Hydrogen supply system for liquid hydrogen storage material for hydrogen internal combustion engine

A hydrogen internal combustion engine and liquid hydrogen storage technology, applied in the direction of charging systems, internal combustion piston engines, combustion engines, etc., can solve the problems of poisoning fuel cells, inconvenient use, high dehydrogenation temperature, etc., to improve energy utilization and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

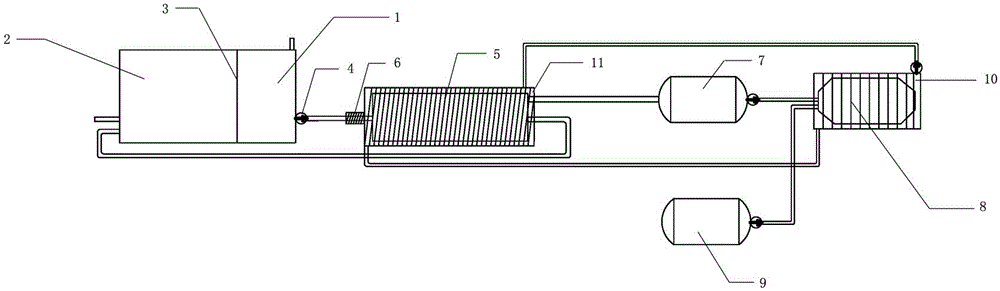

[0041] From figure 1It can be seen that the hydrogen storage tank used to store the liquid hydrogen source material and the liquid hydrogen storage carrier is provided with spaces for storing the liquid hydrogen source material and the liquid hydrogen storage carrier respectively: the first storage room 1 and the second storage room 2, two The storage compartments are separated by movable partitions 3. The first and second storage chambers are respectively provided with an input port and an output port, and the output port of the first storage chamber is provided with a pump 4 , through the operation of the pump, the liquid hydrogen source material is input into the reactor 5 through the input pipe. The reaction kettle adopts a plate reaction kettle, which is filled with a dehydrogenation catalyst.

[0042] A preheating device 6 is installed outside the input pipe connecting the pump and the reactor. The preheating device adopts an electric heater to preheat the liquid hydrog...

Embodiment 2

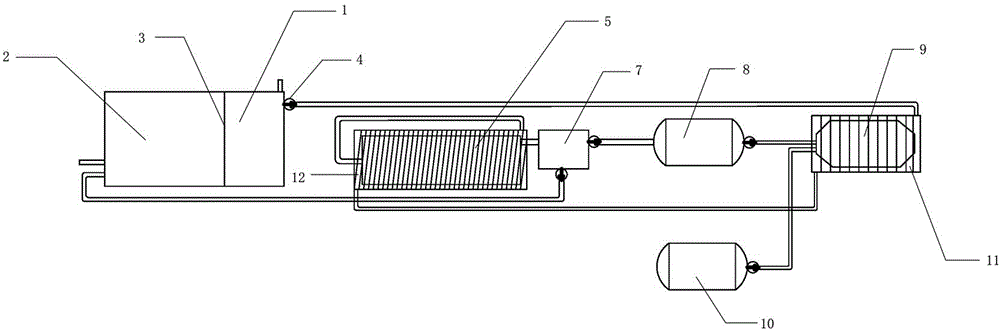

[0046] From figure 2 It can be seen that the hydrogen storage tank used to store the liquid hydrogen source material and the liquid hydrogen storage carrier is provided with spaces for storing the liquid hydrogen source material and the liquid hydrogen storage carrier respectively: the first storage room 1 and the second storage room 2, two The storage compartments are separated by movable partitions 3. The first and second storage chambers are each provided with an input port and an output port, and the output port of the first storage chamber is provided with a pump 4. Through the operation of the pump, the liquid hydrogen source material is input to the radiator 11 arranged outside the hydrogen internal combustion engine. In the pipeline, the heater 12 arranged outside the reactor and the radiator are connected through pipelines. The liquid hydrogen source material cools the hydrogen internal combustion engine and heats the reactor through heat exchange, and finally enters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com