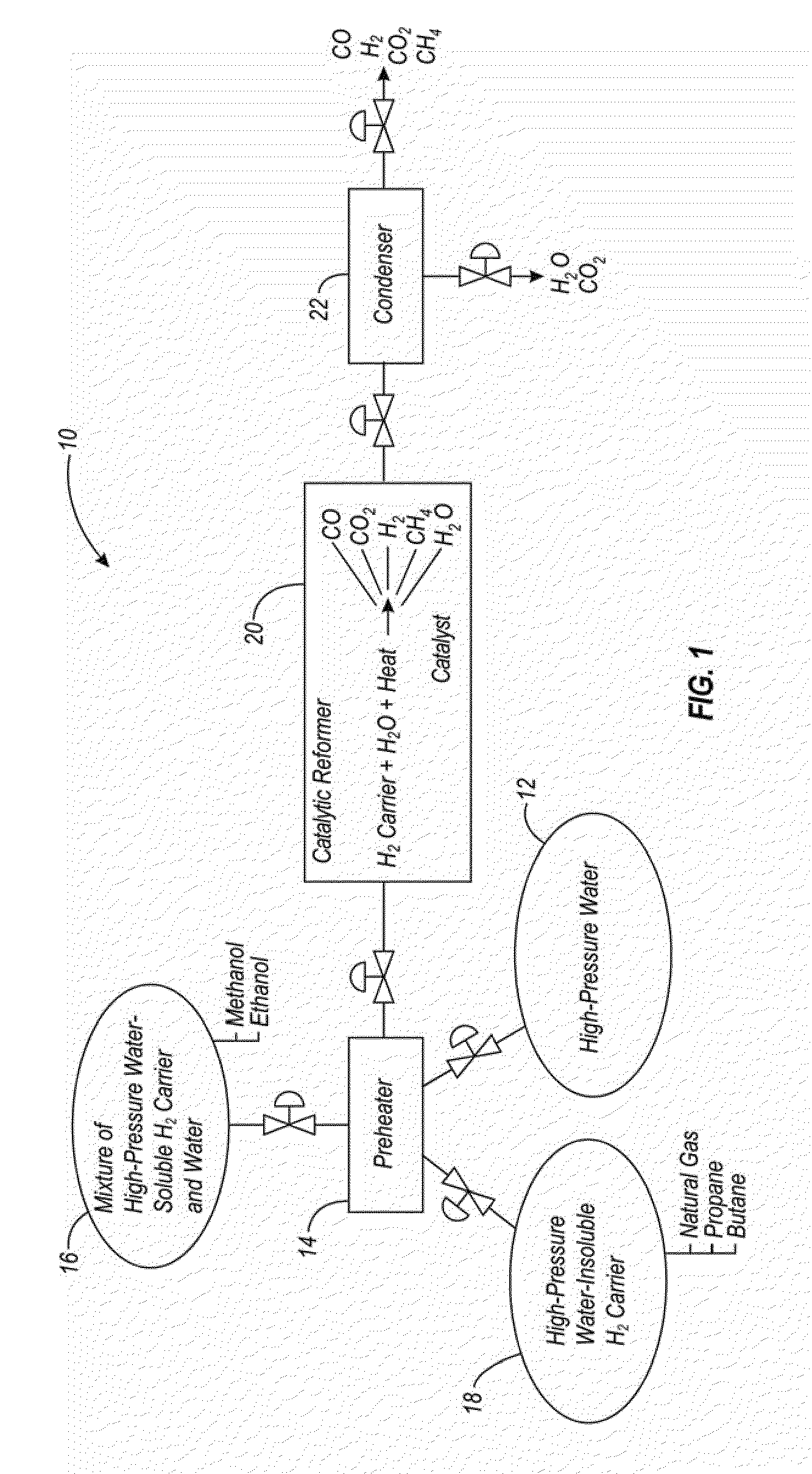

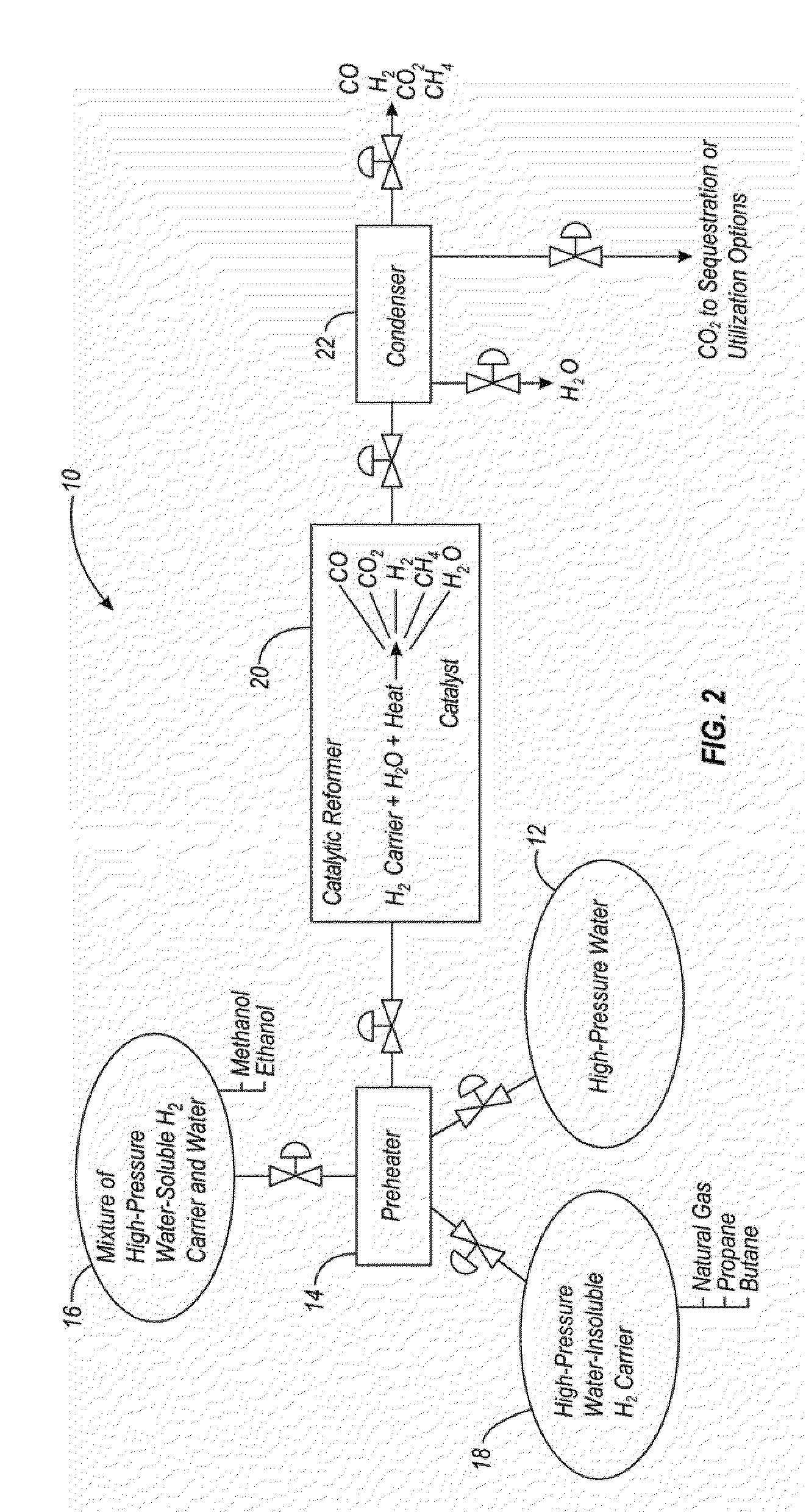

System and process for producing high-pressure hydrogen

ActiveUS20100068571A1Maintenance conditionHydrogen productionCarbon monoxideHigh pressure waterHigh pressure

A method and apparatus are provided for use in producing high-pressure hydrogen from natural gas, methanol, ethanol, or other fossil fuel-derived and renewable hydrocarbon resources. The process can produce hydrogen at pressures ranging from 2000 to 12,000 pounds per square inch (psi) using a hydrogen carrier, with or without high-pressure water, and an appropriate catalyst. The catalyst reacts with the hydrogen carrier and, optionally, high-pressure water, in a catalytic reformer (20) maintained under desired temperature and pressure conditions.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

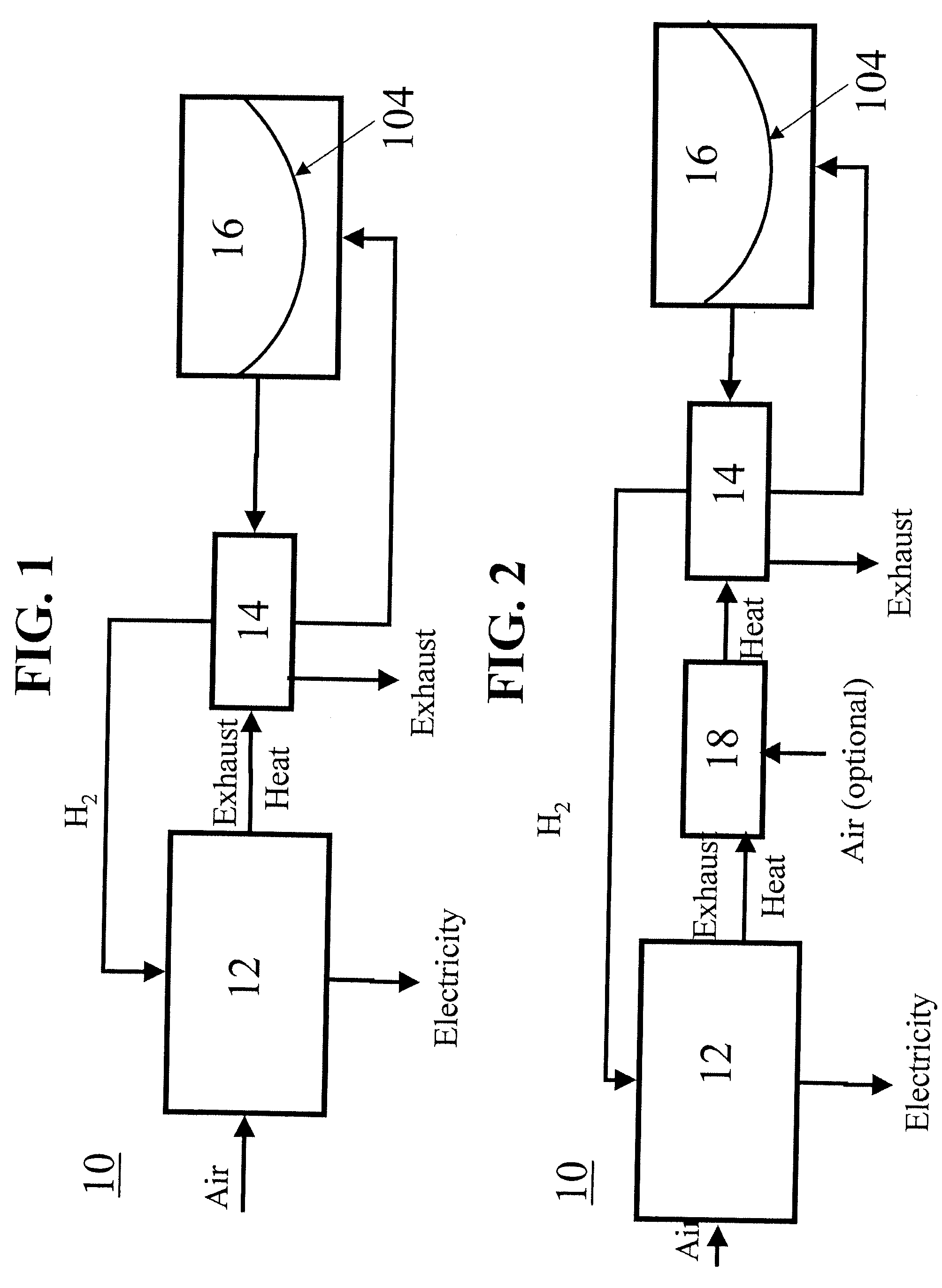

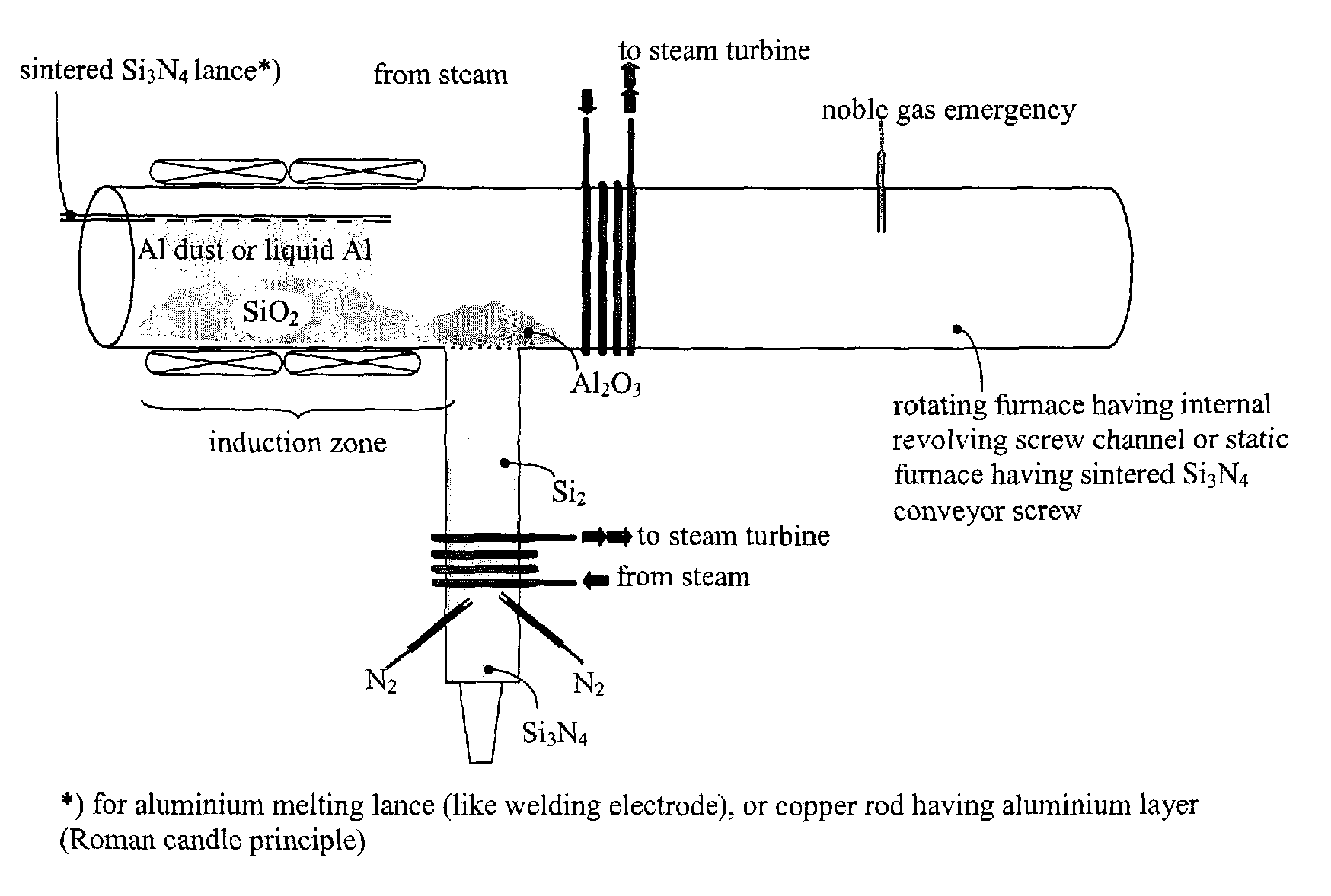

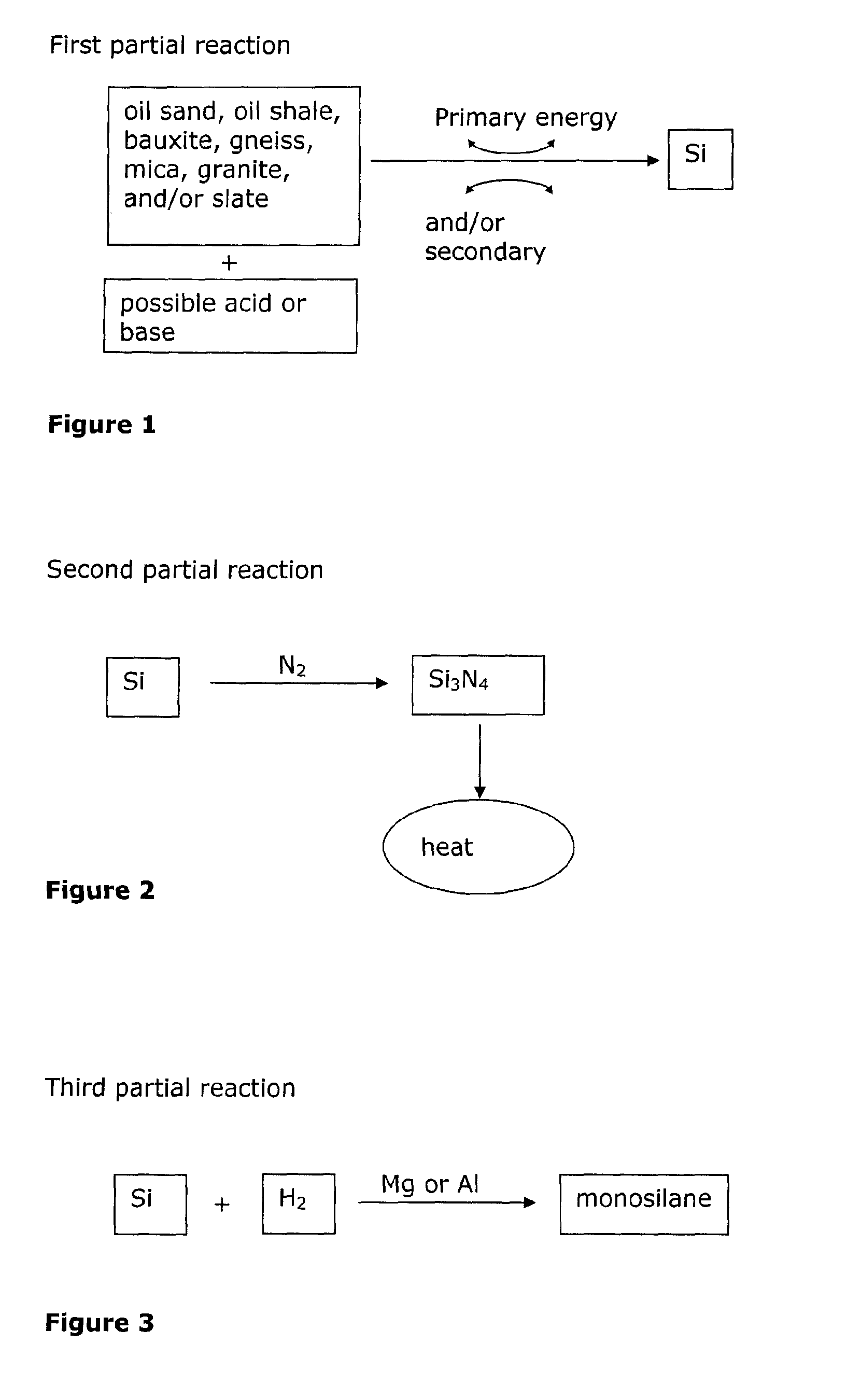

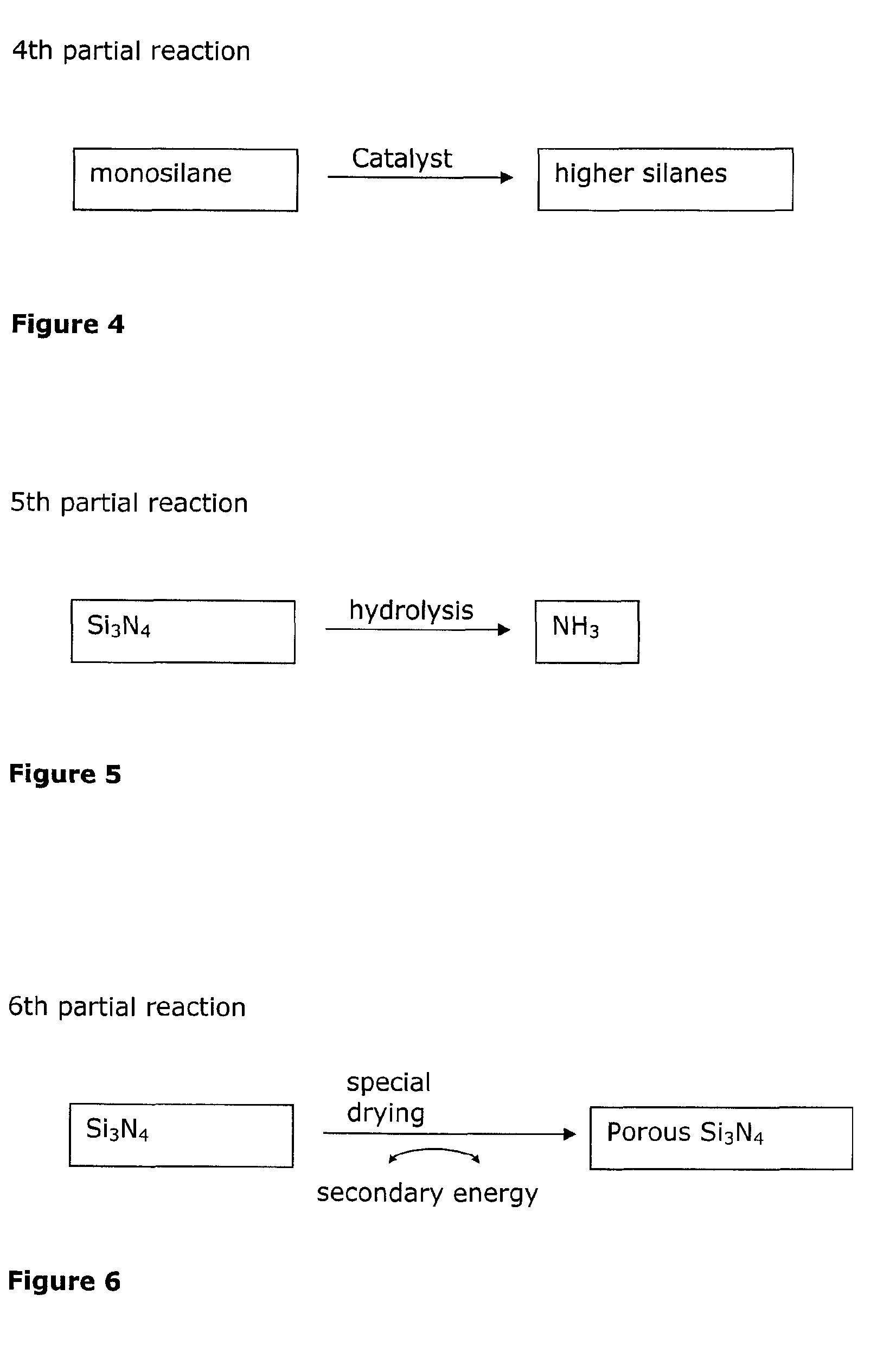

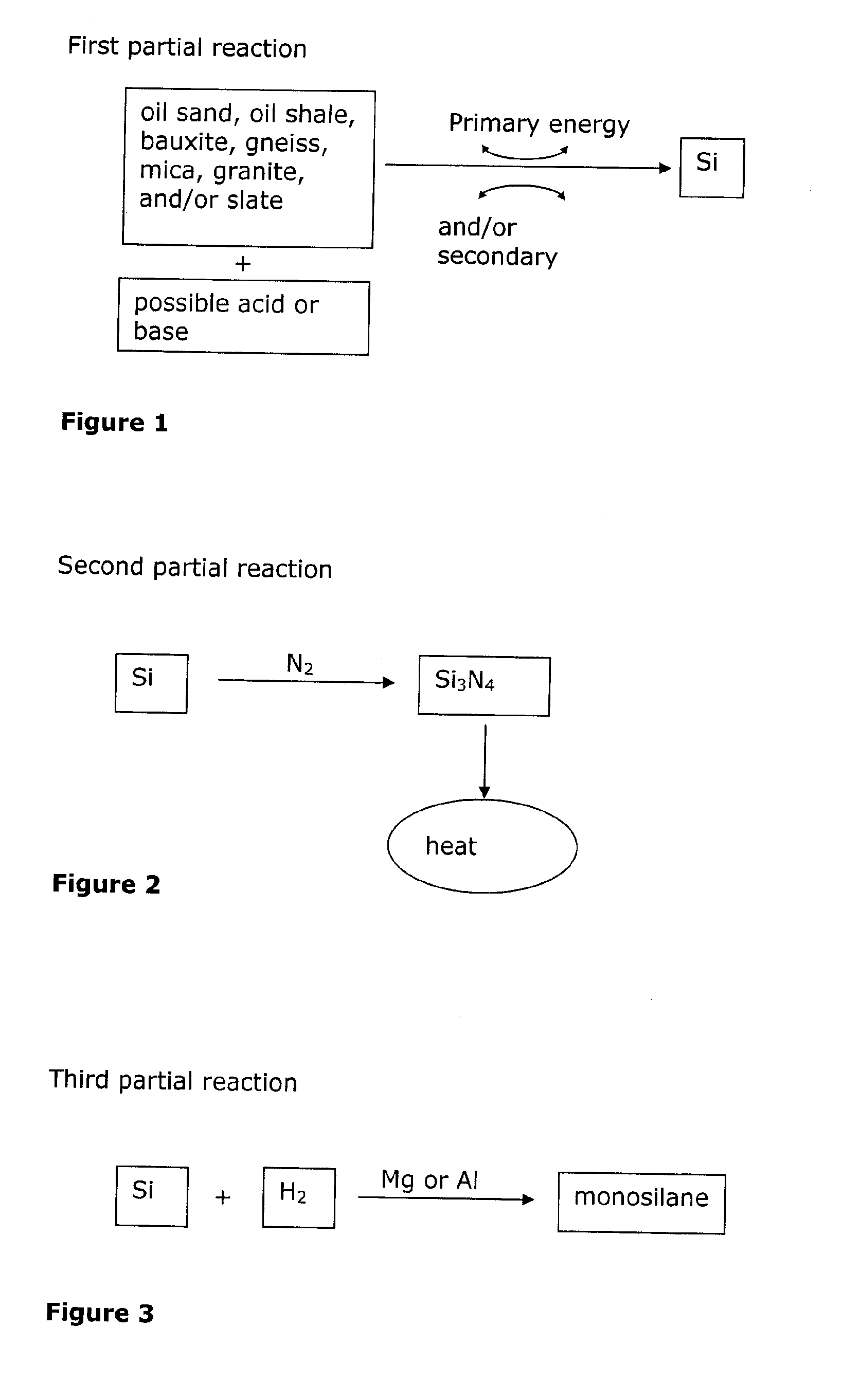

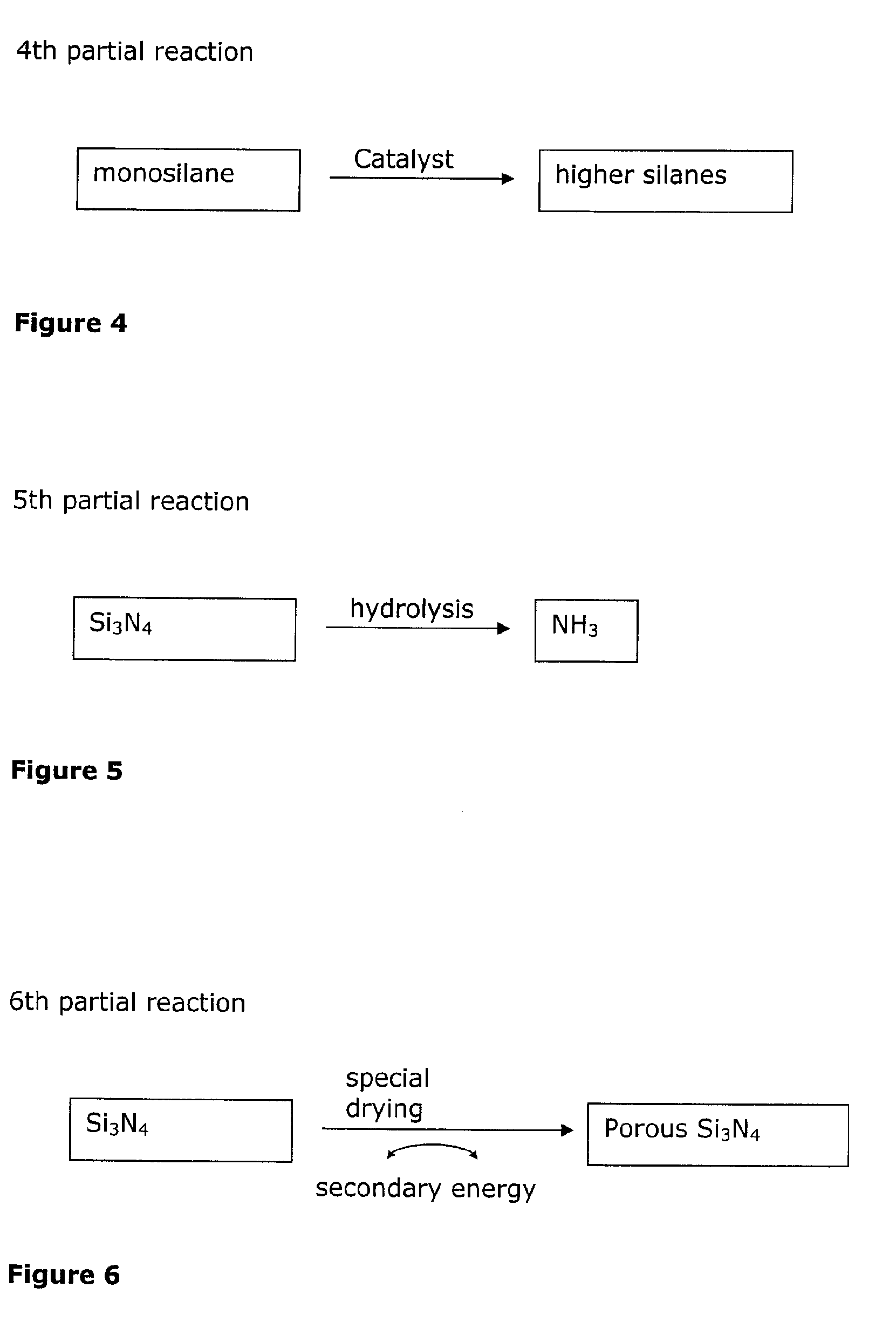

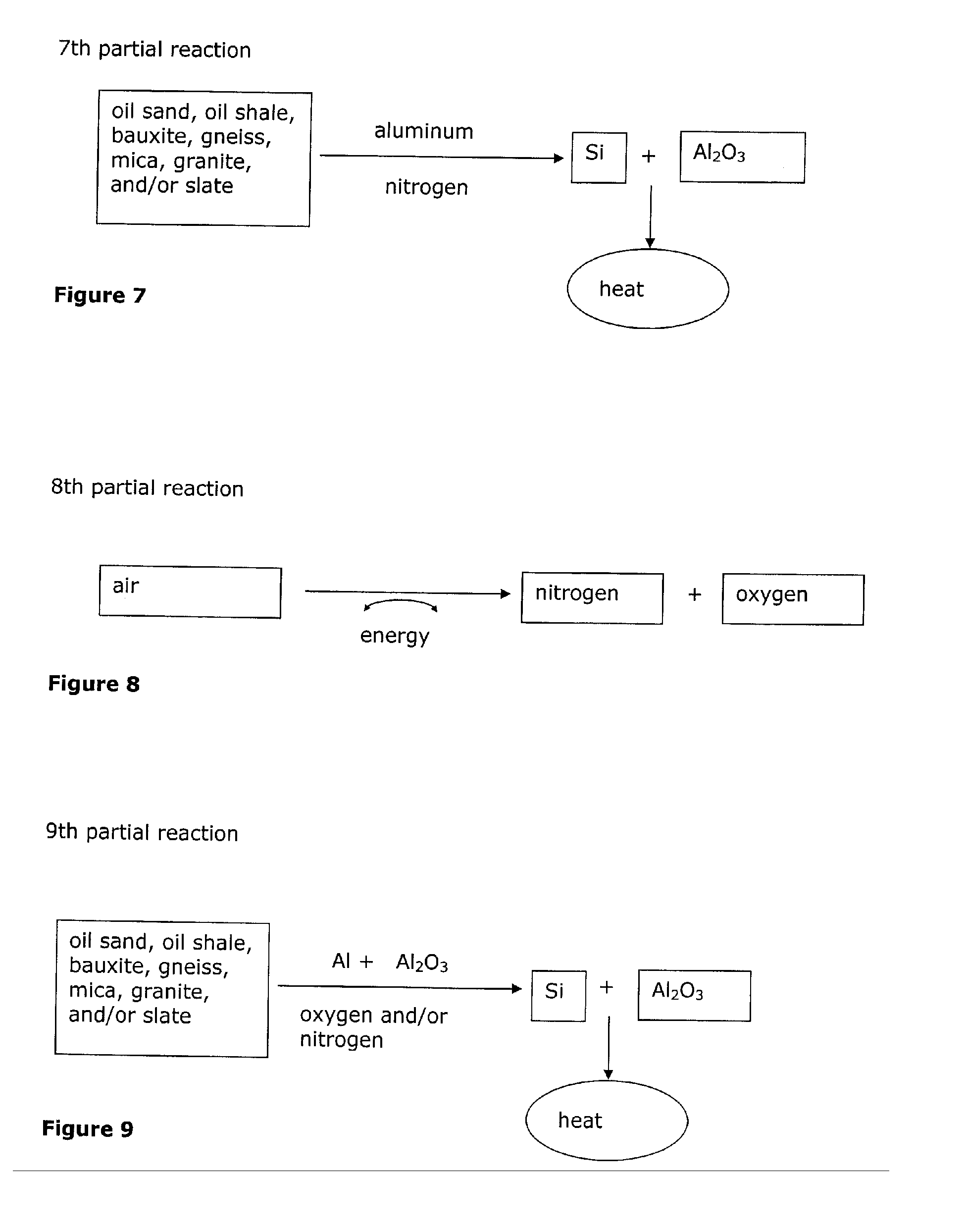

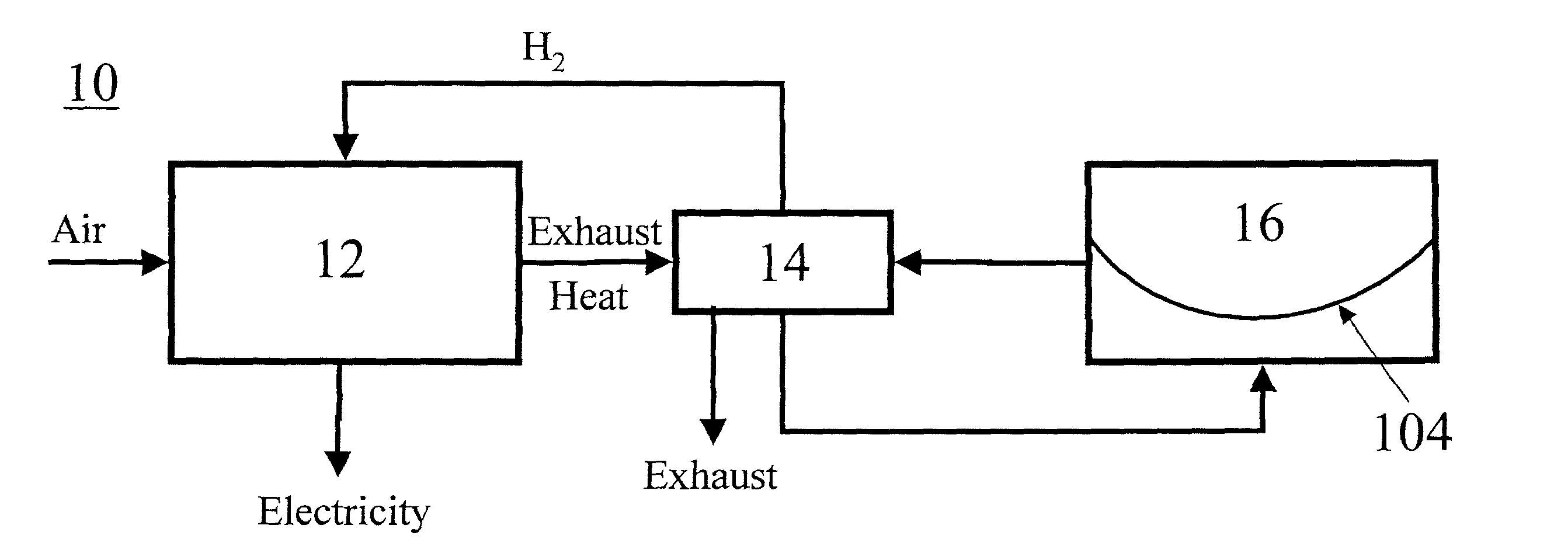

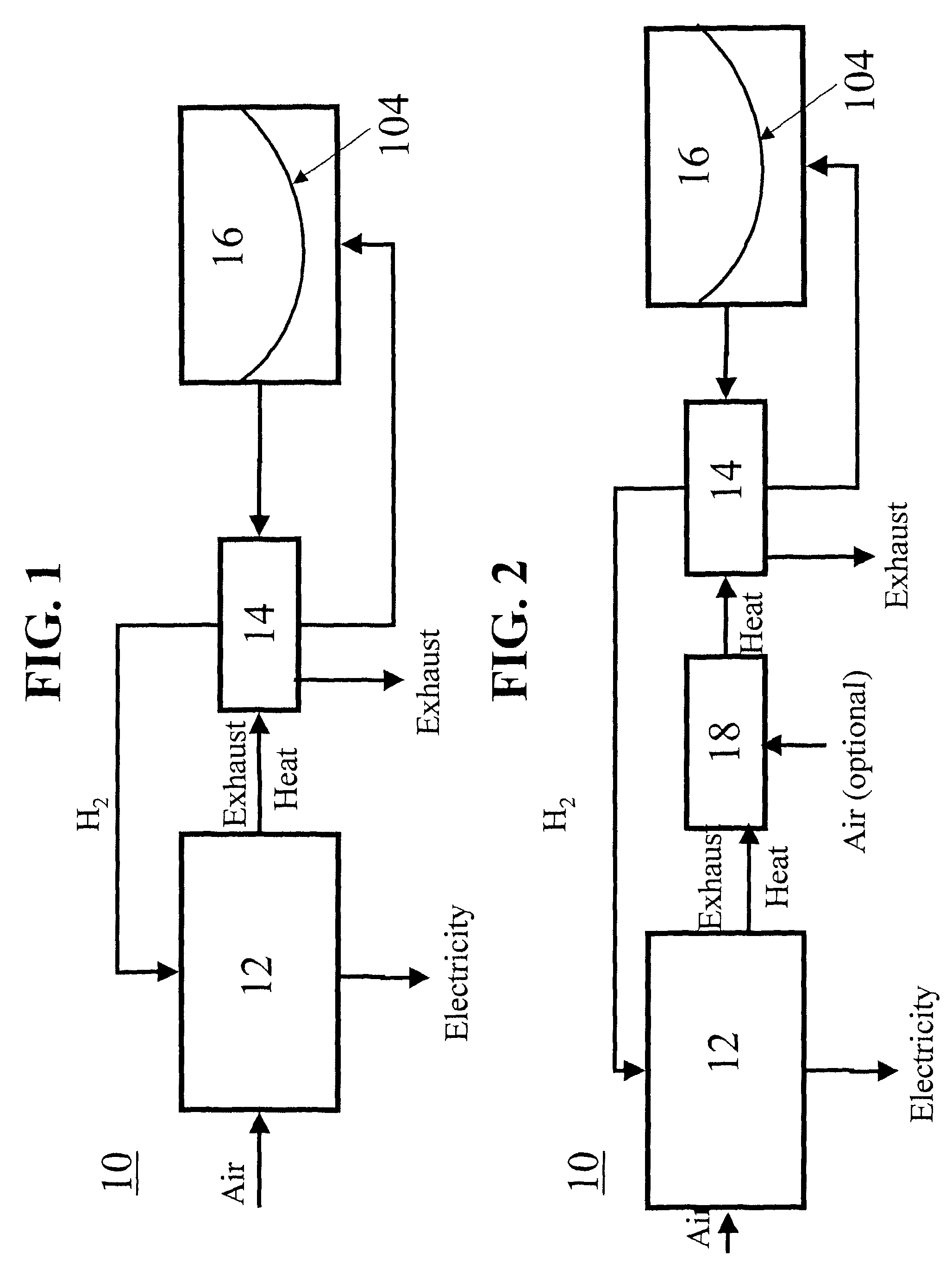

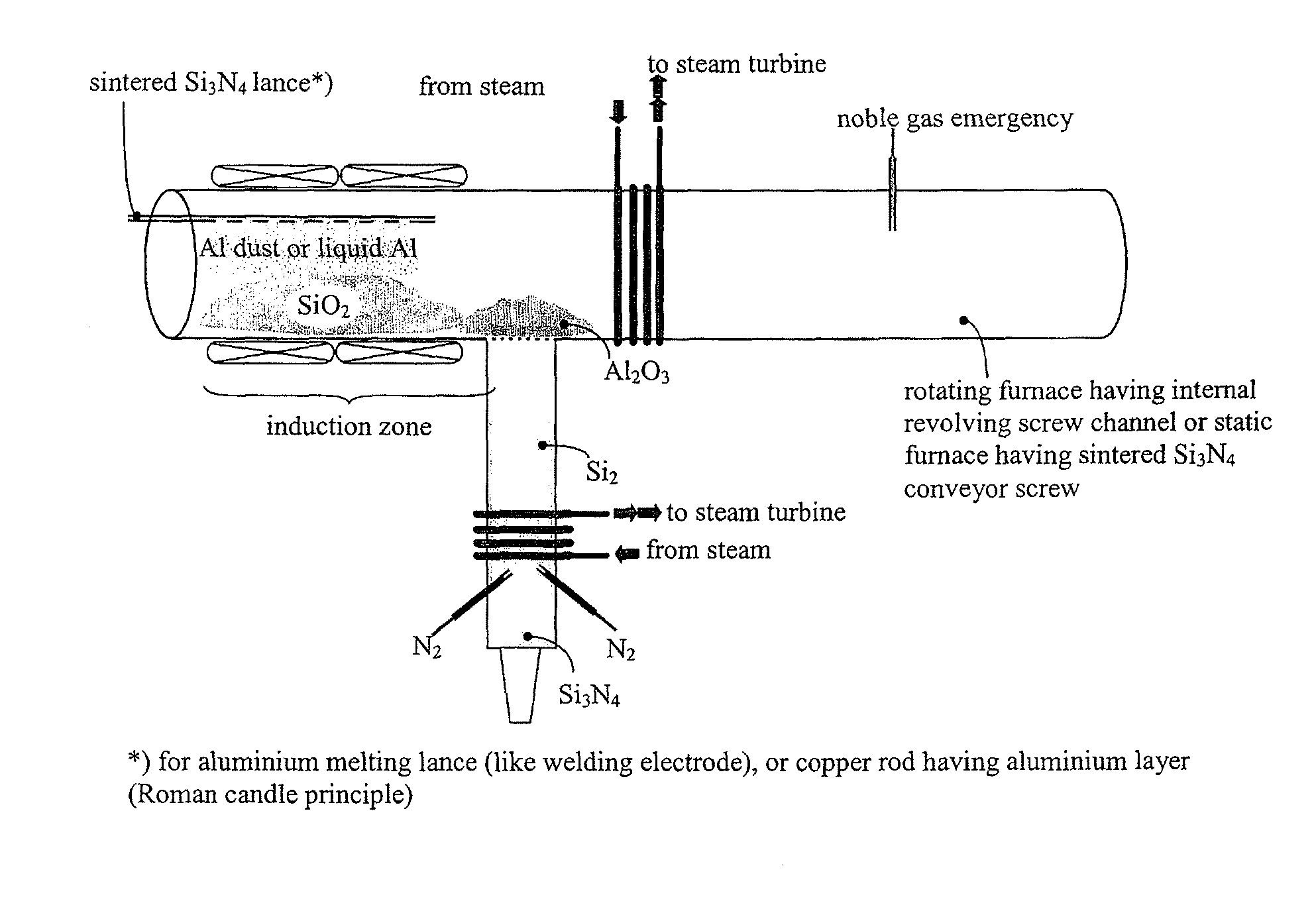

Novel cascaded power plant process and method for providing reversibly usable hydrogen carriers in such a power plant process

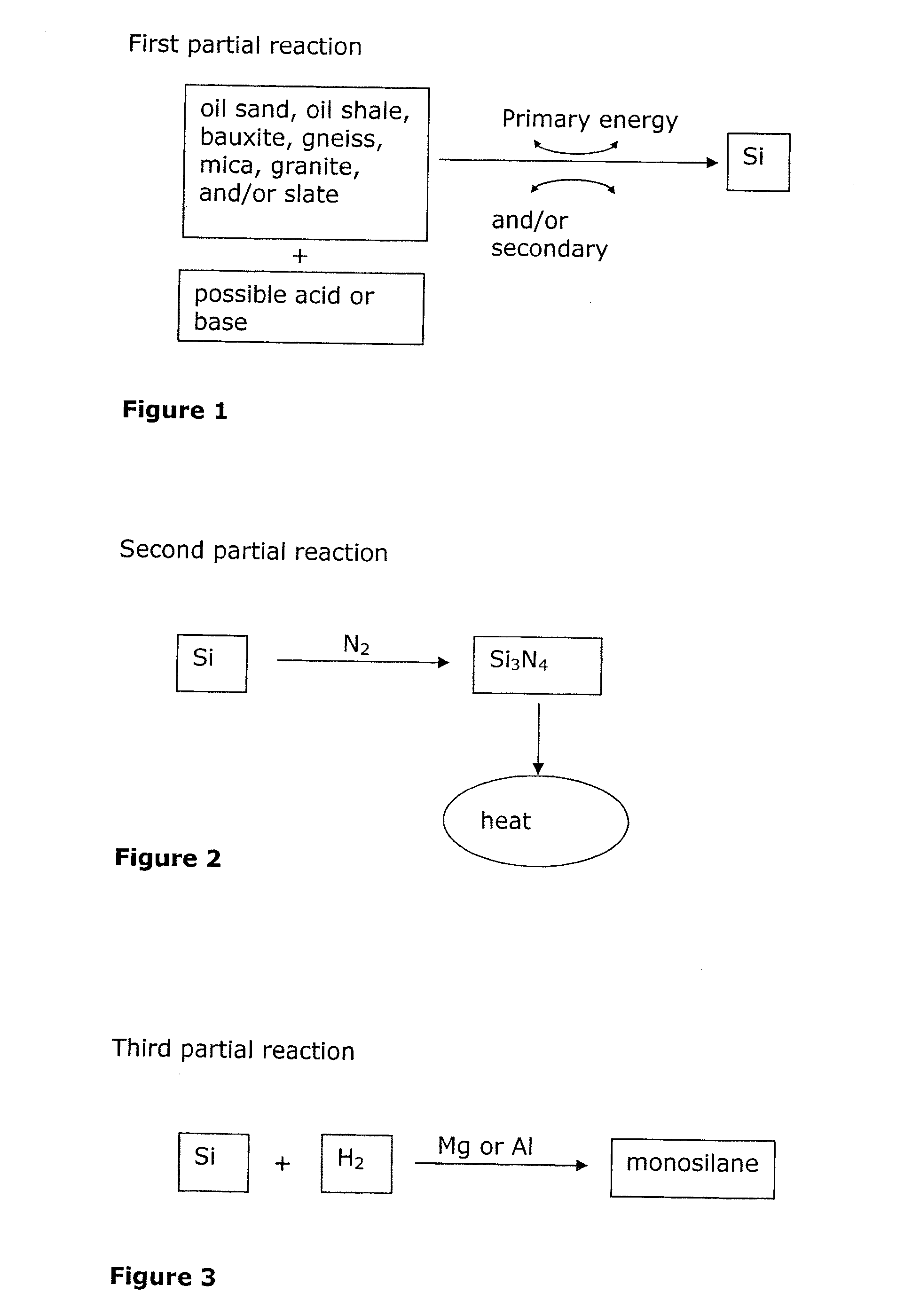

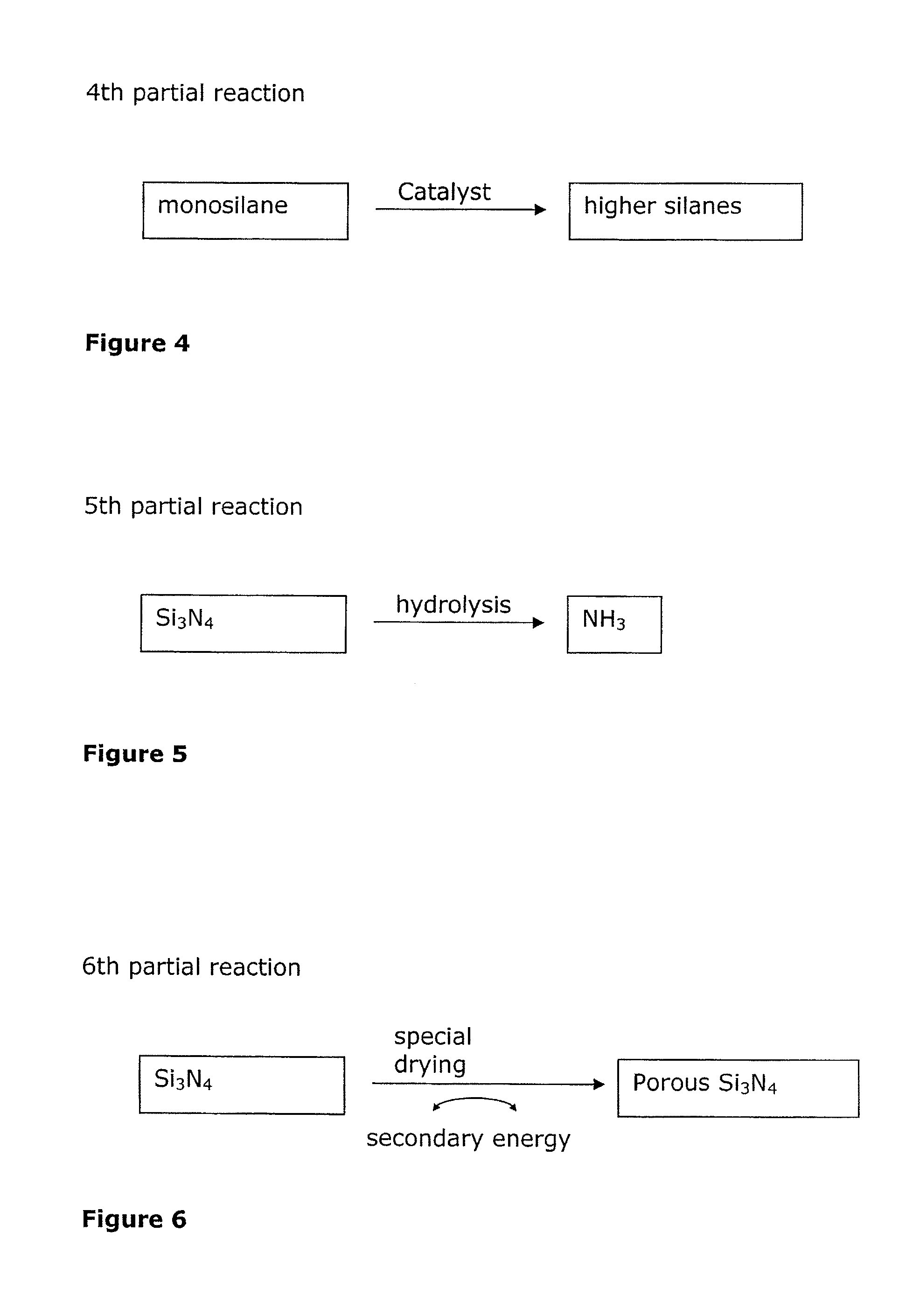

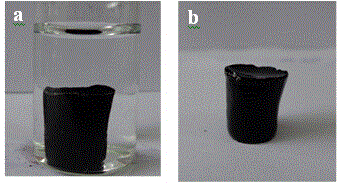

InactiveUS20070264184A1Rapid and efficientEfficient hydrolysisNitrogen compoundsCarbon compoundsHydrogenPower station

The crude oil reserves have a calculable time limit. Starting materials containing silicon dioxide are preferably used as raw materials.

Owner:SILICON FIRE AG

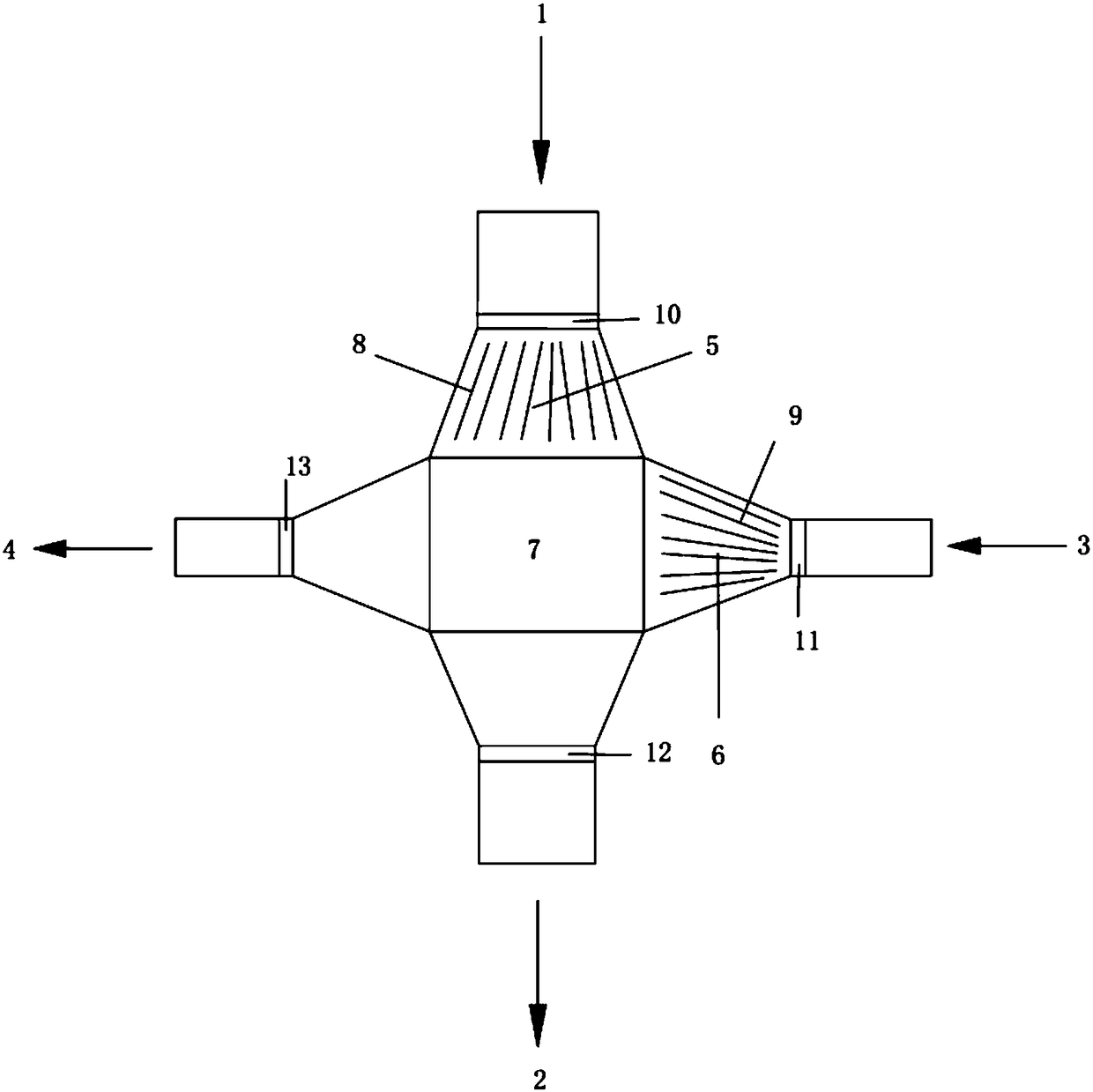

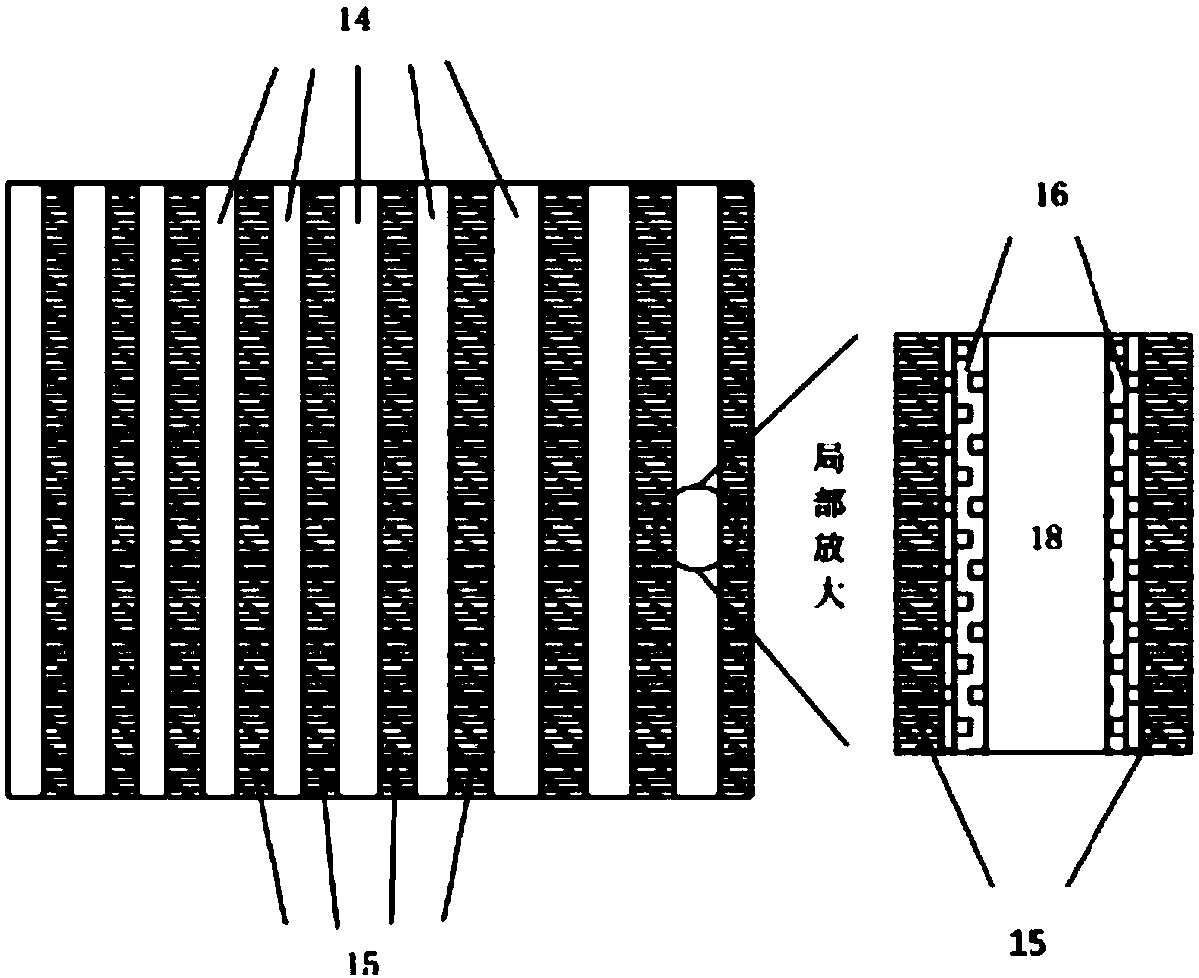

Microchannel reactor applicable to dehydrogenation reaction of liquid hydrogen source materials and dehydrogenation method

PendingCN108067172AEfficiently provideEffectively continue to provideHydrogenChemical/physical/physico-chemical microreactorsHeat carrierSource material

The invention discloses a microchannel reactor applicable to dehydrogenation reaction of liquid hydrogen source materials and a dehydrogenation method. Flow guide plates are arranged in a liquid distributor which is connected above a microchannel reactor body, a high-temperature flange is arranged between the liquid distributor and a hydrogen source material inlet, the lower portion of the microchannel reactor body is provided with a hydrogen storage carrier and hydrogen outlet, and a high-temperature flange is arranged between the microchannel reactor body and the outlet. A heat carrier distributor is connected to an inlet side of the microchannel reactor body, flow guide plates are arranged in the heat carrier distributor, a high-temperature flange is arranged between the heat carrier distributor and a heat carrier inlet, the other side of the microchannel reactor body is provided with a heat carrier outlet, and a high-temperature flange is arranged between the microchannel reactor body and the heat carrier outlet. The microchannel reactor body is internally provided with a plurality of transverse and longitudinal orthogonal microchannels. By the microchannel reactor, reaction efficiency is improved, and reactor cost is effectively reduced.

Owner:国能氢油(广东)科技股份有限公司

Hydrogen enriching exhaust recirculator for waste heat recovery of internal-combustion engine

ActiveCN103075275AIncrease fuel consumptionEasy dischargeNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberExhaust gas recirculation

The invention relates to a hydrogen enriching exhaust recirculator which belongs to the technical field of an internal-combustion engine. The hydrogen enriching exhaust recirculator comprises an engine, hydrogen makers, a control valve, quality flow controllers, a storage tank and an evaporator. A second hydrogen maker and the evaporator are sequentially installed on an exhaust pipe of the engine, an exhaust recirculating cooler and an exhaust recirculating control valve are sequentially installed on a gas outlet pipe of the first hydrogen maker, and a pressurizer, a hydrogen enriching gas storage tank and a third quality flow controller are sequentially installed on a gas outlet pipe of the second hydrogen maker. In the working process of the engine, the combustion phase of the engine is adjusted in real time based on the working conditions of the engine, the exhaust temperature and the pressure signal feedback in the hydrogen enriching gas storage tank to control the temperature of a catalytic bed, a hydrogen-rich gas is generated in a catalytic cracking hydrogen carrier in the hydrogen maker by means of waste heat exhausted by the engine, and the hydrogen-rich gas obtained along with recirculating gas enters into the combustion chamber of the engine to combust with fuel. The hydrogen enriching exhaust recirculator provided by the invention is reasonable in design and simple in structure, and is suitable for the fields of gasoline engines, diesel engines for automobiles and ships, aero-engines and the like.

Owner:浙江和夏科技股份有限公司

Hydrogen storage material and related system

Owner:GENERAL ELECTRIC CO

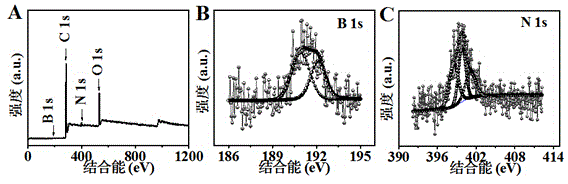

Preparation method for boron carbonitride nanosheet loaded metal nano particle hybrid material

InactiveCN105880629AThe synthesis process is simpleShort cycleNanotechnologyMetal nitrateBoron carbonitride

The invention belongs to the technical field of nano materials, and relates to a preparation method for a boron carbonitride nanosheet loaded metal nano particle hybrid material. The boron carbonitride nanosheet loaded metal nano particle hybrid material is prepared by taking metal nitrate, glycine and boric acid as raw materials through a one-step thermal treatment method. A synthetic method for the boron carbonitride nanosheet loaded metal nano particle hybrid material provided by the invention is simple in synthesis process, and the needed raw materials are cheap and easily available raw materials on the market; and the prepared a boron carbonitride nanosheet loaded metal nano particle hybrid material is soft and porous, and has a very good application prospect on application fields such as capacitors, hydrogen storage carriers and biosensors.

Owner:JIANGSU UNIV

Process and plant for producing and storing hydrogen

A process for producing and storing hydrogen includes providing an intermediate gas mixture having an increased proportion of hydrogen and contacting of the intermediate gas mixture with a hydrogen carrier medium in order to hydrogenate the hydrogen carrier medium.

Owner:HYDROGENIOUS TECH GMBH

Preparation method of benzoic acid

ActiveCN106866403AHigh catalytic efficiencyHigh acid selectivityOrganic compound preparationCarboxylic compound preparationBenzoic acidReaction temperature

The invention discloses a preparation method of benzoic acid. According to the method disclosed by the invention, the benzoic acid is prepared by taking toluene as a raw material, oxygen as an oxidant and a metal porphyrin compound as a catalyst, adding a hydrogen carrier into a reaction system, and carrying out catalytic reaction under conditions that the reaction temperature is 80 DEG C to 130 DEG C and the reaction pressure is 0.3MPa to 1.2MPa. The preparation method disclosed by the invention has the advantages of less catalyst dosage, good catalytic effect, moderate conditions, simple process and the like.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

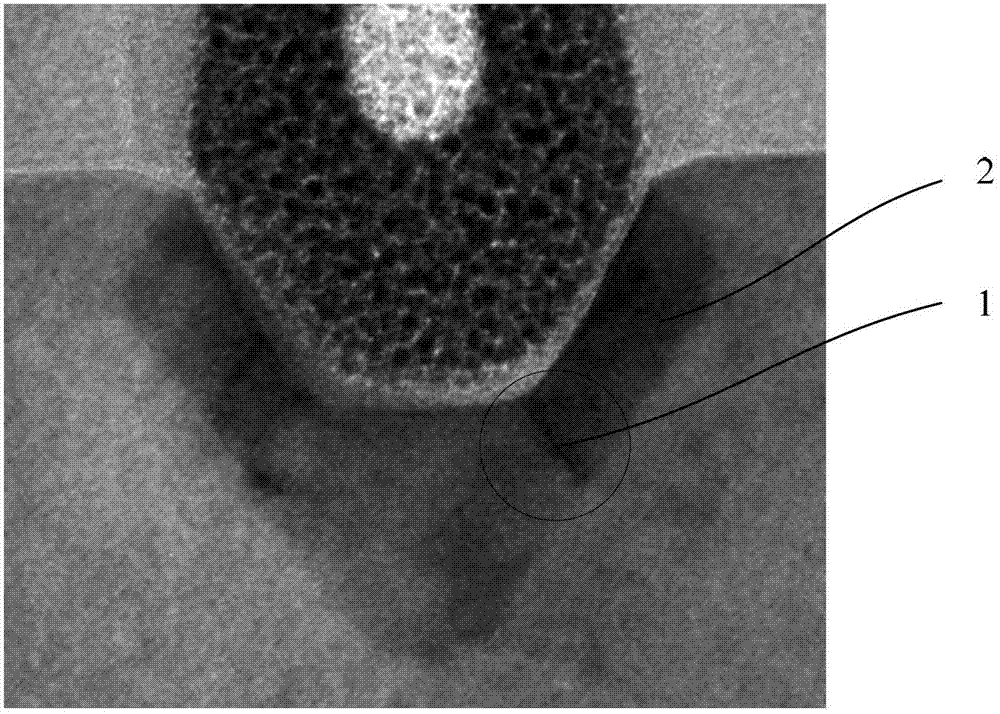

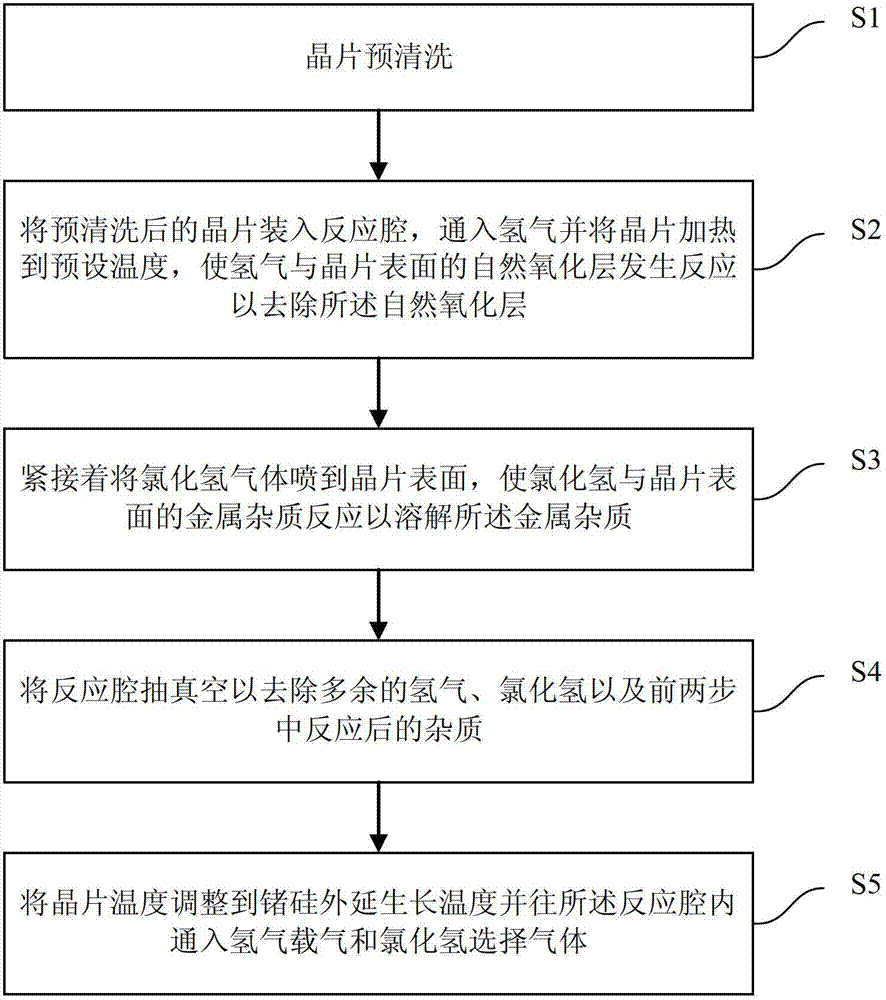

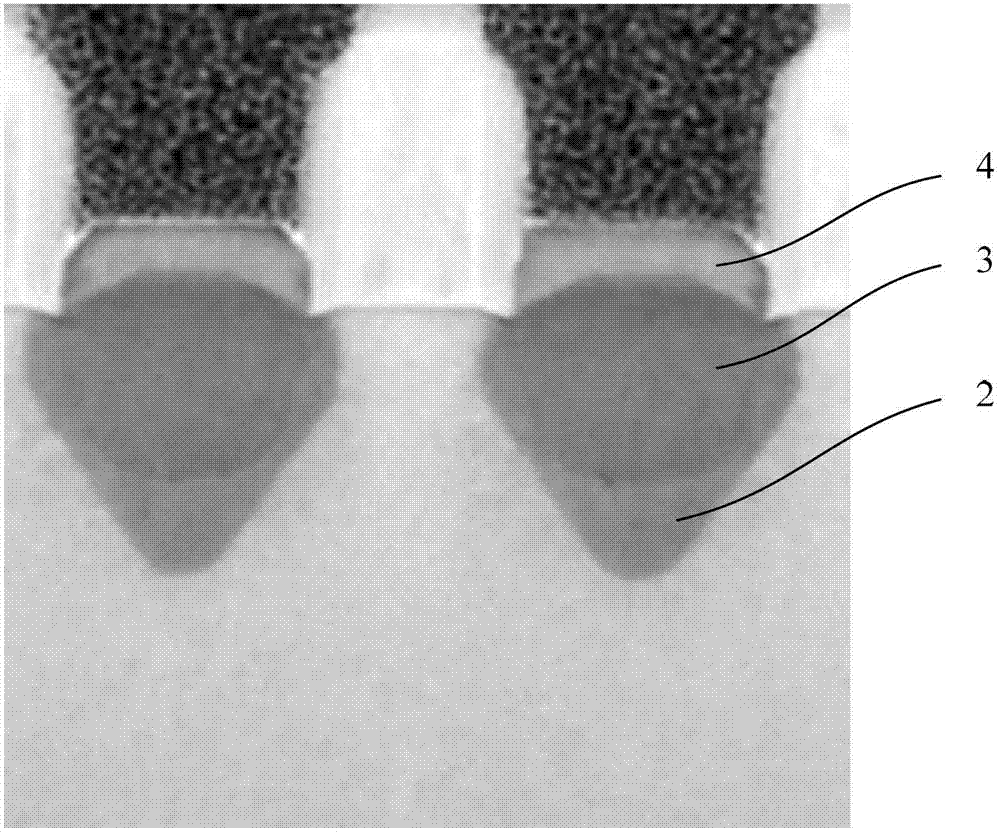

Chip preprocessing method of selective epitaxial growth germanium silicon

ActiveCN103928294AImprove cleanlinessQuality assuranceSemiconductor/solid-state device manufacturingAutoxidationHydrogen

The invention provides a chip preprocessing method of selective epitaxial growth germanium silicon. The method at least comprises the following steps that (1) chip pre-washing is carried out; (2) a chip after pre-washing is arranged into a reaction cavity, hydrogen goes in, the chip is heated to a preset temperature, the hydrogen reacts with an autoxidation layer on the surface of the chip, and accordingly the autoxidation layer is removed; (3) then, hydrogen chloride gas is sprayed to the surface of the chip, and hydrogen chloride reacts with metal impurities on the surface of the chip, so that the metal impurities are dissolved; (4) the reaction cavity is vacuumized, so that surplus hydrogen, hydrogen chloride and impurities in the first two steps after reaction are removed; and (5) chip temperature is adjusted germanium silicon epitaxial growth temperature, and hydrogen carrier gas and hydrogen chloride selective gas go into the reaction cavity. According to the chip processing method, a hydrogen chloride gas way in existing equipment is used, hydrogen chloride processing happens in the reaction cavity, processing time is short, the technology is simple, the cleanliness of the chip can be greatly improved, and the quality of a following germanium silicon epitaxial layer can be guaranteed.

Owner:SEMICON MFG INT (SHANGHAI) CORP

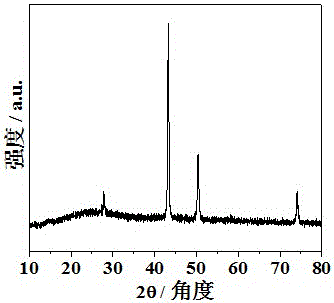

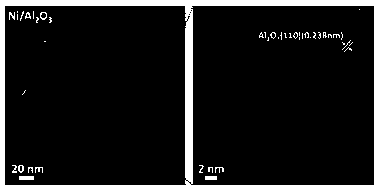

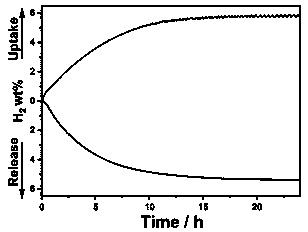

In-situ prepared nickel-based catalyst for catalyzing hydrogen absorption and release of liquid organic hydrogen carrier, and preparation method thereof

ActiveCN111013593ANo complicated preparation processImprove catalytic performanceReversible hydrogen uptakeMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrogen desorption

The invention belongs to the technical field of hydrogen storage and catalysis, and particularly relates to an in-situ prepared nickel-based catalyst for catalyzing hydrogen absorption and release ofa liquid organic hydrogen carrier, and a preparation method thereof, wherein the catalyst comprises a catalyst carrier and an active catalytic component loaded on the catalyst carrier, and the activecatalytic component is nano nickel formed in situ. The preparation method comprises: carrying out heating and thermal insulation on bis(1,5-cyclooctadiene)nickel, a reaction solvent liquid organic hydrogen carrier and a catalyst carrier under a vacuum condition, heating, inflating with hydrogen, and carrying out a reaction. Compared with the catalyst in the prior art, the catalyst has the following advantages that (1) no complex catalyst preparation process exists; and (2) precious metal is not used while excellent catalytic performance of catalyzing of hydrogen absorption and hydrogen desorption of a liquid organic hydrogen carrier is shown, and the catalyst has important significance in practical application of the liquid organic hydrogen carrier.

Owner:苏州清德氢能源科技有限公司

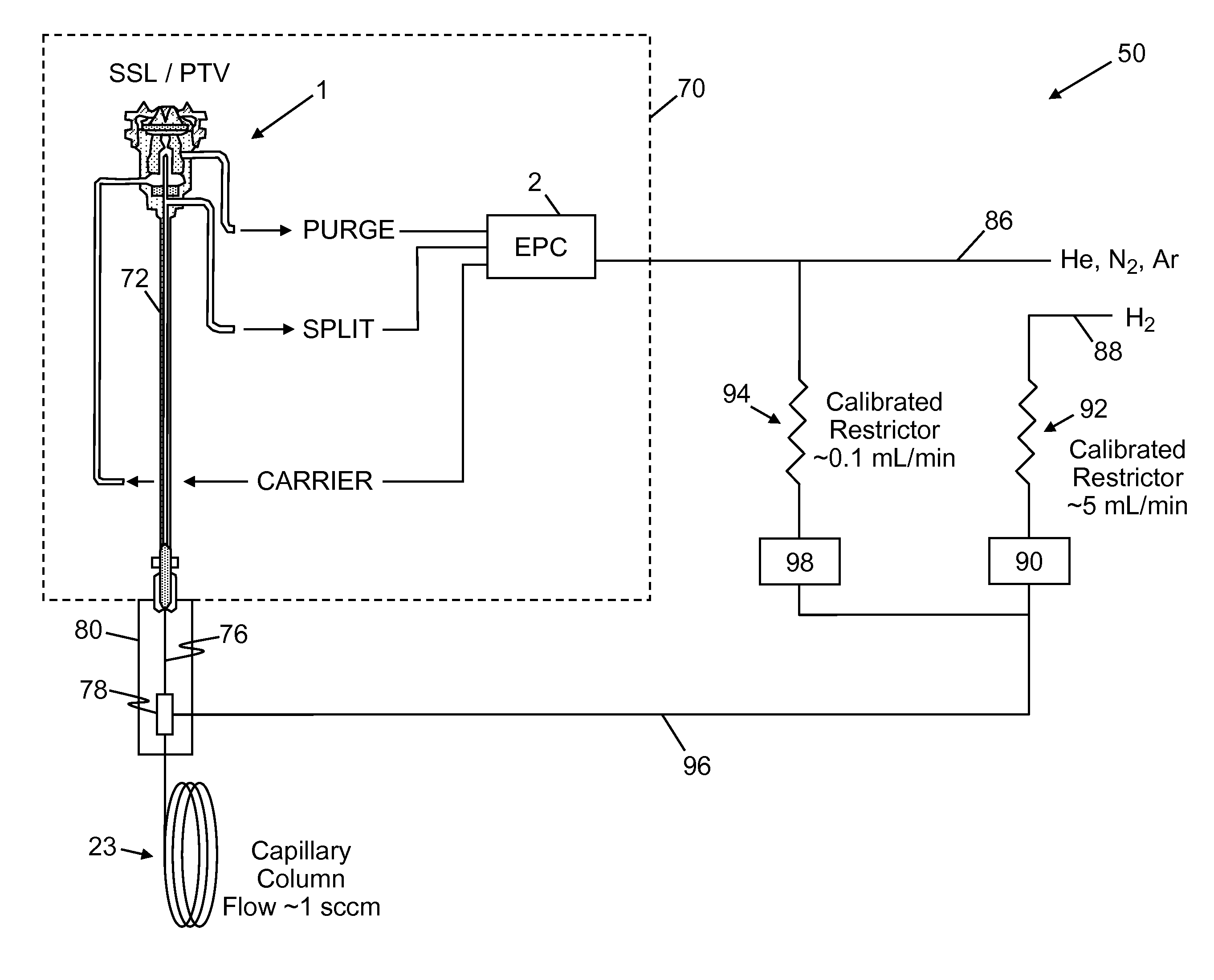

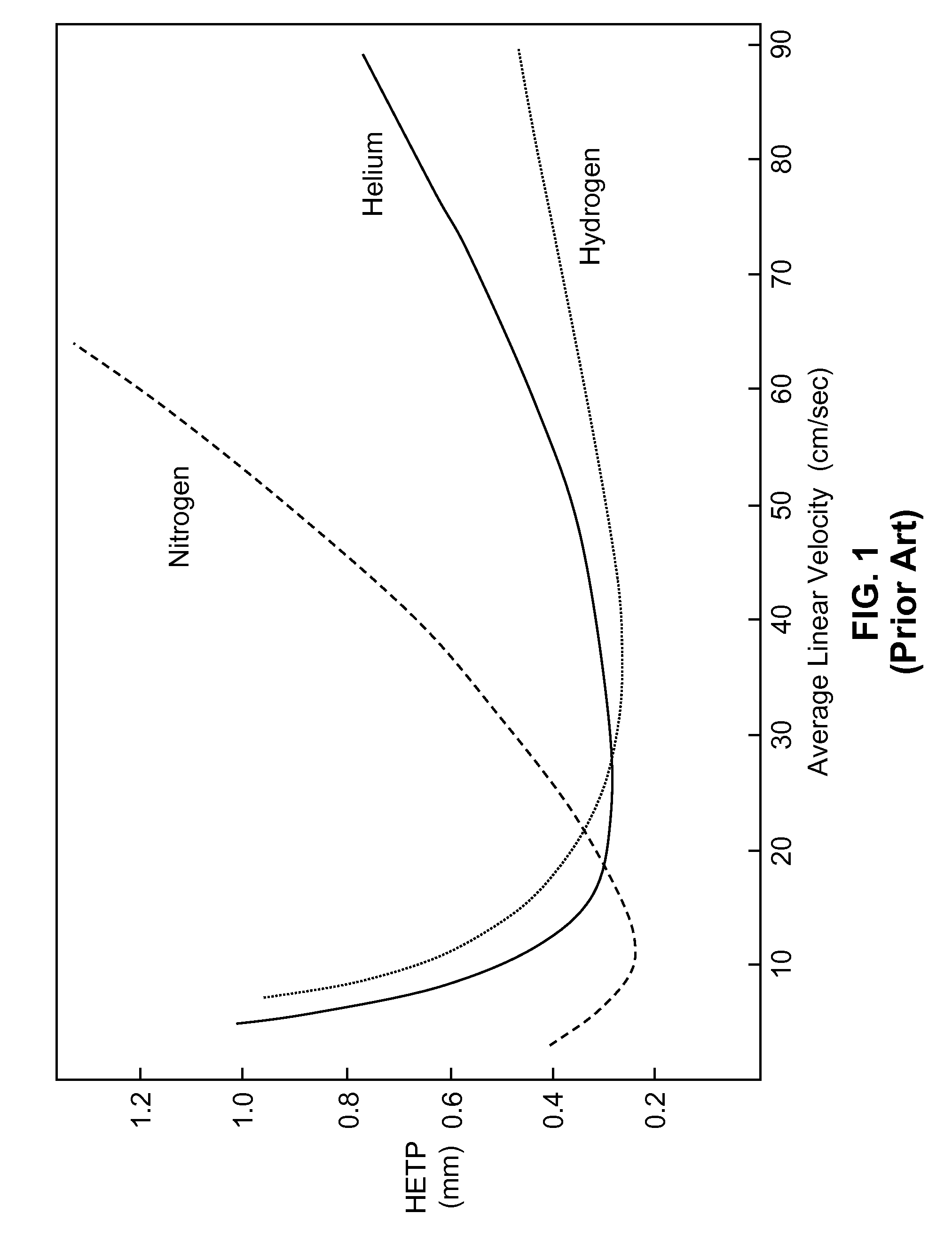

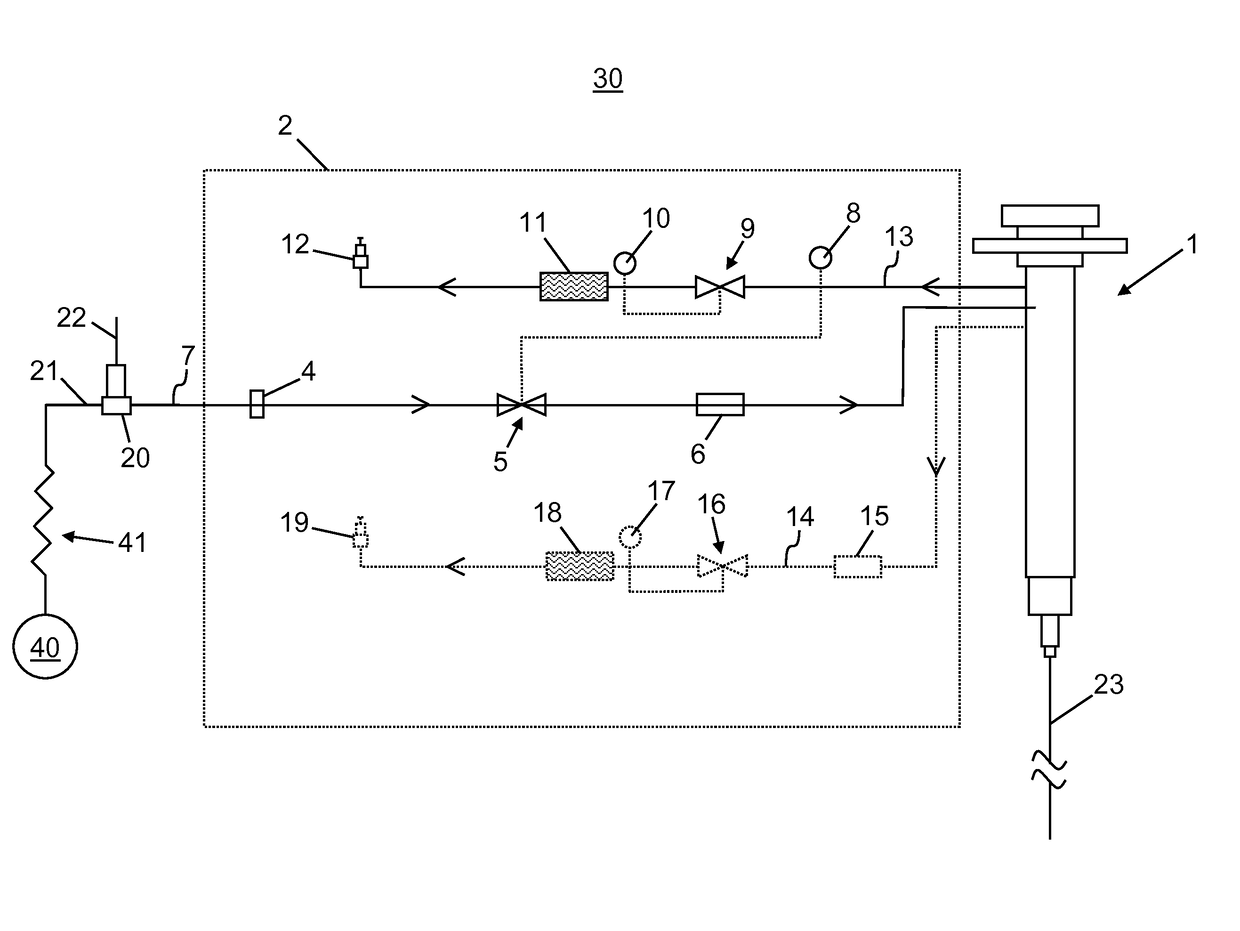

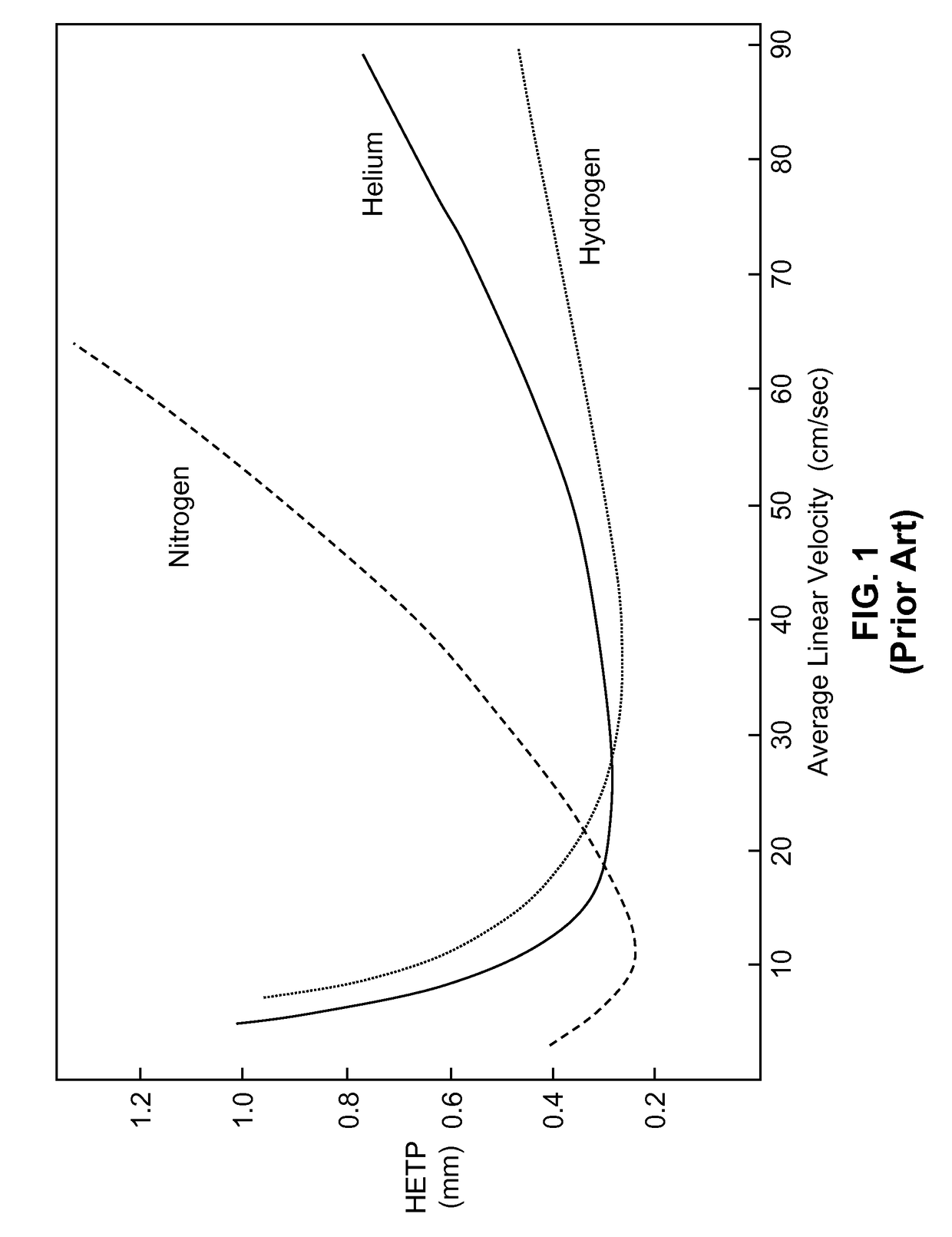

Gas Chromatograph System Employing Hydrogen Carrier Gas

An injection port for a gas chromatograph (GC) is operated such that, during an injection sequence, an inert gas is used for sample transfer to the analytical column while hydrogen is subsequently utilized for the majority of the analytical separation. This allows for a high degree of chromatographic efficiency, while also reducing unwanted chemical reactions involving hydrogen and / or reactive solvents in a hot injection port. Certain embodiments also provide an increased margin of safety when using hydrogen, since the total flow may be limited such that the concentration of hydrogen in the GC oven never exceeds a safety limit, such as the lower explosive limit.

Owner:THERMO FINNIGAN

Gas chromatograph system employing hydrogen carrier gas

An injection port for a gas chromatograph (GC) is operated such that, during an injection sequence, an inert gas is used for sample transfer to the analytical column while hydrogen is subsequently utilized for the majority of the analytical separation. This allows for a high degree of chromatographic efficiency, while also reducing unwanted chemical reactions involving hydrogen and / or reactive solvents in a hot injection port. Certain embodiments also provide an increased margin of safety when using hydrogen, since the total flow may be limited such that the concentration of hydrogen in the GC oven never exceeds a safety limit, such as the lower explosive limit.

Owner:THERMO FINNIGAN

Method for preparing ketone compound through biomimetic catalysis

ActiveCN105597830AImprove conversion rateHigh selectivityPreparation by oxidation reactionsOrganic-compounds/hydrides/coordination-complexes catalystsAlkaneHydrogen

The invention discloses a method for preparing a ketone compound through biomimetic catalysis. According to the method, aromatic alkane, straight-chain alkane and annular alkane are used as raw materials, oxygen is used as an oxidizing agent, a certain number of hydrogen carriers are added, a metalloporphyrin compound is used as a catalyst, the reaction temperature is controlled at 50-80 DEG C, and ketone is obtained through the catalysis reaction at normal pressure. The method has the advantages of being mild in reaction condition, good in catalysis effect, high in selectivity, simple in process, and the like.

Owner:山东尚正新材料科技股份有限公司

Novel cascaded power plant process and method for providing reversibly usable hydrogen carriers in such a power plant process

InactiveUS20100247414A1Rapid and efficientEfficient hydrolysisNitrogen compoundsSiliconHydrogenPower station

The crude oil reserves have a calculable time limit. Starting materials containing silicon dioxide are preferably used as raw materials.

Owner:SILICON FIRE AG

Preparation method of born-nitrogen miscellaneous graphene hydrogel

The invention relates to a preparation method of born-nitrogen miscellaneous graphene hydrogel, and belongs to the technical field of nano materials. According to the preparation method, firstly, graphite oxide is taken as a carbon source, and ammonium pentaborate is used as a born source and a nitrogen source, so that the born-nitrogen miscellaneous graphene hydrogel is prepared by one step under a gentle hydrothermal condition. The synthesis method of the born-nitrogen miscellaneous graphene hydrogel provided by the invention is simple in synthesis process; the required raw materials are low in cost; the conditions are gentle; the prepared born-nitrogen miscellaneous graphene hydrogel has a rich pore structure, and has good application prospect in the application fields such as a capacitor with double electric layers, a hydrogen storage carrier and a biological sensor.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com