Magnesium base composite hydrogen storage material and preparation method thereof

A technology for hydrogen storage materials and equipment, applied in coatings and other directions, can solve the problems of poor hydrogen absorption and desorption kinetic performance, high product activity, difficult storage, activation and high use temperature, so as to achieve stable hydrogen absorption and desorption platform and good hydrogen storage. Dynamic performance, cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The high-purity magnesium used in this experiment was purchased commercially with a purity of more than 99.9%. The magnesium block was cut into regular blocks of L4cm×W4cm×H2cm with a grinding wheel cutter, and the oxide layer on the surface of the magnesium block was removed with a sand mill to be used as an anode. The preparation of magnesium-based hydrogen storage composite materials is roughly divided into two steps, 1) DC arc method to prepare magnesium ultrafine powder; 2) liquid phase reduction method to prepare magnesium-based composite hydrogen storage materials. Both ferric chloride and n-butanol in the liquid phase method are commercially purchased with a purity of more than 99.5%.

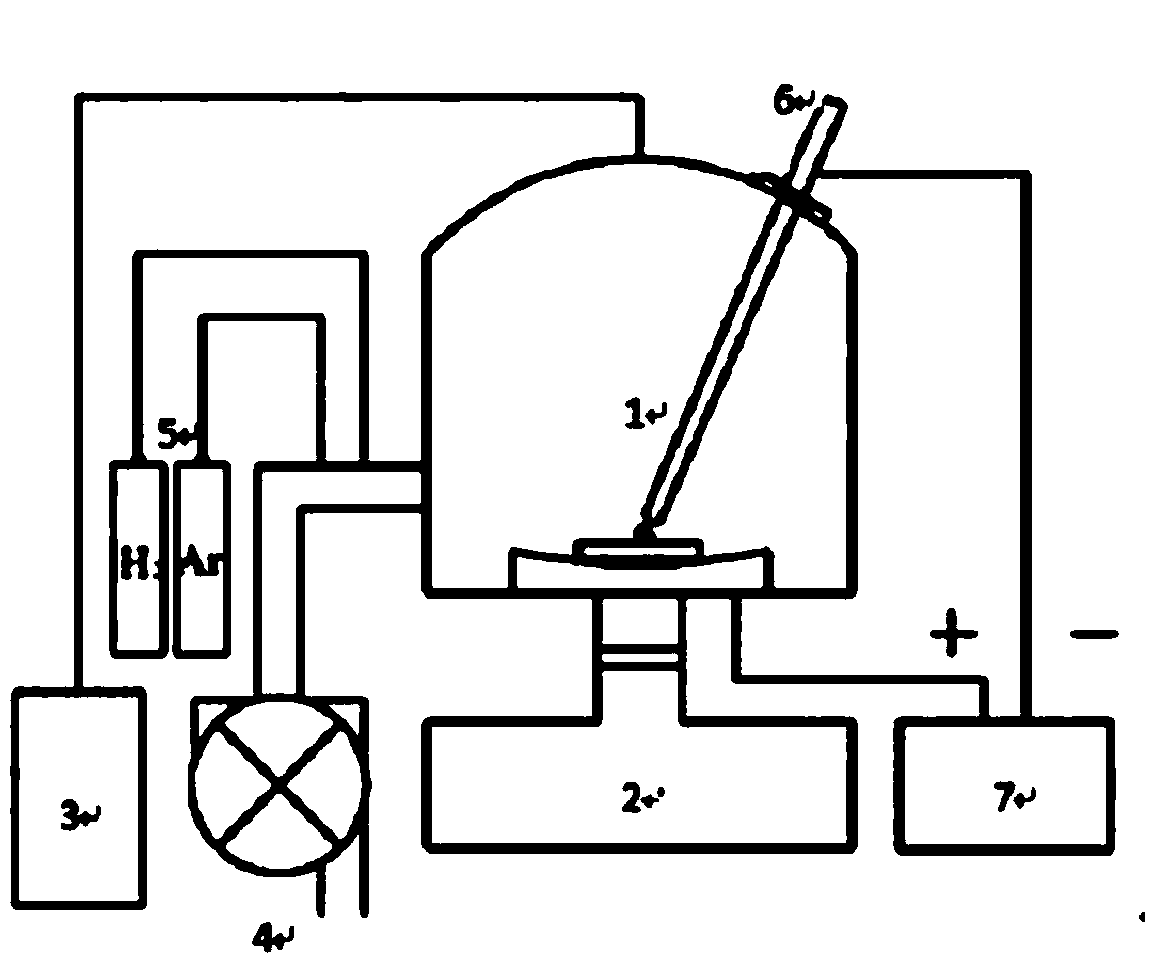

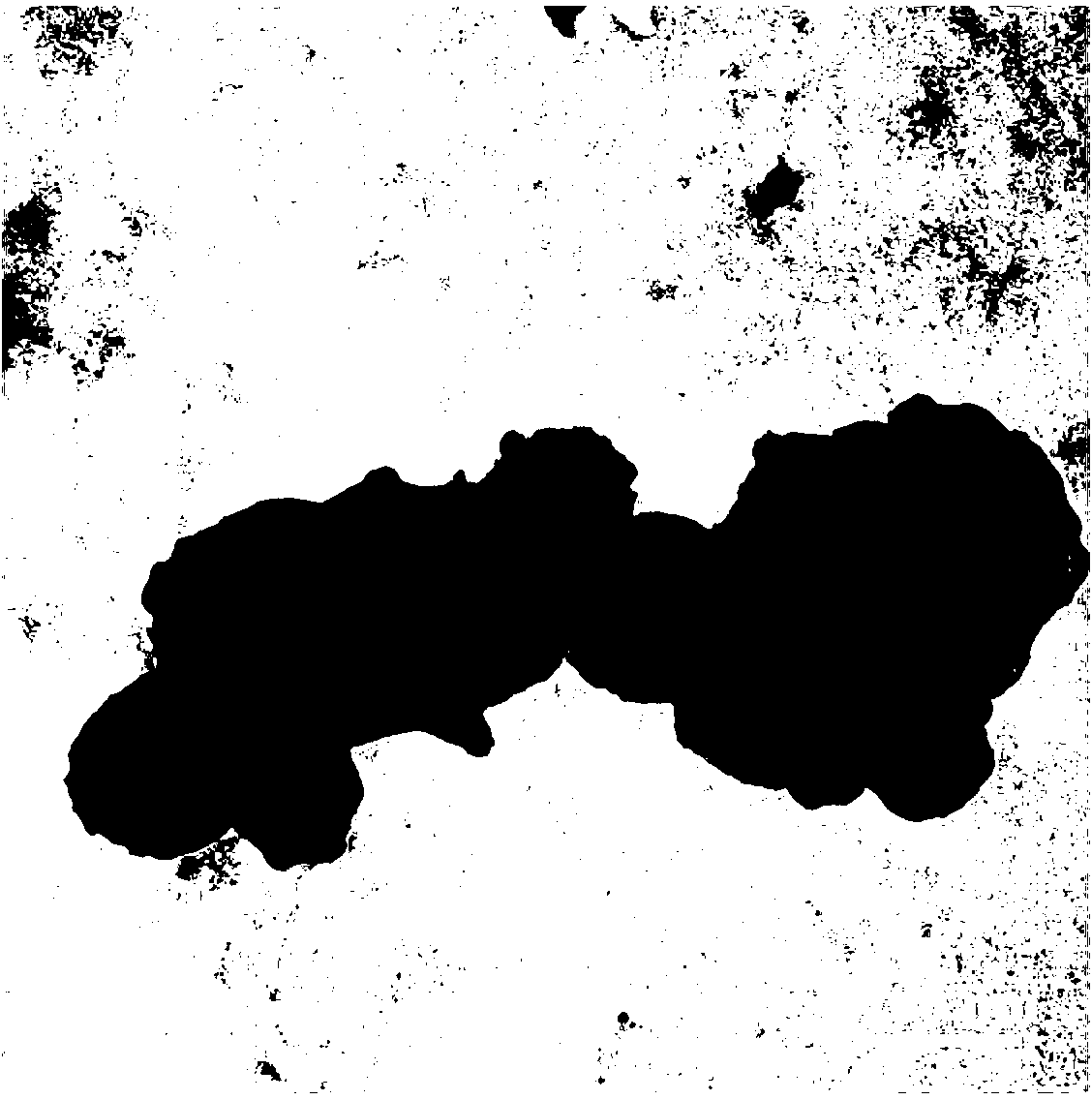

[0045] (1) A method for preparing the magnesium ultrafine powder: a high-purity magnesium block is used as an anode, and a tungsten rod is used as a cathode. Placed in DC arc plasma equipment, when the equipment is pumped to a vacuum of 5×10 -2 Pa, filled with argon to 0.7atm, a...

Embodiment 2

[0049] The method for preparing ultrafine magnesium powder in this experiment is basically the same as that in Example 1. For specific operations, please refer to the relevant parts of Example 1. The following describes the preparation of Mg-Ni composite hydrogen storage materials by liquid phase reduction. Nickel chloride hexahydrate and n-butanol in the liquid phase method are commercially purchased, and the purity is above 99.5%.

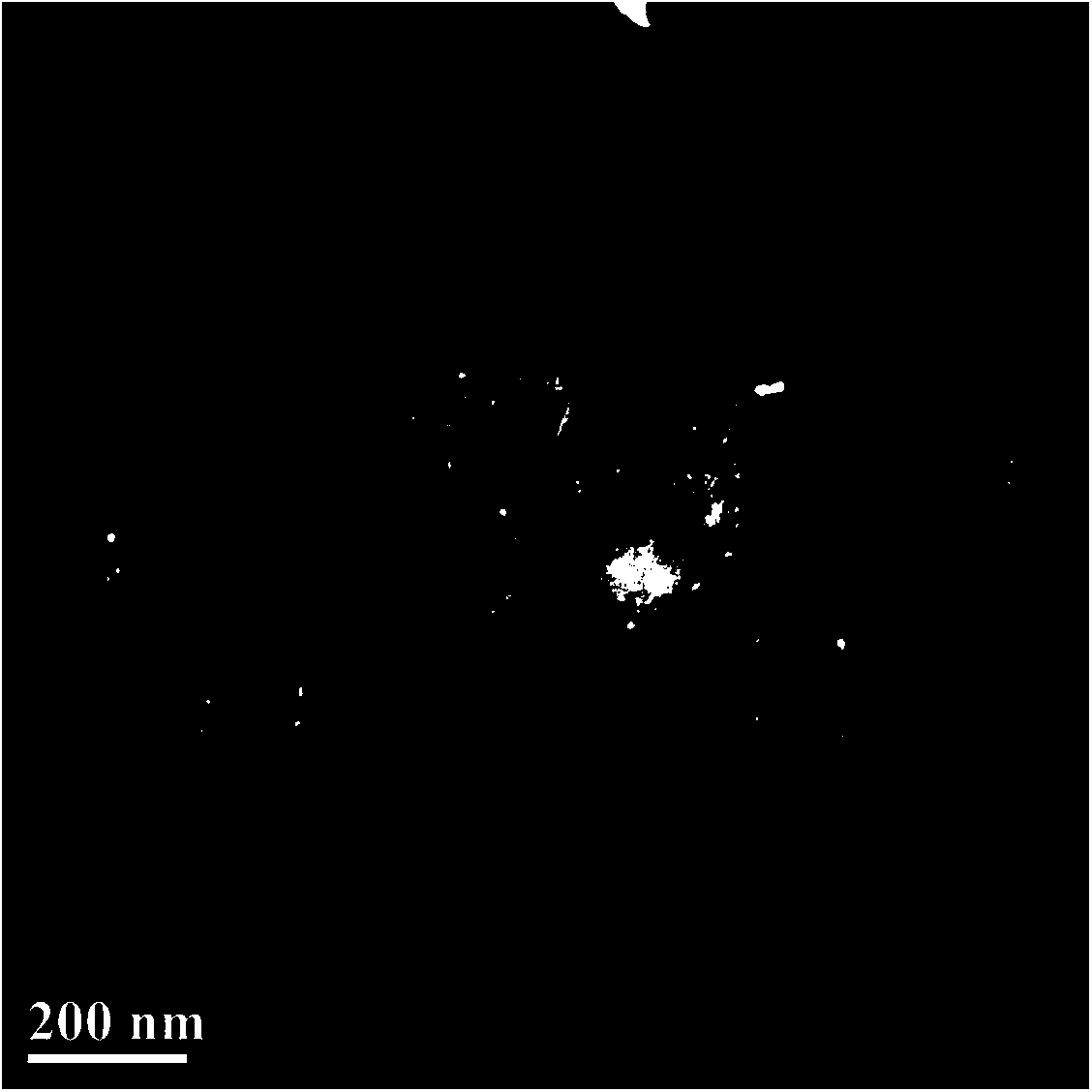

[0050] A method for preparing magnesium-based ultra-fine Mg-Ni composite material through magnesium ultra-fine powder: 0.16gNiCl 2 ·6H 2 O was added to 60mL n-butanol, for the convenience of NiCl 2 ·6H 2 O is dissolved, the solution is magnetically stirred at a speed of 800rpm, and heated to 65°C. After the compound is completely dissolved, 0.80g of the magnesium ultrafine powder is placed in the solution, in order to ensure the ultrafine powder of the cation and the magnesium. The fine powder is fully contacted and reacted, and the solution i...

Embodiment 3

[0053] The method for preparing ultrafine magnesium powder in this experiment is basically the same as that in Example 1. For specific operations, please refer to the relevant parts of Example 1. The following describes the preparation of Mg-Ti composite hydrogen storage materials by liquid phase reduction. Titanium tetrachloride and tetrahydrofuran in the liquid phase method are commercially purchased, and the purity is above 99.5%.

[0054] A method for preparing magnesium-based ultrafine Mg-Ti composite materials through magnesium ultrafine powder: 60μL TiCl 4 Add 60mL tetrahydrofuran, for the convenience of TiCl 4 Dissolve, stir the solution magnetically at a speed of 500rpm, and heat to 60°C. After the compound is completely dissolved, put 0.70g of the magnesium ultrafine powder into the solution. In order to ensure the cation and magnesium ultrafine powder The solids are fully contacted and reacted, and the solution is also magnetically stirred and heated, the stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com