Patents

Literature

79results about How to "Reduce the content of suspended solids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

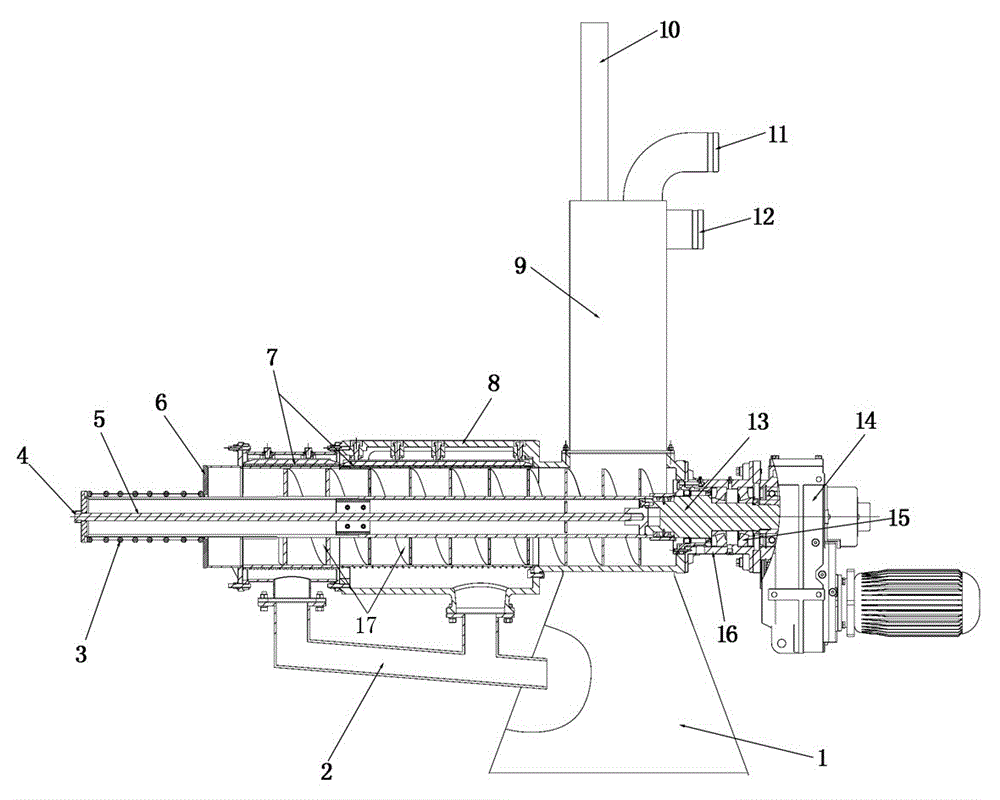

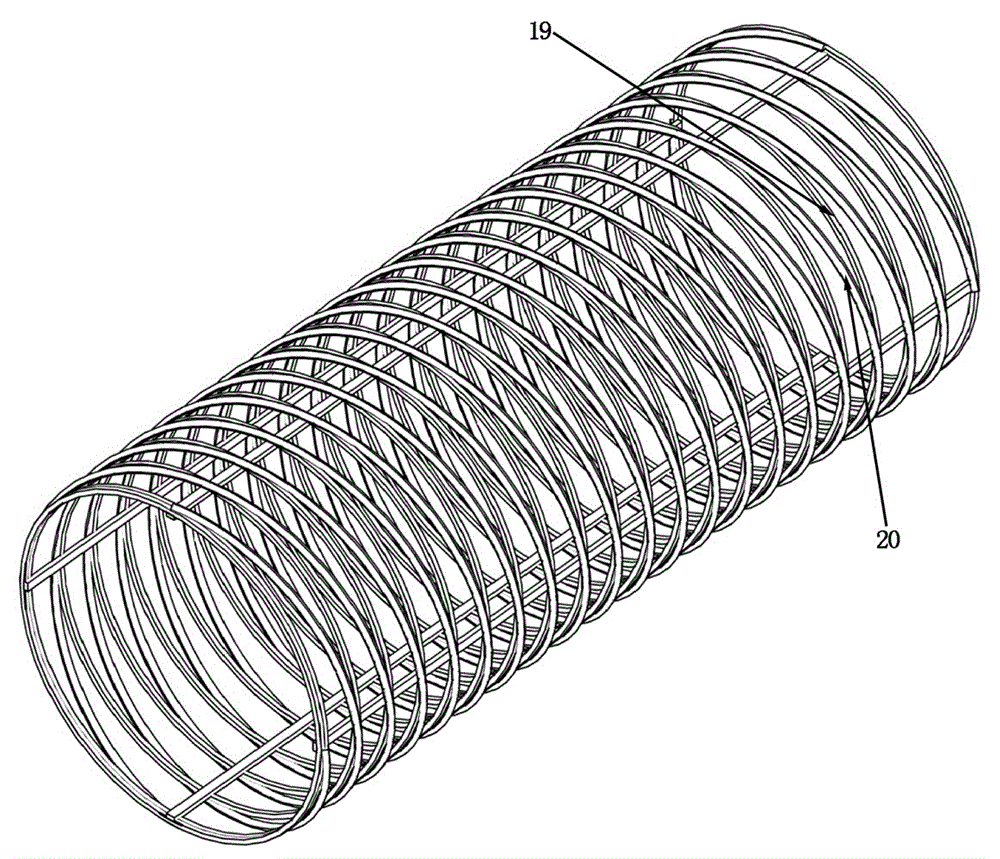

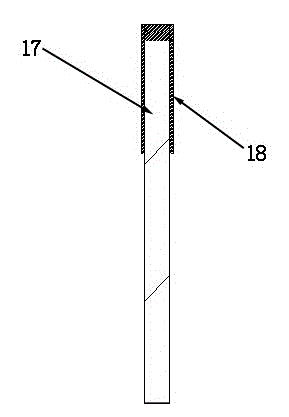

Spiral extrusion type solid-liquid separator and solid-liquid separating method

The invention discloses a spiral extrusion type solid-liquid separator. The spiral extrusion type solid-liquid separator comprises a feeding mechanism, a power mechanism, a spiral extrusion mechanism, a solid discharging mechanism and a liquid discharging mechanism, wherein the spiral extrusion mechanism comprises a main body sleeve, a filter screen cylinder and a packing auger; the filter screen cylinder is arranged in the main body sleeve, and the packing auger is arranged in the filter screen cylinder; blades of the packing auger are composed of spiral blade bodies and high-wear-resisting rubber coating strips coated on the outer edges of the spiral blade bodies; the packing auger comprises a front section packing auger body and a rear section packing auger body; the filter screen cylinder comprises a front section filter screen cylinder body and a rear section filter screen cylinder body; and the solid discharging mechanism is characterized in that an annular cover plate is arranged at the position of a discharging port of the main body sleeve, and the annular cover plate is connected with a compression spring in an abutting manner. Meanwhile, the invention further discloses a solid-liquid separating method using the spiral extrusion type solid-liquid separator. The spiral extrusion type solid-liquid separator has multiple good effects when being used for conducting solid-liquid separation on feces of beasts and birds, biogas residue and the like.

Owner:DINGZHOU SIFENG ENVIRONMENTAL PROTECTION TECH

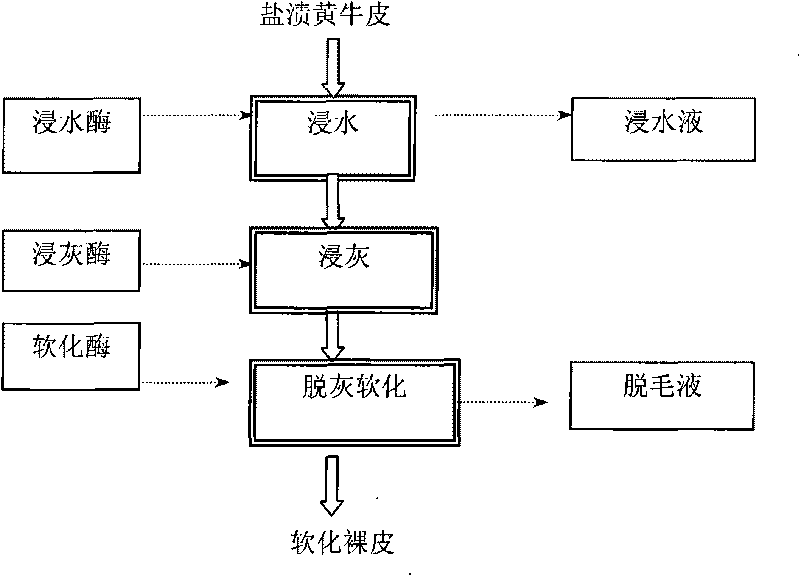

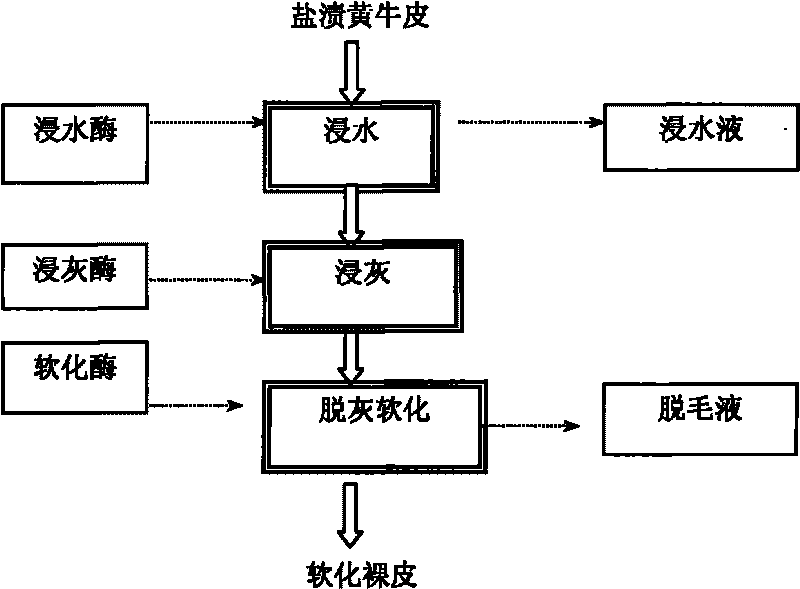

Leather making bio-pretreatment method

The invention discloses a leather making bio-pretreatment method. By using a biotechnology to replace or partly replace a chemical method and utilizing compound enzyme preparations including lipase and protease, the method strengthens processes of soaking and degreasing, accelerates dispersion of collagen fibers, optimizes the enzyme bating process, shortens the treatment time and reduces the consumption of water and the use of a chemical additive. Compared with the traditional leather-making technology, the leather making bio-pretreatment method can accelerate the soaking process and the fiber dispersion process, shorten the process time by 6-12h, realize water saving by about 30 percent and COD (Chemical Oxygen Demand) emission reduction by 20-40 percent, lower the dosage of protosulphide by 40-50 percent and the like. In the invention, on the basis of lowering the consumption of the protosulphide by using a hair-saving method, an environmental friendly auxiliary liming agent which is prepared by utilizing the biotechnology and a physicochemistry principle can completely consume residual sulfide in waste liquid to enable unhairing waste liquid and limed pelts not to contain the sulfide and completely eliminate pollution of the sulfide; therefore, the invention has the advantages of simple operation and low cost without influencing the product quality. In addition, in the whole pretreatment process, the biological enzyme preparation is considered to be utilized to efficiently and harmlessly remove components on animal skin unrelated to leather making.

Owner:FENGAN LEATHER

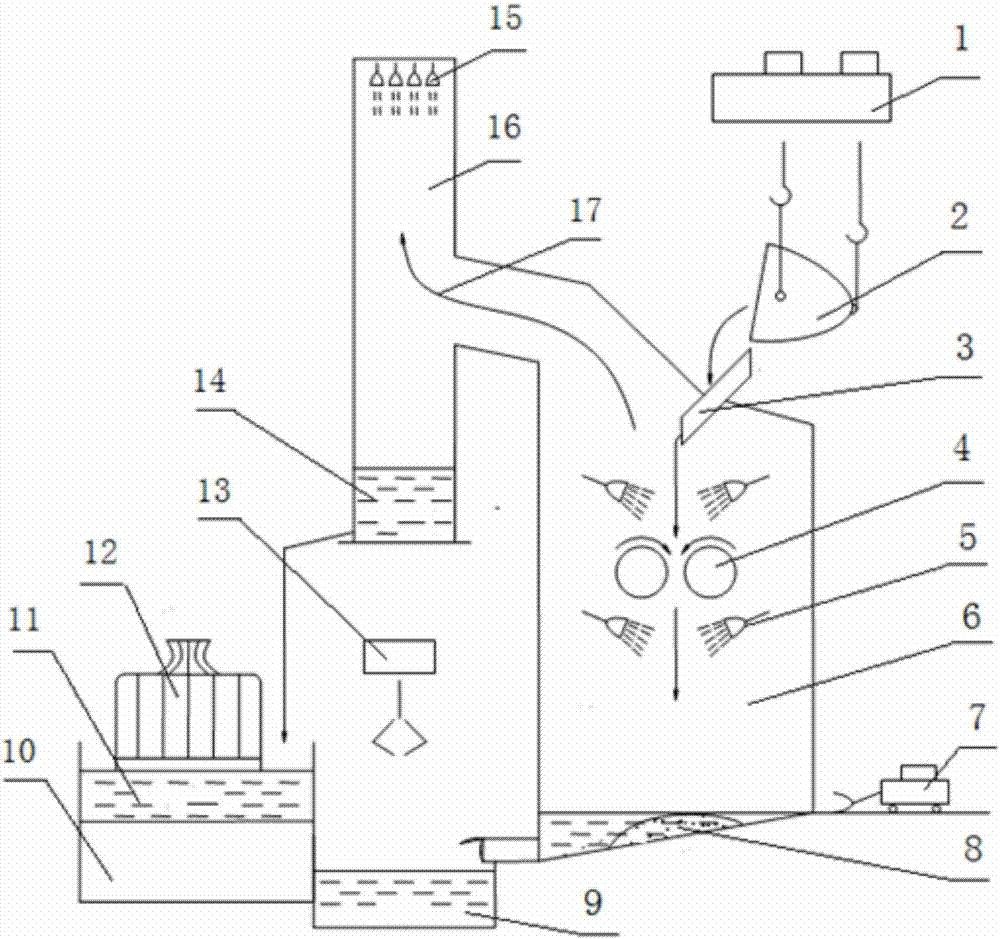

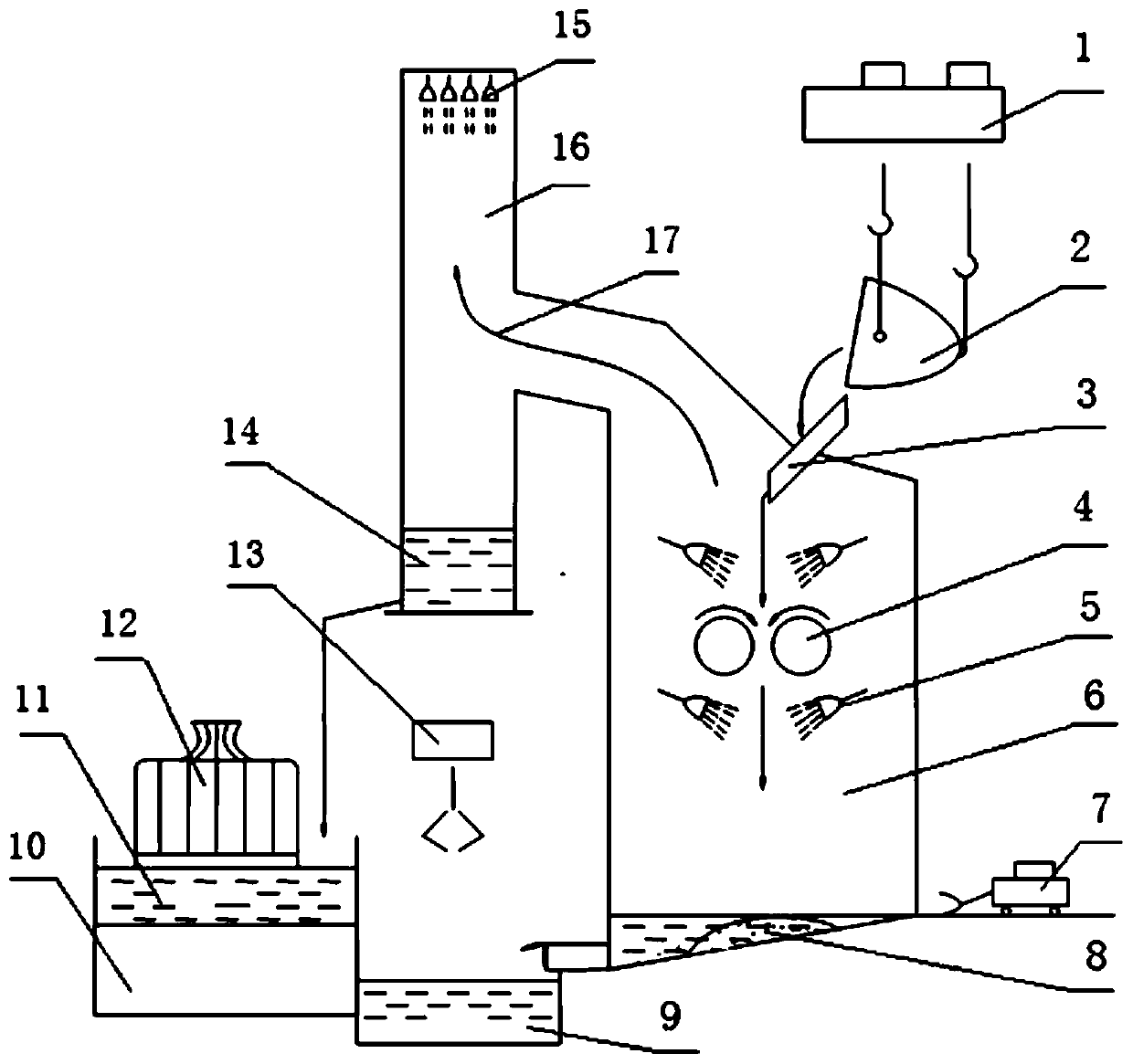

Converter steel slag treatment device and method

ActiveCN107287368AEasy to separateReduce moisture contentRecycling and recovery technologiesCooling towerSlag

The invention relates to a converter steel slag treatment device which comprises a crown block, a slag ladle, a chute, a forklift, a steel slag pool, a bottom filtering pool, a water pump house, a water storage tank, a cooling tower, a bridge-type grab crane, a chimney, a hydraulic roller couple, nozzles, a granulating room and a condensate water tank, wherein a lifting hook of the crown block is connected with the slag ladle, the outlet of the slag ladle is connected with the inlet of the chute, and the outlet of the chute is connected with the upper part of the hydraulic roller couple; nozzles a are symmetrically arranged on the two sides of the upper part and the two sides of the lower part of the hydraulic roller couple, and the hydraulic roller couple and the nozzles a are all arranged in the granulating room; the steel slag pool is arranged at the lower part of the granulating room, and the forklift is arranged on the outer side of the lower part of the granulating room. The invention further discloses a converter steel slag treatment method. The flow of the method is as follows: steel slag dumping, steel slag crushing, steel slag granulating, slag washing water filtering and vapor condensation recovery. The converter steel slag treatment device has the advantages of high slag treatment efficiency, compact occupied area, energy conservation, environment protection and no pollution, adapts the fast-paced production mode of a converter, is good for magnetic separation extracting of grain steel and comprehensive application of grain slag, and has remarkable economical benefit.

Owner:北京中冶设备研究设计总院有限公司

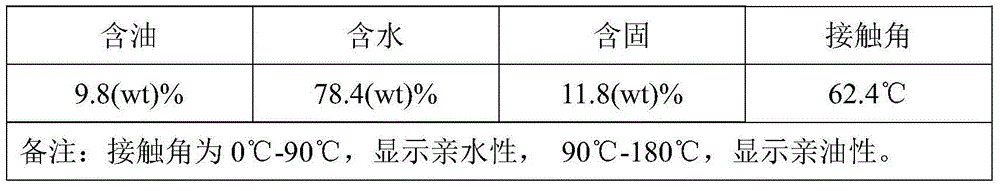

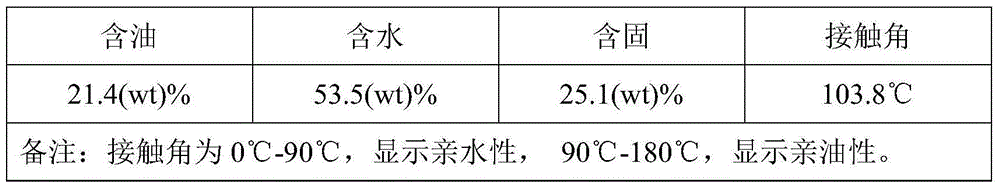

Environment-friendly oil field sludge treating agent and preparation method thereof

InactiveCN105198181AReduce oil sands contentReduce oil contentSludge treatmentSludgeSURFACTANT BLEND

The invention discloses an environment-friendly oil field sludge treating agent and a preparation method thereof. The environment-friendly oil field sludge treating agent comprises surface active substances and a PH value regulator, wherein the surface active substances are an anionic surfactant and a nonionic surfactant. The preparation method comprises the following steps: adding the anionic surfactant into a reaction kettle according to a proportion, adding water, stirring for 10 minutes, controlling the temperature to be 50 DEG C, adding the PH value regulator, stirring for 5 minutes, adding the nonionic surfactant, and stirring for 10 minutes, so as to obtain the environment-friendly oil field sludge treating agent. The environment-friendly oil field sludge treating agent can be used for not only stripping crude oil on the surface of sludge for cleaning, but also reducing the oil sand content of oil slick at the upper part of sludge, and the oil content and the suspension content of water in the middle of the sludge, thereby being low in carbon and environmentally friendly.

Owner:XINJIANG KELI NEW TECH DEV

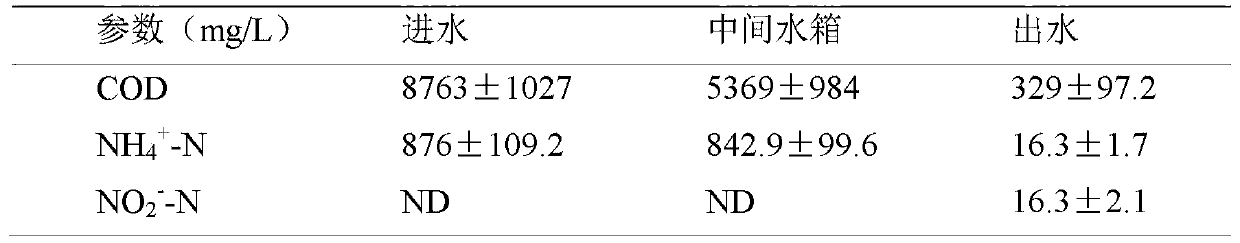

Kitchen wastewater treatment method

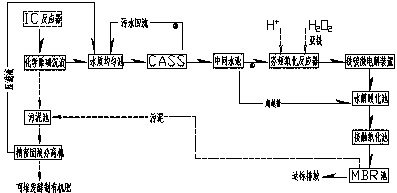

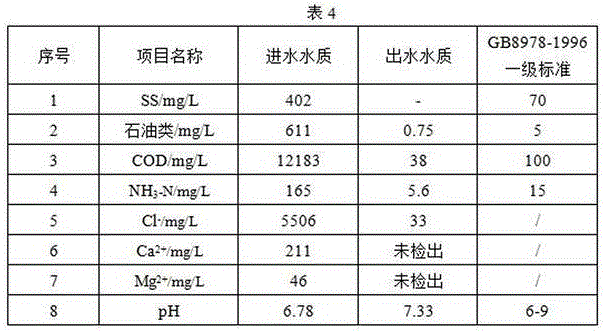

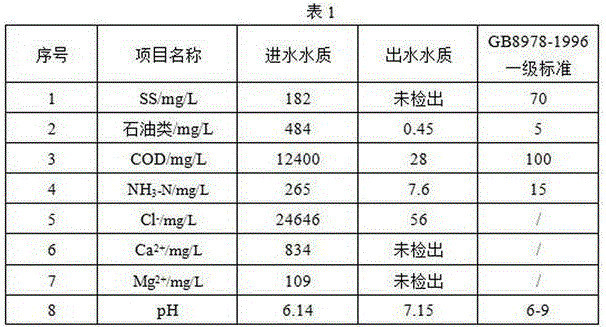

InactiveCN103739173AInhibition of bloomsInhibition of reproductionMultistage water/sewage treatmentChemical oxygen demandElectrolysis

The invention discloses a kitchen wastewater treatment method which comprises the following steps: 1, chemical phosphorus removal is performed on kitchen wastewater flowing out from an IC (internal circulation) reactor; 2, after passing through a water quality equalization tank, the wastewater enters a CASS (Cyclic Activated Sludge System) to react, so that soluble substrates, organisms, phosphorus and an synchronous nitrification and denitrification effect are removed; 3, after the wastewater flows into an intermediate water tank to be subjected to volume regulation, the wastewater enters a Fenton oxidation reactor and an iron-carbon micro-electrolysis device so as to improve biodegradability of the wastewater; 4, after passing through the Fenton oxidation reactor and the iron-carbon micro-electrolysis device, the wastewater directly enters a hydrolysis acidification pool from the intermediate water tank, suspended matter and iron ions are removed and sludge is separated, hydrolyzed and acidified; 5, the wastewater is subjected to aerated oxidation to remove COD (Chemical Oxygen Demand) content; 6, the wastewater enters an MBR (Meane Biological Reactor) pool and hardly degradable substances are degraded, so that the drained wastewater reaches the take-over standard of a sewage treatment plant; 7, after the sludge discharged from a chemical phosphorus removal pool and the MBR pool is processed by a precision solid-liquid separator, solids are prepared into an organic fertilizer and filter-pressing liquid enters the water quality equalization tank.

Owner:HUNAN HAISHANG ENVIRONMENTAL PROTECTION INVESTMENT CO LTD

Treatment process for gas field foam water up-to-standard discharge

InactiveCN106348514AReduce foamingReduce dosageWaste water treatment from quariesWater treatment parameter controlWater qualityEvaporation

The invention discloses a treatment process for gas field foam water up-to-standard discharge. The treatment process comprises the following procedures: performing oil isolation treatment, performing demulsification treatment, performing water quality conditioning treatment, performing coagulation treatment, performing synergic oxidation treatment, performing complexing coagulantion enhancement treatment, performing softening treatment, performing falling film / forced circulation evaporation crystallization treatment, and finally performing up-to-standard discharge on obtained condensed water. By adopting the treatment process, low-cost up-to-standard discharge treatment on various types of high-salt foam water can be achieved.

Owner:SICHUAN YANGSEN PETROLEUM TECH CO LTD

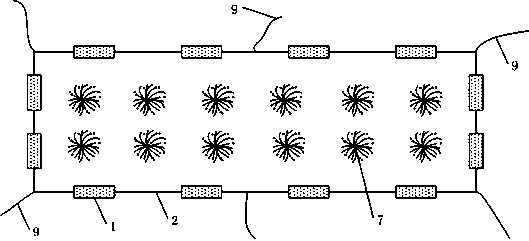

Combined artificial wetland process system for nitrogen and phosphorus removal

InactiveCN106495407ARealize efficient purificationGuaranteed long-term stable operationTreatment using aerobic processesWater/sewage treatment by irradiationConstructed wetlandProcess systems

The invention discloses a combined artificial wetland process system for nitrogen and phosphorus removal. The combined artificial wetland process system comprises a water incoming pipe, a water outgoing pipe and combined artificial wetlands mutually connected serially between the water incoming pipe and the water outgoing pipe, each combined artificial wetland comprises an aerobic biological pond in the upper reach and an artificial wetland in the lower reach, and each artificial wetland comprises a plurality of artificial wetland units; in the artificial wetland of the first combined artificial wetland, the artificial wetland units are parallelly connected mutually and are all vertical underflow artificial wetland units; in the artificial wetland of each of other combined artificial wetlands except for the first combined artificial wetland, the artificial wetland comprises a plurality of groups formed by the artificial wetland units which are serially connected mutually, and the groups are mutually connected parallelly; the artificial wetland units in each group include horizontal underflow artificial wetland units and surface flow artificial wetland units. The combined artificial wetland process system has an efficient nitrogen and phosphorus removal function and can obviously improve water quality.

Owner:HUNAN XIANDAO YANGHU RECLAIMED WATER CO LTD

Method for comprehensively improving quality of eutrophic water body

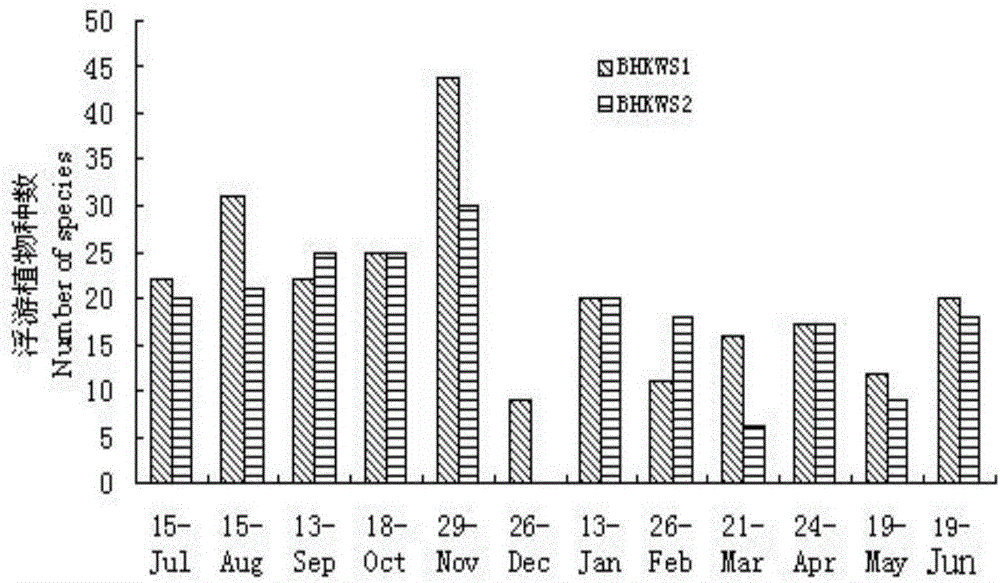

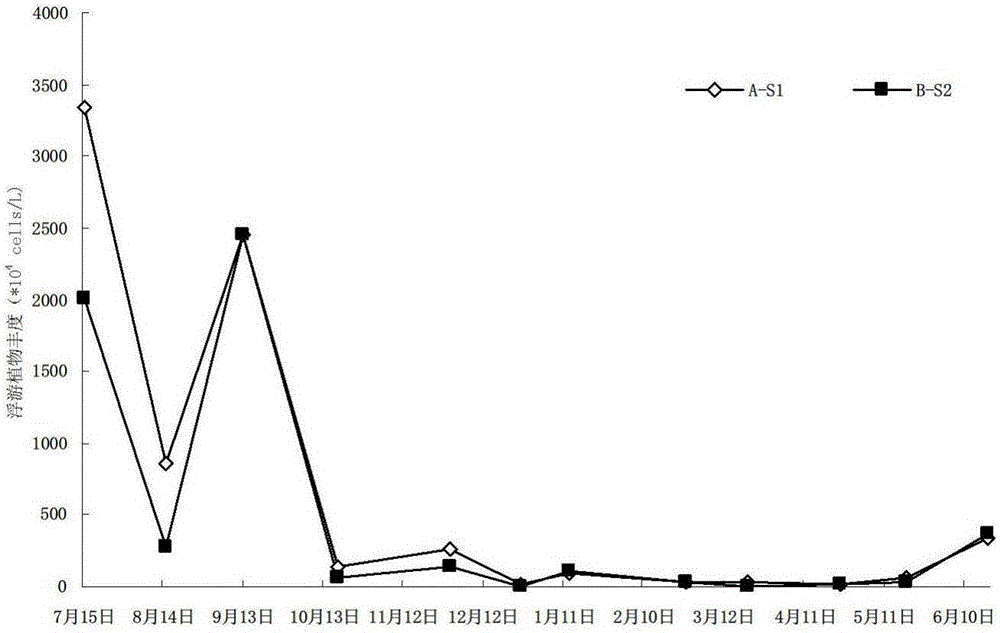

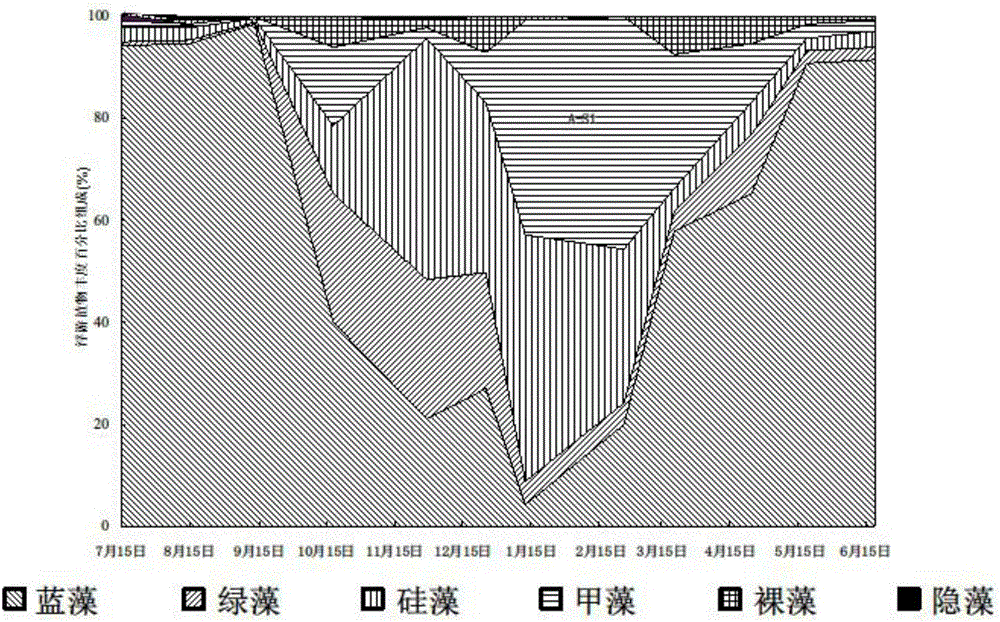

InactiveCN106277577AImprove water qualityInhibition of eutrophication trendsWater treatment parameter controlMultistage water/sewage treatmentPhytoplankton community structureTotal nitrogen

The invention discloses a method for comprehensively improving quality of an eutrophic water body. The method includes the following steps of early-stage processing, dividing the water body, constructing an ecological floating bed, arranging an artificial attachment medium and planting vegetation. According to the method for comprehensively improving quality of the eutrophic water body, the water body dividing technology, the ecological floating bed technology, the artificial attachment medium and the vegetation planting and recovering technology are comprehensively used, the composition of phytoplankton structure in the water body can be changed, the percentage of diatom is increased, the percentage of blue-green algae is reduced, the possibility of cyanobacterial bloom is reduced, the eutrophication trend of the water body is correspondingly inhibited, the eutrophication degree of the water body is reduced, and water quality condition is improved. By adopting the method, the concentration of chlorophyll and chemical oxygen consumption in the water body can be reduced, the content of total nitrogen and total phosphorus is reduced, the content of suspended solids in the water body is reduced, the transparency of the water body is improved, the eutrophication trend is inhibited, and the quality of the eutrophication water body is effectively improved.

Owner:GUIZHOU NORMAL UNIVERSITY

Method for pretreating organic wastewater

InactiveCN107365010ASimple structureHigh densityWater contaminantsWaste water treatment from animal husbandryHigh concentrationPretreatment method

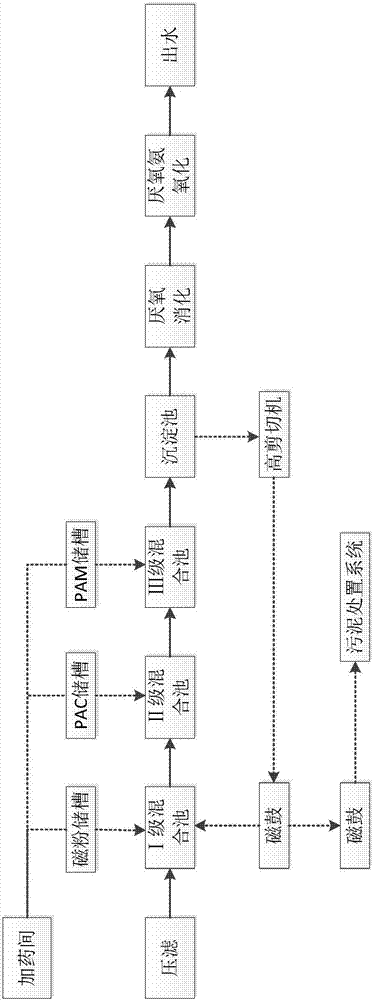

The invention discloses a method for pretreating organic wastewater. The method comprises the following steps: (1) adding a magnetic seed into organic wastewater to be treated, and quickly stirring for 1-2 minutes; (2) adding a flocculating agent, and quickly stirring for 1-2 minutes; (3) adding coagulant aid, quickly stirring for 5-30 seconds, and slowly stirring for 1-2 minutes; (4) standing to precipitate, draining and discharging slurry, wherein the speed of quickly stirring is 150-400r / min, and the speed of slow stirring is 30-80r / min. According to the method, heavy metal, antibiotic and other micropollutants can be removed by adding the magnetic seed to reinforce the coagulating process, so that high solid content, and the suspended solid content, COD concentration and total phosphorous concentration of high-concentration wastewater can be effectively reduced, and load of subsequent treatment units can be reduced.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

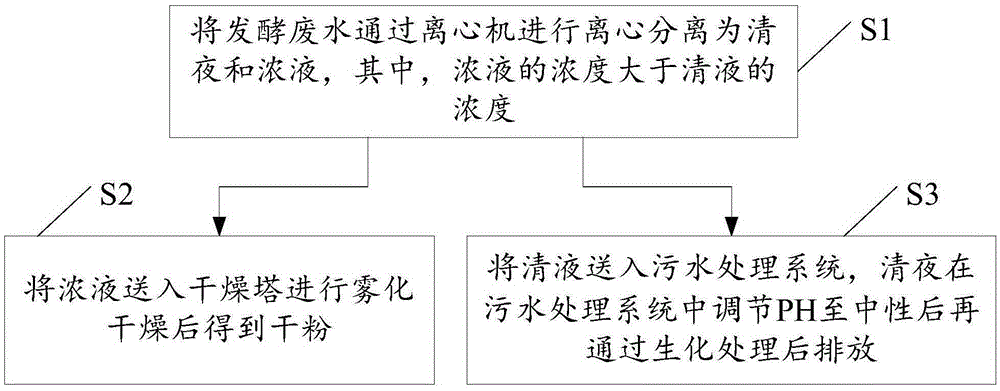

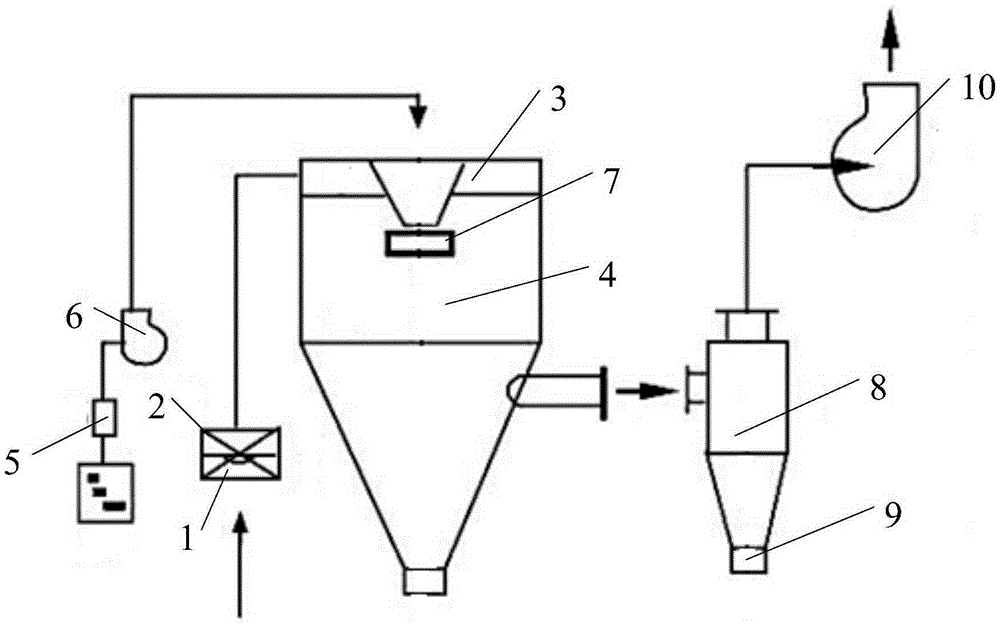

Fermentation wastewater processing method and biological feed

InactiveCN105417844AReduce the content of suspended solidsReduce loadWater/sewage treatment by centrifugal separationAccessory food factorsWastewaterSewage

The invention discloses a fermentation wastewater processing method and biological feed. The method includes the following processing steps of conducting centrifugal separation on fermentation wastewater through a centrifugal machine to obtain clean liquid and concentrated liquid, wherein the biomass concentration of the concentrated liquid is larger than the biomass concentration of the clean liquid; sending the concentrated liquid into a drying tower to be subjected to spray drying, and obtaining dry powder; sending the clean liquid into a sewage processing system, regulating PH of the clean liquid in the sewage processing system to be neutral, conducting biochemical processing on the clean liquid, and discharging the clean liquid. In this way, the separated clean liquid is sent into the sewage processing system, the COD and the suspended matter content in fermentation wastewater are lowered, the technical problem that the normal biochemical reaction is not facilitated after fermentation wastewater directly enters the sewage processing system is solved, and therefore loads of subsequent sewage processing are reduced, and remarkable environment protection benefits are achieved.

Owner:BEIJING SHOUGANG LANZATECH TECH CO LTD

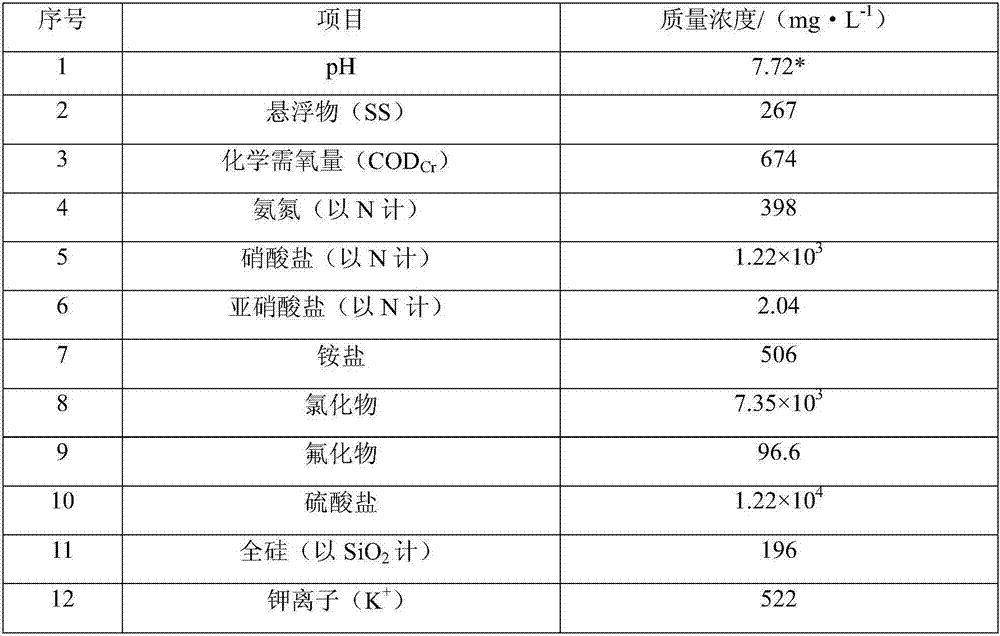

Treatment method of desulfurization wastewater

InactiveCN106882892AAchieving zero emissionsAchieve separationMultistage water/sewage treatmentWater/sewage treatment by neutralisationUltrafiltrationWastewater

The invention relates to the field of wastewater treatment and discloses a treatment method of desulfurization wastewater. The method comprises pretreatment, ultrafiltration treatment, nanofiltration treatment, membrane concentration treatment, MVR evaporative crystallization and flue evaporation treatment on the desulfurization wastewater in sequence. Pretreatment, ultrafiltration, nanofiltration, membrane concentration, MVR evaporative crystallization treatment and flue evaporation treatment are organically combined, so that zero emission of the desulfurization wastewater is achieved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Method for separating and extracting crude oil from oil sand

InactiveCN103113912ALow costReduce oil contentLiquid hydrocarbon mixture productionOrganic solventSulfate

The invention discloses a method for separating and extracting crude oil from oil sand. The method comprises the following steps of: (1) adding an organic solvent to the oil sand, fully stirring and curing so as to reduce the viscosity and specific gravity of the crude oil in the oil sand; (b) adding water and an emulsifying agent to the treated oil sand, and fully emulsifying and dispersing to form suspension liquid with water as a dispersion phase; (c) adding sulfuric acid to the suspension liquid so as to adjust the pH value of the suspension liquid till the suspension liquid is acid; (d) adding a saturated solution or powder of ferrous sulfate to the acid suspension liquid so that the concentration of the ferrous sulfate in the suspension liquid is 3.5-5g / L; (e) adding hydrogen peroxide to the uniformly stirred acid suspension liquid so that the concentration of hydrogen peroxide in the suspension liquid is 8-15ml / L and fully stirring; and (f) realizing three-phase separation of oil, water and sand by a physical method. The thorough recovery of the crude oil can be realized by using the method for treating dirty oil sand; and according to the method, the treatment energy consumption is very low, and no lots of industrial wastewater is generated.

Owner:天津市朗敦环保科技有限公司

Cleaning production auxiliaries for pretreatment

The invention provides a pre-treating clean production additive with the characteristics of high efficiency and short flow. The characteristic additive components includes: enzyme 90%, pure water 1%, hydrogen peroxide decomposer 3%, NaCl 5%, and other additives. The invention is mainly used in the fabric working procedures of polishing and desizing. The smooth and soft fabric effect can be achieved through the enzyme hydrolyzing fabric in order to enable the fabric fluff to be divorced from the fabric surface, and meanwhile the slurry on the grey clothes can be removed through desizing reaction in order to guarantee the qualities of printing and dyeing products. The dosages of water, electricity, and gas are saved, and the cost for processing waste water is reduced.

Owner:SUZHOU HUACHOU TECH

Purification device for aquaculture tail water

PendingCN107720940AClear structureEasy to installTreatment using aerobic processesWater contaminantsEngineeringSteel tube

The invention provides a purification device for aquaculture tail water. The purification device comprises foam float pieces, steel pipes and a nylon net, wherein the foam float pieces are tied to thesteel pipes, and a square is defined by the four steel pipes tied with the foam float pieces floats on the water surface; the nylon net extends upwards out of the water surface and goes deep downwards into the water, and the parts, extending upwards out of the water surface, of the nylon net are tied to the steel pipes through ropes; a floating plant control-culture fence is defined by the square, defined by the four steel pipes tied with the foam float pieces, and the nylon net tied to the steel pipes; the lower end of the nylon net is weighed down by a stone cage filled with stone. The purification device for the aquaculture tail water can realize purification of the aquaculture tail water, occupies little space and is low in cost, simple to maintain and high in purification efficiency.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

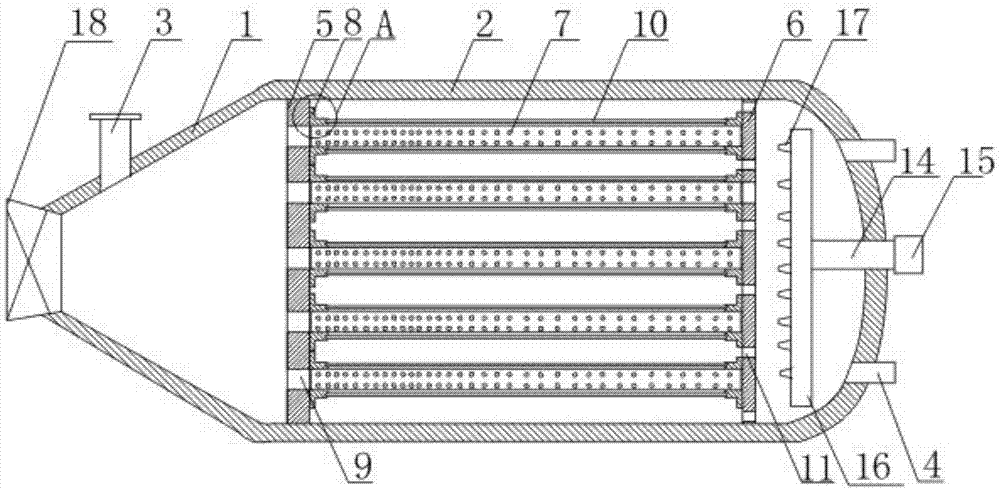

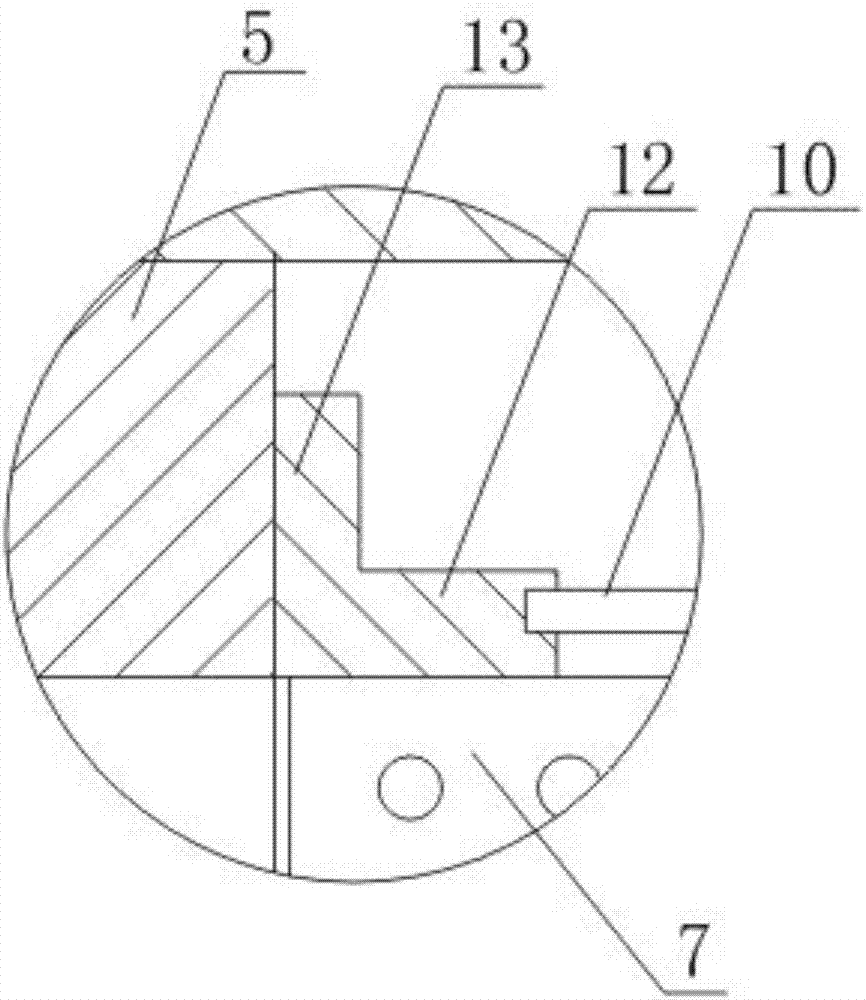

Decomposing titanium liquor purification method and filter for same

ActiveCN106966427AImprove quality stabilityReduce the content of suspended solidsTitanium dioxideFiltration circuitsTitanium dioxideTitanium

The invention relates to a titanium dioxide production method, in particular to a decomposing titanium liquor purification method and a filter for the same during titanium dioxide production. The decomposing titanium liquor purification method includes the steps of precipitating decomposing titanium liquor, and filtering precipitated decomposing titanium liquor through a tubular filter so as to obtain purified decomposing titanium liquor. The decomposing titanium liquor purification method is time saving, labor saving and capable of reducing production cost and improving product performance and is widely applicable.

Owner:XIANGYANG LOMON TITANIUM IND CO LTD

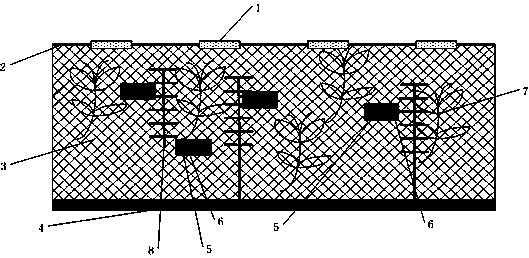

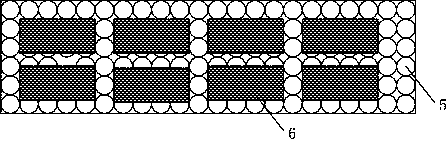

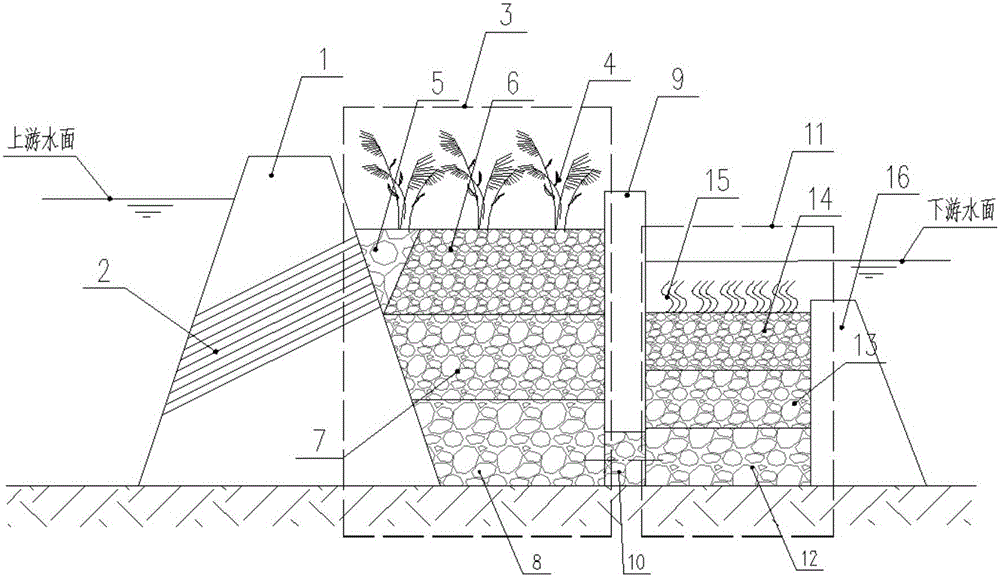

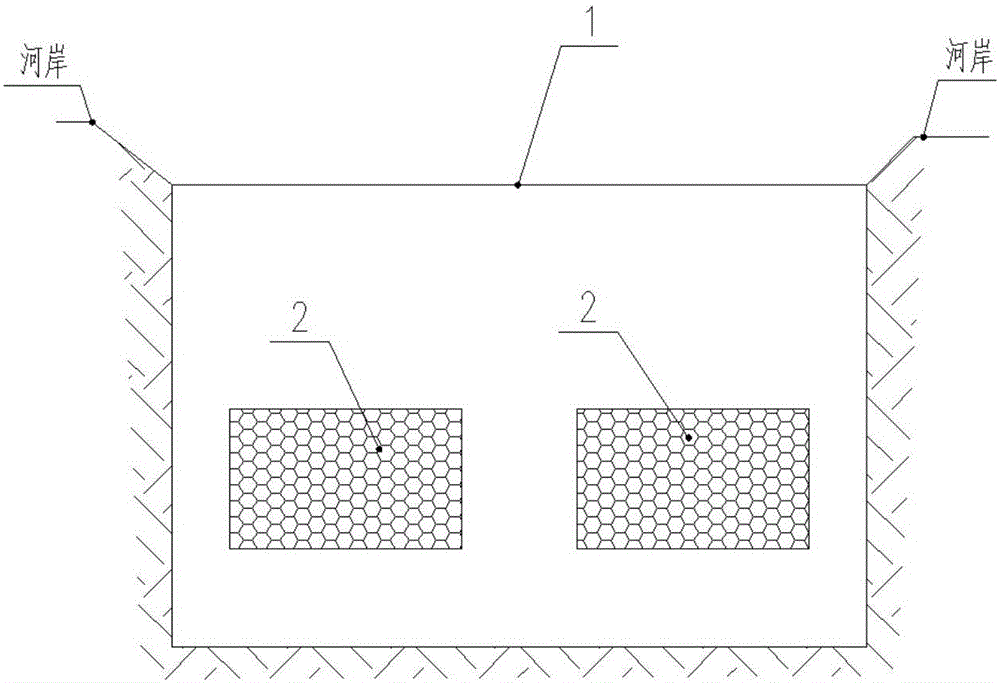

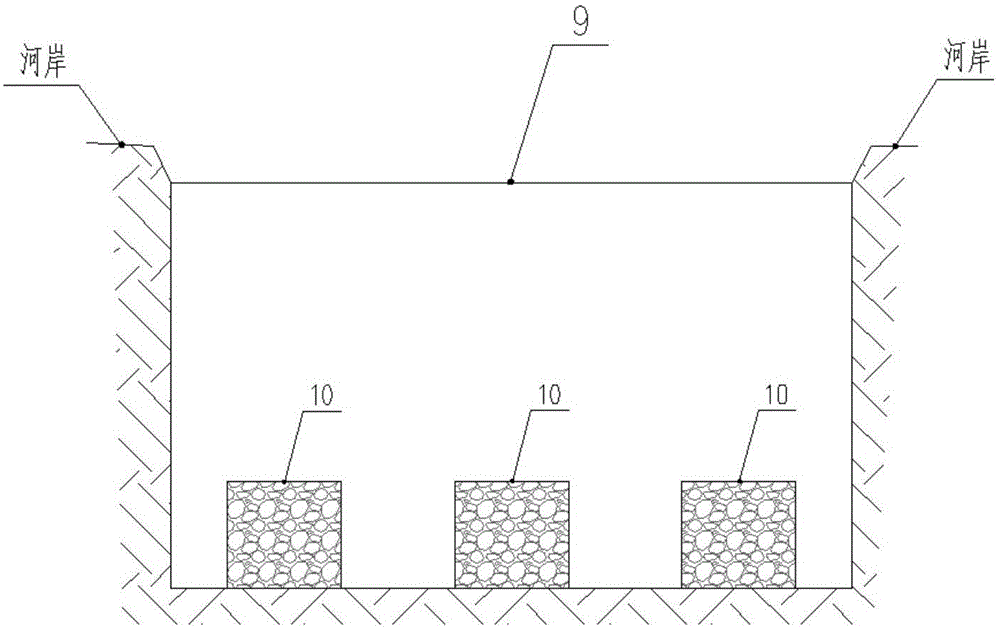

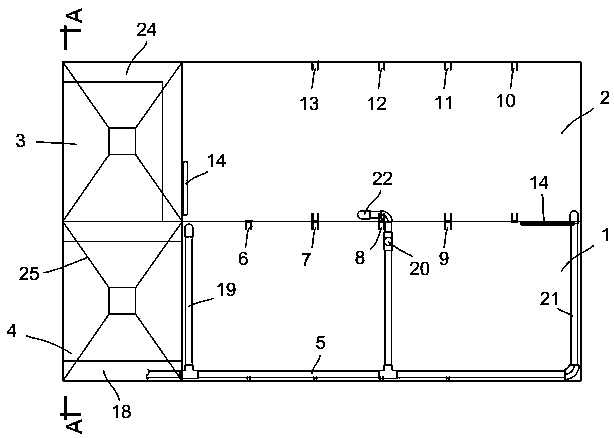

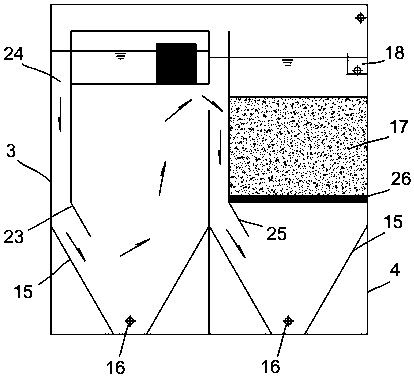

Anti-blocking baffling type percolation dam

ActiveCN105152348AReduce the content of suspended solidsReduce processing loadWater contaminantsSustainable biological treatmentEngineeringMulti element

The invention discloses an anti-blocking baffling type percolation dam which comprises a retaining dam body, a downstream percolation area, a partition wall, an upstream percolation area and a side wall. A water body in a river channel flows into the downstream percolation area through a water inlet inclined pipe arranged on the retaining dam body, then passes through a water passing hole in the bottom of the partition wall to flow into the upstream percolation area and flows out of the top of the upstream percolation area. The water inlet inclined pipe is adopted for water inputting, the upstream and downstream baffling mode is adopted in the percolation areas, emerging and sinking multi-element vegetable layers are adopted, and the dam has the advantages of being good in anti-blocking effect, high in filtering efficiency and good in purification and landscape effect.

Owner:WUHAN ZHONGKE HYDROBOLOGY ENVIRONMENTAL ENG

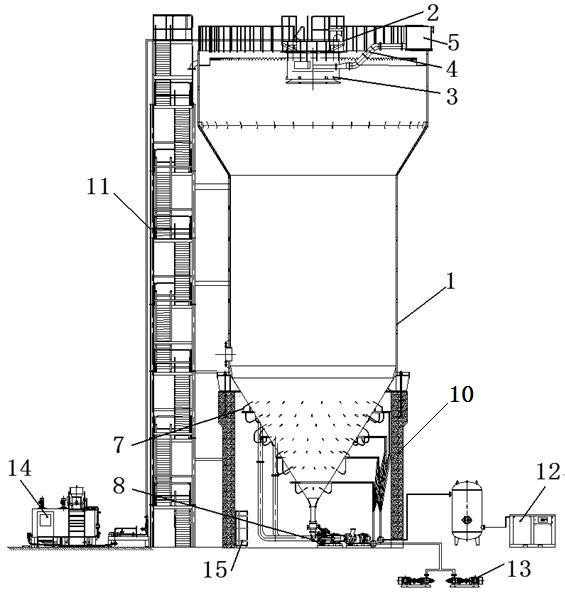

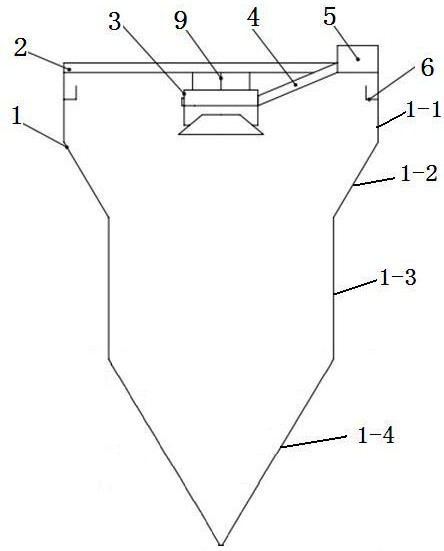

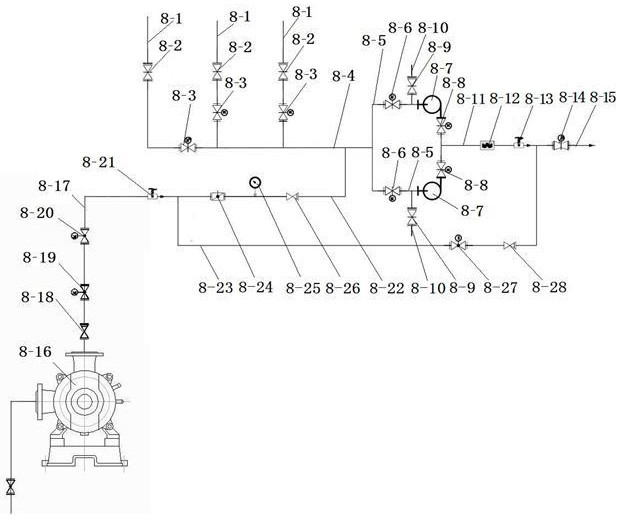

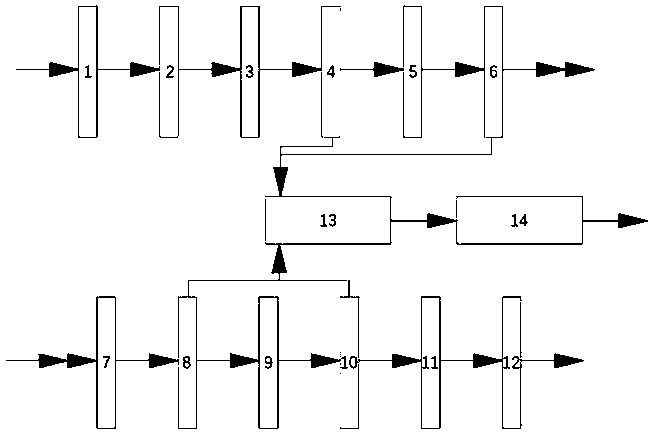

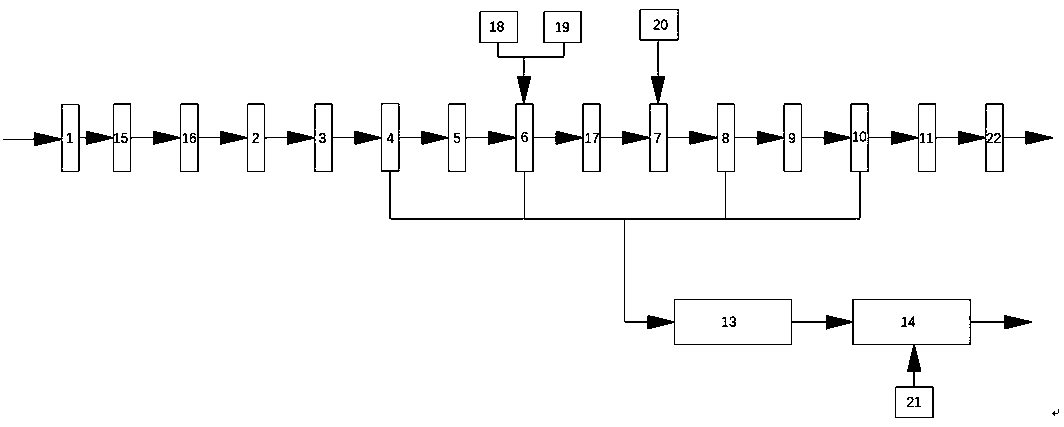

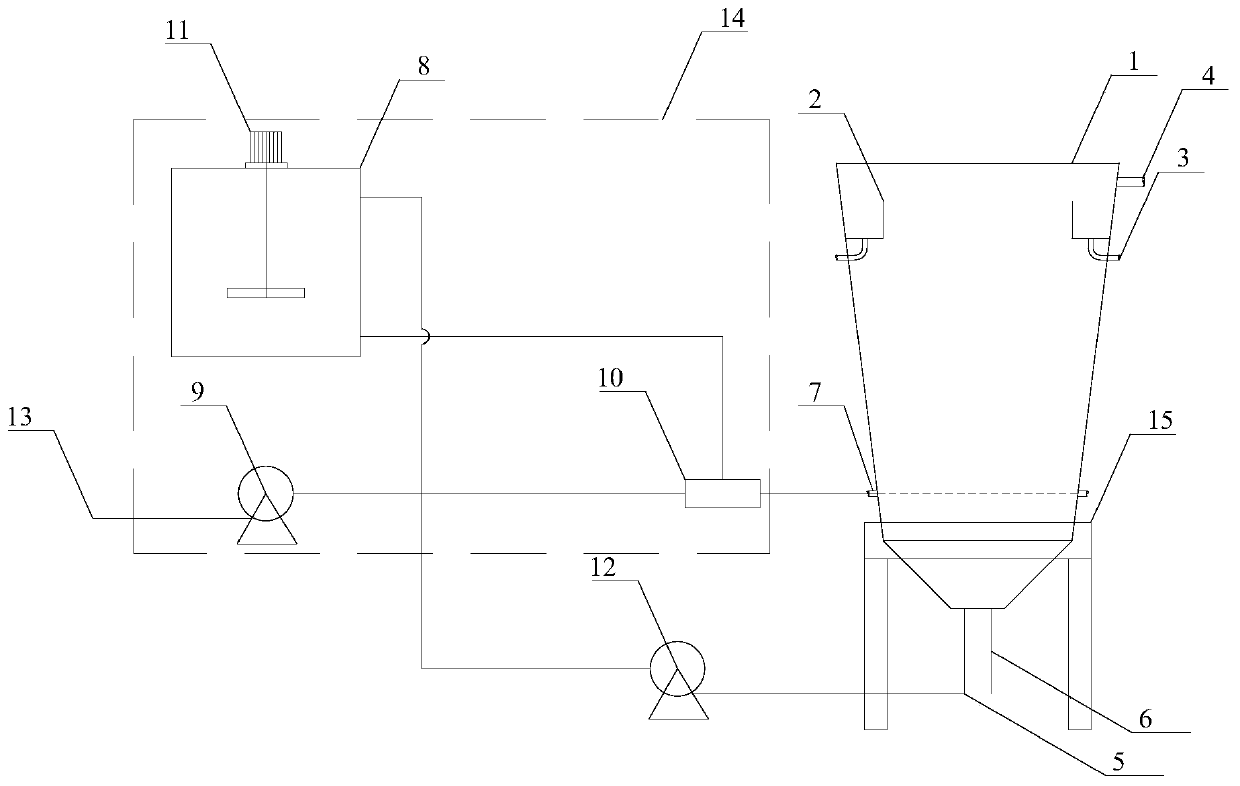

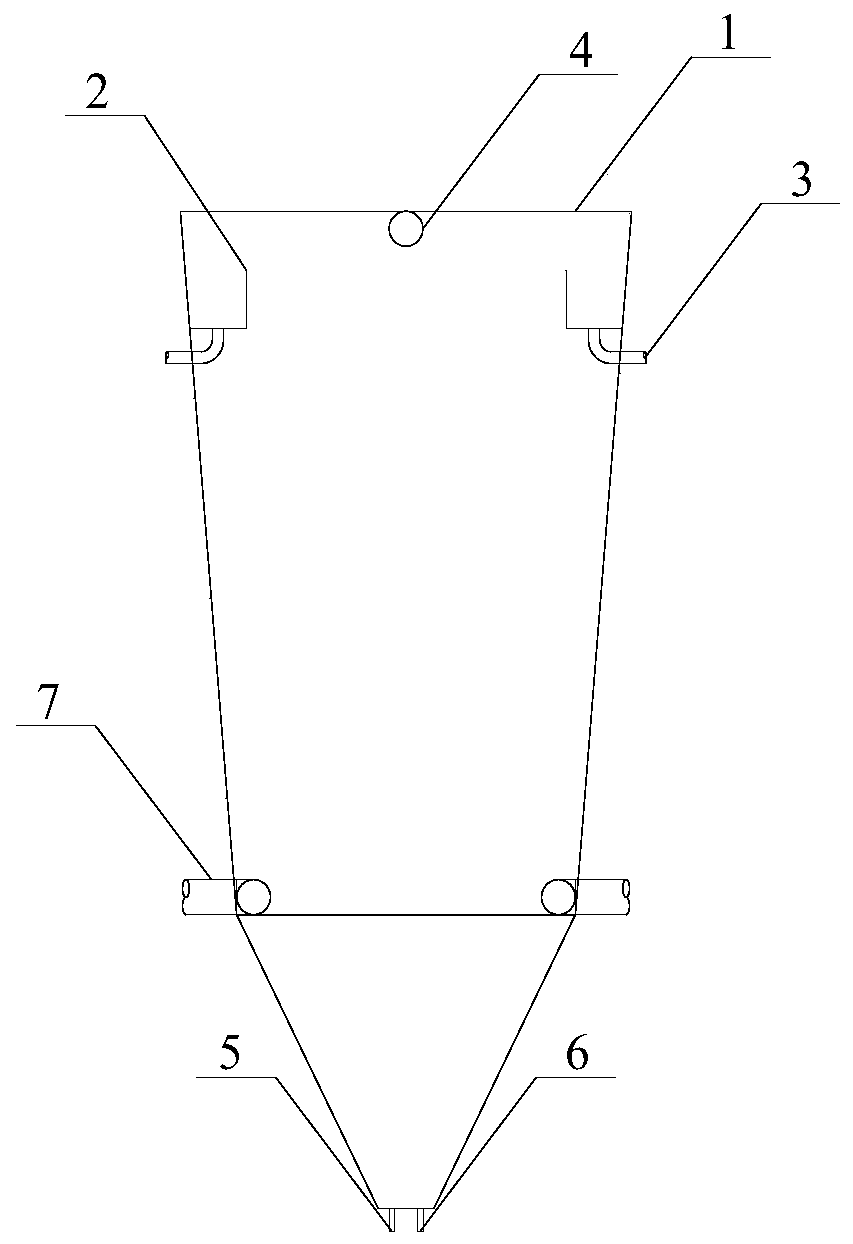

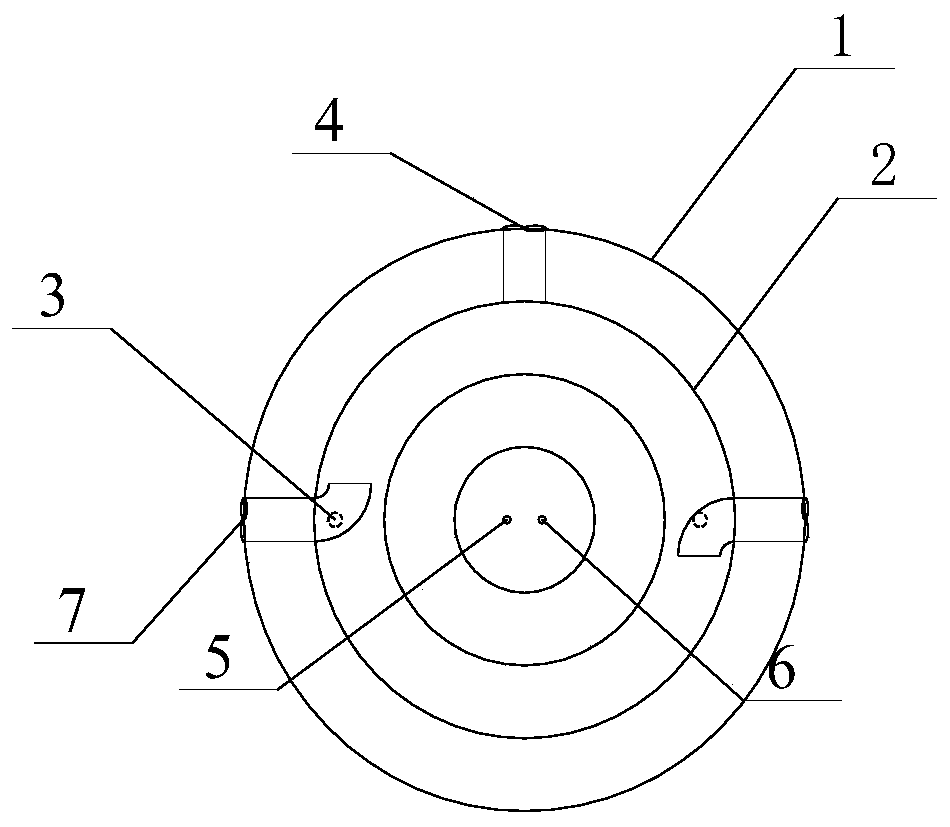

Fine-fraction high-concentration tailing filling and thickening device

ActiveCN113513363AImprove concentrationImprove the cycle efficiency of mining and chargingWaste water treatment from quariesWater/sewage treatment by centrifugal separationEngineeringSlurry

The invention discloses a fine-fraction high-concentration tailing filling and thickening device which comprises a tank body part, a wind-water slurry making system, an underflow conveying system, an electric control system, a flocculating agent preparing and adding system and the like. The wind-water slurry making system comprises an annular water pipe group and an annular gas pipe group; annular water pipes of all layers of the annular water pipe group and annular air pipes of all layers of the annular air pipe group are located at different height positions and distributed in an inverted cone shape, the annular water pipes and the annular air pipes of each layer are respectively connected with a plurality of high-pressure rubber water (air) spraying pipes, valves and external water (wind) slurry making nozzles; and the annular water pipes are connected with a water supply and drainage header pipe, and the annular air pipes are connected with an air supply and exhaust header pipe. By means of the fine-fraction high-concentration tailing filling and thickening device, the material storage capacity is large, the mining and filling circulation efficiency of a mine is improved, no power part exists, fault points are few, power consumption is low, and the operation cost is low; and long-time continuous steady-state slurry discharging is achieved, the stability of technological parameters and the working efficiency of filling operation are improved, the concentration capacity of the thickening device is improved, and the continuity of filling operation of the thickening device is guaranteed.

Owner:山金重工有限公司

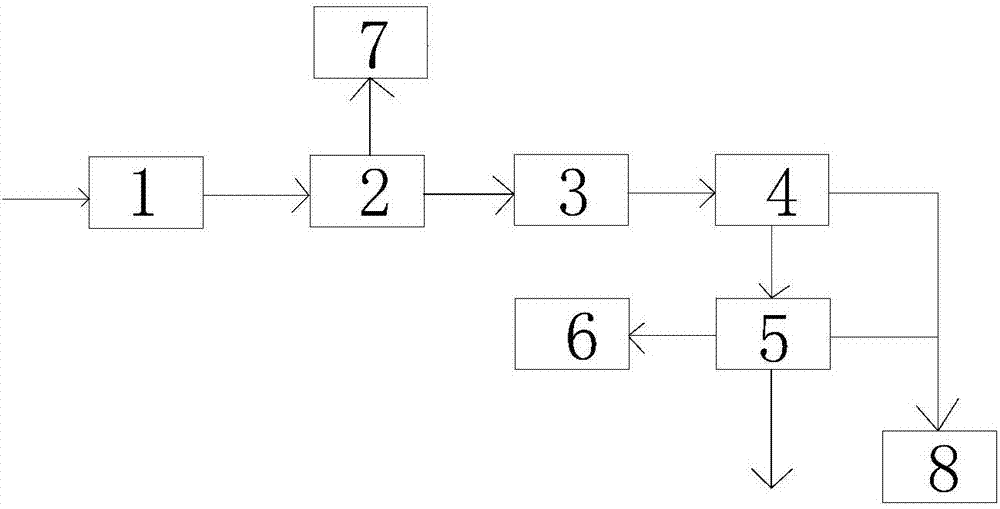

Engineering method for recycling high-suspended solid concentration wastewater

InactiveCN108793597AEffective reductionExtended service lifeTreatment using aerobic processesTreatment involving filtrationWater supplyPrimary treatment

The invention relates to an engineering method for recycling high-suspended solid concentration wastewater, and provides a reliable novel scheme tested in practice for treating and recycling the wastewater rich in suspended solids. The specific process adopts a primary treatment-secondary treatment-tertiary treatment design process, and comprises a sludge treatment system, and a recycle water supply system is connected in the follow-up process. Especially, a spiral grid machine, a vibrating screen classifier, an integrated air flotation device, a vertical fiber cloth filter and the like are reasonably matched, thereby performing multi-stage solid-liquid separation on the wastewater, and fully exerting the functions and advantages of various equipment, so that a large amount of suspended solids and organic matter in the wastewater can be effectively removed. Finally, the water resources are recycled by a recycling system, and discharged mud and discharged slag are treated by the sludgeto be recycled or form a mud cake for further treatment. The method provided by the invention solves the problem that the influent suspended matter content is too high and the effluent water is difficult to reach the recycle water standard, and the treatment effect is good, the utilization value of useful resources is also improved, and the generalizability is extremely high.

Owner:TONGJI UNIV

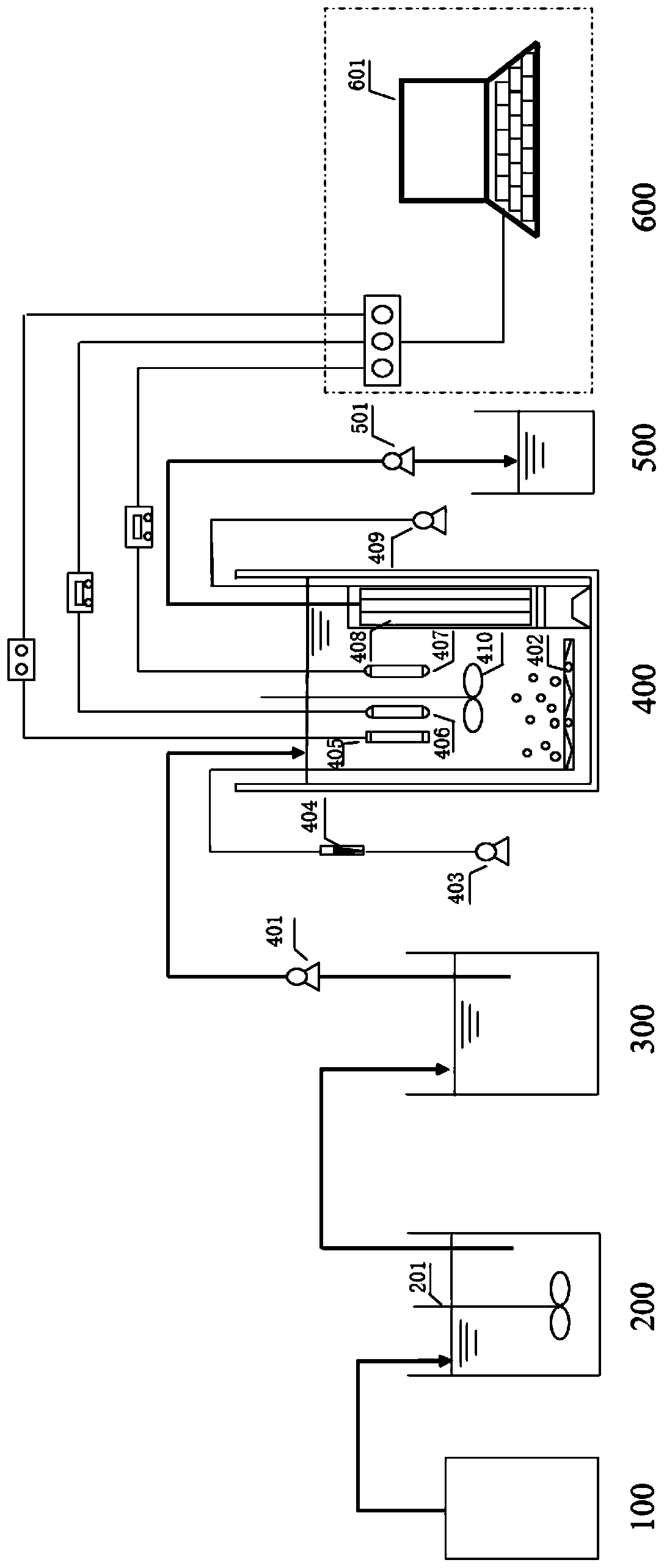

Wastewater treatment method and wastewater treatment system based on sequencing batch membrane biological reaction

PendingCN110902967AImprove floc structure and densityImprove floc settling performanceWater treatment parameter controlWater contaminantsChemistryTreatment system

The invention discloses a wastewater treatment method and a wastewater treatment system based on a sequencing batch membrane biological reaction. The treatment method comprises the following steps: performing a magnetic coagulation reaction on wastewater to be treated so as to obtain first wastewater; and carrying out a biological denitrification reaction on the first wastewater to allow the firstwastewater to reach the standard, thereby completing wastewater treatment. A magnetic coagulation device provided by the invention is especially innovative for a high-solid-content and high-concentration wastewater pretreatment method, and through addition of magnetic seeds, the structure and density of floc are effectively improved, the precipitation performance of the floc is enhanced, and coagulation treatment effect is improved; and the magnetic coagulation method adopted by the invention can effectively reduce the suspended solid content, COD concentration and total phosphorus concentration of high-solid-content and high-concentration wastewater, and thus reduces the load of a subsequent biological treatment unit.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

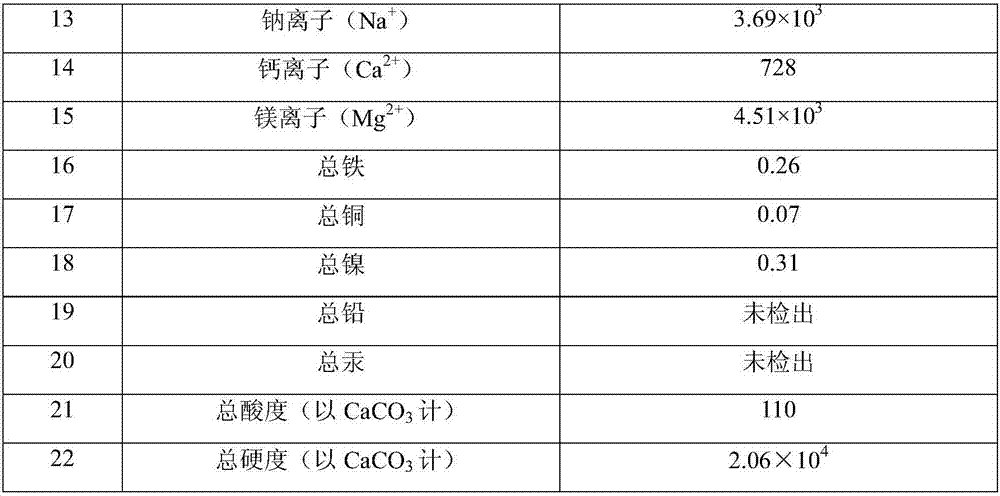

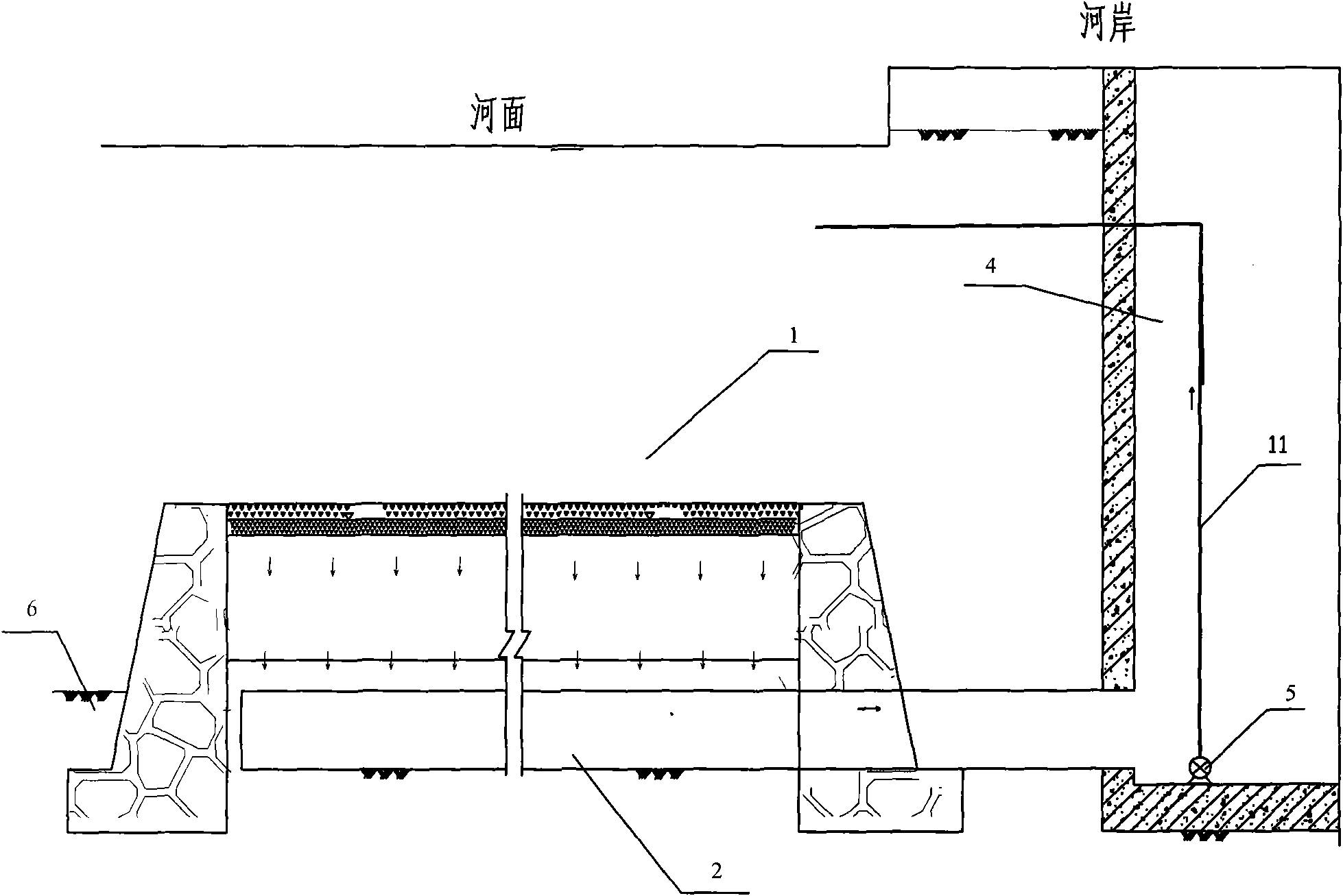

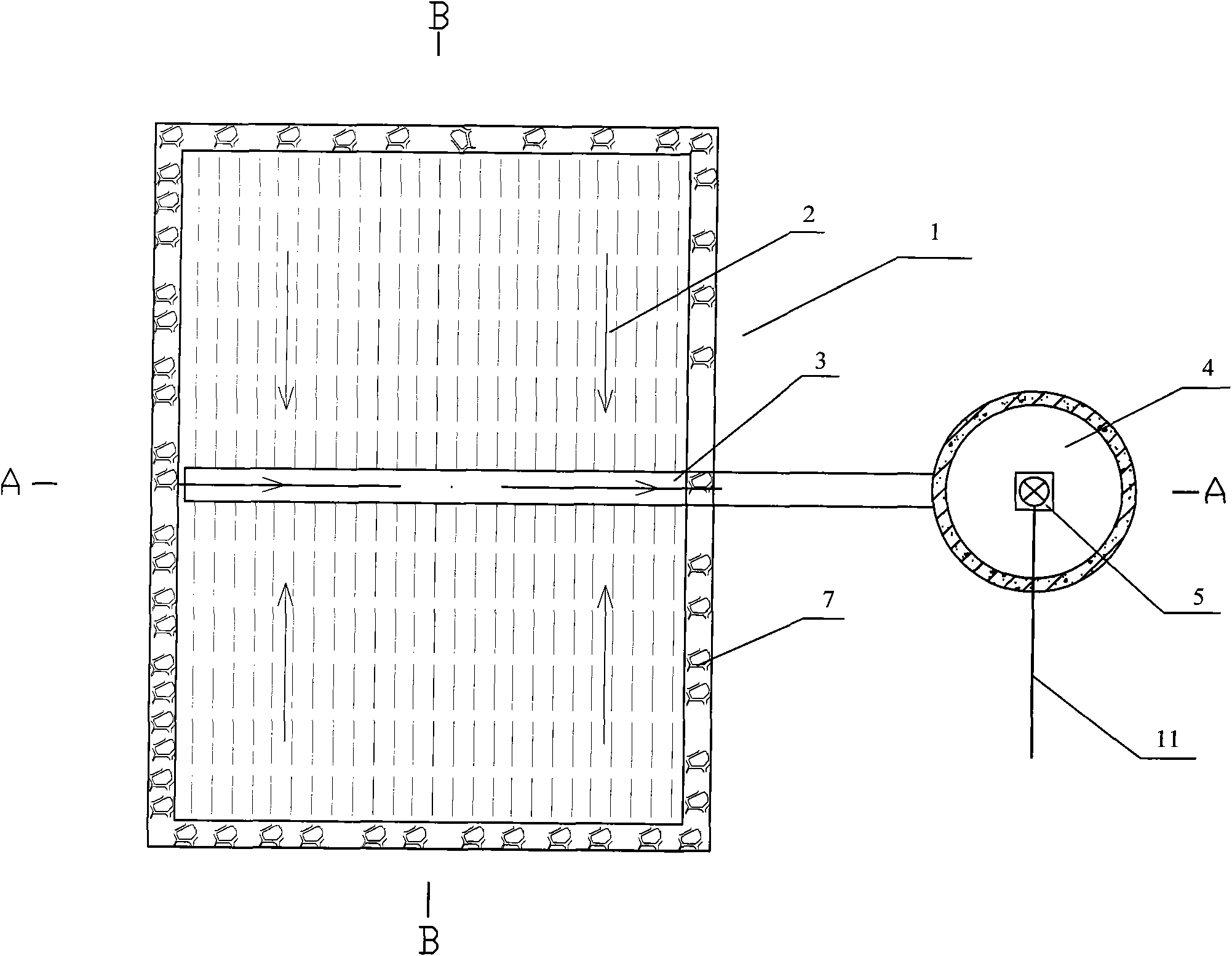

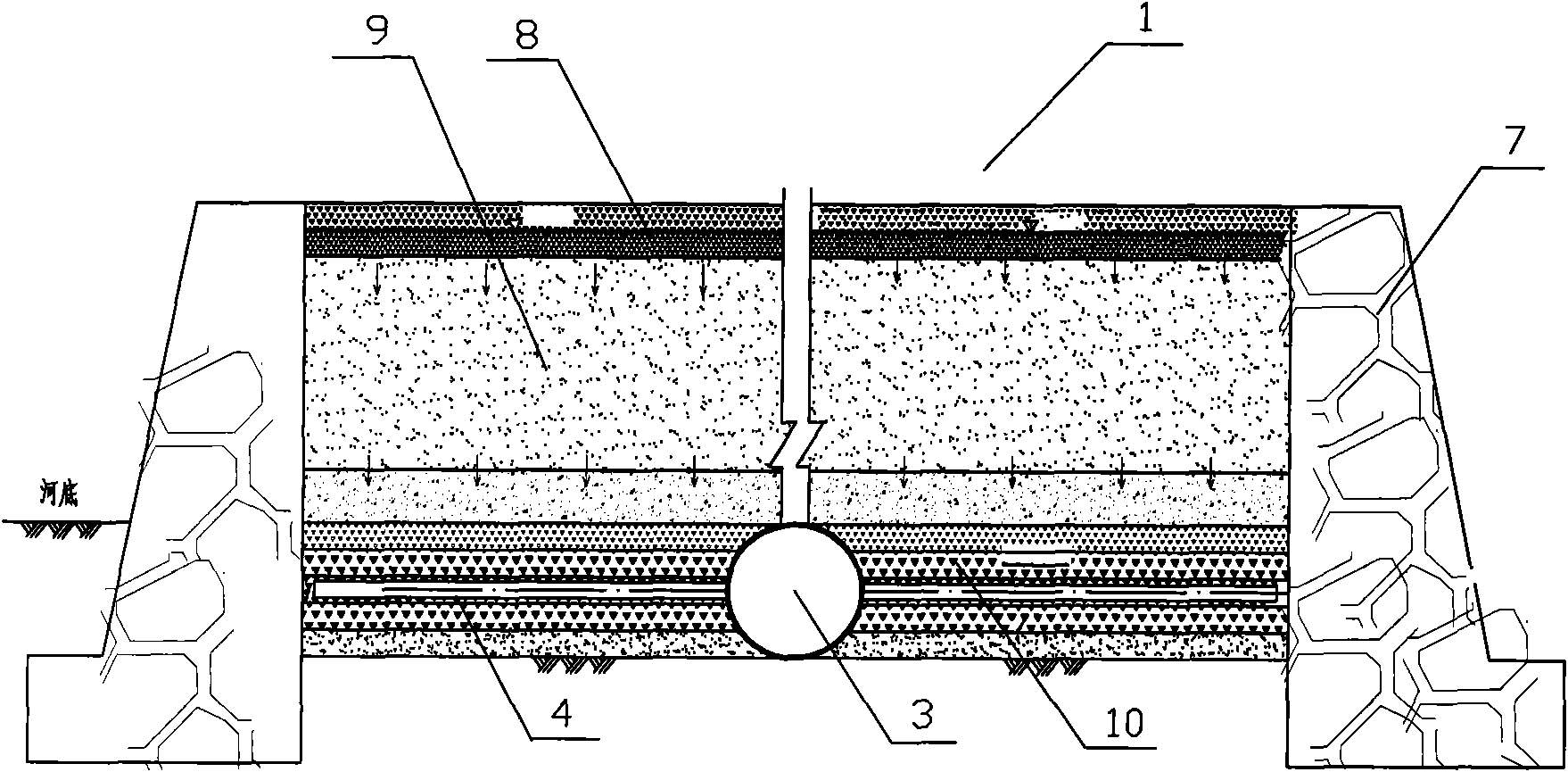

Filter-well circulating purification system and method for purifying river by using same

ActiveCN102070212AReduce the content of suspended solidsImprove effluent qualityWater/sewage treatmentPipingRiver water

The invention relates to a filter-well circulating purification system and a method for purifying river by using the same. The system consists of a filter bed, water filter pipes, a collector pipe, a filter well, a submersible pump and a connection pipeline, wherein a mortar stone masonry wall is formed at the periphery of the filter bed, and an erosion preventing layer, a filter material layer and a bearing layer are arranged inside a stonewall sequentially from top to bottom; the collector pipe is arranged on the middle part of the bearing layer horizontally, and one end of the collector pipe passes through the stonewall closed to one side of a river bank and is connected with the filter well; a plurality of openings are formed on both sides of the collector pipe, and each opening is connected with one water filter pipe; the water filter pipes are arranged on the middle part of the bearing layer horizontally; a plurality of open holes are formed on each water filter pipe; the filter well is arranged outside a riverway, and the bottom surface of the filter well is lower than a river bed; and the submersible pump is arranged at the bottom of the filter well, and a water outlet of the submersible pump is connected with an upstream riverway by a pipeline. After being filtered by the filter material layer, the river is collected to the filter well outside the riverway by the water filter pipe and the collector pipe, is pumped by the submersible pump and is conveyed to the upstream of the filter well by the pipeline, so that a water body in the riverway is filtered, purified and circulated.

Owner:BEIJING WATER SCI & TECH INST

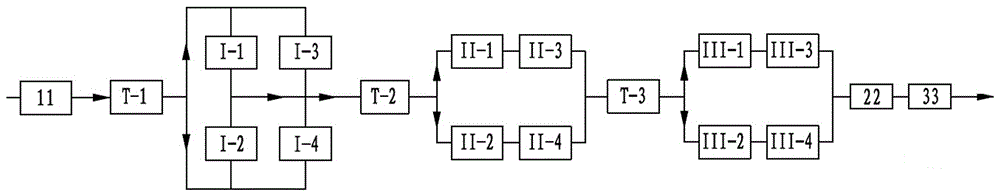

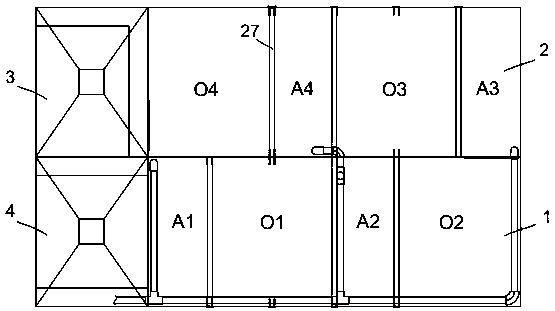

Multistage AO-MBBR (anaerobic-moving bed biofilm reactor) technological sewage treatment device with adjustable stage number and treatment method

PendingCN109292980AGuaranteed treatment effectAdaptableWater contaminantsTreatment involving filtrationMoving bed biofilm reactorMedicine

The invention discloses a multistage AO-MBBR (anaerobic-moving bed biofilm reactor) technological sewage treatment device with an adjustable stage number and a treatment method implemented by the aidof the multistage AO-MBBR technological sewage treatment device, and belongs to the technical field of sewage treatment. The multistage AO-MBBR technological sewage treatment device comprises a firstbiochemical reaction basin, a second biochemical reaction basin, a sedimentation basin, a phosphorus removal filter basin and a water inlet main pipe. A first insertion groove, a second insertion groove, a third insertion groove and a fourth insertion groove are formed in an inner basin wall of the first biochemical reaction basin; a fifth insertion groove, a sixth insertion groove, a seventh insertion groove and an eighth insertion groove are formed in a basin wall of the second biochemical reaction basin, and the first biochemical reaction basin is communicated with the second biochemical reaction basin; the sedimentation basin is communicated with the second biochemical reaction basin, a water via net is arranged at a communicated position of the sedimentation basin and the second biochemical reaction basin, a sludge sedimentation hopper and a sludge discharge pipe are arranged in the sedimentation basin, the sludge discharge pipe is arranged at the bottom of the sludge sedimentation hopper, and the sedimentation basin is further communicated with the phosphorus removal filter basin. The multistage AO-MBBR technological sewage treatment device and the treatment method have the advantages that multistage AO systems which are serially connected with one another are formed, the locations of insertion plates can be adjusted, accordingly, the multistage AO-MBBR technological sewage treatment device and the treatment method are high in adaptability to domestic sewage with different levels of pollution load, effluent treatment procedures are pertinent, and sewage treatment effects can be guaranteed.

Owner:上海更清环保设备有限公司

Method for wastewater zero discharging of leather industry

InactiveCN105198112AReduce CODReduce BOD loadMultistage water/sewage treatmentLeather industryLiquid waste

The invention discloses a method for wastewater zero discharging of the leather industry. The method is characterized by comprising the following steps of 1, cow leather preprocessing, 2, softening processing, 3, oxidation aeration processing, 4, sedimentation, and 5, filtering and oil removal. According to the softening processing in the leather manufacturing process, fur is prevented from being degraded by a chemical reducing agent, and COD and BOD loads in a depilation waste liquid are reduced. According to the oxidation aeration processing, the load impact resistance is large; the physical technology is utilized for reducing the dosage of harmful chemical substances and lowering the suspended matter content in wastewater, a solid-liquid separator is used for solid-liquid separation, and the amount of metal ions is decreased; according to the step of filtering and oil removal, oil components are removed, the processing efficiency is high, it is ensured that water flows out stably, the water quality is reliable, resources are saved, and the environment is protected.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

Organic high-polymer coagulant aid

InactiveCN103086490AReduce dosageReduce concentrationWater/sewage treatment by flocculation/precipitationAluminium chlorideOrganic synthesis

The invention relates to an organic high-polymer coagulant aid, and is mainly used for solving the problem that when an organic synthesized high-polymer coagulant aid is exclusively used for treating oilfield sewage, the dosage is large and the effect is poor. The organic high-polymer coagulant aid comprises the following ingredients in percentage by weight: 80-90% of cationic polyacrylamide, and 10-20% of aluminium polychloride. The organic high-polymer coagulant aid is good in oilfield sewage treatment effect, and low in dosage and dosing concentration, and greatly reduces the contents of oil and suspended solids in water after sewage is filtrated.

Owner:大庆腾辉石油工程技术服务有限公司

A converter steel slag treatment device and method

ActiveCN107287368BGuaranteed uptimeReduce moisture contentRecycling and recovery technologiesCooling towerThermodynamics

The invention relates to a converter steel slag treatment device which comprises a crown block, a slag ladle, a chute, a forklift, a steel slag pool, a bottom filtering pool, a water pump house, a water storage tank, a cooling tower, a bridge-type grab crane, a chimney, a hydraulic roller couple, nozzles, a granulating room and a condensate water tank, wherein a lifting hook of the crown block is connected with the slag ladle, the outlet of the slag ladle is connected with the inlet of the chute, and the outlet of the chute is connected with the upper part of the hydraulic roller couple; nozzles a are symmetrically arranged on the two sides of the upper part and the two sides of the lower part of the hydraulic roller couple, and the hydraulic roller couple and the nozzles a are all arranged in the granulating room; the steel slag pool is arranged at the lower part of the granulating room, and the forklift is arranged on the outer side of the lower part of the granulating room. The invention further discloses a converter steel slag treatment method. The flow of the method is as follows: steel slag dumping, steel slag crushing, steel slag granulating, slag washing water filtering and vapor condensation recovery. The converter steel slag treatment device has the advantages of high slag treatment efficiency, compact occupied area, energy conservation, environment protection and no pollution, adapts the fast-paced production mode of a converter, is good for magnetic separation extracting of grain steel and comprehensive application of grain slag, and has remarkable economical benefit.

Owner:北京中冶设备研究设计总院有限公司

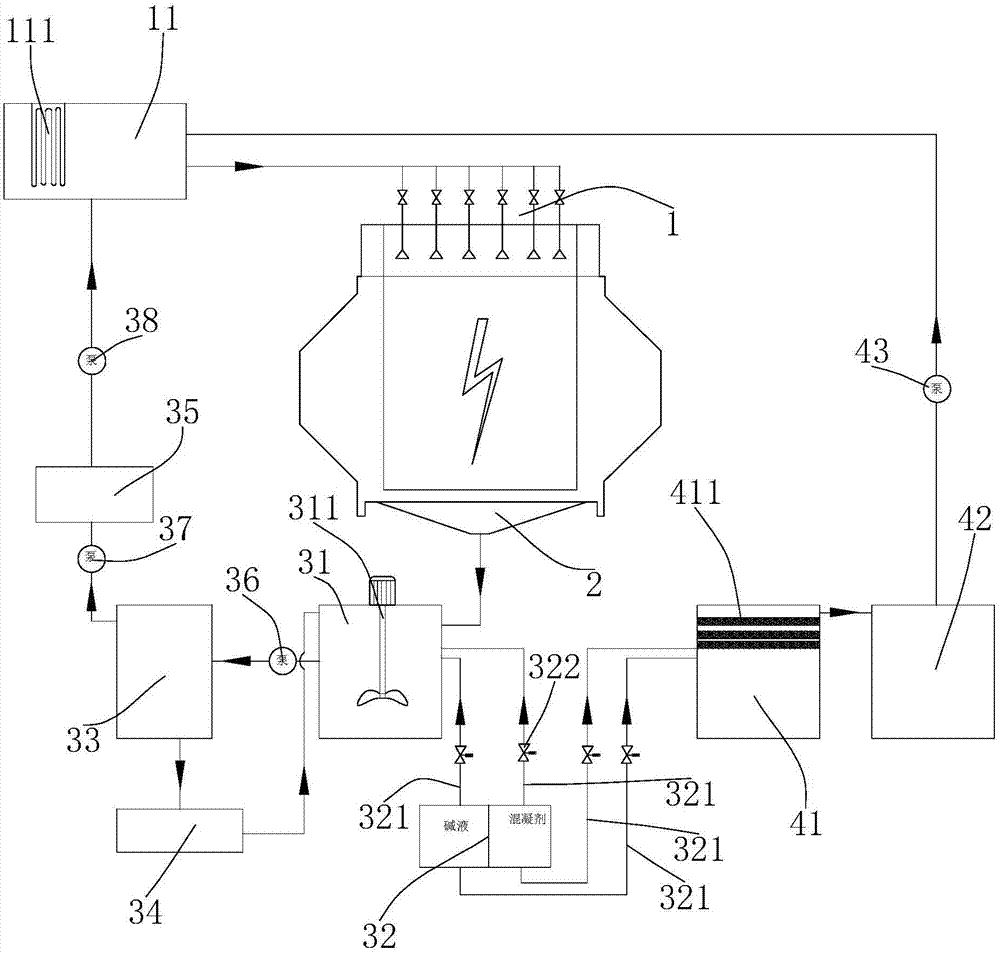

Ash water circulation treatment system of wet electric precipitator

InactiveCN107082510AReduce the content of suspended solidsReduce corrosionTreatment involving filtrationWater/sewage treatment by ion-exchangeIon exchangeWater circulation

The invention discloses an ash water circulation treatment system of a wet electric precipitator. The ash water circulation treatment system comprises an ash water tank for collecting ash water, a spraying device for removing dust, a circulating water system and a process water system, wherein ion exchange equipment is further connected between a sedimentation basin and the spraying device. The ash water circulation treatment system has the following advantages and effects: alkali liquor and a coagulant are respectively added into a circulating water pool and a process water pool, so that slightly soluble matters in water are changed into soluble sodium salt, suspended solids coagulate and settle down, and the content of the suspended solids is reduced; moreover, the PH value of the water is controlled to be 7 or less, the water is in a near-neutral and slightly acidic state, and corrosion to metal can be reduced.

Owner:浙江诸暨骏达环保设备有限公司

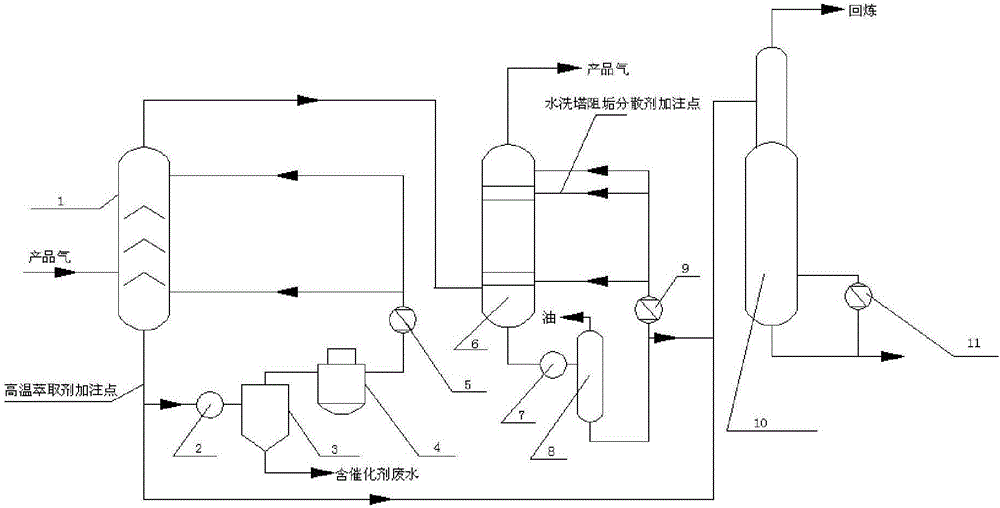

Method for solid removal of MTO quenched water and online cleaning of water scrubber

InactiveCN106643276AReduce differential pressureImprove efficiencyFatty/oily/floating substances removal devicesTreatment involving filtrationPressure differenceTower

The invention relates to a method for solid removal of MTO (Methanol to Olefins) quenched water and online cleaning of a water scrubber. The method comprises the following steps: (1) adding a high-temperature extraction agent into the quenched water drained from the bottom of a quench tower and then pouring into a separating device, returning the separated clean water to the quench tower and discharging the waste water containing a catalyst into a sewage disposal system; (2) adding a dirt dispersion agent for the water scrubber into a seriously scaled part of the water scrubber, circulating the drug in the water scrubber, discharging the newly formed scales in the water scrubber in the manner of following the outward draining water, peeling off the scales formed on tower plates and tower walls in the water scrubber by the dirt dispersion agent for the water scrubber, smashing into fine particles and then discharging from the bottom of the water scrubber in the manner of following the outward draining water. The method has the beneficialeffects that the scales remained in the water scrubber and a heat exchanger can be greatly reduced; the pressure difference of the water scrubber can be obviously reduced; theefficiency of the heat exchanger can be greatly increased; the cleaning period of the heat exchanger can be doubled or above; and according to the method, the solid content and suspended solid content in the quenched water can be effectively reduced.

Owner:天津市瑞德赛恩新材料开发有限公司

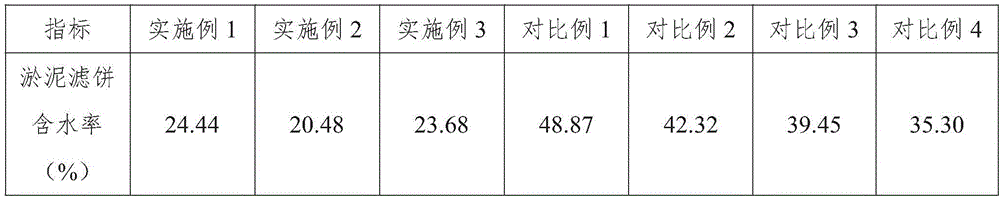

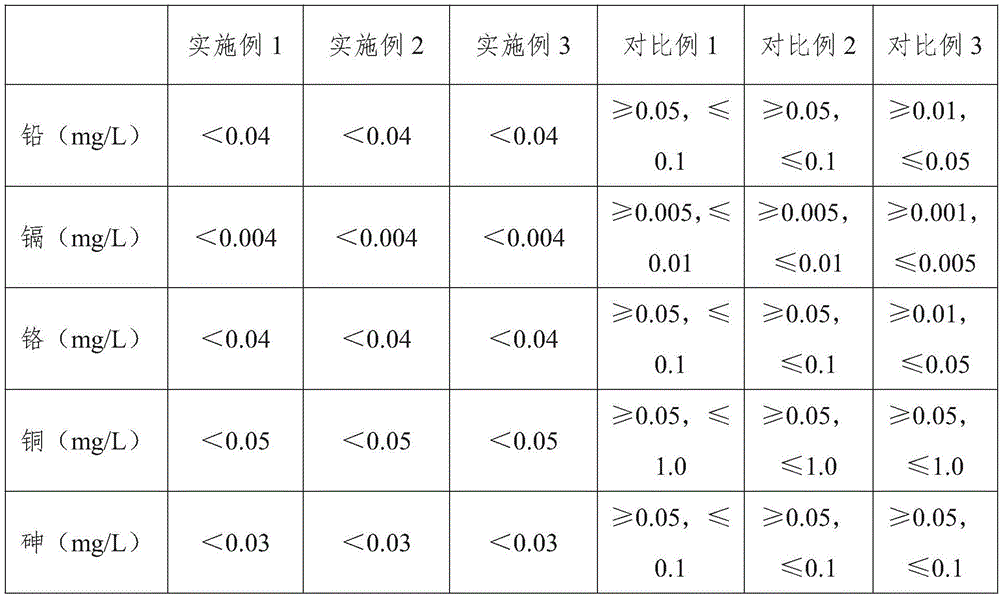

Quick dewatering process for city watercourse sludge

ActiveCN105776817AReduce turbidityLow absorbanceSludge treatment by de-watering/drying/thickeningCelluloseWater quality

The invention belongs to the field of sludge treatment, and particularly relates to a quick dewatering process for city watercourse sludge. The dewatering process for the city watercourse sludge includes putting the sludge into a stacking pool, stirring the sludge, adding polyanionic celluloses, performing initial dewatering, adding composite flocculants, stirring evenly, and deterring the sludge in a belt filter press to obtain dewatered sludge. The dewatering process has the advantages of simple operation, good dewatering effect and capability of improving water quality of sludge filter liquor and reducing environment pollution, is a low-cost environment-friendly sludge dewatering process and is beneficial to mass promotion and application.

Owner:广州珞珈环境技术有限公司

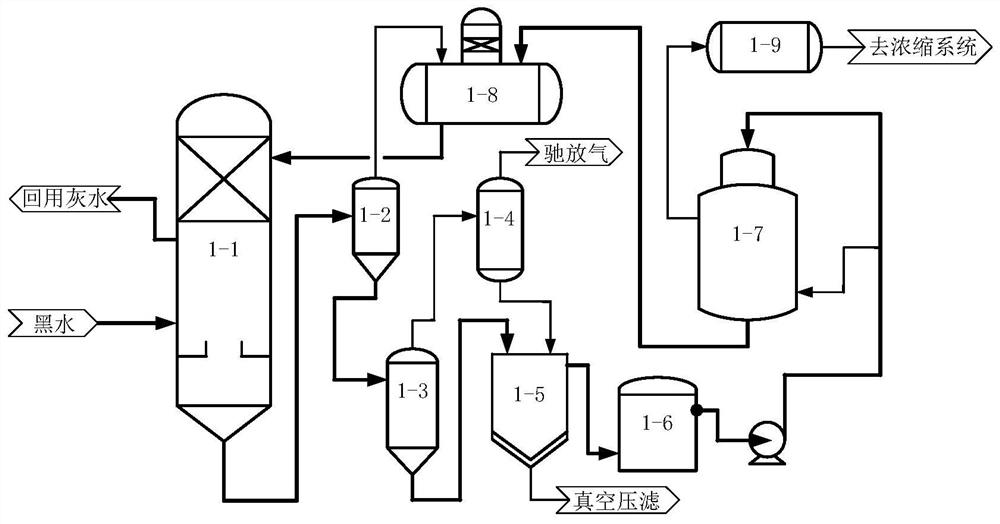

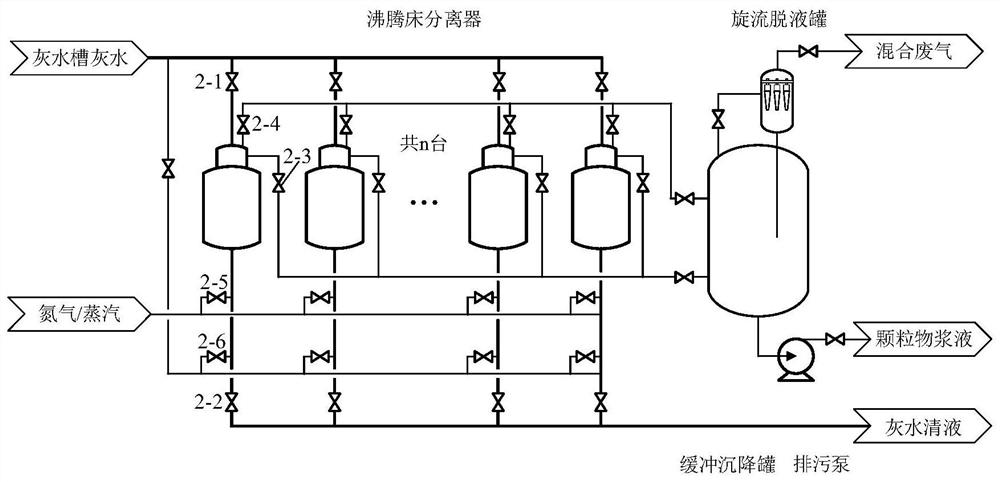

Flash evaporation-sedimentation-fluidized bed separation combined purification method and device for coal gasification black water

PendingCN112624472AMake up for the problem of insufficient separation efficiencySolve the problem of deep purificationTreatment involving filtrationMultistage water/sewage treatmentFine particulateDeaerator

The invention relates to a flash evaporation-sedimentation-fluidized bed separation combined purification method and device for coal gasification black water. The flash evaporation-sedimentation-fluidized bed separation combined purification method for the coal gasification black water comprises the following steps: (i) carrying out flash evaporation treatment on the coal gasification black water; (ii) feeding the coal gasification black water having been subjected to flash evaporation treatment into a sedimentation tank, conducting sedimentation and separating, feeding bottom concentrated suspended matters into a vacuum filter pressing system, and feeding a supernatant of the sedimentation tank, namely coal gasification ash water, into an ash water tank; (iii) pumping the coal gasification ash water out of the ash water tank, and sending the coal gasification ash water to a fluidized bed separator to deeply remove fine particles in the coal gasification ash water; (iv) sending the coal gasification ash water purified by the fluidized bed separator to a deaerator for deoxygenation; and (v) after the fluidized bed separator is operated for a period of time and a pressure difference is 0.3 MPa, mixing the coal gasification ash water and nitrogen, and reversely feeding the obtained mixture to regenerate a separation medium of the fluidized bed separator. The invention further provides the flash evaporation-sedimentation-fluidized bed separation combined purification device for coal gasification black water.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing improved water washing treating agent

InactiveCN105296180AEasy to cleanReduce oil sands contentInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSODIUM DODECYL BENZENE SULFONATESodium hydroxide

The invention discloses a method for preparing an improved water washing treating agent. The method comprises the following steps: 1) adding 5wt%-10wt% of sodium dodecyl benzene sulfonate into an enamel reaction still, and starting a stirrer for continuously stirring sodium dodecyl benzene sulfonate at the temperature of (50+ / -1) DEG C when the temperature inside the enamel reaction still is controlled to be (50+ / -1) DEG C all the time; 2) adding 82(wt%-85wt% of water into the enamel reaction still, and continuously stirring sodium dodecyl benzene sulfonate and water which are added into the enamel reaction still for 10 min for uniform mixing through the stirrer; 3) gradually adding 1wt% of polysorbate into the enamel reaction still, and continuously stirring sodium dodecyl benzene sulfonate, water with polysorbate which are added into the enamel reaction for 10 min for uniform mixing through the stirrer; 4) sequentially adding 2wt%-8wt% of sodium hydroxide and 1wt%-5wt% of sodium carbonate into the enamel reaction still, and continuously stirring sodium dodecyl benzene sulfonate, water, polysorbate, sodium hydroxide and sodium carbonate which are added into the enamel reaction for 5 min for uniform mixing through the stirrer, so as to synthesize the improved water washing treating agent. The method is easy, feasible, and low in implementation cost.

Owner:XINJIANG KELI NEW TECH DEV +1

Suspended media layer filtration system based on hydraulic fluid layer formation

PendingCN110204103AEfficient removalImprove water qualityWater contaminantsTreatment involving filtrationFlocculationReflux

The invention relates to a suspended medium layer filtering system based on hydraulic fluid layering, belonging to the technical field of sewage treatment. The suspended medium layer filtering systemcomprises a filtering device, a reflux pump, a water inlet dosing system and a main body bracket. The filtering device is arranged on the main body bracket, and the main body bracket is arranged on the ground. The water inlet dosing system, the reflux pump and the filtering device form a circulation loop. According to the invention, a medium layer is adopted for filtering, a suspended medium layeris formed through hydraulic flow state, suspended impurities in sewage are effectively removed by utilizing the net catching and flocculation effects of the medium layer, the content of suspended substances in effluent is reduced, the effluent quality is improved, and the suspended medium layer filtering system has the characteristics of low energy consumption, low medicine consumption and convenient operation and maintenance.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com