Converter steel slag treatment device and method

A converter steel slag and processing device technology, which is applied in the field of steelmaking auxiliary equipment technology, can solve the problems of unsuitable for fast-paced production of converter, complex and special composition, large floor area, etc., and achieve reliable and efficient steam recovery, mechanization degree and slag High processing efficiency and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

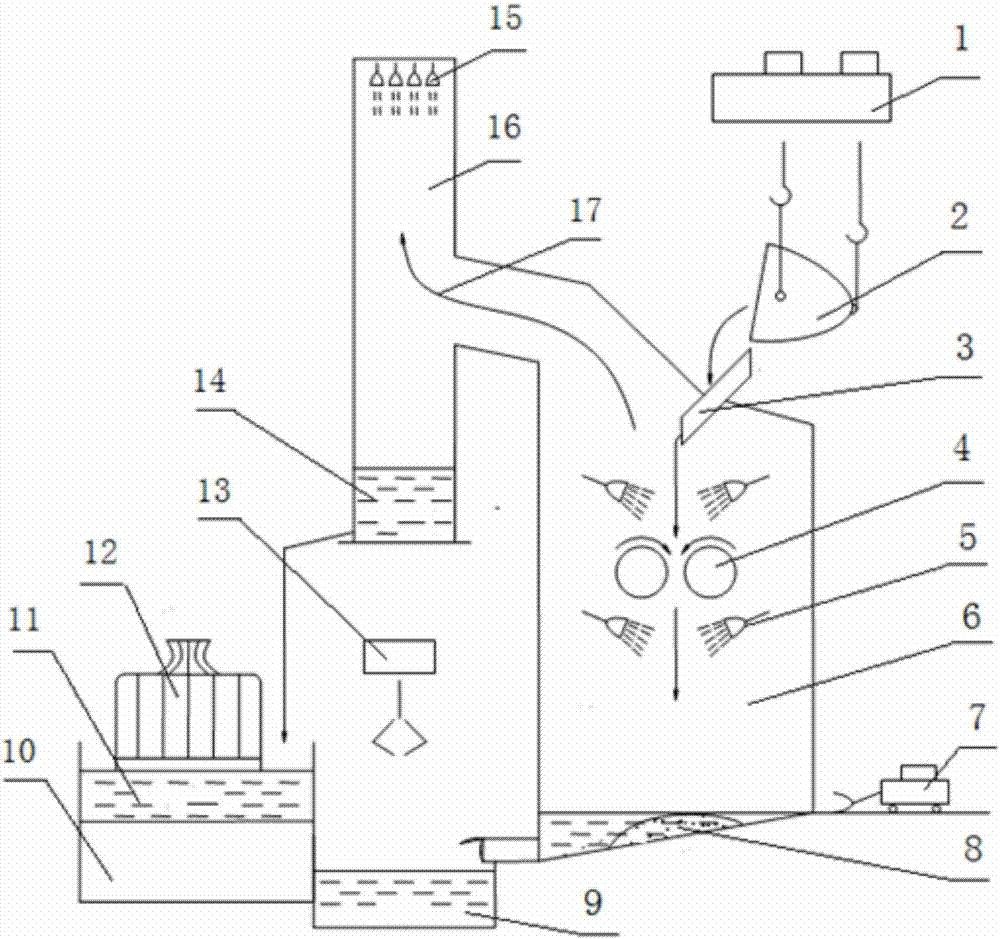

[0008] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings: figure 1 It is a structural diagram of a converter steel slag treatment device and method; the device includes a crane 1, a slag tank 2, a chute 3, a hydraulic roller 4, a nozzle a5, a granulation room 6, a forklift 7, a steel slag pool 8, and a bottom filter Pool 9, water pump house 10, water storage tank 11, cooling tower 12, bridge grab crane 13, condensate pool 14, nozzle b15, chimney 16; crane hook 1 is connected to slag tank 2; slag tank 2 outlet is connected to chute 3 The entrance position is connected; the outlet position of the chute 3 is connected with the upper side of the hydraulic counter-roller 4; the upper and lower sides of the hydraulic counter-roller 4 are symmetrically installed with nozzles a5; the hydraulic counter-roller 4 and the nozzle a5 are both arranged in the granulation room 6 inside; the lower part of the granulation ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com