System and method for controlling and optimizing hydrogen utilization factor of alloy hydrogen-storage fuel cell

A technology of fuel cells and fuel cell units, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of reduced hydrogen discharge capacity of hydrogen storage tanks, unusable hydrogen storage capacity, and reduced fuel cell power, achieving simple system, The effect of optimizing the effective hydrogen release amount and improving the utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A detailed description will be given below in conjunction with the accompanying drawings.

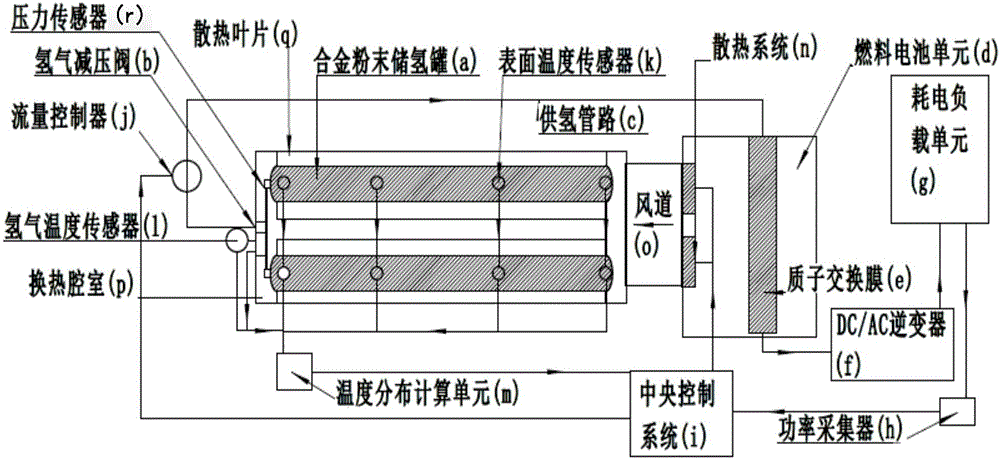

[0019] attached figure 1 Design structure diagram for alloy hydrogen storage-fuel cell power generation backup power system, such as figure 1 As shown, the system includes alloy hydrogen storage unit, fuel cell unit d, temperature distribution calculation unit m, central control system i, power collector h, power consumption load unit g, DC / AC inverter f; alloy hydrogen storage unit Including alloy powder hydrogen storage tank a, heat exchange chamber p, surface temperature sensor k, air duct o, heat dissipation blade q, hydrogen temperature sensor l, flow controller j, hydrogen pressure reducing valve b, pressure sensor r, hydrogen supply pipe Road c; fuel cell unit d including proton exchange membrane e, cooling system n; alloy powder hydrogen storage tank a, hydrogen pressure reducing valve b, hydrogen pipeline c fuel cell unit d, DC / AC inverter f, power consumption load Uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com