Patents

Literature

313 results about "Hydrogen desorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

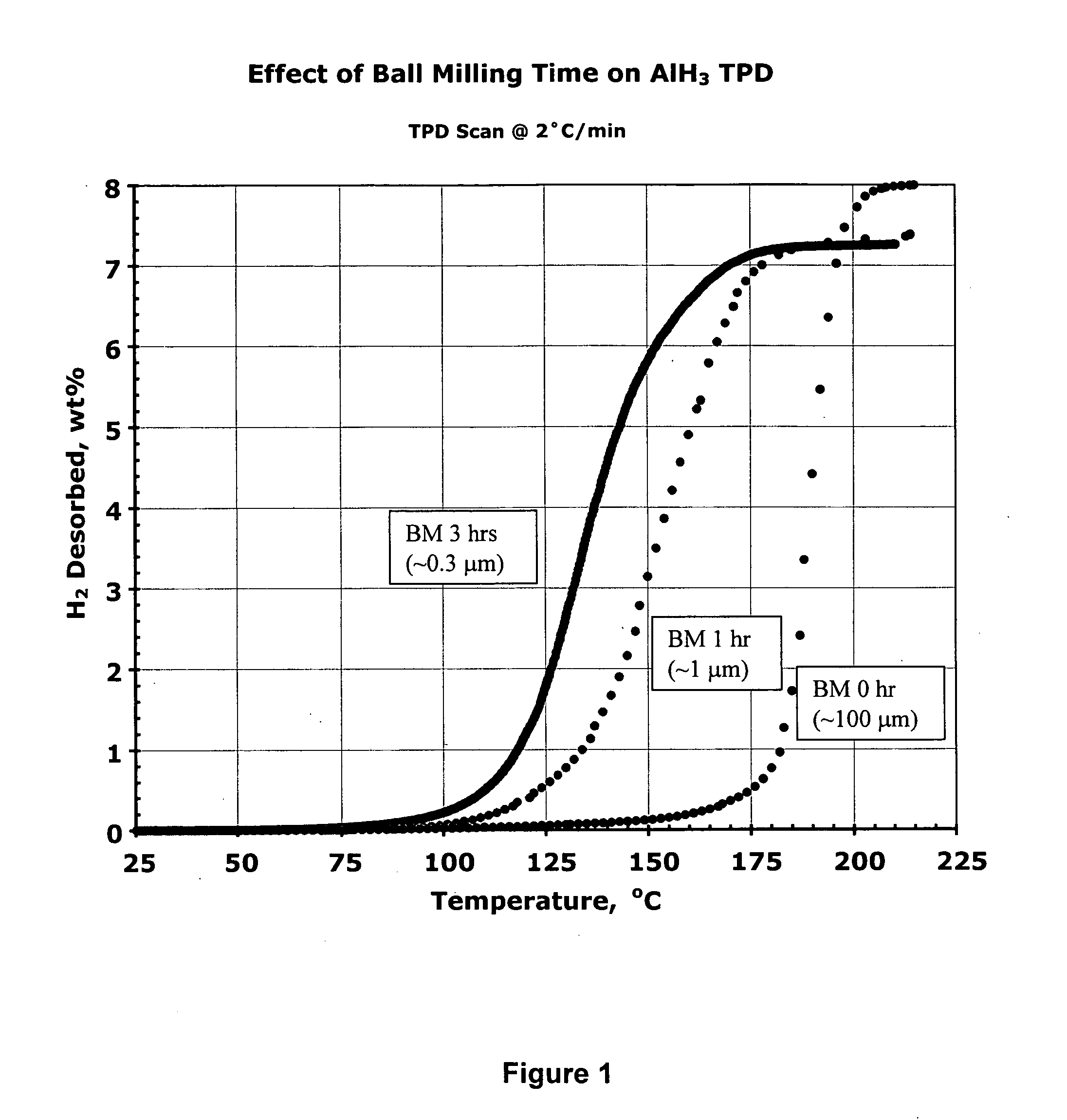

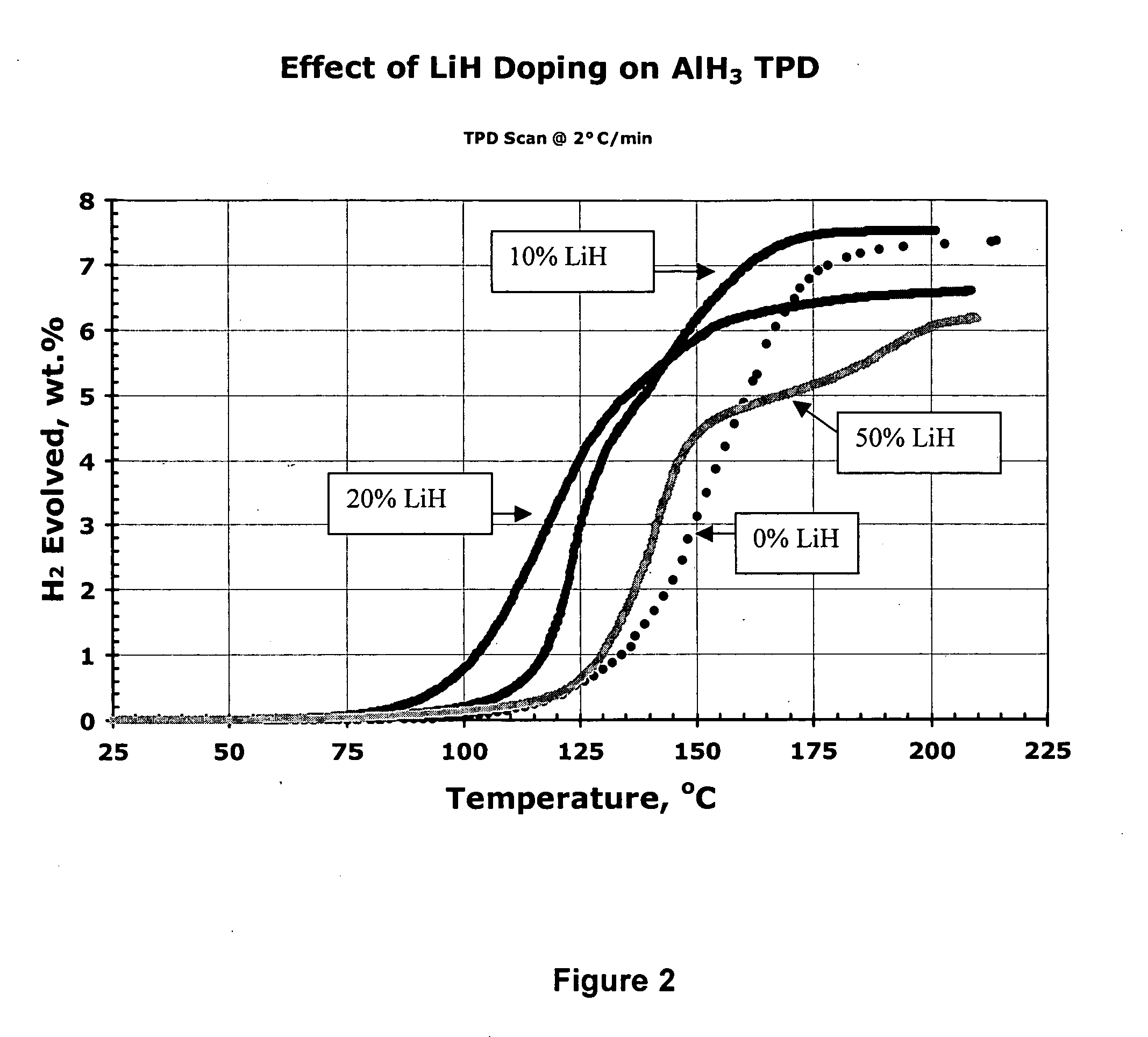

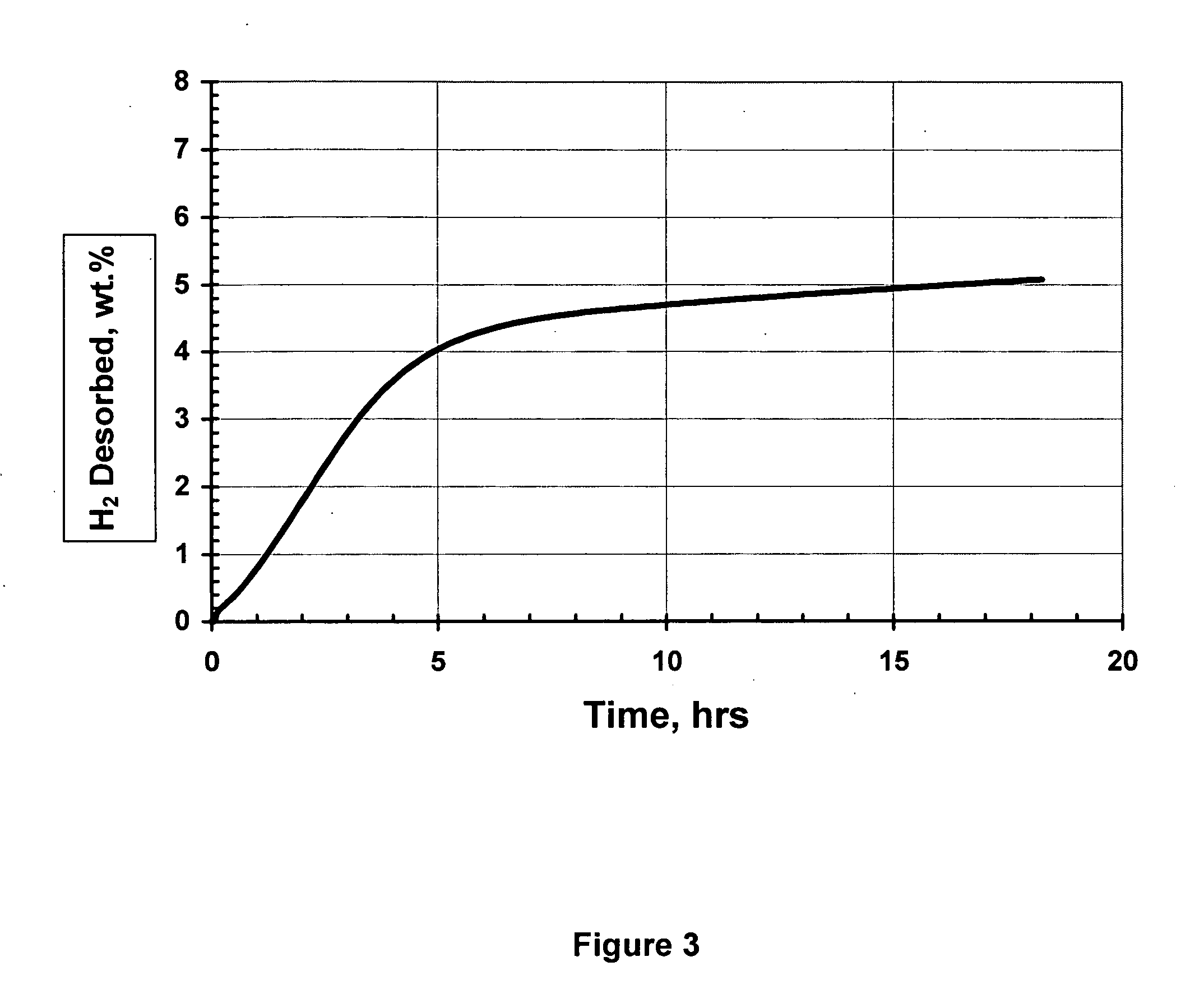

Activated aluminum hydride hydrogen storage compositions and uses thereof

InactiveUS20070025908A1Improve hydrogen storage performanceImproved desorption kineticsAlkali/alkaline-earth/beryllium/magnesium hydridesOther chemical processesHydrogen desorptionALUMINUM HYDRIDE

In one aspect, the invention relates to activated aluminum hydride hydrogen storage compositions containing aluminum hydride in the presence of, or absence of, hydrogen desorption stimulants. The invention particularly relates to such compositions having one or more hydrogen desorption stimulants selected from metal hydrides and metal aluminum hydrides. In another aspect, the invention relates to methods for generating hydrogen from such hydrogen storage compositions.

Owner:BROOKHAVEN SCI ASSOCS

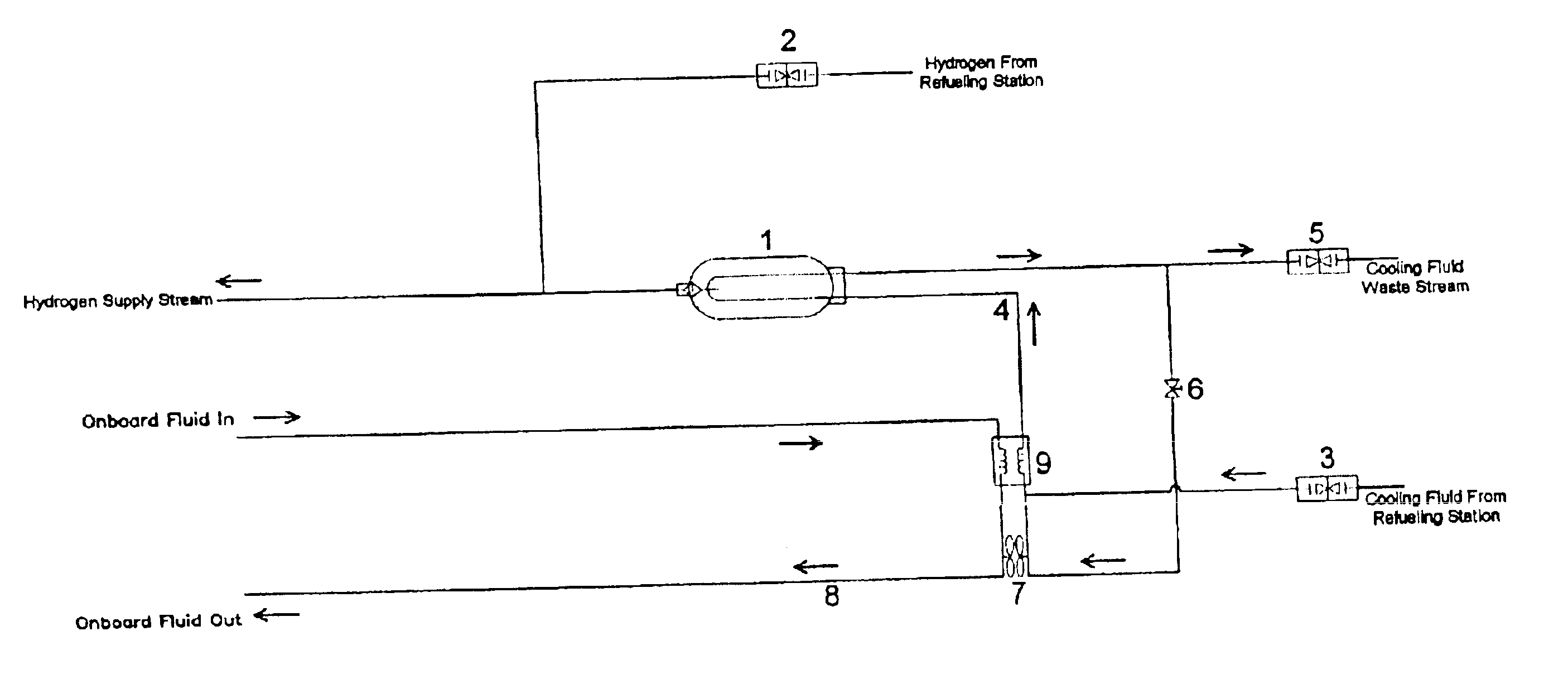

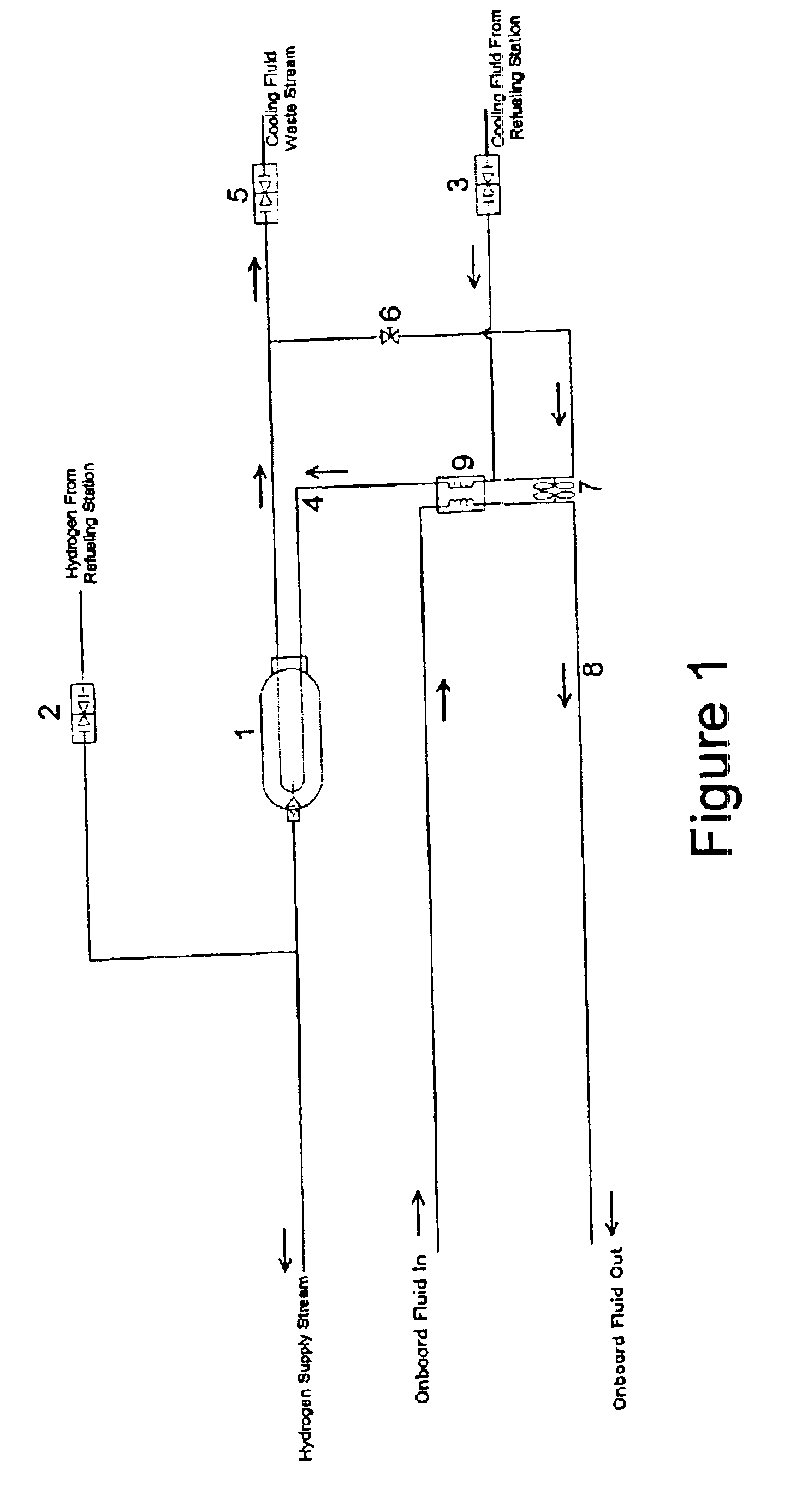

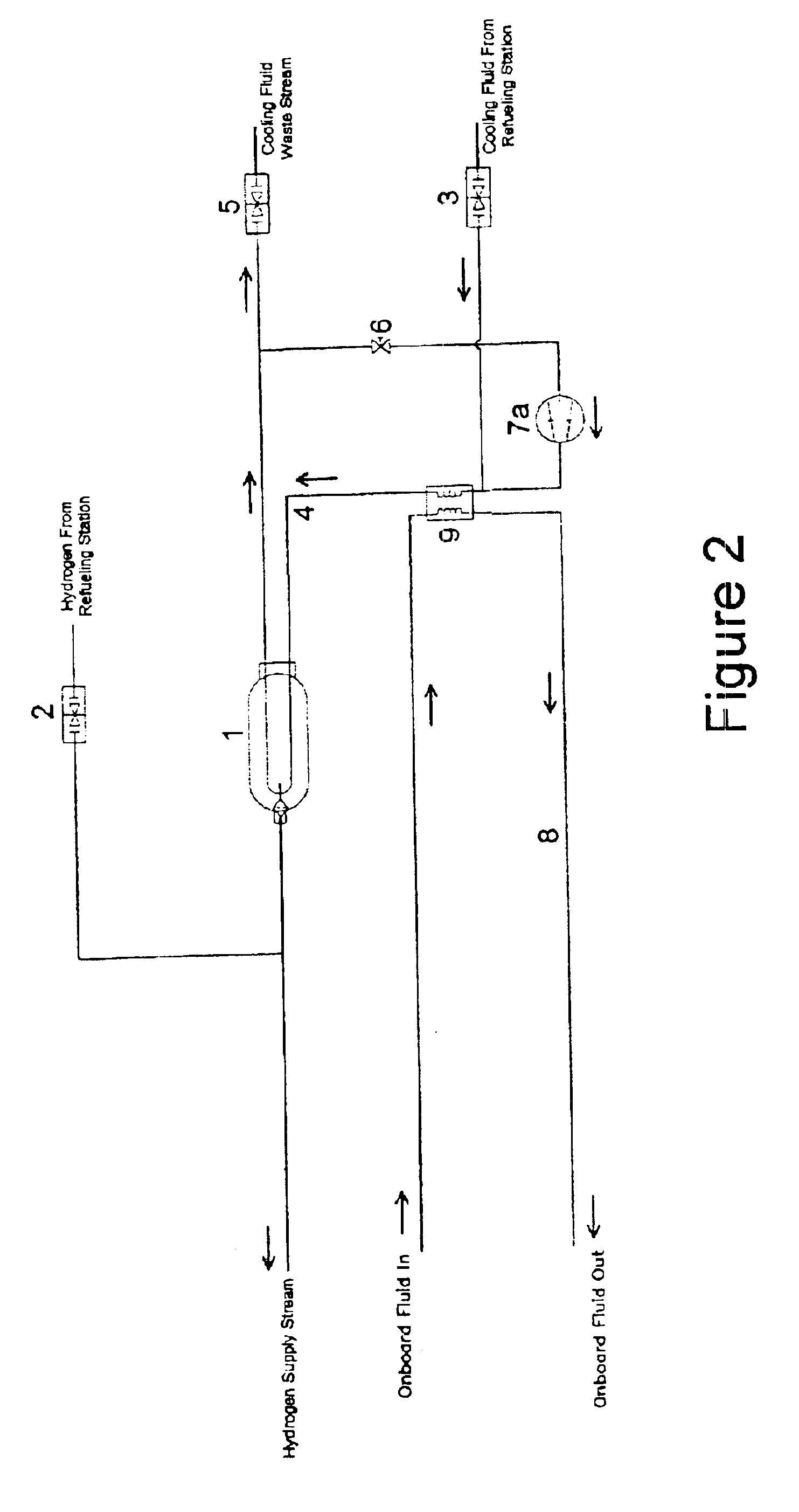

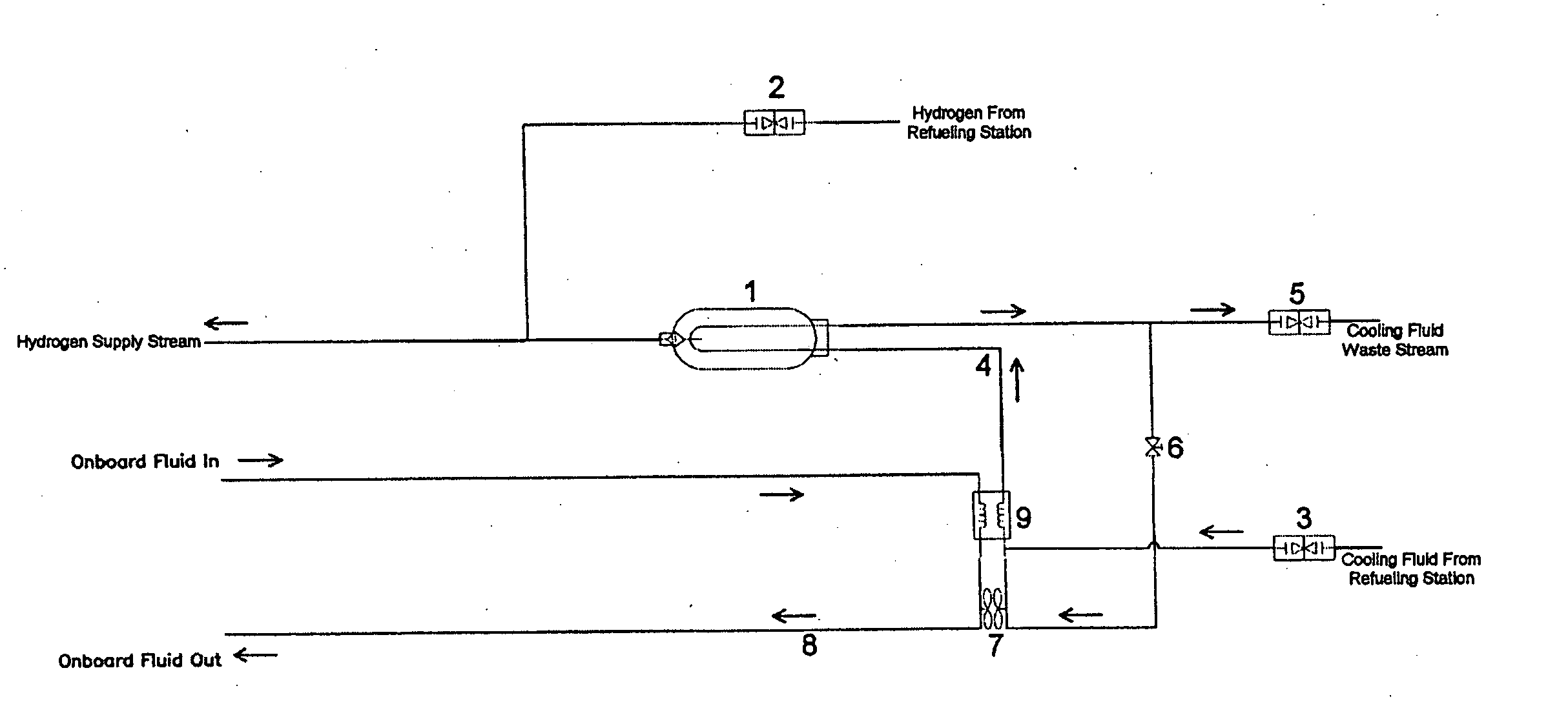

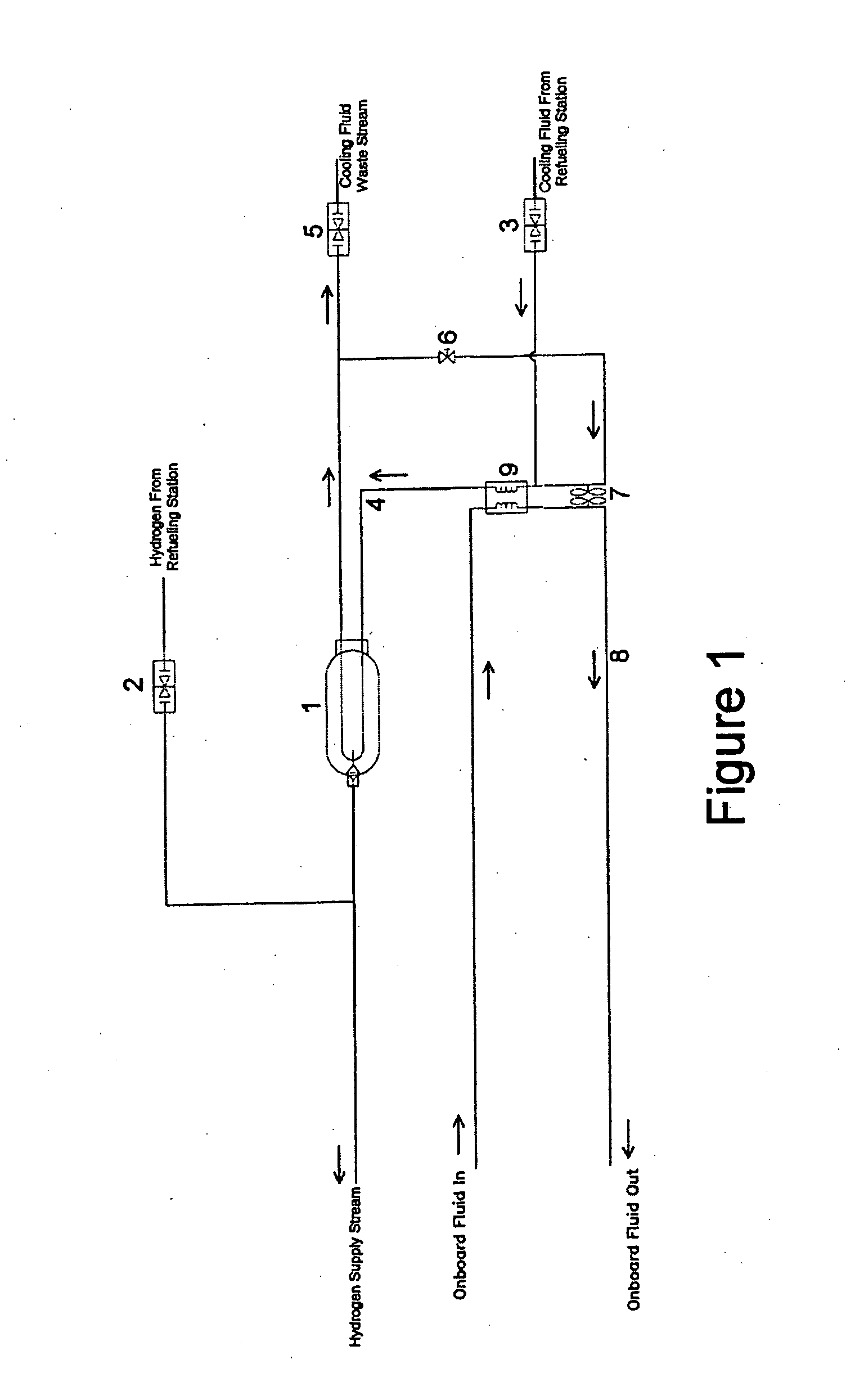

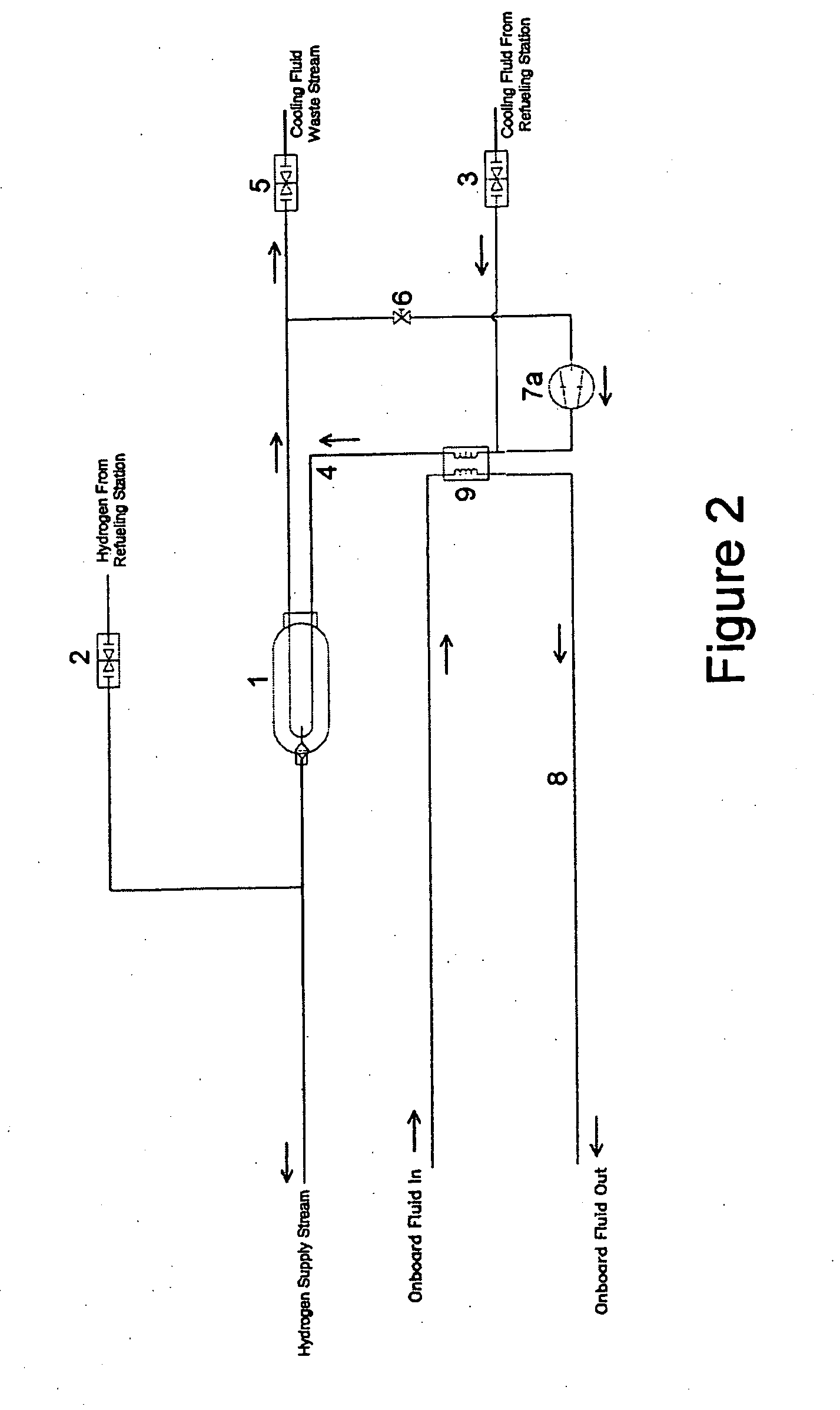

Onboard hydrogen storage unit with heat transfer system for use in a hydrogen powered vehicle

InactiveUS6860923B2Remove heatReversible hydrogen uptakeGas handling applicationsProcess engineeringHydrogen desorption

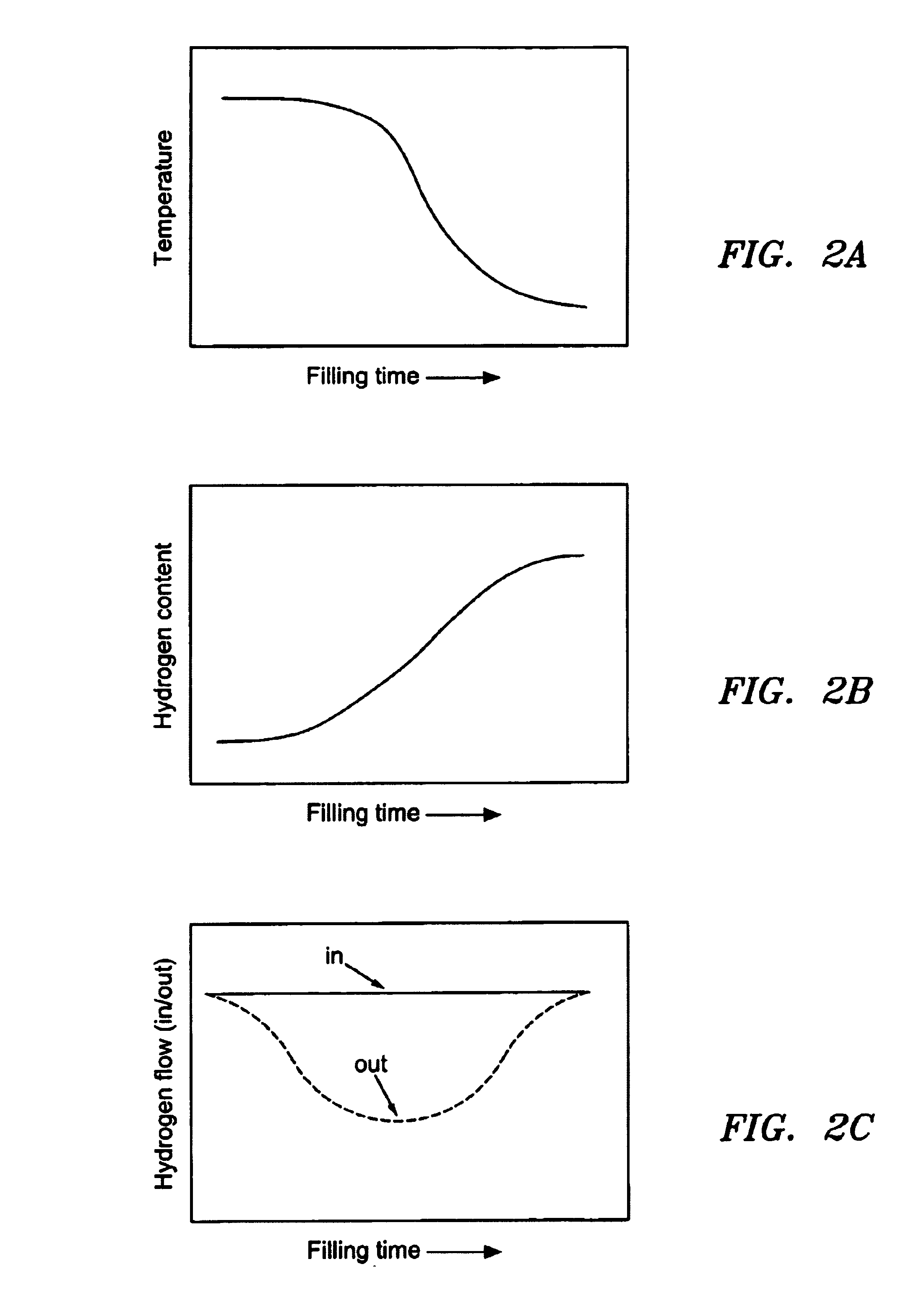

An onboard hydrogen storage unit with heat transfer system for a hydrogen powered vehicle. The system includes a hydrogen storage vessel containing a hydrogen storage alloy configured to receive a stream of hydrogen and provide hydrogen for use in powering a vehicle. During refueling a cooling / heating loop is used to remove the heat of hydride formation from the hydrogen storage alloy and during operation of the vehicle the heating / cooling loop is used to supply heat to the hydrogen storage alloy to aid in hydrogen desorption.

Owner:VODIK LABS LLC

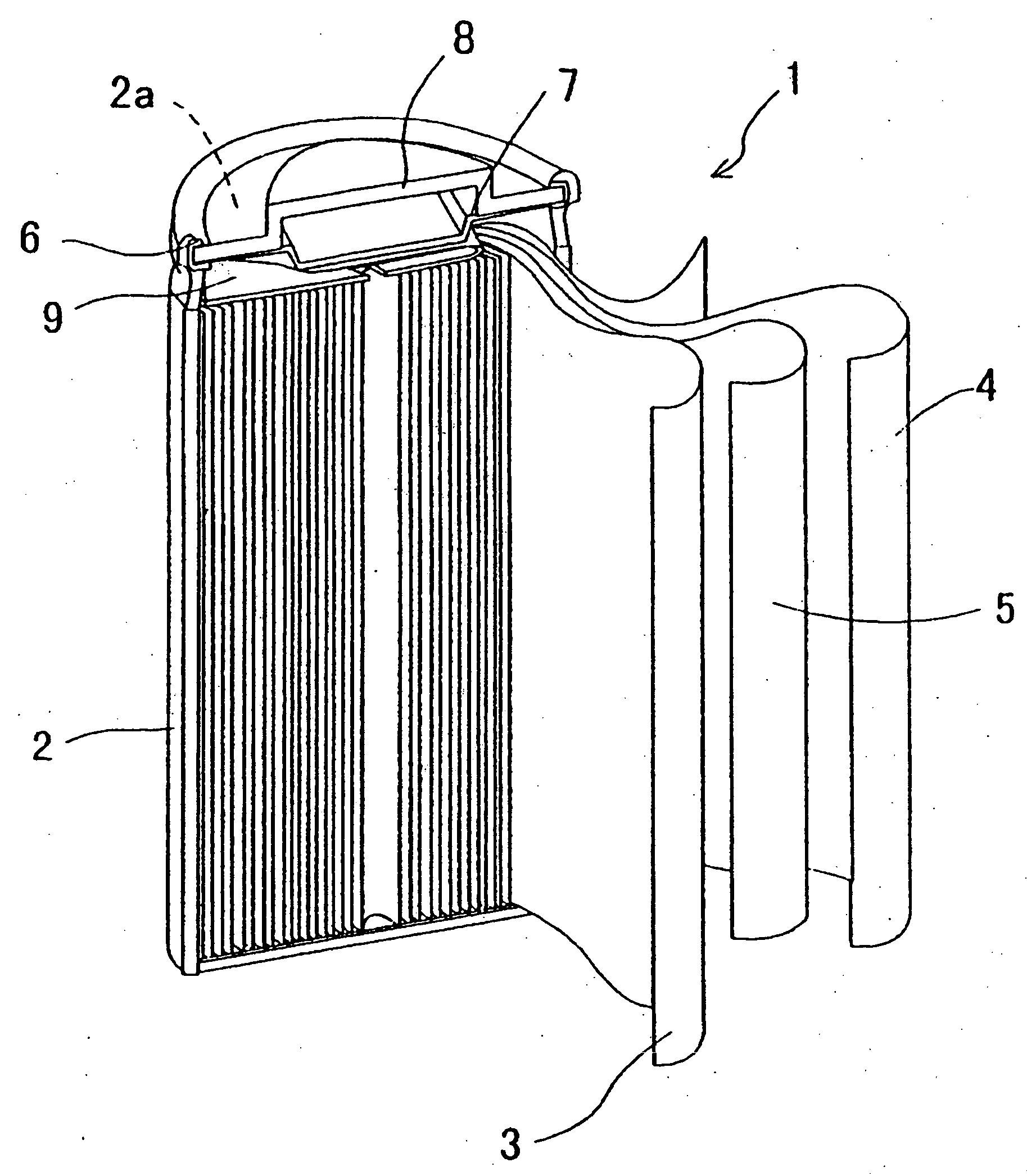

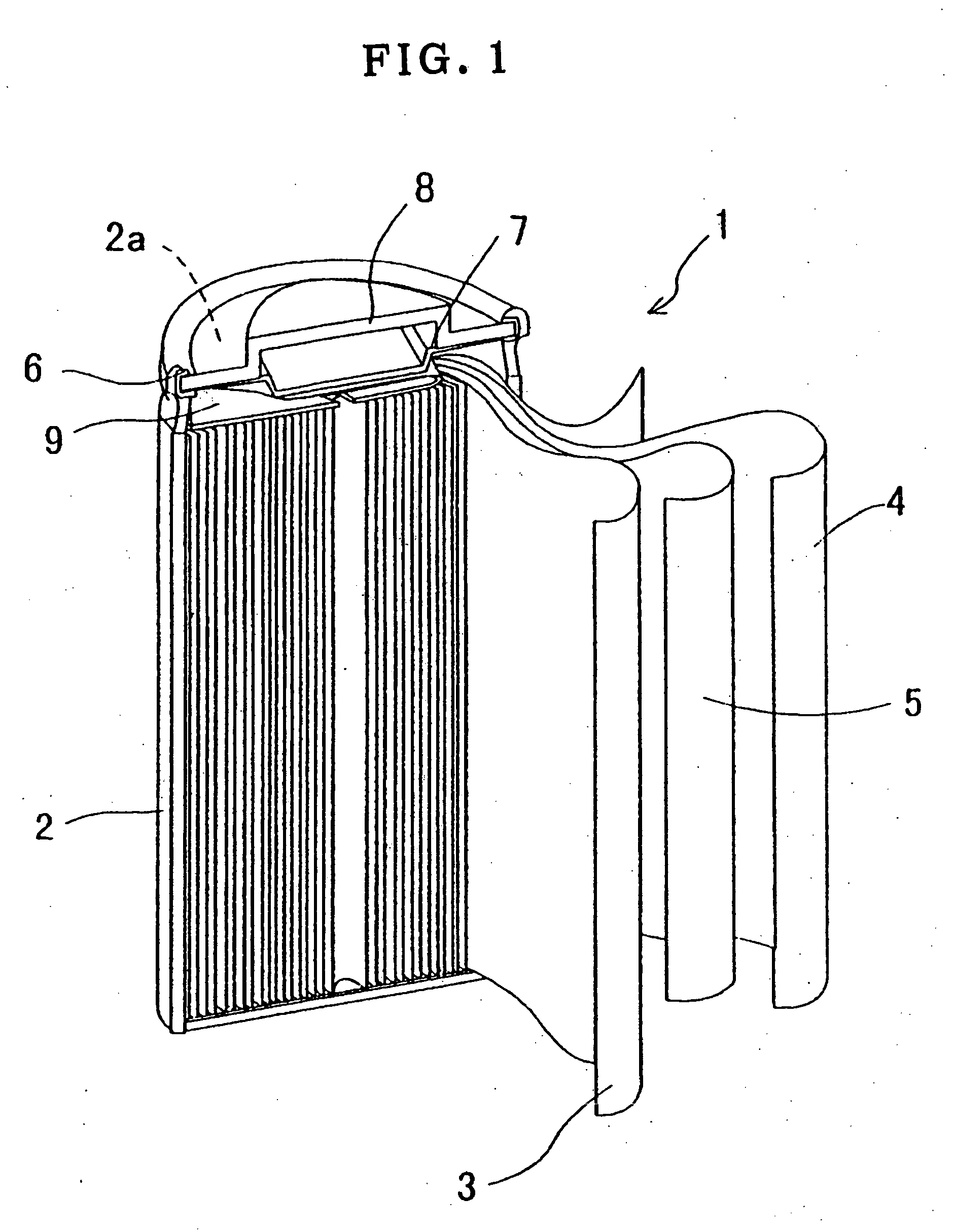

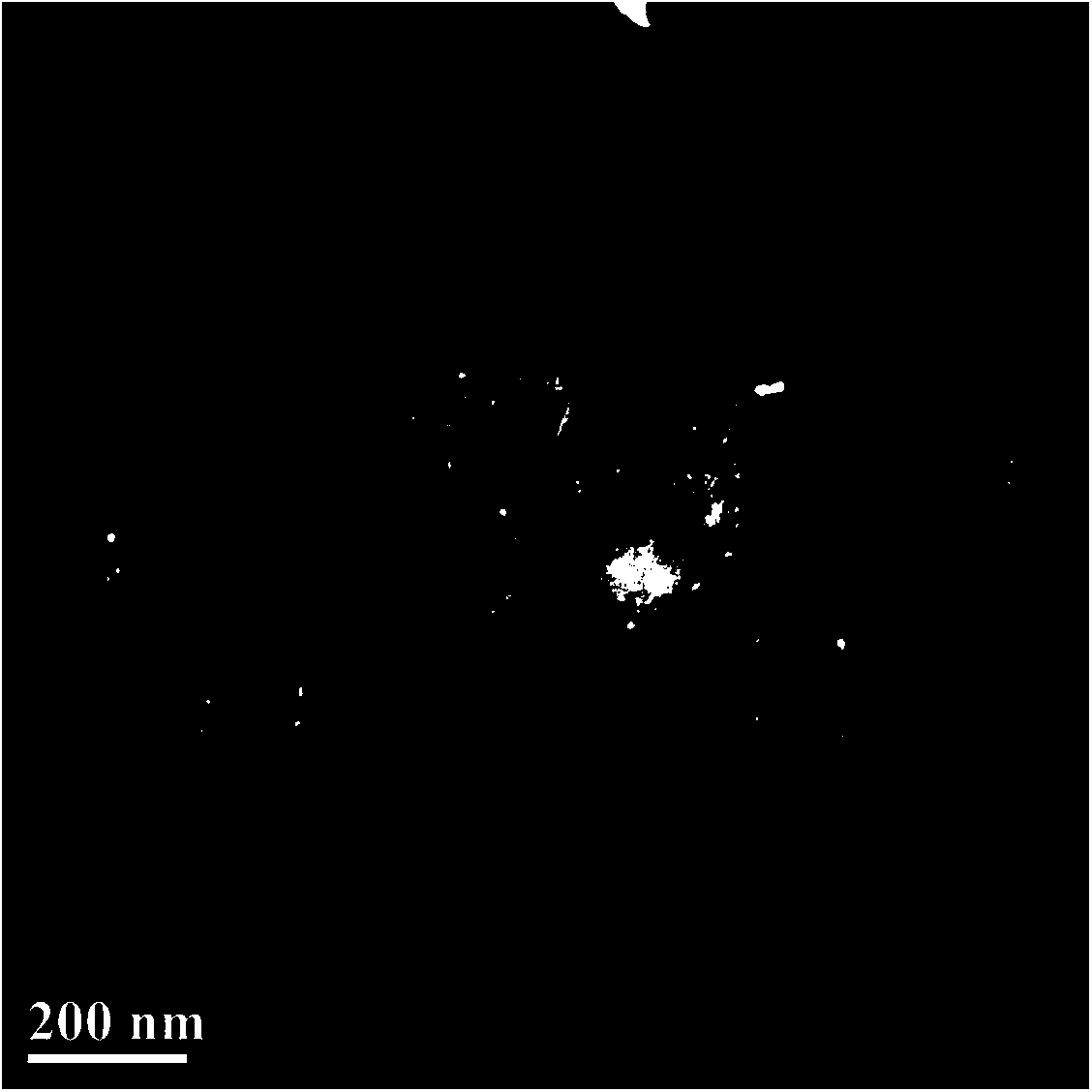

Closed nickel-hydrogen storage battery and its production method

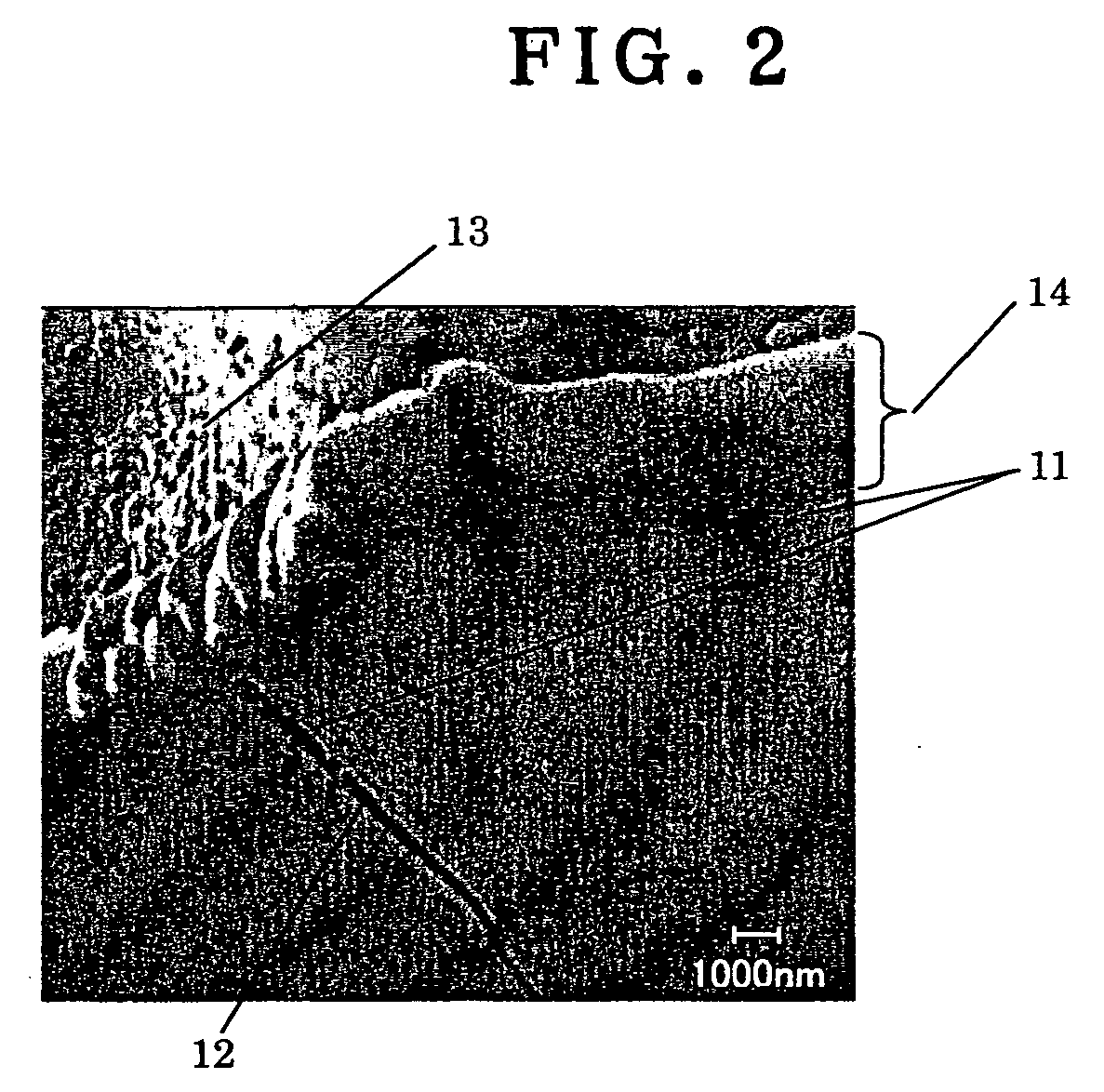

One problem with a sealed type nickel-metal hydride battery is that the high-rate discharge capability is inferior to that of a nickel-cadmium storage battery, because of a slow transfer rate of charges to the surface of a hydrogen storing alloy that is a negative electrode. Another problem is that the use of an alloy having excellent life characteristics takes much time for initial activation of battery characteristics. The invention provides a solution to the aforesaid problems by the provision of a sealed type nickel-metal hydride battery (1) improved in high-rate discharge capability and charge-discharge cycle characteristics. To this end, the invention is characterized by locating a 50 nm to 400 nm thick nickel-rich layer (11) on the surface of a hydrogen storing alloy powder, and locating the nickel-rich layer (11) as well on the surface of cracks (12) that open at the surface of alloy, and more preferably setting the mass saturation magnetization of the alloy powder at 2.5 to 9 emu / g and the content of magnetic nickel at 0.5 to 1.9 mmol per gram of the hydrogen storing alloy powder. A succession of hydrogen absorption step, alkali treatment step, product removal step, hydrogen desorption step and partial oxidization step by air are applied to the hydrogen storing alloy powder to obtain alloy powder, which is then used to obtain a battery having the aforesaid features. The invention is effectively applied to corrosion-resistant hydrogen storing alloys containing Er, Y and Yb.

Owner:GS YUASA INT LTD

Preparation method for lithium-ion battery cathode material with high initial coulomb efficiency

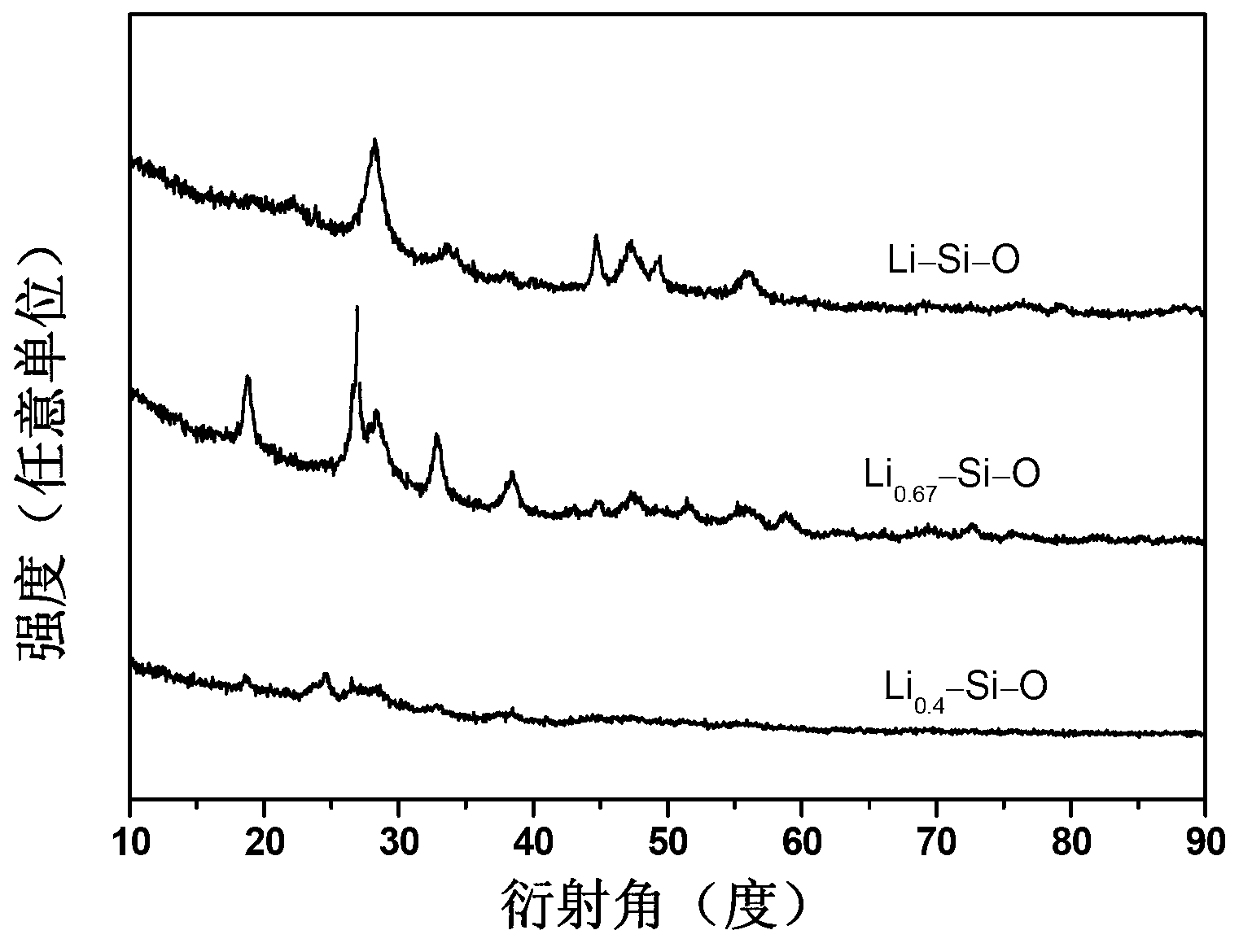

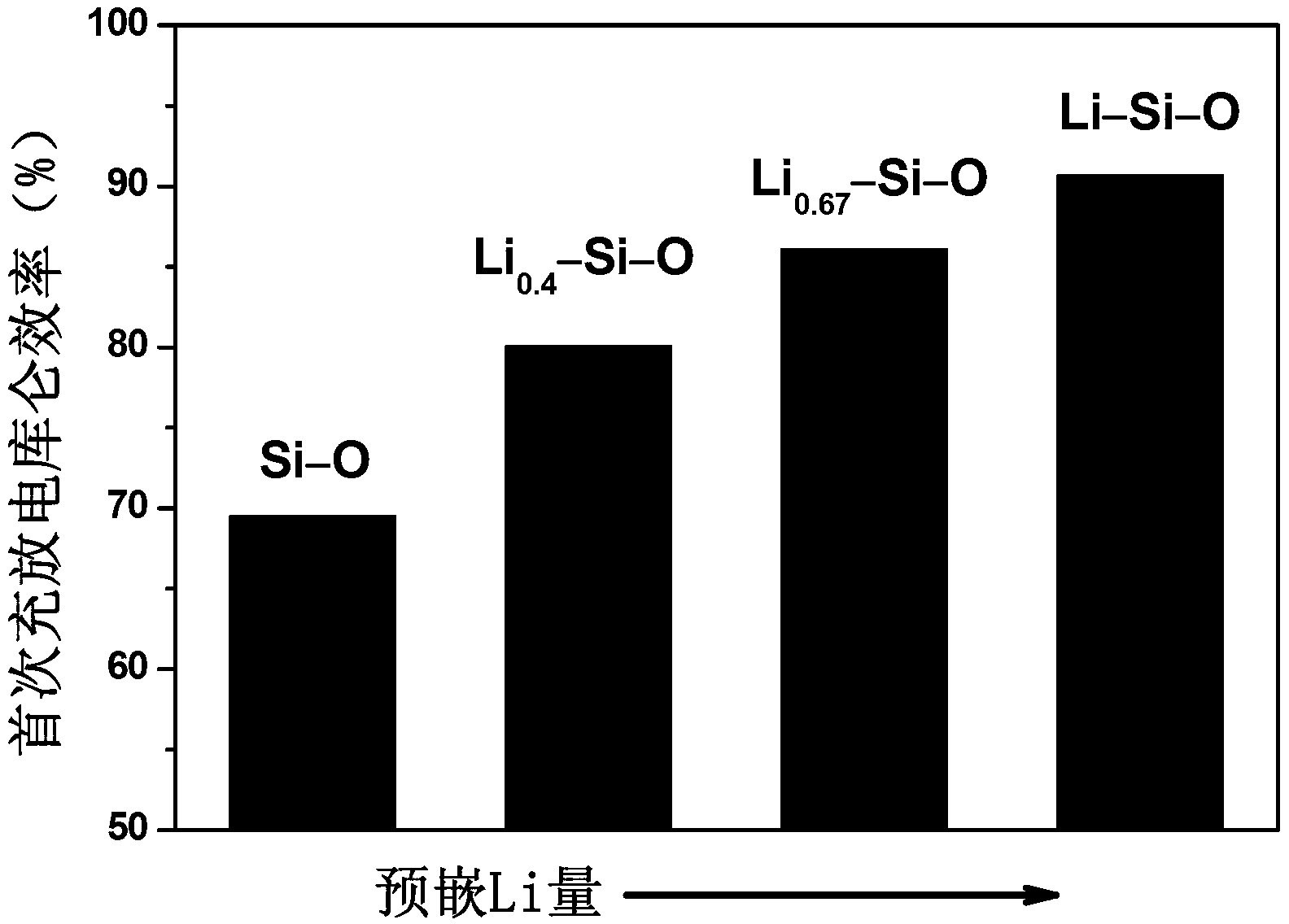

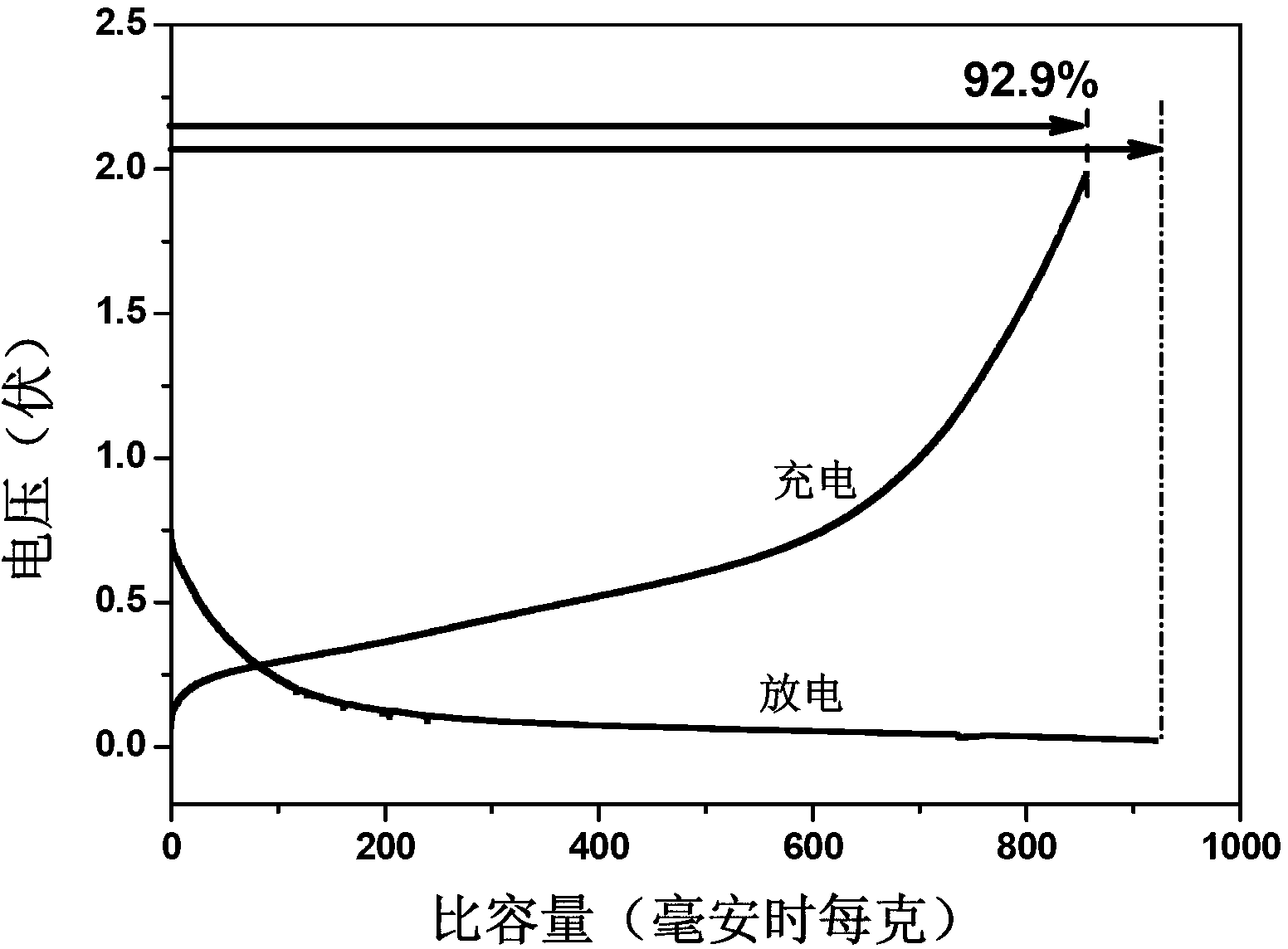

ActiveCN103258992AImprove the first Coulombic efficiencySimple methodCell electrodesHydrogenHigh energy

The invention discloses a preparation method for a lithium-ion battery cathode material with a high initial coulomb efficiency. The preparation method comprises the following steps of: (1) mixing LiH with SiO to obtain a mixture; (2) heating the mixture to a predetermined temperature in a vacuum or an inert atmosphere, and performing heat-insulating hydrogen desorption to obtain a hydrogen desorption product; and (3) performing high-energy ball milling on the hydrogen desorption product to obtain the lithium-ion battery cathode material. According to the preparation method provided by the invention, a Li-Si-O compound is formed in the lithium-ion battery cathode material via partial chemical pre-embedment of lithium, so that the initial coulomb efficiency of the lithium-ion battery cathode material is increased to be greater than 90%; and the preparation method is simple, effective, economic and practical.

Owner:ZHEJIANG UNIV

Portable all-solid hydrogen production material as well as preparation method and application thereof

ActiveCN104649225AEven contactIncrease hydrogen productionHydrogen productionUnit massHydrogen fuel cell

The invention belongs to the field of hydrogen production materials, and particularly relates to a portable all-solid hydrogen production material as well as a preparation method and application thereof. The all-solid hydrogen production material comprises a solid matter reacting with water to release hydrogen and a water-containing solid matter in a molar ratio of (1-12): (1-3). Water required for hydrolysis is provided by the water-containing solid for the first time; and the two solids are sufficiently mixed at a hydrogen desorption temperature, so that the hydrogen production matters comes into contact with water molecules more uniformly, then the actual water consumption for hydrolysis is greatly reduced and the hydrogen production quantity of a unit mass material is improved. Meanwhile, the hydrogen production material is all-solid, so additional water is not needed; and the temperature in the hydrogen production process can be controlled, so that the hydrogen production material is more convenient to carry and operate, and the hydrogen source of a hydrogen fuel battery is more compact and smaller.

Owner:苏州清德氢能源科技有限公司

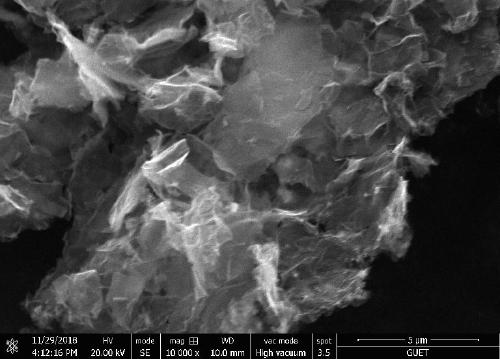

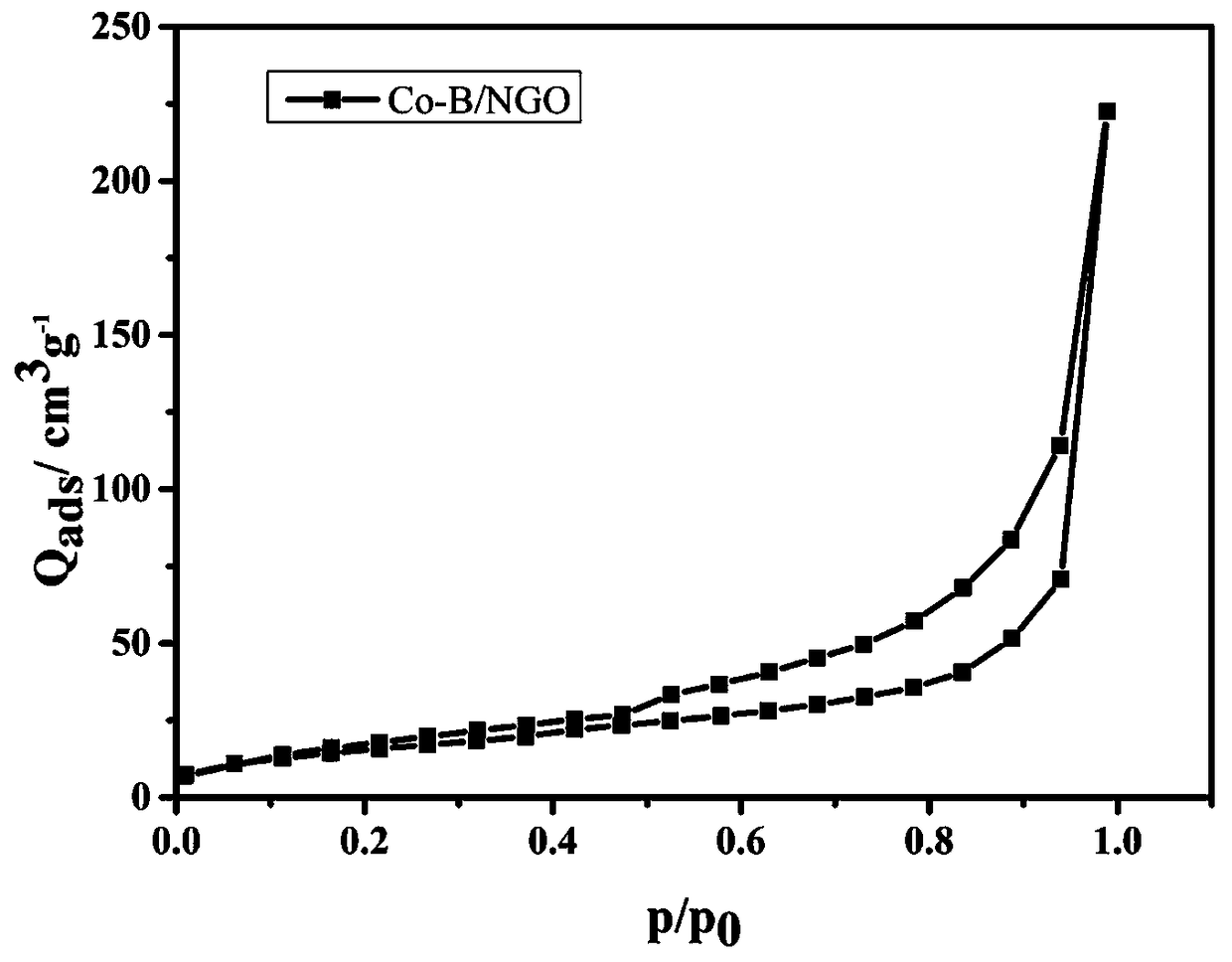

Co-B/NGO composite nanometer material as well as preparation method and application thereof

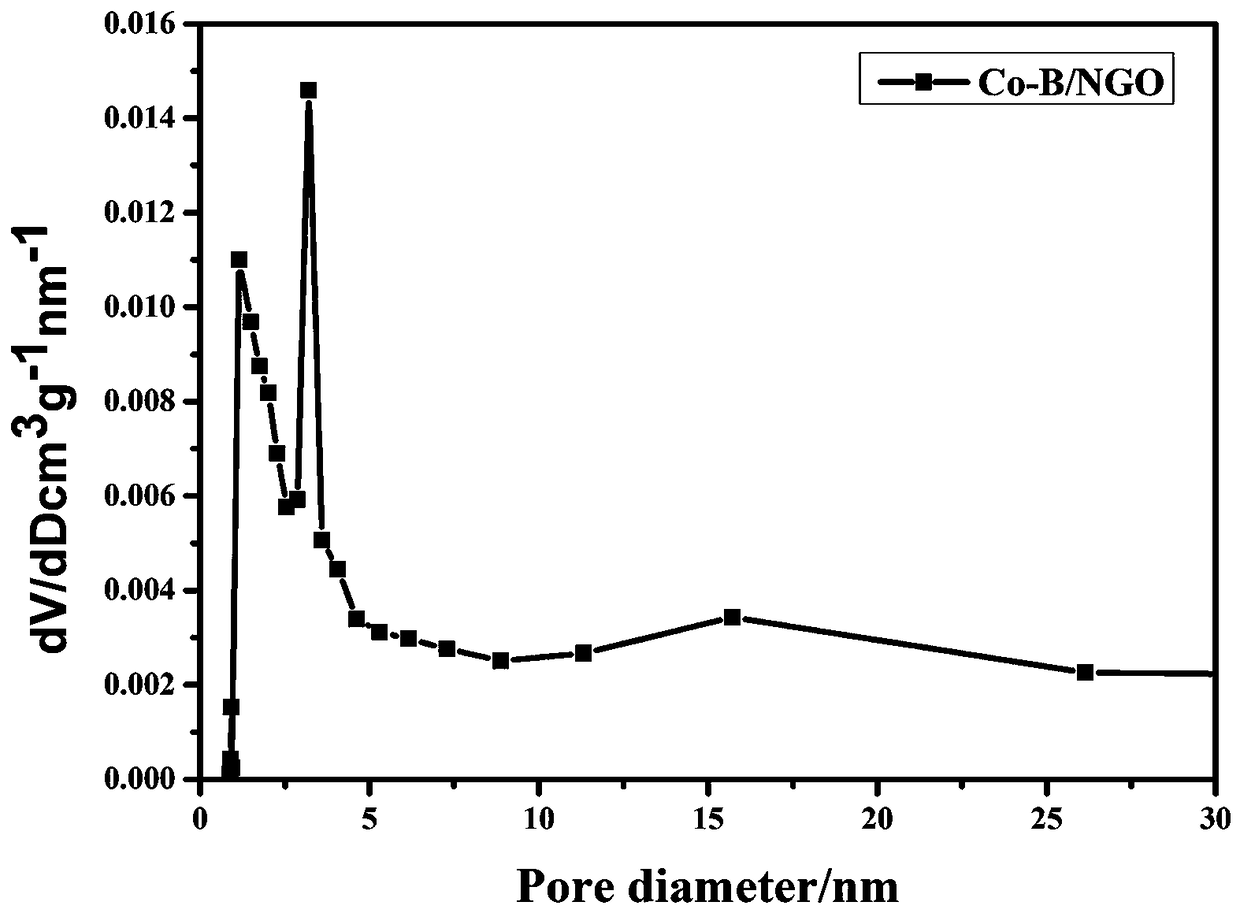

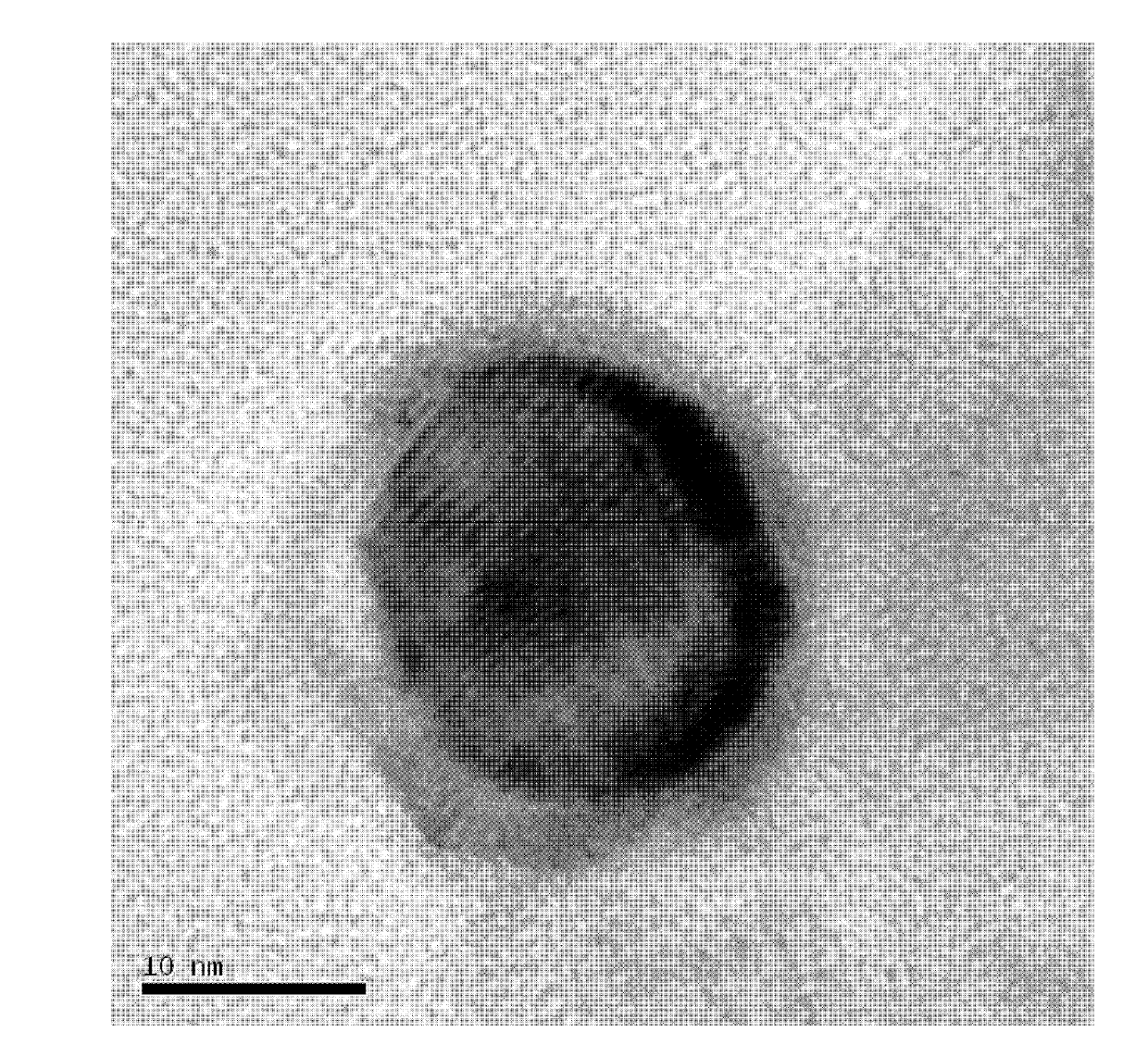

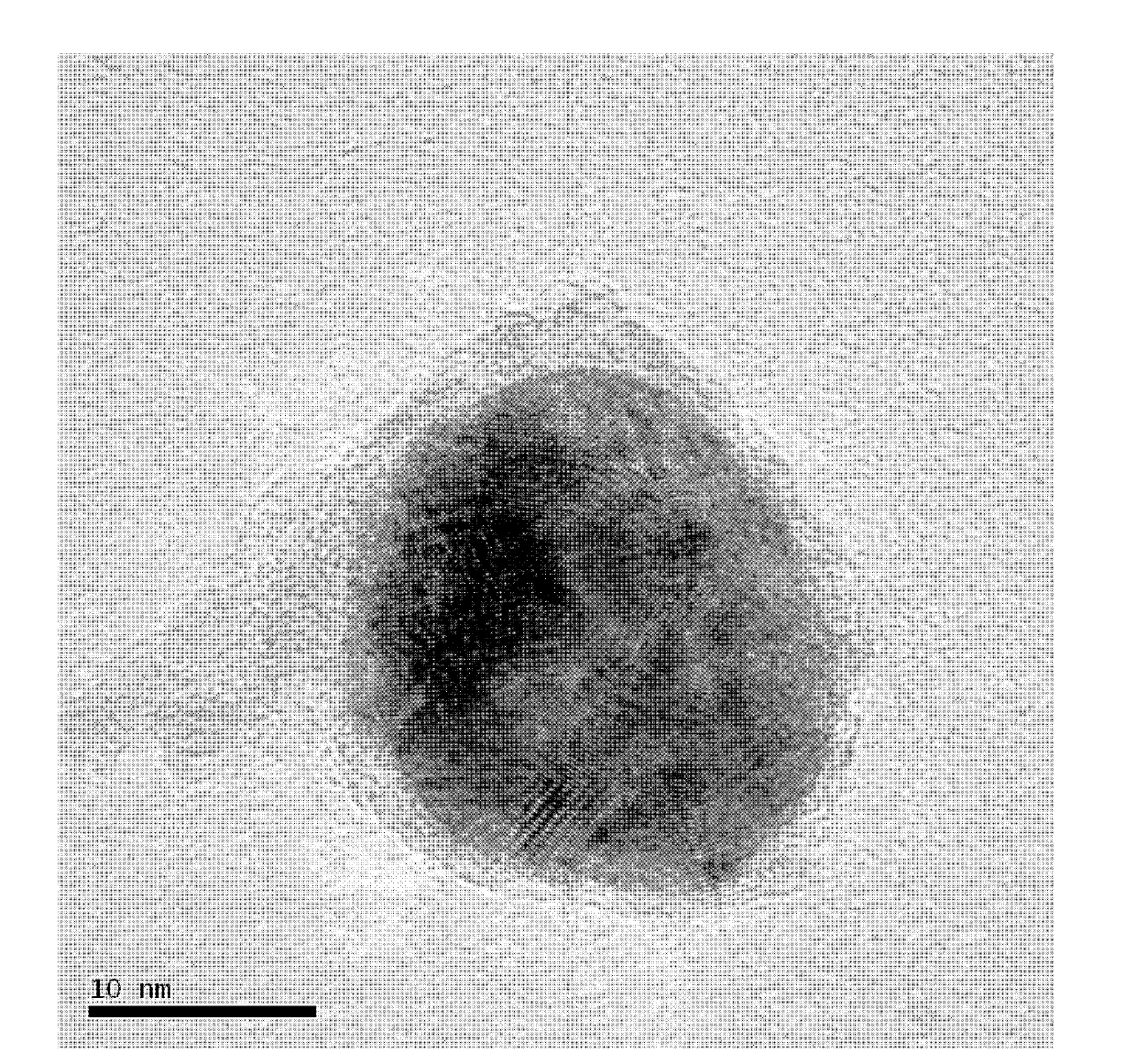

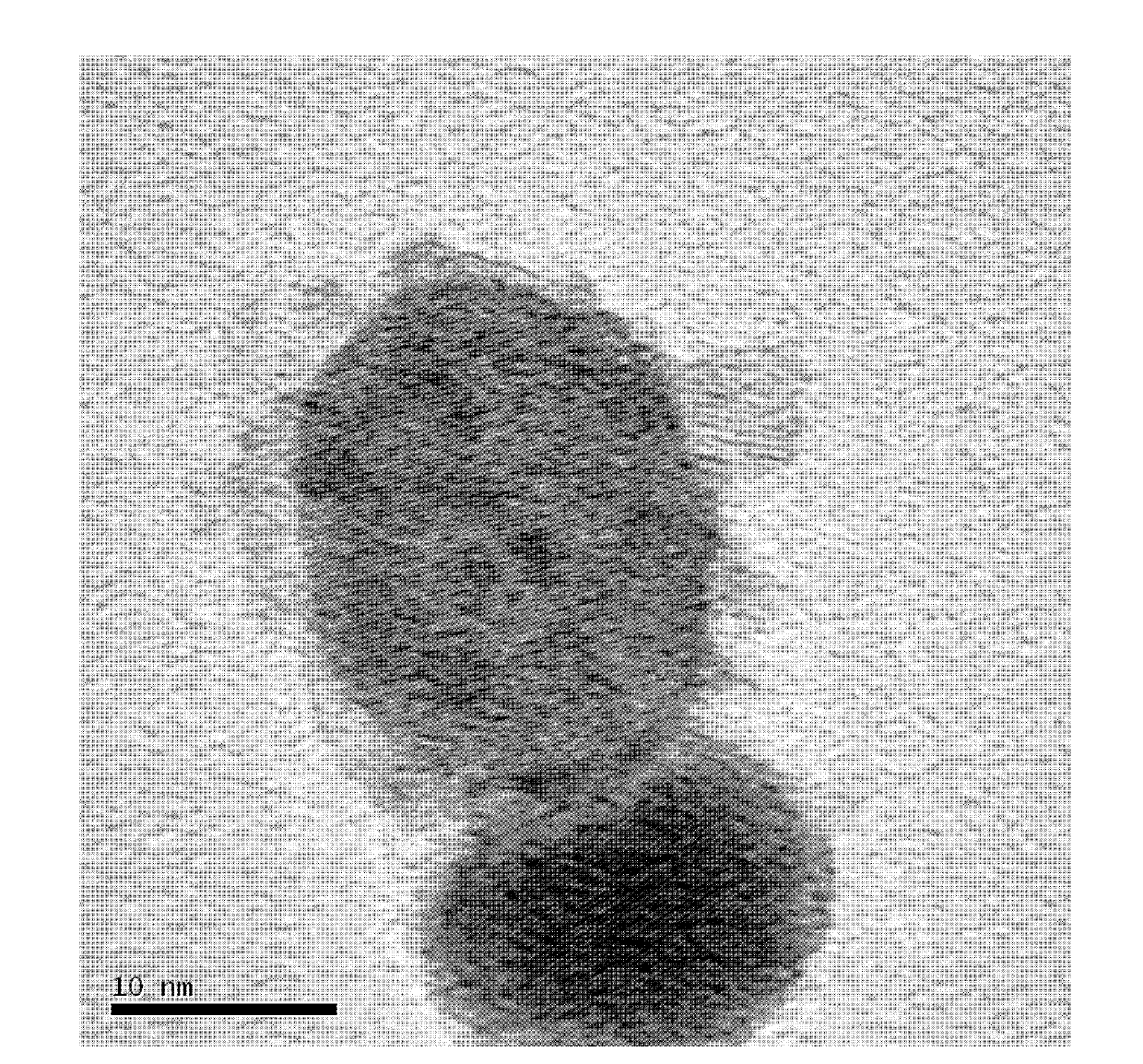

InactiveCN109499576AChange catalytic performanceLower activation energyMaterial nanotechnologyCatalyst activation/preparationFreeze-dryingHydrogen desorption

The invention discloses a Co-B / NGO composite nanometer material. The Co-B / NGO composite nanometer material is prepared by firstly performing in-site reduction on nitrogen-doped graphene and inorganiccobalt salt through sodium borohydride and then performing freezing-drying, the specific area is 40-100 m<2>g<-1>; the material is magnetic, and can be attracted by a magnet. When the composite nanometer material is used as a catalyst for hydroboron hydrogen generation by hydrolysis, the hydrogen desorption rate is 500-1700mL / min<-1>g<-1>, and the hydrogen production rate is 100%; the material canbe adsorbed and recycled by the magnet, the recycling rate reaches 99.5%, and the hydrogen production rate after being circulated is maintained at 100-1530mL min<-1>g<-1>, namely, maintaining 50-85%of the initial hydrogen production rate. The preparation method comprises the following steps: 1) precursor preparation: adding nitrogen-doped graphene and inorganic cobalt salt in an aqueous solutionfor ultrasonic dispersion mixing, reducing by using sodium borohydride, and finally centrifuging and washing to obtain a precursor; 2) preparation of the Co-B / NGO composite nanometer material: freeze-drying the precursor to obtain the Co-B / NGO composite nanometer material. The Co-B / NGO composite nanometer material disclosed by the invention is simple in preparation, has more excellent catalysis performance, and has an extensive application prospect in the application field of the hydroboron hydrogen generation by hydrolysis.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Ternary transition-metal catalyst for ammonia borane hydrolysis and preparation method thereof

InactiveCN102513125AImprove catalytic performanceReduce manufacturing costHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsHydrogen desorptionTernary operation

The invention discloses a ternary transition-metal catalyst for ammonia borane hydrolysis and a preparation method thereof. The catalyst provided by the invention is a Ag0.04@CoxNi0.96-x(x=0-0.96) catalyst with a core-shell structure. According to the invention, ammonia borane is used as a reducing agent to directly reduce a mixed solution of silver nitrate, cobalt salt and nickel salt at different proportions to obtain the catalyst which is directly used for catalyzing ammonia borane hydrolysis. Due to the core-shell structure, the series of catalysts have high catalytic activity. By the adoption of the series of the catalysts for catalyzing ammonia borane hydrolysis at room temperature, the maximum hydrogen desorption rate can reach 1627.3 mlmin<-1>g<-1> and activation energy of the reaction is 28.54 kJmol<-1>. The core-shell structured ternary transition-metal catalyst has characteristics of small particle size, large specific surface area, many catalytic active sites and the like, is beneficial to catalytic hydrolysis of ammonia borane, has advantages of rich resources, low production cost and the like in comparison with a traditional noble metal catalyst, and is a promising catalyst.

Owner:天津天环光伏太阳能有限公司

Operation of a hydrogen storage and supply system

InactiveUS6986258B2Facilitated releasePromote sportsNon-pressured vesselsHydrogen technologiesPorous mediumProcess engineering

This invention provides for an apparatus and a method for operation of a cryogenic hydrogen storage system that contains a porous medium configured to adsorb hydrogen. The hydrogen storage and supply system includes a hydrogen source apparatus, a cryosorptive storage apparatus, and a fuel recycle loop. Methods and devices that allow for an energy efficient release of hydrogen from the cryosorptive apparatus are described. At the outset of a fuel release, the cryosorptive hydrogen storage apparatus contains cold, pressurized hydrogen. Release of hydrogen from the storage apparatus is a process that consumes heat, thereby drawing down both the temperature and pressure. Heat can be provided to the cryosorptive storage apparatus by various direct approaches, or through the influx of warm, recycled hydrogen. The hydrogen storage and release apparatus contains a recycle loop, which warms a portion of the effluxing hydrogen, and returns it to the storage apparatus, thereby maintaining pressure and temperature conditions that support continued hydrogen desorption from the storage medium.

Owner:NANOMIX

Adiabatic tank for metal hydride

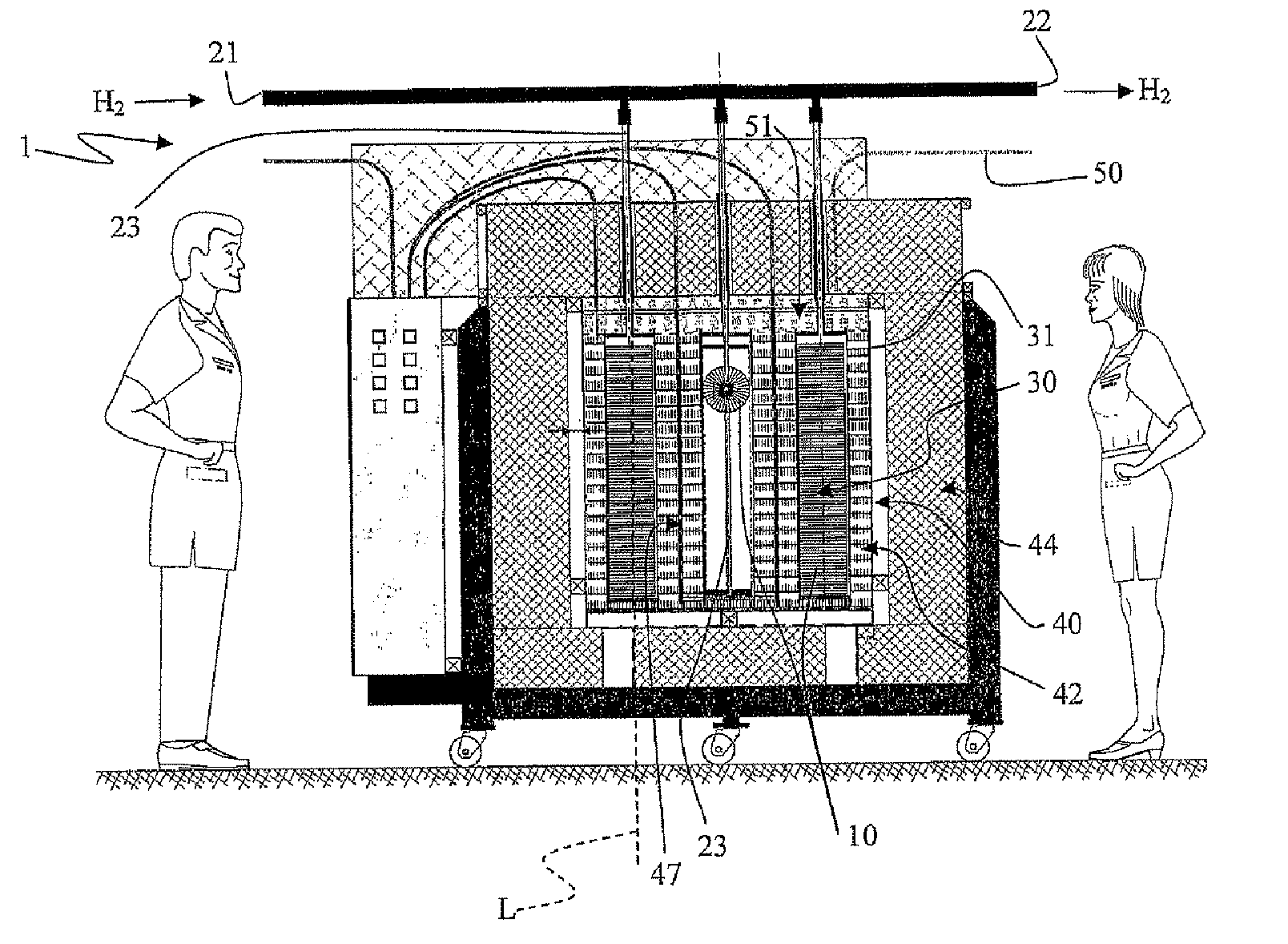

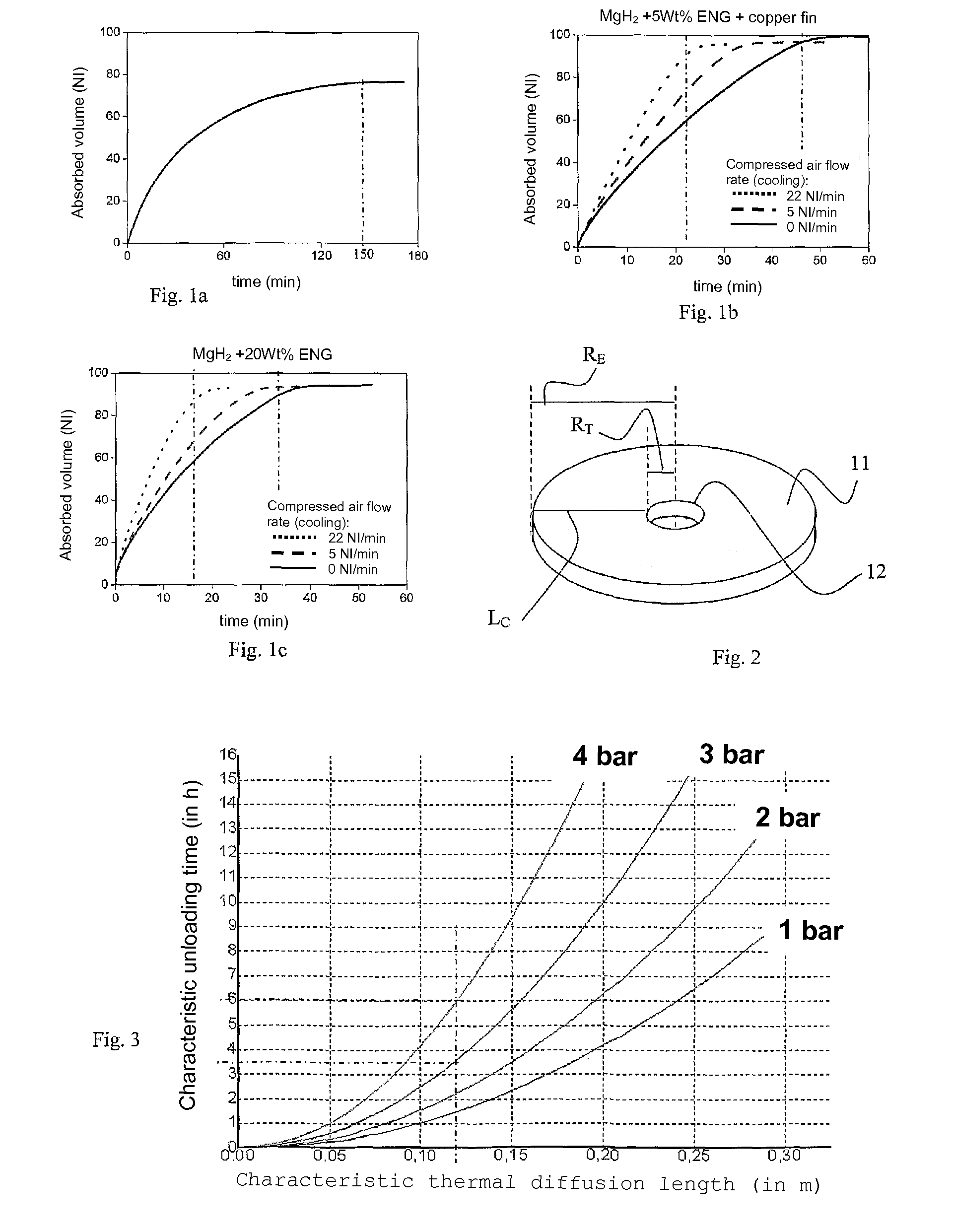

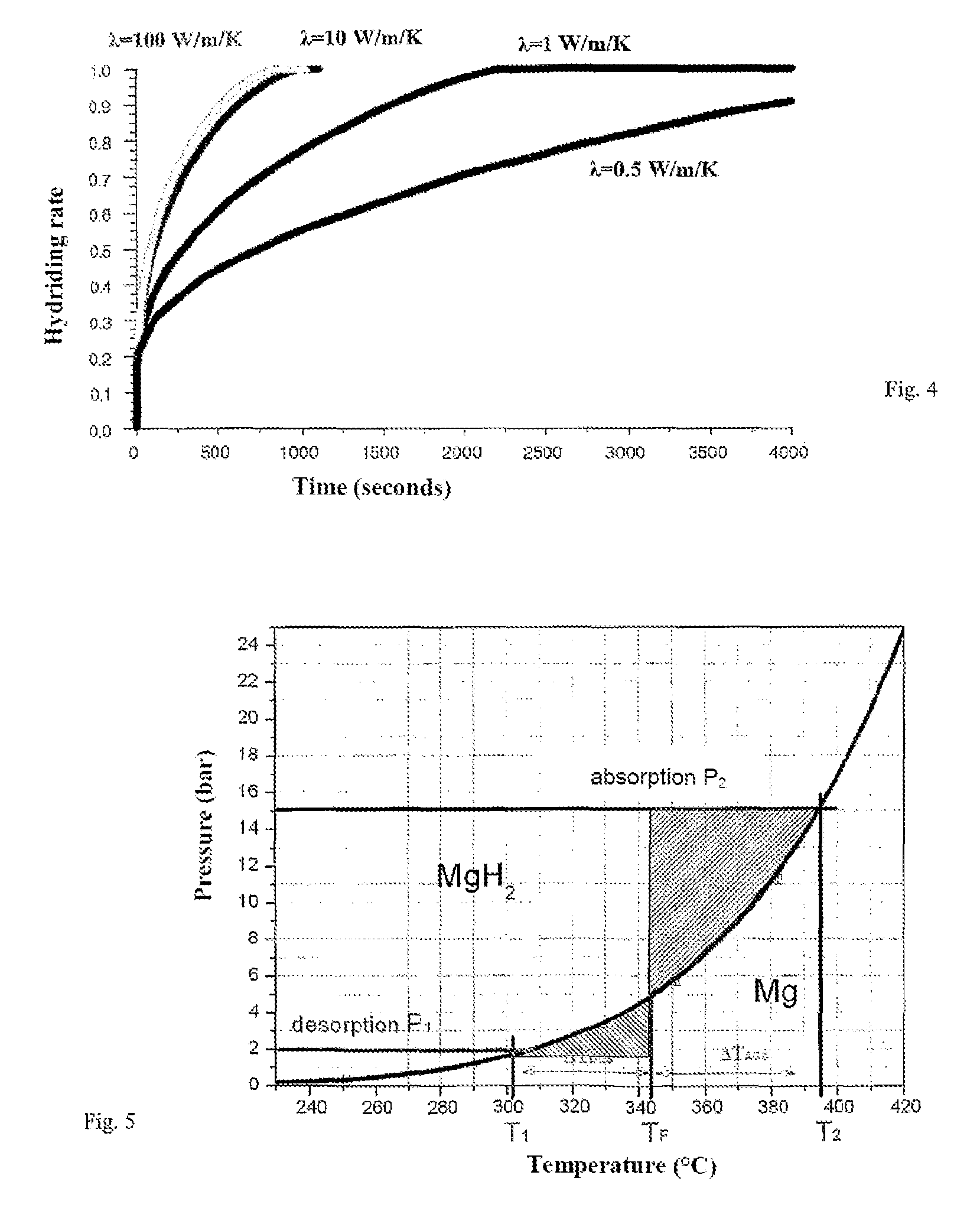

InactiveUS8636834B2Easy to manufactureFast hydrogen absorption kineticsAlkali/alkaline-earth/beryllium/magnesium hydridesReversible hydrogen uptakeHeat conductingMolten salt

The invention relates to a safe hydrogen-storing tank that is easy to manufacture and enables the quick kinetic absorption of hydrogen, which reduces the variations in volume and has a low cost in terms of material and energy. The invention has the aim of providing a tank for storing hydrogen, including a hydrogen inlet (21) and a hydrogen outlet (22) in fluid communication with at least one solid body (10-11) capable of the exothermal absorption and endothermal desorption of hydrogen, wherein said at least one solid body (10-11) is made of a compacted material containing light metal hydride and a heat-conducting matrix, and wherein said at least one solid body (10-11) is in heat-transfer relation with at least one heat recovery material (42) free from salt or molten-salt compounds and capable of absorbing the heat generated by the hydrogen absorption and of releasing said absorbed heat so as to provide heat for hydrogen desorption.

Owner:CENT NAT DE LA RECHERCHE SCI +1

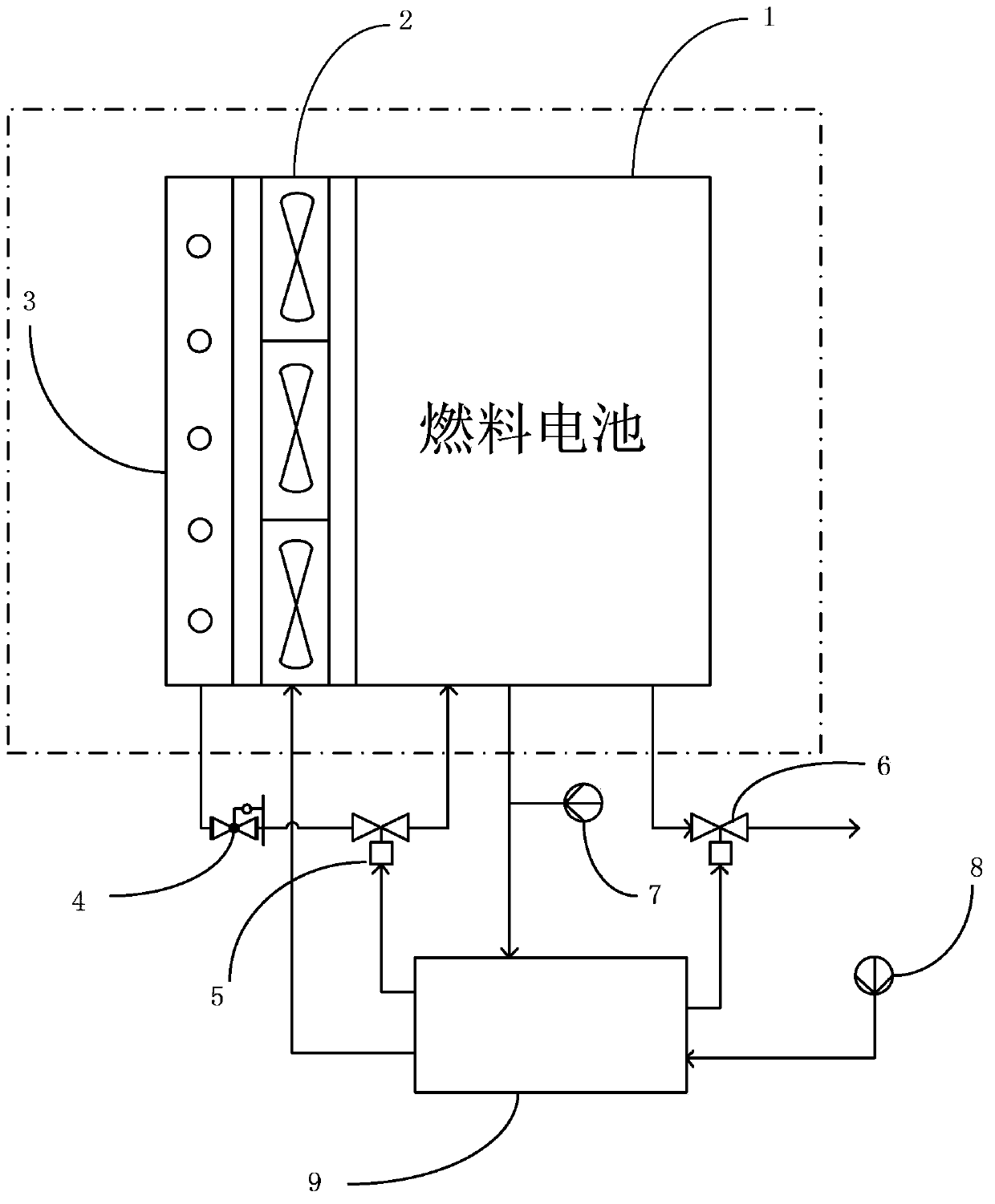

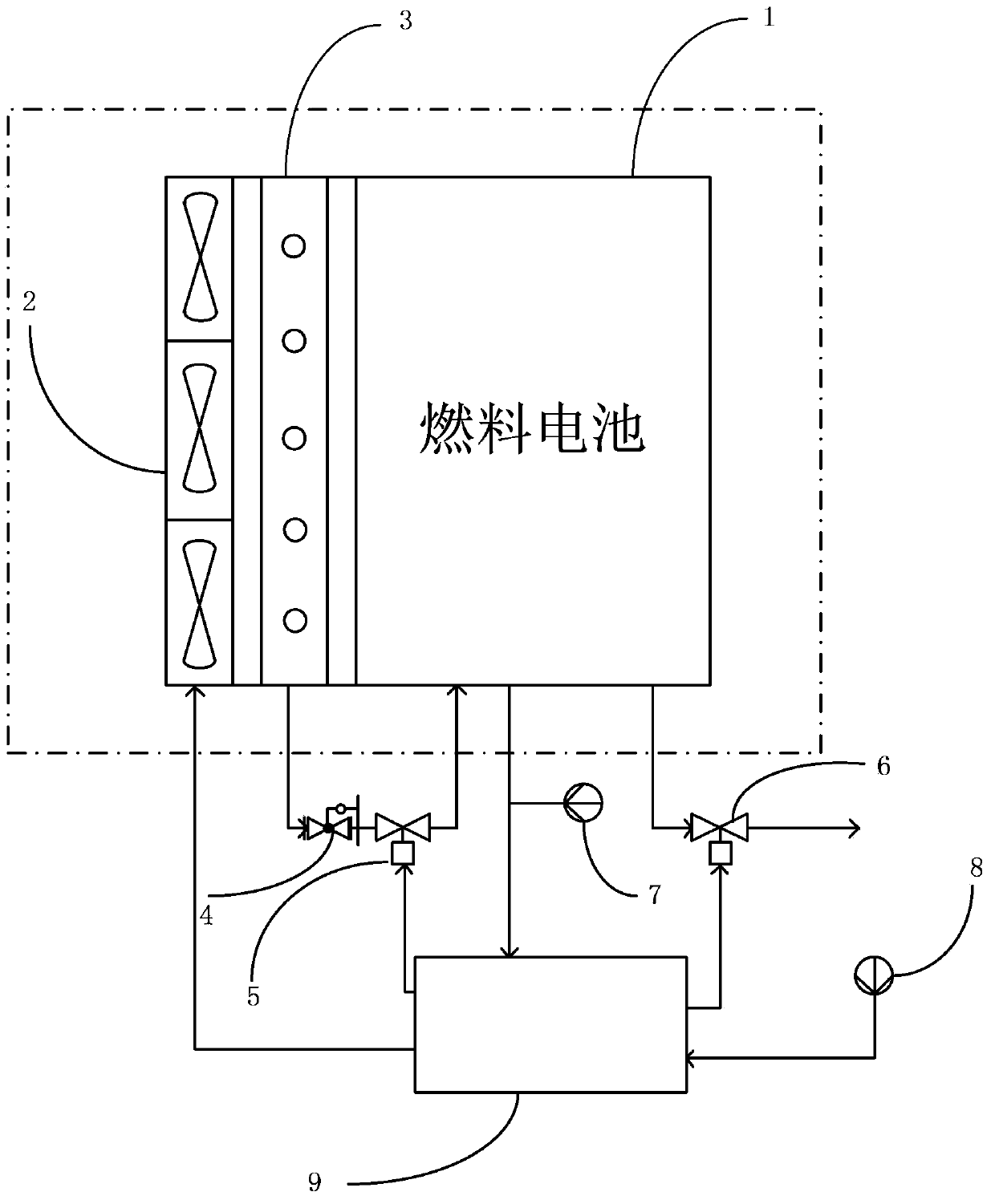

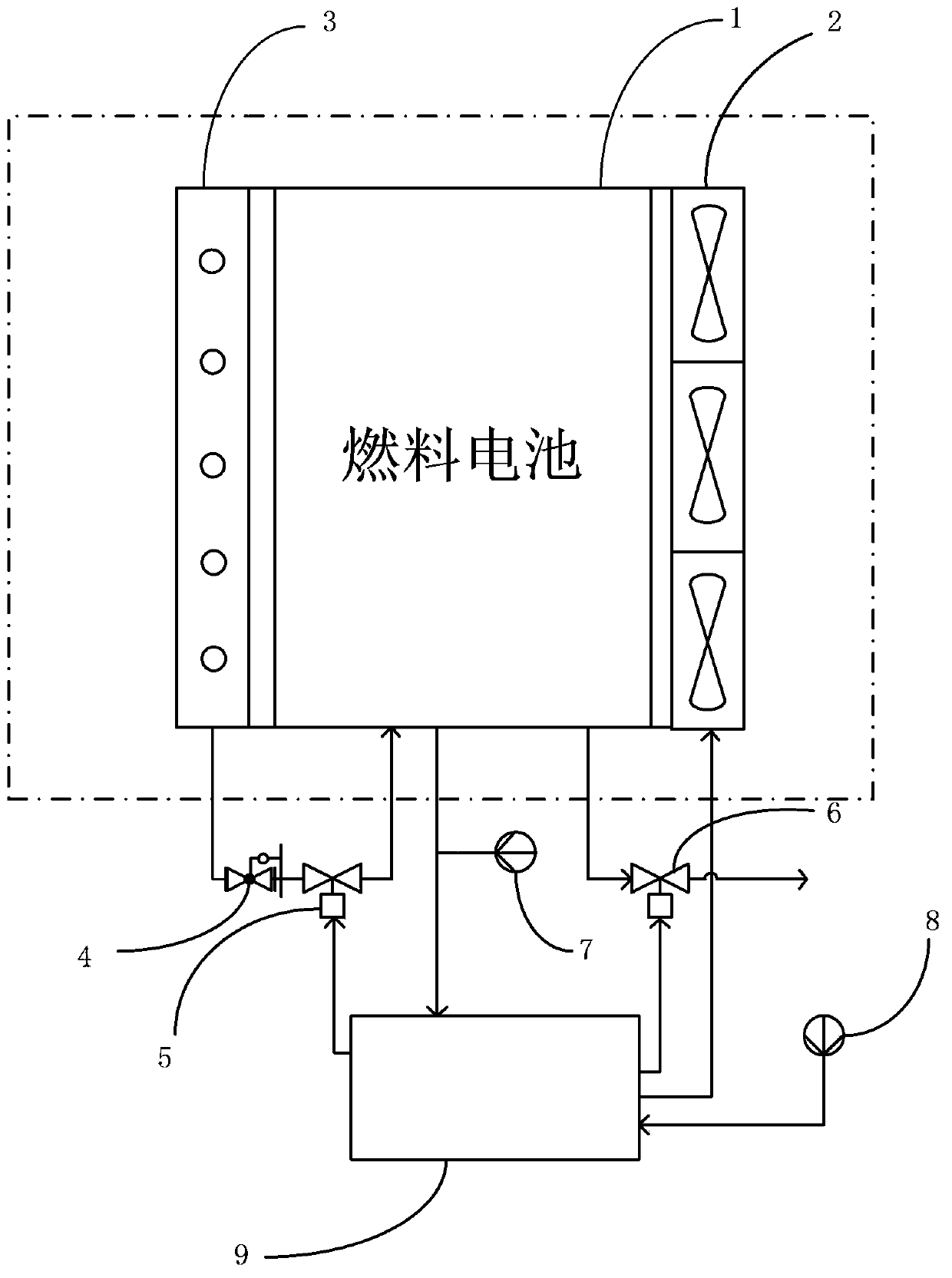

Air-cooled fuel cell system and coupling heat control method thereof

InactiveCN103401004ANormal temperatureNormal working temperatureFuel cell heat exchangeFuel cellsWorking temperature

The invention discloses an air-cooled fuel cell system and a coupling heat control method thereof. The method comprises the following steps of: acquiring the current environment temperature of a fuel cell; acquiring the current working temperature of the fuel cell; controlling the rotation direction of a fuel cell fan according to the environment temperature; and controlling the rotation speed of the fuel cell fan according to the working temperature of the fuel cell. The rotation direction and rotation speed of the cooling fan are controlled according to the acquired working temperature and environment temperature of the fuel cell by virtue of the heat coupling characteristic of hydrogen desorption for heat absorption of an alloy hydrogen storage container and reaction for heat release of the fuel cell, so that effective coupling heat control over the hydrogen storage container and the fuel cell is realized, the hydrogen desorption efficiency of the hydrogen storage container at low environment temperature can be improved, the working conditions of the fuel cell at high environment temperature are improved, and the environmental adaptability of the air-cooled fuel cell system is further improved.

Owner:SOUTHWEST JIAOTONG UNIV

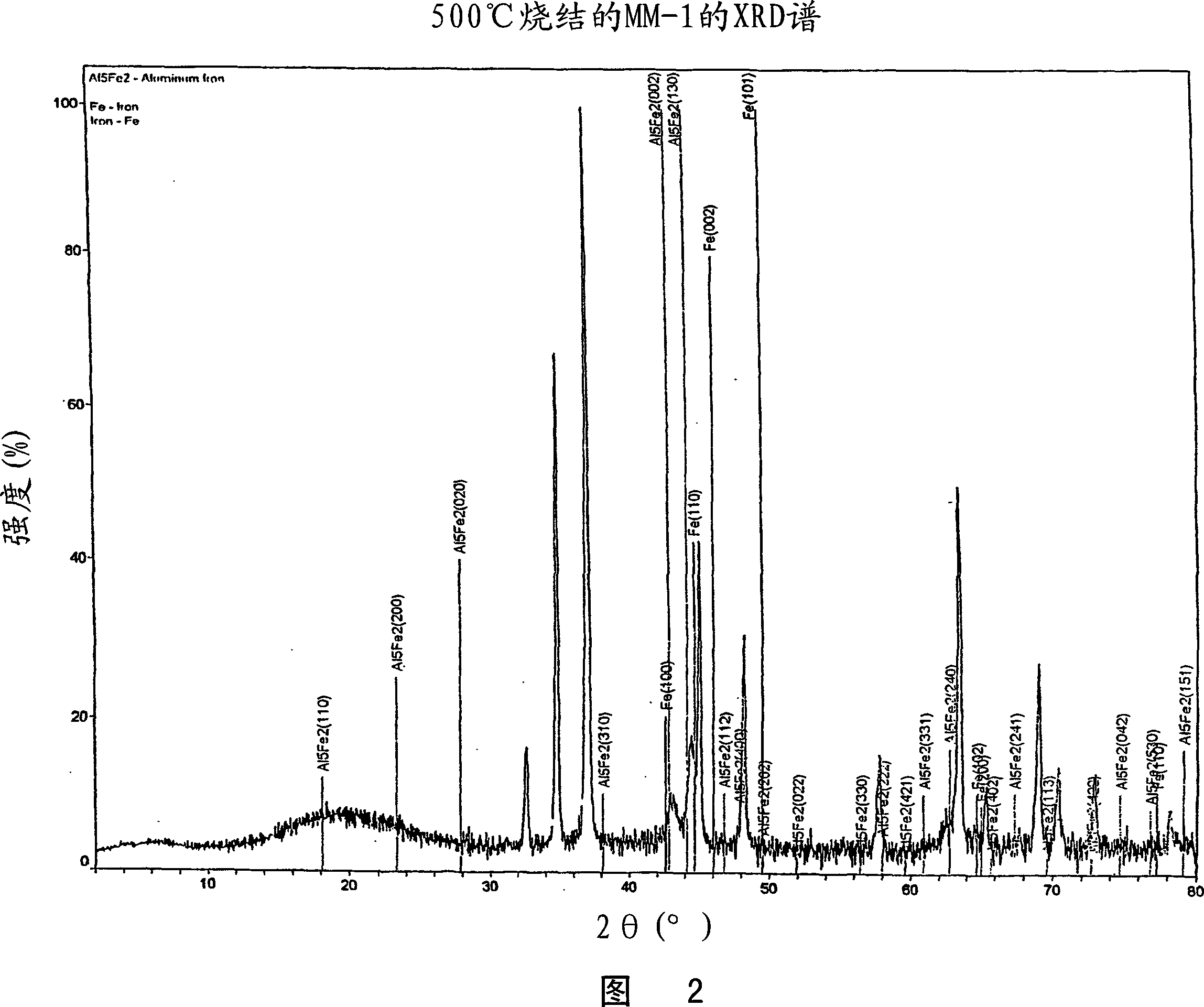

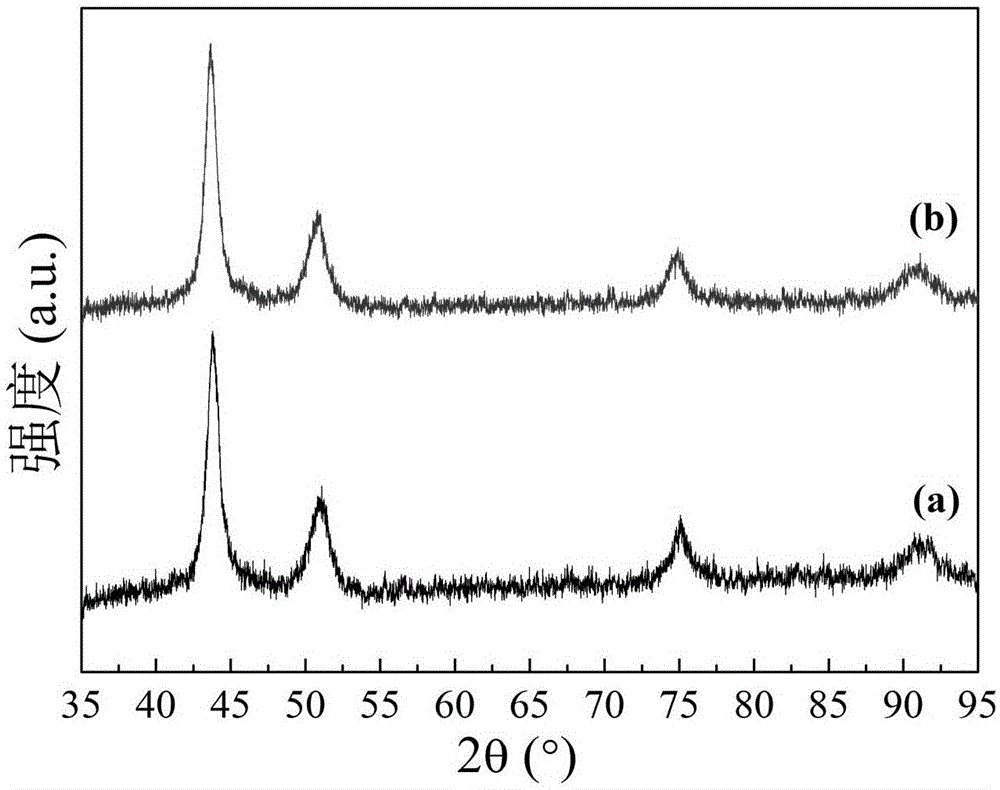

Method for producing a magnetic alloy powder

InactiveUS6352597B1Improve propertiesImprove magnetic propertiesTransportation and packagingMetal-working apparatusHydrogen pressureHydrogen desorption

A method is disclosed enabling a technologically controllable and economical production of a hard-magnetic powder composed of a samarium-cobalt base alloy for highly coercive permanent magnets. The method is based on a HDDR treatment in which a starting powder is subjected to hydrogenation with disproportionation of the alloy in a first method step under hydrogen and, in a subsequent, second method step under vacuum conditions, a hydrogen desorption with recombination of the alloy. A starting powder containing samarium and cobalt is treated in the first method step either at a high temperature in the range of 500° C. to 900° C. and with a high hydrogen pressure of >0.5 MPa or by applying an intensive fine grinding at a low temperature in the range of 50° C. to 500° C. and with a hydrogen pressure of >0.15 MPa. By means of the method of the invention, magnetic alloy powders can be produced from samarium-cobalt base alloys; highly coercive permanent magnets can be produced from these magnetic alloy powders, particularly by hot compacting or plastic bonding.

Owner:INST FUER FESTKOERPER & WERKSTOFFORSCHUNG DRESDEN EV

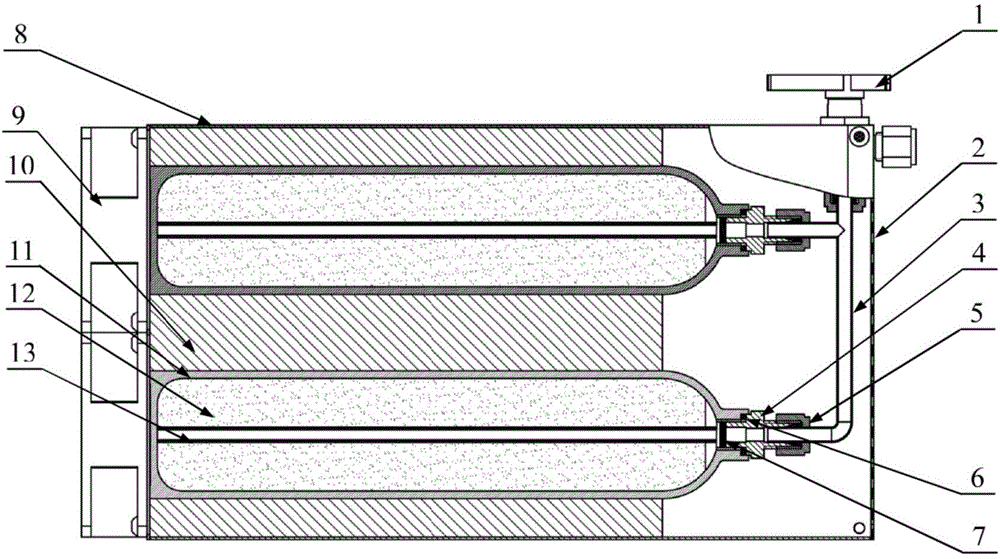

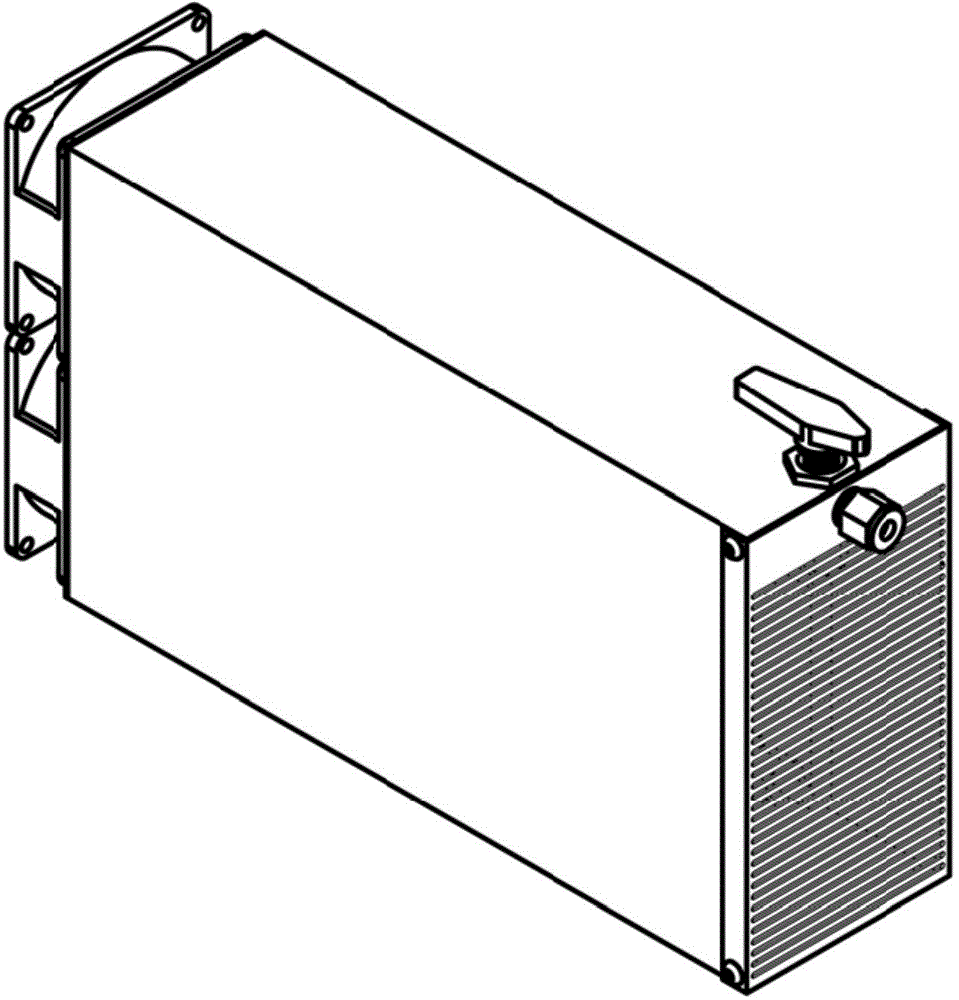

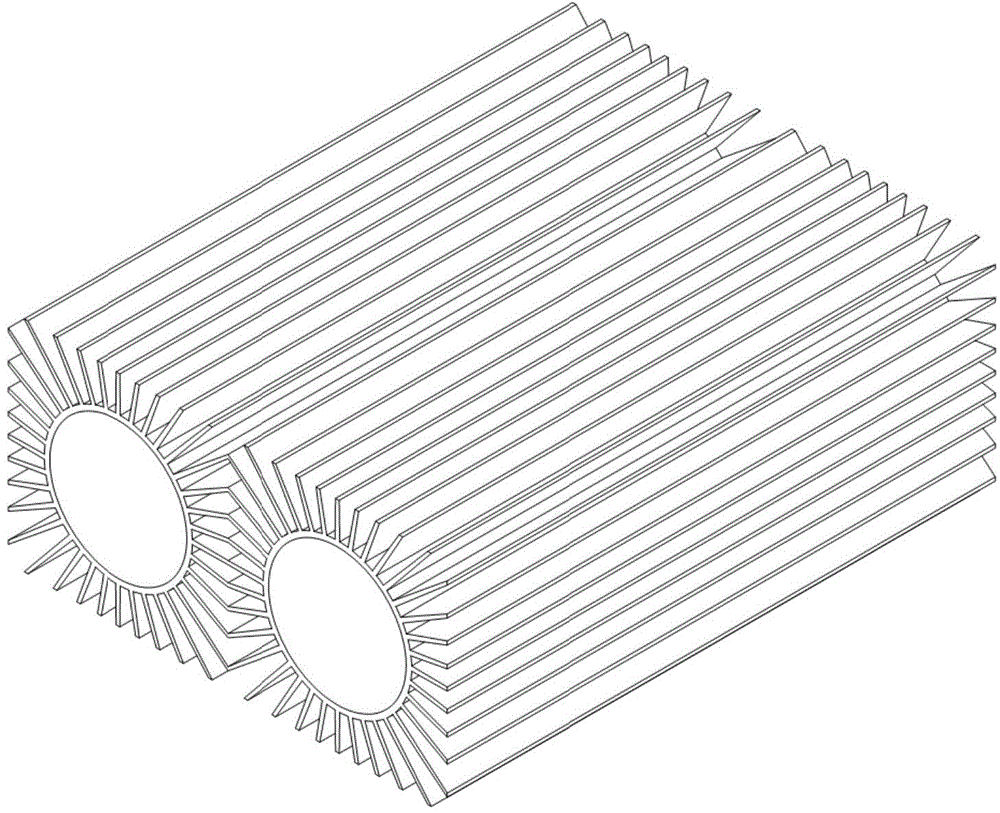

Metal hydride hydrogen storage device

InactiveCN104676239ASimple structureEasy to processContainer filling methodsPressure vesselsEngineeringHeat transfer efficiency

The invention discloses a metal hydride hydrogen storage device, which belongs to the technical field of hydrogen storage. The device is composed of a valve, a front cover, a gas path tube, a bottleneck connector, a clamping sleeve, a sealing gasket, a filter disc, a shell, two fans, a longitudinal heat transfer finned tube, a hydrogen storage container, a hydrogen storage material bed body, and a porous gas guide tube, wherein the bottleneck connector is connected with a hydrogen storage bottle body and the gas path tube by the sealing gasket and the clamping sleeve; the gas path tube is connected with the porous gas guide tube and the valve by the filter disc; the front cover and the two fans are arranged on the shell, and the longitudinal heat transfer finned tube and a hydrogen storage bottle are arranged in the shell; and the hydrogen storage material bed body and the porous gas guide tube are arranged in the hydrogen storage bottle body. The metal hydride hydrogen storage device disclosed by the invention is simple in structure, and easy to manufacture and process; and the longitudinal heat transfer finned tube can ensure the uniform heat transfer of the hydrogen storage container while the heat transfer efficiency of the hydrogen storage container is improved, so that the uniformity of hydrogen desorption of the hydrogen storage material bed body in the hydrogen storage container is ensured, and the hydrogen desorption performance is significantly improved.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

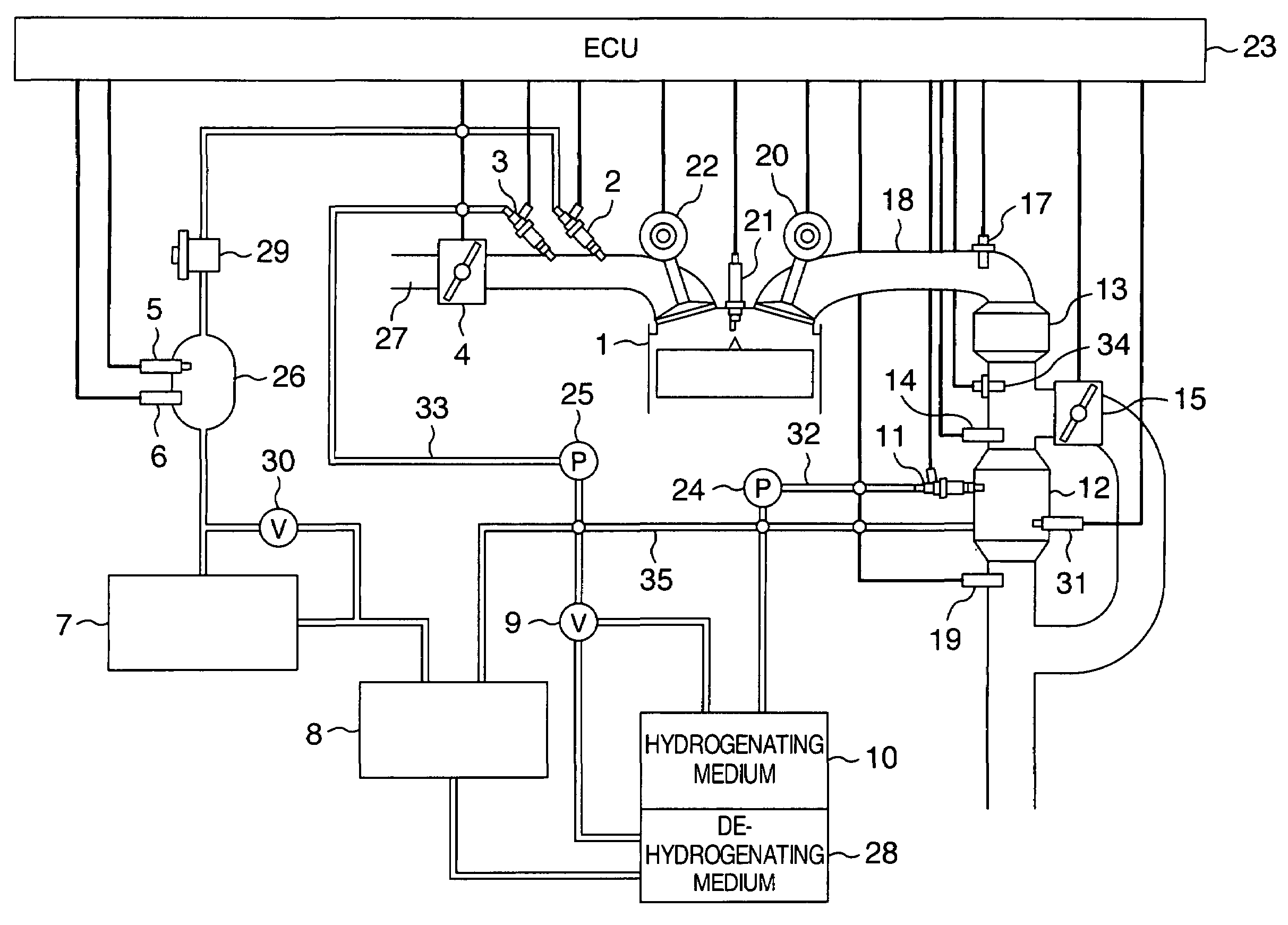

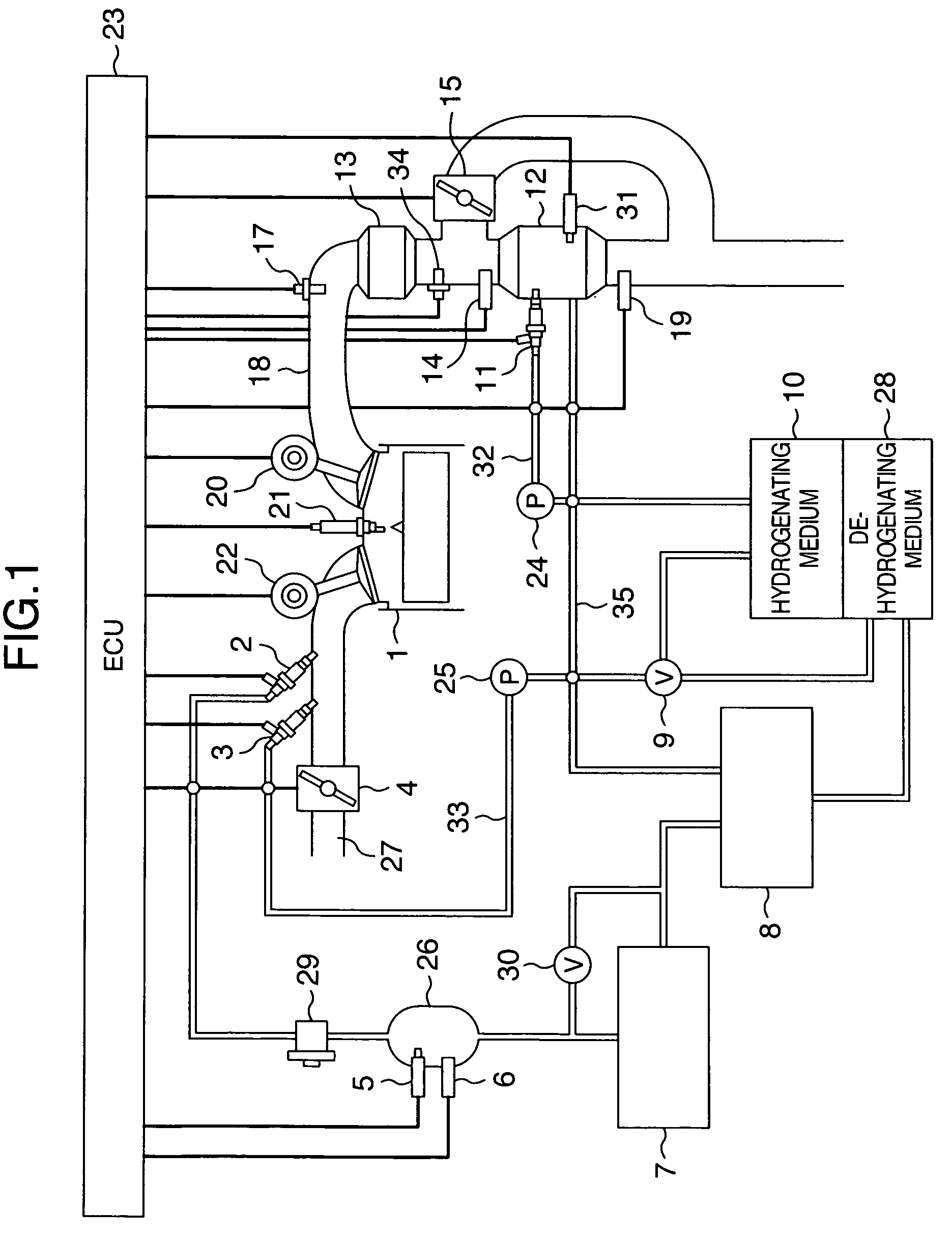

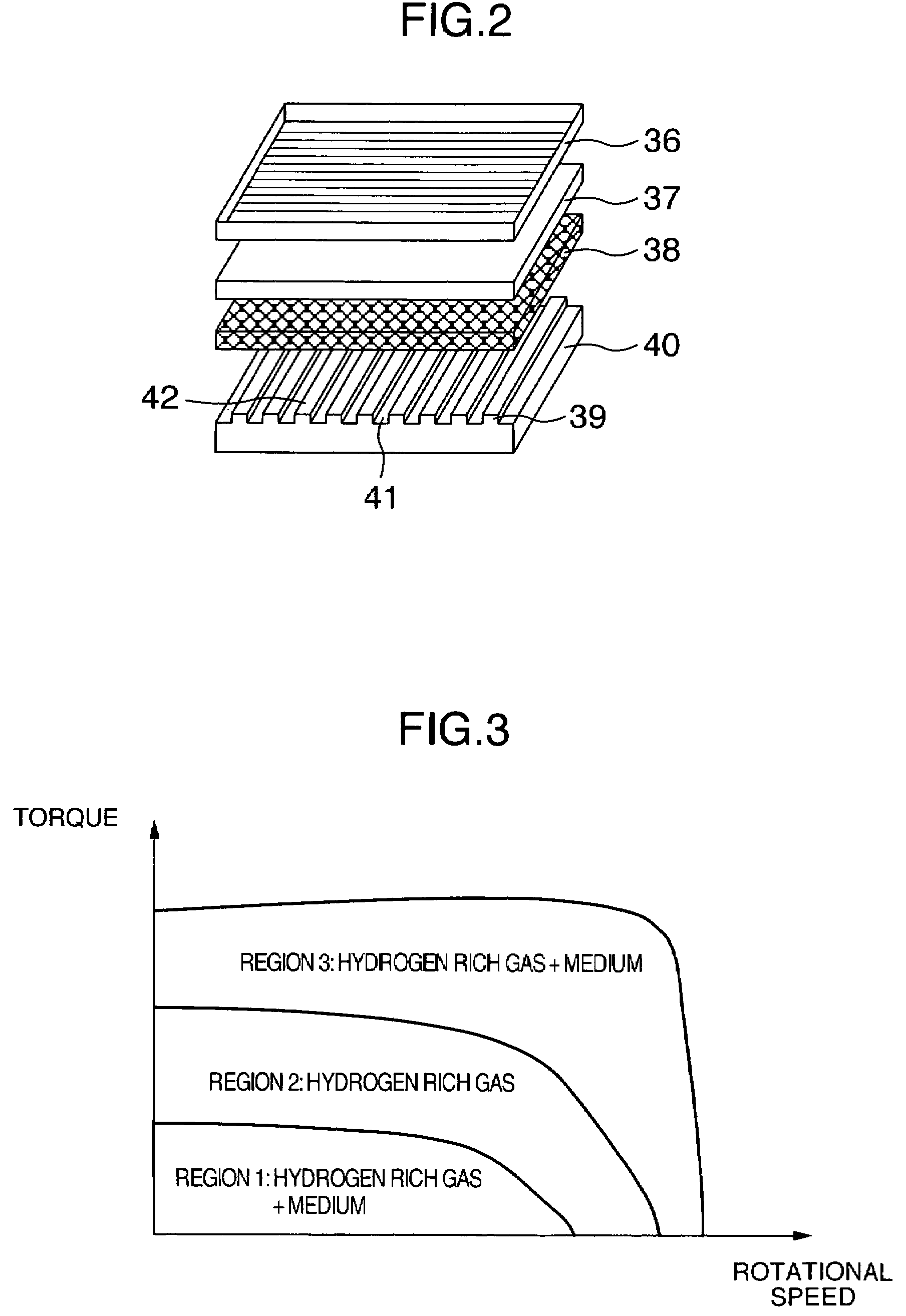

Engine system

InactiveUS7568452B2Efficiently generate a hydrogen rich gasImprove efficiencyHydrogenInternal combustion piston enginesProduct gasHydrogen desorption

An object of the invention is to provide an engine system driving an engine by using a hydrogen rich gas generated from a medium chemically repeating a hydrogen absorption and a hydrogen desorption as one of fuels, in which the engine system can efficiently generate a hydrogen rich gas from the medium. In an engine system which mounts a medium chemically repeating a hydrogen absorption and a hydrogen desorption thereon, is provided with a hydrogen supplying apparatus generating or storing a hydrogen rich gas from the medium, and drives an engine by using the hydrogen rich gas as one of fuels, the engine system has a detecting portion detecting an operating state of the engine, and a medium supplying amount control means controlling a supplying amount of the medium supplied to the hydrogen supplying apparatus in correspondence to a result of detection of the detecting portion.

Owner:HITACHI LTD

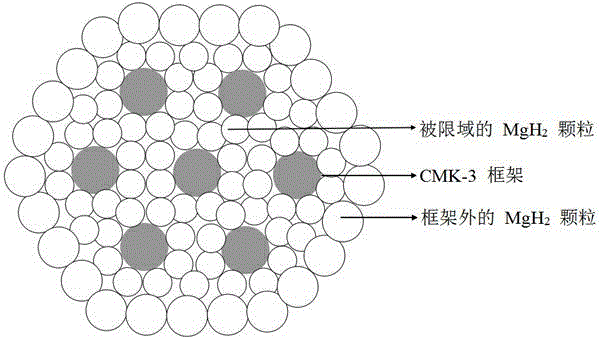

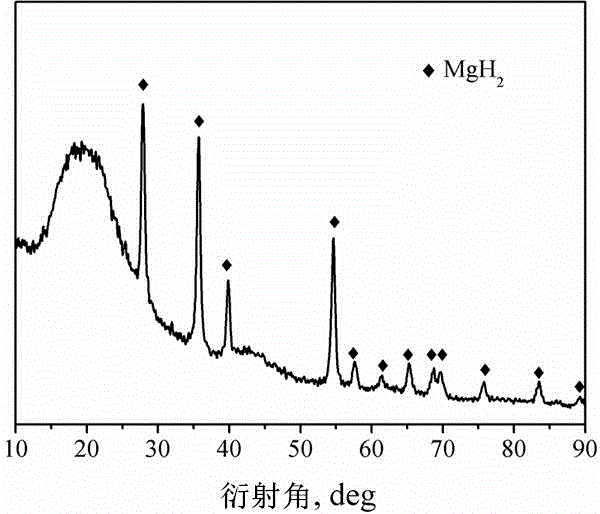

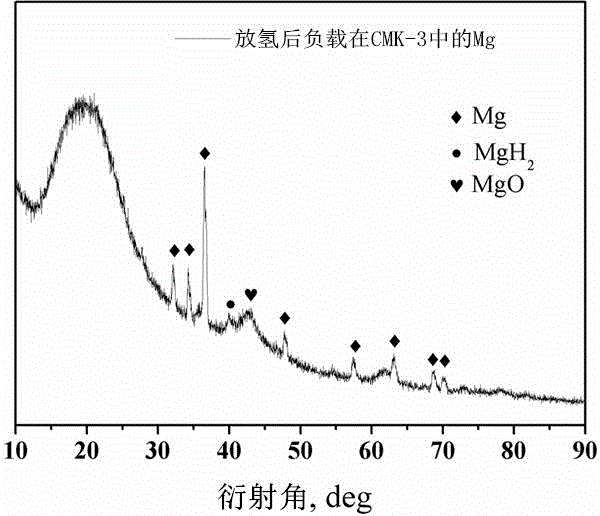

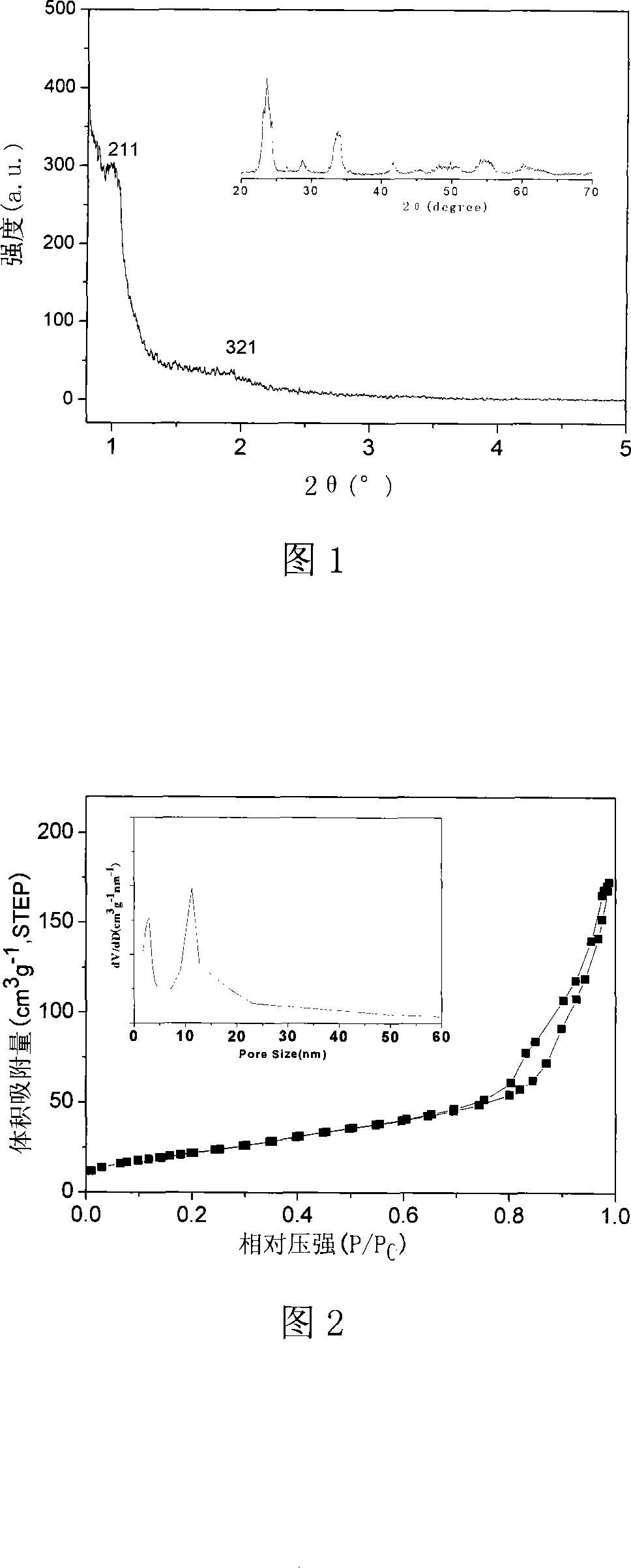

Method for preparing nanometer limited range magnesium-based hydrogen storage material

InactiveCN104649229AImprove mechanical propertiesLow costAlkali/alkaline-earth/beryllium/magnesium hydridesDispersityNew energy

The invention discloses a method for preparing a nanometer limited range magnesium-based hydrogen storage material. The nanometer limited range method belongs to the technical field of new energy materials. The method is characterized in that the hydrogen storage material is formed by loading magnesium hydride (MgH2) in nanopores of a mesoporous framework material. The method comprises the following steps: dipping dibutyl magnesium (MgBu2) and a mesoporous framework material, replacing MgBu2 with MgH2 loaded inside and outside the nanopores of the mesoporous framework material in a high-pressure reactor under high temperature and high pressure, washing MgH2 loaded outside the pores away by using pentane, drying, thereby obtaining the material. The nanometer limited range magnesium-based hydrogen storage material prepared by the method can release hydrogen at room temperature and has excellent properties in hydrogen absorption and desorption kinetics and hydrogen desorption thermodynamics. The method disclosed by the invention is easy to operate and high in synthesis speed and the prepared material is high in dispersity; therefore, the method has ideal application prospects.

Owner:SHANGHAI UNIV

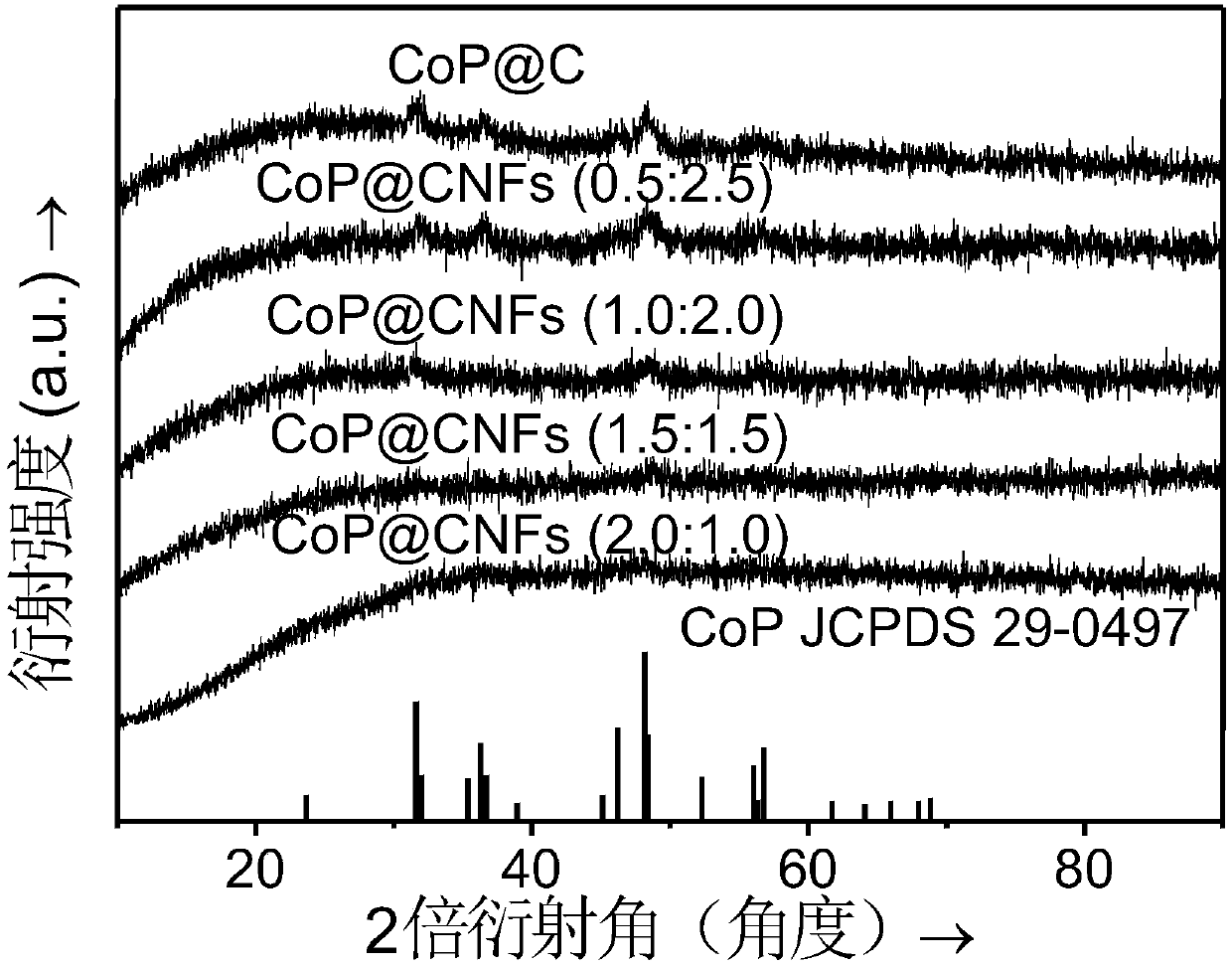

Metal phosphide-porous carbon framework composite material, and preparation method and application thereof

ActiveCN107744822ASmall particle sizeLarge specific surface areaCatalyst activation/preparationHydrogen productionPorous carbonMetal-organic framework

The invention discloses a preparation method of a metal phosphide-porous carbon framework composite material. The method comprises the following steps: calcining a bimetallic metal organic framework material to obtain a porous carbon framework material, respectively placing the porous carbon framework material and a phosphorus source in two ends of a tubular furnace, introducing an inert gas, heating the tubular furnace to a certain temperature, carrying out a phosphating reaction, and washing the obtained reaction product with an acid to obtain the metal phosphide-porous carbon framework composite material. The invention also discloses the metal phosphide-porous carbon framework composite material and an application thereof. The metal phosphide-porous carbon framework composite material prepared through the preparation method has the advantages of large specific surface area, small particle size of metal phosphide, and excellent catalytic hydrogen desorption performance. The porous metal phosphide with a large specific surface area is obtained by using a bimetallic metal organic framework as a self-template through a selective phosphating technology capable of phosphating Co3O4 ornickel oxide but incapable of phosphating zinc oxide under the same conditions; and the preparation method has the advantages of simplicity, novelty and low cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

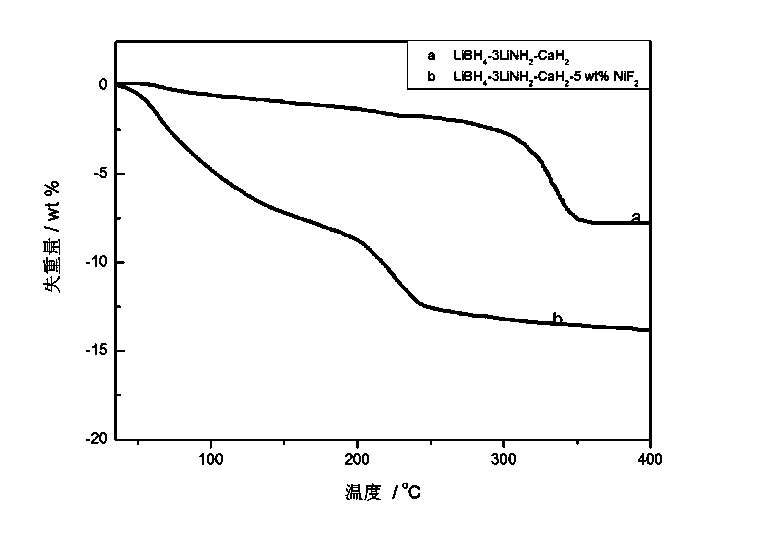

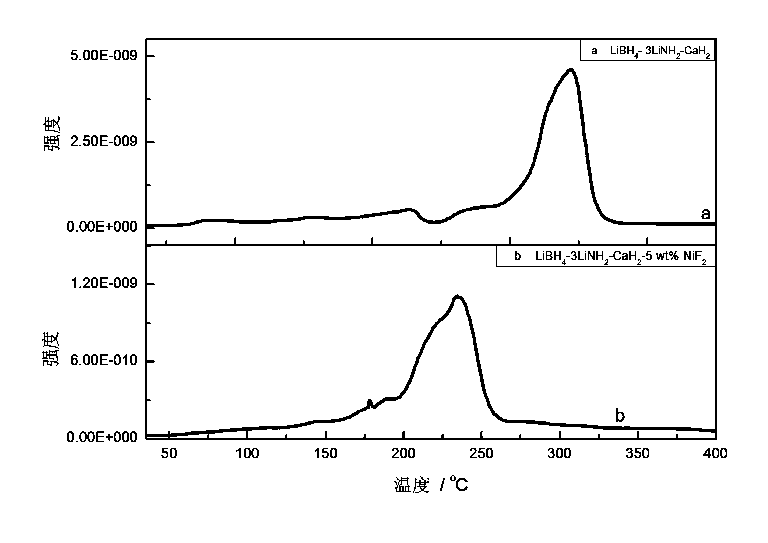

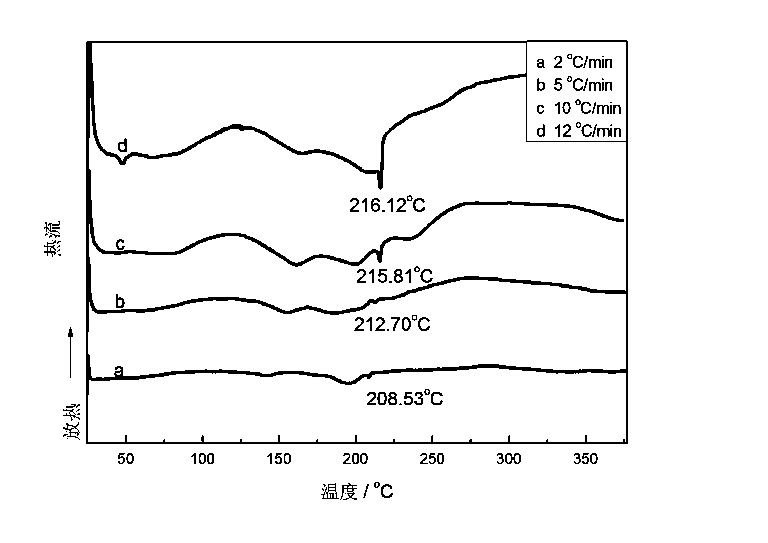

NiF2-dopped LiBH4-LiNH2-CaH2 composite hydrogen storage material and preparation method thereof

InactiveCN103539066AImprove hydrogen absorption and desorption performanceLow hydrogen release temperatureHydrogen productionHydrogen desorptionChemistry

The invention relates to a preparation method of an NiF2-dopped LiBH4-LiNH2-CaH2 composite hydrogen storage material, in particular relates to a hydrogen storage material which improves the hydrogen desorption performance of an LiBH4-LiNH2-CaH2 system through doping NiF2 and a preparation method thereof, and belongs to the technical field of modification. The composite material is prepared by utilizing a mechanical milling method, when the doping amount of NiF2 is 5wt%, the system starts greatly desorbing hydrogen at 47 DEG C, the main hydrogen desorption peak temperature is 234 DEG C, and the hydrogen desorption amount reaches 3.75wt% at 175 DEG C within 5000s; the hydrogen desorption amount reaches 5.03wt% within 5h; the hydrogen desorption amount reaches 6wt% at 200 DEG C within 5000s; the hydrogen desorption amount reaches 6.55wt% at 270 DEG C within 1000s. The composite hydrogen storage material which is prepared by ball milling has good hydrogen storage and desorption performances, and the prepared NiF2-dopped LiBH4-LiNH2-CaH2 composite hydrogen storage material has good hydrogen desorption performance at low temperatures.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

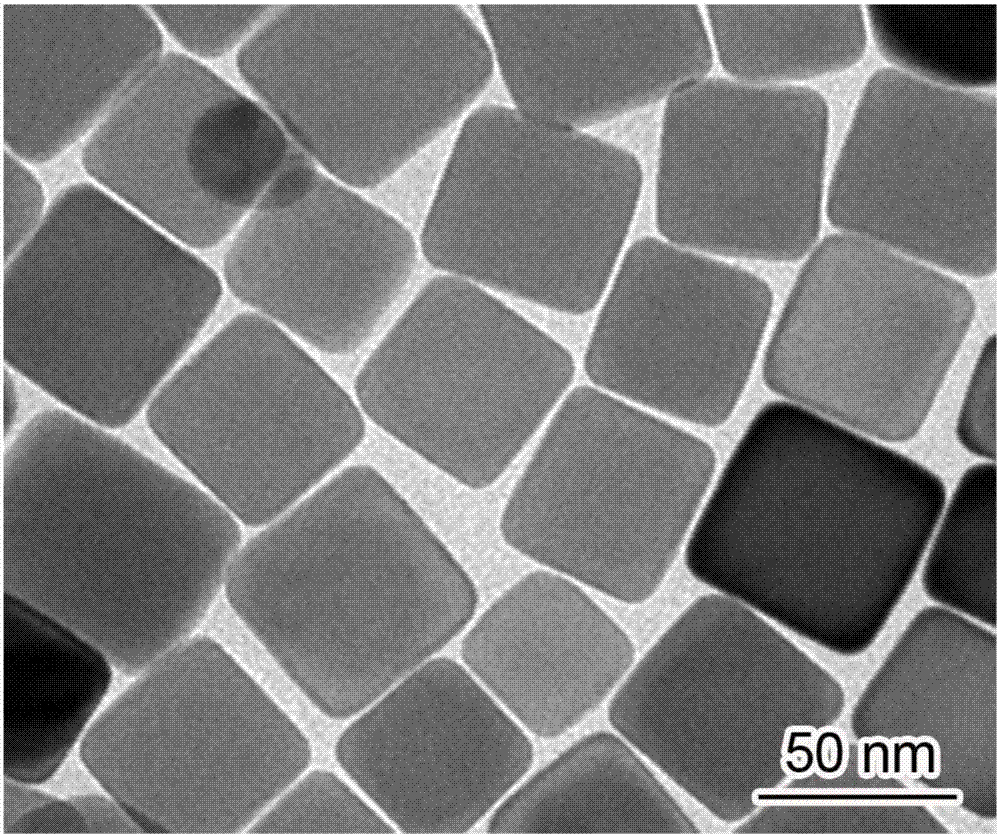

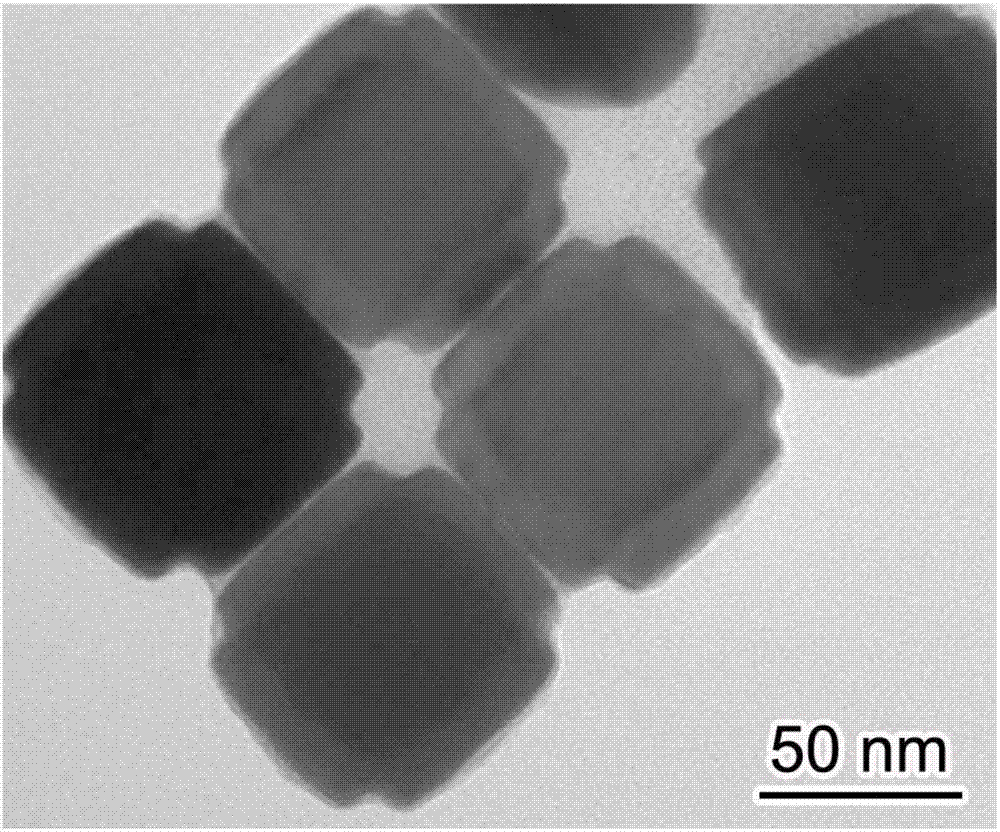

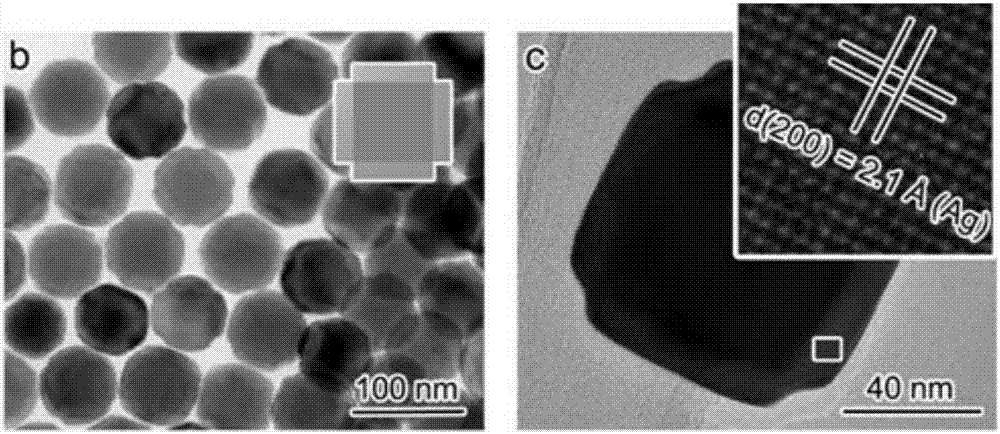

A palladium-silver bimetallic composite material and a preparing method thereof

ActiveCN106914238AReduce catalytic activityReduced strengthMetal/metal-oxides/metal-hydroxide catalystsHydrogenPalladium atom

A palladium-silver bimetallic composite material is provided. The composite material includes silver nanometer crystals and a palladium-silver alloy layer on the surface of the silver nanometer crystals. The invention also provides a preparing method of the composite material. The preparing method includes mixing the silver nanometer crystals, a reductant, an etching agent, a surface protectant, a solvent and a palladium source compound, and then reacting the mixture to obtain the composite material. The nanometer crystals having a core shell structure are prepared by a provided synthetic method. Dispersed palladium atoms grow on the surfaces of the silver nanometer crystals, thus effectively weakening strength of palladium-hydrogen bonds and facilitating hydrogen desorption. In addition, low-cost silver nanometer particles are adopted inside the composite material, and palladium active points are distributed on the surfaces of the silver nanometer crystals, and therefore the activity of the composite material as a catalyst is high and the cost is low.

Owner:UNIV OF SCI & TECH OF CHINA

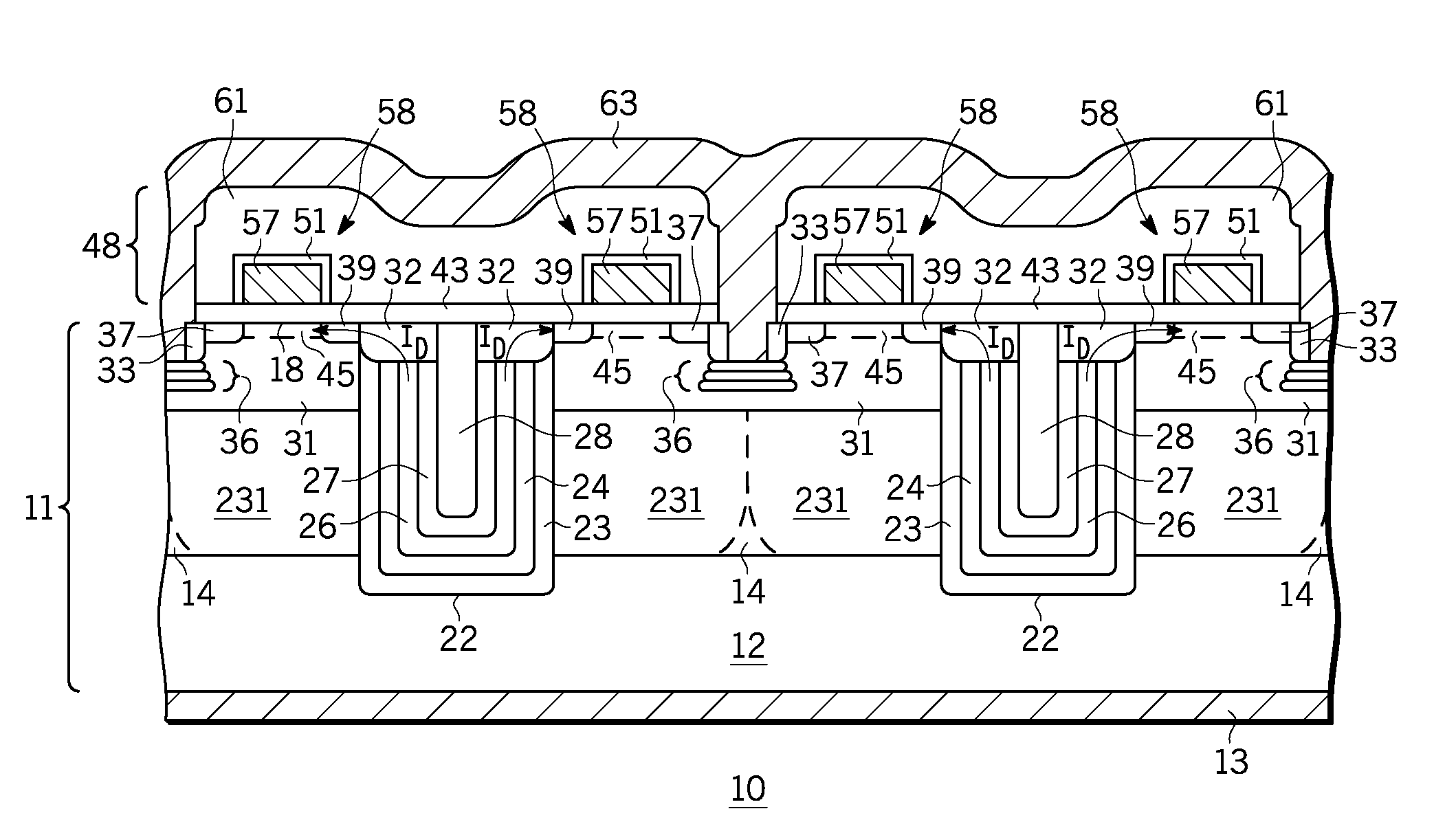

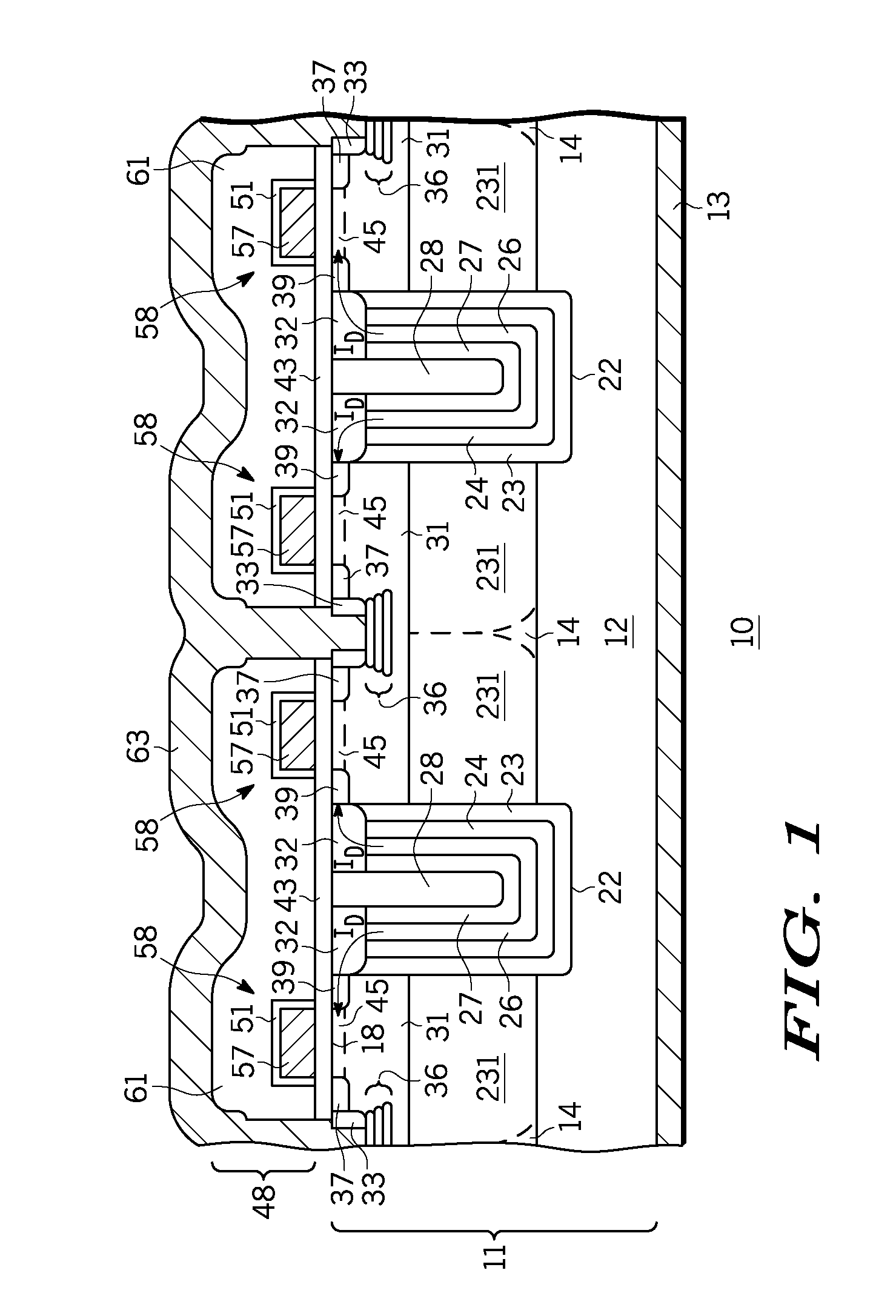

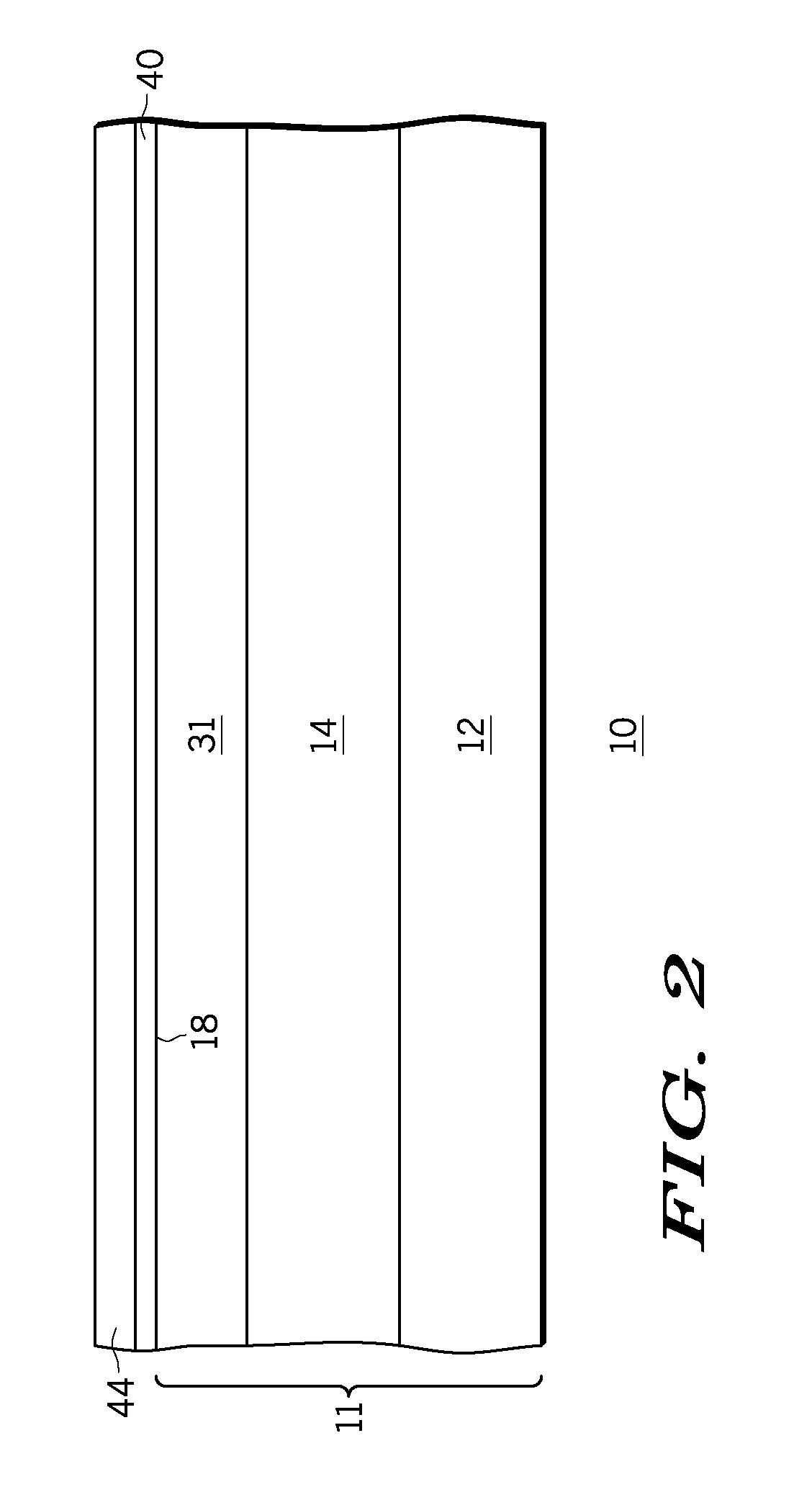

Method of forming a semiconductor device having trench charge compensation regions

ActiveUS20080081440A1TransistorSemiconductor/solid-state device manufacturingEngineeringHydrogen desorption

In one embodiment, a method of forming a semiconductor device with trench charge compensation structures includes exposing the trench sidewalls to a reduced temperature hydrogen desorption process to enhance the formation of monocrystalline semiconductor layers.

Owner:SEMICON COMPONENTS IND LLC

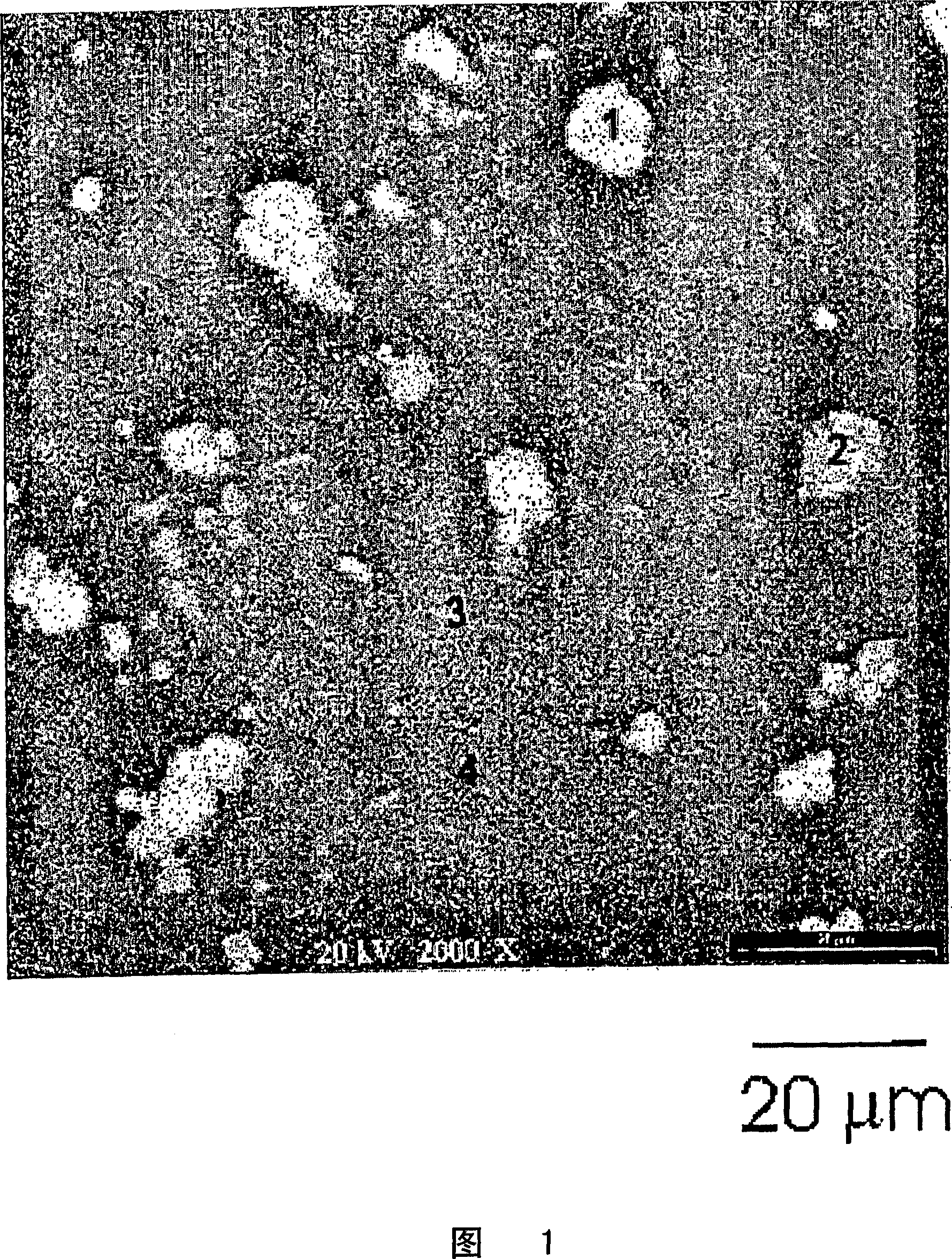

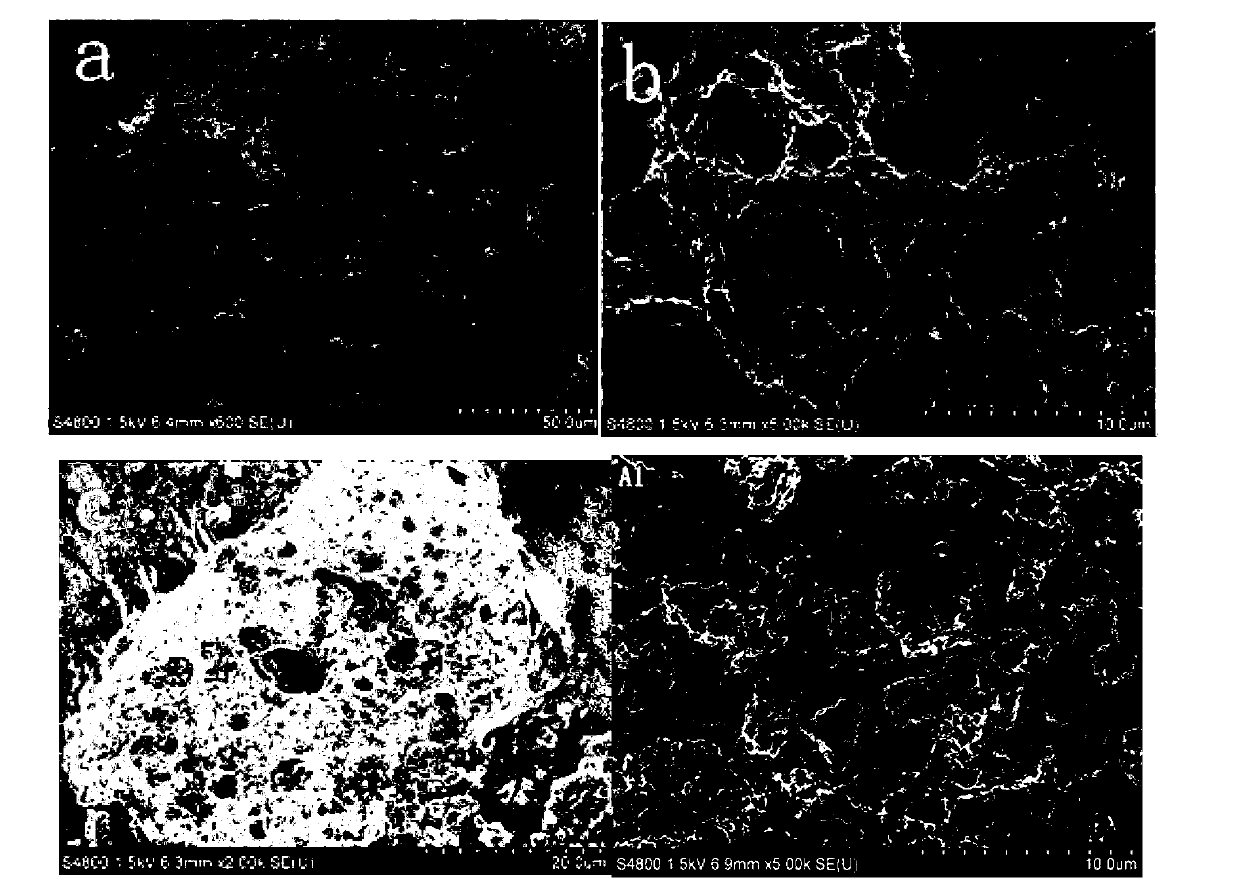

Catalyzed hydrogen desorption in mg-based hydrogen storage material and methods for production thereof

A magnesium-based hydrogen storage material including magnesium or a magnesium-based hydrogen storage alloy and a hydrogen desorption catalyst which is insoluble in said magnesium-based hydrogen storage alloy and is in the form of: 1) discrete dispersed regions of catalytic material in the bulk of said magnesium or magnesium-based hydrogen storage alloy; 2) discrete dispersed regions on the surface of particles of said magnesium or magnesium-based hydrogen storage alloy; 3) a continuous or semi-continuous layer of catalytic material on the surface of said magnesium or magnesium-based hydrogen storage alloy which is in bulk or particulate form; or 4) combinations thereof. Methods of producing the material are also disclosed.

Owner:TEXACO OVONIC HYDROGEN SYST LLC

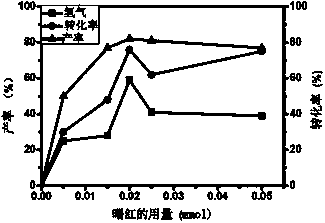

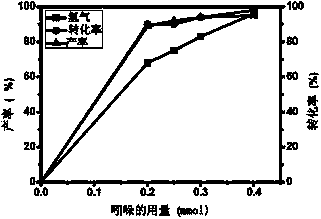

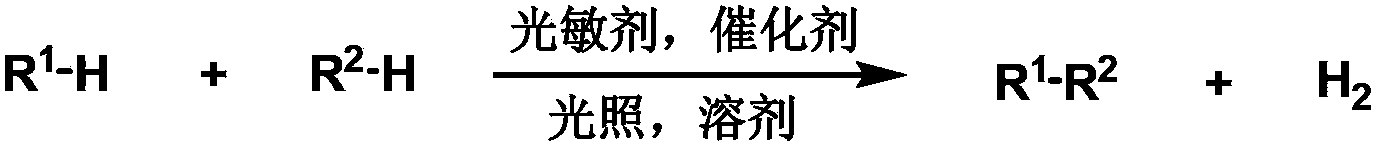

Visible light catalyzed cross-coupling hydrogen desorption method

ActiveCN103449945ACross-couplingOrganic chemistry methodsPhosphorus organic compoundsOrganic dyeHydrogen desorption

The invention discloses a visible light catalyzed cross-coupling hydrogen desorption method. The method takes an organic dye as the photo-sensitizer, adopts platinum sol, palladium sol, hydrated ruthenium dioxide, hydrated ruthenium trioxide, ruthenium sulphate, ruthenium nitrate, or hydrated ruthenium dioxide nano particles loaded on water-soluble graphene as the catalyst, utilizes visible lights to irradiate a solution of tertiary amine and nucleophilic reagent in an atmosphere of inert gas without any oxidant, and only obtains cross-couple products and hydrogen gas. The method has the advantages of high reaction efficiency, atom economy, and environment-friendliness, and develops a novel reaction type.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

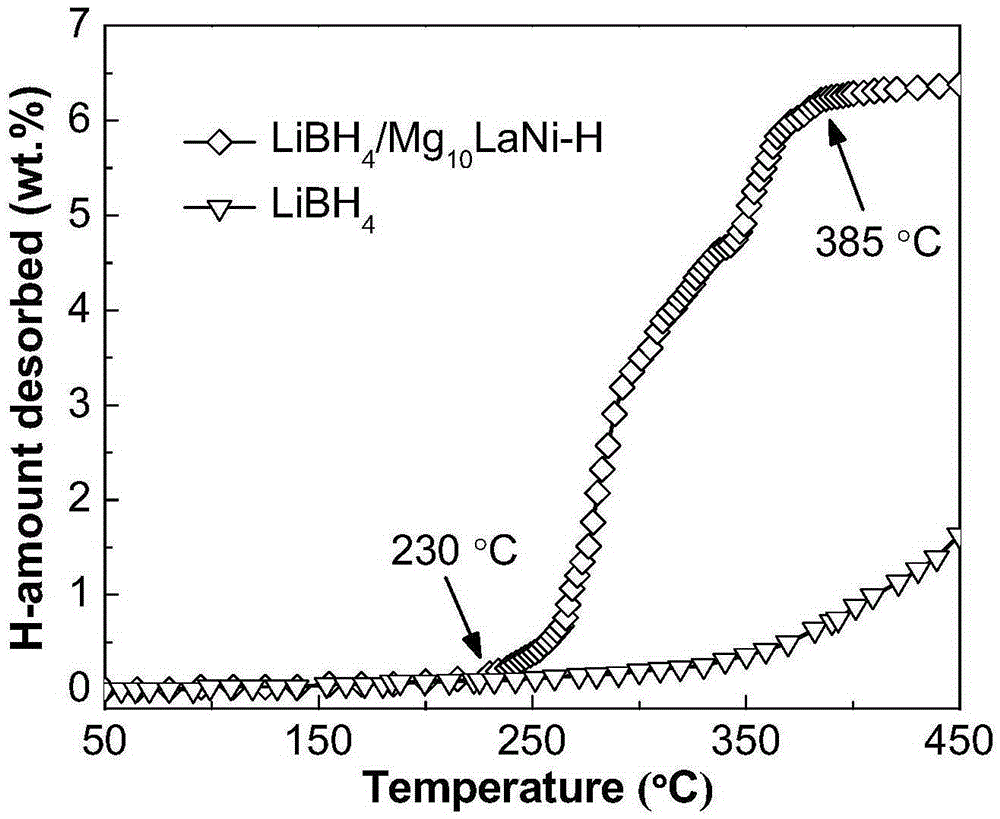

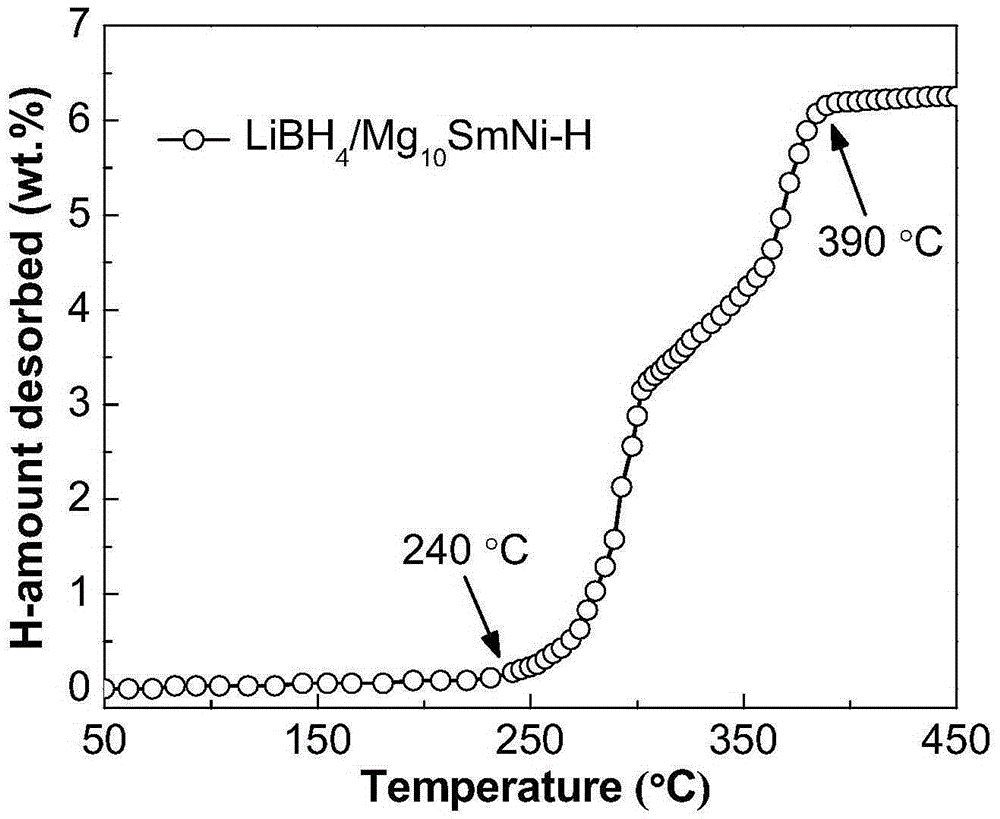

Composite hydrogen storage material and preparation method thereof

InactiveCN105271113AImprove hydrogen storage performanceShorten the diffusion distanceHydrogen productionRare earthHydrogen desorption

The invention discloses a composite hydrogen storage material and a preparation method thereof and belongs to the technical field of hydrogen storage materials. The composite hydrogen storage material comprises lithium borohydride and amorphous-state magnesium-rare earth-nickel alloy hydride in the mole ratio being (6-7):1, wherein a magnesium-rare earth-nickel alloy is Mg10LaNi or Mg10SmNi. During preparation, elementary magnesium, rare earth and nickel are taken as raw materials, an amorphous-state magnesium-rare earth-nickel alloy is obtained through a smelting and melt-spinning technology, amorphous-state magnesium-rare earth-nickel alloy hydride is obtained through ball milling and low-temperature hydrogenation, and finally, lithium borohydride and amorphous-state magnesium-rare earth-nickel alloy hydride are mixed. The provided composite hydrogen storage material has low hydrogen desorption temperature and high hydrogen desorption capacity, and a preparation process is simple, safe and reliable.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

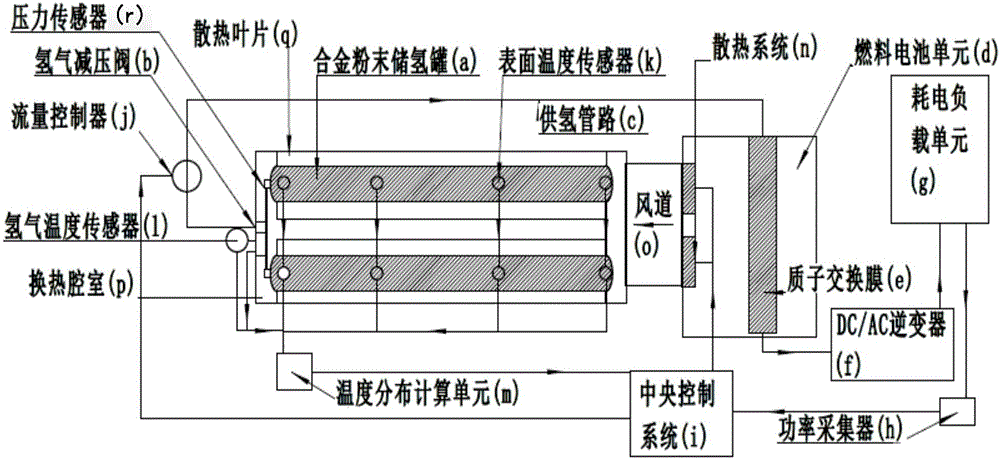

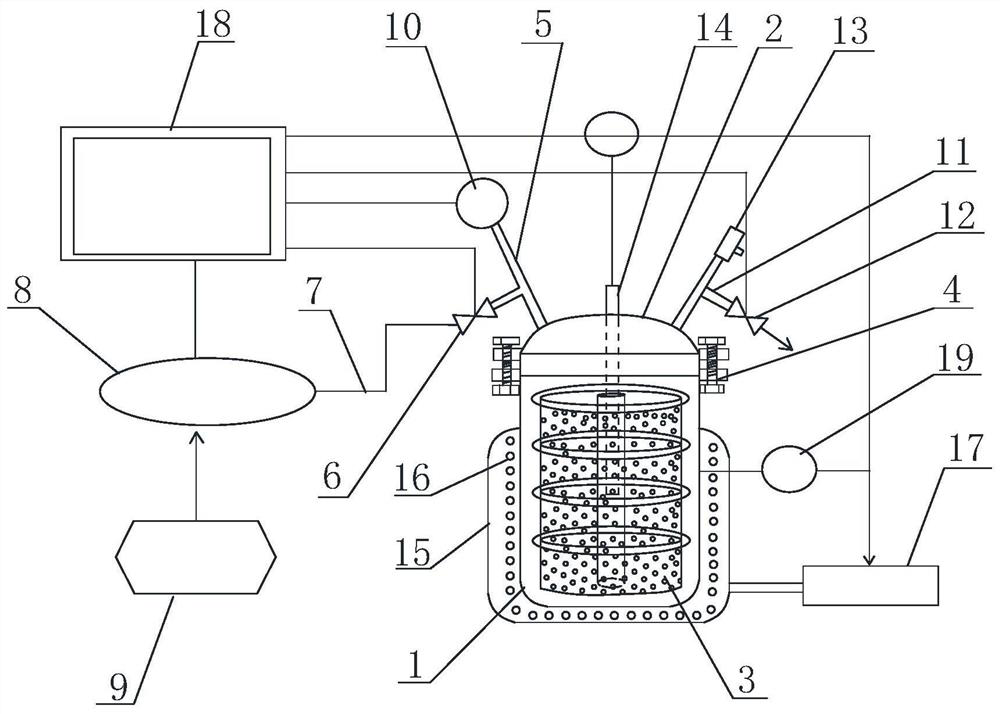

System and method for controlling and optimizing hydrogen utilization factor of alloy hydrogen-storage fuel cell

ActiveCN106684407AImprove utilization efficiencyOptimizing effective hydrogen releaseFuel cellsControl systemHydrogen fuel cell

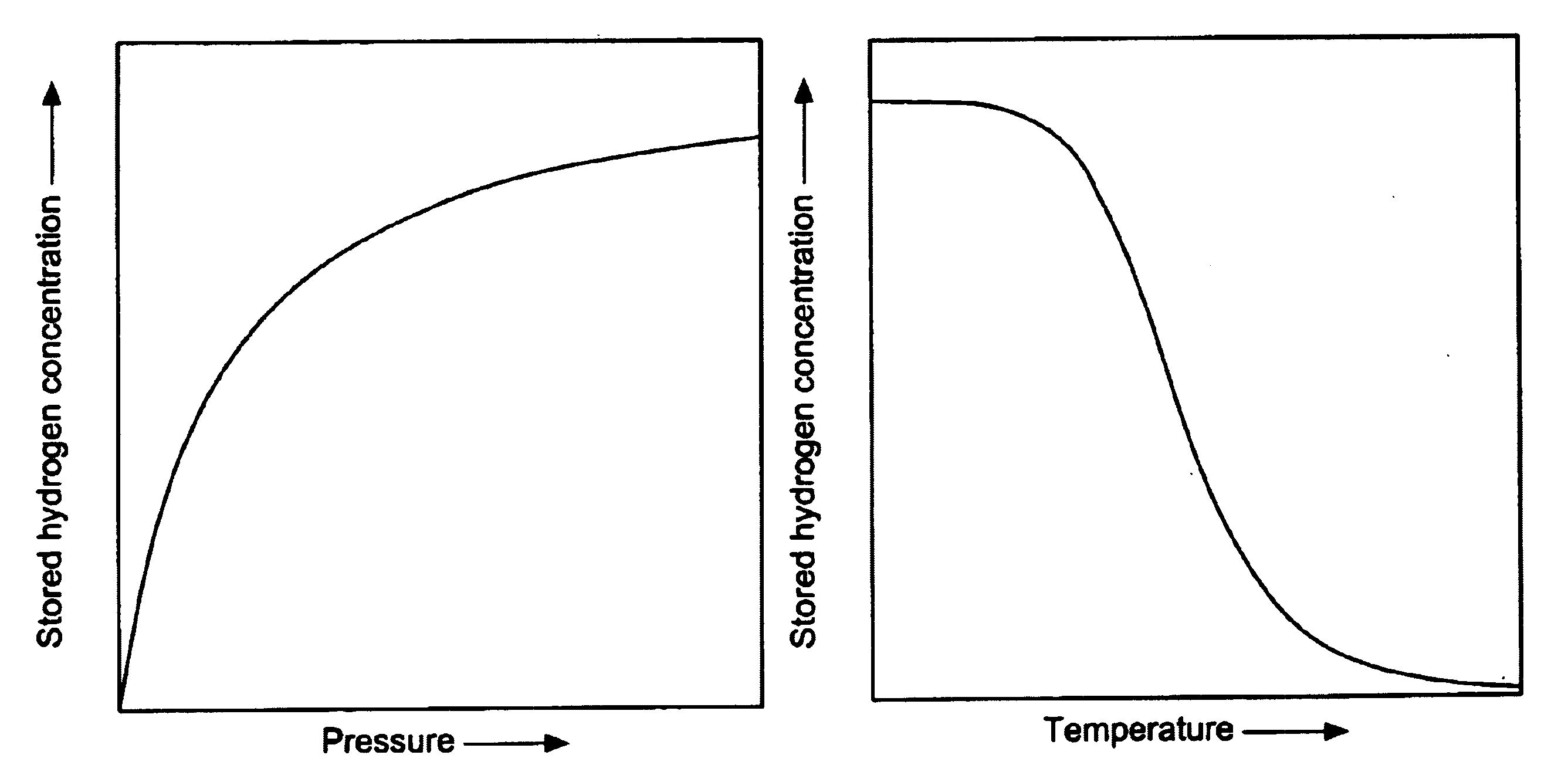

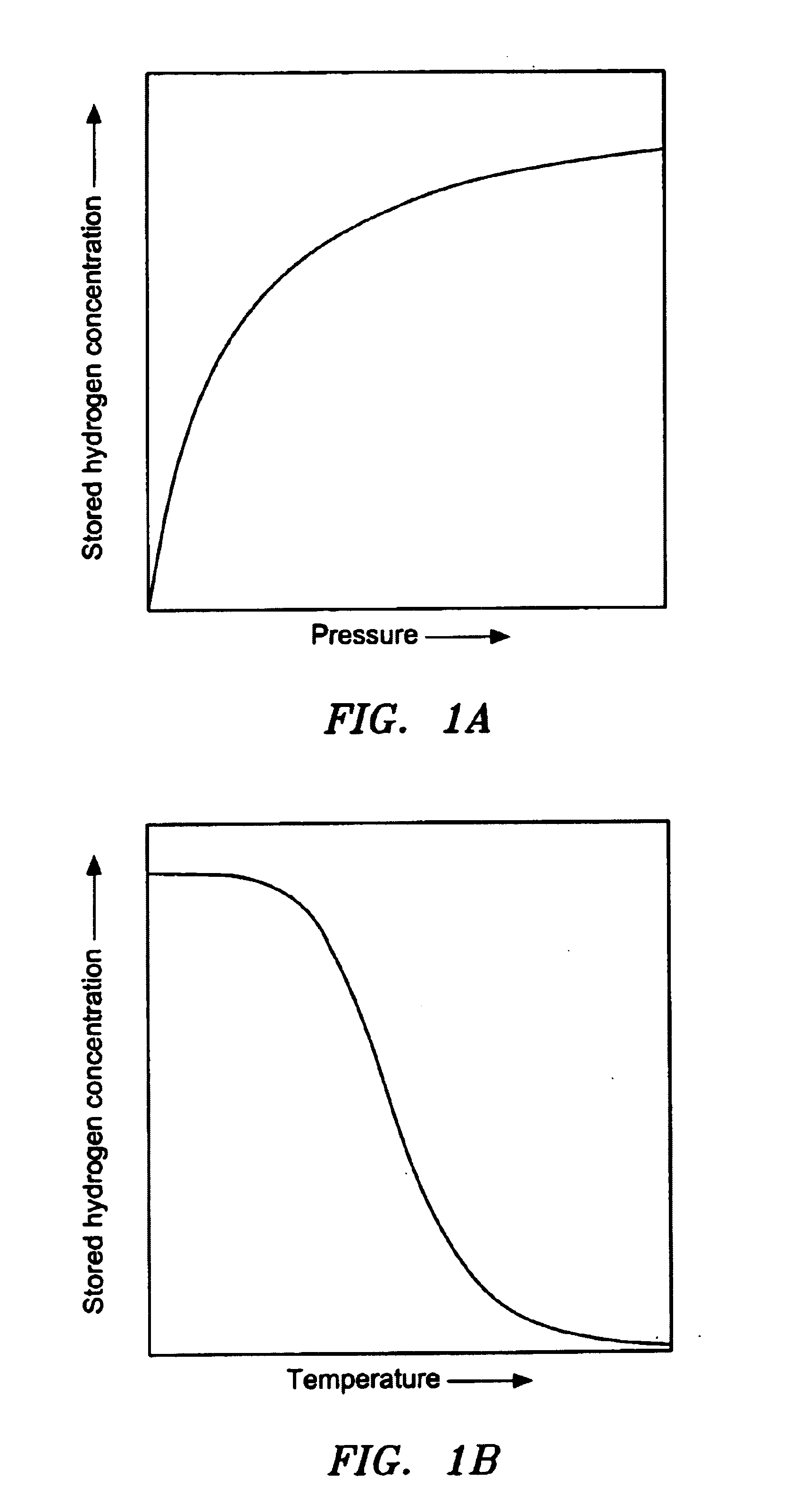

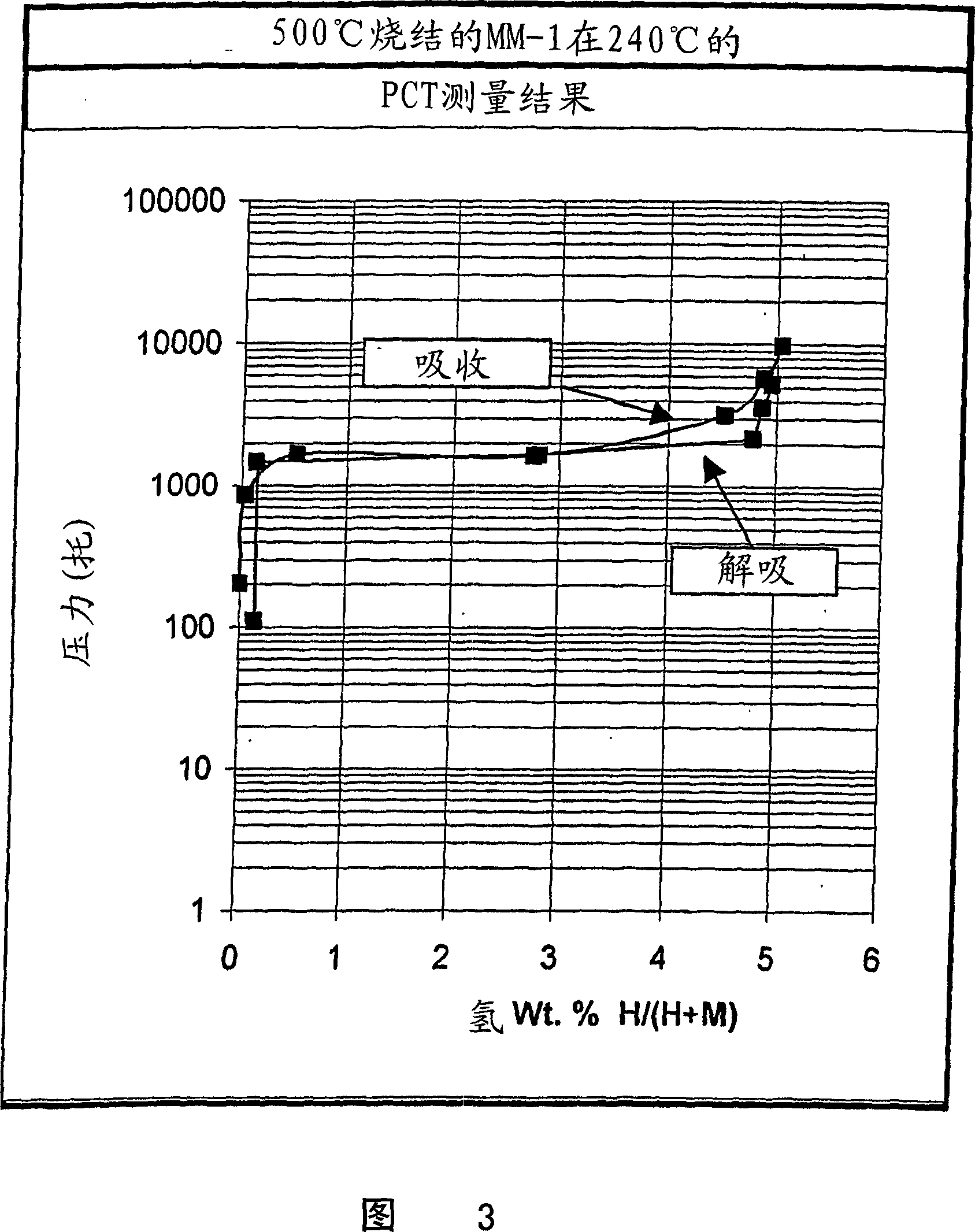

The invention belongs to the technical and control field of fuel cells, and in particular relates to a system and method for controlling and optimizing hydrogen utilization factor of an alloy hydrogen-storage fuel cell. The problem that a large amount of hydrogen reserves are wasted since the effective hydrogen utilization efficiency of an alloy hydrogen-storage tank cannot achieve the optimal is solved. The invention provides a system and method for controlling and optimizing hydrogen utilization factor of an alloy hydrogen-storage fuel cell. The system comprises an alloy hydrogen-storage unit, a fuel cell unit d, a temperature distribution computing unit m, a central control system I, a power acquirer h, a power consumption loading unit g and a DC / AC inverter f. The optimal hydrogen desorption temperature and the heat required for maintaining the temperature are computed through a hydrogen desorption PCT curve of the hydrogen-storage alloy and the heat conductivity of a hydrogen-storage alloy powder block body, and then the heat supply of a fuel cell radiation system is adjusted to warm the hydrogen-storage alloy tank, the effective hydrogen desorption amount of the alloy hydrogen-storage tank is maximally optimized, and the hydrogen utilization efficiency is greatly improved.

Owner:GRIMAT ENG INST CO LTD

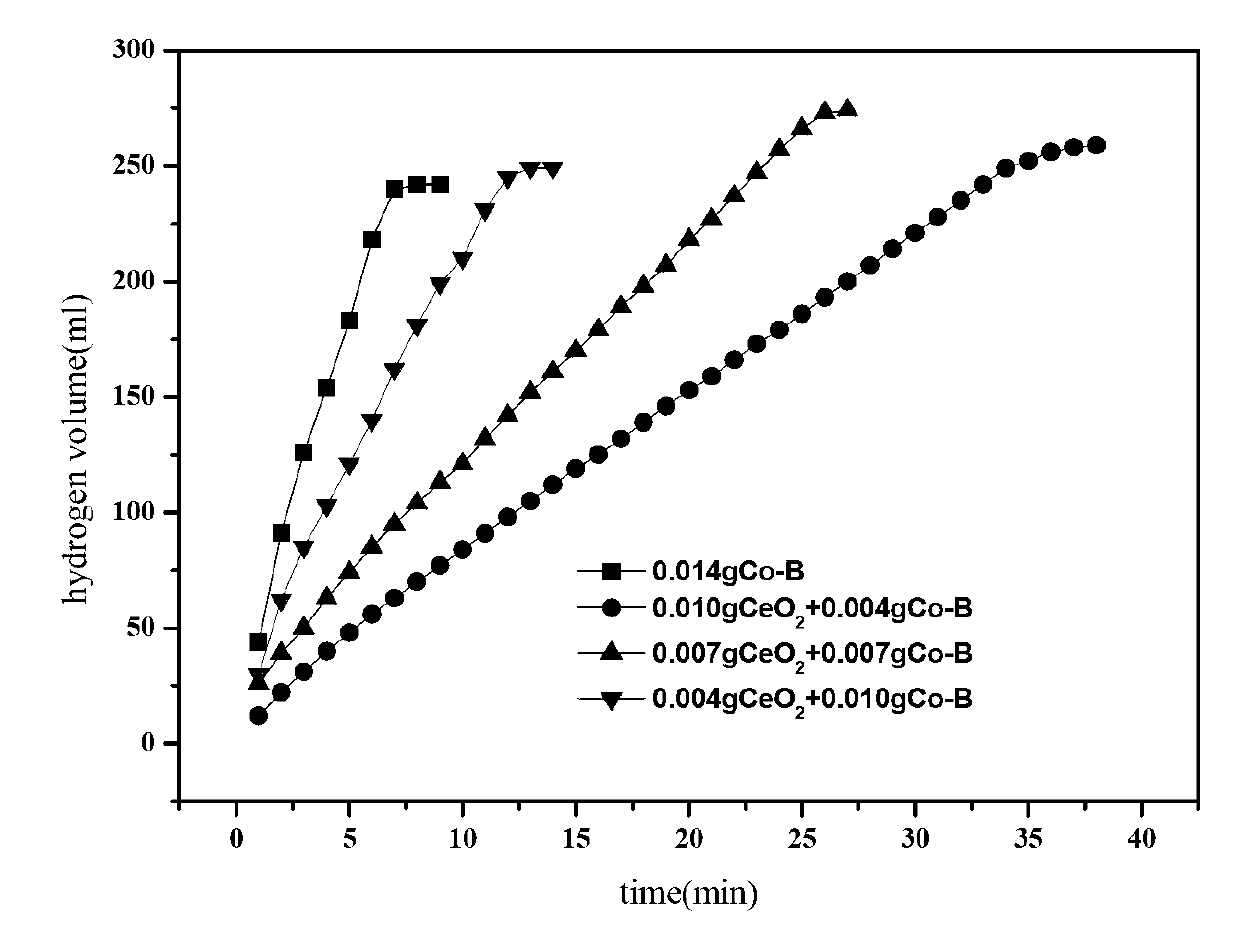

Method for increasing hydrogen desorption capacity by sodium borohydride through hydrolysis

InactiveCN103130182ASimple methodHigh hydrogen releaseHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsRare earthHydrogen desorption

The invention provides a method for increasing hydrogen desorption capacity by sodium borohydride through hydrolysis, which is characterized in that a Co-B catalyst and a rare earth oxide are uniformly stirred to obtain a mixture by a glass rod, the mass fraction of the rare earth oxide in the mixture is 25-75%, and then the mixture is added in a sodium borohydride alkaline aqueous solution. According to the invention, the mixture of Co-B catalyst and the rare earth oxide are performed with hydrogen desorption reaction by sodium borohydride through hydrolysis, the method is simple, and the hydrogen desorption capacity is obviously increased.

Owner:CHANGAN UNIV

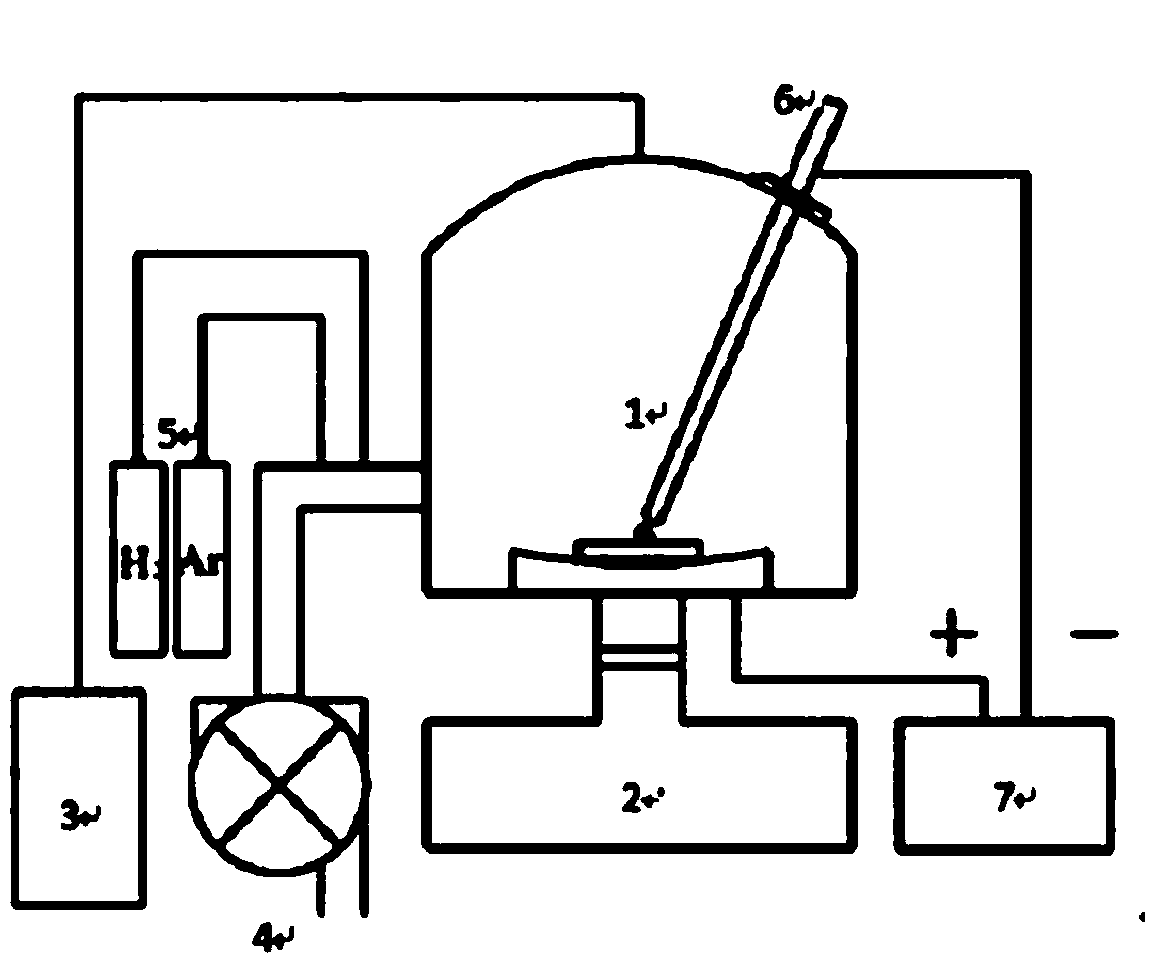

Magnesium base composite hydrogen storage material and preparation method thereof

ActiveCN103658641ALow costSimple and controllable electric arc pulverizationCoatingsDelayed reactionHydrogen desorption

The invention discloses a magnesium base composite hydrogen storage material. The magnesium base composite hydrogen storage material is of a core-shell structure, wherein the core is magnesium ultrafine powder particles and is placed inside the magnesium base composite hydrogen storage material, and the shell is made of transition metal and is placed on the outer layer of the magnesium base composite hydrogen storage material. The invention further discloses a preparation method of the magnesium base composite hydrogen storage material. The method includes the following steps that magnesium metal is melted and evaporated and then is cooled, so that the magnesium ultrafine powder particles are obtained; the magnesium ultrafine powder particles and transition metal kations undergo a replacement reaction, and the transition metal coats the magnesium ultrafine powder particles to be turned into the magnesium base composite hydrogen storage material. Raw materials for preparing the magnesium ultrafine powder particles are magnesium blocks, cost is low, an electric arc powder process and a replacement coating process are simple and controllable, meanwhile, the productive rate is high, and the magnesium base composite hydrogen storage material is suitable for large-scale industrial production; the magnesium base composite hydrogen storage material can form the good core-shell structure, and is good in hydrogen storage dynamics performance, stable in hydrogen absorption and desorption platform, small in delayed reaction, high in hydrogen absorption speed and low in hydrogen desorption temperature.

Owner:SHANGHAI MG POWER TECH CO LTD

Onboard hydrogen storage unit with heat transfer system for use in a hydrogen powered vehicle

InactiveUS20050139493A1Reversible hydrogen uptakeGas handling applicationsProcess engineeringHydrogen desorption

An onboard hydrogen storage unit with heat transfer system for a hydrogen powered vehicle. The system includes a hydrogen storage vessel containing a hydrogen storage alloy configured to receive a stream of hydrogen and provide hydrogen for use in powering a vehicle. During refueling a cooling / heating loop is used to remove the heat of hydride formation from the hydrogen storage alloy and during operation of the vehicle the heating / cooling loop is used to supply heat to the hydrogen storage alloy to aid in hydrogen desorption.

Owner:VODIK LABS LLC +1

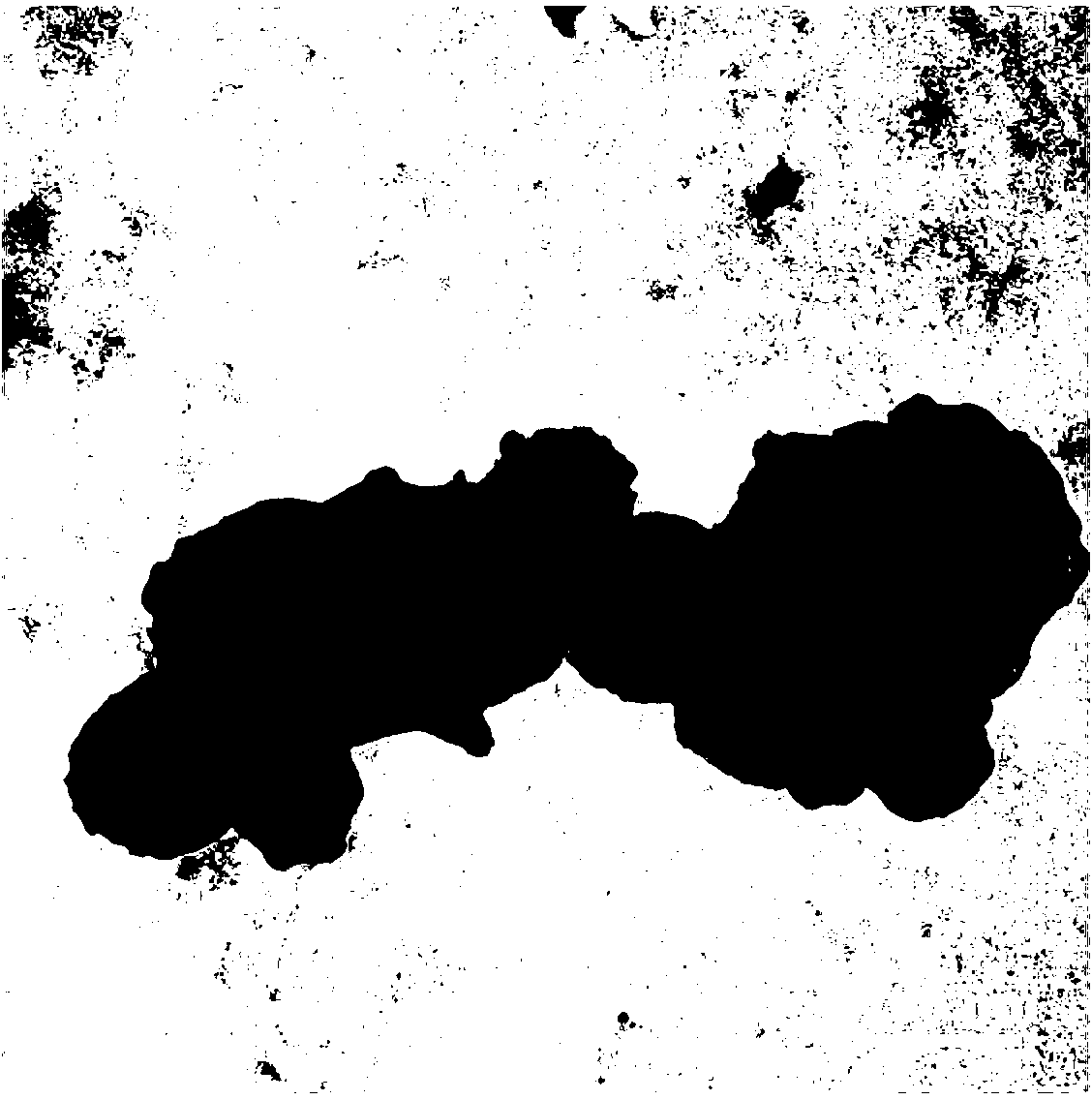

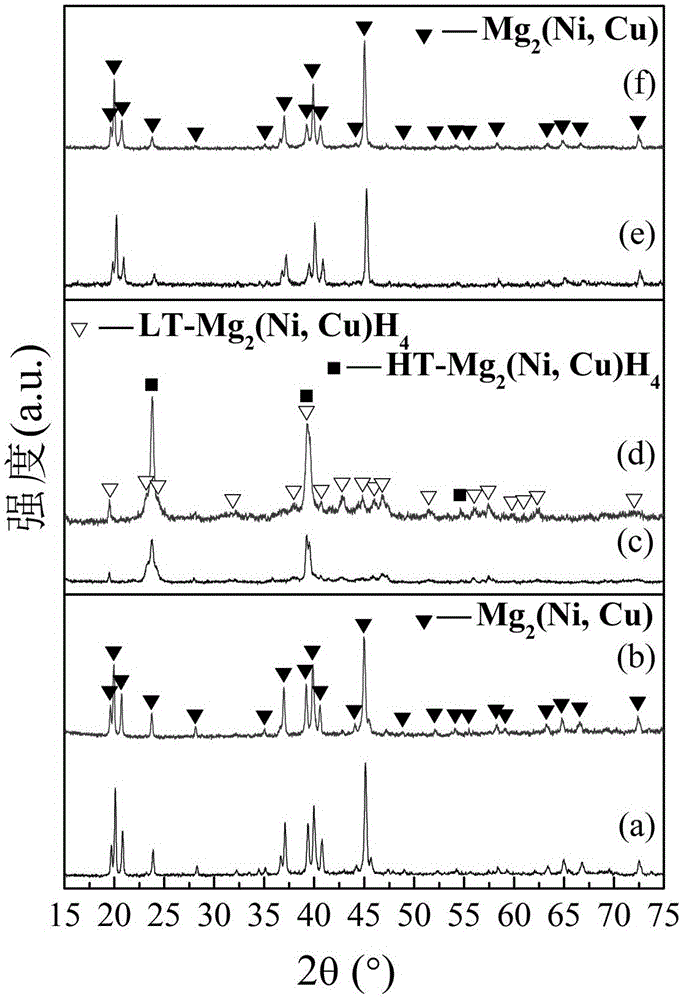

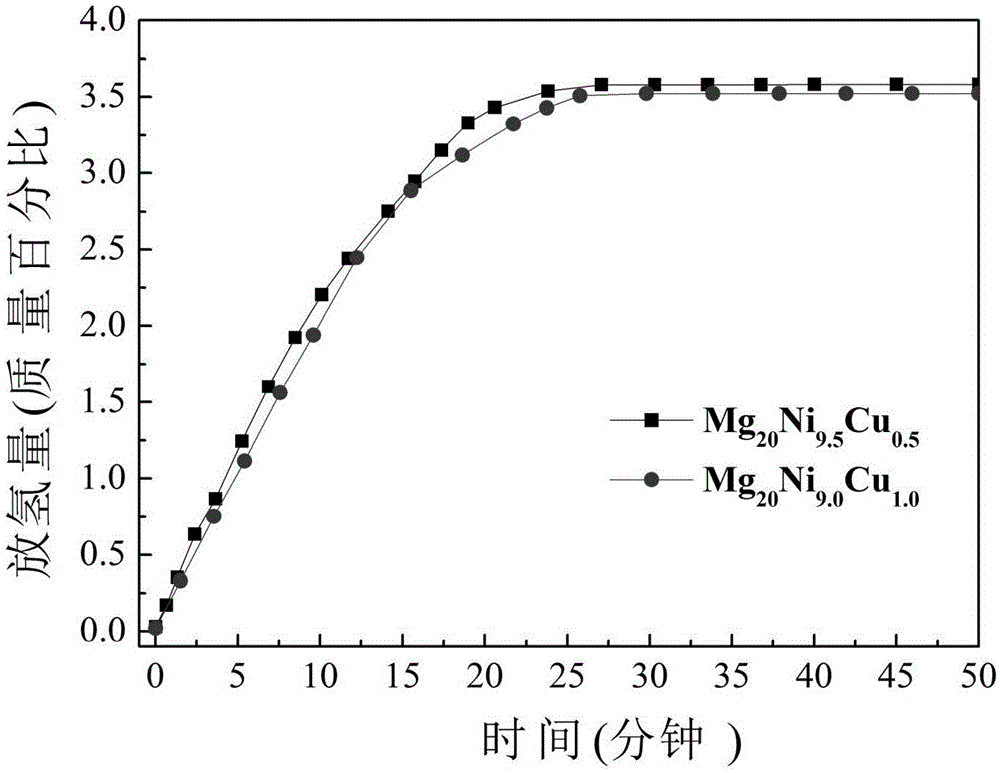

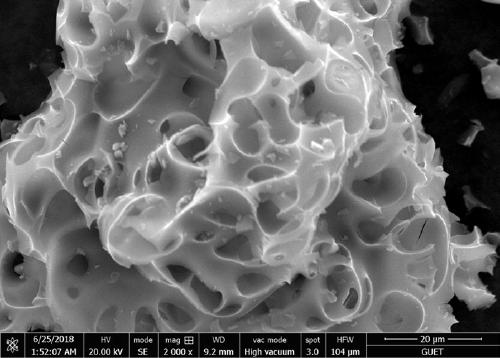

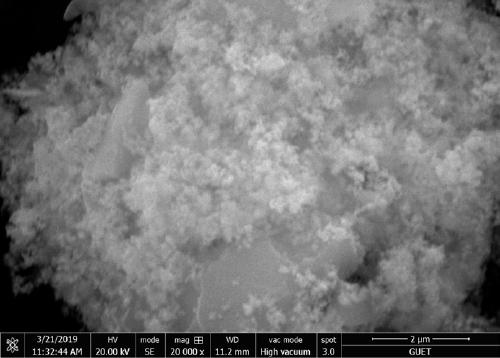

Mg2Ni-based ternary Mg-Ni-Cu reversible hydrogen storage material and preparation method thereof

ActiveCN105132770AHigh hydrogen storage capacityGood low temperature hydrogen desorption kineticsHydrogen desorptionSolid solution

The invention discloses a Mg2Ni-based ternary Mg-Ni-Cu reversible hydrogen storage material and a preparation method thereof, and belongs to the technical field of hydrogen storage. According to the composition range of the hydrogen storage material, Mg accounts for 66.7% in alloy atoms, Ni and Cu account for 33.3% in the alloy atoms, Cu accounts for 0-12% in Ni and Cu atoms, and the purity of raw materials is not lower than 99.5%. According to the method, Ni(Cu) solid solution powder high in chemical stability is prepared firstly, and then the solid solution powder and Mg powder are mixed and sintered according to a proportion to obtain the Mg2Ni-based ternary Mg20Ni10-xCux reversible hydrogen storage material high in purity, wherein x is larger than 0 and smaller than or equal to 1.2. The material is high in hydrogen storage capacity (larger than 3.5 wt%) and good in low-temperature hydrogen desorption kinetics performance. Cu replaces Ni being precious metal, so that the material use cost is lowered. The preparation method has the remarkable advantages that the process is gentle, simple and easy to control, the production equipment is low in cost, the production process is free of pollution and industrial mass production is easy to achieve.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Nitrogen-doped porous carbon material supporting CoB nanoparticles, preparation method and application thereof

ActiveCN110124721AChange catalytic performanceUniform pore size distributionCatalyst activation/preparationHydrogen productionActivation methodHydrogen

The invention discloses a nitrogen-doped porous carbon material loaded with CoB nanoparticles. A nitrogen-containing compound is added to a porous carbon material, and the irregular spherical nitrogen-doped porous carbon material is produced by a hydrothermal method, an activation method and a high-temperature heat treatment method; and then CoB is supported on the nitrogen-doped porous carbon material by an in-situ reduction method to obtain the nitrogen-doped porous carbon material loaded with CoB nanoparticles. CoB nanoparticles are uniformly supported on the surface and in pores of the irregular spherical nitrogen-doped porous carbon material, the final product is in a regular spherical shape finally, the specific surface area of the final product is 1359-2524 m<2> / g, and the pore sizedistribution of the final product is 1.60-2.40 nm. The preparation method comprises the following steps: 1) preparing a nitrogen-doped porous carbon material; and 2) supporting the CoB nanoparticles.The material serves as a sodium borohydride hydrolytic hydrogen-releasing catalyst, the hydrogen desorption rate reaches 1200-2500 ml / min*g, the cycle performance is good, and the hydrogen-releasingquantity is maintained at 50-60%. The material is simple to prepare, has more excellent catalytic performance, and has a wide application prospect in the fields of application of hydrogen energy, fuelcells and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

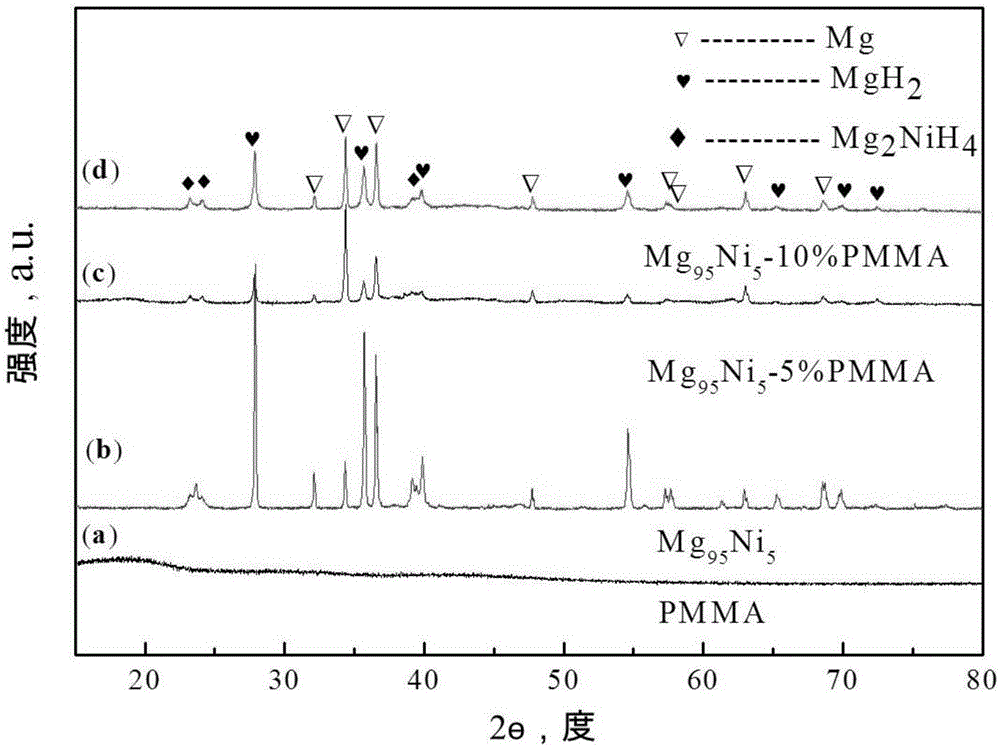

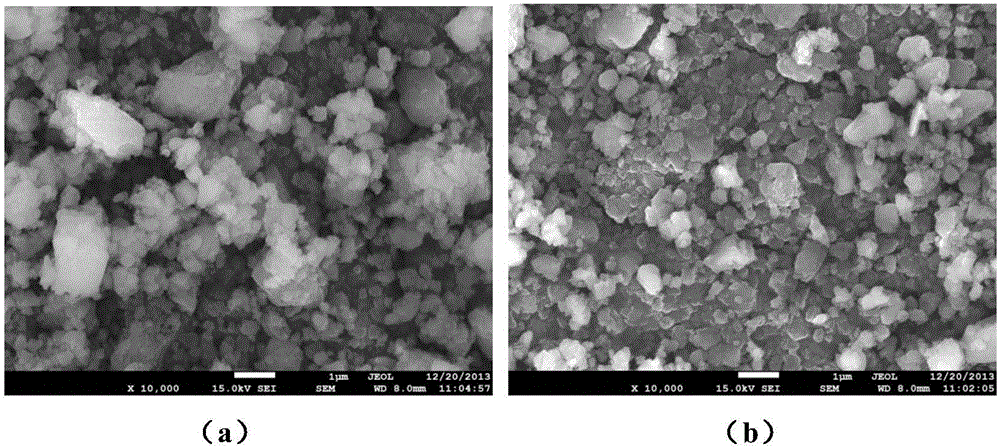

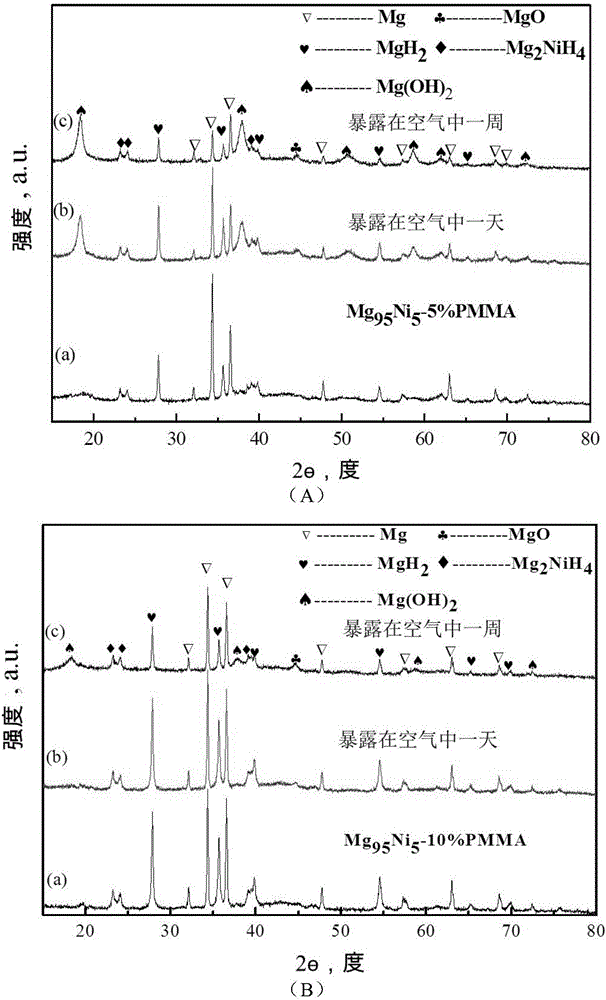

Polymer wrapped nano magnesium based hydrogen storage material and preparation method thereof

ActiveCN106566965AAnti-oxidation and chalking resistanceExcellent hydrogen absorption and desorption performance at low temperatureTransportation and packagingMetal-working apparatusMaterials preparationPolymer science

The invention relates to a polymer wrapped nano magnesium based hydrogen storage material and a preparation method thereof, and belongs to the technical field of hydrogen storage material preparation. The hydrogen storage material is prepared from the following components in percentage by weight: 80 to 98% of magnesium-nickel alloy, and 2 to 20% of polymer. Magnesium powder and nickel powder are taken as the raw materials and then are mixed and preprocessed; the mixture is hydrogenated, burned, and synthesized, and finally the product and polymers are fiercely and mechanically ball-milled to prepare the hydrogen storage material. The hydrogen storage material has excellent low temperature hydrogen absorption / desorption dynamics performances: at a temperature of 473K, the hydrogen absorption amount can reach 3.73 wt.% with 60 minutes; the hydrogen desorption amount can reach 1.02 wt.% within 120 minutes; at a temperature of 523 K, the hydrogen absorption amount is as high as 4.04 wt.% within 60 minutes, and the hydrogen desorption amount can reach 2.18 wt.% within 120 minutes. The hydrogen storage material can be used to store / transport hydrogen and prepare hydrogen fuel battery.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

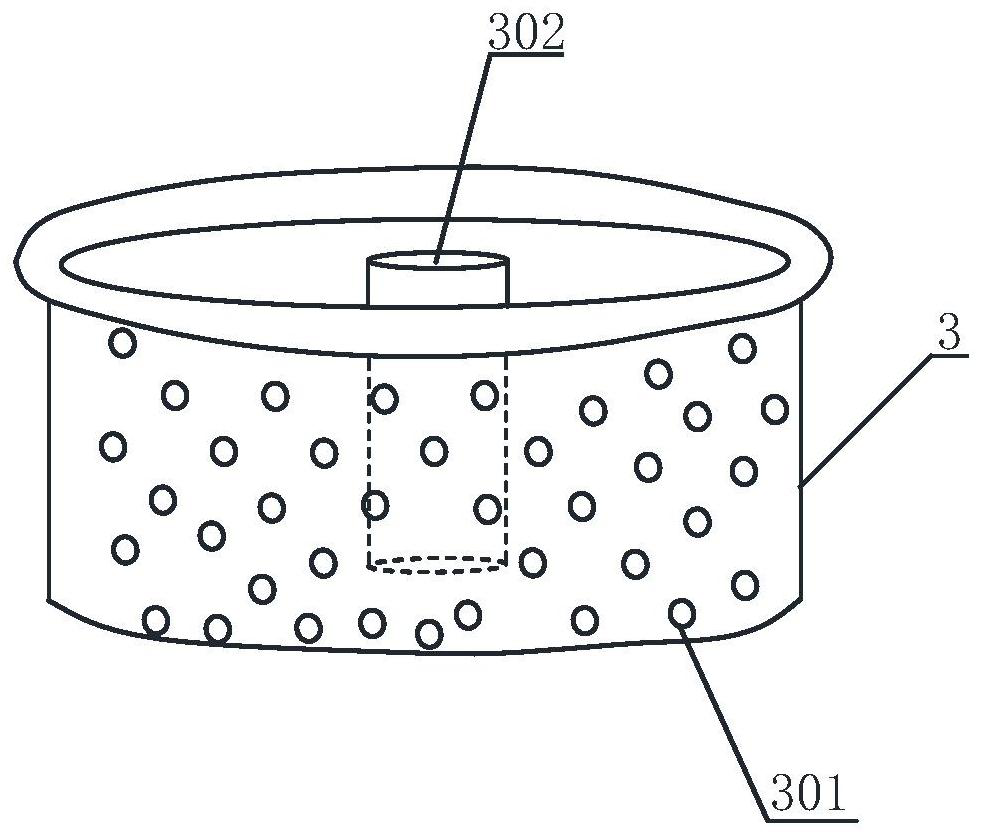

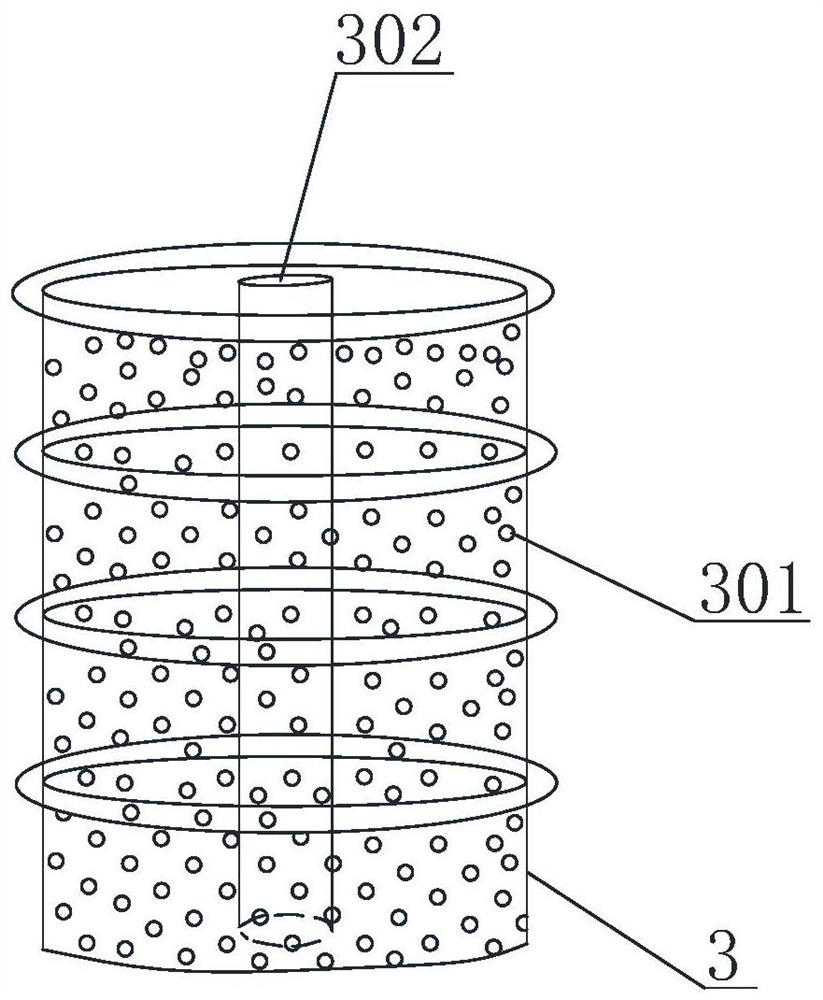

Automatic control hydrogen absorption and desorption system and method for solid hydrogen storage material

ActiveCN112082087AFast heatingEvenly heatedVessel mounting detailsVessel wallsAutomatic controlHydrogen pressure

The invention discloses an automatic control hydrogen absorption and desorption system for a solid hydrogen storage material. The automatic control hydrogen absorption and desorption system comprisesa hydrogen filling pipe section, a hydrogen desorption pipe section and a stainless steel hydrogen storage tank. The stainless steel hydrogen storage tank comprises a stainless steel tank body and a tank body cover, and a plurality of metal baskets are arranged in the stainless steel tank body. A hydrogen filling hole and a hydrogen desorption hole are formed in the left end and the right end of the tank body cover respectively, and a temperature measuring hole is formed in the middle of the tank body cover. The hydrogen filling hole is connected with a hydrogen compressor through a hydrogen filling pipeline. The hydrogen desorption hole is connected with a hydrogen desorption pipeline. A thermocouple is inserted in the temperature measuring hole, and the lower part of the thermocouple extends into a central pipe. A heat preservation layer is arranged on the outer side of the stainless steel tank body, an electromagnetic heating coil is arranged in the heat preservation layer, and theheat preservation layer and the electromagnetic heating coil form an electromagnetic heating sleeve with a heat preservation function. The hydrogen compressor and the thermocouple are respectively connected with a computer control device. The automatic control hydrogen absorption and desorption system can achieve automatic control of temperature and hydrogen pressure, can be suitable for most solid hydrogen storage materials and has a wide application range.

Owner:SHANDONG UNIV OF SCI & TECH

Meso-porous C/WO3 electro-catalyst and preparation method thereof

ActiveCN101181679ACell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon compositesHydrogen desorption

The invention provides a mesoporous C / WO3 electro-catalyst and a preparation method thereof, which pertains to inorganic energy materials field. The catalyst of the invention takes the mesoporous C / WO3 as a main body, a novel electro-catalyst is formed after loading a certain quantity of activated carbon and platinum analogs of traditional technology is not adopted. Preparation steps are that: a mesoporous WO3 of the high specific surface is prepared by hard template duplication method of silica, then the activated carbon is blended with the mesoporous WO3 in ethanol solution, and the mixture is conducted with anultrasonic dispersion process; ethanol is volatilized gradually at room temperature and the carbon composite mesoporous C / WO3 electro-catalyst is obtained. Hydrogen desorption oxidation activity of the catalyst of the invention can be compared with the existing commercial 20wt percent Pt / C activator, and preparation cost of battery activator is obviously reduced.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com