Treatment process for gas field foam water up-to-standard discharge

A treatment process, bubble drainage technology, applied in water/sewage treatment, mining wastewater treatment, water treatment parameter control, etc., can solve the problem of severe foaming, achieve the effect of reducing foaming and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

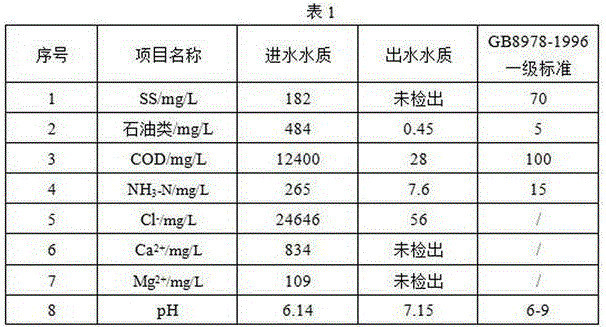

Embodiment 1

[0034] A treatment process for gas field bubble drainage up to standard discharge, the manufacturing process is as follows:

[0035](1) Oil separation treatment

[0036] Because there is a lot of oil floating on the surface of the waste water (bubble drainage), it is necessary to carry out oil separation treatment in advance. The specific process is: collect the waste water to be treated and add it to the oil separation tank, let it stand for 20 minutes, open the side valve to let the waste water flow out by itself , to trap the surface oil layer.

[0037] (2) Demulsification treatment

[0038] Add a demulsifier to the waste water after the oil separation treatment to separate the emulsified oil in the waste water, and then carry out the oil separation treatment again after separation.

[0039] In this step, the demulsifier is an AR-type demulsifier, and the AR-type demulsifier is a novel oil-soluble non-ionic demulsifier formed by the polymerization of alkylphenol-formaldeh...

Embodiment 2

[0060] A treatment process for gas field bubble drainage up to standard discharge, the manufacturing process is as follows:

[0061] (1) Oil separation treatment

[0062] Collect the waste water to be treated (soak and drain) and add it to the oil trap, let it stand for 20 minutes, open the side valve to let the waste water flow out by itself, and trap the oil layer on the surface.

[0063] (2) Demulsification treatment

[0064] Add AR type demulsifier with HLB value of 4 to the waste water after oil separation treatment. The amount of AR type demulsifier added is 5mg / L, so that the emulsified oil in the waste water is separated, and after separation, oil separation treatment is carried out again.

[0065] (3) Water quality adjustment treatment

[0066] A saturated sodium hydroxide solution with a concentration of 4.5 mol / L is added to the waste water after the demulsification treatment, and the pH value of the waste water is adjusted to 8-9.5.

[0067] (4) Coagulation trea...

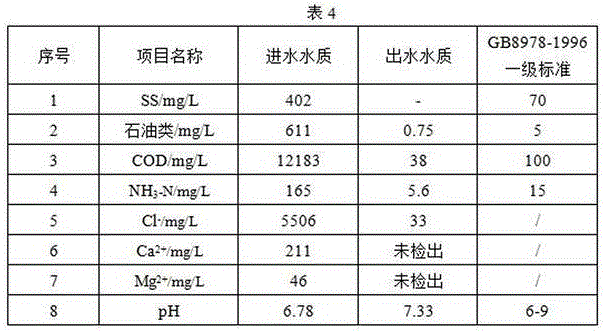

Embodiment 3

[0080] A treatment process for gas field bubble drainage up to standard discharge, the manufacturing process is as follows:

[0081] (1) Oil separation treatment

[0082] Collect the waste water to be treated (soak and drain) and add it to the oil trap, let it stand for 20 minutes, open the side valve to let the waste water flow out by itself, and trap the oil layer on the surface.

[0083] (2) Demulsification treatment

[0084] Add an AR-type demulsifier with an HLB value of 8 to the wastewater after the oil-separation treatment. The amount of the AR-type demulsifier added is 2 mg / L to separate the emulsified oil in the wastewater, and then perform oil-separation treatment again after separation .

[0085] (3) Water quality adjustment treatment

[0086] A saturated sodium hydroxide solution with a concentration of 4.5 mol / L is added to the waste water after the demulsification treatment, and the pH value of the waste water is adjusted to 8-9.5.

[0087] (4) Coagulation tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com