Patents

Literature

35results about How to "Reduce particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

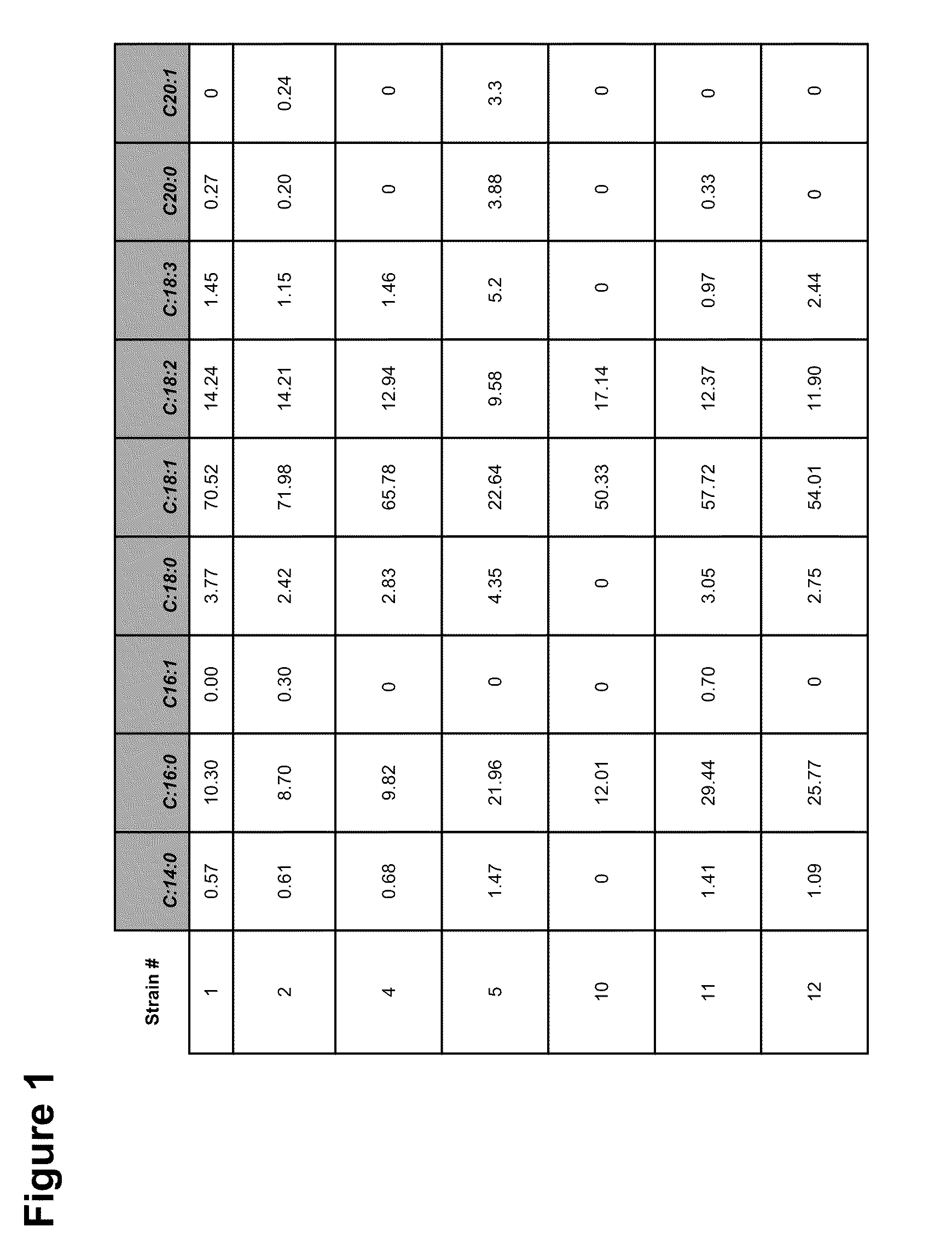

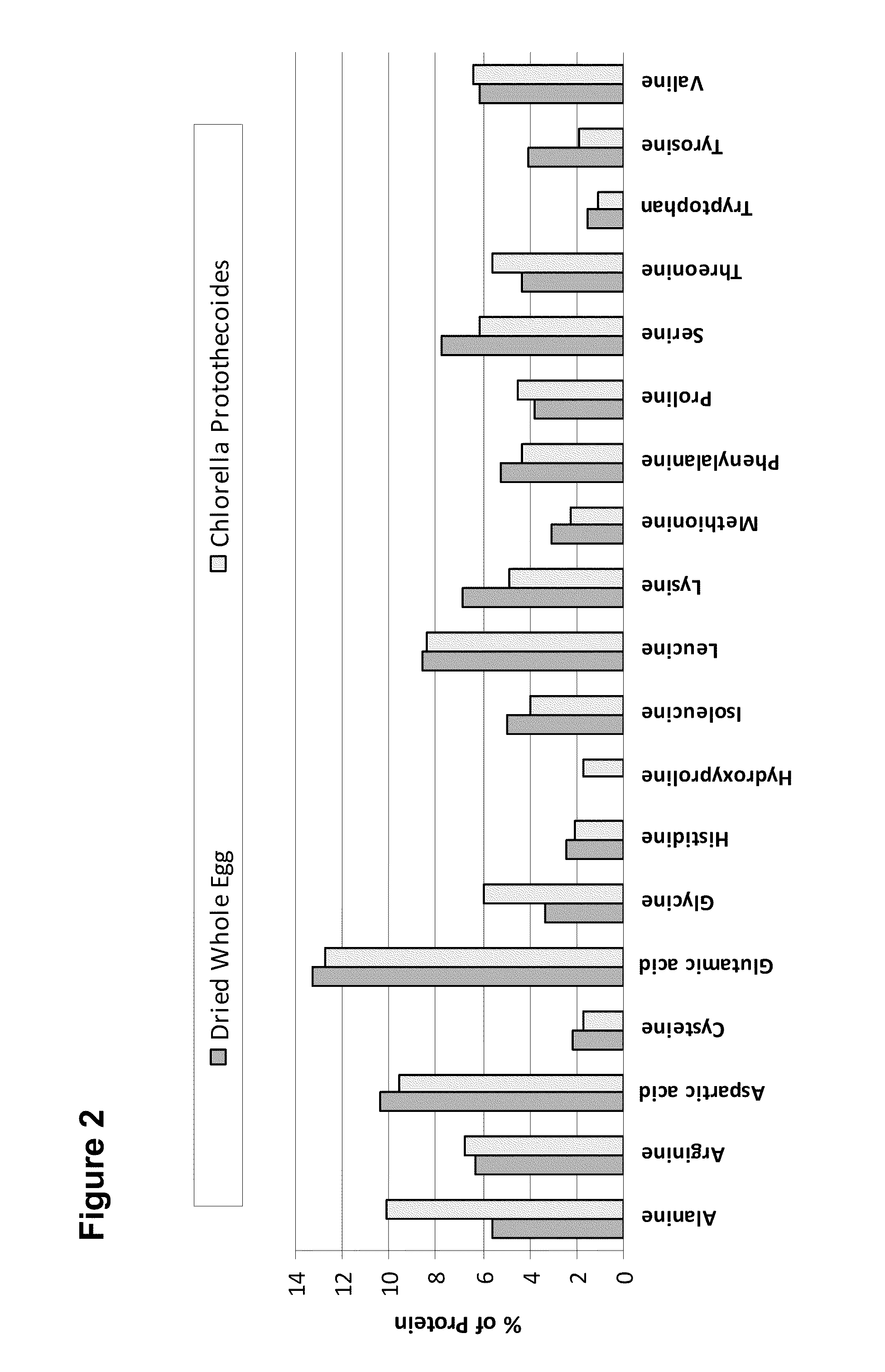

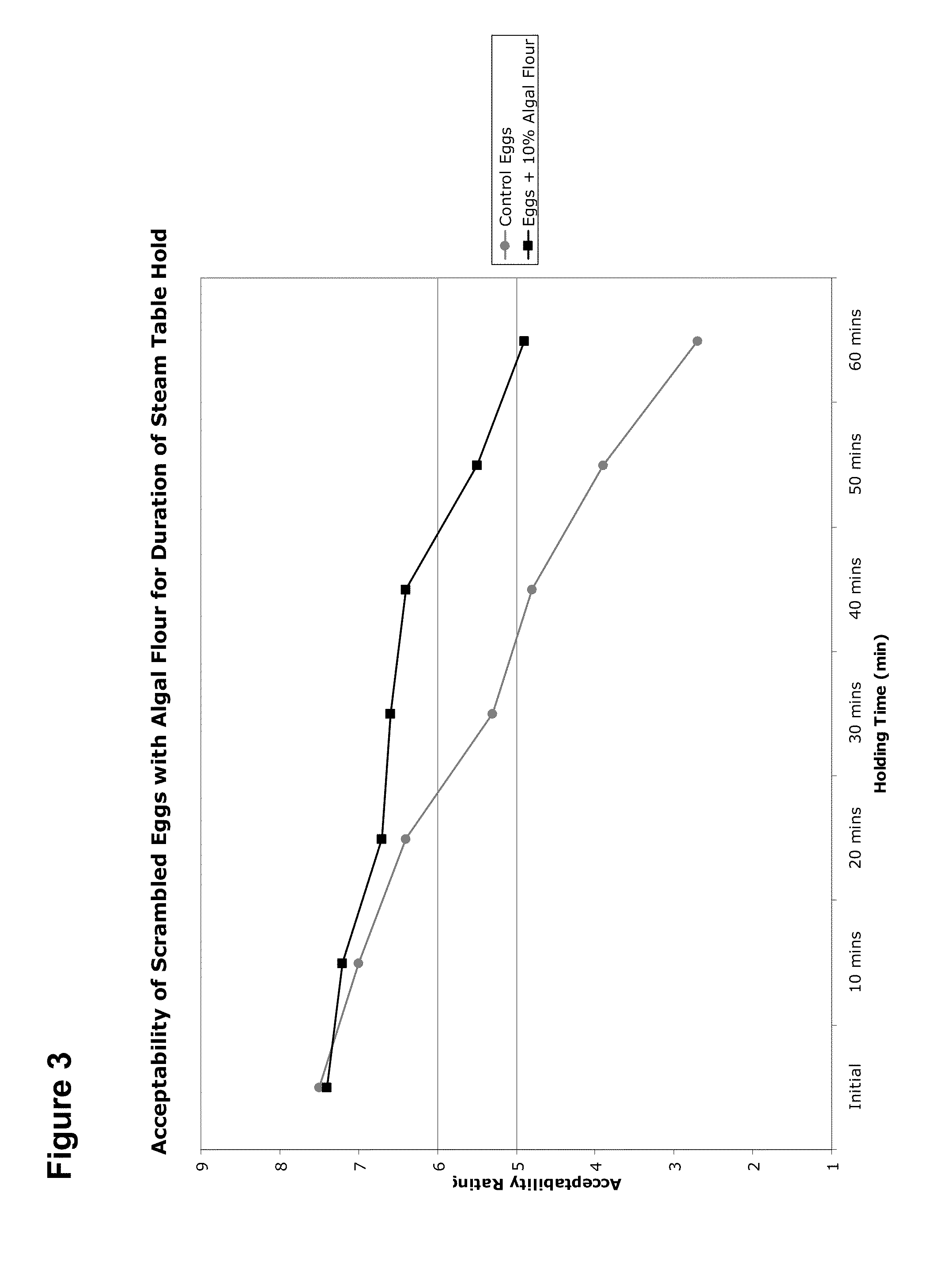

Microalgal Flour

InactiveUS20100303989A1Reduce particle sizeReduce color pigmentationDough treatmentSpread compositionsEmulsionFat replacement

Compositions of microalgae-derived flour are disclosed from multiple genera, species, and strains of edible microalgae. Microalgae used in the invention are free of algal toxins and contain varying levels of primarily monounsaturated triglyceride oil. Flours disclosed herein are formulated as free flowing blendable powders, mixed food ingredients, oxidation stabilized, homogenized and micronized, and combinations therein. Flours disclosed herein also form self stabilizing emulsions in slurries with manageable viscosities. Innovative methods of formulating flours and incorporating them into food compositions are also disclosed. The invention also comprises flours with significant digestible protein and unique dietary fiber content and associated water binding, texturizing, and healthy oil delivery attributes. Novel methods of oil and fat replacement using flours of the invention are also disclosed. Flours of the invention can be manufactured from edible and inedible heterotrophic fermentation feedstocks, including corn starch, sugar cane, glycerol, and depolymerized cellulose.

Owner:CORBION BIOTECH INC

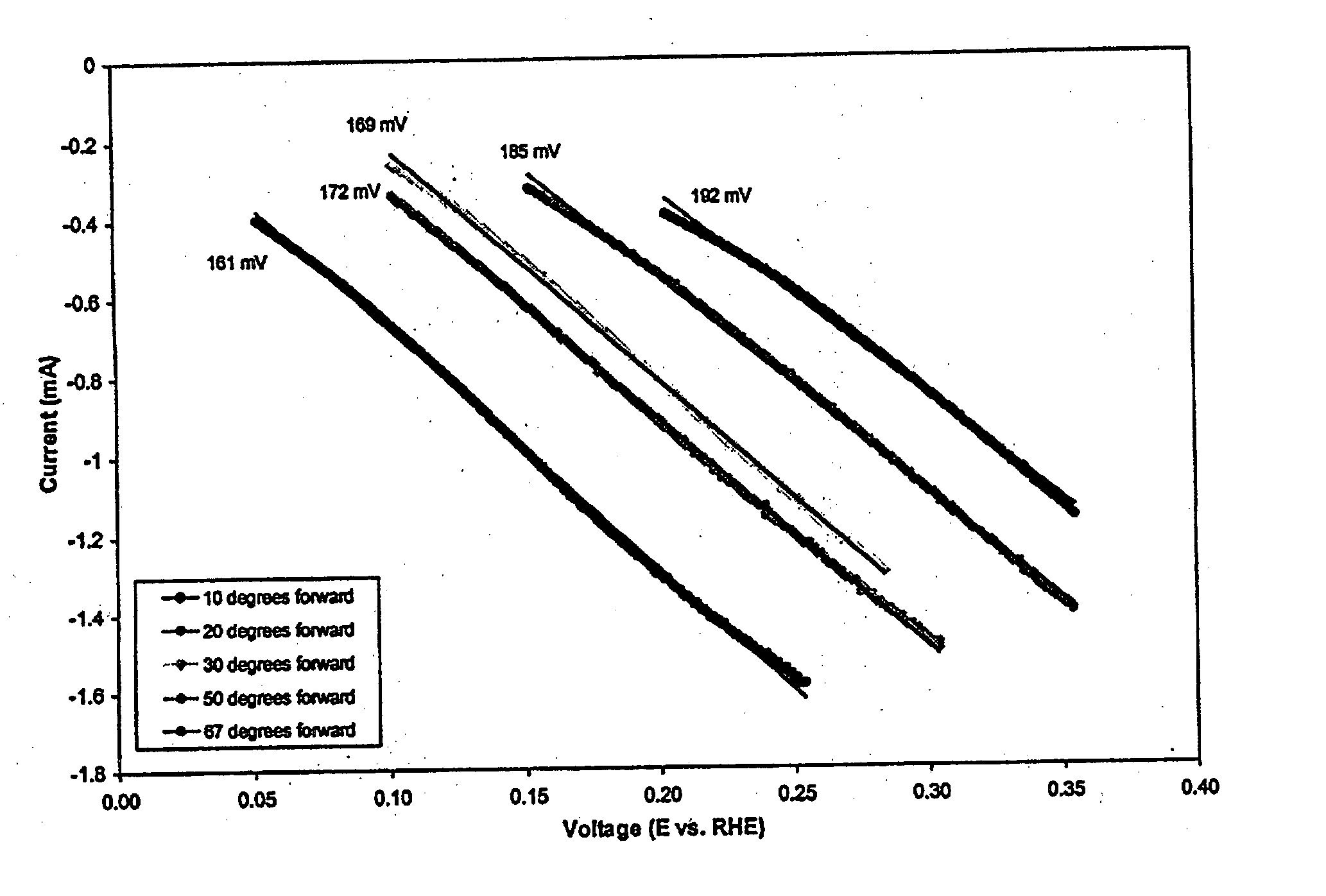

Oxygen reduction catalyst

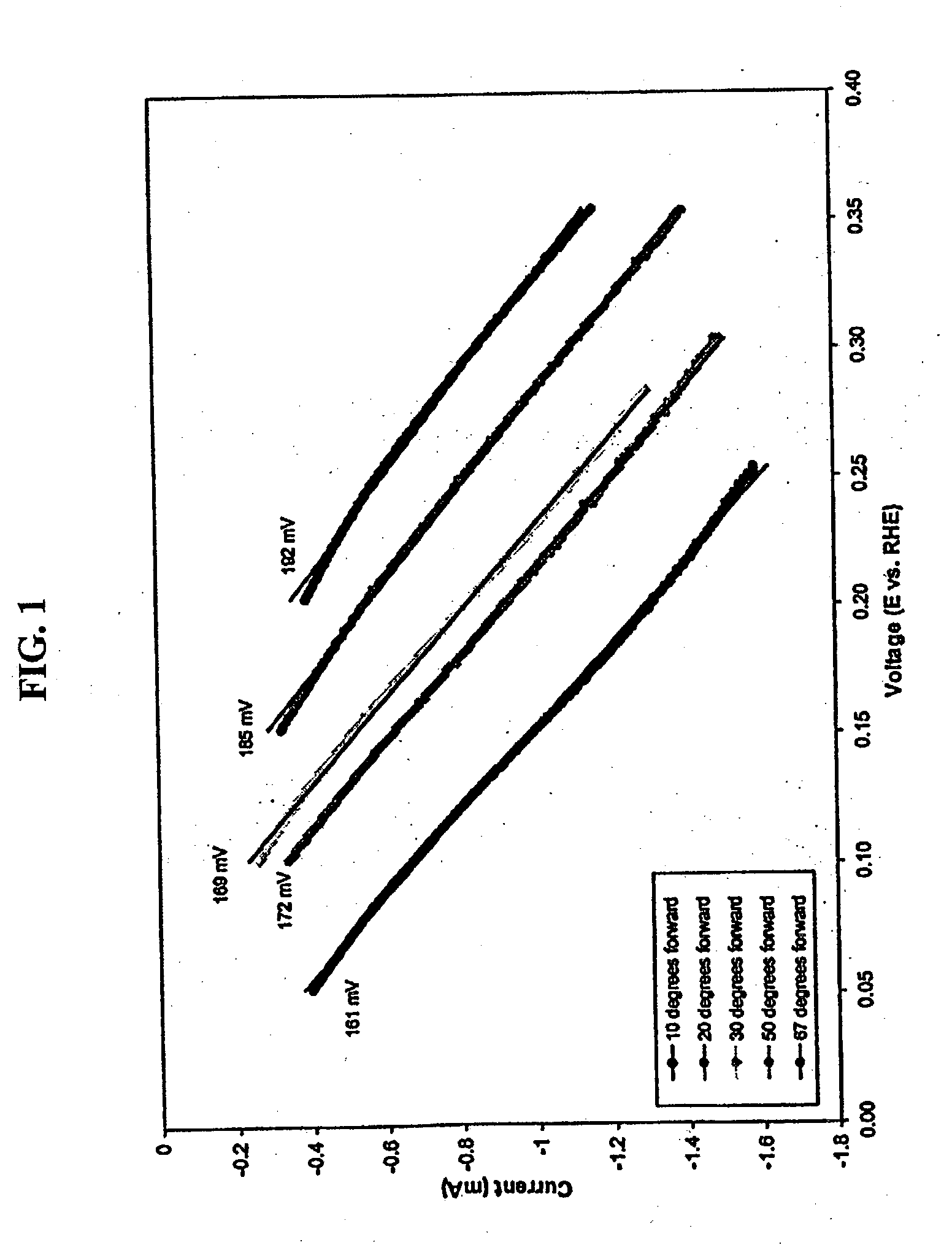

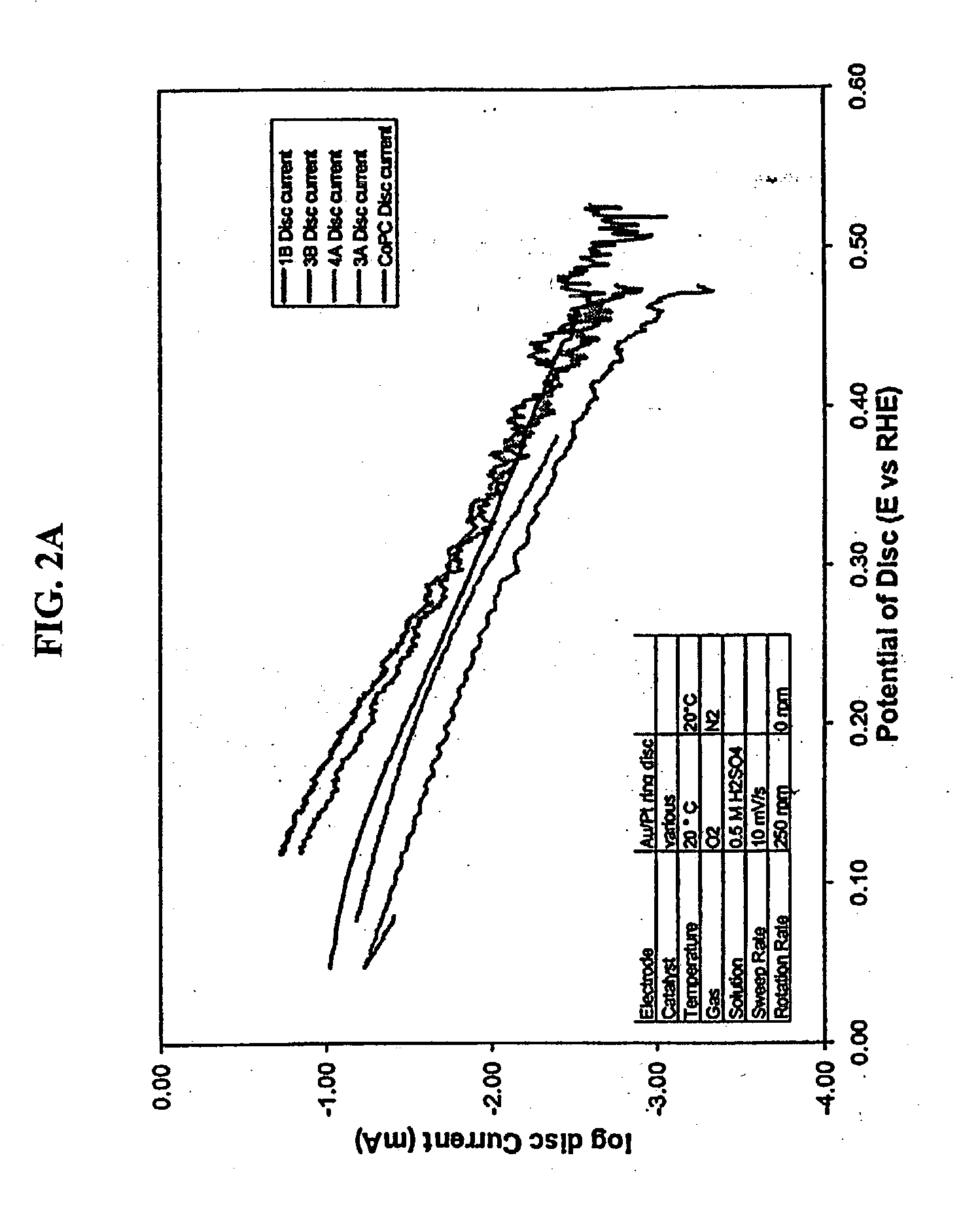

InactiveUS20030228972A1Reduce particle sizeIncrease catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesSol-gelCoordination complex

A oxygen reduction catalyst includes a coordination complex of a transition metal and a nitrogen-carbon ligand. The catalyst may be formed by preparing a sol-gel with a metal salt such as a cobalt salt in an alcohol and adding the ligand slowly while refluxing. The catalyst may be adsorbed onto carbon powder and heat treated.

Owner:UNIV TECH INT

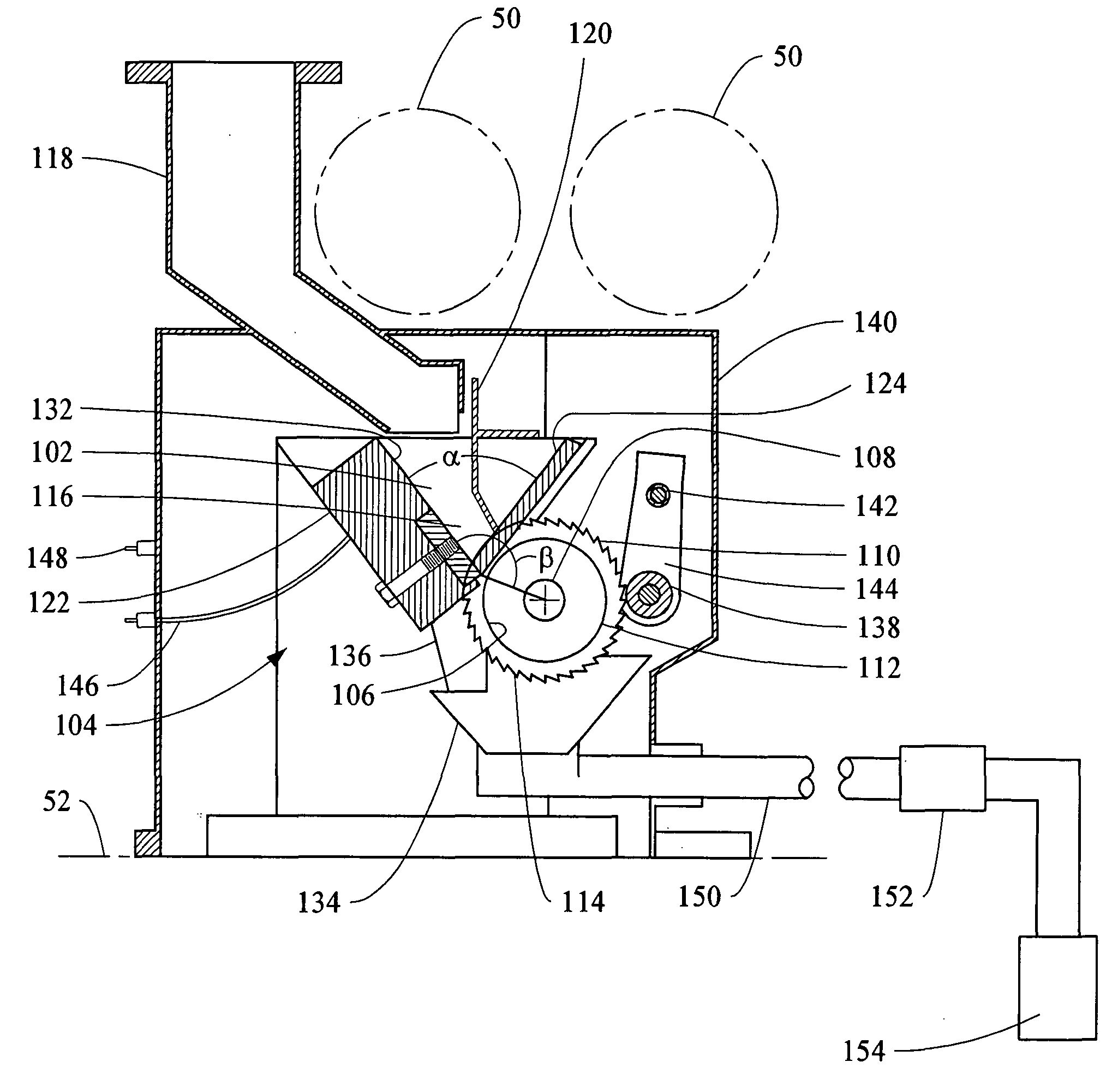

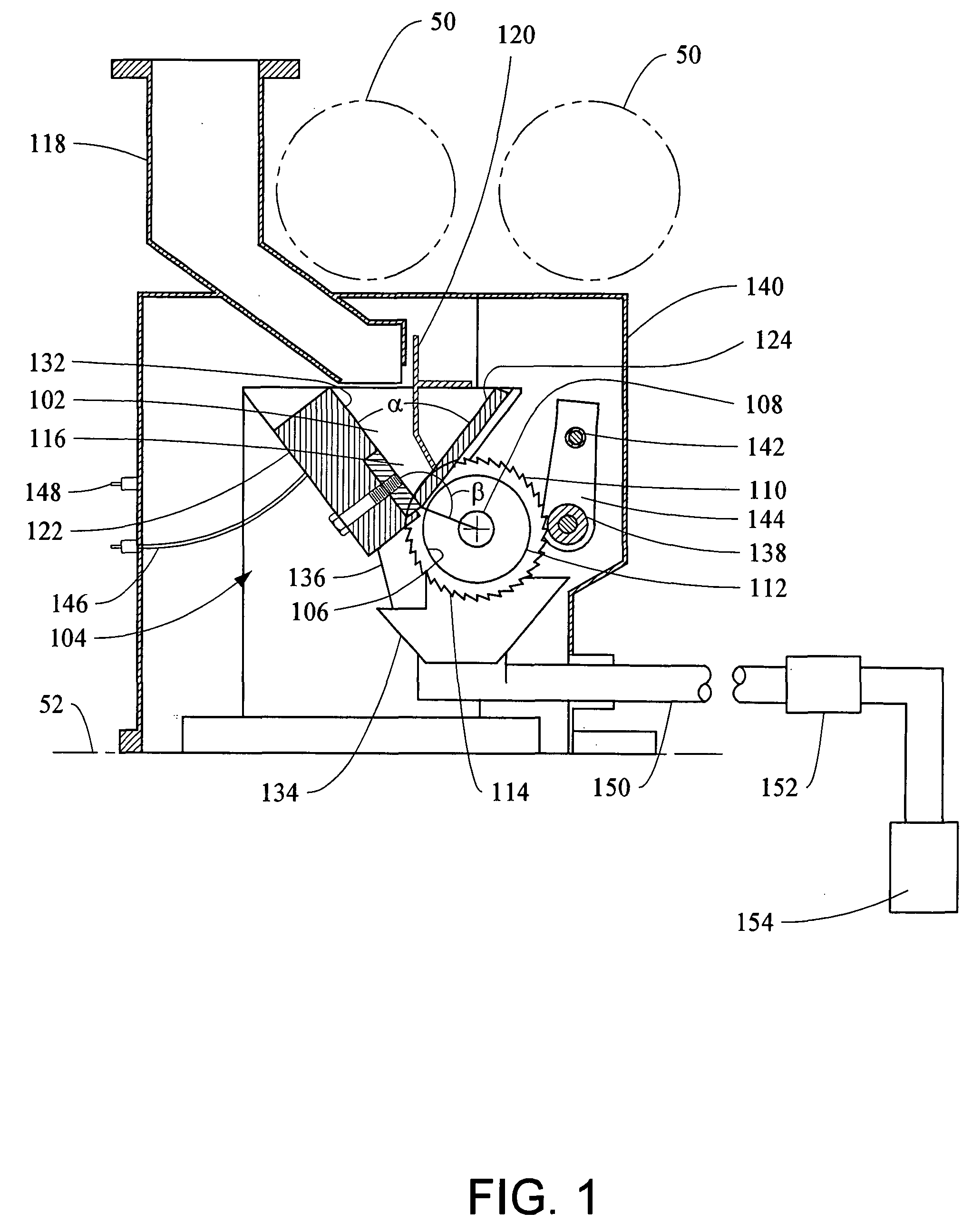

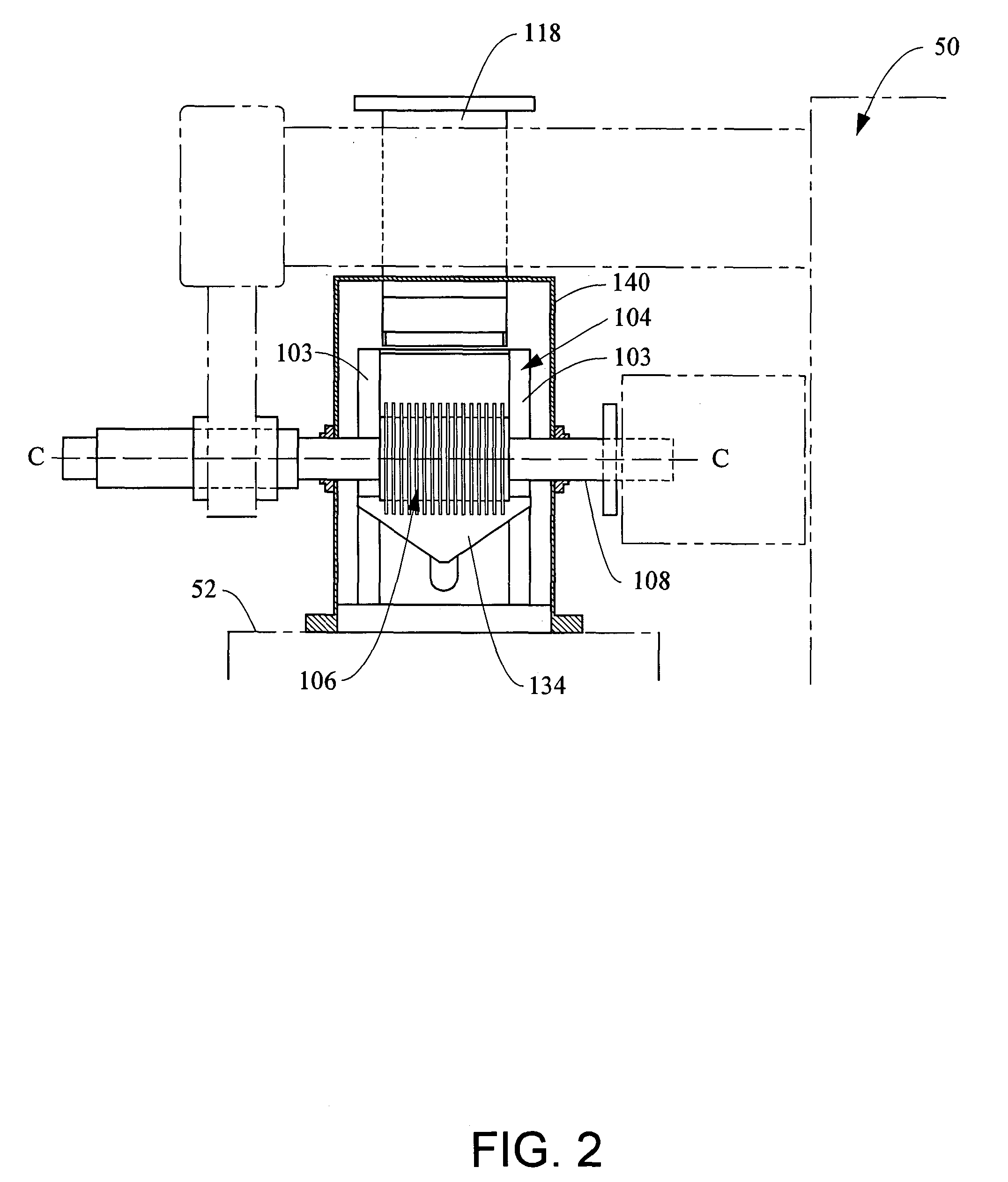

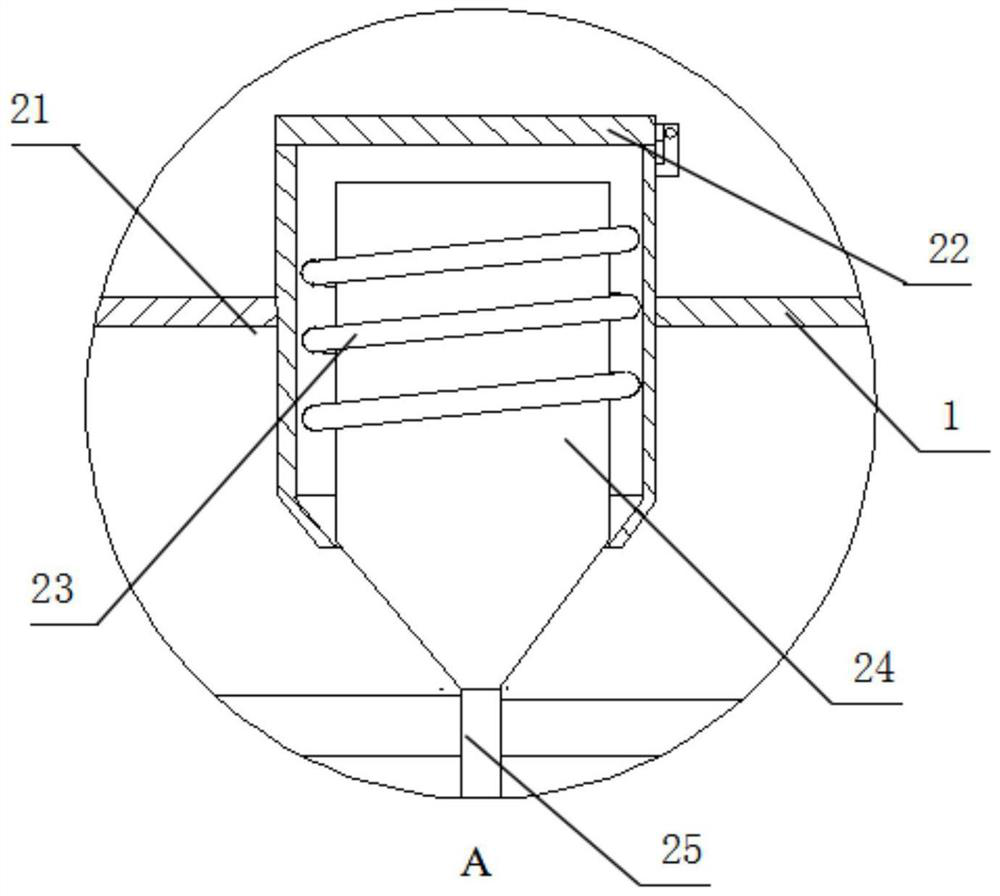

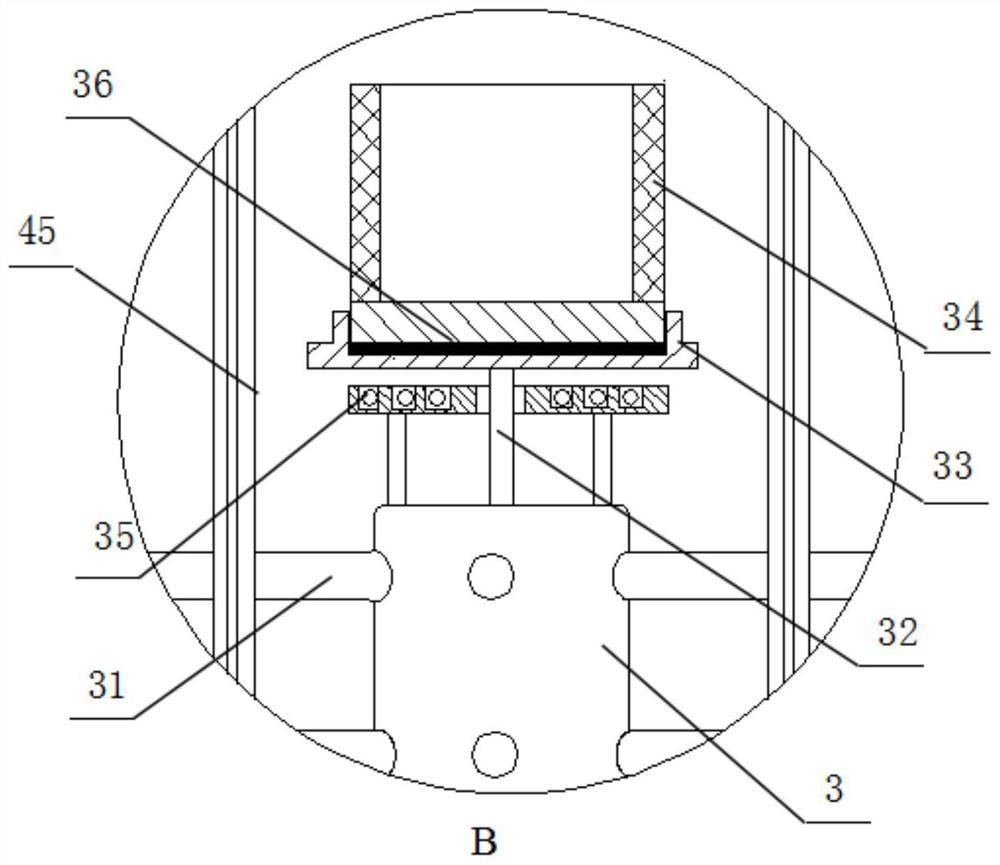

Comminution apparatus

A comminution apparatus for reducing a particle size of a material includes a cutting chamber defining an interior volume, wherein the cutting chamber includes first and second member forming an angle therebetween. Each of the first and second members include a plurality of slots therethrough providing access to the interior volume. The apparatus further includes a rotatable arbor disposed outside the interior volume of the cutting chamber and supporting a plurality of toothed blades thereon. During rotation of the arbor a portion of each of the blades enters an interior volume of the cutting chamber through the slots in the first member and exits the interior volume of the cutting chamber through the slots in the second member. The comminution apparatus may be used to process various feed materials to desired sizes, and is particularly useful for reducing the size of materials otherwise difficult to cut to small size. Such materials include, for example, zirconium, titanium, magnesium, niobium, calcium, copper, potassium, hafnium and aluminum

Owner:ATI PROPERTIES

Cross-blending material between polythene in high density and polythene in superhigh molecular weight

This invention discloses a method for preparing a blend of high-density polyethylene and ultrahigh molecular weight polyethylene, and its application. The method comprises: modifying ultrahigh molecular weight polyethylene with composite dispersant (resin with low melting point and low viscosity, and lubricant), blending with high-density polyethylene, and extruding. The blend comprises: ultrahigh molecular weight polyethylene 10-30 wt. %, composite dispersant 2-15 wt. %, and high-density polyethylene 5-10 wt. %. The obtained blend has a melt flow index of 0.1-0.3 g / 10 min (190 deg.C, 2.16 kg), and can be processed into thin film of 20-100 mum by blow molding or tape casting. The thin film prepared by blow molding has higher tensile and tearing strength than neat high-density polyethylene thin film, and fewer crystal spots on the surface than that prepared by simple blending.

Owner:广州广化塑料管道有限公司

Pollutant emission control sorbents and methods of manufacture

InactiveUS20070122619A1Reduce particle sizeCell electrodesUsing liquid separation agentSulfide saltEnvironmental chemistry

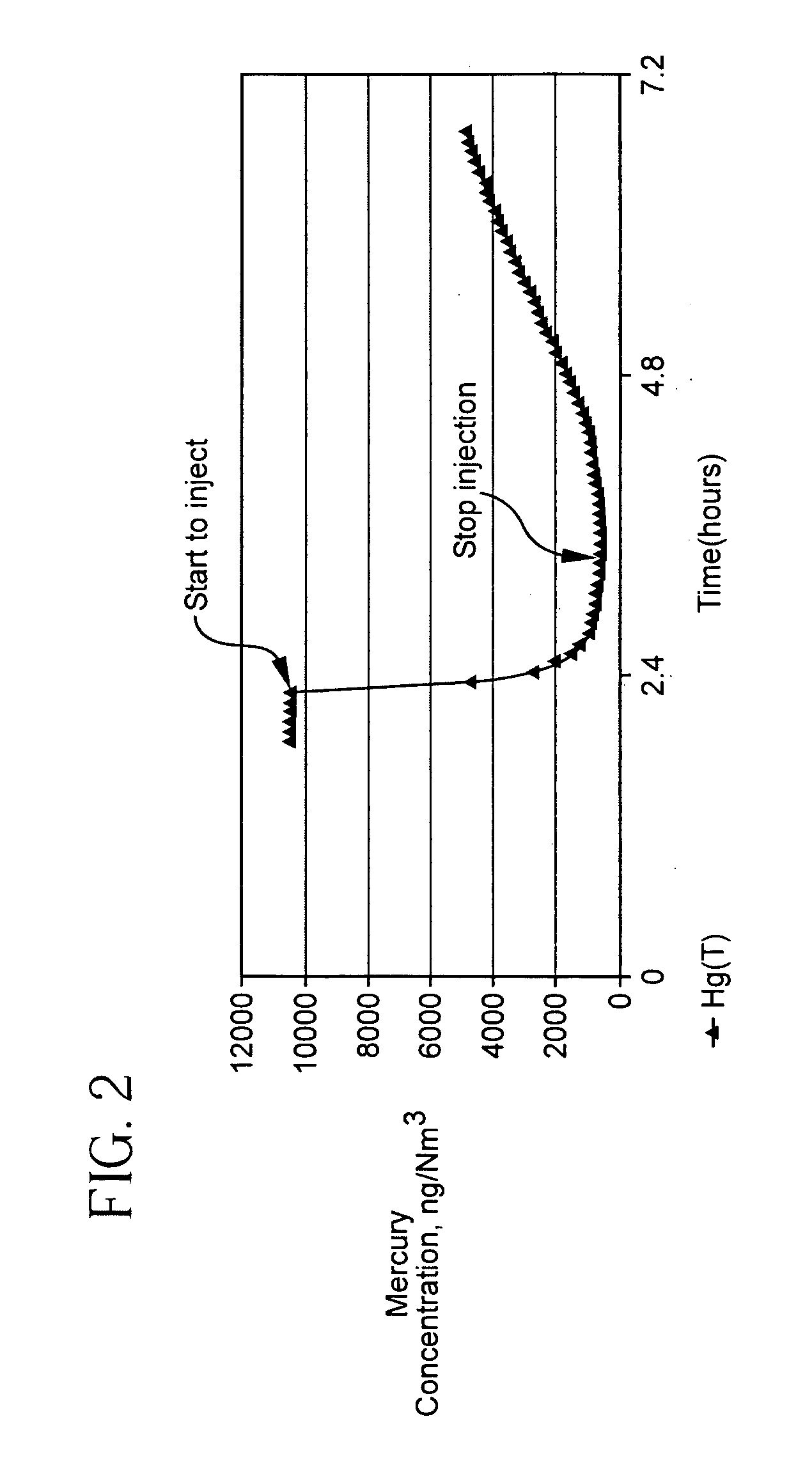

Sorbents for removal of mercury and other pollutants from gas streams, such as a flue gas stream from coal-fired utility plants, and methods for their manufacture and use are disclosed. The methods include mixing fly ash particles with a sulfide salt and a metal salt to form a metal sulfide on the outer surface of the fly ash particles.

Owner:BASF CATALYSTS LLC

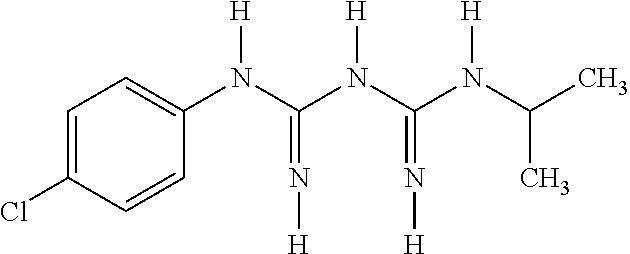

Method for improving the dissolution profile of a biologically active material

InactiveUS20120165323A1Improve dissolution profileReduce particle sizeBiocidePowder deliveryEngineeringBiological activity

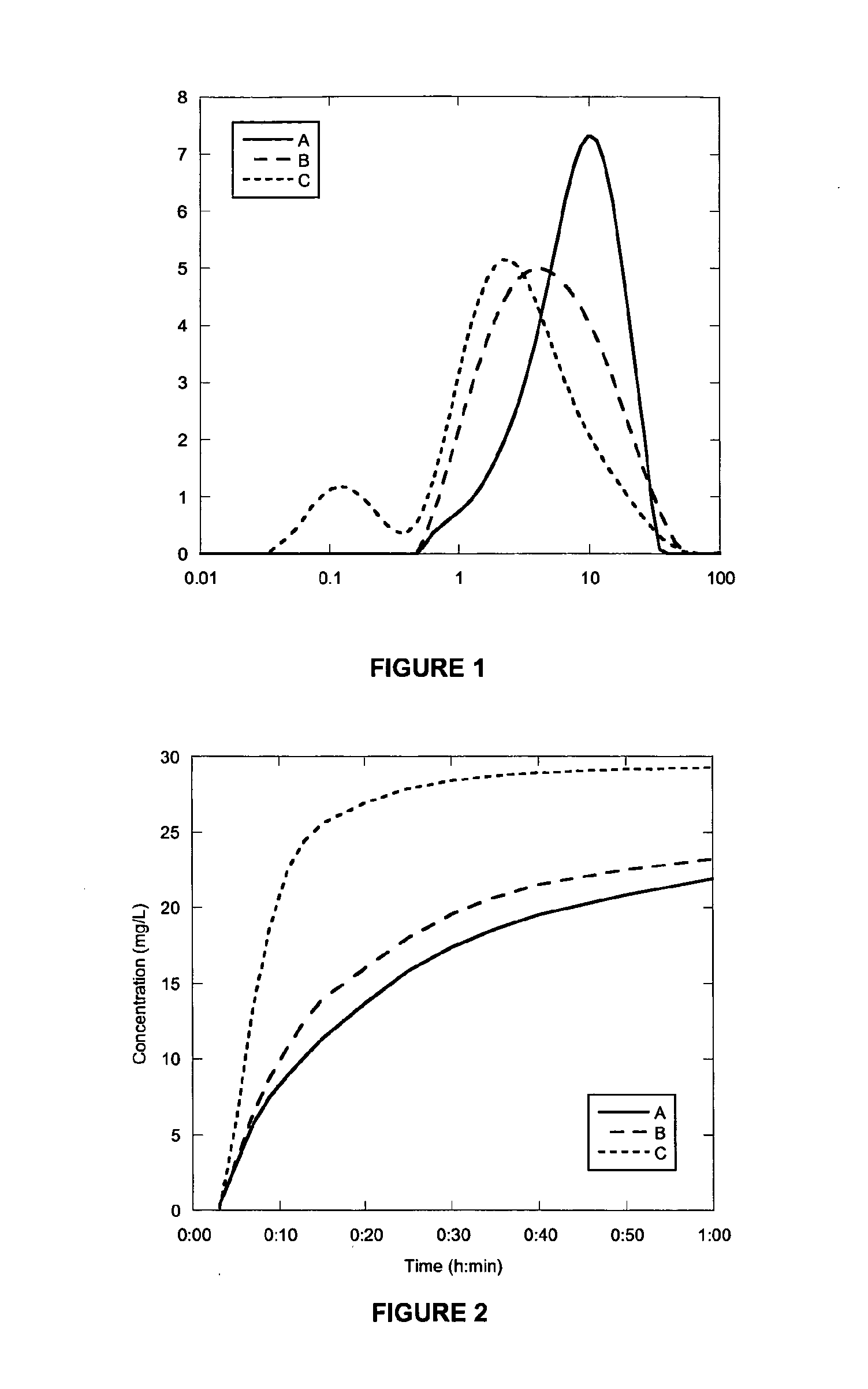

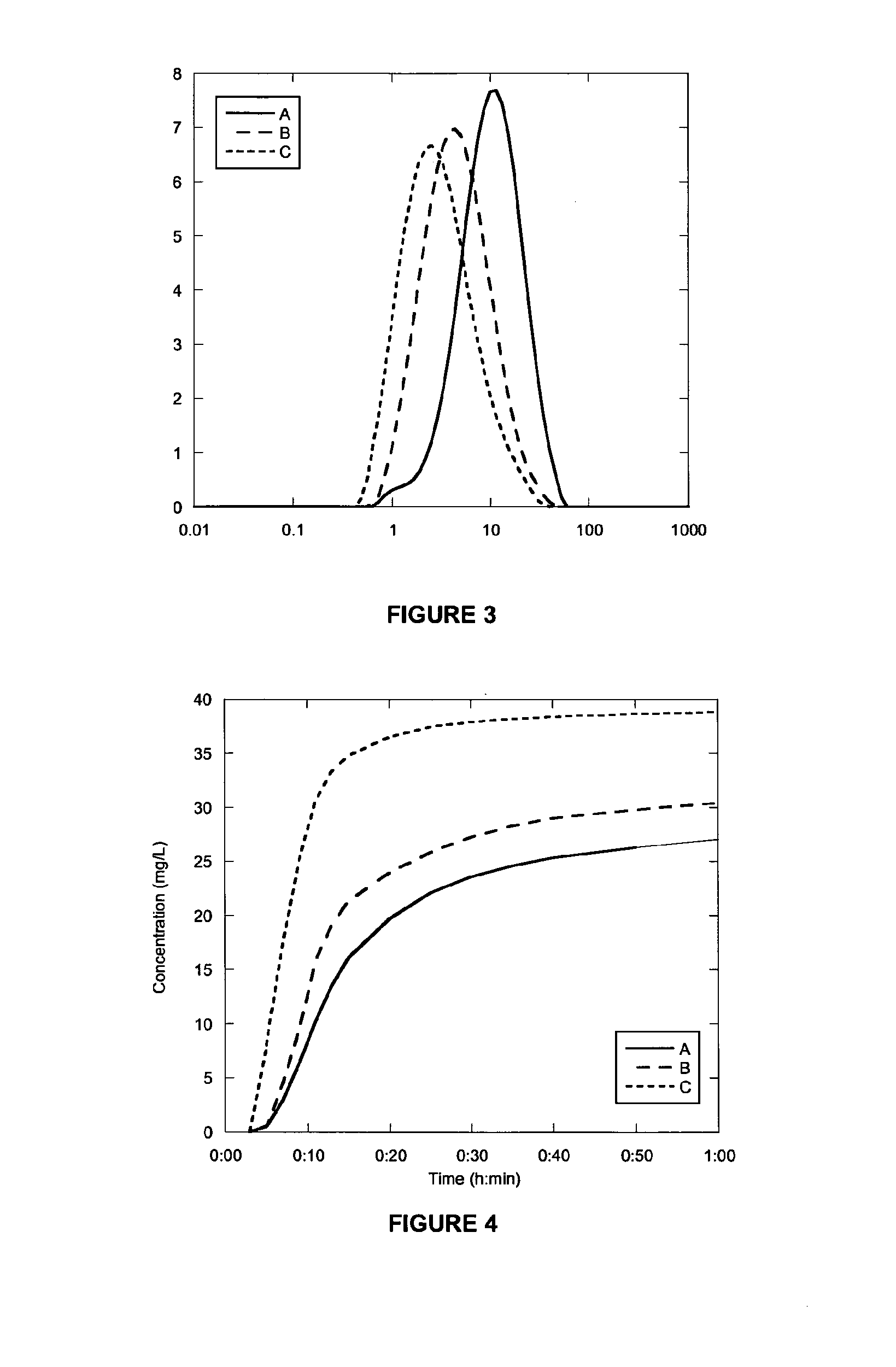

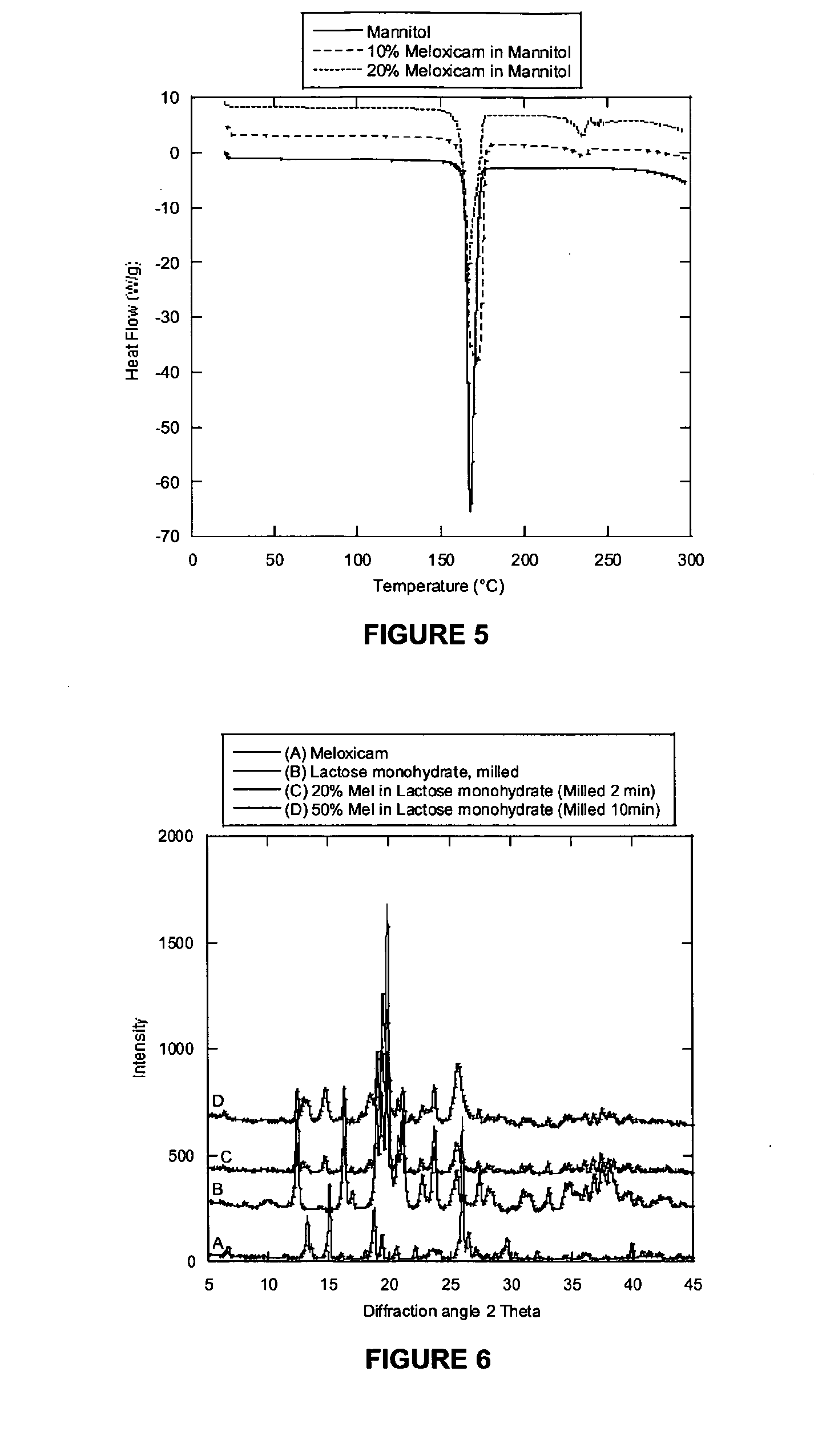

The present invention relates to a method for improving the dissolution profile of a biologically active material comprising the steps of dry milling a solid biologically active material and a millable grinding matrix in a mill comprising a plurality of milling bodies, for a time period sufficient to produce particles of the biologically active material dispersed in an at least partially milled grinding material.

Owner:ICEUTICA PTY LTD

Krumbuster 4X

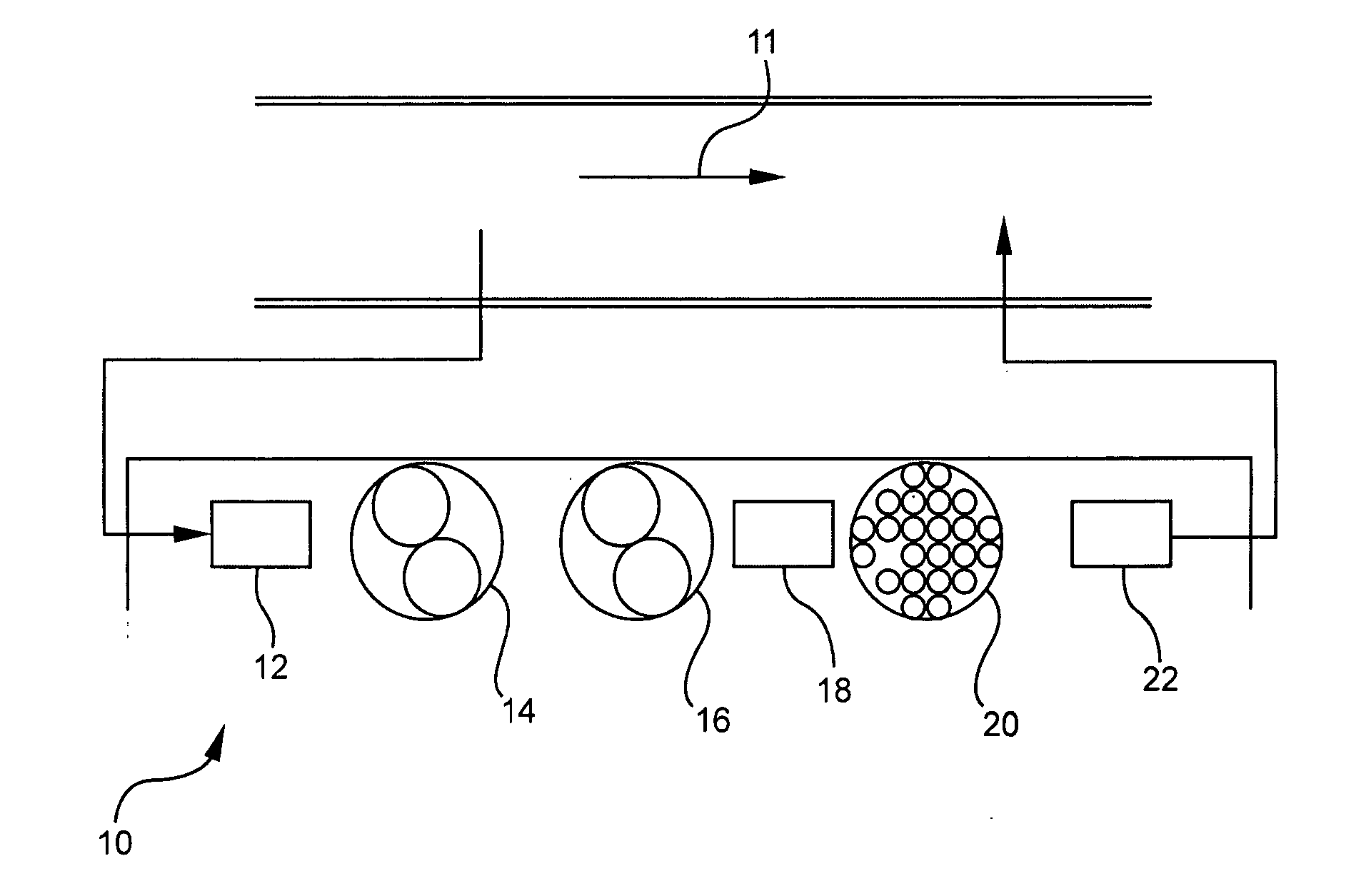

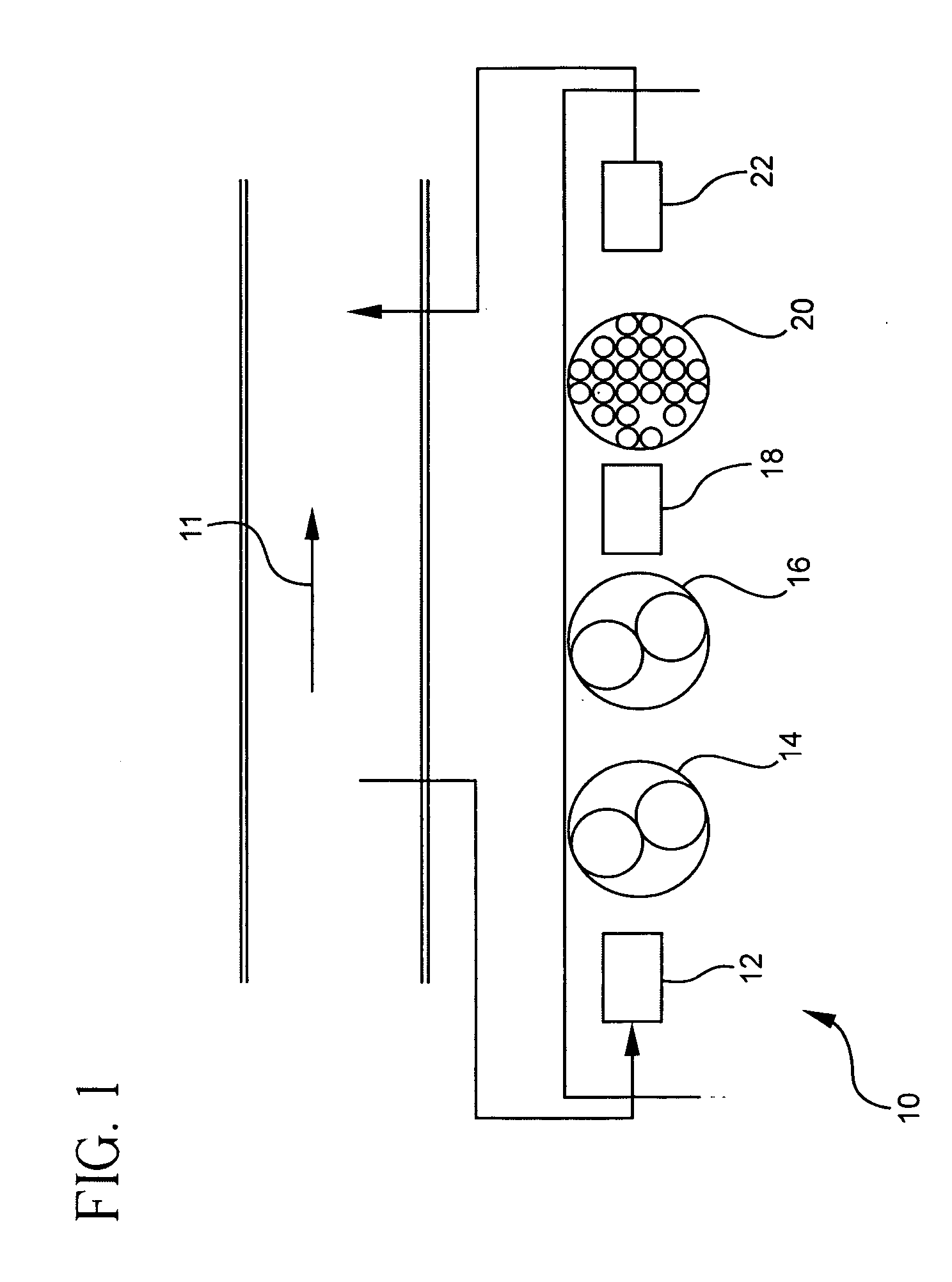

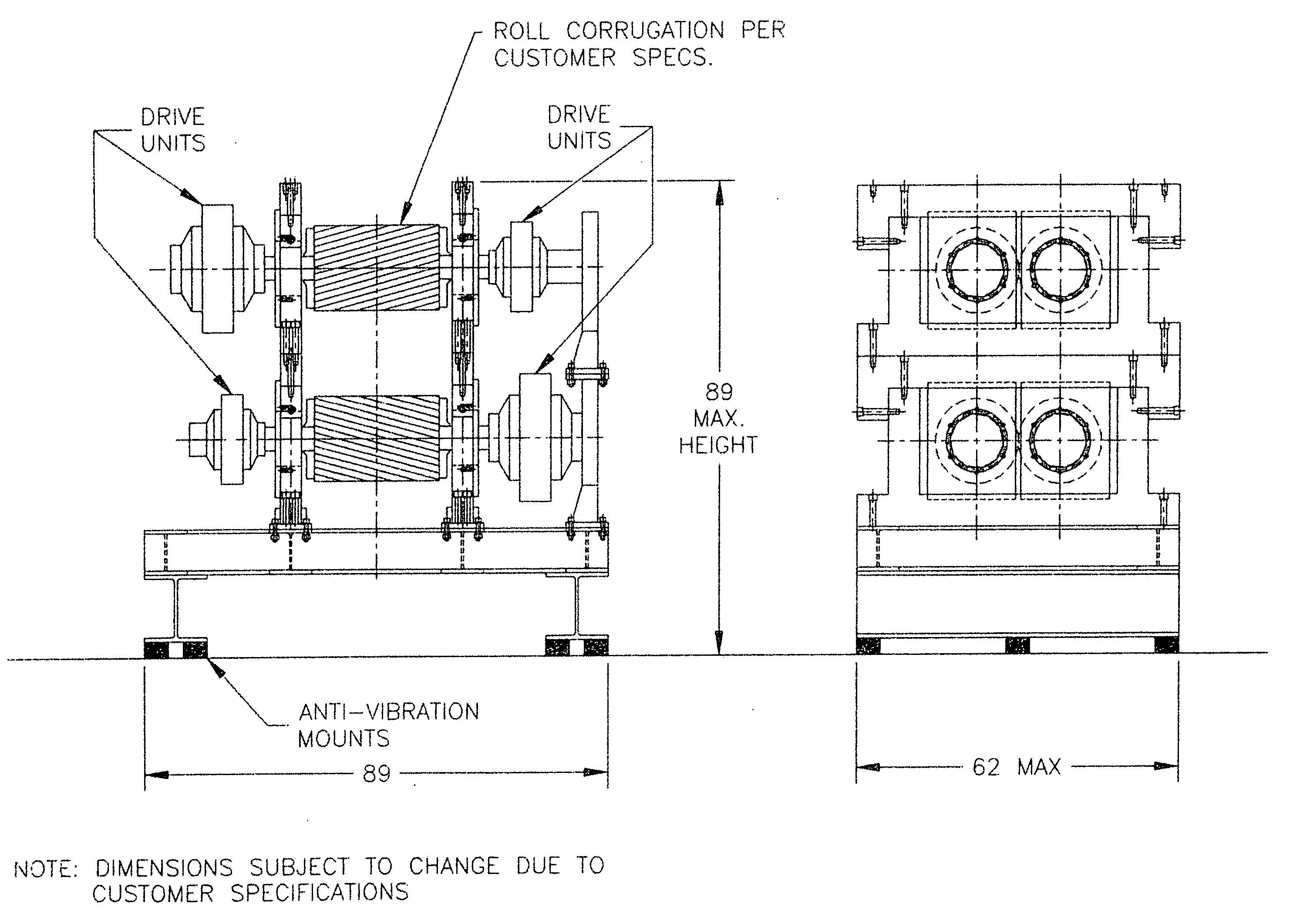

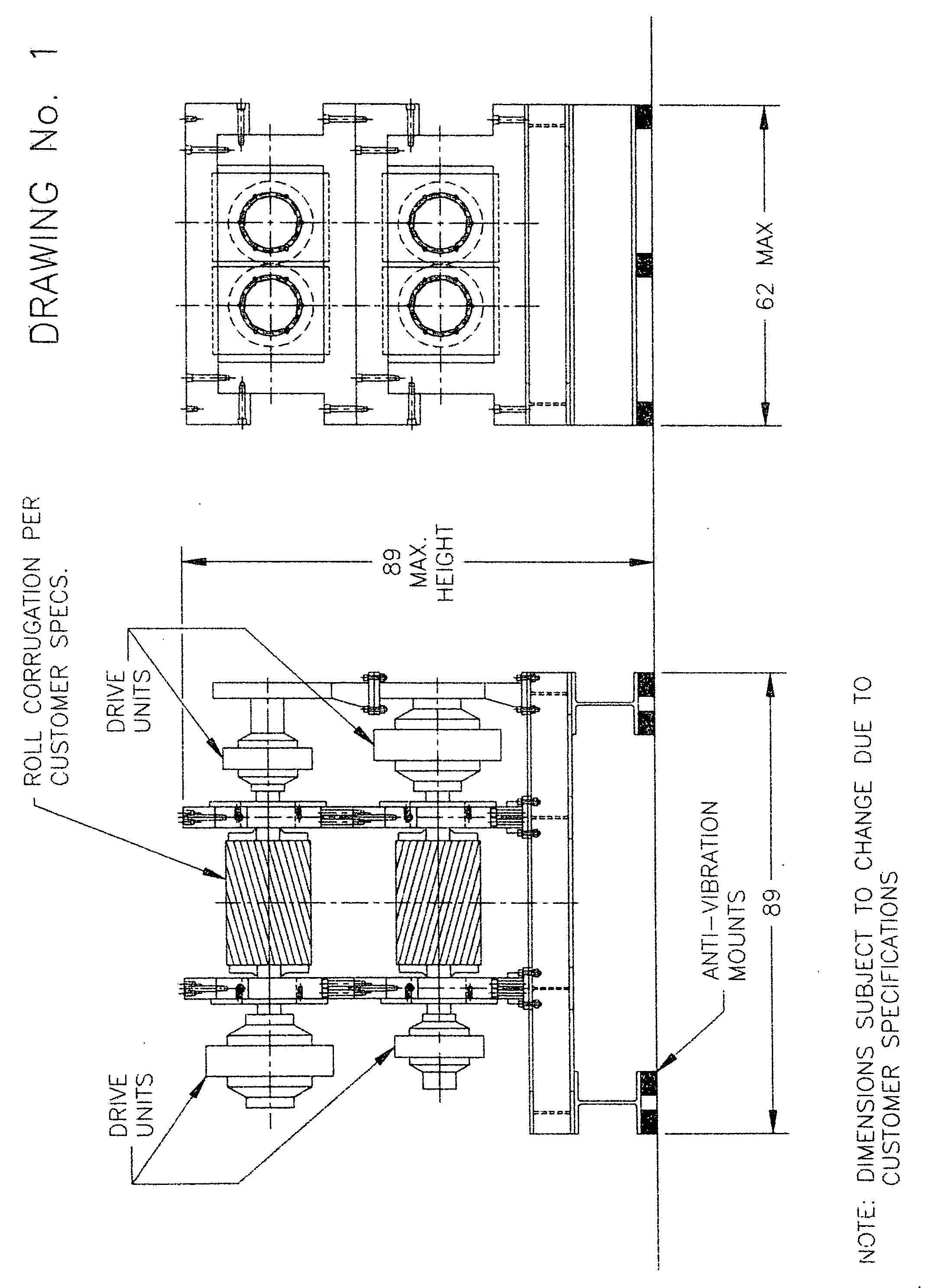

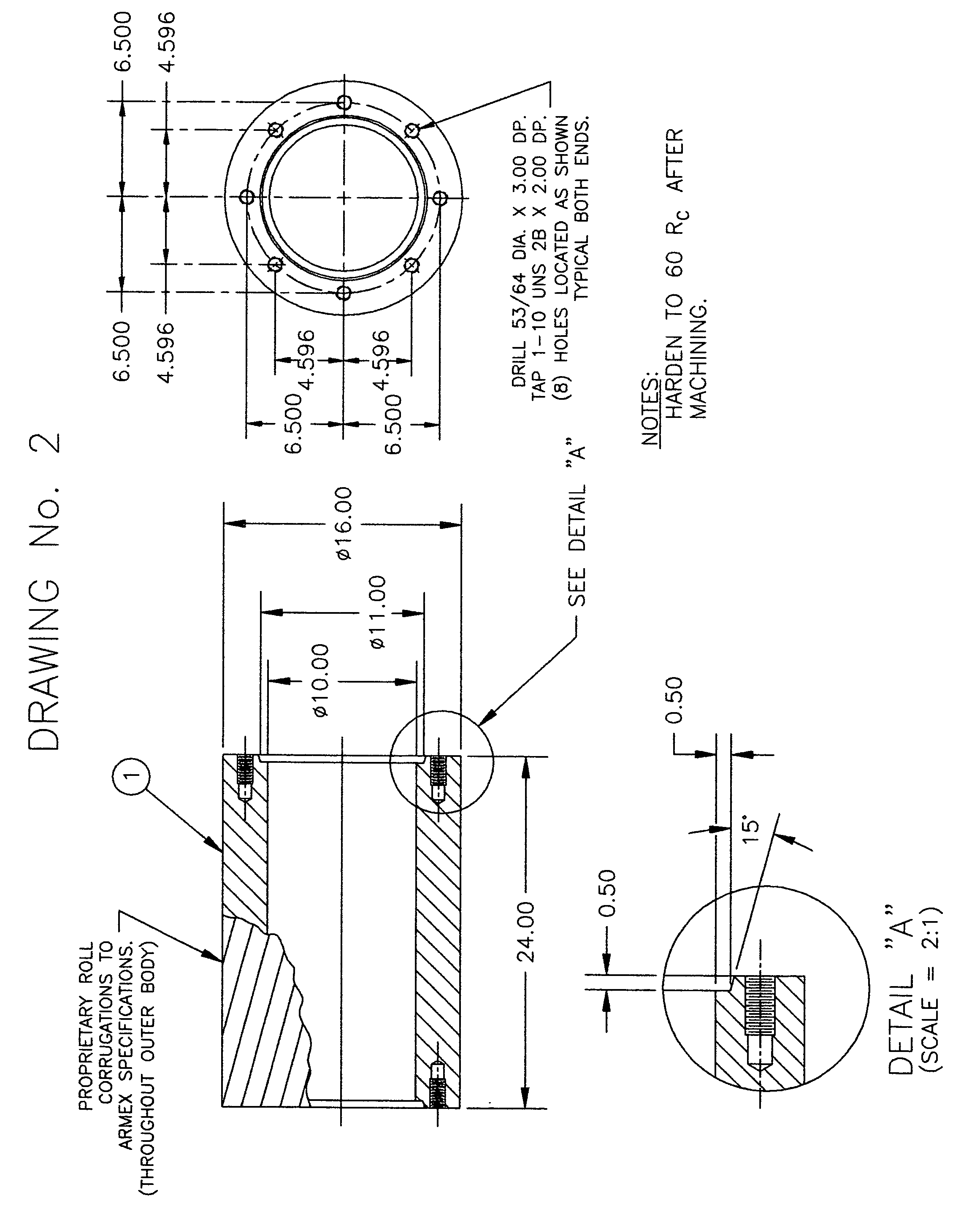

InactiveUS20050205701A1Reduce particle sizeSmall particle sizePlastic recyclingTyresDrive motorEngineering

The present invention relates to a material processing apparatus. The apparatus includes a frame including a pair of laterally opposed parallel sides and a base, and at least a first pair of substantially cylindrical material processing rolling assemblies, wherein each pair of rolling assemblies are driven by a hydraulic drive motor assembly, such that using the hydraulic drive motors, the rolling assemblies can be driven at a variable friction ratio.

Owner:ECO GREEN EQUIP

Preparation method of tungsten and cobalt solder for cathodes and brazing component manufacturing method and application thereof

ActiveCN103921012AReduce particle sizeImprove uniformityTransportation and packagingWelding/cutting media/materialsTungstenCobalt

The invention discloses a preparation method of tungsten and cobalt solder for cathodes and a brazing component manufacturing method and application thereof. The preparation method includes reducing tungsten powder and cobalt powder; grinding mixture of the tungsten powder and the cobalt powder which are reduced to obtain tungsten and cobalt solder, wherein the weight ratio of the tungsten powder and the cobalt powder is 1:2-5. The invention further provides a brazing component manufacturing method and application thereof in cathode components. Purity of the tungsten powder and the cobalt powder is improved by reducing the same at the high temperature, and then the mixture of the tungsten powder and the cobalt powder which are reduced according to a certain proportion is ground, so that particle size of the tungsten and cobalt solder is greatly reduced, and uniformity of the same is improved. Meanwhile, precipitation of cathodal active materials can be prevented during welding by controlling the mixture of the tungsten powder and the cobalt powder which are reduced within the certain proportion, and stability of cathode matrixes is increased.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

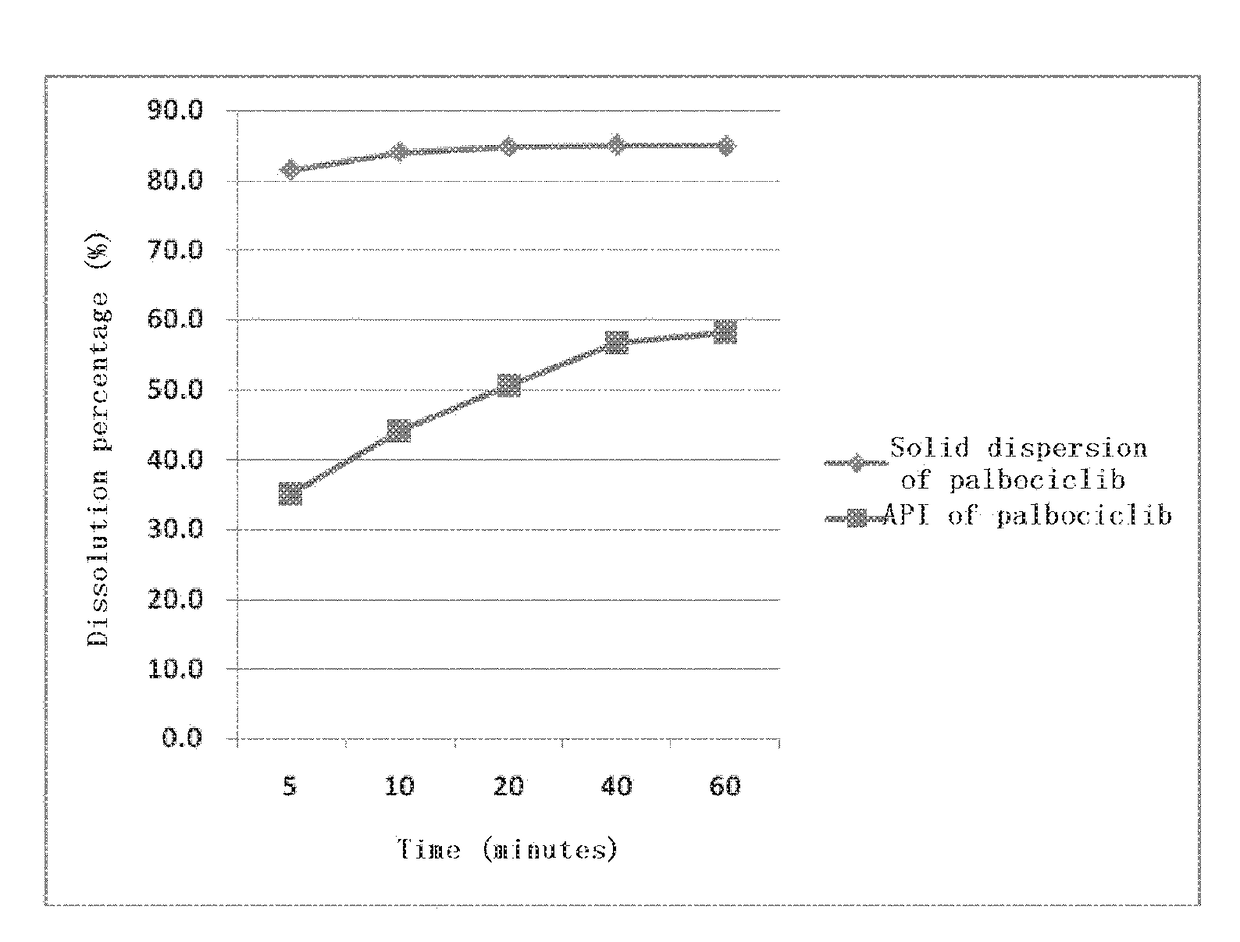

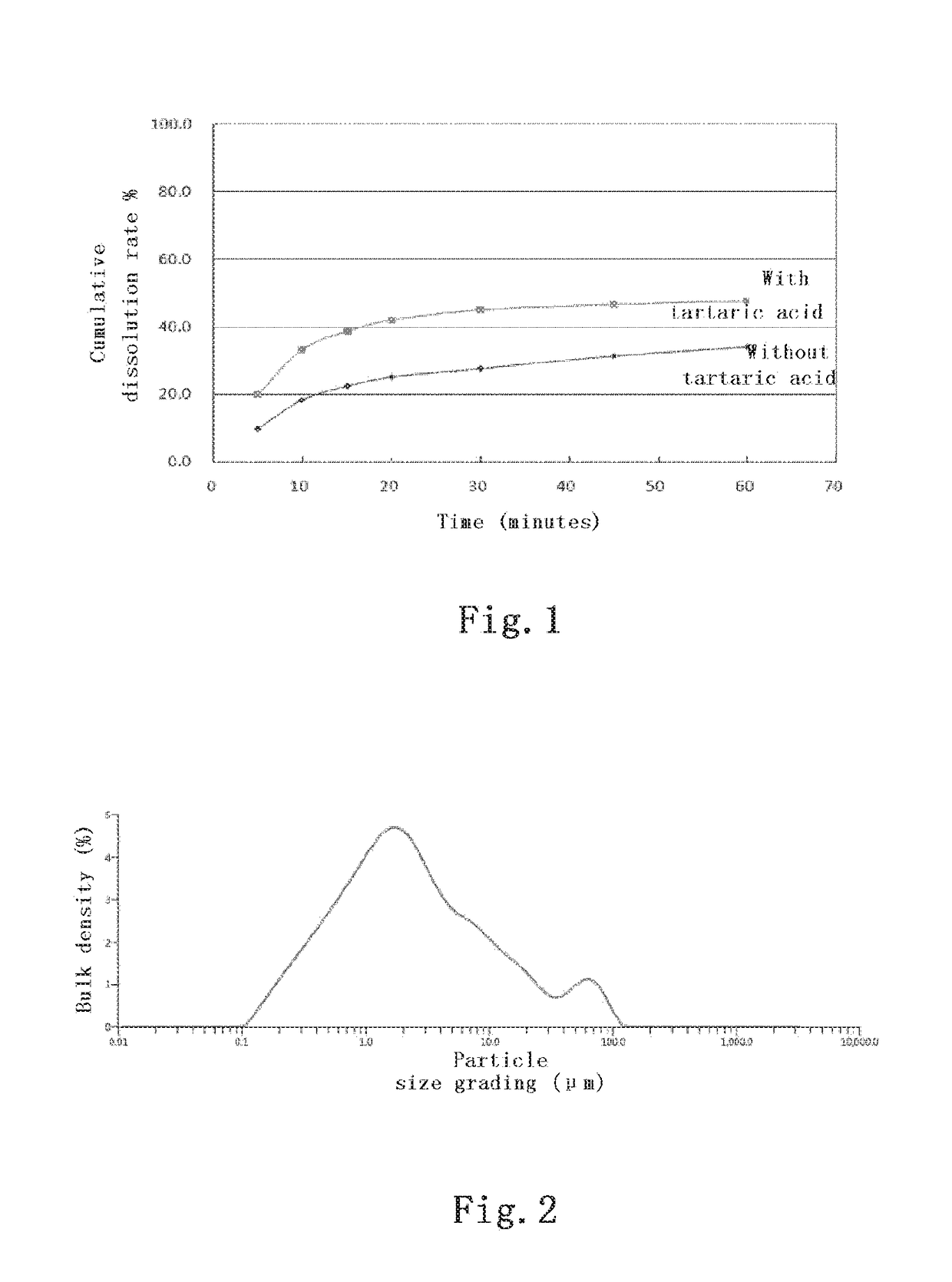

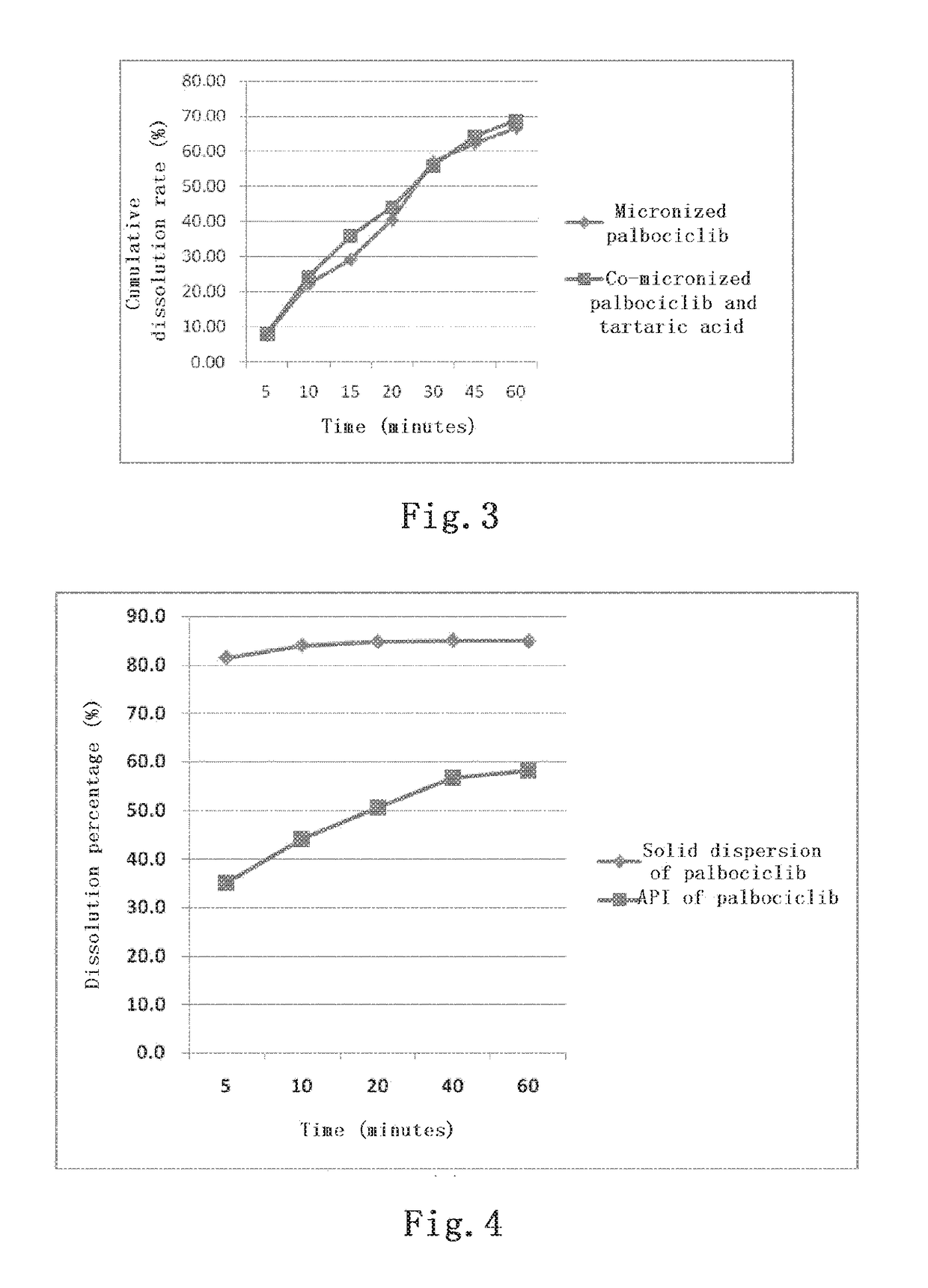

Pharmaceutical formulation of palbociclib and a preparation method thereof

ActiveUS20170281631A1Increase dissolutionReduce particle sizePowder deliveryOrganic active ingredientsDrugSolubility

The present invention belongs to the pharmaceutical field, and in particular, it relates to a pharmaceutical formulation of palbociclib and a preparation method thereof. The pharmaceutical formulation comprises palbociclib, an acidic auxiliary material, and optionally a hydrophilic high-molecular material, which has better solubility and in vitro dissolution property as compared with the conventional formulation and can be used for enhancing in vivo absorption and bioavailability of palbociclib.

Owner:SHENZHEN PHARMACIN CO LTD

1-(1H-1,2,4-Triazol-1-YL)Butan-2-OL Derivative For Pharmaceutical Use, and The Use Of a 1-(1H-1,2,4-Triazol-1-YL)Butan-2-OL Derivative With Substantially Undefined Crystal Shape For Preparing Said 1-(1H-1,2,4-Triazol-1-YL)Butan-2-OL Derivative

ActiveUS20110159096A1Reduce particle sizeOrganic active ingredientsBiocideCrystal habit1,2,4-Triazole

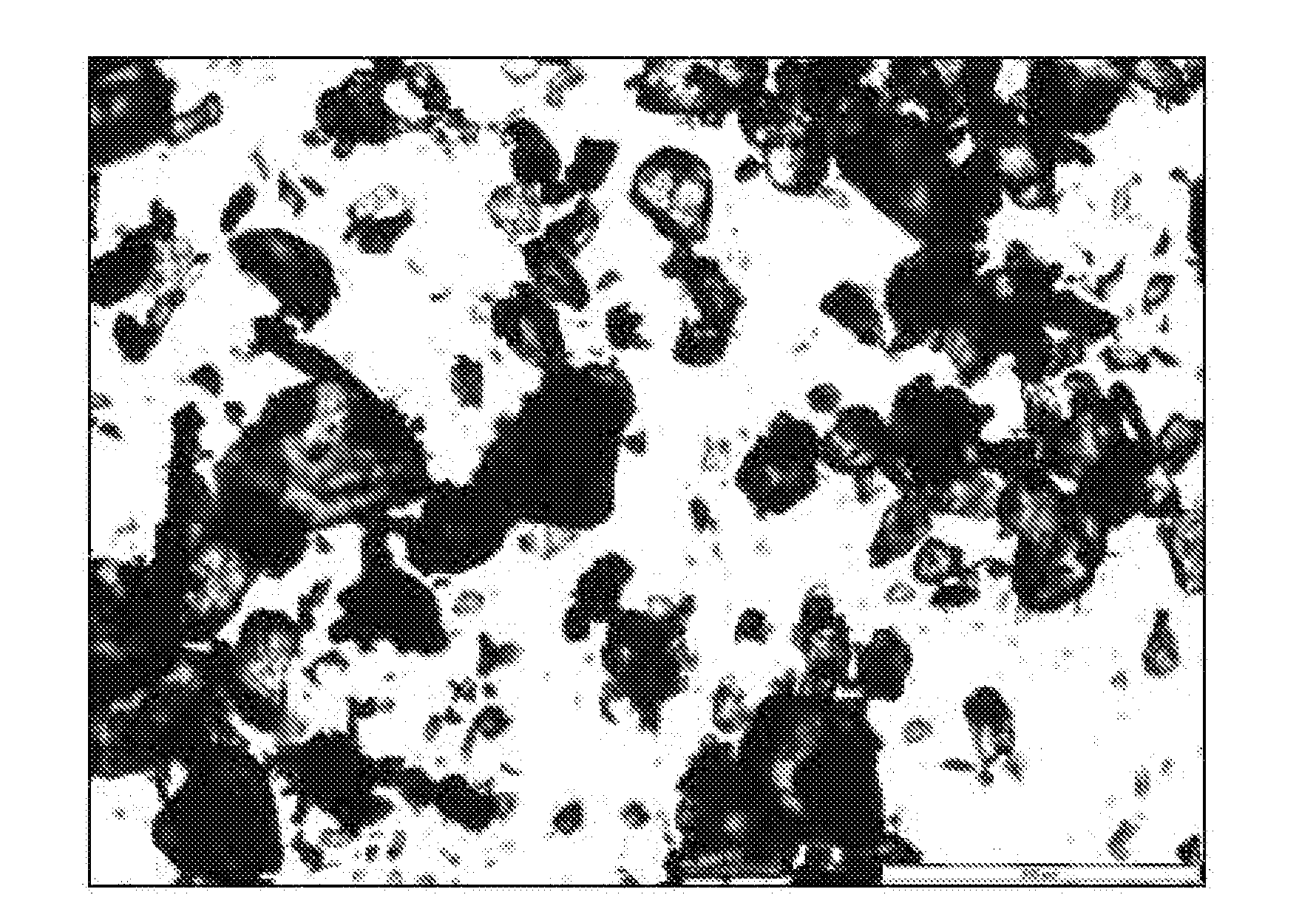

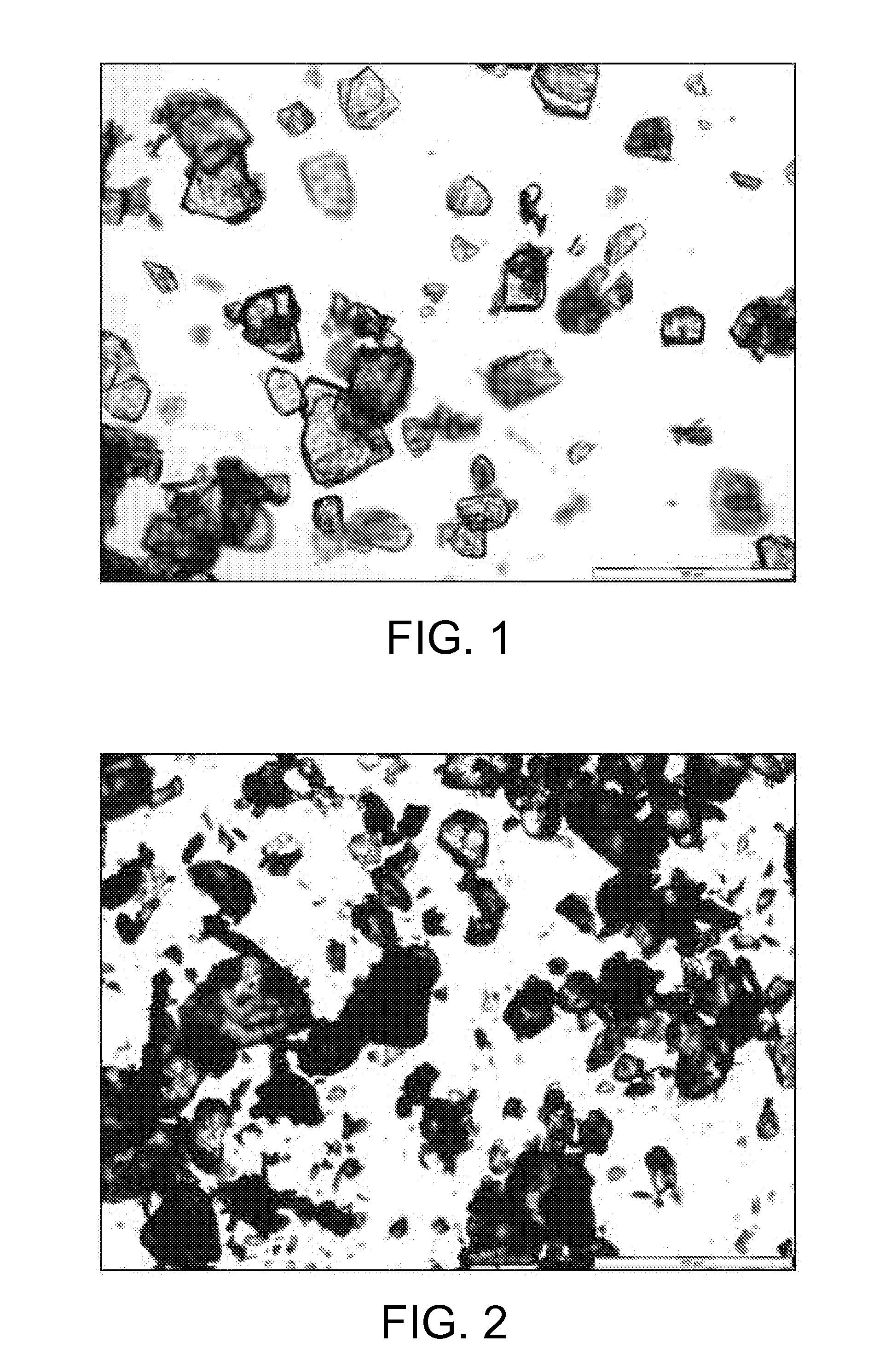

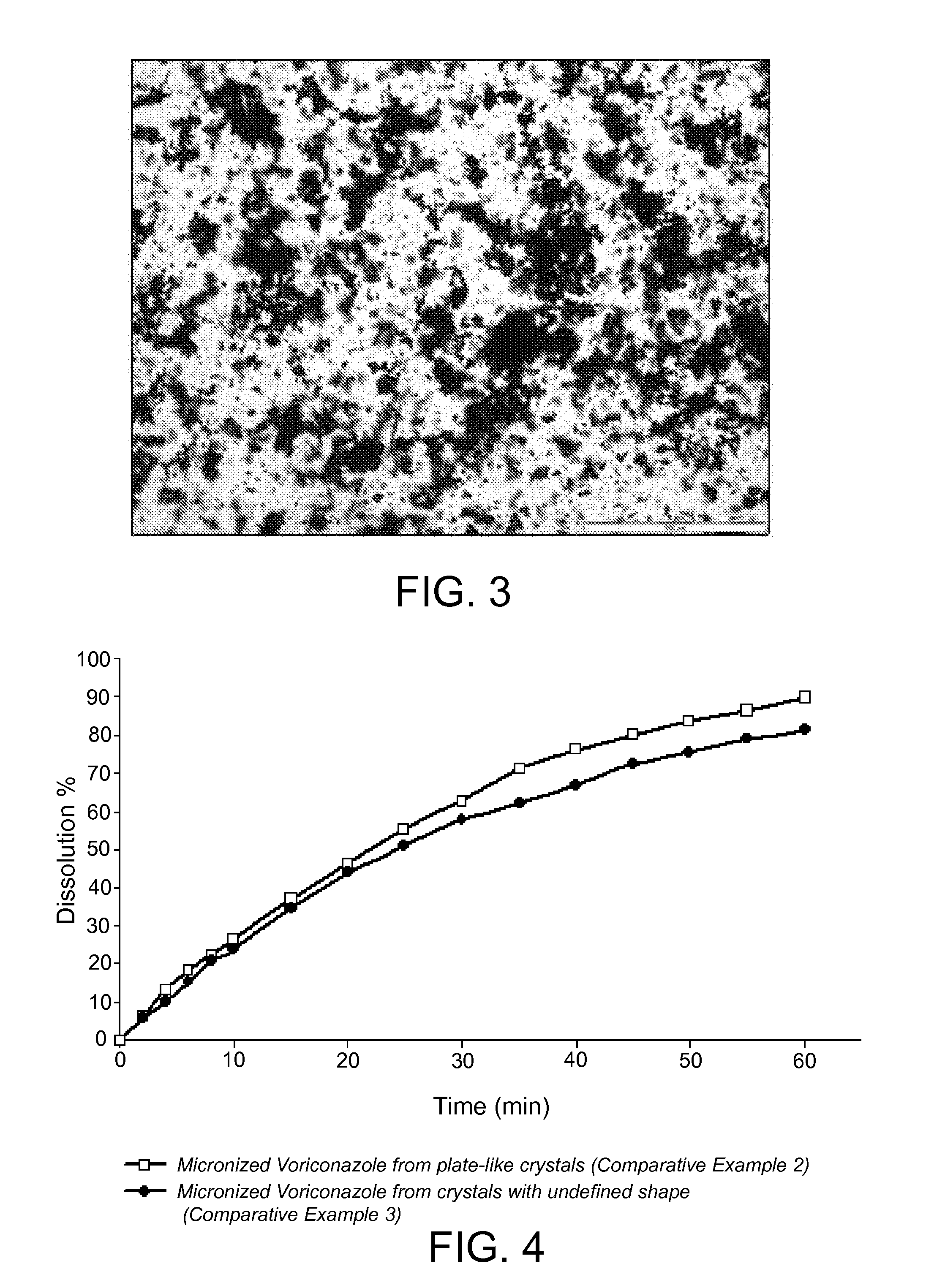

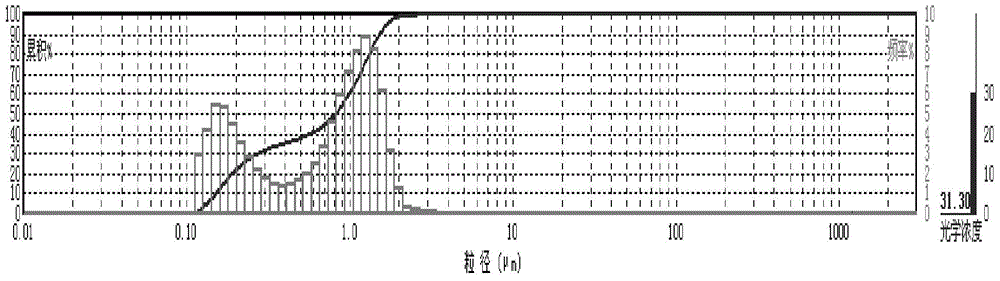

The present invention relates to voriconazole, processes of preparing voriconazole, and pharmaceutical compositions and therapeutic uses thereof. In particular, the present invention also relates to voriconazole prepared from voriconazole having a substantially undefined shape and / or crystal habit. The invention further relates to voriconazole having a modified sphericity factor and / or specific surface area and / or Sauter diameter compared to voriconazole known from the prior art.

Owner:MEDICHEM

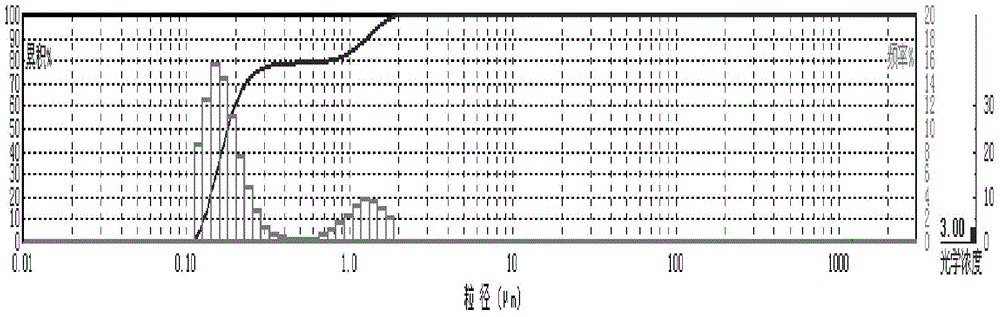

Emulsion cefquinome sulfate injection and preparation method thereof

InactiveCN104127382AReduce particle sizeIncrease the viscosity of the injectionAntibacterial agentsOrganic active ingredientsEmulsionChemistry

The invention specifically relates to an emulsion cefquinome sulfate injection and a preparation method thereof, belonging to the technical field of veterinary antibiotic preparations. The invention provides the emulsion cefquinome sulfate injection to overcome technical problems. According to a technical scheme in the invention, the emulsion cefquinome sulfate injection comprises the following raw materials: cefquinome sulfate, 2.5% g / mL; an emulsifier, 0.1 to 2% w / w; a suspending aid, 0.1 to 10% w / w; deflocculant, 0.1 to 10% w / w; and balancing injection water. The invention further provides a preparation method for the injection. The injection is uniformly dispersed, has a small particle size, does not settle in a long period of time and has wide application prospects.

Owner:CHONGQING ACAD OF ANIMAL SCI

Pigment dispersions and printing inks with improved coloristic properties

ActiveUS20150252201A1Reduce particle sizeSimilar and good color characteristicInksOrganic dyesSolventPrinting ink

The present invention describes a pigment dispersion and a printing ink and coating employing the pigment dispersion. The pigment dispersion includes a pigment, binder and solvent. The pigment dispersion has a mean particle size less than about 120 nm. The printing ink or coating includes the pigment dispersion in addition to a solvent. The printing ink or coating has a solid binder to pigment ratio greater than about 1.5.

Owner:SUN CHEM CORP

An activated lignin composition, a method for the manufacturing thereof and use thereof

ActiveUS20180086916A1Reduce particle sizeHigh shearWood working apparatusAldehyde/ketone condensation polymer adhesivesLigninMaterials science

Owner:STORA ENSO OYJ

LiF-EMBEDDED SiG POWDER FOR LITHIUM ION BATTERY

ActiveUS20180241033A1Reduce particle sizeSmall particle sizeSiliconGrapheneNanometreLithium electrode

A nanographitic composite for use as an anode in a lithium ion battery is described, including: particles of an electroactive material; and a coating over the electroactive particles comprising a plurality of graphene nanoplatelets and an SEI modifier additive wherein the SEI modifier additive is a dry powder that is disposed over at least part of the surface of the electroactive material particles.

Owner:XG SCI

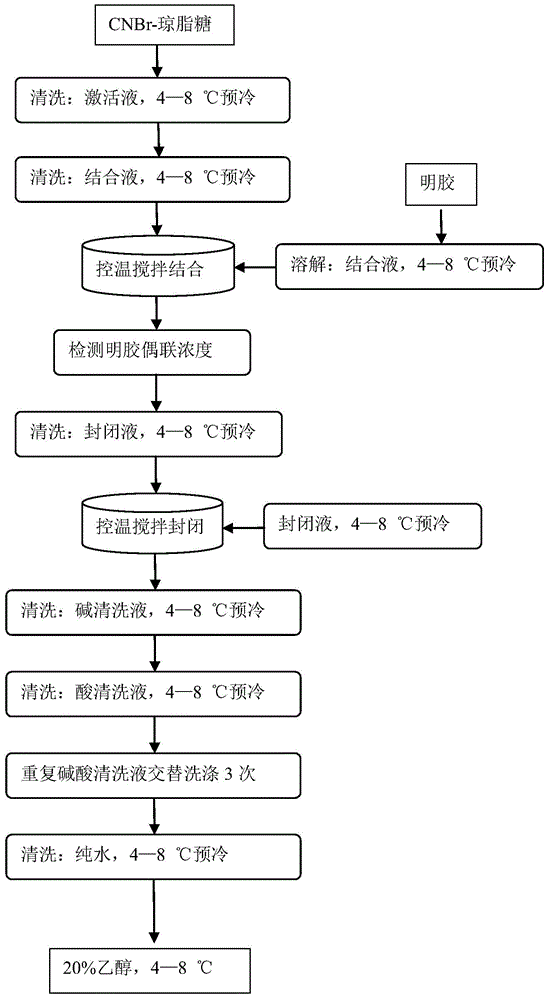

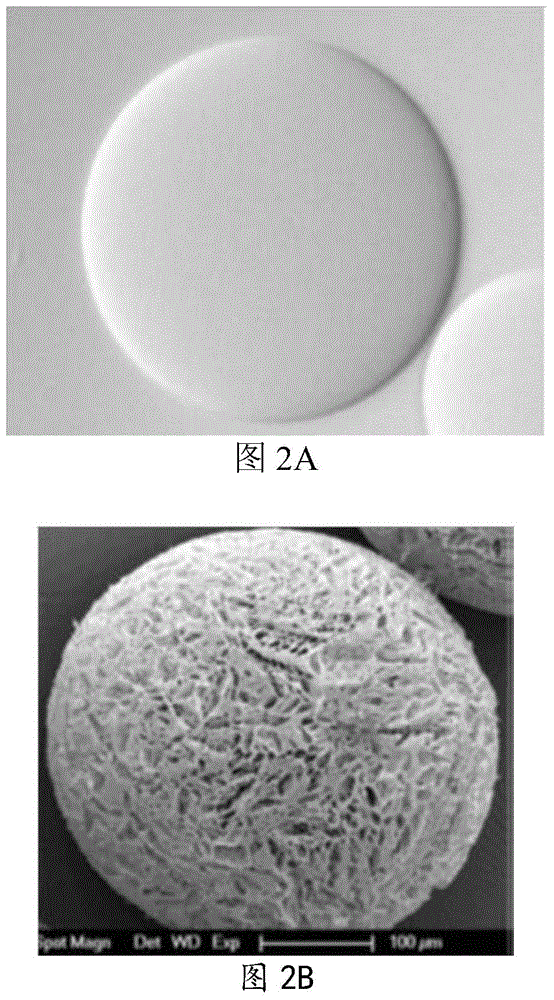

Preparing method and application of gelatin affinity chromatography media

ActiveCN104984739AImprove roundnessHigh resolutionOther chemical processesSolid sorbent liquid separationFiberLiquid temperature

The invention relates to preparing of gelatin affinity chromatography media and a method for separation and purification of fibronectin using the gelatin affinity chromatography media. Activation liquid is used for ligand washing activation of CNBr-agarose affinity chromatography media, and then combination liquid is used for washing. A gelatin solution is prepared, the CNBr-agarose affinity chromatography media washed by the combination liquid are added, and temperature control stirring coupling is carried out. Gelatin coupling concentration is detected, combination liquid washing is carried out, and sealing liquid temperature control stirring sealing is carried out. Acid washing liquid and base washing liquid alternating washing is carried out, water washing is then carried out, and the gelatin affinity chromatography media are obtained. The gelatin affinity chromatography media are placed in a chromatographic column. Equilibrium liquid is used for balancing the chromatographic column. Samples flow through the gelatin affinity chromatography media. The preparing method of the gelatin affinity chromatography media has the advantages that purifying efficiency is high, the production cycle is short, and the technology is simple.

Owner:WUHAN HUIYAN BIOTECH

Atovaquone with a particle size diameter range (D90) of greater than 3 microns to about 10 microns

Owner:ALPHAPHARM PTY LTD

System and method for preparing ferronickel from laterite-nickel ore

The invention provides a system and a method for preparing ferronickel from laterite-nickel ore, belongs to the field of metal smelting, and solves the problems of difficulties in transporting, drying and crushing of the high-moisture raw laterite-nickel ore as well as the easiness in ringing and difficulty in reducing, caused by pelletizing difficulty. The method comprises the following steps of 1), pretreating the raw materials; 2) pelletizing; 3) implementing magnetizing roast and water quenching; and 4) grinding the ore, and implementing dry-separation. By means of the system and the method, the problems can be effectively solved, the consumption of electric power and water in the process of grinding and magnetic separation of the laterite-nickel ore roasted ore is reduced, and the piling risk of low tailings is reduced.

Owner:山西环能工程项目管理有限公司

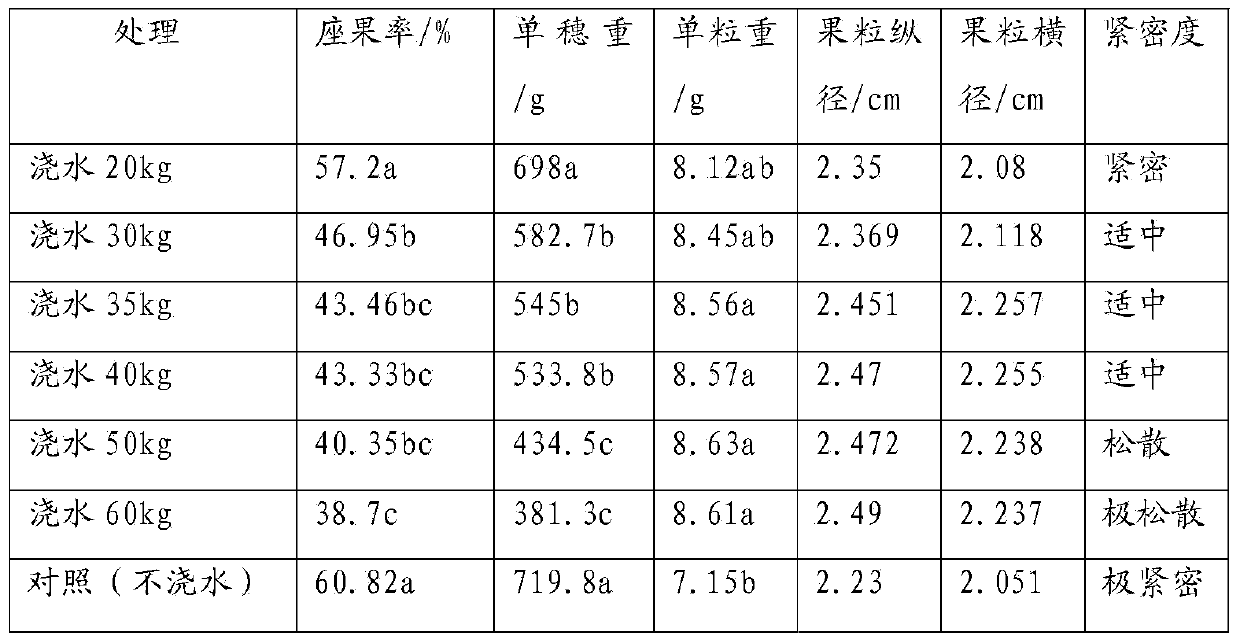

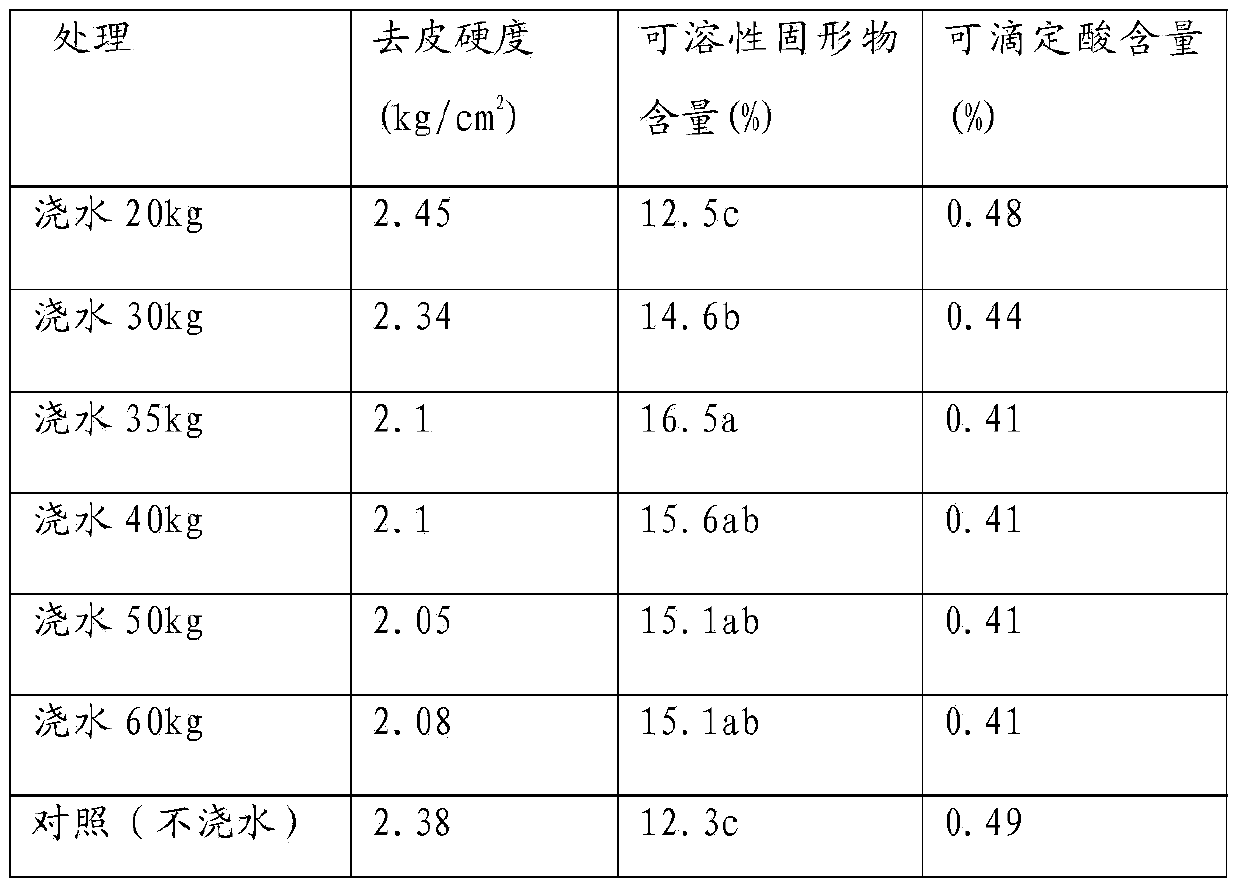

Spike pruning method for Benibalad grape

InactiveCN104206197AGuarantee uniform specificationDense growthCultivating equipmentsHorticulture methodsPlant hormoneBud

The invention discloses a spike pruning method for Benibalad grape. Watering is carried out once in the early stage of grape blooming, namely 0%-30% of the grape blooms, and the water quantity of 35-40 kg; the flower spike is trimmed after the full-bloom stage, namely 70-80% of the grape blooms, an auxiliary spike, and three to five branches on the upper part of the spike shoulder are trimmed, a spike tip is not trimmed, and twenty to twenty-three branches of the whole flower spike are kept. After the flower spike is trimmed, the width of the spike shoulder is maintained, the width of the spike tail is 3-4.5 cm, and the length of the spike is 11-13 cm. Through quantitative watering and timely flower spike trimming, the distribution of plant hormones in the spike is regulated, the hypogenetic inflorescence of grape variety with high natural fruit setting rate is enabled to realize bloom dropping and bud falling, the flower thinning effect is realized, the competing for nutrients in the blooming process of the flower buds is reduced, the size of the grape spike is controlled, the fruit size is increased, the workload of fruit thinning is reduced, and the fruit quality is improved.

Owner:ZHENJIANG WANSHAN HONGBIAN AGRI PARK

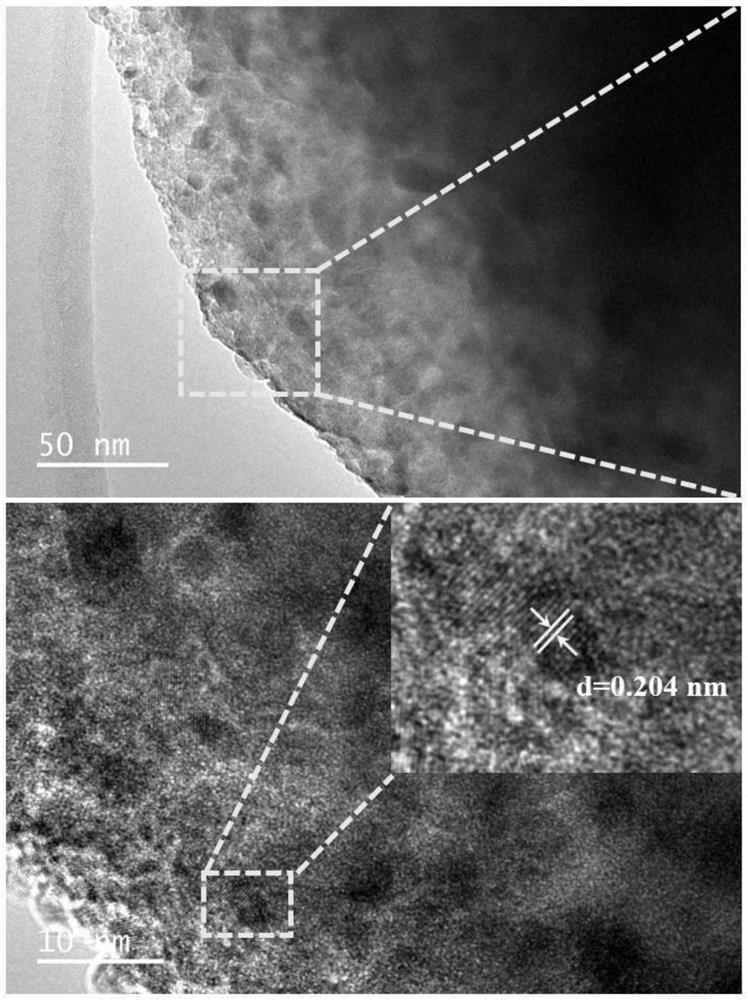

Catalyst for synthesizing diethyl oxalate by CO gas-phase coupling of ethyl nitrite and preparation method thereof

ActiveCN111495388AReduce loadInhibition of agglomerationCatalyst activation/preparationPreparation by carbon monoxide or formate reactionPtru catalystFixed bed

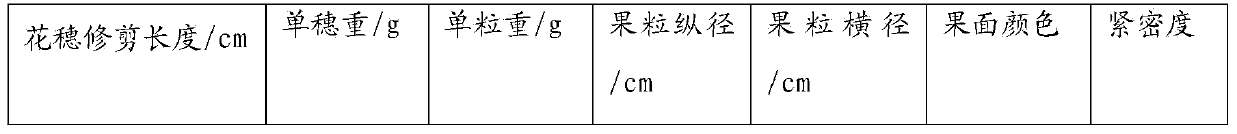

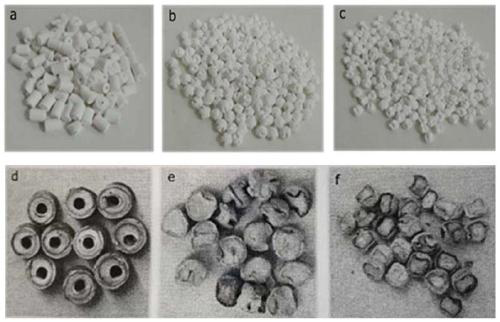

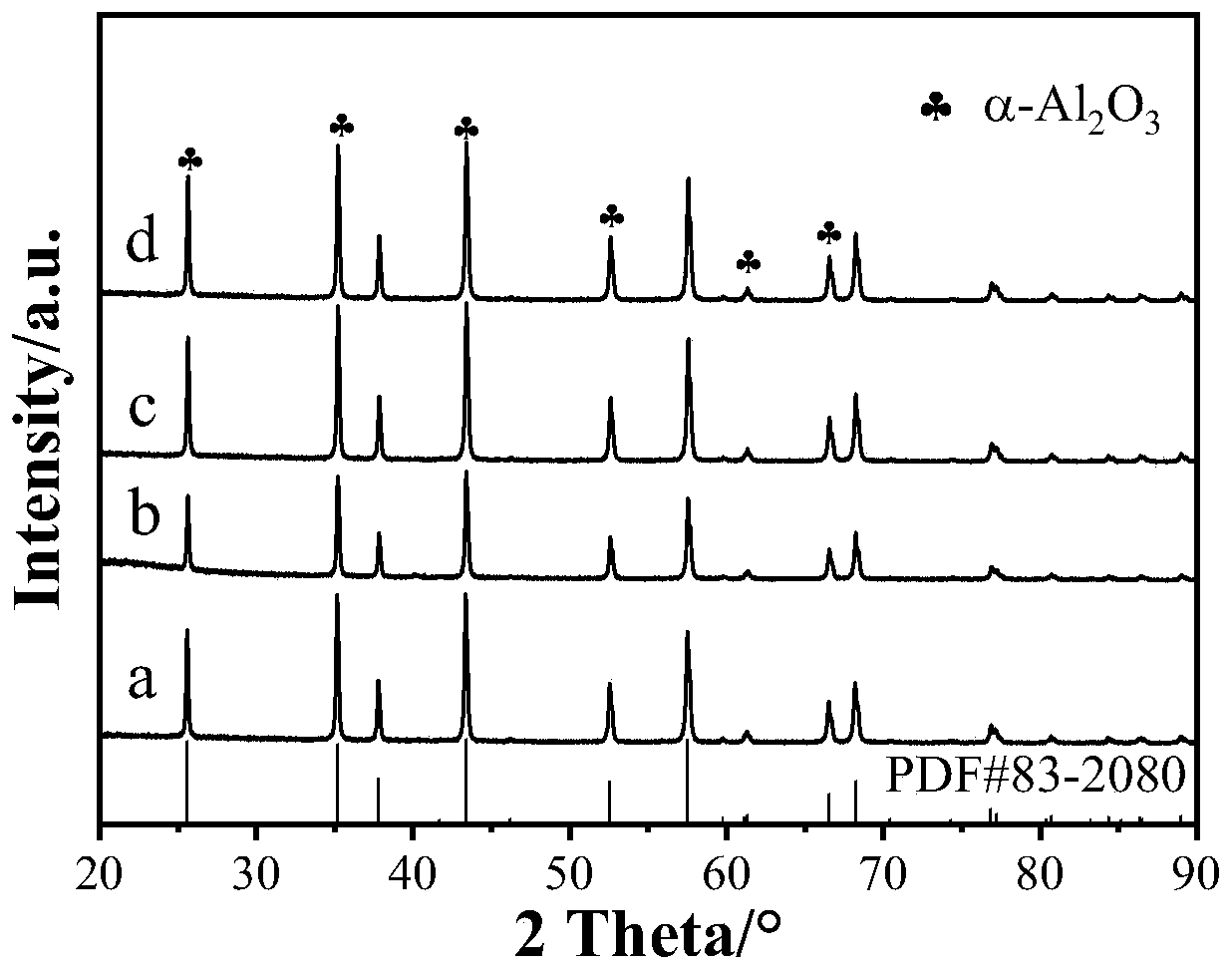

The invention relates to a catalyst for synthesizing diethyl oxalate by CO gas-phase coupling of ethyl nitrite and a preparation method thereof. The catalyst comprises a carrier, an active component palladium and a metal auxiliary agent iron, wherein the carrier is commercial hollow columnar [alpha]-Al2O3, the content of the active component palladium accounts for 0.1-1.0 wt% of the weight of thecarrier, and the content of the metal auxiliary agent iron accounts for 0.1-1.0 wt% of the weight of the carrier. According to the preparation method, a commercial hollow columnar carrier is adopted,and vegetable tannin and / or anhydrous dextrose and / or polyvinylpyrrolidone are / is added, so that palladium metal nanoparticles in the catalyst are smaller, the dispersity is higher, and the palladiumloading capacity is lower. The catalytic activity of the catalyst is basically improved by more than two times, the cost of the catalyst is reduced by more than four times, the prepared catalyst carrier is suitable for filling of a fixed bed with high space velocity by taking industrialization as a reference, and more precious experience is provided for industrialization of diethyl oxalate production.

Owner:TIANJIN UNIV

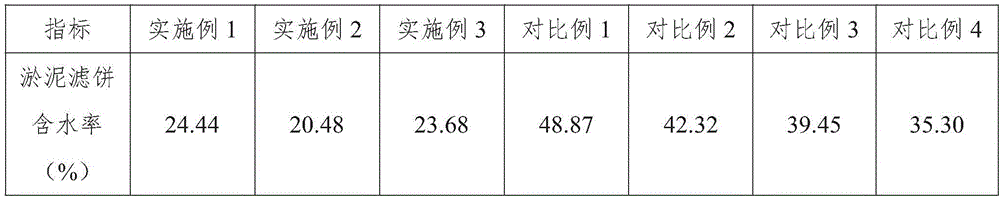

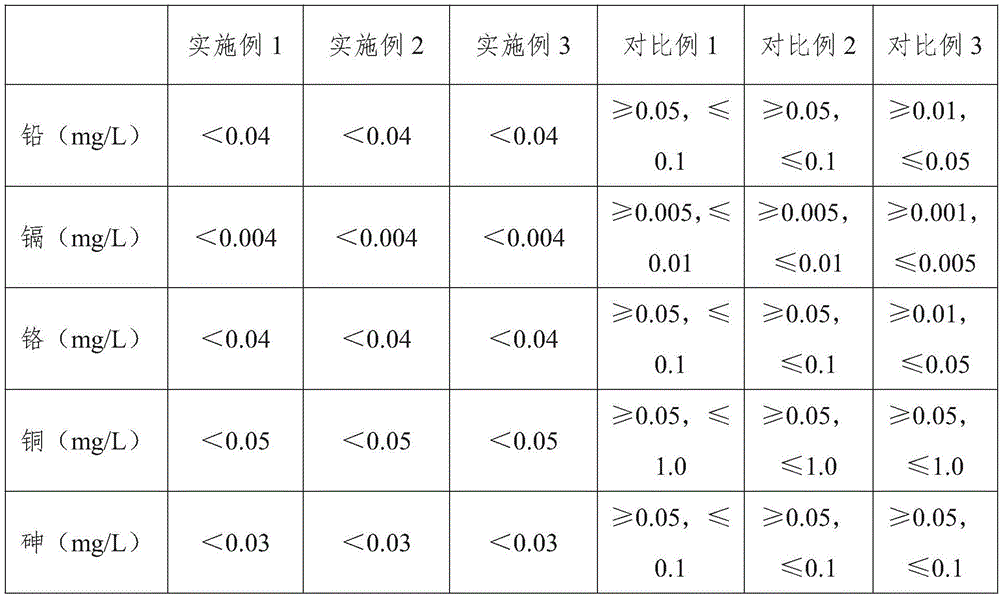

Quick dewatering process for city watercourse sludge

ActiveCN105776817AReduce turbidityLow absorbanceSludge treatment by de-watering/drying/thickeningCelluloseWater quality

The invention belongs to the field of sludge treatment, and particularly relates to a quick dewatering process for city watercourse sludge. The dewatering process for the city watercourse sludge includes putting the sludge into a stacking pool, stirring the sludge, adding polyanionic celluloses, performing initial dewatering, adding composite flocculants, stirring evenly, and deterring the sludge in a belt filter press to obtain dewatered sludge. The dewatering process has the advantages of simple operation, good dewatering effect and capability of improving water quality of sludge filter liquor and reducing environment pollution, is a low-cost environment-friendly sludge dewatering process and is beneficial to mass promotion and application.

Owner:广州珞珈环境技术有限公司

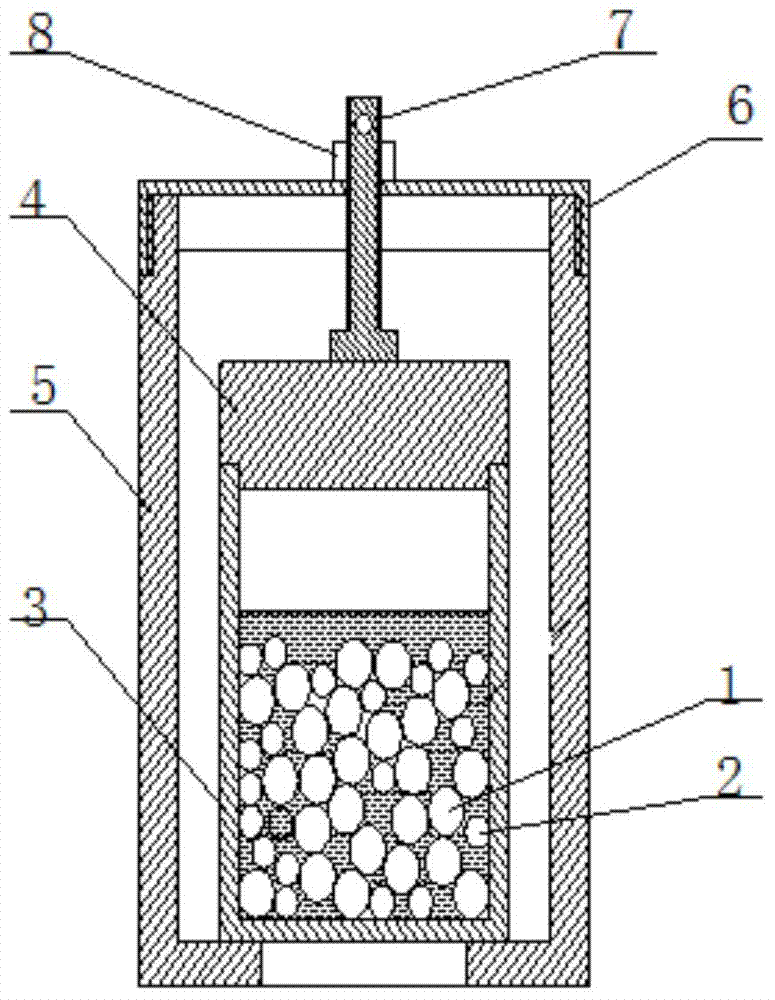

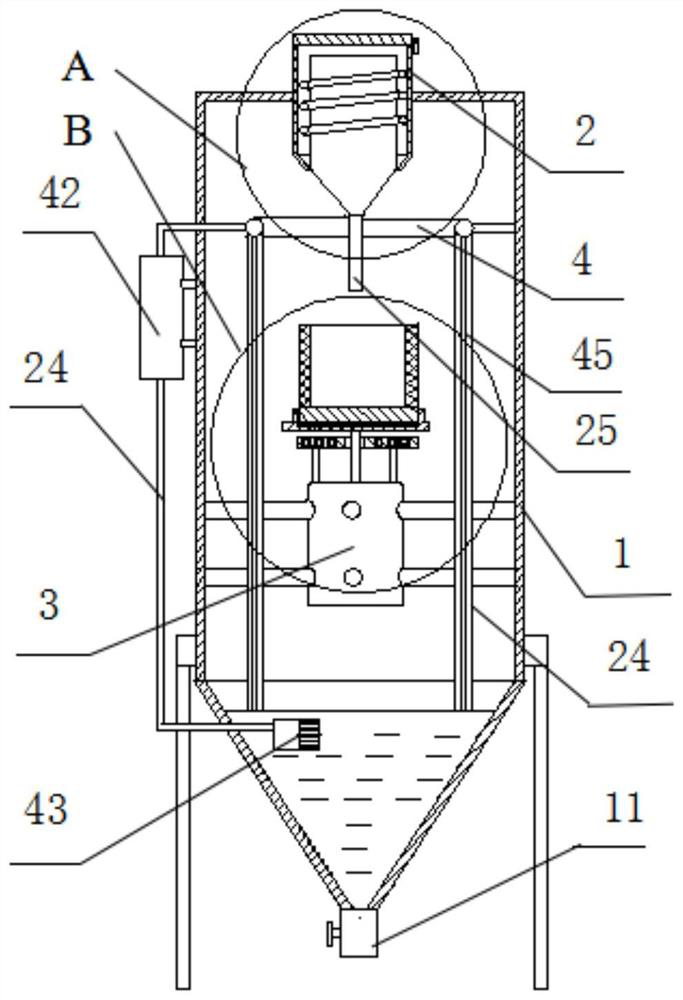

Metal powder material preparation device and method

PendingCN111940749AReduce particle sizeQuality improvementTransportation and packagingMetal-working apparatusWater pipeRotational axis

The invention provides a metal powder material preparation device and method. The device comprises a tank, a rotating motor and an annular water pipe; a melting furnace is arranged at the top of the tank, and circulating water is contained in the bottom of the tank; the rotating motor is fixedly connected to the inner wall of the tank, a rotating shaft is arranged on the rotating motor, the upperend of the rotating shaft is connected with a rotating table, a rotating barrel is fixedly arranged on the rotating table, and screen holes are distributed in the barrel wall of the rotating barrel; and a circle of drainage holes are formed in the lower edge of the annular water pipe, the annular water pipe communicates with the upper end of a circulating water pipe, the lower end of the circulating water pipe extends into circulating water, and a circulating booster pump is arranged in the middle of the circulating water pipe. The device has the beneficial effects that the screen holes are distributed in the barrel wall of the rotating barrel of the device, the screen holes can prevent liquid drops of metal liquid thrown out of the rotating barrel from being too large, and therefore the quality of metal solid powder materials is improved; and the annular water pipe can spray impact water flow downwards, and the impact water flow further crushes the metal liquid drops and enables the metal liquid drops to be rapidly cooled to form metal powder.

Owner:沙洋富栩新材料技术有限公司

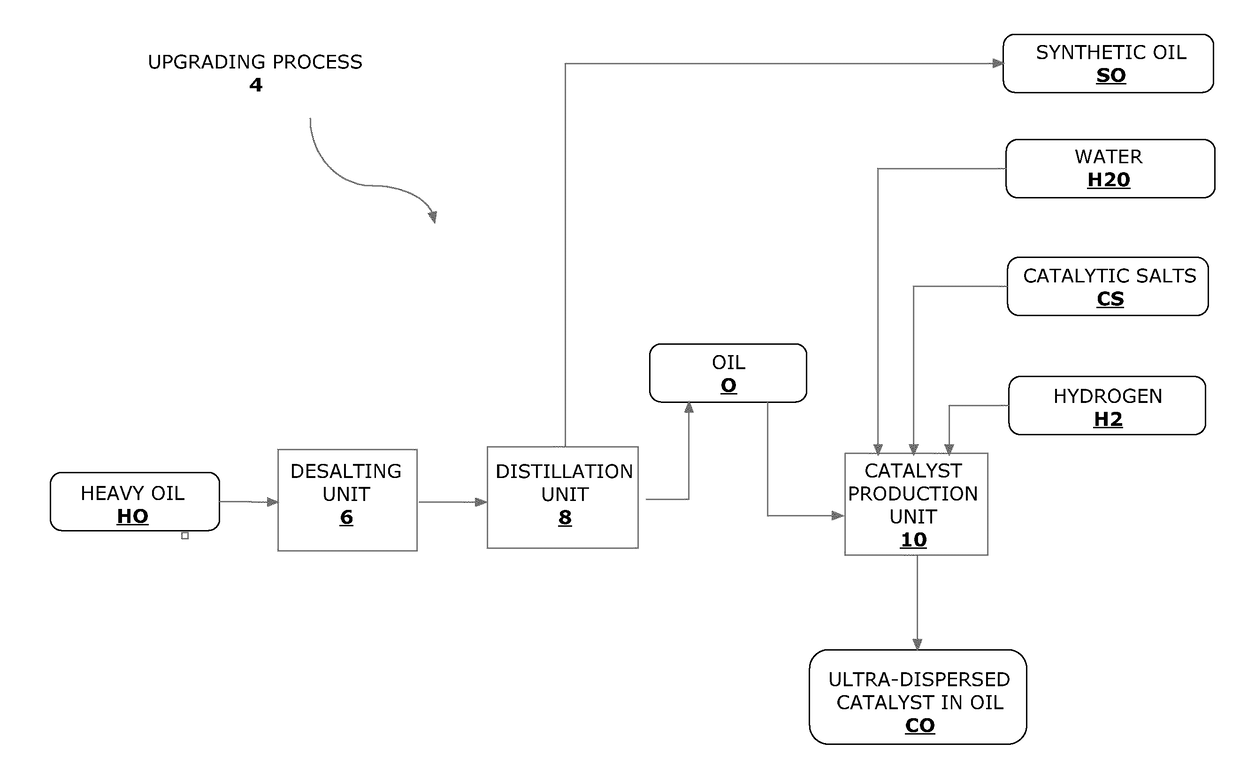

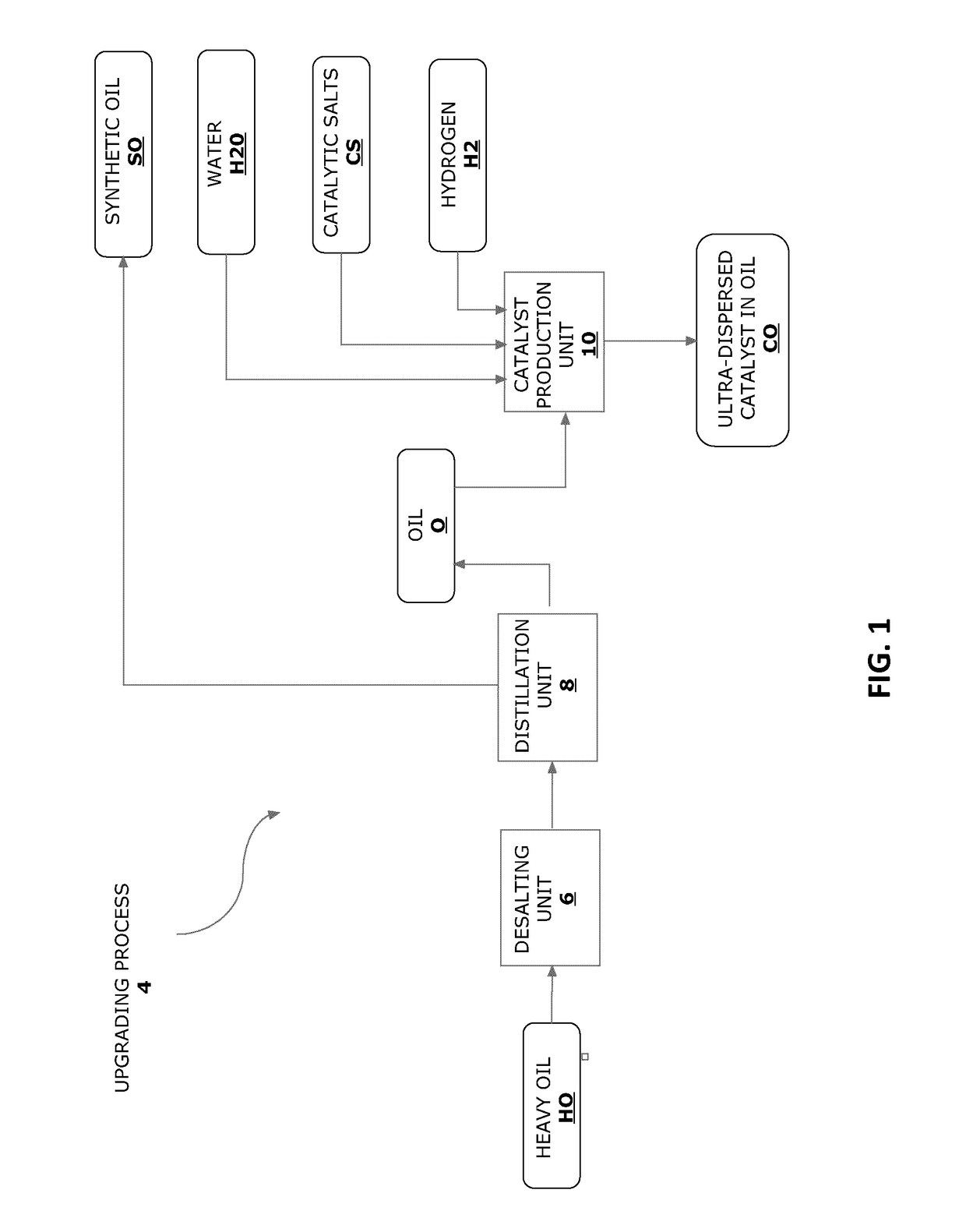

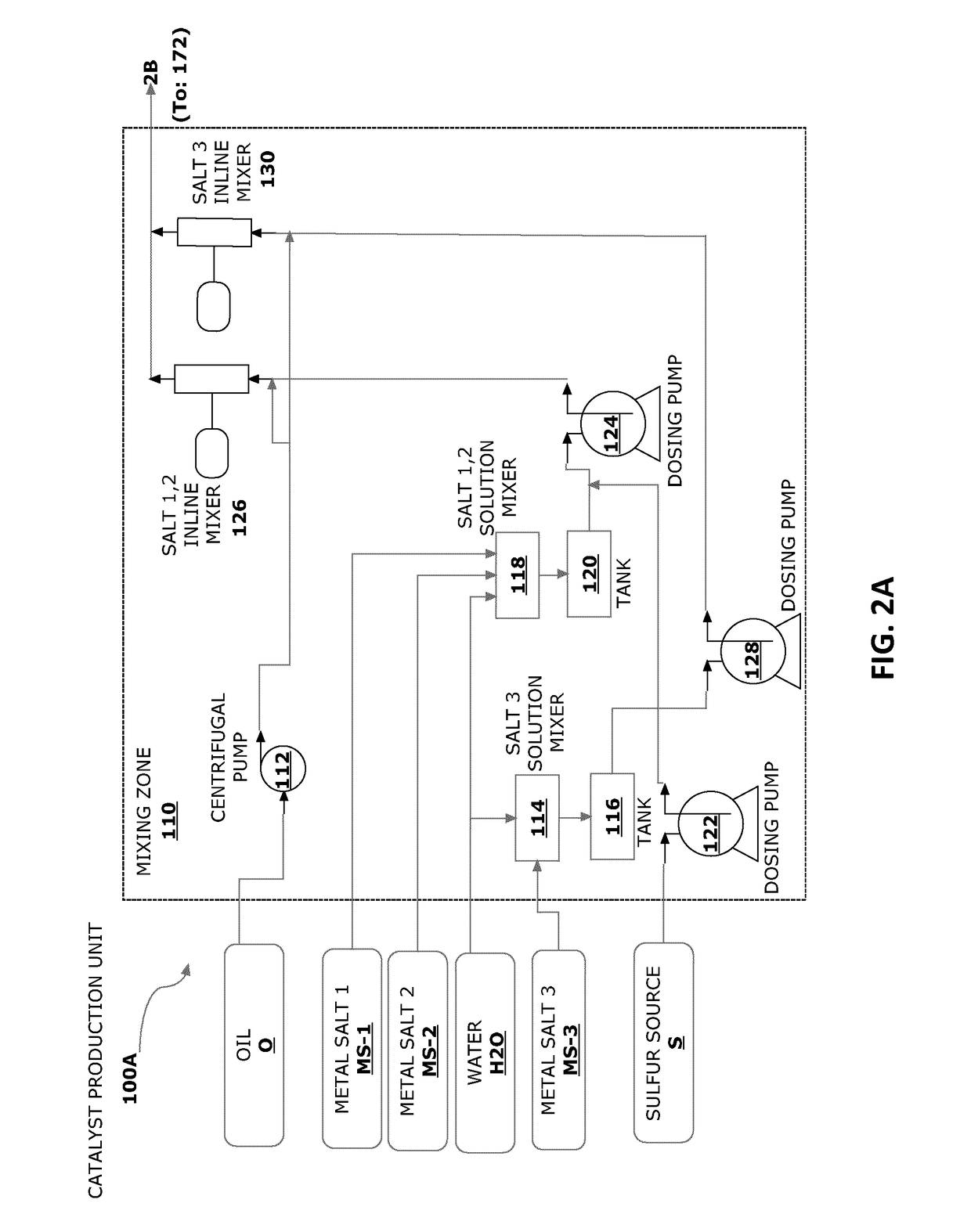

Catalyst preparation unit for use in processing of heavy hydrocarbons

ActiveUS20180086990A1Reduce particle sizeSmall particle sizeHydrocarbon distillationCatalyst activation/preparationProduct gasHydrocarbon

A catalyst preparation unit for producing an activated hydrocarbon-catalyst mixture. The catalyst preparation unit includes one or more catalyst reactant input conduits; a hydrocarbon input conduit; a water input conduit; one or more catalyst reactant mixing and conveyance systems for receiving and mixing catalyst reactants from the catalyst component input conduits and water provided by the water input conduit to provide one or more catalyst reactant solutions; one or more hydrocarbon mixing and conveyance systems for receiving and mixing the catalyst reactant solutions and hydrocarbons provided by the hydrocarbon input conduit to produce a hydrocarbon-catalyst reactant mixture; at least one reactor located downstream of the mixers, for receiving and activating the hydrocarbon-catalyst reactant mixture, thereby producing the activated hydrocarbon catalyst mixture; a gas / liquid separator located downstream of the reactor, for removing vapors and gas from the activated hydrocarbon-catalyst mixture; and an output conduit for transporting the activated hydrocarbon-catalyst mixture away from the catalyst preparation unit.

Owner:PC CUPS LTD

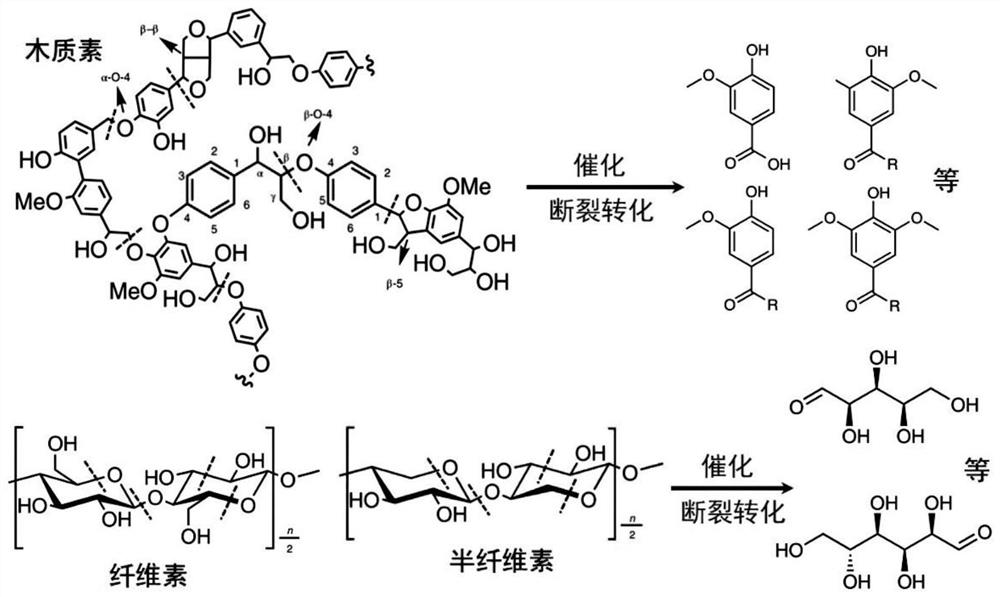

Method for preparing biomass fuel by catalyzing rice straw

InactiveCN108913176AReduce particle sizeIncreases chances of effective chemical reaction collisionsPhysical/chemical process catalystsBiofuelsRice strawSolvent

The invention discloses a method for preparing biomass fuel by catalyzing rice straw. The method comprises the following steps that the rice straw serves as a main raw material, primary pretreatment is carried out on the rice straw so as to obtain straw powder, then secondary pretreatment is carried out on the straw powder so as to obtain a straw suspension II. According to the method, the structure of cellulose is changed through the pre-treatment process, the size of particles of the cellulose is decreased, the probability of effective chemical reaction collision between cellulose moleculesand a solvent is improved, and the yield of a final target product is increased; and a catalyst carrier is used for adsorbing a catalyst, then the carrier is taken as a unit, a target substrate is catalyzed, and therefore a good effect is achieved.

Owner:ANHUI SHENGBAO NEW ENERGY TECH CO LTD

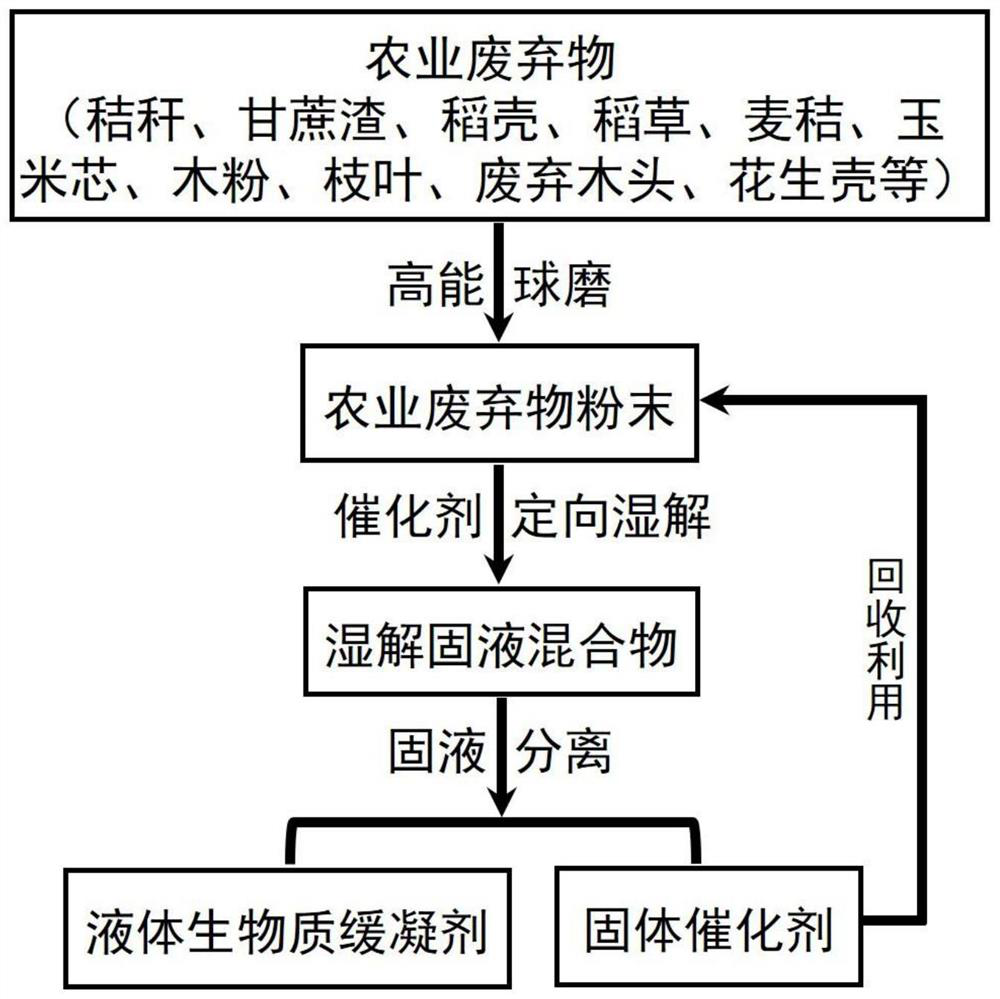

Method for preparing biomass retarder from agricultural wastes, and application of biomass retarder

The invention provides a method for preparing a biomass retarder from agricultural wastes, and application of the biomass retarder. The method comprises the following steps: 1) performing high-energy ball milling on the agricultural wastes to obtain agricultural waste powder; 2) carrying out directional wet degradation on the agricultural wastes obtained in the step 1) through a metal-loaded solid acid catalyst; and 3) carrying out solid-liquid separation on the wet decomposition product to obtain the liquid biomass retarder, and recovering the catalyst at the same time. The biomass retarder prepared by the invention is good in water solubility, green, degradable, excellent in performance and low in cost, the whole production process is low in energy consumption and small in pollution, and the biomass retarder can be used as a cement retarder in cement admixtures. The invention provides a feasible technical path for high-value utilization of agricultural wastes and application of the agricultural wastes in the field of construction industry.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Method for preparing coix seed oil composite nanoparticles

ActiveCN111228420AStable packaged functional propertiesExtended stayImmunological disordersMacromolecular non-active ingredientsBiotechnologyAlcohol ethyl

The invention discloses a method for preparing coix seed oil composite particles. The method comprises the following steps: dissolving an alcohol-soluble protein in an ethanol solution, adding coix seed oil so as to prepare a dispersion solution, then, adding a polysaccharide solution until the mass percent of polysaccharides in the dispersion solution is 0.1%-0.5%, adjusting a pH value to 2-7, carrying out rotary evaporation to remove ethanol, then, adding a cationic solution until the mass percent of cations in a reaction system is 0.05%-0.50%, and carrying out spray drying, thereby obtaining the coix seed oil composite nanoparticles. According to the method disclosed by the invention, wall material loss of the nanoparticles is lowered, particle sizes of the nanoparticles can be furtherreduced through a static crosslinked action of the cations and the polysaccharides, and a protective layer of a coix seed oil-alcohol-soluble protein is formed; and in a process that the coix seed oil-alcohol-soluble protein enters an intestinal tract of a human body, wall material loss of the alcohol-soluble protein is reduced, and the coix seed oil can reach the intestinal tract in good condition.

Owner:FOSHAN UNIVERSITY

Bean puffed food and preparation method thereof

PendingCN111357939AShorten the lengthReduce particle sizeFood freezingFood ingredientsNutritive valuesProcess engineering

The invention relates to bean puffed food and a preparation method thereof. The preparation method includes the following steps: putting dry beans in water to soak for 5-15 h, adopting a grinding wheel mill to perform grinding so as to obtain first soybean milk, and using a colloid mill to perform grinding so as to obtain second soybean milk; ripening the second soybean milk, and adding a coagulating agent to prepare jellied bean curd; and performing mechanical expression on the jellied bean curd, performing freezing until the central temperature is below -18 DEG C, and performing frying, deoiling and seasoning so as to obtain the bean puffed food. The preparation method fully utilizes bean dregs, so that green and pollution-free production can be realized, massive waste can be avoided, the exquisite taste of products can be guaranteed, and the crispness and nutritional values of the products can be enhanced; and therefore, bases can be provided for the product production utilizing whole beans.

Owner:劲仔食品集团股份有限公司

Organic fertilizer preparation formula and preparation and application methods thereof

PendingCN114507105APromote fermentationReduce particle sizeBio-organic fraction processingAlkali orthophosphate fertiliserBiotechnologyMicroorganism

The invention discloses a preparation formula of an organic fertilizer and a preparation and application method thereof. The preparation formula of the organic fertilizer comprises the following raw materials: rabbit manure; fine bran; a phosphate-solubilizing microbial agent; a silicate microbial agent; rapeseed oil residue; carbonizing the rice hulls; root nodules and nitrogen-fixing bacteria inoculants; and water. The preparation process of the organic fertilizer has the advantages of better fermentation process, high harmful substance removal rate, lower cost, simplicity and convenience in raw material purchase, and greatly shortened fermentation period compared with aerobic fermentation, and in addition, the carbonized rice hulls of porous media are selected as a microbial community reproduction place, so that the interaction rate of microorganisms and soil can be ensured, and the yield of the organic fertilizer is improved. When being applied, the organic fertilizer can be directly sprayed into soil where crop roots are located by a screen, so that the existing organic fertilizer packaging, granulating and transporting cost can be reduced.

Owner:华威远

Preparation method of woven bag flat wires with high stability

InactiveCN110540708AImprove dispersion uniformityReduce tanglingFilament/thread formingMasterbatchWinding machine

The invention belongs to the technical field of plastic woven bag processing, and discloses a preparation method of woven bag flat wires with high stability. The preparation method comprises the following steps: S1, performing swelling pretreatment on ultrahigh-molecular-weight polyethylene and paraffin oil; S2, blending and drying the obtained swollen body, polypropylene particles, polypropylene-graft-maleic anhydride (PP-g-MAH), trimellitic anhydride, an antioxidant, a filling master batch, a light stabilizer, a nucleating agent and hydroquinone; S3, carrying out extruding formation on the material obtained by blending and drying to obtain a film; S4, cooling the film by water, and then cutting the cooled film into blank wires; S5, drawing the blank wires into flat wires by a drawing machine; and S6, shaping the flat wires, and winding the shaped flat wires by a winding machine. According to the invention, polypropylene and ultrahigh-molecular-weight polyethylene are blended to prepare the plastic woven bag flat wires, and the plastic woven bag flat wires have high tensile strength and high stability under different temperature conditions.

Owner:ZAOYANG DONGHANG WOVEN PRINTING CO LTD

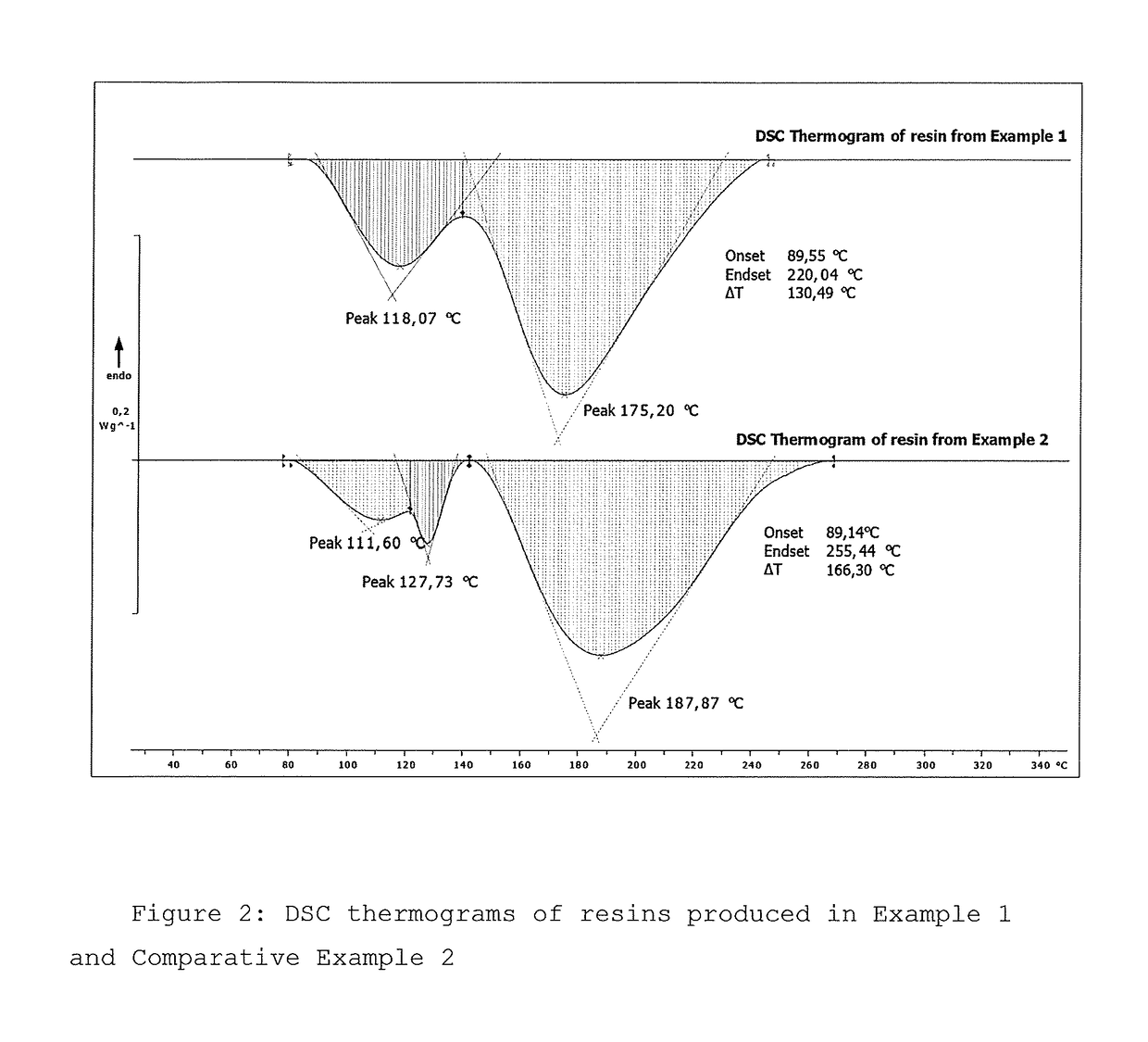

Carrier for electrophotographic developer and process of producing the same

InactiveUS7144670B2Reduce particle sizeExcellent performanceDevelopersElectrographic processes using charge patternBrown iron oxideEngineering

A resin-coated carrier for an electrophotographic developer and a process of producing the carrier. The carrier comprises a ferrite core mainly comprising iron oxide, primarily having a spinel structure, and having a volume average particle size of 20 to 45 μm and a resin coat, wherein the carrier has a magnetization of 65 to 80 emu / g in a magnetic field of 1 KOe, the core has an electric current value of 50 to 150 μA and a surface smoothness uniformity of 75% or higher, and the amount of the resin coat is 0.1 to 5.0% by weight based on the core.

Owner:POWDERTECH

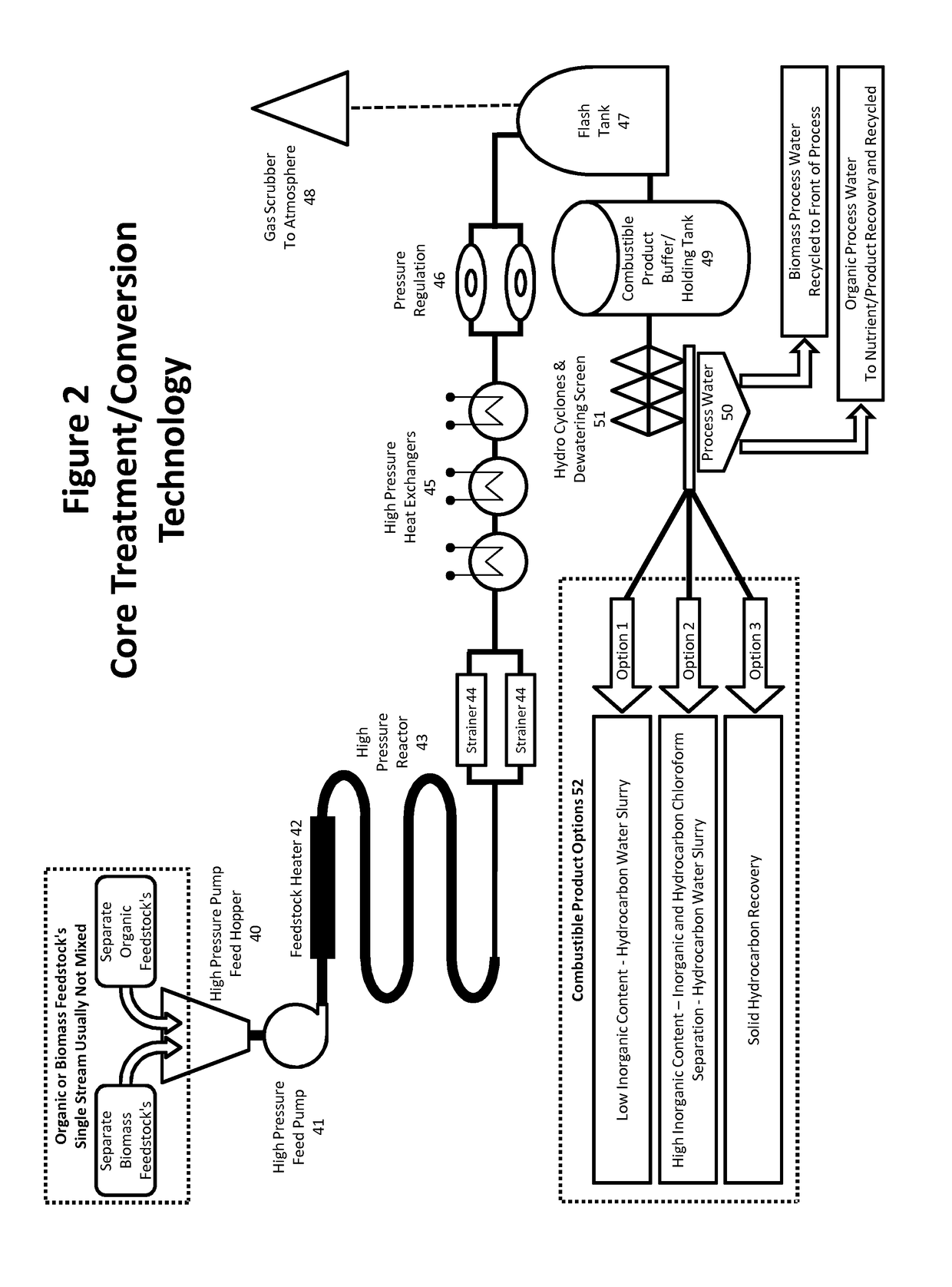

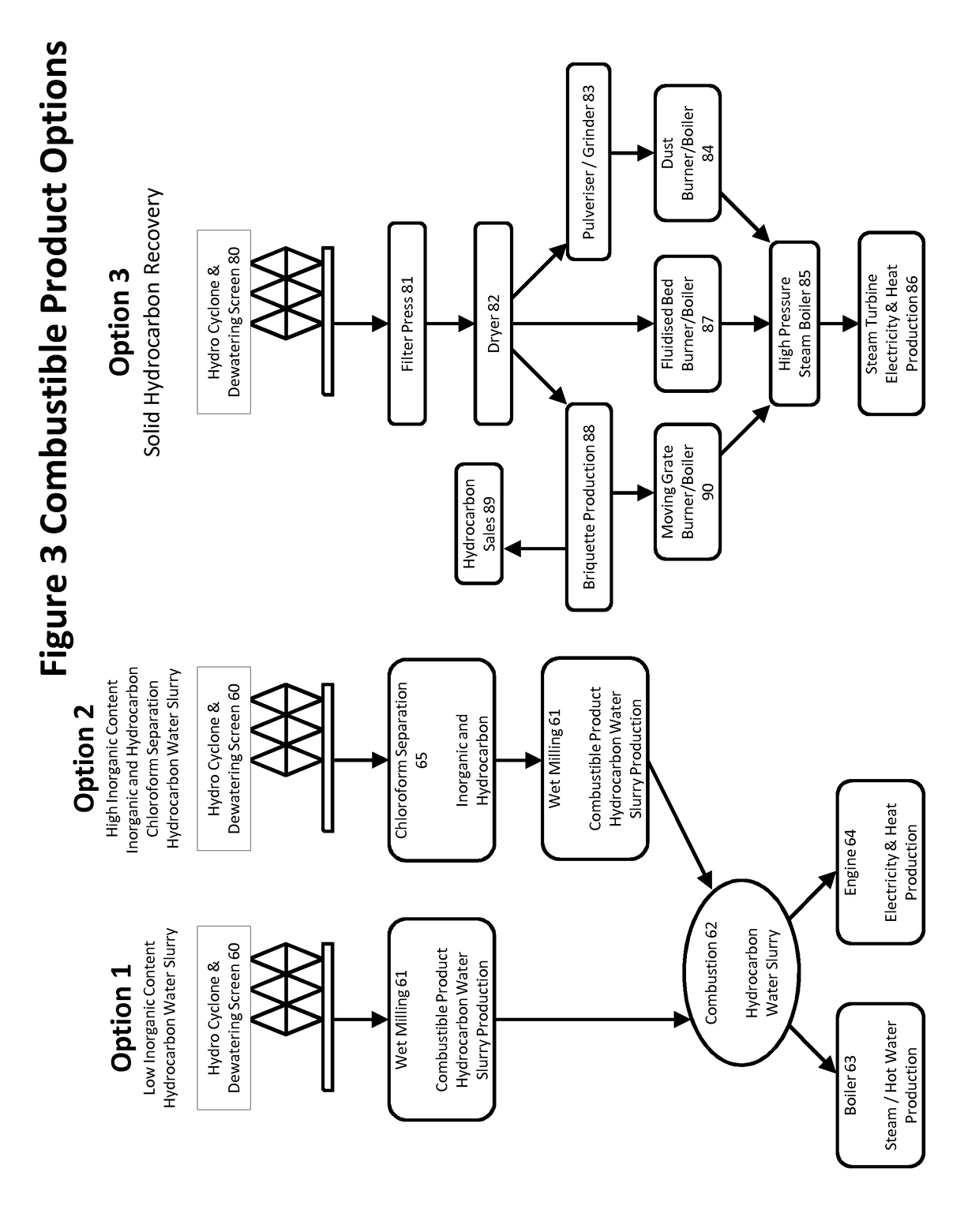

Process for producing a combustible product

InactiveUS20190078032A1Reduce particle sizeHigh calorific valueBiofuelsSolid fuelsEmulsionBiomass feedstock

A process for producing combustible product from an organic or biomass feedstock, the process comprising: mixing the feedstock with an alkaline material to give an alkaline aqueous mixture; heating the mixture by ohmic heating to a temperature in the range of about 280° C. to about 320° C. and reacting the mixture under subcritical conditions at the said temperature range and a pressure of about 6.6 to about 11.6 MPa (65 bar gauge to about 115 bar gauge); and removing at least some of the water to leave a combustible product, which may be used to form an aqueous slurry, suspension or emulsion and combusted in a suitable engine.

Owner:INDAL CHEM GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com