Quick dewatering process for city watercourse sludge

A technology for rapid dewatering of river silt, applied in water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, sludge treatment, etc. It can solve problems such as poor dewatering effect and substandard discharge of sludge residual water. , to achieve the effect of being conducive to promotion and application, good dehydration effect, and improving dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

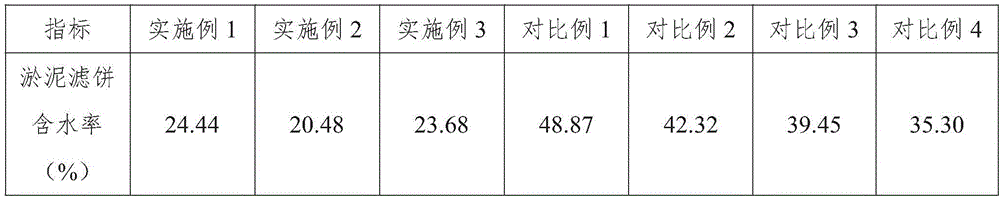

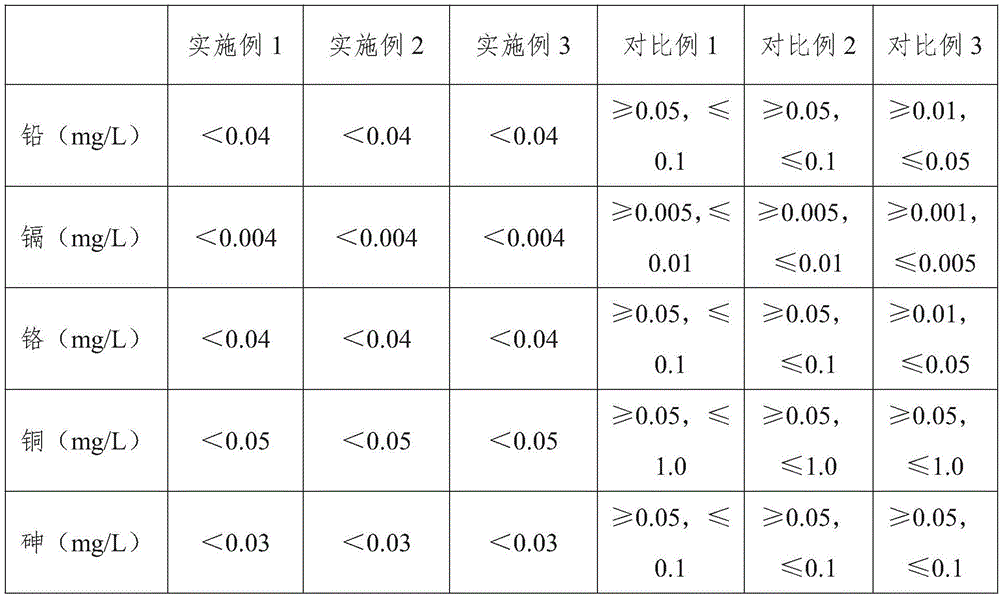

Embodiment 1

[0028] Embodiment 1, a kind of rapid dehydration process of urban river silt

[0029] S1 Put the silt in the river channel into the storage tank through the cutter suction boat or excavator, remove the impurities of the silt, thicken it and stir it to get the mud;

[0030] S2 Stir the mixture obtained in step S1 evenly, sprinkle 0.05% of the total weight of the mud on the surface of the polyanionic cellulose, let it stand for 20 minutes, remove the viscous liquid on the surface, and perform preliminary dehydration to obtain the initial dewatered slurry;

[0031] S3 is the composite flocculant of 90mg / L to the concentration of 0.01% of the initial dewatered slurry obtained in step S2, and the composite flocculant is composed of polyferric sulfate, polyanionic cellulose and chitosan oligosaccharide The weight ratio is 1:1:5, stirred evenly, and after standing for 60 minutes, the mud is put into the belt filter press with a screw pump. The washing water pressure of the upper and ...

Embodiment 2

[0032] Embodiment 2, a kind of rapid dehydration process of urban river silt

[0033] S1 Put the silt in the river channel into the storage tank through the cutter suction boat or excavator, remove the impurities of the silt, thicken it and stir it to get the mud;

[0034] S2 Stir the mixture obtained in step S1 evenly, sprinkle 0.08% of the total weight of the slurry on the surface of the slurry with polyanionic cellulose, let it stand for 15 minutes, remove the viscous liquid on the surface, and perform preliminary dehydration to obtain the initial dewatered slurry;

[0035] S3 adds the concentration of 0.04% of the initial dewatered slurry gross weight to the initial dewatered slurry obtained in step S2 and is a composite flocculant of 80mg / L, and the composite flocculant is composed of polyferric sulfate, polyanionic cellulose and chitosan oligosaccharide The weight ratio is 2:1:4, stir evenly, and after standing for 50min, use a screw pump to put the mud into the belt fil...

Embodiment 3

[0036] Embodiment 3, a kind of rapid dehydration process of urban river silt

[0037] S1 Put the silt in the river channel into the storage tank through the cutter suction boat or excavator, remove the impurities of the silt, thicken it and stir it to get the mud;

[0038]S2 Stir the mixture obtained in step S1 evenly, sprinkle 0.1% of the total weight of the mud on the surface of the polyanionic cellulose, let it stand for 10 minutes, remove the viscous liquid on the surface, and perform preliminary dehydration to obtain the initial dewatered slurry;

[0039] S3 adds the concentration of 0.08% of the initial dewatered slurry gross weight to the initial dewatered slurry obtained in step S2 and is a composite flocculant of 70mg / L, and the composite flocculant is composed of polyferric sulfate, polyanionic cellulose and chitosan oligosaccharide The weight ratio is 3: 2: 3, stir evenly, and after standing for 40 minutes, use a screw pump to put the mud into the belt filter press....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com