Composite hydrogen storage material and preparation method thereof

A technology of hydrogen storage materials and raw materials, which is applied in the field of composite hydrogen storage materials and its preparation, can solve the problem of low hydrogen release, achieve the effects of improving hydrogen storage performance, good hydrogen storage performance, and shortening the distance of atomic diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

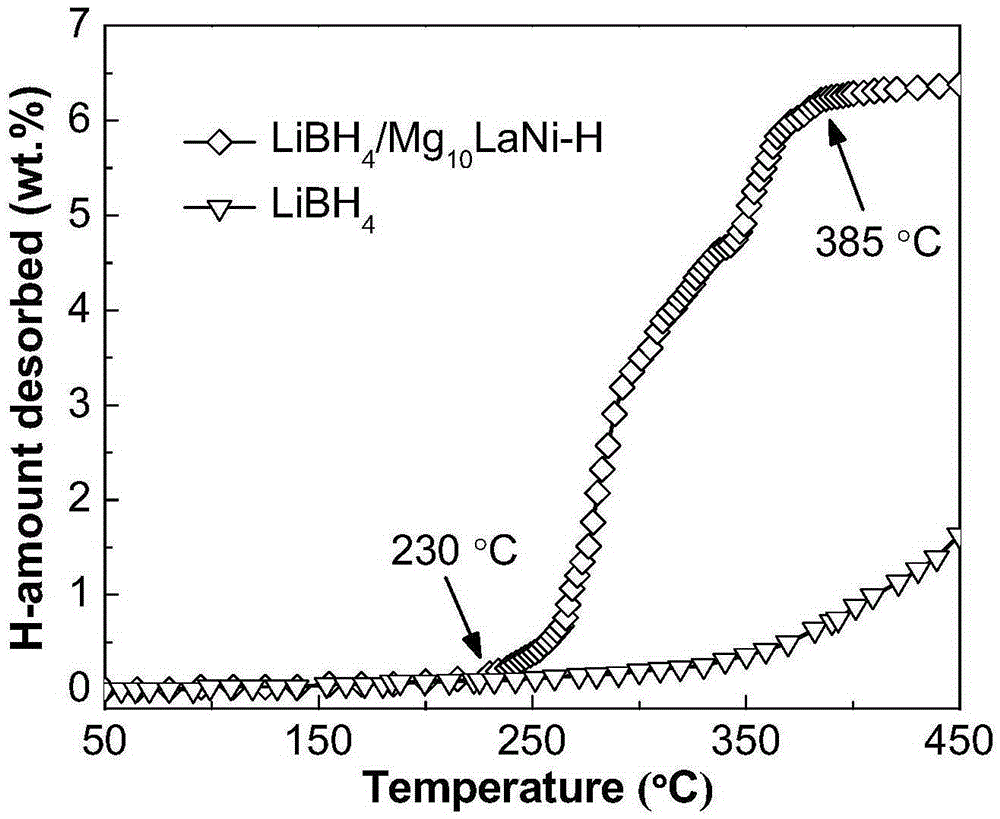

Embodiment 1

[0022] According to Mg 10 The composition of LaNi weighs magnesium block (purity 99%, add 18wt.% more burning loss), lanthanum block (purity 99.5%, add 3wt.% more burning loss) and nickel sheet (purity 99.5%), and use induction The method of smelting melts the weighed magnesium block, lanthanum block and nickel sheet into an alloy, and further adopts the method of stripping (the edge stripping speed of the copper roller is 40m / s) to obtain amorphous Mg 10 LaNi alloy. amorphous Mg 10 After the LaNi alloy is ground into 100-mesh alloy powder, it is ball milled under 1MPa hydrogen pressure for 2h (ball-to-material ratio 30:1, speed 400rpm), and then heated to 250°C under 3.5MPa hydrogen pressure and kept for 4h to obtain amorphous Mg 10 LaNi alloy hydride. Weigh lithium borohydride and amorphous Mg according to the molar ratio of 7:1 10 LaNi alloy hydride powder, and mix uniformly, can obtain described lithium borohydride / Mg 10 LaNi hydride composite hydrogen storage materia...

Embodiment 2

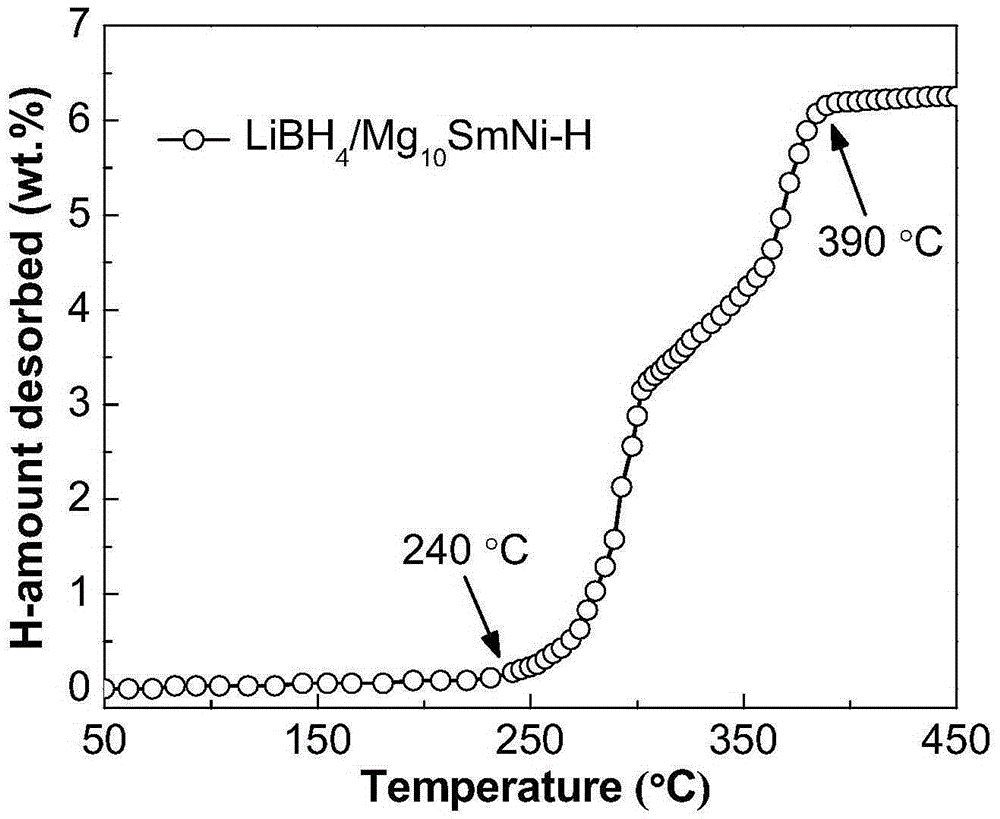

[0024] According to Mg 10 The components of SmNi were weighed respectively magnesium block (purity 99%, add 18wt.% more burning loss), samarium block (purity 99.5%, add 3wt.% more burning loss) and nickel sheet (purity 99.5%), using induction The method of smelting melts the weighed magnesium block, samarium block and nickel sheet into an alloy, and further adopts the method of stripping (the edge stripping speed of the copper roller is 40m / s) to obtain amorphous Mg 10 SmNi alloy. amorphous Mg 10 After the SmNi alloy is ground into 100-mesh alloy powder, it is ball-milled under 0.5MPa hydrogen pressure for 5h (ball-to-material ratio 30:1, speed 400rpm), and then heated to 250°C under 3.5MPa hydrogen pressure and kept for 2h to obtain amorphous Mg 10 SmNi alloy hydride. Weigh lithium borohydride and amorphous Mg according to the molar ratio of 6.5:1 10 SmNi alloy hydride powder, and mix evenly, can obtain described lithium borohydride / Mg 10 SmNi hydride composite hydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com